Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2009

GM-3400T/XJUC

BRIDGEABLE TWO-CHANNEL POWER AMPLIFIER

ORDER NO.

CRT4513

GM-3400T

GM-3400T

GM-3400T

/XJEW5

/XJES

/XJUC

For details, refer to "Important Check Points for Good Servicing".

K-ZZZ. DEC. 2009 Printed in Japan

Page 2

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

CAUTION

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or

other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

2

GM-3400T/XJUC

Page 3

5 678

56

7

8

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

GM-3400T/XJUC

3

Page 4

1234

1234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

1. SERVICE PRECAUTIONS ............................................................................................................................... 5

1.1 SERVICE PRECAUTIONS......................................................................................................................... 5

1.2 NOTES ON SOLDERING .......................................................................................................................... 7

2. SPECIFICATIONS ............................................................................................................................................ 8

2.1 SPECIFICATIONS...................................................................................................................................... 8

2.2 PANEL FACILITIES .................................................................................................................................. 10

2.3 CONNECTION DIAGRAM ....................................................................................................................... 11

3. BASIC ITEMS FOR SERVICE........................................................................................................................ 12

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 12

3.2 JIGS LIST ................................................................................................................................................ 12

4. BLOCK DIAGRAM.......................................................................................................................................... 12

5. DIAGNOSIS.................................................................................................................................................... 13

5.1 CONNECTOR FUNCTION DESCRIPTION............................................................................................. 13

6. SERVICE MODE ............................................................................................................................................ 13

7. DISASSEMBLY............................................................................................................................................... 14

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 15

9. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 16

9.1 PACKING ................................................................................................................................................. 16

9.2 EXTERIOR............................................................................................................................................... 18

10. SCHEMATIC DIAGRAM ............................................................................................................................... 20

10.1 AMP UNIT(GUIDE PAGE)...................................................................................................................... 20

11. PCB CONNECTION DIAGRAM ................................................................................................................... 26

11.1 AMP UNIT.............................................................................................................................................. 26

12. ELECTRICAL PARTS LIST .......................................................................................................................... 30

4

GM-3400T/XJUC

Page 5

5 678

56

7

8

C

D

F

A

B

E

1. You should conform to the regulations governing the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by electrostatic

induction.

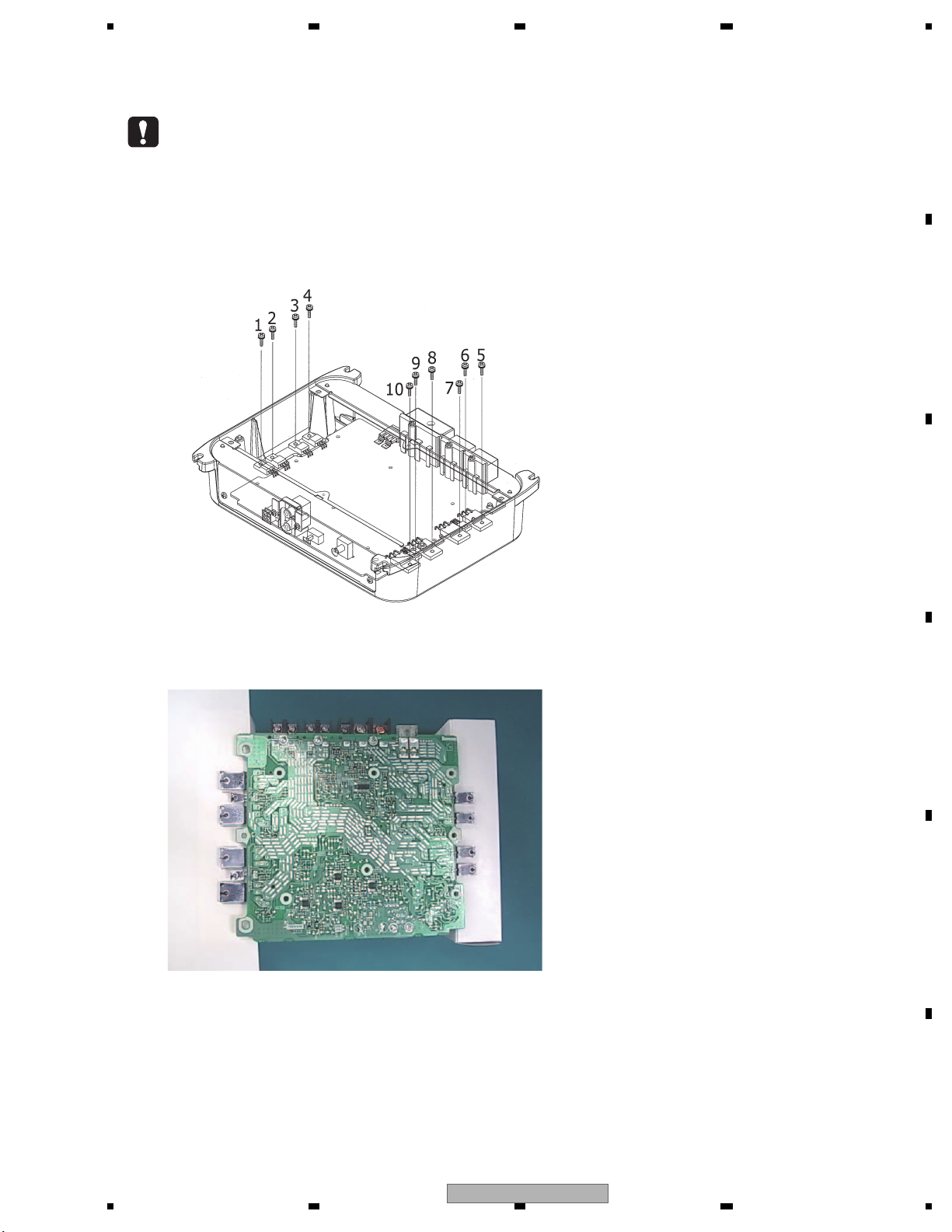

3. When you tighten the screws No. 1 to 10, tightly hold a transistor or a diode to be fixed to prevent the part from

turning by the force of tightening the screw.

(If the part turned, a stress will be applied to the solder and may cause a failure such as a solder crack.)

4. When you replace a part fixed to the heatsink (Q515, Q516, Q517,Q518, Q519, Q520, Q803, Q804, D821 and D822),

adjust the position of the part according to the following.

Put the Amp Unit on blocks.

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

GM-3400T/XJUC

5

Page 6

1234

1234

C

D

F

A

B

E

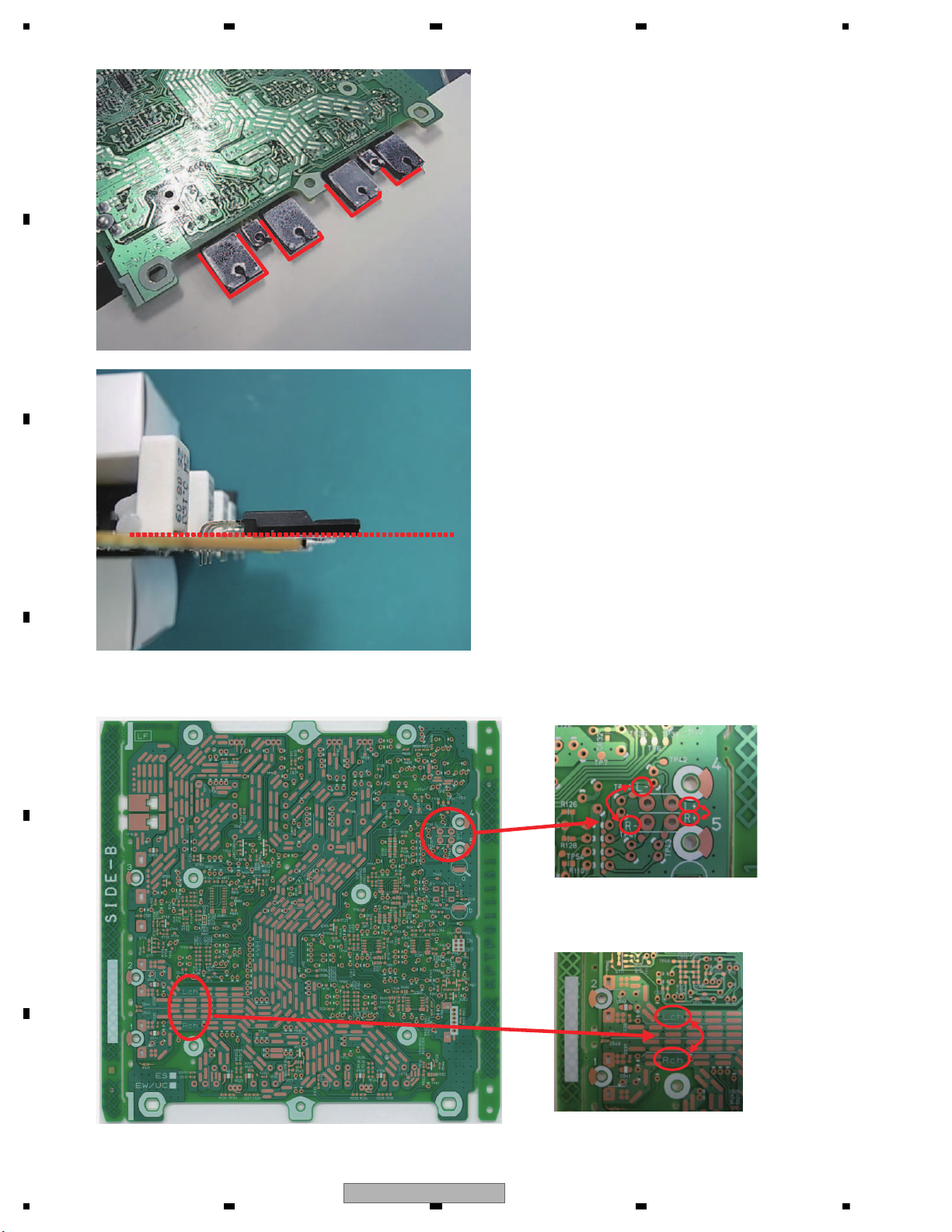

Put a paper between the block and the Amp Unit,

and outline transistors and diodes.

Put a part to replace in the outline.

Align the bottom of a transistor or a diode with the

top of the PC board, and solder it.

Apply grease, GEM1057 to the back of the part.

5. Silk-prints of "L" and "R" on the Amp Unit are printed wrongly each other. ("L" should be "R", and "R" should be "L".)

6

GM-3400T/XJUC

Page 7

5 678

56

7

8

C

D

F

A

B

E

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1.2 NOTES ON SOLDERING

GM-3400T/XJUC

7

Page 8

1234

1234

C

D

F

A

B

E

2. SPECIFICATIONS

Power source...........................14.4 V DC (10.8 V to 15.1 V

allowable)

Grounding system................. Negative type

Current consumption .......... 15 A (at continuous power,

4 ohm)

Average current drawn........ 4 A (4 ohm for two channels)

7.8 A (4 ohm for one channel)

Fuse ......................................... 25 A × 1

Dimensions (W × H × D) ...263 mm × 61 mm × 206

mm(10-3/8 in. × 2-3/8 in. ×

8-1/8 in.)

Weight ..................................... 2 kg (4.4 lbs)

(Leads for wiring not in-

cluded)

Maximum power output ...... 120 W × 2 (4 ohm)

/ 350 W × 1 (4 ohm)

Continuous power output ..60 W × 2 (at 14.4 V, 4 ohm

, 20 Hz to 20 kHz 0.2% THD)

175 W × 1 (at 14.4 V, 4 ohm

, 20 Hz to 20 kHz 0.8% THD)

85 W × 2 (at 14.4 V, 2 ohm

, 20 Hz to 20 kHz 0.8% THD)

Load impedance ................... 4 ohm (2 ohm to 8 ohm allowable)

(Bridge connection: 4 ohm to 8

ohm allowable)

Frequency response............ 10 Hz to 50 kHz (+0 d B,

–1

dB)

Signal-to-noise ratio............ 95 dB (IHF-A network)

Distortion ................................ 0.01 % (10 W, 1 kHz)

Separation .............................. 70 dB (1 kHz)

Low pass filter:

Cut off frequency......... 80 Hz

Cut off slope.................. –12 dB/oct

Gain control:

RCA ................................. 200 mV to 6.5 V

Speaker ........................... 0.8 V to 26 V

Maximum input level / impedance:

RCA .................................. 6.5 V / 22 k ohm

Speaker ............................ 26 V / 9 0 k ohm

CEA2006 Specifications

Power output .......................... 60 W RMS × 2 Channels (at

14.4 V, 4 ohm and

1 % THD

+N)

175 W RMS × 1 Channels

(at 14.4 V, 4 ohm BRIDGE and

1 % THD+N)

85 W RMS × 2 Channels (at

14.4 V, 2 ohm and

1 % THD

+N)

S/N ratio .................................. 75 dBA (reference: 1 W into

4 ohm)

Notes

• Specifications and the design are subject to

modifications without notice due to improvements.

• The average current drawn is nearly the maximum current drawn by this unit when an

audio signal is input. Use this value when

working out total current drawn by multiple

power amplifiers.

Backup current ......................0.1 mA or less

GM-3400T/XJUC

2.1 SPECIFICATIONS

8

GM-3400T/XJUC

Page 9

5 678

56

7

8

C

D

F

A

B

E

GM-3400T/XJEW5, GM-3400T/XJES

Power source..........................14.4 V DC (10.8 V to 15.1 V

allowable)

Grounding system................. Negative type

Current consumption .......... 15 A (at continuous power,

4 ohm)

Average current drawn........ 4 A (4 ohm for two channels)

7.8 A (4 ohm for one channel)

Backup current ....................... 0.1 mA or less

Fuse ......................................... 25 A × 1

Dimensions (W × H × D) ...263 mm × 61 mm × 206

mm

Weight ..................................... 2 kg (Leads forwiring not in-

cluded)

Maximum power output ....... 120 W × 2 (4 ohm)

/ 350 W × 1(4 ohm)

Continuous power output ... 60 W × 2 (at 14.4 V, 4 ohm)

, 20 Hz to 20 kHz 0.2% THD)

175 W × 1 (at 14.4 V, 4 ohm)

, 20 Hz to 20 kHz 0.8% THD)

85 W × 2 (at 14.4 V, 2 ohm)

, 20 Hz to 20 kHz 0.8% THD)

Load impedance ................... 4 ohm (2 ohm to 8 ohm allowable)

(Bridge connection: 4 ohm to 8

ohm allowable)

Frequency response............. 10 Hz to 50 kHz (+0 d B, –1

dB)

Signal-to-noise ratio............ 95 dB (IEC-A network)

Distortion ................................ 0.01 % (10 W, 1 kHz)

Separation ............................. 70 dB (1 kHz)

Low pass filter:

Cut off frequency......... 80 Hz

Cut off slope.................. –12 dB/oct

Gain control:

RCA ................................ 200 mV to 6.5 V

Speaker .......................... 0.8 V to 26 V

Maximum input level / impedance:

RCA ................................ 6.5 V / 22 k ohm

Speaker .......................... 26 V / 9 0 k ohm

Notes

• Specifications and the design are subject to

modifications without notice due to improvements.

• The average current drawn is nearly the maximum current drawn by this unit when an

audio signal is input. Use this value when

working out total current drawn by multiple

power amplifiers.

GM-3400T/XJUC

9

Page 10

1234

1234

C

D

F

A

B

E

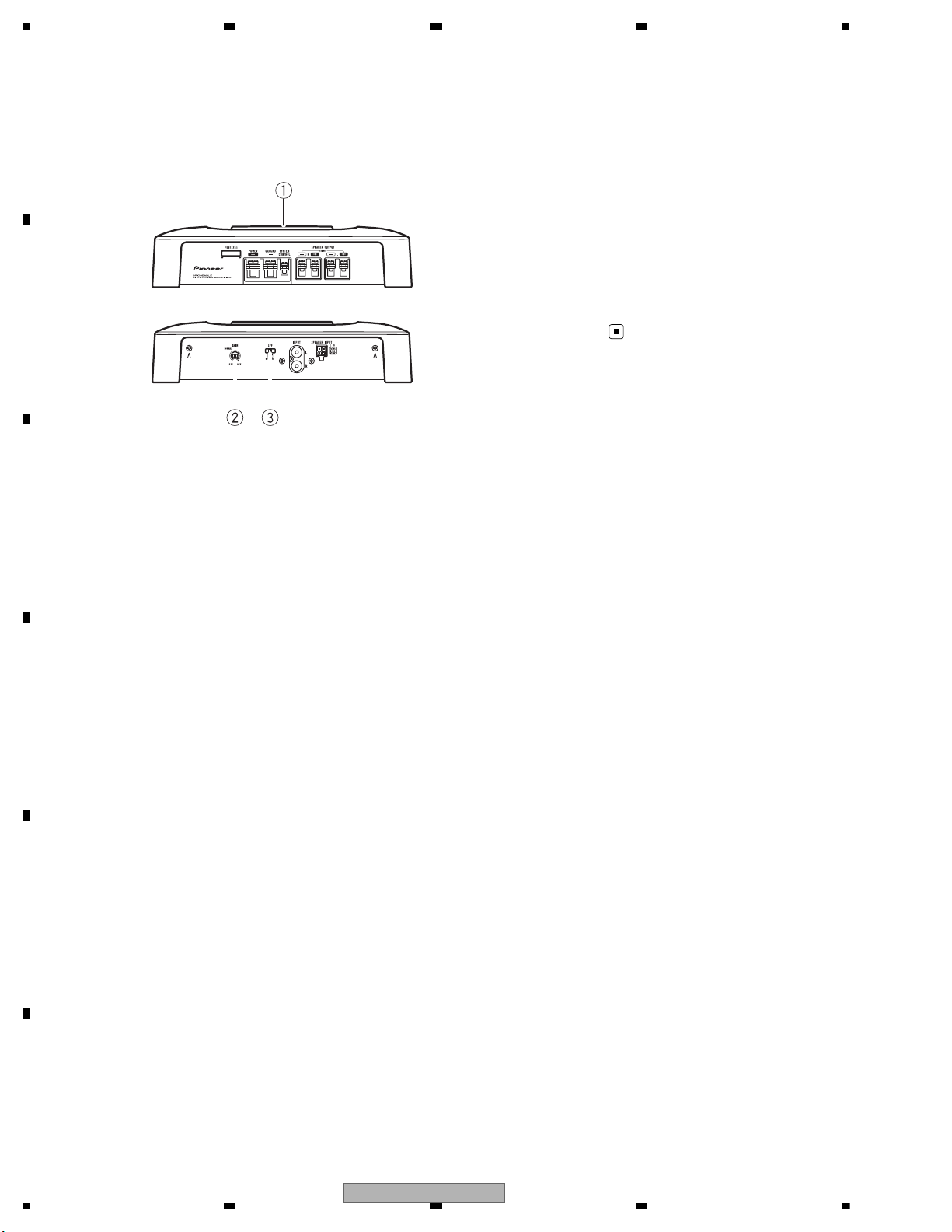

2.2 PANEL FACILITIES

What ’s what

Front side

Rear side

To adjust the switch, use a flathead screwdriver if needed.

1 Power indicator

The power indicator lights up to indicate

power ON.

2 GAIN (gain) control

If output remains low, even when the car

stereo volume is turned up, turn controls to

lower level. If distortion occurs when the car

stereo volume is turned up, turn these controls to higher level.

• For use with an RCA equipped car stereo

(standard output of 500 mV), set to the

NORMAL position. For use with an RCA

equipped Pioneer car stereo, with max.

output of 4 V or more, adjust level to

match that of the car stereo output.

• If you hear too much noise when using

the speaker input terminals, turn the

gain control to higher level.

3 LPF (low-pass filter) switch

Switch the settings based on the connected

speaker.

• When the Subwoofer is connected:

Select ON . This eliminates high range

frequency and outputs low range frequency.

• When the full range speaker is connected:

Select OFF . OFF outputs the entire frequency range.

10

GM-3400T/XJUC

Page 11

5 678

56

7

8

C

D

F

A

B

E

Connection diagram

1 Special red battery wire

RD-223 (sold separately)

After completing all other amplifier connections, finally connect the battery wire terminal

of the amplifier to the positive (

) battery

terminal.

2 Ground wire (Black)

RD-223 (sold separately)

Connect to metal body or chassis.

3 Car stereo with RCA output jacks (sold sepa-

rately)

4 External output

5 Connecting wire with RCA pin plugs (sold se-

parately)

6 Speaker input terminal

7 RCA input jack

8 System remote control wire (sold separately)

Connect male terminal of this wire to the system remote control terminal of the car stereo

(SYSTEM REMOTE CONTROL ). The female

terminal can be connected to the auto-antenna relay control terminal. If the car stereo

lacks a system remote control terminal, connect the male terminal to the power terminal

via the ignition switch.

9 Speaker output terminals

Please see the following section for speaker

connection instructions. Refer to Connections

when using the speaker input wire.

a Fuse (25 A) × 1

b Fuse (30 A) × 2

c Grommet

d Rear side

e Front side

2.3 CONNECTION DIAGRAM

GM-3400T/XJUC

11

Page 12

1234

1234

C

D

F

A

B

E

3. BASIC ITEMS FOR SERVICE

To keep the product quality after servicing, please confirm following check points.

demrifnoc eb ot metIserudecorP.oN

1 Confirm whether the customer complain has

been solved.

The customer complain must not be

reappeared.

Audio and operations must be normal.

2 Check the output sound. Audio and operations must be normal.

retfa ecnaraeppa sti no trid ro sehctarcs oNkcehc ecnaraeppA3

receiving it for service.

See the table below for the items to be checked regarding audio:

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

- Lubricants and Glues List

Name

Grease

Bond

Grease No.

GEM1057

GYL1006

Remarks

Applying to Heatsink

Applying to choke coil, resistor and capacitor

N

G

s

3.1 CHECK POINTS AFTER SERVICING

3.2 JIGS LIST

ame

4. BLOCK DIAGRAM

rease No.

There is not information to be shown in this chapter.

mark

12

GM-3400T/XJUC

Page 13

5 678

56

7

8

C

D

F

A

B

E

5. DIAGNOSIS

5.1 CONNECTOR FUNCTION DESCRIPTION

6. SERVICE MODE

There is not information to be shown in this chapter.

GM-3400T/XJUC

13

Page 14

1234

1234

C

D

F

A

B

E

7. DISASSEMBLY

1

1

2

- Removing the Case (Fig.1)

Remove the four screws

and then remove the Case.

Fig.1

3

1

1

1

1

1

2

2

2

2

2

1

2

2

2

2

2

3

3

3

3

3

3

3

3

Case

- Removing the Amp Unit (Fig.2)

Remove the eight screws

and then remove the Amp Unit.

Remove the two screws.

Amp Unit

Fig.2

Remove the ten screws.

When you tighten the screws indicated

by Arrow 2, tightly hold a transistor or

a diode to be fixed to prevent the part

from turning by the force of tightening

the screw.

(If the part turned, a stress will be

applied to the solder and may cause a

failure such as a solder crack.)

14

GM-3400T/XJUC

Page 15

5 678

56

7

8

C

D

F

A

B

E

Bonding Position

1

GYL1006

1

1

1

1

1

8. EACH SETTING AND ADJUSTMENT

There is not information to be shown in this chapter.

1

1

1

GM-3400T/XJUC

15

Page 16

1234

1234

C

D

F

A

B

E

9. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

""

9.1 PACKING

16

GM-3400T/XJUC

Page 17

5 678

56

7

8

C

D

F

A

B

E

(1) PACKING SECTION PARTS LIST

Mark

Mark No. Description Part No.

1 Cushion CZH6698

* 2 Polyethylene Bag CEG1250

* 3 Warranty Card

4 Cord Assy CZD5517

* 5 Polyethylene Bag

6Unit Box

See Contrast table(2)

See Contrast table(2)

See Contrast table(2)

No. Description Part No.

7 Contain Box CZH6703

8 •••••

9 Owner's Manual

10 Screw Assy CEA5330

11 Screw BYC40P180FTB

* 12 Polyethyene Seet CNM4338

See Contrast table(2)

(2) CONTRAST TABLE

GM-3400T/XJUC, GM-3400T/XJEW5 and GM-3400T/XJES are constructed the same except for the following:

Mark No. Description GM-3400T/XJUC GM-3400T/XJEW5 GM-3400T/XJES

* 3 Warranty Card CRY1276 CRY1279 Not used

* 5 Polyethylene Bag CZE2992 CZE2991 CZE2991

6 Unit Box CZH6702 CZH6700

7

9 Owner's Manual CZR5552 CZR5551 CZR5553

Contain Box

CZH6703 CZH6701 CZH6705

CZH6704

Owner's Manual,Installation Manual

Part No. Language

CZR5551 English, Spanish(Espanol), German, French, Italian, Dutch, Russian

CZR5552 English, French, Spanish(Espanol)

CZR5553 English, Spanish(Espanol), Portuguese(B), Arabic

GM-3400T/XJUC

17

Page 18

1234

1234

C

D

F

A

B

E

9.2 EXTERIOR

18

GM-3400T/XJUC

Page 19

5 678

56

7

8

C

D

F

A

B

E

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

> 1 Fuse(25 A) CEK1329

2 Screw PBH26P120FTC

3 Screw BBZ30P080FTB

4 Screw BBZ30P080FTC

5 Screw BBZ30P080FTC

Mark No. Description Part No.

9 Panel F (2CH) CZN8458

10 Panel R (2CH) CZN8459

11 Amp Unit

See Contrast table (2)

12 Holder CZN8430

13 Screw PPZ30P100FNN

6 Screw BSZ30P060FTB

7 Screw PPZ30P100FTB

14 Screw PPZ30P100FTB

15 Case Unit

See Contrast table (2)

8 Chassis (Botom) CZN8457

(2) CONTRAST TABLE

GM-3400T/XJUC, GM-3400T/XJEW5 and GM-3400T/XJES are constructed the same except for the following:

Mark No. Description GM-3400T/XJUC GM-3400T/XJEW5 GM-3400T/XJES

11 Amp Unit CZW5581 CZW5581 CZW5582

15 Case Unit CZX6655 CZX6654 CZX6654

GM-3400T/XJUC

19

Page 20

1234

1234

C

D

F

A

B

E

10. SCHEMATIC DIAGRAM

A

A-a

A-a A-b

A-a

A-b

A-b

A-a

Large size

SCH diagram

Guide page

Detailed page

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

IC301

1

A_OUT2A_-IN3A_+IN4V-

5

B_+IN6B_-IN

8

V+

7

B_OUT

R103

22K

R104

22K

C101

470P

C102

470P

C103

47P

C10747P

C108 47P

C104

47P

R805

4.7K

R806

4.7K

C805

0.0047

C806

0.0047

C822

0.001

C823

0.001

C820

NM

R311

56

R312

C832

NM

C833

NM

C812

0.033

C811

0.033

C821

NM

D110

1SS355

D112

1SS355

D111

1SS355

D109

1SS355

JA101

CKB1068-B

JA103

CKM1463-A

1

L+

2

R+

3

L-

4

R-

R809

1/2W

22

R810

1/2W

22

R820

NM

R821

1/2W

22

R822

1/2W

22

R807

1/2W

120

R808

1/2W

120

R823

1/2W

NM

R824

1/2W

NM

Q803

FKV550N

G

S

D

Q804

FKV550N

G

S

D

C810

3300/16

105

D101

1SS355

D105

1SS355

D103

1SS355

D107

1SS355

D102

1SS355

D106

1SS355

D104

1SS355

D108

1SS355

VR301

10K

TP6

TP7

TP8

TP9

TP10

TP26

TP27

TP28

TP29

TP30

TP31

TP32

TP33

TP34TP35

TP36

TP37

TP38TP39

TP40

TP41

TP42

TP43

TP44

TP45

TP46

TP47

TP48

TP49

TP51

TP50

TP56

TP57

TP58

TP59

TP60TP61

C113

NM

C114

NM

TP52

TP53

TP54

TP55

D821

FML-22S

D822

FML-22R

R812

11K

R813

27K

Q802

KTA1504S

OYG

Q801

KTA1504S

OYG

R827

1/2W10

R828

1/2W10

C824

3300/35

105

C825

3300/35

105

D806

MTZJ16B

D805

MTZJ16B

R825

NM

R826

NM

R711

100

R125

NM

R126

NM

R127

NM

R128

NM

C123

NM

C124

NM

C125

NM

C126

NM

TH7

47

R119

1/4W

470

R120

1/4W

470

R121

51K

1/4W

R122

51K

1/4W

R123

51K

1/4W

R124

51K

1/4W

R803

3.3K

R804

3.3K

E1

E2

C2

Vcc

OPC

Ref

2IN-

2IN+

R101

NM

R829

1/2W

3.3K

R830

1/2W

3.3K

R305

68K

R306

68K

R307

68K

R308

68K

C304

0.022

C303

0.022

C302

0.039

C301

0.039

R831

NM

L802

NM

R113

NM

R114

NM

C119

NM

Q823

KTC3875S

Q824

KTC3875S

R310

2.2K

R309

2.2K

KN802

NM

*L803

BL02RN1R3N1A

*L804

BL02RN1R3N1A

R11110K

0.25%

R10910K

0.25%

R10710K

0.25%

R10510K

0.25%

R112 10K

0.25%

R110 10K

0.25%

R108 10K

0.25%

R106 10K

0.25%

S301

00221461

Q822

KTC9015

ABC

EC

B

Q821

KTC9014

ABCD

EC

B

IC101NJM4565M-D

1

AOUTPUT2A-INPUT3A+INPUT

4

V-

5

B+INPUT

6

B-INPUT

8

V+7BOUTPUT

IC102

1

AOUTPUT2A-INPUT3A+INPUT

4

V-

5

B+INPUT

6

B-INPUT

8

V+7BOUTPUT

C115

10/25

C117

10/25

C118

10/25

C116

10/25

C105

NM

R833

3.9K

R834

3.3K

Q825

KTC9014

ABCD

R832

1/4W

100

R835

0

T801

C831

220/35

C830

220/35

C112

10/25

C111

10/25

R836

1/2W

NM

R837

1/2W

NM

R838

1/2W

NM

R839

1/2W

NM

R313

130K

R314

130K

C827

22/25

C826

22/25

C106 0.0047

C828

47/16

C829

47/16

*JW123

*JW122

*JW124

*JW126

10:5

Lch

Rch

SP LEVEL INPUT

OFF

LPF

OFF

LPF

MI

LPFBUFFER/ISO.AMP

+15V

-15V

+VH

-VH

+VD

-VD

RCA INPUT

LPF OFF

GAIN

MODEL L803 L804 JW122 JW123 JW124 JW126

GM-3400T/XJEW5

GM-3400T/XJUC

GM-3400T/XJES

NJM4565M-D

NJM4558MD

0 dB / 0 dB

0 dB

-31.5 dB ~

VD VH 15 V

1 W +27.8 V +28.0 V +15.1 V

OUTPUT -27.8 V -27.9 V -15.2 V

10.1 AMP UNIT(GUIDE PAGE)

20

GM-3400T/XJUC

Page 21

5 678

56

7

8

C

D

F

A

B

E

A

A-b

R801 15K

R311

56

R312

56

R521

1.1K

R523

4.7K

R525

2.2K

R526

2.2K

R522

1.1K

R524

4.7K

C529

NM

C534

NM

C532

NM

C531

NM

C533

NM

C528

NM

C530

NM

R54147K

D501

MA111

R54247K

D502

MA111

R545

47K

R546

47K

C801 0.001

C709

0.01

R815 47K

R814 1K

C701

NM

C538

0.033

C537

0.033

KN801

CZK2969-A-T

Q522

KTC3911S

GL

Q521

KTC3911S

GL

R544

560K

R543

560K

JA804

CND2458-A

JA805

CND2458-A

C541

3216

NM

C542

3216

NM

C803

3216

NM

Q515

KTC3114A

Q516

KTC3114A

R730

16K

R729

6.8K

R728

12K

VR301

10K

TP1

TP2

TP3

TP4

TP5

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP18

TP20

TP24

TP26

TP27

TP60TP61

TP66TP67

TP68

TP69

TP70TP71TP72TP73

TP74TP75

TP77

TP78TP79

TP81

TP82

TP83

TP84

TP85

TP86

TP87

TP88

TP89

TP90

TP91

TP92

TP93

TP94

TP95

TP96

TP97

TP19

C5390.001C5400.001

JA801

CKE1055-A

1

+B

2

GND

3

REM

JA501

CKE1057-A

1

L-

2

L+

JA502

CKE1057-A

1

R-

2

R+

Q511

2SA1038S

Q512

2SA1038S

Q514

2SC2389S

Q513

2SC2389S

R701

1/4W

2.2K

R722

100

R714

10K

R713

330K

C702 0.001

R812

11K

R813

27K

R712

22K

R704

4.7K

R705

2.2K

Q703

KN2907AS

D804

1A4-E

D803

1A4-E

C802

0.01

2012

C804

0.22

IC501

1

A_OUT

2

A_-IN3A_+IN

4

V-

5

B_+IN6B_-IN

8

V+7B_OUT

R509

15K

R511

15K

R510

15K

R512

15K

R516

47K

R518

47K

R515

47K

R517

47K

R504

270

R503

270

D706

1SS133

C525

0.001

C526

0.001

R519

1/4W

120

R528

1/4W

120

R527

1/4W

120

R520

1/4W

120

R537

2W

0.1

R539

2W

0.1

R540

2W

0.1

R538

2W

0.1

R547

1/4W

10

R548

1/4W

10

R717

47

Q712

DTA124EKA

C535

NM

C536

NM

R706

NM

R707

NM

R711

100

R709

2.2K

D705

NHSB046AT

R702

7.5K

R716

1K

R715

220

C708

0.01

Q302

2SC2412K

R

Q301

2SC2412K

R

R301

10K

R302

10K

C527

NM

Q517

2SD2439

OP

Q519

2SB1588

OP

Q518

2SD2439

OP

Q520

2SB1588

OP

R720

NM

C704

NM

R723

47K

R724

22K

L801

36uH

K000225700

R726

33K

TH701

470

R507

1/4W

560

R513

1/4W

560

R514

1/4W

560

R508

1/4W

560

D702

1SS133

Q702

2SC2412K

R

Q705

2SC2412K

R

Q710

2SC2412K

R

Q711

2SC2412K

R

Q713

2SC2412K

R

IC801KIA494AF

1

1IN+

2

1IN-

3

FEEDBACK

4

DTC

5

CT

6

RT

7

GND

8C19

E1

10

E2

11

C2

12

Vcc

13

OPC

14

Ref

15

2IN-

16

2IN+

Q709

2SA1037AK

R

R725

330

R727

2.2K

TH702

10K

R703

2.2K

1/4W

R721

1/2W

4.7K

D701

MTZJ7.5B

C711

NM

C513

NM

C515

NM

C514

NM

C516

NM

C508

68P

C507

68P

R505

22K

2012

R506

22K

2012

R310

2.2K

R309

2.2K

C706

0.22

C521

0.22

C524

0.22

C522

0.22

C523

0.22

C543

NM

C544

NM

R733

1/4W

100

R732

2.7K

Q714

2SA1037AKR

S301

C503

100/10

C504

100/10

D707

HZS3A2TD-E

R708

22K

D708

1SS133

D709

1SS133

R802

NM

R734

NM

C707

22/25

C703

100/16

C710

220/6.3

C712

NM

C807 220/6.3

R502

10K

R501

10K

C502

33P

C501

33P

C505

68P

C506

68P

C517

10P

C520

10P

C518

10P

C519

10P

R529

22

3216

R531

22

3216

R532

22

3216

R530

22

3216

R534

47K

R533

47K

R535

47K

R536

47K

R731

6.8K

R710

3.9K

D711

1SS133

D710

1SS133

C512

10P

C511

10P

C510

10P

C509

10P

OFF

LPF

OFF

LPF

MIN MAX

SP OUTPUT

LPF OFF

FUSE (25A)

GAIN

BLUE LED

NJM2068MD

A

AMP UNIT

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

NOTE :

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

NM : No Mount

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

>

-31.5 dB ~ -2.2 dB

Silk-prints of "L" and "R" on the Amp Unit

are printed wrongly each other.

("L" should be "R", and "R" should be "L".)

+29 dB

-9.3 dB

GM-3400T/XJUC

21

Page 22

1234

1234

C

D

F

A

B

E

A-a A-b

A-b

R311

56

R312

56

R521

1.1K

R523

4.7K

R525

2.2K

R526

2.2K

R522

1.1K

R524

4.7K

C529

NM

C534

NM

C532

NM

C531

NM

C533

NM

C528

NM

C530

NM

R54147K

D501

MA111

R54247K

D502

MA111

R545

47K

R546

47K

C538

0.033

C537

0.033

Q522

KTC3911S

GL

Q521

KTC3911S

GL

R544

560K

R543

560K

C541

3216

NM

C542

3216

NM

Q515

KTC3114A

Q516

KTC3114A

TP66TP67

TP68

TP69

TP70TP71TP72TP73

TP74TP75

TP77

TP78TP79

TP81

TP82

TP83

TP84

TP85

TP86

TP87

TP88

TP89

TP90

TP91

TP92

TP93

TP94

TP95

TP96

TP97

C5390.001C5400.001

JA501

CKE1057-A

1

L-2L+

JA502

CKE1057-A

1

R-2R+

Q511

2SA1038S

Q512

2SA1038S

Q514

2SC2389S

Q513

2SC2389S

IC501

1

A_OUT

2

A_-IN

3

A_+IN

4

V-

5

B_+IN

6

B_-IN

8

V+

7

B_OUT

R509

15K

R511

15K

R510

15K

R512

15K

R516

47K

R518

47K

R515

47K

R517

47K

R504

270

R503

270

C525

0.001

C526

0.001

R519

1/4W

120

R528

1/4W

120

R527

1/4W

120

R520

1/4W

120

R537

2W

0.1

R539

2W

0.1

R540

2W

0.1

R538

2W

0.1

R547

1/4W

10

R548

1/4W

10

Q712

DTA124EKA

C535

NM

C536

NM

R706

NM

R707

NM

Q302

2SC2412K

R

Q301

2SC2412K

R

R301

10K

R302

10K

C527

NM

Q517

2SD2439

OP

Q519

2SB1588

OP

Q518

2SD2439

OP

Q520

2SB1588

OP

R507

1/4W

560

R513

1/4W

560

R514

1/4W

560

R508

1/4W

560

C513

NM

C515

NM

C514

NM

C516

NM

C508

68P

C507

68P

R505

22K

2012

R506

22K

2012

C521

0.22

C524

0.22

C522

0.22

C523

0.22

C543

NM

C544

NM

C503

100/10

C504

100/10

D708

1SS133

D709

1SS133

R734

NM

C712

NM

R502

10K

R501

10K

C502

33P

C501

33P

C505

68P

C506

68P

C517

10P

C520

10P

C518

10P

C519

10P

R529223216

R531223216

R532223216

R530223216

R534

47K

R533

47K

R535

47K

R536

47K

C512

10P

C511

10P

C510

10P

C509

10P

MIN MAX

SP OUTPUT

NJM2068MD

A

AMP UNIT

Silk-prints of "L" and "R" on the Amp Unit

are printed wrongly each other.

("L" should be "R", and "R" should be "L".)

+29 dB

-9.3 dB

22

GM-3400T/XJUC

Page 23

5 678

56

7

8

C

D

F

A

B

E

A-a A-b

A-b

R801 15KNMC801 0.001

C709

0.01

R815 47K

R814 1K

C701

NM

KN801

CZK2969-A-T

JA804

CND2458-A

JA805

CND2458-A

C803

3216

NM

R730

16K

R729

6.8K

R728

12K

TP1

TP2

TP3

TP4

TP5

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP18

TP20

TP24

TP19

JA801

CKE1055-A

1+B2

GND3REM

R701

1/4W

2.2K

R722

100

R714

10K

R713

330K

C702 0.001

R712

22K

R704

4.7K

R705

2.2K

Q703

KN2907AS

D804

1A4-E

D803

1A4-E

C802

0.01

2012

C804

0.22

D706

1SS133

R52

1/4W

120

R717

47

R709

2.2K

D705

NHSB046AT

R702

7.5K

R7161KR715

220

C708

0.01

R720

NM

C704

NM

R723

47K

R724

22K

L801

36uH

K000225700

R726

33K

TH701

470

R50

1/4W

560

D702

1SS133

Q702

2SC2412K

R

Q705

2SC2412K

R

Q710

2SC2412K

R

Q711

2SC2412K

R

Q713

2SC2412K

R

IC801KIA494AF

1

1IN+21IN-3FEEDBACK

4

DTC5CT6RT7GND8C1

9

E110E211C2

12

Vcc13OPC14Ref152IN-162IN+

Q709

2SA1037AK

R

R725

330

R727

2.2K

TH702

10K

R703

2.2K

1/4W

R721

1/2W

4.7K

D701

MTZJ7.5B

C711

NM

C706

0.22

C52

0.22

R733

1/4W

100

R732

2.7K

Q714

2SA1037AKR

D707

HZS3A2TD-E

R708

22K

D708

1SS133

D709

1SS133

R802

NM

R734

NM

C707

22/25

C703

100/16

C710

220/6.3

C712

NM

C807 220/6.3

R731

6.8K

R710

3.9K

D711

1SS133

D710

1SS133

FUSE (25A)

BLUE LED

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

NOTE :

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

NM : No Mount

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

>

GM-3400T/XJUC

23

Page 24

1234

1234

C

D

F

A

B

E

A-bA-a

A-a

A-b

IC301

1

A_OUT

2

A_-IN

3

A_+IN

4

V-

5

B_+IN

6

B_-IN

8

V+

7

B_OUT

R103

22K

R104

22K

C101

470P

C102

470P

C103

47P

C10747P

C108 47P

C104

47P

R311

56

R312

56

C812

0.033

C811

0.033

D110

1SS355

D112

1SS355

D111

1SS355

D109

1SS355

JA101

CKB1068-B

JA103

CKM1463-A

1

L+2R+3L-4R-

D101

1SS355

D105

1SS355

D103

1SS355

D107

1SS355

D102

1SS355

D106

1SS355

D104

1SS355

D108

1SS355

VR301

10K

TP36

TP37

TP38

TP40

TP41

TP42

TP43

TP44

TP45

TP46

TP47

TP48

TP49

TP51

TP50

TP56

TP57

TP58

TP59

TP60TP61

C113

NM

C114

NM

TP52

TP53

TP54

TP55

R827

Q712

DTA124EKA

R706

NM

R707

NM

R125

NM

R126

NM

R127

NM

R128

NM

R

1

R

1

C123

NM

C124

NM

C125

NM

C126

NM

R119

1/4W

470

R120

1/4W

470

R121

51K

1/4W

R122

51K

1/4W

R123

51K

1/4W

R124

51K

1/4W

R101

NM

R305

68K

R306

68K

R307

68K

R308

68K

C304

0.022

C303

0.022

C302

0.039

C301

0.039

R831

NM

L802

NM

R113

NM

R114

NM

C119

NM

R310

2.2K

R309

2.2K

KN802

NM

R11110K

0.25%

R10910K

0.25%

R10710K

0.25%

R10510K

0.25%

R112 10K

0.25%

R110 10K

0.25%

R108 10K

0.25%

R106 10K

0.25%

S301

00221461

IC101NJM4565M-D

1

AOUTPUT

2

A-INPUT

3

A+INPUT

4

V-

5

B+INPUT

6

B-INPUT

8

V+

7

BOUTPUT

IC102

1

AOUTPUT

2

A-INPUT

3

A+INPUT

4

V-

5

B+INPUT

6

B-INPUT

8

V+

7

BOUTPUT

C115

10/25

C117

10/25

C118

10/25

C116

10/25

C105

NM

D708

1SS133

D709

C112

10/25

C111

10/25

R313

130K

R314

130K

C106 0.0047

Lch

Rch

SP LEVEL INPUT

OFF

LPF

OFF

LPF

MIN MAX

LPFBUFFER/ISO.AMP

+15V

+VD

RCA INPUT

LPF OFF

GAIN

NJM4565M-D

NJM4558MD

0 dB / 0 dB

0 dB

-31.5 dB ~ -2.2 dB

VD VH 15 V

1 W +27.8 V +28.0 V +15.1 V

OUTPUT -27.8 V -27.9 V -15.2 V

-9.3 d

24

GM-3400T/XJUC

Page 25

5 678

56

7

8

C

D

F

A

B

E

A-a

A-b

A-bA-a

R805

4.7K

R806

4.7K

C805

0.0047

C806

0.0047

C822

0.001

C823

0.001

C820

NM

R815 47K

C832NMC833

NM

C821

NM

R809

1/2W

22

R810

1/2W

22

R820

NM

R821

1/2W

22

R822

1/2W

22

R807

1/2W

120

R808

1/2W

120

R823

1/2W

NM

R824

1/2W

NM

Q803

FKV550N

G

S

D

Q804

FKV550N

G

S

D

C810

3300/16

105

TP6

TP7

TP8

TP9

TP10

TP26

TP27

TP28

TP29

TP30

TP31

TP32

TP33

TP34TP35

TP38TP39

D821

FML-22S

D822

FML-22R

R812

11K

R813

27K

Q802

KTA1504S

OYG

Q801

KTA1504S

OYG

R827

1/2W10

R828

1/2W10

C824

3300/35

105

C825

3300/35

105

D806

MTZJ16B

D805

MTZJ16B

R825

NM

R826

NM

R711

100

R709

2.2K

TH701

470

R803

3.3K

R804

3.3K

IC801KIA494AF

1

1IN+21IN-3FEEDBACK

4

DTC5CT6RT7GND8C1

9

E110E211C2

12

Vcc13OPC14Ref152IN-162IN+

R829

1/2W

3.3K

R830

1/2W

3.3K

Q823

KTC3875S

Q824

KTC3875S

Q714

2SA1037AKR

*L803

BL02RN1R3N1A

*L804

BL02RN1R3N1A

Q822

KTC9015

ABC

EC

B

Q821

KTC9014

ABCD

EC

B

R708

22K

D708

1SS133

D709

R833

3.9K

R834

3.3K

Q825

KTC9014

ABCD

R832

1/4W

100

R835

0

T801

C831

220/35

C830

220/35

C807 220/6.3

R836

1/2W

NM

R837

1/2W

NM

R838

1/2W

NM

R839

1/2W

NM

C827

22/25

C826

22/25

C828

47/16

C829

47/16

R710

*JW123

*JW122

*JW124

*JW126

10:5

+15V

-15V

+VH

-VH

+VD

-VD

MODEL L803 L804 JW122 JW123 JW124 JW126

GM-3400T/XJEW5

GM-3400T/XJUC

GM-3400T/XJES

GM-3400T/XJUC

25

Page 26

1234

1234

C

D

F

A

B

E

11. PCB CONNECTION DIAGRAM

A

A

AMP UNIT

Capacitor

Connector

P.C.Board

Chip Part

SIDE B

SIDE A

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

FRONT

11.1 AMP UNIT

26

GM-3400T/XJUC

Page 27

5 678

56

7

8

C

D

F

A

B

E

A

SIDE A

GM-3400T/XJUC

27

Page 28

1234

1234

C

D

F

A

B

E

A

A

AMP UNIT

28

GM-3400T/XJUC

Page 29

5 678

56

7

8

C

D

F

A

B

E

A

SIDE B

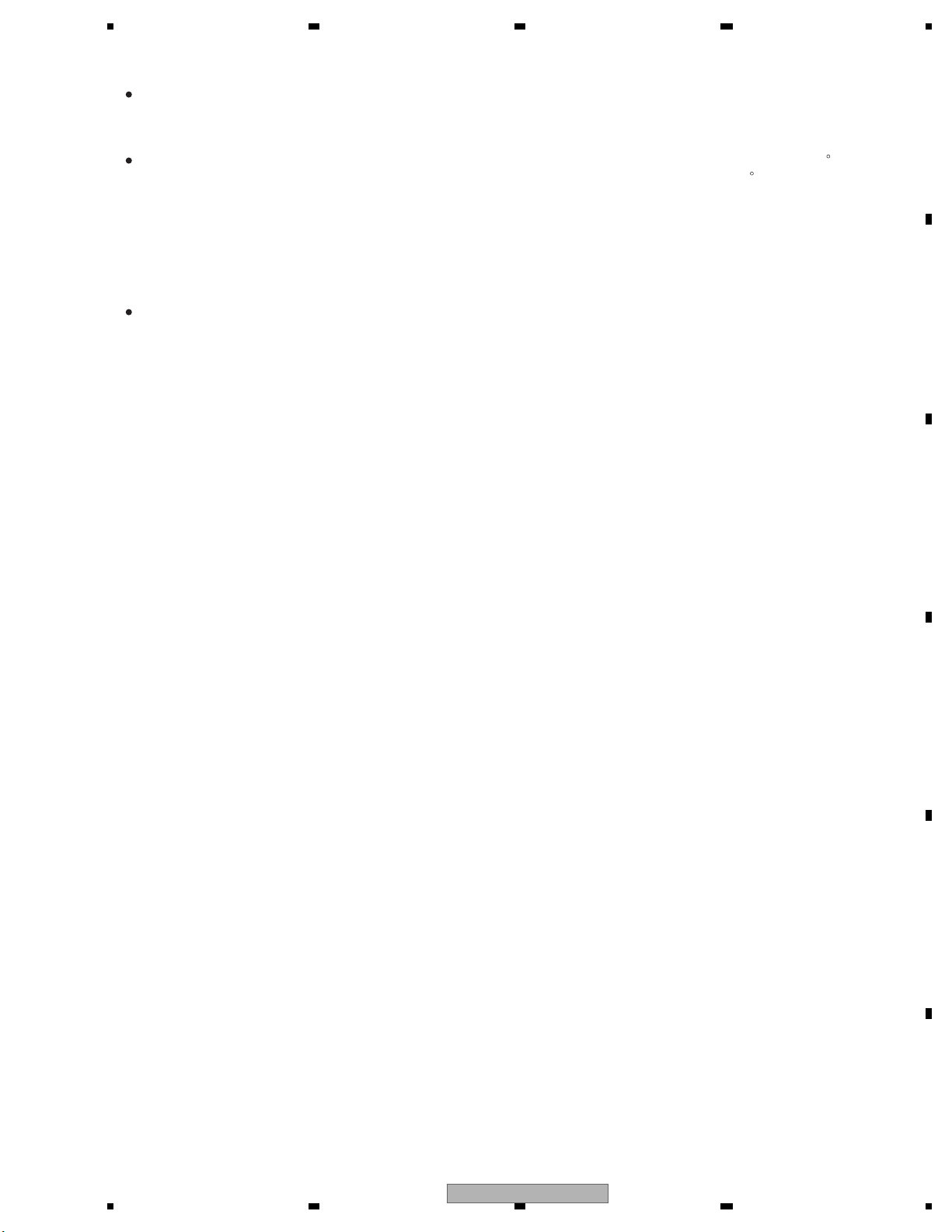

Silk-prints of "L" and "R" on the Amp Unit

are printed wrongly each other.

("L" should be "R", and "R" should be "L".)

GM-3400T/XJUC

29

Page 30

1234

1234

C

D

F

A

B

E

12. ELECTRICAL PARTS LIST

NOTE:

Parts whose parts numbers are omitted are subject to being not supplied.

The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Meaning of the figures and others in the parentheses in the parts list.

Example) IC 301 is on the point (face A, 91 of x-axis, and 111 of y-axis) of the corresponding

PC board.

IC 301 (A, 91, 111) IC NJM2068V

Circuit Symbol and No. Part No.

Unit Number : CZW5581(UC,EW5)

Unit Number : CZW5582(ES)

Unit Name : Amp Unit

A

Unit Number : CZW5581(UC,EW5)

Unit Number : CZW5582(ES)

Unit Name : Amp Unit

MISCELLANEOUS

IC 101 IC NJM4565MD

IC 102 IC NJM4565MD

IC 301 IC NJM4558MD

IC 501 IC NJM2068MD

IC 801 IC KIA494AF

Q 301 Transistor 2SC2412K

Q 302 Transistor 2SC2412K

Q 511 Transistor 2SA1038S

Q 512 Transistor 2SA1038S

Q 513 Transistor 2SC2389S

Q 514 Transistor 2SC2389S

Q 515 Transistor KTC3114

Q 516 Transistor KTC3114

Q 517 Transistor 2SD2439

Q 518 Transistor 2SD2439

Q 519 Transistor 2SB1588

Q 520 Transistor 2SB1588

Q 521 Transistor KTC3911S

Q 522 Transistor KTC3911S

Q 702 Transistor 2SC2412K

Q 703 Transistor KN2907AS

Q 705 Transistor 2SC2412K

Q 709 Transistor 2SA1037K

Q 710 Transistor 2SC2412K

Q 711 Transistor 2SC2412K

Q 712 Chip Digital Transistor DTA124EKA

Q 713 Transistor 2SC2412K

Circuit Symbol and No. Part No.

Q 714 Transistor 2SA1037K

Q 801 Transistor KTA1504S

Q 802 Transistor KTA1504S

Q 803 Transistor FKV550N

Q 804 Transistor FKV550N

Q 821 Transistor KTC9014

Q 822 Transistor KTC9015

Q 823 Transistor KTC3875S

Q 824 Transistor KTC3875S

Q 825 Transistor KTC9014

D 101 Diode 1SS355

D 102 Diode 1SS355

D 103 Diode 1SS355

D 104 Diode 1SS355

D 105 Diode 1SS355

D 106 Diode 1SS355

D 107 Diode 1SS355

D 108 Diode 1SS355

D 109 Diode 1SS355

D 110 Diode 1SS355

D 111 Diode 1SS355

D 112 Diode 1SS355

D 501 Diode 1SS355

D 502 Diode 1SS355

D 701 Diode MTZJ7R5(B)

D 702 Diode 1SS133

D 705 Chip LED NHSB046AT

D 706 Diode 1SS133

D 707 Diode HZS3L(A2)

D 708 Diode 1SS133

D 709 Diode 1SS133

D 803 Diode 1A4-E

D 804 Diode 1A4-E

D 805 Diode MTZJ16(B)

D 806 Diode MTZJ16(B)

D 821 Diode FML22S

D 822 Diode FML22R

L 801 Choke Coil 36 uH CZT2944

L 803 Coil(ES) CZT2945

L 804 Coil(ES) CZT2945

T 801 Transformer CZT2946

30

GM-3400T/XJUC

Page 31

5 678

56

7

8

C

D

F

A

B

E

Circuit Symbol and No. Part No.

TH701 Posistor CZC2982

TH702 Thermistor CZC2994

Circuit Symbol and No. Part No.

R 518 RS1/16S473J

R 519 120 ohm CZC2986

R 520 120 ohm CZC2986

S 301 Switch(LPF-OFF) CZS2928

VR301 Variable Resistor 10 kohm CZC2975

JA101 Pin Jack CKB1068

JA103 Socket CKM1463

JA501 Terminal CKE1057

R 521 RS1/16S112J

R 522 RS1/16S112J

R 523 RS1/16S472J

R 524 RS1/16S472J

R 525 RS1/16S222J

JA502 Terminal CKE1057

JA801 Terminal CKE1055

R 526 RS1/16S222J

R 527 120 ohm CZC2986

JA804 Terminal CND2458

JA805 Terminal CND2458

KN801 Terminal CZK2969

R 528 120 ohm CZC2986

R 529 RS1/8S220J

R 530 RS1/8S220J

RESISTORS

R 531 RS1/8S220J

R 532 RS1/8S220J

R 103 RS1/16S223J

R 104 RS1/16S223J

R 105 10 kohm CCN1152

R 106 10 kohm CCN1152

R 107 10 kohm CCN1152

R 533 RS1/16S473J

R 534 RS1/16S473J

R 535 RS1/16S473J

R 536 RS1/16S473J

R 537 0.1 ohm CZC2974

R 108 10 kohm CCN1152

R 109 10 kohm CCN1152

R 110 10 kohm CCN1152

R 111 10 kohm CCN1152

R 112 10 kohm CCN1152

R 538 0.1 ohm CZC2974

R 539 0.1 ohm CZC2974

R 540 0.1 ohm CZC2974

R 541 RS1/16S473J

R 542 RS1/16S473J

R 119 470 ohm CZC2987

R 120 470 ohm CZC2987

R 121 51 kohm CZC2988

R 122 51 kohm CZC2988

R 123 51 kohm CZC2988

R 543 RS1/16S564J

R 544 RS1/16S564J

R 545 RS1/16S473J

R 546 RS1/16S473J

R 547 10 ohm CZC2984

R 124 51 kohm CZC2988

R 301 RS1/16S103J

R 302 RS1/16S103J

R 305 RS1/16S683J

R 306 RS1/16S683J

R 548 10 ohm CZC2984

R 701 2.2 kohm CZC2980

R 702 RS1/16S752J

R 703 2.2 kohm CZC2980

R 704 RS1/16S472J

R 307 RS1/16S683J

R 308 RS1/16S683J

R 309 RS1/16S222J

R 310 RS1/16S222J

R 311 RS1/16S560J

R 705 RS1/16S222J

R 708 RS1/16S223J

R 709 RS1/16S222J

R 710 RS1/16S392J

R 711 RS1/16S101J

R 312 RS1/16S560J

R 313 RS1/16S134J

R 314 RS1/16S134J

R 501 RS1/16S103J

R 502 RS1/16S103J

R 712 RS1/16S223J

R 713 RS1/16S334J

R 714 RS1/16S103J

R 715 RS1/16S221J

R 716 RS1/16S102J

R 503 RS1/16S271J

R 504 RS1/16S271J

R 505 RS1/10S223J

R 506 RS1/10S223J

R 507 560 ohm CZC2981

R 717 RS1/16S470J

R 721 RD1/2PM472J

R 722 RS1/16S101J

R 723 RS1/16S473J

R 724 RS1/16S223J

R 508 560 ohm CZC2981

R 509 RS1/16S153J

R 510 RS1/16S153J

R 511 RS1/16S153J

R 512 RS1/16S153J

R 725 RS1/16S331J

R 726 RS1/16S333J

R 727 RS1/16S222J

R 728 RS1/16S123J

R 729 RS1/16S682J

R 513 560 ohm CZC2981

R 514 560 ohm CZC2981

R 515 RS1/16S473J

R 516 RS1/16S473J

R 517 RS1/16S473J

R 730 RS1/16S163J

R 731 RS1/16S682J

R 732 RS1/16S272J

R 733 100 ohm CZC2985

R 801 RS1/16S153J

GM-3400T/XJUC

31

Page 32

1234

1234

C

D

F

A

B

E

Circuit Symbol and No. Part No.

R 803 RS1/16S332J

R 804 RS1/16S332J

R 805 RS1/16S472J

R 806 RS1/16S472J

R 807 RD1/2PM121J

R 808 RD1/2PM121J

R 809 RD1/2PM220J

R 810 RD1/2PM220J

R 812 RS1/16S113J

R 813 RS1/16S273J

Circuit Symbol and No. Part No.

C 537 CKSRYB333K50

C 538 CKSRYB333K50

C 539 CQMA102J50

C 540 CQMA102J50

C 702 CKSRYB102K50

C 703 100 uF/16 V CZC2991

C 706 CKSRYB224K16

C 707 22 uF/25 V CZC2989

C 708 CKSRYB103K50

C 709 CKSRYB103K50

R 814 RS1/16S102J

R 815 RS1/16S473J

R 821 RD1/2PM220J

R 822 RD1/2PM220J

R 827 RD1/2PM100J

R 828 RD1/2PM100J

R 829 RD1/2PM332J

R 830 RD1/2PM332J

R 832 100 ohm CZC2985

R 833 RS1/16S392J

R 834 RS1/16S332J

R 835 RS1/16S0R0J

CAPACITORS

C 101 CCSRCH471J50

C 102 CCSRCH471J50

C 103 CCSRCH470J50

C 104 CCSRCH470J50

C 106 CQMA472J50

C 107 CCSRCH470J50

C 108 CCSRCH470J50

C 111 CEAT100M50

C 112 CEAT100M50

C 115 CEAT100M50

C 710 220 uF/6.3 V CZC2992

C 801 CCSRCH102J50

C 802 CKSQYB103K50

C 804 CFTLA224J50

C 805 CKSRYB472K50

C 806 CKSRYB472K50

C 807 220 uF/6.3 V CZC2992

C 810 3 300 uF/16 V CZC2977

C 811 CKSRYB333K50

C 812 CKSRYB333K50

C 822 CCSRCH102J50

C 823 CCSRCH102J50

C 824 3 300 uF/35 V CZC2978

C 825 3 300 uF/35 V CZC2978

C 826 22 uF/25 V CZC2989

C 827 22 uF/25 V CZC2989

C 828 47 uF/16 V CZC2990

C 829 47 uF/16 V CZC2990

C 830 220 uF/35 V CZC2993

C 831 220 uF/35 V CZC2993

C 116 CEAT100M50

C 117 CEAT100M50

C 118 CEAT100M50

C 301 CFTLA393J50

C 302 CFTLA393J50

C 303 CKSRYB223K50

C 304 CKSRYB223K50

C 501 CCSRCH330J50

C 502 CCSRCH330J50

C 503 CEAT101M10

C 504 CEAT101M10

C 505 CCSRCH680J50

C 506 CCSRCH680J50

C 507 CCSRCH680J50

C 508 CCSRCH680J50

C 517 CCSRCH100D50

C 518 CCSRCH100D50

C 519 CCSRCH100D50

C 520 CCSRCH100D50

C 521 CKSRYB224K16

C 522 CKSRYB224K16

C 523 CKSRYB224K16

C 524 CKSRYB224K16

C 525 CKSRYB102K50

C 526 CKSRYB102K50

32

GM-3400T/XJUC

Loading...

Loading...