Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

ORDER NO.

RRV3122

EFX-1000

DJ EFFECTOR

EFX-1000

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

EFX-1000 KUCXJ AC120V

EFX-1000 TLTXJ AC110 - 240V

EFX-1000 WYXJ AC220 - 240V

EFX-1000 WAXJ AC220 - 240V

For details, refer to "Important Check Points for good servicing".

T-IZY JUNE 2005 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

C

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

E

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Health & Safety Code Section 25249.6 - Proposition 65

AC Leakage Test

F

2

1234

EFX-1000

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

EFX-1000

E

F

3

7

8

Page 4

1234

CONTENTS

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 7

A

B

C

2.1 PACKING SECTION .................................................................................................................................. 7

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 CONTROL PANEL SECTION .................................................................................................................. 10

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................12

3.1 BLOCK DIAGRAM ................................................................................................................................... 12

3.2 OVERALL WIRING DIAGRAM................................................................................................................. 18

3.3 MAIN ASSY (1/3) ..................................................................................................................................... 20

3.4 MAIN ASSY (2/3) ..................................................................................................................................... 22

3.5 MAIN ASSY (3/3) ..................................................................................................................................... 24

3.6 CTRL (1/2), SW1 and SW2 ASSYS......................................................................................................... 26

3.7 CTRL ASSY (2/2)..................................................................................................................................... 28

3.8 7SEG ASSY............................................................................................................................................. 30

3.9 MIDI ASSY............................................................................................................................................... 32

3.10 ACIN, ENCB and MVR ASSYS.............................................................................................................. 33

3.11 POWER SUPPLY UNIT.......................................................................................................................... 34

3.12 VOLTAGES............................................................................................................................................. 36

3.13 WAVEFORMS........................................................................................................................................ 38

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 43

4.1 MAIN ASSY ............................................................................................................................................. 44

4.2 CTRL, SW1 and SW2 ASSYS ................................................................................................................. 48

4.3 MIDI, ACIN, ENCB and MVR ASSYS...................................................................................................... 52

4.4 POWER SUPPLY UNIT............................................................................................................................ 54

5. PCB PARTS LIST ........................................................................................................................................... 56

6. ADJUSTMENT ............................................................................................................................................... 71

7. GENERAL INFORMATION............................................................................................................................. 72

7.1 DIAGNOSIS ............................................................................................................................................. 72

7.1.1 TEST MODE ...................................................................................................................................... 72

7.1.2 REWRITING THE FIRMWARE.......................................................................................................... 78

7.1.3 POWER ON SEQUENCE.................................................................................................................. 90

7.1.4 DISASSEMBLY.................................................................................................................................. 92

7.2 PARTS...................................................................................................................................................... 94

7.2.1 IC ....................................................................................................................................................... 94

8. PANEL FACILITIES ........................................................................................................................................ 98

D

E

F

4

1234

EFX-1000

Page 5

5678

1. SPECIFICATIONS

• KUCXJ type

1. General

Power supply ......................................................... AC 120 V, 60 Hz

Power consumption ..................................................................16 W

Operating temperature ................. +5°C to +35°C (+41°F to +95°F)

Relative humidity ....................... 5% to 85% (without condensation)

Weight ........................................................................ 2.4 kg (5.3 lb)

Maximum external dimensions ..... 320 (W) x 234 (D) x 101 (H) mm

12-19/32 (W) x 9-7/32 (D) x 3-31/32 (H) in.

2. Audio Unit

Sampling rate ........................................................................ 96 kHz

A/D, D/A Resolution .............................................................. 24 bits

Frequency characteristics ....................................... 20 Hz to 22 kHz

S/N ratio ................................................................................. 83 dB

Distortion ............................................................................... 0.02 %

Headroom ................................................................................19 dB

Input level ............................................... –10 dBV / +4 dBu (22 kΩ)

Output level ......................................................... –10 dBV / +4 dBu

(RCA pin jacks: 1 kΩ, Phone jacks: 1 kΩ)

*–10 dBV / +4 dBu is switchable.

3. Input/Output terminals

Audio line input terminal

RCA pin jacks ............................................................................ 2

Phone jacks (1/4-inch/6.3 mm in diameter) ............................... 2

Audio line output terminal

RCA pin jacks ............................................................................ 2

Phone jacks (1/4-inch/6.3 mm in diameter) ............................... 2

Digital input terminal

RCA pin jack .............................................................................. 1

Digital output terminal

RCA pin jack .............................................................................. 1

EFX LINK connector (mini-DIN) ..................................................... 1

MIDI input terminal (5-pin DIN) ...................................................... 1

MIDI output terminal (5-pin DIN) .................................................... 1

• TLTXJ type

1. General

Power supply ....................................... AC 110 V - 240 V, 50/60 Hz

Power consumption ..................................................................16 W

Operating temperature .............................................. +5°C to +35°C

Relative humidity ....................... 5% to 85% (without condensation)

Weight .................................................................................... 2.4 kg

Maximum external dimensions ..... 320 (W) x 234 (D) x 101 (H) mm

2. Audio Unit

Sampling rate ........................................................................ 96 kHz

A/D, D/A Resolution .............................................................. 24 bits

Frequency characteristics ....................................... 20 Hz to 22 kHz

S/N ratio ................................................................................. 83 dB

Distortion ............................................................................... 0.02 %

Headroom ................................................................................19 dB

Input level ............................................... –10 dBV / +4 dBu (22 kΩ)

Output level .......................................................... –10 dBV / +4 dBu

(RCA pin jacks: 1 kΩ, Phone jacks: 1 kΩ)

*–10 dBV / +4 dBu is switchable.

3. Input/Output terminals

Audio line input terminal

RCA pin jacks ............................................................................ 2

Phone jacks (1/4-inch/6.3 mm in diameter) ............................... 2

Audio line output terminal

RCA pin jacks ............................................................................ 2

Phone jacks (1/4-inch/6.3 mm in diameter) ............................... 2

Digital input terminal

RCA pin jack .............................................................................. 1

Digital output terminal

RCA pin jack .............................................................................. 1

EFX LINK connector (mini-DIN) ..................................................... 1

MIDI input terminal (5-pin DIN) ....................................................... 1

MIDI output terminal (5-pin DIN) .....................................................1

A

B

C

4. Accessories

Operating instructions .................................................................... 1

Digital link cable ............................................................................. 1

Power cord ..................................................................................... 1

Warranty ......................................................................................... 1

NOTE:

Specifications and design are subject to possible modification

without notice.

4. Accessories

Operating instructions .................................................................... 1

Digital link cable ............................................................................. 1

Power cord ..................................................................................... 1

NOTE:

Specifications and design are subject to possible modification

without notice.

D

E

F

56

EFX-1000

5

7

8

Page 6

1234

• WYXJ type

A

1. General

Power supply ....................................... AC 220 V - 240 V, 50/60 Hz

Power consumption ..................................................................16 W

Operating temperature .............................................. +5°C to +35°C

Relative humidity ....................... 5% to 85% (without condensation)

Weight .................................................................................... 2.4 kg

Maximum external dimensions ..... 320 (W) x 234 (D) x 101 (H) mm

2. Audio Unit

Sampling rate ........................................................................ 96 kHz

A/D, D/A Resolution .............................................................. 24 bits

Frequency characteristics ....................................... 20 Hz to 22 kHz

S/N ratio .................................................................................. 83 dB

B

Distortion ............................................................................... 0.02 %

Headroom ................................................................................19 dB

Input level ............................................... –10 dBV / +4 dBu (22 kΩ)

Output level .......................................................... –10 dBV / +4 dBu

(RCA pin jacks: 1 kΩ, Phone jacks: 1 kΩ)

*–10 dBV / +4 dBu is switchable.

3. Input/Output terminals

Audio line input terminal

RCA pin jacks ............................................................................ 2

Phone jacks (1/4-inch/6.3 mm in diameter) ............................... 2

Audio line output terminal

RCA pin jacks ............................................................................ 2

C

Phone jacks (1/4-inch/6.3 mm in diameter) ............................... 2

Digital input terminal

RCA pin jack .............................................................................. 1

Digital output terminal

RCA pin jack .............................................................................. 1

EFX LINK connector (mini-DIN) ..................................................... 1

MIDI input terminal (5-pin DIN) .......................................................1

MIDI output terminal (5-pin DIN) .....................................................1

• WAXJ type

1. General

Power supply ........................................AC 220 V - 240 V, 50/60 Hz

Power consumption ................................................................. 16 W

Operating temperature .............................................. +5°C to +35°C

Relative humidity ...................... 5% to 85% (without condensation)

Weight .................................................................................... 2.4 kg

Maximum external dimensions...... 320 (W) x 234 (D) x 101 (H) mm

2. Audio Unit

Sampling rate ........................................................................ 96 kHz

A/D, D/A Resolution ............................................................... 24 bits

Frequency characteristics ....................................... 20 Hz to 22 kHz

S/N ratio .................................................................................. 83 dB

Distortion ............................................................................... 0.02 %

Headroom................................................................................ 19 dB

Input level ................................................ –10 dBV / +4 dBu (22 kΩ)

Output level .......................................................... –10 dBV / +4 dBu

(RCA pin jacks: 1 k, Phone jacks: 1 kΩ)

*–10 dBV / +4 dBu is switchable.

3. Input/Output terminals

Audio line input terminal

RCA pin jacks ........................................................................... 2

Phone jacks (1/4-inch/6.3 mm in diameter) ............................. 2

Audio line output terminal

RCA pin jacks ........................................................................... 2

Phone jacks (1/4-inch/6.3 mm in diameter) .............................. 2

Digital input terminal

RCA pin jack ............................................................................. 1

Digital output terminal

RCA pin jack ............................................................................. 1

EFX LINK connector (mini-DIN) ..................................................... 1

MIDI input terminal (5-pin DIN) ...................................................... 1

MIDI output terminal (5-pin DIN) .................................................... 1

4. Accessories

Operating instructions .....................................................................1

Digital link cable ..............................................................................1

Power cord ......................................................................................1

D

NOTE:

Specifications and design are subject to possible modification

without notice.

Accessories

Power cord

(KUCXJ : ADG7021)

(TLTXJ : ADG1127)

(WYXJ : ADG1127)

E

(WAXJ : ADG7079)

Digital link cable

(8P DIN cable)

(DKP3724)

L= 2 m

4. Accessories

Operating instructions .................................................................... 1

Digital link cable ............................................................................. 1

Power cord ..................................................................................... 1

NOTE:

Specifications and design are subject to possible modification

without notice.

Operating Instructions

Warranty (KUCXJ type only)

F

6

1234

EFX-1000

Page 7

>

5678

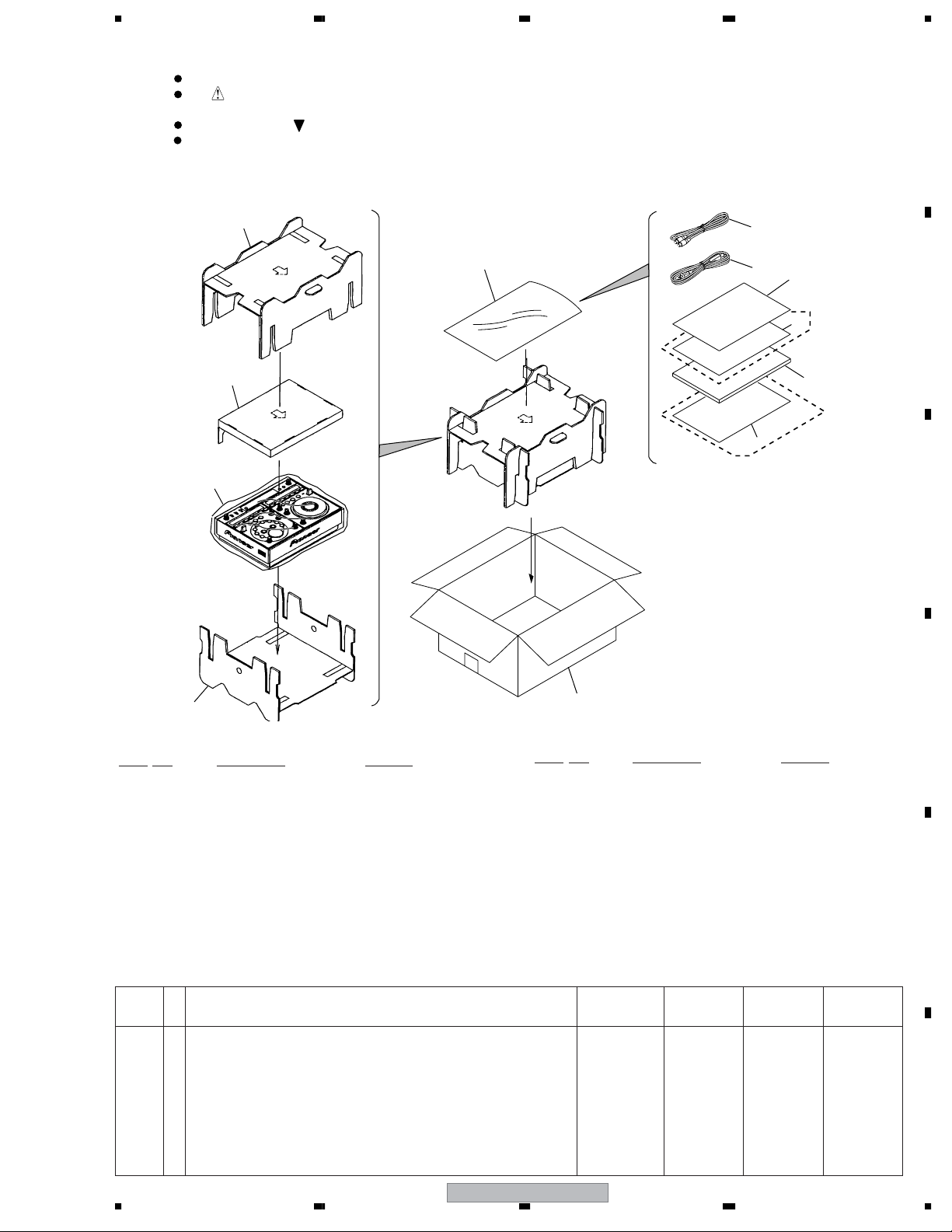

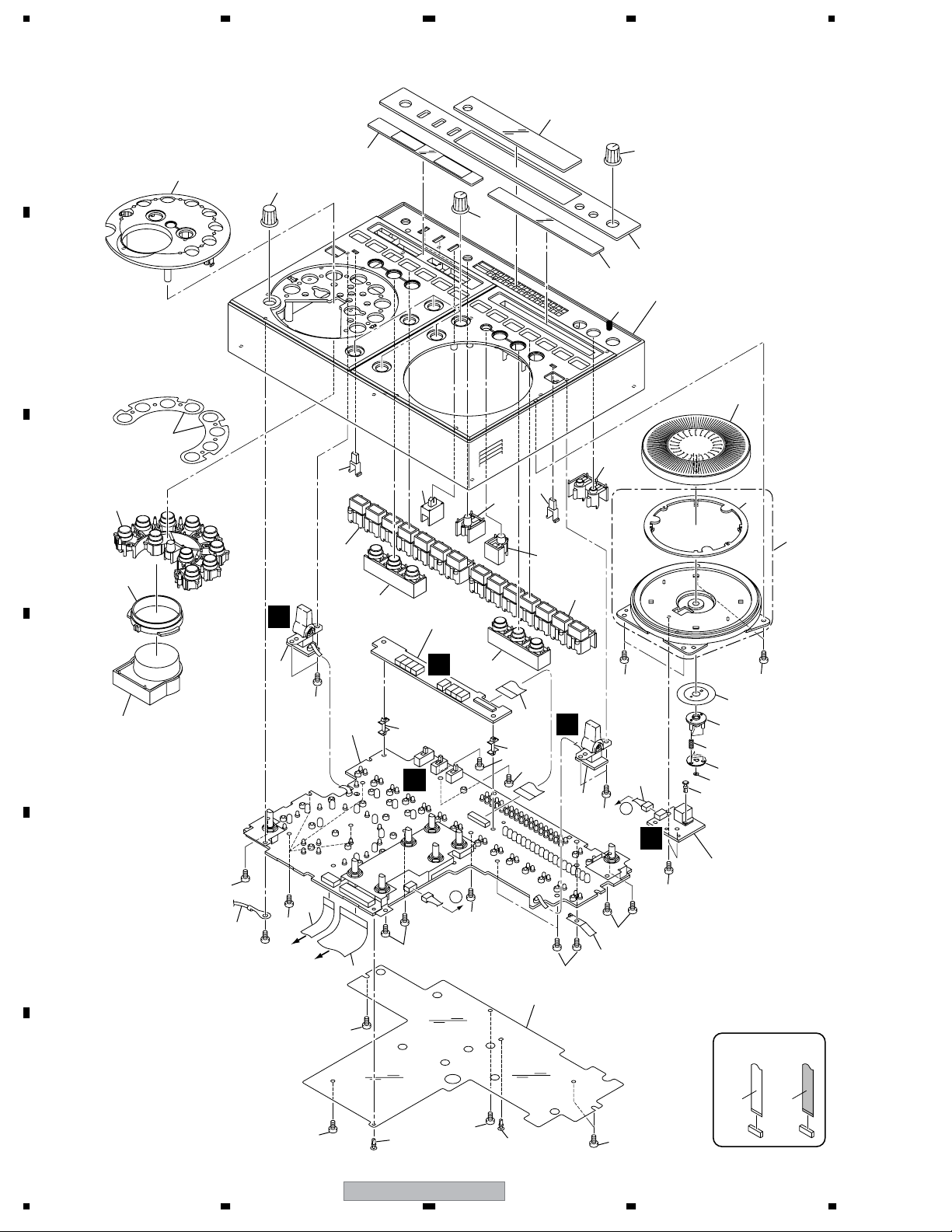

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING SECTION

7

9

11

A

3

2

1

5

KUCXJ

12

Only

4

WYXJ

6

Only

B

C

8

10

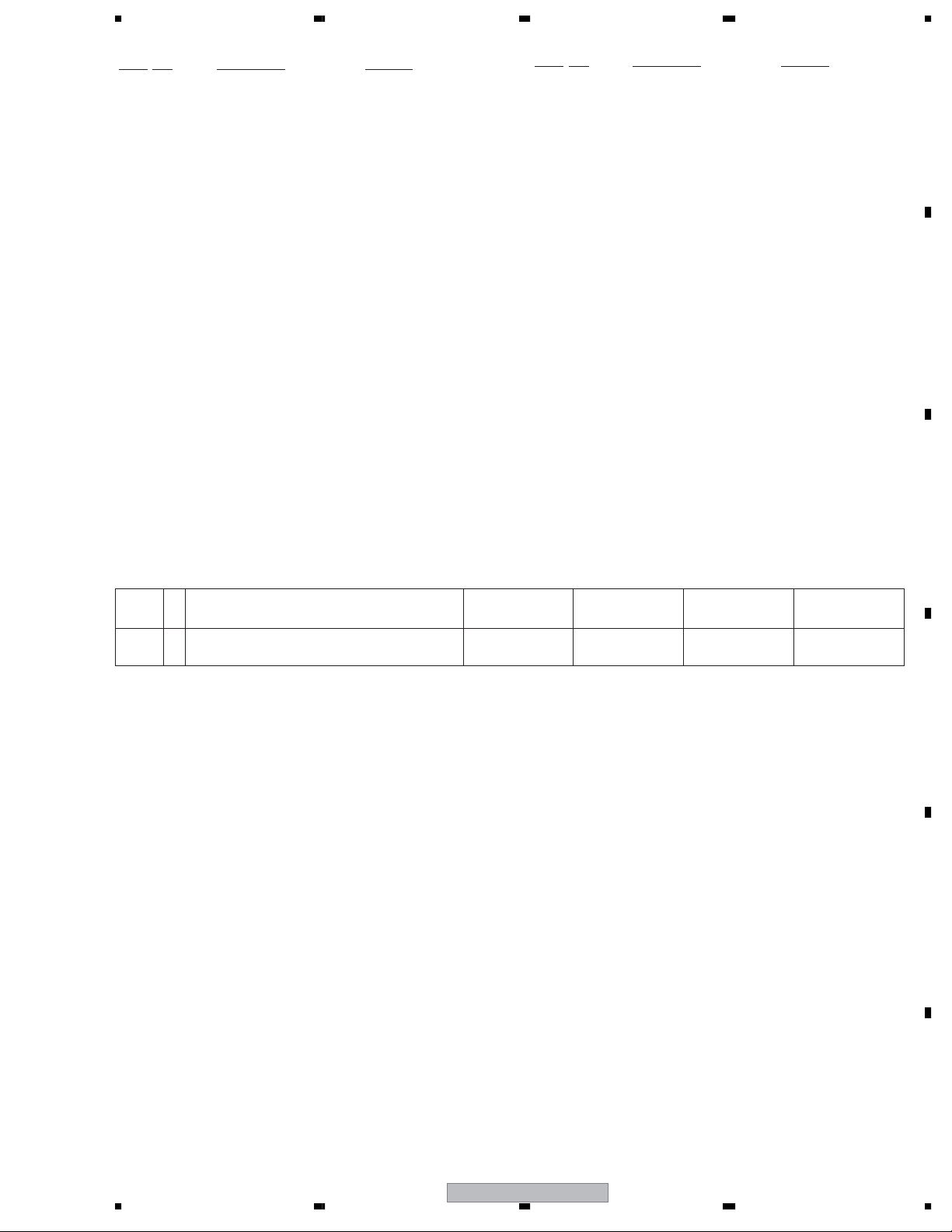

(1) PACKING SECTION PARTS LIST

No. Description Part No.

No. Description Part No.

Mark

1Powe Cord See Contrast table (2)

NSP 2 Polyethylene Bag AHG7117

3 Digital Link Cable(8P DIN Cable)DKP3724

4 Operating Instructions See Contrast table (2)

NSP 5 User Registration SH DRM1262

Mark

6 WEE Caution Card See Contrast table (2)

7Pad (A) DHA1645

8Pad (B) DHA1687

9Pad (C) DHA1647

10 Packing Case See Contrast table (2)

11 Sheet RHX1006

NSP 12 Limited Warranty See Contrast table (2)

(2) CONTRAST TABLE

EFX-1000/KUCXJ, TLTXJ, WYXJ and WAXJ are constructed the same except for the following:

Mark No. Symbol and Description

>

NSP 12 Limited Warranty ARY7043 Not used Not used Not used

1Power Cord ADG7021 ADG1127 ADG1127 ADG7079

4 Operating Instructions (Chinise/English) DRB1367 Not used Not used Not used

4 Operating Instructions (English/Spanish/ Chinese) Not used DRB1369 Not used Not used

4 Operating Instructions (English/French/Duch/German/Italian/Spanish) Not used Not used DRB1368 Not used

4 Operating Instructions (English) Not used Not used Not used DRB1370

6 WEE Caution Card Not used Not used ARM7099 Not used

10 Packing Case DHG2476 DHG2477 DHG2475 DHG2479

EFX-1000/

KUCXJ

EFX-1000

56

7

EFX-1000/

TLTXJ

EFX-1000/

WYXJ

EFX-1000/

WAXJ

8

D

E

F

7

Page 8

1234

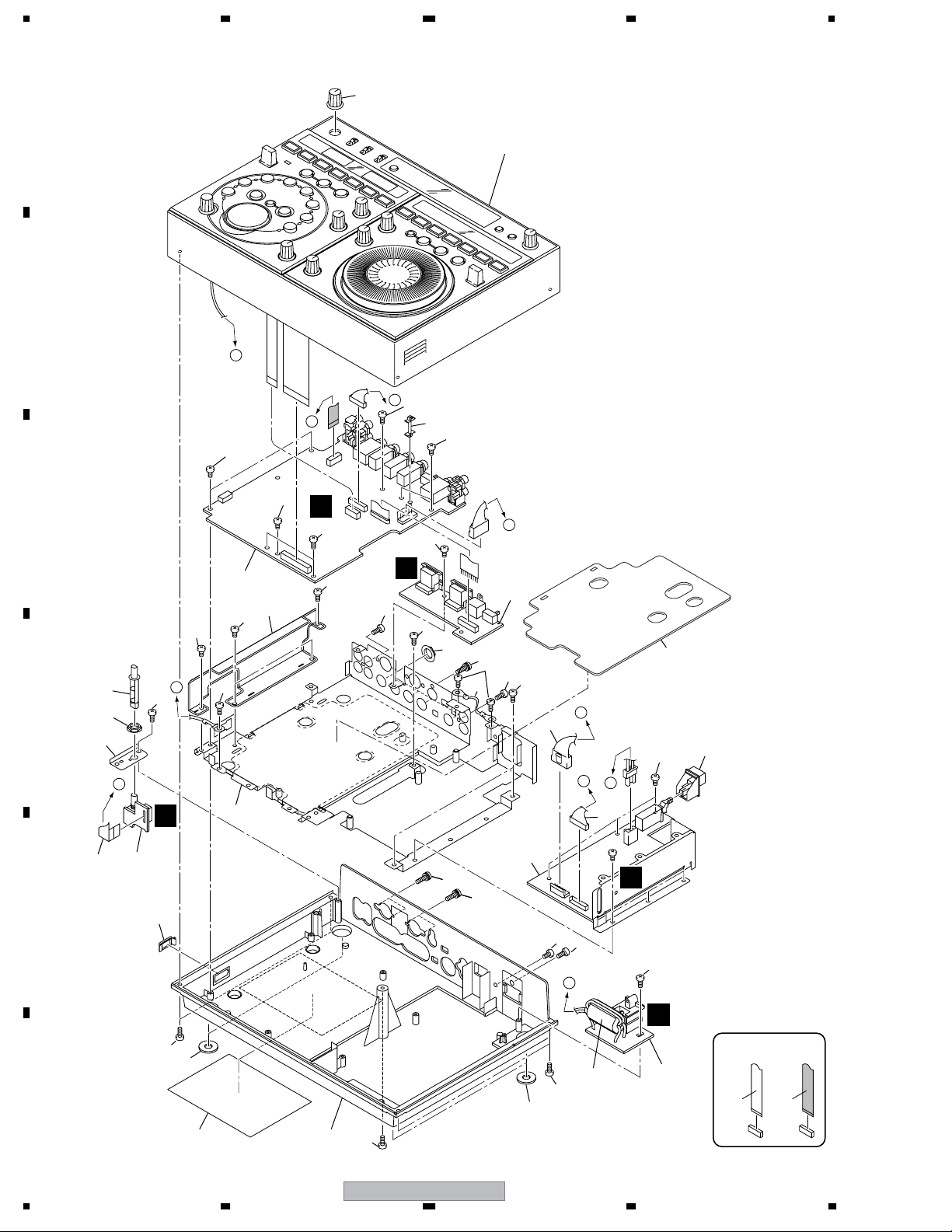

2.2 EXTERIOR SECTION

A

B

A

29

18

Refer to

"2.3 CONTROL PANEL SECTION" .

C

29

B

17

31

31

C

1

13

29

15

D

26

14

B

A

30

I

4

6

E

20

29

29

16

A

29

29

30

F

29

29

28

28

27

28

28

D

3

31

23

19

28

29

30

7

29

D

8

C

E

9

5

29

J

30

30

30

E

G

12

F

22 21

8

1234

30

EFX-1000

12

10

30

2

NON-CONTACT

SIDE

CONTACT SIDE

Page 9

>

>

5678

(1) EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 MAIN BOARD Assy DWX2401

2ACIN Assy See Contrast table (2)

3 MIDI Assy DWX2402

4 MVR Assy DWX2444

5POWER SUPPLY Unit DWR1377

No. Description Part No.

Mark

16 Main Shield Assy DXB1851

NSP 17 PCB Holder REC1220

18 Knob VOL DAA1168

19 Power Knob DAC1895

20 Blind Cap DNK4218

A

6 10P Flexible Cable DDD1293

NSP 7 Earth Lead Wire DE005VF0

8 Connector Assy DKP3725

9 Connector Assy DKP3741

10 Ferrite Core DTH1196

11 • • • • •

12 Insulator MO DEC2250

13 Insulation Sheet B DEC2823

14 VOL Support Plate MASTER DNF1719

15 Extension Shaft DNK4348

NSP 21 Chassis See Contrast table (2)

22 Block Label DRW2271

23 E Wave Sheet DEC2881

24 • • • • •

25 • • • • •

26 Nut M7 DBN1011

27 Nut M12 DBN1012

28 Screw PMH30P100FTB

29 Screw BBZ30P060FTB

30 Screw BPZ30P080FTB

31 Screw BBZ30P080FTC

(2) CONTRAST TABLE

EFX-1000/KUCXJ, TLTXJ, WYXJ and WAXJ are constructed the same except for the following:

Mark No. Symbol and Description

2ACIN Assy DWR1382 DWR1381 DWR1381 DWR1381

NSP 21 Chassis DNK4618 DNK4621 DNK4617 DNK4620

EFX-1000/

KUCXJ

EFX-1000/

TLTXJ

EFX-1000/

WYXJ

EFX-1000/

WAXJ

B

C

D

E

F

56

EFX-1000

9

7

8

Page 10

1234

2.3 CONTROL PANEL SECTION

A

34

38

B

36

C

31

39

22

D

40

21

30

28

23

26

1

40

33

21

32

35

37

44

17

29

45

20

25

24

3

D

41

47

2

E

11

B

27

47

11

47

14

43

47

15

18

19

47

6

C

10

4

A

47

16

H

5

47

E

9

MAIN CN102

F

47

To

MAIN CN402

7

To

47

8

47

42

47

A

47

47

13

47

12

47

42

47

47

NON-CONTACT

SIDE

CONTACT SIDE

10

EFX-1000

1234

Page 11

5678

CONTROL PANEL SECTION PARTS LIST

Mark

No. Description Part No.

1 7SEG Assy DWG1584

2 CTRL Assy DWG1585

3 SW1 Assy DWS1353

4 SW2 Assy DWS1354

5 ENCB Assy DWX2403

6 20P Flexible Cable DDD1274

7 10P Flexible Cable DDD1290

8 28P Flexible Cable DDD1292

NSP 9 Earth Lead Wire DE015VF0

10 Small Connector PF04PP-C05

A

11 PC Support DEC2736

12 Insulation Sheet A DEC2807

13 Earth Plate (CU) VBK1070

14 JOG Spring DBH1540

15 Encoder Plate DEC2498

16 Nyron Rivet DEC2735

17 JOG Dial DNK4337

18 Encoder Holder DNK4339

19 Smoother DNK4346

20 JOG Holder Assy DXA1992

21 Knob VOL DAA1168

22 Knob TIME DAA1169

23 Button Effect DELAY DAC2223

24 Button Effect JET DAC2224

25 Button MEMORY DAC2225

26 Button HOLD DAC2226

27 Button LOW DAC2227

28 Button METER DAC2228

29 Button LB DAC2229

30 Slide Knob DAC2230

31 Button BEAT DAC2231

32 aluminum Panel DAH2330

33 Window LEVEL DAH2331

34 Window TIME DAH2332

35 Window JOG DAH2333

B

C

D

36 Sheet DED1175

37 Control Panel DNK4340

38 Escutcheon DNK4342

39 TAP Display Ring DNK4343

40 Indicator DNK4344

41 Button TAP Assy DXA1993

42 Nyron Rivet 3x4.5 RBM-003

43 Washer WT26D060D050

44 Earth Spring DBH1539

45 Pom Ring DNK4345

46 Screw BBZ30P060FTB

47 Screw BPZ30P080FTB

56

EFX-1000

E

F

11

7

8

Page 12

2

4

6

8

0

1234

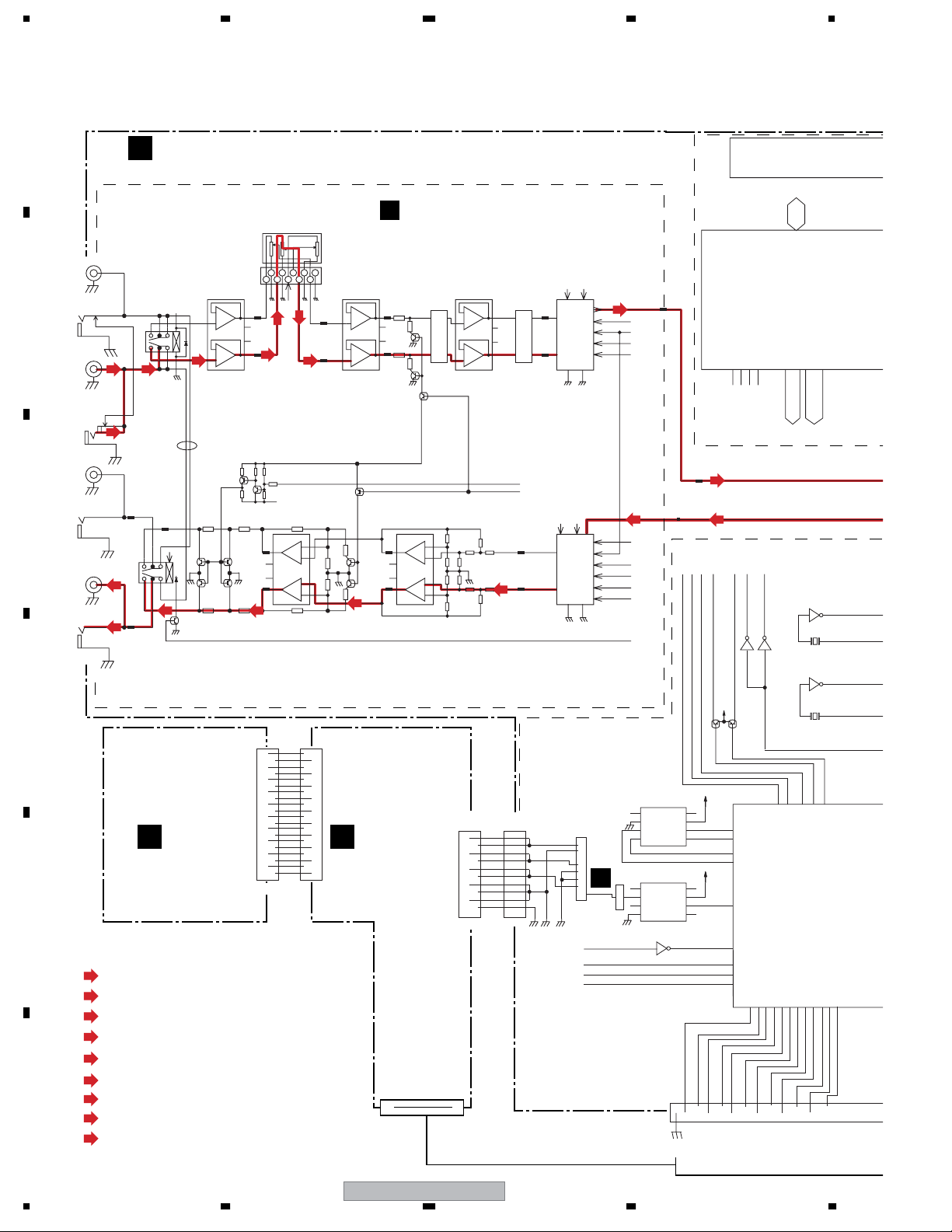

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

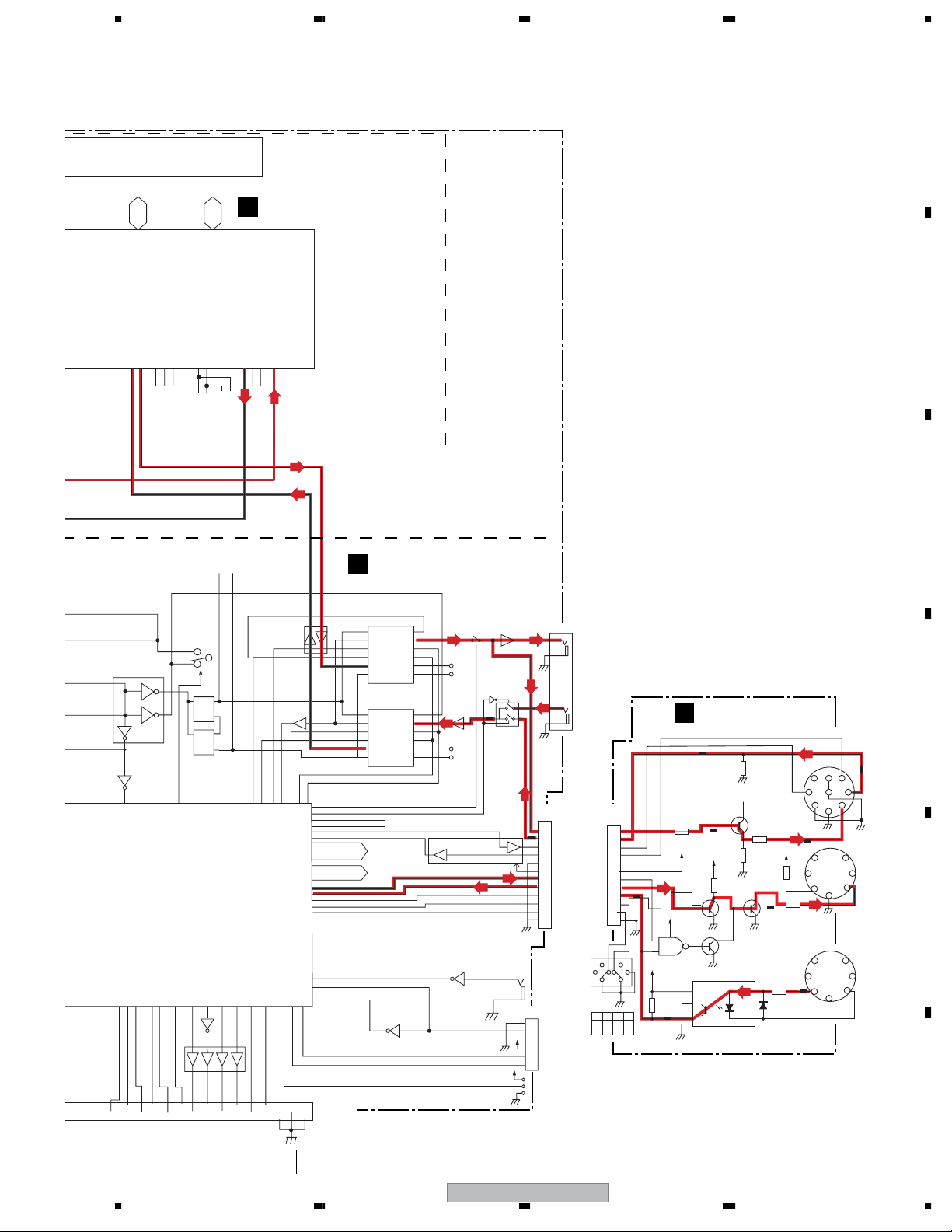

3.1 BLOCK DIAGRAM

A

• AUDIO BLOCK

B

C

D

E

F

R IN

(RCA)

R IN

(PHONE)

L IN

(RCA)

L IN

(PHONE)

R OUT

(RCA)

R OUT

(PHONE)

L OUT

(RCA)

L OUT

(PHONE)

(MID)

(DIG)

(EFX)

(DS_SRC)

(SRC_DS)

(DS_DA)

(DS_AD)

(HP)

A

MAIN BOARD ASSY

VR1201

INPUT TRIM VR

4

10

6

(HP)

(HP)

RY301

VSR1008

L CH

R CH

VSR-1008

4

7

3

4

89

7

RY201

3

89

BYPASS

LINE

V+12

2

V+12

2

10

2

3

1

R CH

6

7

5

8

2

3

IC201

NJM4580MD

Q302

Q301

L CH

R CH

+15V

4

-15V

1

L CH

Q204 Q205

Q304

Q303

+15V

-15V

+15V

-15V

1

8

4

7

IC303

NJM4580MD

1

10

1

Q307

V3R3

CN200

789

5

6

R CH

5

2

3

L CH

IC202

NJM4580MD

2

3

6

5

CN715CN601

1

1

2

3

5

7

9

-

~

E B

7SEG ASSY CTRL ASSY

@

$

^

2

3

4

4

5

6

6

7

8

0

=

!

#

%

&

"Refer to Control Block""Refer to Control Block"

8

9

0

=

~

!

@

#

$

%

^

&

: AUDIO SIGNAL ROUTE (Digital Signal (MIDI))

: AUDIO SIGNAL ROUTE (Digital Signal)

: SIGNAL ROUTE (EFX LINK)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to SRC)

: AUDIO SIGNAL ROUTE (Digital Signal (SRC to DSP)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to D/A)

: AUDIO SIGNAL ROUTE (Digital Signal (A/D to DSP)

: AUDIO SIGNAL ROUTE (Phones L ch)

: AUDIO SIGNAL ROUTE (L ch)

A

1/3 MAIN BOARD ASSY

300kHz

LPF

Q202

7

8

+15V

4

-15V

1

Q298

R CH

1

Q306

+15V

8

4

-15V

Q305

7

L CH

IC301

NJM4580MD

1£

Q201

6

5

2

3

IC203

NJM4580MD

Q299

2

3

6

5

1

2

3

4

5

6

7

8

9

0

CN705

V3R3: 1,3,9,14,27,43,49

GND : 6,12,28,4146,52

DQ 6

DQ 7

DQ 8

DQ 9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

ED10

ED11

ED12

ED13

ED14

ED15

113

112

V+5A V3R3

300kHz

LPF

R CH

7

8

+15V

4

-15V

1

L CH

MUTE

GAINSWOUT

R CH

L CH

CN102CN701

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

0

0

HRDYn

DSPCSn

DSPRST1n

DSPINTn

6 7

R CH

1

2

L CH

5 8

IC200

AK5381VT

V+5A V3R3

6 5

8

R CH

7

L CH

4 9

IC300

PCM1742KE

CN101

(DS_AD)

9

13

11

12

10

ADCDT

ADRSTN

SCK

AD_64FS

AD_96K

(DS_DA)

BCK

1

16

15

14

13

1

2

3

4

5

6

7

8

LRCK

3

DAMLN

TSRCCK

TSRCTXD

BYPASS

IC415

BR93L66F-W

8

7

6

5

TO POWER SUPPLY UNIT

(CN201)

IC417

M51957BFP

J

1

L

2

P

3

F

4

6 2

VCC:4

GND:8

D610A002BPY225-K

176

135

DSPRST1n

DSPINTn

DIGITAL SIGNAL(A/D To DSP)

(DS_AD)

DACDT

DIGITAL SIGNAL(DSP To D/A)

(DS_DA)

DAMLN

DVL

ADRSTn

BYPASS

MUTE

TC7SU04F

V3R3

Q411

Q401

V3R3

1

2

56

3

52

4

57

58

V3R3

8

7

92

6

5

IC404

1

84

TC7WH04FU

108

110

135

357 9 - ~

246 8 0 =

ED 9

119

120

117

118

111

IC500

140

145

HRDYn

DSPCSn

CLKIN(DPS)

SCK(A/D)

IC503

IC310

TC7SU04F

GND:3

VCC:5

24

24

474927

ED 6

ED 7

ED 8

121

122

123

81

121

122

HA1-4

22.5792Mhz

90

123

1011134244454748505153

DQ 4

DQ 5

DE 4

ED 5

127

128

IC416

2

TC7SU04F

X401

1

TC7WH04F

120

124

DQ 2

DQ 3

ED 2

ED 3

130

129

HD0-15

IC409

GND:4

VCC:8

106

125

126

DQ 1

ED 1

131

4

7

127

24578

DQ 0

ED 0

132

GND:3

VCC:5

3

19

CS

CE0

102

128

115

12

SS6

SS4

SS5

SS7

TMCW

TMCCW

DISPCONTn

SS0

SS1

SS2

SS3

BEATMIX

EFX-1000

1234

Page 13

5678

IC411

IC411

IC501

K4S281632F-UC-75-K

39

RAS

CASWELDQM

UDQM

SDWEn

SDCAS

SDRAS

BE0

BE1

108

V3R3B: 5,9,25,44,47,55,58,65,72,84,87,96,107,114,126,141,162,183,188,206

V1R2 : 3,11,14,22,29,35,40,43,46,50,51,53,60,67,80,89,96,104,105,116,124

: 133,149,157,169,171,177,181,190,195,196,201,208

GND : 4,10,15,23,26,30,34,39,45,48,49,54,59,66,73,81,85,88,97,106,115,125

: 134,142,148,158,163,170,182,189,184,199,203,207

20

27

OUTSRCDT

INSRCDT

ECLKOUT

EA15

151

204

DSPRDN

DSPCLK

A10

A11

BA0BACLK

EA12

EA13

EA14

150

DSPWRN

A 8

A 9

EA10

EA11

21,24,38

64FS

96kHz

A 4

A 5

A 6

A 7

EA 6

EA 7

EA 8

EA 9

8,16,19,36

AD_64FS

23242526293031323334223520213818171615

A 0

A 1

A 2

A 3

A

3/3 MAIN BOARD ASSY

EA 2

EA 3

EA 4

EA 5

626364686970717476869391909477757983110

333132

37

BCK

LRCK

AD_96k

(DS_AD)

DACDT

ADCDT

A

B

(DS_DA)

DIGITAL SIGNAL(DSP To SRC)

DIGITAL SIGNAL(SRC To DSP)

(SRC_DS)

64fs

96kHz

IC410

TC74VHC00F

GND:7

VCC:1

10

11

IC405

3 5

6 2

TC7WH04F

7 1

IC418

GND:3

4 2

VCC:5

97

119

114

118

@$ ^ * ) + ™

!

#%& (_¡£

4

1,2,9

IC413

2211

15

7

96kHz

IC414

1,7,9,10,16:V3R3

IC413

3,4,5,6,8:GND

1,9,10,16:V3R3

IC414

3,4,5,6,8:GND

51

IC400

PEG097A8-K

(HD64F2377-K)

VCC:4,41,72,98,99,111,112

VSS:2,10,18,25,40,50,70,95,102,129

116

142

3 2

IC411

TC74VHC125FTS

IC404

7 1

6 5

138

TC7WHU04FU

11 12

113

117

TC74VHC161FT

23

24

VCC:4

GND:8

8 9

IC411

VCC:14

RSCRSTn

TSCRSTn

131

130

63,64,65,66,67,68,69,71

73,74,75,76,77,78,79,80

45

44

GND:7

JGMIX

BEATCHR

JGCHR

BEATDPT

JGDPT

EFOUTLEVEL

EXPOUT

EXPCLK

EXPSTBn

EXPBLK

JGA

JGB

56

IC407

6.14MHz

IC407

TSRCRXD

TSRCCSn

83

(DS_SRC)

INSRCDT

12 11

3 2

RSRCCSn

59

826133

133

134

6,7,8,11

26

54

55

42

43

28

141

139

OUTSRCDT

TC74VHC125FT

6 5

GND:7

VCC:14

TC74VHC125FT

TSRCCK

TSRCTXD

DIG MUTE

30

DIGINSEL

60

88

89

HD0-15

HA1-4

14

143,144

1

CN402

A

2/3 MAIN BOARD ASSY

IC401

CS8420-CSZD1

ISCLK

13

1

SDA

2

AD0

RST

9

14

SDIN

12

ILRCK

CS8420-CSZD1

16

OSCLK

1

SDA

2

AD0

9

RST

18

SDOUT

16

OLRCK

MIDI OUT

IC402

DSPWRN

DSPRDN

OMCK

CCLK

OMCK

CDIN

CCLK

CDIN

RXP

21

26

TXP

27

28

6,23

7,22

21

4

27

28

6,23

7,22

MIDI IN

6 5

V+5D1

GNDA

Q409

(DIG)

V+5D2

GNDA

Q412

Q403

TC7W66FU

IC412

TC74VHC125FTS

VCC:14

(MID)

GND:7

(MID)

Q405

Q408

Q400

(DIG)(DIG)

(EFX)

3

(DIG)

6 5

1 2

7

IC403

VCC:8

GND:4

(EFX)

J403

VCC:8

GND:4

1

2

12 11

3

4

5

6

7

8

9

0

=

S1000

JA401

FOOT SW

CN400

6

GND

FLWR

5

NC

4

V3R3

3

REM1

2

REM2

1

-10dB

+ 4dB

S201

EFX-1000

DIGITAL OUT

JA400

DIGITAL IN

CN1001

MINI DIN

TXD

DIN

MIXRXD

GND

+5V

MIDI PASS

MIDI TXD

MIDI RXD

FSEL1

FSEL2

GND

9

8

7

1,5

6,10

6,10

96k48k 44k

1

2

3

4

5

6

7

8

9

0

=

1,5

HLL

HHL

7

C

F

MIDI ASSY

(EFX)

R1020

180

V+5D1

R1013

Q1002

1k

V+5D1

V+5D1

(MID)

Q1003

V+5D1

5

4

2

1

IC1002

3

4

2

TC7SH08FU

V+5D1

3

6

R1001

5

R1008

560

4

R1010

220

Q1001

IC1001

PC900V0NSZX

(MID)

R1009

1

2

68

Q1000

(EFX)

V+5D1

R1004

220

D1002

1SS355

R1003

220

R1002

220

8

5 3

2

GNDF GNDD1

6

1

4

(MID)

6

1

4

7

6

4

EFX LINK

1

9

7

3

MIDI OUT

5

2

7

3

MIDI IN

5

2

D

E

F

13

8

Page 14

1234

• CONTROL BLOCK

A

B

CTRL ASSY

B

C

Refer to next page

D

E

(EXP.)

SS7 KSC0

1 3 5 7 9 11 13 15 17 19 21 23 25 27

2 4 6 8 10 12 14 16 18 20 22 24 26 28

LED MATRIX

KEY MATRIX

A B C D E F G H

J K L M N O P Q R S T

JGDPT

EFOUTLEVEL

EXPOUT

EXPCLK

EXPSTBn

EXPBLK

JGA

JGB

JGCHR

BEATDPT

A B C D E F G H

SS7

BEATMIX

JGMIX

BEATCHR

SS6

SS5

SS4

SS3

SS2

SS1

Q702

I

DISPCONTn

SS0

SEG19

Q721 Q728

SEG12

SEG11

V+12ADIG 7

TMCW

TMCCW

V+12A

Q716

Q762

CN705

V+5A

V+12A

Q729

V+12ADIG 0

Q769

IC703

TC74VHC04FS

Q717 Q718

D105

RPI-2150N

JOG A

JOG B

V3R3

V+5A

Q740

SEG0

V+12A

V+ 5A

V+ 5D

D722

V3R3

I

V+ 5A

VR701

EFFECT OUT

LEVEL

51 SEG 0

52 SEG 1

23 SEG 2

24 SEG 3

55 SEG 4

56 SEG 5

57 SEG 6

58 SEG 7

59 SEG 8

60 SEG 9

61 SEG10

62 SEG11

63 SEG12

64 SEG13

65 SEG14

66 SEG15

67 SEG16

68 SEG17

69 SEG18

70 SEG19

83 DIG 0

84 DIG 1

85 DIG 2

86 DIG 3

87 DIG 4

88 DIG 5

89 DIG 6

90 DIG 7

91 KSC 0

92 KSC 1

93 KSC 2

94 KSC 3

95 KSC 4

96 KSC 5

V+12

Q720Q719

V3R3

DEPTH

N

V3R3

JOG DEPTH

V3R3

GNDL

GNDL

GNDL

GNDF

1 3 5 7 9

2 4 6 8 10

VR702

BEAT

VR703

V3R3

2.2k

V+5D

P

O

BK0

41

V+12A

V+5D

V3R3

V3R3

J K L M

EXPBLK 45

UPD16306B

BK 1

BK 2

8

9

BK0

D842

V+12

V+12

CHARACTER

CHARACTER

EXPSTBn 43

IC705

BK 3

BK 4

10111213141516171819202122

CN701

VR704

BEAT

R

VR705

JOG

Q

EXPOUT 36

EXPCLK 38

BK 5

BK 6

BK 7

BK 8

BK 9

BK10

V3R3

V3R3

BK11

BK12

BK13

VR706

BEAT MIX

VR707

JOG MIX

BK14

BK15

2.2k

V+12A

T

S

BK16

23

BK16

D858

TO MAIN BOARD ASSY (CN402) TO MAIN BOARD ASSY (CN102)

A A

F

14

EFX-1000

1234

Page 15

E

7SEG ASSY

5678

A

TIME

4/4

1

10

2

9

3

8

7

4

56

D615

TIME

3/4

1

10

2

9

3

8

7

4

56

D614

TIME

2/4

1

10

2

9

3

8

7

4

56

D613

TIME

1/4

1

10

2

9

3

8

7

4

56

D612

RHYTHM

COUNT

1

2

3

4

56

D619

BPM

10

9

8

7

3/3

1

10

2

9

3

8

7

4

56

D618

AUTO MANU

D601

D602

D603

D604

BPM

2/3

1

10

2

9

3

8

7

4

56

D617

RHYTHM

D605

D606

D608

D620

MIDI

BPM

1/3

1

10

2

9

3

8

4

7

5

6

D616

5 SEG4

4 SEG3

3 SEG2

2 SEG1

1 SEG0

6 SEG5

7 SEG6

8 SEG7

17 DIG7A

16 DIG6A

15 DIG5A

14 DIG4A

12 DIG3A

11 DIG2A

10 DIG1A

9 DIG0A

18 SEG16

13 SEG17

B

C

TO CTRL ASSY (CN715)

B

20 DIG4

19 DIG3

CN601

D

56

EFX-1000

E

F

15

7

8

Page 16

1234

A

LED Matrix

SEG23 - SEG20 SEG19 SEG18 SEG17 SEG16 SEG15 SEG14 SEG13 SEG12 SEG11

PHASE

DIG0

DIG1

− RING-LP

−−

SHIFTER-

LP

VOCODER

-LP

WAH-LP JET-LP LMUP07 LMUP06 LMUP05 LMUP04 LMUP03

HUMANIZER

-LP

ZIP-LP − LMUP14 LMUP13 LMUP12 LMUP11

B

C

D

DIG2

DIG3

DIG4

DIG5

DIG6

DIG7

Key Matrix

KSC0

KSC1

KSC2

KSC3

KSC4

KSC5

KSC6

KSC7

−

−−−RYTH-DS TAP-DS − LMDW14 LMDW13 LMDW12 LMDW11

−−−MIDI-DS AUTO-DS HOLD-LP AUTO-LP PLAY-LP − LMR-LP

− TAPB-LP TAPB-LP TAPB-LP TAPB-LP -1/2R-LP -8/1R-LP -4/1R-LP -2/1R-L 8/1R-LP

− TRNS-LP

− RYTH-LP PHAS-LP FILT-LP FLAN-LP LOW-LP MID-LP HI-LP − JEF-ON

LMOUT-

LP

LMIN-LP LINK-LP − LMDW07 LMDW06 LMDW05 LMDW04 LMDW03

PICH

ECHO-LP

ECHO-LP DELY-LP -1/1R-LP -3/4R-LP -1/4R-LP -1/8R-LP 3/4R-LP

SS7 SS6 SS5 SS4 SS3 SS2 SS1 SS0

EFFECT MIDI BYPASS LINK METER FTJO-SW FTBT-SW BLK-SEL

PHAS FILT TRAN FLAN PAN ECHO DELAY BEATSW

8/1 4/1 2/1 1/1 3/4 1/2 1/4 1/8

MEMO

AQUA REVE HAMO RING WAH ZIP JET JOGSW

− −−−

− −−−−−−−

− −−−−−−−

−

TAPSW RHMSW BPMSW HI MID LOW

HOLDSW JAUTOSW PLAYSW MEMOSW

E

F

16

1234

EFX-1000

Page 17

5678

SEG10 SEG9 SEG8 SEG7 SEG6 SEG5 SEG4 SEG3 SEG2 SEG1 SEG0

LMUP02 LMUP01 LMUP00 BPM1-LP −−−−−−BPM1-LP

LMUP10 LMUP09 LMUP08 BPM2-LP −−−−−−BPM2-LP

LMDW02 LMDW01 LMDW00 BPM3-LP −−−−−−BPM3-LP

A

LMDW10 LMDW09 LMDW08 RYT1-LP −−−−−−RYT1-LP

LML-LP

4/1R-LP 2/1R-LP 1/1R-LP TM2-LP −−−−−−TM2-LP

1/2R-LP 1/4R-LP 1/8R-LP TM3-LP −−−−−−TM3-LP

BEF-ON BPM-LP +8/1R-LP TM4-LP −−−−−−TM4-LP

BYPASS-

LP

− TM1-LP −−−−−−TM1-LP

B

C

D

56

EFX-1000

E

F

17

7

8

Page 18

1234

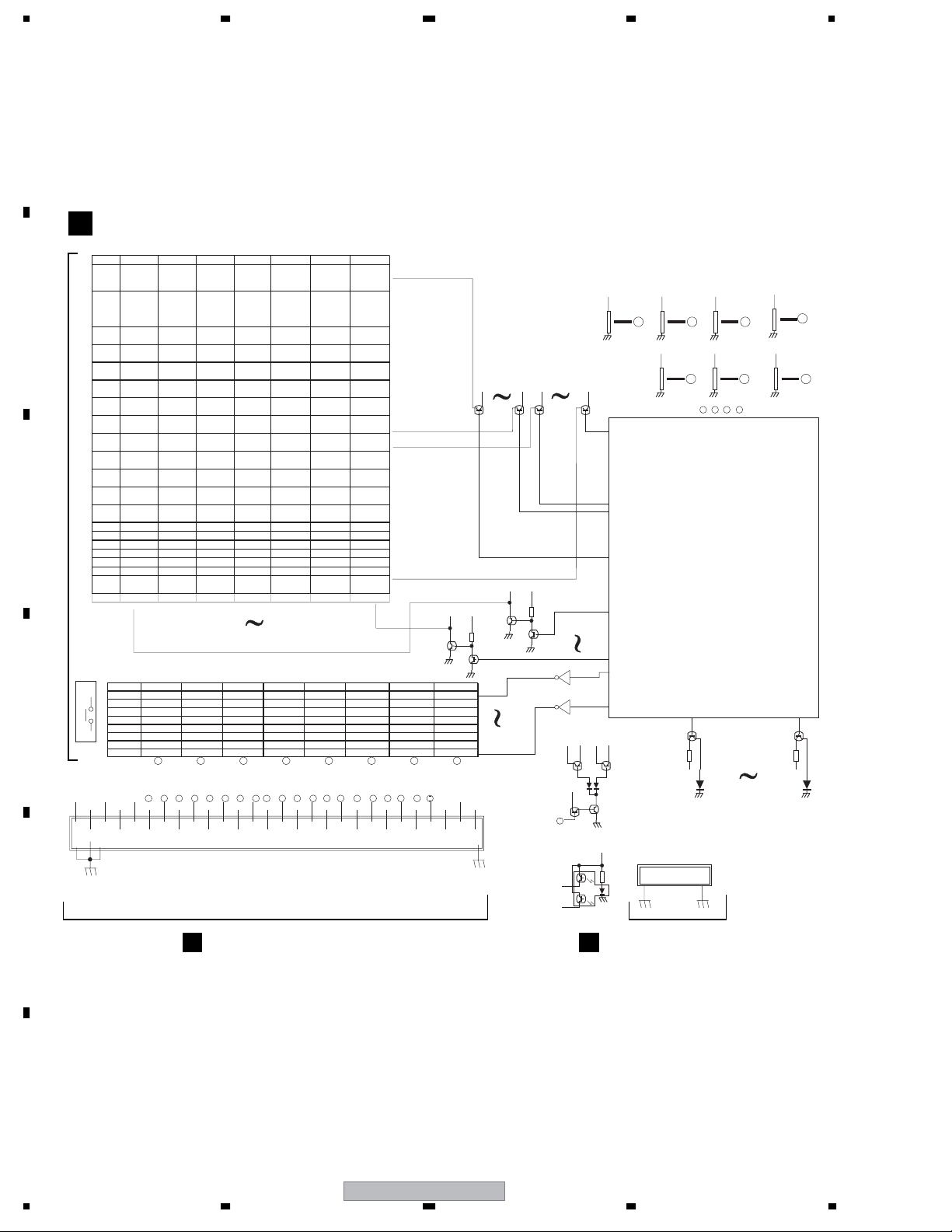

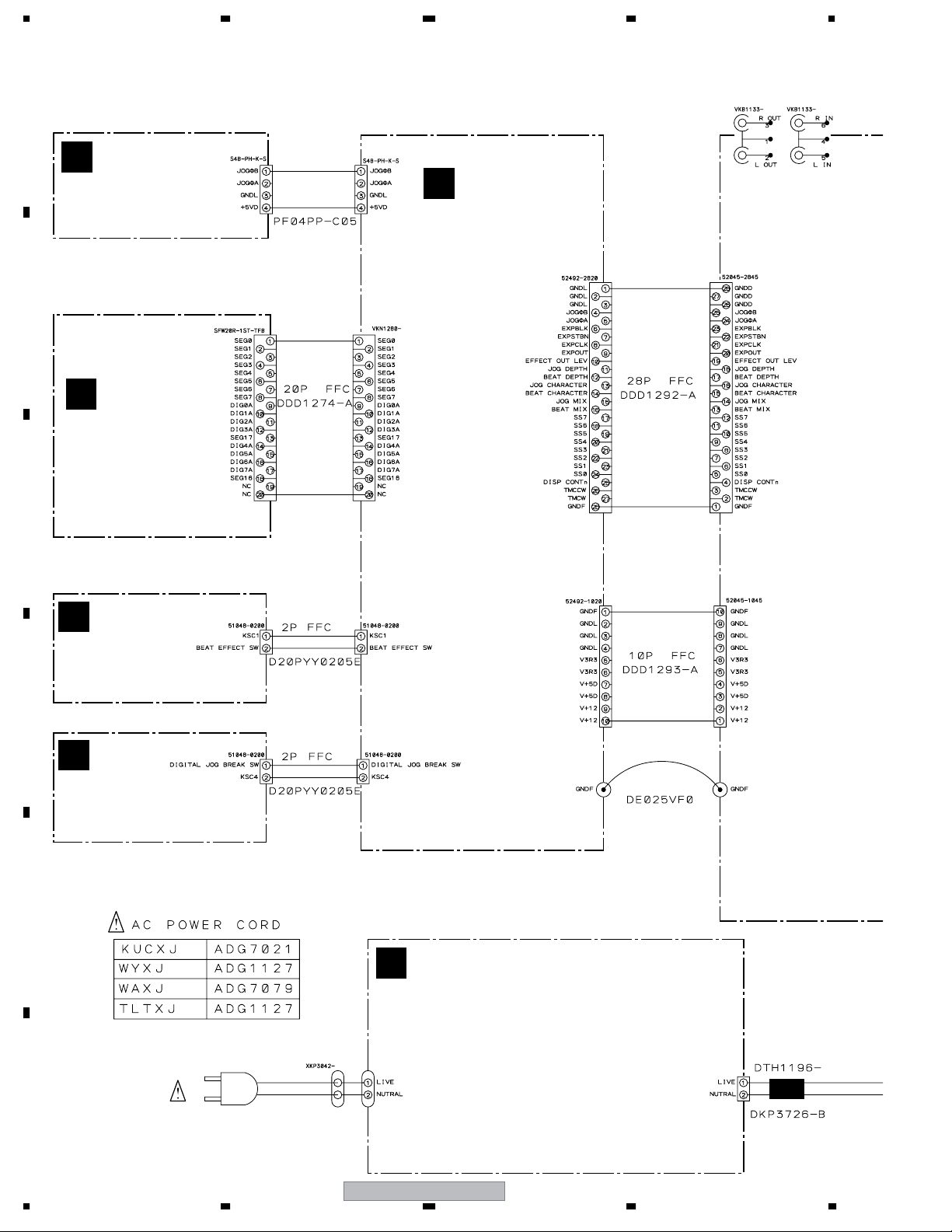

3.2 OVERALL WIRING DIAGRAM

A

H

ENCB ASSY

(DWX2403)

B

E

7SEG ASSY

(DWG1584)

C

CN104

CN601

4P CONNECTOR

CABLE

CN713

CN715

B

CTRL ASSY

(DWG1585)

CN705

JA301 JA301

CN402

D

SW1 ASSY

(DWS1353)

D

C

SW2 ASSY

(DWS1354)

E

F

J701

J702 J902

AC POWER CORD

CN701

J901

GND CABLE

ACIN ASSY

G

WYXJ,TLTXJ,WAXJ: (DWR1381)

KUCXJ: (DWR1382)

AN1101

AN1101

AN1101

WYXJ, TLTXJ, WAXJ: XKP3041

KUCXJ: XKP3042

CN102

J1101

J1102

TERRITE CORE

2P CONNECTOR

CABLE

18

EFX-1000

1234

Page 19

5678

JA201 JA202 JA302 JA303

MAIN BOARD ASSY

A

(DWX2401)

JA401

JA400

CN200

J403

CN201

CN1001

I

MVR ASSY

(DWX2444)

F

A

B

C

8P CONNECTOR

CABLE

CN101

CN100CN202

5P CONNECTOR

CABLE

MIDI ASSY

(DWX2402)

D

CN400

E

CN101

CN201

POWER SUPPLY

(DWR1377)

56

÷

When ordering service parts, be sure to refer to "EXPLODED

VIEWS and PARTS LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the

importance of the safety factor of the part. Therefore, when

replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

EFX-1000

F

19

7

8

Page 20

1234

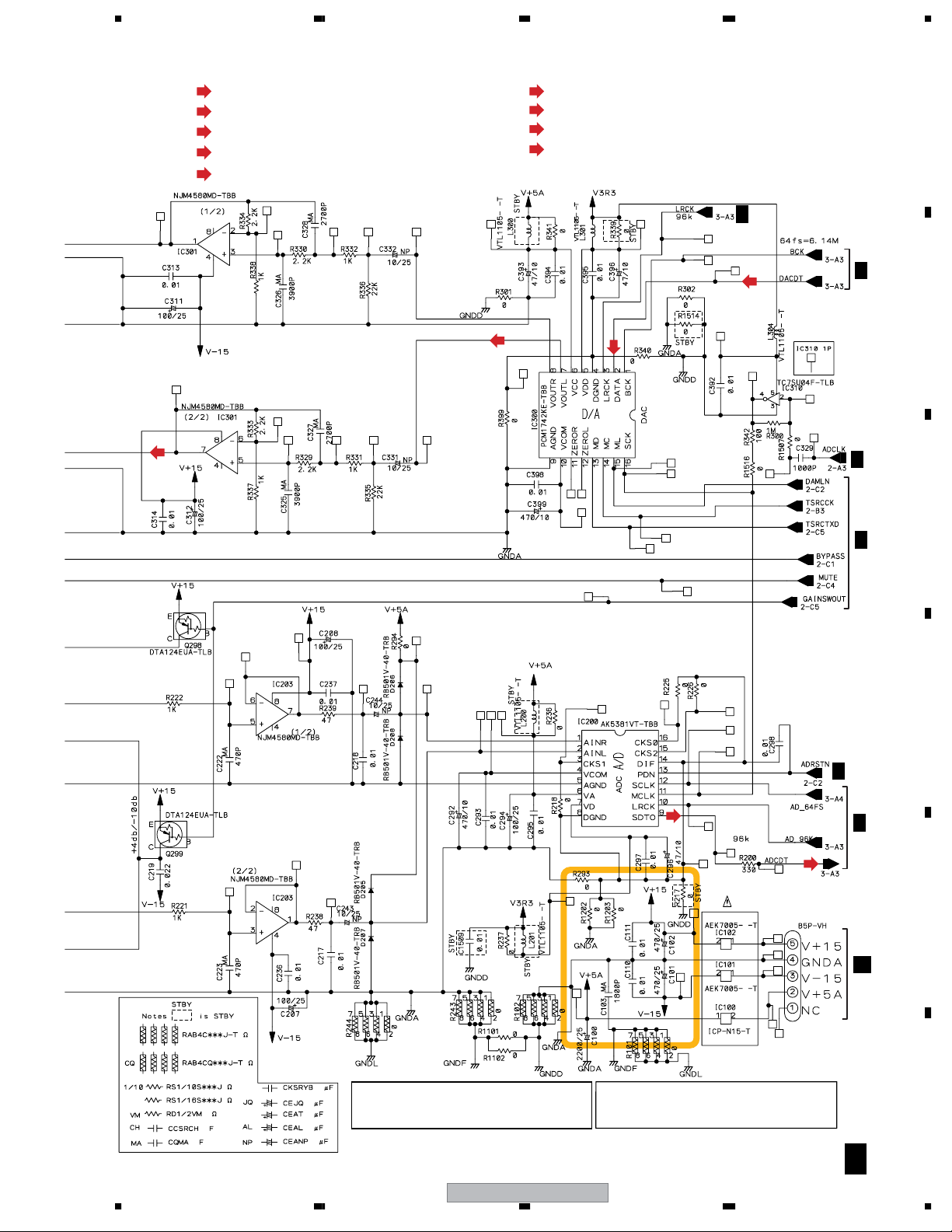

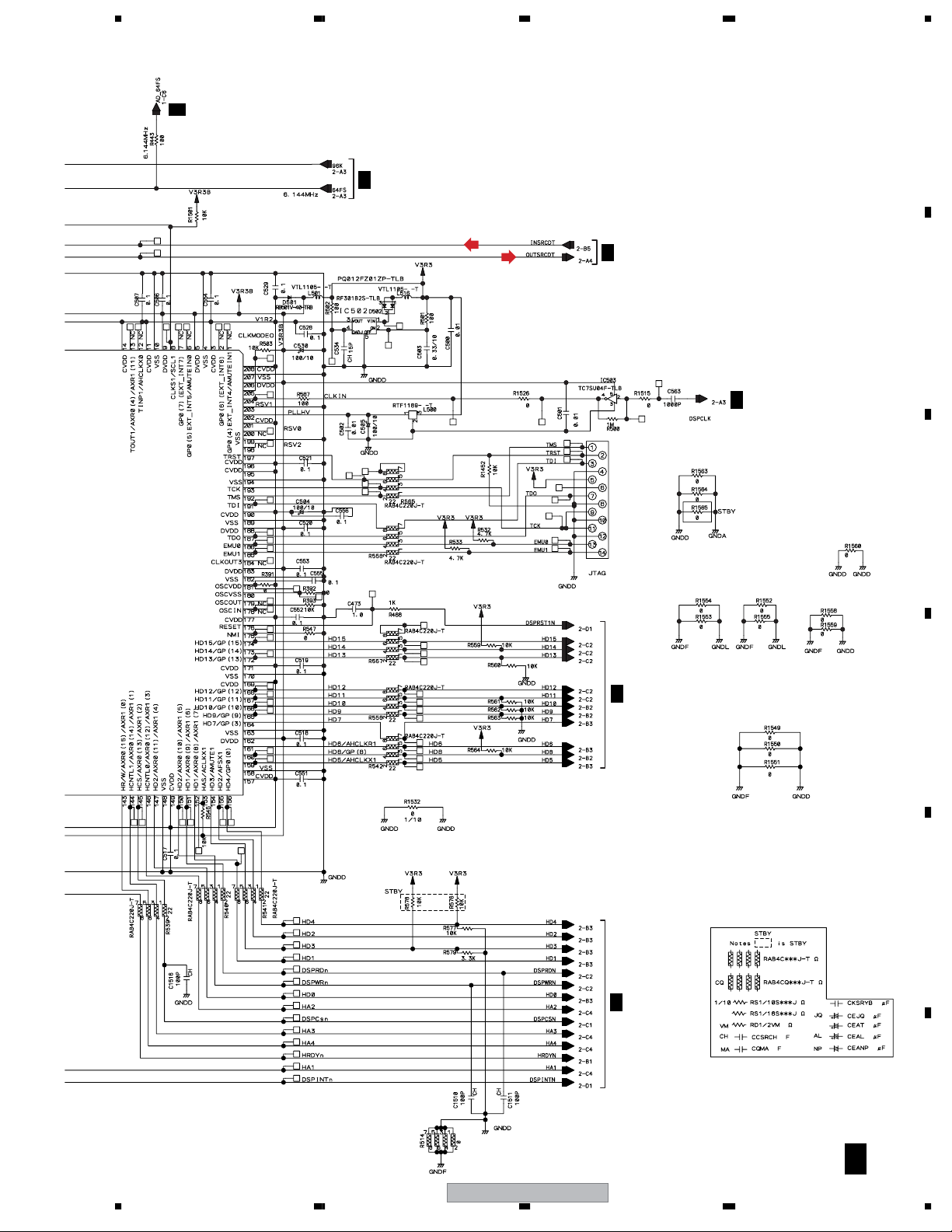

3.3 MAIN ASSY (1/3)

MAIN BOARD ASSY (1/3) (DWX2401)

A

A

B

(HP)

C

2/3A

D

E

F

20

A 1/3

(HP)

2/3A

CN200

CN1201

I

EFX-1000

1234

Page 21

5678

(MID)

: AUDIO SIGNAL ROUTE (Digital Signal (MIDI))

(DIG)

: AUDIO SIGNAL ROUTE (Digital Signal)

(EFX)

: SIGNAL ROUTE (EFX LINK)

(DS_SRC)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to SRC)

(SRC_DS)

: AUDIO SIGNAL ROUTE (Digital Signal (SRC to DSP)

(DS_DA)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to D/A)

(DS_AD)

: AUDIO SIGNAL ROUTE (Digital Signal (A/D to DSP)

(HP)

: AUDIO SIGNAL ROUTE (Phones L ch)

: AUDIO SIGNAL ROUTE (L ch)

(DS_DA)

3/3A

(DS_DA)

A

3/3A

B

2/3

A

C

(DS_AD)

(DS_AD)

A

2/3A

D

2/3

3/3A

E

J

CN202

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. ICP-N15, MFD BY ROHM

CO., LTD. FOR IC100.

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. AEK7005 MFD, BY

LITTELFUSE INK. FOR IC101and IC102.

EFX-1000

56

CN100

F

A 1/3

21

7

8

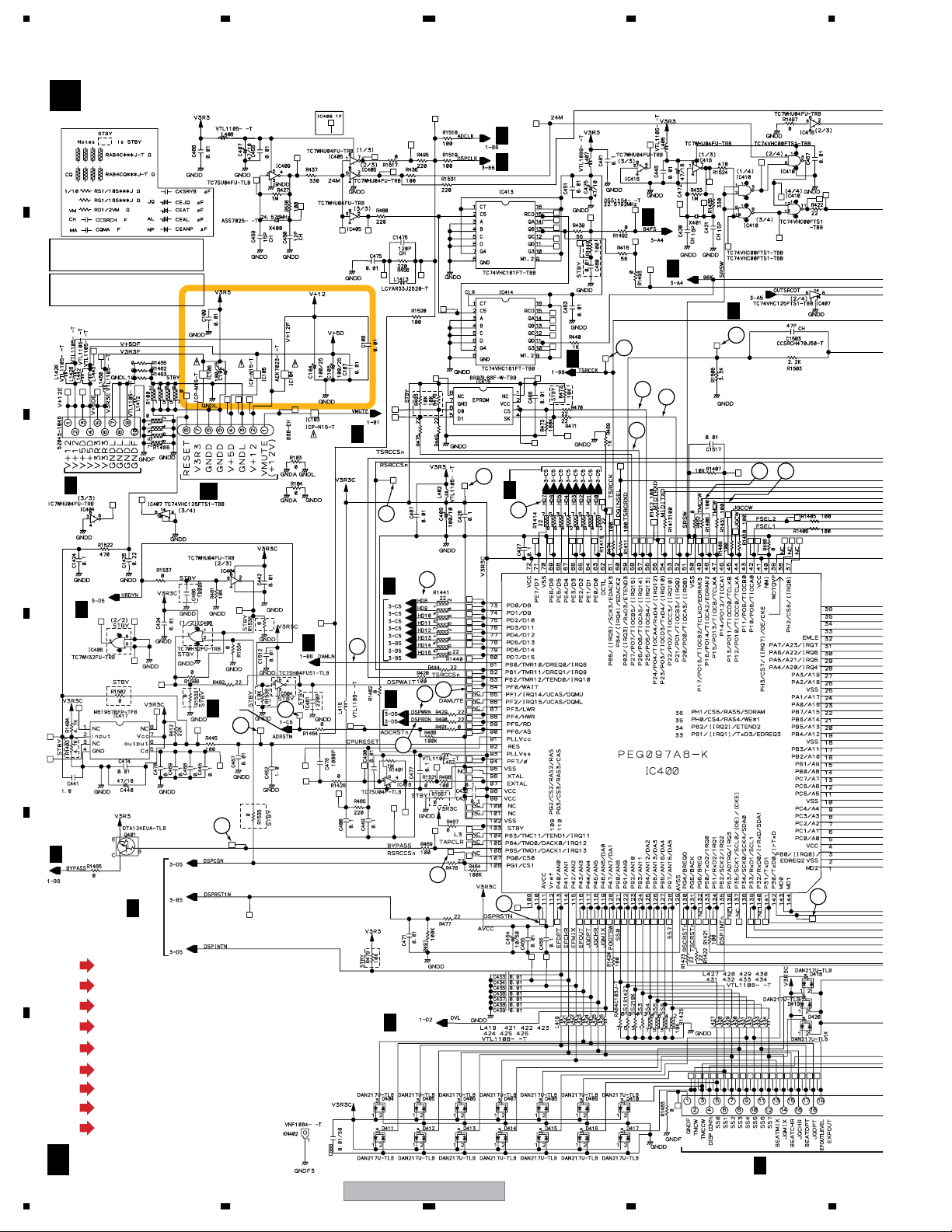

Page 22

1234

3.4 MAIN ASSY (2/3)

MAIN BOARD ASSY (2/3) (DWX2401)

A

A

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. ICP-N15, MFD BY ROHM

CO., LTD. FOR IC103, IC105 and IC106.

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. AEK7023 MFD, BY

LITTELFUSE INK. FOR IC104.

B

1/3

A

3/3

A

A

3/3

3/3A

A

3/3

15b

12b

1/3A

16a

16b

A

15a

1/3

1a

1/3A

8a

18b

3/3

A

22a

18a

3/3A

20a

18b

CN102

CN701

1/2

B

C

A

3/3

D

J

A

CN201

1/3

1b

3a

CN101

4a

A

1/3

16c

28b 28a

1/3A

7a

E

3/3A

4b

10b

F

22

(MID)

: AUDIO SIGNAL ROUTE (Digital Signal (MIDI))

(DIG)

: AUDIO SIGNAL ROUTE (Digital Signal)

(EFX)

: SIGNAL ROUTE (EFX LINK)

(DS_SRC)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to SRC)

(SRC_DS)

: AUDIO SIGNAL ROUTE (Digital Signal (SRC to DSP)

(DS_DA)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to D/A)

(DS_AD)

: AUDIO SIGNAL ROUTE (Digital Signal (A/D to DSP)

(HP)

: AUDIO SIGNAL ROUTE (Phones L ch)

: AUDIO SIGNAL ROUTE (L ch)

A 2/3

1234

A

1/3

EFX-1000

CN705

1/2

B

Page 23

5678

A

13a

33

(DS_SRC)

29b

13b

9a

6a

(DIG)

(DIG)

JA400

B

(DIG)

12a

(SCR_DS)

15c

(EFX)

J403

(MID)

(EFX)

(MID)

24

C

CN1001

F

1/3A

29a

32

(DIG)

26

3/3

A

5a

25

2a

11b

CN402

11a

1c

23

D

3/3A

19a

JA401

1/3A

CN400

E

10a

F

56

EFX-1000

A 2/3

23

7

8

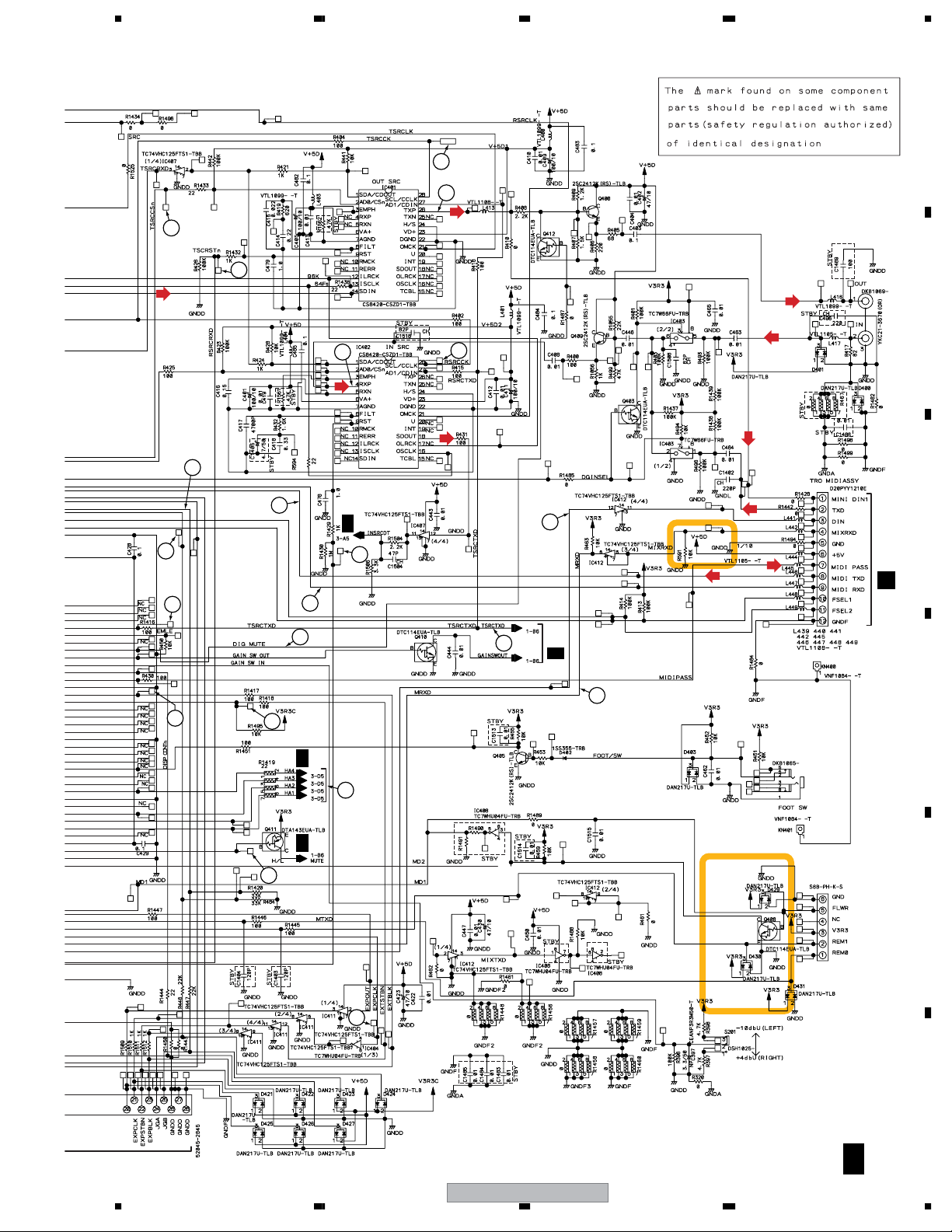

Page 24

1234

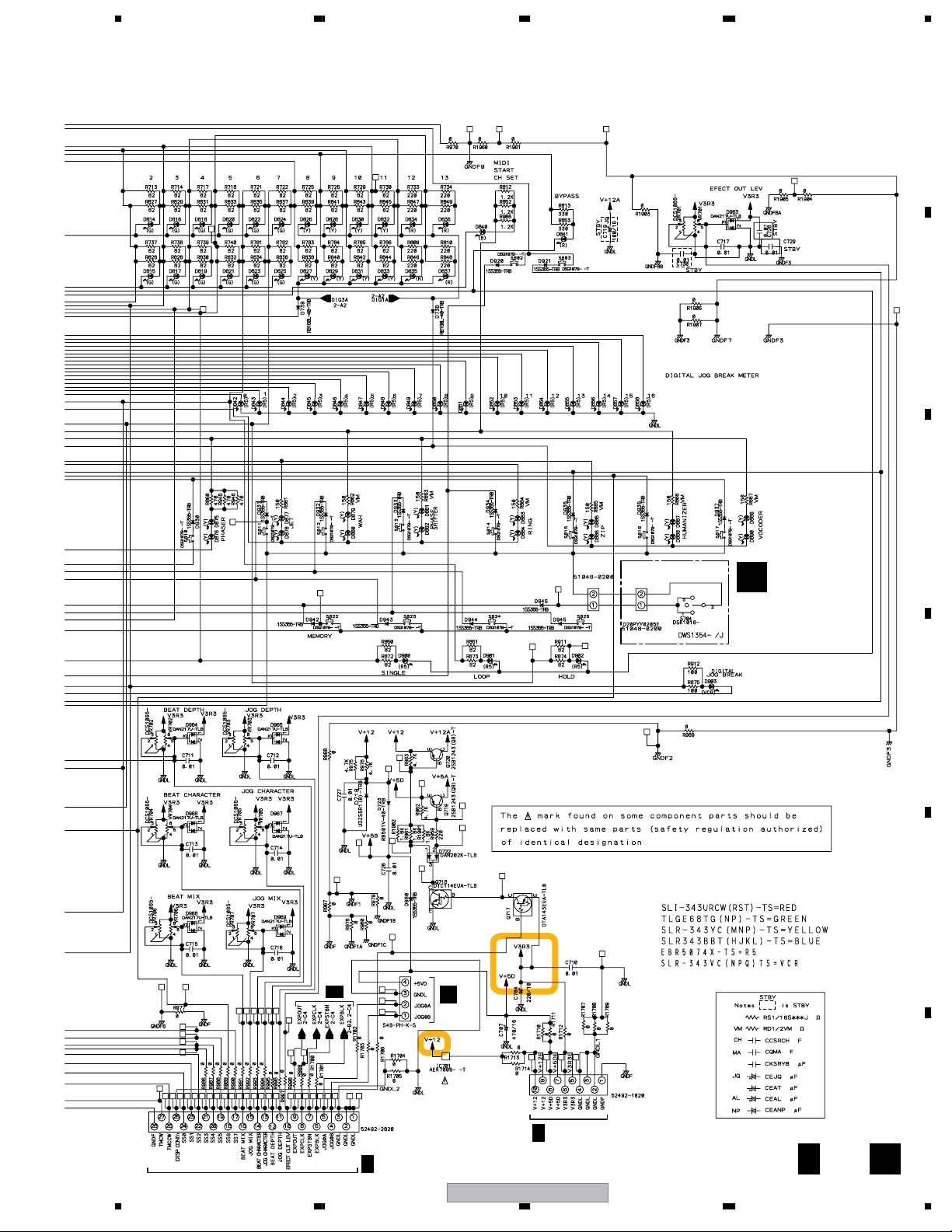

3.5 MAIN ASSY (3/3)

MAIN BOARD ASSY (3/3) (DWX2401)

A

A

(MID)

: AUDIO SIGNAL ROUTE (Digital Signal (MIDI))

(DIG)

: AUDIO SIGNAL ROUTE (Digital Signal)

(EFX)

: SIGNAL ROUTE (EFX LINK)

(DS_SRC)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to SRC)

(SRC_DS)

B

C

: AUDIO SIGNAL ROUTE (Digital Signal (SRC to DSP)

(DS_DA)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to D/A)

(DS_AD)

: AUDIO SIGNAL ROUTE (Digital Signal (A/D to DSP)

(HP)

: AUDIO SIGNAL ROUTE (Phones L ch)

: AUDIO SIGNAL ROUTE (L ch)

(DS_AD)

(DS_DA)

1/3A

(SRC_DS)

(DS_SRC)

D

E

F

A 3/3

24

EFX-1000

1234

Page 25

5678

1/3A

A

2/3

A

(SRC_DS)

2/3A

(DS_SRC)

B

A

2/3

CN405

C

2/3A

D

E

56

EFX-1000

2/3A

F

A 3/3

25

7

8

Page 26

1234

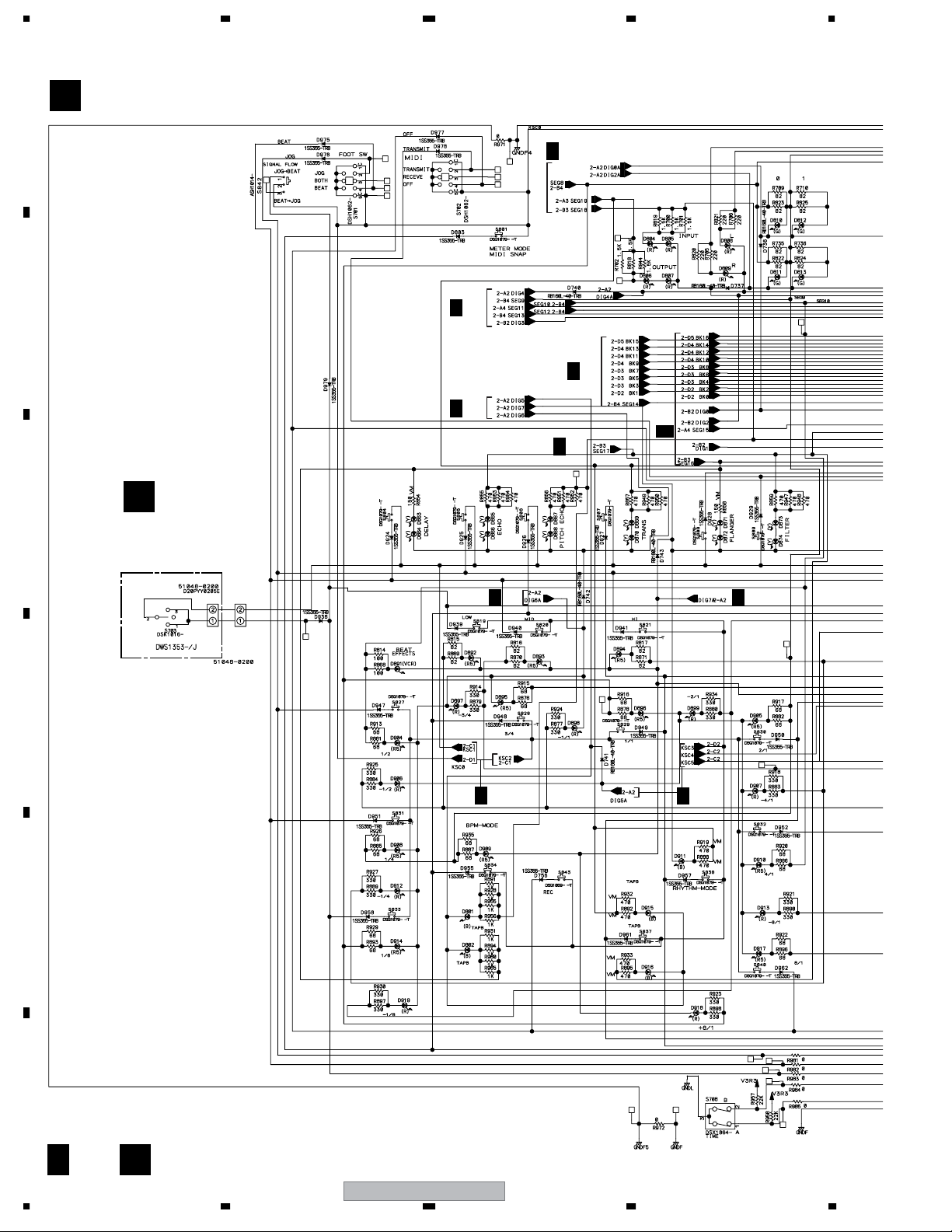

3.6 CTRL (1/2), SW1 and SW2 ASSYS

CTRL ASSY (1/2) (DWG1585)

B

A

2/2B

B

C

D

SW1 ASSY

(DWS1353)

SWITCHES

S701 : FOOT SWITCH MODE SELECTOR

D

S702 : MIDI MODE SELECT

S708 : BEAT EFFECT TIME/BPM

S801 : METER MODE/MIDI SNAP

S802 : MIDI START/CH SET

S803 : BYPASS

S804 : BEAT EFFECT SELECT (DELAY)

S805 : BEAT EFFECT SELECT (ECHO)

S806 : BEAT EFFECT SELECT (PITCH ECHO)

S807 : BEAT EFFECT SELECT (TRANS)

S808 : BEAT EFFECT SELECT (FLANGER)

S809 : BEAT EFFECT SELECT (FILTER)

S810 : BEAT EFFECT SELECT (PHASER)

S811 : DIGITAL JOG BREAK EFFECT (JET)

S812 : DIGITAL JOG BREAK EFFECT (WAH)

S813 : DIGITAL JOG BREAK EFFECT (PHASE SHIFTER)

S814 : DIGITAL JOG BREAK EFFECT (RING)

S815 : DIGITAL JOG BREAK EFFECT (ZIP)

S816 : DIGITAL JOG BREAK EFFECT (HUMANIZER)

S817 : DIGITAL JOG BREAK EFFECT (VOCODER)

S819 : EFFECT FREQUENCY (LOW)

S820 : EFFECT FREQUENCY (MID)

E

S821 : EFFECT FREQUENCY (HI)

S822 : JOG MEMORY

S823 : JOG MEMORY SIGNAL PLAY

S824 : JOG MEMORY LOOP PAY

S825 : JOG HOLD

S827 : BEAT SELECT (1/2)

S828 : BEAT SELECT (3/4)

S829 : BEAT SELECT (1/1)

S830 : BEAT SELECT (2/1)

S831 : BEAT SELECT (1/4)

S832 : BEAT SELECT (4/1)

S833 : BEAT SELECT (1/8)

S834 : BPM MODE

S837 : TAP/SHIFT

S838 : RHYTHM MODE

S840 : BEAT SELECT (8/1)

S842 : SIGNAL FLOW

S843 : RHYTHM REC

J701

J901

2/2B

2/2B

2/2B

B

2/2

2/2

B

B

2/2

2/2B

2/2

B

B

2/2

F

26

B 1/2

D

EFX-1000

1234

Page 27

5678

A

B

J902

J702

C

C

SW2 ASSY

(DWS1354)

D

E

2/2B

H

CN104

CN713

CN701

CN705

CN402

1/3

A

56

EFX-1000

CN102

2/3

A

F

B 1/2

7

8

C

27

Page 28

1234

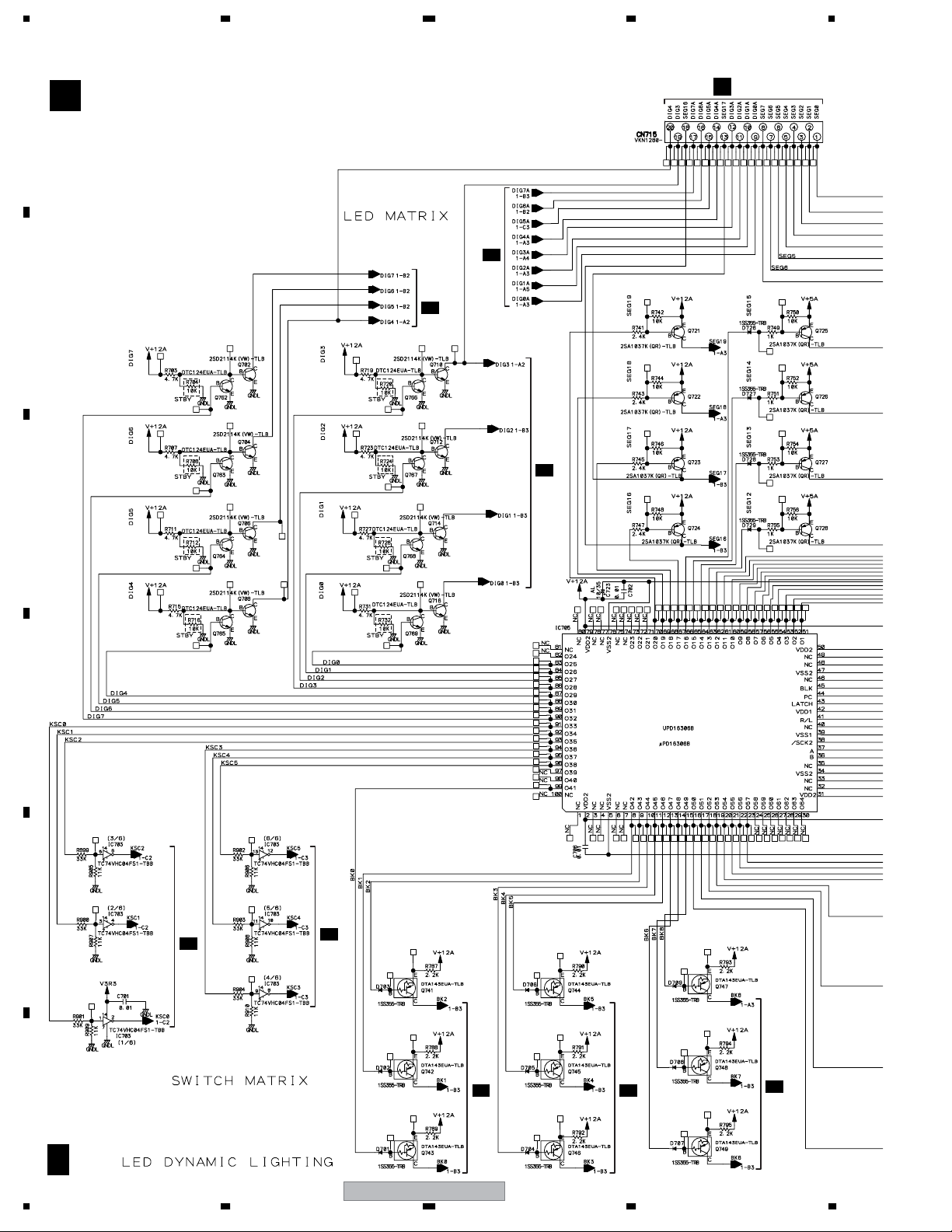

3.7 CTRL ASSY (2/2)

CTRL ASSY (2/2) (DWG1585)

B

A

B

1/2

B

CN601

E

1/2B

1/2

B

C

D

E

F

28

B 2/2

1/2B

1234

1/2B

1/2B

EFX-1000

1/2B

1/2B

Page 29

5678

A

B

1/2B

1/2B

C

1/2B

D

1/2B

1/2B

1/2B

56

EFX-1000

E

F

B 2/2

29

7

8

Page 30

1234

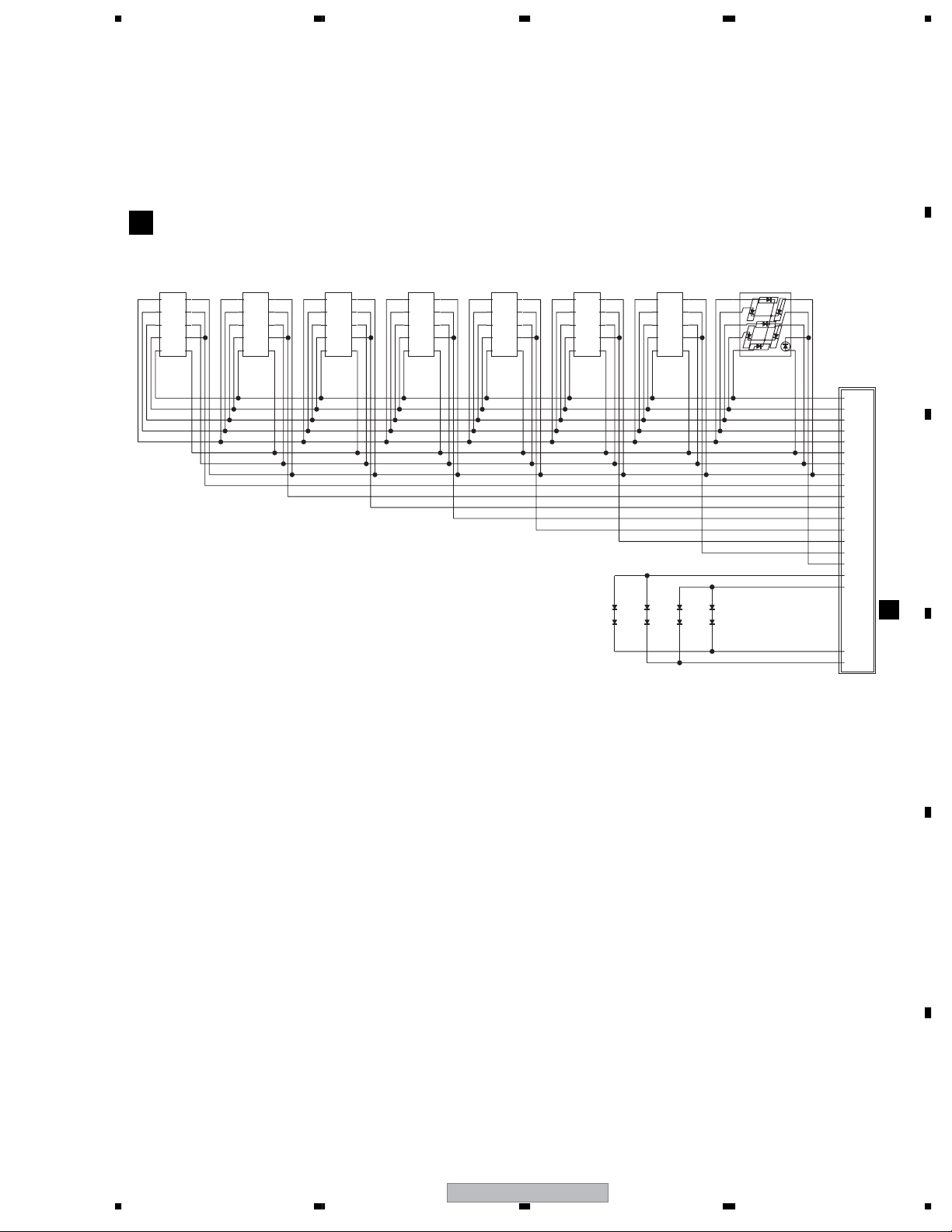

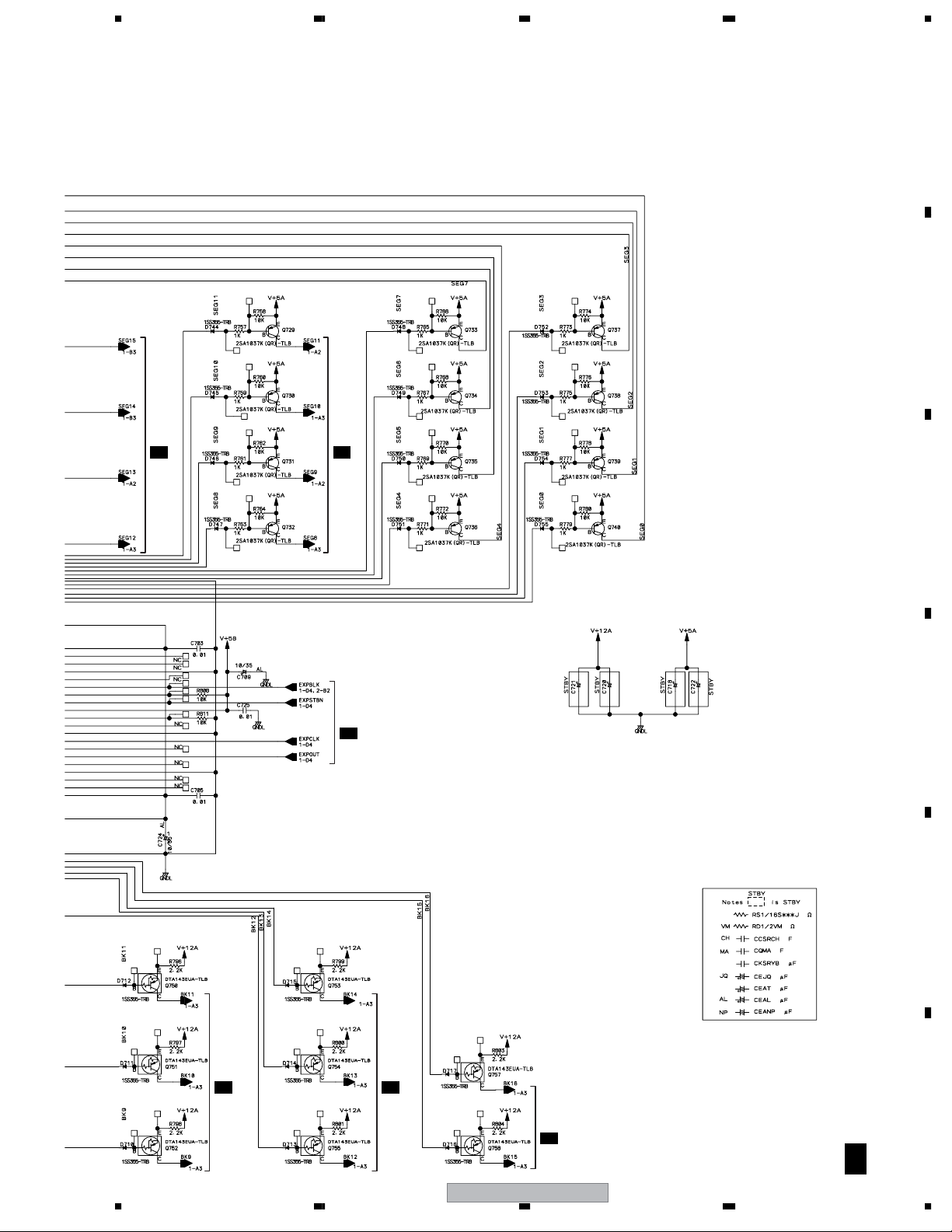

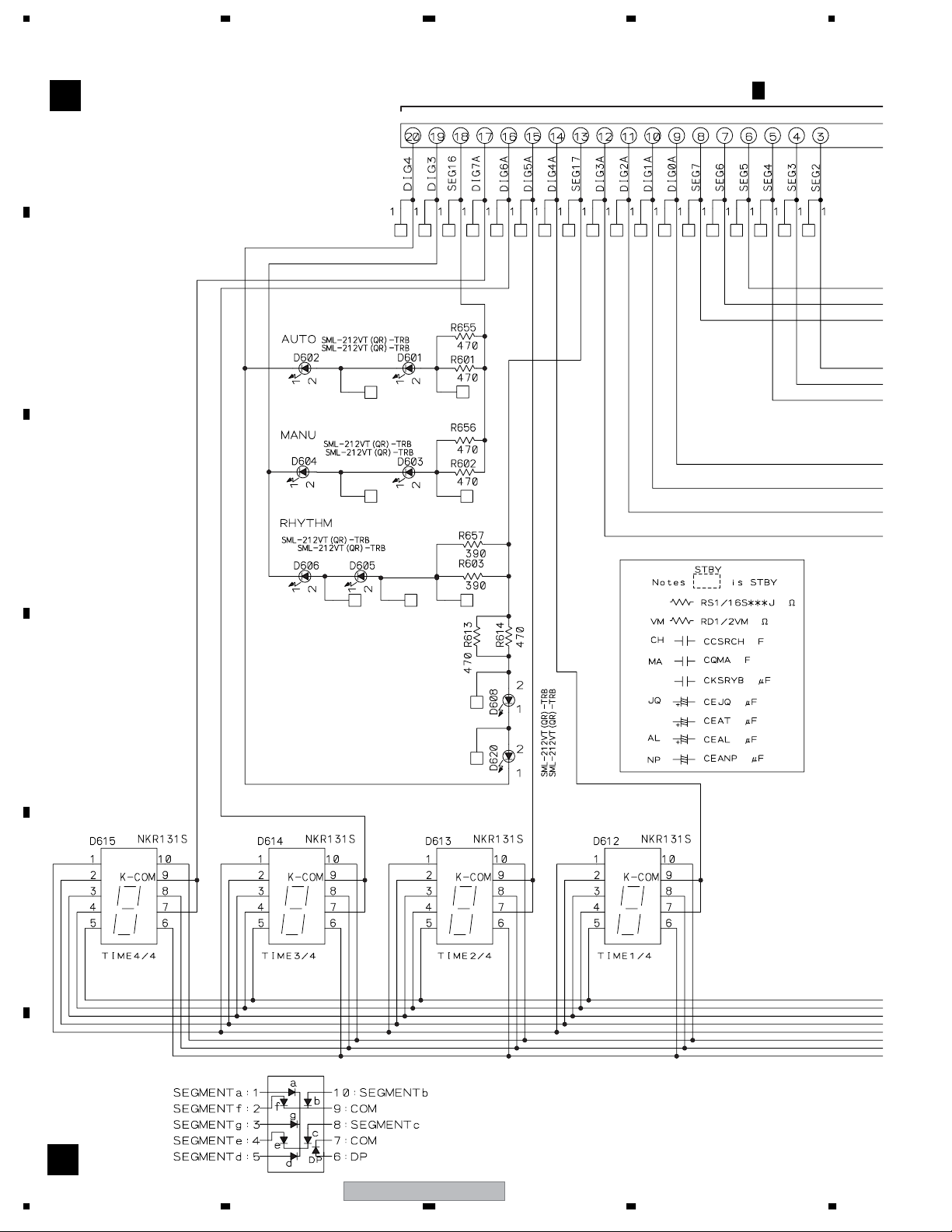

3.8 7SEG ASSY

7SEG ASSY (DWG1584)

E

A

B

CN715

2/2

B

C

D

E

F

E

30

1234

EFX-1000

Page 31

5678

A

CN601

B

C

D

E

56

EFX-1000

F

E

31

7

8

Page 32

1234

3.9 MIDI ASSY

A

MIDI ASSY (DWX2402)

F

B

(EFX)

(EFX)

(EFX)

C

J403

2/3

A

D

E

(EFX)

(EFX)

(MID)

(MID)

(MID)

(MID)

(EFX)

(EFX)

(MID)

: AUDIO SIGNAL ROUTE (Digital Signal (MIDI))

(DIG)

: AUDIO SIGNAL ROUTE (Digital Signal)

F

F F

32

(EFX)

: SIGNAL ROUTE (EFX LINK)

(DS_SRC)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to SRC)

(SRC_DS)

: AUDIO SIGNAL ROUTE (Digital Signal (SRC to DSP)

EFX-1000

1234

(DS_DA)

: AUDIO SIGNAL ROUTE (Digital Signal (DSP to D/A)

(DS_AD)

: AUDIO SIGNAL ROUTE (Digital Signal (A/D to DSP)

(HP)

: AUDIO SIGNAL ROUTE (Phones L ch)

: AUDIO SIGNAL ROUTE (L ch)

Page 33

5678

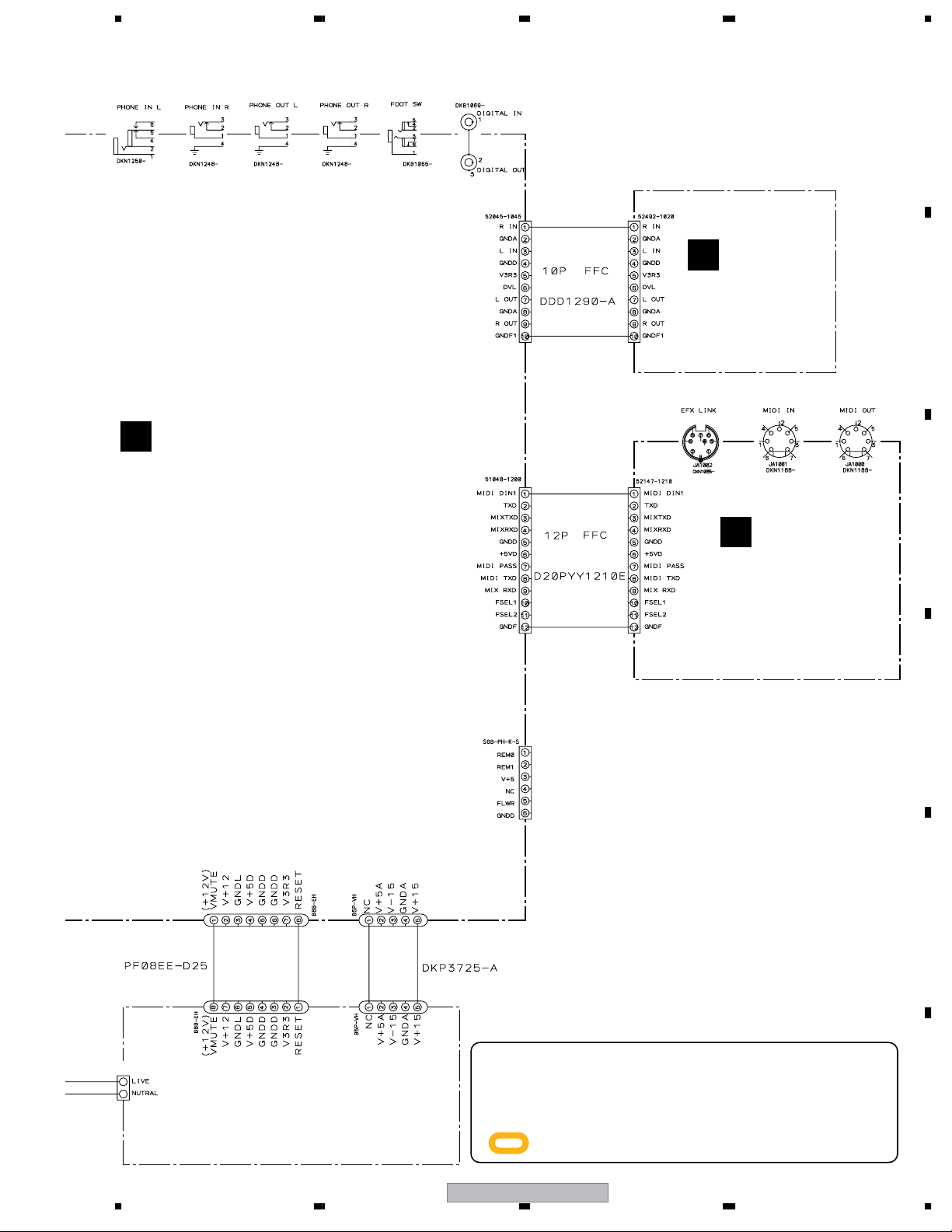

3.10 ACIN, ENCB and MVR ASSYS

A

G

ACIN ASSY

KUCXJ: (DWR1382)

WYXJ, TLTXJ, WAXJ:

(DWR1381)

LIVE

NUTRAL

AN1101

AC POWER CORD

ENCB ASSY (DWX2403)

H

J1101

LIVE

NUTRAL

J1102

J

CN101

MVR ASSY (DWX2444)

I

B

C

CN1201

B 1/2

CN713

CN104

A 1/3

CN200

D

E

F

HG

I HG I

56

EFX-1000

7

8

33

Page 34

1234

C

D

C

C

1

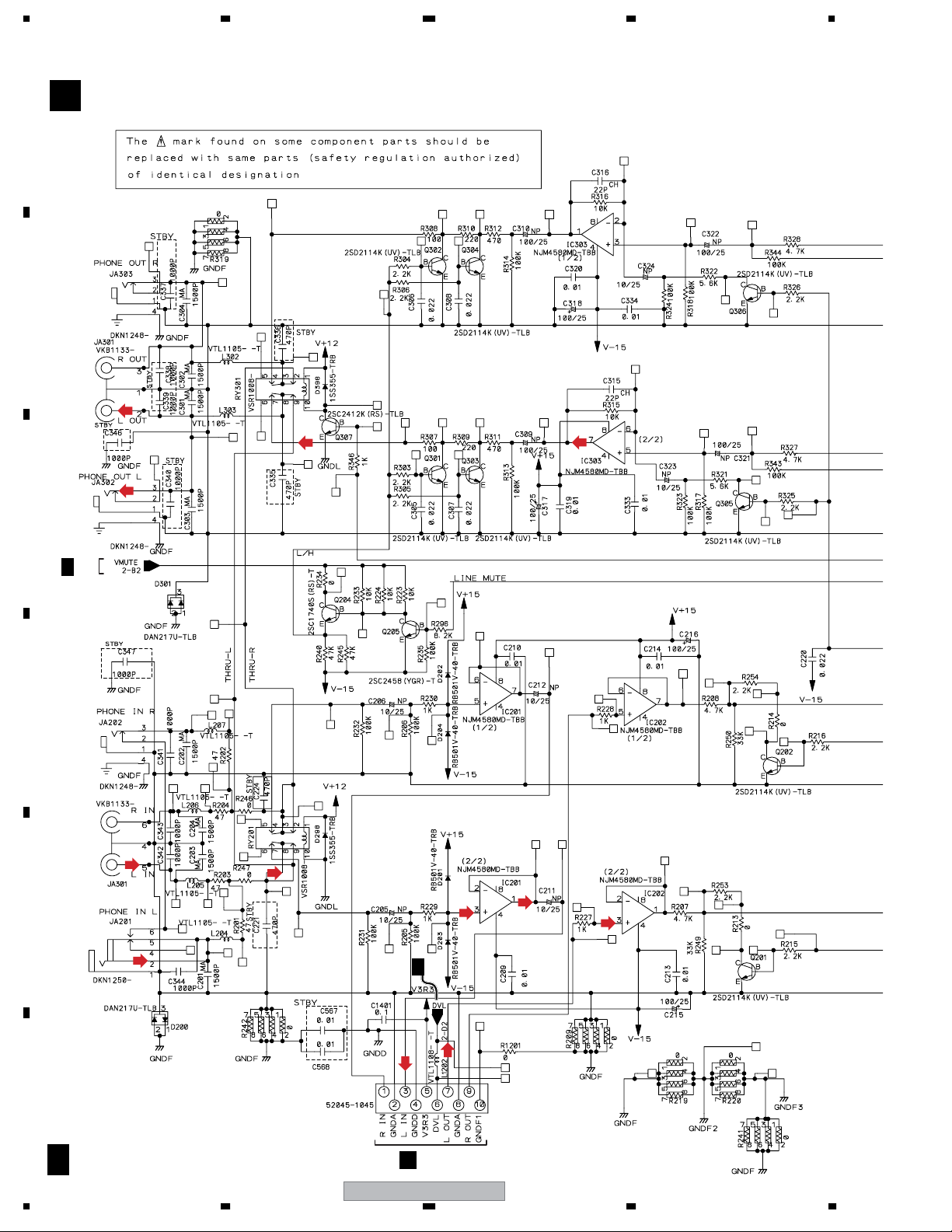

3.11 POWER SUPPLY UNIT

POWER SUPPLY UNIT (DWR1377)

J

A

• NOTE FOR FUSE REPLACEMENT

CAUTION -

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

B

CN101

LIVE

1

C

J1101, J1102

SW101

F101

Z101

C101

G

JE4

NEUTRAL

D

3

C102

L101 L102

C103

JE1

C104

R101

R102

D201

AC+

AC-

R118

R119

R116

R120

TH101

R104 R117

JB1

L105

Q101

D104

R108

C107

R107

L103

T101

D501

JA4 JC3

JC2

D103

C115

JB3

R115

JC4

JB2

D601

C604

D70

C703

D801

R122

R112

JE3

R113

C112

C113

IC101

PC101

76

3

152

R114

C111

AC IN

ZD101

E

F

JE2

C114

Q102

R121

C108

8

R109

4

C109

J

34

1234

EFX-1000

Page 35

5678

A

T101

D501

JA4 JC3

JC2

D201

C302

D301

C401

R401

D401

C402

C501

JA2

C301

R402

C201

JB5

PC101

R403

R404

IC401

R301

R405

C403

R201

C202

L401

C404

JE5

R406

R407

D202

R501

D502

ZD501

R502

R503

Q501

R504

L601

R505

Q502

C502

Q503

C506

JB4

C503

D503

1

34

R506

IC501

C504

CN201

1

MUTE

12V

2

B

CN101

RESET

8

JA3

JB6

2

C505

C503

5VD

4

7

3.3V

GND

3

5

GND

GND

6

A

C

D

JC4

JB2

D601

L701

C702

L801

R801

R601C601

C701

R701

C604

D701

C703

C801 C802

D801

EFX-1000

56

C602

ZD601

CN202

C603

C803

JA5

5

+15V

5VA

2

GND

4

CN100

1

GND

3

-15V

A

E

F

J

35

7

8

Page 36

1234

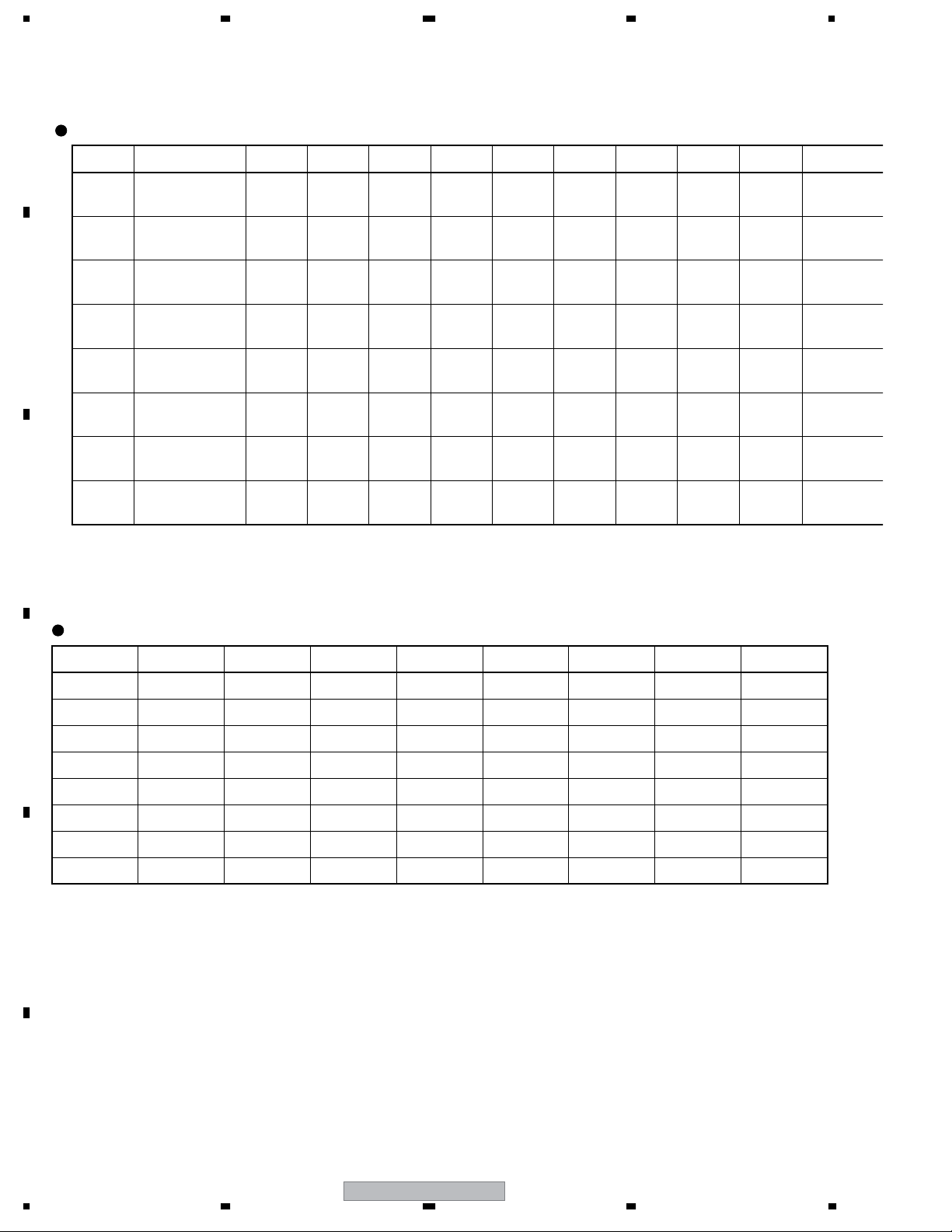

3.12 VOLTAGES

MAIN BOARD ASSY

A

A

IC200

AK5381VT-TBB

Pin Voltage (V)

1 2.6

2 2.6

30

4 2.6

50

6 5.2

7 3.1

80

9 0.7–1.4

10 1.5

11 1.7

12 1.5

B

13 3.1

14 0

15 0

16 0

IC201

NJM4580MD-TBB

Pin Voltage (V)

10

20

30

4 -15.4

50

60

70

8 15.2

C

IC202

NJM4580MD-TBB

Pin Voltage (V)

10

20

30

4 -15.4

50

60

70

8 15.2

IC203

NJM4580MD-TBB

D

Pin Voltage (V)

10

20

30

4 -15.4

50

60

70

8 15.2

IC415

BR93L66F-W-TBB

Pin Voltage (V)

10

2 3.1

E

30

44

50

6 0.4

70

80

IC416

TC7WHU04FU-TRB

Pin Voltage (V)

1 1.5

2 3.2

30

40

5 3.2

F

60

7 1.6

8 3.2

36

1234

IC300

PCM1742KE-TBB

Pin Voltage (V)

1 1.6

21

3 1.6

40

5 3.1

6 5.2

7 2.6

8 2.6

90

10 3.2

11 0

12 0

13 0.1

14 3.1

15 3.1

16 1.7

IC301

NJM4580MD-TBB

Pin Voltage (V)

10

20

30

4 -15.4

50

60

70

8 15.2

IC303

NJM4580MD-TBB

Pin Voltage (V)

10

20

30

4 -15.4

50

60

70

8 15.2

IC310

TC7SU04F-TLB

Pin Voltage (V)

1 1.6

2 1.7

30

4 1.7

5 3.2

IC417

M51957BFP-TFB

Pin Voltage (V)

1 0.3

2 1.6

3 0.2

40

5 1.2

6 3.1

7 3.1

80

IC418

TC7SU04F-TLB

Pin Voltage (V)

1 1.6

2 1.7

30

4 1.7

5 3.2

IC400

PEG097A8-K

Voltage (V)

Pin

1 3.2

2 0

3 3.2

4 3.2

5 0

6 3.2

7 3.2

8 3.2

9 0

10 0

11 2.5

12 0

13 0

14 0

15 0

16 0

17 0

18 0

19 0

20 0

21 0

22 0

23 3

24 0.3

25 0

26 0

27 0

28 0

29 3.2

30 0

31 0

32 0

33 0.1

34 0

35 0

36 0

37 0

38 0

39 3.1

40 0

41 3.2

42 0

43 0

44 2.2

45 2.2

46 0

47 3.2

48 0

49 3.2

50 0

51 0

52 4

53 0

54 3.2

55 0.8

56 0

57 0.4

58 0

59 3

60 0

61 3.2

62 0

63 3.2

64 3.2

65 3.2

66 0.6

67 0

68 3.2

69 3.2

70 0

71 3.2

72 3.2

Voltage (V)

Pin

73 3.2

74 0.9

75 0.9

76 0.9

77 3.2

78 0.9

79 3.2

80 3.2

81 3.2

82 3.2

83 3.2

84 0

85 0

86 0

87 0

88 3.2

89 3.2

90 3.2

91 3.2

92 3.2

93 0

94 3.2

95 0

96 1.3

97 1.7

98 3.2

99 3.2

100 0

101 0

102 0

103 3.2

104 0

105 0

106 3.2

107 0

108 3.2

109 0

110 3.2

111 3.2

112 3.2

113 1.6

114 1.6

115 1.6

116 1.6

117 1.6

118 1.6

119 1.6

120 1.6

121 0

122 0

123 0

124 0

125 0

126 0

127 0

128 0

129 0

130 3.1

131 3.1

132 0

133 3.2

134 3.2

135 3.2

136 0

137 0

138 2.5

139 0.9

140 3.1

141 0

142 2.9

143 0

144 3.2

EFX-1000

IC401

CS8420-CSZD1-TBB

Voltage (V)

Pin

1 5

2 3.1

3 5

4 2.5

5 2.5

6 5

7 0

8 2.2

9 3.1

10 2.6

11 0

12 1.5

13 1.6

14 1.2–2.5

15 4.7

16 4.7

17 4.7

18 0

19 5

20 4.8

21 1.6

22 0

23 6

24 0

25 2.5

26 2.6

27 0

28 3.1

IC402

CS8420-CSZD1-TBB

Voltage (V)

Pin

1 5

2 3.1

3 5

4 2.5

5 2.5

6 5

7 0

8 0

9 3.1

10 2.5

11 5

12 4.8

13 4.8

14 4.8

15 4.9

16 1.6

17 1.5

18 0

19 5

20 4.9

21 1.6

22 0

23 5

24 0

25 5

26 0

27 0.8

28 3.1

IC403

TC7W66FU-TRB

Pin Voltage (V)

1 1.6

2 1.6

33

40

5 1.6

6 1.6

70

8 3.2

IC404

TC7WHU04FU-TRB

Pin Voltage (V)

1 2.5

20

30

40

50

6 3.2

7 3.2

8 3.2

IC405

TC7WHU04FU-TRB

Pin Voltage (V)

1 1.6

2 1.6

3 1.6

40

5 1.6

6 1.6

7 1.6

8 3.2

IC407

TC74VHC125FTS1-TBB

Pin Voltage (V)

10

25

35

40

5 0.1

6 0.1

70

80

90

10 0

11 0.1

12 0.1

13 0

14 5.2

IC409

TC7SU04FU-TLB

Pin Voltage (V)

1 1.6

2 1.6

30

4 1.6

5 3.2

IC410

TC74VHC00FTS1-TBB

Pin Voltage (V)

10

20

3 3.2

4 1.6

5 3.2

6 1.6

70

8 3.2

90

10 1.6

11 1.6

12 1.6

13 3.2

14 3.2

IC411

TC74VHC125FTS1-TBB

Pin Voltage (V)

10

2 2.9

3 1.3

40

5 3.2

6 0.3

70

8 0.1

9 0.3

10 0

11 0.3

12 3

13 0

14 3.2

IC412

TC74VHC125FTS1-TBB

Pin Voltage (V)

10

20

30

40

50

6 3.2

70

80

90

10 0

11 4.9

12 3.2

13 0

14 5.2

IC413

TC74VHC161FT-TBB

Pin Voltage (V)

1 3.2

2 1.6

30

40

50

60

7 3.2

80

9 3.2

10 3.2

11 1.6

12 1.6

13 1.5

14 1.6

15 0.2

16 3.2

IC414

TC74VHC161FT-TBB

Pin Voltage (V)

1 3.2

2 1.5

30

40

50

60

7 0.2

80

9 3.2

10 3.2

11 1.6

12 1.6

13 1.6

14 1.6

15 0.2

16 3.2

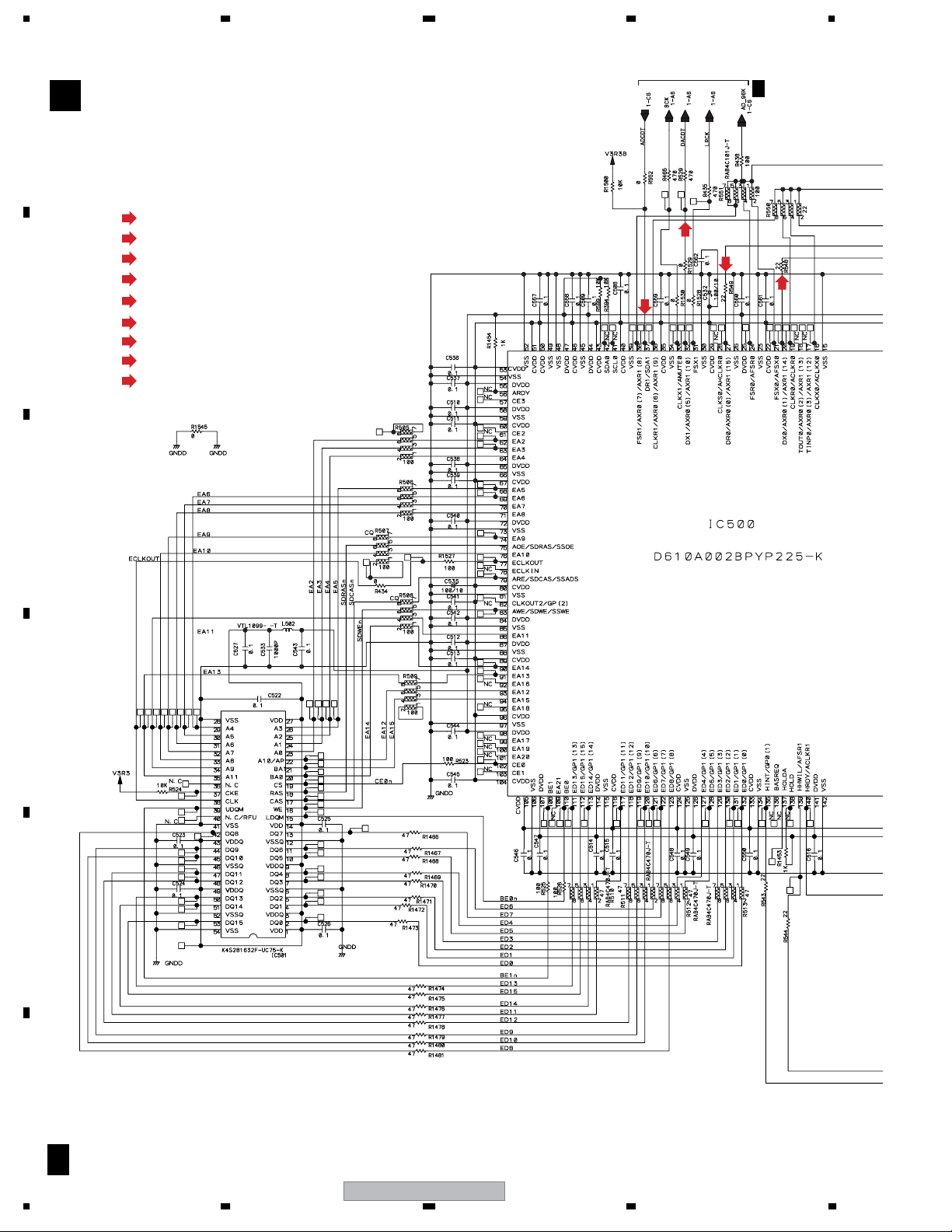

Page 37

5678

MAIN BOARD ASSY

A

IC500

D610A002BPYP225-K

Pin Voltage (V)

10

20

3 1.2

40

5 3.2

60

70

8 1.5

9 3.2

10 0

11 1.2

12 0

13 0

14 1.2

15 0

16 1.5

17 0

18 0

19 1.5

20 1

21 1.5

22 1.2

23 0

24 1.5

25 3.2

26 0

27 0.1

28 0

29 1.2

30 0

31 1.6

32 1

33 1.6

34 0

35 1.2

36 1.5

37 0.7–1.4

38 1.5

39 0

40 1.2

41 3.1

42 3.1

43 1.2

44 3.2

45 0

46 1.2

47 3.2

48 0

49 0

50 1.2

51 1.2

52 0

Pin Voltage (V)

53 1.2

54 0

55 3.2

56 3.2

57 3.1

58 3.2

59 0

60 1.2

61 3.2

62 0

63 0

64 3.1

65 3.2

66 0

67 1.2

68 3.1

69 3.1

70 3.1

71 3.1

72 3.2

73 0

74 1.6

75 3.2

76 0.3

77 1.6

78 0.1

79 3.1

80 1.2

81 0

82 0

83 3.1

84 3.2

85 0

86 0

87 3.2

88 0

89 1.2

90 1.9

91 0

92 0

93 0

94 1.9

95 0

96 1.2

97 0

98 3.2

99 0

100 0

101 0

102 0

103 3.2

104 1.2

Pin Voltage (V)

105 1.2

106 0

107 3.2

108 3

109 0

110 3

111 3

112 3

113 3

114 3.2

115 0

116 1.2

117 3

118 3

119 3

120 3

121 3

122 3

123 3

124 1.2

125 0

126 3.2

127 3

128 3

129 3

130 3

131 3

132 3

133 1.2

134 0

135 3.2

136 0

137 3.2

138 3.2

139 3.2

140 3.2

141 3.2

142 0

143 2.5

144 3.2

145 3.1

146 3.1

147 3.1

148 0

149 1.2

150 3.1

151 3.1

152 3.1

153 3.2

154 0.6

155 3.1

156 0

Pin Voltage (V)

157 1.2

158 0

159 3.1

160 3.1

161 3.1

162 3.1

163 0

164 3.1

165 0.9

166 0.9

167 0.9

168 3.1

169 1.2

170 0

171 1.2

172 0.9

173 3.2

174 3.1

175 0

176 3.2

177 1.2

178 0

179 0

180 0

181 1.2

182 0

183 3.2

184 1.6

185 3.2

186 3.2

187 3.2

188 3.2

189 0

190 1.2

191 3.2

192 3.2

193 3.2

194 0

195 1.2

196 1.2

197 0

198 3.2

199 0

200 0

201 3.2

202 3.2

203 0

204 1.7

205 3.2

206 3.2

207 0

208 1.2

IC501

K4S281632F-UC75-K

Pin Voltage (V)

1 3.1

23

3 3.1

43

53

60

73

83

9 3.1

10 3

11 3

12 0

13 3

14 3.1

15 3

16 3.1

17 3.1

18 3.2

19 0

20 1.9

21 1.9

22 0

23 0

24 0

25 3.1

26 3.1

27 3.1

28 0

29 3.1

30 3.1

31 3.1

32 1.6

33 0.3

34 0

35 0

36 0

37 3.1

38 1.6

39 3

40 0

41 0

42 3

43 3.1

44 3

45 3

46 0

47 3

48 3

49 3.1

50 3

51 3

52 0

53 3

54 0

IC502

PQ012FZ01ZP-TLB

Pin Voltage (V)

1 2.7

2 3.2

3 1.2

4 3.3

50

IC503

TC7SU04F-TLB

Pin Voltage (V)

1 1.6

2 1.7

30

4 1.7

5 3.2

CTRL ASSY

B

IC703

TC74VHC04FS1

Pin Voltage (V)

1 2.7

2 0.4

3 2.7

4 0.4

5 2.7

6 0.4

70

8 0.4

9 2.7

10 0.4

11 2.7

12 0.4

13 2.7

14 3.1

IC705

UPD16306B

Pin Voltage (V) Pin Voltage (V)

10518

2 12.3 52 8

30538

40549

50558

6056 12.3

70578

8 12.3 58 8

9 12.3 59 11

10 12.3 60 11

11 12.3 61 12.3

12 12.3 62 12.3

13 12.3 63 12.3

14 12.3 64 11

15 12.3 65 11

16 12.3 66 11

17 12.3 67 0

18 12.3 68 3.9

19 12.3 69 3.9

20 12.3 70 6.7

21 12.3 71 5.1

22 12.3 72 5.1

23 12.3 73 5.1

24 12.3 74 0

25 12.3 75 0

26 12.3 76 0

27 12.3 77 0

28 12.3 78 0

29 12.3 79 12.3

30 12.3 80 0

31 12.3 81 0

32 0 82 5.1

33 0 83 10.6

34 0 84 10.6

35 0 85 10.6

36 4.5 86 10.6

37 3 87 10.6

38 1 88 10.6

39 0 89 10.6

40 0 90 10.6

41 0 91 10.7

42 5 92 10.7

43 4.9 93 10.7

44 5 94 10.7

45 4.9 95 10.7

46 0 96 10.7

47 0 97 10.7

48 0 98 10.7

49 0 99 12.3

50 12.3 100 0

ENCB ASSY

H

D105

RPI-2150N

Pin Voltage (V)

1 4.8

20

3 3.6

4 3.6

50

6 1.4

A

B

C

D

E

F

56

EFX-1000

37

7

8

Page 38

1234

250

sec

250

sec

sec

3.13 WAVEFORMS

A

Note : The encircled numbers denote measuring point in the schematic diagram.

1b

5a6a6a

1a1b1b

1c

H:1sec/dev V:2V/div

1a

V3R3C

Power(VCC)

CPU RESET

MICON Reset

1c

MUTE

B

MUTE

H:20msec/dev V:2V/div

1b

CPU RESET

MICON Reset

5a

SRC RESET

Input SRC Reset

RSRCRXD

Output SRC Reset

RSRCRXD

10a

11a

11b

H:100µsec/dev V:2V/div

250

µsec

250µsec 250

µsec

8 byte

10a

EXPCLK

Extended Port IC

Control Clock

11a

EXTSTBN

Extended Port IC

STB

11b

EXTBLK

Extended Port IC

BLK

1b

1c

H:1sec/dev V:2V/div

2a

1b

CPU RESET

MICON Reset

1c

MUTE

MUTE

2a

DIG MUTE

C

4sec

1b

1c

3a

H:1sec/dev V:2V/div

D

1b

H:20msec/dev V:2V/div

4a4b4b

E

Coaxial MUT

1b

CPU RESET

MICON Reset

1c

MUTE

MUTE

3a

BYPASS

BYPASS

1b

CPU RESET

MICON Reset

ADRSTN

4a

A/D Reset

DSP RSTN

DSP Reset