Page 1

REC BALANCE

D

TIMER

REC

PLAY

OFF

/RPT

POWER

—OFF _ON

STEREO CASSETTE DECK

DOLBY

NR

DIGITALNRDIGITAL

Î

Ωı¿∫>≥?Û

COUNTERDISP OFF

METER

MODE

RESET

RANGE

SOURCE

/TAPE

MONITOR

FLEX

INPUT

Digital

Digital Processing System

20bit A/D•D/A CONVERTER

OPEN/CLOSE

3078

DOLBY B-C NR HX PRO

LR

•¶¡1

Legato Link Conversion

3

2

1

CD-DECK SYNCHRO

BLE XD

REC LEVEL

5

4

6

7

8

9

0

10

DIGITAL/CD

SYNCHRO

PHONES

STEREO CASSETTE DECK

CT-S670D

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV1955

Type

Model

Power Requirement

CT-S670D

HYXJ AC220–230V

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............3

3. SCHEMATIC DIAGRAM................................... 10

4. PCB CONNECTION DIAGRAM .......................20

5. PCB PARTS LIST.............................................27

6. ADJUSTMENT.................................................. 30

Remarks

7. GENERAL INFORMATION .............................. 33

7.1 PARTS .......................................................33

7.1.1 IC ......................................................33

7.1.2 DISPLAY ..........................................35

7.2 DIAGNOSIS................................................36

7.2.1 DISASSEMBLY ................................36

7.2.2 TEST MODE.....................................36

7.3 BLOCK DIAGRAM...................................... 39

8. PANEL FACILITIES AND SPECIFICATIONS

.......................................................40

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V . Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Lane Crawford Place, Singapore 0923

PIONEER ELECTRONIC CORPORATION 1998

T–DZR APR. 1998 Printed in Japan

Page 2

CT-S670D

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which

may cause birth defects or other reproductive harm (California Health & Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact with

the solder. Also, when soldering do not inhale any smoke or fumes produced.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

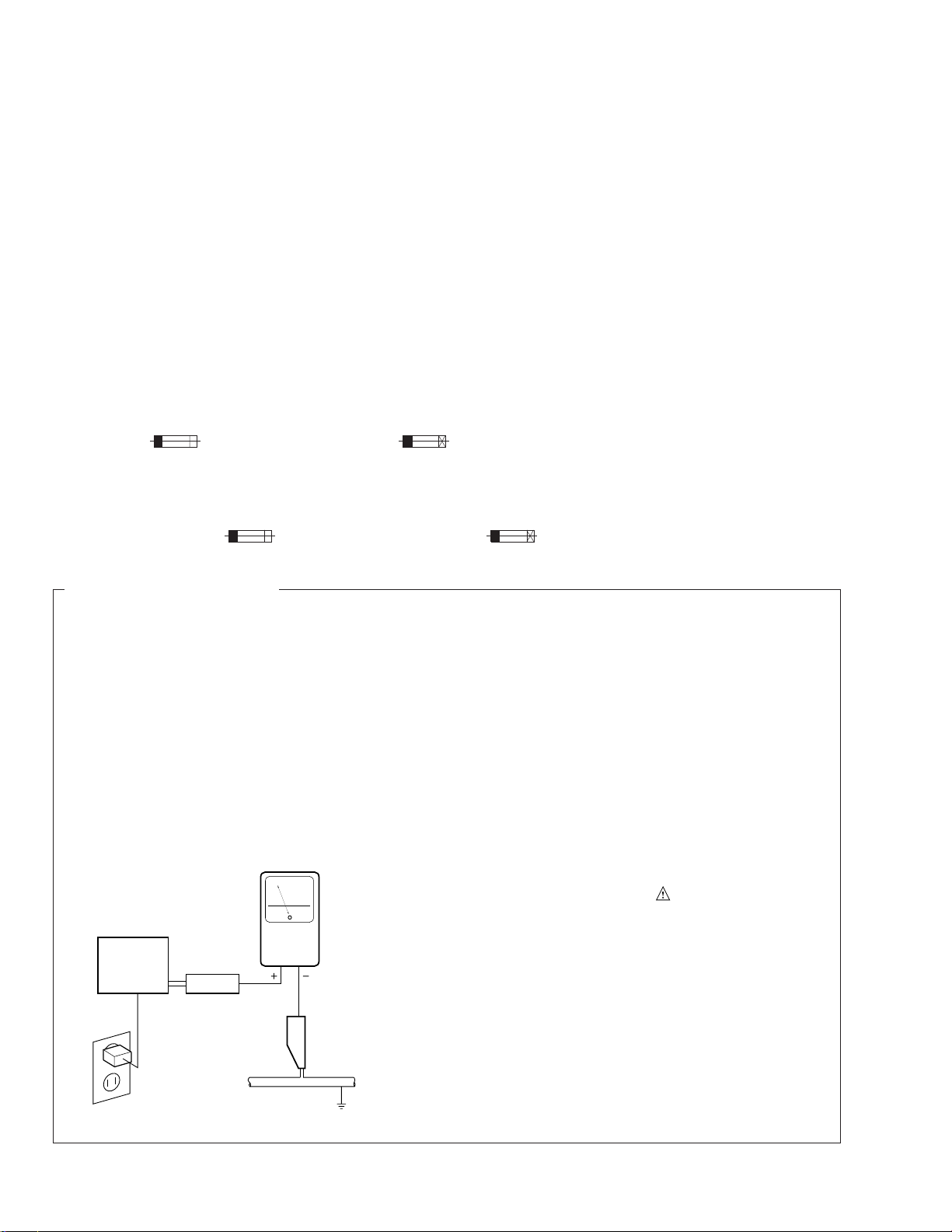

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

Page 3

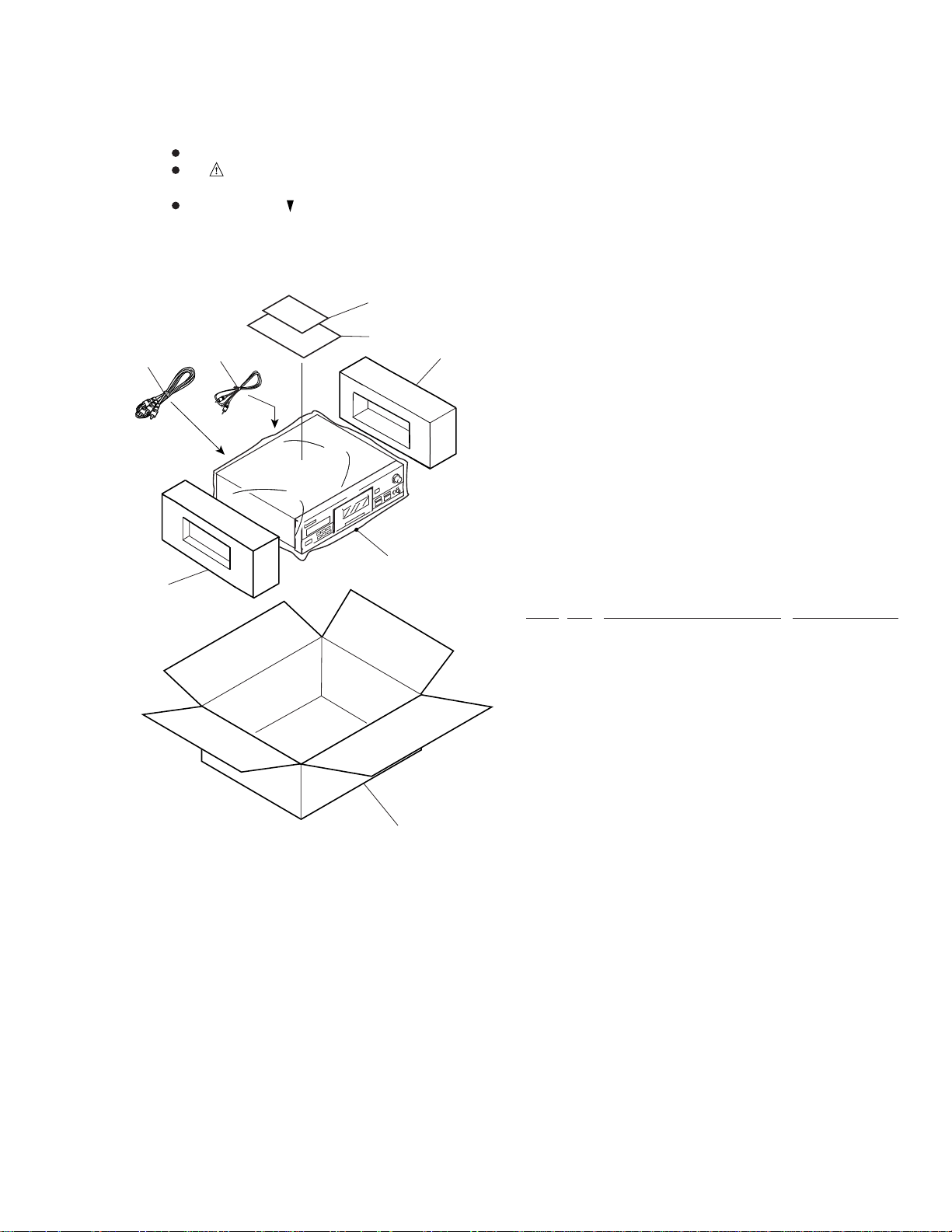

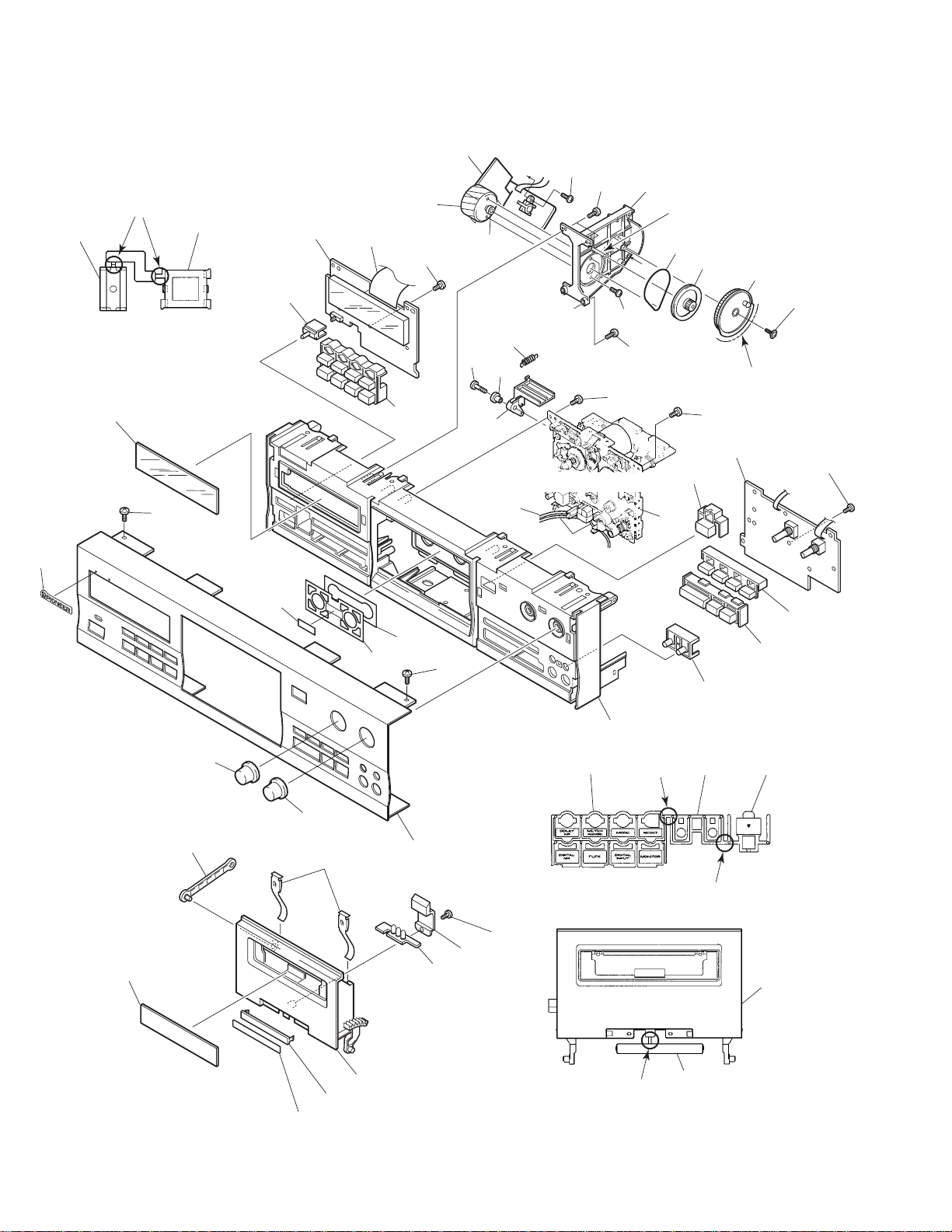

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

2.1 PACKING

8

CT-S670D

6

1

5

7

4

2

PACKING PARTS LIST

Mark No. Description Part No.

1 Pad (L) RHA1213

2 Pad (R) RHA1212

3 Packing Case RHG1871

4 Sheet (750 × 600 × 0.5) Z23-007

5 CD • DECK SYNCHRO Control RDE1044

Code

6 Connection Code with Pin Plugs RDE1036

(Audio Cord: L= 1.0 m)

7 Operating Instructions RRE1161

(English/French/German/Italian/

Dutch/Swedish/Spanish/

3

NSP 8 Warranty Card ARY7009

Portuguese)

3

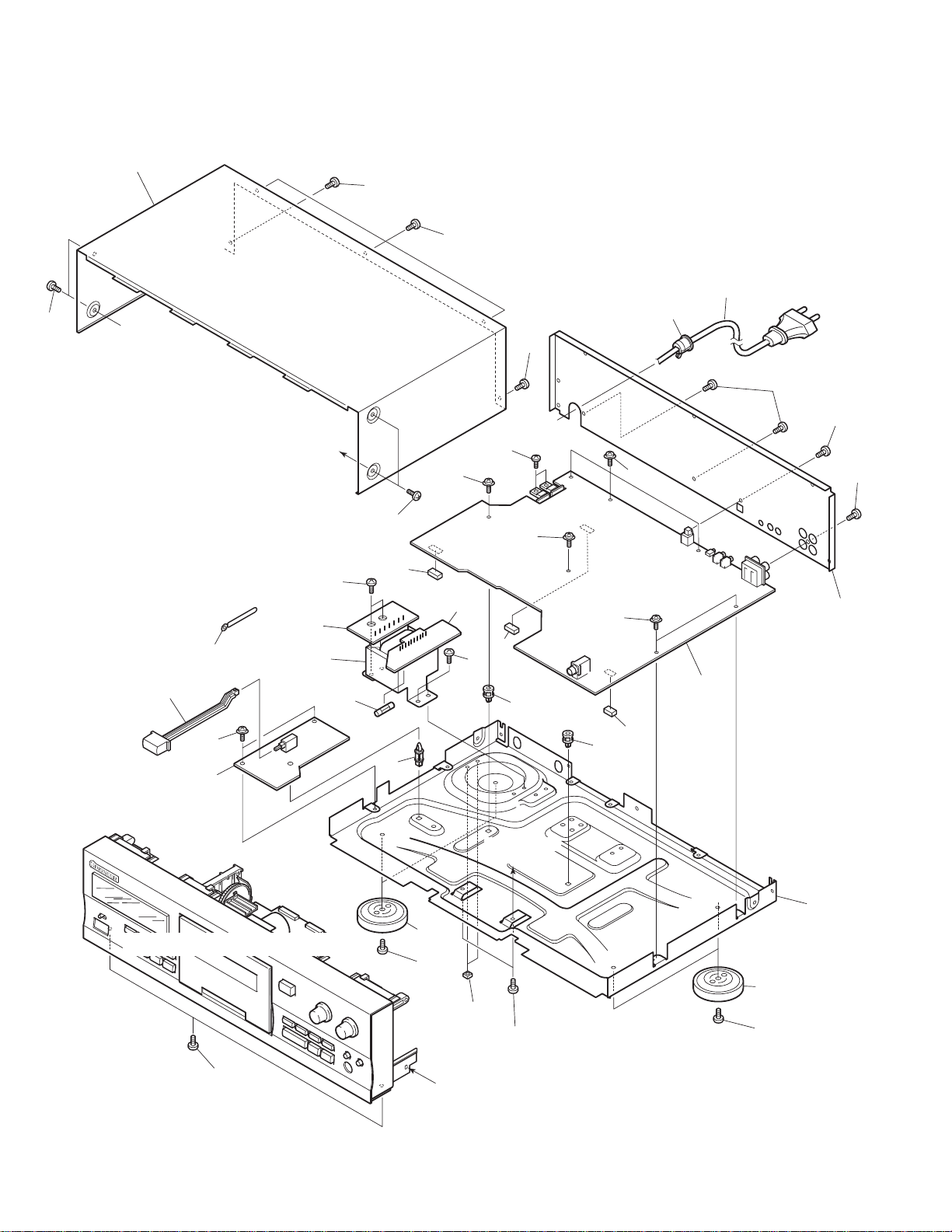

Page 4

CT-S670D

2.2 EXTERIOR

15

20

20

20

5

3

20

19

19

27

23

21

26

12

A

22

20

21

6

10

4

13

2

21

21

22

24

9

To Mechanism

Unit

21

21

1

28

9

19

8

7

Refer to " 2.3 FRONT PANEL SECTION".

29

11

19

16

29

11

19

A

4

Page 5

EXTERIOR PARTS LIST

Mark No. Description Part No.

CT-S670D

NSP 2 TRN 2 UNIT RWZ4281

NSP 7 Main Chassis RNB1132

NSP 9 PCB Spacer PNY–404

NSP 10 FL Spacer PEB1033

NSP 12 TRANS 1 PCB RNZ3294

NSP 13 PCB Holder AEC–703

NSP 23 Binder ZCA–T18S

NSP 24 Spacer REC1319

NSP 25 …………………

1 MAIN UNIT RWZ4279

3 Strain Relief CM–22B

4 Fuse (FU801: T1.25A) AEK1055

5 AC Power Cord PDG1058

6 Power Transformer RTT1345

(AC220–230V)

8 Rear Panel RNA2199

11 Insulator PNW2766

14 …………………

15 Bonnet REA1276

16 Disc Guard REC1305

17 …………………

18 …………………

19 Screw BBZ30P080FCC

20 Screw BBZ30P080FZK

21 Screw BBZ30P060FCC

22 Screw IBZ30P150FCC

NSP 26 PWSW UNIT RWZ4280

27 Power Button RAC2193

NSP 28 FL Spacer PEB1137

29 Screw BBT30P080FCC

5

Page 6

CT-S670D

2.3 FRONT PANEL SECTION

Cut

33

No. 33 Cut Part

21

26

Not used

33

24

15

39

A

5

1

3

44

19 (1/3)

7

18

43

32

11

Refer to

" 2.4 MECHANISM UNIT ".

38

45

37

31

17

45

13

A

4

Froil PN397

6

8

31

19 (3/3)

10

16

Froil PN397

2

44

25

12

42

27

42

35

29

34

9

22

41

24

30

31

14

19 (1/3)

No. 19 Cut Part

Cut

19 (2/3)

19 (2/3)

Cut

20

19 (3/3)

23 (1/2)

Cut

23 (2/2)

28

23(2/2)

23(1/2)

No. 23 Cut Part

6

Page 7

FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

1 FL UNIT RWX1146

2 OPSW UNIT RWX1142

3 FFC 33P (60V) RDD1400

4 Mechanism Unit RYM1271

5 DC Motor/0.75W PXM1010

6 Rubber Belt PEB1127

7 Motor Pulley PNW1634

8 Pulley Gear RNK1517

9 Spring RBK1004

10 Arm Gear RNK2304

11 SW Lever RNK1897

12 Joint Arm RNK2243

13 Loading Base Assy 2 RXA1750

14 Panel Stay RNT1247

NSP 15 POCM UNIT RWZ4282

CT-S670D

16 Screw IPZ20P080FMC

17 Screw BMZ26P040FMC

18 Spring RBH1008

19 Function Button B RAC2191

20 Play Button B RAC2204

21 FL Lens RAH2846

22 Front Panel RAH2848

23 Door Pocket RAH2843

24 Screw BBT30P080FCC

25 Door Lens RAH2782

26 Name Plate AAM7004

27 Indicating Panel REE–113

28 Door Plate RAH2850

29 Stabilizer B REB1085

30 Digi Lens RAC2200

31 Screw BBZ30P060FCC

32 Eject Collar RLA1303

33 Slide Knob RAC2203

34 Stabilizer Panel RAH1483

35 Manual Button RAC2195

36 …………………

37 Connector Assy 3P RKP1673

38 Connector Assy 2P RKP1681

39 Screw BBZ26P060FMC

40 …………………

NSP 41 LED UNIT RWX1143

42 VOL Knob RAC2197

43 Screw BBZ26P100FMC

44 Screw BBZ30P080FZK

45 Screw BBZ30P100FMC

7

Page 8

CT-S670D

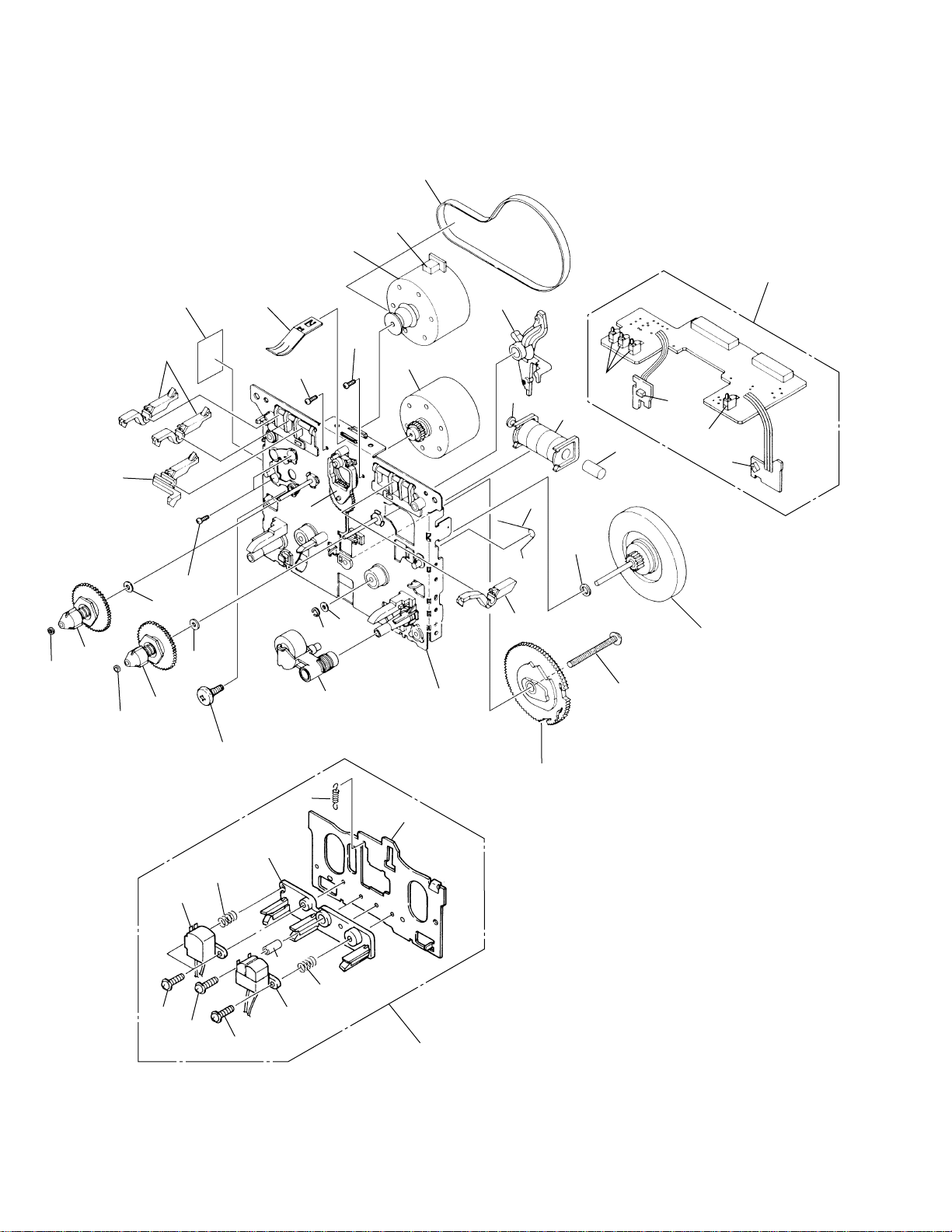

2.4 MECHANISM UNIT SECTION

7

26

28

10

42

45

23

15

16

31

15

16

19

30

36

19

38

14

17

41

11

40

14

6

2

22

32

29

24

5

8

1

13

44

This screw No. 44 is the part to hold the

cam gear for servicing, when the hook

holding the cam gear No. 24 is broken.

9

5

9

12

21

27

33

20

4

39

20

37

34

43

3

35

8

Page 9

MECHANISM UNIT SECTION PARTS LIST

Mark No. Description Part No.

1 FIXED CORE RLA1130

2 PLUNGER RLA1132

3 HEAD (R/P) RPB1047

4 HEAD (E) RPB1060

5 PUSH SW RSG1018

6 MTR REEL BLK RXM1057

7 MTR MAIN BLK RXM1058

8 SOLENOID BLK RXP1010

9 PHOTO-TRANSISTOR SPI33534FG

10 MAIN BELT REB1163

11 PINCH ROLLER ASSY RXA1183

12 FLYWHEEL ASSY RXA1772

13 WASHER WA26D045D025

14 SCREW 2.6 × 6.4 ZN RBA1076

15 WASHER RBF–057

16 REEL BASE BLK RXA1184

17 IDLER BLK RXA1248

18 …………………

19 WASHER 2.1 × 0.25T RBF1038

20 AZIMUTH SPRING RBH1076

CT-S670D

21 HAED BASE SPRING RBL1003

22 SLIDE SPRING RBH1239

23 PLAY ARM RNK1525

24 CAM GEAR (3R) RNK1672

25 …………………

NSP 26 SPACER REC1319

27 HEAD BASE RNE1390

28 SPRING CASSETTE RBK1048

29 CHASSIS BASE BLK RXA1557

30 DETECTOR LEVER (REC) RNK1527

31 METAL DETECTOR LEVER (L) RNK1529

32 DETECTOR LEVER (P) RNK1543

33 HEAD SPACER RNK2106

34 SCREW PMZ20P080FMC

35 PLATE HD BLK RXA1488

36 SCREW PMA26P050FMC

37 F LOOK SCREW M2 × 10 RBH1031

38 SCREW RBA1101

39 SPACER RLA1275

40 WASHER WA26D047D050

41 WASHER YE15FUC

42 HOLDER CUSHION (L) RED1027

43 F LOOK SCREW 2 × 8 RBA1102

44 SCREW TT2 × 15 RBA1068

45 PCB CONTROL BLK RXA1771

9

Page 10

1

234

CT-S670D

3. SCHEMATIC DIAGRAM

3.1 OVERALL SCHEMATIC DIAGRAM

A

Note: When ordering service parts, be sure to refer to "EXPLODED

VIEWS and PARTS LIST" or "PCB PARTS LIST".

CN702 (3/4)

AKB7015

CN702 (4/4)

AKB7015

MECHA UNIT

(RYM1271)

B3B-PH-K-S

P.B

HEAD

B

REC

HEAD

ERASE

HEAD

CN81

RECINH

HARF

B3B-PH-K-S

D20PYY0710G

POCM UNIT

G

(RWZ4282)

(

A

D20PWY0510G

A

1/4 to A 4/4

)

LED UNIT

F

(RWX1143)

PG02MR-F30

173981-2

MAIN UNIT

CrO2

(RWZ4279)

METAL

CN82

C

R.M

C.M

D

D20PYY1010G

FL UNIT

E

(RWX1146)

10

1234

Page 11

5

67

8

CT-S670D

B

OPSW UNIT

(RWX1142)

D20PWY0310G

(

B

1/2, B 2/2

A

)

(

A

1/4 to A 4/4

MAIN UNIT

(RWZ4279)

D20PWY0610G

52147-0610

)

CN702 (1/4)

AKB7015

CN702 (2/4)

AKB7015

JA911

JA912

JA1801

GPIF32R

A

B

DXWW0315E

TRN 2 UNIT

D

(RWZ4281)

FU801

T1.25AL250V

H1, H2:

AKR7001

POWER

TRANSFORMER

RTT1345

C

PWSW UNIT

(RWZ4280)

TRNS 1 PCB

(RNZ3294)

CN1001

JA901

JA601

AC POWER CORD

PDG1058

NEUTRAL

LIVE

AC220–230V

50/60Hz

C

D

D20PWW0615G

11

5

6

7

8

Page 12

1

234

CT-S670D

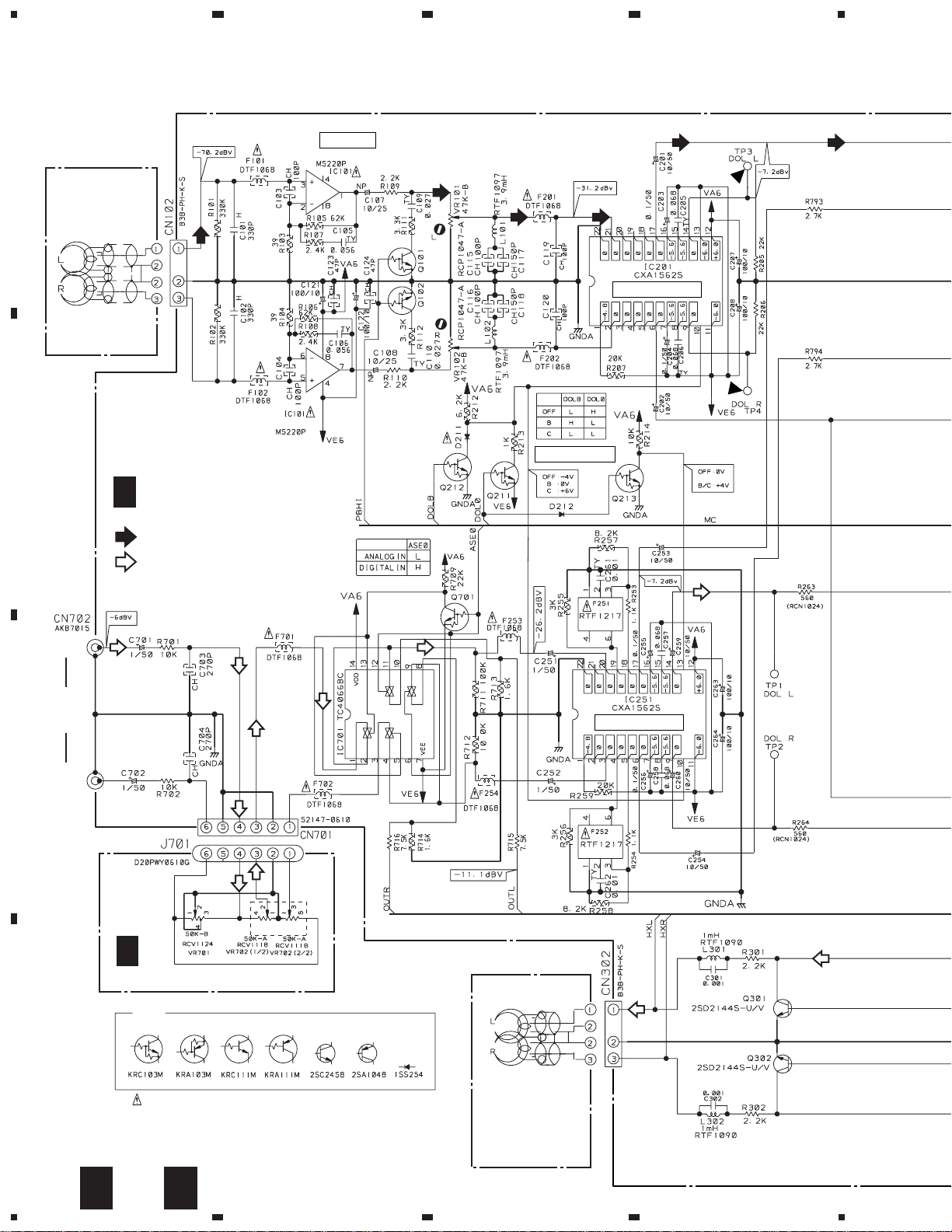

3.2 MAIN UNIT (1/4) AND OPSW UNIT (1/2)

A

MECHA UNIT

(1/4)

(RYM1271)

B

P. B HEAD

RPB1047 (1/2)

A

MAIN UNIT (1/4)

1/4

(RWZ4279)

: PLAYBACK SIGNAL ROUTE

: RECORDING SIGNAL ROUTE

PB AMP

PB LEVEL

ADJ.

BIAS

TRAP

DOLBY B/C NR

DOLBY CONT

C

D

Lch

LINE

INPUT

Rch

B

1/2

OPSW UNIT (RWX1142)

NOTE

If the parts are not identified in the diagram the followings are used.

The mark found on some component parts indicates the importance of the

safety factor of the part. Therefore, when replacing, be sure to use parts of

identical designation.

REC HEAD

RPB1047 (2/2)

MECHA UNIT

(2/4)

(RYM1271)

DOLBY B/C NR

12

A 1/4 B 1/2

1234

Page 13

5

67

8

CT-S670D

TAPE/SOURCE/REC MONI

LINE OUT

BUFFER

A

Lch

LINE

OUT

Rch

B

HP AMP

C

PB/REC

METER AMP

D

A

2/4

REC AMP

5

6

A

2/4

A

3/4

7

8

A 1/4

13

Page 14

1

CT-S670D

3.3 MAIN UNIT (2/4)

234

A

B

A

MAIN UNIT (2/4)

2/4

(RWZ4279)

DSP

A

1/4

C

LRCK, BCLK (FROM DIR)

ON/OFF

NOTE

If the parts are not identified in the diagram the followings are used.

D

14

A 2/4

The mark found on some component parts indicates the importance of the

safety factor of the part. Therefore, when replacing, be sure to use parts of

identical designation.

1234

Page 15

5

67

8

CT-S670D

A

RAM

X'TAL/VCO

X1731:

18.432 MHz

X'TAL

A

B

3/4

C

DIR

D

5

6

7

8

A 2/4

15

Page 16

1

234

CT-S670D

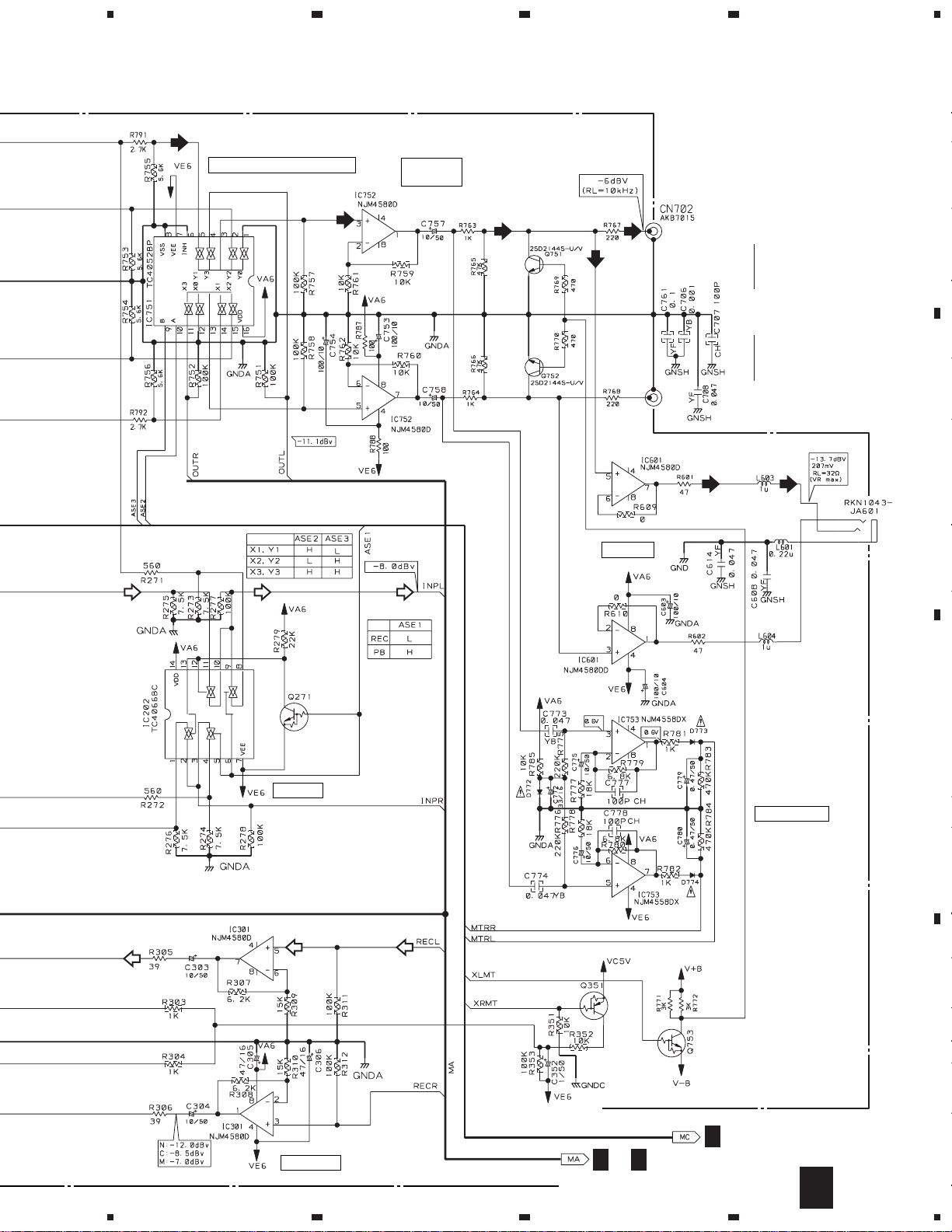

3.4 MAIN UNIT(3/4), PWSW UNIT AND TRN2 UNIT

A

B

A

MAIN UNIT (3/4)

3/4

(RWZ4279)

S5688G

S5688G

S5688G

S5688G

C1025C1026

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TIME NO. ICP-N15, MFD BY

ROHM CO., LTD. FOR IC1003 and IC1004.

HEAT SINK

POWER SUPPLY

10/50

1000/16

10/50

470/25

EARTH METAL

FITTING

470/25

POWER OFF

C

C

TRN1 PCB

(RNZ3294)

FU801

AKR7001

D

TRN2 UNIT

D

(RWZ4281)

16

A 3/4

1234

C D

T1.25AL250V

NOTE FOR FUSE REPLACEMENT

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TIME AND RATINGS ONLY.

PWSW UNIT

(RWZ4280)

AC POWER CORD

PDG1058

AC220–230V

50/60 Hz

Page 17

A

2/4

5

67

8

CT-S670D

MECHA UNIT (3/4)

(RYM1271)

A

A

1/4

BIAS OSC

160 kHz

HX PRO

(RPB1060)

B

BLEXD

CONT

BIAS CONTROL

D/A CONVERTER

NOTE

If the parts are not identified in the diagram the followings are used.

A

4/4

C

D

The mark found on some component parts indicates the importance of the

safety factor of the part. Therefore, when replacing, be sure to use parts of

identical designation.

5

6

7

8

A 3/4

17

Page 18

1

234

CT-S670D

3.5 MAIN UNIT (4/4), OPSW UNIT (2/2), FL UNIT, LED UNIT AND POCM UNIT

MAIN UNIT (4/4)

4/4

(RWZ4279)

NOTE

If the parts are not identified in the diagram the followings are used.

The mark found on some component parts indicates the importance of the

safety factor of the part. Therefore, when replacing, be sure to use parts of

identical designation.

MEMORY

MC

A

A

3/4

A

B

FL HOLDER

C

E

FL UNIT (RWX1146)

SWITCHES:

FL UNIT

S1503: COUNTER RESET

S1504: FLEX

S1505: METER RANGE/DISO OFF

S1506: COUNTER MODE

S1507: DIGITAL- NR

S1508: DOLBY NR

S1509: DIGITAL IN

S1510: MONITER

OPSW UNIT

S1601:

S1602: EJECT

S1603: REC

S1604: PAUSE

S1605: CD SYNC

D

S1607: MUTE

S1608: PLAY

S1609: F F

S1610: REW

S1611: BLE XD

STOP

B

2/2

OPSW UNIT

(RWX1142)

18

A 4/4 B 2/2

1234

E

Page 19

5

67

8

CT-S670D

MC

MECHA CONTROL

A

G

POCM UNIT

(RWZ4282)

B

HOLDERHOLDER

µ-COM

MECHA UNIT (4/4)

(RYM1271)

C

D

LED UNIT

F

(RWX1143)

5

6

7

A 4/4

F

G

8

19

Page 20

1

234

CT-S670D

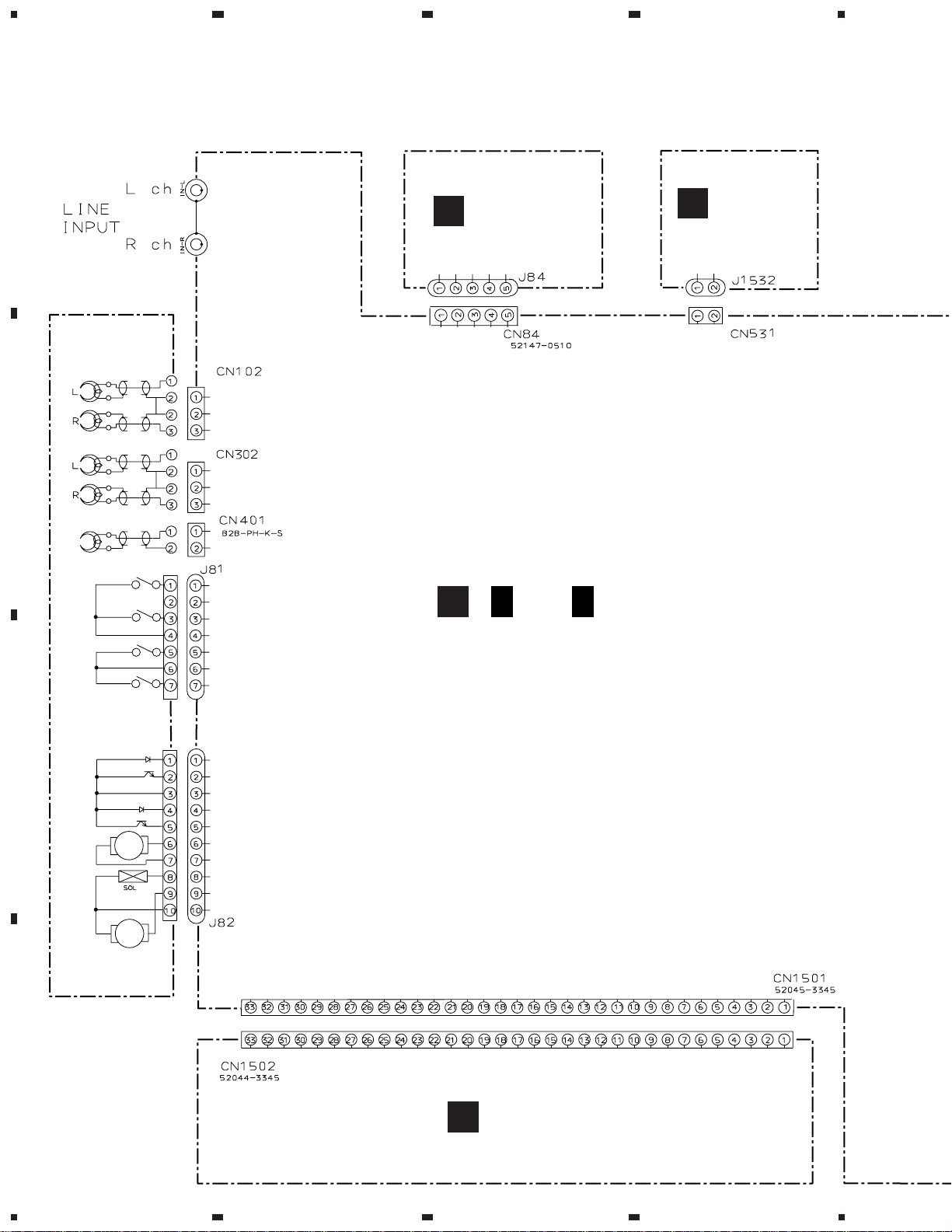

4. PCB CONNECTION DIAGRAM

A

B

NOTE FOR PCB DIAGRAMS:

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol in PCB

Diagrams

BCE

BCE

DGS

Symbol in Schematic

Diagrams

BCE

BCEBCE

DGSDGS

BCE

4.1 LED UNIT AND POCM UNIT

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Symbol in PCB

Diagrams

3. The parts mounted on this PCB include all necessary parts

for several destination.

For further information for respective destinations, be sure

to check with the schematic diagram.

4. Viewpoint of PCB diagrams

Symbol in Schematic

Diagrams

CapacitorConnector

Part Name

Resistor array

3-terminal

regulator

SIDE A

P. C. Board Chip Part

SIDE B

SIDE A

LED UNIT

F

RNP1724–A

C

POCM UNIT

G

D

A

CN531

A

CN84

RNP1725–A

20

F

G

1234

Page 21

1

23

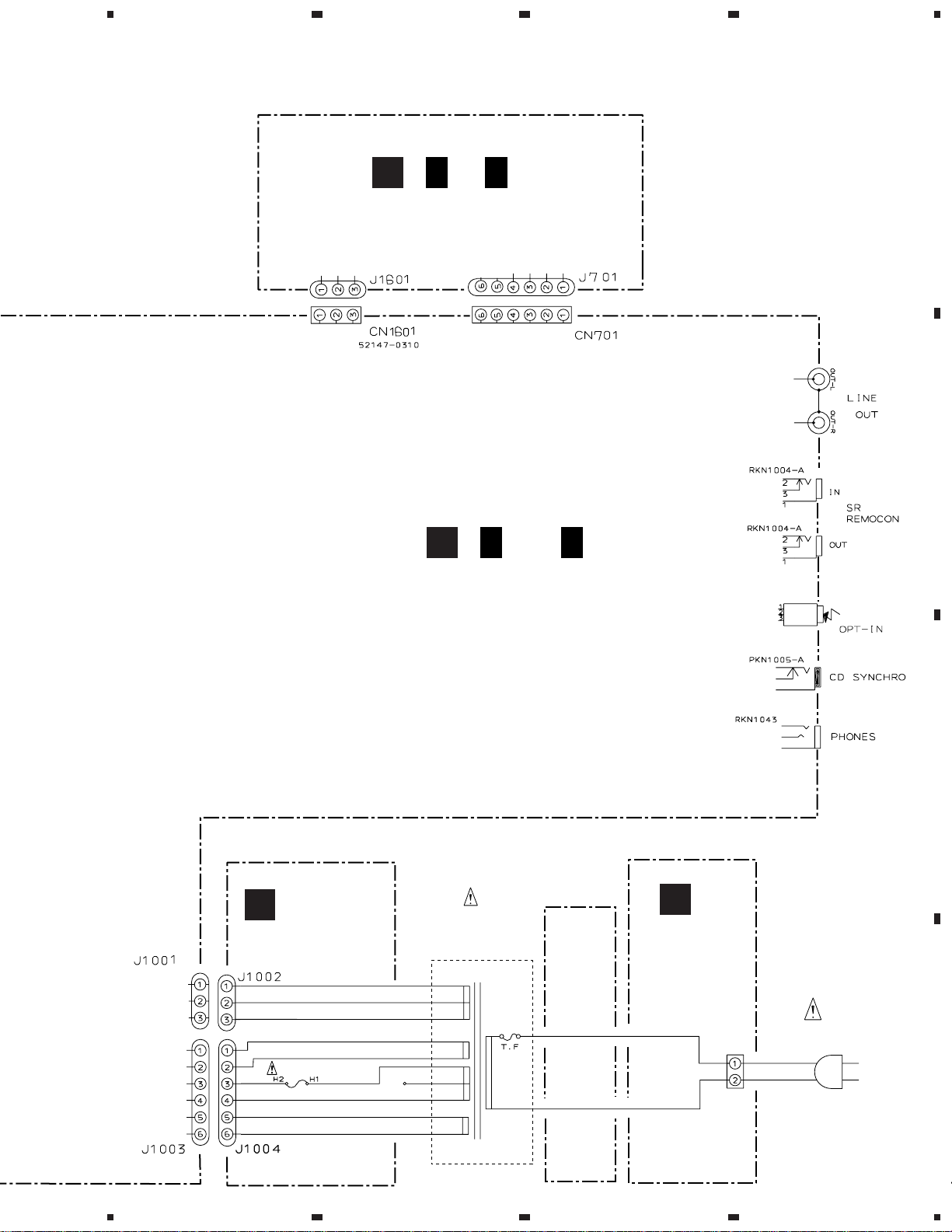

4.2 PWSW UNIT, TRN2 UNIT AND TRN1 PCB

D

TRN2 UNIT

4

CT-S670D

A

SIDE A

A

J1001

A

J1003

TRN1 PCB

POWER TRANSFORMER

B

AC POWER CORD

1

NEUTRAL

LIVE

C

PWSW UNIT

2

C

PNP1725–A

D

3

C

D

4

21

Page 22

1

CT-S670D

234

4.3 MAIN UNIT

IC1012

IC1013

IC1011

Q1001

Q1003

IC1003

IC1001

Q1002

Q1004

IC1004

Q753

Q351

IC1821

A

B

D

J1002

D

J1004

E

CN1502

A

MAIN UNIT

Q531

IC1014

Q1731

Q1005

Q572

Q571

IC591

IC801

C

Q801

|

Q807

MECHA UNIT

CN82

MECHA UNIT

CN81

RNP1725–A

F

J1532

G

J84

D

22

A

1234

Page 23

5

67

8

CT-S670D

SIDE A

A

Q751

Q752

Q902

IC753

IC752

IC301

VR102

IC202

VR101

MECHA UNIT

PB HEAD

Q271

Q401

|

Q403

Q301

Q302

IC601

IC751

Q102

IC201

IC101

Q101

IC251

IC701

B

C

MECHA

UNIT

ERACE HEAD

MECHA

UNIT

REC HEAD

Q701

Q211

|

IC451

Q213

B

J701

B

J1601

VR601

A

5

6

7

8

23

D

Page 24

CT-S670D

A

IC1801

IC1751

1

A

MAIN UNIT

234

B

C

IC1701

D

24

A

1234

Page 25

5

67

8

CT-S670D

SIDE B

IC1802

A

IC1761

B

IC1741

IC1851

IC1731

IC501

IC551

C

RNP1725–A

D

5

6

7

8

A

25

Page 26

1

CT-S670D

234

4.4 OPSW UNIT AND FL UNIT

A

B

OPSW UNIT

B

A

CN1601

SIDE A

A

CN701

E

FL UNIT

C

D

RNP1724–A

A

CN1501

26

B

E

1234

Page 27

5. PCB PARTS LIST

NOTES :

Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex. 1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by

J = 5%, and K = 10%).

1

560 Ω = 56 × 10

47k Ω = 47 × 10

= 561................................................... RD1/4PU 5 6 1 J

3

= 473 .................................................. RD1/4PU 4 7 3 J

0.5 Ω = R50 ...................................................................... RN2H Â 5 0 K

1 Ω = 1R0 ......................................................................... RS1P 1 Â 0 K

Ex. 2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω = 562 × 10

1

CT-S670D

= 5621 ........................................... RN1/4PC 5 6 2 1 F

Mark No. Description Part No.

LIST OF PCB ASSEMBLIES

NSP MOTHER UNIT RWM2045

NSP PWSW UNIT RWZ4280

NSP TRN 2 UNIT RWZ4281

NSP POCM UNIT RWZ4282

NSP SUB UNIT RWM2049

NSP LED UNIT RWX1143

A

MAIN UNIT RWZ4279

FL UNIT RWX1146

OPSW UNIT RWX1142

MAIN UNIT

SEMICONDUCTORS

IC1701 AK7712A-VQ

IC591 AT24C01-10PC

IC201, IC251 CXA1562S

IC1003, IC1004 ICP-N15

IC1001 M5218AP

IC101 M5220P

IC1751 M5M51008BFP-70L

IC551 M62354GP

IC753 NJM4558DX

IC301, IC601, IC752 NJM4580D

IC1011, IC1012 NJM7805FA

IC1821 PD0052

IC501 PD5431A

IC1013 PQ12RF11

IC1014 S-806D

IC801 TA7288P

IC751 TC4052BP

IC202, IC701 TC4066BP

IC1741 TC74HC00AF

IC1851 TC74HC125AF

IC1761 TC7S08F

IC1731 TC7SU04F

IC451 UPC1297CA

Q1002, Q1005 2SA1048

Q1004 2SB1566

Mark No. Description Part No.

Q401, Q402 2SC1815

Q1001, Q571, Q572, Q802, Q806 2SC2458

Q805 2SC3246

Q803, Q804 2SD1858X

Q301, Q302, Q403, Q751, Q752 2SD2144S

Q1003 2SD2395

Q351 KRA103M

Q101, Q102, Q1731, Q211–Q213 KRC103M

Q271, Q531, Q701, Q753, Q801 KRC103M

Q807, Q902 KRC103M

D1021, D1022 1SS254

D1023 1SS254

D211, D212, D402 1SS254

D772–D774, D820–D827 1SS254

D901–D903, D908–D910 1SS254

D1731–D1733, D1821 1SS355

D1005, D1006 HZS6C1L

D1020 MTZJ6.2B

D1011 S2VB20

D1001–D1004, D1015, D1016 S5688G

D1019 S5688G

D801 S5688G

COILS AND FILTERS

F101, F102, F201, F202 DTF1068

F253, F254, F701, F702 DTF1068

L603, L604 LAU1R0J

L901, L902 LAU1R0K

L904 LAU4R7J

L601 LAUR22J

L402 LFA121K

L1801 LFA151K

L1701, L1702, L1731, L1741, L1751 LFA1R0K

L1821, L1822, L1851 LFA1R0K

X501 (8.389 MHz) RSS1042

X1731 (18.432 MHz) RSS1052

L451, L452 (160 kHz) RTD1074

L401 (OSC COIL F=160 kHz) RTD1076

L301, L302 (1 mH) RTF1090

L101, L102 (3.9 mH) RTF1097

L1802 (EMI FILTER) RTF1171

F251, F252 (MPX FILTER) RTF1217

27

Page 28

CT-S670D

Mark No. Description Part No. Mark No. Description Part No.

CAPACITORS

C459, C460 CCCSL271K2H

C1834 CCSQCH100D50

C103, C104, C115, C116 CCSQCH101J50

C119, C120, C463, C707 CCSQCH101J50

C777, C778 CCSQCH101J50

C117, C118 CCSQCH151J50

C1734, C1735 CCSQCH180J50

C1823 CCSQCH220J50

C703, C704, C905 CCSQCH271J50

C123, C124, C805, C807 CCSQCH470J50

C1020, C1742, C1751, C1761 CEAT100M50

C775, C776, C803 CEAT100M50

C1017, C121, C122, C207, C208 CEAT101M10

C263, C264, C603, C604 CEAT101M10

C1016 CEAT101M16

C1019 CEAT101M50

C352 CEAT1R0M50

C1825 CEAT2R2M50

C407, C465, C772 CEAT330M16

C1721, C1722, C1732, C1802, C1804 CEAT470M16

C1821, C1838, C1851, C305, C306 CEAT470M16

C406, C501 CEAT470M16

C1015 CEAT472M25

C203, C204, C255, C256 CEATR10M50

C779, C780 CEATR47M50

C1762, C1801, C1822, C1839, C761 CKSQYF104Z25

C1712, C1805, C1833, C801, C802 CKSQYF473Z50

C906 CKSQYF473Z50

C101, C102 CQHA331J2A

C402 CQHA392J2A

C301, C302 CQMA102J50

C405 CQMA123J50

C401, C404 CQMA332J50

C1824 CQMA473J50

C403 CQMA682J50

C1014 (1000 µF/16V) PCH1122

C461, C462 (470 pF/500V) RCG1006

C753, C754 (100 µF/10V) RCH1133

C1706, C1708, C1711, C1716 VCH1083

(22 µF/25V)

RESISTORS

R525 RA4T103J

R205, R206 RCN1023

R263, R264 RCN1024

R402 RD1/2LMF1R0J

R408 RD1/2VM330J

R403, R404 RD1/2VM4R7J

R787, R788 RD1/4PU101J

R1005, R1006, R763, R764 RD1/4PU102J

R519, R701, R702 RD1/4PU103J

R253, R254 RD1/4PU112J

C1005, C1006, C1719, C1720 CEBA100M50

C201, C202, C253, C254 CEBA100M50

C259, C260, C303, C304 CEBA100M50

C757, C758 CEBA100M50

C1725–C1728, C251, C252 CEBA1R0M50

C701, C702 CEBA1R0M50

C1025, C1026 CEBA222M16

C1009, C1010 CEBA471M25

C107, C108 CEYANP100M25

C261, C262, C451, C452 CFTYA103J50

C455, C456 CFTYA223J50

C109, C110 CFTYA273J50

C1007, C1008, C105, C106 CFTYA563J50

C205, C206, C257, C258 CFTYA683J50

C1815 CGCYF104Z25

C505 CKCYF103Z50

C1001, C1002, C1011, C1012, C1021 CKCYF473Z50

C1024, C608, C614, C708 CKCYF473Z50

C706 CKSQYB102K50

C1713, C1733, C1736, C1852 CKSQYB103K50

C502–C504, C552, C591, C804 CKSQYB103K50

C806, C901, C902 CKSQYB103K50

C457, C458 CKSQYB123K50

C555, C556 CKSQYB221K50

C1831, C1832, CKSQYB223K50

C1723, C1724 CKSQYB332K50

C773, C774 CKSQYB473K50

C453, C454 CKSQYB821K50

C1701–C1705, C1707, C1709, C1710 CKSQYF104Z25

C1714, C1715, C1731, C1741, C1752 CKSQYF104Z25

R401, R406 RD1/4PU123J

R1001, R1002 RD1/4PU151J

R805, R808, R814 RD1/4PU152J

R577, R578 RD1/4PU202J

R767, R768 RD1/4PU221J

R109, R110, R301, R302 RD1/4PU222J

R812, R813 RD1/4PU223J

R791–R794, R804 RD1/4PU272J

R1727, R1728, R531 RD1/4PU301J

R771, R772 RD1/4PU302J

R806 RD1/4PU332J

R305, R306 RD1/4PU390J

R1003, R1004, R601, R602 RD1/4PU470J

R271, R272 RD1/4PU561J

R1015 RD1/4PU562J

R715, R716 RD1/4PU752J

R1017 RFA1/4PL820J

VR101, VR102 (47 kΩ) RCP1047

R807 RS2LMF560J

Other Resistors RS1/10S J

OTHERS

CN531 MT CONNECTOR 2P 173981-2

CN701 6P JUMPER CONNECTOR 52147-0610

CN84 5P JUMPER CONNECTOR 52147-0510

CN1601 3P JUMPER CONNECTOR 52147-0310

CN1501 33P FFC CONNECTOR 52045-3345

CN401 KR CONNECTOR 2P B2B-PH-K-S

JA1801 OPTICAL LINK IN GP1F32R

CN702 4P PIN JACK AKB7015

JA601 HEADPHONE JACK RKN1043

J81 2m/m PITCH WIRE 7P D20PYY0710G

28

Page 29

CT-S670D

Mark No. Description Part No. Mark No. Description Part No.

JA911, JA912 REMOTO JACK RKN1004

CN102, CN302 SP CONNECTOR B3B-PH-K-S

JA901 MINI JACK PKN1005

J1003 2m/m PITCH WIRE 6P D20PWW0615G

J1001 PARALLEL CORD DXWW0315E

LED UNIT

F

SEMICONDUCTORS

D1531–D1533 (PURE GREEN ) MBG5074X

J82 2m/m JUMPER WIRE 10P D20PYY1010G

PWSW UNIT

C

SWITCH

S991 RSA1001

CAPACITOR

C991 (10000pF/250V) ACG7020

OTHERS

FL UNIT

E

SEMICONDUCTORS

D1501–D1503 1SS254

SWITCHES

S1501 ( SLIDE SW ) RSH1041

S1503–S1510 VSG1009

GROUND PLATE VNF-091

PCB BINDER VEF1040

7P CABLE HOLDER 51048-0700

10P CABLE HOLDER 51048-1000

TERMINAL RKC-061

PCB BINDER VEF1040

OTHER

J1532 CONNECTOR ASSY PG02MR-F30

TRN 2 UNIT

D

OTHERS

H1, H2 FUSE CLIP AKR7001

G

POCM UNIT

OTHERS

J84 2m/m PITCH WIRE D20PWY0510G

REAF SW VSK1011

RESISTORS

All Resistors RD1/4PU J

OTHERS

CN1502 33P FFC CONNECTOR 52044-3345

V1501 FL TUBE RAW1163

OPSW UNIT

B

SWITCHES

S1601–S1605, S1607–S1611 VSG1009

RESISTORS

VR702 (50 kΩ–A) RCV1118

VR701 (50 kΩ–B) RCV1124

Other Resistors RD1/4PU J

OTHERS

J1601 3P JUMPER WIRE D20PWY0310G

J701 2m/m JUMPER WIRE D20PWY0610G

29

Page 30

CT-S670D

6. ADJUSTMENT

Adjustment points and Measurement points are shown in Fig. 6–5.

6.1 MECHANICAL ADJUSTMENT

Tape Speed Adjustment

Mode Test Tape Adjusting Point

PLAY NCT-111 (3kHz) Capstan Motor 3000Hz ± 5Hz

Specifications/Ratings

(Playback Frequency)

Note) Always use a ceramic screwdriver

for adjustment.

6.2 ELECTRICAL ADJUSTMENT

Adjustment Conditions

(1) The mechanical adjustments must be completed first.

(2) The head must be cleaned and demagnetized.

(3) Turn the power on allow the deck to warm up for at least a few

minutes before commencing any electrical adjustments.

(4) The reference signal is 0 dBV = 1 Vrms.

(5) Connect a10 kΩ load resistance to the OUTPUT terminals.

(6) Unless otherwise specified, the switches listed below are left in

the positions indicated.

DOLBY NR : OFF

DIGITAL NR : OFF

List of Adjustments

Playback Section

(1) Head Azimuth Adjustment

(2) Playback Level Adjustment

Recording Section

(1) Bias Oscillator Adjustment

(2) Recording Bias and Recording Level Automatic Adjustment

NOTE: This unit has an automatic tape selection feature.

Remarks

Test Tape

STD–331E : Playback adjustment (See Fig. 6–1)

STD–632 : NORMAL blank tape

STD–622 : CrO2 blank tape

STD–611 : METAL blank tape

∗As the reference recording level is 250 nwb/m for STD–331E,

the recording level will be higher by 4 dB for STD–331B

(160nwb/m). When adjusting, pay careful attention to the type

of tape used.

0 dB

30

30s

315 Hz

0 dB: 315 Hz, 250 nwb/m

30 s 30 s 30 s 10s 10s ................................................................................................................ 10s

6.3 kHz 10 kHz 315 Hz 14 kHz

12.5

kHz

Fig. 6–1 Constants of the Test Tape STD–331E

Dolby noise reduction and HX Pro headroom extension manufactured

under license from Dolby Laboratories Licensing Corporation. HX Pro

originated by Bang & Olufsen.

“DOLBY”, the double-D symbol and “HX PRO” are trademarks of Dolby

Laboratories Licensing Corporation.

10 kHz

8 kHz 4 kHz 2 kHz

6.3

kHz

1 kHz

500Hz250Hz125

Hz

63 Hz 40 Hz

–20 dB

Page 31

CT-S670D

PLAY BACK

250

3dB

10k

3dB

Fig. 6–2 Frequency Response Zone

6.2.1 Playback Section

(1) Head Azimuth Adjustment

Turn VR101 and VR102 to mechanical center position.

No. Mode Input Signal / Test Tape

1

PLAY

Play the 10 kHz/–20 dB section

of STD–331E test tape

adjustment screw

RECORDING

12.5k

4dB

315 Hz = 0 dB 315 Hz = 0 dB

250

3dB

Adjustment Measurement Adjustment

Location Location Value

Head azimuth

(Fig. 6–3)

LINE OUT

(L/R ch)

Maximum playback

signal level

10k

3dB 5dB

12.5k

Lock the screw with silicon

bond after completing

adjustment.

Remarks

Fig. 6–3 Head Azimuth Adjustment

(2) Playback Level Adjustment

This adjustment determines the DOLBY NR level, and must be performed with great care.

No. Mode Input Signal / Test Tape

1

PLAY

Play the 315 Hz/ 0 dB section of

STD–331E test tape

Adjustment Measurement Adjustment

Location Location Value

VR101L ch

R ch VR102

TP3 (L ch)

TP4 (R ch)

(MAIN Unit)

6.2.2 Recording Section

(1) Bias Oscillation Frequency Adjustment

No. Mode Input Signal / Test Tape

1 TP11

REC

Load the STD–611 test tape with

no input signal.

Adjustment Measurement Adjustment

Location Location Value

L401

Head Azimuth Adjustment Screw

Remarks

–6.7 dBV

Remarks

160 kHz ± 1 kHz

31

Page 32

CT-S670D

(2) Recording Bias and Recording Level Automatic Adjustment

1 Press the MODE key, RESET key and the PAUSE key together to enter the into test mode.

‘

2 Press the MODE key, PAUSE key and the MUTE key together to clear all memory data. At this time, “CLR” is displayed on the

counter.

‘

3 Press the STOP key to set the level (MS) display to “10” (mechanism operation check mode).

‘

4 Press the XD FLAT key to set the level (MS) display to “80” (automatic adjustment mode).

‘

5 When the test tape (STD–632) is inserted and the REC key is pressed, “B” flashes on the counter and bias adjustment is started. When

adjustment is completed correctly, “B” will light steadily, and then “R” will flash and adjustment of the recording level will start. When

the adjustment is completed correctly, “BR” will light to indicate that the adjustment has been completed correctly. When at the time

“B” lights, this indicates a bias adjustment error, and when “R” lights, this indicates a recording level adjustment error. At the time

of an error, the adjustment value is not written to the memory.

Adjustment error: The following causes can be considered.

Recording is not being done.

The adjustment tape is damaged seriously.

There is no adjustment data. The tape is near the tape end.

Circuit trouble (defective contact etc.)

‘

6 When the STOP key is pressed, automatic adjustment mode is cancelled, the level (MS) display becomes “10” (mechanism operation

check mode), and “TUNE” is displayed on the counter.

‘

7 Press the RESET key to leave test mode.

Counter Display

Fig. 6–4 FL Display Position

Level (MS) Display

L401

TP11

IC202

R402

TP4

R206

TP3

R205

MAIN UNIT

IC201

IC251

IC751

VR102

IC101

VR101

IC701

32

Front

Fig. 6–5 Adjustment and Measurement Points

Page 33

7. GENERAL INFORMATION

CT-S670D

7.1 PARTS

7.1.1 IC

PD5431A (IC501: MAIN UNIT)

System Control Micro-computer

Pin Function

No. Name I/O Description

1 MTRR I Level meter R ch input

2 MTRL I Level meter L ch input

3 XNRR O NORMAL Tape Recording: “L”

4 XNRL O NORMAL Tape Recording: “L”

5 METR O METAL Tape Recording: “H”

6 METL O METAL Tape Recording: “H”

7 VCOI O DIR VCO oscillation control Stop: “H”

8 SCK O Clock output to DSP

9 SO O Data output to DSP

10 SI I Data input from DSP

¶ The information shown in the list is basic information and may

not correspond exactly to that shown in the schematic diagrams.

No. Name I/O Description

28 SOLB O Solenoid control terminal B

29 CPM O Capstan motor control terminal

30 DIG1 O Digital input select terminal 1

31 DIG2 O Digital input select terminal 2

32 SSEN I Supply side sensing input terminal

33 REMT I Remote control input terminal

34 POFF I Power off input terminal

35 REST I Reset input terminal

36 XCIN I Sub clock input terminal

37 XCOUT O Sub clock output terminal

11 RSTB O Reset output to DSP

12 PDB O Power down output to DSP

13 RQB O Request output to DSP

14 CSB O DSP chip select

15 RM2 O Motor driver control terminal 2

16 RM1 O Motor driver control terminal 1

17 RM0 O Motor driver control terminal 0

18 RMPL O Reel motor torque control terminal

19 XL3 I/O BLE · XD BIAS control terminal 3 (L ch)

20 XL2 I/O BLE · XD BIAS control terminal 2 (L ch)

21 XL1 I/O BLE · XD BIAS control terminal 1 (L ch)

22 XL0 I/O BLE · XD BIAS control terminal 0 (L ch)

23 XR3 I/O BLE · XD BIAS control terminal 3 (R ch)

24 XR2 I/O BLE · XD BIAS control terminal 2 (R ch)

25 XR1 I/O BLE · XD BIAS control terminal 1 (R ch)

38 XIN I Clock input terminal

39 XOUT O Clock output terminal

40 VSS I GND

41 X12V O VC12V control terminal “H”: 12V ON

42 TSEN I Take up side sensing input terminal

43 BIAS O Bias control terminal “H”: Bias ON

44 TOCD O CD SYNCHRO control terminal

45 SW3 Switch input terminal 3

| | I |

48 SW0 Switch input terminal 0

49 RMPS O PLAY torque SLOW terminal (Used at DTC)

50 DAT I/O EEPROM/DAC data input/output terminal

51 CLK O EEPROM/DAC clock input/output terminal

52 NC I OPEN

53 CSDA O DAC chip select terminal

54 ERR I DIR error input terminal

26 XR0 I/O BLE · XD BIAS control terminal 0 (R ch)

27 SOLA O Solenoid control terminal A

55 441k I f=44.1 input terminal

56 EMPH I Emphasis input terminal

33

Page 34

CT-S670D

PD5431A

No. Name I/O Description

57 G1 FL FL grid terminal 1

58 G2 FL FL grid terminal 2

59 G3 FL FL grid terminal 3

60 G4 FL FL grid terminal 4

61 G5 FL FL grid terminal 5

62 G6 FL FL grid terminal 6

63 G7 FL FL grid terminal 7

64 G8 FL FL grid terminal 8

65 G9 FL FL grid terminal 9

66 G10 FL FL grid terminal 10

67 P14 FL FL segment terminal 14

68 P13 FL FL segment terminal 13

69 P12 FL FL segment terminal 12

70 P11 FL FL segment terminal 11

No. Name I/O Description

87 ASE1 O Analog switch control terminal 1

88 ASE0 O Analog switch control terminal 0

89 VEE I Power supply terminal (built-in pull-down resistor)

90 CDJC I CD SYNCHRO JACK detection terminal

91 VCC I POWER SUPPLY

92 CDIN I CD SYNCHRO input terminal

93 AVSS I GND (built-in A/D converter)

94 VREF I Power supply (built-in A/D converter)

95 VER1 AD Switching version for destination 1

96 VER0 AD Switching version for destination 0

97 KEY0 AD Key input terminal 0 (AD)

98 KEY1 AD Key input terminal 1 (AD)

99 KEY2 AD Key input terminal 2 (AD)

100 KEY3 AD Key input terminal 3 (AD)

71 P10 FL FL segment terminal 10

72 P9 FL FL segment terminal 9

73 P8 FL FL segment terminal 8

74 P7 FL FL segment terminal 7

75 P6 FL FL segment terminal 6

76 P5 FL FL segment terminal 5

77 P4 FL FL segment terminal 4

78 P3 FL FL segment terminal 3

79 P2 FL FL segment terminal 2

80 P1 FL FL segment terminal 1

81 DOL0 O DOLBY IC terminal “H”: DOLBY OFF

82 LDNR O D-NR LED control terminal

83 XLMT O LINE MUTE terminal “H”: MUTE OFF

84 XRMT O REC MUTE terminal “H”: MUTE OFF

85 ASE3 O Analog switch control terminal 3

86 ASE2 O Analog switch control terminal 2

34

Page 35

7.1.2 DISPLAY

RAW1163 (V1501: FL UNIT)

FL Tube

¶ Pin Assignment

¶ Pin Connection

CT-S670D

Note 1) F1, F2....... Filament

2) NP .............No Pin

3) NC ........... No Connection

4) DL ............ Datum Line

5) 1G–10G.... Grid

¶ Grid Assignment

¶ Anode Connection

35

Page 36

CT-S670D

7.2 DIAGNOSIS

7.2.1 DISASSEMBLY

Removing the Door Plate

Catch the door plate with your fingers

and pull it to the front.

7.2.2 TEST MODE

(1) Entering the Test Mode

While mechanism is stop, press the MODE key, RESET key and

PAUSE key together to enter the test mode.

(2) Exiting the Test Mode

Press the RESET key.

Counter Display

Level (MS) Display

(3) Main Test Mode Items

Mechanism Operation Check

Mechanism SW Check, CD Synchro Check

Automatic Adjustment

NTF Error Code Display

(4) Shifting to Test Mode State

TEST MODE “ OFF ”

RESET Key

TEST MODE “ ON ”

Press the STOP Key

Mechanism Operation Check

Level (MS) Display: “ 10 ”

MODE Key + RESET Key + PAUSE Key

Press the MODE Key

Press the METER RANGE Key

Press the XD FLAT Key

Counter Display and Level (MS) Display

Mechanism SW Check, CD Synchro Check

Level (MS) Display: “ 20 ”

NTF Error Code Display

Level (MS) Display: “ 7

Automatic Adjustment

Level (MS) Display: “ 80 ”

∗ ”

36

Page 37

(5) Mechanism Operation Check

Operations specifications

Input Key FL Display Adjustment and Check

STOP 10 The Mechanism operates without the cassette half in this mode.

(6) Mechanism SW Check, CD Synchro Check

Entering the check mode

When the mechanism operation check mode, press the MODE key.

Exiting the check mode

When the STOP key is pressed, mechanism operation check mode is set.

Operations specifications

Input Key FL Display Adjustment and Check

CT-S670D

MODE 20 Cassette Half SW Check

DIGITAL/CD CD SYNC CD Synchro Check

SYNCHRO When the cord whose input and output are short- circuited is connected,

When there is a cassette half, counter shows “H” at the second digit from the left.

Accidental Erasure detection SW Check

FWD recordable: “ 3 ” lights up

Timer SW Check

TIMER REC : REC indicator lights up

OFF :

TIMER PLAY : PLAY indicator lights up

Tape Type Check

When there is a tape, display is made at the first digit from the left on the counter.

NORMAL TAPE : “ n ”

CrO2 TAPE : “ C ”

METAL TAPE : “ M ”

and the DIGITAL/CD SYNCHRO key is pressed, " CD SYNC " display lights up.

(7) Automatic Adjustment

For details, refer to “ 6. ADJUSTMENT ”.

Entering the check mode

When the mechanism operation check mode, press the XD FLAT key.

Exiting the check mode

When the STOP key is pressed, mechanism operation check mode is set.

Operations specifications

Input Key FL Display Adjustment and Check

1 Memory data will be cleared when the MODE key, PAUSE key and MUTE key are pressed together.

STOP 10 2 Enter the mechanism operation check mode

XD FLAT 80 3 Enter the automatic adjustment mode

REC 4 Execute adjustment of recording bias and recording level.

End of adjustment : “ BR ” lights up

Bias adjustment error : “ B ” lights up

Recording level adjustment error : “ R ” lights up

STOP TUNE 5 Exiting the automatic adjustment mode: “ TUNE ” lights up

37

Page 38

CT-S670D

(8) NTF Error Code Check Mode

Entering the check mode

In mechanism operation check mode, press the METER RANGE key to set the level (MS) display to “ 7* ”.

When the METER RANGE key is pressed again, the error code for the previous error is displayed (max. 3 errors).

Exiting the check mode

When the STOP key is pressed, mechanism operation check mode is set.

When repair has been completed, reset the recorded reeor. (Press the MODE key and RESET key together.)

Check mode display

Counter

Service Number

Error Counter

Test Mode No.

NTF Error display

Error

Location

BLE B1 The takeup-side reel base has stopped during The tape end has been reached.

Loading L1 During OPEN/CLOSE operation, the loading The tape has not been set correctly.

Mechanism M1 The takeup-side reel base has stopped and the The reel motor has stopped.

Digital D1 The digital input 1 does not receive a digital input

Service No. Occurrence Condition Cause

BLE operation. The reel motor has stopped.

The capstan motor has stopped.

B2 No signal has been recorded on the tape during The used tape differs widely from the caracteristics

BLE operation. of the standard tape.

The internal oscillator is not oscillating.

Defect of compensation circuit parts, defective contact, etc.

mechanism has not reached the target position. Entry of foreign objects etc.

supply-side reel base is operating. The tape has become wound to the capstan because

of static electricity.

signal of fs = 44.1 kHz.

D2 The digital input 2 does not receive a digital input

signal of fs = 44.1 kHz.

Resetting the error code

To reset, press the MODE key and MUTE key together.

38

Page 39

7.3 BLOCK DIAGRAM

IC 751

TC4052BP

CT-S670D

:PLAYBACK SIGNAL

:RECORDING SIGNAL

(DIGITAL IN )

M5M51008B

FL-70L

39

Page 40

CT-S670D

8. PANEL FACILITIES AND SPECIFICATIONS

PANEL FACILITIES

167539824 0=-

REC BALANCE

LR

CD-DECK SYNCHRO

BLE XD

•¶¡1

78

Legato Link Conversion

REC LEVEL

5

4

3

2

1

0

D

TIMER

REC

PLAY

OFF

/RPT

POWER

—OFF _ON

STEREO CASSETTE DECK

DOLBY

METER

NR

RANGE

DIGITALNRDIGITAL

FLEX

Ωı¿∫>≥?Û

COUNTERDISP OFF

MODE

INPUT

Î

RESET

SOURCE

/TAPE

MONITOR

$%#@^ !~

1 POWER switch

2 TIMER switch (TIMER REC, OFF, PLAY/RPT)

REC : Set to this position to perform timer recording.

OFF : Set to this position under ordinary conditions

(when not using the timer or repeat functions).

PLAY/RPT : Set to this position to perform timer playback or

repeat playback.

3 Function display

4 Display OFF/METER RANGE button

(DISP OFF/METER RANGE)

5 Counter mode button (TIME/COUNT)

6 Counter reset button (RESET)

7 Digital indicator

Lights while the Digital NR is ON.

8 OPEN/CLOSE button (0)

9 Operation buttons

7 : Stop

3 : Play

1 : Rewind/music search

¡ : Fast forward/music search

• : Recording mute

8 : Pause

¶ : Recording

OPEN/CLOSE

Digital

Digital Processing System

20bit A/D•D/A CONVERTER

0

3

DOLBY B-C NR HX PRO

0 Recording Balance control (REC BALANCE)

- BLE XD button

= Recording Level control (REC LEVEL)

~ DIGITAL/CD SYNCHRO button

! Headphones jack (PHONES)

@ MONITOR button

# DIGITAL INPUT button

$ FLEX button

% DIGITAL NR button

^ DOLBY* NR button (OFF/B/C)

*

÷

Dolby noise reduction and HX Pro headroom extension

manufactured under license from Dolby Laboratories Licensing Corporation. HX Pro originated by Bang & Olufsen.

÷

“DOLBY”, the double-D symbol and “HX PRO” are trademarks of Dolby Laboratories Licensing Corporation.

10

DIGITAL/CD

SYNCHRO

6

7

8

9

PHONES

FUNCTION DISPLAY

123 4 5 6 7 8

#

@

!

PLAY REC

DISP OFF

TAPE SOURCE

—20—

dB

L

R

—

dB

B TIME

C

REMAIN

DIGITAL IN

CD SYNC

15—12—10—8—6—4—2—0

—4—3—2—1—

5

012 34 5 6

—————

1 PLAY indicator

This lights during the play and play pause modes and flashes

during the music search mode.

2 REC indicator

This lights during the recording and recording pause modes

and flashes during the recording mute mode.

3 Display off indicator (DISP OFF)

Lights when the display off function is selected.

4 DOLBY NR B/C indicator

5 TIME COUNT mode

Lights up in the time counter mode.

6 REMAIN mode

Lights up in the remain counter mode.

40

BLE

XD

FLEX

ALCA

—

246

—

—————

—

90-=~

———

dB

MS

—

—

7 AUTO BLE XD indicator

The display is as follows during the BLE XD system operation:

Flashing : Adjustments being performed

Lit : Adjustments completed

8 Peak level (MS) indicator

9 ALCA SYSTEM indicator

Lights when the ALCA system is used.

0 FLEX indicator

This indicator lights when the FLEX button is pressed.

- Counter indicator

= DIGITAL/CD SYNCHRO indicator (DIGITAL/CD SYN-

CHRO)

This indicator lights steadily when the CD SYNC button is

pressed and the operation starts.

~ DIGITAL IN indicator

This indicator lights when the DIGITAL IN button is pressed.

! Level meter

Holds peak for about 1.3 seconds.

The “¶” mark beside the 0 dB mark indicates the Dolby NR

system standard level.

@ TAPE/SOURCE indicator

# PLAY indicator

This lights during the play and recording modes and flashes

during the pause mode.

Page 41

SPECIFICATIONS

CT-S670D

System ..................................................... 4-track, 2-channel stereo

Heads ................................. Combined Hard permalloy recording/

Hard Permalloy playback head x 1

“Ferrite” erasing head x 1

Motor .................................................. DC servo capstan motor x 1

DC servo reel motor x 1

DC servo motor x 1

Wow and Flutter ..................... No more than 0.05% (WRMS, JIS)

No more than ±0.14% (DIN)

Fast Winding Time .......... Approximately 90 seconds (C-60 tape)

Frequency Response

–20 dB recording:

TYPE IV (Metal) tape .................................. 20 to 21,000 Hz ±6dB

TYPE II (High/CrO2) tape ............................ 20 to 20,000 Hz ±6dB

TYPE I (Normal) tape ................................ 20 to 20,000 Hz ±6dB

Signal-to-Noise Ratio ........................................... More than 60 dB

Digital-NR ON (Dolby-NR OFF) .........................More than 82 dB

Digital-NR ON (Dolby-NR B or C type ON) ............. More than 90 dB

(TYPE I tape, 3rd distortion 3%, IEC, DIN AUDIO)

Harmonic Distortion ........................................ No more than 0.6%

(at -4dB: 160 nwb/m)

Input ....................................................................... RCA pin-jack x 2

LINE (INPUT) ............................. 100 mV (Input impedance 23 kΩ)

Output

LINE (OUTPUT) ......................... 0.5 V (Output impedance 1.2 kΩ)

Headphones .............................. 1.33 mW (Load impedance 32 Ω)

Miscellaneous

Power Requirements ................................. AC 220-230 V, 50/60 Hz

Power Consumption ................................................................. 23 W

Dimensions ...................................... 420(W) x 128(H) x 277(D) mm

Weight (without package) ....................................................... 4.5kg

Subfunctions

÷ DOLBY HX PRO system

÷ DOLBY B/C type NR systems

÷ Music search up to ±15 selections

÷ DIGITAL/CD•DECK SYNCHRO recording capability

÷ Peak level meter with peak-hold function

÷ Automatic space recording mute

÷ Automatic tape selector

÷ 3-mode electronic 4-digit tape counter (TAPE/TIME/REMAIN)

÷ Headphone jack

÷ DIGITAL FLEX system (Frequency Level Expander)

÷ DIGITAL SUPER AUTO BLE XD system

÷ LAST MEMORY

÷ DIGITAL NR

÷ Legato Link Conversion

÷ Power Eject

÷ DIGITAL SYNCHRO recording capability

÷ MPX filter (Interlocks with DOLBY NR)

÷ TIMER Recording/Playback start

÷ Display off

÷ Repeat playback

Accessories

Operating instructions ................................................................... 1

Connection cord with pin plugs .................................................... 2

CD•DECK SYNCHRO control cord ................................................. 1

Warranty card ................................................................................. 1

NOTE:

Specifications and design subject to possible modifications without notice, due to improvements.

POWER-CORD CAUTION

Handle the power cord by the plug. Do not pull out the plug by

tugging the cord and never touch the power cord when your hands

are wet as this could cause a short circuit or electric shock. Do

not place the unit, a piece of furniture, etc., on the power cord, or

pinch the cord. Never make a knot in the cord or tie it with other

cords. The power cords should be routed such that they are not

likely to be stepped on. A damaged power cord can cause a fire

or give you an electrical shock. Check the power cord once in a

while. When you find it damaged, ask your nearest PIONEER authorized service center or your dealer for a replacement.

41

Loading...

Loading...