Page 1

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE NV Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2000

K-ZZY. NOV. 2000 Printed in Japan

ORDER NO.

CRT2588

UNIVERSAL MULTI-CD SYSTEM

CDX-FM677 X1N/UC,ES

CDX-FM673 X1N/UC

CDX-FM677/X1N/UC

- This service manual should be used together with the following manual(s):

Model No. Order No. Mech. Module Remarks

CX-892 CRT2356 C7 CD Mech. Module:Circuit Description, Mech. Description, Disassembly

CONTENTS

1. SAFETY INFORMATION ............................................2

2. EXPLODED VIEWS AND PARTS LIST.......................3

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM...12

4. PCB CONNECTION DIAGRAM ................................26

5. ELECTRICAL PARTS LIST ........................................34

6. ADJUSTMENT..........................................................38

7. GENERAL INFORMATION .......................................46

7.1 DIAGNOSIS ........................................................46

7.1.1 TEST MODE..............................................46

7.1.2 DISASSEMBLY .........................................52

7.1.3 CONNECTOR FUNCTION DESCRIPTION54

7.2 PARTS .................................................................55

7.2.1 IC................................................................55

7.2.2 DISPLAY....................................................59

7.3 OPERATIONAL FLOW CHART...........................60

8. OPERATIONS AND SPECIFICATIONS.....................61

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

2

8

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 2

2

CDX-FM677,FM673

1. SAFETY INFORMATION

- CDX-FM677/X1N/UC and CDX-FM673/X1N/UC

CAUTION

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely; you should not risk trying to do so

and refer the repair to a qualified service technician.

W

ARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

California to cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

A transport screw has been attached to the

set in order to protect it during transportation. After removing the transport screw,

cover the hole with the supplied seal.

Be sure to remove the transport screw

before mounting the set. The removed

transport screw should be retained in the

accessory bag for use the next time the set

is transported.

Seal

After removing the transport screw, cover the hole

with the supplied seal.

Transport screw

Attach to the original position before

transporting the set.

- CD Player Service Precautions

1. For pickup unit(CXX1285) handling, please refer

to"Disassembly"(see page 52).

During replacement, handling precautions shall be

taken to prevent an electrostatic discharge(protection

by a short pin).

2. During disassembly, be sure to turn the power off

since an internal IC might be destroyed when a connector is plugged or unplugged.

3. Please checking the grating after changing the service pickup unit(see page 39).

4. Since these screws protects the mechanism during

transport, be sure to affix it when it is transported for

repair, etc.

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 3

3

CDX-FM677,FM673

26

33

27

28

17

24

35

4

8

6

11

10

7

9

32

31

25

18

16

15

21

22

20

13

16

2

14

19

23

12

3

5

1

29

30

29

36

30

38

39

41

40

37

34

2. EXPLODED VIEWS AND PARTS LIST

2.1 PACKING

Q

TEL 13942296513 QQ 376315150 892498299

Q

TEL

7

3

13942296513

6

3

1

5

1

5

0

Q

Q

7

3

8

6

3

1

9

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 4

4

CDX-FM677,FM673

Part No.

Mark No. Description CDX-FM677/X1N/UC CDX-FM673/X1N/UC CDX-FM677/X1N/ES

1 Accessory Assy CEA2767 CEA2770 CEA2768

2 Spring CBH-865 CBH-865 CBH-865

3 Cord CDE4289 CDE4289 CDE4289

4 Cord CDE5812 CDE5812 CDE5812

5 Cord CDE5814 CDE5814 CDE5814

6 Screw Assy CEA1962 CEA1962 CEA1962

7 Screw CBA1295 CBA1295 CBA1295

* 8 Polyethylene Sheet CNM5158 CNM5158 CNM5158

9 Screw HMB60P500FMC HMB60P500FMC HMB60P500FMC

10 Screw HMF40P080FZK HMF40P080FZK HMF40P080FZK

11 Nut NF60FMC NF60FMC NF60FMC

12 Screw Assy CEA1965 CEA1965 CEA1965

* 13 Polyethylene Bag CEG-127 CEG-127 CEG-127

14 Screw IMS30P050FZK IMS30P050FZK IMS30P050FZK

15 Clamper CEF1010 CEF1010 CEF1010

* 16 Polyethylene Bag CEG-158 CEG-158 CEG-158

17 Polyethylene Bag CEG1185 CEG1185 *CEG1263

18 Battery CEX1065 Not used CEX1065

19 Bracket CNC8061 CNC8061 CNC8061

20 Cushion CNM3182 CNM3182 CNM3182

21 Fastener(Soft) CNM3872 CNM3872 CNM3872

22 Fastener(Rough) CNM4041 CNM4041 CNM4041

23 Panel CNS5428 CNS5428 CNS5428

* 24 Polyethylene Bag CEG1099 CEG1099 CEG1099

25 Polyethylene Bag CEG1185 CEG1185 CEG1042

26 Carton CHG4283 CHG4281 CHG4282

27 Sub Carton CHG4295 CHG4295 CHG4295

28 Contain Box CHL4283 CHL4281 CHL4282

29 Protector CHP2133 CHP2133 CHP2133

30 Protector CHP2135 CHP2135 CHP2135

31 Seal CNM5599 CNM5599 CNM5599

32-1 Installation Manual CRD3324 CRD3322 CRD3326

32-2 Owner’s Manual CRD3323 CRD3321 CRD3325

* 32-3 Card ARY1048 ARY1048 Not used

33 Antenna Select Assy CWM7445 CWM7445 CWM7445

34 Display Assy CXB6804 CXB6803 CXB6804

35 Remote Control Assy CXB6798 Not used CXB6798

36 Magazine Assy CXB4027 CXB4027 CXB4027

37 Angle Assy CXB3591 CXB3591 CXB3591

* 38 Caution Card CRP1090 CRP1090 CRP1090

* 39 Caution Card CRP1232 CRP1232 CRP1232

40 Air Cushioned Bag CEG1055 CEG1055 CEG1055

41 Cover CEG1062 CEG1062 CEG1062

- PACKING SECTION PARTS LIST

NOTE:

- Parts marked by “*”are generally unavailable because they are not in our Master Spare Parts List.

- Screws adjacent to

∇ mark on the product are used for disassembly.

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

7

3

13942296513

6

3

1

5

1

5

0

Q

Q

7

3

8

6

3

9

1

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 5

5

CDX-FM677,FM673

- Owner’s Manual

Model Part No. Language

CDX-FM677/X1N/UC CRD3323 English, French

CDX-FM673/X1N/UC CRD3321 English, French

CDX-FM677/X1N/ES CRD3325 English, Spanish, Portuguese(B), Arabic

- Installation Manual

Model Part No. Language

CDX-FM677/X1N/UC CRD3324 English, French

CDX-FM673/X1N/UC CRD3322 English, French

CDX-FM677/X1N/ES CRD3326 English, Spanish, Portuguese(B), Arabic

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 6

6

CDX-FM677,FM673

2.2 EXTERIOR

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 7

7

CDX-FM677,FM673

1 Screw BMZ26P040FMC

2 Screw BMZ30P040FZK

3 Button CAC6363

4 Screw CBA1460

5 Spring CBH1859

6 Connector CDE5525

7 Connector CDE6480

8 Cord CDE5812

9 Resistor RS1/2PMF102J

10 Cap CNS1472

11 Upper Case

See Contrast table(2)

12 Arm CNC8058

13 Insulator CNM6074

14 Panel CNS5216

15 Damper CNV5591

16 Antenna Select Assy CWM7445

17 Cord CDE4087

18 Antenna Cable CDH1207

19 Chassis CNA1555

20 Case CNB1764

21 Antenna Select Unit CWX2580

22 Plug(CN502) CKS1222

23 Plug(CN501) CKS2812

24 Antenna Jack(CN503) CKX1006

25 Extension Unit

See Contrast table(2)

26 Screw BMZ26P060FMC

27 Jack(CN401) CKN1022

28 Plug(CN801) CKS-460

29 Connector(CN802) CKS3195

30 Connector(CN803)

See Contrast table(2)

31 Connector(CN201) CKS3920

32 Holder CNC8056

33 Holder CNC8070

34 Remote Control Unit

See Contrast table(2)

35 Cover See Contrast table(2)

36 Display Assy See Contrast table(2)

37 Screw BPZ20P100FZK

38 Button CAC5887

39 Cord CDE5834

40 Cover CNS5223

41 LCD(LCD901) CAW1514

42 Holder CNC8062

43 Lighting Conductor CNV5594

44 Rubber CNV5599

45 Grille Unit

See Contrast table(2)

46 Grille Assy See Contrast table(2)

47 Door CAT2198

48 Door CAT2199

49 Lower Case Unit CXB7005

50

CD Mechanism Module(C7R2) See Contrast table(2)

51 Screw IMS20P030FZK

52 Screw IMS26P040FMC

53 Transistor(Q801) 2SD2396

54 IC(IC902)

See Contrast table(2)

* 55 Caution Card CRP1232

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

Part No.

Mark No. Symbol and Description CDX-FM677/X1N/UC CDX-FM673/X1N/UC CDX-FM677/X1N/ES

11 Upper Case CNB2389 CNB2394 CNB2389

25 Extension Unit CWX2559 CWX2558 CWX2559

30 Connector(CN803) CKS3407 Not used CKS3407

34 Remote Control Unit CXB6798 Not used CXB6798

35 Cover CNS6439 Not used CNS6439

36 Display Assy CXB6804 CXB6803 CXB6804

45 Grille Unit CXB6810 CXB6809 CXB6810

46 Grille Assy CXB6828 CXB6827 CXB6828

50

CD Mechanism Module(C7R2) CXK4865 CXK4861 CXK4865

54 IC(IC902) TSOP1840SB1 Not used TSOP1840SB1

(2) CONTRAST TABLE

CDX-FM677/X1N/UC,CDX-FM673/X1N/UC and CDX-FM677/X1N/ES are constructed the same except for

the following:

Q

TEL 13942296513 QQ 376315150 892498299

Q

7

3

6

3

1

5

1

5

0

4

2

9

8

9

2

8

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

5

1

3

6

7

1

5

0

8

9

9

4

2

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 8

8

CDX-FM677,FM673

2.3 CD MECHANISM MODULE

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 9

9

CDX-FM677,FM673

1 Connector CDE6069

2 CD Core Unit

See Contrast table(2)

3 Connector(CN701) CKS1963

4 Connector(CN101) CKS2272

5 Screw BMZ20P025FMC

6 Screw(M2x2.5) CBA1037

7 Screw(M2x2.5) CBA1041

8 Screw(M2x2) CBA1176

9 Screw(M2x4) CBA1362

10 Screw(M2x1.4) CBA1387

11 Screw(M2x2.5) CBA1493

12 Screw(M2x1.6) CBA1476

13 Screw(M2x3) CBA1486

14 Washer CBF1038

15 Spring CBH2172

16 Spring CBH2173

17 Spring CBH2174

18 Spring CBH2175

19 Spring CBH2285

20 Spring CBH2177

21 Spring CBH2178

22 Spring CBL1390

23 Spring CBL1393

24 Short Pin CBL1239

25 Volume(VR801) CCW1023

26 Screw(M2x1.5) CBA1491

27 Shaft CLA3894

28 Arm CNC8482

29 Lever CNC7902

30 Lever CNC7904

31 Lever CNC7905

32 Lever CNC7906

33 Arm CNC7908

34 Arm CNC7909

35 Holder CNC7911

36 Holder CNC7912

37 Frame CNC7917

38 Frame CNC7918

39 Lever CNC7919

40 Stopper CNC7920

41 Frame CNC7921

42 Bracket CNC8354

43 Plate CNC8375

44 Cover CNC8434

45 Sheet CNM6009

46 Spacer CNM6428

47 Sheet CNM6296

48 PCB CNP5227

49 PCB CNP5228

50 Ball CNR1189

51 Gear CNR1531

52 Belt CNT1086

53 Gear CNV5472

54 Gear CNV5473

55 Rail CNV5920

56 Lever CNV6091

57 Gear CNV5477

58 Arm CNV5478

59 Holder CNV5480

60 Guide CNV5921

61 Guide CNV5922

62 Holder CNV5483

63 Holder CNV5484

64 Clamper CNV5485

65 Gear CNV5486

66 Gear CNV5562

67 Holder CNV5563

68 Lighting Conductor CNV5785

69 Mechanism PCB CWX2303

70 Connector(CN801) CKS1965

71 Connector(CN802) CKS3486

72 Damper Unit CXA7714

73 Chassis Unit CXB4463

74 •••••

75 Chassis Unit CXB4461

76 Magazine Holder Unit CXB4459

77 Frame Unit CXB4426

78 Arm Unit CXB2855

79 Screw Unit CXB4464

80 •••••

81

Motor Unit(M851)(SPINDLE) CXB3003

82

Motor Unit(M854)(CARRIAGE) CXB3004

83 Screw JFZ20P025FMC

84 Motor Unit(M853)(TRAY) CXB4421

85 Screw JFZ20P025FMC

86 Motor Unit(M852)(ELV) CXB3006

87 Screw JFZ20P025FMC

88 Lever Unit CXB3938

89 •••••

90 Gear Unit CXB5061

Mark No. Description Part No. Mark No. Description Part No.

(1) CD MECHANISM MODULE SECTION PARTS LIST

Q

TEL 13942296513 QQ 376315150 892498299

Q

7

3

6

3

1

5

1

5

0

4

2

9

8

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

1

3

6

7

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 10

10

CDX-FM677,FM673

91 Screw JGZ17P025FZK

92 Pickup Unit(Service) CXX1285

93 •••••

94 •••••

95 Screw IMS26P040FMC

96 Screw JFZ20P025FNI

97 Photo-transistor(Q851) PT4800

98

Spring Switch(S851,S853) CSN1051

99 LED(D851) CN504-2

100 Spring Switch(S852) CSN1052

Mark No. Description Part No.

(2) CONTRAST TABLE

CDX-FM677/X1N/UC, CDX-FM673/X1N/UC and CDX-FM677/X1N/ES are constructed the same except for

the following:

Part No.

Mark No. Symbol and Description CDX-FM677/X1N/UC CDX-FM673/X1N/UC CDX-FM677/X1N/ES

2 CD Core Unit CWX2493 CWX2492 CWX2493

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 11

11

CDX-FM677,FM673

2.4 MAGAZINE ASSY

1 Magazine Assy CXB4027

2 Label CRW1418

3 Tray CNV5341

- MAGAZINE ASSY SECTION PARTS LIST

Mark No. Description Part No.

Q

TEL 13942296513 QQ 376315150 892498299

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

w

w

13942296513

w

.

xia

o

y

u

Q

Q

1

2

9

8

0

5

1

5

1

3

6

7

3

6

3

.

c

o

m

4

9

8

2

9

9

Page 12

PICKUP UNIT (SERVICE) (P8)

MECHANISM

PCB

HOLOGRAM

UNIT

FOCUS ACT.

TRACKING ACT.

FO+

LD(–)

LASER

DIODE

CARRIAGE

MOTOR

MONITOR

DIODE

MD

TO+

+5V

M

SPINDLE

MOTOR

M

TRY

MOTOR

HOME SW

TRPSW

DSPSW

M

Q851

D851

D

SWITCH PCB

E

MOTOR PCB

C

S853

4

3

7

5

11

8

9

2

1

10

17

12

27

16

15

5

15

4

3

CN801

CN802

S852

S851

14

9

98

39

AC/F/E/BD

FD/TD/SD/MD

I13/I04/I02

97

11

16

15

17

18

3

5

10

12

DISC

TRP

DSP

DISC

TRP

DSP

92

95

91

EJECT SW

MAG SW

ELV

MOTOR

M

17

8

22

12

13

16

17

18

12

27

16

15

11

8

9

2

1

4

3

7

5

10

Q101

VD

PD

LIMIT

xtal

XTAL

L+

LD

cs

23

21

1

75

3

24

IPIN

IPOUT

IPPW

KYDT

DPDT

FMIPSW

XIN

XOUT

13

15

48

4

2

1

2

130

22

32

31

33

SYSPW

33

DISPPW

33

KYDT

BUSP

15

CDMUTE

PREN

LOUT

BUSM

DPDT

FMIPSW

29

CDMUTE

76

PREN

88

8

5

6

20

CONT

ejsw

mag

disk

TRP

DSP

11

74

75

X202

16.93MHz

X701

10.00MHz

IC 301

BA5986FM

IC 302

LB1836M

IC 604

BA4560F

IC 603

BA4560F

VD

Q771

VDD

IC 705

TC7SH32F

IC 702

LC35256FT-70U

SRAM

IC 703

HA12187FP

IP-BUS DRIVER

IC 701

PD5638A

CN701

C

19asensfm

asens

bsens

reset

ASENIN

BSENIN

ASENB

13 12

5

18 10

11

14

18

14

11

4

13

10

9

8

21

SYSPW

5

20

DISPPW

6

7

21

15

12

19 9

SVC2

11

5

6

12 7

4RESET SW

Q770

IC 704

PAJ002A

CK/DT/CS

VD

5V

POWER

10

31

5V REGULATOR

IC 202

BA05FP

1

VD

POWER

VD

10

16

22524

A

CD CORE UNIT

B

VR802

Q701

VREF

adena

98

ELVREF

ELVPVO

94

93

3

VDD

EVREF

GND

EPVO

LINEAR POSITION SENSOR

VR801

4CH SERVO DRIVER

MOTOR DRIVER

SYSTEM

CONTROLLER

CN101

S801

S803

S802

RF AMP, SERVO, DSP, DAC

IC 201

UPD63711GC

12

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

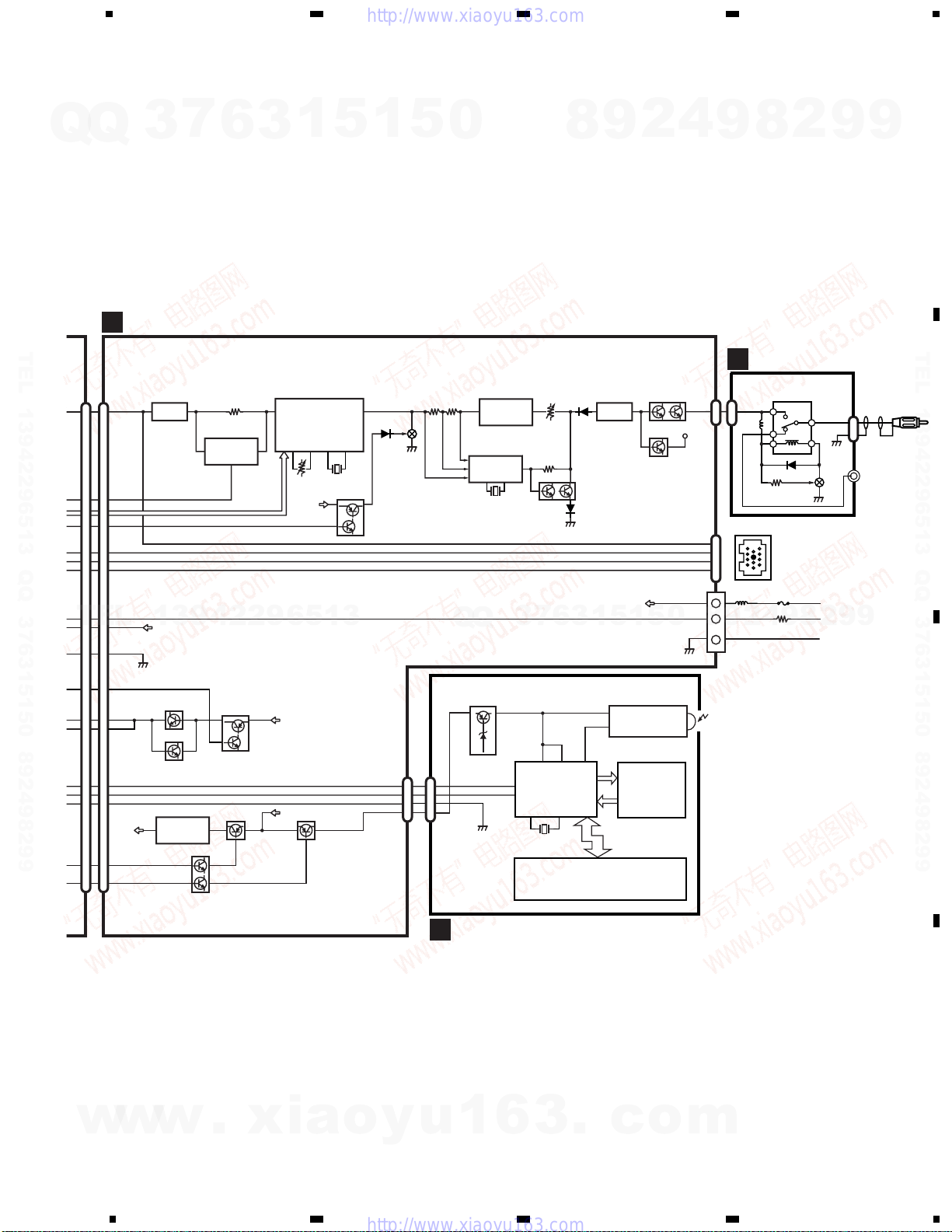

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM(CDX-FM677/X1N/UC)

Q

Q

3

7

6

3

1

5

1

5

0

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

8

6

3

9

5

1

4

2

0

5

1

2

8

9

2

4

8

9

9

8

9

2

9

9

9

TEL 13942296513 QQ 376315150 892498299

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 13

8

22

12

13

16

17

18

15

BUSP

BUSM

ASENB

KYDT

DPDT

FMIPSW

REN

USM

PSW

PRE-ENPHASIS

STEREO MODULATOR

01

CN201

19

ASENIN

SVC

5

11

14

18

14

CDMUTE

11

PREN

LCH

4

13

10

9

8

21

SYSPW

5

20

DISPPW

6

7

21

15

12

SVC

Q201

BUP

Q301

VR302

2

14

1

13

IC 201

BU4066BCF

X301

38kHz

VR301

LIN

BAL2

BAL1

38KOSC2

38KOSC3

18

17 16 5 6

MPXOUT

IC 301

BA1404F

PLL

148

9

6

12

IC 401

BU2611FS

AMP

12

IC 302

BA4560F

X401

7.2MHz

Q401

L402

CTC1079

Q402

TP30

Q403 Q404

2

LOUT

CN401

1

BUSP1

7

LOUT

5

BUSM1

8

ASENBUS

CN803

L201

CTF1333

Q802

Q803Q805

BUP

Q801

1

VD

VD

VD

VD

POWER

10

16

22524

Q806

BUP

BUP

ACC

GND

3

2

1

CN801

BUP

IP-BUS OUT

2

KYDT

3

DPDT

4

1PADD1/LCH

1

SWDACC

CN802

1

3

IC 801

NJM78L06A

Q804

BUP

VDD

B

EXTENSION UNIT

BATT.

GND

FUSE

2A

ACC

DPDT

KYDT 9

8

SI

SO

2

3

KEY

MATRIX

LCD 901

CAW1514

IC 902

TSOP1840SB1

REMOTE CONTROL

SENSOR

5V REGULATOR

78

23 10

V3

VCC

IC 901

PD6294A

SWDACC

CN901

1

2

2

3

4

1

X901

4.9152MHz

X1

X0

GND

Q901

1

3

INT1

G

DISPLAY ASSY

RF OUT

Q501

RY501

RELAY

1

RF IN

F

ANTENNA SELECT UNIT

CN501

CDRFIN

13

CDX-FM677,FM673

5

6

78

5

6

78

D

C

B

A

Q

Q

3

7

6

3

1

5

1

5

0

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

8

6

3

9

1

5

1

4

2

5

0

9

9

8

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 14

14

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

1kΩ(B)

10kΩ(B)

1

12

6

13

10

4

8

VR801 CCW1023

LINEAR POSITION SENSOR

M852

CXB3006

RF AMP,

MO

4CH S

CN801

CN802

M853

CXB4421

M851

CXB3003

M854

CXB3004

CSN1052

CSN1051

CSN1051

CN504-2 PT4800

PICKUP UNIT(SERVICE)

C

MECHANISM

PCB

SWITCH PCB

D

MOTOR PCB

E

CXX1285

3.2 CD MECHANISM MODULE

Note: When ordering service parts, be sure to refer to “EXPLODED VIEWS AND PARTS LIST” or “ELECTRICAL PARTS

LIST”.

A

1/2

C

D

E

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

2

9

8

0

5

2

8

9

4

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 15

15

CDX-FM677,FM673

5

6

78

5

6

78

D

C

B

A

18

7

2

5

19

20

15

17

16

12

21

3

9

11

10

AMP, SERVO, DSP, DAC

MOTOR DRIVER

CD CORE UNIT

A

A

2/2

Decimal points for resistor

and capacitor fixed values

are expressed as :

2.2 2R2

0.022 R022

←

←

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

NOTE :

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

A

1/2

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

w

w

w

.

xia

o

y

u

1

6

3

.

o

m

c

Page 16

16

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

SYSTEM CONTROLLER

A

1/2

FM677 : PD5638A

FM673 : PD5639A

*1

*1

*1

*1

*2

A

2/2

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 17

17

CDX-FM677,FM673

5

6

78

5

6

78

D

C

B

A

SRAM

IP-BUS DRIVER

B

CN201

*1

*1

*1

*1 : FM677 model only

*2 : FM673 model only

A

2/2

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

w

w

13942296513

w

.

xia

o

y

7

3

Q

Q

u

1

6

3

6

3

.

1

1

5

c

0

5

o

9

8

m

4

2

9

8

2

9

9

Page 18

18

CDX-FM677,FM673

1 RFI 0.5V/div. 0.5µs/div.

Normal mode: play

1 CH1: RFI 1V/div.

2 CH2: MIRR 5V/div.

Test mode: Tracking open

0.5ms/div.

1 CH1: RFI 1V/div.

2 CH2: MIRR 5V/div.

Normal mode: The defect part

passes 800µm

0.5ms/div.

3 CH1: FD 0.5V/div.

4 CH2: FOR 2V/div.

Test mode: No disc, Focus close

0.2s/div.

3 CH1: FD 0.5V/div.

5 CH2: FOK 2V/div.

Normal mode: Focus close

0.2s/div.

6 CH1: FE 0.5V/div.

7 CH2: XSI 2V/div.

Normal mode: Focus close

1ms/div.

REFO

→

8 CH1: TE 0.5V/div.

9 CH2: TD 0.5V/div.

Test mode: 32 tracks jump (REV)

0.5ms/div.

8 CH1: TE 0.5V/div.

9 CH2: TD 0.5V/div.

Test mode: Single jump (REV)

0.5ms/div.

8 CH1: TE 0.5V/div.

9 CH2: TD 0.5V/div.

Test mode: 100 tracks jump (REV)

5ms/div.

6 CH1: FE 0.1V/div.

3 CH2: FD 0.2V/div.

Normal mode: Play

20ms/div.

3 CH1: FD 0.5V/div.

0 CH2: MD 1V/div.

Normal mode: Focus close (12cm)

0.5s/div.

3 CH1: FD 0.5V/div.

0 CH2: MD 1V/div.

Normal mode: Focus close (8cm)

0.5s/div.

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

GND

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

- Waveforms

Note:1. The encircled numbers denote measuring pointes in the circuit diagram.

2. Reference voltage

REFO:2.5V

REFO

→

REFO

→

REFO

→

REFO

→

Q

Q

3

7

6

3

1

5

1

5

0

4

2

9

8

9

2

8

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

7

3

5

1

5

1

3

6

0

8

9

2

9

4

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 19

19

CDX-FM677,FM673

8 CH1: TE 0.2V/div.

9 CH2: TD 0.2V/div.

Normal mode: play

8 CH1: TE 0.5V/div.

! CH2: SD 0.5V/div.

TEST mode:100Tracks jump(FWD)

5ms/div.

0 MD 0.5V/div. 0.1s/div.

Normal mode: Play (12cm)

0 MD 1V/div. 10ms/div.

Long Search (12cm)

@ EFM 1V/div. 5µs/div.

Normal mode: Play

8 CH1: TE 1V/div.

# CH2: TEC 1V/div.

Test mode: Focus close

Tracking open

2ms/div.

8 CH1: TE 0.5V/div.

6 CH2: FE 0.5V/div.

Normal mode:

AGC after focus close

0.2s/div.

20ms/div.

% SCKO 2V/div. 1µs/div.

Normal mode: Play

^ DOUT 2V/div. 10µs/div.

Normal mode: Play

& LRCK 2V/div. 20µs/div.

Normal mode: Play

* VD 5V/div. 50ms/div.

Normal mode: No disc

GND

→

REFO

→

REFO

→

GND

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

GND

→

REFO

→

GND

→

REFO

→

GND

→

REFO

→

Q

TEL 13942296513 QQ 376315150 892498299

Q

7

3

6

3

1

5

1

5

0

8

9

4

2

9

2

8

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

5

1

3

6

7

3

Q

2

8

9

4

2

9

8

0

5

1

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 20

20

CDX-FM677,FM673

( CH1: R OUT 2V/div.

) CH2: L OUT 2V/div.

Normal mode: Play (1kHz 0dB)

6 CH1: FE 0.2V/div.

3 CH2: FD 0.5V/div.

Normal mode: During AGC

1ms/div.

8 CH1: TE 0.2V/div.

9 CH2: TD 0.5V/div.

Normal mode: During AGC

1 CH1: RFI 1V/div.

⁄ CH2: HOLD 5V/div.

Normal mode: The defect part passes

800µm(B.D)

500µs/div.

1ms/div.

0.5ms/div.

3 CH1: FD 1V/div.

⁄ CH2: HOLD 5V/div.

Normal mode: The defect part passes

800µm(B.D)

0.5ms/div.

9 CH1: TD 0.1V/div.

⁄ CH2: HOLD 5V/div.

Normal mode: The defect part passes

800µm(B.D)

0.5ms/div.

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

REFO

→

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

9

8

2

4

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 21

21

CDX-FM677,FM673

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 22

47KΩ(B)

CN701

19kHz LPF

ADD ON MODE

LOOP FILTER

6V REG.

3V REG.

5V REG.

VD REGULATOR

IP

8

5

1

*1

*1

*1

A

2/2

22

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

3.3 EXTENSION UNIT

B

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

4

2

9

8

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 23

33KΩ(B)

F

CN501

G

CN901

BU

ACC

GND

FUSE 2A

1K(1/2W)

CEK1018

MAX AMP PILOT BUFFER AMP

IP-BUS

B

EXTENSION UNIT

8 9 10 11

56 7

1234

1

2

3

4

5

*1

*1 : FM677 model only

23

CDX-FM677,FM673

5

6

78

5

6

78

D

C

B

A

B

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

3

6

7

3

Q

Q

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 24

24

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

3.4 ANTENNA SELECT UNIT

F

B

CN401

F

TUNER

ANTENNA

ANTENNA SELECT UNIT

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

1

5

6

3

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 25

25

CDX-FM677,FM673

1

2

34

1

2

34

D

C

B

A

3.5 DISPLAY ASSY

G

KEY CONTROL AND

LCD DRIVER

B

CN802

G

DISPLAY ASSY

FM677 model

FM673 model

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

6

7

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 26

E

E

IC, Q

ADJ

M

M852

ELV

B

CN201

C

CN801

E

F

REFO

EREF

EPVO

1

25

26

50

51

75

76

100

CD CORE UNIT

A

26

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

Capacitor

Connector

P.C.Board

Chip Part

SIDE A

SIDE B

2. Viewpoint of PCB diagrams

SIDE A

4. PCB CONNECTION DIAGRAM

4.1 CD CORE UNIT

NOTE FOR PCB DIAGRAMS

1. The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic diagram.

A

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 27

E

E

IC, Q

RESET

EJECT

MAG

CD CORE UNIT

A

27

CDX-FM677,FM673

1

2

34

1

2

34

D

C

B

A

SIDE B

A

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 28

28

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

B

4.2 EXTENSION UNIT

E

E

E

E

E

IC, Q ADJ

A

CN701

G

CN901

F

CN501

IP-BUS

MOD

BAL

TV

CORD

EXTENSION UNIT

B

SIDE A

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

7

3

6

3

1

9

9

2

8

9

4

2

9

8

0

5

1

5

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 29

29

CDX-FM677,FM673

1

2

34

1

2

34

D

C

B

A

B

E

E

IC, Q

EXTENSION UNIT

B

SIDE B

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

9

9

2

8

9

4

2

9

8

0

5

1

5

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 30

30

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

4.4 SWITCH PCB

SWITCH PCB

D

C

4.3 MECHANISM PCB

A

CN101

E

D

MECHANISM PCB

C

M

M854

CRG

M

M851

SPDL

HOME

TRP

DSP

D851

PICKUP UNIT

(SERVICE)

C

D

Q

Q

TEL 13942296513 QQ 376315150 892498299

7

3

6

3

1

5

1

5

0

8

2

9

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 31

31

CDX-FM677,FM673

1

2

34

1

2

34

D

C

B

A

4.5 MOTOR PCB

MOTOR PCB

E

F

4.6 ANTENNA SELECT UNIT

E

ANTENNA

B

CN401

TUNER

ANTENNA SELECT UNIT

F

C

Q

TEL 13942296513 QQ 376315150 892498299

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 32

IC, Q

B

CN802

POWER P.MODE

PAUSE

DISC DOWN

DISC UP

TRACK DOWN

TRACK UP

DISPLAY ASSY

G

32

CDX-FM677,FM673

1

23

4

1234

D

C

B

A

4.7 DISPLAY ASSY

SIDE A

G

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

1

3

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 33

E

E

E

IC, Q

33

CDX-FM677,FM673

1

2

34

1

2

34

D

C

B

A

SIDE B

G

DISPLAY ASSY

G

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 34

34

CDX-FM677,FM673

Unit Number : CWX2559 (FM677 model)

: CWX2558 (FM673 model)

Unit Name : Extension Unit

MISCELLANEOUS

IC 201 IC (FM677 model) BU4066BCF

IC 301 IC BA1404F

IC 302 IC BA4560F

IC 401 IC BU2611FS

IC 801 IC NJM78L06A

Q 201 Transistor IMD3A

Q 202 Transistor FMG12

Q 301 Transistor DTC143TK

Q 401 Transistor IMX1

Q 402 Transistor 2SC2059K

Q 403 Transistor 2SC2059K

Q 404 Transistor 2SC2059K

Q 801 Transistor 2SD2396

Q 802 Transistor IMD2A

Q 803 Transistor 2SB710A

Q 804 Transistor IMH10A

Q 805 Transistor 2SB710A

Q 806 Transistor IMX1

D 201 Diode MA152WA

D 301 Diode MA111

D 302 Diode RB706D40

D 401 Diode DA204K

D 402 Diode KV1440

D 403 Diode MA111

D 801 Diode 1SR139-400

D 802 Diode 1SR139-400

D 803 Diode UDZS5R1(B)

D 804 Diode UDZS5R1(B)

D 805 Diode UDZ3R3(B)

L 201 Filter CTF1333

L 202 Filter CTF1333

L 301 Inductor LCTB2R2K2125

L 302 Inductor CTF1302

L 401 Inductor LCTB2R2K2125

L 402 Coil CTC1079

L 403 Inductor LCTB2R2K2125

L 404 Inductor LCTA1R0J3225

L 405 Inductor LCTA101J3225

L 406 Inductor LCTAR68J3225

X 301 Radiator 38.000kHz CSS1372

X 401 Crystal Resonator 7.2MHz CSS1030

VR 301 Semi-fixed 47kΩ(B) CCP1233

VR 302 Semi-fixed 33kΩ(B) CCP1232

RESISTORS

R 201 RS1/16S471J

R 202 RS1/16S471J

R 203 RS1/16S472J

R 204 RS1/16S472J

R 205 RS1/16S361J

R 206 RS1/16S361J

R 207 (FM677 model) RS1/16S225J

R 208 (FM677 model) RS1/16S225J

R 209 RS1/16S223J

R 210 RS1/16S223J

R 211 RS1/16S681J

R 212 RS1/16S681J

R 213 RS1/16S112J

R 214 RS1/16S112J

R 215 RS1/16S362J

R 216 RS1/16S362J

R 231 (FM677 model) RS1/16S101J

R 232 (FM677 model) RS1/16S101J

R 301 RS1/16S362J

R 302 RS1/16S823J

R 303 RS1/16S681J

R 304 RS1/16S392J

R 305 RS1/16S102J

R 306 RS1/16S392J

R 307 RS1/16S102J

R 308 RS1/16S392J

R 309 RS1/16S513J

R 310 RS1/16S103J

R 311 RS1/16S103J

R 312 RS1/16S103J

R 313 RS1/16S513J

R 314 RS1/16S101J

R 315 RS1/16S221J

R 316 RS1/10S104J

R 317 RS1/10S104J

R 318 RS1/16S683J

R 319 RS1/16S123J

R 320 RS1/16S472J

R 322 RS1/16S393J

R 323 RS1/16S0R0J

R 324 RS1/16S0R0J

R 401 RS1/16S223J

R 402 RS1/16S681J

R 403 RS1/16S362J

R 404 RS1/16S242J

R 405 RS1/16S822J

R 406 RS1/16S103J

R 407 RS1/16S103J

R 408 RS1/16S560J

R 409 RS1/16S103J

R 410 RS1/16S103J

R 411 RS1/16S332J

R 412 RS1/16S101J

R 413 RS1/16S222J

R 414 RS1/16S104J

R 415 RS1/16S244J

R 416 RS1/16S154J

R 417 RS1/16S152J

R 418 RS1/16S331J

R 419 RS1/16S122J

5. ELECTRICAL PARTS LIST

NOTE:

- Parts whose parts numbers are omitted are subject to being not supplied.

- The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

B

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

w

w

3

7

6

3

1

13942296513

w

.

xia

5

o

1

y

5

u

0

Q

Q

1

3

6

7

3

8

6

3

.

9

1

1

5

c

2

5

o

4

0

m

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Page 35

35

CDX-FM677,FM673

R 420 RS1/16S470J

R 421 RAB4C471J

R 801 RS1/16S183J

R 802 RS1/16S822J

R 803 RS1/16S204J

R 804 RS1/16S913J

R 805 RS1/8S391J

R 806 RS1/16S681J

R 807 (FM677 model) RS1/16S0R0J

R 808 RS1/4S152J

R 809 RS1/16S223J

R 810 RS1/16S223J

R 811 RS1/4S152J

R 812 RS1/16S181J

R 813 RS1/16S560J

R 814 (FM677 model) RS1/16S102J

R 815 (FM677 model) RS1/16S473J

R 816 (FM677 model) RS1/16S0R0J

R 817 RS1/4S750J

R 818 RS1/16S102J

R 819 RS1/16S152J

R 820 RS1/4S121J

R 823 RS1/10S222J

CAPACITORS

C 201 CEAL330M6R3

C 202 CEAL330M6R3

C 203 CKSRYB103K50

C 204 CKSRYB103K50

C 205 CKSRYB392K50

C 206 CKSRYB392K50

C 207 (FM677 model) CKSRYB332K50

C 208 (FM677 model) CKSRYB332K50

C 209 CEAL1R0M50

C 210 CEAL1R0M50

C 211 CKSRYB102K50

C 212 CKSRYB102K50

C 213 CKSRYB102K50

C 214 CKSRYB102K50

C 301 CEAL100M16

C 302 CKSRYB103K50

C 303 CCSRCH120J50

C 304 CEAL220M16

C 305 CKSRYB104K16

C 306 CKSRYB103K50

C 307 CCSRCH101J50

C 308 CEALR47M50

C 309 CKSRYB103K50

C 310 CEAL100M16

C 311 CCSRCH160J50

C 312 CEAL100M16

C 313 CKSRYB104K16

C 314 CKSRYB105K10

C 315 CEAL220M16

C 316 CKSRYB104K16

C 317 CCSRCH271J50

C 318 CCSQCH162J50

C 319 CEAL100M16

C 401 CCSRCH270J50

C 402 CCSRCH270J50

C 403 CKSRYB104K16

C 404 CKSRYB102K50

C 405 CKSRYB473K16

C 406 CEALNP330M10

C 407 CEAL470M6R3

C 408 CKSRYB104K16

C 409 CCSRCH180J50

C 410 CCSRCH100D50

C 411 CCSRCH330J50

C 412 CCSRCH180J50

C 413 CCSRCK1R0C50

C 414 CKSRYB103K50

C 415 CCSRCK1R0C50

C 416 CKSRYB103K50

C 417 CKSRYB103K50

C 418 CCSRCJ3R0C50

C 419 CKSRYB103K50

C 421 CKSRYB473K16

C 422 CEAL220M16

C 801 CEAL100M16

C 802 CEAT471M16

C 803 CKSRYB224K16

C 806 CEAT471M16

C 807 CKSRYB473K16

C 808 CKSRYB103K50

C 809 CEAL220M16

C 810 CKSRYB104K16

C 811 0.1F/5.5V (FM677 model) CCL1055

C 812 CKSQYB224K16

C 813 CKSRYB334K10

C 814 CEJA221M6R3

C 815 CEJA101M10

C 816 CEAS331M6R3

C 817 CKSRYB103K50

C 818 CKSRYB104K16

C 819 CKSRYB224K16

Unit Number : CWX2493 (FM677 model)

: CWX2492 (FM673 model)

Unit Name : CD Core Unit

MISCELLANEOUS

IC 201 IC UPD63711GC

IC 202 IC BA05FP

IC 301 IC BA5986FM

IC 302 IC LB1836M

IC 603 IC BA4560F

IC 604 IC BA4560F

IC 701 IC (FM677 model) PD5638A

IC 701 IC (FM673 model) PD5639A

IC 702 IC (FM677 model) LC35256FT-70U

IC 703 IC (FM677 model) HA12187FP

IC 704 IC PAJ002A

IC 705 IC (FM677 model) TC7SH32F

Q 101 Transistor 2SB1132

Q 701 Transistor DTA144EK

Q 770 Transistor 2SB1184F5

Q 771 Transistor (FM677 model) 2SC2412K

D 601 Diode UDZ7R5(B)

D 730 Diode (FM677 model) 1SS356

D 770 Diode 1SS355

X 202 Ceramic Resonator 16.93MHz CSS1536

X 701 Radiator 10.00MHz CSS1428

S 801 Push Switch(EJECT) CSG1139

S 802 Push Switch(RESET) CSG1139

S 803 Spring Switch(MAG) CSN1044

VR 802 Semi-fixed 1kΩ(B) CCP1338

RESISTORS

R 101 RS1/8S120J

R 102 RS1/8S100J

R 103 RS1/16S222J

R 201 RS1/16S104J

R 205 RS1/16S103J

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

A

Q

TEL 13942296513 QQ 376315150 892498299

Q

TEL

w

w

3

7

6

3

1

13942296513

w

.

xia

5

o

1

y

5

u

0

Q

Q

1

7

3

6

3

4

2

9

8

0

5

1

5

1

3

6

.

c

o

9

9

8

m

2

8

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Page 36

36

CDX-FM677,FM673

R 206 RS1/16S393J

R 207 RS1/16S182J

R 213 RS1/16S103J

R 214 RS1/16S103J

R 215 RS1/16S123J

R 253 RS1/16S681J

R 254 RS1/16S681J

R 256 RS1/16S681J

R 257 RS1/16S681J

R 258 RS1/16S681J

R 259 RS1/16S102J

R 260 RS1/16S681J

R 298 RS1/16S681J

R 301 RS1/16S103J

R 302 RS1/16S153J

R 303 RS1/16S103J

R 304 RS1/16S103J

R 305 RS1/16S103J

R 306 RS1/16S752J

R 307 RS1/16S103J

R 308 RS1/16S752J

R 309 RAB4C332J

R 311 RS1/16S102J

R 651 RN1/16SE1502D

R 652 RN1/16SE1502D

R 653 RN1/16SE1502D

R 654 RN1/16SE1502D

R 659 RN1/16SE1202D

R 660 RN1/16SE1202D

R 661 RN1/16SE1202D

R 662 RN1/16SE1202D

R 663 RS1/16S103J

R 664 RS1/16S103J

R 665 RS1/16S103J

R 666 RS1/16S103J

R 669 RS1/16S101J

R 670 RS1/16S101J

R 671 RS1/16S752J

R 672 RS1/16S103J

R 673 RS1/16S271J

R 701 (FM677 model) RS1/16S681J

R 702 RS1/16S102J

R 703 RS1/16S222J

R 704 RS1/16S563J

R 705 RS1/16S104J

R 706 RS1/16S222J

R 707 RS1/16S104J

R 708 (FM677 model) RS1/16S0R0J

R 712 (FM677 model) RS1/16S0R0J

R 714 RS1/16S0R0J

R 715 (FM677 model) RS1/16S473J

R 716 RS1/16S103J

R 717 RS1/16S473J

R 718 RS1/16S681J

R 719 RS1/16S0R0J

R 721 RS1/16S222J

R 722 RS1/16S222J

R 724 (FM677 model) RS1/16S681J

R 725 RS1/16S222J

R 726 RS1/16S104J

R 727 RS1/16S513J

R 729 RS1/16S473J

R 730 RS1/16S473J

R 731 RS1/16S222J

R 732 RS1/16S683J

R 733 RS1/16S222J

R 734 RS1/16S473J

R 735 RS1/16S222J

R 736 RS1/16S103J

R 737 RS1/16S433J

R 738 (FM677 model) RS1/16S104J

R 739 RS1/8S1R0J

R 740 RS1/8S2R0J

R 741 RS1/16S102J

R 742 RS1/16S104J

R 743 RS1/16S104J

R 744 RS1/16S223J

R 747 RS1/16S472J

R 750 (FM677 model) RAB4C473J

R 751 (FM677 model) RAB4C473J

R 752 (FM677 model) RS1/16S3602D

R 753 (FM677 model) RS1/16S6801D

R 754 (FM677 model) RS1/16S221J

R 755 (FM677 model) RS1/16S104J

R 756 (FM677 model) RS1/16S221J

R 759 RS1/16S472J

R 760 RS1/16S104J

R 761 RS1/16S104J

R 762 (FM673 model) RS1/16S104J

R 764 RS1/16S473J

R 765 RS1/16S471J

R 766 RS1/16S471J

R 767 RS1/16S471J

R 768 (FM677 model) RS1/10S101J

R 769 (FM677 model) RS1/10S101J

R 770 (FM677 model) RS1/16S104J

R 801 RS1/10S221J

R 802 RS1/10S271J

R 804 RS1/16S562J

R 805 RS1/16S562J

R 806 RS1/16S102J

CAPACITORS

C 101 CKSRYB102K50

C 102 CKSRYB104K16

C 103 CEV101M6R3

C 104 CEV470M6R3

C 105 CKSRYB224K16

C 106 CKSRYB224K16

C 107 CKSRYB224K16

C 201 CKSRYB104K16

C 202 CEV101M6R3

C 203 CKSRYB104K16

C 204 CKSRYB332K50

C 205 CKSRYB104K16

C 206 CKSRYB392K50

C 207 CKSRYB104K16

C 208 CCSRCH270J50

C 209 CCSRCJ3R0C50

C 210 CCSRCH181J50

C 211 CCSRCH510J50

C 212 CKSRYB682K50

C 213 CKSRYB104K16

C 214 CKSRYB104K16

C 215 CKSRYB104K16

C 216 CKSRYB104K16

C 217 CKSRYB104K16

C 218 CKSRYB104K16

C 219 CKSRYB104K16

C 220 CKSRYB104K16

C 253 CKSRYB471K50

C 271 CEV101M6R3

C 272 10µF/16V CCH1399

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

w

w

3

7

6

3

1

13942296513

w

.

xia

5

o

1

y

5

u

0

Q

Q

1

3

6

7

3

8

6

3

.

9

1

1

5

c

2

5

o

4

0

m

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Page 37

37

CDX-FM677,FM673

C 273 CKSRYB224K16

C 301 CEV101M10

C 302 CKSRYB224K16

C 651 CCSRSL391J50

C 652 CCSRSL391J50

C 653 CCSRCH181J50

C 654 CCSRCH181J50

C 655 CCSRCH181J50

C 656 CCSRCH181J50

C 661 CKSRYB104K16

C 664 CKSRYB103K25

C 665 CEV470M6R3

C 666 CKSRYB103K25

C 702 CKSRYB473K16

C 703 CKSRYB473K16

C 707 CKSRYB103K25

C 708 CKSRYB104K16

C 710 (FM677 model) CKSRYB103K25

C 711 (FM677 model) CKSRYB102K50

C 712 (FM677 model) CKSRYB102K50

C 714 CKSRYB104K16

C 715 22µF/10V CCH1403

C 717 CKSRYB103K25

C 718 CKSRYB103K25

C 719 CKSRYB102K50

C 720 CKSRYB102K50

C 721 (FM677 model) CKSRYB103K25

C 722 CKSRYB103K25

C 723 CKSRYB104K16

C 724 CKSRYB471K50

C 725 CKSRYB473K16

C 727 CKSRYB473K16

C 801 CKSRYB103K25

C 802 CKSRYB104K16

C 803 CKSRYB103K25

Unit Number : CXB6804 (FM677 model)

: CXB6803 (FM673 model)

Unit Name : Display Assy

MISCELLANEOUS

IC 901 IC PD6294A

IC 902 IC (FM677 model) TSOP1840SB1

Q 901 Transistor 2SD1767

Q 902 Transistor 2SB710A

Q 903 Transistor DTC114EK

D 901 Diode UDZS5R6(B)

D 902 Diode MA153

D 903 Diode MA153

X 901 Ceramic Resonator 4.9152MHz CSS1449

S 901 Switch CSG1110

S 902 Switch CSG1110

S 903 Switch CSG1110

S 904 Switch CSG1110

S 905 Switch CSG1110

S 906 Switch CSG1110

S 907 Switch CSG1110

IL 901 Lamp 14V 40mA CEL1608

IL 902 Lamp 14V 40mA CEL1608

LCD 901 LCD CAW1514

RESISTORS

R 901 RS1/16S102J

R 902 RS1/16S332J

R 903 RS1/16S471J

R 904 RS1/16S471J

R 905 RS1/16S332J

R 906 RS1/16S223J

R 907 (FM673 model) RS1/16S473J

CAPACITORS

C 901 CKSRYB473K16

C 902 CSZSR100M16

C 903 CSZSR100M16

C 904 CKSRYB104K16

C 905 CKSRYB104K16

C 906 CKSRYB104K16

Unit Number : CWX2580

Unit Name : Antenna Select Unit

MISCELLANEOUS

Q 501 Transistor 2SC1740S

D 501 Diode 1SS133

L 501 Ferri-Inductor LAU4R7K

RY 501 Relay CSR1014

RESISTORS

R 501 RD1/4PU683J

R 502 RD1/4PU103J

CAPACITORS

C 501 CKCYB102K50

C 502 CEAL101M10

Unit Number :

Unit Name : Mechanism PCB

Q 851 Photo-transistor PT4800

S 853 Spring Switch(HOME) CSN1051

Unit Number :

Unit Name : Switch PCB

D 851 LED CN504-2

S 851 Spring Switch(TAP) CSN1051

S 852 Spring Switch(DSP) CSN1052

Unit Number :

Unit Name : Motor PCB

M 853 Motor Unit(TRAY) CXB4421

Miscellaneous Parts List

Pickup Unit(P8)(Service) CXX1285

M 851 Motor Unit(SPINDLE) CXB3003

M 852 Motor Unit(ELV) CXB3006

M 854 Motor Unit(CARRIAGE) CXB3004

VR 801 Volume 10kΩ(B) CCW1023

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

C

D

E

G

F

Q

TEL 13942296513 QQ 376315150 892498299

Q

TEL

w

w

3

7

6

3

1

5

1

5

13942296513

w

.

xia

o

y

u

0

Q

Q

1

7

3

6

3

4

2

9

8

6

5

1

3

.

c

1

0

5

o

9

9

8

m

2

8

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Page 38

38

CDX-FM677,FM673

- Precautions

• This unit uses a single power supply (+5V) for the regulator. The signal reference potential, therefore, is

connected to REFO(approx. 2.5V) instead of GND.

If REFO and GND are connected to each other by mistake during adjustments, not only will it be impossible to measure the potential correctly, but the servo

will malfunction and a severe shock will be applied to

the pick-up. To avoid this, take special note of the following.

Do not connect the negative probe of the measuring

equipment to REFO and GND together. It is especially

important not to connect the channel 1 negative

probe of the oscilloscope to REFO with the channel 2

negative probe connected to GND.

Since the frame of the measuring instrument is usually at the same potential as the negative probe, change

the frame of the measuring instrument to floating status.

If by accident REFO comes in contact with GND,

immediately switch the regulator or power OFF.

• Always make sure the regulator is OFF when connecting and disconnecting the various filters and wiring

required for measurements.

• Before proceeding to further adjustments and measurements after switching regulator ON, let the player

run for about one minute to allow the circuits to stabilize.

• Since the protective systems in the unit's software are

rendered inoperative in test mode, be very careful to

avoid mechanical and /or electrical shocks to the system when making adjustment.

• Disc detection during tray extraction and return operations is performed by means of the photo transistor

in this unit. Consequently, if the inside of the unit is

exposed to a strong light source with the outer casing

removed for repairs or adjustment, the following malfunctions may occur:

*Even with a disc loaded, the unit detects "no disc"

and cannot start play.

*Although a 12-cm disc is loaded, the unit detects

"8cm disc" mistakenly.

When the unit malfunctions this way, either re-position the light source, move the unit or cover the photo

transistor.

• During exchanging discs, do not press the keys for

the discs to be exchanged.

Key to adjustment text HEAD UNIT (6 keys type)

inside (12 keys type)

BAND BAND

TRK+/FF TRK+/FF

TRK-/REV TRK-/REV

71

82

93

10 4

11 5

12 6

DISC- DISCSOURCE ON/OFF SOURCE ON/OFF

6. ADJUSTMENT

6.1 CD ADJUSTMENT

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

7

3

13942296513

6

3

1

5

1

5

0

7

3

Q

Q

8

6

3

9

1

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 39

39

CDX-FM677,FM673

• Note :

CD mechanism modules the grating angle of the pickup unit cannot be adjusted after the pickup unit is changed.

The pickup unit in the CD mechanism module is adjusted on the production line to match the CD mechanism

module and is thus the best adjusted pickup unit for the CD mechanism module. Changing the pickup unit is thus

best considered as a last resort. However, if the pickup unit must be changed, the grating should be checked

using the procedure below.

• Purpose :

To check that the grating is within an acceptable range.

• Symptoms of Mal-adjustment :

If the grating is off by a large amount symptoms such as being unable to close tracking, being unable to perform

track search operations, or track searching taking a long time, may appear.

• Method :

• Measuring Equipment • Oscilloscope, Two L.P.F.

• Measuring Points • E, F, REFO

• Disc • ABEX TCD-784

• Mode • TEST MODE

• Checking Procedure

1. Enter Test mode, then select Multi-CD player and switch the 5V regulator on.

2. Using the TRK+ and TRK- buttons, move the pickup unit to the innermost track.

3. Press key 9 to close focus, the display should read "91". Press key 9 2 times. Enter Rough Servo mode. Press key

8 to implement the tracking balance adjustment the display should now read "81".

4. As shown in the diagram above, monitor the LPF outputs using the oscilloscope and check that the phase difference is within 75° . Refer to the photographs supplied to determine the phase angle.

5. If the phase difference is determined to be greater than 75° try changing the pickup unit to see if there is any

improvement. If, after trying this a number of times, the grating angle does not become less than 75° then the

mechanism should be judged to be at fault.

• Note

Because of eccentricity in the disc and a slight misalignment of the clamping center the grating waveform may be

seen to "wobble" ( the phase difference changes as the disc rotates). The angle specified above indicates the average angle.

• Hint

Change the disc changes the clamp position and may decrease the "wobble".

REFO

E

F

E

F

L.P.F.

L.P.F.

CD CORE UNIT

Xch

Ych

Oscilloscope

100kΩ

100kΩ

390pF

390pF

6.2 CHECKING THE GRATING

- Checking the Grating After Changing the Pickup Unit

Q

7

3

Q

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

u

1

6

3

w

.

xia

o

y

.

c

o

m

Page 40

40

CDX-FM677,FM673

Grating waveform

45˚

0˚

75˚

60˚

30˚

90˚

Echt Xch 20mV/div, AC

Fcht Ych 20mV/div, AC

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

Page 41

41

CDX-FM677,FM673

• Note :

This mechanisms is detects the height of the stage using slide-variable resistance.

To absorb dislocation of the stage height caused by differences in the mechanism and the CD core unit, adjustment

must be made for each CD-mechanism module using a variable resistor.

Normally, readjustment is not needed, as this has been adjusted at the factory. However, adjustment of elevation is

required according to the procedure explained below if an elevation error has occurred or if the CD core unit has

been removed.

• Purpose :

To adjust and confirm whether or not elevation operates correctly.

• Adjustment Method :

• Measuring Equlpment: Oscilloscope, One L.P.F.

• Measuring Points : EREF, EPVO

• Setting : Without a magazine in Test mode

With the mechanism placed upside-down (Place the CD mechanism module so that the CD

core unit is above.)

• Confirmation Procedure

1. Enter Test mode, then select Multi-CD player.

2. Press key 7 to enter Mechanism Test mode.

3. Press key 12 twice to specify the amount of movement.

6.3 ADJUSTMENT OF ELEVATION WHEN THE CD CORE UNIT HAS BEEN REMOVED

FOR MAINTENANCE

- Adjustment When Error Code 60 is Displayed Because of Malfunctioning Elevation

TRACK FUNCTION

'"

TRACK FUNCTION

72 00' 00"

EREF

EPVO

Oscilloscope

CD CORE UNIT

L.P.F.

47kΩ

1µF

Examples of display

TRACK FUNCTION

72 00' 02"

TRACK FUNCTION

72 00' 01"

The amount of movement

changes each time key 12 is

pressed.

maximum movement

i

Key 12

i

during movement

i

Key 12

i

minimum movement

TRACK FUNCTION

72 00' 00"

i

i

Key 12

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

1

5

1

3

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

w

13942296513

w

w

.

xia

o

y

u

Q

Q

1

5

1

3

6

7

3

6

3

.

c

1

5

o

9

8

0

m

9

2

8

9

4

2

9

Page 42

42

CDX-FM677,FM673

4. Press key 9 to set ELV/TRAY mode to TRAY.

5. Press key FF to release the clamp and return the tray to the magazine.

6. Press key 9 to enter Elevation Move mode.

7. Use key FF/REV to operate elevation and set if to the graduation of the third step

(Fig. 1).

8. Make the adjustment.

Use VR802 to adjust the difference in potential between EREF and EPVO to 0 ±10

mV.

9. When adjustment is completed, press key BAND to exit Mechanism Test mode.

10. Confirm operation of the mechanism.

Place the mechanism horizontally (CD core unit below). Take care not to short-circuit the PCB.

11. Confirm the height of the stage. Use the DISC± key to select Disc No.3.

Check if the stopper bend of the clamp lever is engaged in the groove of the frame

stopper (Fig. 2-4).

• Note :

The stopper bend will be pressed downward into the groove for final clamping. Confirm the engagement position

of the stopper bend.

• If the stopper bend is engaged in the center and pressed downward, adjustment is completed. Go to step 15.

• If the stopper bend is dislocated, check the amount of dislocation by following steps 12 to 14.

TRACK FUNCTION

72 00' 02"

TRACK FUNCTION

72 00' 02"

TRACK FUNCTION

'"

TRACK FUNCTION

04 00' 00"

Examples of display

TRACK FUNCTION

72 01' 02"

Release the clamp

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

4

2

9

2

8

9

9