Pioneer CDJ-200 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

NECESSARY INFORMATION FOR DHHS RULES

MARKED ON THE TOP COVER BELOW:

CAUTION – LASER RADIATION WHEN OPEN.

DO NOT STARE INTO BEAM

ORDER NO.

RRV3095

CDJ-200

COMPACT DISC PLAYER

CDJ-200

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

CDJ-200 KUCXJ AC120V

CDJ-200 RLTXJ AC110-120V/AC220-240V

CDJ-200 WYXJ AC220-240V

CDJ-200 RFXJ AC110-120V/AC220-240V

For details, refer to "Important Check Points for good servicing".

T-IZY MAR. 2005 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 - Proposition 65

C

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

E

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

AC Leakage Test

F

2

1234

CDJ-200

5678

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 780 – 785 nm

LABEL CHECK (for RLTXJ, WYXJ and RFXJ types)

for WYXJ for WYXJ for RLTXJ

for RFXJ

A

B

C

(Printed on the chassis)

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S1901) for detecting loading

completion is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch is not

in LPS1 terminal side (when the mechanism is not clamped

and LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side. ( if LPS1 signal is low

level ).

In the test mode∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 41 of TC94A15FG

(IC105) on the MAIN Assy is connected to GND, or else the

terminals of Q105 are shorted to each other (fault condition).

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

∗ : See page 51.

D

E

F

56

CDJ-200

3

7

8

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

CDJ-200

5678

CONTENTS

1. SPECIFICATIONS.............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST.............................................................................................................8

2.1 PACKING SECTION ...................................................................................................................................8

2.2 EXTERIOR SECTION ..............................................................................................................................10

2.3 CONTROL PANEL SECTION...................................................................................................................12

2.4 SLOT-IN MECHANISM SECTION ............................................................................................................14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................16

3.1 BLOCK DIAGRAM....................................................................................................................................16

3.2 OVERALL WIRING DIAGRAM .................................................................................................................18

3.3 MAIN ASSY (1/2)......................................................................................................................................20

3.4 MAIN ASSY (2/2)......................................................................................................................................22

3.5 RLYB ASSY ..............................................................................................................................................23

3.6 DISP, KSWB, INDB, SLDB, JLED and JOGB ASSYS..............................................................................24

3.7 JACK ASSY..............................................................................................................................................26

3.8 ACIN, TRNS, SLMB, SECB and REGB ASSYS.......................................................................................28

3.9 VOLTAGES................................................................................................................................................30

3.10 WAVEFORMS.........................................................................................................................................32

4. PCB CONNECTION DIAGRAM ......................................................................................................................34

4.1 JACK ASSY..............................................................................................................................................35

4.2 MAIN and RLYB ASSYS...........................................................................................................................36

4.3 DISP, KSWB, INDB, SLDB, JLED and JOGB ASSYS..............................................................................38

4.4 ACIN, TRNS, SLMB, SECB and REGB ASSYS.......................................................................................42

5. PCB PARTS LIST............................................................................................................................................46

6. ADJUSTMENT ................................................................................................................................................50

7. GENERAL INFORMATION .............................................................................................................................51

7.1 DIAGNOSIS..............................................................................................................................................51

7.1.1 SERVICE MODE................................................................................................................................51

7.1.2 POWER ON SEQUENCE ..................................................................................................................58

7.1.3 DISASSEMBLY ..................................................................................................................................59

7.2 PARTS ......................................................................................................................................................64

7.2.1 IC........................................................................................................................................................64

7.2.2 FL .......................................................................................................................................................76

8. PANEL FACILITIES .........................................................................................................................................77

A

B

C

D

E

F

56

CDJ-200

5

7

8

1234

1. SPECIFICATIONS

• KUCXJ type

1. General

A

System..............................Compact disc digital audio system

Power requirements.....................................AC 120 V, 60 Hz

Power consumption.......................................................14 W

Operating temperature............+5˚C – +35˚C (+41˚F – +95˚F)

Operating humidity...............................................5 % – 85 %

(There should be no condensation of moisture.)

Weight..............................................................3.2 kg (7.1 lb)

Dimensions.........................216 (W) × 292 (D) × 99.5 (H) mm

8 – 1/2 (W) × 11 –1/2 (D) × 3 – 15/16 (H) in

2. Audio section

B

Frequency response........................................4 Hz – 20 kHz

Signal-to-noise ratio..........................110 dB or more (JEITA)

Distortion.................................................... .0.006 % (JEITA)

3. Accessories

• Operating instructions........................................................1

• Power cord........................................................................1

• Audio cable....................................................................... 1

• Control cable..................................................................... 1

• Forced eject pin (housed in a groove in the bottom panel)... 1

• Limited warranty................................................................1

C

NOTE:

Specifications and design are subject to possible modification

with-out notice.

• WYXJ type

1. General

System.......................... Compact disc digital audio system

Power requirements .................... AC 220-240 V, 50/60 Hz

Power consumption ..................................................... 16 W

Operating temperature .................................. +5°C – +35°C

D

Operating humidity ............................................ 5 % – 85 %

(There should be no condensation of moisture.)

Weight ....................................................................... 3.2 kg

Dimensions ..................... 216 (W) x 292 (D) x 99.5 (H) mm

• RLTXJ, RFXJ types

1. General

System........................... Compact disc digital audio system

Power requirements .... AC 110-120 V/220-240 V, 50/60 Hz

Power consumption ..................................................... 16 W

For Taiwan: 17 W

Operating temperature .................................. +5°C – +35°C

Operating humidity ........................................... 5 % – 85 %

(There should be no condensation of moisture.)

Weight ........................................................................3.2 kg

Dimensions ...................... 216 (W) x 292 (D) x 99.5 (H) m

m

2. Audio section

Frequency response...................................... 4 Hz – 20 kHz

Signal-to-noise ratio ....................... 110 dB or more (JEITA)

Distortion ................................................... 0.006 % (JEITA)

3. Accessories

• Operating instructions ..................................................... 1

• Power cord ...................................................................... 1

• Audio cable ..................................................................... 1

• Control cable ................................................................... 1

• Forced eject pin (housed in a groove in the bottom panel)... 1

NOTE:

Specifications and design are subject to possible modification

with-out notice.

Voltage selector (RLTXJ, RFXJ types only)

• You can find the voltage selector switch on the bottom plate

of the unit.

The factory setting for the voltage selector is 220 – 240 V.

Please set it to the correct voltage for your country or region.

• For Taiwan, please set to 110 – 120 V before using.

Before changing the voltage, disconnect the AC power cord.

Use a medium size screwdriver to change the voltage

selector switch.

220-240V

2. Audio section

Frequency response...................................... 4 Hz – 20 kHz

Signal-to-noise ratio ....................... 110 dB or more (JEITA)

Distortion ................................................... 0.006 % (JEITA)

3. Accessories

E

• Operating instructions ..................................................... 1

• Power cord ...................................................................... 1

• Audio cable ..................................................................... 1

• Control cable ................................................................... 1

• Forced eject pin (housed in a groove in the bottom panel)... 1

NOTE:

Specifications and design are subject to possible modification

with-out notice.

F

6

1234

110-120V

CDJ-200

5678

Accessories

Power cord

(KUCXJ : ADG7021)

(RLTXJ : ADG1154)

(WYXJ : ADG1154)

(RFXJ : ADG7097)

Audio cable

(VDE1064 or XDE3045)

L= 1.5m

Control cable

(ADE7108 or XDE3063)

L= 1 m

Forced eject pin

(housed in a groove

in the bottom panel)

(DEX1008)

A

B

C

D

E

56

CDJ-200

F

7

7

8

1234

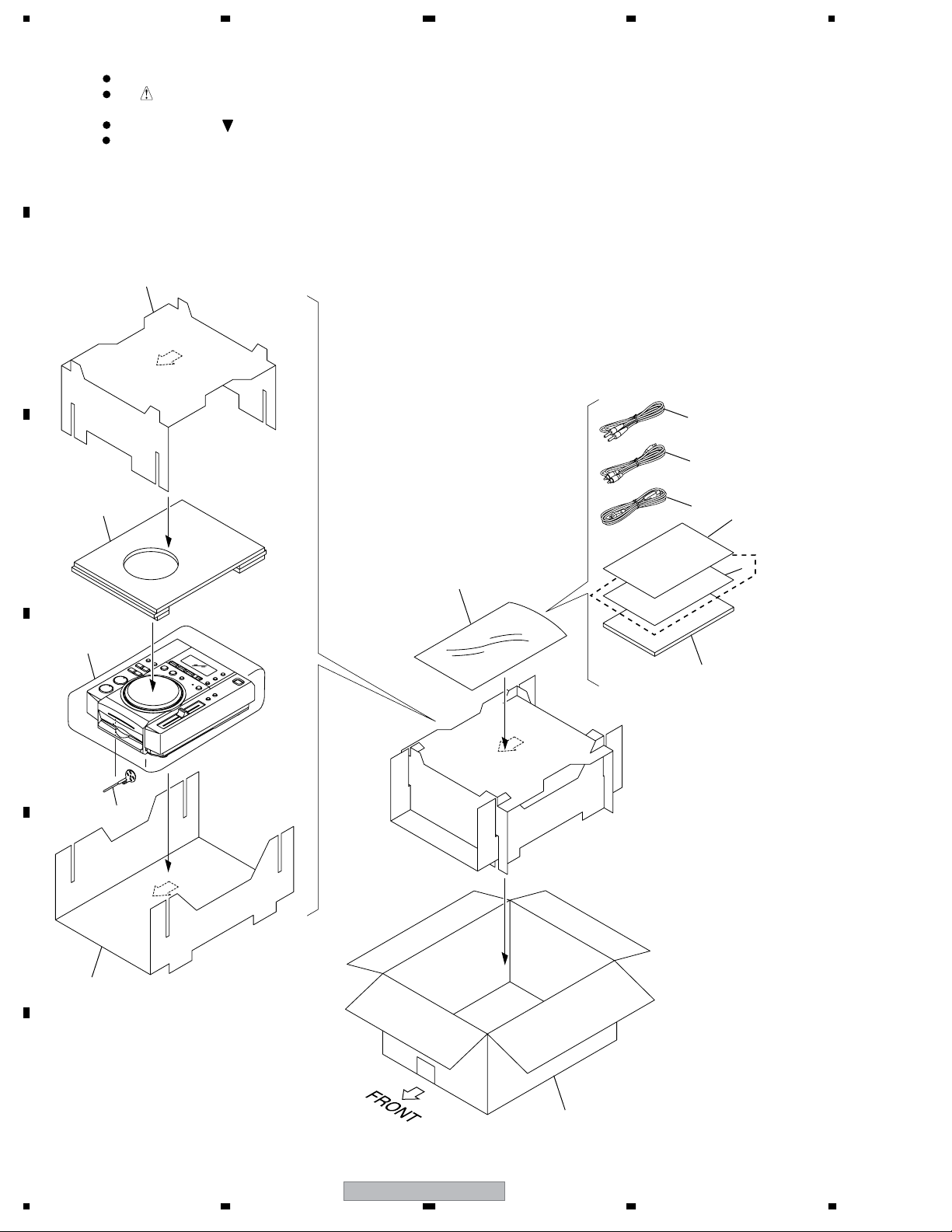

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING SECTION

10

B

C

12

3

2

1

7

KUCXJ

6

8

9

5

D

4

E

11

Only

F

8

1234

CDJ-200

13

>

5678

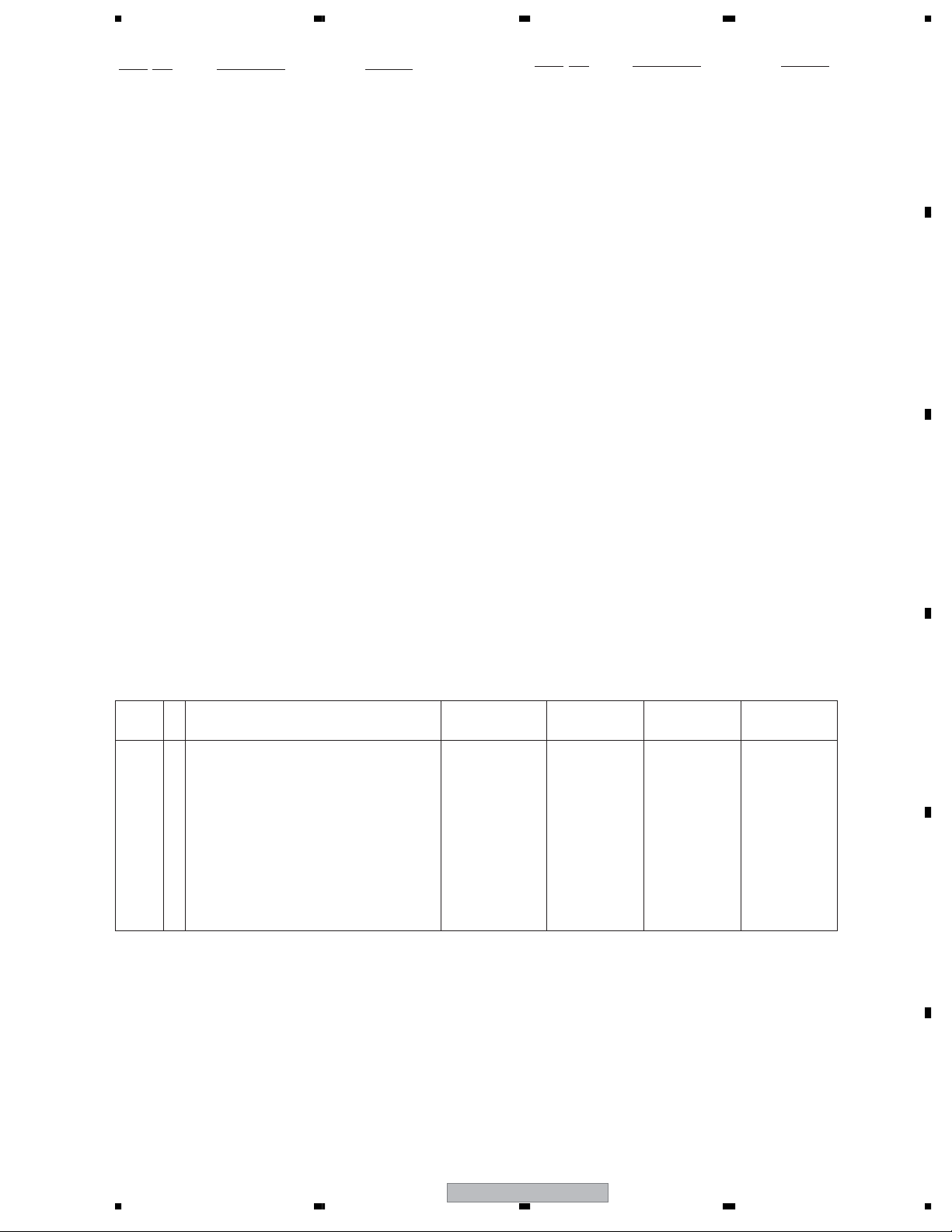

(1) PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1Power Cord See Contrast table (2)

2Audio Cable

3 Control Cable

4Forced Eject Pin DEX1008

5 Operating Instructions See Contrast table (2)

NSP 6 Limited Warranty See Contrast table (2)

NSP 7 User Seat DRM1262

NSP 8 Polyethylene Bag AHG7117

(0.06 x 230 x 340)

9Packing Sheet AHG7015

VDE1064 or XDE3045

ADE7108 or XDE3063

A

10 Pad A DHA1638

11 Pad B DHA1639

12 Pad C DHA1640

13 Packing Case See Contrast table (2)

(2) CONTRAST TABLE

CDJ-200/KUCXJ, RLTXJ, WYXJ and RFXJ are constructed the same except for the following:

Mark No. Symbol and Description

>

NSP 6 Limited Warranty ARY7043 Not used Not used Not used

1Power Cord ADG7021 ADG1154 ADG1154 ADG7097

5 Operating Instructions DRB1377 DRB1378 DRB1376 DRB1378

13 Packing Case DHG2495 DHG2496 DHG2494 DHG2500

CDJ-200/

KUCXJ

CDJ-200/

RLTXJ

CDJ-200/

WYXJ

CDJ-200/

RFXJ

B

C

D

56

CDJ-200

E

F

9

7

8

1234

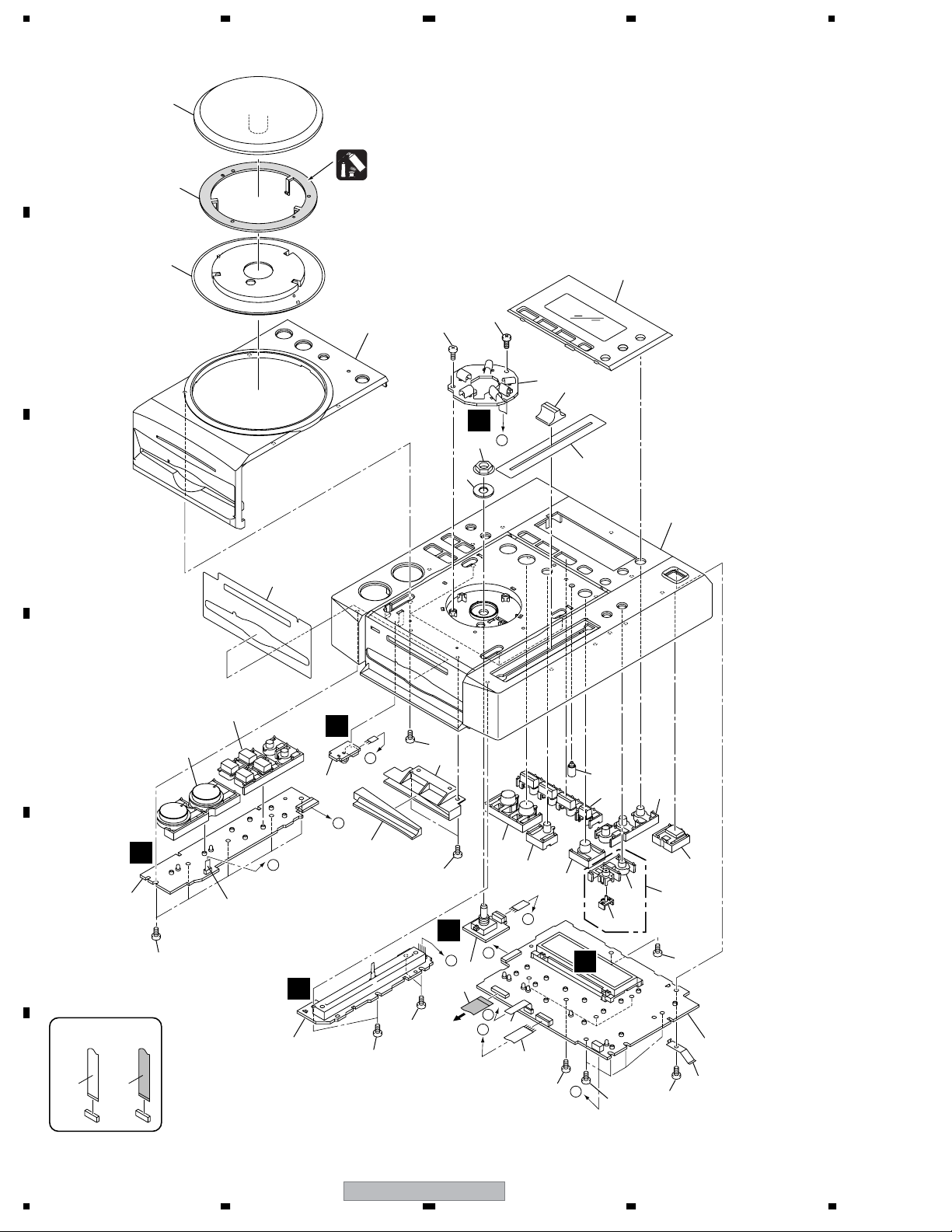

2.2 EXTERIOR SECTION

23

A

K

18

40

43

40

Refer to

"2.3 CONTROL PANEL SECTION".

A

J

1

B

41

C

D

29

B

27

A

27

29

22

25

21

41

32

C

40

40

31

28

L

I

L

41

33

40

15

F

41

K

39

H

41

G

5

38

F

4

6

J

16

K

20

9

17

41

G

34

WYXJ Only

10

J

N

41

40

L

D

B

27

E

29

24

41

E

D

41

41

M

36

35

RLTXJ, RFXJ Only

32

I

14

8

41

37

41

I

H

M

M

3

11

41

42

E

Refer to

"2.4 SLOT-IN MECHANISM SECTION".

F

NON-CONTACT

SIDE

CONTACT SIDE

13

10

1234

29

27

30

41

A

41

7

12

C

41

19

26

2

B

19

CDJ-200

>

>

5678

(1) EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 MAIN Assy DWG1587

2RLYB Assy DWX2429

3JACK Assy DWX2433

4ACIN Assy See Contrast table (2)

5 TRNS Assy See Contrast table (2)

6 SLMB Assy DWS1355

7 SECB Assy DWR1394

8 REGB Assy DWR1393

9 Fuse (FU11) See Contrast table (2)

10 Power Transformer (T22) See Contrast table (2)

11 24P Flexible Cable DDD1275

12 32P Flexible Cable DDD1276

13 24P Flexible Cable DDD1278

14 9P Flexible Cable DDD1279

15 Earth Lead Unit/300V DDF1032

16 Connector Assy PF03PP-B17

17 Power Button DAC2254

NSP 18 Silicone Sheet D5 L DEB1456

19 Insulator DEC2250

20 Protector DEC2808

21 PU Caution DEC2856

22 PCB Stay DNH2640

No. Description Part No.

Mark

23 Heatsink DNH2641

24 Trans. Plate DNH2670

25 Card Spacer DNK2769

NSP 26 Chassis See Contrast table (2)

27 Damper CNV6011

28 Earth Spring DBH1398

29 Float Spring G5 DBH1494

30 FPC Guard DBK1282

31 Mecha Plate DNH2642

32 Nyron Rivet (3 x 4.5) RBM-003

33 Cord Clamper RNH-184

34 Caution Label HE See Contrast table (2)

35 Caution Label See Contrast table (2)

36 Caution Label See Contrast table (2)

37 Nut M12 DBN1012

38 DM Screw DBA1260

39 Screw BBZ40P060FTC

40 Screw BBZ30P060FTC

41 Screw BPZ30P080FTC

42 Jumper Wire 6P(J904) D20PDY0610E

43 15P Flexible Cable DDD1277

A

B

C

(2) CONTRAST TABLE

CDJ-200/KUCXJ, RLTXJ, WYXJ and RFXJ are constructed the same except for the following:

Mark No. Symbol and Description

4ACIN Assy DWR1388 DWR1389 DWR1387 DWR1389

5 TRNS Assy DWR1391 DWR1392 DWR1391 DWR1392

>

>

>

NSP 26 Chassis DNK4423 DNK4424 DNK4386 DNK4427

9 Fuse (FU11 : 2.0A/125V) REK1111 Not used Not used

9 Fuse (FU11 : T1AL250V) Not used REK1022 REK1022

10 Power Transformer (T22) DTT1172 DTT1171 DTT1171

34 Caution Label HE Not used Not used PRW1233 Not used

35 Caution Label Not used Not used VRW1094 Not used

36 Caution Label Not used PRW1018 Not used DRW2248

CDJ-200/

KUCXJ

CDJ-200/

RLTXJ

CDJ-200/

WYXJ

CDJ-200/

RFXJ

Not used

REK1022

DTT1171

D

E

F

56

CDJ-200

11

7

8

1234

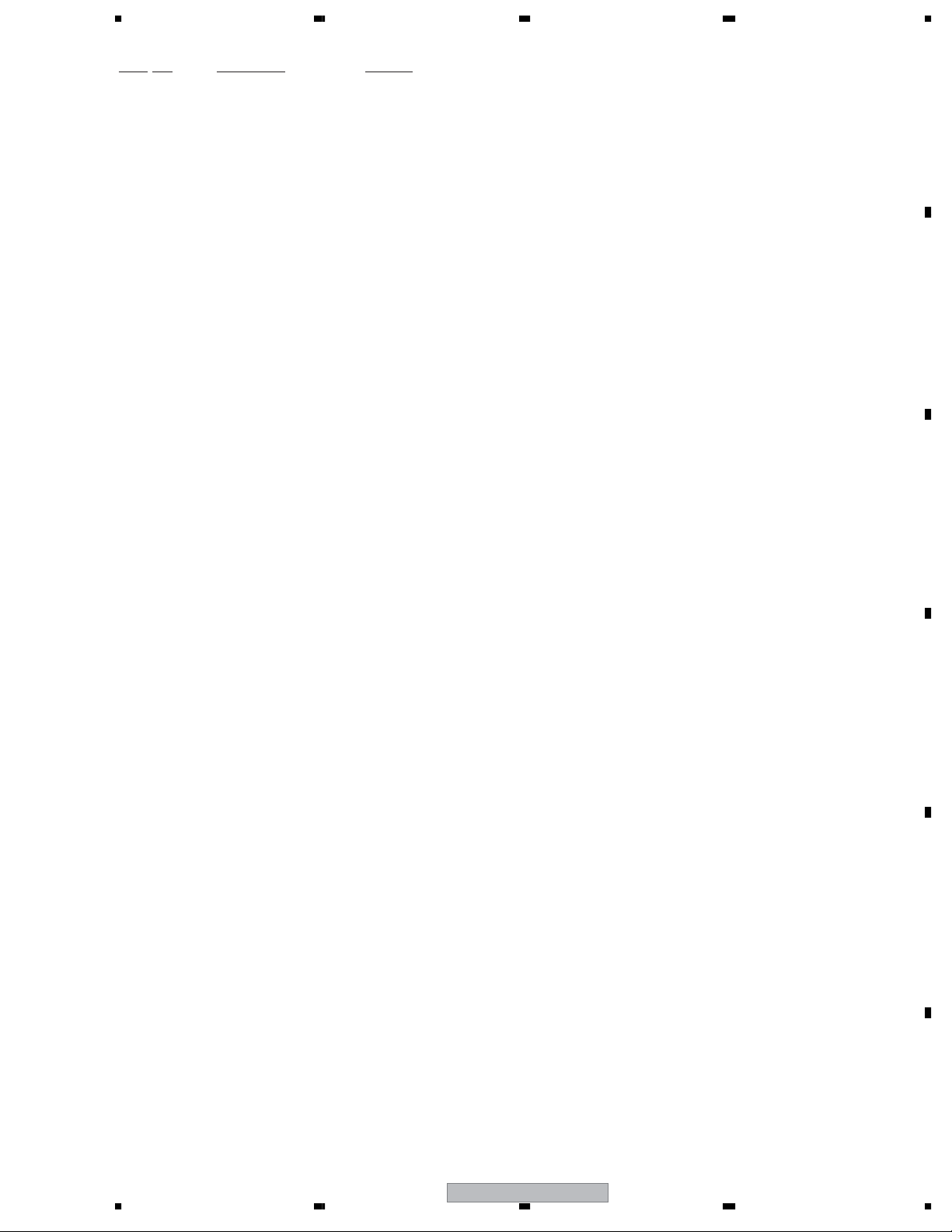

2.3 CONTROL PANEL SECTION

23

21

22

Dyefree

GEM1036

(ZLX-ME413A)

20

34

34

27

5

28

A

B

G

D

33

35

C

16

19

D

E

F

D

2

NON-CONTACT

SIDE

CONTACT SIDE

34

18

9

E

34

34

25

34

H

To MAIN

CN105

26

15

10

11

12

C

B

E

6

7

C

37

D

38

34

C

E

31

34

30

13

14

29

34

1

17

34

8

A

36

A

3

B

24

F

4

34

12

CDJ-200

1234

5678

CONTROL PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 DISP Assy DWG1588

2 KSWB Assy DWS1356

3 INDB Assy DWX2438

4 SLDB Assy DWX2430

5 JLED Assy DWX2432

6 JOGB Assy DWX2431

7 15P Flexible Cable DDD1277

8 PLAY Button DAC2244

9 SEARCH Button DAC2245

10 LOOP Button DAC2246

A

11 RELOOP Button DAC2270

12 BEAT LOOP Button DAC2271

13 TIME Button DAC2249

14 EJECT Button DAC2253

15 JET Button DAC2266

16 Slide Sheet (GRAY) DAH2374

17 Earth Plate DBK1224

18 Vessel Sheet DEC2751

19 Control Panel A DNK4384

20 Control Panel B DNK4385

21 Jog Dial DNK4387

22 POM Ring DNK4388

23 Jog Lens DNK4389

24 Front Lens DNK4390

25 Reflector DNK4391

26 BEAT Lens DNK4392

27 Display Panel DNK4492

28 Slide Knob (SILVER) DNK4448

29 TEMPO Button Assy DXA2014

30 TEMPO Button DAC2258

31 TEMPO Lens DNK4421

32 • • • • •

33 Nut M9 DBN1008

34 Screw BPZ30P080FTC

35 JOG Washer DBF1002

B

C

D

36 Jumper Wire 3P D20PDY0305E

37 Jumper Wire 4P D20PDY0405E

38 Jumper Wire 6P D20PDY0610E

56

CDJ-200

E

F

13

7

8

1234

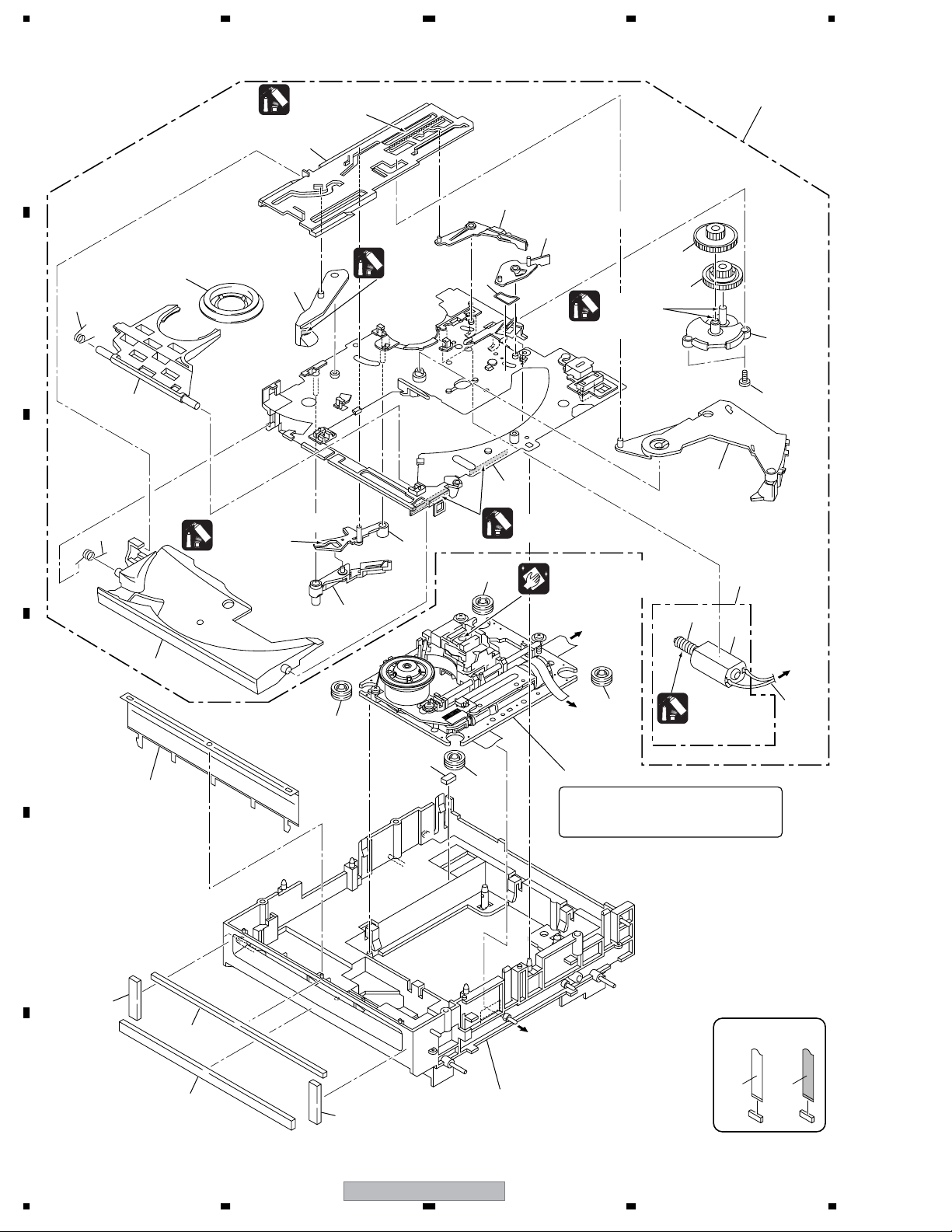

2.4 SLOT-IN MECHANISM SECTION

Grease

A

GYA1001

(ZLB-PN397B)

1

11

20

21

Dyefree

23

B

7

10

GEM1036

(ZLX-ME413A)

9

Grease

GYA1001

(ZLB-PN397B)

13

19

C

8

Dyefree

GEM1036

15

(ZLX-ME413A)

16

Dyefree

GEM1036 (ZLX-ME413A)

25

Cleaning liquid : GEM1004

Cleaning paper : GED-008

RLYB CN12

To

(Pickup)

12

18

17

22

24

14

3

4

5

To

RLYB CN16

(Loading Motor)

25

D

25

To

RLYB CN14

(Stepping Motor)

Grease

GYA1001

(ZLB-PN397B)

6

27

31

25

2

Note:

The TM. Assy 03-S is supplied only in

assembly form, not as a single part.

E

30

29

F

28

30

26

To MAIN CN102

(Spindle Motor)

NON-CONTACT

SIDE

CONTACT SIDE

14

CDJ-200

1234

5678

SLOT-IN MECHANISM SECTION PARTS LIST

Mark No. Description Part No.

NSP 1 Slot-in Mecha SV Assy DXA2005

2 TM. Assy 03-S VXX2909

3 DC Motor Assy-S DXX2510

NSP 4 Worm Gear DNK3910

NSP 5 DC Motor S (ROHS) DXM1230

6 Connector Assy PF02PY-B22

7 Clamp Spring DBH1374

8 Guide Spring DBH1375

9 SW Lever Spacer SV DEC2831

10 Loading Lever DNK3406

A

11 Main Cam DNK3407

12 Disc Guide DNK3478

13 Clamp Arm DNK3576

14 Eject Lever DNK3684

15 Lever AP DNK3835

16 Lever BP DNK3836

17 Loading Gear DNK3911

18 Drive Gear DNK3912

19 Loading Base SV DNK4369

20 SW Lever SV1 DNK4370

21 SW Lever SV2 DNK4371

22 Gear Holder SV DNK4372

23 Clamper 04 Assy DXB1859

24 Screw BPZ20P060FTC

25 Floating Rubber (SI) VEB1351

26 Float Base 04 Assy DXB1838

27 Spacer POR (T3) DEB1566

28 Vessel Cushion A DEC2852

29 Vessel Cushion B DEC2853

30 Vessel Cushion C DEC2854

31 Front Sheet DED1132

B

C

D

56

CDJ-200

E

F

15

7

8

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

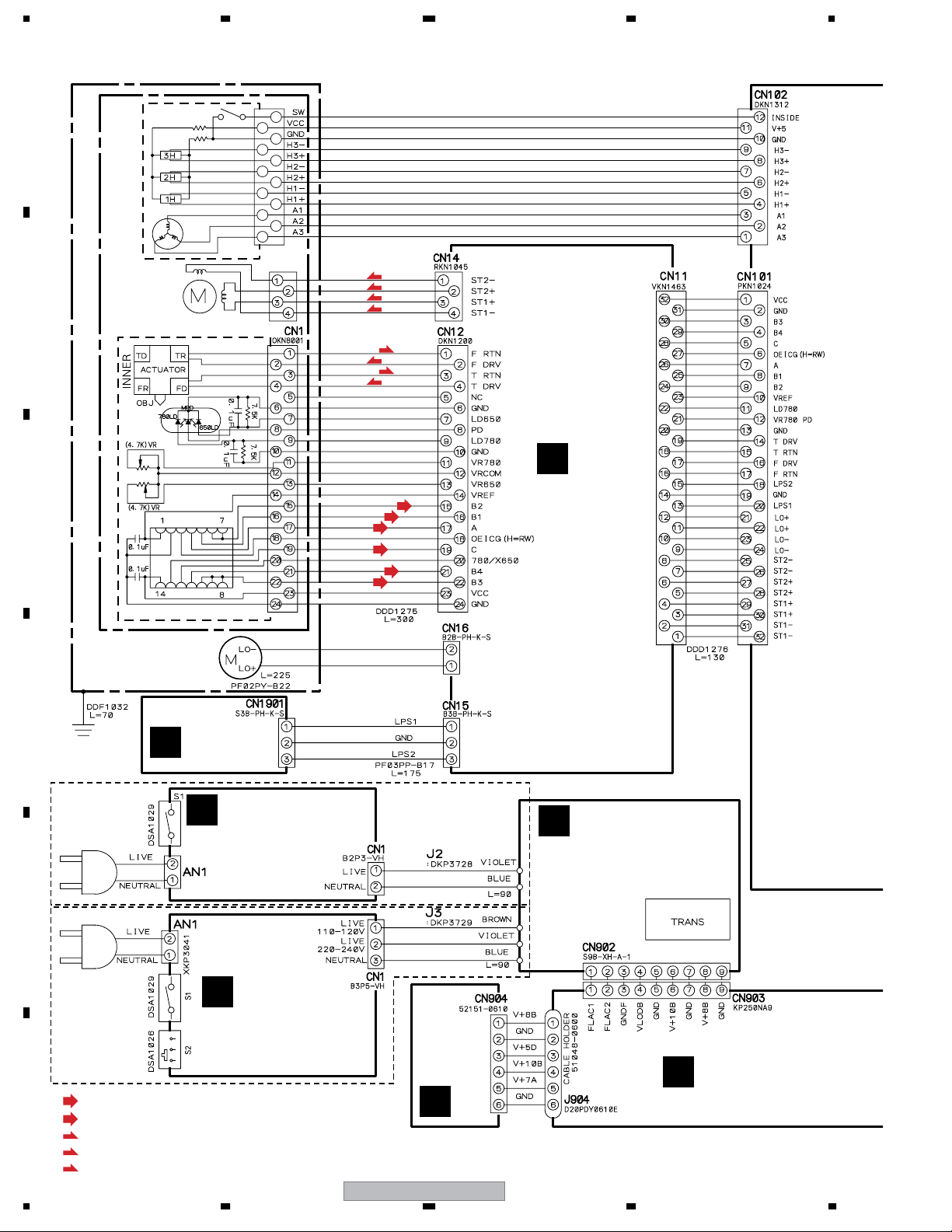

3.1 BLOCK DIAGRAM

A

TM. ASSY 03-S (VXX2909)

SPINDLE

MOTOR 04

STEPPING

MOTOR 04

B

PICKUP ASSY

C

D

E

DC MOTOR

ASSY-S

(DXX2510)

L

SLMB ASSY

N

For KUCXJ, WYXJ

RLYB ASSY

B

REGB ASSY

SECB ASSY

M

COMPARATOR

DIGITAL OUT

CONTROL

ACIN ASSY

J

For RLTXJ, RFXJ

F

ACIN ASSY

J

16

1234

S2

S1

BROWN

VIOLET

BLUE

J2

J3

CDJ-200

TRNS ASSY

K

5678

A

MAIN ASSY

A

B

D

KSWB ASSY

JACK ASSY

I

E

INDB ASSY

PHONES

C

AUDIO OUT

D

E

H

JOGB ASSY

SLDB ASSY

F

DISP ASSY

C

G

JLED ASSY

56

CDJ-200

F

17

7

8

1234

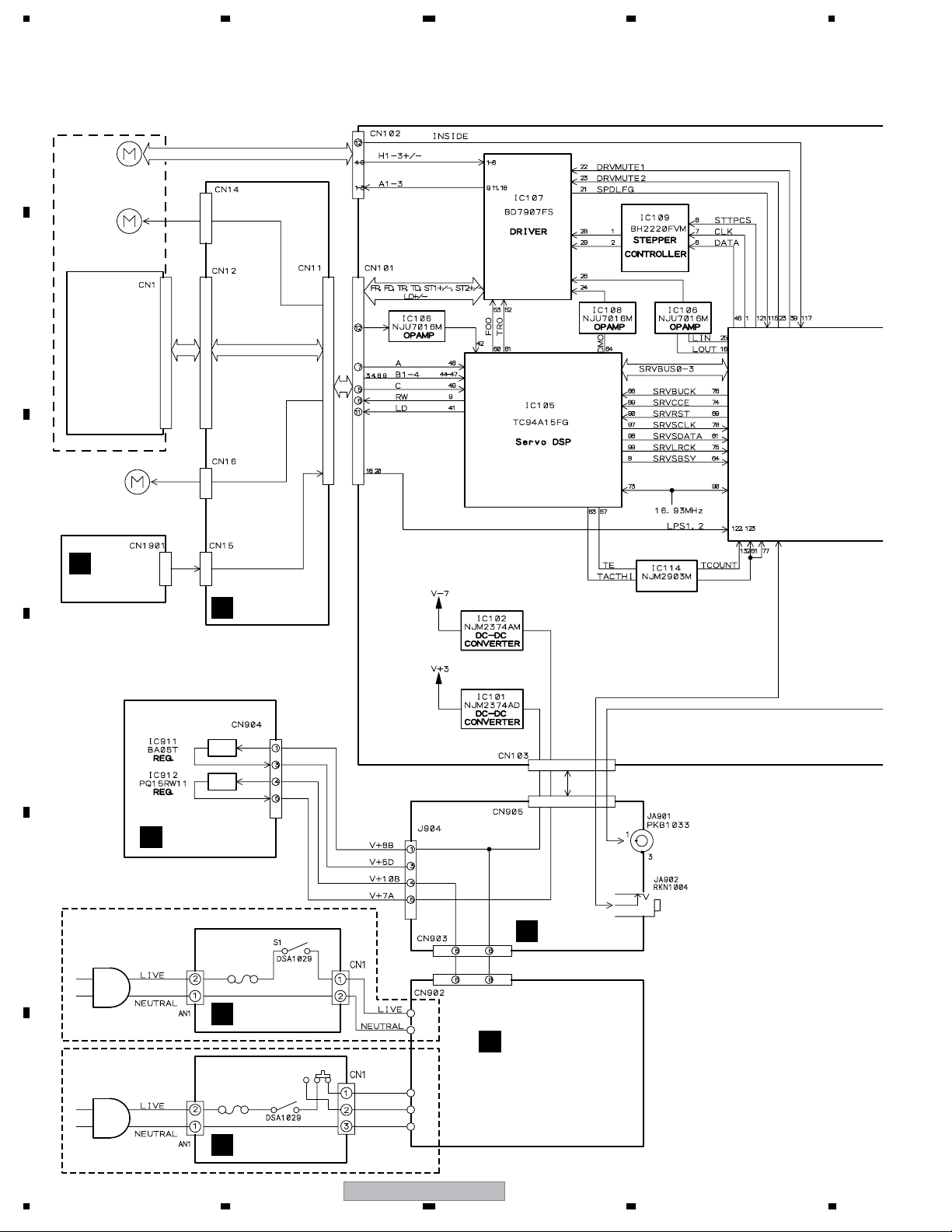

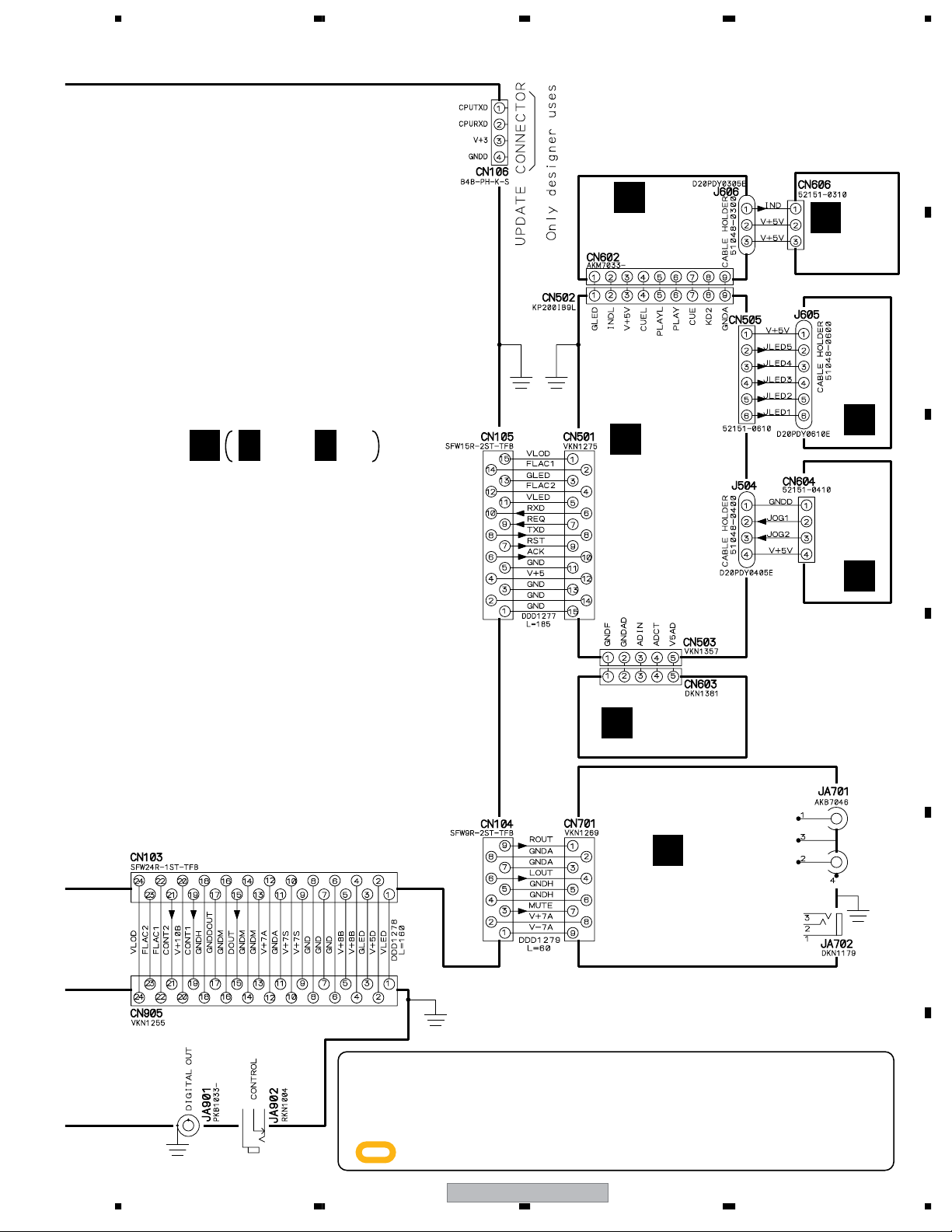

3.2 OVERALL WIRING DIAGRAM

A

SPINDLE MOTOR 04

STEPPING

MOTOR 04

B

TM. ASSY 03-S (VXX2909)

SLOT-IN MECHA SV ASSY (DXA2005)

C

1

2

3

4

5

6

7

8

9

10

11

12

(S)

(S)

(S)

(S)

(F)

(F)

(T)

(T)

B

RLYB ASSY

(DWX2429)

(RF)

(T)

(T)

(RF)

(RF)

(RF)

D

FOR

KUCXJ, WYXJ

E

FOR

RLTXJ, RFXJ

(RF)

(T)

F

(F)

(T)

(S)

18

PICKUP ASSY

DC MOTOR

ASSY-S

(DXX2510)

SLMB ASSY

L

(DWS1355)

POWER CORD

KUCXJ : ADG7021

WYXJ : ADG1154

POWER CORD

RLTXJ : ADG1154

RFXJ : ADG7097

J

KUCXJ : XKP3042

WYXJ : XKP3041

ACIN ASSY

(RLTXJ, RFXJ : DWR1389)

: RF DATA SIGNAL ROUTE

: TRACKING DATA SIGNAL ROUTE

: FOCUS SERVO LOOP LINE

: TRACKING SERVO LOOP LINE

: STEPPING SERVO LOOP LINE

1234

ACIN ASSY

(KUCXJ : DWR1388)

(WYXJ : DWR1387)

J

REGB ASSY

CDJ-200

(DWR1393)

N

K

TRNS ASSY

(KUCXJ, WYXJ : DWR1391)

(RLTXJ, RFXJ : DWR1392)

SECB ASSY

M

(DWR1394)

5678

A

D

KSWB ASSY

(DWS1356)

E

INDB ASSY

(DWX2438)

JLED ASSY

(DWX2432)

B

G

A

A 1/2, A 2/2

MAIN ASSY (DWG1587)

C

DISP ASSY

(DWG1588)

SLDB ASSY

F

(DWX2430)

JACK ASSY

(DWX2433)

C

JOGB ASSY

(DWX2431)

H

D

L

AUDIO OUT

I

R

E

PHONES

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

÷

56

: The power supply is shown with the marked box.

CDJ-200

F

19

7

8

1234

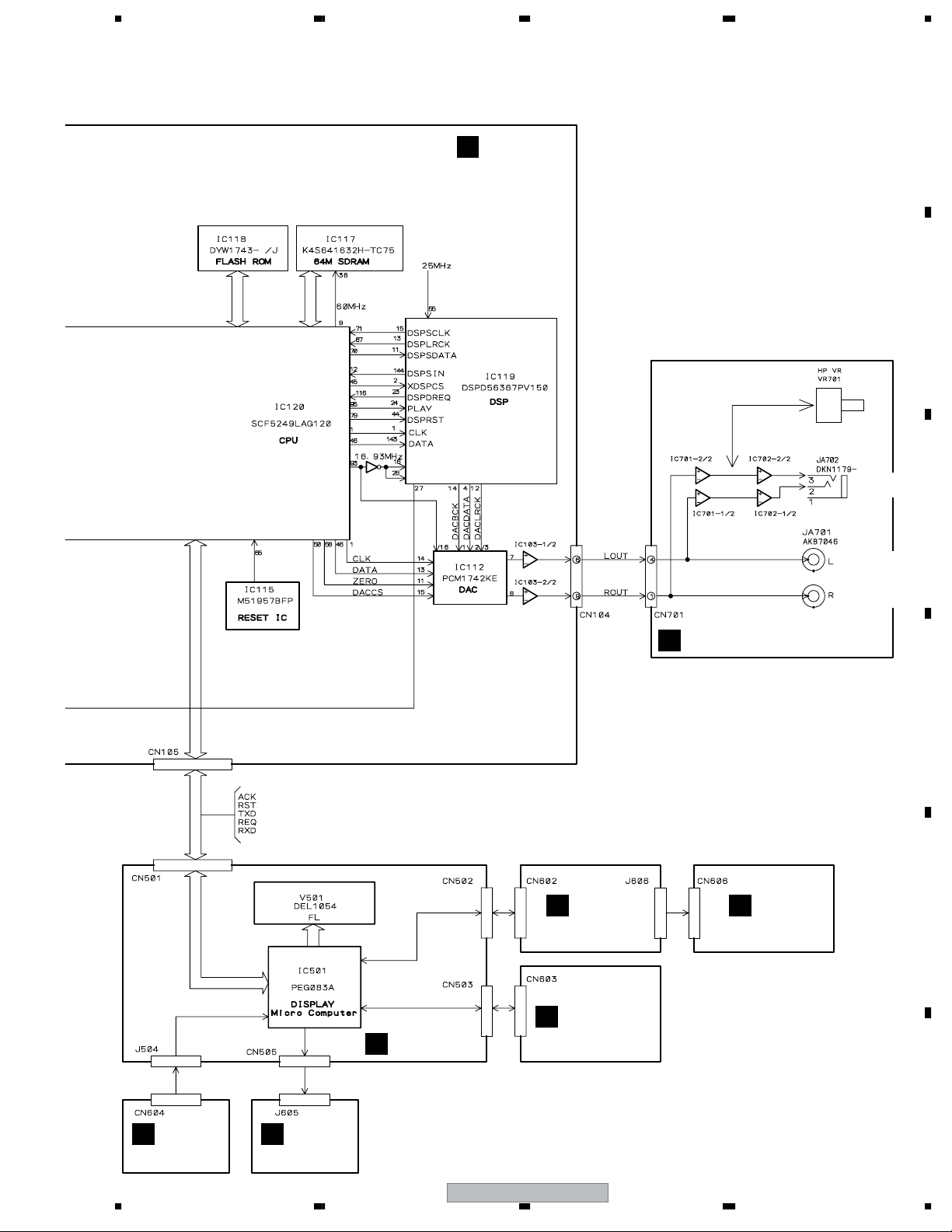

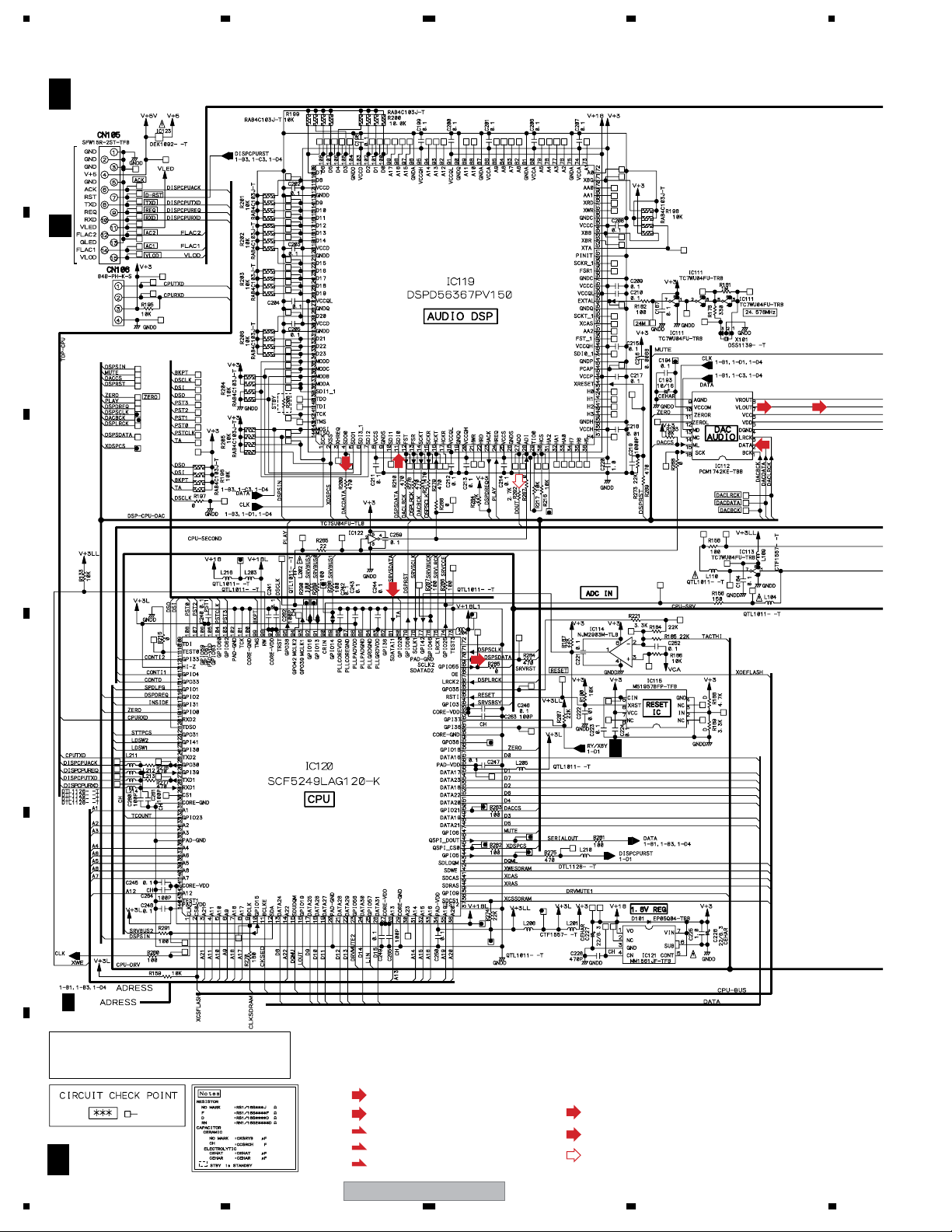

3.3 MAIN ASSY (1/2)

A

B

C

A 1/2

CN501

C

UPDATE

CONNECTOR

MAIN ASSY (DWG1587)

(D)

(D)

(D)

(D)

(D)

D

2/2A

E

2/2A

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. DEK1092- 466.200

F

MFD, BY LITTELFUSE INK. FOR IC123.

A 1/2

20

1234

(RF)

: RF DATA SIGNAL ROUTE

(T)

: TRACKING DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: STEPPING SERVO LOOP LINE

CDJ-200

(D)

: AUDIO DATA SIGNAL ROUTE

: AUDIO SIGNAL ROUTE (L ch)

: AUDIO SIGNAL ROUTE (Digital)

5678

13

10

I

CN701

M

CN905

A

B

(T)

(RF)

(T)

(RF)

9

7

1

(RF)

(RF)

12

8

2

(S)

(S)

(S)

(S)

6

5

C

3

4

(F)

(F)

(T)

(T)

15 16

(T)

(RF)

(RF)

(RF)

(T)

(RF)

B

D

CN11

E

14

(D)

(T)

(F)

(F)

(S)

(S)

(S)

(S)

(T)

(S)

(S)

(S)

(S)

11

(F)

(F)

(T)

(T)

To

SPINDLE

MOTOR

04

F

56

CDJ-200

A 1/2

21

7

8

1234

3.4 MAIN ASSY (2/2)

A

B

C

A 2/2

MAIN ASSY (DWG1587)

2/2A

2/2

A

D

E

F

22

A 2/2

CDJ-200

1234

5678

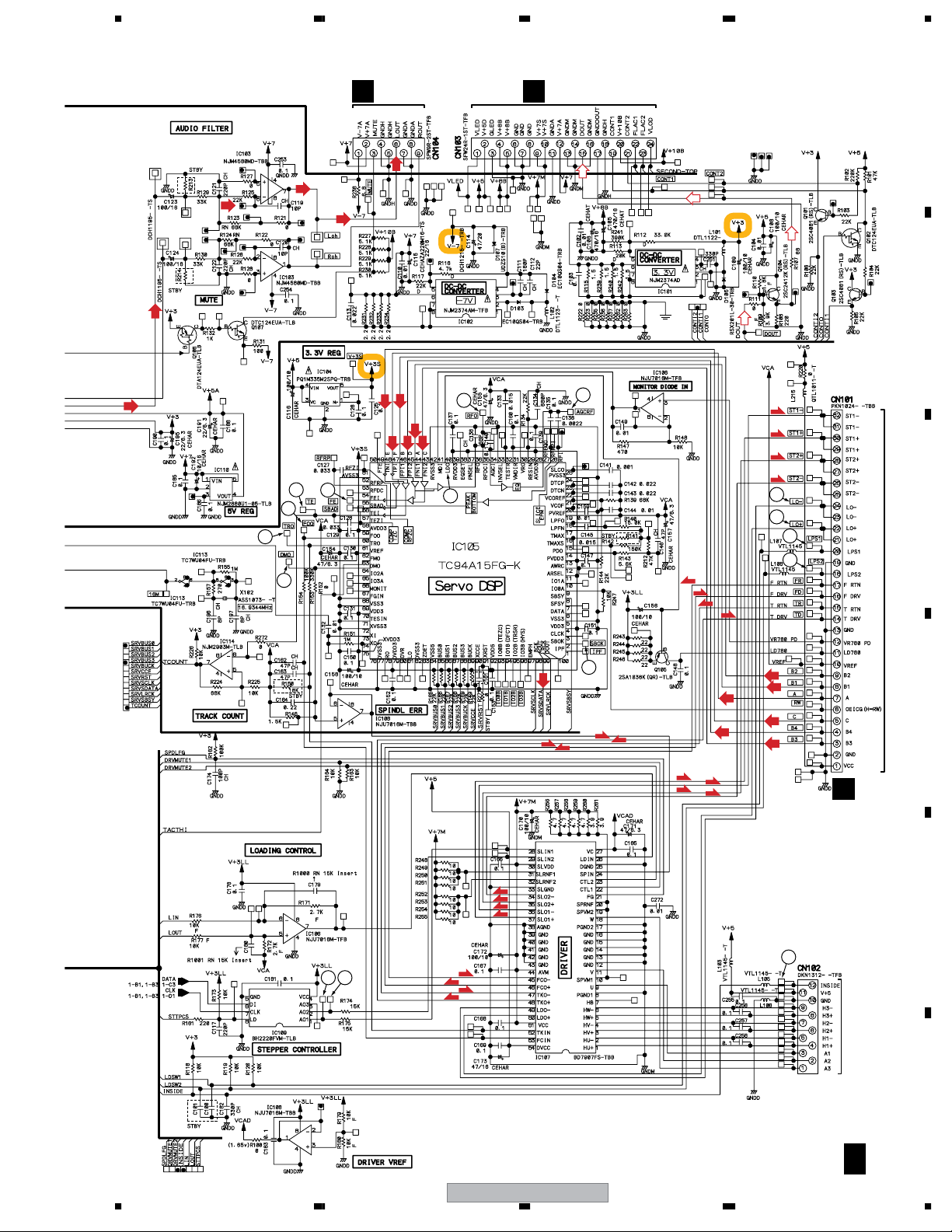

3.5 RLYB ASSY

RLYB ASSY (DWX2429)

B

(RF)

: RF DATA SIGNAL ROUTE

(T)

: TRACKING DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: STEPPING SERVO LOOP LINE

A

CN101

A 1/2

(S)

(S)

(S)

(S)

(S)

(S)

(S)

(S)

To

STEPPING

MOTOR 04

To

DC MOTOR

B

ASSY-S

(S)

(S)

(S)

(S)

L

CN1901

C

(F)

(F)

(T)

(T)

(F)

(F)

(T)

(T)

(RF)

(RF)

(T)

(T)

(RF)

(RF)

(RF)

(RF)

(T)

(RF)

(RF)

D

(T)

(F)

(T)

(T)

(F)

(T)

(T)

(RF)

(RF)

E

To

PICKUP

ASSY

CN1

(T)

(T)

(F)

(F)

F

56

CDJ-200

B

23

7

8

1234

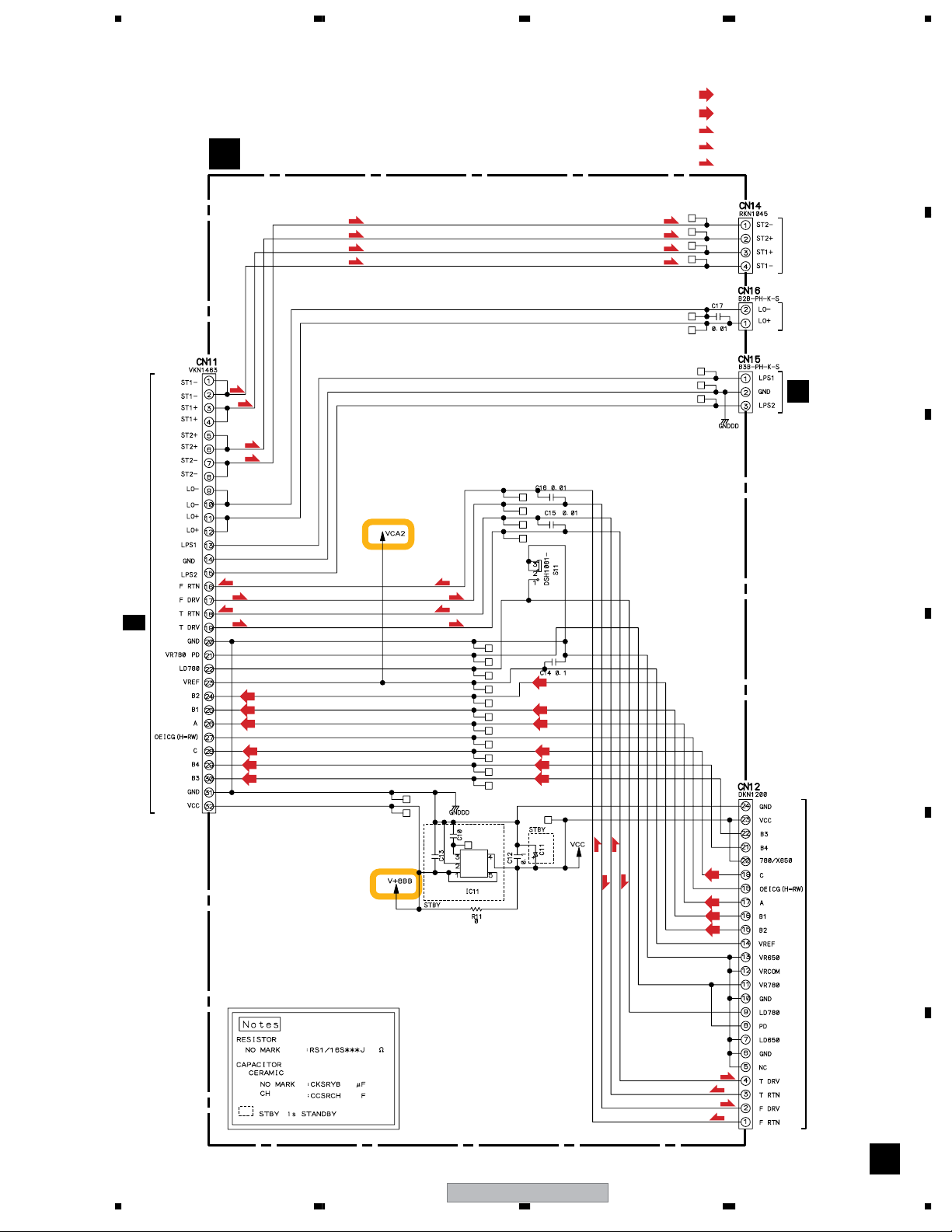

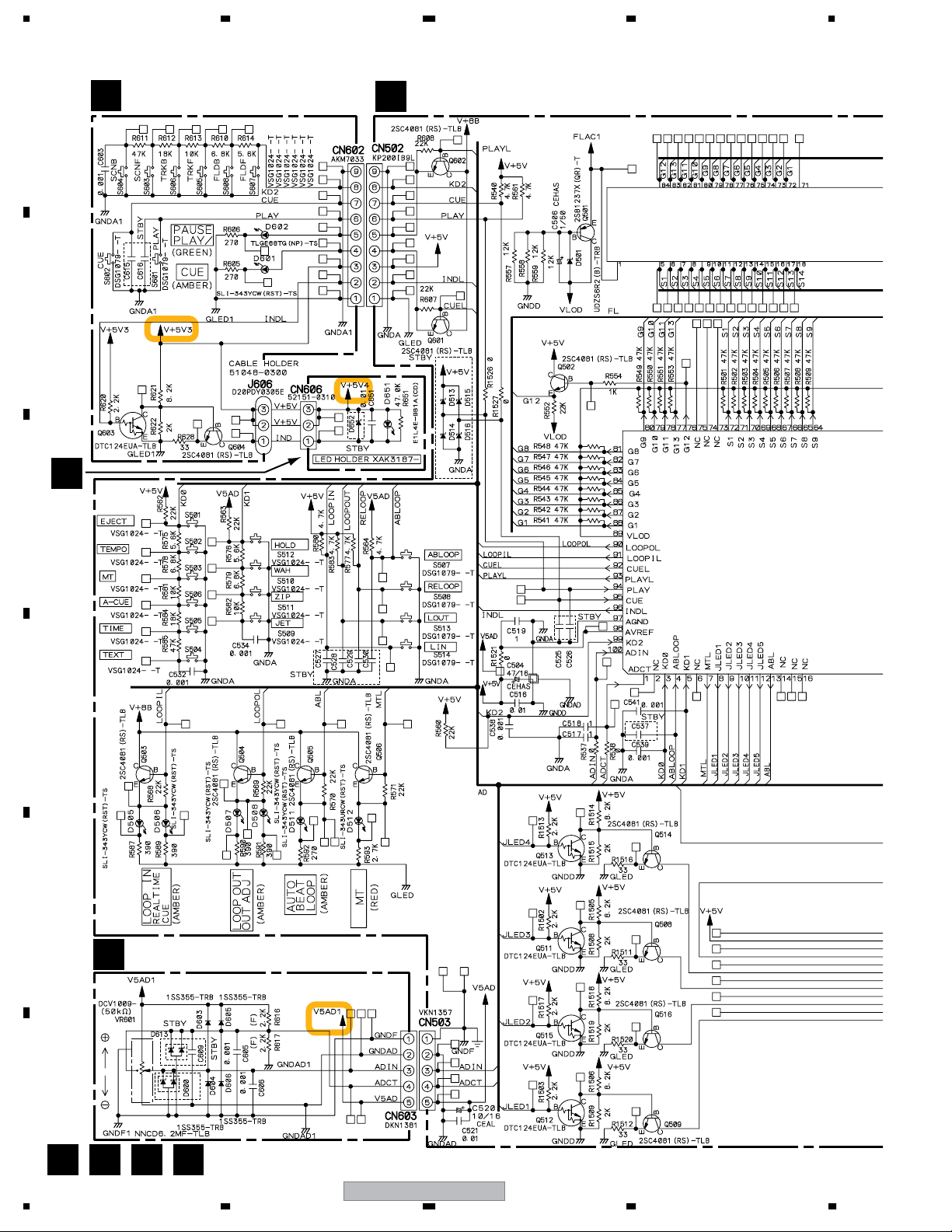

3.6 DISP, KSWB, INDB, SLDB, JLED and JOGB ASSYS

KSWB ASSY (DWS1356)

A

B

D

INDB ASSY (DWX2438)

DISP ASSY (DWG1588)

C

E

C

D

E

SLDB ASSY (DWX2430)

F

F

C D E F

24

1234

CDJ-200

Loading...

Loading...