Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2003

CDJ-1000MK2

COMPACT DISC PLAYER

CDJ-1000MK2

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

CDJ-1000MK2 KUCXJ AC120V

CDJ-1000MK2 TLXJ AC110- 240V

CDJ-1000MK2 WYXJ AC220- 240V

ORDER NO.

RRV2802

For details, refer to "Important symbols for good services"

T-ZZY JULY 2003 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement par ts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

C

Health & Safety Code Section 25249.6 – Proposition 65

(FOR USA MODEL ONLY)

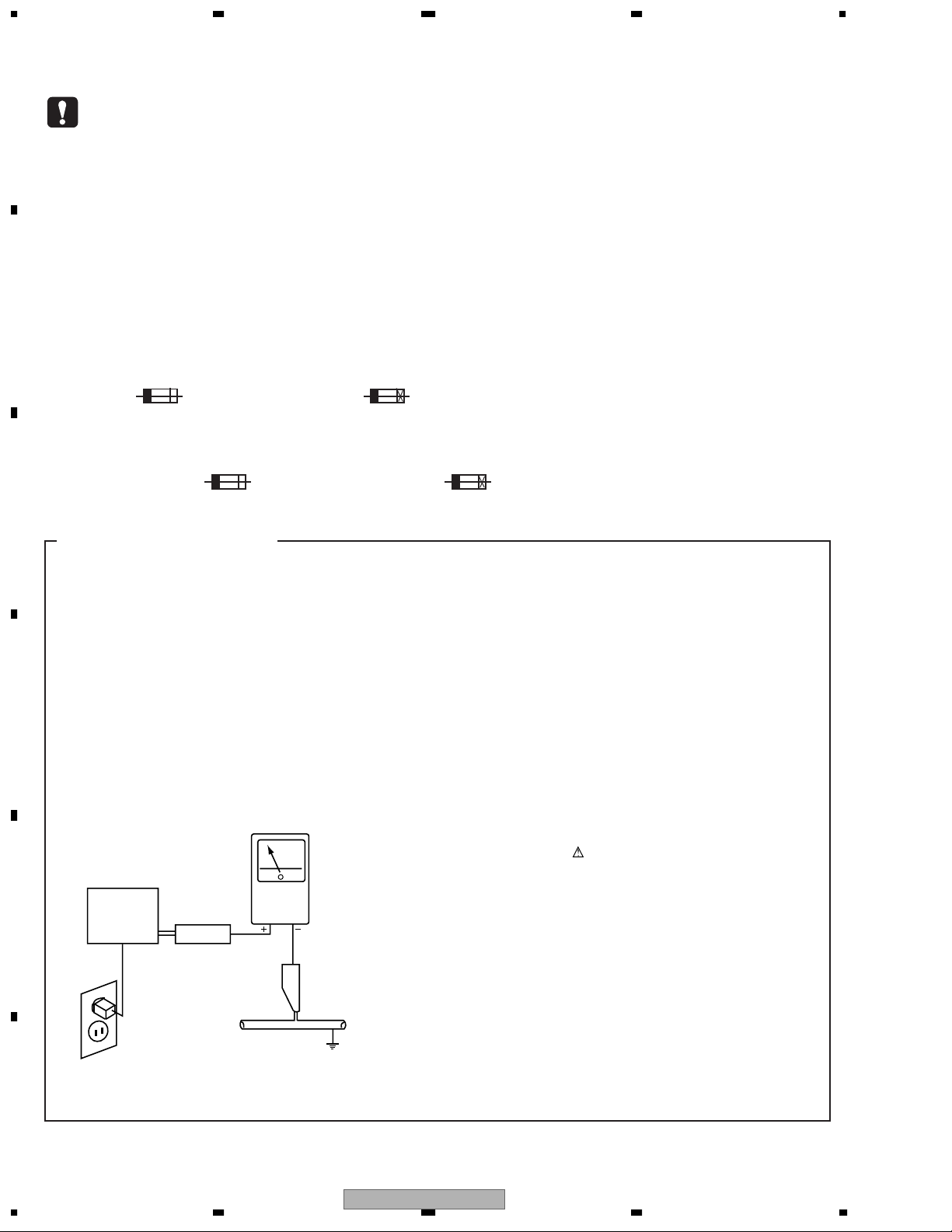

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

D

E

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

F

2

1234

CDJ-1000MK2

Page 3

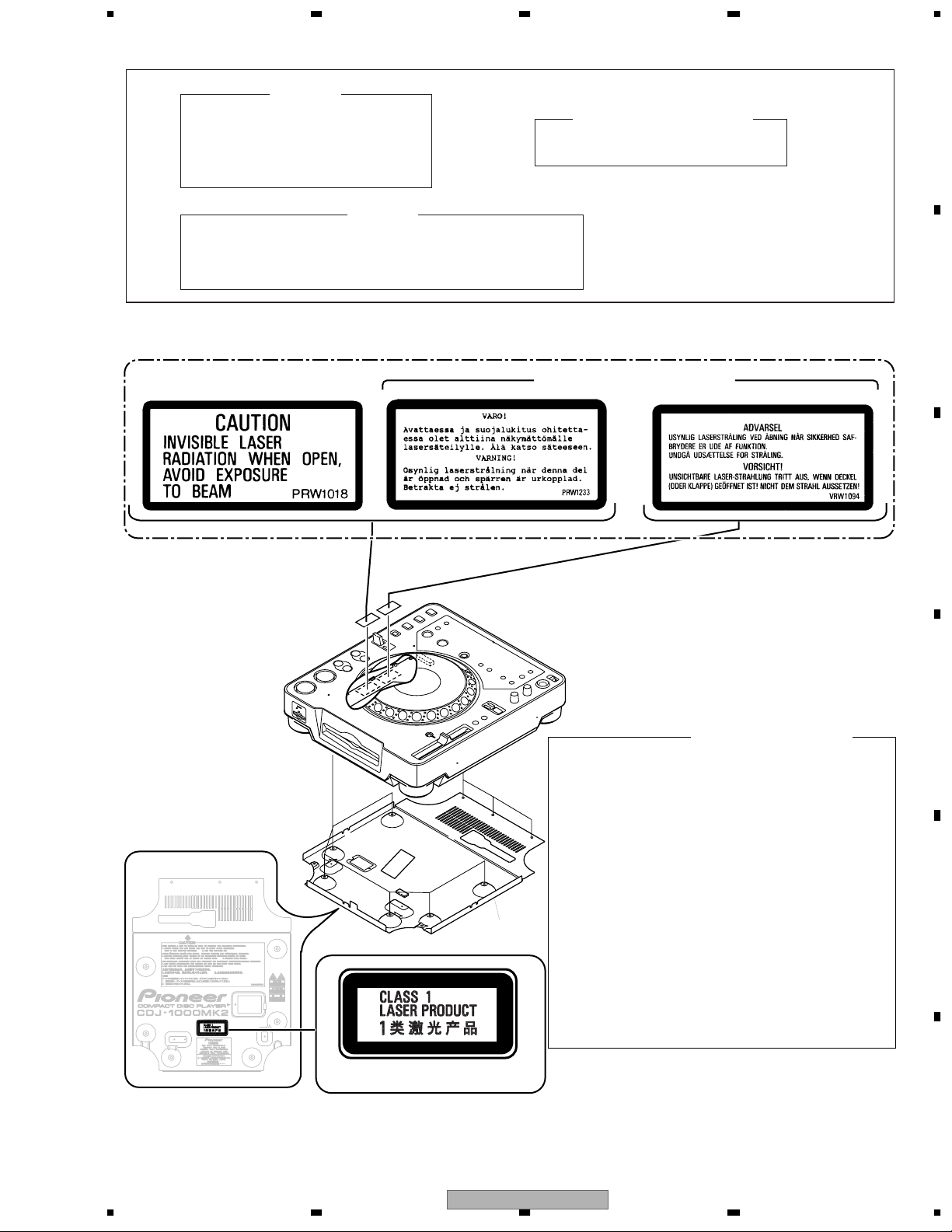

5678

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 780 – 785 nm

WARNING !

The AEL(accessible emission level) of the laser power output is less then CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should servicing operation of the apparatus.

LABEL CHECK

CDJ-1000MK2/ WYXJ Type OnlyCDJ-1000MK2/ TLXJ Type Only

Printed on the Bottom Plate 2.

Bottom Plate 2

∗ : Refer to page 68.

1. Laser Interlock Mechanism

The position of the switch (S510) for detecting loading

completion is detected by the system microprocessor,

and the design prevents laser diode oscillation when the

switch is not in LPS1 terminal side (when the mechanism

is not clamped and LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side. ( if LPS1 signal is

low level ).

In the test mode* the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 4 of AN8702NFH

(IC800) on the MAIN ASSY is connected to GND, or else

the terminals of Q600 are shorted to each other (fault

condition).

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

Additional Laser Caution

A

B

C

D

E

F

56

CDJ-1000MK2

7

8

3

Page 4

1234

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

A

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

B

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

C

D

E

F

4

1234

CDJ-1000MK2

Page 5

5678

CONTENTS

1. SPECIFICATIONS.............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST.............................................................................................................7

2.1 PACKING ....................................................................................................................................................7

2.2 EXTERIOR SECTION (1/2)........................................................................................................................8

2.3 EXTERIOR SECTION (2/2)......................................................................................................................10

2.4 SLOT-IN MECHANISM SECTION ............................................................................................................12

2.5 TRAVERSE MECHANISM ASSY-S ..........................................................................................................13

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................14

3.1 BLOCK DIAGRAM....................................................................................................................................14

3.2 OVERALL WIRING DIAGRAM .................................................................................................................16

3.3 MAIN (1/4) and SPCN ASSYS .................................................................................................................18

3.4 MAIN (2/4), FLRB and SLMB ASSYS ......................................................................................................20

3.5 MAIN (3/4) and MMCB ASSYS ................................................................................................................22

3.6 MAIN ASSY (4/4)......................................................................................................................................24

3.7 DABB, JACB and DOUT ASSYS..............................................................................................................26

3.8 MFLB (1/2) and RSWB ASSYS................................................................................................................28

3.9 MFLB (2/2) ASSY .....................................................................................................................................30

3.10 KSWB and SLDB ASSYS.......................................................................................................................31

3.11 JFLB and JOGB ASSYS.........................................................................................................................32

3.12 SW POWER SUPPLY and PSWB ASSYS .............................................................................................34

4. PCB CONNECTION DIAGRAM ......................................................................................................................42

4.1 MAIN ASSY ..............................................................................................................................................42

4.2 SPCN, STCN, FLRB, SLMB and MMCB ASSYS.....................................................................................46

4.3 DABB, JACB and DOUT ASSYS..............................................................................................................48

4.4 MFLB and RSWB ASSYS ........................................................................................................................50

4.5 KSWB ASSY.............................................................................................................................................54

4.6 SLDB ASSY..............................................................................................................................................55

4.7 JFLB and JOGB ASSYS...........................................................................................................................56

4.8 SW POWER SUPPLY and PSWB ASSYS ...............................................................................................58

5. PCB PARTS LIST............................................................................................................................................59

6. ADJUSTMENT ................................................................................................................................................64

7. GENERAL INFORMATION .............................................................................................................................65

7.1 DIAGNOSIS..............................................................................................................................................65

7.1.1 SERVICE MODE................................................................................................................................65

7.1.2 DISASSEMBLY ..................................................................................................................................75

7.1.3 On Discharge of the Capacitor...........................................................................................................80

7.1.4 CLEANING.........................................................................................................................................80

7.1.5 POWER ON SEQUENCE ..................................................................................................................81

7.2 PARTS ......................................................................................................................................................84

7.2.1 IC........................................................................................................................................................84

8. PANEL FACILITIES .........................................................................................................................................93

A

B

C

D

56

CDJ-1000MK2

E

F

7

8

5

Page 6

1234

1. SPECIFICATIONS

CDJ-1000MK2/ KUCXJ type

1. General

A

System ................................................................. Compact disc digital audio system

Power requirements ........................................................................... AC 120 V, 60 Hz

Power consumption ............................................................................................ 33 W

Operating temperature ...................................................................... +5 ˚C – +35 ˚C

Operating humidity .....................................................................................5% – 85%

(There should be no condensation of moisture.)

Weight ................................................................................................ 4.2 kg (9.26 lb)

Dimensions ........................................................

12 – 5/8 (W) x 14 – 9/16 (D) x – 1/8 (H) in

2. Audio section

Frequency response .............................................................................. 4 Hz – 20 kHz

B

Signal-to-noise ratio ............................................................ 115 dB or more (JEITA)

Distortion ............................................................................................ 0.006% (JEITA)

CDJ-1000MK2/ TLXJ type

1. General

System ................................................................. Compact disc digital audio system

Power requirements ............................................................ AC 110–240 V, 50/60 Hz

Power consumption ............................................................................................ 31 W

Operating temperature ........................................................................ +5˚C – +35˚C

Operating humidity .....................................................................................5% – 85%

(There should be no condensation of moisture.)

C

Weight ................................................................................................................ 4.2 kg

Dimensions ........................................................ 320 (W) x 370 (D) x 105 (H) mm

2. Audio section

Frequency response .............................................................................. 4 Hz – 20 kHz

Signal-to-noise ratio ............................................................ 115 dB or more (JEITA)

Distortion ............................................................................................0.006% (JEITA)

320 (W) x 370 (D) x 105 (H) mm

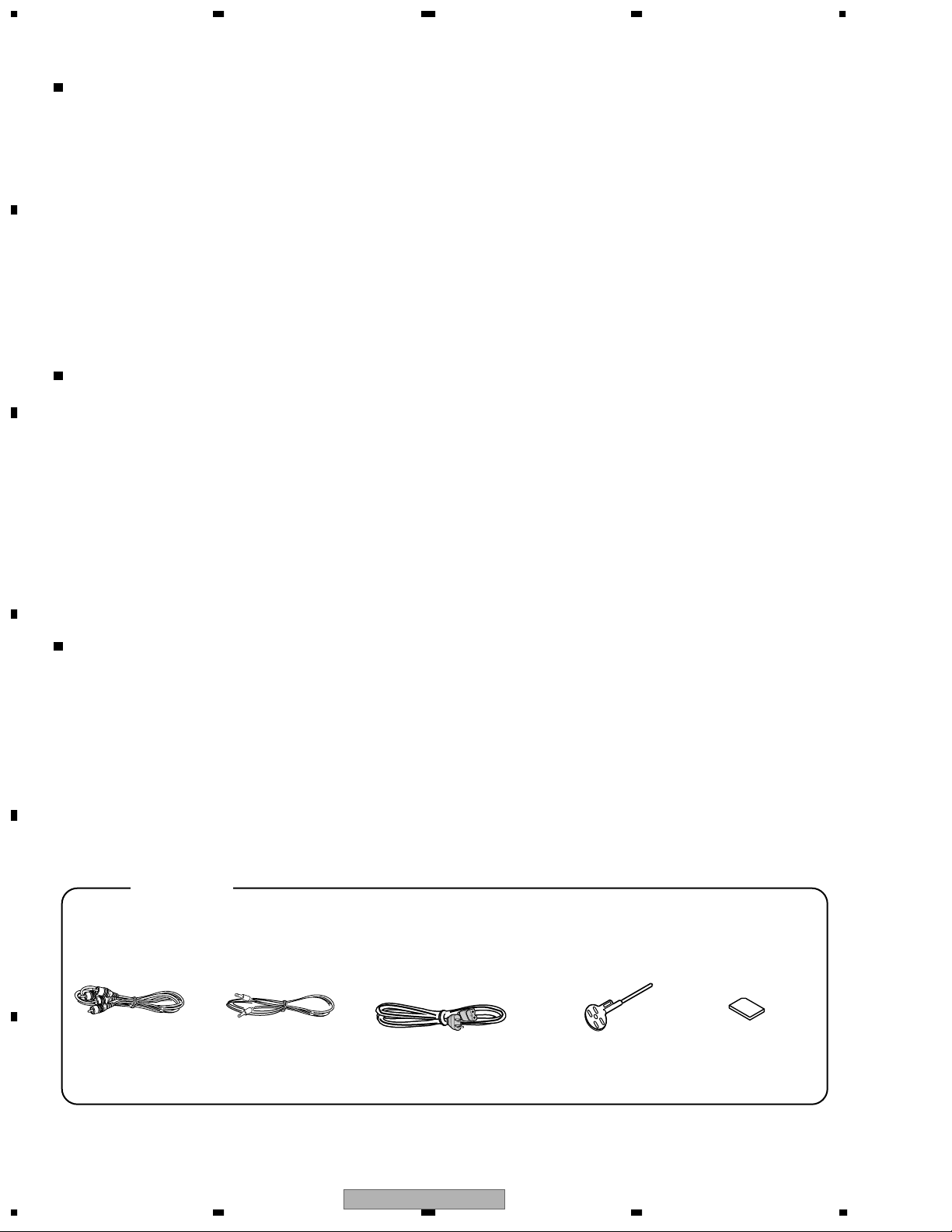

3. Accessories

Operating instructions ........................................................................................ 1

Power cord ........................................................................................................... 1

Audio cable .......................................................................................................... 1

Control cord ........................................................................................................ 1

Forced eject pin (housed in a groove in the bottom panel) ............................ 1

Multimedia Card (MMC) (16 MB) .................................................................... 1

Limited warranty ................................................................................................. 1

NOTE:

Specifications and design are subject to possible modification without notice.

3. Accessories

Operating instructions ........................................................................................ 1

Power cord ........................................................................................................... 1

Audio cable .......................................................................................................... 1

Control cord ........................................................................................................ 1

Forced eject pin (housed in a groove in the bottom panel) ............................ 1

Multimedia Card (MMC) (16 MB) .................................................................... 1

NOTE:

Specifications and design are subject to possible modification without notice.

CDJ-1000MK2/ WYXJ type

1. General

System ................................................................. Compact disc digital audio system

Power requirements ...............................................................AC 220-240V, 50/60 Hz

Power consumption ............................................................................................ 31 W

D

Operating temperature ........................................................................ +5˚C – +35˚C

Operating humidity .....................................................................................5% – 85%

(There should be no condensation of moisture.)

Weight ................................................................................................................ 4.2 kg

Dimensions ........................................................ 320 (W) x 370 (D) x 105 (H) mm

2. Audio section

Frequency response .............................................................................. 4 Hz – 20 kHz

Signal-to-noise ratio ............................................................ 115 dB or more (JEITA)

Distortion ............................................................................................ 0.006% (JEITA)

Accessories

E

Audio Cable

(VDE1064) L=1.5m

Control Cord

(PDE-319) L=1 m

3. Accessories

Operating instructions ........................................................................................ 1

Power cord ........................................................................................................... 1

Audio cable .......................................................................................................... 1

Control cord ........................................................................................................ 1

Forced eject pin (housed in a groove in the bottom panel) ............................ 1

Multimedia Card (MMC) (16 MB) .................................................................... 1

NOTE:

Specifications and design are subject to possible modification without notice.

Power Cord

(KUCXJ type : ADG7021

(TLXJ, WYXJ type: ADG1154)

Forced Eject Pin

(DEX1013)

MMC Memory Card

(DWX2326)

F

6

1234

CDJ-1000MK2

Page 7

2

7

11

10

9

13

8

12

15

14

4

6

5

1

3

5678

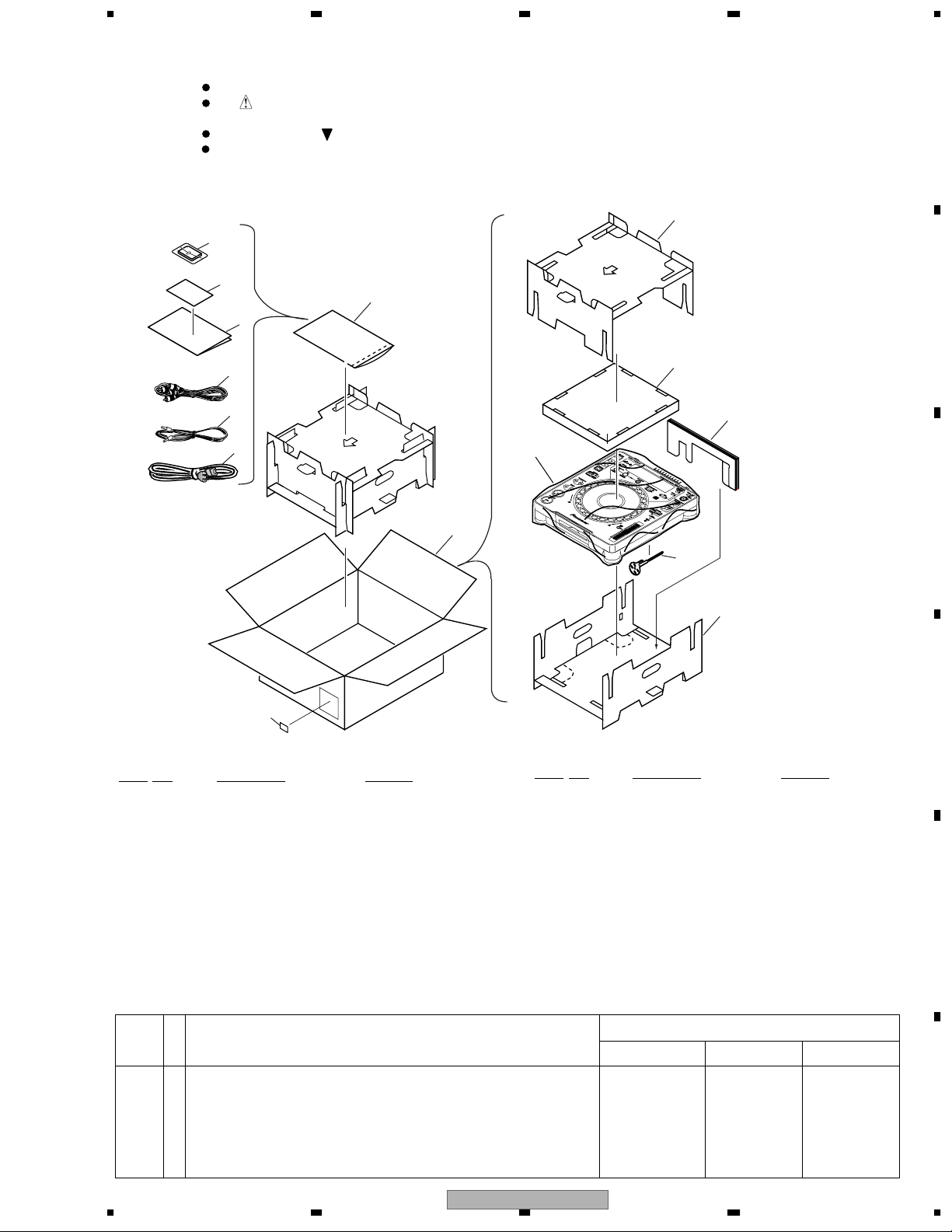

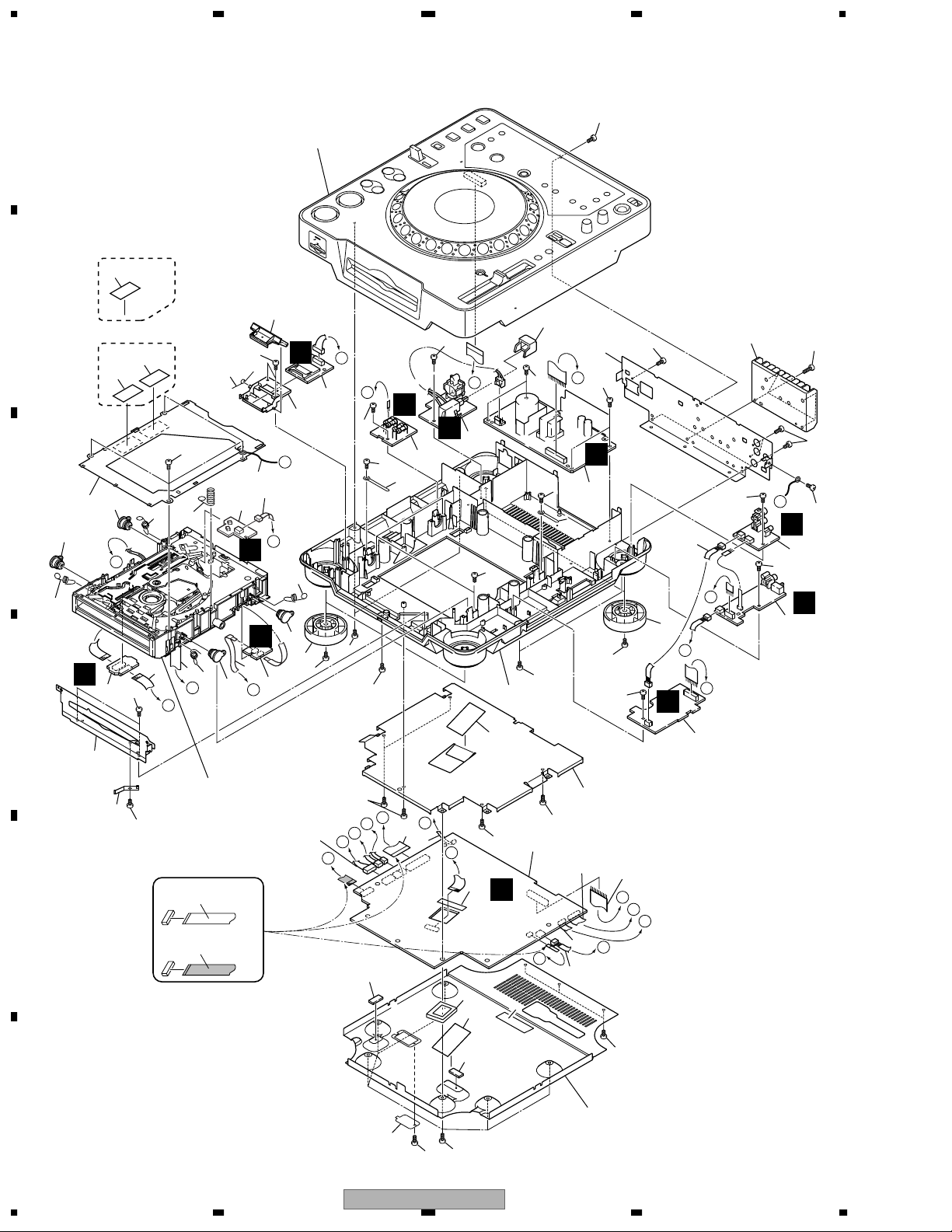

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

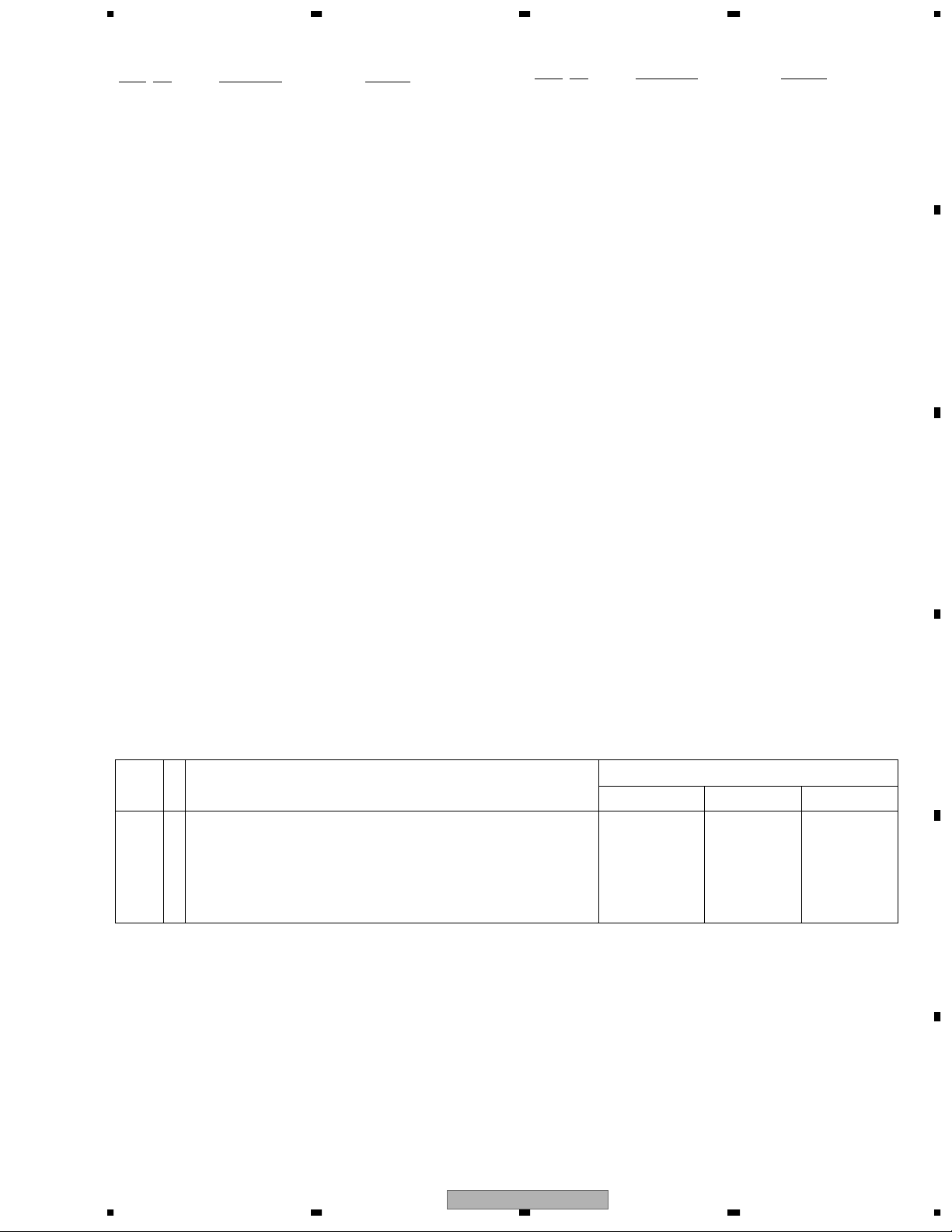

2.1 PACKING

A

B

C

PACKING Parts List

Mark

Mark

No. Description Part No.

1 Power Cord See Contrast Table(2)

>

NSP 2 Warranty Card See Contrast Table(2)

3 Forced Eject Pin DEX1013

4 Operating Instructions See Contrast Table(2)

5 Control Cord (L= 1m) PDE-319

6 Audio Cable (L= 1.5m) VDE1064

NSP 7 Polyethylene Bag Z21-038

(230 x 340 x 0.03)

No. Description Part No.

8 Pad (A) DHA1533

9 Pad (B) DHA1534

10 Pad (C) DHA1535

11 Pad (D) DHA1536

12 Packing Case See Contrast Table(2)

13 Sheet RHX1006

NSP 15 Label VRW1629

14 MMC Memory Card DWX2326

(2) CONTRAST TABLE

CDJ-1000MK2/KUCXJ, TLXJ and WYXJ types are constructed the same except for the following:

Mark No. Symbol and Description

> 1 Power Cord ADG7021 ADG1154 ADG1154

NSP 2 Warranty Card ARY7043 Not used Not used

4 Operating Instructions (English) DRB1339 Not used Not used

4 Operating Instructions (English, Spanish, Chinese) Not used DRB1340 Not used

4 Operating Instructions (English, French, German, Italian, Dutch, Spanish) Not used Not used DRB1338

12 Packing Case DHG2363 DHG2364 DHG2362

KUCXJ type TLXJ type WYXJ type

Part No.

D

E

F

56

CDJ-1000MK2

7

8

7

Page 8

1234

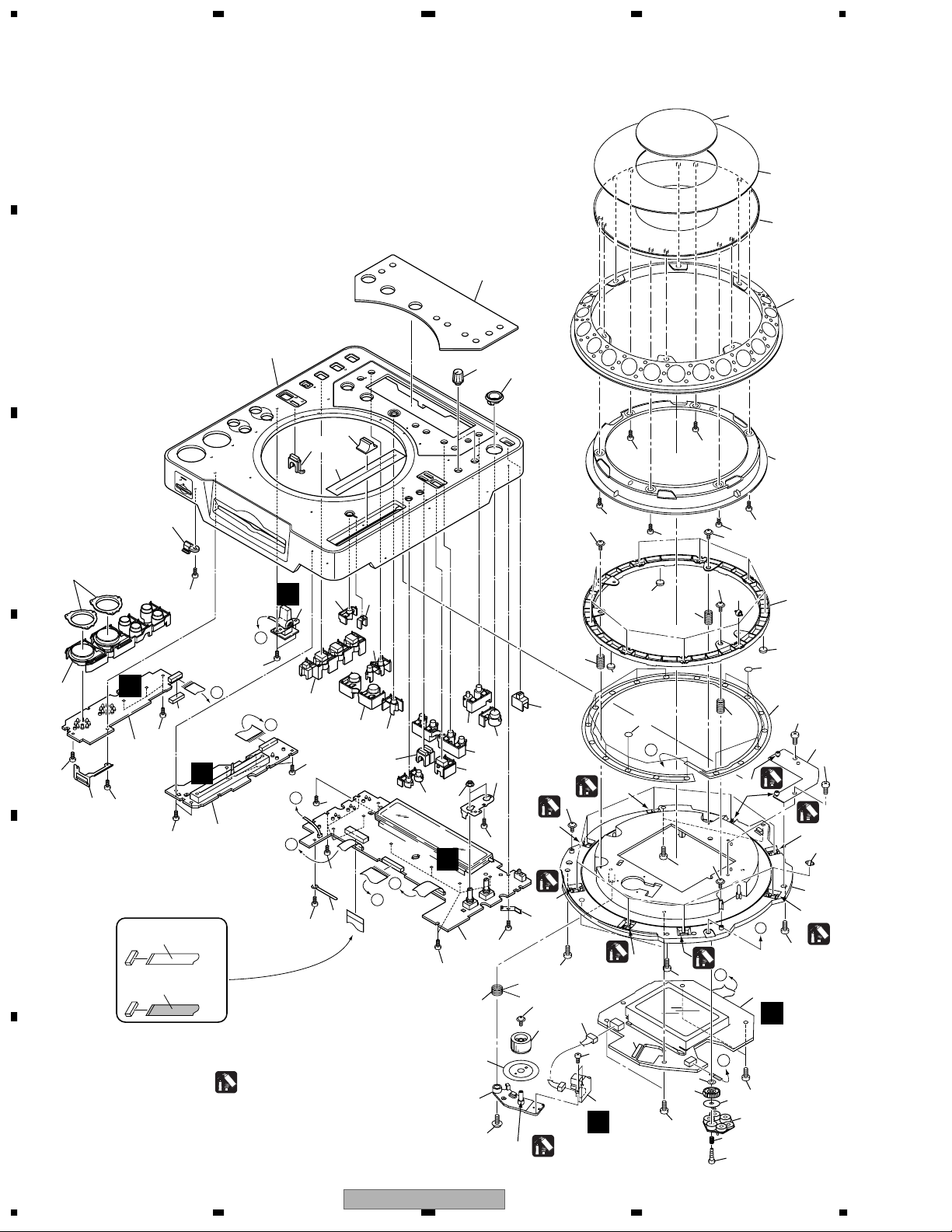

2.2 EXTERIOR SECTION (1/2)

A

TLXJ Type Only

51

B

WYXJ Type Only

46

50

44

C

33

25

33

B

3

D

31

25

K

13

47

L

Refer to

"2.3 Exterior (2/2) section".

40

47

39

47

15

23

26

5

J

E

C

33

14

4

F

18

25

G

30

10

Q

47

55

55

47

47

27

36

I

6

F

A

H

2

38

M

25

33

37

47

47

47

47

47

D

32

55

55

56

56

48

28

C

47

47

29

49

47

P

11

47

M

48

H

47

47

17

E

37

B

D

G

7

8

47

I

9

Refer to

" 2.4 Slot -IN Mechanism section".

34

48

NON-CONTACT

SIDE

E

CONTACT SIDE

F

24

8

1234

47

I

45

12

19

H

47

1

A

F

415352

48

G

53

54

43

41

48

K

J

A

L

41

CDJ-1000MK2

47

16

21

20

35

42

22

C

D

E

B

48

Page 9

5678

EXTERIOR SECTION (1/2) Parts List

Mar

k No. Description Part No.

1 MAIN Assy DWX2303

2 MMCB Assy DWX2304

3 SPCN Assy DWX2170

4 STCN Assy DWX2171

5 SLMB Assy DWX1309

6 PSWB Assy

7 DABB Assy DWX2305

8 JACB Assy DWX2306

9 DOUT Assy DWX2307

10 FLRB Assy DWX2308

11 SW POWER SUPPLY Assy DWR1370

12 25P Flexible Cable/60V DDD1196

13 12P Flexible Cable/60V DDD1197

14 4P Flexible Cable/60V DDD1198

15 Earth Lead Unit/300V DDF1024

16 Connector Assy 3P DKP3562

17 Connector Assy 6P DKP3654

18 FPC D5 Slot DNP1948

19 Jumper Wire 03P D20PYY0310E

20 Jumper Wire 05P D20PYY0510E

21 Jumper Wire 09P D20PYY0910E

22 Jumper Wire 15P D20PYY1510E

23 Connector Assy PF03PP-B30

24 Connector Assy PF09PP-D15

25 Float Spring (G5) DBH1494

26 Earth Spring DBH1398

27 Chassis DNK3869

NSP 28 Rear Panel

29 Heat Sink DNG1082

See Contrast Table(2)

See Contrast Table(2)

Mar

k No. Description Part No.

30 Power Knob DAC1895

31 Front Plate DNH2480

32 Cord Clamper RNH-184

33 Damper CNV6011

34 Earth Plate (CU) VBK1070

35 Shield Case DNH2481

36 Shield Cushion DEC2445

37 Insulator Assy DXA1904

38 Memory Holder DNK3884

39 Flap Spring DBH1487

40 SD Flap DNK3883

NSP 41 Silicone Rubber D5L DEB1456

42 Bottom Plate 2 DNH2558

43 Bottom Cushion DEC2444

44 Mecha Plate DNH2339

45 Bottom Cover DNH2559

46 Caution Label

47 Screw BPZ30P080FZK

48 Screw BBZ30P060FZK

49 Screw BBZ30P120FZK

50 Caution Label HE

51 Caution Label See Contrast Table(2)

52 65 Label See Contrast Table(2)

53 Protect Sheet DEC2559

54 PU Packing DEC2593

55 Screw SBPZ30P140FMC

56 Cord Clamper ZCB-069Z

See Contrast Table(2)

See Contrast Table(2)

A

B

C

(2) CONTRAST TABLE

CDJ-1000MK2/KUCXJ, TLXJ and WYXJ types are constructed the same except for the following:

Mark No. Symbol and Description

KUCXJ type TLXJ type WYXJ type

6 PSWB Assy DWS1312 DWS1311 DWS1311

NSP 28 Rear Panel DNC1647 DNC1648 DNC1646

46 Caution Label Not used Not used VRW1094

50 Caution Label HE Not used Not used PRW1233

51 Caution Label Not used PRW 1018 Not used

52 65 Label ARW7050 Not used Not used

Part No.

D

E

F

56

CDJ-1000MK2

7

8

9

Page 10

1234

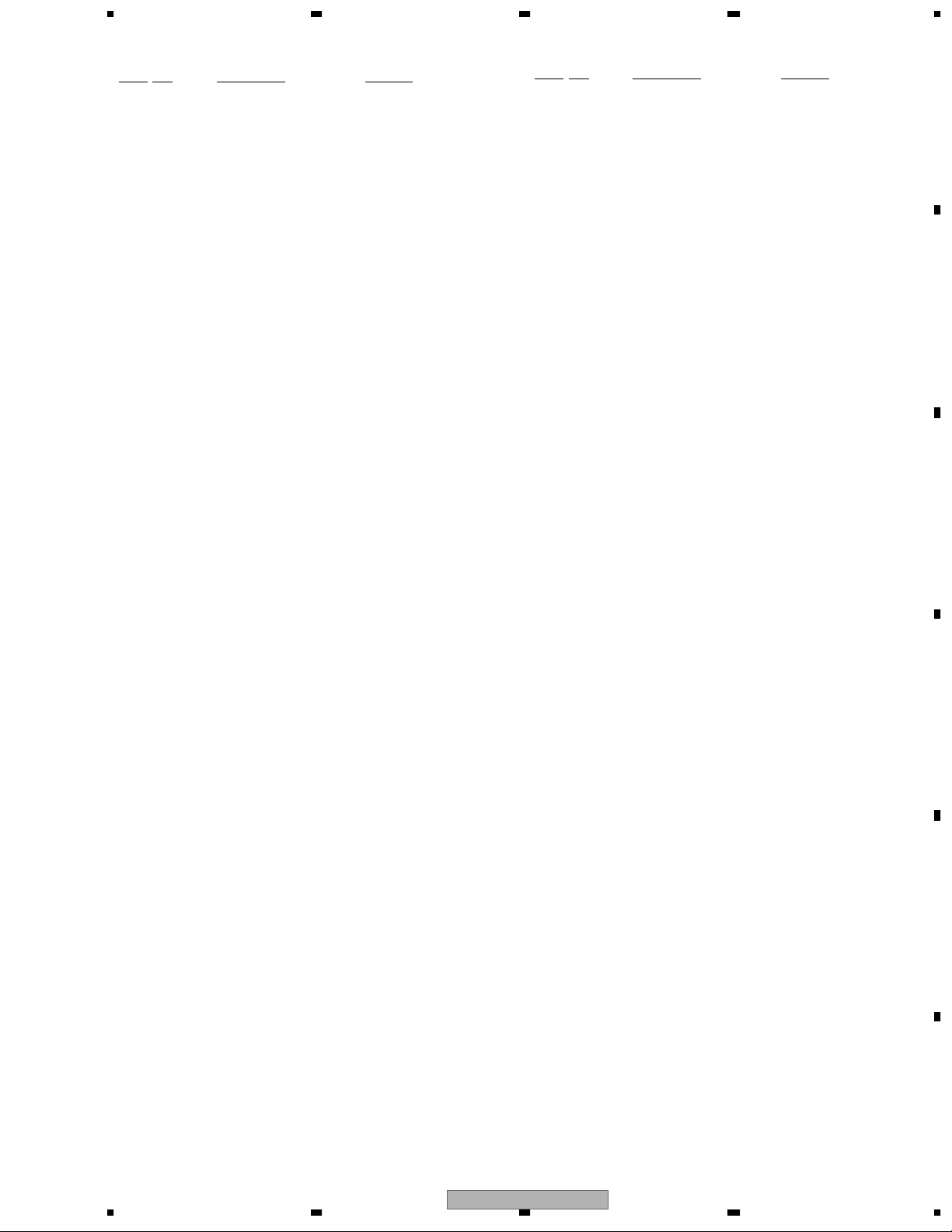

2.3 EXTERIOR SECTION (2/2)

A

42

B

20

43

25 (2/2)

41

C

22

44

21

10

10

10

10

10

10

17

10

16

56

57

58

10

23

45

40

45

L

C

66

45

2

M

45

3

24

D

45

K

E

45

D

30

45

31

29

27

28

25 (1/2)

32

19

36

33

34

45

18

35

48

37

64

1

*

4

26

45

E

C

5252

52

50

F

1

*

J

45

E

F

NON-CONTACT

SIDE

CONTACT SIDE

1.

Grease: GYA1001 (ZLB-PN397B)

*

45

39

D

B

1

45

45

47

11

53

64

1

*

38

1

*

51

65

6

10

54

45

7

O

1

*

45

48

45

45

59

67

64

10

63

48

*

1

*

B

55

52

50

14

45

13

45

1

1

*

63

12

1

*

A

45

5

N

F

45

45

60

61

49

62

10

1234

CDJ-1000MK2

Page 11

5678

EXTERIOR SECTION (2/2) Parts List

Mark

No. Description Part No.

1 MFLB Assy DWG1567

2 KSWB Assy DWS1324

3 SLDB Assy DWS1325

4 RSWB Assy DWS1310

5 JFLB Assy DWG1568

Mark

No. Description Part No.

51 Spacer DEC2554

52 Ring Cushion DEC2604

53 Gear Arm DNK4065

54 D Gear DNK4066

55 SW Ring DNK4070

A

6 JOGB Assy DWG1569

7 Connector Assy PF04PP-B07

8• • • • •

9• • • • •

10 Screw PBA1062

11 Encoder Plate DEC2498

12 JOG Holder 2 DNK4175

13 JOG Stay Assy DXB1780

14 Sheet SW DSX1060

15 • • • • •

16 JOG Plate DAH2052

17 JOG Panel DAH2182

18 VR Stay DNF1663

19 Flange Nut (M9) DBN1004

20 Control Panel DNK4180

21 Eject Guard DNK3958

22 Card Lens DNK3885

23 Ring Lens DNK3880

24 Set Knob (PLAY) Assy DXB1762

25 Mode Lens DNK3881

26 Set Knob (HS) DAC1986

27 Set Knob (LOOP) DAC1995

28 Re-loop Knob DAC1992

29 Set Knob (TIME) DAC1991

30 Tempo Reset Knob DAC1993

31 Tempo Lens DNK3882

32 Set Knob (MT) DAC1987

33 Mode Select Knob DAC1989

34 Set Knob (SC) DAC1988

35 Eject Knob DAC1990

56 JOG A DNK4172

57 JOG B DNK4173

58 JOG C DNK4174

59 Gear DNK4176

60 Smoother DNK4177

61 ADJ Plate DNK4178

62 Screw BPZ20P100FMC

63 Roller A Assy DXB1773

64 Screw IPZ30P100FMC

65 Screw BPZ20P060FMC

66 FFC Guard DEC2586

67 Washer WA42D080D050

B

C

D

36 Set Knob (MEMO) DAC1994

37 Slide SW Knob DAC1926

38 Earth Plate (CU) VBK1070

NSP 39 Cord Clamper ZCB-069Z

40 Card Plate DBK1212

41 Slide Sheet 1C DAH1988

42 Display Panel DAH2022

43 Slide Knob DNK2936

44 Rotary Knob C DAA1143

45 Screw BPZ30P080FZK

46 • • • • •

47 Arm Spring DBH1503

48 SW Spring 25 DBH1514

49 Gear Spring 200 DBH1525

50 SW Cushion HH48/2 DEC2538

56

CDJ-1000MK2

E

F

7

8

11

Page 12

1234

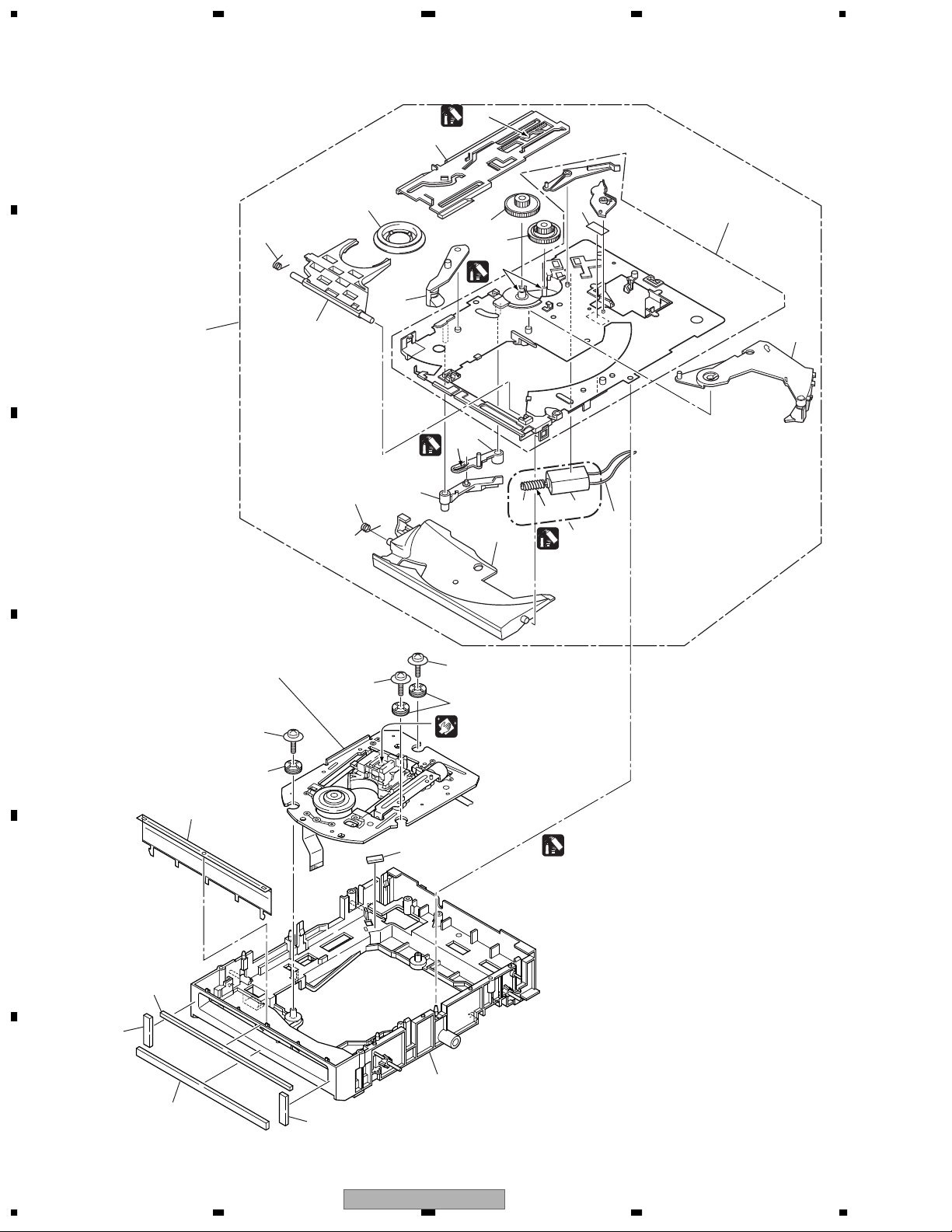

2.4 SLOT-IN MECHANISM SECTION

A

7

17

3

B

18

C

10

6

4

8

3

*

5

15

14

3

*

9

2

*

13

16

1

3

*

2

29

11

12

Refer to " 2.5 TRAVERSE MECHANISM ASSY-S ".

D

27

E

22

21

26

25

19

26

28

26

25

Cleaning liquid (GEM1004)

Cleaning paper (GED-008)

*

*

20

Dyefree : GEM1036 (ZLX-ME413A)

2.

Grease: GYA1001 (ZLB-PN397B)

3.

F

12

1234

23

21

CDJ-1000MK2

Page 13

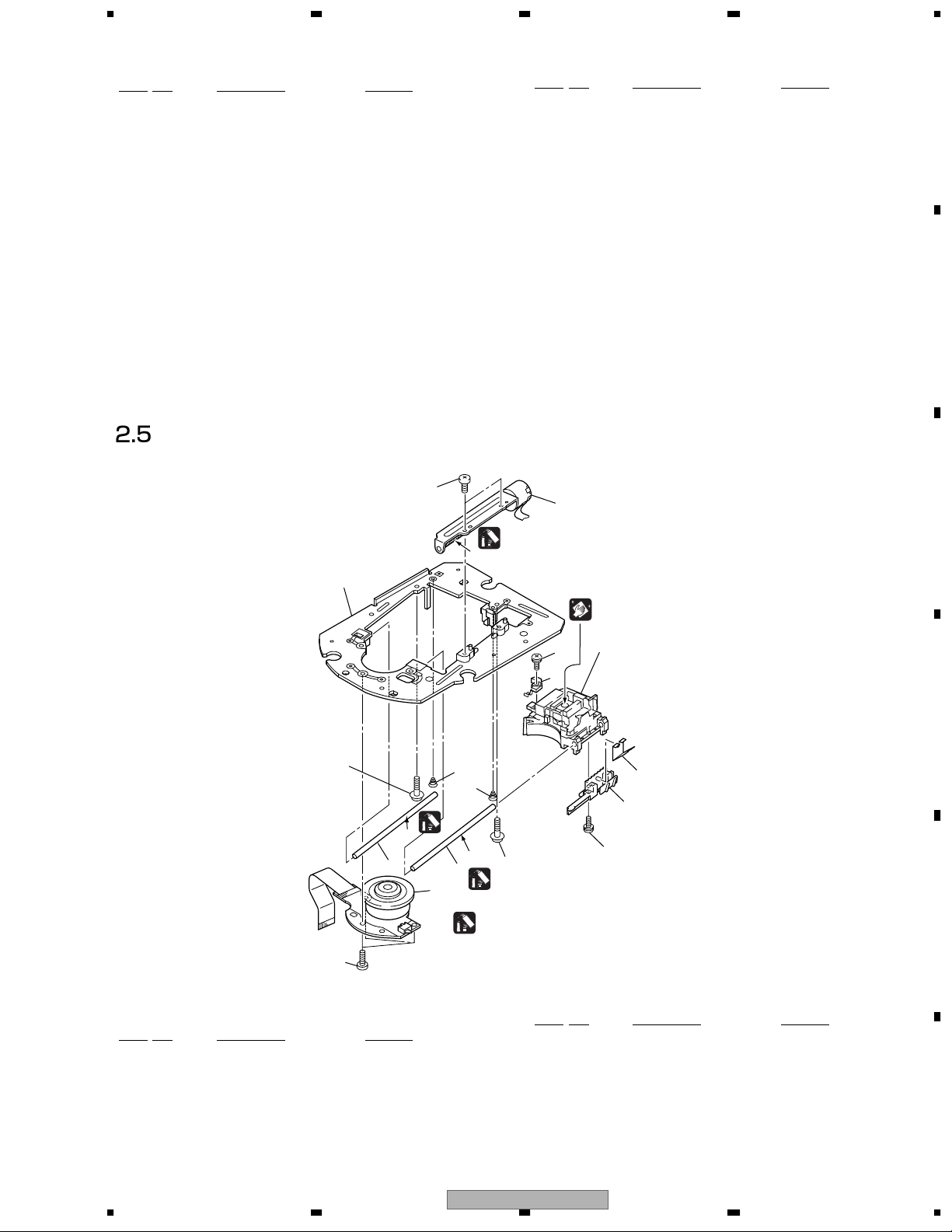

12

10

2

5

7

3

9

11

5

4

6

8

1

13

8

6

4

*

5

*

4

Grease: GYA1001 (ZLB-PN397B)

*

4.

Grease: GEM1007 (ZLB-PN948P)

*

5.

*

4

Cleaning liquid (GEM1004)

Cleaning paper (GED-008)

5678

SLOT-IN MECHANISM SECTION Parts List

Mark

No. Description Part No.

NSP 1 DC Motor DXM1093

2 Connector Assy PF02PY-B32

3 Clamp Spring DBH1374

4 Guide Spring DBH1375

5 SW Lever Spacer (PET) DEC2420

Mark

No. Description Part No.

16 Disc Guide DNK3914

17 Clamper D4 Assy DXA1881

NSP 18 Slot-in Mechanism G5 Assy DXA1906

19 Traverse Mechanism Assy-S DXX2502

20 Float Base (G5) Assy DXB1748

A

6 Loading Lever DNK3406

7 Main Cam DNK3407

8 Lever B DNK3558

9 Lever A DNK3564

10 Clamp Arm DNK3576

11 Loading Base Assy-S DEA1022

12 Eject Lever DNK3684

NSP 13 Worm Gear DNK3910

14 Loading Gear DNK3911

15 Drive Gear DNK3912

TRAVERSE MECHANISM ASSY-S

21 Vessel Cushion C DEC2457

22 Vessel Cushion A DEC2455

23 Vessel Cushion B DEC2456

24 • • • • •

25 Float Rubber D3 DEB1404

26 Float Fastener DBA1139

27 Front Sheet DED1132

28 Spacer POR (T3) DEB1566

29 Loading Motor Assy-S DEA1008

B

C

TRAVERSE MECHANISM ASSY-S Parts List

No. Description Part No.

Mark

NSP 1 Spindle Motor DXM1138

NSP 2 Stepping Motor DXM1142

NSP 3 Pickup Assy VWY1069

NSP 4 Adjust Screw DBA1119

NSP 5 Precision Screw DBA1124

NSP 6 Skew Spring DBH1437

56

Mark No. Description Part No.

NSP 7 Joint Spring DBK1188

NSP 8 Guide Shaft DLA1840

NSP 9 Slider G4 DNK3733

NSP 10 Mechanism Frame G5 DNK3776

NSP 11 Joint DNK3777

12 Screw BPZ20P080FMC

13 Screw BPZ26P080FMC

CDJ-1000MK2

D

E

F

7

8

13

Page 14

1234

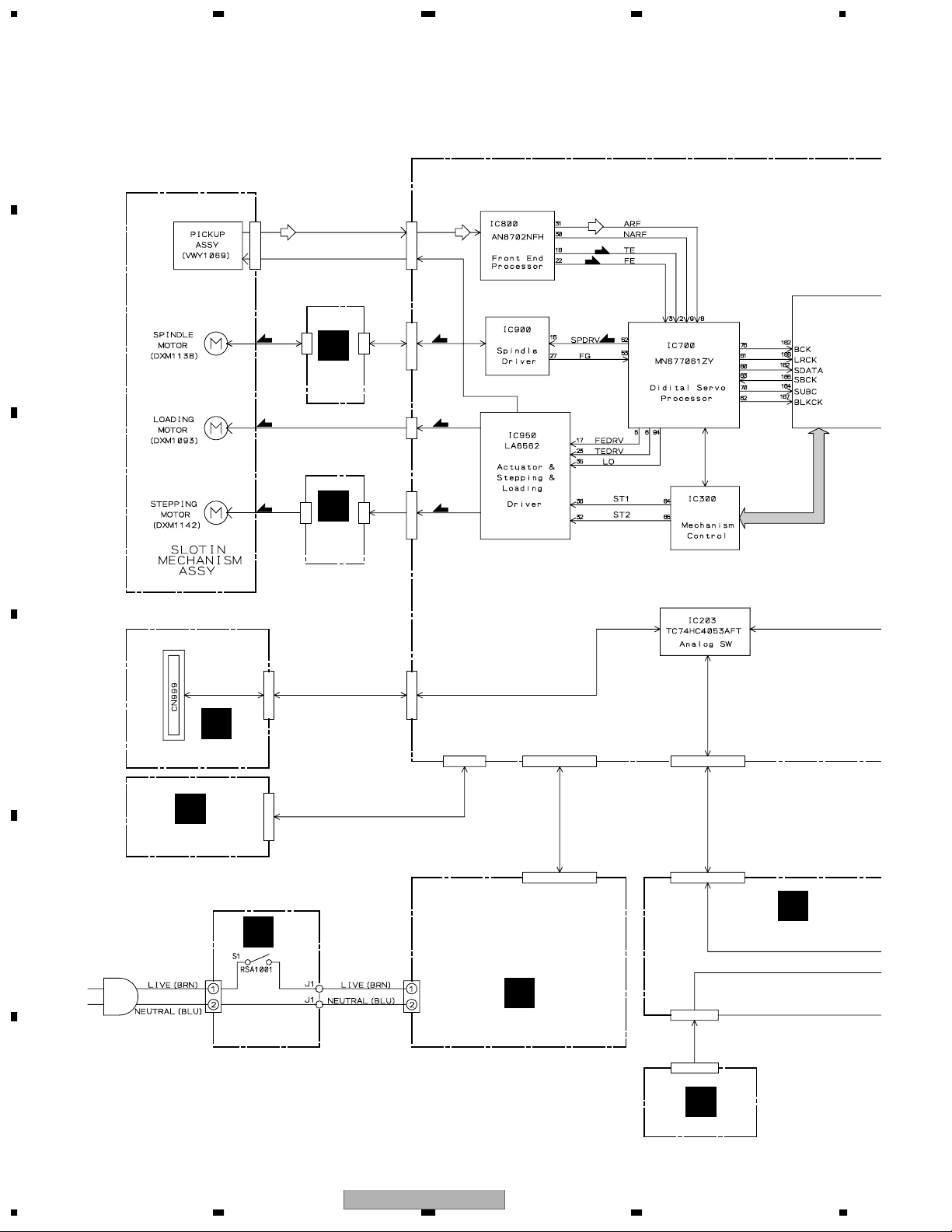

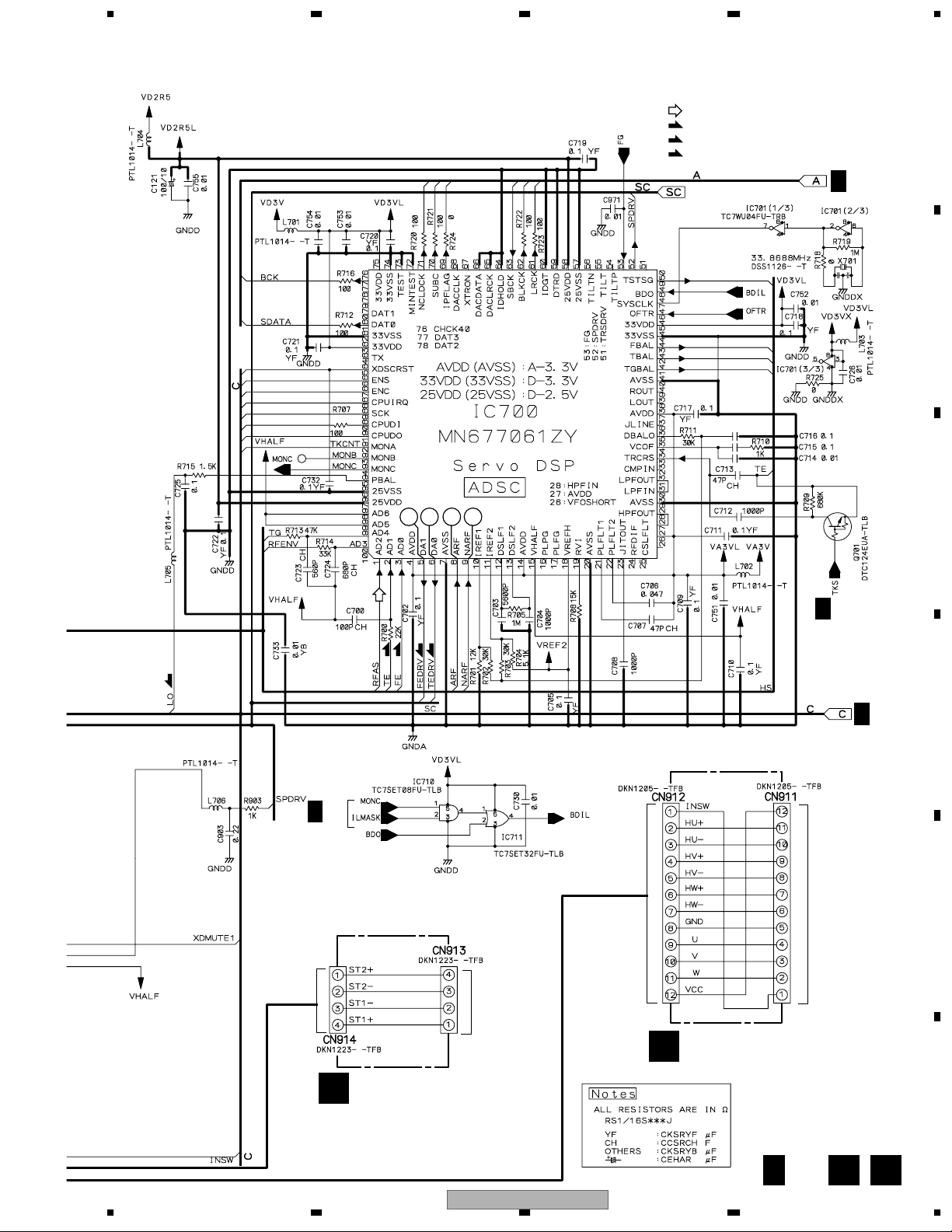

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

CN801

B

(RF)

CN911

(SM)

CN912

B

CN800

#

CN900

47

(RF)

LB11975

(RF)

(FS)

(TS)

(SM)(SM)

SPCN

ASSY

CN302

C

(LM)

CN914CN913

(CM)

C

CN950

(LM)

(CM)

PD3446AB

STCN

ASSY

CN202CN99

D

MMC CARD

CONNECTOR

F

MMCB ASSY

CN1501

CN102

CN101

CN203

D

FLRB ASSY

CN201 CN1101

E

Q

AN1

PSWB ASSY

F

CN101

P

SW POWER SUPPLY ASSY

J1701

J1701

K

RSWB ASSY

J

MFLB ASSY

14

1234

CDJ-1000MK2

Page 15

5678

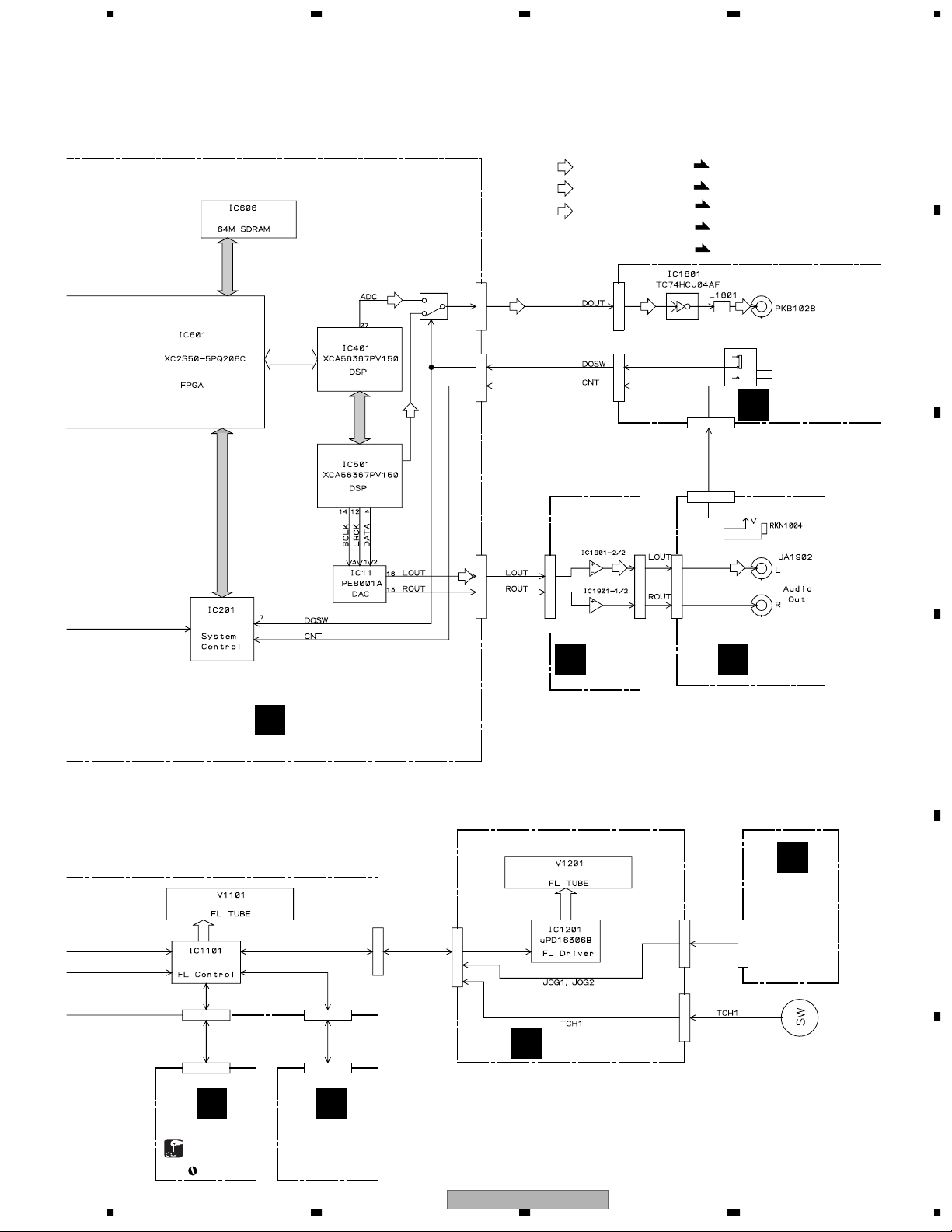

A

SIGNAL ROUTE

K4S641632F-TC75

IC605

TC7WT241FU

(D)

(D)

(D)

: DIGITAL SIGNAL

(PB)

: PB SIGNAL

(RF)

: RF SIGNAL

CN12

11

CN13

2

4

CN1801

(D)(D)

CN1802

2

4

(FS)

: FOCUS SERVO LOOP LINE

(TS)

: TRACKING SERVO LOOP LINE

(SM)

: SPINDLE MOTOR ROUTE

(CM)

: CARRIAGE MOTOR ROUTE

(LM)

: LOADING MOTOR ROUTE

JA1801

Digital Out

(D)

S1801

Digital Out Mode SW

DOUT ASSY

J1801

I

2

B

DJ/ NORMAL

PD3445A8

DEL1051

PE5387A

9

MAIN ASSY

A

J1101 J1103

CN1102

(PB)

J1202

5

6

7

CN11

4

1

4

1

(PB)

CN1901 CN1902

DABB

G

ASSY

DEL1050

161

CN1602

CN1201

6

CN1903

1

2

1

2

CN1904

(PB)

H

1

2

JA1901

Control Jack

BKB1017

JACB

ASSY

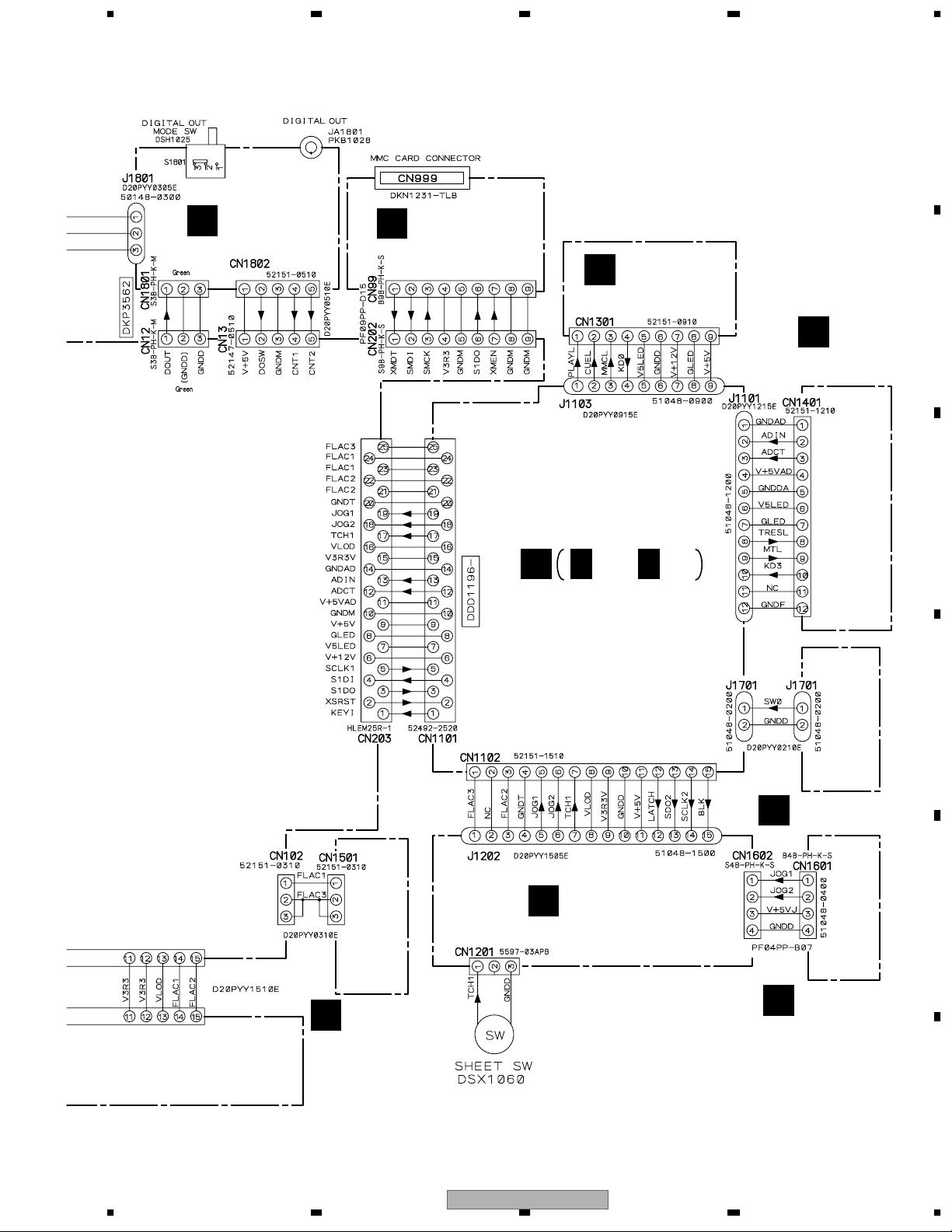

O

JOGB ASSY

CN1601

C

D

E

CN1401 CN1301

L

SLDB ASSYMKSWB ASSY

TEMPO

ZERO ADJ.

VR1402

56

JFLB ASSY

N

CDJ-1000MK2

SHEET SW

DSX1060

F

7

8

15

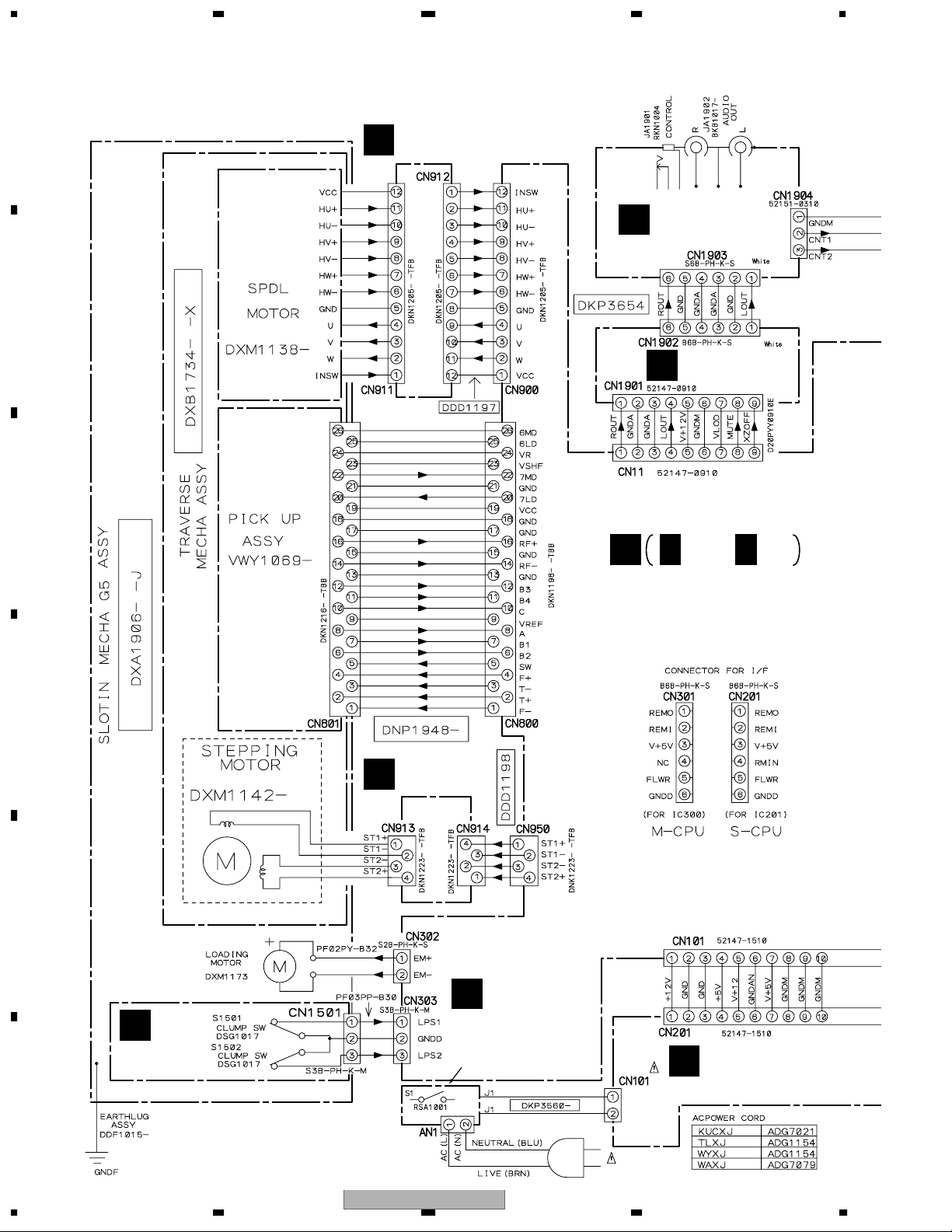

Page 16

1234

3.2 OVERALL WIRING DIAGRAM

A

B

SPCN ASSY

B

(DWX2170)

JACB ASSY

H

(DWX2306)

G

DABB ASSY

(DWX2305)

C

A

A 1/4 - A 4/4

MAIN ASSY

(DWX2303)

D

STCN ASSY

C

(DWX2171)

E

Q

E

SLMB ASSY

(DWS1309)

F

AN1

KUCXJ: AKP7032

TLXJ, WYXJ: BKP1046

16

1234

CDJ-1000MK2

PSWB ASSY

(KUCXJ : DWS1312)

(TLXJ, WYXJ

: DWS1311)

SW POWER

P

SUPPLY ASSY

(DWR1370)

Page 17

5678

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

DOUT ASSY

I

(DWX2307)

MMCB ASSY

F

(DWX2304)

KSWB ASSY

L

(DWS1324)

M

SLDB ASSY

(DWS1325)

A

B

C

FLRB ASSY

D

(DWX2308)

J

MFLB ASSY

(DWG1567)

J 1/2, J 2/2

JFLB ASSY

N

(DWG1568)

RSWB ASSY

K

(DWS1310)

JOGB ASSY

O

(DWG1569)

D

E

56

CDJ-1000MK2

F

7

8

17

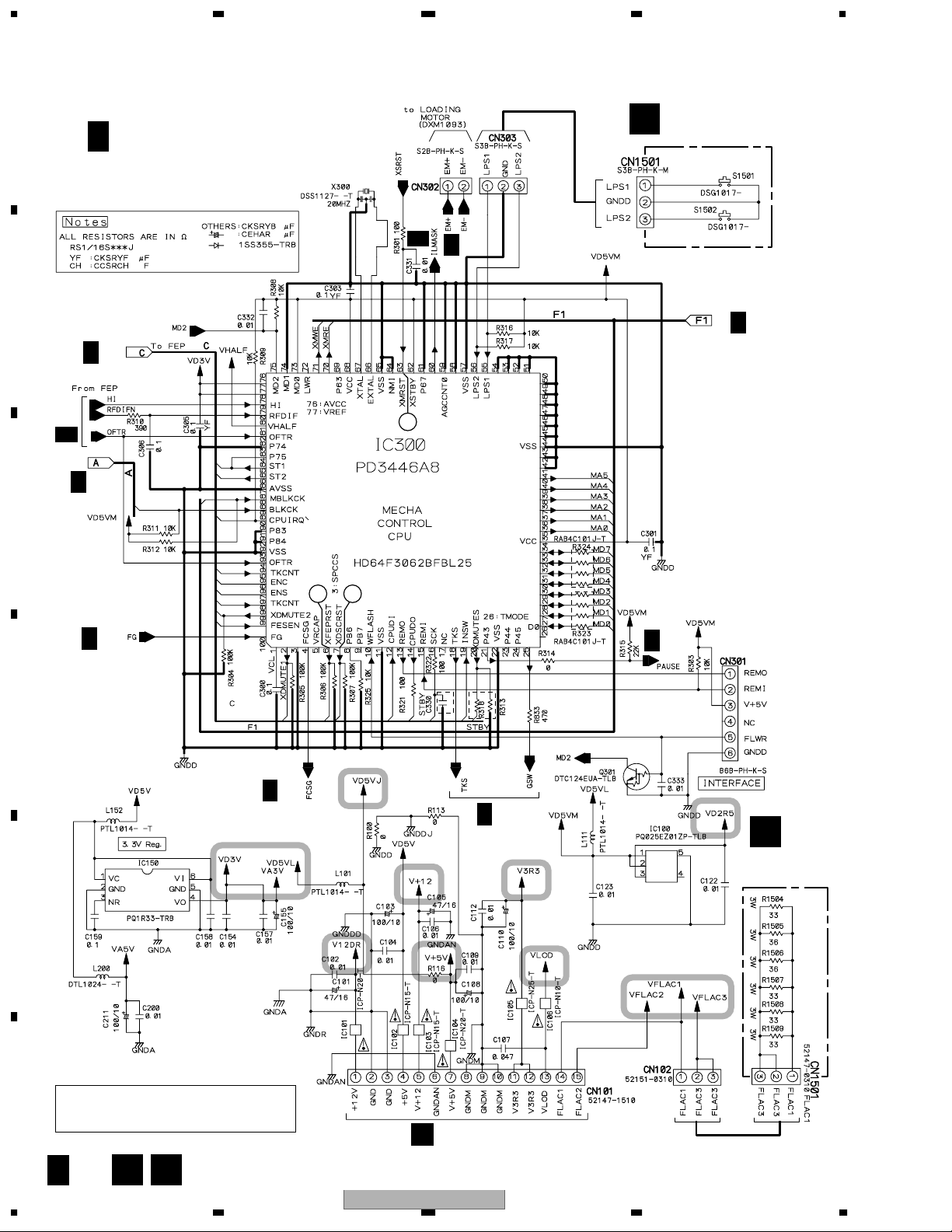

Page 18

1234

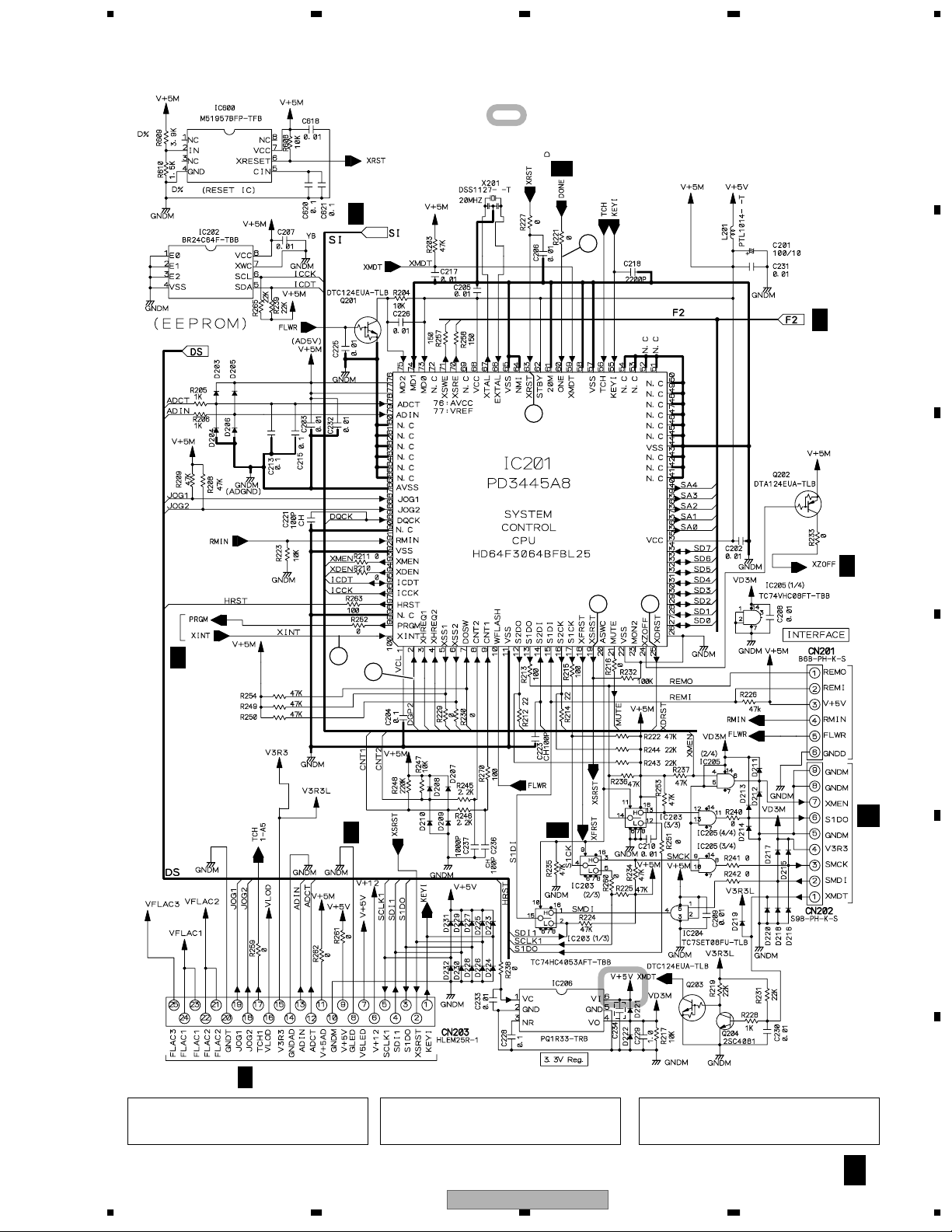

3.3 MAIN (1/4) and SPCN ASSYS

A

A 1/4

B

MAIN ASSY (DWX2303)

To PICKUP ASSY CN801

A 2/4

6

4

(FS)

(TS)

A 2/4

C

A 2/4

A 2/4

A 2/4

D

A 2/4

E

(L)

(L)

13

12

5

7

(FS)

(TS)

(L)

(FS)

(TS)

A 2/4

A 2/4

(FS)

F

A 1/4

18

1234

CDJ-1000MK2

Page 19

5678

: RF SIGNAL ROUTE

(L)

: LOADING MOTOR SIGNAL ROUTE

(FS)

: FOCUS SERVO SIGNAL ROUTE

(TS)

: TRACKING SERVO SIGNAL ROUTE

A

A 2/4, 3/4

B

19181011

C

A 2/4

(TS)

(FS)

(TS)

(L)

(FS)

A 2/4

D

A 2/4

To

SPINDLE

STCN ASSY

C

(DWX2171)

To

STEPPING

MOTOR

SPCN ASSY

B

(DWX2170)

MOTOR

(CN2220)

E

F

56

CDJ-1000MK2

A 1/4

7

B C

19

8

Page 20

1234

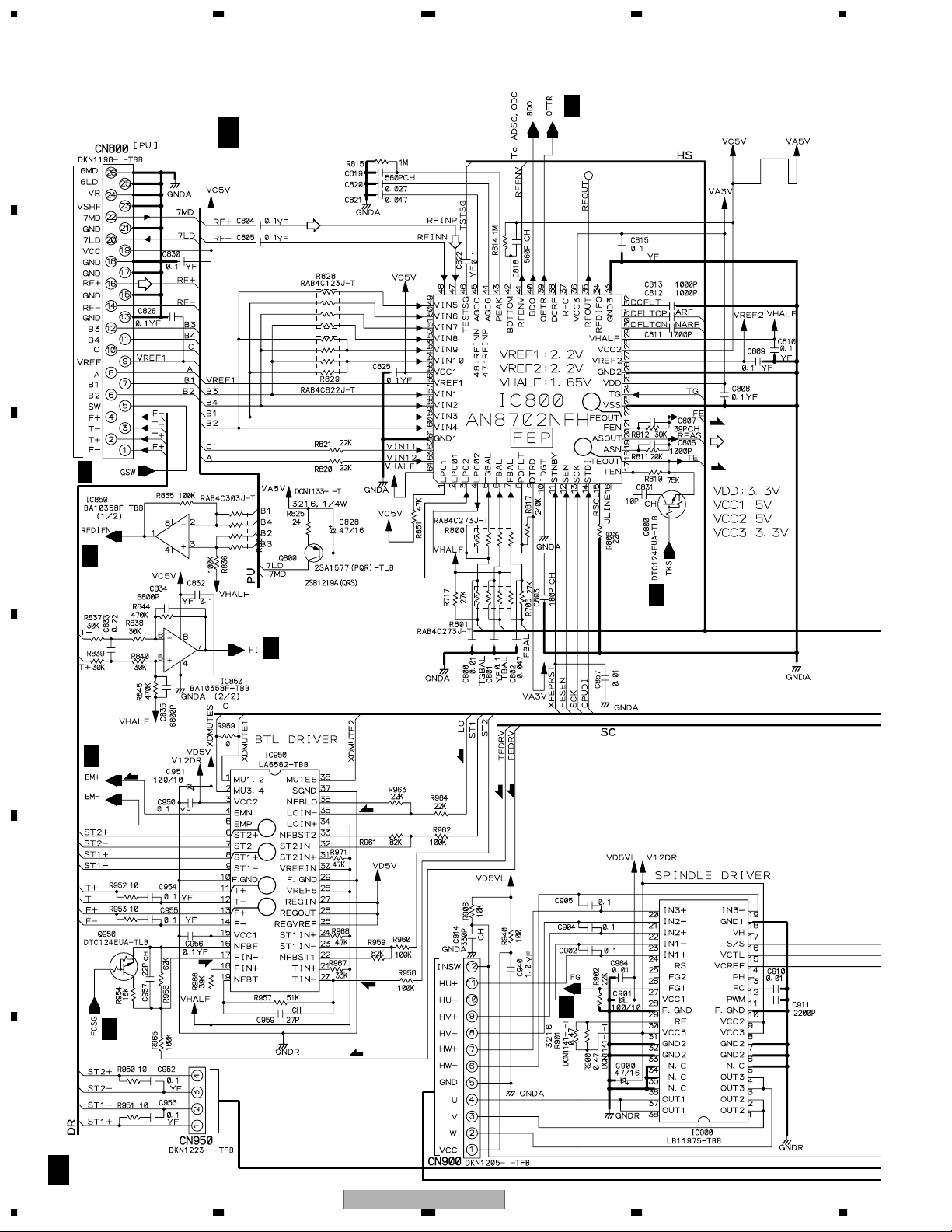

3.4 MAIN (2/4), FLRB and SLMB ASSYS

A

A 2/4

B

MAIN ASSY (DWX2303)

A 1/4

A 1/4

SLMB ASSY

E

(DWS1309)

CLAMP

CLAMP

A 3/4

A 1/4

A 1/4

36

A 1/4

C

4335

A 1/4

D

A 4/4

A 1/4

A 1/4

D

FLRB ASSY

(DWX2308)

E

F

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE, REPLACE ONLY WITH

SAME TYPE NO. ICP-N20, MFD BY ROHM

CO., LTD. FOR IC101 AND IC104.

A 2/4

20

E D

1234

CN201

P

CDJ-1000MK2

Page 21

5678

A 3/4,4/4

: The power supply is shown with the marked box.

A 3/4

26

A 3/4

1

A

B

C

A 3/4

21

A 4/4

3030

A 3/4

A 3/4

2 34

D

F

CN99

E

CN1101

J 1/2

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE, REPLACE ONLY WITH

SAME TYPE NO. ICP-N15, MFD BY ROHM

CO., LTD. FOR IC102 AND IC103.

56

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE, REPLACE ONLY WITH

SAME TYPE NO. ICP-N25, MFD BY ROHM

CO., LTD. FOR IC105.

CDJ-1000MK2

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE, REPLACE ONLY WITH

SAME TYPE NO. ICP-N10, MFD BY ROHM

CO., LTD. FOR IC106.

7

F

A 2/4

21

8

Page 22

1234

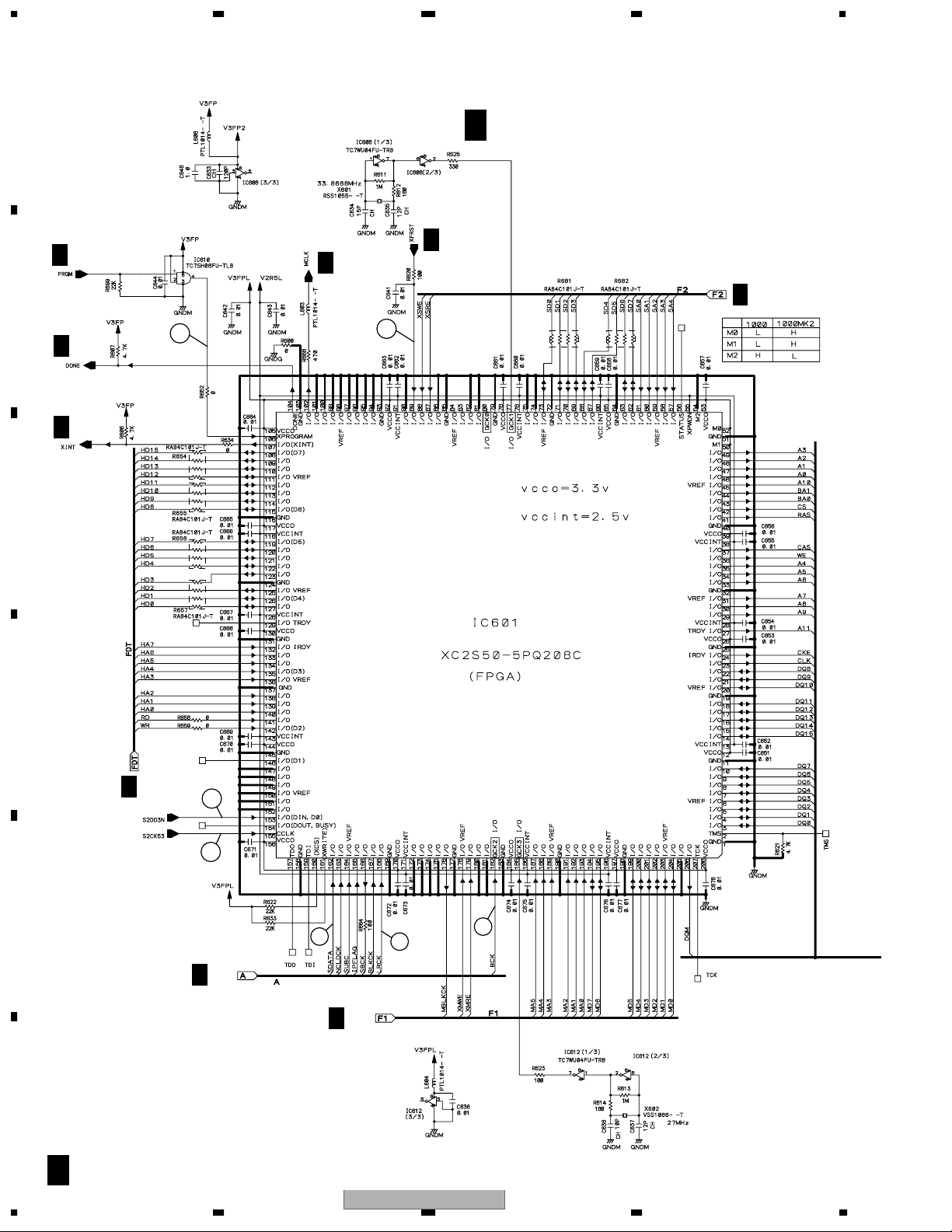

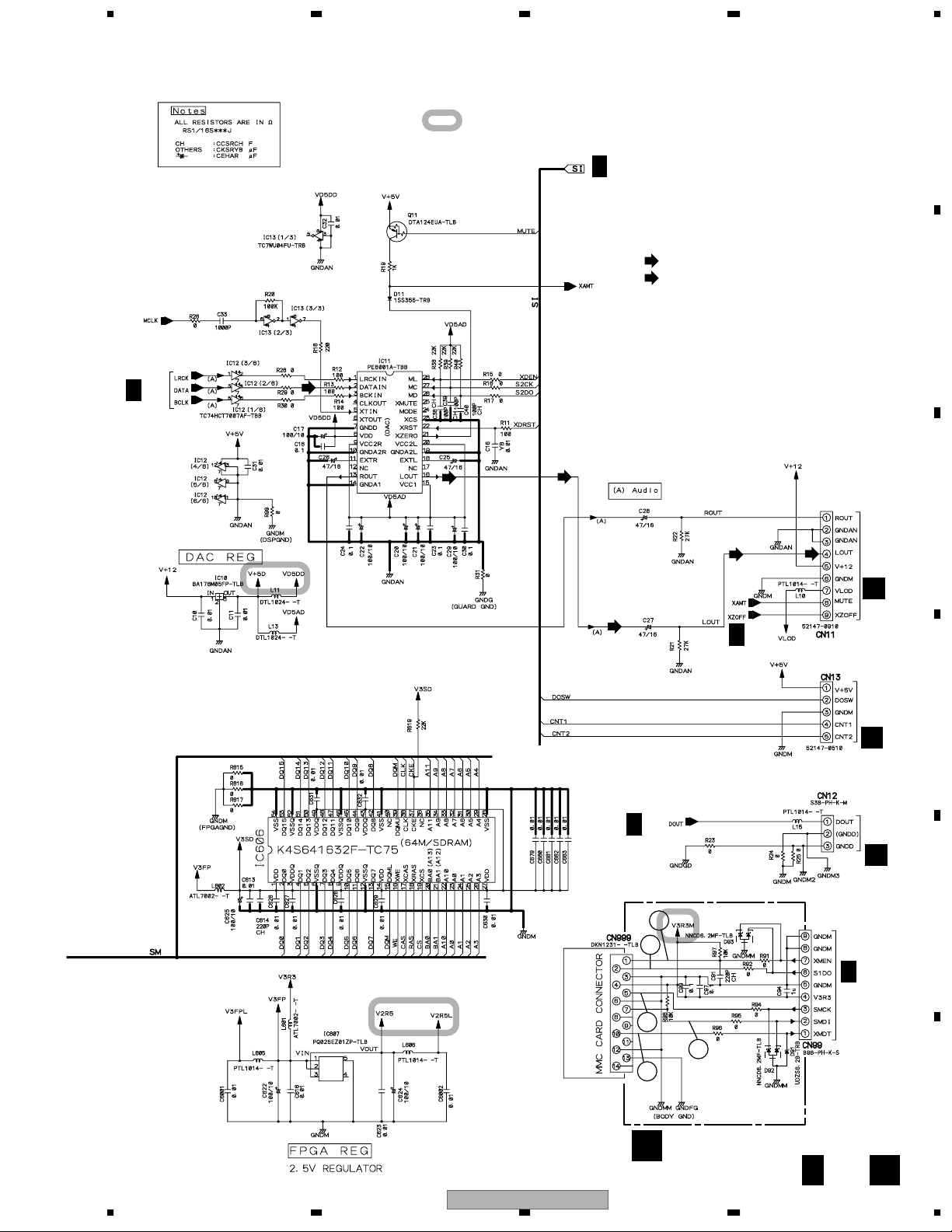

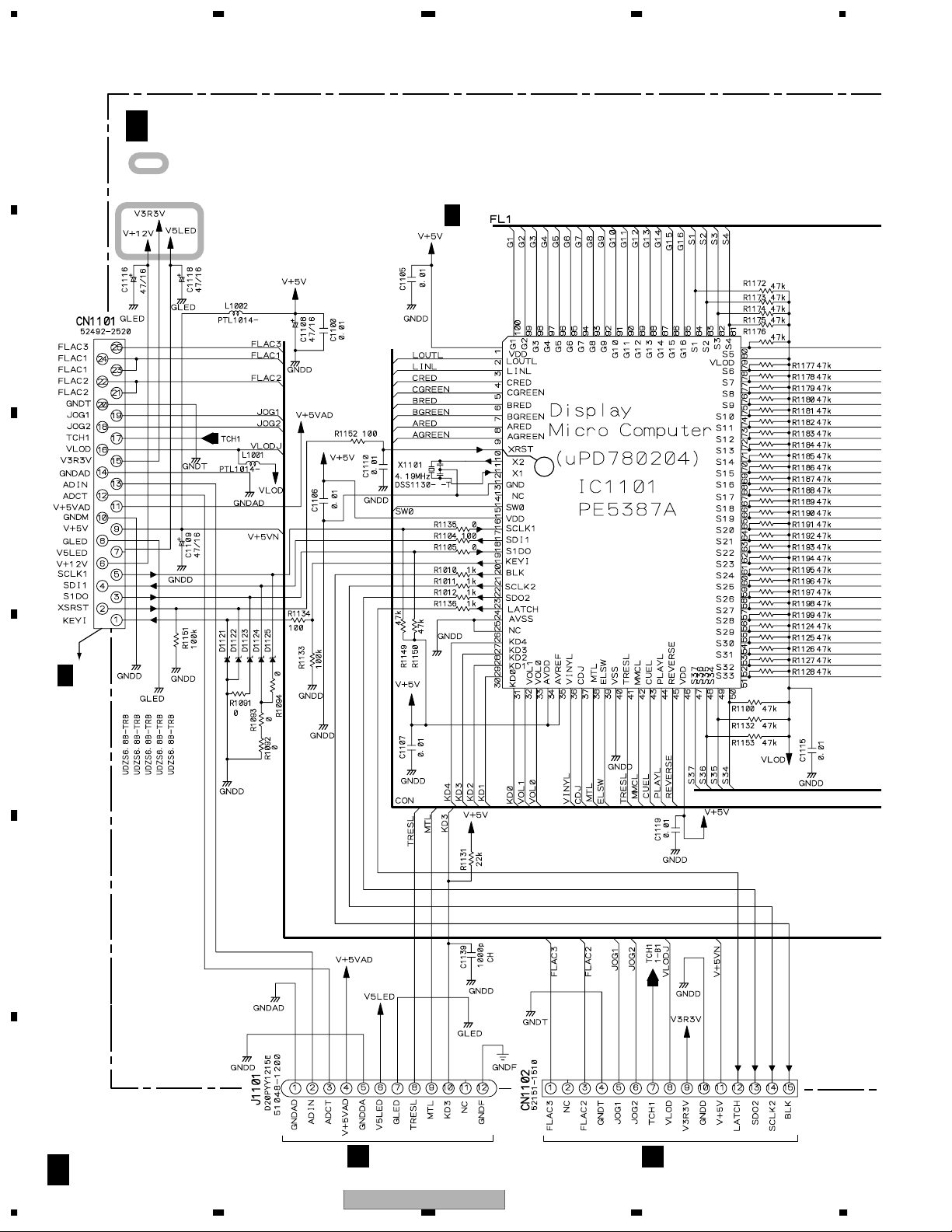

3.5 MAIN (3/4) and MMCB ASSYS

A

A 3/4

MAIN ASSY (DWX2303)

A 2/4

B

20

A 3/4,4/4

A 2/4

3

A 2/4

A 2/4

A 2/4

C

D

A 4/4

E

25

24

14

16

15

A 1/4

A 2/4

F

A 3/4

22

1234

CDJ-1000MK2

Page 23

5678

A 4/4

: The power supply is shown with the marked box.

A

A 2/4,4/4

: PB AUDIO SIGNAL ROUTE

(D)

: DIGITAL DATA SIGNAL ROUTE

B

(D)

C

A 4/4

41

40

A 2/4

A 2/4

CN202

CN1901

G

CN1802

I

CN1801

I

D

E

56

CDJ-1000MK2

39

38

MMCB ASSY

F

(DWX2304)

7

42

A 3/4

8

F

F

23

Page 24

1234

3.6 MAIN ASSY (4/4)

A

B

C

A 2/4,3/4

A 2/4

22

A 4/4

MAIN ASSY (DWX2303)

A 3/4

D

2931

33

E

28

32

A 3/4

A 2/4,3/4

F

A 4/4

24

1234

CDJ-1000MK2

Page 25

5678

A

: The power supply is shown with the marked box.

(D)

: DIGITAL DATA SIGNAL ROUTE

B

27

C

D

(D)

E

(D)

A 3/4

A 3/4

56

CDJ-1000MK2

A 3/4

F

A 4/4

7

8

25

Page 26

1234

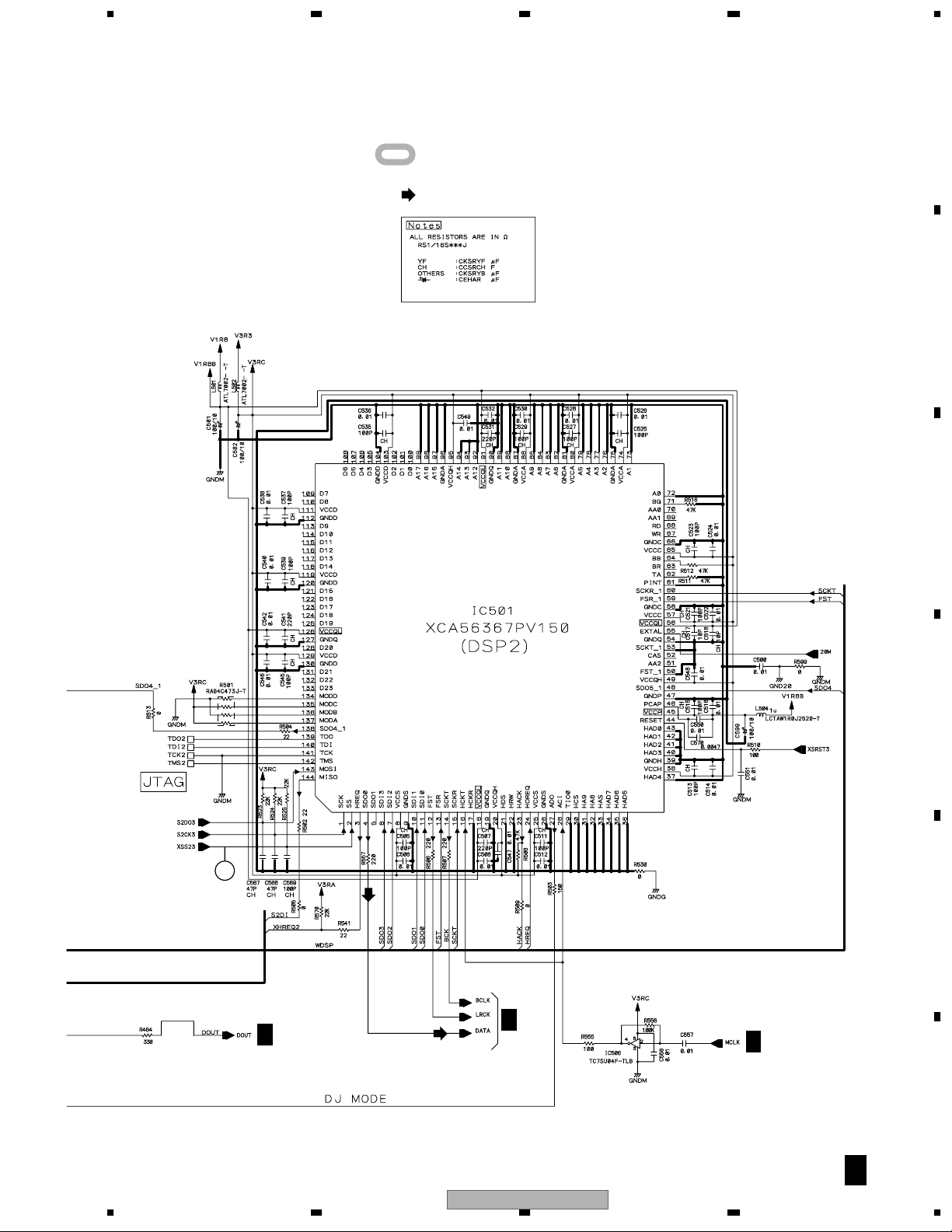

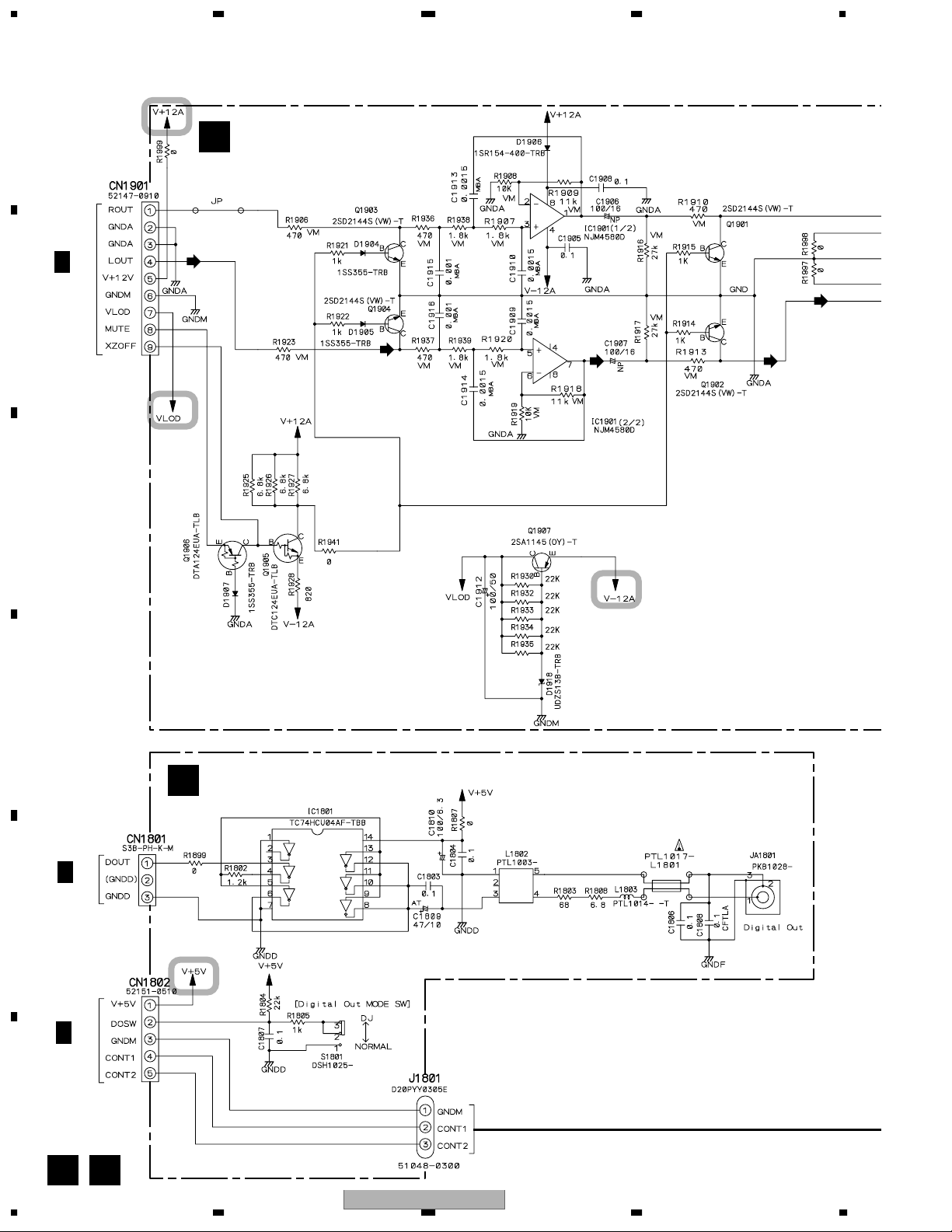

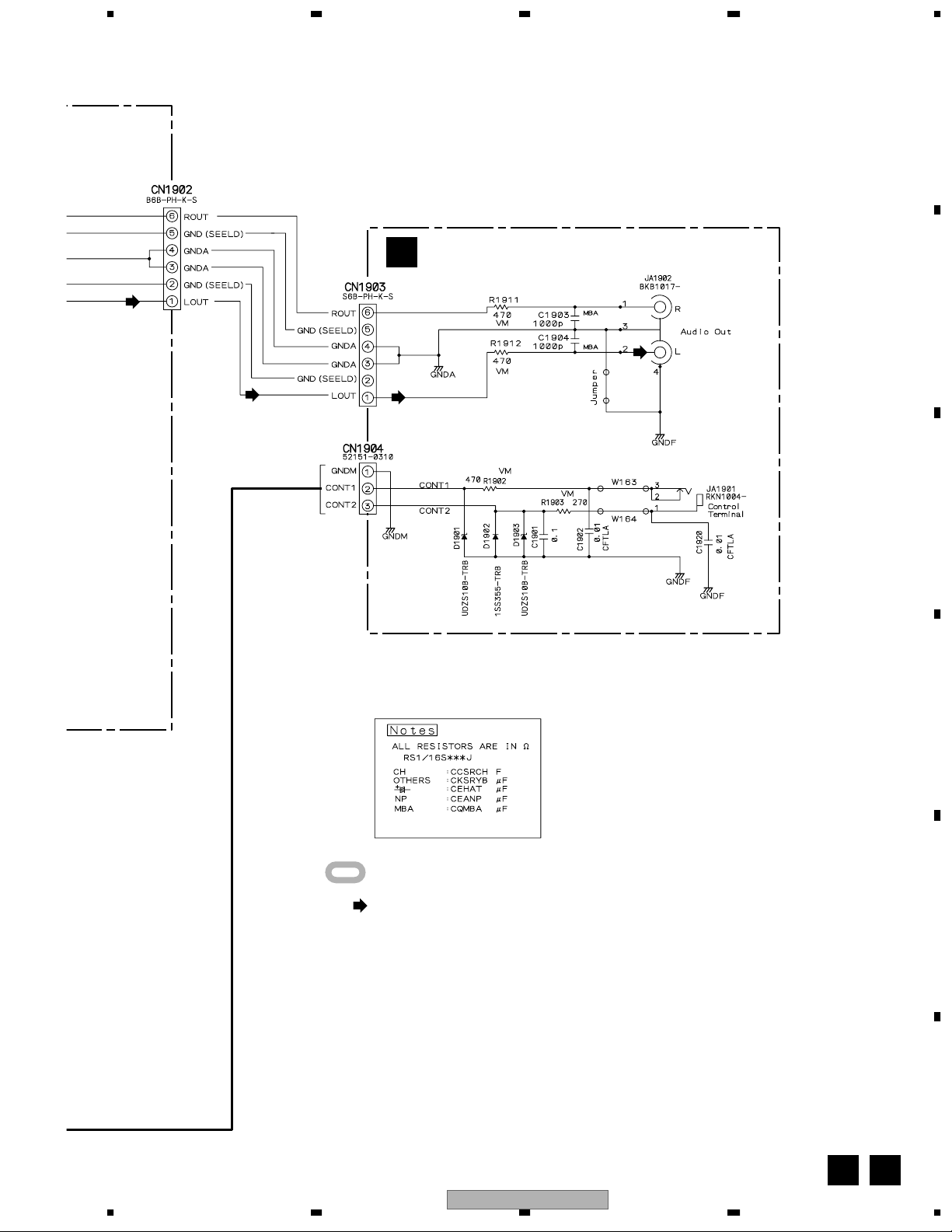

3.7 DABB, JACB and DOUT ASSYS

A

DABB ASSY (DWX2305)

G

A 3/4

CN11

B

C

D

DOUT ASSY (DWX2307)

I

A 3/4

CN12

E

F

A 3/4

CN13

G I

26

1234

CDJ-1000MK2

Page 27

5678

A

JACB ASSY (DWX2306)

H

B

: The power supply is shown with the marked box.

: PB AUDIO SIGNAL ROUTE

C

D

E

56

CDJ-1000MK2

F

G H

7

8

27

Page 28

1234

3.8 MFLB (1/2) and RSWB ASSYS

A

J 1/2

B

MFLB ASSY (DGW1567)

: The power supply is shown with the marked box.

J 2/2

37

C

A 2/4

CN203

D

E

F

J 1/2

28

CN1401

M

CDJ-1000MK2

1234

N

J1202

Page 29

5678

SWITCHES

MFLB ASSY

S1101 : A

S1102 : B

S1103 : C

S1104 : DISPLAY

TEXT/WAVE

S1105 : TIME MODE

S1106 : 0 (EJECT)

S1107 : SELECT

VINYL – CDJ

S1109 : 2 CALL

S1110 : CALL 3

S1111 : MEMORY

S1112 : DELETE

S1113 : IN/REALTIME CUE

S1114 : LOOP OUT

S1115 : RELOOP/EXIT

S1116 : 2 WAVE

S1117 : WAVE 3

S1118 : EJECT LOCK

S1119 : SELECT

RSWB ASSY

S1701 : FWD – REV

A

B

C

10k-B

10k-B

J 2/2

CN1301

L

56

CDJ-1000MK2

D

E

K

RSWB ASSY

(DWS1310)

J 1/2

7

K

8

F

29

Page 30

1234

3.9 MFLB (2/2) ASSY

A

J 2/2

MFLB ASSY (DGW1567)

J 1/2

J 1/2

B

C

D

J 1/2

E

J 1/2

F

J 2/2

30

1234

CDJ-1000MK2

Page 31

5678

3.10 KSWB and SLDB ASSYS

J 1/2

J1103

KSWB ASSY (DWS1324)

L

A

B

J 1/2

J1101

SWITCHES

KSWB ASSY

S1301 : CUE

S1302 : 6

S1303 : 4

S1304 : ¢

S1305 : 1

S1306 : ¡

SLDB ASSY (DWS1325)

M

SWITCHES

SLDB ASSY

S1401 : TEMPO RESET

S1402 : MASTER TEMPO

S1403 : TEMPO RANGE

TEMPO ZERO

POINT ADJ.

C

D

E

: The power supply is shown with the marked box.

CDJ-1000MK2

56

F

L M

7

8

31

Page 32

1234

3.11 JFLB and JOGB ASSYS

A

JFLB ASSY (DWG1568)

N

B

C

D

E

CN1102

J 1/2

F

N

32

1234

CDJ-1000MK2

Page 33

5678

A

B

IC1201

UPD16306B

DRIVER IC

C

D

To SHEET SW

E

JOGB ASSY (DWG1569)

O

: The power supply is shown with the marked box.

56

CDJ-1000MK2

F

N O

7

8

33

Page 34

1234

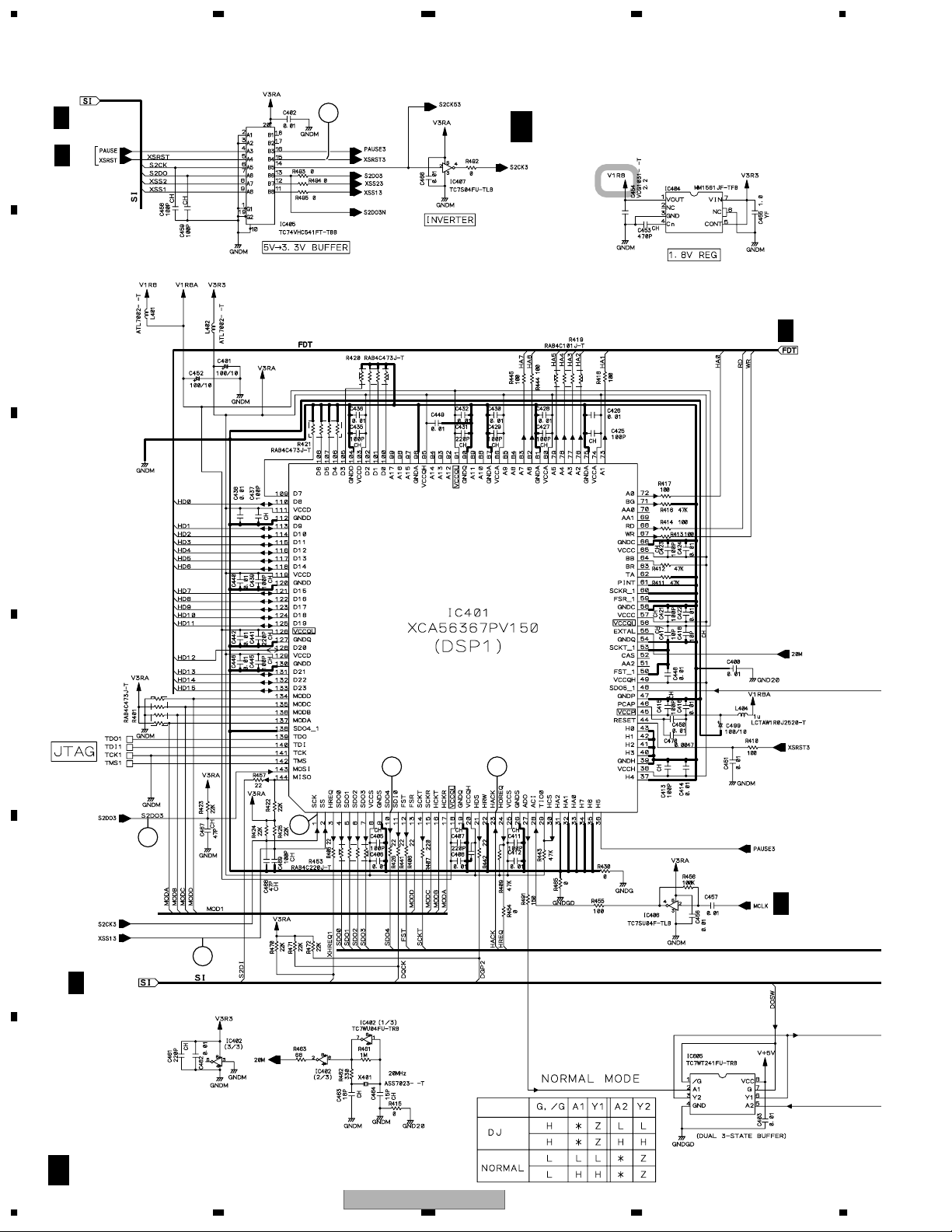

3.12 SW POWER SUPPLY and PSWB ASSYS

A

+12V

5

+5V Servo3GND7+5V

GND

6

4

3.3V123.3V

11

+12V Servo

GND

2

A 2/4

CN101

GND9GND

8

GND

10

-38.5V

13

FLAC 115FLAC 2

14

CN201

C212 R219

C209

L206

B

D206

R206

ZD203

L207

R201

C201

C

R224

C217

D201

D202

R212

PC101

R218

C216

D205

R202

R211

IC202

C207

C202

R210

C203

R203

C210

IC201

R205

C214

Q201

R217 R215

R208

VR201

C215

C213

R214

Q202

C204

R209

R222

R306

ZD201

R301

R307

D302

D310

D301

C306

L301

D308

R302

D303

C307 R310

D305

R303

R305

C301

Q301

Q302

VR301

C302

D309

D304

C303

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

S3

T101

P1 S4

D

PC

D101

E

C102

P2

L103 L202

C107

R107

D104

Q101

L105

R117

R104

C105

R118R119

C104

L101 L102

R108

TH101

PC

S2

L104

R115 R220R122

D103 D204

R120

R101R102

C103

B2 S5

C115

R113

3

76

IC101

8

R109

S1

4

Q102

ZD101

C113

152

C112

R112

R114

C109

C108

R121

S8

C111

PC101

S7

B1

CAUTION -

• NOTE FOR FUSE REPLACEMENT

AC IN

C114

LIVE

NEUTRAL

AN1 ;

KUCXJ : AKP7032

TLXJ, WYXJ : BKP1046

(TLXJ, WYXJ : DWS1311)

PSWB ASSY (KUCXJ : DWS1312)

C101

SW POWER SUPPLY ASSY (DWR1370)

F

P

F101

1 1

CN101

2

Q

P Q P Q

34

1234

CDJ-1000MK2

Page 35

1

2

1

2

IC201- 63pin (XRST)

V: 2V/div. H: 20mS/div.

IC201- 19pin (XSRST)

V: 2V/div. H: 20mS/div.

Mode: Power ON

1

3

1

3

IC201- 63pin (XRST)

V: 2V/div. H: 50mS/div.

IC601- 89pin (XFRST)

V: 2V/div. H: 50mS/div.

4

5

4

5

IC800- 18pin (TE)

V: 1V/div. H: 200µS/div.

IC950- 11pin (T+)

V: 500mV/div. H: 200µS/div.

6

7

6

7

IC800- 22pin (FE)

V: 1V/div. H: 50mS/div.

IC950- 13pin (F+)

V: 1V/div. H: 50mS/div.

4

4

IC800- 18pin (TE)

V: 500mV/div. H: 500µS/div.

Mode: 1track Jump

6

6

IC800- 22pin (FE)

V: 200mV/div. H: 500µS/div.

10

10

IC700- 6pin (TEDRV)

V: 200mV/div. H: 5µS/div.

11

11

IC700- 5pin (FEDRV)

V: 100mV/div. H: 20mS/div.

12

13

12

13

IC950- 8pin (ST1+)

V: 5V/div. H: 20mS/div.

IC950- 6pin (ST2+)

V: 5V/div. H: 20mS/div.

Mode: Search

14

14

IC601- 162pin (SDATA)

V: 2V/div. H: 1µS/div.

15

15

IC601- 182pin (BCK)

V: 2V/div. H: 500nS/div.

16

16

IC601- 168pin (LRCK)

V: 2V/div. H: 5µS/div.

17

17

IC604- 3pin (VCOOUT)

V: 2V/div. H: 20nS/div.

Mode: Play

18

19

18

19

IC700- 8pin (ARF)

V: 200mV/div. H: 50nS/div.

IC700- 9pin (NARF)

V: 200mV/div. H: 50nS/div.

Mode: Power ON

Mode: Focus Up/Down

Mode: Search

Mode: Play

Mode: Play

Mode: Play

Mode: Play

Mode: Play

Mode: 3100rpm/ Inside Play

Mode: Focus

A 2/4

MAIN ASSY

A 2/4, 3/4

MAIN ASSY

A 1/4

MAIN ASSY

A 3/4

MAIN ASSY

A 1/4

MAIN ASSY

A 1/4

MAIN ASSY

A 1/4

MAIN ASSY

A 3/4

MAIN ASSY

A 1/4

MAIN ASSY

A 1/4

MAIN ASSY

A 1/4

MAIN ASSY

A 1/4

MAIN ASSY

A 3/4

MAIN ASSY

A 3/4

MAIN ASSY

WAVEFORMS

5678

A

B

C

D

E

56

CDJ-1000MK2

F

7

8

35

Page 36

1234

MAIN ASSY

A

A

IC201 - pin 63 [XRST]

1

A 2/4

A 3/4

A 2/4

1

20

B

21

A 3/4

A 2/4

C

20

V: 5V/div. H: 1msec/div.

IC601 - pin 106 [PRGM]

20

V: 5V/div. H: 1msec/div.

IC201 - pin 100 [XINT]

21

V: 5V/div. H: 1msec/div.

IC601 - pin 106 [PRGM]

20

V: 2V/div. H: 5µsec/div.

IC201 - pin 100 [XINT]

21

V: 2V/div. H: 5µsec/div.

MFLB ASSY

J

IC201 - pin 100 [XINT]

21

A 2/4

A 3/4

A 3/4

A 2/4 A 2/4

21

24

25

26

A 2/4

A 3/4

A 4/4

26

3

V: 5V/div. H: 100msec/div.

IC601 - pin 155 [S2CK53]

24

V: 5V/div. H: 100msec/div.

IC601 - pin 153 [S2D03N]

25

V: 5V/div. H: 100msec/div.

IC201 - pin 60 [D0NE]

26

V: 5V/div. H: 100msec/div.

IC201 - pin 60 [D0NE]

26

V: 5V/div. H: 1msec/div.

IC601 - pin 89 [XFRST]

3

V: 5V/div. H: 1msec/div.

IC405 - pin 15 [XSRST3]

22

V: 5V/div. H: 1msec/div.

A 4/4

A 4/4

A 4/4

27

28

29

30

A 4/4

A 4/4

A 4/4

A 2/4

27

28

IC501 - pin 2 [XSS23]

27

V: 5V/div. H: 500µsec/div.

IC401 - pin 2 [XSS13]

28

V: 5V/div. H: 500µsec/div.

IC401 - pin 23 [HACK]

29

V: 5V/div. H: 500µsec/div.

IC201 - pin 2 [DGP2]

30

V: 5V/div. H: 500µsec/div.

Zoom-up

IC501 - pin 2 [XSS23]

27

V: 5V/div. H: 50msec/div.

IC401 - pin 2 [XSS13]

28

V: 5V/div. H: 50msec/div.

IC401 - pin 10 [SD04_1]

31

V: 5V/div. H: 50msec/div.

IC201 - pin 2 [DGP2]

30

V: 5V/div. H: 50msec/div.

A 2/4

A 3/4

1

3

A 2/4

1

IC201 - pin 63 [XRST]

1

V: 2V/div. H: 200msec/div.

IC601 - pin 89 [XFRST]

3

V: 2V/div. H: 200msec/div.

Reset timing

IC201 - pin 63 [XRST]

1

V: 2V/div. H: 200msec/div.

IC201 - pin 25 [XDRST]

34

V: 2V/div. H: 200msec/div.

Reset timing

21

IC601 - pin 106 [PRGM]

20

A 3/4

A 2/4

A 3/4

D

A 3/4

20

21

24

25

A 3/4

E

A 2/4

A 3/4

A 3/4

20

21

24

25

F

V: 5V/div. H: 100msec/div.

IC201 - pin 100 [XINT]

21

V: 5V/div. H: 100msec/div.

IC601 - pin 155 [S2CK53]

24

V: 5V/div. H: 100msec/div.

IC601 - pin 153 [S2D03N]

25

V: 5V/div. H: 100msec/div.

IC601 - pin 106 [PRGM]

20

V: 5V/div. H: 5µsec/div.

IC201 - pin 100 [XINT]

21

V: 5V/div. H: 5µsec/div.

IC601 - pin 155 [S2CK53]

24

V: 5V/div. H: 5µsec/div.

IC601 - pin 153 [S2D03N]

25

V: 5V/div. H: 5µsec/div.

22

A 2/4

A 3/4

A 4/4

A 4/4

26

3

22

27

IC201 - pin 60 [D0NE]

26

V: 5V/div. H: 100msec/div.

IC601 - pin 89 [XFRST]

3

V: 5V/div. H: 100msec/div.

IC405 - pin 15 [XSRST3]

22

V: 5V/div. H: 100msec/div.

IC501 - pin 2 [XSS23]

27

V: 5V/div. H: 100msec/div.

31

30

A 4/4

27

28

32

33

A 4/4

28

27

32

33

IC501 - pin 2 [XSS23]

27

V: 5V/div. H: 500µsec/div.

IC401 - pin 2 [XSS13]

28

V: 5V/div. H: 500µsec/div.

IC401 - pin 1 [S2CK3]

32

V: 5V/div. H: 500µsec/div.

IC401 - pin 143 [S2D03]

33

V: 5V/div. H: 500µsec/div.

Zoom-up

IC401 - pin 2 [XSS13]

28

V: 5V/div. H: 50msec/div.

IC501 - pin 2 [XSS23]

27

V: 5V/div. H: 50msec/div.

IC401 - pin 1 [S2CK3]

32

V: 5V/div. H: 50msec/div.

IC401 - pin 143 [S2D03]

33

V: 5V/div. H: 50msec/div.

34

A 2/4

1

34

35

A 2/4

A 2/4

J 1/2

A 4/4

1

Mecha. com.

36

FL com.

37

DSP

22

IC201 - pin 63 [XRST]

1

V: 5V/div. H: 500msec/div.

IC300 - pin 7 [XDSCRST]

43

V: 5V/div. H: 500msec/div.

IC300 - pin 6 [XFEPRST]

35

V: 5V/div. H: 500msec/div.

Reset timing

IC201 - pin 63 [XRST]

1

V: 5V/div. H: 200msec/div.

IC300 - pin 63 [XSRST]

36

V: 5V/div. H: 200msec/div.

IC1101 - pin 10 [XSRST]

37

V: 5V/div. H: 200msec/div.

IC405 - pin 15 [XSRST]

22

V: 5V/div. H: 200msec/div.

Reset timing

36

1234

CDJ-1000MK2

Page 37

A 3/4 A 3/4

A 3/4

38

CN999 - pin 10 [XMDT]

V: 5V/div. H: 200msec/div.

39

CN999 - pin 5 [SMCK]

V: 5V/div. H: 200msec/div.

40

CN999 - pin 2 [S1D0]

V: 5V/div. H: 200msec/div.

41

CN999 - pin 1 [XMEN]

V: 5V/div. H: 200msec/div.

A 3/4

38

CN999 - pin 10 [XMDT]

V: 5V/div. H: 200msec/div.

39

CN999 - pin 5 [SMCK]

V: 5V/div. H: 200msec/div.

40

CN999 - pin 2 [S1D0]

V: 5V/div. H: 200msec/div.

42

CN999 - pin 7 [SMDI]

V: 5V/div. H: 200msec/div.

39

CN999 - pin 5 [SMCK]

V: 5V/div. H: 1sec/div.

40

CN999 - pin 2 [S1D0]

V: 5V/div. H: 1sec/div.

42

CN999 - pin 7 [SMDI]

V: 5V/div. H: 1sec/div.

41

CN999 - pin 1 [XMEN]

V: 5V/div. H: 1sec/div.

39

CN999 - pin 5 [SMCK]

V: 5V/div. H: 20msec/div.

40

CN999 - pin 2 [S1D0]

V: 5V/div. H: 20msec/div.

42

CN999 - pin 7 [SMDI]

V: 5V/div. H: 20msec/div.

41

CN999 - pin 1 [XMEN]

V: 5V/div. H: 20msec/div.

A 3/4

39

CN999 - pin 5 [SMCK]

V: 5V/div. H: 20msec/div.

40

CN999 - pin 2 [S1D0]

V: 5V/div. H: 20msec/div.

42

CN999 - pin 7 [SMDI]

V: 5V/div. H: 20msec/div.

41

CN999 - pin 1 [XMEN]

V: 5V/div. H: 20msec/div.

38

39

40

41

39

40

42

41

38

39

40

42

39

40

42

41

39

40

42

41

MAIN ASSY

A

MMC Card IN 1 at LOOP memory and delete

MMC Card IN 2

HOT CUE REC

HOT CUE CALL

5678

A

B

C

D

E

F

56

CDJ-1000MK2

7

8

37

Page 38

1234

VOLTAGES

A

IC700 (MN677061ZY)

Pin No. Voltage (V)

1 2.1

2 1.4

3 1.6

4 3.3

5 1.6

6 1.6

70

8 1.6

9 1.6

10 1.5

11 1.5

12 1.6

13 1.5

B

C

D

E

F

14 3.3

15 1.7

16 2.2

17 0.2

18 2.1

19 1.4

20 0

21 1

22 1

23 2

24 1.6

25 1.1

26 1.1

27 3.3

28 1.1

29 1.1

30 0

31 1

32 1

33 1.6

34 1.6

35 1

36 1.2

37 1.6

38 3.3

39 0

40 1.6

41 0

42 1.6

43 0

44 1.8

45 0

46 3.3

47 0

48 1.6

49 0

50 0

51 1.7

52 1.9

53 1.5

54 1.1

55 1.1

56 1.1

57 0

58 2.4

59 0

60 0

61 1.6

62 0

63 0.3

64 0

65 0

66 0

67 0

68 1.6

69 0.2

70 0.1

71 3.2

72 0

73 0

74 0

75 3.3

76 1.7

77 0

78 0

79 1.7

80 1.6

81 0

82 3.3

83 84 4.9

85 4.8

86 4.9

87 3.2

88 4.9

89 4.8

90 0.7

Voltage measurement mode

DJ MODE: PLAY , VINAL , MMC IN , MASTER TEMPO: OFF , SRIDER: 0%, HOT CUE: OFF

A

1/4

MAIN ASSY

IC700 (MN677061ZY)

Pin No. Voltage (V)

91 0 to 3.2

92 0

93 0

94 1.6

95 0

96 2.4

97 1.7

98 1.7

99 1.6

100 2.3

IC701 (TC7WU04FU)

Pin No. Voltage (V)

1 1.7

2 1.7

3 3.3

4 0

5 0

6 1.7

7 1.6

8 3.3

IC710 (TC7SET08FU)

Pin No. Voltage (V)

1 0

2 0 to 4.9

3 0

4 0

5 3.3

IC711(TC7SET32FU)

Pin No. Voltage (V)

1 0

2 0

3 0

4 0

5 3.3

IC800 (AN8702NFH)

Pin No. Voltage (V)

1 4.9

2 2.2

3 0.2

4 3.2

5 1.7

6 1.7

7 1.7

8 3.9

9 3.3

10 0

11 4.9

12 4.9

13 4.9

14 4.9

15 1.2

16 1.7

17 1.8

18 1.4

19 1.7

20 2.2

21 1.7

22 1.6

23 0

24 1.6

25 3.3

26 0

27 2.1

28 4.9

29 1.7

30 2

31 2

32 2

33 0

34 1.6

35 1.5

36 3.3

37 2

38 1

39 0

40 0

41 2.4

42 1.4

43 1.7

44 2.5

45 2.6

46 2.1

47 2

48 2

49 2.2

50 2.2

51 2.2

52 2.2

53 2.3

54 2.3

55 4.9

56 2.1

57 2.3

58 2.3

59 2.3

60 2.3

61 0

62 2.2

63 2.2

64 1.7

IC850 (BA10358F)

Pin No. Voltage (V)

1 1.6

2 2.2

3 2.2

4 0

5 2.4

6 2.4

7 1.7

8 4.9

IC900 (LB11975)

Pin No. Voltage (V)

1 10

2 10

3 10

4 10

5 0

6 0

7 0

8 11.8

9 11.8

10 0

11 2.4

12 2

13 0.1

14 1.7

15 1.9

16 4.9

17 0.1

18 0

19 1.8

20 1.8

21 1.8

22 1.8

23 1.8

24 1.8

25 5

26 2.8

27 1.5

28 5

29 0

30 11.7

31 11.8

32 0

33 0

34 0

35 0

36 0

37 10

38 10

IC950(LA6562)

Pin No. Voltage (V)

1 4.9

2 4.9

3 11.8

4 0

5 5.5

6 3.7

7 7.6

8 5.4

9 5.7

10 0

11 2.5

12 2.5

13 2.5

14 2.5

15 5

16 1.6

17 1.6

18 1.6

19 1.6

20 1.6

21 1.6

22 1.3

23 1.6

24 1.6

25 5

26 5

27 5

28 1.6

29 0

30 1.6

31 1.6

32 1.6

33 1.3

34 1.6

35 1.6

36 1.6

37 0

38 0

A

2/4

MAIN ASSY

IC100 (PQ025EZ01ZP)

Pin No. Voltage (V)

1 4.9

2 4.9

3 2.4

4 0

5 0

IC150 (PQ1R33)

Pin No. Voltage (V)

1 4.9

2 0

3 1.3

4 3.3

5 0

6 4.9

IC202(BR24C64F)

Pin No. Voltage (V)

1 0

2 0

3 0

4 0

5 5

6 5

7 0

8 5

IC203(TC74HC4053AFT)

Pin No. Voltage (V)

15

2 0.1

3 5

4 4.9

5 4.9

6 0

7 0

8 0

9 0

10 0

11 0

12 4.2

13 5

14 4.2

15 0.2

16 5

IC204 (TC7SET08FU)

Pin No. Voltage (V)

1 3.3

2 5

3 0

4 5

5 5

IC205 (TC74VHC08FT)

Pin No. Voltage (V)

1 0

2 0

3 0

4 5

5 3.3

6 3.3

7 0

8 3.3

9 5

10 3.3

11 3.3

12 5

13 3.3

14 3.3

IC206(PQ1R33)

Pin No. Voltage (V)

1 5

2 0

3 1.3

4 3.3

5 0

6 5

38

1234

CDJ-1000MK2

Page 39

5678

1 0

2 1.4

3 0

4 0

5 1.2

6 5

7 5

8 0

Pin No. Voltage (V)

IC600 (M51957BFP)

1 3.3

2 2.1

3 3.3

4 2.1

5 2.1

60

7 2.1

8 2.1

9 3.3

10 2.1

11 2.1

12 0

13 2.1

14 3.3

15 0

16 3.3

17 2.7

18 2.7

19 0

20 0

21 0

22 0

23 0

24 0

25 0

26 0

27 3.3

28 0

29 0

30 0

31 0

32 0

33 0

34 0

35 0

36 0

37 2.3

38 1.3

39 0

40 0

41 0

42 2.1

43 3.3

44 2.1

45 2.1

46 0

47 2.1

48 2.1

49 3.3

50 2.1

51 2.1

52 0

53 2.1

54 0

Pin No. Voltage (V)

IC606 (K4S641632F)

1 1.6

2 1.6

3 0

4 0

5 3.3

6 1.7

7 1.7

8 3.3

Pin No. Voltage (V)

IC608(TC7WU04FU)

1 11.8

2 0

3 5

Pin No. Voltage (V)

IC10 (BA178M05FP)

1 3.3

2 3.3

3 2.5

4 0

5 0

Pin No. Voltage (V)

IC607 (PQ025EZ01ZP)

1 2 3 4 5 2.4

6 7 0

8 5

9 5

10 0

11 12 13 2.5

14 0

15 5

16 2.5

17 18 19 0

20 5

21 4.4

22 5

23 0

24 25 26 0.1

27 4.9

28 5

Pin No. Voltage (V)

IC11(PE8001A)

1 5

2 3.3

3 0

4 3.3

5 3.3

Pin No. Voltage (V)

IC610 (TC7SH08FU)

1 1.8

2 1.8

3 0

4 0

5 3.3

6 1.7

7 1.7

8 3.3

Pin No. Voltage (V)

IC612 (TC7WU04FU)

1 2.6

2 2.6

3 0

4 0

5 5

6 2.6

7 2.4

8 5

Pin No. Voltage (V)

IC13 (TC7WU04FU)

1 1.6

2 2.5

3 1.6

4 2.5

5 1.6

6 2.5

7 0

8 0

9 0

10 0

11 0

12 0

13 0

14 5

Pin No. Voltage (V)

IC12 (TC74HCT7007AF)

MAIN ASSY

3/4

A

MAIN ASSY

2/4

A

1 3.2

20

30

4 3.3

5 4.8

6 4.7

75

85

9 4.9

10 0

11 0

12 0.1

13 4.3

14 2.9

15 0.1 to 0.2

16 0

17 5

18 5

19 5

20 0

21 0

22 0

23 0

24 5

25 5

26 0

27 1.1

28 2.5

29 1.1

30 2.5

31 1.2

32 1.2

33 1.2

34 1.2

35 5

36 0

37 5

38 5

39 0

40 5

41 0

42 0

43 0

44 0

45 0

46 0

47 0

48 0

49 0

50 0

51 0

52 0

53 0

54 0

55 1

56 5

57 0

58 0

59 0

60 3.3

61 0

62 5

63 5

64 0

65 0

66 2.5

67 2.5

68 5

69 5

70 5

71 5

72 5

73 5

74 0

75 5

1 3.1

2 4.9

30

40

5 2.5

6 4.9

7 4.9

80

90

10 0

11 0

12 4.8

13 4.9

14 0.9

15 4.9

16 4.9

17 0

18 4.9

19 4.9

20 0to4.9

21 0

22 0

23 0

24 0 to 4.9

25 4.9

26 4.9

27 1.7

28 0.3

29 1

30 0.4 to 0.7

31 1

32 1

33 0.5 to 1

34 0.2 to 0.5

35 4.9

36 2.6 to 2.8

37 0.6

38 4.4

39 0.2

40 4.2 to 4.5

41 2

42 0

43 0

44 0

45 0

46 0

47 0

48 0

49 0

50 0

51 0

52 0

53 0

54 0

55 4.9

56 0

57 0

58 0

59 0

60 0 to 4.9

61 0

62 4.9

63 5

64 0

65 0

66 2.5

67 2.4

68 4.9

69 4.9

70 4.9

71 4.9

72 4.9

73 4.9

74 0

75 4.9

76 3.3

77 3.3

78 1.7

79 1.6

80 1.7

81 0

82 0

83 2 to 2.6

84 2 to 2.6

85 1.2 to 2.5

86 0

87 0

88 0.1

89 3.2

90 0

Pin No. Voltage (V)

IC300 (PD3446A8)

76 5

77 5

78 2.4

79 2.4

80 0

81 0

82 0

83 0

84 0

85 0

86 0

87 5

88 0

89 3.3

90 0

91 0

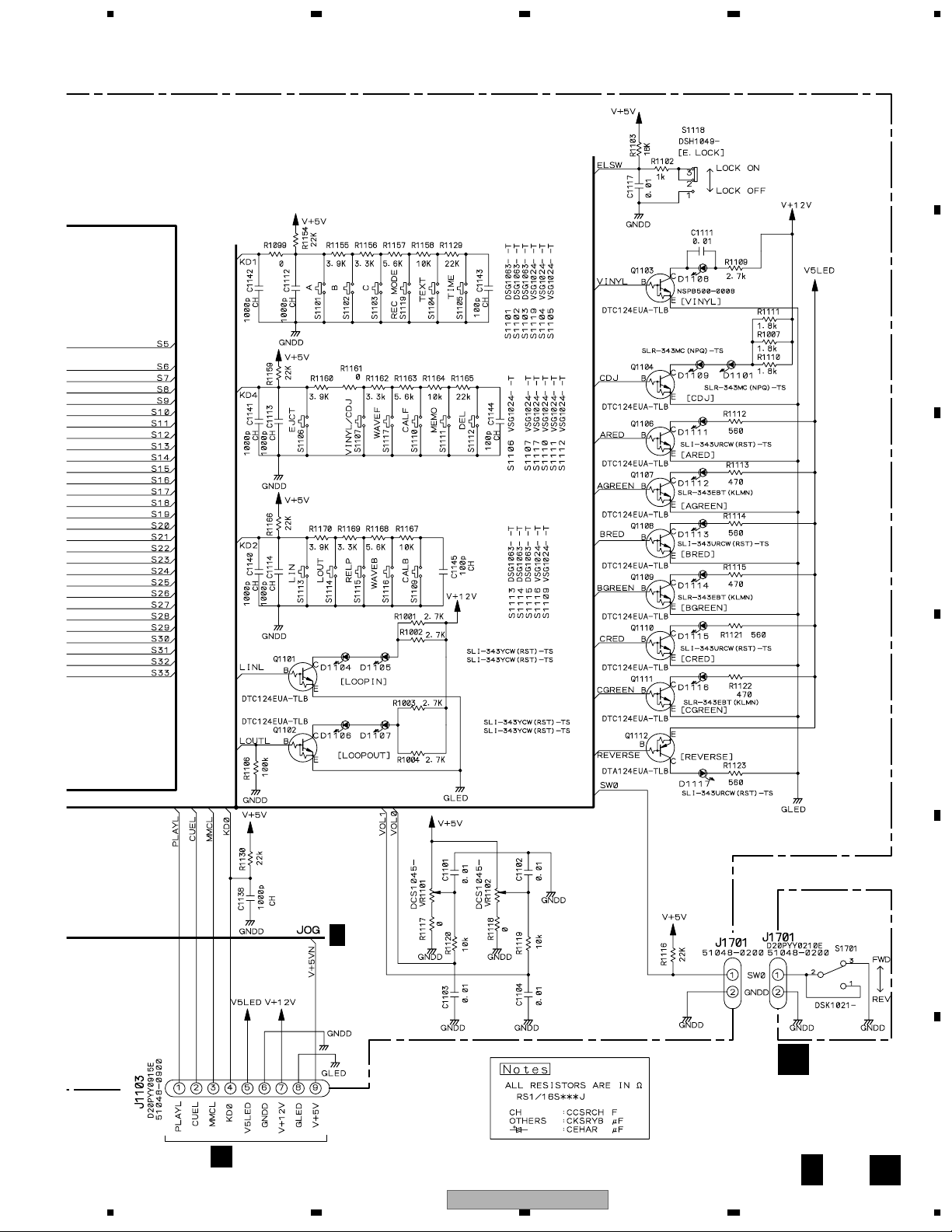

92 0

93 5

94 5

95 5

96 5

97 5

98 0

99 5

100 3.1

Pin No. Voltage (V)

IC300 (PD3446A8)

Pin No. Voltage (V)

IC201 (PD3445A8)

Pin No. Voltage (V)

IC201 (PD3445A8)

91 0

92 0

93 0

94 0 to 2.6

95 4.9

96 4.8

97 0 to 2.3

98 0

99 4.9

100 1.5

A

56

CDJ-1000MK2

7

B

C

D

E

F

39

8

Page 40

1234

A

3/4

A

IC601 (XC2S50-5PQ208C)

Pin No. Voltage (V)

1 0

2 0.2

3 2.1

4 2.1

5 2.1

6 2.1

7 2.1

8 2.1

9 2.1

10 2.1

11 0

12 3.3

13 2.5

14 2.1

B

C

D

E

F

15 2.1

16 2.1

17 2.1

18 2.1

19 0

20 2.1

21 2.1

22 2.1

23 1.3

24 2.3

25 0

26 3.3

27 0

28 2.5

29 0

30 0

31 0

32 0

33 0

34 0

35 0

36 3.3

37 2.7

38 2.5

39 3.3

40 0

41 2.7

42 0

43 0

44 0

45 0

46 0

47 0

48 0

49 0

50 3.3

51 0

52 3.3

53 3.3

54 0

55 2.5

56 0

57 5

58 0

59 5

60 5

61 0

62 1.1

63 1.1

64 0

65 3.3

66 2.5

67 1

68 1.1

69 2.4

70 2.5

71 1.2

72 0

73 2.4

74 0

75 0

76 2.5

77 1.6

78 3.3

79 0

80 0

81 0

82 0

83 0

84 0

85 0

86 0

87 0

88 0

89 5

90 0

MAIN ASSY

IC601 (XC2S50-5PQ208C)

Pin No. Voltage (V)

91 2.5

92 3.3

93 0

94 0

95 0

96 0

97 0

98 0

99 0

100 0

101 0

102 1.6

103 0

104 3.3

105 3.3

106 3.1

107 0

108 0

109 0

110 0

111 0

112 0

113 0

114 0

115 0

116 0

117 3.3

118 2.5

119 0

120 0

121 3.2

122 0

123 0

124 0

125 0

126 0

127 0.1

128 2.5

129 0

130 3.3

131 0

132 0

133 0

134 0

135 0

136 3.2

137 0

138 0

139 0

140 3.2

141 3

142 3.2

143 2.5

144 3.3

145 0

146 0

147 0

148 0

149 0

150 0

151 0

152 0

153 0.1

154 0

155 3.2

156 3.3

157 1.4

158 0

159 2.5

160 2.3

161 2.3

162 1.7

163 3.2

164 0.1

165 0.1

166 0.4

167 0.1

168 1.6

169 0

170 3.3

171 2.5

172 0

173 0

174 0

175 0

176 0

177 0

178 5

179 4.8

180 0

IC601 (XC2S50-5PQ208C)

Pin No. Voltage (V)

181 0

182 1.6

183 0

184 3.3

185 1.6

186 2.5

187 2

188 4.2to4.5

189 0.2

190 0

191 4.4

192 0.6

193 2.6to2.8

194 0.2

195 1.8

196 2.5

197 3.3

198 0

199 1.7

200 1

201 1.1to1.5

202 0.3

203 1

204 1.5

205 0

206 0

207 2.5

208 3.3

IC401(XCA56367PV150)

Pin No. Voltage (V)

1 0.1

2 3.1

3 0.1

4 0.1

5 0.1

6 0.1

7 0.1

8 3.3

9 0

10 0.1

11 3.3

12 1.6

13 3.3

14 1.6

15 3.3

16 3.3

17 3.3

18 1.8

19 0

20 3.3

21 0

22 0

23 0.2

24 3.3

25 3.3

26 0

27 1.2

28 1.7

29 0

30 0

31 0

32 0

33 0

34 0

35 0

36 0

37 0

38 3.3

39 0

40 0

41 0

42 0

43 0

44 3.3

45 1.8

46 0.4

47 0

48 3.3

49 3.3

50 0

51 3.3

52 3.3

53 0

54 0

55 1.6

56 1.8

57 3.3

58 0

59 0

60 0

61 0

62 0

63 64 0

65 3.3

66 0

67 3.2

68 3

69 3.3

70 2.9

71 0

72 3.2

73 0

74 3.3

75 0

76 0

77 3.2

78 0

79 0

80 3.3

81 0

A

4/4

MAIN ASSY

IC401(XCA56367PV15)

Pin No. Voltage (V)

82 0

83 0

84 85 0

86 3.3

87 0

88 89 0

90 0

91 1.8

92 93 94 0

95 3.3

96 0

97 0

98 3.3

99 0

100 0

101 0

102 0

103 3.3

104 0

105 0

106 0

107 0

108 0

109 0

110 0.1

111 3 .3

112 0

113 0

114 0

115 0

116 0

117 3.2

118 0

119 3.3

120 0

121 0

122 0

123 0

124 0

125 0

126 1.8

127 0

128 0

129 3.3

130 0

131 0

132 0

133 0

134 3.3

135 3.3

136 3.3

137 3.3

138 0

139 1.3

140 3.2

141 0

142 3.2

143 0.1

144 2.9

IC402(TC7WU04FU)

Pin No. Voltage (V)

1 1.7

2 1.8

30

40

5 3.3

6 1.8

7 1.8

8 3.3

IC404 (MM1561JF)

Pin No. Voltage (V)

1 1.8

20

30

4 0.6

5 3.3

60

7 3.3

IC405 (TC74VHC541FT)

Pin No. Voltage (V)

1 0

2 0

3 0

4 1.1

5 5

6 4.9

7 0.1

8 4.7

9 4.8

10 0

11 3.1

12 3

13 0.1

14 3.2

15 3.3

16 0

17 0

18 0

19 0

20 3.3

IC407 (TC7S04FU)

Pin No. Voltage (V)

1 0

2 3.2

3 0

4 0.1

5 3.3

IC605 (TC7WT241FU)

Pin No. Voltage (V)

15

2 1.1

3 2.5

40

5 1.6

6 2.5

75

85

40

1234

CDJ-1000MK2

Page 41

1 0.1

2 3

3 3.3

4 1.6

5 0

6 0.1

7 0.1

8 3.3

9 0

10 0.1

11 0.1

12 1.6

13 1.6

14 1.6

15 1.6

16 1.7

17 0

18 1.8

19 0

20 3.3

21 0

22 0

23 0.2

24 3.3

25 3.3

26 0

27 1.6

28 1.7

29 0

30 0

31 0

32 0

33 0

34 0

35 0

36 0

37 0

38 3.3

39 0

40 0

41 0

42 0

43 0

44 3.3

45 1.8

46 0.4

47 0

48 0.1

49 3.3

50 0

51 1

52 1

53 0

54 0

55 1.6

56 1.8

57 3.3

58 0

59 1.6

60 1.6

61 0

62 0

63 3.3

64 3.3

65 3.3

66 0

67 0.9

68 0.9

69 0.9

70 0.9

71 0

72 0

73 0

74 3.3

75 0

76 0

77 0

78 0

79 0

80 3.3

81 0

82 0

83 0

84 0

85 0

86 3.3

87 0

88 0

89 0

90 0

Pin No. Voltage (V)

IC501(XCA56367PV150)

91 1.8

92 0

93 0

94 0

95 3.3

96 0

97 0

98 0

99 0

100 0

101 0

102 0

103 3.3

104 0

105 3.3

106 0

107 0

108 0

109 0

110 3.3

111 3 .3

112 0

113 0

114 3.2

115 3.2

116 0

117 0

118 0

119 3.3

120 0

121 0

122 0

123 0

124 0

125 0

126 1.8

127 0

128 0

129 3.3

130 0

131 0

132 0

133 0

134 0

135 3.2

136 0

137 3.2

138 3.3

139 1

140 3.2

141 0

142 3.2

143 0.1

144 2.9

Pin No. Voltage (V)

IC501(XCA56367PV150)

MAIN ASSY

4/4

A

MFLB ASSY

1/2

J

10

25

3 2.5

4 2.5

5 2.5

6 2.6

70

8 2.6

9 2.5

10 2.6

11 2.5

12 2.6

13 2.5

14 5

Pin No. Voltage (V)

IC1801 (TC74HCU04AF)

DOUT ASSY

I

1 5

2 5

3 5

4 0

5 0

6 0

7 0

8 0

9 0

10 5

11 2.4

12 2.1

13 0

14 5

15 0

16 5

17 4.9

18 0.1

19 4.3

20 1

21 3.8

22 4.7

23 0.2

24 0

25 0

26 0

27 5

28 5

29 5

30 5

31 5

32 2.7

33 2.2

34 5

35 5

36 5

37 0

38 5

39 0.3

40 0

41 5

42 5

43 11.7

44 0

45 5

46 5

47 -28.6 to -30.5

48 -21.7 to -23.7

49 -14.7

50 -16.8

51 -12.9

52 -12.8

53 -12.7

54 -10.8

55 -12.8

56 -12.8

57 -8.9

58 -12.7

59 -16.7

60 -18.7

61 -20.6 to -21.1

62 -16.6

63 -30.3

64 -32.3

65 -34.3

66 -32.4

67 -32.3

68 -32.3

69 -32.3

70 -28.4 to -31.4

71 -28.3 to -29.1

72 -30.4 to -31.2

73 -31.7 to -33.4

74 -34.5 to -36.3

75 -34.8 to -35.3

76 -36.2 to -37.1

77 -30.6 to -31

78 -32.3 to -33.3

79 -38.4

80 -32.2 to -34.6

81 -32.9 to -36.2

82 -33.1 to -35.7

83 -32.4 to -35.9

84 -30.2 to -32.9

85 -36.4

86 -36.3

87 -36.4

88 -36.4

89 -36.4

90 -36.4

Pin No. Voltage (V)

IC1101 (PE5387A)

Pin No. Voltage (V)Pin No. Voltage (V)

IC1201 (UPD16306B) IC1201 (UPD16306B)

91 -36.4

92 -36.4

93 -36.4

94 -36.4

95 -36.4

96 -36.4

97 -36.4

98 -36.4

99 -36.4

100 -36.4

Pin No. Voltage (V)

IC1101 (PE5387A)

JFLB ASSY

N

10

20

30

4 -13.1

50

60

70

8 11.2

Pin No. Voltage (V)

IC1901 (NJM4580D)

DABB ASSY

G

10

2 3.2

30

40

5 -38.3

60

70

8 -26.9 to -27.8

9 -29.7 to -30.8

10 -27 to -27.9

11 -26.8 to -27.8

12 -38.4

13 -32.6

14 -32.6

15 -32.6

16 -32.6

17 -32.6

18 -33.1

19 -32.7

20 -32.8

21 -32.8

22 -32.8

23 -35.5

24 -38.4

25 -38.4

26 -38.4

27 -38.3

28 -38.3

29 -38.3

30 -38.3

31 3.2

32 0

33 0

34 -38.3

35 0

36 -33.6

37 -33.6

38 -37.9

39 -38.3

40 -35.5

41 -33.4

42 -33.4

43 -33.5

44 -38.3

45 -37.2

46 0

47 -38.3

48 0

49 0

50 3.2

51 -29.7 to -30.7

52 -29.7 to -30.7

53 -29.7 to -30.7

54 -29.7 to -30.7

55 -29.7 to -30.7

56 -29.7 to -30.7

57 -29.7 to -30.7

58 -29.7 to -30.7

59 -29.7 to -30.7

60 -29.7 to -30.7

61 -29.7 to -30.7

62 -29.7 to -30.7

63 -29.7 to -30.7

64 -29.7 to -30.7

65 -29.7 to -30.7

66 -29.7 to -30.7

67 -29.7 to -30.7

68 -29.7 to -30.7

69 -29.7 to -30.7

70 -29.7 to -30.7

71 -29.7 to -30.7

72 -29.7 to -30.7

73 -29.7 to -30.7

74 0

75 0

76 -38.3

77 0

78 0

79 3.2

80 0

81 0

82 -29.7 to -30.7

83 -29.7 to -30.7

84 -29.7 to -30.7

85 -29.7 to -30.7

86 -29.7 to -30.7

87 -29.7 to -30.7

88 -29.7 to -30.7

89 -29.7 to -30.7

90 -29.7 to -30.7

91 -29.7 to -30.7

92 -29.7 to -30.7

93 -29.7 to -30.7

94 -29.7 to -30.7

95 -29.7 to -30.7

96 -29.7 to -30.7

97 -29.7 to -30.7

98 -29.7 to -30.7

99 -29.7 to -30.7

100 0