Page 1

COMPACT DISC PLAYER

CDJ-100S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2027

Type

KUC AC120V ––––––––––

RL AC110–120V/220–240V With the voltage selector

WY AC220–240V ––––––––––

Model

CDJ-100S

Power Requirement

The voltage can be converted by the following method.

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............4

3. SCHEMATIC DIAGRAM................................... 10

4. PCB CONNECTION DIAGRAM .......................24

5. PCB PARTS LIST.............................................30

6. ADJUSTMENT.................................................. 33

7. GENERAL INFORMATION .............................. 39

7.1 PARTS .......................................................39

7.1.1 IC .......................................................39

7.1.2 DISPLAY ...........................................41

7.2 DIAGNOSIS................................................42

7.2.1 ERROR DISPLAY ............................. 42

7.2.2 DISASSEMBLY .................................42

7.3 BLOCK DIAGRAM...................................... 46

8. PANEL FACILITIES AND SPECIFICATIONS

.......................................................47

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

PIONEER ELECTRONIC CORPORATION 1998

T–DZY SEPT. 1998 Printed in Japan

Page 2

CDJ-100S

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

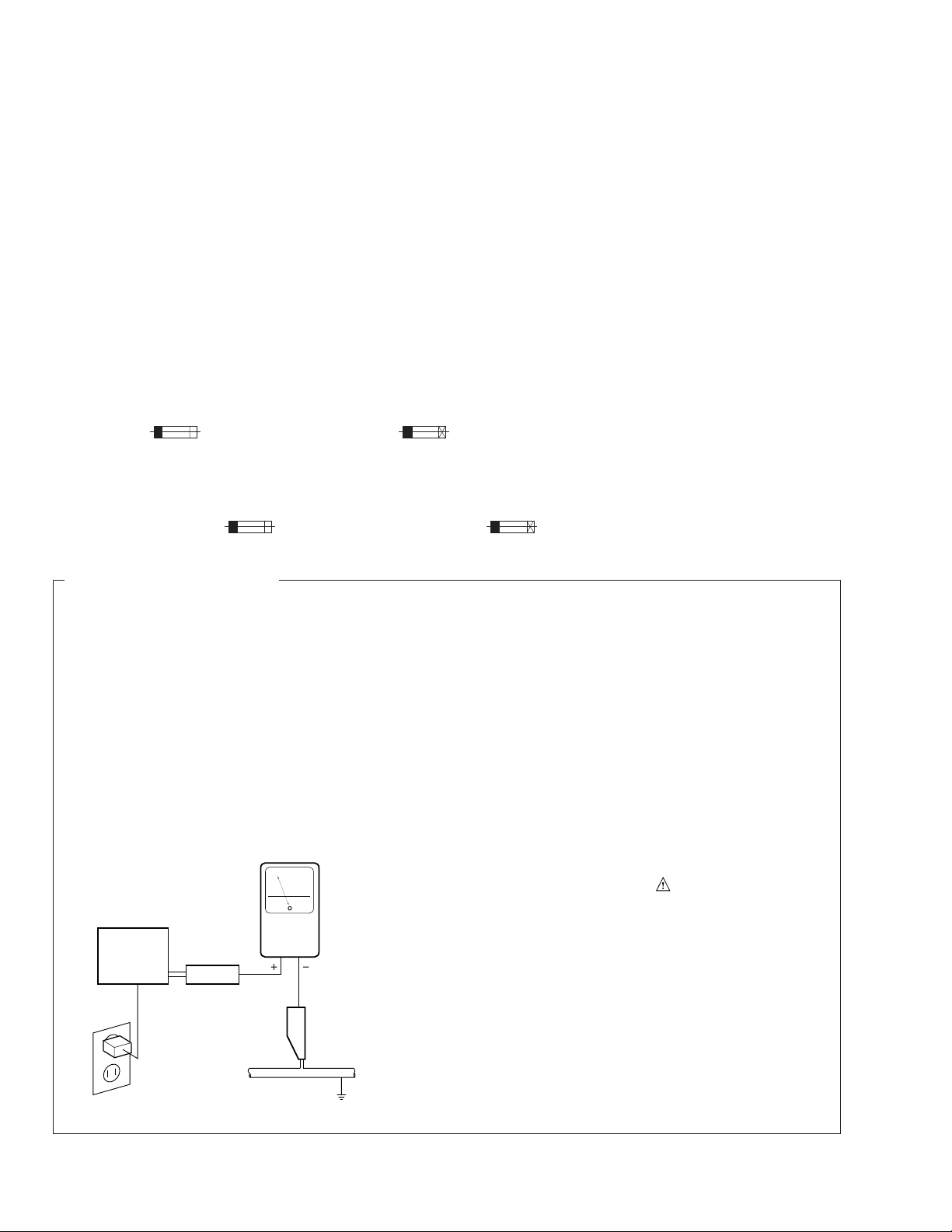

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

Page 3

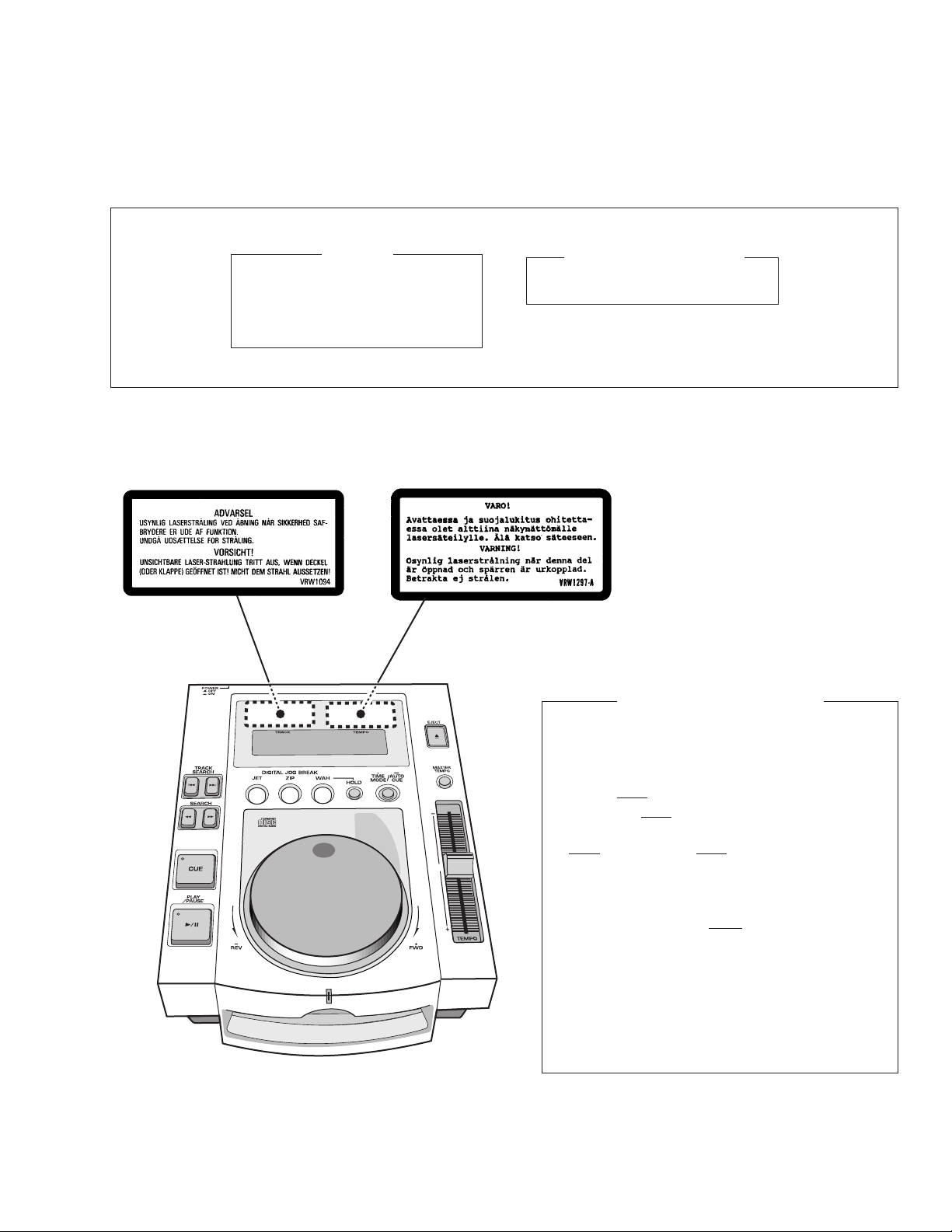

CDJ-100S

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LABEL CHECK (for WY type)

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mw

WAVELENGTH: 780 – 785 nm

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S1) for detecting loading

completion is detected by the system microprocessor, and

the design prevents laser diode oscillation when the switch

is not in LPS1 terminal side (when the mechanism is not

clamped and LPS1 signal is high level.) Thus, the interlock

will no longer function if the switch is deliberatery set to

LPS1 terminal side. ( if LPS1 signal is low level ).

In the test mode∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 33 of CXA1782CQ

(IC101) on the MOTHER BOARD ASSY is connected to

GND, or pin 43 of IC701 (LDON) is connected to low level

(ON), or else the terminals of Q101 are shorted to each

other (fault condition).

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

∗ : Refer to page 34.

3

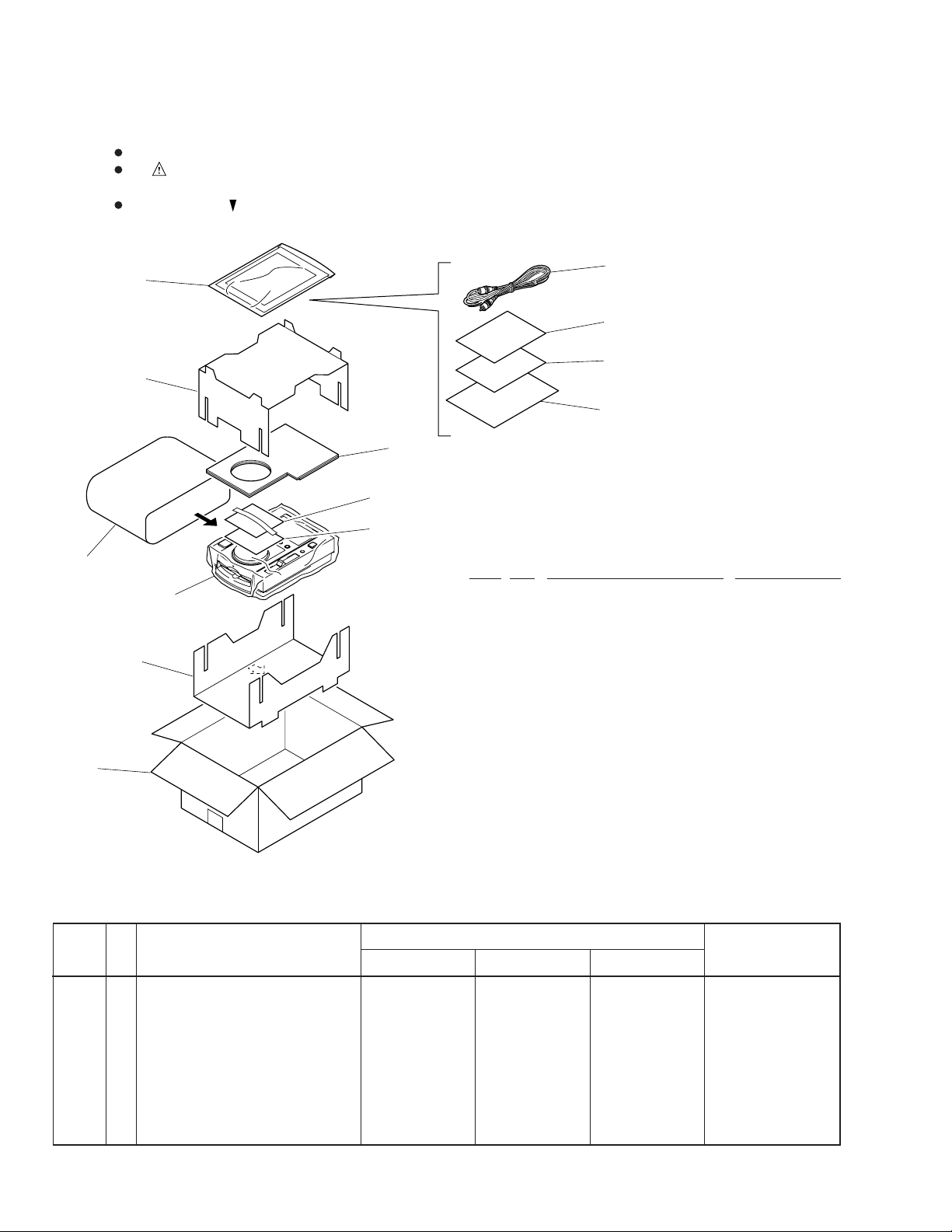

Page 4

CDJ-100S

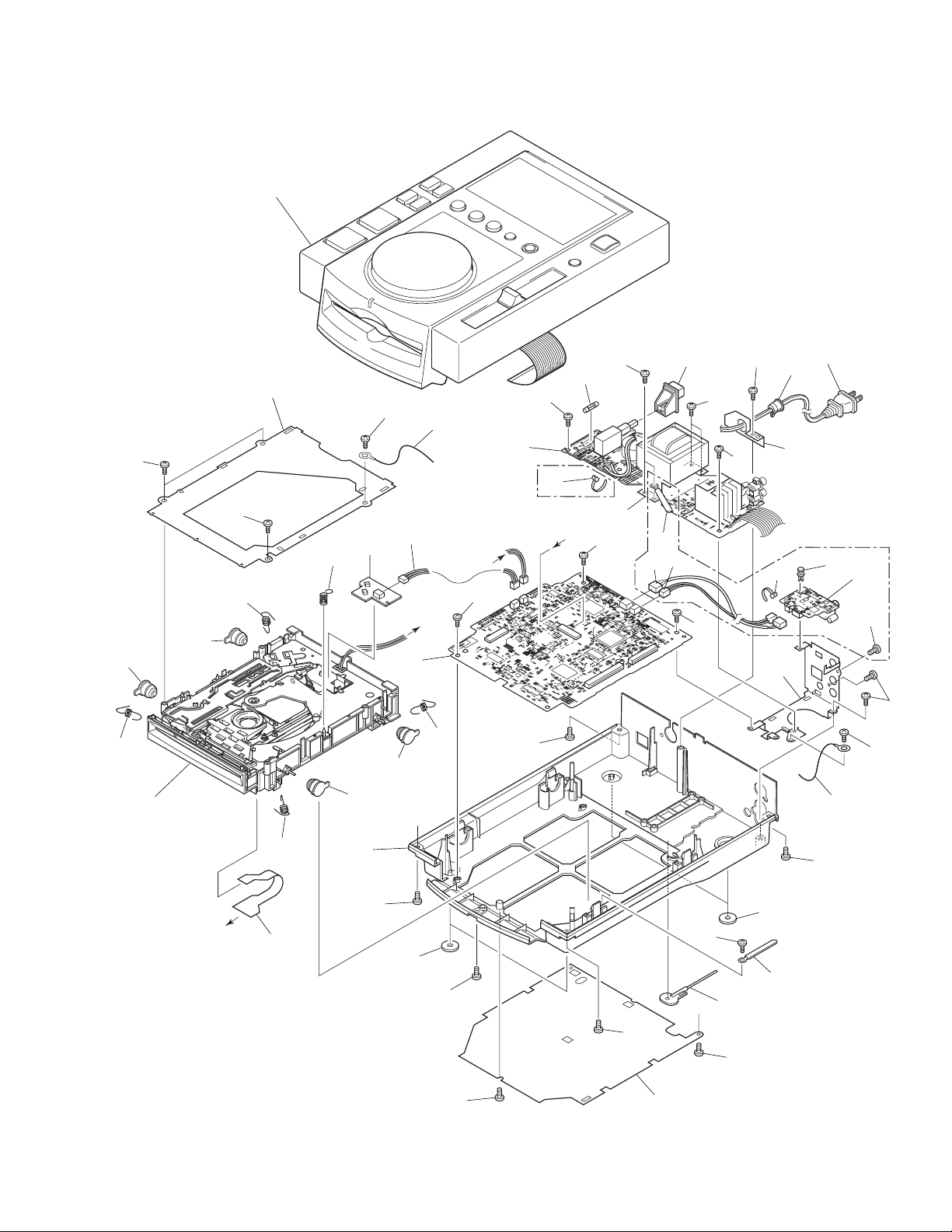

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

2.1 PACKING

6

9

13 (RL type Only)

8 (KUC type Only)

1

7

2

12

11

(1) PACKING PARTS LIST

10

5

3

4

Mark No. Description Part No.

1 Pad (A) DHA1411

2 Pad (B) DHA1412

3 Pad (C) DHA1413

4 Packing Case

5 Packing Sheet Z23–026

(550 × 550 × 0.5)

6 Audio Cable (L= 1.5m) VDE1033

7 Operating Instructions

NSP 8 Limited Warranty

9 Polyethylene Bag Z21–038

(0.03 × 230 × 340)

10 Polyethylene Bag DHL1106

NSP 11 Silica Gel AEN7001

NSP 12 Caution SG DRM1199

NSP 13 Caution Card 220V

(2) CONTRAST TABLE

CDJ-100S/KUC, RL and WY are constructed the same except for the following:

No.

Symbol and Description

KUC type RL type WY type

Part No.

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

RemarksMark

4 Packing Case DHG1852 DHG1851 DHG1850

7 Operating Instructions (English) DRB1232 Not used Not used

7 Operating Instructions Not used DRB1229 Not used

(English/Spanish/Chinese)

7 Operating Instructions Not used Not used DRB1227

(English/French/German/Italian/

Dutch/Spanish)

NSP 8 Limited Warranty DRY1177 Not used Not used

NSP 13 Caution Card 220V Not used ARR7003 Not used

4

Page 5

KUC type Only

RL, WY types Only

30

4

31

28

28

Refer to "2.4 SLOT-IN

MECHANISM ASSY".

Refer to "2.3 EXTERIOR (2/2)".

14

28

28

19

15

28

20

9

23

22

23

22

22

22

23

28

6

28

28

24

21

3

12

28

1

27

7

8

17

31

10

32

11

28

28

25

13

28

28

2

27

5

18

28

23

28

28

26

29

16

32

28

28

6

28

A

B

B

C

C

A

2.2 EXTERIOR (1/2)

CDJ-100S

5

Page 6

CDJ-100S

(1) EXTERIOR (1/2) PARTS LIST

Mark No. Description Part No.

1 MOTHER BOARD ASSY

2 TRANS BOARD ASSY

NSP 3 SL MECHA BOARD ASSY DWS1294

NSP 4 DIGITAL OUT BOARD ASSY

5 Strain Relief

6 Earth Lead Unit/300V DDF1010

7 Connector Assy

8 Connector Assy (2P)

9 S Flex DNP1748

10 Power Transformer

11 AC Power Cord

12 Connector Assy PF03PP–B30

13 Fuse (FU1)

NSP 14 Slot-in Mechanism Assy DXA1845

15 Insulator DEC2235

16 Insulator MO DEC2250

17 Earth Plate DNF1588

18 Cable Stay DNF1589

19 Bottom Plate

NSP 20 Chassis

21 Earth Spring DBH1398

22 Float Spring DBH1428

23 Damper DEC2236

24 Mecha Holder DNH2339

25 Power Knob DAC1895

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

Mark No. Description Part No.

26 Push Rod DEX1008

27 Screw BBZ30P080FMC

28 Screw BPZ30P080FZK

29 Screw BPZ30P140FMC

30 Nylon Rivet (3 × 4.5)

31 Binder ZCA–SKB90BK

NSP 32 Binder Z09–061

See Contrast table (2)

(2) CONTRAST TABLE

CDJ-100S/KUC, RL and WY are constructed the same except for the following:

No.

Symbol and Description

KUC type RL type WY type

1 MOTHER BOARD Assy DWM2078 DWM2079 DWM2079

2 TRANS BOARD Assy DWR1298 DWR1301 DWR1300

NSP 4 DIGITAL OUT BOARD Assy DWZ1082 Not used Not used

5 Strain Relief CM–22C CM–22B CM–22B

7 Connector Assy DKP3408 Not used Not used

8 Connector Assy (2P) DKP3409 Not used Not used

10 Power Transformer (AC120V) DTT1148 Not used Not used

10 Power Transformer Not used DTT1149 Not used

(AC110–120V/220–240V)

10 Power Transformer (AC220–240V) Not used Not used DTT1150

11 AC Power Cord PDG1063 PDG1003 PDG1003

13 Fuse (FU1) VEK1009 AEK1051 AEK1051

19 Bottom Plate DNH2341 DNH2338 DNH2338

NSP 20 Chassis DNK3562 DNK3561 DNK3553

30 Nylon Rivet (3 × 4.5) RBM–003 Not used Not used

Part No.

RemarksMark

6

Page 7

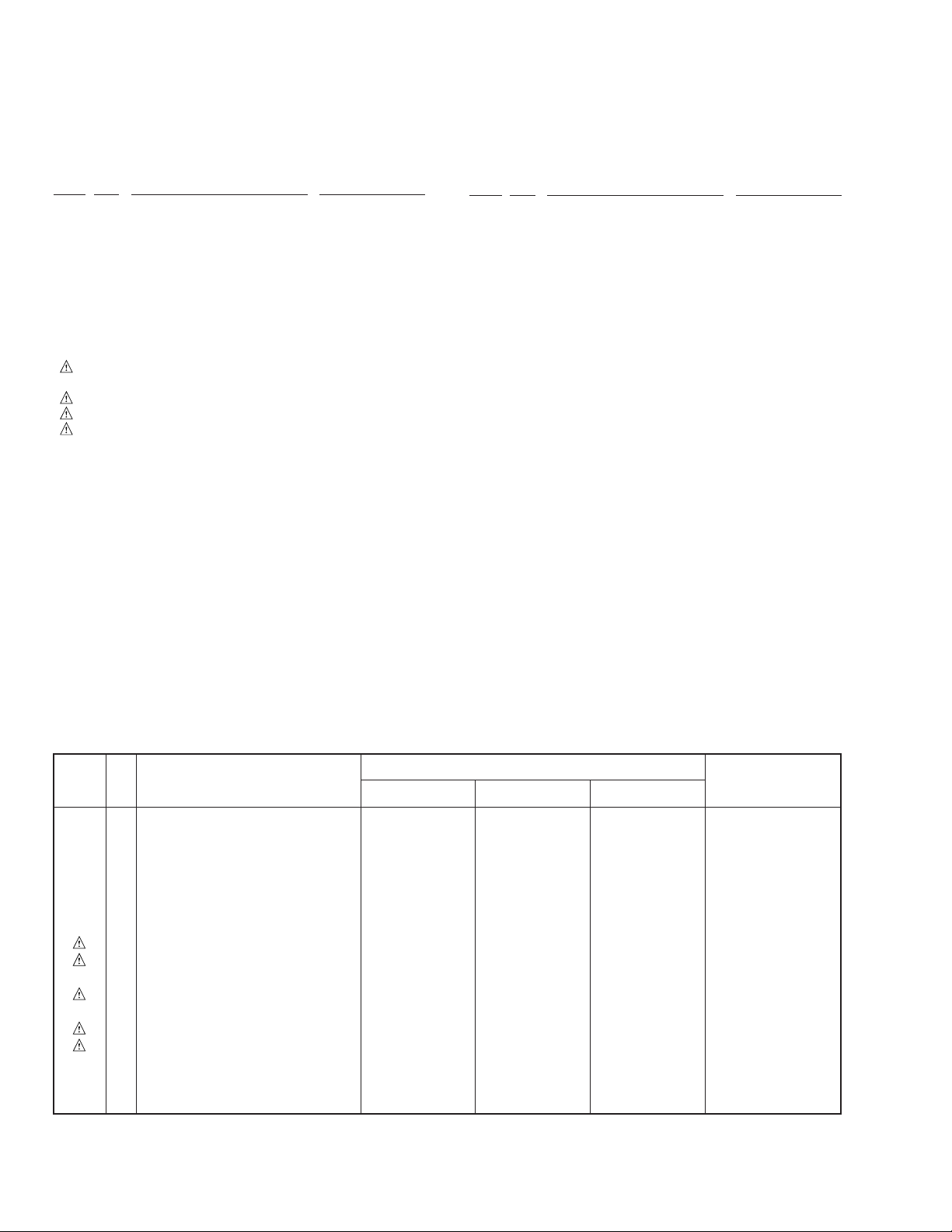

2.3 EXTERIOR (2/2)

CDJ-100S

∗1

17

5

23

12

13

15

Dyefree ME-413A: ZLX-ME413A

∗1

11

14

10

(1) EXTERIOR (2/2) PARTS LIST

Mark No. Description Part No.

25

3

22

A

4

4

22

16

19

20

18

1

22

22

6

26

27

7

21

(KUC type Only)

(WY type Only)

9

8

NSP 19 Knob A DAC1890

22

A

22

3

22

2

24

22

NSP 24 Binder Z09–061

NSP 27 Caution Label HE

1 DISPLAY BOARD ASSY DWG1503

2 36P F·F·C/60V DDD1131

3 Earth Lead Unit/300V PDF1104

4 Cushion C DEC2259

5 POM Ring DNK3556

6 Knob B DAC1891

7 Time Knob DAC1892

8 MT Knob DAC1893

9 Eject Knob DAC1894

10 Slide Sheet DAH1855

11 Display Plate DAH1886

12 Ring Plate DAH1887

13 Jog Washer DBF1001

14 Slide Knob DNK2936

15 Control Panel DNK3552

16 Disc Indicator DNK3555

17 Jog Dial DNK3625

18 Knob A Assy DXA1846

20 LED Lens PNW2019

21 65 Label

22 Screw BPZ30P080FZK

23 Nut (M9) DBN1004

25 Earth Plate VBK1070

26 Caution Label

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

(2) CONTRAST TABLE

CDJ-100S/KUC, RL and WY are constructed the same except for the following:

No.

Symbol and Description

KUC type RL type WY type

21 65 Label ORW1069 Not used Not used

26 Caution Label Not used Not used VRW1094

NSP 27 Caution Label HE Not used Not used VRW1297

Part No.

RemarksMark

7

Page 8

CDJ-100S

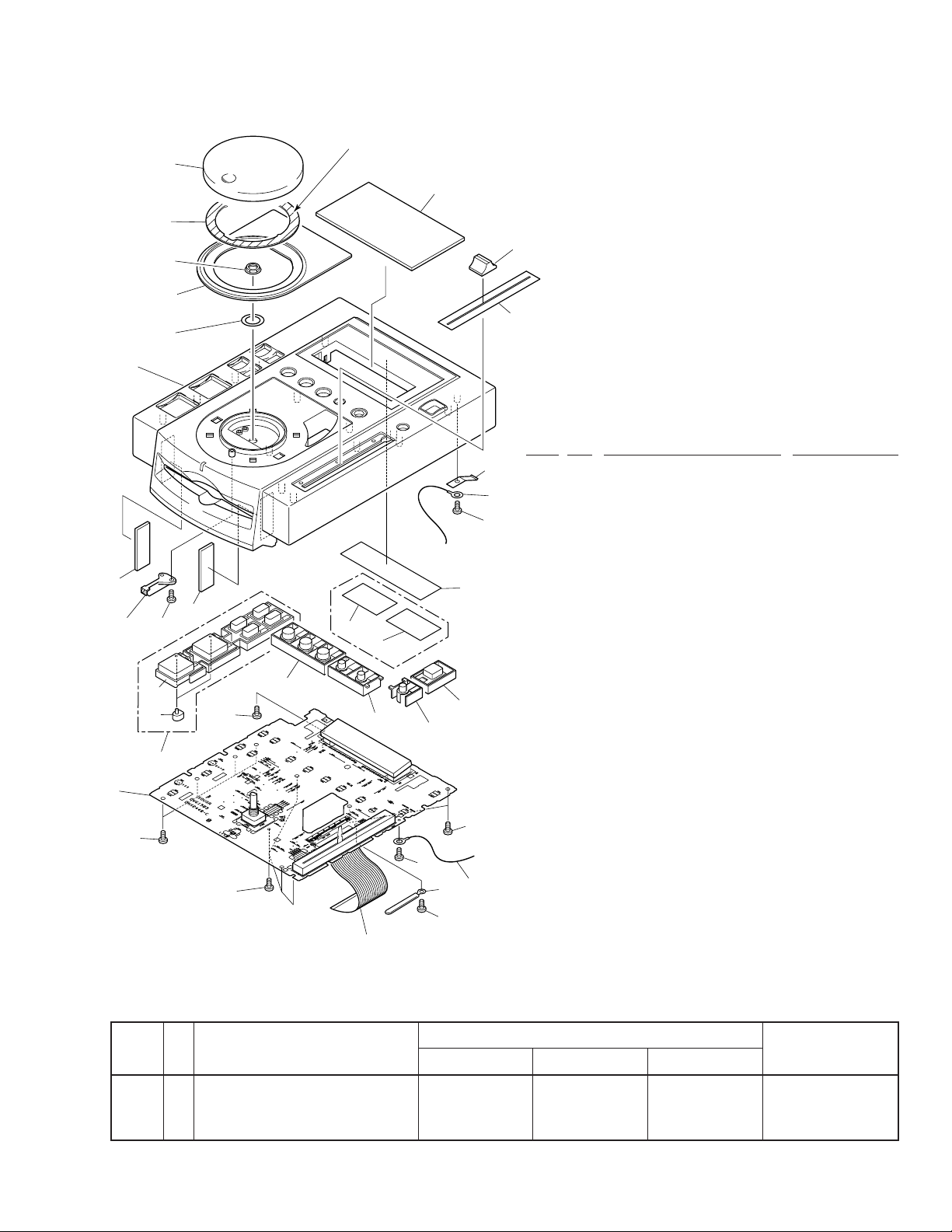

2.4 SLOT-IN MECHANISM ASSY

6

1

17

2

12

∗2

∗2

7

∗1

Dyefree ME-413A: ZLX-ME413A

∗2

Froil PN-397B: ZLB-PN397B

20

11

3

22

4

14

15

9

∗1

∗2

10

5

23

8

9

21

Refer to " 2.5 SERVO

MECHANISM ASSY SECTION".

9

16

19

18

13

To MOTHER BOARD

ASSY CN201

8

Page 9

CDJ-100S

SLOT-IN MECHANISM ASSY PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 Clamper Assy DXA1821

2 Clamp Spring DBH1374

3 Guide Spring DBH1375

4 Lever B DNK3558

5 Loading Motor Assy-S DEA1008

6 Main Cam DNK3407

7 Loading Gear DNK3409

NSP 8 Worm Gear DNK3410

9 Mount Bush DEB1328

10 Connector Assy PF02PY-B27

11 Clamp Arm DNK3404

12 Drive Gear DNK3565

13 Float Base Assy DXB1683

14 Disc Guide DNK3478

15 Front Sheet DED1132

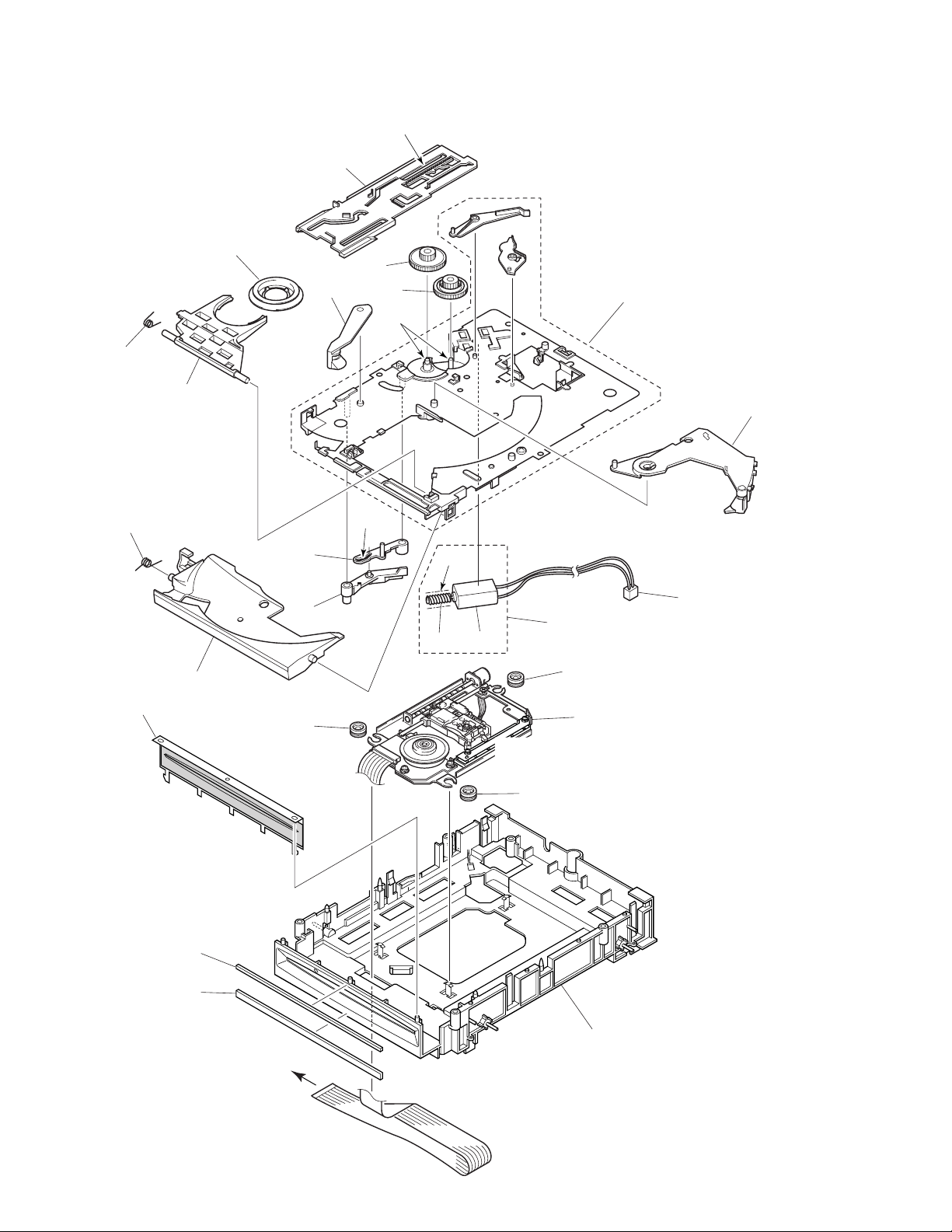

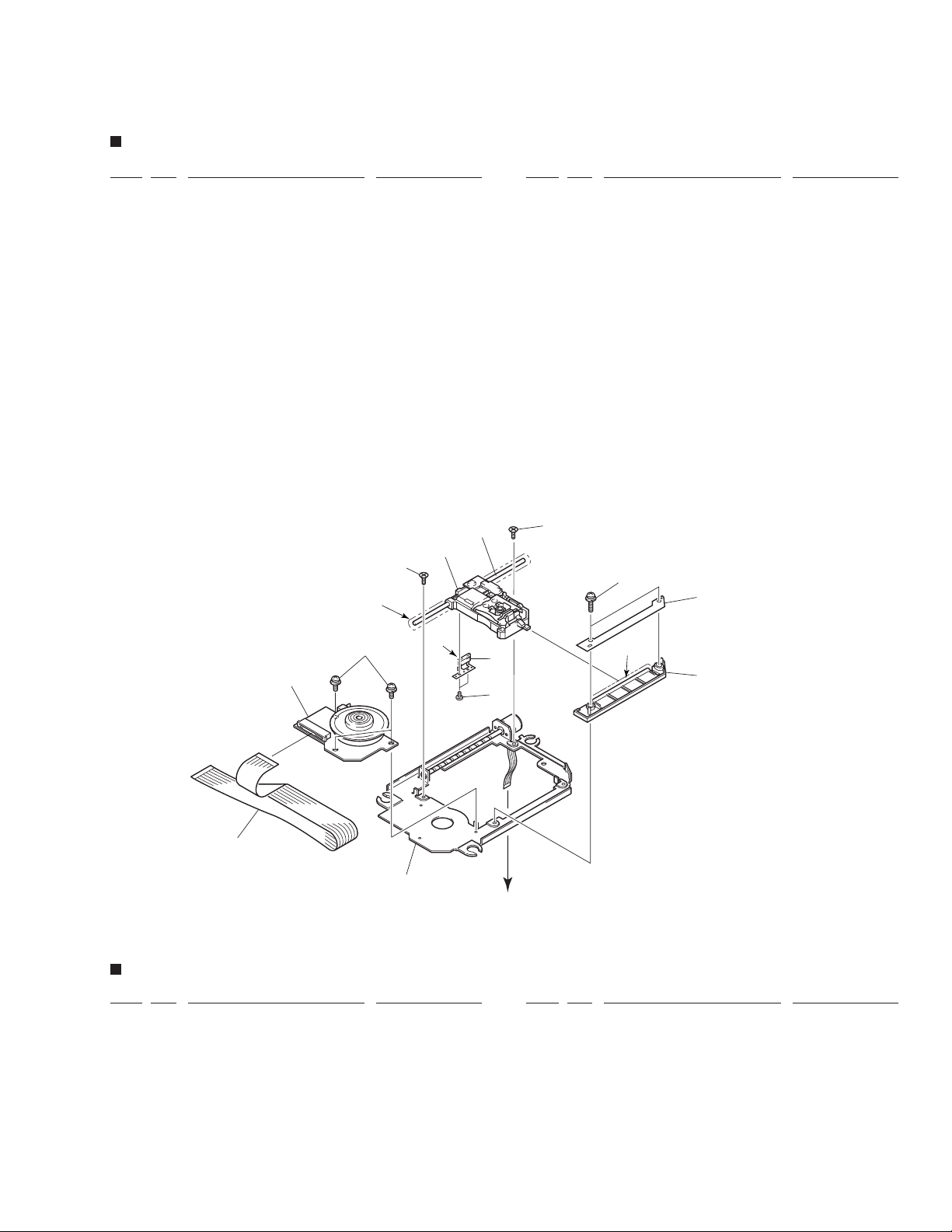

2.5 SERVO MECHANISM ASSY

6

∗2

14

1

∗3

12

16 Eject Lever DNK3548

17 Loading Lever DNK3406

18 Cushion A DEC2257

19 Cushion B DEC2258

20 Loading Base Assy-S DXX2431

21 Servo Mechanism Assy-S DXX2432

22 Lever A DNK3564

NSP 23 Loading Motor DXM1093

7

2

9

6

13

10

∗1

8

11

3

To MOTHER BOARD

SERVO MECHANISM ASSY PARTS LIST

Mark No. Description Parts No.

1 Spindle Motor DXM1084

2 Screw Guide DNK3238

3 Pulse Motor Frame DXM1085

4 …………………………

5 …………………………

6 Screw CMZ20P060FMC

7 Guide Shaft DLA1731

ASSY CN202

Mark No. Description Parts No.

NSP 12 Pickup Assy DWY1069

∗1

Dyefree ME-413A: ZLX-ME413A

∗2

Froil PN-948P: ZLB-PN948P

∗3

Froil C-1Z: ZLB-C1Z

8 Sub Guide Shaft DNK3638

9 Screw ABA7022

10 Stopper DNH2355

11 SPD Card DDX1165

13 Screw PMA20P080FMC

14 Screw PMH20P040FCC

9

Page 10

1

234

CDJ-100S

3. SCHEMATIC DIAGRAM

Note: When ordering service parts, be sure to refer to "EXPLODED VIEWS AND PARTS LIST" or "PCB PARTS LIST".

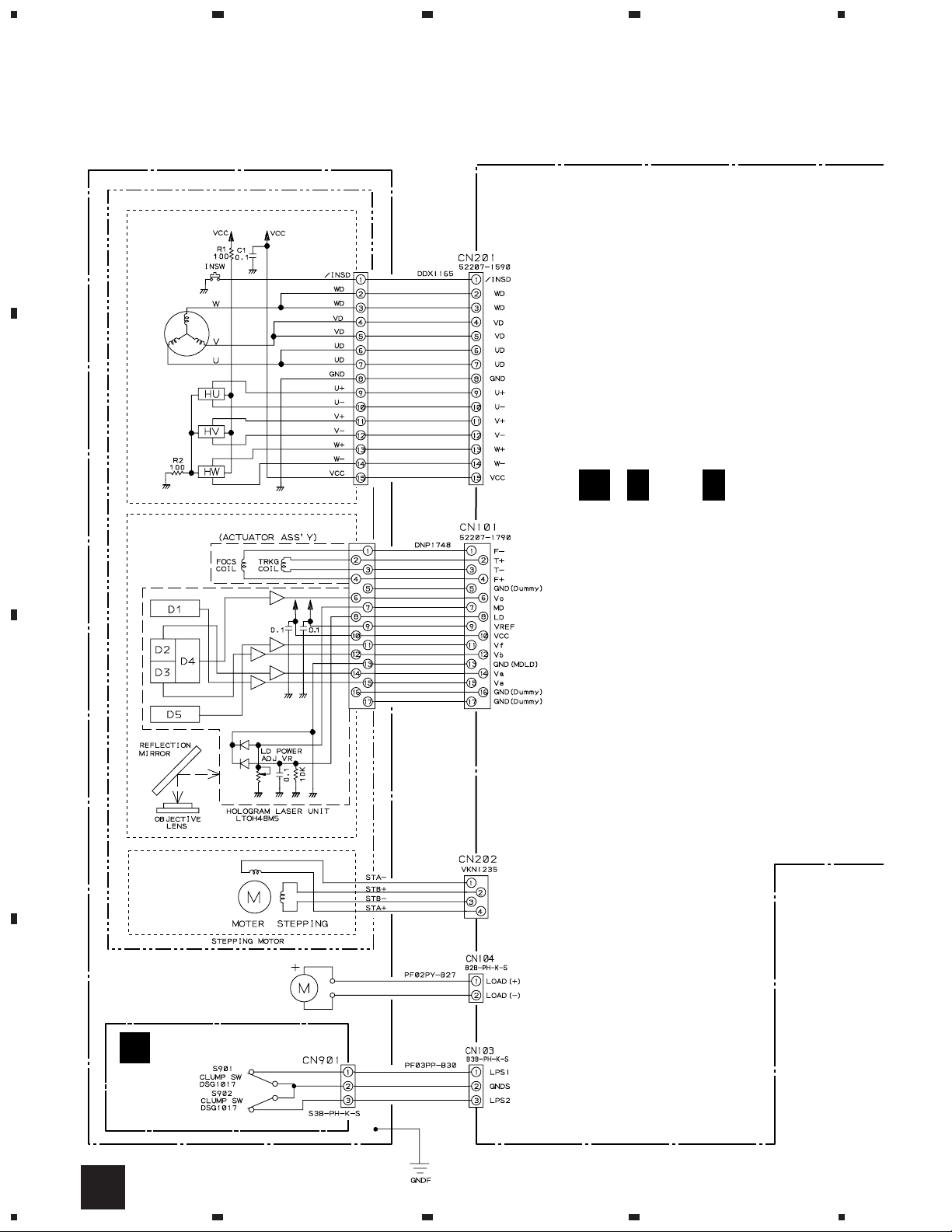

3.1 OVERALL CONNECTION DIAGRAM

A

SLOT-IN MECHANISM ASSY (DXA1845)

SERVO MECHANISM ASSY-S (DXX2432)

SPINDLE MOTOR ASSY (DXM1084)

B

PICKUP ASSY (DWY1069)

B (

MOTHER BOARD ASSY

(DWM2078: KUC type)

(DWM2079: RL and WY types)

B

1/3 to B 3/3

)

C

PULSE MOTOR

FRAME

(DXM1085)

LOADING MOTOR ASSY-S

(DEA1008)

SL MECHA BOARD ASSY

A

D

10

A

(DWS1294)

EARTH LEAD UNIT

PDF1104

1234

Page 11

5

T

B (

MOTHER BOARD ASSY

(DWM2078: KUC type)

(DWM2079: RL and WY types)

B

1/3 to B 3/3

)

67

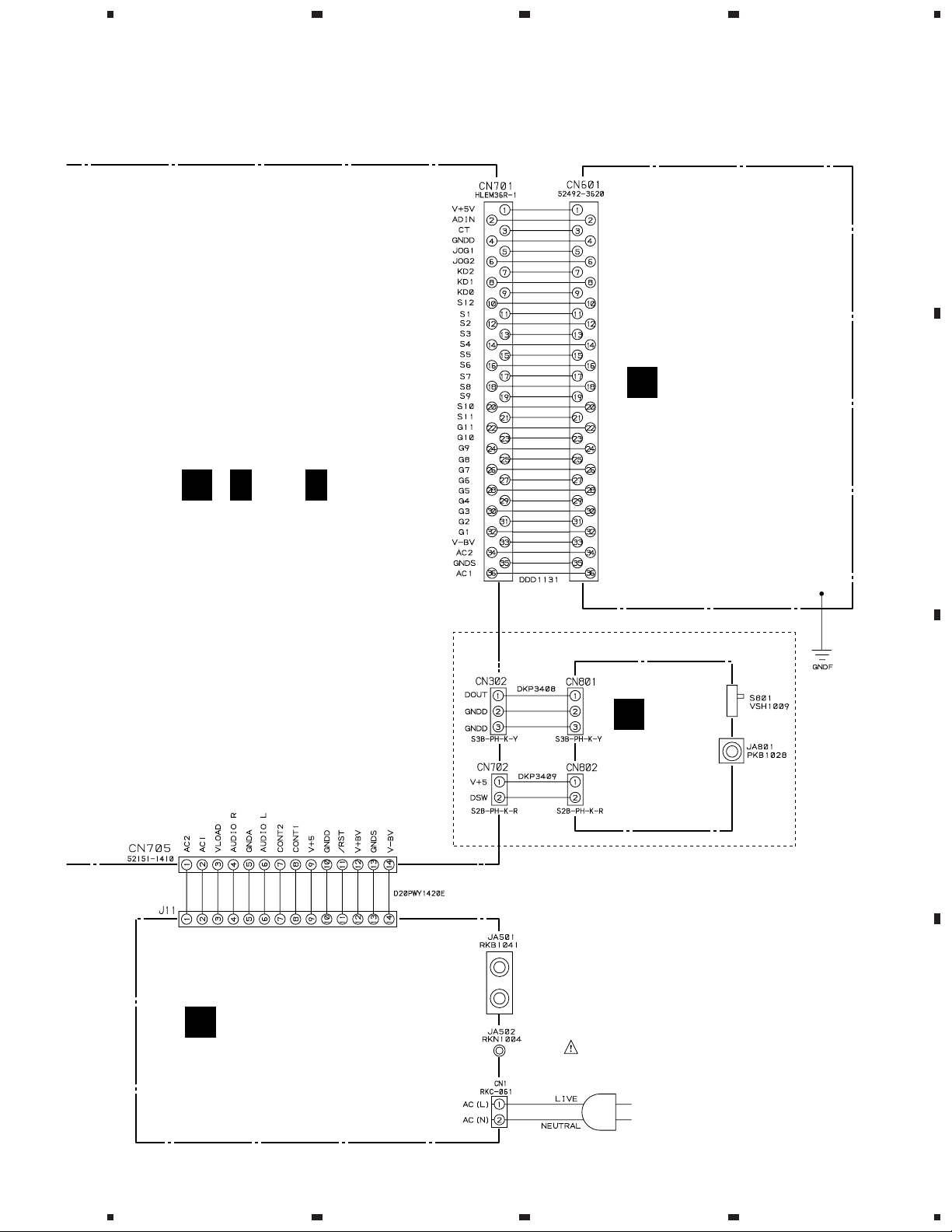

CDJ-100S

DISPLAY BOARD ASSY

D

(DWG1503)

8

A

B

TRANS BOARD ASSY

(DWR1298: KUC type)

C

(DWR1301: RL type)

(DWR1300: WY type)

E

DIGITAL OUT

BOARD ASSY

(DWZ1082)

AC POWER CORD

PDG1015 (KUC)

PDG1003 (RL, WY)

KUC type Only

AC120V (KUC)

AC110–120V, 220–240V (RL)

AC220–240V (WY)

EARTH LEAD UNI

DDF1010

C

D

11

5

6

7

8

Page 12

1

234

CDJ-100S

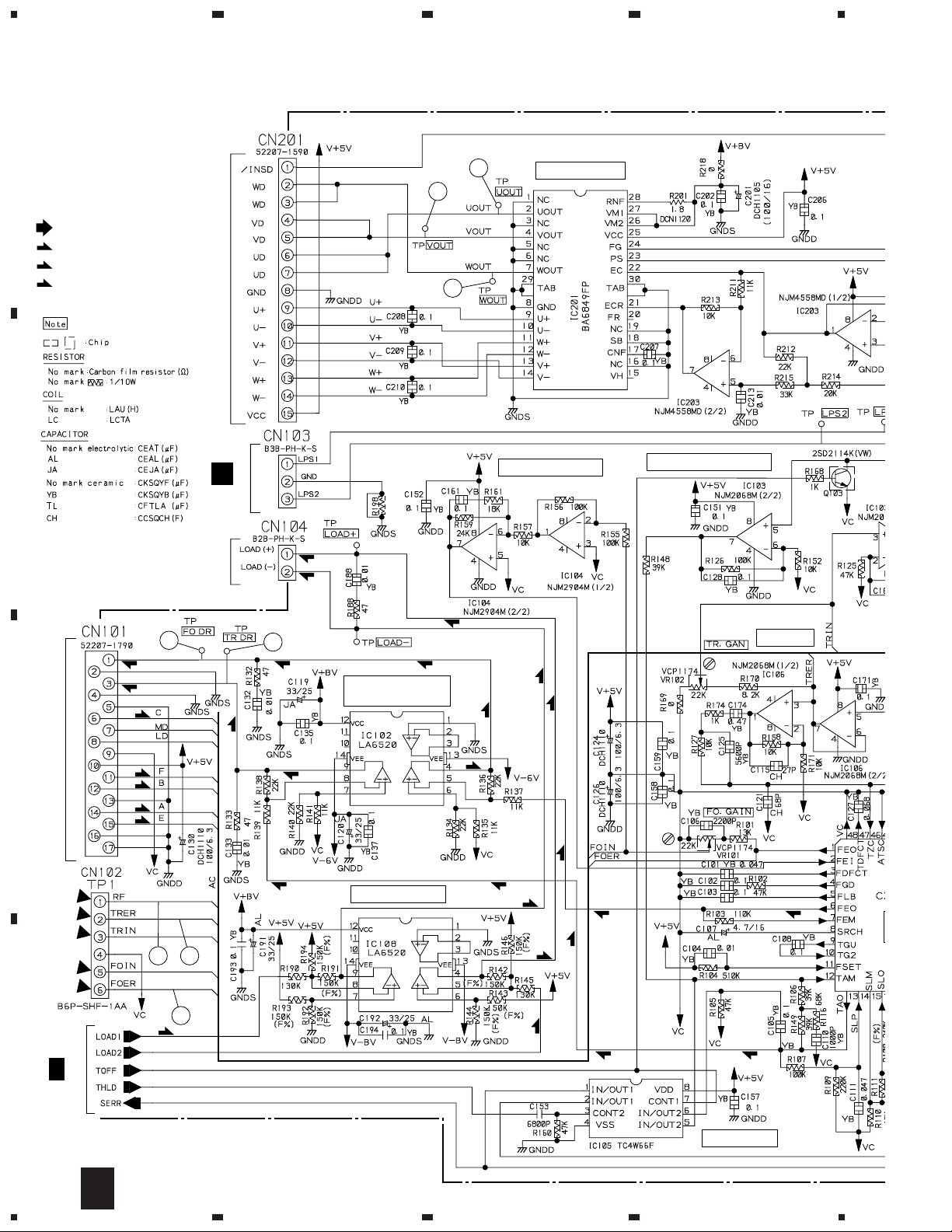

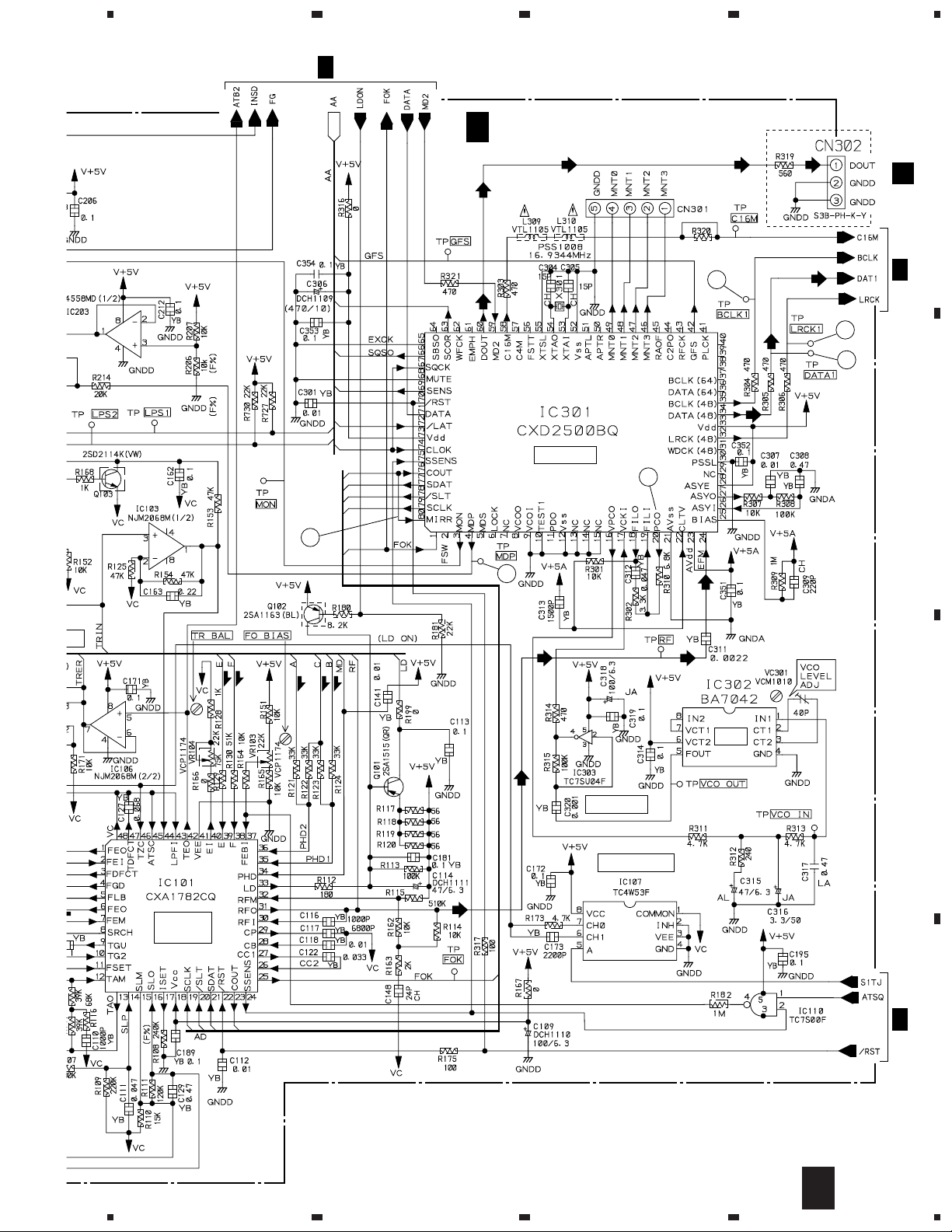

3.2 MOTHER BOARD ASSY (1/3)

A

SIGNAL ROUTE

: RF and Audio Signal Route

(F)

: Focus Servo Loop

(T)

: Tracking Servo Loop

(L)

: LOADING Drive

B

To LOADING MOTOR

ASSY

To SPINDLE MOTOR ASSY

A

CN901

(L)

(L)

7

SPINDLE DRIVE

8

6

FOCUS DC BOOST

TRACKING DC BOOST

(L)

4

(F)

(T)

(F)

C

To PICKUP ASSY

(T)

(F)

(F)

(T)

1 3

2

(L)

D

B

3/3

5

(F)

TRACKING, FOCUS

DRIVE

(T)

(T)

(T) (T)

LOADING DRIVE

(F)

(F)

(F)

(L)

(L)

(F)

(L)

(F) (F)

(L)

(T)

(L)

(T) (T)

TZC AMP

12

B 1/3

ANALOG SW

1234

Page 13

5

67

8

CDJ-100S

B

3/3

17

B

MOTHER BOARD ASSY (1/3)

(DWM2078: KUC type)

1/3

(DWM2079: RL and WY types)

DECODER

20

13

KUC ONLY

12

11

E

CN801

B

2/3

A

B

16

P

(T) (T)

(F)

SERVO

CONTROL

(F)

(F)(F)

VCO

C

INVERTER

ANALOG SW

B

3/3

D

5

6

7

8

B 1/3

13

Page 14

CDJ-100S

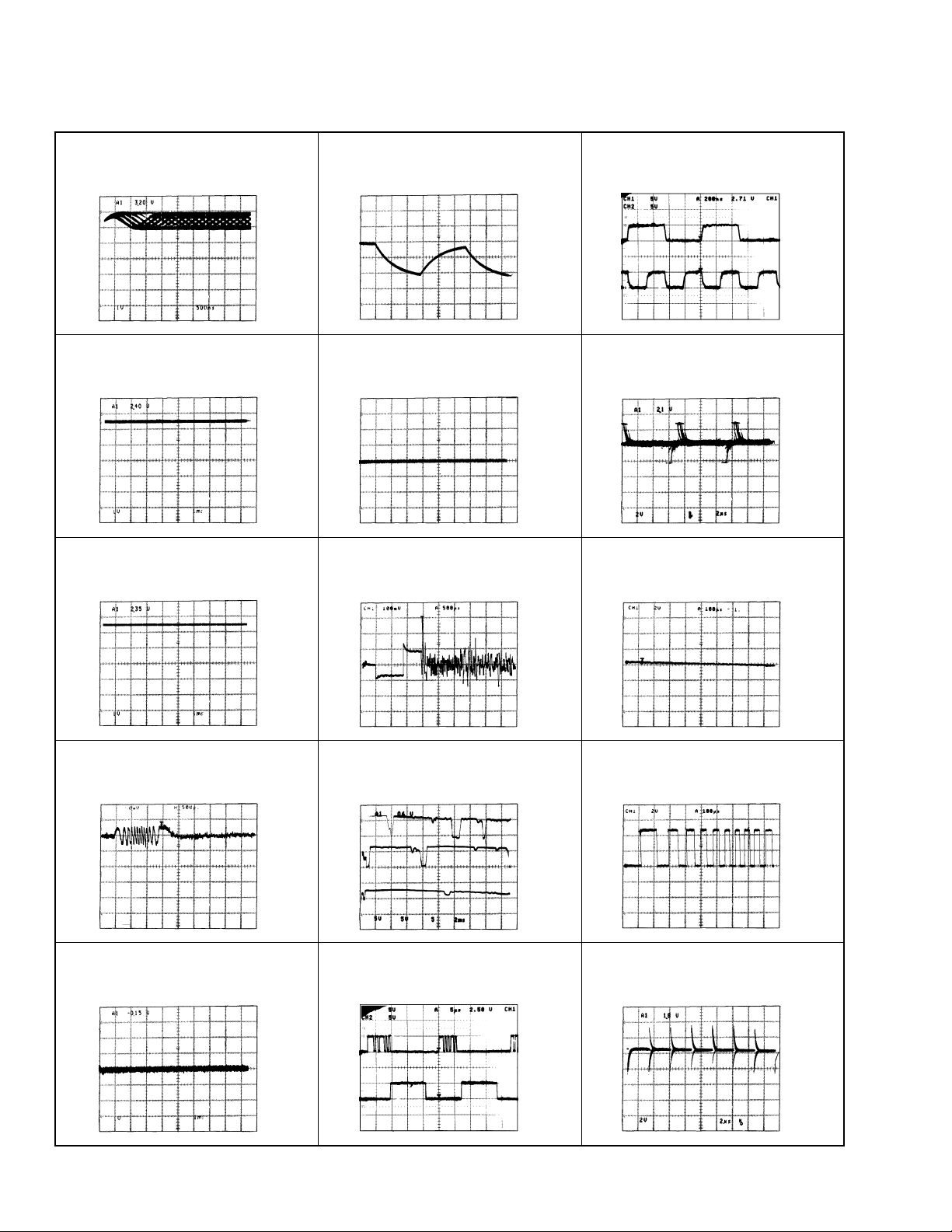

Waveforms of MOTHER BOARD ASSY (1/3)

Note : The encircled numbers denote measuring points in the schematic diagram.

1

TP1 – Pin 1 : PLAY MODE (RF)

1 V/div, 500 ns/div

1

2

TP1 – Pin 6 : PLAY MODE (FOER)

1 V/div, 1 ms/div

2

– GND

– GND

4

TP – FODR : TEST MODE

(FOCUS IN)

5 V/div, 200 ms/div

4

5

TP – TRDR : PLAY MODE

1 V/div, 1 ms/div

5

– +5V

– GND

– –5V

– GND

∗

1 14T-JUMP : After switching to the pause mode,

~

-

~

#

2 V/div, 2 µs/div

Press the manual search key.

TP – DATA1

TP – BCLK1

TP – MDP : PLAY MODE

PLAY MODE

5 V/div, 200 ns/div

– GND

– GND

#

– GND

3

TP1 – Pin 2 : PLAY MODE (TRER)

1 V/div, 1 ms/div

3

3

TP1 – Pin 2 : 14T-JUMP (∗1) MODE

(TRER)

1 V/div, 2 ms/div

3

– GND

4

TP – FODR : PLAY MODE

1 V/div, 1 ms/div

– GND

5

TP – TRDR : 14T-JUMP (∗1) MODE

1 V/div, 200 µs/div

5

6

TP – WOUT

7

TP – UOUT

8

TP – VOUT

6

7

8

-

TP – DATA1

=

TP – LRCK1

PLAY MODE

5 V/div, 2 ms/div

– GND

– GND

– GND

– GND

PLAY MODE

5 V/div, 5 µs/div

$

IC301-Pin80(MIRR) : PLAY MODE

2 V/div, 100 µs/div

$

$

IC301-Pin80(MIRR) : 14T-JUMP (∗1)

MODE

2 V/div, 100 µs/div

$

&

IC301 – Pin20 (PCO) : PLAY MODE

2 V/div, 2 µs/div

– GND

– GND

14

4

– GND

-

=

– GND

– GND

&

– GND

Page 15

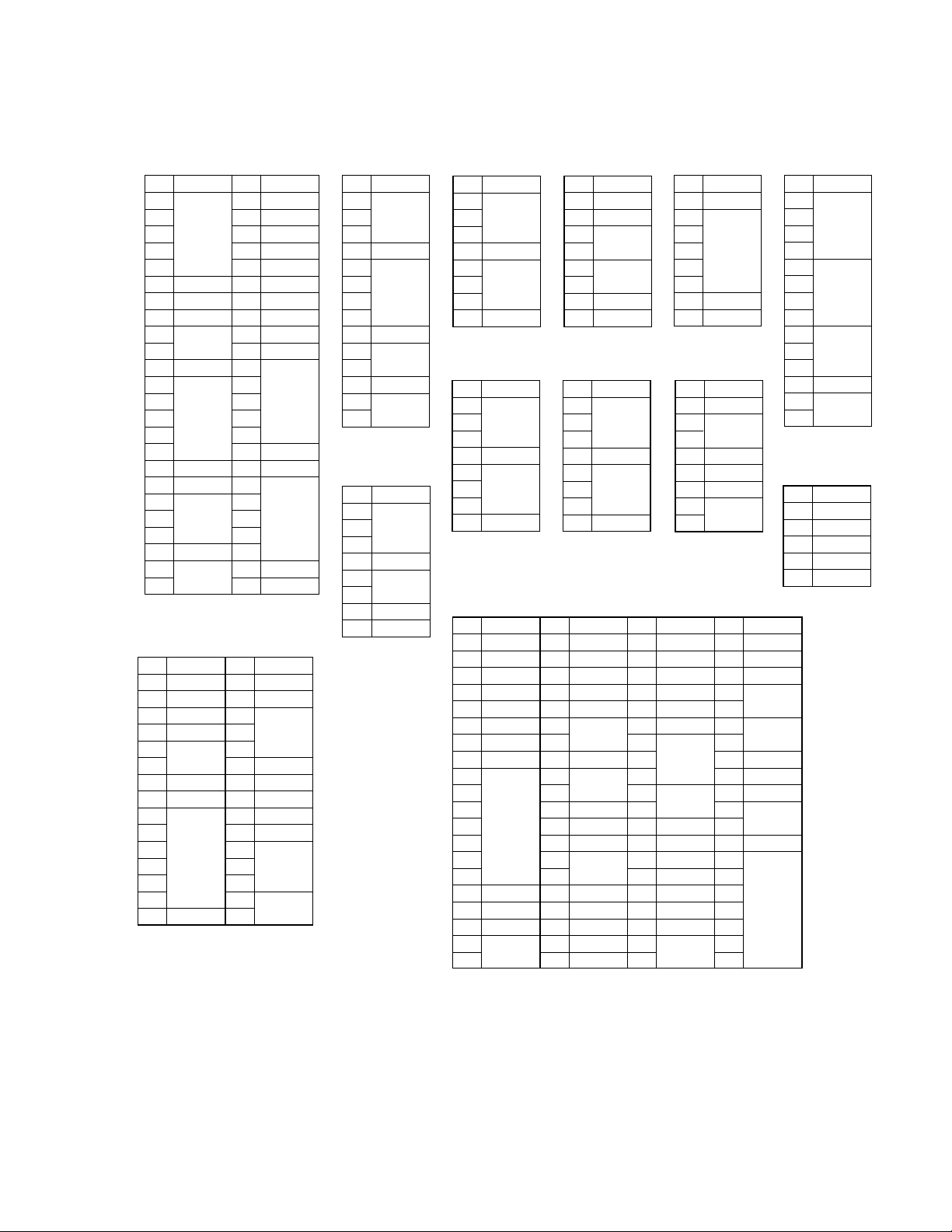

Voltages of MOTHER BOARD ASSY (1/3)

Set: DJ mode PLAY

IC101

(CXA1782CQ)

Voltage [ V ]

No.

1

2

+2.53

4

5

+2.76

+2.57

+2.78

9

+2.5

10

+0.811

12

13

+2.514

15

16

+1.217

+4.918

19

0 to +520

21

+4.922

23

0 to +5

24

IC201

(BA6849FP)

Voltage [ V ]

No.

1

0

2

+6.0

0

3

4

+6.0

5

0

6

+6.07

08

9

10

11

+2.5

12

13

14

15

+0.5

No.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

No.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Voltage [ V ]

+4.9

+0.6

+0.7

+1.6

+2.3

+2.5

+3.5

+2.5

+3.4

0

+2.5

+2.2

0

+2.5

+2.4

+2.5

Voltage [ V ]

0

+0.5

0

+2.6

+2.5

+4.9

+2.4

+4.9

+7.5

0

IC102

(LA6520)

Voltage [ V ]

No.

1

2

0

3

–0.3

4

5

6

+1.6

7

8

9

–0.1

10

11

12

13

14

0

+8.0

–8.7

IC203

(NJM4558MD)

Voltage [ V ]

No.

1

2

+2.5

3

0

4

5

+2.6

6

7

+2.7

+4.98

IC103

(NJM2068M)

No.

IC104

(NJM2904M)

No.

IC301

(CXD2500BQ)

No.

10

11

12

13

14

15

16

19

20

Voltage [ V ]

1

2

3

4

5

7

Voltage [ V ]

1

2

3

4

5

7

Voltage [ V ]

1

2

3

4

5

6

9

+2.5

0

+2.56

+4.98

+2.5

0

+2.56

+4.98

+4.9

0

+4.9

+2.7

0

+4.9

07

+4.98

0

+2.6

+2.517

018

+2.6

IC105

(TC4W66F)

No.

1

2

3

4

5

6

7

IC106

(NJM2068M)

No.

1

2

3

4

5

7

Voltage [ V ]

No.

21

0

22

+2.5

+4.9

23

+1 to +4

24

25

+0.9

26

+2.5

27

+4.928

29

0

30

+2.531

32

0 to 5

33

+5

34

0 to 5

35

36

+2.5

+2.437

+2.538

39

0

+4.9

40

Voltage [ V ]

+2.6

+2.5

0

+2.5

0

+4.98

Voltage [ V ]

+2.5

0

+2.56

+4.98

No.

41

42

43

44

45

46

47

49

50

51

52

53

54

55

56

59

60

IC107

(TC4W53F)

Voltage [ V ]

No.

1

2

3

4

5

6

7

IC302

(BA7042)

Voltage [ V ]

No.

1

2

3

4

5

6

7

8

Voltage [ V ]

+2.3

+4.9

+2.5

0

+4.9

+4.4

048

+1.2

0

+2.6

+2.7

0

+2.8

+1.457

+2.158

0

+2.5

0

+2.5

+4.98

+2.4

+2.1

0

+3.5

+4.9

+2.4

No.

61

62

63

64

65

66

67

69

70

71

72

73

74

75

76

77

78

79

80

CDJ-100S

IC108

(LA6520)

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

IC303

(TC7SU04F)

No.

1

2

3

4

5

Voltage [ V ]

0

+2.5

0 to +5

0

0 to +5

068

0 to +5

+4.9

0 to +5

+4.9

0 to +5

Voltage [ V ]

0

+2.5

0

+8.0

–8.7

Voltage [ V ]

0

+2.5

0

+2.6

+4.9

15

Page 16

1

234

CDJ-100S

3.3 MOTHER BOARD ASSY (2/3)

MOTHER BOARD ASSY (2/3)

A

B 2/3

B 1/3

B

(DWM2078: KUC type)

(DWM2079: RL and WY types)

IC402 (MB814800–70PJ)

Pin No.

Voltage [ V ]

Pin No.

Voltage [ V ]

DRAM (512k × 8 bit)

SIGNAL ROUTE

: RF and Audio Signal Route

1

2 3 4 5 6 7 8 9 10 11 12 13 14

+4.9 +4.90 to +5

15 16 17 18 19 20 21 22 23 24 25 26 27 28

00 0

0 to +5 0 to +5

Set: DJ MODE PLAY

0 to +50

! IC401 Pin 24 (SDA)

@ IC401 Pin 25 (SCL)

PLAY MODE 5 V/div, 20 µs/div

!

@

– GND

– GND

14 15

DSP

C

D

16

B 2/3

1234

Page 17

5

67

8

CDJ-100S

B 3/3

IC401 (MN19413A–P)

Pin No.

1

2

4

6

7

8

9

10

12

13

14

16

17

18

19

20

21

22

23

24

Voltage [ V ]

+1.5

+4.93

0 to +55

0

+2.4

011

0 to +515

+4.9

0

0 to +5

025

Pin No.

28

29

30

32

33

34

35

36

38

39

41

42

43

44

46

47

48

49

Voltage [ V ]

0 to +537

0 to +545

026

+4.927

031

040

050

MUTE

Pin No.

51

52

53

54

55

56

57

58

59

60

71

72

Voltage [ V ]

0 to +5

Set: DJ MODE PLAY

+4.9

061

+2.562

+2.663

+4.964

+2.465

+2.566

067

+4.968

069

+4.970

0

+1.473

+4.974

075

Pin No.

76

77

78

79

80

81

82

83

84

90

92

93

96

99

100

Voltage [ V ]

+4.9

+4.9

+1.085

+2.486

+1.088

+2.589

+4.991

+2.394

+1.5

+4.998

+1.5

0

0

0

087

0

0

095

097

B

C

J11

A

LPF

C

+7.5

0

0

+1.2

0

+1.2

5

6

7

8

B 2/3

17

D

Page 18

1

234

CDJ-100S

3.4 MOTHER BOARD ASSY (3/3)

Waveforms

9

A

TP – STA +

0

TP – STA –

9

0

%

TP – RST : POWER ON

2 V/div, 5 ms/div

%

B

%

TP – RST : POWER OFF

2 V/div, 10 ms/div

PLAY MODE

5 V/div, 5 µs/div

– GND

– GND

– GND

B

3/3

10 9

To Pulse Motor Frame

AUTO TRACKING BALANCE

MOTHER BOARD ASSY (3/3)

(DWM2078: KUC type)

(DWM2079: RL and WY types)

STEPPING DRIVE

%

– GND

^

TP – RST3 : POWER ON

2 V/div, 1 µs/div

C

^

^

TP – RST3 : POWER OFF

2 V/div, 200 ms/div

– GND

IC901

(NJM2904M)

Pin No.

1

2

3

4

6

7

8

Voltage [ V ]

+2.5

0

+2.45

+2.5

+2.2

+4.9

IC902

(NJM2904M)

Voltage [ V ]

Pin No.

+2.2

1

2

+2.5

3

0

4

5

+2.5

6

+2.6

7

+7.4

8

Set: DJ MODE PLAY

18

^

– GND

D712, D713,

D

B

18

B 3/3

1234

2/3

D729, D730: 1SS355

Page 19

5

IC206

(MPC17A85ZVM)

1

Pin No.

Voltage [ V ]

Pin No.

Voltage [ V ]

Pin No.

Voltage [ V ]

Pin No.

Voltage [ V ]

2345678

0 +4.6 +4.9 0 +1.5 +0.2 +0.4 +0.5

9 10111213141516

+0.4 +4.9 +1.50 +0.1 +0.5 0+4.8

17

18 19 20 21 22 23 24

+0.2+3.2 +0.5

25 26 27 28 29 30

+2.5 +4.9 +4.9

Set: DJ MODE PLAY

+19.3

+4.8

0 to +5

+11.9

+7.2+1.4

67

8

CDJ-100S

IC701 (PD4977B)

Voltage [ V ]

Voltage [ V ]

Voltage [ V ]

Voltage [ V ]

1

Pin No.

Pin No.

Pin No.

Pin No.

2 3 4 5 6 7 8 9 10 11 12 13 14

21 22 23 24 25 26 27 28 29 30 31 32 33 34

+4.9 +4.9 +2.4 +2.5 +2.5+2.2+2.3 +2.6 +2.50000

0 to +5

41

42 43 44 45 46 47 48 49 50 51 52 53 54

+4.9 +3.0 +4.9

0

61 62 63 64 65 66 67 68 69 70 71 72 73 74

0

+4.9

–30.5 to +5 –30.5 to +5 –30.5 to +5

+4.900 0 0

00+4.9 +4.8

0 to +5

–30.5 –30.5

SIGNAL ROUTE

(L)

Set: DJ MODE PLAY

15 16 17 18 19 20

0 to +5 0 to +5–30.5 to +5

+4.9

35 36 37 38 39 40

55 56 57 58 59 60

+4.9

75 76 77 78 79 80

: LOADING DRIVE

+4.9

(L)(L)

(L)(L)

A

B

19

IC701

PD4977B

SYSTEM CONTROL

EXCEPT KUC

KUC ONLY

B

1/3

E

CN802

C

D

CN601

D

5

6

7

FFC DDD1131

B 3/3

8

19

Page 20

1

CDJ-100S

3.5 TRANS BOARD ASSY

234

A

B

CN705

B

2/3

+5V REGULATOR

HEAT SINK

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TIME NO. ICP-N25, MFD BY

ROHM CO., LTD. FOR IC91.

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF

C

TRANS BOARD ASSY

(DWR1298: KUC type)

C

(DWR1301: RL type)

(DWR1300: WY type)

D

FIRE. REPLACE ONLY WITH SAME TIME NO. ICPN10, MFD BY ROHM CO., LTD. FOR IC92.

SIGNAL ROUTE

: RF and Audio Signal Route

20

C

1234

Page 21

5

67

8

CDJ-100S

POWER TRANSFORMER

DTT1148

POWER TRANSFORMER

DTT1149

NOTE FOR FUSE REPLACEMENT

CAUTION: FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME

TIME AND RATINGS ONLY.

NOTE FOR FUSE REPLACEMENT

CAUTION: FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME

TIME AND RATINGS ONLY.

A

AC POWER CORD

PDG1015

AC120V

60 Hz

B

RL type

POWER TRANSFORMER

DTT1150

NOTE FOR FUSE REPLACEMENT

CAUTION: FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME

TIME AND RATINGS ONLY.

AC POWER CORD

PDG1003

AC110–120V/

220–240V

50/60 Hz

C

WY type

AC POWER CORD

PDG1003

AC220–240V

50/60 Hz

D

C

5

6

7

8

21

Page 22

1

234

CDJ-100S

3.6 DISPLAY BOARD and DIGITAL OUT BOARD ASSEMBLIES

A

D FLIP–FLOP

B

FL HOLDER

DEB1396 × 2

C

D

B

3/3

CN701

DISPLAY BOARD ASSY

D

(DWG1503)

LED ON/OFF

Short: TEST MODE

Short: AGING MODE

ENCODER

22

D

1234

Page 23

5

67

8

CDJ-100S

(GRN)

(YEL)

SWITCHES:

S601: TRACK SEARCH (4)

S602: SEARCH (1)

S603: PLAY/PAUSE (6)

S604: TRACK SEARCH (¢)

S605: SEARCH (¡)

S606: CUE

S607: DIGITAL JOG BREAK (JET)

S608: MASTER TEMPO

S609: DIGITAL JOG BREAK (ZIP)

S610: DIGITAL JOG BREAK (WAH)

S611: EJECT (0)

S613: TIME MODE/AUTO CUE

S615: DIGITAL JOG BREAK (HPLD)

(GRN)

LED HOLDER

(GRN)

S601, S602, S604, S605,

S607–S611, S613, S615: VSG1008

S603, S606: DSG1063

SLIDER VR

A

B

KUC type Only

B

1/3

CN302

B

3/3

CN702

5

DIGITAL OUT BOARD ASSY

E

(DWZ1082)

C

SIGNAL ROUTE

: RF and Audio Signal Route

EARTH

PLATE

ANK1074

D

6

7

EARTH LEAD UNIT

E

8

D

23

Page 24

1

234

CDJ-100S

4. PCB CONNECTION DIAGRAM

4.1 SL MECHA BOARD, MOTHER BOARD, TRANS BOARD and

DIGITAL OUT BOARD ASSEMBLIES

A

SIDE A

MOTHER BOARD ASSY

B

SLOT-IN MECHANISM

ASSY

Stepping Motor

B

Loading Motor Assy

A

SL MECHA BOARD

ASSY

C

Spindle Motor Assy

Pickup Assy

(DNP1873–C)

D

VR101–VR104 VC301

24

IC206

IC103 IC104 IC105

A

B

1234

IC303 IC302 IC405 IC109 Q403

IC106Q103

IC107 IC402

IC201 IC110 IC902 IC901 IC108

IC101 Q101 Q102 IC701

IC401IC301IC203

Q404 Q401 Q402

Page 25

5

67

8

CDJ-100S

SIDE A

(DNP1872–C)

C

TRANS BOARD ASSY

AC POWER CORD

DIGITAL OUT

E

BOARD ASSY

(DNP1873–C)

KUC type Only

NOTE FOR PCB DIAGRAMS:

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol in PCB

Diagrams

BCE

BCE

Symbol in Schematic

Diagrams

BCE

BCE

BCEBCE

Part Name

Transistor

Transistor

with resistor

A

B

Q401 Q402 Q406

D

CN601

IC95

IC94

IC93

Q1

IC91

IC23

IC92

(DNP1873–C)

DGSDGS

DGS

3. The parts mounted on this PCB include all necessary parts

for several destination.

For further information for respective destinations, be sure

to check with the schematic diagram.

4. Viewpoint of PCB diagrams

P. C. Board Chip Part

CapacitorConnector

Field effect

transistor

Resistor array

3-terminal

regulator

SIDE A

SIDE B

C

D

B

5

6

7

C E

8

25

Page 26

1

CDJ-100S

234

DIGITAL OUT

SIDE B

E

BOARD ASSY

A

C

TRANS BOARD ASSY

(DNP1873–C)

B

C

D

(DNP1873–C)

26

C E

1234

Page 27

5

67

8

CDJ-100S

MOTHER BOARD ASSY

B

SIDE B

A

(DNP1872–C)

B

C

D

B

5

6

7

8

27

Page 28

1

234

CDJ-100S

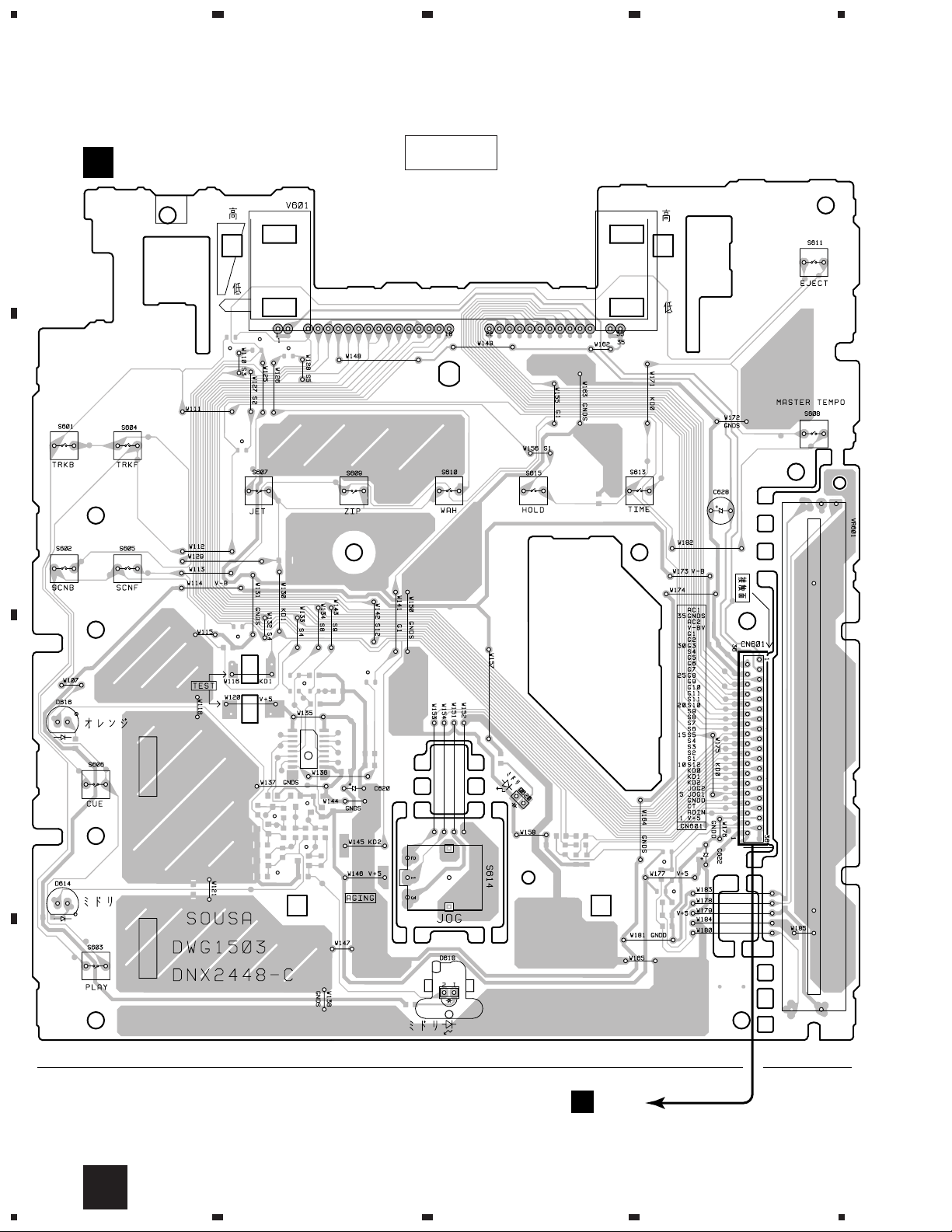

4.2 DISPLAY BOARD ASSEMBLY

A

B

DISPLAY BOARD ASSY

D

SIDE A

C

D

(DNP1873–C)

28

VR601

CN701

B

D

1234

Page 29

1

23

4

CDJ-100S

DISPLAY BOARD ASSY

D

SIDE B

A

B

(DNP1873–C)

C

IC602

Q608 Q609

Q610 Q602

Q603 Q601

D

1

2

3

4

29

D

Page 30

CDJ-100S

5. PCB PARTS LIST

NOTES : ÷ Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

÷ The

÷ When ordering resistors, first convert resistance values into code form as shown in the following examples.

LIST OF WHOLE PCB ASSEMBLIES

mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Ex. 1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by

J = 5%, and K = 10%).

560 Ω = 56 × 10

47k Ω = 47 × 10

0.5 Ω = R50 ...................................................................... RN2H Â 5 0 K

1 Ω = 1R0 ......................................................................... RS1P 1 Â 0 K

Ex. 2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω = 562 × 10 1 = 5621 ........................................... RN1/4PC 5 6 2 1 F

1

= 561................................................... RD1/4PU 5 6 1 J

3

= 473 .................................................. RD1/4PU 4 7 3 J

Mark

NSP SUB BOARD ASSY DWX1892 DWX1891 DWX1898

NSP SL MECHA BOARD ASSY DWS1294 DWS1294 DWS1294

NSP DIGITAL OUT BOARD ASSY DWZ1082 Not used Not used

Symbol and Description

KUC type RL type WY type

MOTHER BOARD ASSY DWM2078 DWM2079 DWM2079

DISPLAY BOARD ASSY DWG1503 DWG1503 DWG1503

TRANS BOARD ASSY DWR1298 DWR1301 DWR1300

Part No.

CONTRAST OF PCB ASSEMBLIES

MOTHER BOARD ASSY

B

DWM2078 and DWM2079 are constructed the same except for the following:

Mark

Symbol and Description

DWM2078 DWM2079

C709 CKSQYB103K50 Not used

C719, C720 CKSQYB104K25 Not used

R319 RS1/10S561J Not used

R708 Not used RS1/10S223J

R738 RS1/10S102J Not used

Part No.

Remarks

Remarks

CN302 S3B-PH-K-Y Not used

CN702 S2B-PH-K-Y Not used

TRANS BOARD ASSY

C

DWR1298, DWR1301 and DWR1300 are constructed the same except for the following:

Mark Symbol and Description

DWR1298 DWR1301 DWR1300

S2 Voltage Selector Not used DSA1026 Not used

30

Part No.

Remarks

Page 31

PARTS LIST FOR CDJ-100S/KUC

CDJ-100S

Mark No. Description Part No.

B

MOTHER BOARD ASSY

SEMICONDUCTORS

IC201 BA6849FP

IC302 BA7042

IC101 CXA1782CQ

IC301 CXD2500BQ

IC102, IC108 LA6520

IC402 MB814800-70PJ

IC401 MN19413A-P

IC206 MPC17A85ZVM

IC103, IC106 NJM2068M

IC104, IC901, IC902 NJM2904M

IC203, IC405 NJM4558MD

IC701 PD4977B

IC107 TC4W53F

IC105 TC4W66F

IC110 TC7S00F

IC303 TC7SU04F

Q102 2SA1163

Q101 2SA1515

Q103, Q401, Q402, Q405, Q406 2SD2114K

Q403 DTC124EK

D712, D713, D729, D730 1SS355

D735–D738, D901–D904 1SS355

COILS AND FILTERS

L201 (39 µH) DTL1070

L401 LFA220J

L309, L310 VTL1105

CAPACITORS

C304, C305, C445, C446 CCSQCH150J50

C309 CCSQCH221J50

C148 CCSQCH240J50

C115 CCSQCH270J50

C453–C456 CCSQCH390J50

C451, C452 CCSQCH471J50

C121 CCSQCH680J50

C705, C714 CEAL101M6R3

C191, C192 CEAL330M25

C315, C415 CEAL470M6R3

C107 CEAL4R7M16

C91, C92 CEJA101M16

C219, C318, C401 CEJA101M6R3

C404 CEJA1R0M50

C405, C407, C463, C464 CEJA220M25

C119, C120 CEJA330M25

C316 CEJA3R3M50

C317 CFTLA474J50

C110, C116, C320 CKSQYB102K50

C104, C112, C118, C132, C133 CKSQYB103K50

C141, C188, C213, C220–C224 CKSQYB103K50

C231, C301, C307, C403, C421 CKSQYB103K50

C702, C709, C905 CKSQYB103K50

C102, C103, C105, C108, C113 CKSQYB104K25

C128, C135, C137, C151, C152 CKSQYB104K25

Mark No. Description Part No.

C157–C159, C161, C162 CKSQYB104K25

C171, C172, C181, C189 CKSQYB104K25

C193–C195, C202, C206–C210 CKSQYB104K25

C212, C218, C314, C319 CKSQYB104K25

C351–C354, C402, C406 CKSQYB104K25

C408–C412, C416, C433, C434 CKSQYB104K25

C481, C482, C701, C704, C706 CKSQYB104K25

C713, C717, C719, C720 CKSQYB104K25

C901, C902, C94 CKSQYB104K25

C907 CKSQYB105K10

C711, C712 CKSQYB122K50

C313 CKSQYB152K50

C106, C173, C311 CKSQYB222K50

C163, C903, C904 CKSQYB224K16

C225 CKSQYB332K50

C122 CKSQYB333K50

C111 CKSQYB473K25

C101, C312, C703 CKSQYB473K50

C129, C174, C308 CKSQYB474K16

C125 CKSQYB562K50

C117, C153 CKSQYB682K50

C127 CKSQYB683K25

C201 (100 µF/16V) DCH1105

C93 (330 µF/ 16V) DCH1108

C306 (470 µF/ 10V) DCH1109

C109, C124, C126, C130 DCH1110

(100 µF/6.3V)

C114 (47 µF/6.3V) DCH1111

VC301 (40 pF) VCM1010

RESISTORS

R403, R404 (82 Ω) ACN7049

R223, R224 (1.6 Ω, 1/4W) DCN1109

R201 (1.8 Ω, 1/4W) DCN1120

R461, R462 RN1/10SE2202D

R206, R207 RS1/10S1002F

R142–R144, R146, R191–R194 RS1/10S1503F

R108 RS1/10S2403F

VR101–VR104 (22 kΩ) VCP1174

Other Resistors RS1/10S J

OTHERS

CN201 CONNECTOR (15P) 52207-1590

CN101 CONNECTOR (17P) 52207-1790

CN104 CONNECTOR POST (2P) B2B-PH-K-S

CN103 CONNECTOR POST (3P) B3B-PH-K-S

CN102 TOP POST (6P) B6P-SHF-1AA

P.C. BOARD DNP1872

X401 (20 MHz) DSS1104

X701 (4.19 MHz) DSS1105

CN701 FFC CONNECTOR 36P HLEM36R-1

X301 (16.9344 MHz) PSS1008

CN202 FFC CONNECTOR 4P VKN1235

31

Page 32

CDJ-100S

Mark No. Description Part No.

D

DISPLAY BOARD ASSY

SEMICONDUCTORS

IC602 HD74HC175FP

Q601–Q603 2SC2412K

Q608–Q610 PDTA124EK

D601, D602, D604–D608 1SS355

D610–D613, D625, D691 1SS355

D620 GL3EG43

D618 MPG4361F

D614 SLP3118C51H

D616 SLP4118C51H

SWITCHES AND RELAYS

S603, S606 DSG1063

S614 DSX1051

S601, S602, S604, S605 VSG1008

S607–S611, S613, S615 VSG1008

CAPACITORS

C628 CEJA220M50

C602–C604, C609, C614, C615 CKSQYB103K50

C608, C610, C613, C616, C618 CKSQYB104K25

RESISTORS

VR601 (10 kΩ–B) DCV1009

Other Resistors RS1/10S J

OTHERS

CN601 FFC CONNECTOR 36P 52492-3620

V601 FL INDICATOR TUBE DEL1031

C

TRANS BOARD ASSY

FL HOLDER DEB1396

SEMICONDUCTORS

IC92 ICP-N10

IC91 ICP-N25

IC23 PQ05RR12

Q1 2SB1566

D11–D14, D52 11E2 (TB2)

D502 1SS355

D54 MTZJ27A

D55 MTZJ33B

COILS AND FILTERS

L1 VTL-004

L501, L502 VTL1105

Mark No. Description Part No.

C32 CEAT471M6R3

C12, C23, C24, C591, C83 CKSQYB104K25

C505 CKSQYF103Z50

C11, C13–C17, C56 CKSQYF104Z50

C501, C502 CQMA152J50

RESISTORS

R60 RD1/4VM222J

R551 RD1/4VM271J

Other Resistors RS1/10S J

OTHERS

J11 14P PARALLEL WIRE D20PWY1420E

JA501 PIN JACK 2P RKB1041

JA502 JACK (REMOTE) RKN1004

H1, H2 FUSE HOLDER RKR1003

A

SL MECHA BOARD ASSY

HEAT SINK DNG1077

TERMINAL 2P RKC-061

PCB BINDER VEF1040

SWITCHES AND RELAYS

S901, S902 DSG1017

OTHERS

CN901 KR CONNECTOR 3P S3B-PH-K-S

DIGITAL OUT BOARD ASSY

E

SEMICONDUCTORS

IC801 TC74HCU04AF

COILS AND FILTERS

L801 PTL1003

SWITCHES AND RELAYS

S801 VSH1009

CAPACITORS

C806 CEJA101M6R3

C805 CEJA470M35

C804, C807 CKSQYB103K50

C801, C808, C809 CKSQYB104K25

RESISTORS

All Resistors RS1/10S J

SWITCHES AND RELAYS

S1 RSA1001

CAPACITORS

C1–C3 (10000 pF/AC250V) ACG7020

C25 CEAT102M16

C21 CEAT103M16

C55 CEAT220M50

C52, C54 CEAT221M50

32

OTHERS

JA801 PIN JACK 1P PKB1028

Page 33

6. ADJUSTMENT

Adjustment points

1.2.3.4.5.6.

CD TEST DISC

8-cm DISC

(With at least about

20 minutes recording)

screwdriver

(small)

Precise

screwdriver

screwdriver

(medium)

screwdriver

(large)

39 kΩ

0.001 µF

Low-frequency

oscillator

Dual-trace

oscilloscope

(10 : 1 probe)

Low pass filter 1

(39 kΩ + 0.001 µF)

39 kΩ

0.0018 µF

100 kΩ

Low pass filter 2

(39 kΩ + 0.0018 µF)

Resistor

(100 kΩ)

= Page 36~38

2.3.4.5.6. = Page 36~38

Exchange

MOTHER BOARD ASSY

Exchange

SERVO MECHANISM ASSY

When

6.1 PREPARATIONS

6.1.1 Jigs and Measuring Instruments

6.1.2 Necessary Adjustment Points

CDJ-100S

33

Page 34

CDJ-100S

6.2 ADJUSTMENT

6.2.1 How to Start/Cancel Test Mode

[ Precautions for Test Mode ]

(1) If a soiled or damaged disc is played back and a GFS error is generated, the system may not perform a STOP operation and may run out of

control, although muting ON/OFF will be performed. If the system does run out of control, press the CUE key to switch the power OFF.

(2) Do NOT press any key while an OPEN/CLAMP, SPINDLE KICK, or FOCUS SEARCH operation is in progress. Be sure to wait until the

operation is completed before calling the next operation.

TEST MODE : ON

SIDE B

DISPLAY BOARD ASSY

TEST MODE : PLAY

TEST DISC : YEDS-7

inwards outwards

Pickup Move

TEST MODE : DISPLAY

Switch Status Display

(W116)

(W120)

Short Point

V+5

KD1

Focus servo : ON

Spindle motor : START

Spindle servo : CLOSE

OFF

ON

KD1

(W116)

V+5

(W120)

Short Point

SIDE B

DISPLAY BOARD ASSY

CLOSE OPEN

Tracking servo :

SLOT-IN MECHANISM Operation Status

EJECT:

LOAD:

TEST MODE : STOP = CANCEL

STOP all operations.

34

INSIDE SW

S901 SW

S902 SW

Page 35

6.2.2 Test Mode Key Locations

RF Adjustment Mode (Outer circumference feed)

Tracking Balance Adjustment Mode (Center circumference feed)

Note: The tracking servo is OFF.

Fine movement in direction towards the

outer circumference of the carriage

Fine movement in direction towards the

inner circumference of the carriage

Focus ON

Carriage towards the outer circumference

Carriage towards the inner circumference

STOP All Operation

CDJ-100S

LD ON

Tracking, Spindle Servo ON

6.2.3 Adjustment Location

MOTHER BOARD ASSY

VR101 : FO GAIN

VR102 : TR GAIN

VR103 : FO BIAS

VR104 : TR BAL

VC301 : VCO LEVEL

TP1

1 RF

2 TRER

3 TRIN

4 VC

5 FOIN

6 FOER

CN102

1

2

3

4

5

6

VR103

VR104

VR102

VR101

1

CN102

6

IC302

45

8

1 (TP VCO IN)

IC301

IC201

REAR

SIDE A

VC301

IC401

IC402

IC701

DISPLAY BOARD ASSY

SIDE B

TEST

FRONT

35

Page 36

CDJ-100S

6.2.4 Check and Adjustment

1. VCO Adjustment

Test mode

None disc

START

IC302 Pin 1

TP (VCO IN)

GND

MOTHER BOARD ASSY

1

MOTHER BOARD ASSY

Player

VC301

Probe (10:1)

GND

Note: Adjustment of VC301 may not be made if the

SLOT-IN MECHANISM ASSY is installed.

Before adjustment, remove the SLOT-IN

MECHANISM ASSY.

DC voltage

2.5±0.2V

Oscilloscope

DC Mode

V: 50mV/div

H: 10mSec/div

2. Focus BIAS Adjustment

Test mode

None disc

START

TP1

(CN102)

FOER

MOTHER BOARD ASSY

VC

6

4

Player

VR103

MOTHER BOARD ASSY

Probe (10:1)

GND

DC voltage

0±50mV

Oscilloscope

DC Mode

V: 5mV/div

H: 10mSec/div

36

Page 37

4. RF Level Adjustment

1

2

3. Tracking Error Barance Adjustment

Probe (10:1)

VR104

A=B

Oscilloscope

DC Mode

V: 10mV/div

H: 5mSec/div

START

TP1

(CN102)

Player

TRER

VC

39kΩ

0.001µF

Low pass filter 1

Test mode

FOCUS servo

SPDL servo

TRKG servo

=

=

=

CLOSE

CLOSE

OPEN

TEST DISC

PLAY

R=35

VC

A

B

GND

GND

Player

TP1

(CN102)

RF

VC

START

Probe (10:1)

Oscilloscope

AC Mode

V: 50mV/div

H: 10mSec/div

MOTHER BOARD ASSY

MOTHER BOARD ASSY

MOTHER BOARD ASSY

4

VR

1.1VP-P

±0.2V

Test mode

FOCUS servo

SPDL servo

TRKG servo

=

=

=

CLOSE

CLOSE

CLOSE

TEST DISC

PLAY

PICKUP ASSY

LD POWER

TIME Key - ON

Disc: Outer circumference

4

6.2.4 Check and Adjustment

CDJ-100S

37

Page 38

CDJ-100S

5. Focus Servo Loop Gain Adjustment

6.2.4 Check and Adjustment

Test mode

FOCUS servo

SPDL servo

TRKG servo

TEST DISC

Disc: Center circumference

=

=

=

WAH Key - ON

PLAY

START

TP1

(CN201)

FOER

MOTHER BOARD ASSY

FOIN

VC

6

5

4

CLOSE

CLOSE

CLOSE

MOTHER BOARD ASSY

Player

100kΩ

0.0018µF

Low pass filter 2

VR101

39kΩ

UNDER

Probe (10:1)

Probe (10:1)

GND

GND

JUST

Lissajous Waveform

Oscilloscope

X-Y Mode

X: 20mV/div

Y: 5mV/div

Low-frequency

oscillator

1.2kHz

1Vp-p

GND

UPPER

6. Tracking Servo Loop Gain Adjustment

Test mode

FOCUS servo

SPDL servo

TRKG servo

TEST DISC

Disc: Center circumference

START

TRER

TRIN

MOTHER BOARD ASSY

WAH Key - ON

PLAY

TP1

(CN201)

2

3

VC

4

=

=

=

CLOSE

CLOSE

CLOSE

VR102

MOTHER BOARD ASSY

Player

39kΩ

100kΩ

0.001µF

Low pass filter 1

UNDER

Probe (10:1)

Probe (10:1)

GND

GND

JUST

Lissajous Waveform

Oscilloscope

X-Y Mode

X: 50mV/div

Y: 5mV/div

Low-frequency

oscillator

1.4kHz

2Vp-p

GND

UPPER

38

Page 39

7. GENERAL INFORMATION

CDJ-100S

7.1 PARTS

7.1.1 IC

PD4977B (IC701: MOTHER BOARD ASSY)

System Control Micro-computer

Pin Assignment (Top view)

P123/FIP29

P122/FIP28

P121/FIP27

P120/FIP26

P117/FIP25

P116/FIP24

P115/FIP23

P114/FIP22

64636261605958575655545352

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

12345678910111213

VDD

P94/FIP6

P93/FIP5

P92/FIP4

P91/FIP3

P90/FIP2

P81/FIP1

P80/FIP0

Block Diagram

P113/FIP21

P112/FIP20

P111/FIP19

P110/FIP18

P107/FIP17

P106/FIP16

V

LOAD

P105/FIP15

P104/FIP14

P103/FIP13

P102/FIP12

P101/FIP11

P100/FIP10

P97/FIP9

P96/FIP8

P95/FIP7

P127/FIP33

P126/FIP32

P125/FIP31

P124/FIP30

IC701

(PD4977B)

P27/SCK0

P24/BUSY

P25/SI0/SB0

P26/SO0/SB1

¶ The information shown in the list is basic information and may

not correspond exactly to that shown in the schematic diagrams.

P31/TO1

P30/TO0

P03/INTP3/CI0

P00/INTP0/TI0

IC

P72

P71

P70

Vcc

51

5049484746

14

1516171819

P23/STB

P21/SO1

P22/SCK1

RESET

P20/SI1

P02/INTP2

P01/INTP1

45

20

P74

P73

AVss

444342

212223

P17/ANI7

P16/ANI6

P15/ANI5

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

P14/ANI4 P32/TO2

P33/TI1

P34/TI2

P35/PCL

P36/BUZ

P37

X2

X1

Vss

XT2

P04/XT1

AVREF

AVDD

P10/ANI0

P11/ANI1

P12/ANI2

P13/ANI3

TO0/P30

TI0/INTP0/P00

TO1/P31

TI1/P33

TO2/P32

TI2/P34

CI0/INTP3/P03

CI0/SB0/P25

CO0/SB1/P26

SCK0/P27

CI1/P20

SO1/P21

SCK1/P22

STB/P23

BUSY/P24

ANI0/P10 – ANI0/P17

AV

AV

AV

REF

INTP0/TI0/P00 – INTP3/CI0/P03

BUZ/P36

PCL/P35

16-bit TIMER/

EVENT COUNTER

8-bit TIMER/

EVENT COUNTER 1

8-bit TIMER/

EVENT COUNTER 2

WATCHDOG TIMER

PORT0

PORT1

PORT2

PORT3

P00

P01 – P03

P04

P10 – P17

P20 – P27

P30 – P37

WATCH TIMER

6-bit UP/DOWN

COUNTER

SERIAL

INTERFACE 0

SERIAL

INTERFACE 1

78K/0

CPU

CORE

ROM

RAM

DD

SS

A/D CONVERTER

INTERRUPT

CONTROL

BUZZER OUTPUT

CLOCK OUTPUT

CONTROL

VDDVSSIC

PORT7

PORT8

PORT9

PORT10

PORT11

PORT12

FIP CONTROLLER/

DRIVER

SYSTEM

CONTROL

P70-P74

P80, P97

P90 – P97

P100 – P107

P110 – P117

P120 – P127

FIP0 – FIP33

V

LOAD

RESET

X1

X2

XT1/P04

XT2

39

Page 40

CDJ-100S

Pin Function

No. Name I/O Description

1 GRID 7 FL grid output 7

| | O |

7 GRID 1 FL grid output 1

8 VDD –– Connected to VDD.

9 CNT2 I External control input

10 CNT1 I/O External control input/output

11 DSPS I DSP memory sampling. (During sampling: H)

12 P0 O

13 INT1 O

14 CLOK O Serial clock [for IC301 (CXD2500BQ)]

15 DATA O Serial data output [for IC301 (CXD2500BQ)]

16 SQSO I Sub-code Q serial data input.

17 RST I CPU reset. (L : reset)

18 DSPC I DSP data compare input. (H: comparing)

19 DPDT I/O DSP data output

20 GND ref –– Ground potential for the A/D converter.

21 RST3 O DSP reset output (L : reset)

22 DPCK O DSP clock output

23 MD2 O IC301 (CXD2500BQ) Digital out control terminal

24 INT0 O Not used

25 ATB I A/D input for ATB.

26 SERR I A/D input to control the stepping motor.

27 CT I Slider center tap voltage input.

28 ADIN I Slider voltage input.

29 VDD –– Analog power for the A/D converter.

30 VDD ref –– Standard voltage input for the A/D converter.

31 FCOK I Focus OK input. (H : OK, L : NG)

32 XT2 –– Not used

33 GND –– Connected to GND.

34 X1 Oscillator pulses for the main system.

35 X2

36 LPS1 I Load position SW1 input

37 LOAD2 I/O Slot-in motor output 2

38 S1TJ O Servo control output (1 Track Jump: H)

39 LOAD I/O Slot-in motor output 2

40 GFS I Frame sync lock input. (H : OK, L : NG)

Not used

(L: OFF, H: ON)

(above 0.5 V : ATB, below : no ATB)

–– (4.194304 MHz)

(Switch ON: L/ OFF: H)

No. Name I/O Description

41 STCK O Stepping motor control output

42 XLAT O LSI control data latch pulse

43 LDON O Laser diode output (L: OFF, H: ON)

44 PALS I Interrupt input for RAM-internal display pulses.

45 FG I FG pulse input

46 SCOR I Interrupt input for sub-code sync

47 JOG1 I Interrupt input for jog dial pulses

48 IC –– Connected to GND.

49 F/R O Stepping motor forward/reverse output

50 ATSQ O Auto focus output (During auto focus: H)

51 INSD I Slider inside switch input. (L : inside)

52 VDD O Connected to VDD.

53 SENS I LSI operation status input

54 TOFF O Switching analog switch output

(Tracking ON/OFF: H/L, Track count search: H)

55 THOLD O Switching analog switch output

(1, 10 and 100 track jump: H)

56 MUTE O Muting output (L: ON, H: OFF)

57 JOG2 I Jog dial pulse input

58 KD2

| | I Key-scan data input

60 KD0

61 DSW I Digital out ON/OFF input switch

(L: ON, H: OFF)

62 LPS2 I Load position SW2 input (Switch ON: L/ OFF: H)

63 SEG12 O FL segment output 12

64 SEG1 FL segment output 1

| | O |

70 SEG7 FL segment output 7

71 VLOAD –– Connected to FIP controller/driver pull-down

resistance. (–31V)

72 SEG8 FL segment output 8

| | O |

75 SEG11 FL segment output 11

76 NC O Not used

77 GRID11 FL grid output 11

| | O |

80 GRID8 FL grid output 8

40

Page 41

7.1.2 DISPLAY

DEL1031 (V601: DISPLAY BOARD ASSY)

FL Tube

Pin Assignment

CDJ-100S

1

35

Pin Connection

Pin No. 1

Assignment

F12F13NP4S15S26S37S48S59S610S711S812S913S1014S1115S1216S1317S1418S1519NL20NL21NL22G123G224G325G426G527G628G729G830G931G1032G1133NP34F235F2

Anode and Grid Assignment (1/2)

G1 G2 G3 G4 G5 G6 G7 G8 G9 G10

S15

S14 S13 S11 S10 S7 S6

G11

Anode and Grid Assignment (2/2)

G1 G2 G3 G4 G5 G6 G7 G8 G9 G10 G11

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S1

S2

S6

S7

S9

S13

S14

S1

S2

S6

S7

S9

S13

S14

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

REMAIN

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

M

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

F

S1

S2

S5

S6

S7

S9

S10

S11

S13

S14

S5 S3 S2

S1

S1

S2

S5

S6

S7

S9

S13

S14

Note) F1, F2: Filament G1 to G11: Grid

S1 to S15: Anode NP: No pin

NL: No Lead

G3 to G8

S6

S7

S10

S4

S14

S12

S3

S1

S5

S8

S11

S1

S2

S3

S5

S6

S7

S15

S13

S15

G1, G2, G9, G10

S10

S5

S11

S13

S14

S15

S10

S11

S11

S5

S6

S13

S14

S2

S9

S1

S2

S7

S9

S5

41

Page 42

CDJ-100S

7.2 DIAGNOSIS

7.2.1 ERROR DISPLAY

When the player detects an error during operation, if will immediately stop and display an error code in the display window.

Error Code Number

Displayed Error

Code Number

Type of Error

TOC READ ERROR

FG PULSE ERROR

PLAYER ERROR

PLAYER ERROR

S901 SW

MECHANICAL ERROR

MECHANICAL

TIME OUT

7.2.2 DISASSEMBLY

<< PRECAUTIONS >>

Be sure to disconnect the power cable from the AC outlet

whenever removing the card flexible cable from the

connector for maintenance, etc. Hold the both sides of the

card flexible cable with both hands to disconnect the

cable straight. (Even if the power has been switched OFF,

previously charged voltage may remain in the capacitor,

etc. If the electrodes of the card flexible cable and those

of the connector come in contact by accident, a malfunction

may occur.)

Error Contents

TOC date cannot be read after 20 seconds.

Disc is rotating, but rotation cannot be ascertained.

Disc loaded cannot be played properly (GFS NG).

Disc loaded cannot be played properly (FOCUS NG)

The servo mechanism is not clamped even after the

max. operation time has passed.

The pickup does not return to the inside even after the

max. operation time has passed. (INSIDE: 5s)

1

Screw A

Possible Cause = Remedy

The disc is soiled.

Either IC201 (spindle driver IC) or Pin

45 of IC701 (system control microcomputer) is damaged.

• The disc is soiled.

• The disc is scarred.

• The disc is soiled.

• The disc is scarred.

• The slot-in mechanism is defective.

• S901 SW is damaged.

The servo mechanism is defective.

2

1

Screw A

Removal of the Servo Mechanism Assy

1 Remove the five screws A at the bottom of the body.

2 Open the top panel part as shown in the figure.

Note: Perform the work after spreading a cloth or similar to prevent

damage to the top panel.

42

1

Screw A

Page 43

CDJ-100S

3 Remove the binder, the card flexible cable (36P FFC/60V), and the top panel part.

4 Disconnect the earth lead unit.

5 Remove the four float springs.

5

5

5

5

Float Spring

Earth Lead Unit

4

3

Binder

3

6 Remove the left side damper, slightly raise left side of

the slot-in mechanism assy, and disconnect the flexible

cables (CN101, CN201, CN202) on the lower side.

7 Disconnect the connectors (CN103, CN104), and slide

the slot-in mechanism assy to the side on which the

damper has been removed.

7

SLOT-IN MECHANISM ASSY

7

CN104

CN103

6

6

8 Remove the three screws B, and then remove the mecha holder.

Note: An earth spring is located between the mecha holder and the

mechanism assy (right side). Take care not to lose this spring.

8

Screw B

Mecha Holder

8

Screw B

Screw B

8

Earth Spring

Hook

Damper

43

Page 44

CDJ-100S

9 Disengage the hooks on the left and right side (2 each), and

remove the loading base assy.

0 Remove the servo mechanism assy.

LOADING BASE ASSY

10

SERVO MECHA ASSY

Hook

9

Hook

9

9

9

DISPLAY BOARD Assy

1

Remove the jog dial and the slide knob at the top of the body, and

then remove the nut (M9) and jog washer.

Jog Dial

1

Nut (M9)

Jog Washer

1

Slide Knob

2 Disconnect the earth lead unit.

3 Remove the 13 screws F.

DISPLAY BOARD ASSY

Earth Lead Unit

2

Removal of the Each P. C. Boards

TRANS BOARD Assy

With the slot-in Mechanism Assy removed, disconnect the

1

connector (CN705).

2 Remove the screw C and disconnect the cable stay.

3 Remove the seven screws D, raise front side of the TRANS

BOARD assy, and remove it.

Cable Stay

TRANS BOARD ASSY

Screw D

Screw D

2

Screw C

Screw D

3

1

MOTHER BOARD

ASSY

CN705

Screw F

3

(× 13)

Caution for the time of assembly

Turn the jog dial and check for abnormalities like uneven turning

etc.

Nut Tightening Torque: 8 kg · cm or less

44

Page 45

Exchange Methods for Rotary Encoder (S614: DSX1051) and

Slide Volume (VR601: DCV1009)

Rotary Encoder (S614: DSX1051)

1

Remove the jog dial, the nut (M9) and the jog washer at the top of

the unit. (Refer to "Removal of the DISPLAY BOARD Assy".)

2 Unsolder the rotary encoder and cut the 8 locations shown in the

figure with nippers or similar.

3 Raise the P.C. board while paying attention to the jumper wires

and remove the rotary encoder.

DISPLAY BOARD ASSY

Slide Volume (VR601: DCV1009)

Remove the slide knob from the top of the unit. (Refer to

1

"Removal of the DISPLAY BOARD Assy".)

2 Remove the two screws A.

3 Unsolder the slide volume and cut the 11 locations shown

in the figure with nippers or similar.

4 Raise the circuit board while paying attention to the jumper

wires and remove the slide volume.

CDJ-100S

2

Screw A

Solder

3

2

Solder

2

Cut

Solder

2

Rotary Encoder

Pay attention to solder crack

for the jumper wires, shortcircuits, etc.

2

Cut

2

Cut

Measuring Points (TP) for Diagnosis

Remove the two screws G at the bottom plate. Then measuring at

the each points becomes possible.

Screw G

2

Screw A

3

Cut

3

Solder

Cut

3

Solder

4

3

3

Cut

Screw G

Bottom Plate

MOTHER BOARD ASSY

SIDE B

45

Page 46

CDJ-100S

7.3 BLOCK DIAGRAM

IC801

Digital Out

(TC74HCU04AF)

DIGITAL OUT

BOARD ASSY

KUC type Only

AUDIO OUT

CONT OUT

IC303

Inverter

(TC7SU04F)

VCO

IC302

Vari Pitch Circuit

(BA7042)

IC101

(CXA1782CQ)

Servo Control IC

(Built-in RF Amp)

IC104 (NJM2904M)

IC103, IC106 (NJM2068M)

IC107 (TC4W53F)

Servo Control Circuit

IC105 (TC4W66F)

DRAM

20 MHz (ASP)

DSP

Decoder

ATB

(NJM2904M)

IC901, IC902

IC402

(MB814800-70PJ)

IC401

(MN19413A–P)

IC301

(CXD2500BQ)

16.9344 MHz

LPF

IC405

(NJM4558MD)

Q403

MUTE

IC701

(DTC124EK)

(PD4977B)

S1

Power SW

(RSA1001)

S2

Power Transformer

(DSA1026)

Voltage Selector

RL type Only

IC23

(PQ05RR12)

+5V Regulator

TRANS BOARD ASSY

+5V

RST

FU1

±B

VR601

Slider VR

(DCV1009)

MOTHER BOARD ASSY

SLOT-IN MECHANISM ASSY

46

IC102

(LA6520)

Tracking,

Focus Drive

(DWY1069)

Pickup Assy

IC108

(LA6520)

Loading Drive

(DXM1084)

Spindle Motor

IC201

(BA6849FP)

Spindle Drive

Inside SW

Stepping Motor

IC206

Stepping Drive

(MPC17A85ZVM)

(DXX2432)

Servo Mechanism Assy–S

(DXM1093)

Loading Motor

System Control Micro-computer

DISPLAY BOARD ASSY

Inside SW

Clamp SW

Button

Operation

FL

V601

(DEL1031)

S614

Encoder

(DSX1051)

IC602

LED Drive

(HD74HC175FP)

Page 47

8. PANEL FACILITIES AND SPECIFICATIONS

PANEL FACILITIES

Top Panel

- MASTER TEMPO button

÷ The master tempo function is turned ON/OFF.

÷ If the button is held depressed for 2 seconds or

more, the tempo adjust dial's variable range is

changed (±10% or +10% to –16%). When the variable range is changed, the newly selected numerical range is displayed for about 2 seconds (10.0 /

16.0).

÷ The variable range is set by default to the ±10 set-

ting whenever power is first turned on.

= TIME MODE/AUTO CUE button

Two functions are available.

[Time display]

Each time this button is pressed, the time display

changes between the elapsed playback time of the

track and the remaining playback time of the track

(REMAIN).

÷ The REMAIN display appears when power is turned

ON.

[Auto Cue function]

When a disc is initially loaded or when performing

track search, this function automatically sets the cue

point (the point immediately preceding actual sound

output).

÷ The Auto Cue function defaults to OFF when power

is first turned on.

1 POWER switch

(Located on rear panel)

Provides electrical power to the player.

2 Display window

3 DIGITAL JOG BREAK buttons

(JET, ZIP, WAH, HOLD)

4 TRACK SEARCH buttons (4, ¢)

5 SEARCH buttons (1, ¡)

6 CUE button/indicator

7 PLAY/PAUSE button/indicator (6)

8 Loading indicator

Flashes while disc is being loaded or removed

through loading slot, and lights steadily when a disc

is loaded in the player.

9 Force ejection hole

0 EJECT button

When this button is pressed, disc rotation stops and

the disc is ejected from the player's loading slot.

~ TEMPO control knob

The playback tempo can be changed with this knob.

The center clicked position is for normal playback

tempo. If you slide the knob (down) towards you (+

side), the music tempo quickens. If the knob is away

from you (– side), the music tempo slows.

! Jog dial (+ FWD/– REV)

@ Disc loading slot

Insert discs with label side up.

÷ When playing 8 cm (3-inch) discs, insert the disc in

a commercially available CD adapter before loading it in the CD player.

# DIGITAL OUT switch

(Located on rear panel)

CDJ-100S

47

Page 48

CDJ-100S

Display Window

1 TRACK number display

Displays the current number of the track playing.

2 CUE indicator

Flashes when it is possible to input cue point, and

lights steadily after the completion of input.

3 Time display (REMAIN)

The elapsed playback time of the track being played

(when the REMAIN indicator is off) or the remaining

playback time of the track being played (when the

REMAIN indicator is on) is displayed in minutes (M)

and seconds (S), or frames (F).

4 Playback tempo display

Tempo changes made with the TEMPO control knob

are performed in 0.1% steps in the ±10% range. 0 to

+10% in the +10% to –16% range is indicated in 0.1%

steps and 0.2% steps from 0 to –16%.

5 MT indicator

Lights when the MASTER TEMPO function is used.

6 A.CUE indicator

Lights when the AUTO CUE function is used.

7 Playback address display

The elapsed playback time or remaining playback time

of the track playing is roughly indicated with the fullscaled bar graph.

÷ When no disc is in the

disc compartment................................................off

÷ When displaying elapsed

playback time .............. lights up from the left side

÷ When displaying remaining

playback time .............. turns off from the left side

÷ When remaining playback time is

less than 30 seconds ..................................... blinks

8 WAH indicator

Lights or blinks when WAH function is active.

9 Pause indicator (*)

Blinks during pause mode.

0 ZIP indicator

Lights or blinks when ZIP function is active.

- JET indicator

Lights or blinks when JET function is active.

= Play indicator (#)

Lights during playback.

SPECIFICATIONS

1. General

System ................................ Compact disc digital audio system

Power requirementsAC 120 V, 60 Hz

Power consumption .............................................................. 12 W

Operating temperature ..................+5˚C – +35˚C (+41°F – +95°F)

Operating humidity ....................................................... 5% – 85%

(There should be no condensation of moisture.)

Weight.............................................................. 2.2 kg (4 lbs 14 oz)

Dimensions.........................217.7 (W) × 310.7 (D) × 94.5 (H) mm

8-9/16 (W) × 12-1/4 (D) × 3-3/4 (H) in.

2. Audio section

Frequency response ..................................... 4 Hz – 20 kHz (EIAJ)

Signal-to-noise ratio................................... 96 dB or more (EIAJ)

Output level ............................................................................ 2.0 V

Channels ...........................................................2-channel (stereo)

3. Accessories

÷ Operating instructions ............................................................. 1

÷ Audio cable ...............................................................................1

÷ Limited warranty ......................................................................1

NOTE:

Specifications and design are subject to possible modification

without notice.

Maintenance:

We recommend regular maintenance to ensure the safe

and proper function of this unit.

Extended service life can be expected if the unit maintained properly.

48

Loading...

Loading...