Page 1

ORDER NO.

CRT3656

CD-IB100 — /XJ/E5

RR

iPod

RR

ADAPTER

CD-IB100

—

/XJ/E5

For details, refer to "Important Check Points for Good Servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

K-ZZD. FEB. 2006 Printed in Japan

Page 2

1234

SAFETY INFORMATION

CAUTION

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

W

ARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

California to cause cancer, birth defects or other reproductive harm.

B

Health & Safety Code Section 25249.6 - Proposition 65

- Service Precaution

1.You should conform to the regulations governing the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by

electrostatic induction.

C

D

E

F

2

1234

CD-IB100 — /XJ/E5

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

CD-IB100 — /XJ/E5

E

F

7

8

3

Page 4

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR................................................................................................................................................. 8

3. SCHEMATIC DIAGRAM ................................................................................................................................. 10

3.1 SCHEMATIC DIAGRAM(GUIDE PAGE) .................................................................................................. 10

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 16

4.1 MAIN PWB UNIT...................................................................................................................................... 16

5. ELECTRICAL PARTS LIST ............................................................................................................................ 18

6. ADJUSTMENT ............................................................................................................................................... 20

6.1 TEST MODE ............................................................................................................................................ 20

7. GENERAL INFORMATION ............................................................................................................................. 22

7.1 DIAGNOSIS ............................................................................................................................................. 22

7.1.1 DISASSEMBLY ..................................................................................................................................... 22

7.1.2 CONNECTOR FUNCTION DESCRIPTION.......................................................................................... 23

7.2 IC ............................................................................................................................................................. 24

8. OPERATIONS ................................................................................................................................................ 26

C

D

E

F

4

1234

CD-IB100 — /XJ/E5

Page 5

5678

1. SPECIFICATIONS

A

B

C

D

E

56

CD-IB100 — /XJ/E5

F

7

8

5

Page 6

N

1234

2. EXPLODED VIEWS AND PARTS LIST

OTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

• The > mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

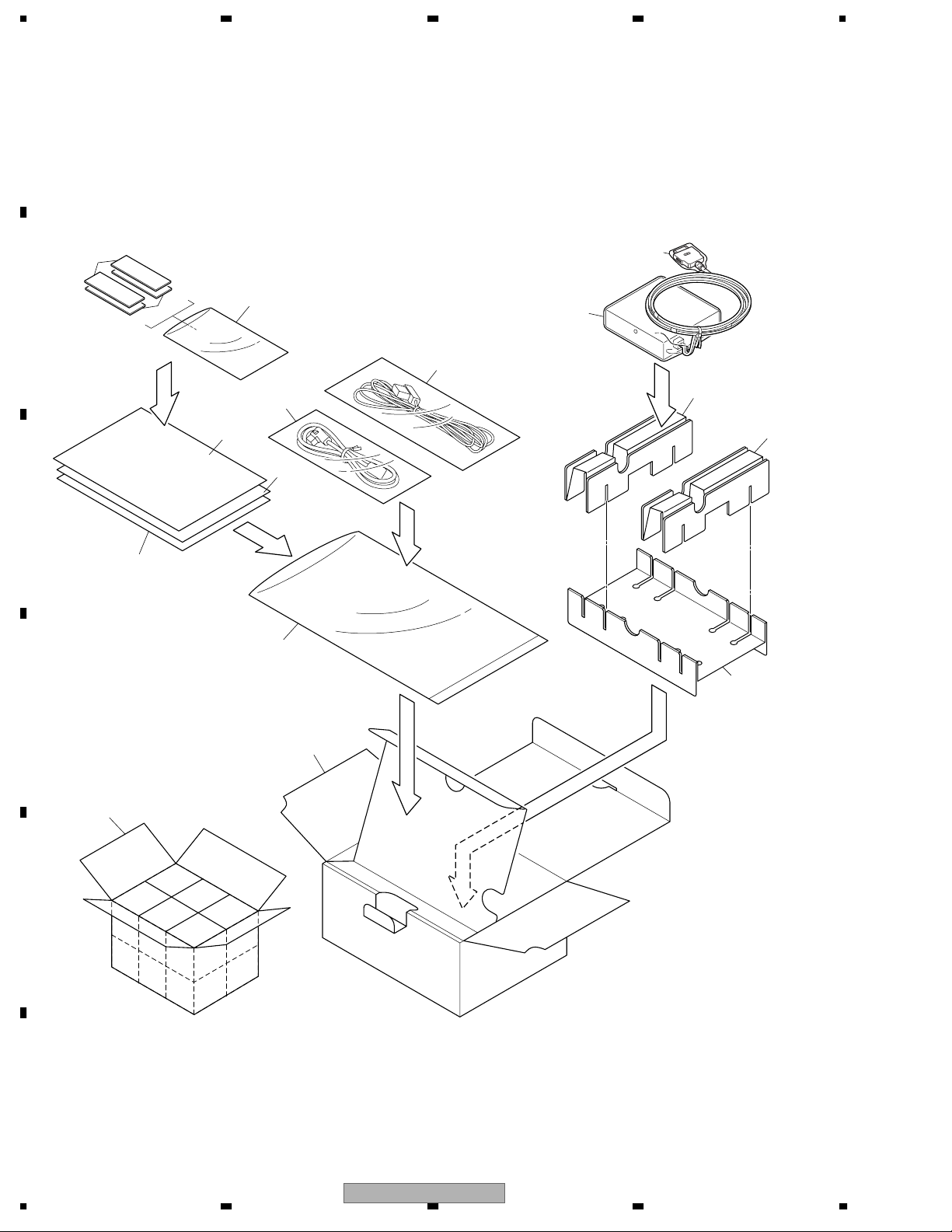

2.1 PACKING

"

12

15

13

1

5

6

7

9

B

C

11

8

14

2

2

3

D

4

10

E

F

6

1234

CD-IB100 — /XJ/E5

Page 7

5678

PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 Protect Bag CZE2966

2 Spacer(S) CZH6631

3 Spacer(L) CZH6632

* 4 Carton CZH6650

5 DC Cord Assy(ES) CZD2993

6 BUS Cord Assy CZD2995

7 Owner's Manual CZR2997

8 Owner's Manual CZR2998

Owner's Manual

Mark No. Description Part No.

9 Polyethylene Bag CZE2962

* 10 Contain Box CZH6651

* 11 Velcro Fastener(Hard) CZE2964

* 12 Velcro Fastener(Soft) CZE2965

* 13 Polyethylene Bag CZE2967

* 14 Polyethylene Bag CZE2970

* 15 Caution Card CRP1332

A

Part No. Language

CZR2997 English, Spanish, German, French, Italian

CZR2998 Dutch, Portuguese(B), Traditional Chinese, Arabic

B

C

D

56

CD-IB100 — /XJ/E5

E

F

7

8

7

Page 8

1234

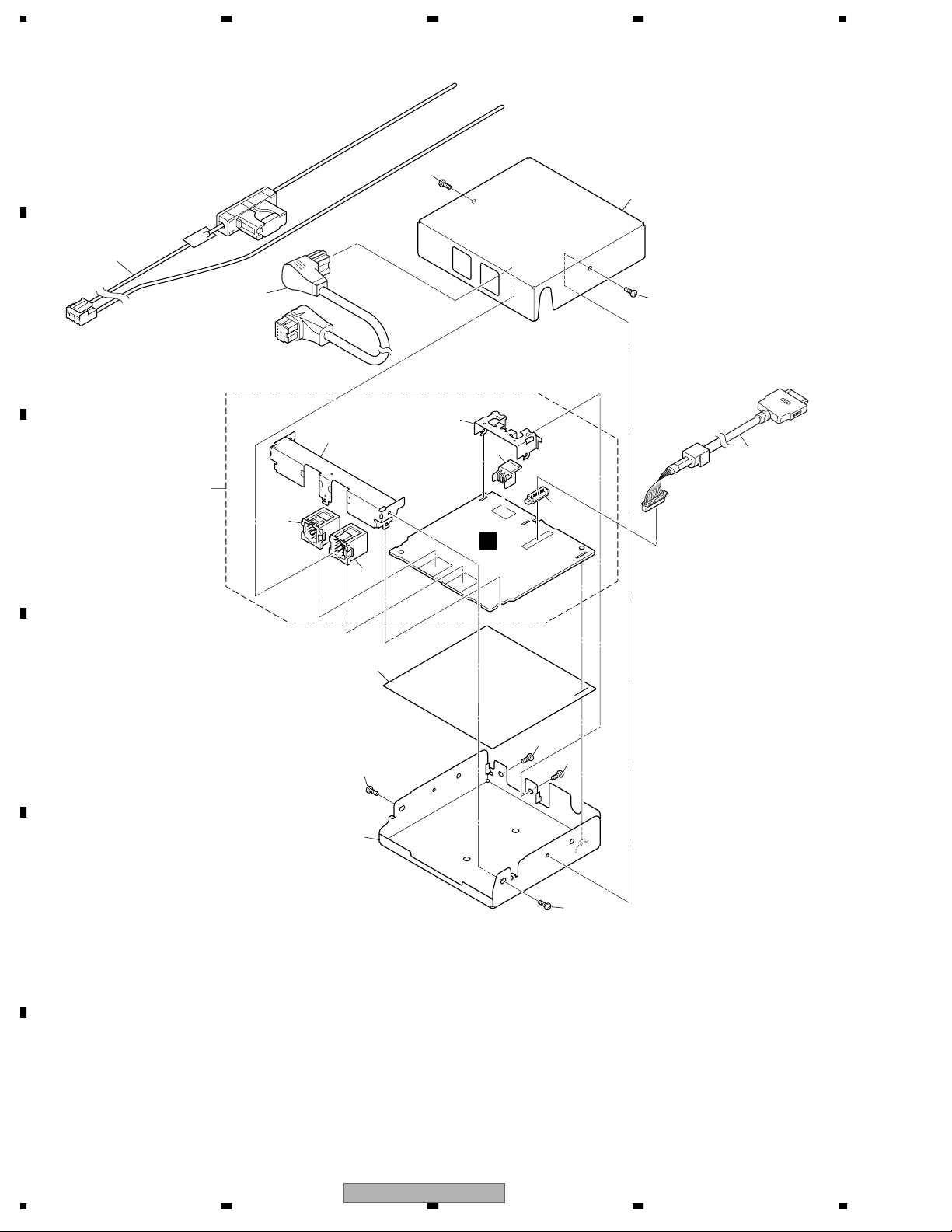

2.2 EXTERIOR

A

2

1

14

B

7

C

3

13

12

8

11

10

1

4

A

9

6

D

1

1

1

5

E

F

8

1234

CD-IB100 — /XJ/E5

1

Page 9

5678

EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 Screw BSZ26P060FTB

2 DC Cord Assy(ES) CZD2993

3 BUS Cord Assy CZD2995

4 Cord Assy CZD5510

5 Chassis(Bottom) CZN6966

6 Insulator CZN6969

7 Main PWB Unit CZW5563

8 Plug(CN1) CZK2960

9 Connector(CN4) CKS3409

10 Connector(CN3) CKS3414

A

11 Connector(CN2) CKS4833

12 Holder(BUS) CZN6967

13 Holder(Power Supply) CZN6968

14 Chassis(Top) CZN8341

B

C

D

56

CD-IB100 — /XJ/E5

E

F

7

8

9

Page 10

1234

3. SCHEMATIC DIAGRAM

3.1 SCHEMATIC DIAGRAM(GUIDE PAGE)

A

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

Large size

A-b

A-b

SCH diagram

Guide page

Detailed page

I-POD

ACC ID

I-POD:+1.35dBs

A-a A-b

A-a

A-a

B

A-a

F/W POWER

I-POD ISOR

C

PSENSG

D

E

PSENS

3.3V 5V

5V 3.3V

SYSTEM CONTROLLER

F

A

10

1234

CD-IB100 — /XJ/E5

Page 11

5678

A

A-b

MAIN PWB UNIT

A

CD-CH ISOR

SW AMP

ASENS

MUTE

CD-CH

IP-BUS:+2.00dBs

IP-BUS IN

IP-BUS:+2.21dBs

I-POD:+2.21dBs

IP-BUS OUT

B

C

D

8.1V

BSENS

5.0V

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

CD-IB100 — /XJ/E5

530µH

56

BU

E

>

F

A

7

8

11

Page 12

1234

A

B

C

A-b

1 2

I-POD ISOR

5V 3.3V

A-b

A-a

A-a

F/W POWER

D

3.3V 5V

PSENS

E

ACC ID

I-POD:+1.35dBs

PSENSG

F

A-a

12

I-POD

CD-IB100 — /XJ/E5

1234

Page 13

5678

SYSTEM CONTROLLER

3

A

A-b

B

C

A-b

A-a

A-a

D

E

56

CD-IB100 — /XJ/E5

F

A-a

7

8

13

Page 14

1234

A

IP-BUS IN

I-POD:+2.21dBs

IP-BUS:+2.21dBs

IP-BUS:+2.00dBs

B

CD-CH

IP-BUS OUT

MAIN PWB UNIT

A

C

A-b

A-a

CD-CH ISOR

MUTE

D

E

F

A-b

14

ASENS

SW AMP

1 2

CD-IB100 — /XJ/E5

1234

Page 15

5678

A

BU

>

B

530 H

C

A-b

A-a

D

ASENS

5.0V

8.1V

BSENS

3

CD-IB100 — /XJ/E5

56

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

E

F

A-b

7

8

15

Page 16

1234

4. PCB CONNECTION DIAGRAM

4.1 MAIN PWB UNIT

A

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

Connector

P.C.Board

Capacitor

Chip Part

SIDE A

SIDE B

B

C

D

MAIN PWB UNIT

A

IC,Q

DC Cord Assy(ES)(Power Supply)

Cord Assy(iPod)

SIDE A

E

F

FRONT

A

16

1234

CD-IB100 — /XJ/E5

Page 17

5678

A

MAIN PWB UNIT

A

IC,Q

SIDE B

B

C

D

56

CD-IB100 — /XJ/E5

E

F

A

7

8

17

Page 18

N

1234

5. ELECTRICAL PARTS LIST

OTE:

A

• Parts whose parts numbers are omitted are subject to being not supplied.

• The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

• The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

• Meaning of the figures and others in the parentheses in the parts list.

B

Example) IC 301 is on the point (face A, 91 of x-axis, and 111 of y-axis) of the corresponding

PC board.

IC 301 (A, 91, 111) IC NJM2068V

Circuit Symbol and No. Part No.

Unit Number : CZW5563

Unit Name : Main PWB Unit

C

A

Unit Number : CZW5563

Unit Name : Main PWB Unit

MISCELLANEOUS

IC 1 IC BA3131FS

IC 2 IC TA2050FS1

IC 3 IC HA12241FP

IC 4 IC PE5483B

IC 5 IC TC7SET08FUS1

D

IC 6 IC TC7SH08FUS1

IC 7 IC PST3433UL

IC 9 IC TA2050FS1

Q1 Tr ansistor IMH3A

Q2 Tr ansistor DTA114EU

Q3 Tr ansistor DTC124EUA

Q4 Tr ansistor 2SD1767

Q5 Tr ansistor 2SC2412K

Q6 Tr ansistor 2SA1162

Q7 Tr ansistor DTC144EU

Q8 Tr ansistor DTC144EK

E

Q9 Tr ansistor 2SD1767

Q10Transistor DTC124EUA

Q11Transistor DTA114EU

Q15Transistor DTC124EUA

Q18Transistor 2SA2060

Q19Transistor 2SA1162

Q20Transistor DTC124EUA

Q23Transistor DTC114EUA

Q25Transistor 2SC4081

Q27Transistor 2SA2060

Q28Transistor DTA114EU

F

Q29Transistor DTC124EUA

D1 Diode 1SR154-400

D2 Diode HZS6L(B1)

18

1234

Circuit Symbol and No. Part No.

D3 Diode HZS7L(C2)

D4 Diode 1SS355

D5 Diode HZS9L(B2)

D9 Diode 1SR139-400

D14 Diode HZM6.2ZMWA

D29 Diode HZM6.2ZMWA

D30 Diode HZS22L(1)

L1 Choke Coil 530 µH CTH1282

L2 Inductor CZT2935

X1 Radiator 12.58 MHz CSS1601

RESISTORS

R1 RS1/16S222J

R3 RS1/16S124J

R4 RS1/16S124J

R5 RS1/16S181J

R6 RS1/16S181J

R7 RS1/16S223J

R8 RS1/16S223J

R9 RS1/16S102J

R10 RS1/16S102J

R11 RS1/16S223J

R12 RS1/16S223J

R13 RS1/16S473J

R14 RS1/16S473J

R15 RS1/16S473J

R16 RS1/16S562J

R17 RS1/16S123J

R18 RS1/16S912J

R19 RS1/16S473J

R20 RS1/16S473J

R21 RS1/16S473J

R22 RS1/16S123J

R23 RS1/16S562J

R24 RS1/16S473J

R25 RS1/16S821J

R26 RS1/16S821J

R27 RS1/16S101J

R28 RS1/16S101J

R29 RS1/16S103J

CD-IB100 — /XJ/E5

Page 19

5678

Circuit Symbol and No. Part No.

R30 RS1/16S333J

R31 RS1/16S102J

R32 RS1/16S103J

R34 RS1/16S912J

R35 RS1/16S473J

R36 RS1/16S104J

R37 RS1/16S473J

R38 RS1/16S473J

R39 RS1/16S103J

R44 RS1/16S222J

R45 RS1/16S821J

R47 RS1/16S101J

R48 RS1/16S104J

R49 RS1/16S122J

R51 RS1/16S103J

R52 BPR26CR47J

R54 RS1/16S101J

R55 RS1/16S104J

R56 RS1/16S103J

R58 RS1/16S473J

R59 RS1/16S473J

R60 RS1/8S102J

R61 RS1/16S103J

R62 RS1/16S473J

R63 RS1/16S103J

R64 RS1/16S473J

R65 RS1/16S473J

R66 RS1/16S104J

R67 RS1/16S472J

R72 RS1/16S514J

R73 RS1/16S393J

R74 RS1/16S102J

R75 RS1/16S102J

R76 RS1/16S102J

R77 RS1/16S102J

R80 RS1/16S103J

R82 RS1/16S102J

R83 RS1/16S103J

R88 RS1/16S102J

R89 RS1/16S102J

R91 RS1/16S102J

R94 RS1/16S473J

R97 RS1/16S222J

R98 RS1/16S124J

R99 RS1/16S103J

R 100 RS1/16S223J

R 101 RS1/16S223J

R 103 RS1/8S102J

R 106 RS1/16S103J

R 107 RS1/10S220J

R 108 RS1/10S220J

R 110 RS1/16S472J

R 111 RS1/16S472J

R 112 RS1/16S104J

R 113 RS1/16S104J

R 115 RS1/8S102J

R 116 RS1/8S102J

R 117 RS1/16S222J

R 118 RS1/16S103J

Circuit Symbol and No. Part No.

CAPACITORS

C1 1 000 µF/16 V CCH1234

C2 470 µF/16 V CCH1080

C3 CEAT101M16

C4 CKSRYB103K50

C7 CKSRYB104K50

C8 1 µF/50 V CCH1501

C9 1 µF/50 V CCH1501

C101 µF/50 V CCH1501

C111 µF/50 V CCH1501

C12 CEALNP100M10

C13 CEALNP100M10

C14 CEJQ220M16

C15 CEJQ220M16

C16 CEJQ220M16

C17 CEAT101M16

C18 CEAT470M10

C19 CEALNP100M10

C20 CEALNP100M10

C21 CEJQ470M6R3

C22 CKSRYB103K50

C23 CKSRYB102K50

C24 CKSRYB102K50

C25 CEAL470M6R3

C26 CKSRYB103K50

C27 CKSRYB104K50

C28 CEAL470M6R3

C30 10 µF/16 V CZC2660

C31 10 µF/16 V CZC2660

C32 CKSRYB104K50

C33 CEAT101M16

C35 CKSRYB103K50

C39 CKSRYB103K50

C411 µF/50 V CCH1501

C42 CKSQYB104K50

C43 CKSRYB104K50

C44 CKSRYB104K50

C47 CKSRYB104K50

C48 CKSRYB104K50

C49 CKSRYB104K50

C50 CKSRYB104K50

C51 CKSRYB104K50

C52 CKSRYB104K50

C53 CCSRCH102J50

C54 CCSRCH102J50

C59 CEAL4R7M25

C60 CEAL4R7M25

C61 CEAL4R7M25

C62 CEAL4R7M25

C63 CEAL220M10

C64 CEAL220M10

C70 CKSRYB104K50

C71 CKSRYB104K50

C72 CEAT101M16

C73 CKSRYB103K50

A

B

C

D

E

F

56

CD-IB100 — /XJ/E5

7

8

19

Page 20

1234

6. ADJUSTMENT

6.1 TEST MODE

A

B

Test mode

Test mode is the special mode used for the check of the failure state of an iPod adapter, or isolation of failure with iPod.

-Test mode function

(1) Check of communication between an iPod adapter and a main unit

(2) Check of charge function

(3) Change of test mode cancellation trigger

(4) Check of voice line of an iPod adapter (iPod is required)

<How to enter in the test mode>

By putting a main unit into the test mode, an iPod adapter also enters in the test mode operation.

(The way to enter in the test mode is according to the specification of a main unit.)

Example) In the case of DEH-P6700MP/XN/UC (IP-BUS model) pressing 4 + 6 Key simultaneously Reset

<How to cancel the test mode >

AccOFF/RESET (main unit) cancels the test mode.

Connect an iPod adapter to a main unit and enter in the test mode.

(1) Check of communication between an iPod adapter and a main unit

C

When switching source of a main unit to EXT (iPod), the following displays appear.

- It is possible to check whether communication between an iPod adapter and a IP-BUS is normal.

- It is possible to identify which one of "unexpected connection" or "expected connection" the model is in the

state of a display.

Display at the time of unexpected connection

i P o d - - 0 0 These 8 figures are displayed.

Display at the time of expected connection

* * * * * * 0 0 is displayed.

D

Note * portion may change with models and may be blank.

(2) Check of charge function

When pressing 1 key of 1 - 6 keys of a main unit, it is possible to turn ON/OFF of a charge circuit of the iPod adapter.

By checking ON/OFF of the No. 1 pin of a DOCK connector at the iPod adapter side and a backup power supply in

the No. 11 or 12 pin at an iPod side, it is possible to check whether the charge circuit system is running normally.

Since the state of charging is displayed if an iPod is connected, it is also possible to check whether charging is performed

normally.

Display sample (in the case of an unexpected connection unit).

E

i P o d - - 0 0 Charge circuit OFF

i P o d - - 1 0 Charge circuit ON

(3) Change of test mode cancellation trigger

When pressing 2 key of 1 - 6 keys of a main unit, it is possible to change the cancellation trigger in test mode to either

AccOFF or RESET.

Display sample (in the case of an expected connection)

* * * * * * 0 0 Cancellation trigger Acc OFF

F

* * * * * * 0 1 Cancellation trigger RESET

Although it is not usually used in the service, if setting up accidentally, cancel it by Backup OFF.

20

1234

CD-IB100 — /XJ/E5

Page 21

5678

(4) Check of voice line of an iPod adapter (iPod is required)

Usually, when iPod is connected, it becomes impossible to use the key of iPod except RESET, but if it enters in this mode,

it is possible to operate the other keys.

- An iPod adapter does not check whether the iPod has been connected, and it is possible to operate on an IP-BUS.

- Since communication with an iPod is not performed, a logo (pioneer) is not displayed on the iPod.

Since it is possible to produce a sound by playing an iPod, when the sound of the iPod does not come out from a main unit,

it shows that the iPod is out of order.

In the normal mode, since communication of data and charging are performed, a logo (pioneer) and "now charging" are

displayed in the window of the iPod.

By checking whether the keys of an iPod are operatable or not, it is possible to see if it is normal or not.

A

B

C

D

E

56

CD-IB100 — /XJ/E5

F

7

8

21

Page 22

1234

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 DISASSEMBLY

A

- Removing the Chassis (Fig.1)

1

Remove the two screws and then

remove the Chassis.

B

Chassis(Top)

1

—

1

NOTE : The Chassis(Top) may appear slightly different to photo shown above.

C

- Removing the Main PWB Unit (Fig.2)

2

1

Straighten the tab at location indicated.

2

Remove the four screws and then remove

the Main PWB Unit.

D

2

E

2

1

Main PWB Unit

Fig.1

2

Fig.2

F

22

1234

CD-IB100 — /XJ/E5

Page 23

5678

7.1.2 CONNECTOR FUNCTION DESCRIPTION

A

B

10

11

7

9

8

4

6

3

2

5

1

11P CONNECTOR IP-BUS BLUE

1

BUS +

2

BUSG1

3

BUSG1

4

NC

5

BUS -

6

BUSG1

7

BUSL1

8

ASENS

9

BUSR1

10

BUSR2

11

BUSL2

6

5

1

2

3

7

4

8

9

10

11

11P CONNECTOR IP-BUS BLACK

BUS +

1

BUSG5

2

BUSG5

3

NC

4

BUS -

5

BUSG5

6

BUSL3

7

ASENS

8

BUSR3

9

BUSAG1

10

BUSAG1

11

PIN 30

PIN 1

CORD ASSY CONNECTOR

F/W GND

1

2

F/W GND

3

-

4

-

5

-

6

-

7

-

8

-

9

-

10

ACC-IDENTIFY

F/W PWR

11

12

F/W PWR

ACC PW

13

14

-

ACC-DETECT

15

16

ACC-DETECT

-

17

DOCK TX

18

DOCK RX

19

ACC-DETECT

20

21

-

22

-

23

-

24

-

25

-

26

-

AUDIO L

27

28

AUDIO R

29

AUDIO GND

30

SGND

1

3

2

DC CONNECTOR

GND

1

-

2

B.U

3

C

D

E

56

CD-IB100 — /XJ/E5

F

7

8

23

Page 24

1234

)

o.

e

n

CNot used

3RO

t

pp

7.2 IC

Pin Functions (PE5483B

A

1,2N

4-10 NC Not used

11 reset I Chip reset input

12,13 NC Not used

14 VSS GND

15 X2 Crystal connection for system clock oscillation

16 X1 I Crystal connection for system clock oscillation

17 REGOFF Regulator operation specification signal

18 REGC Capacity connection for regulator output stability

19 VDD Power supply

Pin N

20 MODEL I Model select input

B

21 SYSPW O System power control output

22 DALMON O System operation situation output

23 NC Not used

24 IPPW O Driver power control output

25 IPSELECT O Selector switch output

26 PID O Communication mode (UART) notification output

27 NC Not used

28 MUTE O Mute output

29-37 NC Not used

38 psensg I Connection sense input

39 TESTIN I Chip test input

40 VSS GND

C

41 VDD Power supply

42,43 NC Not used

44 PPOWER O Power control output

45-64 NC Not used

65 TESTSCK O Serial clock output

66 TESTSI I Serial data input

67 TESTO O Serial data output

68-72 NC Not used

73 IC I GND

74-81 NC Not used

82 AVDD Power supply for A/D converter

83 AVREF1 Standard voltage for A/D converter

D

84 AVSS GND for A/D converter

85 RX I Data input (IE-BUS)

86 TX O Data output (IE-BUS)

87 nmi I NMI input

88,89 NC Not used

90 psens I Connection sense input

91 NC Not used

92 asens I ACC sense input

93 bsens I Backup sense input

94 NC Not used

95 RXIPOD I Serial data input

E

96 TXIPOD O Serial data output

97-100 NC Not used

PE5483B

81

80

Pin Nam

I/O Function and Operatio

MDATA I/O ROM data input / outpu

51

50

F

100

24

31

1

1234

30

CD-IB100 — /XJ/E5

Page 25

5678

PST3433UL

VOUT

VDD

TA2050FS1

1

2

NC

Vref

IN1(-)

NC

13 9101112141516

4 VSS

3 NC

IN1(+)

IN2(+)

TC7SET08FUS1,TC7SH08FUS1

IN B

IN A

GND

NC

IN2(-)

1

2

3

NC

A

5 VCC

B

4 OUT Y

C

HA12241FP

+

24 876513

OUT1

VREF

BIAS

VREF

NC

VCCstb

GND

+

-

RECEIVER

OUTPUT

NC

VCC

+BUS

DRIVER

OUTPUT

(current)

COM

NC

+

-

+

D

OUT2

-BUS

5678

E

132

4

S1 R out S2 GND

56

CD-IB100—/XJ/E5

F

7

8

25

Page 26

1234

8. OPERATIONS

A

B

C

D

E

F

26

1234

CD-IB100—/XJ/E5

Page 27

5678

A

B

C

D

E

56

CD-IB100—/XJ/E5

F

7

8

27

Page 28

1234

A

B

C

D

E

F

28

1234

CD-IB100—/XJ/E5

Loading...

Loading...