Pioneer CDIB-100 Service manual

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE NV Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2005

K-ZZB. MAR. 2005 Printed in Japan

ORDER NO.

CRT3422

iPod ADAPTER

CD-IB100/XM/E

CD-IB100/XM/E

For details, refer to "Important check points for good servicing".

2

1

234

12

34

F

E

D

C

B

A

CD-IB100/XM/E

SAFETY INFORMATION

CAUTION

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

- Service Precaution

You should conform to the regulations governing the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

3

5

6

7

8

F

E

D

C

B

A

5

6

7

8

CD-IB100/XM/E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

4

1

234

12

34

F

E

D

C

B

A

CD-IB100/XM/E

CONTENTS

SAFETY INFORMATION............................................2

1. SPECIFICATIONS.......................................................4

2. EXPLODED VIEWS AND PARTS LIST ......................5

2.1 PACKING..............................................................5

2.2 EXTERIOR............................................................6

3. SCHEMATIC DIAGRAM.............................................8

3.1 SCHEMATIC DIAGRAM (GUIDE PAGE) .............8

4. PCB CONNECTION DIAGRAM................................14

4.1 MAIN PCB UNIT................................................14

5. ELECTRICAL PARTS LIST........................................16

6. ADJUSTMENT.........................................................18

7. GENERAL INFORMATION.......................................20

7.1 DIAGNOSIS .......................................................20

7.1.1 DISASSEMBLY.........................................20

7.1.2 CONNECTOR FUNCTION DESCRIPTION

......21

7.2 IC ........................................................................22

8. OPERATIONS...........................................................24

1. SPECIFICATIONS

Power source . . . . . . . . . . . . .14.4 V DC (10.8 - 15.1 V allowable )

Grounding system . . . . . . . . .Negative type

Max. current consumption . . .2.0 A

Dimensions ( W x H x D ) . . . .95 x 25 x 91 mm

(3-3/4 x 1 x 3-5/8 in.)

Weight . . . . . . . . . . . . . . . . . . .0.32 kg ( 0.7 lbs )

5

5

6

7

8

F

E

D

C

B

A

5

6

7

8

CD-IB100/XM/E

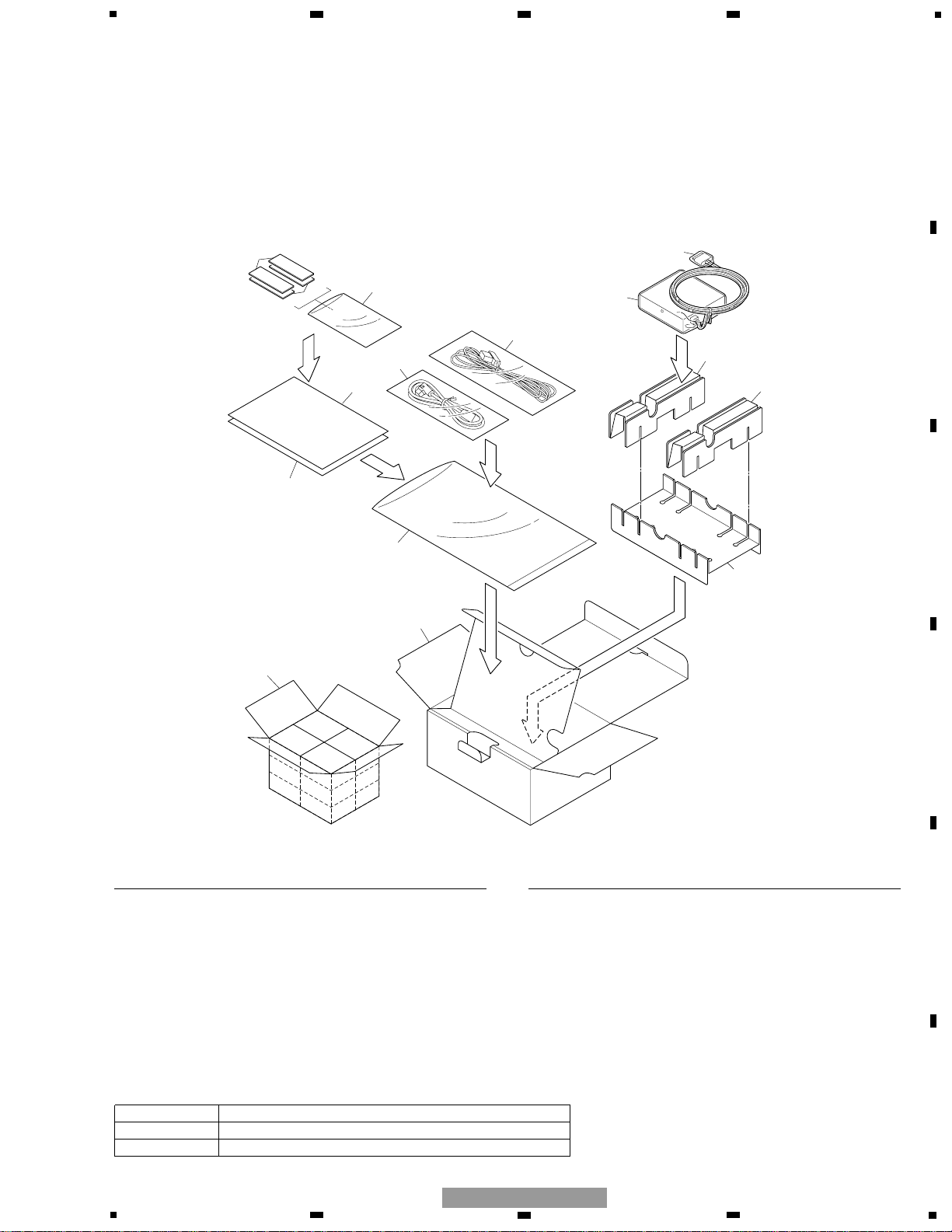

- PACKING SECTION PARTS LIST

1 Protect Bag CZE2966

2 Spacer(S) CZH6631

3 Spacer(L) CZH6632

4 Carton CZH6635

5 DC Cord Assy CZD2993

6 BUS Cord Assy CZD2995

7 Owner’s Manual CZR2983

8 Owner’s Manual CZR2984

9 Polyethylene Bag CZE2962

10 Contain Box CZH6636

* 11 Velcro Fastener(Hard) CZE2964

* 12 Velcro Fastener(Soft) CZE2965

* 13 Polyethylene Bag CZE2967

14 Polyethylene Bag CZE2970

Mark No. Description Part No. Mark No. Description Part No.

2. EXPLODED VIEWS AND PARTS LIST

11

12

13

5

2

2

3

6

7

8

9

4

10

1

14

NOTE:

- Parts marked by “*” are generally unavailable because they are not in our Master Spare Parts List.

- The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

- Screws adjacent to

∇ mark on the product are used for disassembly.

- For the applying amount of lubricants or glue, follow the instructions in this manual.

( In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING

- Owner's Manual

Part No. Language

CZR2983 English, Spanish, German, French, Italian

CZR2984 Dutch, Portuguese(B), Chainese(T), Arabic

6

1

234

12

34

F

E

D

C

B

A

CD-IB100/XM/E

2

A

1

1

14

4

3

13

8

11

12

7

10

9

6

1

1

1

1

5

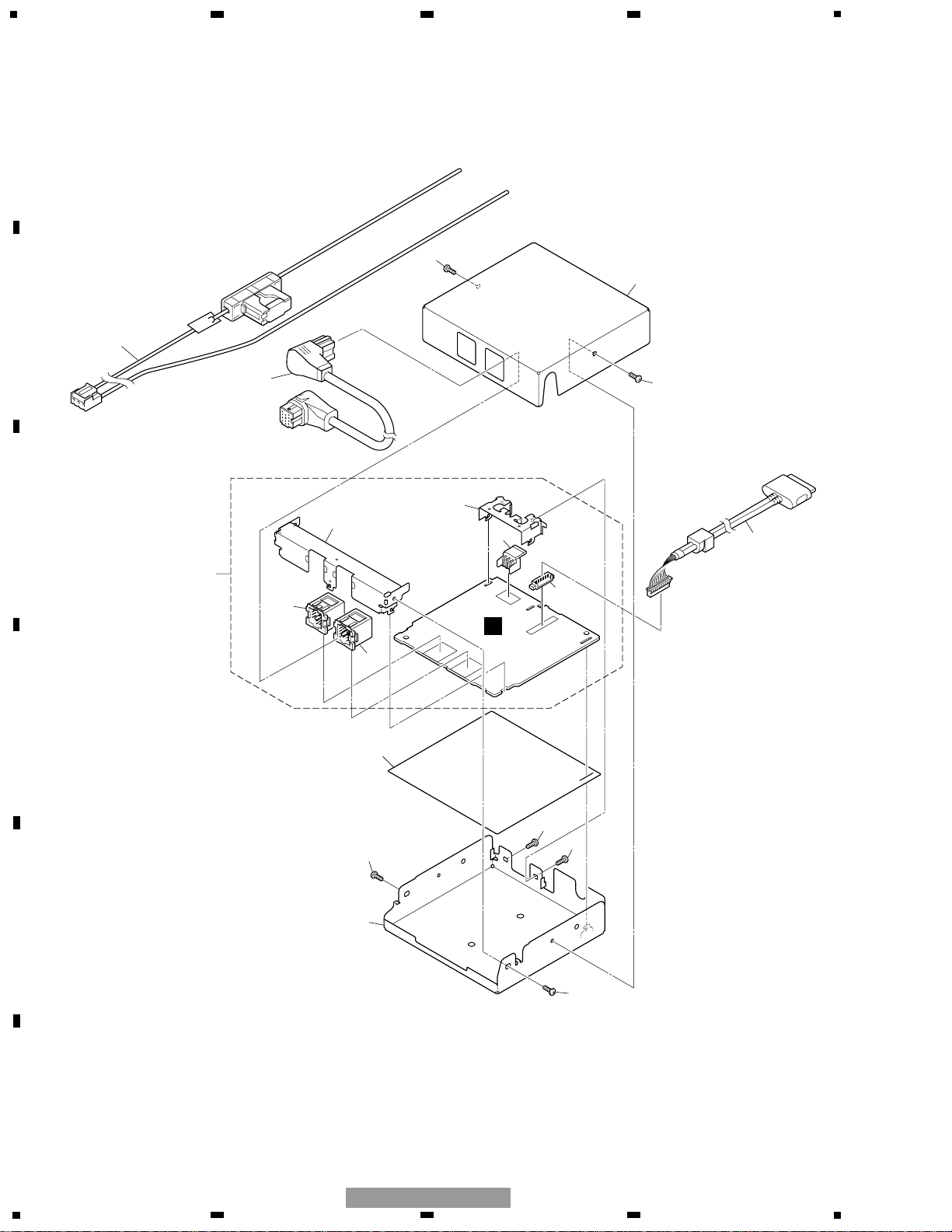

2.2 EXTERIOR

7

5

6

7

8

F

E

D

C

B

A

5

6

7

8

CD-IB100/XM/E

1 Screw BSZ26P060FTC

2 DC Cord Assy CZD2993

3 BUS Cord Assy CZD2995

4 I/P Cord Assy CZD2996

5 Chassis(Bottom) CZN6966

6 Insulator CZN6969

7 Main PWB Unit CZW5553

8 Plug(CN1) CZK2960

9 Connector(CN4) CKS3409

10 Connector(CN3) CKS3414

11 Connector(CN2) CKS4833

12 Holder(BUS) CZN6967

13 Holder(Power Supply) CZN6968

14 Chassis(Top) CZN6999

- EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

A-a A-b

A-aA-a

A-b A-b

A-b A-b

A-a A-a

Large size

SCH diagram

Guide page

Detailed page

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A-a

A

NC

NC

NC

NC

NC

NC

PPOWER

NC

NC

VDD

VSS

TESTIN

psensg

NC

NC

NC

NC

NC

NC

NC

NCNCNCNCNCNCNCICNCNCNCNCNC

TESTO

TESTSI

TESTSCKNCNCNCNCNCNCNCNCNCNCNCNCNCNC

NC

NC

ROMDATA

NCNCNCNCNCNCNC

reset

NC

NC

VSS

X2

X1

REGOFF

REGC

VDD

MODEL

SYSPW

DALMON

NC

IPPW

IPSELECT

PID

NC

MUTE

NC

NC

NC

AVDD

AVREF1

AVSS

RX

TX

nmi

NC

NC

psens

NC

asens

bsens

NC

RXIPOD

TXIPOD

NC

NC

NC

NC

R37

47K

()

(

)

SYSTEM CONTROLLER

I-POD

ACC ID

F/W POWER

I-POD ISOR

PSENSG

PSENS

3.3V 5V

5V 3.3V

I-POD:+1.35dBs

8

1

234

12

34

F

E

D

C

B

A

CD-IB100/XM/E

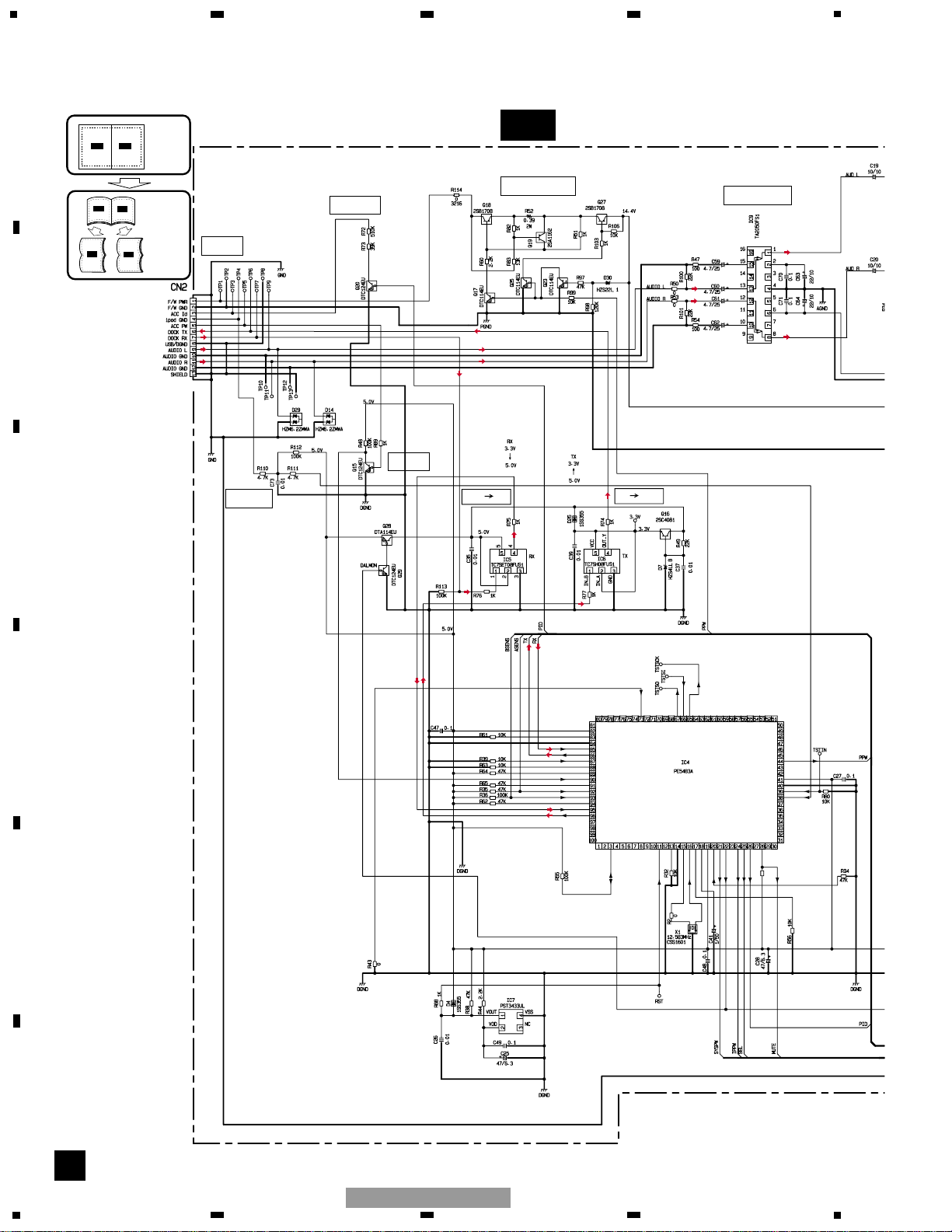

3. SCHEMATIC DIAGRAM

3.1 SCHEMATIC DIAGRAM (GUIDE PAGE)

Loading...

Loading...