Page 1

Models:

UL-101-2P (2 pole, 24VDC)

UL-101-4P (4 pole, 24VDC)

Installation

UltraTouch must be installed in pairs with an anti-tie down

circuit between them to force the user to activate both units

concurrently to initiate hazardous motion. Install units in

such a manner that the wrist or forearm cannot activate

both units while reaching into the point of operation. They

shall be located a minimum of 25” apart, center to center.

Install both units the proper distance away from the point of

operation in accordance with OSHA regulations.

WARNING: Do not over-tighten the four hold down

screws (diagram item #12). Tighten unit on top of gasket

to obtain a snug t and no more.

WARNING: This unit does not contain anti-tie-down

circuitry. This function is performed either by a UL-601

unit or your own control system. This is an initiation

device only and not a safety device.

Troubleshooting System

Red light, but no Green light when Hand inserted into

channel:

A) Excessive Sun or incandescent light over top the

UL-101

B) Conductive grease, or liquid in the channel

C) Proximity of channel to nearby metal objects

D) Did not wait 15 seconds at power-up

E) Heavy gloves may require factory adjustment.

UL: listed 42EL File SA11766

(UL508 & subject491)

Standards:

IEC ratings:

Temp:

Life:

CSA: C22.2 142-M1987

IEC 60947-5-1

Dold Safety output relays UL,CSA,CE certied

Ue=24vdc, Ui=600vac, Uimp=600vac

Utilization: (A400) AC15 ,(N250) DC13

IP40 (when mounted with gasket)

1A slo-blow input protection

no output protection

Operating: 0°C to 55°C (32°F to 131°F)

Storage: -40°C to 85°C (-40°F to 185°F)

Mechanical: 50,000,000 cycles

Min Electrical: 200,000 cycles

(replaceable safety relays)

Operation

Each UltraTouch contains an optical sensor, capacitive

sensor and circuitry that requires the user to activate both

sensors within a 1/4 sec of each other. When you insert

your hand into the slot, (1) you break the infrared beam,

and (2) your mass is detected by the capacitive sensor (this

dual sensor system prevents accidental activation of the unit

due to shirt sleeves, etc.) The Green LED will light and the

relay(s) will energize.

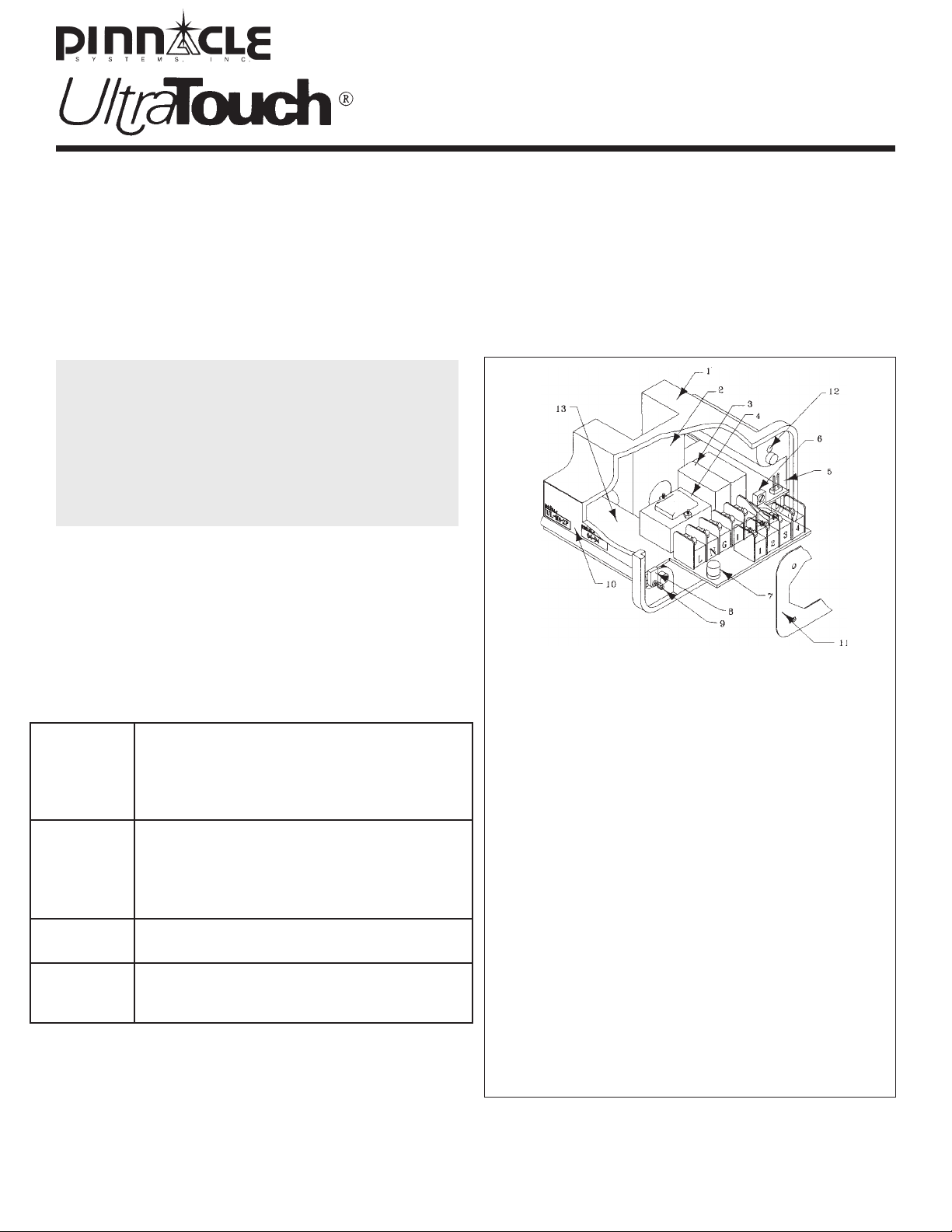

Item Part No. Description

1 11-057 IR plastic housing

2 21-024 Brass plate (cap. sensor)

3 32-001 Captive contact relay(s)

7 20-022 1A fuse

8 11-022 Lock down tabs

9 22-008 #4 Phillips at head screw

10 26-019 Identication label

11 21-008 Gasket

12 22-010 #6-32 x 5/8” Phillips screw

13 52-064 Entire sub-assembly

Terminal Description

L & N 24VDC (polarity protected)

G Earth Ground (required)

1 & 2 Open when green --|/|-3 & 4 Closed when green --| | - Contacts rated at 2 amps @ 120VAC

Pinnacle Systems, Inc.

3715 Swenson Avenue • St. Charles, IL 60174

Customer Service: 630-443-8542 (CST)

(Please have Model, Serial, and Software Revision numbers available)

Sales and Marketing: 800-569-7697 (EST)

www.pinnaclesystems.com

sales@pinnaclesystems.com

service@pinnaclesystems.com

Second Relay & Terminal Strip:

Repeat of Terminals 1-4 (UL-101-4P)

PN#: 28-012R4

Page 2

SAFETY DISTANCE FORMULA

Each operator hand control shall be located at a distance from the point of

operation so that the operator cannot release either hand control and reach into the point of

operation prior to die closure or prior to cessation of slide motion during the closing of the

stroke.

Below is the formula for calculating the safety distance of the palm buttons:

The machine should be measured with the machine running at its fastest speed with its heaviest die or tooling and the stop time being measured at the 90°

position in the down stroke. The following formula should be used when

calculating the safety distance.

Ds = K x (Ts + Tc + Tr + Tbm)

Ds = Minimum safety distance between the device and the nearest point of

operation hazard (in inches).

K = Hand speed constant. This value has been determined by various

studies and although these studies indicate speeds of 63 in./sec. to

over 100 in./sec., they are not conclusive determinations. The

employer should determine this value by considering all factors,

including physical ability of the operator.

Ts = Stop time of the machine tool measured at the final control element.

Tc = Response time of the control system.

Ts & Tc are usually measured by a stop time measurement device.

Tr = Response time of the presence sensing device and its interface, if

any, as stated by the manufacturer or measured by the employer.

Tbm = Additional time allowed for the brake monitor to compensate for

variations in normal stopping time.

Palm buttons used as operator hand controls must be installed in accordance with the installation instructions and applicable local regulations, such as OSHA, ANSI or European standards. The complete machine control system as well as the guarding systems must be considered, including interface, safety distance, ancillary guarding, and all control elements that

affect safety. Consult with your local regulatory agency before installing the palm buttons.

WARNING: DO NOT use on full revolution power presses. This type of press cannot be

stopped in mid-stroke.

Loading...

Loading...