Page 1

Pro Tools

TDM Installation Guide

Version 5.1.1 for Windows 2000

Digidesign Inc.

3401-A Hillview Avenue

Palo Alto, CA 94304 USA

tel: 650·842·7900

fax: 650·842·7999

Technical Support (USA)

650·842·6699

650·856·4275

Product Information (USA)

650·842·6602

800·333·2137

Fax on Demand (USA)

1·888·USE·DIGI (873·3444)

International Offices

Visit the Digidesign Web site

for contact information.

World Wide Web

www.digidesign.com

Digidesign FTP Site

ftp.digidesign.com

Page 2

Copyright

This User’s Guide is copyrighted ©2001 by Digidesign, a

division of Avid Technology, Inc. (hereafter “Digidesign”), with

all rights reserved. Under copyright laws, this manual may not

be duplicated in whole or in part without the written consent of

Digidesign.

DIGIDESIGN, AVID and PRO TOOLS are trademarks or

registered trademarks of Digidesign and/or Avid Technology,

Inc. All other trademarks are the property of their respective

owners.

All features and specifications subject to change without

notice.

PN 932709178-00 REV A 05/01

Page 3

contents

Chapter 1. Pro Tools TDM System Requirements

Pro Tools TDM Systems

System Requirements

Digidesign Registration

About the Pro Tools Guides

Chapter 2. Connecting SCSI Drives

SCSI Requirements

Connecting SCSI Drives

Initializing and Maintaining SCSI Drives

Using Macintosh Drives on Windows Systems

Chapter 3. Installing Pro Tools Hardware

Pro Tools TDM Cards

Installing Pro Tools Cards

Connecting Audio Interfaces

Detecting Pro Tools Cards

Chapter 4. Connecting Your Studio

The 888/24 I/O Interface

Changing Operating Levels of Individual 888/24 I/O Channels

Making Signal Connections to the 888/24 I/O

Using 888/24 I/O As Standalone Audio Converter

The 882/20 I/O Interface

Making Signal Connections to the 882/20 I/O

Using 882/20 I/O As Standalone Audio Converter

The 1622 I/O Interface

Making Signal Connections to the 1622 I/O Interface

Using 1622 I/O As Standalone Audio Converter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Contents

iii

Page 4

Connecting Equipment with Digital Audio Ins and Outs

Connecting Effects Units

Connecting MIDI Devices

Connecting SMPTE Synchronization Devices

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 5. Installing Pro Tools Software

Upgrading to Windows 2000

Configuring Your Computer

Installing Pro Tools Software

Cannot Create DAE Deck Or Error Number 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 6. Checking Your TDM System and Launching Pro Tools

Starting Up Your System

Running DigiTest

Launching Pro Tools For the First Time

Installing the Demo Session

Opening the Demo Session

Chapter 7. Calibrating the 888/24 I/O

About Calibration

Calibrating the 888/24 I/O

Appendix A. Slot Order

Card Order Guidelines For Each Pro Tools System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . 47

Appendix B. DigiTest Error Codes

Index

TDM Installation Guide

iv

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Page 5

chapter 1

Pro Tools TDM System Requirements

Pro Tools TDM Systems

Pro Tools 5.1 for Windows 2000 Pro supports

the following TDM (Time Division Multiplexing) systems.

Pro Tools MIX-Series

(Pro Tools 24 MIX, MIXplus and MIX3)

A core system includes:

• MIX Core card

• MIX Farm card (MIXplus contains one card

and MIX3 contains two cards)

• Pro Tools software

• Digidesign audio interface (sold separately)

A core system provides:

• Up to 64 tracks of recording and playback of

24-bit and 16-bit audio files

• TDM digital mixing and DSP plug-in environment

• Non-linear, random-access editing and mix

automation

• MIDI recording, playback and editing

Pro Tools 24

A core system includes:

• d24 Audio card

• DSP Farm card

• Pro Tools software

• Digidesign audio interface (sold separately)

A core system provides:

• Up to 32 tracks of recording and playback of

24-bit and 16-bit audio files

• TDM digital mixing and DSP plug-in environment

• Non-linear, random-access editing and mix

automation

• MIDI recording, playback and editing

Pro Tools 24 requires a MIX Farm card to

support up to 64 tracks.

Audio Interfaces

To record and play audio you must have one of

the following Digidesign audio interfaces:

888/24 I/O

◆

Analog: XLR (balanced or unbalanced) con-

nectors, +4 dBu or –10 dBV

◆

Digital: XLR (AES/EBU) or RCA (S/PDIF) con-

nectors

Chapter 1: Pro Tools TDM System Requirements

1

Page 6

882/20 I/O

◆

Analog: 1/4" TRS (balanced or unbalanced)

connectors, +4 dBu or –10 dBV

◆

Digital: RCA (S/PDIF) connectors

1622 I/O

◆

Analog: 1/4" TRS (balanced or unbalanced)

connectors. Inputs are variable from +4 dBu to

–10 dBV; outputs are selectable between +4 dBu

or –10 dBV

Digital: RCA (S/PDIF) connectors

◆

Digidesign ADAT Bridge I/O

◆

Analog: 1/4" TRS (balanced) connectors, +4

dBu or –10 dBV

Digital: XLR (AES/EBU) or RCA (S/PDIF) con-

◆

nectors

◆

Optical: Two pairs of EIAJ fiber optic connectors

System Requirements

The CPU, hard disk, monitoring and MIDI requirements for Pro Tools differ depending on

your system configuration. The requirements

for each configuration are listed below.

Compatibility Information

Digidesign can only assure compatibility and

provide support for hardware and software it

has tested and approved. For a list of Digidesignqualified computers, operating systems, and

third-party devices, refer to the latest compatibility information on the Digidesign Web site:

www.digidesign.com/

Computer Requirements

◆

A Digidesign-qualified, uniprocessor

Pentium II or Pentium III-based (highly recommended) computer:

• 256 MB RAM (required for 64-voice performance).

• 1 unused PCI slot for Pro Tools 24 MIX systems.

• 2 unused adjacent PCI slots for

Pro Tools 24 or Pro Tools 24 MIXplus systems.

• 3 unused adjacent PCI slots for Pro Tools 24

MIX3 systems.

• For expanded systems, the expansion chassis card takes the place of the Pro Tools card

in the PCI slot and the Pro Tools card is

placed in the chassis.

• VIA Apollo Pro133 (for Pentium III),

tel 440BX (for Pentium II or III).

• Phoenix or Award BIOS.

• A CD-ROM drive.

• An AGP display card is strongly recommended.

• Windows 2000 Professional Edition with

Service Pack 1 or higher.

◆

A 17-inch or larger color monitor. Black and

white monitors are not supported.

◆

Additional RAM is highly recommended if

you plan to use other audio or MIDI applications concurrently with Pro Tools.

or

, In-

TDM Installation Guide

2

Page 7

Hard Drive Requirements

For audio recording and storage, all Pro Tools

TDM systems require one or more Digidesignqualified SCSI drives attached to a qualified PCI

SCSI HBA card or qualified built-in SCSI HBA

connector on the motherboard.

FAT32 drives are highly recommended for

both system and storage drives.

Pro Tools MIX-series systems

24-bit performance, use 4 hard drives, with audio files distributed among them.

Pro Tools 24 systems

performance, use 2 hard drives, with audio files

distributed among them.

IDE drives are not supported for use as studio

drives on Windows-based Pro Tools systems. If

you intend to use an IDE drive, your session

must be limited to 16 bits. 24-bit sessions are

not compatible with IDE drives.

For best 32-track, 24-bit

It is recommended that you remove IDE

drives and drivers from any Pro Tools

system. SCSI boot drives provide better

Pro Tools performance. However, if you

are using an Expansion Chassis, IDE

drives and drivers must be removed

from your system. For more information, see the

stallation Guide.

Pro Tools Expanded System In-

For best 64-track,

For 64-track sessions that have substantial edit

densities (such as one edit every third of a second across 64 voices) or large amounts of crossfades, up to four SCSI drives may be required, allocated with 16 tracks per drive and two drives

per SCSI channel.

Refer to the Digidesign Web site for compatible

hard drives and SCSI HBA cards:

www.digidesign.com/

MIDI Requirements

Both USB and serial MIDI interfaces work effectively with Pro Tools. Serial MIDI interfaces offer the tightest possible MIDI timing.

Digidesign Registration

Make sure to complete and return the registration card included with Pro Tools TDM system.

Registered users are entitled to one year of free

technical support, and will receive periodic software updates and upgrade notices.

For audio recording and storage, all Pro Tools

TDM systems require one or more Digidesignqualified drives.

To provide full 64-track, 24-bit, 48 kHz performance, a TDM system must include at least two

Digidesign-qualified SCSI hard drives attached

to a qualified SCSI HBA (host bus adapter) card.

Chapter 1: Pro Tools TDM System Requirements

3

Page 8

About the Pro Tools Guides

PDF versions of the Pro Tools guides are installed automatically with Pro Tools, and can be

easily accessed from the Help menu in

Pro Tools. To read the guide online, or print it,

you must install

Pro Tools Installer CD).

Conventions Used in This Guide

Digidesign guides use the following conventions to indicate menu choices and key commands:

Convention Action

Acrobat Reader

(included on the

Choose and Select

The words “choose” and “select” are often interchangeable in conversational english. In this

guide, however, there is a distinction between

the two terms.

Select

When the guide instructs you to

something, it stays selected. This is the case with

dialog box options and menu items that enable

or disable an option.

Choose

something, a one-time action is performed. This

is the case with most menu commands; they

perform their chosen action only once.

When the guide instructs you to

select

choose

File > Save

Session

Control+N While pressing the Control key,

Shift-click While pressing the Shift key, click

Right-click Click with the right mouse button

The following symbols are used to highlight important information:

Choose Save Session from the

File menu

press the N key

the mouse button

User Tips are helpful hints for getting the

most from your system.

Important Notices include information that

could affect your data or the performance of

your system.

Cross References point to related sections in

other Digidesign guides.

TDM Installation Guide

4

Page 9

chapter 2

Connecting SCSI Drives

Pro Tools sessions and audio files are stored on

SCSI hard drives. SCSI hard drives are the recommended recording media for Pro Tools TDM systems.

Although Pro Tools lets you record to your system drive, this is generally not recommended.

Performance for recording and playback on system drives is worse than on non-system drives,

resulting in lower track counts and fewer plugins.

SCSI hard drives offer several advantages over

ATA/IDE drives. First, SCSI drives can be external and therefore provide portable audio storage

that is easily moved between systems. Second,

SCSI drives offer better performance when recording to large numbers of tracks. Furthermore, 24-bit sessions cannot be guaranteed to

record or playback from ATA/IDE drives.

SCSI Requirements

For 64-track sessions that have substantial edit

densities (such as one edit every third of a second across 64 voices) or large amounts of crossfades, up to four SCSI drives may be required, allocated with 16 tracks per drive and two drives

per SCSI channel.

SCSI drives must provide a data transfer rate of

at least 9 MB per second of sustained throughput.

Pro Tools 24 requires a MIX Farm card (or

the discontinued Pro Tools 24 Expansion

Kit) to support up to 64 tracks.

Refer to the Digidesign Web site for compatible

hard drives and HBA cards:

www.digidesign.com/

Software RAID is not supported for audio

drives.

High-Performance SCSI Drives and SCSI Host Bus Adapters

To provide full 64-track, 24-bit, 48 kHz performance, a Pro Tools TDM system must include at

least two Digidesign-qualified SCSI hard drives

attached to a qualified SCSI HBA host bus

adapter (HBA) card.

Chapter 2: Connecting SCSI Drives

5

Page 10

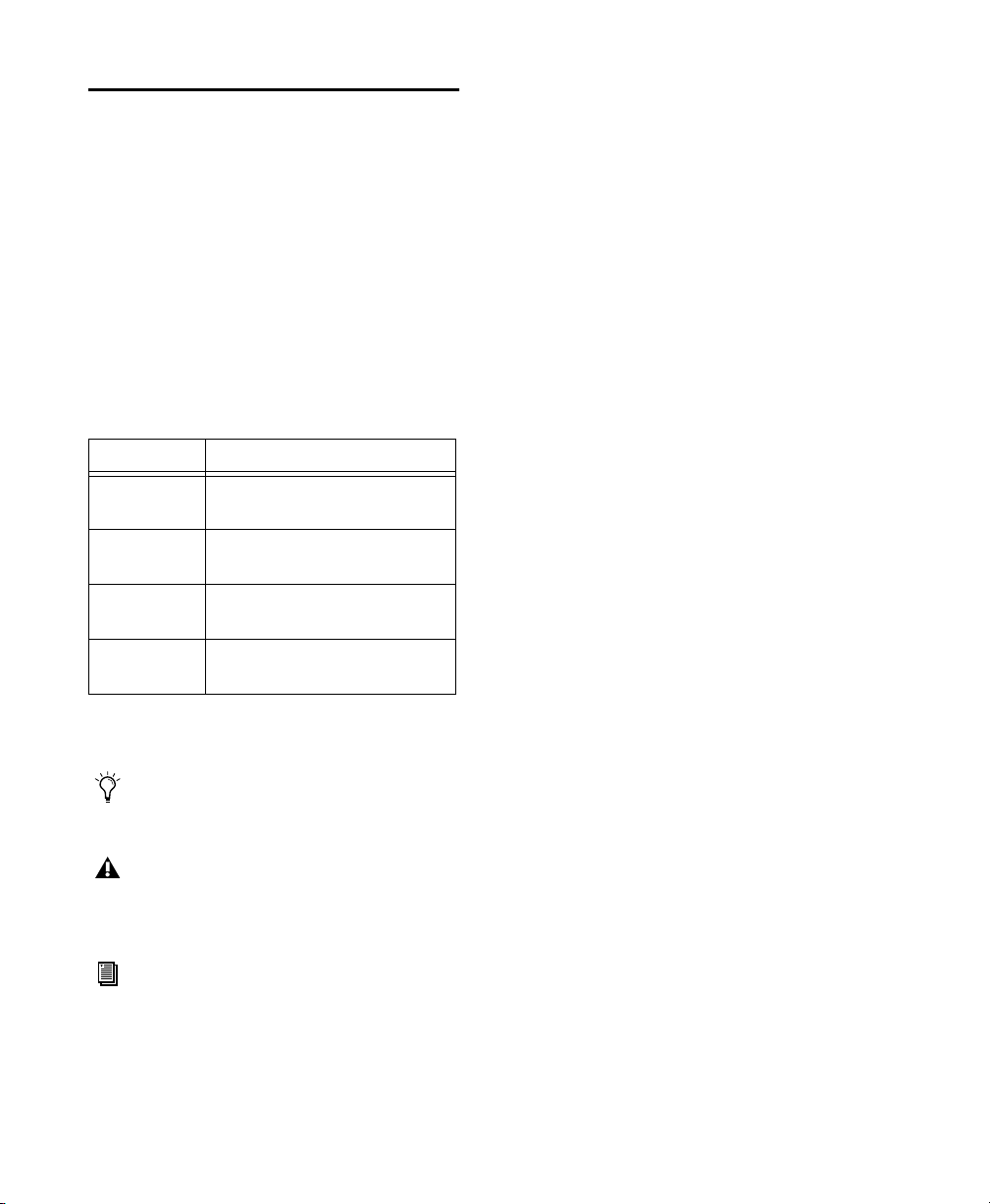

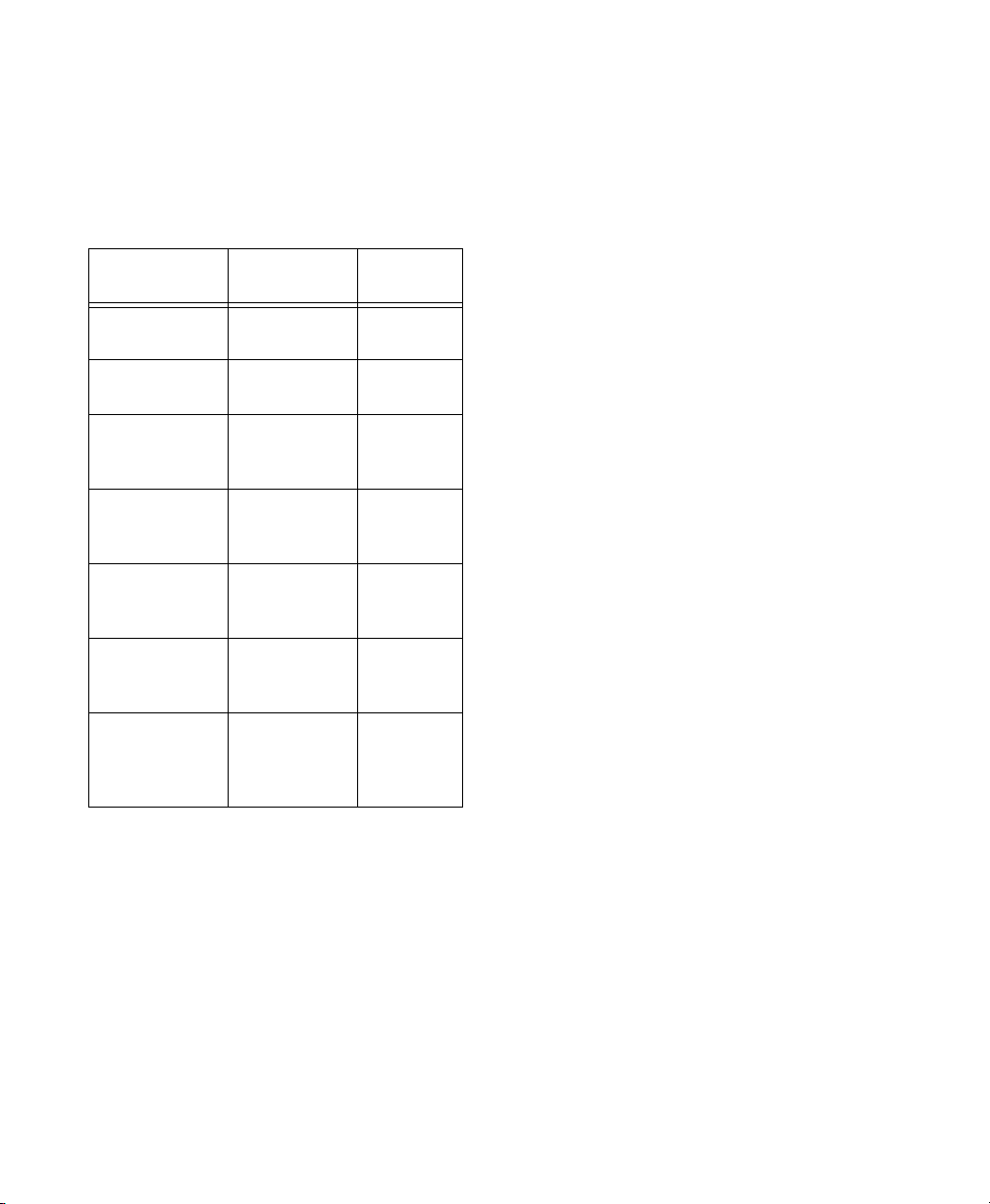

SCSI Cables

Use shorter SCSI cables to improve reliability.

Table 1 provides guidelines for maximum cable

lengths according to SCSI type.

Table 1: Maximum cable length and number of drives

supported according to SCSI type

SCSI type and

transfer rate

Fast SCSI

10 MB/sec

Wide SCSI

20 MB/sec

Ultra SCSI

20 MB/sec

(8-bit narrow)

Ultra SCSI

40 MB/sec

(16-bit wide)

Ultra SCSI

20 MB/sec

(8-bit narrow)

Ultra SCSI

40 MB/sec

(16-bit wide)

maximum

cable length

3 meters 8

3 meters 16

3 meters 5

3 meters 5

1.5 meters 6–8

1.5 meters 6–8

maximum #

of drives

Using these guidelines:

• 64 mono tracks of 24-bit audio takes up about

480 MB of hard drive space per minute.

• 64 mono tracks of 16-bit audio takes up about

320 MB of hard drive space per minute.

• 32 mono tracks of 24-bit audio takes up about

240 MB of hard drive space per minute.

• 32 mono tracks of 16-bit audio takes up about

160 MB per minute.

A 9-gigabyte drive holds:

• 18 minutes of 64 tracks, 24-bit audio

• 28 minutes of 64 tracks, 16-bit audio

• 37 minutes of 32 tracks, 24-bit audio

• 56 minutes of 32 tracks, 16-bit audio

Distribute Audio Across Multiple Drives

For best recording and playback performance,

don’t record and play back all audio files in a

session from the same drive. Instead, use

Pro Tools disk allocation features to distribute

audio files between multiple SCSI drives. See the

Pro Tools Reference Guide

for details.

Ultra2 SCSI

Low Voltage Differential (LVD)

80 MB/sec

12 meters 16

Disk Space for Audio Tracks

Audio tracks recorded at 24-bit resolution at a

CD-fidelity sampling rate of 44.1 kHz require

about 7.5 MB of hard drive space per minute.

The same tracks recorded at 16-bit resolution require about 5 MB per minute. Stereo tracks require about twice as much hard drive space.

TDM Installation Guide

6

Separate Video and Audio Files

If you are working with imported movies, store

movie files on a different SCSI bus than audio

files. If audio files reside on disks connected to a

SCSI HBA card, store video data on drives connected to a different SCSI bus.

Dual-Channel SCSI HBA Cards

If you use a dual-channel SCSI HBA card, equally

allocate audio files to drives connected to each

of the two busses on the card for optimal performance.

Page 11

Connecting SCSI Drives

To connect an external SCSI drive:

1

Turn off power to both the computer and the

hard drive.

2

Attach a SCSI cable from the SCSI port of the

hard drive to the SCSI port of the SCSI HBA card

or computer depending on your system’s SCSI

requirements.

3

Secure the cable’s connectors to the hard drive

and computer. Loose cables can cause data loss.

4

Connect additional drives by daisy-chaining

from one drive to another. Keep cable lengths to

a minimum (see Table 1).

5

Verify that the last SCSI device connected is

properly terminated. See “SCSI Termination” on

page 7.

6

Attach power cables to the hard drives.

SCSI Termination

If your computer’s SCSI chain is not properly

terminated, your system will not function correctly. Terminate only the last device on the

chain, using the termination type recommended by the hard drive manufacturer.

Use either an external terminator plug or enable

the device’s internal terminators. If you are using a terminator plug, it is recommended that

you purchase and use an

active

terminator.

Initializing and Maintaining SCSI Drives

SCSI hard drives used for audio recording on

TDM systems must be formatted for the FAT32,

FAT16 or NTFS files system. Under Windows

2000, FAT32 and NTFS drive partition sizes are

almost limitless. FAT16 partitions have a limit of

4096 MB.

TDM Windows systems require that you use Microsoft Windows Disk Administration software

for drive formatting and partitioning. Use only

one disk utility for all drives in a system.

Pro Tools for Windows 2000 allows you to

connect Macintosh-formatted hard drives

and play sessions created on Pro Tools for

Macintosh when using MacOpener from

DataViz. A demo version of MacOpener is

included on your Pro Tools CD-ROM.

To format a new drive:

1

Turn on your hard drives, computer, and any

other peripherals.

2

Use Microsoft’s Disk Management software,

located in the Administrative Tools control

panel under Computer Management > Storage.

Refer to your Windows 2000 manual or help for

information on how to use the Disk Management software.

Do not enable internal termination and install an external terminator plug on the

same drive. This causes SCSI errors. See

your hard drive’s documentation for information regarding which type of termination

it uses.

Chapter 2: Connecting SCSI Drives

7

Page 12

Formatting Drives

High-Level Formatting

There are two different types of formatting:

high-level formatting and low-level formatting.

Low-Level (Physical) Formatting

Low-level formatting means completely erasing

the hard drive and rewriting each sector address

on the drive. In low-level formatting, the sector

and track addresses, error-correction codes, and

other details are written on the platters of the

hard drive in the form of a magnetic pattern. A

low-level format permanently erases all data on

the drive.

When is Low-Level Formatting Necessary?

Virtually all hard drives come pre-formatted

from the manufacturer. Low-level formatting is

generally unnecessary except in rare circumstances. They are:

If you want to change the Sector Size of the

◆

drive. This is not recommended by Digidesign.

Digidesign systems only recognize 512-byte sectors.

◆

If you want to perform permanent deletion of

data.

◆

If a drive is being changed from one platform

to another. For example if you are switching

from a Macintosh to a Windows-based system,

the drive must be high-level re-formatted for the

new operating system.

High-level formatting a drive replaces the drive’s

directory, volume partition map and drivers. Information about the drive is created and drivers

that communicate this information to the host

CPU are installed. The drive itself is not erased,

nor is verification performed.

When is High-Level Formatting Necessary?

It is generally necessary to high-level format a

hard drive in one of the following cases:

◆

If a new drive is being prepared for use on a

computer for the first time and the drive is not

already high-level formatted.

◆

If you suspect that the directories containing

the drive’s information have become corrupted.

Partitioning Drives

Partitioning divides a physical drive into multiple, unique volumes, almost as if you were creating virtual hard drives. Partitioning is usually

performed when the drive is high-level formatted.

Windows 2000 allows drives formatted

with the NTFS or FAT32 file systems to be

seen as whole volumes. FAT16 formatted

drives have a partition size limit of 4096

MB. Single Pro Tools audio files cannot exceed 2048 MB in size.

If you choose low-level formatting, keep in

mind that it can take up to three hours or more

(depending on the size of the drive). Avoid

power interruptions and computer bus resets

during the format operation or permanent damage to the drive could occur. In addition, leave

the drive powered on for at least 30 minutes

prior to formatting so that the drive has time to

make any necessary thermal adjustments or recalibrations.

TDM Installation Guide

8

Page 13

Seek Times on Partitioned Drives

Seek times are actually faster on partitioned

drives (assuming that reads and writes are performed on a single partition), since the heads

only have to seek within the partition boundaries, rather than the whole capacity of the

drive.

In addition, smaller partitions perform faster

than larger partitions. However, this comes at

the expense of contiguous storage space. When

you partition a drive, find the compromise that

best suits your performance and storage requirements.

Avoid distributing audio files within a session over different partitions on the same

drive since this adversely affects drive performance.

Increased fragmentation increases the chance of

disk errors, which can interfere with playback of

audio, and result in performance errors.

Optimizing (Defragmenting) Drives

To prevent fragmentation, you can optimize

your drive, which rearranges your files into a

contiguous format. Most optimizing software

lets you run a check on a drive to find out the

percentage of fragmentation. If your drive

shows moderate to heavy fragmentation, consider optimizing it.

If you use your system for intensive editing, or if

you frequently delete audio or fade files from

your hard drive, optimize your drives on a

weekly basis, or even every few days, since it

doesn’t take long for even a large hard drive to

become fragmented.

Avoiding File Fragmentation

For maximum recording and playback efficiency, write data to your hard drive in a contiguous fashion. This minimizes the seek requirements to play back the data. Unfortunately,

your computer can’t always store the sound files

in this way and must write to disk wherever it

can find space.

To avoid fragmentation, format drives with

higher cluster sizes (such as 32K or 64K.)

In multitrack recording, audio tracks are written

in discrete files, spaced evenly across the disk.

While fragmentation of individual files may be

zero, the tracks are far enough apart that playback is still very seek-intensive. Also, the remaining free space on the disk is discontiguous,

increasing the likelihood of file fragmentation

on subsequent record passes.

Back Up Data Before Optimizing

Since your files are rewritten by the optimization process, always make a backup copy of the

data on your hard drive before you optimize it.

Additionally, use a hard drive utility to find and

repair any problems before optimizing data. If

there is any damage to your hard drive's directories prior to optimizing, serious data loss may result.

Chapter 2: Connecting SCSI Drives

9

Page 14

Using Macintosh Drives on Windows Systems

Pro Tools for Windows enables you record and

play back sessions directly from a Macintoshformatted (HFS or HFS+) drive connected to a

Windows system. This functionality requires

that all Macintosh session and audio files be

stored on Macintosh-formatted drives.

To mount HFS or HFS+ drives on a Windows system, you must use the MacOpener

utility by DataViz. A demo version of MacOpener is included with Pro Tools Windows.

For details on sharing sessions between

Macintosh and Windows systems, see the

Pro Tools Reference Guide.

Installing the MacOpener Utility

The MacOpener installer was placed on your

hard drive when you installed Pro Tools, in the

following location:

Program Files\Digidesign\Pro Tools\Pro Tools Utilities\MacOpener 2000 Demo

To Install MacOpener:

1 Locate the macopener2000.exe file in the

above location and double-click it to launch the

installer.

2 Follow the on-screen instructions to install

MacOpener.

3 When installation is complete, restart your

computer.

™

software

To enable the settings on the MacOpener Driver:

1 Choose Start > Programs > MacOpener 5.0 >

MacOpener Driver Preferences.

2 Under Driver Settings, select Enable Mac-

Opener Driver.

3 Under Extension Mapping, select Do not add

the PC extension to the Mac file name.

Mounting HFS Drives

If the MacOpener utility is installed and enabled, no additional steps are required to mount

HFS drives. They appear as normal system drives

after you connect them and restart your computer.

Formatting and Maintaining HFS and HFS+ Drives

Although you can use MacOpener to format HFS

and HFS+ drives from a Windows machine, it is

not recommended for use with Pro Tools. We

recommend that you connect the drives to a

Macintosh computer (if possible) and use the

ExpressPro-Tools software from ATTO (included

on the Mac Pro Tools CD-ROM).

Windows Disk Utility Software on HFS Drives

Do not use a Windows disk utility software (such

as Norton Utilities for Windows) on HFS drives.

These utilities do not recognize HFS-formatted

drives and try to reformat them. This causes format errors on the HFS drive, resulting in data

loss.

Enabling the MacOpener Driver

When you are finished installing MacOpener,

the MacOpener driver must be enabled to

mount HFS and HFS+ drives.

TDM Installation Guide10

If you need to perform disk maintenance on an

HFS-formatted drive, connect the drive to a

Macintosh computer and use a Macintosh utility.

Page 15

chapter 3

Installing Pro Tools Hardware

WARNING: There have been changes in

the installation process since the last release of Pro Tools. To avoid problems,

please read and follow the installation instructions carefully.

Pro Tools TDM Cards

Pro Tools TDM cards differ depending on the

system configuration. Card components for

each configuration are listed below.

If you are installing an expanded system in

your computer, or using an Expansion

Chassis to add additional cards to your system, refer to the

included with your Pro Tools system.

Pro Tools MIX-Series Hardware

Pro Tools MIX-series hardware comes in three

configurations:

Pro Tools 24 MIX Includes a single MIX Core

card and a 5-node TDM ribbon cable for connecting to other optional TDM-equipped cards.

Pro Tools 24 MIXplus Includes a MIX Core card,

a MIX Farm card, and a 5-node TDM ribbon cable for connecting the MIX Core to the MIX

Farm and other optional TDM-equipped cards.

Expanded Systems Guide

Pro Tools MIX3 Includes a MIX Core card, two

MIX Farm cards, and a 5-node TDM ribbon cable for connecting the MIX Core to the MIX

Farm cards and other optional TDM-equipped

cards.

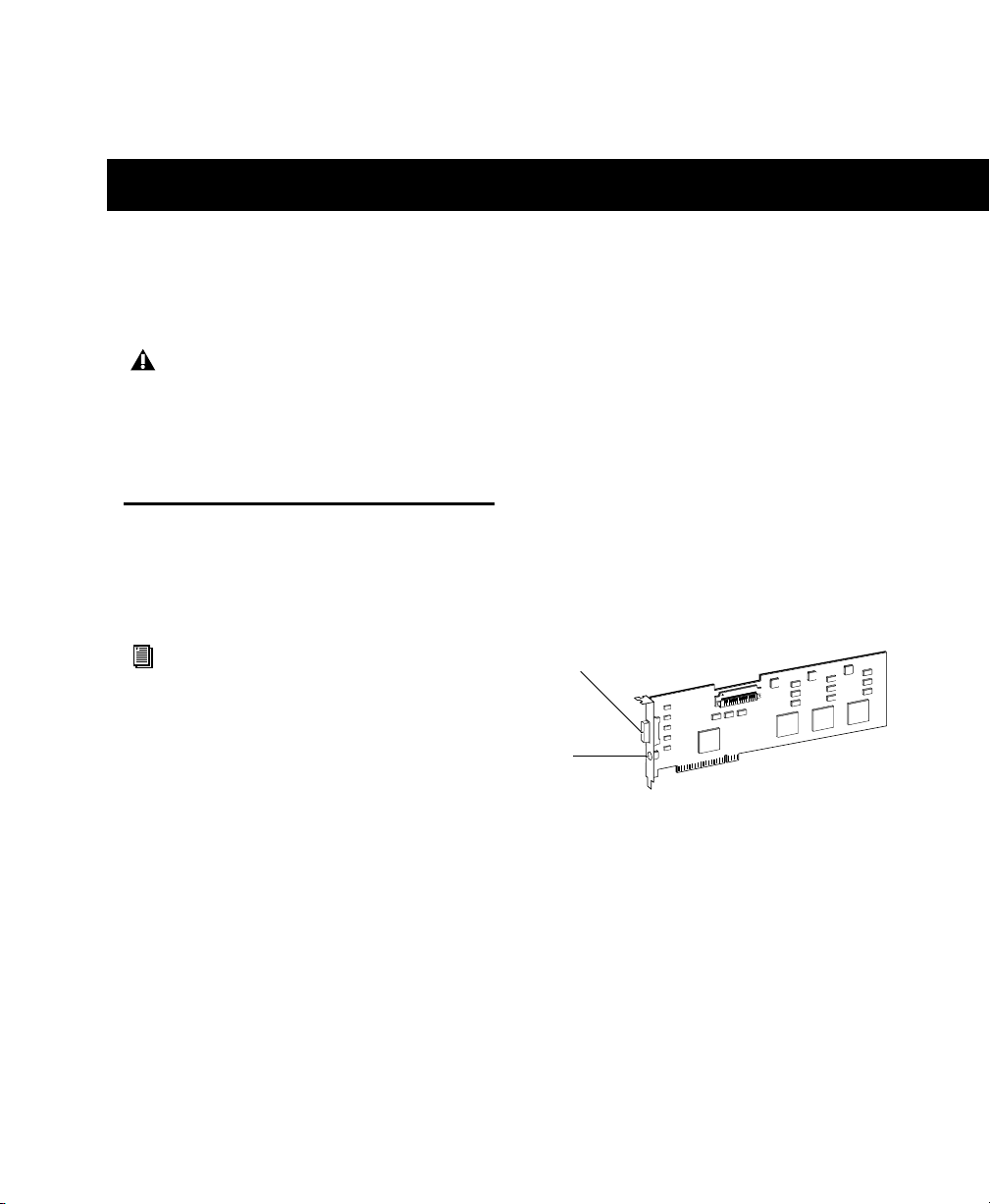

The MIX Core Card

The MIX Core card provides 24-bit, 64-track, 16channel I/O, direct-to-disk recording and playback to your Pro Tool MIX-series system, as well

as DSP power for its mixing and processing capabilities.

audio interface port

audio interface

DigiSerial

port

port

DigiSerial port

MIX Core card

This card includes a connector for attaching a

single 888/24 I/O, 882/20 I/O, or 1622 I/O Audio Interface. If you purchase the optional 16channel peripheral cable adapter, you can attach two 8-channel audio interfaces. The DigiSerial port is for connecting a Digidesign Universal Slave Driver, or a 9-pin device for use with

the Pro Tools MachineControl option.

Chapter 3: Installing Pro Tools Hardware 11

Page 16

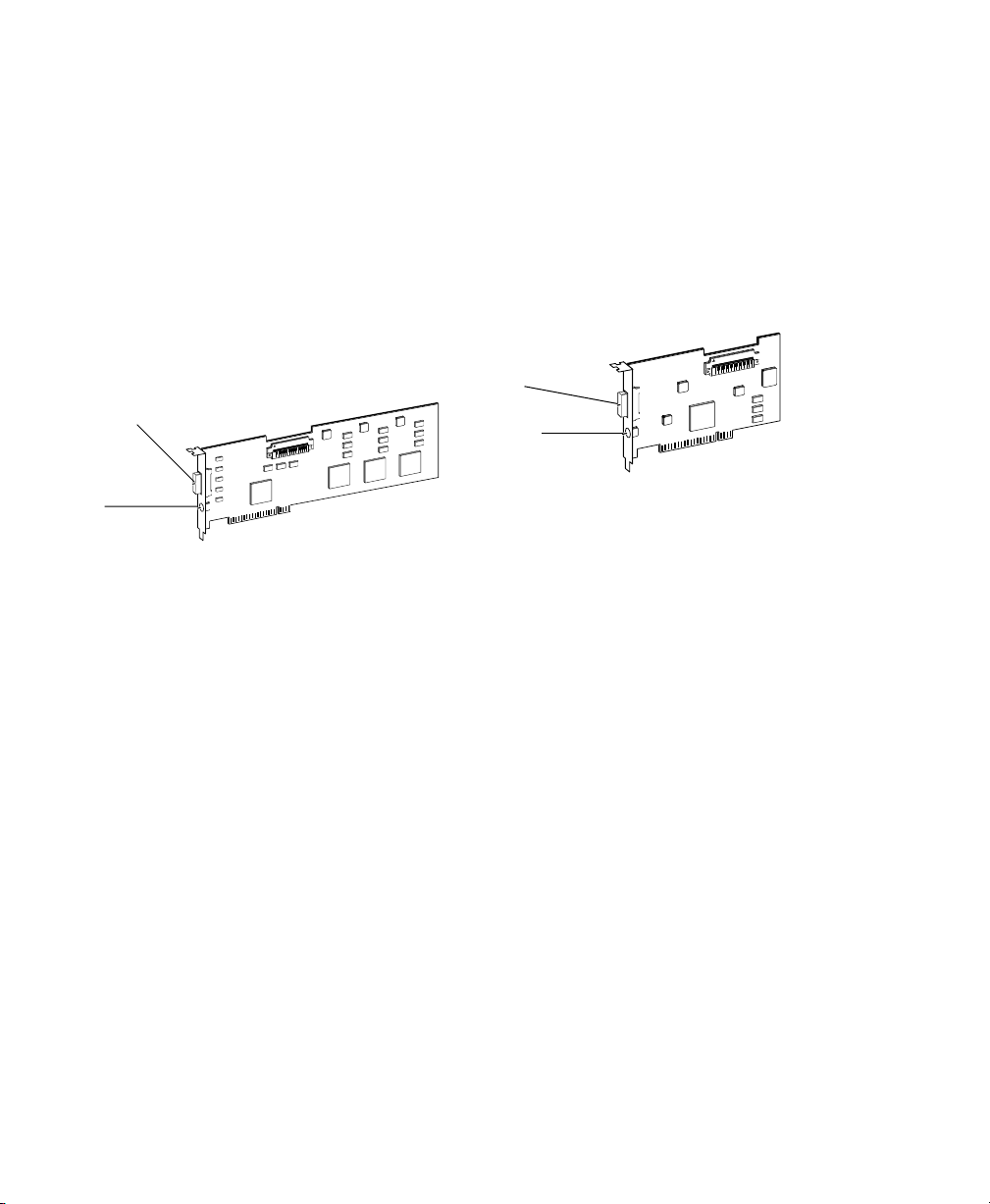

The MIX Farm Card

The d24 Audio Card

The MIX Farm card provides more DSP power

for mixing, processing, and DSP software such

as the DigiRack plug-ins included with

Pro Tools. It also provides a connector for attaching a single 888/24 I/O, 882/20 I/O, or

1622 I/O Audio Interface. If you purchase the

optional 16-channel peripheral cable adapter,

you can attach two 8-channel audio interfaces.

The DigiSerial port is for connecting a Digidesign Universal Slave Driver, or a 9-pin device for

use with the Pro Tools MachineControl option.

audio interface

port

DigiSerial

audio interface

port

port

DigiSerial port

MIX Farm card

Pro Tools 24 Hardware

Pro Tools 24 system hardware consists of a d24

audio card, a DSP Farm card, and a 5-node TDM

ribbon cable for connecting them.

The d24 audio card provides 24-bit, 32-track, 16channel I/O, direct-to-disk recording and playback capabilities to your Pro Tools 24 system. It

also provides a connector for attaching a single

888/24 I/O, 882/20 I/O, or 1622 I/O Audio Interface. If you purchase the optional 16-channel

peripheral cable adapter, you can attach two 8channel audio interfaces.

audio interface

port

audio interface

DigiSerial

port

port

DigiSerial port

d24 card

The DigiSerial port is for connecting an optional

Digidesign Universal Slave Driver, or a 9-pin device for use with the Pro Tools MachineControl

option.

TDM Installation Guide12

Page 17

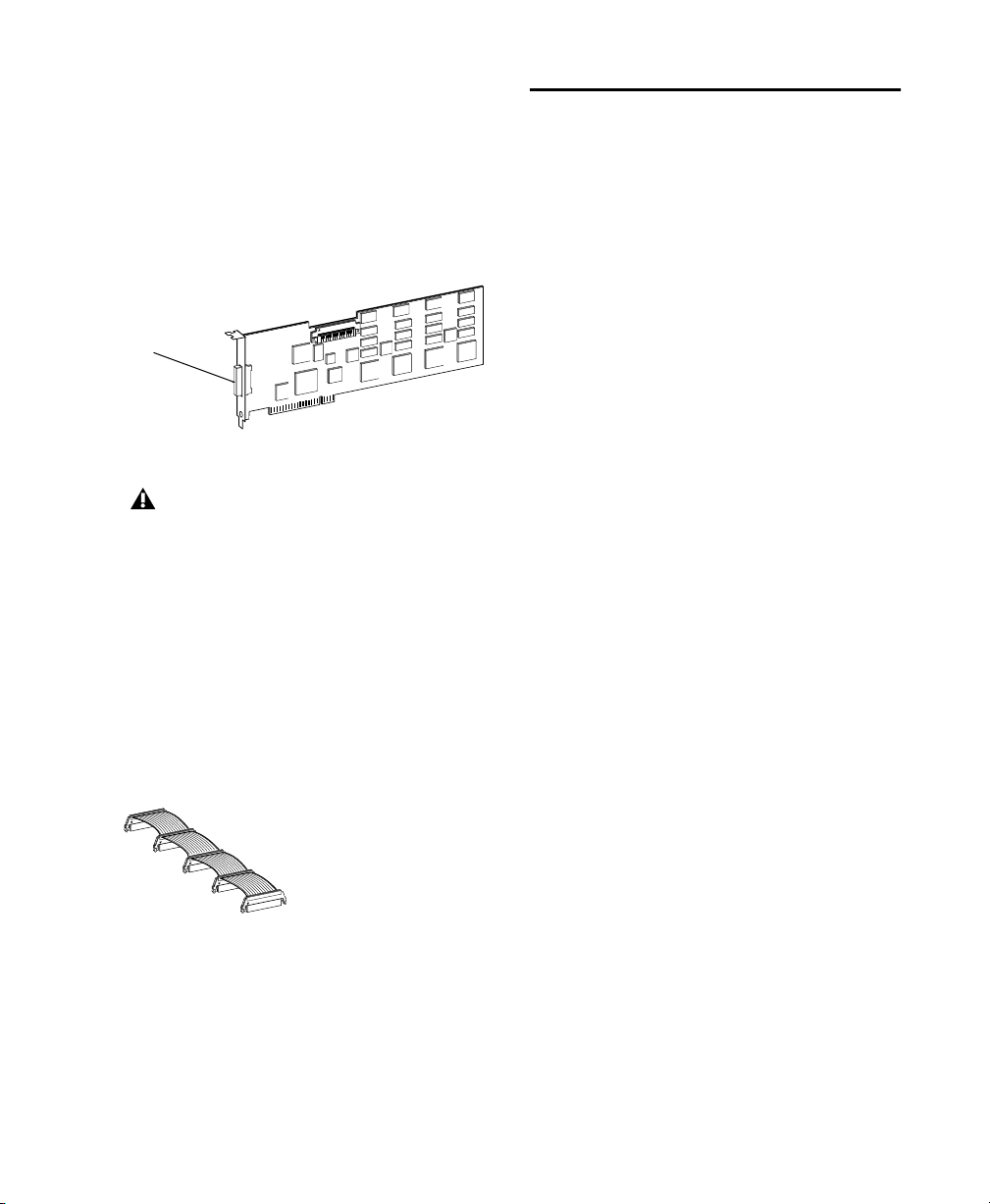

The DSP Farm

The DSP Farm provides the power for the

Pro Tools 24 system’s mixing and processing capabilities. It powers DSP software such as the DigiRack plug-ins included with Pro Tools. It also

provides a connector for attaching an 8-channel

audio interface.

audio interface

port

audio interface

port

DSP Farm card

Installing Pro Tools Cards

Before you begin to physically install your

Pro Tools cards, we recommended temporarily

disable the warning option, “Display a message

before installing an unsigned file.” This expedites and automates much of the installation

process. If you do not temporarily disable the

warning, warning messages (that you are installing an unsigned driver) appear after each DSP

chip during the detecting Pro Tools phase of installation.

To temporarily disable the warning option:

1 Turn on your computer.

The 1622 I/O Audio Interface is not supported by the DSP Farm. It must be connected to a MIX Core, MIX Farm, or d24

card. Only one 1622 I/O can be connected

to any of these cards. The optional 16channel peripheral cable adapter is not supported by the 1622 I/O.

The TDM Ribbon Cable

The TDM ribbon cable is used to connect multiple cards in your Pro Tools system so they can

share data along the TDM bus.

TDM Ribbon Cable

A 5-node cable comes with your system. If you

plan to use your system with an expansion chassis, you can order a TDM cable with more nodes

from your Digidesign dealer.

2 Right-click the My Computer icon located on

your Windows desktop.

3 Choose Properties.

4 Select the Hardware Tab.

5 In the Device Manager section of the dialog

box that appears, select the Driver Signing button.

6 In Driver Signing Options, select “Ignore – In-

stall All Files Regardless Of File Signature.”

7 Click OK twice.

8 Turn your computer off.

9 Proceed with physically installing your

Pro Tools cards.

Chapter 3: Installing Pro Tools Hardware 13

Page 18

To install Pro Tools cards:

1 Turn off your computer and any peripherals.

Leave your computer’s power cable plugged in

so the computer is grounded.

2 Open the computer case. For additional de-

tails on installing a card in your computer, refer

to its User’s Guide.

Before handling any card, discharge any

static electricity from your clothes or body

by touching a grounded metal surface, such

as the power supply case inside your computer.

3 Remove the metal access port cover behind

the expansion slot you want to use by removing

the screw (if present) and sliding the cover out

from the access port.

4 If installing a SCSI HBA card, install it in the

lowest or highest PCI slot in your computer.

5 Install the primary MIX Core or d24 card

(clock master with primary audio interface) in

the next available slot.

6 Install the remaining TDM cards in slots adja-

cent to the MIX card or d24 card.

Pro Tools cards must be installed in a specific order that is dependent on the slot numbering of

the model of computer you are using.

See Appendix A, “Slot Order” for more details on determining slot order.

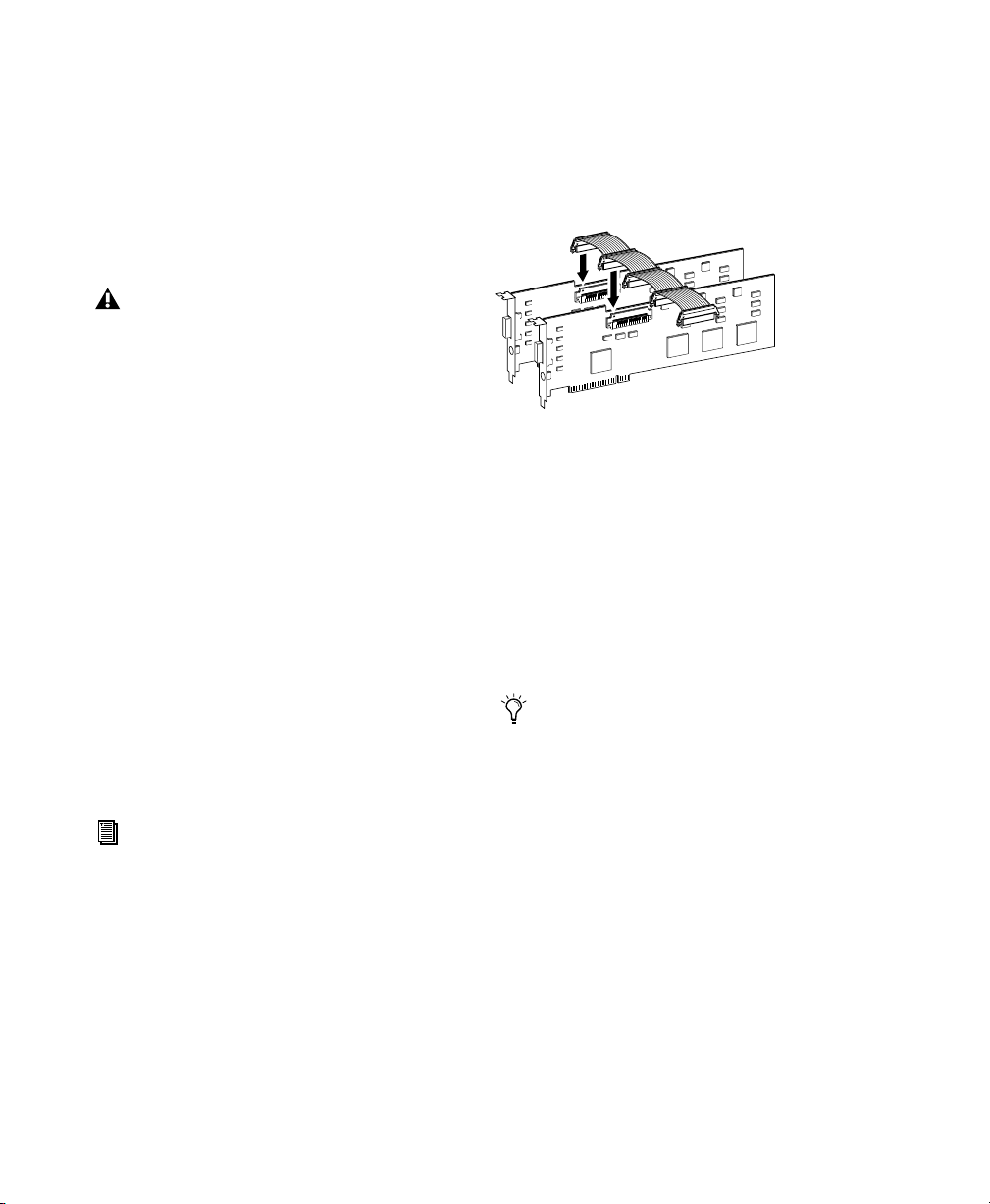

Connect all TDM cards with the TDM ribbon cable:

1 Connect the first node of the cable to the first

TDM card. Make sure the TDM cable is facing

the right direction—align the white triangles on

the cable plug with the triangle on the card.

Attaching the TDM ribbon cable to MIX Core and

MIX Farm cards

2 Push down gently but firmly until the node is

fully connected to the card. When the plug is

properly seated, the two tabs on the side of the

cable’s TDM connector click shut. To detach the

ribbon cable, squeeze the tabs on the TDM connector inward.

3 Attach the remaining nodes on the TDM cable

to subsequent cards.

It is OK to have ribbon connectors that go

unused. They should reside after the last

TDM card.

4 Secure the cards in place with the slot access

port screws you removed earlier and close your

computer.

Group similar cards together (put all MIX Farm

cards next to each other, for example).

7 If installing a SCSI HBA card, install it in the

highest numbered remaining slot.

TDM Installation Guide14

Page 19

Connecting Audio Interfaces

Pro Tools provides you with a choice of the

888/24 I/O, 882/20 I/O, 1622 I/O, or ADAT

Bridge I/O interfaces. These devices supply the

inputs and outputs for your system.

For instructions on connecting an ADAT

Bridge I/O, see the ADAT Bridge I/O Installation Guide.

Connect the Pro Tools audio interfaces:

1 Connect the primary audio interface to the

primary Mix Core or d24 card with the provided

interface cable. The primary audio interface

functions as the clock master.

2 Connect additional audio interfaces to subse-

quent Digidesign audio cards.

If you are connecting both 888/24 and 882/20

or 1622 I/O Audio Interfaces to your system, for

best system performance, connect the 888/24 to

your core Pro Tools card, followed by any additional 888/24 interfaces to the next highest-priority cards. Then connect the 882/20 or

1622 I/O interfaces to subsequent cards.

The 1622 I/O Audio Interface is not supported by the DSP Farm. It must be connected to a MIX Core, MIX Farm, or d24

card. Only one 1622 I/O can be connected

to any of these cards. The optional 16channel peripheral cable adapter is not supported by the 1622 I/O.

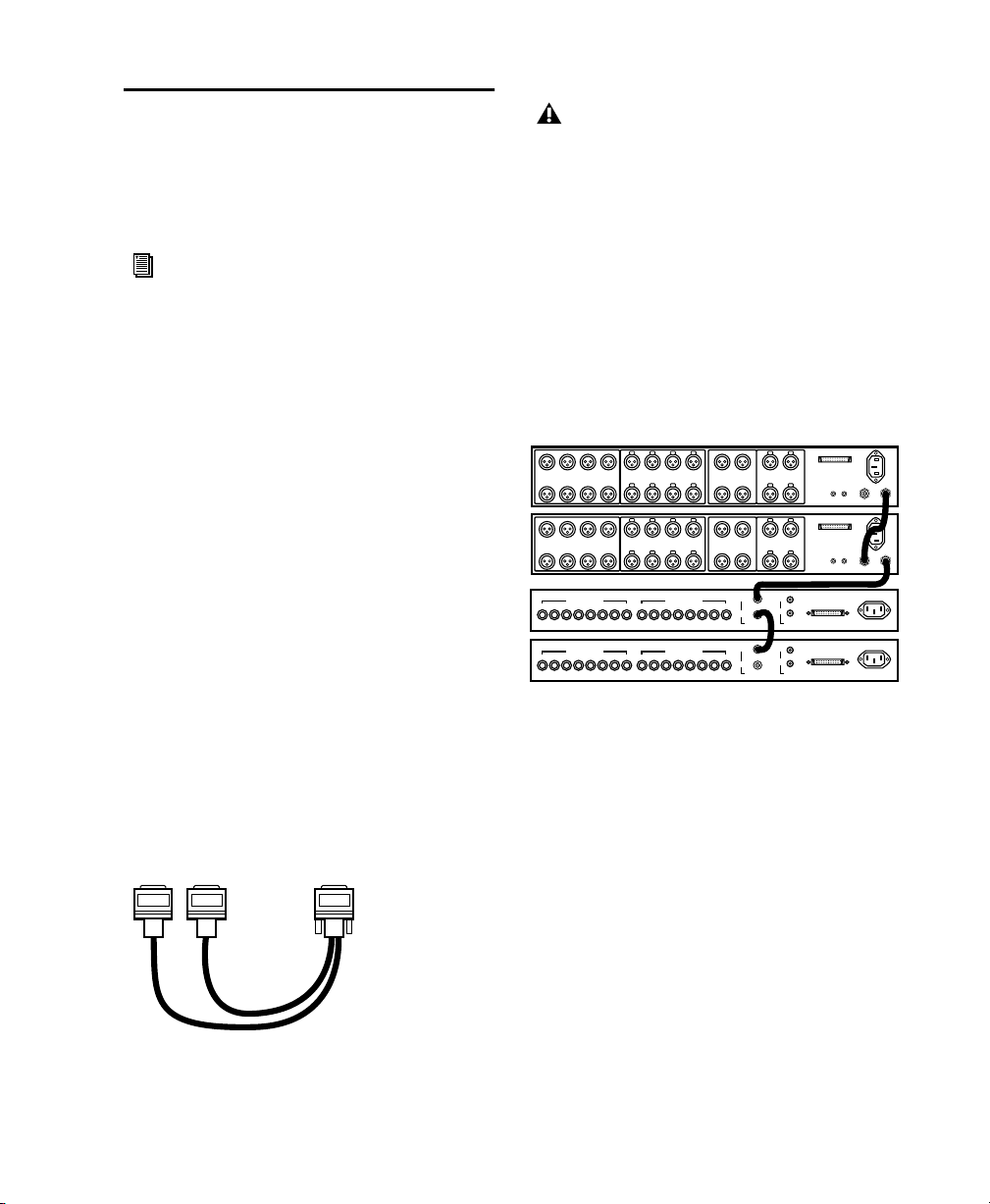

3 If using multiple audio interfaces, connect the

Slave Clock Out of the primary interface to the

Slave Clock In of the second interface with the

provided BNC cable. Connect the Slave Clock

Out of the second interface to the Slave Clock In

of the next audio interface (and so forth).

78563412785634125/6

ANALOG OUTPUT ANALOG INPUT AES/EBU OUTPUT AES/EBU INPUT

78563412785634125/6

ANALOG OUTPUT ANALOG INPUT AES/EBU OUTPUT AES/EBU INPUT

ANALOG OUTPUTSANALOG INPUTS

1234567812345678

ANALOG OUTPUTSANALOG INPUTS

1234567812345678

1/2

7/8

3/4

1/2

7/8

3/4

IN

OUT

IN

OUT

IN

SLAVE CLOCK

SLAVE CLOCKINS/PDIF

COMPUTER

5/6

1/2

7/8

3/4

S/PDIFINS/PDIF

SLAVE CLOCKINSLAVE CLOCK

OUT

OUT

COMPUTER

5/6

1/2

7/8

3/4

S/PDIFINS/PDIF

SLAVE CLOCKINSLAVE CLOCK

OUT

OUT

IN

COMPUTER

OUT

S/PDIF

COMPUTER

OUT

Connecting multiple audio interfaces together

You can use Digidesign’s 16-channel peripheral

cable adapter (optional) to connect two 8-channel audio interfaces to a single MIX Core, MIX

I/O, d24, or MIX Farm card.

to audio interface

to Audio

cables

Interface

cable

to Audio

Interface

cable

to Pro Tools

to Pro Tools card

card

Optional 16-channel peripheral cable adapter

Chapter 3: Installing Pro Tools Hardware 15

Page 20

Detecting Pro Tools Cards

To detect Pro Tools Cards:

1 Start or restart or your computer.

2 Start up Windows 2000, logging in with Ad-

ministrator privileges.

3 The Found New Hardware Wizard dialog pops

up automatically. Click Next. If Digidesign DSP

devices are found and installed automatically,

skip to step 13.

4 Select the “Search For A Suitable Driver For My

Device (Recommended)” option in the Install

Hardware Device Drivers dialog. Click Next.

5 In the Locate Driver Files dialog, check (only)

the CD-ROM option under Optimal Search Locations. Click Next.

6 In the Locate File window, select the Drivers

folder (on your Pro Tools CD-ROM). Click

Open.

7 Open “dalwdm.inf” or “dalwdm.”

If you do not follow the steps above or if you

cancel any of the steps, your computer may not

recognize your Pro Tools cards and you may receive the error message, “Cannot Create DAE

Deck.” To resolve this error message, see “Cannot Create DAE Deck Or Error Number 4” on

page 46.

8 Click OK in the Found New Hardware Wizard

dialog.

9 Click Next to install the multimedia controller

in the Driver Files Search Results dialog.

10 Click Yes in the Digital Signature Not Found

dialog, if present.

11 Click Finish in the Completing Found New

Hardware dialog (indicating that a DSP is found.

12 Repeat step 10 for each DSP chip found.

There are 6 DSP chips on MIX cards, 4 DSP chips

on DSP Farm cards, and 1 on d24 cards.

13 Re-enable the warning option, “Display a

message before installing an unsigned file.” See

“Installing Pro Tools Cards” on page 13.

14 You are now ready to install Pro Tools Soft-

ware.

TDM Installation Guide16

Page 21

chapter 4

Connecting Your Studio

Pro Tools can be connected to a mixer, amplification system, digital recorders, and SMPTE synchronization devices.

Instructions are based on the following audio interfaces:

• 888/24 I/O

• 882/20 I/O

• 1622 I/O

If you have an ADAT Bridge I/O interface,

refer to the ADAT Bridge I/O User’s Guide

for details on connecting it to your studio.

At the end of the chapter is general information

on connecting Pro Tools to digital equipment,

effects units, MIDI gear, and SMPTE synchronization devices.

The 888/24 I/O Interface

This section explains each of the connectors and

indicators on the front and back panels of the

888/24 I/O interface, how they are used, and offers suggestions for connecting the 888/24 I/O

to your studio.

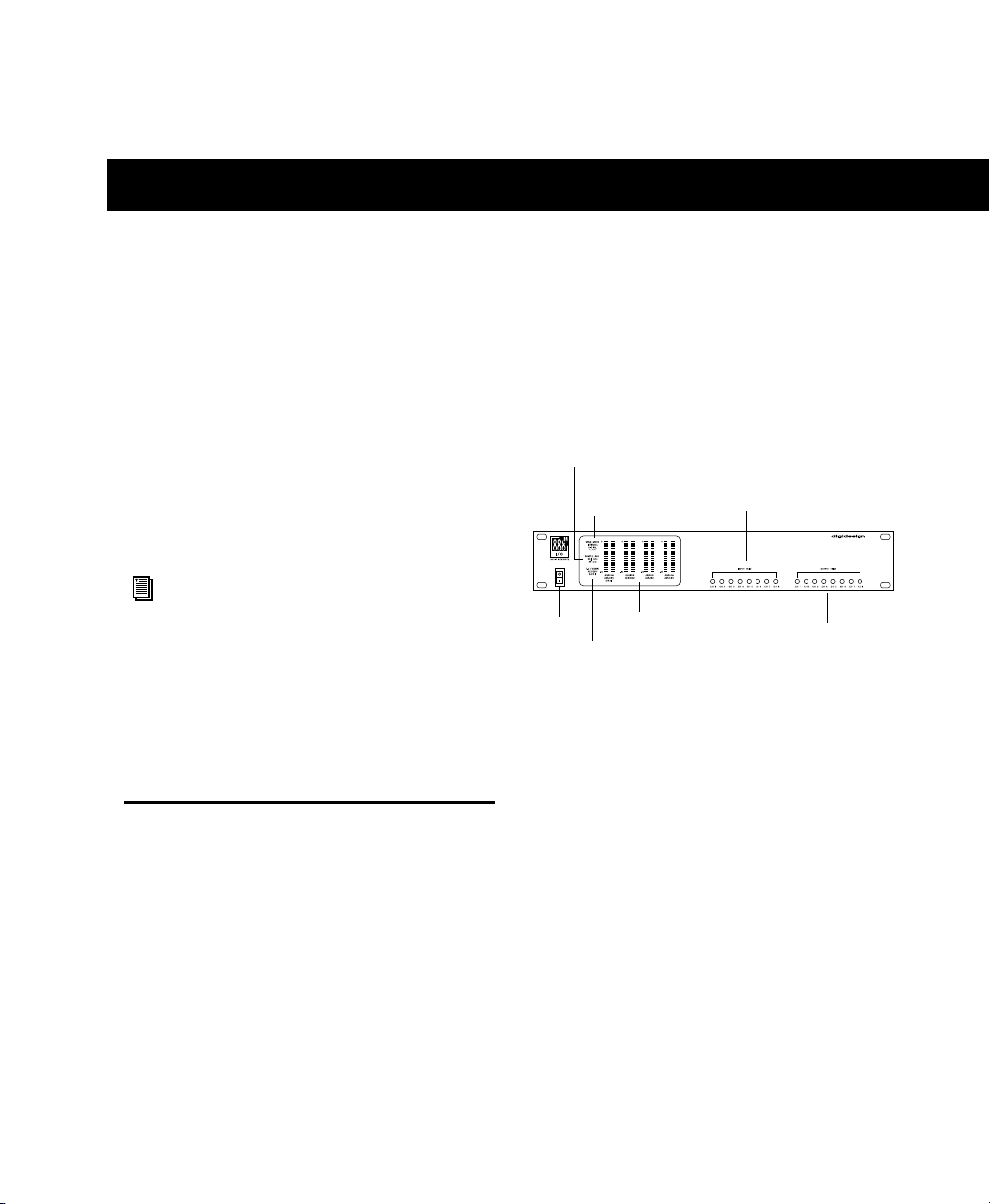

888/24 I/O Front Panel

The 888/24 I/O has the following front panel indicators, moving from left to right:

Sample

Rate

Sync

Mode

Power

Front panel of the 888/24 I/O

Level Meters

1–2 Format

Power

This switch applies power to the 888/24. The “I”

position is on. The “O” position is off.

Input Level

Trims

Output Level

Trims

Chapter 4: Connecting Your Studio 17

Page 22

Sync Mode

The Sync Mode LEDs indicate which sample rate

clock reference is currently used by the analogto-digital converters (ADCs) and the digital-toanalog converters (DACs).

Internal This is the 888/24 I/O standard setting.

In this mode, the 888/24 I/O sample rate is generated by its internal crystal oscillator (whose

frequency is determined by the Sample Rate setting in the Session Setup window). Activate internal mode whenever the 888/24 I/O is not

synchronized to an external clock source.

Digital This setting indicates that an AES/EBU or

S/PDIF word clock signal is currently the source

for the 888/24 I/O sample rate. This is the setting to use for inputting material from DAT recorders or other digital devices.

To use the 888/24 I/O digital inputs and outputs

as effects sends and returns to digital effects devices, set the 888/24 I/O to Internal mode. Set

the digital effects device to accept an external

digital clock (from the 888/24 I/O) so it synchronizes itself to Pro Tools.

The 888/24 I/O can only synchronize to and receive word clock lock on channels 1–2 of its digital inputs. To synchronize your system to an

external digital clock source, it must be connected to digital inputs 1–2 of the 888/24 I/O.

In an expanded Pro Tools system, the system

clock is carried by the audio interface connected

to the first Pro Tools card in your system. This

audio interface acts as the master interface in

your system. All other audio interfaces are

slaved to it.

Because some digital audio devices do not

output proper clock when they are not playing back, leaving the 888/24 I/O in Digital

mode may cause Pro Tools audio playback

quality to suffer, or play back at the wrong

pitch. If you are using digital I/O, reset the

Sync Mode from Digital to Internal after inputting material.

Slave This LED is lit when the 888/24 I/O sample rate is synchronized to another Digidesign

audio interface or synchronization peripheral.

In this mode, the sample rate of the slave interface is derived from the frequency of the incoming master clock signal present at the Slave

Clock In (256x) port.

The 888/24 I/O automatically switches to this

mode when a Slave Clock Out signal from another Digidesign interface, Universal Slave

Driver, Video Slave Driver, or SMPTE Slave

Driver is connected to the 888/24 I/O Slave

Clock In port.

In expanded Pro Tools systems, the Super Clock

output of the master audio interface locks all

other interfaces together with sample accuracy,

keeping all signals phase-synchronous.

When slaving to a Digidesign Universal

Slave Driver, Video Slave Driver, or SMPTE

Slave Driver, set the clock source to Internal.

The audio interface automatically switches

to Slave mode when it detects the 256x input clock

TDM Installation Guide18

Page 23

Sample Rate and 1–2 Format Indicators

These LEDs indicate the sample rate of the

888/24 I/O internal crystal oscillator and the

digital format (AES/EBU or S/PDIF) of the audio

input signal to channels 1 and 2.

The choice of digital format for these two channels is made in the Session Setup window or

Hardware Setup dialog. Digital input pairs 3–4,

5–6, and 7–8 of the 888/24 I/O are always

AES/EBU. Sample Rate is set in the Session Setup

window or Hardware Setup dialog in Pro Tools.

The 888/24 I/O provides the following sample

rates:

48 kHz This is a standard sampling rate of many

professional audio devices. It is recommended

for use with devices that cannot receive digital

transfers at 44.1 kHz.

44.1 kHz This is the compact disc standard sampling rate and the Pro Tools default sample rate.

To avoid the need for sample rate conversion,

use this rate when you are recording material

that will ultimately be published on a compact

disc.

When you are using an external digital

source such as a DAT recorder, the front

panel of the 888/24 I/O indicates only the

internal oscillator sample rate, not that of

the external digital source.

Level Meters

The 888/24 I/O level meters monitor the channel outputs of Pro Tools. Input levels are monitored on-screen in the Pro Tools software.

The 888/24 I/O is factory calibrated so that a

meter reading of –18 dB corresponds to the

888/24 I/O nominal operating level (which can

be set to either +4 dBu or –10 dBV). If you sent

the output to an analog device with a VU meter,

this would correspond to “0 VU” on the VU

meter.

The red LED indicators on the audio interface

indicate both full-code (highest level before

clipping) and clipping of Pro Tools output signals. The on-screen meters in Pro Tools software

indicate clipping when at least three consecutive full-code samples follow each other.

Input Level Trims

The 888/24 I/O analog inputs are factory calibrated at a –18 dB nominal level, referenced to a

full code signal. This means that at the nominal

reference input level (either +4 dBu or –10 dBV),

you have 18 dB of headroom before clipping.

The input level trim pots allow adjustment of

the 888/24 I/O input levels to match the operating level of your external equipment. Adjustments can be made with a Phillips screwdriver.

Output Level Trims

The 888/24 I/O analog outputs are factory calibrated at a –18 dB nominal level, referenced to a

full code signal. This means that at the nominal

reference output level (either +4 dBu or

–10 dBV), you have 18 dB of headroom before

clipping. The output level trim pots allow adjustment of the 888/24 I/O output levels to

match the operating level of your external

equipment. Adjustments can be made with a

Phillips screwdriver.

Chapter 4: Connecting Your Studio 19

Page 24

To calibrate the input and output levels of the

888/24 I/O to match your mixing console or

other devices in your studio, use Calibration

Mode and the Signal Generator TDM Plug-In in

Pro Tools.

Instructions for calibrating the 888/24 I/O

appear in Chapter 7, “Calibrating the

888/24 I/O.”

888/24 I/O Back Panel

The 888/24 I/O has the following back panel

connectors, moving from left to right:

Power

Analog Inputs

Analog Outputs

Back panel of the 888/24 I/O

AES/EBU

Outputs

Analog Audio Outputs

AES/EBU

Inputs

Interface

50-pin

S/PDIF

I/O

Input

Slave

Clock

I/O

1–8 of the 888/24 I/O are software selectable in

pairs between analog or digital format, analog

input to a channel pair is disabled when digital

input format is chosen for that channel.

The 888/24 I/O analog audio connectors are balanced XLRs with pin 2 wired hot, (or “+”); pin 3

cold, (or “–”); and pin 1 ground.

AES/EBU Digital Outputs 1–8

The 888/24 I/O AES/EBU output jacks are balanced, 3-conductor, XLR connectors which output a 24-bit digital data stream. Output is continuously active on both the AES/EBU and

S/PDIF jacks even when the 888/24 I/O input selector is set to analog.

AES/EBU Digital Inputs 1–8

The AES/EBU digital format is used in many professional digital audio devices, including some

DAT recorders. The AES/EBU inputs on the

888|24 interface are balanced, 3-conductor XLR

connectors which accept a full 24-bit digital

data stream.

For AES/EBU connections, we strongly recommend using 110-ohm cables with a length that

does not exceed 30 meters.

These are balanced male XLR connectors for analog audio output connections. All eight output

channels are continuously active. The

888/24 I/O analog outputs feature 24-bit digitalto-analog converters.

Analog Audio Inputs

These are balanced female XLR connectors for

analog audio input connections. The

888/24 I/O analog inputs feature 24-bit analogto-digital converters. Because input channels

TDM Installation Guide20

Input channels 1–8 of the 888/24 I/O are software selectable in pairs between analog or digital format. Digital input to a channel pair is disabled when analog input format is chosen for

that channel in the Hardware Setup dialog. Input to AES/EBU input channels 1–2 is disabled

when S/PDIF digital format is chosen for these

inputs in the Pro Tools Session Setup window.

Page 25

50-pin Interface Connector

This 50-pin Computer connector is used to connect the 888/24 I/O to a MIX card, d24 audio

card, Disk I/O card, or a DSP Farm card. The necessary cable is supplied with your audio interface. If you plan to connect two 888/24 audio

interfaces to a single MIX card or d24 card, a 16channel peripheral cable adapter is necessary.

(This cable is available from your Digidesign

dealer.)

S/PDIF Digital Input/Output

When the 888/24 I/O Sync Mode is set to Internal, connecting a valid Slave Clock Out signal to

this port causes the 888/24 I/O to automatically

switch to Slave mode. When the 888/24 I/O is

the master interface or the first interface in a

chain, Digital mode overrides the Slave Clock

input, and an incoming Slave Clock Out signal

will not switch the 888/24 I/O to Slave mode.

Because crucial timing data is passed over these

ports, use high-quality, 75-ohm RG-59 cables

for making connections, and keep total cable

length to less than 3 meters between interfaces.

The Sony Philips Digital Interface Format

(S/PDIF) is used in many professional and consumer CD players and DAT recorders. The

888/24 I/O S/PDIF in/out jacks are unbalanced

2-conductor phono (RCA) jacks which utilize a

full 24-bit digital data stream. To avoid RF interference, use 75-ohm coaxial cable for S/PDIF

transfers and do not exceed a cable length of 10

meters.

Because input channels 1–2 of the 888/24 I/O

are software selectable between analog or digital

format, input to these two digital channels is

disabled when analog input is chosen or when

AES/EBU digital format is chosen in the

Pro Tools Session Setup window. Output is continuously active on both the AES/EBU and

S/PDIF output jacks, regardless of which digital

input format is selected for channels 1–2.

Slave Clock In/Out

The Slave Clock Out jack is a standard BNC type

connector that outputs a 256 times sample rate

Super Clock signal for slaving and synchronizing multiple Digidesign interfaces and synchronization peripherals together.

Power Input

This connector accepts a standard AC power cable. The interface automatically selects power

(100 V to 240 V) and automatically works with a

standard modular cable to connect to AC power

receptacles in any country.

Chapter 4: Connecting Your Studio 21

Page 26

Changing Operating Levels of

Individual 888/24 I/O

Channels

The 888/24 I/O is factory set to +4 dBu operating levels for input and output. However, the

888/24 I/O allows you to individually switch

any of its analog inputs or outputs to either a

+4 dBu or –10 dBV operating level by moving

internal jumpers on its circuit board.

output level adjustment switches

+4 dBu or -10 dBV

input level adjustment

switches +4 dBu or -10 dBV

Input and output level switches inside the 888/24 I/O

To change the operating level of an input channel:

1 Turn off your computer and the 888/24 I/O.

output level

adjustment switches

+4 dBu or -10 dBV

input level

adjustment switches

+4 dBu or -10 dBV

5 Inside the 888/24 I/O chassis, next to each of

the channel input trims, there is a jumper

switch with a removable cap. Locate the jumper

switch for the channel you want to modify.

Gently lift the cap off the 3-pronged connector.

Place it in the position corresponding to the operating level that you desire. For +4 dBu levels,

place it over the rear two prongs. For –10 dBV

levels, place it over the front two prongs.

6 When you have made the desired changes, re-

place the top of the 888/24 I/O.

7 Replace the four front panel screws using the

hex wrench.

8 Replace the top screws with a Phillips screw-

driver.

pull off jumper

pull off

jumper

-10

+4

-10

4

+

-10

4

+

place

place jumper

in this position

jumper in

to set input

this position

to +4 dBu level

to set input

to +4 dBu

level

place

place jumper

jumper in

in this position

to set input

this position

to -10 dBV level

to set input

to -10 dBV

level

Setting the input level jumper switches

2 With a Phillips screwdriver, remove the screws

from the top of the 888/24 I/O.

3 Using the 1/16-inch hex wrench included

with the 888/24 I/O, carefully remove the front

four panel screws as noted on the bag containing the hex wrench.

4 Lift the top off of the 888/24 I/O.

TDM Installation Guide22

To change the operating level of an output

channel:

1 Turn off your computer and the 888/24 I/O.

2 Using the 1/16-inch hex wrench included

with the 888/24 I/O, carefully remove the front

four panel screws as noted on the bag containing the hex wrench.

3 With a Phillips screwdriver, remove the screws

from the top of the 888/24 I/O and lift the top

off of the 888/24 I/O.

Page 27

4 To find the channel output switches, detach

the front part of the ribbon cable at the right

side of the chassis. To do this, grip both sides of

the black connector and gently pull up.

5 With the ribbon cable out of the way you’ll

see eight 3-pronged jumper switches, each with

a removable cap. Locate the switch for the channel you want to modify.

remove jumper

place

jumper in

this position

to set

output to

+4 dBu level

0

-1

4

+

place jumper

in this position

to set output

to +4 dBu level

place

place jumper

in this position

jumper in

to set output

to -10 dBV level

this position

to set

output to

-10 dBV

level

detach

detach

ribbon cable

ribbon

cable

Setting the output level jumper switches

6 Gently lift the cap off of the jumper switch.

Place it in the position corresponding to the operating level that you desire. For +4 dBu levels,

place it over the left two prongs. For –10 dBV

levels, place it over the right two prongs.

7 When you have made the desired changes, re-

connect the ribbon cable and put the top back

on the 888/24 I/O.

8 Replace the four front panel screws using the

hex wrench.

Making Signal Connections to

the 888/24 I/O

Depending on how you plan to use the

888/24 I/O, the way you connect it to your studio will vary.

Choosing Between +4 dBu and

–10 dBV Operation Modes

The 888/24 I/O can be set to operate at +4 dBu

or –10 dBV input and output levels (see “Changing Operating Levels of Individual 888/24 I/O

Channels” on page 22). It is important that you

determine which line level mode is appropriate

for your studio. In +4 dBu operating mode, the

888/24 I/O is a 24-bit digital audio device capable of producing audio signals at or near

+26 dBu. Check the owner’s manual for your

mixer, power amplifier or effects processor to see

if it can handle this load. If it cannot, consider

setting the 888/24 I/O to operate at –10 dBV

line levels.

Consider the following when connecting a

mixer:

◆ If your mixer cannot handle more than 1.5 V

(RMS) inputs at +4 dBu, then set the 888/24 I/O

to run at –10 dBV line level.

◆ If your mixer can handle up to 8.5 V (RMS) in-

puts, or has pads or attenuators on its inputs,

then you can use the +4 dBu setting on the

888/24 I/O.

9 Replace the top screws with a Phillips screw-

driver.

Most manuals contain device input specifications, including whether or not there are pads or

attenuators. Consult the manufacturer of your

mixer or power amplifier for further information.

Chapter 4: Connecting Your Studio 23

Page 28

Setting Up Your Studio

The following diagram illustrates a typical studio setup, with the 888/24 I/O connected to a

mixing console, effects and other equipment.

Digital Inputs/Outputs

Channel 3-4

To Digital Effects Devices

Analog

Audio

Outputs 5-8

Tape Returns

or Inputs 1-4

Computer 1

1/2

5/6

AES/EBU INPUT

3/4

/2

1

7/8

UT

P

/

5/6

S

F

I

D

P

/

S

O

4

AES/EBU OUTP

3/

N

8

7/

Analog

Audio

Inputs 5-8

Channel

Outputs 1-4

I

Digital Inputs/Outputs

To DAT Recorder

1

3

T

2

5

G INPU

LO

ANA

4

7

6

1

8

3

2

5

LOG OUTPUT

ANA

4

7

6

8

K

C

O

L

C

E

V

A

L

S

K

T

C

U

O

O

L

C

E

V

A

L

S

N

I

F

I

D

T

U

Channel 1-2

Effects Devices

Digital Effects Devices

(set to external sync)

DAT Recorder

Using 888/24 I/O As

Standalone Audio Converter

The 888/24 I/O can be used apart from

Pro Tools as a standalone 8-channel, 24-bit, analog-to-digital or digital-to-analog converter.

Before you use the 888/24 I/O in standalone

mode:

1 Turn off the 888/24 I/O.

2 Do not turn on your computer while the

888/24 I/O is in standalone mode. If you do, the

888/24 I/O stops functioning in standalone

mode.

Instruments

Connected to Console

Power Amp

and Speakers

Typical studio configuration

The 888/24 I/O analog audio connectors are balanced XLRs with pin 2 wired hot (or “+”), pin 3

cold (or “–”), and pin 1 ground.

If you are connecting a balanced system, connect pin 1 and shield at the input only (not at

the output). This prevents ground loops between the shield and pin 1 conductor.

If you are connecting an unbalanced signal to

the 888/24 I/O inputs or outputs, connect only

pin 2 to the “+” signal, and pins 1 and 3 to

ground at all inputs only.

To use the 888/24 I/O as a standalone A/D

converter:

1 Turn off any digital devices that send a word

clock signal to the 888/24 I/O channel 1–2 digital input ports.

2 Turn on the 888/24 I/O. The 888/24 I/O

searches briefly for a word clock signal on channels 1–2 of its digital input ports.

3 If the 888/24 I/O does not detect word clock,

it functions as a standalone A/D converter using

its internal clock. In this mode, use analog inputs 1–8 and AES/EBU outputs 1–8.

The default sample rate of the 888/24 I/O

in standalone A/D mode is 44.1 kHz.To

change this default setting to 48 kHz, you

must open the 888/24 I/O and manually reset it by moving an internal jumper switch.

Instructions for doing this are provided in

the 888/24 I/O Installation Guide.

TDM Installation Guide24

Page 29

To use the 888/24 I/O as a standalone D/A

converter:

1 Make sure that a digital device providing a

word clock signal is connected to AES/EBU inputs 1–2 of the 888/24 I/O and turned on.

2 Turn on the 888/24 I/O. The 888/24 I/O

searches for a valid word clock or a word clock

signal on channels 1–2 of its digital input ports.

3 When a valid word clock lock is recognized,

the 888/24 I/O enters Digital mode and function as a standalone D/A converter using

AES/EBU inputs 1–8 and analog outputs 1–8.

The 888/24 I/O D/A sample rate is determined

by the sample rate it detects on channels 1–2 of

its AES/EBU inputs.

The 888/24 I/O defaults to listening to a

digital word clock signal on channels 1–2 of

its AES/EBU digital input ports. To use a

S/PDIF device as your source of word clock,

you must reset this default by opening the

888/24 I/O and moving an internal jumper

switch. Instructions for doing this are provided in the 888/24 I/O Installation Guide.

That guide also provides instructions for

changing other standalone mode default parameters such as sample rate and DAC

muting.

The 882/20 I/O Interface

This section explains all of the connectors and

indicators on the front and back panels of the

882/20 I/O interface, how they are used, and offers suggestions for connecting the 882/20 I/O

to your studio.

882/20 I/O Interface Front Panel

The 882/20 I/O has the following front panel indicators, moving from left to right:

Ch 1–2

Input

20

Power

Sync Mode

Front panel of the Digidesign 882/20 I/O

Power

This switch applies power to the 882/20. The “I”

position is on. The “O” position is off.

Sync Mode

Sample

Rate

Signal

Present

LEDs

To return the 888/24 I/O to Pro Tools-based

operation:

■ Turn on your computer.

– or –

■ If your computer is on, launch Pro Tools.

The Sync Mode LEDs indicate which sample rate

clock reference is currently used by the analogto-digital converters (ADCs) and the digital-toanalog converters (DACs).

Internal This is the 882/20 I/O standard setting.

In this mode, the 882/20 I/O sample rate is generated by its internal crystal oscillator (whose

frequency is determined by the Sample Rate setting in the Session Setup window). Activate internal mode whenever the 882/20 I/O is not

synchronized to an external clock source.

Chapter 4: Connecting Your Studio 25

Page 30

Digital This setting indicates that a S/PDIF word

clock signal is the source for the 882/20 I/O

sample rate. This is the setting you would use for

inputting material from DAT machines or other

S/PDIF digital devices.

To use the 882/20 I/O digital input and output

as an effects send and return to a digital effects

device, set the 882/20 I/O to Internal mode. Set

the digital effects device to accept an external

digital clock (from the 882/20 I/O) so it synchronizes with Pro Tools.

In an expanded system, the system clock is carried by the audio interface connected to the first

Pro Tools card in your system. This audio interface acts as the master interface in your system,

and all other audio interfaces slave to it. Only

the master interface allows you to set the Sync

Mode. Slaved interfaces do not allow this parameter selection.

Because some digital audio devices do not

output proper clock when they are not playing back, leaving the 882/20 I/O in Digital

mode may cause Pro Tools audio playback

quality to suffer, or to play back at the

wrong pitch. If you are using digital I/O, reset the Sync Mode from Digital to Internal

after inputting material.

Slave This LED is lit when the 882/20 I/O sample rate is synchronized to another Digidesign

audio interface or synchronization peripheral.

In this mode, the sample rate of the slave interface is derived from the frequency of the incoming master clock signal present at the Slave

Clock In (256x) port. The 882/20 I/O automatically switches to this mode when a Slave Clock

Out signal from another Digidesign interface,

Universal Slave Driver, Video Slave Driver, or

SMPTE Slave Driver is connected to its Slave

Clock In port.

In expanded Pro Tools systems, the Super Clock

output of the master audio interface locks all

other interfaces together with sample accuracy,

keeping all signals phase-synchronous.

When slaving to a Digidesign Universal

Slave Driver, Video Slave Driver, or SMPTE

Slave Driver, set the clock source to Internal.

The audio interface automatically switches

to Slave mode when it detects the 256x input clock.

Ch 1–2 Input

This LED indicates the format (analog or digital)

of the audio input signal to channels 1 and 2. In

Pro Tools, you choose analog or digital input for

these two channels in the Session Setup window. Input channels 3 through 8 of the

882/20 I/O are always analog.

Sample Rate

These LEDs display the current sample rate of

the 882/20 I/O internal crystal oscillator, which

can be either 44.1 kHz or 48 kHz. In Pro Tools,

this is set in the Session Setup window.

The 882/20 I/O provides the following sample

rates:

48 kHz This is a standard sampling rate of many

professional audio devices. It is recommended

for use with devices that cannot receive digital

transfers at 44.1 kHz.

TDM Installation Guide26

Page 31

44.1 kHz This is the compact disc standard sampling rate and the Pro Tools default sample rate.

To avoid the need for sample rate conversion,

use this rate when you are recording material

that will ultimately be published on a compact

disc.

When you are using an external digital

source such as a DAT recorder, the front

panel of the 882/20 I/O indicates only the

internal oscillator sample rate, not that of

the external digital source.

Signal Present LEDs

These LEDs indicate whether signal is present

(above the level of –30 dB) at a given channel’s

output. These LEDs indicate the presence of

channel output signals, not input signals. Input

signals are monitored on-screen in the Pro Tools

software. The LEDs do not indicate clipping.

Clipping is indicated by the on-screen meters in

Pro Tools software.

Analog Audio Inputs

These are balanced, 1/4-inch TRS jacks for analog audio input connections. The 882/20 I/O

analog inputs feature 20-bit analog-to-digital

converters.

Input operating levels are switchable between

+4 dBu and –10 dBV operation. Unbalanced

connections are supported through the use of

standard 1/4-inch TRS mono phone plugs.

Because input channels 1–2 of the 882/20 I/O

are software selectable between analog or S/PDIF

digital format, input to these two analog channels is disabled when S/PDIF digital input format is chosen in the Pro Tools Hardware Setup

dialog.

The 882/20 I/O analog inputs are factory calibrated at a –14 dB nominal level, referenced to a

full code signal. This means that at the nominal

reference input level (either +4 dBu or –10 dBV),

you have 14 dB of headroom before clipping.

882/20 I/O Back Panel

The 882/20 I/O has the following back panel

connectors, moving from left to right:

Slave

Clock

In/Out

Analog

Inputs

Back panel of the Digidesign 882/20 I/O

Analog

Outputs

S/PDIF

I/O

50-pin

Interface

Power

Analog Audio Outputs

These are balanced, 1/4-inch TRS jacks for analog audio output connections. The 882/20 I/O

analog outputs feature 20-bit digital-to-analog

converters.

All eight output channels are continuously active. Output operating levels are switchable between +4 dBu and –10 dBV operation. Unbalanced connections are supported through the

use of standard 1/4-inch TRS mono phone

plugs.

The 882/20 I/O analog outputs are factory calibrated at a –14 dB nominal level, referenced to a

full code signal. This means that at the nominal

reference output level (either +4 dBu or

–10 dBV), you have 14 dB of headroom before

clipping.

Chapter 4: Connecting Your Studio 27

Page 32

Slave Clock In/Out

The Slave Clock Out jack is a standard BNC type

connector that outputs a 256x audio sample rate

master Super Clock signal for slaving and synchronizing multiple Digidesign interfaces and

synchronization peripherals together.

The Slave Clock In jack is a standard BNC type

connector designed to receive a Slave Clock Out

signal from another Digidesign interface, a Universal Slave Driver

SMPTE Slave Driver

Digidesign interfaces and synchronization peripherals together.

When the 882/20 I/O Sync Mode is set to Internal, connecting a valid Slave Clock Out signal to

this port causes the 882/20 I/O to automatically

switch to Slave mode. When the 882/20 I/O is

the master interface or the first interface in a

chain, Digital mode overrides the Slave Clock

input, and an incoming Slave Clock Out signal

will not switch the 882/20 to Slave mode.

Because crucial timing data is passed over these

ports, use high-quality, 75-ohm RG-59 cables

for making connections, and keep total cable

length to less than 3 meters between interfaces.

™

, Video Slave Driver™, or

™

for synchronizing multiple

Hardware Setup dialog. To avoid RF interference, use 75-ohm coaxial cable for S/PDIF transfers and do not exceed a cable length of 10

meters.

50-pin Interface Connector

This 50-pin connector is used to connect the

882/20 I/O to a MIX card, d24, Disk I/O, or DSP

Farm card. The necessary cable is supplied with

your audio interface. If you plan to connect two

882/20 I/O interfaces to a MIX card or d24 card,

a 16-channel peripheral cable adapter is necessary. (This cable is available from your Digidesign dealer.)

Power Input

This connector accepts a standard AC power cable. The interface automatically selects power

(100 V to 240 V), and automatically works with

a standard modular cable to connect to AC

power receptacles in any country.

S/PDIF Digital Input/Output

The Sony Philips Digital Interface Format

(S/PDIF) is used in many professional and consumer CD players and DAT recorders. The

882/20 I/O S/PDIF jacks are unbalanced, 2-conductor, phono (RCA) jacks. Because input channels 1–2 of the 882/20 I/O are software selectable between analog or digital format, input to

these two digital channels is disabled when analog input is chosen in the Hardware Setup dialog in Pro Tools. Output is continuously active

on the S/PDIF output jack, even if the

882/20 I/O input selector is set to Analog in the

TDM Installation Guide28

Page 33

Making Signal Connections to

the 882/20 I/O

Depending on how you plan to use the

882/20 I/O, the way you connect it to your studio will vary.

Choosing Between +4 dBu and

–10 dBV Operation Modes

The 882/20 I/O can be set to operate at +4 dBu

or –10 dBV input and output levels. It is important that you determine which line level mode

is appropriate for your studio. In +4 dBu operating mode, the 882/20 I/O is a 20-bit digital audio device capable of producing audio signals at

or near +18 dBu. Check the owner’s manual for

your mixer, power amplifier or effects processor