Page 1

DEKOCAST

Technical Reference And Service Guide

Pinnacle® Systems, Inc.

280 N. Bernardo Avenue

Mountain View, CA 94043

July 2004

Copyright© 2004 Pinnacle® Systems, Inc.

P/N 322100119

Rev. A

Page 2

Preface

This manual is a technical reference for the DekoCast workstations. A technical overview for the workstations are

provided, as well as information on troubleshooting a workstation and replacing software and hardware components

within a workstation.

This manual is intended for the person who sets up and uses the DekoCast workstation, and the Pinnacle Systems

Customer Support Engineer who provides technical support for the workstations over the phone.

Important: This manual references only newer DekoCast systems that were shipped after July 2004 and includes the

model numbers listed below:

• Model: 322202000 -- DekoCast

If the model number of your DekoCast system does not appear in the list above, please refer to the Quick Install

document that was provided on the Application CD with the original shipment of your system.

Trademarks

All brand or product names mentioned her e in are used for identification purposes only and may be trademarks or

registered trademarks of their respective companies.

DekoCast Technical Reference And Service Guide

Copyright © 2004 Pinnacle Systems, Inc.

All Rights Reserved.

Reproduction, adaptation, or translation of this document without pri or written permissio n is prohibited, except as

allowed under copyright laws.

Printed in the United States.

Note: The information in this document is subject to change without notice or obligation.

Pinnacle Systems Part #322100119

Revision A

15 July 2004

JML

2 DekoCast Technical Reference And Service Guide

Page 3

Official Notices And Warranties

Software License Agreement

IMPORTANT—READ CAREFULLY: This Software License Agreement is a legal agreement

between You and Pinnacle (or its suppliers). This System contains certain Pinnacle computer

software (“Software”), associated media, printed materials, and electronic documentation. By

using the Software, You agree to be bound by the terms of this Software License Agreement. If

You do not agree to the terms of this Software License Agreement, Pinnacle is unwilling to

license the Software to You. In such case, You may not use or copy the Software. This system

also contains certain third party software, which is provided to You upon the condition that You

agree to the terms outlined in the third party software licenses included with the materials shipped

with the System.

License: Pinnacle grants to You a nonexclusive, personal, perpetual, nontransferable, limited license

to use the installed Software exclusively on hardware on which Pinnacle has loaded the Software, or

other hardware on which Pinnacle has authorized it to be loaded, but solely in connection with the

operation of Your internal business, and not for the benefit of any third party. Such Software may

only be enabled by Pinnacle or its authorized agent. Pinnacle and its licensors retain all right, title and

interest in and to all Software, but title to the media on which the Software is delivered is transferred

to You.

Restrictions: The Software is copyrighted and may contain material that is protected by patent, trade

secret or other laws pertaining to proprietary rights. You may not copy the Software, except that it

may make a single copy for archival purposes. You may not modify the Software or permit or assist

any third party in doing so. You may not decompile, reverse engineer, disassemble, or otherwise

reduce the Software to source code or other human-readable form, or attempt or permit any third party

to do so. Any violation of this Software license shall be a material breach and shall immediately entitle Pinnacle to exercise any remedy that may exist at law or in equity.

Copyright: All title and copyrights in the Software (and any copies thereof) and the accompanying

printed materials are owned by Pinnacle. All rights not specifically granted under this Software

License Agreement are reserved by Pinnacle.

Limited Warranty: Pinnacle warrants that (a) the Software will perform substantially in accordance

with the published specifications for a period of one year

hardware will be free from defects in materials and workmanship under normal use and service for a

period of one year

This warranty will not apply to repair or replacement necessitated by accident, disaster, improper or

inadequate maintenance, customer or customer-supplied interfacing or machines, unauthorized modifications or repairs, improper electrical current, misuse, abuse or improper installation. This warranty

is personal to You and may not be assigned or transferred. Pinnacle does not warrant that the Software will operate error-free.

THE LIMITED WARRANTY SET FORTH HEREIN IS THE ONLY WARRANTY, EXPRESS,

IMPLIED OR STATUTORY THAT PINNACLE MAKES WITH RESPECT TO THE PRODUCTS.

ALL IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT, ARE DISCLAIMED.

from the date of receipt.

from the date of receipt and (b) any Pinnacle

DekoCast Technical Reference And Service Guide

3

Page 4

Official Notices And Warranties

Limitation of Liability

PINNACLE SHALL NOT BE LIABLE FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES; FOR DAMAGES THAT DIRECTLY OR INDIRECTLY

ARISE FROM YOUR USE OF, OR INABILITY TO USE, THE SYSTEM; FOR

COMMERCIAL LOSS OF ANY KIND; FOR THE PROCUREMENT OF SUBSTITUTE

GOODS--WHETHER ARISING IN TORT, CONTRACT OR ANY OTHER LEGAL THEORY,

EVEN IF PINNACLE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

IN ANY EVENT, PINNACLE’S LIABILITY SHALL BE LIMITED TO THE AMOUNT

ACTUALLY PAID BY YOU FOR THE SYSTEM GIVING RISE TO ANY SUCH DAMAGE.

THIS LIMITATION IS INTENDED TO LIMIT PINNACLE’S LIABILITY AND SHALL

APPLY NOTWITHSTANDING ANY FAILURE OF ESSENTIAL PURPOSE OF ANY

LIMITED REMEDY.

4

DekoCast Technical Reference And Service Guide

Page 5

Table of Contents

OFFICIAL NOTICES AND WARRANTIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Software License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 1: INTRODUCTION TO DEKOCAST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CHAPTER 2: DEKOCAST SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TARGA 3200 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Daria Bypass Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RS-422 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Signal Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Workstation Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Workstation Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CHAPTER 3: INSTALLATION AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DekoCast Workstation Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Repacking A DekoCast Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DekoCast GPI Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DekoCast RS-422 Automation Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Daria Board Signal Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Over-Ride Switch Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C

HAPTER 4: TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

I/O Diagnostic Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Modes Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setup Before Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Automatic Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Manual Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Deko Manifest Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Deko Manifest Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Interpreting Deko Manifest Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CHAPTER 5: SYSTEM MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replacing Workstation Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing A TARGA Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

DekoCast Technical Reference And Service Guide 5

Page 6

Table Of Contents

Replacing The Daria Bypass Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing The RS-422 Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing The SVGA Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Replacing A Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Replacing A Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replacing The Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing The DVD/CD Drive And/Or Floppy Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

System Recovery Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

You Have The Software Disks Supplied By Pinnacle Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configuring A Restored DekoCast OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Installing The DekoCast Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Installing The Daria Bypass Card Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Recreating A DekoCast Drive Image Restore DVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Configuring A New “System” Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configuring A New “Media” Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

APPENDIX A: PINNACLE SYSTEMS CUSTOMER SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

About Deko Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Troubleshooting Questionnaire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Contacting Pinnacle Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Upgrade Information on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

APPENDIX B: USING SHAPED AND UNSHAPED KEYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

About Shaped And Unshaped Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Shaped vs. Unshaped Compositing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Shaped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Unshaped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Mathematical Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Comparison Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

APPENDIX C: DEKOCAST TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

DekoCast Base Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6 DekoCast Technical Reference And Service Guide

Page 7

Chapter 1: Introduction To DekoCast

Contents

This Chapter provides an introduction to the DekoCast Workstation Technical Reference and

Service Guide. A brief description of all of the Chapters and Appendices that can be found in this

document is also described in this section.

This Chapter contains the following sections:

• Introduction

• Using This Manual

DekoCast Technical Reference And Service Guide

7

Page 8

Chapter 1: Introduction To DekoCast

Introduction

DekoCast is an advanced, cost-effective solution for a wide range of master control, channel

branding and localization applications. From weather alerts to coming attractions, DekoCast

handles video, audio, clips and graphics all in one box. DekoCast is a turnkey combination of

real-time character generator, video and audio clip player, audio mixer and router, multi channel

DVE and advanced keying engine. It is the complete solution for automated squeeze and crawl,

squeeze and tease, credit sequences, and other broadcast combinations of re-scaled and positioned

video with real-time playback of clips, graphics, and effects.

This document provides detailed technical information about the DekoCast workstations. It is

meant to be used for initial setup and installation as well as a reference guide for system

maintenance and troubleshooting.

The DekoCast is configured to be a single channel system. This configuration type is described in

“Chapter 2: DekoCast System Overview.”

Important: This manual references only newer DekoCast systems that were shipped after July 2004 and

includes the model numbers listed below:

• Model: 322202000 -- DekoCast Single Channel System

If the model number of your DekoCast system does not appear in the list above, please refer to the Quick

Install document that was provided on the Application CD with the original shipment of your system

Using This Manual

Here is a quick overview of this manual’s Chapters and Appendices

• Chapter 1: Introduction To DekoCast -- Provides an overview of this manual.

• Chapter 2: DekoCast System Overview -- Provides a basic overview of the DekoCast system. The

hardware and channel configuration a DekoCast workstation can have are detailed here.

• Chapter 3: Installation And Set Up -- Explains how to set up a DekoCast workstation after it has

been initially received. This includes installing the hard drives, attaching peripheral devices, testing

the workstation, DekoCast software setup, and control and network connections.

• Chapter 4: Troubleshooting -- This Chapter describes how to use the I/O Diagnostic Utility, and the

Deko Manifest Utility. These two software utilities are provided within the DekoCast workstation

system software as a means to quickly and easily troubleshoot a workstation.

• Chapter 5: System Maintenance -- This Chapter details how to remove and replace various Deko-

Cast workstation components, and the methods for system recovery.

• Appendix A: Pinnacle Systems Customer Support -- Information about additional Deko resources,

a troubleshooting questionnaire, and regional worldwide e-mail and internet contact information is

included here.

• Appendix B: Using Shaped and Unshaped Keying -- An explanation about the methodology and

differences between shaped and unshaped keying when combining video an d key elements is given

here.

• Appendix C: DekoCast Technical Specifications -- Gives the technical specifications for the Deko-

Cast. Specifications for the DekoCast base configuration and ClipDeko option can be found here.

8

DekoCast Technical Reference And Service Guide

Page 9

Chapter 2: DekoCast System Overview

Contents

This Chapter provides a basic overview of the DekoCast system. The hardware configuration and

channel configuration for a typical DekoCast workstation is discussed and also detailed via

illustrations. The inputs and outputs on the front and back panel of the DekoCast workstation are

also described.

This Chapter contains the following sections:

• Hardware Configuration

• Signal Flow

• DekoCast Workstation Front Panel

• DekoCast Workstation Back Panel

DekoCast Technical Reference And Service Guide

9

Page 10

Chapter 2: DekoCast System Overview

Hardware Configuration

The DekoCast workstation is built with a high performance motherboard configuration that is

driven by powerful plug-in cards that manage the video and graphics data that flows through the

system. Each DekoCast workstation is also equipped with a state of the art graphics card that

processes all of the real-time graphic effects that are created in a Deko application. The primary

plug-in cards in a DekoCast workstation are as follows:

• TARGA 3200 Board

• Daria Bypass Board

• RS-422 Board

TARGA 3200 Board

The main Input/Output (I/O) module in the DekoCast system is Pinnacle’s TARGA 3200 plug-in

card. The TARGA 3200 board is an advanced real-time video and audio processing engine that

manages all of the I/O and graphics functions in a DekoCast. A single TARGA 3200 card is

installed on a DekoCast system. It is the TARGA 3200 card that provides the channel output for a

DekoCast system.

Daria Bypass Board

The Daria Bypass card enables DekoCast to pass the SDI Input through to the SDI output of the

system when the system is powered off or not functioning. It serves as a failover mechanism to

assure that valid video is output from the DekoCast even when any portion of the DekoCast

hardware or software malfunctions. The board can be set up so that its bypass functionality will

run automatically, or an optional over-ride switch (not included from the factory) can be installed

to manually force the DekoCast workstation into bypass mode at will. Information on the DB9

connector pinouts used to control the Daria board by a passive bypass switch, and the signal flow

of the TARGA 3200 to Daria, can be found in the “Daria Board Signal Flow” section within

“Chapter 3: Installation And Setup.”

RS-422 Board

A RS-422 plug-in card, which provides two industry standard RS-422 ports to the DekoCast

workstation for automation control, is factory installed on each DekoCast workstation. Additional

information can be found in the “DekoCast RS-422 Automation Control” section within “Chapter

3: Installation And Setup.”

10

DekoCast Technical Reference And Service Guide

Page 11

Chapter 2: DekoCast System Overview

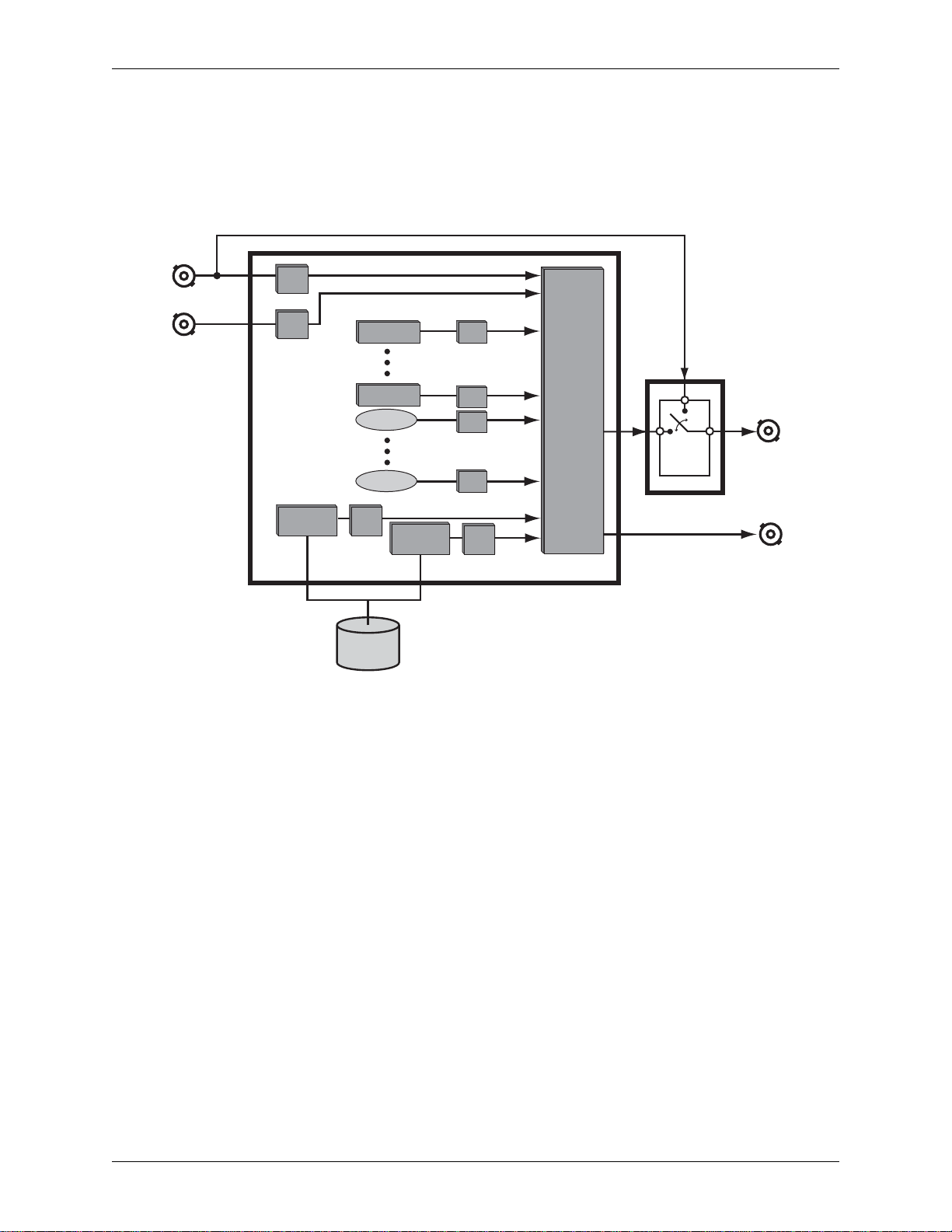

V

Signal Flow

The main hardware processing engine of the DekoCast is the TARGA3200 board. All I/O, clip

processing, effects output, and keying is processed on the TARGA 3200 board. An illustration

that is representative of the signal flow for the DekoCast system is shown in Figure 2-1.

Video

Input

DVE

Deko CG

CAP

CAP

DVE

Internal

Objexs Processing

Clip

CODEC

DVEDeko CG

DVE

DVE

DVE

DVE

Keyer

Bypass

Relay

Daria Board

Video

Output

Key

Output

ideo/Key

Input

DVE

TARGA

3200

Board

Clip

CODEC

Clip Storage

Figure 2-1: DekoCast Signal Flow

Note: For DekoCast systems, the Clip option may or may not be installed. (It depends on how the system was

ordered.)

DekoCast Technical Reference And Service Guide

11

Page 12

Chapter 2: DekoCast System Overview

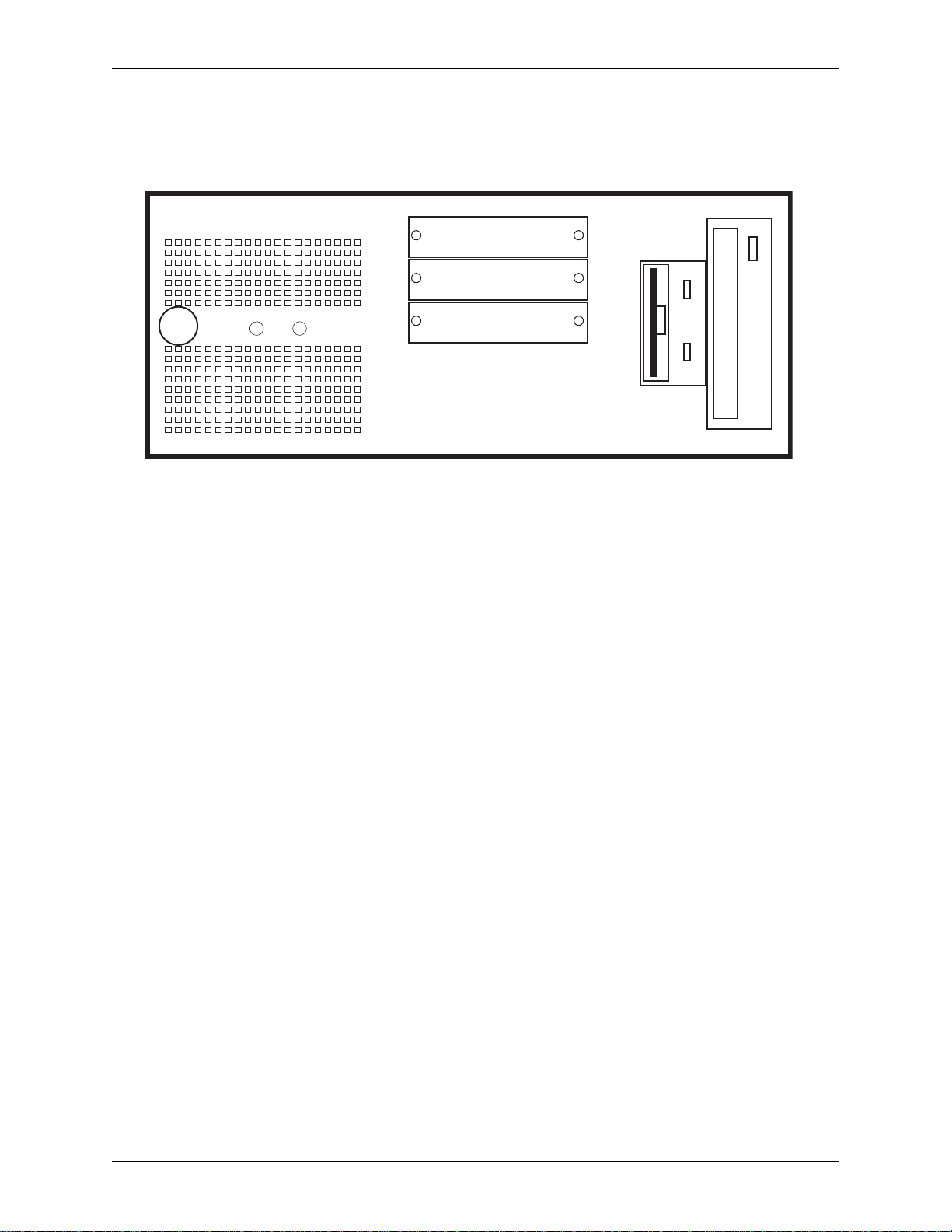

Workstation Front Panel

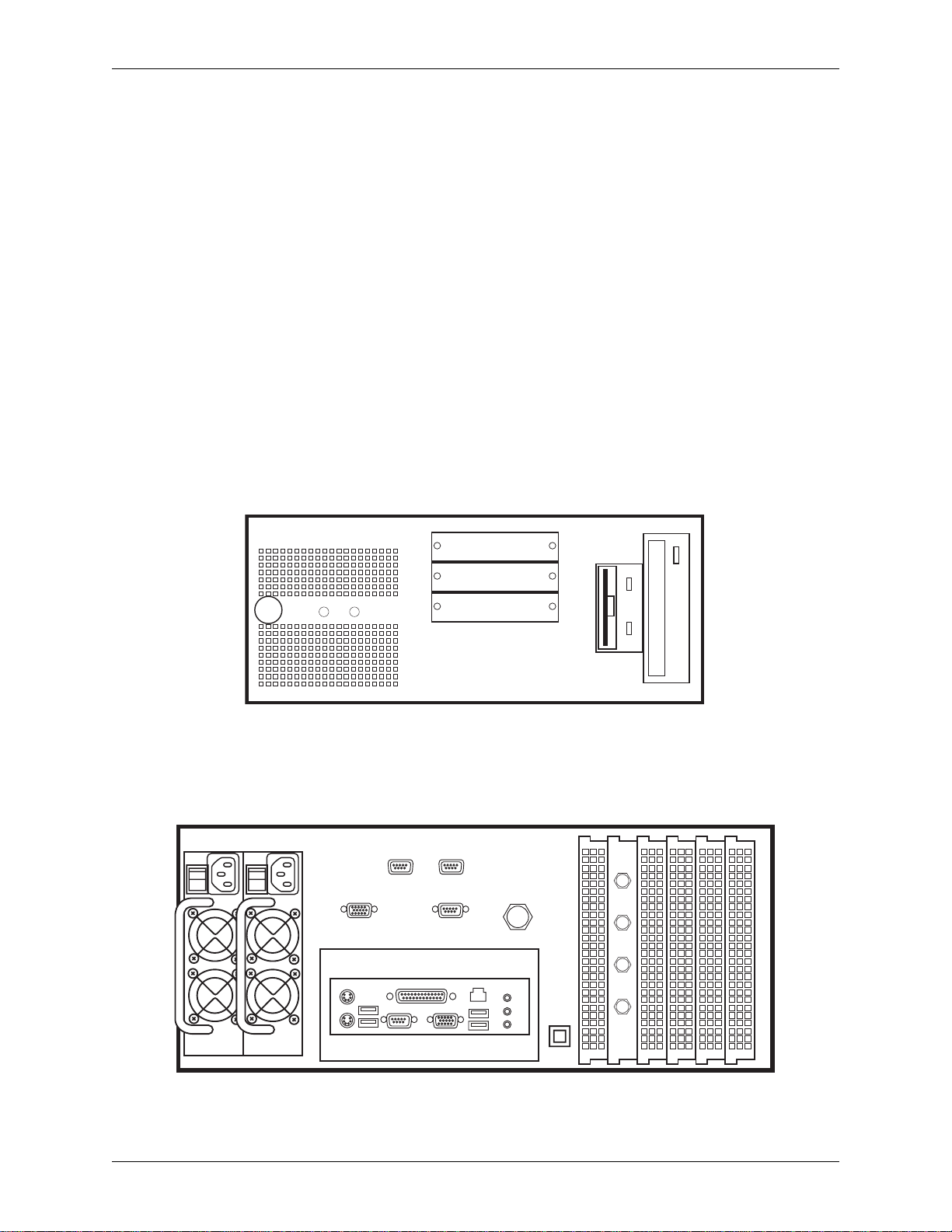

Figure 2-2 shows the front of the DekoCast workstation with the front cover removed.

DVD CD-ROM

SYSTEMSYSTEM

Floppy Drive

MEDIAMEDIA

USB

Power

On/Off

LED LED

Not Used

USB

Figure 2-2: Front Panel of DekoCast workstation (front panel cover removed)

The DekoCast workstations contain a floppy disk drive and a DVD/CD-ROM drive. The right

front panel has openings for inserting floppy disks and DVDs or CDs. To power on the machine,

first turn on the Power Supply switches on the back of a unit, then press the Power On/Off button

on the left side of the front panel. To power off the machine, first close all applications and shut

down the Windows operating system. Then turn of f the Power Supply switches on the back of the

machine. When a machine is powered On, the power light stays lit. A green light flashes

whenever the hard drive accesses data.

12

DekoCast Technical Reference And Service Guide

Page 13

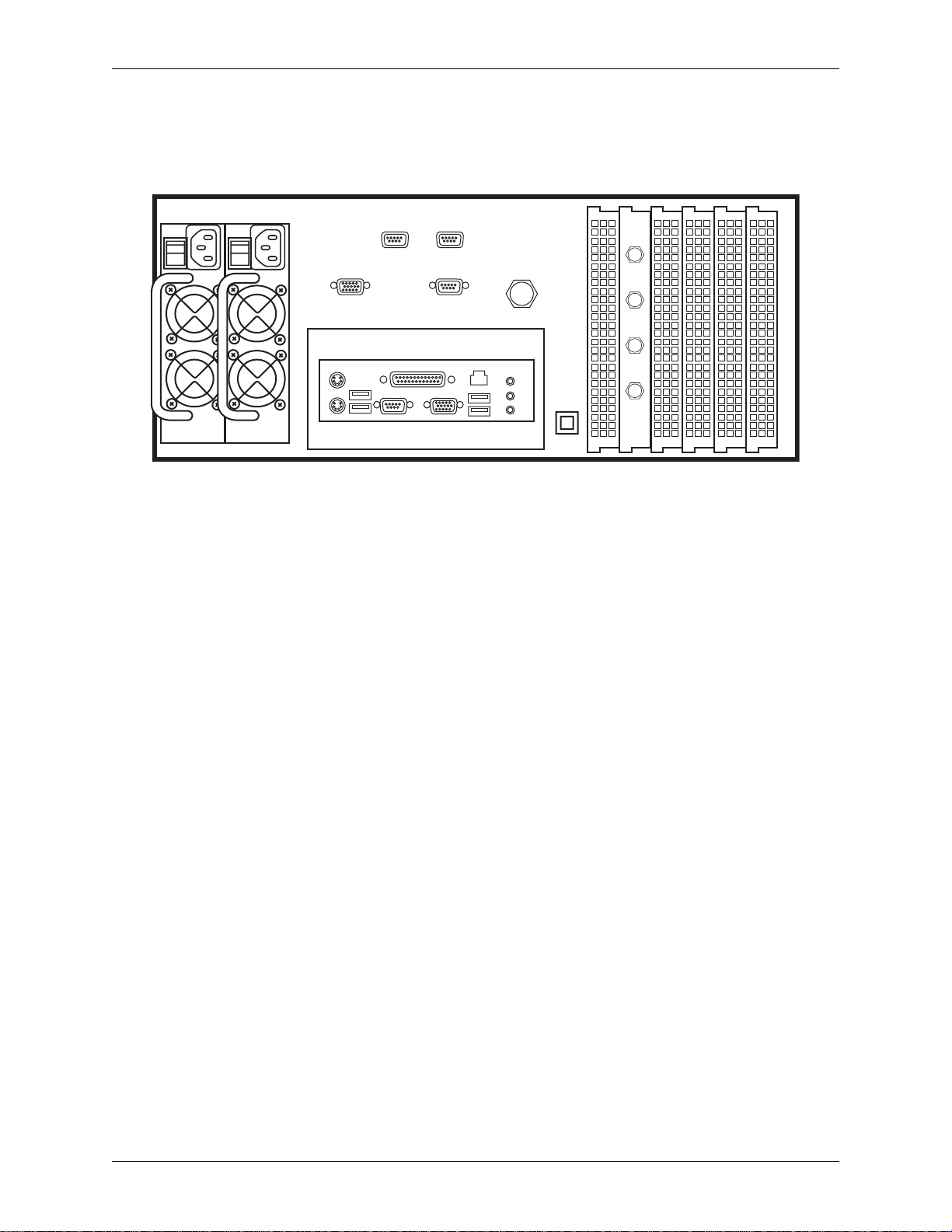

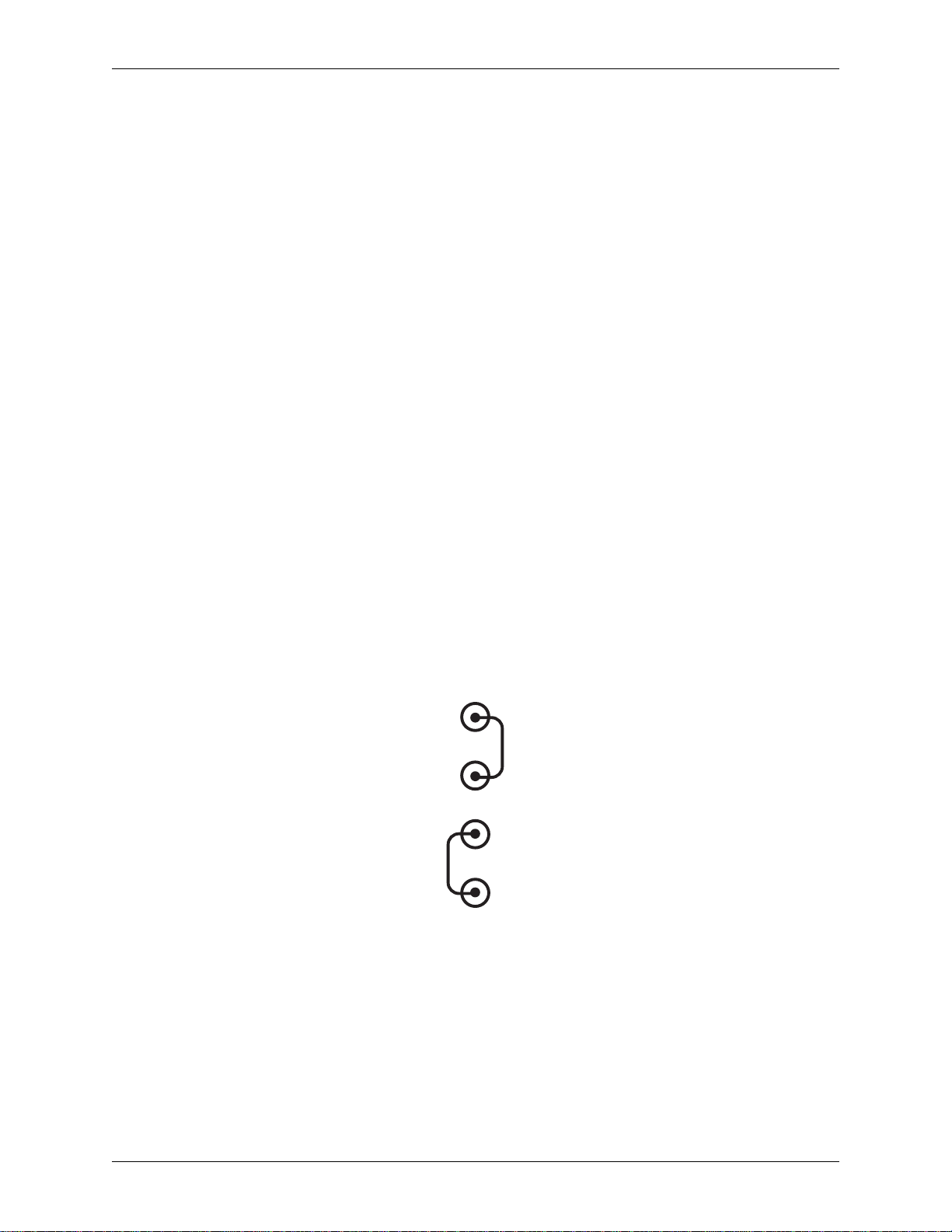

Workst ation Back Panel

Figure 2-3 shows the back of the DekoCast workstation.

Chapter 2: DekoCast System Overview

REDUNDANT POWER SUPPLIES

MOUSE

KEYBRD

SVGA

USB

RS422A RS422A

MANUAL

BYPASS

PARALLEL

SERIAL

UNUSED

NETWORK

USB

REFERENCE

ALARM

SILENCE

VIDEO

IN

VIDEO

OUT

KEY

IN

KEY

OUT

Figure 2-3: Back Panel of DekoCast workstation

The DekoCast workstation back panel (Figure 2-3) has two power supplies on the left, and AGP

and PCI card ventilation covers on the right. BNC connector plates for each TARGA 3200 board

in the workstation also double as ventilation covers. The cables from the TARGA 3200 cards are

fastened to the inside BNCs of the connector plates, which is labeled on the corresponding BNCs

on the outside the connection plates for each connection.

Each DekoCast workstation includes a pair of redundant hot-swappable Power Supplies. In the

event that one of the Power Supplies fails, the other will automatically take over to assure

continued operation of the workstation. A replacement Power Supply can be installed without

disrupting operation.

Important: Pinnacle Systems highly recommends that you purchase at least one spare Power Supply to

use in the event of a Power Supply failure. Contact Pinnacle Systems Customer Support (refer to

Appendix A) for ordering information.

Turn on the Power Supply switches before pressing the Power On/Off switch on the front panel.

When the power supplies are running, the Power LED on each power supply is green. When a

power supply is turned off or is not operational, the LED for that power supply is not lit. If a

power supply is not operational and the Power On/Off switch on the front panel is turned On, an

alarm will sound for the workstation. The workstation alarm can be turned off by pressing the

Alarm Silence button. Instructions for replacing a power supply can be found in Chapter 5:

System Maintenance.

The upper-middle part of the back panel contains the SVGA interface and the Genlock Reference

Input, which is internally connected to the TARGA 3200 board(s).

The recessed lower-middle panel has connectors for a keyboard and mouse, four available USB

ports, one parallel port, one serial port, and one LAN connector.

Important: A dongle which is necessary for the DekoCast software program to run is installed on the

parallel port. Do not remove the dongle.

DekoCast Technical Reference And Service Guide

13

Page 14

Chapter 2: DekoCast System Overview

14

DekoCast Technical Reference And Service Guide

Page 15

Chapter 3: Installation And Setup

Contents

This Chapter describes how to set up a DekoCast workstation after it has been initially received.

Information on installing the hard drives, attaching peripheral devices, testing the workstation,

DekoCast hardware settings software setup, and GPI control and network connections.

This Chapter contains the following sections:

• Unpacking

• DekoCast Workstation Initial Setup

• DekoCast Hardware Settings Window

• DekoCast GPI Input Connections

• DekoCast RS-422 Automation Control

• Daria Board Signal Flow

• Network Configuration

DekoCast Technical Reference And Service Guide

15

Page 16

Chapter 3: Installation And Setup

Unpacking

Please check to make sure that the following items have been included in the DekoCast packages

that were shipped:

-- Software CDs and DVDs

• DekoCast Software Application CD

• DekoCast Restore Image DVD

• Deko Fonts CD

• Instant CD/DVD Software CD

• Windows 2000 CD

These CD's are critical for the proper support of a DekoCast system. Please put them in a safe

location to insure timely support in the event that system maintenance is necessary. Misplacing

any of these CD's may result in a delay in servicing your DekoCast system.

-- Documents

• DekoCast Release Notes

• DekoCast Quick Install Guide

• Product Registration Card

Please read the Release Notes for important information about your new DekoCast System.

Also, take the time to fill out the Product Registration Card and return it to Pinnacle Systems.

Your filling out and sending the registration card enables Pinnacle Systems to inform you of any

important updates for your DekoCast system.

-- Hardware Components

• Main DekoCast Chassis

• System Drive (packed in separate box)

• Media Drive (packed in separate box)

• DekoCast Front Panel Cover

• Standard Mouse

• Standard Keyboard

• Two AC Power Cords (USA)

• Two AC Power Cords (International)

Note: Only two of the supplied power cords will be necessary for the DekoCast workstation. The type used is

dependent on the type of power outlet used in the facility where the DekoCast workstation will be located.

16

DekoCast Technical Reference And Service Guide

Page 17

Chapter 3: Installation And Setup

DekoCast Workstation Initial Setup

Before installing the DekoCast in your rack, the system should be put together, powered up, and

tested via a diagnostic test that comes pre-installed on the system. The steps for initially setting up

the workstation, powering it up, and testing it are as follows:

1. Visually inspect the hardwar e c omponents listed in the “Unpacking” section on the previous page to make sure that none of them were damaged during shipment

If you received a hardware component that was damaged, contact Pinnacle Systems

Customer Support. Contact information can be found in Appendix A of this document.

2. Insert the System hard drive and Media hard drive into their respective drive bays on

the front panel of the DekoCast workstation. Refer to Figure 3-1.

When placing a hard drive into its respective bay, align the drive so that it will properly slide

into the drive bay. Then push the drive so that it completely slides into the bay. This will

connect the drive to its connectors at the back of the bay. Use a screwdriver to completely

tighten the two thumbscrews. To insure that the connection stays intact, tighten the

thumbscrews as much as possible with the screwdriver.

DVD CD-ROM

Power

On/Off

LED LED

SYSTEMSYSTEM

MEDIAMEDIA

Not Used

Floppy Drive

USB

USB

Figure 3-1: Front Panel of DekoCast Workstation (front panel cover removed)

3. Attach the mouse and keyboard to the back panel of the workstation.

The mouse and keyboard connections on the workstation are shown in Figure 3-2.

REDUNDANT POWER SUPPLIES

SVGA

RS422A RS422A

MANUAL

BYPASS

REFERENCE

VIDEO

IN

VIDEO

OUT

MOUSE

USB

KEYBRD

Figure 3-2: Back Panel of the DekoCast Workstation

DekoCast Technical Reference And Service Guide

SERIAL

PARALLEL

UNUSED

NETWORK

USB

ALARM

SILENCE

KEY

KEY

OUT

IN

17

Page 18

Chapter 3: Installation And Setup

4. Attach the front panel cover (supplied) to the front of the DekoCast workstation.

The panel cover is the large plastic front panel cover that has the word DekoCast in red

lettering.

5. Connect a monitor (not supplied) to the DekoCast workstation.

The monitor attaches to the SVGA connector on the back of the DekoCast Workstation.

Refer to Figure 3-2.

6. Connect both AC Power Cords (supplied) the DekoCast workstation.

The AC power cords connect to both Power Supplies located at the back of the workstation.

Refer to Figure 3-2. Use the power cords appropriate for the electrical voltage range used by

the electrical outlet.

7. Turn on the monitor, and then power up the DekoCast workstation.

The workstation is power up by first pushing the Power Supply switches where the AC

Power Cords are connected to “On.” Then push the On/Off button located on the front panel

of the workstation to power up the workstation. When the operating system boots up, the

DekoCast background is displayed on the monitor.

8. Run the automatic mode of the I/O Diagnostic Utility to insure that the TARGA card is

functioning within the workstation.

For the TARGA card to be tested, the SDI channels for that card must be set to loop back.

This is done by taking two BNC cables (75 ohm) and connecting the Input/Output of each

channel as shown in Figure 3-3. The TARGA card BNC connectors are located on the back

panel of the workstation. The cable connection on the card for the test should be: Video Out

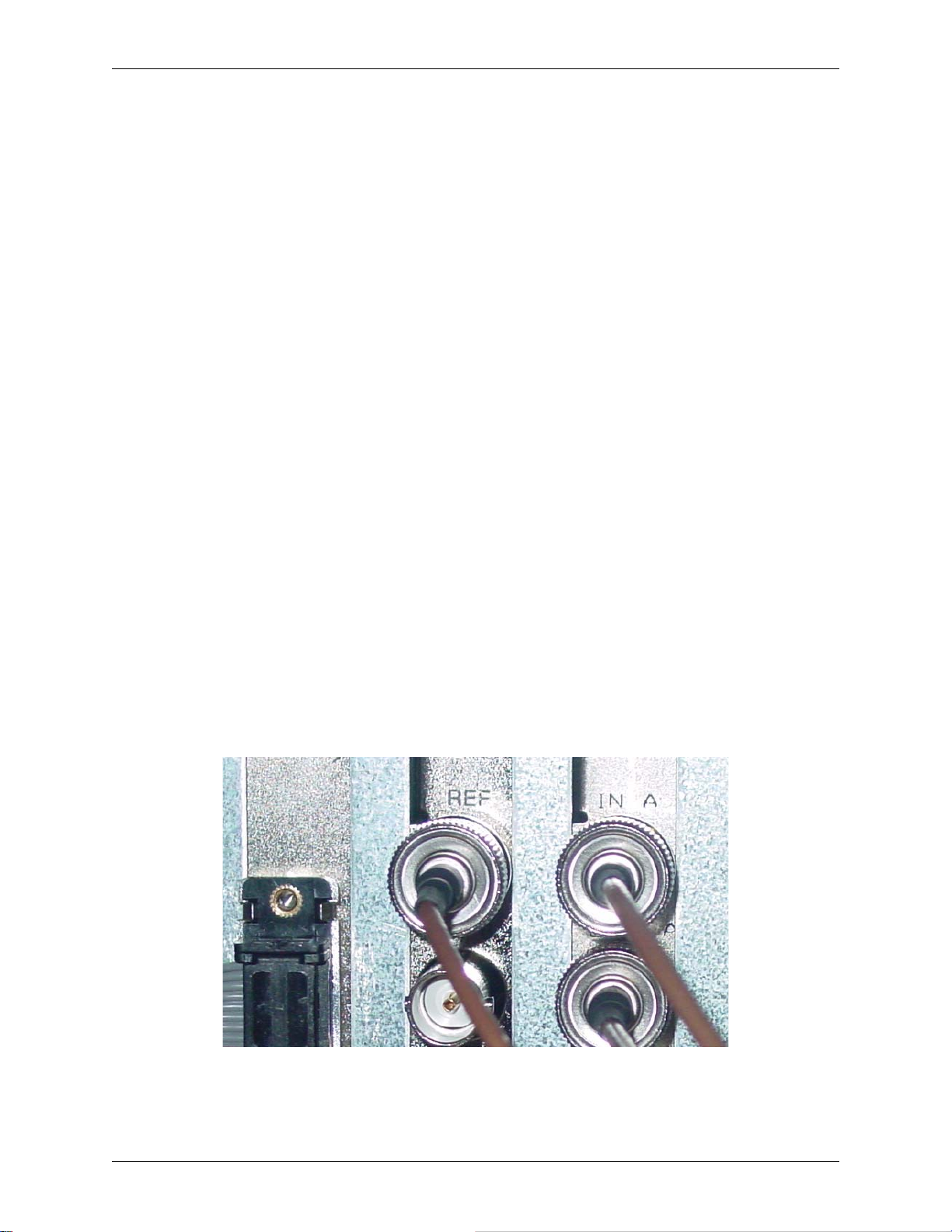

to Video In, and Key Out to Key In. Refer to Figure 3-3.

VIDEO IN

VIDEO OUT

KEY IN

KEY OUT

Figure 3-3: Loop Back Connections on each SDI Channel

Running the I/O Diagnostic Utility on a T ARGA card in a DekoCast workstation is a two step

process. First the “Fail Safe Test” software application program for the Daria Bypass Card

must be started. Once the “Fail Safe Test” application is running, the I/O Diagnostic Utility

program can be started and performed.

18

DekoCast Technical Reference And Service Guide

Page 19

Chapter 3: Installation And Setup

To start the “Fail Safe Test” application, navigate the following path within Windows:

Start menu >> Programs >>Pinnacle Systems >> Daria Passthrough

Then click the program “DariaPassthrough Test Procedure” to open it. Refer to Figure 3-4.

Figure 3-4: Daria Fail Safe Test

Important: Make sure that the “Emulate timeout failure” box is unchecked.

To start the I/O Diagnostic Utility application, navigate the following path to the Diagnostic

software program within Windows:

C:\ >> Program Files >> Pinnacle Systems >> TARGA Tester

Then click the program “I-O Diagnostic” to open it. Refer to Figure 3-5.

Figure 3-5: I/O Diagnostic Utility

Use the pull-down selection box on the upper left-hand side of the I/O Diagnostic window to

select “Board 1.” If you are facing the back panel of the workstation and looking at the

BNCs, then TARGA Board 1 would be the row of BNC’s on the far left. Then click the

“Start Full Test” button on the I/O Diagnostic window to run the automatic mode of the test.

If nothing fails on the test, the channel tested is fine.

A more detailed explanation of the I/O Diagnostic Utility program can be found in “Chapter

4: Troubleshooting” of this manual.

DekoCast Technical Reference And Service Guide

19

Page 20

Chapter 3: Installation And Setup

9. If the workstation is to be rack mounted or moved to another location, disconnect all of

the components and rack mount the workstation chassis.

Each DekoCast workstation chassis is designed so that industry standard rails can be

connected for rack mounting purposes. Each workstation will fit on 19-inch standard

instrument racks.

10. Make any other connections to the workstation that are necessary for the working

environment.

Other connections would include Genlock Reference, Video Input/Output BNCs, RS-422

automation, network cable, etc.

Note: The Audio connections (Speakers, Mic) on the back of the DekoCast chassis (refer to Figure 3-2) are

disabled at the factory and should not be used.

Repacking A DekoCast Workstation

When repacking your DekoCast system for shipment, please be sure to first remove the System

and Media drives and properly pack them with the system. This will protect the drives from

damage during shipment.

20

DekoCast Technical Reference And Service Guide

Page 21

Chapter 3: Installation And Setup

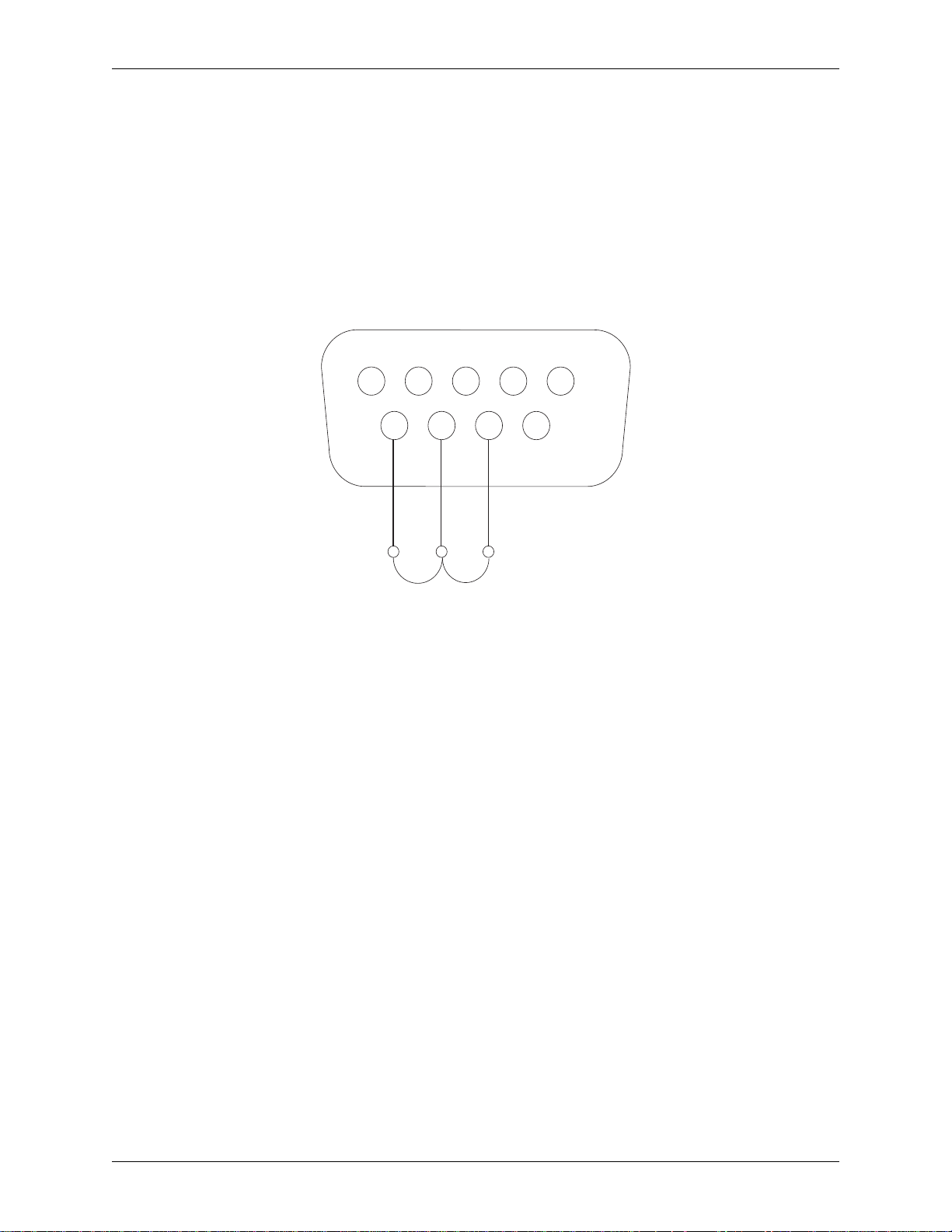

DekoCast GPI Input Connections

GPI’ s (General Purpos e Interface) can be us ed to interf ace DekoCa st with peripheral devices that

are capable of sending and receiving GPI pulses. A GPI Input can be selected from the Deko

Sequencer to trigger through a graphics sequence manually . For details on how to use GPIs within

the Deko application, refer to the “DekoCastCentral Guide” provided with your system.

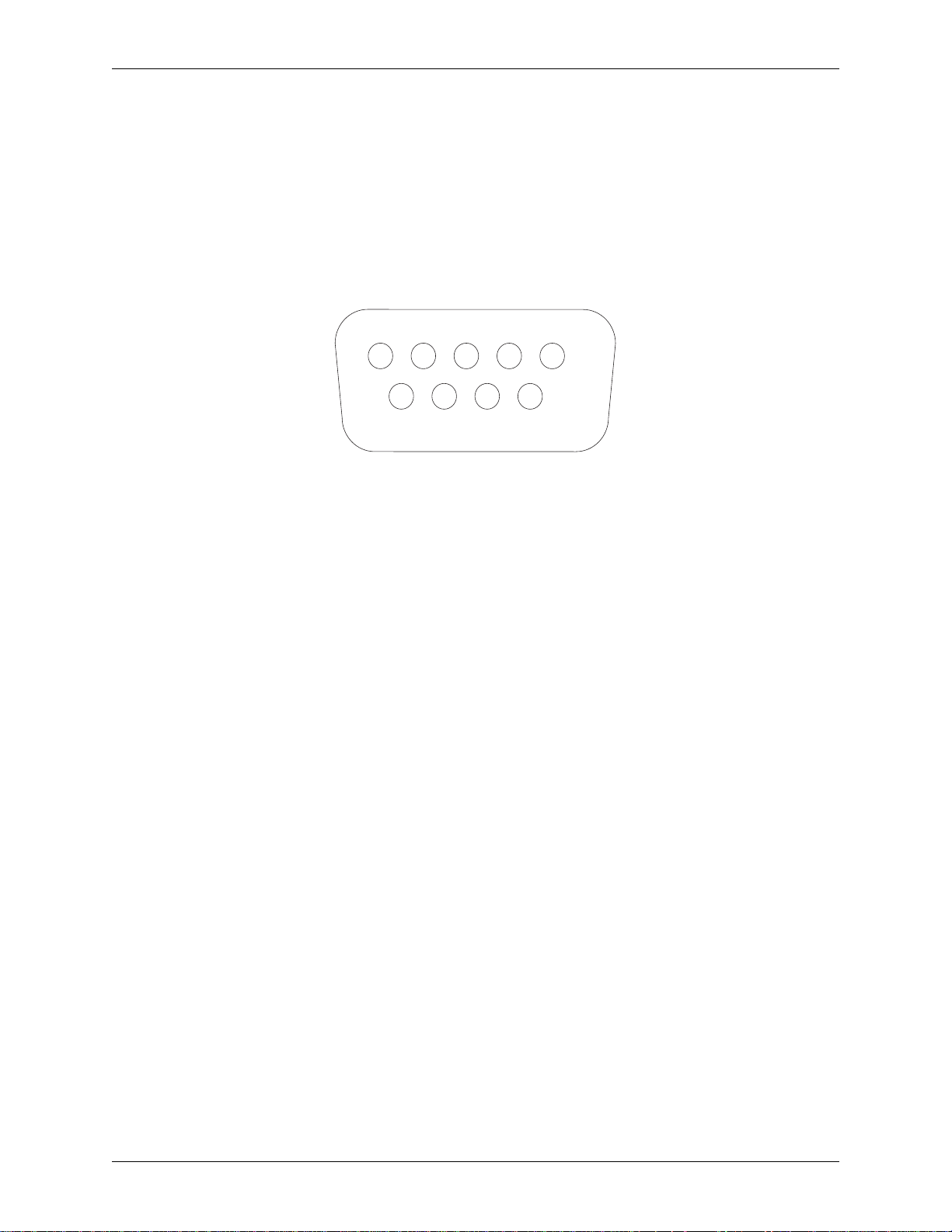

The RS-232 port on the back of your DekoCast system can be repurposed to provide a pair of GPI

inputs. The diagram in Figure 3-7 below shows the pin connections on the RS-232 port that are

used as GPI’s.

12345

6789

Pin 6

Figure 3-6: DekoCast RS-232 Port Pinout

GPI_2

Pin 7

GPI_1

Pin 8

Pins 7 and 8 of the RS-232 connector are mapped to GPI-1 and Pins 6 and 7 are mapped to GPI-2

and can be used to detect a GPI from a standard contact closure (such as a GPI output from a

switcher). These GPI inputs can be selected from the DekoCast Central application to trigger

various events within the DekoCast system. Refer to the User documentation that can be found on

your DekoCast Software Application CD.

If you need more than 2 GPI inputs for your DekoCast, two external boxes are available from

Burst Electronics to provide up to 10 GPI inputs. The specific model numbers and ordering

information is listed as follows:

Model Number Description Ordering Information

GPI-10 RS-232 to GPI Converter, 10 GPI Inputs Must Specify “Pinnacle Firmware” when ordering

GPI-10K RS-232 to GPI Converter, 10 GPI Inputs Must Specify “Pinnacle Firmware” when ordering

(Includes built in Keypad)

For more information, refer to the Burst Electronics website at: www.burstelectronics.com

DekoCast Technical Reference And Service Guide

21

Page 22

Chapter 3: Installation And Setup

d)

R

d)

T

)

G

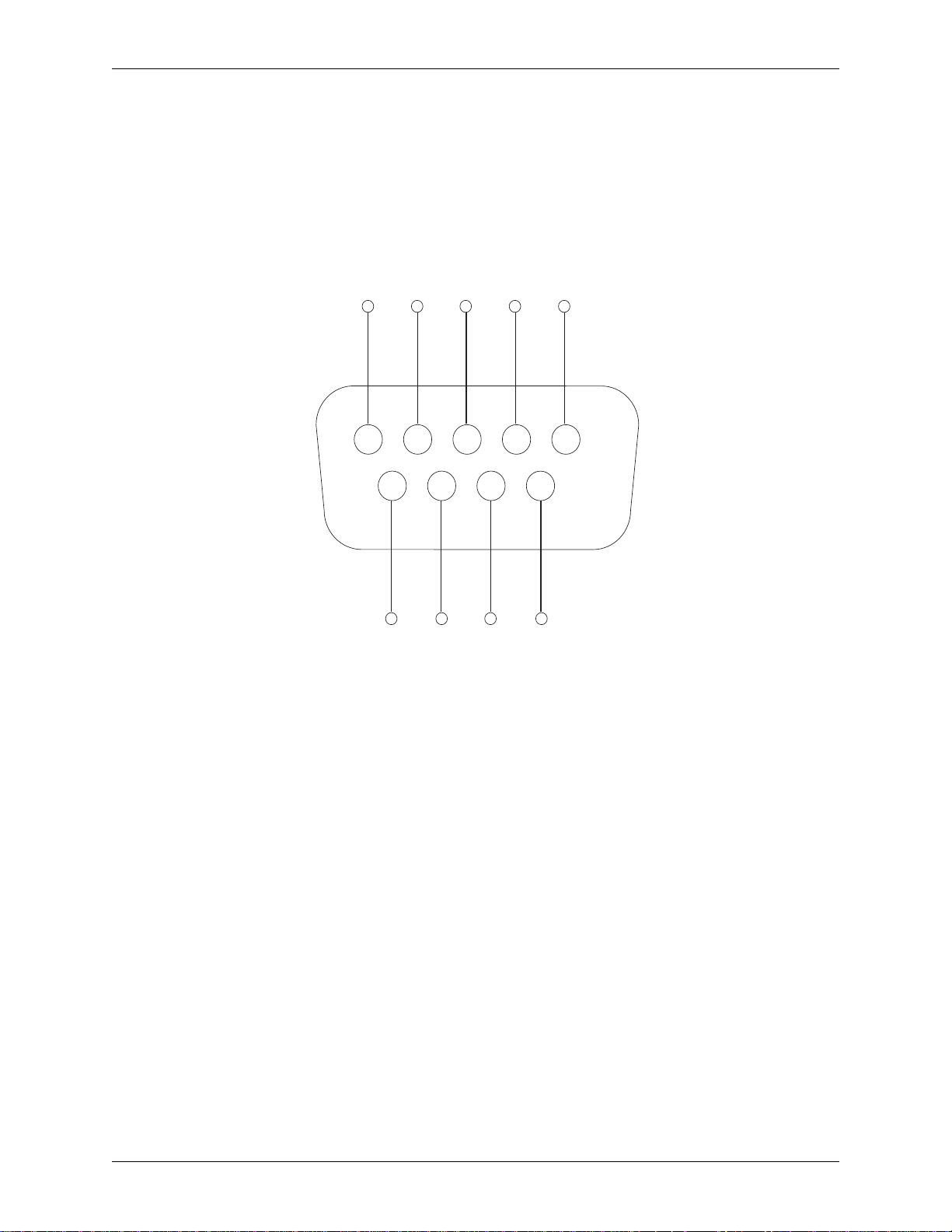

DekoCast RS-422 Automation Control

Your DekoCast system comes equipped with two industry standard RS-422 ports that can be used

for connecting to an automation system or for other control applications. These ports are labeled

as RS-422A and RS-422B on the back of the DekoCast chassis. Refer to Figure 3-2.

The pinouts for the RS-422 ports for automation control are shown in Figure 3-8.

Chassis

GND RX-

TX+

NC NC

12345

6789

GND

X- Receive (Negative End) NC (No Connect_Not Use

X+ Transmit (Positive End) RX+ Receive (Positive End

ND Ground

RX+ NC

TX-

TX- Transmit (Negative En

Figure 3-7: RS-422 Port Pinouts for Automation Control

These RS-422 ports will appear as standard COM3 (RS-422A) and COM4 (RS-422B) ports that

can be selected from the DekoCast Central Application or from a custom application that is

written for your DekoCast. Please refer to the DekoCast User documentation provided on the

application CD for more information.

22

DekoCast Technical Reference And Service Guide

Page 23

Chapter 3: Installation And Setup

Daria Board Signal Flow

The Daria Bypass Card provides a passive bypass relay to the video signal being provided to and

from the TARGA card. That is, the Daria card operates in pass through mode where it passes an

incoming video signal to the TARGA card, and receives an outgoing video from the TARGA

card. The Daria Bypass Card will provide a continuous video signal for the following three

conditions:

1. Loss of power

2. Software lock-up

3. Over-Ride activation (available only if an over-ride switch is installed)

Important: The key output is not affected by the Daria Bypass Card, and therefore not protected from

the above three conditions.

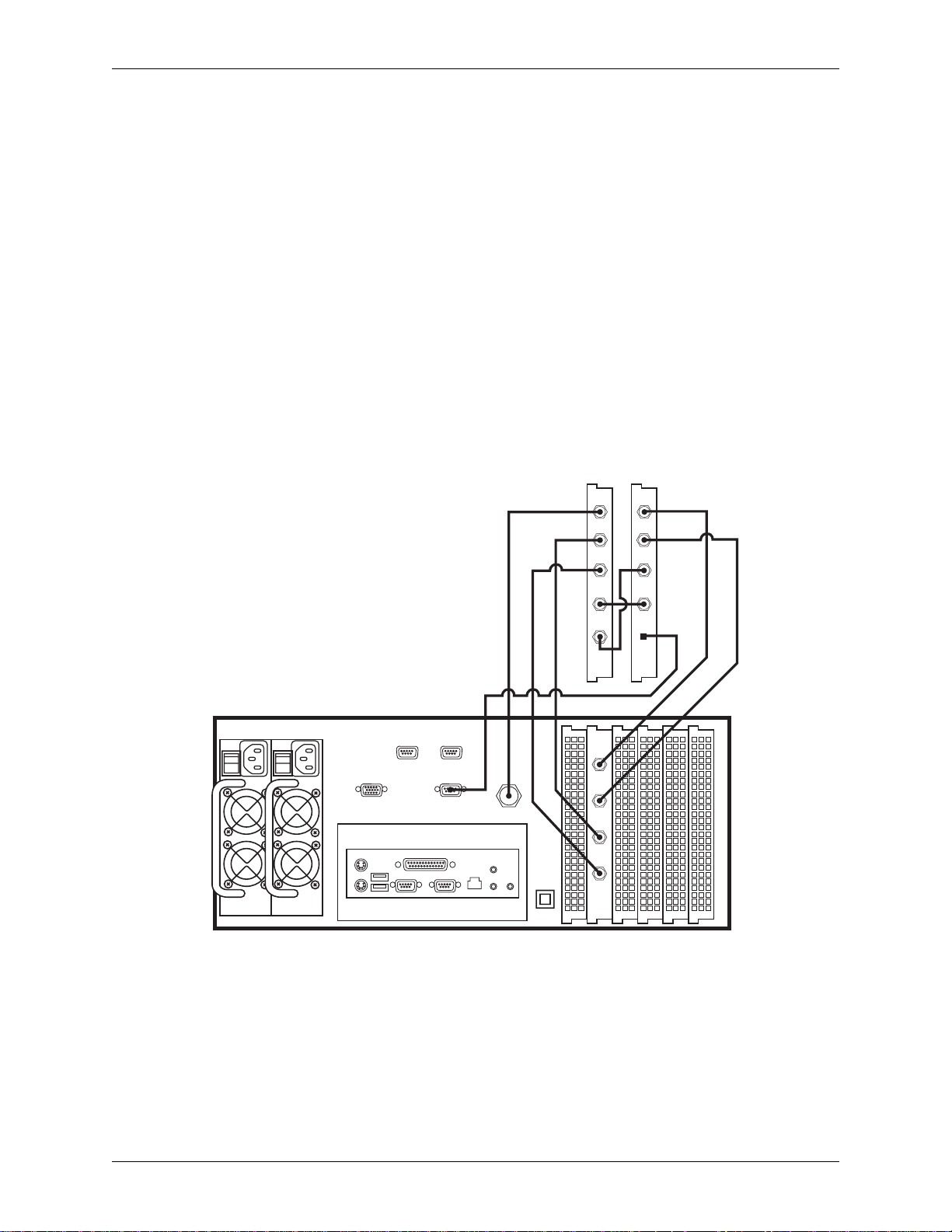

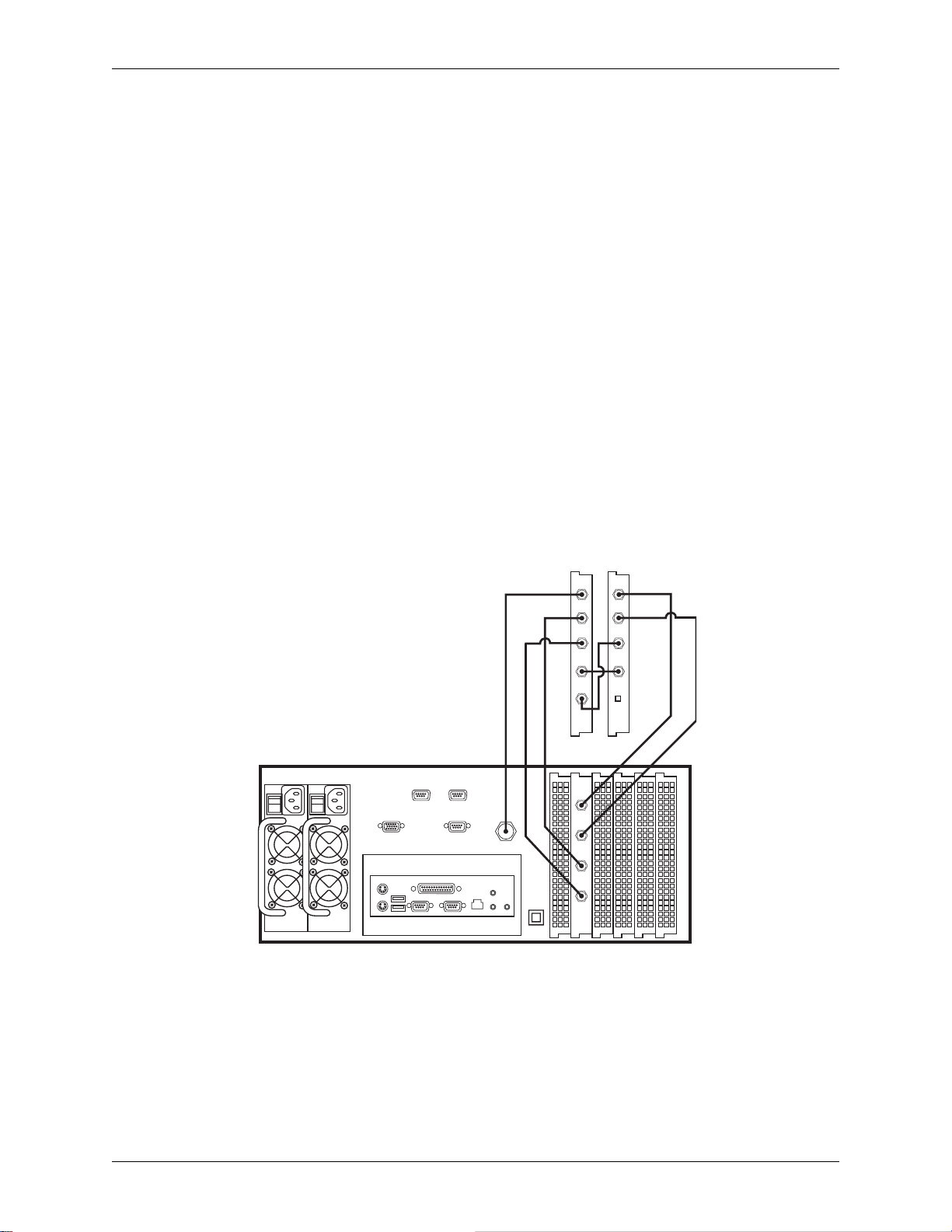

A diagram showing how the TARGA and Daria Bypass Card are connected and thus the signal

flow for video signal protection to occur is shown in Figure 3-9.

TARGA

Inside Of Workstation Chassis

REF

DARIA

IN A

IN B

OUT A

REDUNDANT POWER SUPPLIES

SVGA

MOUSE

KEYBRD

RS422A RS422A

USB

SERIAL

PARALLEL

MANUAL

BYPASS

SERIAL

NETWORK

REFERENCE

SPEAKERS

OUT B

OUT A

VIDEO

VIDEO

ALARM

SILENCE

MIC

IN A

OUT

KEY

KEY

OUT

IN B

OUT B

OVER

RIDE

IN

IN

Figure 3-8: Signal Flow Connections Between TARGA and Daria Bypass Card within DekoCast Workstation

V ideo In and Video Out on a DekoCast system is always active. With that in mind, refer to Figure

3-9 above. The Video connections on the back of the DekoCast workstation are connected

directly to the Daria card. Thus, a video input signal coming into the “VIDEO IN” on the back of

the DekoCast workstation is routed to Daria “IN A.” The signal is then passed within the Daria

Bypass Card to Daria “OUT B” which in turn routes the signal into the TARGA card at TARGA

“IN A.”

DekoCast Technical Reference And Service Guide

23

Page 24

Chapter 3: Installation And Setup

A video output signal from the TARGA card comes out of TARGA “OUT A” and goes into the

Daria Bypass Card at Daria “IN B.” The signal is then passed within the Daria Bypass Card to

Daria “Out A” and sent to “Video Out” on the back of the workstation

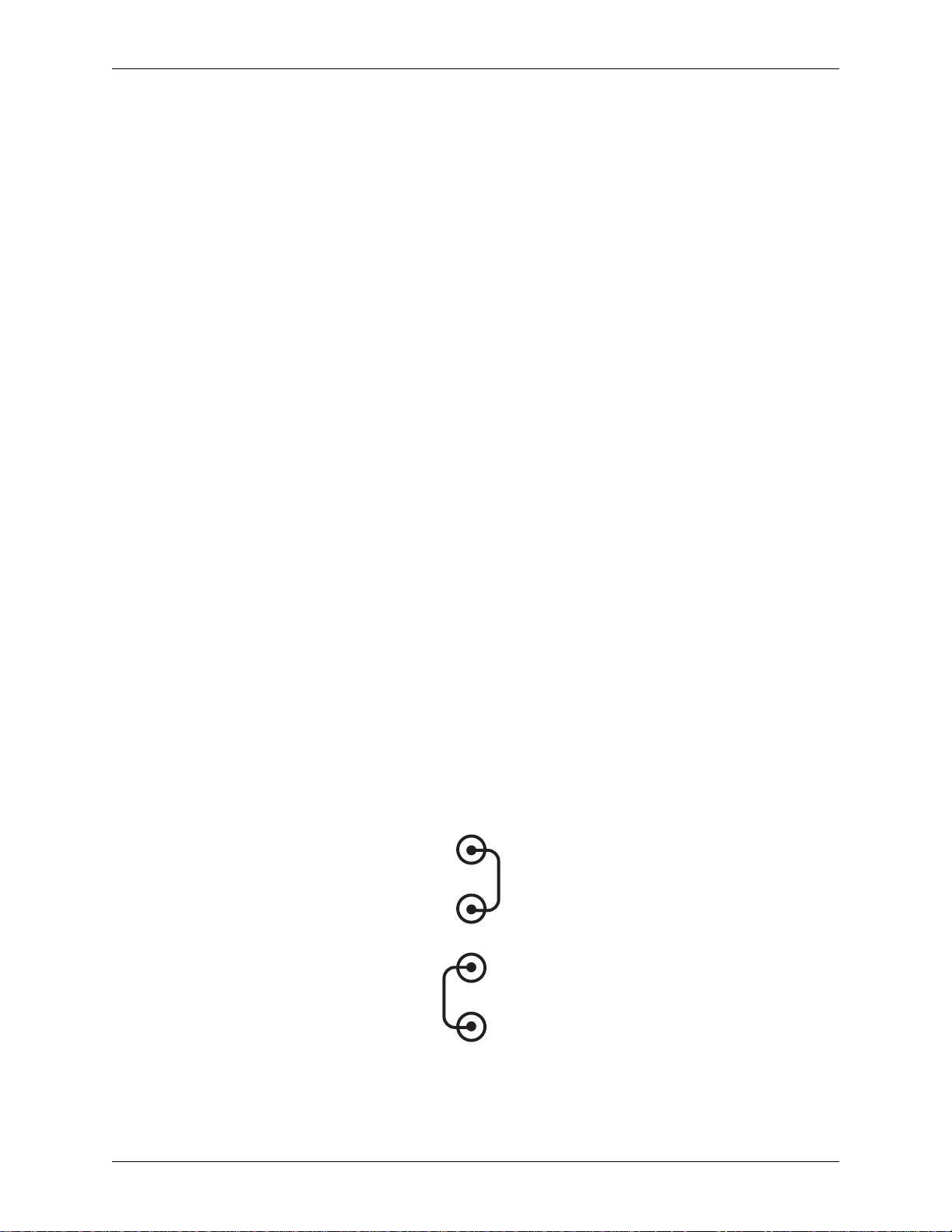

Over-Ride Switch Pinouts

Pins 1 and 2 on a DB9 connector are used to force the Daria bypass board into fail-over mode

(video input hardwired to the output). Refer to Figure 3-10. A simple contact closure will trigger

the bypass mode.

12345

6789

Figure 3-9: Pinouts on a DB9 Connector

Network Configuration

Contact the IT System Administrator at the facility where the DekoCast workstation is to be

installed to obtain detailed information about how to configure your system for the Network.

The following guidelines are outlined for the IT department to use to protect your DekoCast

system from virus infection. While it is understood that all of these guidelines may not be

practical, following them will provide the best level of protection against system infection.

1. NEVER share a folder or drive to “Everyone” with full-access.

2. ALWAYS assign a local Administrator password on every machine. Not assigning a local

Administrator password can introduce a serious security risk.

3. Do not store files with a .exe extension in directories with write permissions.

4. If possible, keep all Pinnacle Live Production equipment on a separate network that is isolated from other machines in the facility.

5. Disallow Internet access on any Pinnacle Live Production machines that do not require it.

6. Do not install anti-virus software on any of the Pinnacle supplied hardware components that

are used on-air.

7. Install and run anti-virus software on all PC components that are not used for on-air play out.

This includes Pinnacle products such as DekoCast Authoring Station, PostDeko, DekoMOS

Clients, Lightning Browse, and Thunder Browse.

24

Note: Please refer to the “Virus Protection Recommendations for Pinnacle Systems Live Production

Products” white paper for additional guidelines on how to protect your Deko system from virus infection.

This and other White Paper and Application Notes can be found on Pinnacle’s website at

www.pinnaclesys.com

DekoCast Technical Reference And Service Guide

Page 25

Chapter 4: Troubleshooting

Contents

This Chapter describes how to use software utilities provided with each DekoCast Workstation

system software as a means to quickly and easily troubleshoot the workstation. Troubleshooting

tips are also provided. Performing these procedures will help streamline the process of getting

your DekoCast Workstation up and running again.

This Chapter contains the following sections:

• I/O Diagnostic Utility

• Deko Manifest Utility

DekoCast Technical Reference And Service Guide

25

Page 26

Chapter 4: Troubleshooting

I/O Diagnostic Utility

The Input/Output (I/O) Diagnostic software test utility provides a range of tests if you, or Pinnacle

Systems Customer Support, suspect that there is a problem with the TARGA 3200 card in a

DekoCast Workstation. The procedures described for performing the I/O Diagnostic should be

perform before contacting Customer Support. If a TARGA card is the problem, downtime is kept

to a minimum since the problem is quickly identified.

Problems that may lead one to run the I/O Diagnostic Utility are as follows:

• No picture being output from the workstation

• Video looks bad or rolls continuously (no genlock)

• Effects of clips stutter

• Video capture and playback not working

• Audio is scrambled

Modes Of Operation

The I/O Diagnostic test can be used in two different modes: automatic or manual. The automatic

testing runs a list of tests until either an error is detected, or until all the tests are successfully

completed. In most instances, the automatic test mode is used. Manual testing allows you to

select a test individually from the list of tests and run it. You can run each test individually by

manual selection if directed to do so by Pinnacle Systems Customer Support.

Setup Before Testing

The setup procedures given below for automatic and manual test modes should be perform before

running the I/O Diagnostic test.

Setup for automatic test mode:

For a TARGA card to be tested, the SDI channels must be set for loop back. This is done by

taking two BNC cables (75 ohm) and connecting a TARGA card that is to be tested to itself. The

cable connection on the card should be: Video Out to Video In, and Key Out to Key In. Refer to

Figure 4-1.

VIDEO IN

VIDEO OUT

KEY IN

KEY OUT

26

Figure 4-1: Loop Back Connections on a TARGA Card

DekoCast Technical Reference And Service Guide

Page 27

Chapter 4: Troubleshooting

Setup for manual test mode:

If the NTSC Genlock or PAL Genlock test is to be done, then an input black burst signal must be

connected to the REF input connector on the back of the DekoCast chassis. An input NTSC

signal source must be used for the NTSC Genlock test. An input PAL signal source must be used

for the PAL Genlock test.

If manual testing of the SDI channels is to be done, the SDI channel to be tested must be set for

loop back. Refer to “Setup for automatic test mode” above and Figure 4-1. Channel 1 is Video

Out (Out A) to Video In (In A). Channel 2 is Key Out (Out B) to Key In (In B).

Automatic Test Procedure

The following steps should be performed for automatic testing of T ARGA card within a DekoCast

Workstation by way of the I/O Diagnostic Utility test:

1. Turn on the DekoCast Workstation.

Only the Windows OS should be running. If any other programs are running on the

workstation, then you should exit out of those programs.

Important: If your workstation is corrupted to the point where it will not boot up when turned on,

contact Pinnacle Systems Technical Support. Contact information can be found in Appendix A.

2. Start the Daria Fail Safe Test software program.

The “Fail Safe Test” software application program for the Daria Bypass Card must be

started before the I/O Diagnostic software test for the TARGA can be run. Once the “Fail

Safe Test” application is running, the I/O Diagnostic Utility program can be started and

performed.

To start the “Fail Safe Test” application, navigate the following path within Windows:

Start menu >> Programs >>Pinnacle Systems >> Daria Passthrough

Then click the program “DariaPassthrough Test Procedure” to open it. Refer to Figure 4-2.

Figure 4-2: Daria Fail Safe Test

Important: Make sure that the “Emulate timeout failure” box is unchecked.

DekoCast Technical Reference And Service Guide

27

Page 28

Chapter 4: Troubleshooting

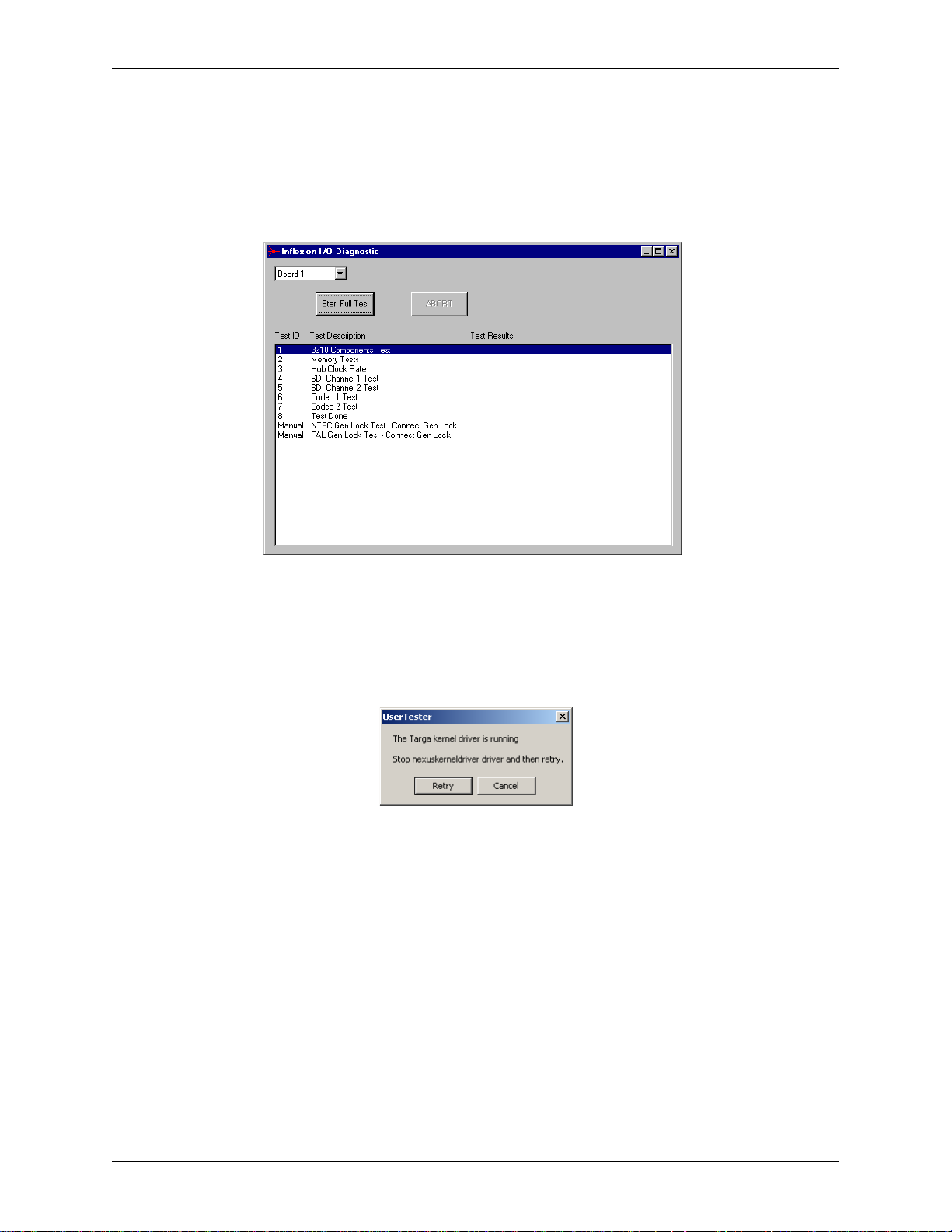

3. Start the I/O Diagnostic software program.

T o start the I/O Diagnos tic Utility application, navigate the following path to the Diagnostic

software program within Windows:

C:\ >> Program Files >> Pinnacle Systems >> TARGA Tester

Then click the program “I-O Diagnostic” to open it. Refer to Figure 4-3.

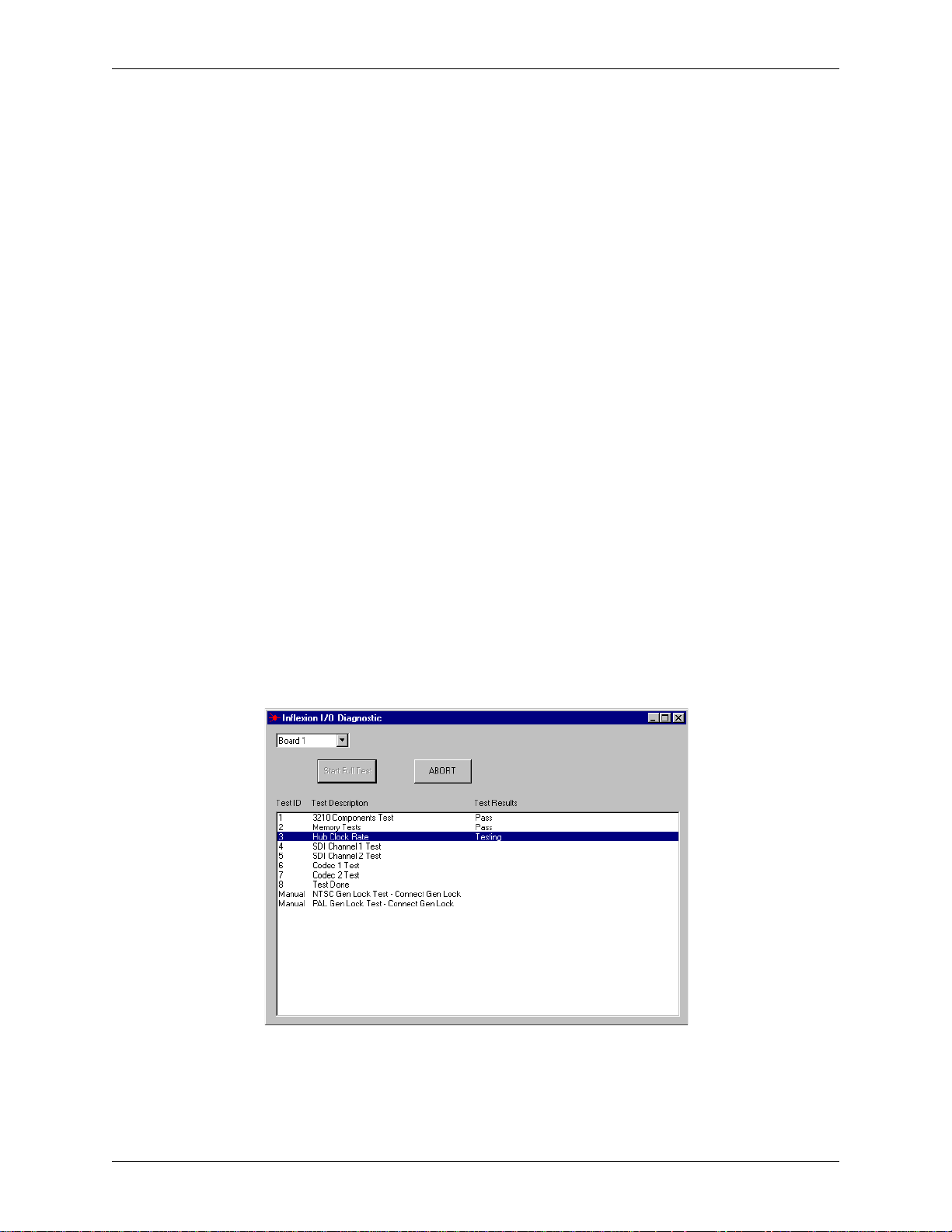

Figure 4-3: Initial start up screen of I/O Diagnostic Test

Note: Depending on the model of the TARGA card in your system, the “3210” indication may appear as a

different number.

Important: If the dialog shown in Figure 4-4 is displayed, then either the Deko program is also

running, or some other program is running that interferes with the I/O Diagnostic.

Figure 4-4: TARGA kernel driver interference dialog

Quit all other programs and restart the workstation. Repeat Step 2 so that only the I/O Diagnostic

program is running.

4. Select the channel that is to be tested.

There is a pull-down selection box on the upper left-hand side of the I/O Diagnostic

window. The default selection in the pull down is Board 1 (i.e., first channel). Refer to

Figure 4-3. The selection and identification of a board is as follows:

• Board 1 -- This is the TARGA card, which is essentially the channel. If you are facing the back

panel of the workstation and looking into the TARGA card bay area, then Board 1 would be the

T ARGA card on the far left. If the workstation top is lifted off, the TARGA card would be seated

right next to the Serial 422 card. (Refer to Figure 5-1 within the “Replacing Workstation Components” section of Chapter 5 for the TARGA card location)

28

DekoCast Technical Reference And Service Guide

Page 29

Chapter 4: Troubleshooting

• Board 2 -- This pull down selection is not used with a DekoCast workstation because DekoCast

only uses one TARGA card.

• Board 3 -- This pull down selection is not used with a DekoCast workstation because DekoCast

only uses one TARGA card.

• Board 4 -- This pull down selection is not used with a DekoCast workstation because DekoCast

only uses one TARGA card.

Important: Loop back must be set up on the TARGA card channel before running the test. Refer to

the “Setup Before Testing” section above for automatic testing procedures.

5. Click the “Start Full Test” button on the I/O Diagnostic window.

Brief descriptions of the tests are as follows:

• 3210 Components Test -- This test checks that the various components on the TARGA card are

functioning in a normal manner.

Note: Depending on the model of the TARGA card in your system, the “3210” indication may appear as a

different number.

• Memory Tests -- This test performs extensive memory testing on the TARGA card.

• Hub Clock Rate -- This is a test to check that the TARGA’s “clock” locks to the oscillator.

• SDI Channel Tests -- This test loops a signal out of the SDI portion of a channel and checks that

the signal comes back into the card exactly the same.

• Codec Tests -- This test checks the encoding and decoding ability of a Codec by putting a fixed

image through the Codec.

When the “Start Full Test” button is clicked, the automatic testing sequence for the channel

(i.e., board) selected in the pull down will begin. The automatic test takes about 3 minutes

to complete. An example of automatic testing in progress is shown in Figure 4-5.

Figure 4-5: I/O Diagnostic automatic test in progress

DekoCast Technical Reference And Service Guide

29

Page 30

Chapter 4: Troubleshooting

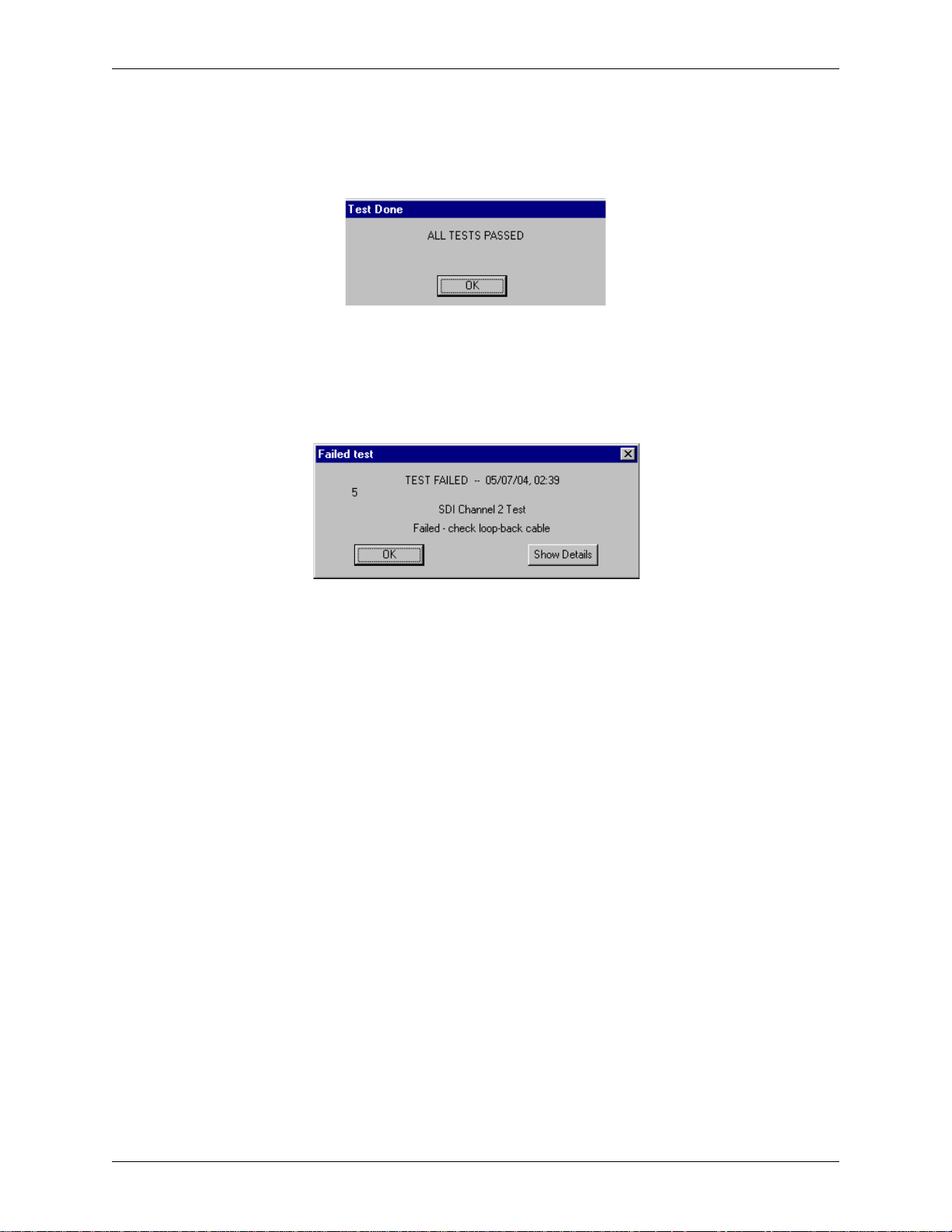

If all automatic tests pass:

If automatic testing completes successfully, a dialog stating that the tests are done and all test

passed will be displayed. Click the “OK” button within the dialog. Refer to Figure 4-6.

Figure 4-6: Dialog shown when all automatic tests pass

If an automatic test fails:

The automatic testing sequence will stop at the point that a test fails, and the dialog shown in

Figure 4-7 will be displayed.

Figure 4-7: Dialog shown when an automatic test fails

Details about a test that fails can be viewed by clicking the “Show Details” button on the Failed

Test dialog. If it was one of the SDI Channel tests that failed, check that the loop through cables

are connected properly to the TARGA card. (Refer to the “Setup Before Testing” section above

for automatic testing setup procedures.)

Perform the following steps if a test fails:

1. After viewing the details, click “OK” on the dialog and repeat the automatic test.

Make sure that the TARGA card is properly seated, and loop through cables are secure and

properly connected before repeating the automatic test sequence.

Important: Power down the workstation before removing the cover to make sure that the TARGA

card is properly seated in its PCI slot.

2. If the test fails again, click “OK” on the Failed Test dialog and save results.

Results can be saved by right clicking on the blue title bar or red icon (upper left-hand

corner) of the I/O Diagnostic window and selecting “Save Results.” Refer to Figure 4-8.

30

DekoCast Technical Reference And Service Guide

Page 31

Chapter 4: Troubleshooting

Figure 4-8: Selecting “Save Results” for I/O Diagnostic window

When saved results is selected, the window shown in Figure 4-9 will be displayed.

Figure 4-9: Save Results Window

3. Type a Filename in the Filename area and a brief description of the problem.

When typing a filename for the Save Results file, make sure to use an extension such as .txt

(an example would be: testfailed.txt as a filename). If you know thew TARGA card’ s serial

number, include when typing a brief description of the problem.

Important: When typing a brief description of the problem do no use the <Enter> key on your

keyboard. The <Enter> key will cause the Save Results window to unexpectedly close.

4. Click the “Save” button.

The Save Results file will be saved in the same folder where the I-O Diagnostic test is

located on the DekoCast Workstation. Pinnacle Systems Technical Support may request

that you send this file to them. An example of a saved T est Results file is shown in Figure 4-

10.

DekoCast Technical Reference And Service Guide

31

Page 32

Chapter 4: Troubleshooting

Figure 4-10: Example of a saved Test Results file

5. Contact Pinnacle Systems Technical Support.

Pinnacle Systems Technical Support will provide you instructions on the procedure to

obtain a replacement TARGA card. Contact information can be found in “Appendix A:

Pinnacle Systems Technical Support.”

Manual Test Procedure

The following steps should be performed for manual testing of the TARGA card within a

DekoCast Workstation by way of the I/O Diagnostic Utility test:

1. Turn on the DekoCast Workstation.

Only the Windows OS should be running. If any other programs are running on the

workstation, then you should exit out of those programs.

Important: If your workstation is corrupted to the point where it will not boot up when turned on,

contact Pinnacle Systems Technical Support. Contact information can be found in Appendix A.

2. Start the Daria Fail Safe Test software program.

The “Fail Safe Test” software application program for the Daria Bypass Card must be

started before the I/O Diagnostic software test for the TARGA can be run. Once the “Fail

Safe Test” application is running, the I/O Diagnostic Utility program can be started and

performed.

To start the “Fail Safe Test” application, navigate the following path within Windows:

Start menu >> Programs >>Pinnacle Systems >> Daria Passthrough

Then click the program “DariaPassthrough Test Procedure” to open it. Refer to Figure 4-11.

32

Figure 4-11: Daria Fail Safe Test

Important: Make sure that the “Emulate timeout failure” box is unchecked.

DekoCast Technical Reference And Service Guide

Page 33

Chapter 4: Troubleshooting

3. Start the I/O Diagnostic software program.

Navigate the following path to the I/O Diagnostic software program:

Start >> Programs >> DekoCast >> Diagnostic Tools

Then click the program “I-O Diagnostic” to open it. A window similar to that shown in

Figure 4-12 should be displayed.

Figure 4-12: Initial start up screen of I/O Diagnostic Test

Note: Depending on the model of the TARGA card in your system, the “3210” indication may appear as a

different number.

Important: If the dialog shown in Figure 4-13 is displayed, then either the Deko program is also

running, or some other program is running that interferes with the I/O Diagnostic.

Figure 4-13: TARGA kernel driver interference dialog

Quit all other programs and restart the workstation. Repeat Step 2 so that only the I/O Diagnostic

program is running.

4. Select the channel that is to be tested.

There is a pull-down selection box on the upper left-hand side of the I/O Diagnostic

window. The default selection in the pull down is Board 1 (i.e., first channel). Refer to

Figure 4-12. The selection and identification of the TARGA is as follows:

• Board 1 -- This is the TARGA card, which is essentially the channel. If you are facing the back

panel of the workstation and looking into the TARGA card bay area, then Board 1 would be the

T ARGA card on the far left. If the workstation top is lifted off, the TARGA card would be seated

right next to the RS- 422 card. (Refer to Figure 5-1 within the “Replacing Workstation Components” section of Chapter 5 for the TARGA card location)

• Board 2 -- This pull down selection is not used with a DekoCast workstation because DekoCast

only uses one TARGA card

DekoCast Technical Reference And Service Guide

33

Page 34

Chapter 4: Troubleshooting

• Board 3 -- This pull down selection is not used with a DekoCast workstation because DekoCast

only uses one TARGA card.

• Board 4 -- This pull down selection is not used with a DekoCast workstation because DekoCast

only uses one TARGA card.

5. Double click the test name that is to be run.

A single test can be performed by left-double clicking the name of the test. An example of

the manual testing window is shown in Figure 4-14.

Figure 4-14: I/O Diagnostic manual testing window

Brief descriptions of the tests are as follows:

• 3210 Components Test -- This test checks that the various components on the TARGA card are

functioning in a normal manner.

Note: Depending on the model of the TARGA card in your system, the “3210” indication may appear as a

different number.

• Memory Tests -- This test performs extensive memory testing on the TARGA card.

• Hub Clock Rate -- This is a test to check that the TARGA’s “clock” locks to the oscillator.

• SDI Channel Tests -- This test loops a signal out of the SDI portion of a channel and checks that

the signal comes back into the card exactly the same.

Important: Loop back must be set up on the TARGA card before running the test. Refer to the

“Setup Before Testing” section above.

• Codec Tests -- This test checks the encoding and decoding ability of a Codec by putting a fixed

image through the Codec.

• Genlock T ests -- The NTSC and the PAL genlock tests both use a black burst or composite signal

as input source to Reference (REF) on the TARGA card. Either test locks the TARGA’s output

to the reference, and then tests to check if it is really locked to the reference output. The test then

checks that unlocking can occur. You must reboot after performing a Genlock test

Important: An input black burst or composite input signal must be connected to the REF 1

connector on the back panel of the workstation if a genlock test is to be done. The input signal

format (i.e., NTSC or PAL) must match the format listed in the test name description.

.

34

DekoCast Technical Reference And Service Guide

Page 35

Chapter 4: Troubleshooting

If manual tests pass:

When a manual test is done, a Pass/Fail message will be displayed in a column to the right of the

test name. Refer to Figure 4-14.

If a manual tests fails:

When a manual test is done, a Pass/Fail message will be displayed in a column to the right of the

test name. Details about a test that fails can be viewed by clicking on the test name with a single

left mouse click which will highlight the test name and test result. Once highlighted, right double

click on the highlighted name for a dialog detailing the failure. If it was one of the SDI Channel

tests that failed, check that the loop through cables are connected properly to the TARGA card

being tested. If a genlock tests failed, check the signal input on the Reference. (Refer to the

“Setup Before Testing” section above for manual testing setup procedures.)

Perform the following steps if a test fails

1. Repeat the manual test.

Make sure that the TARGA card is properly seated, and loop through cables are secure and

properly connected before repeating the manual test.

Important: Power down the workstation before removing the cover to make sure that the TARGA

card is properly seated in its PCI slot.

2. If the test fails again, save the results.

Results can be saved by right clicking on the blue title bar or red icon (upper left-hand

corner) of the I/O Diagnostic window and selecting “Save Results.” Refer to Figure 4-15.

Figure 4-15: Selecting “Save Results” for a manual test failure

When saved results is selected, the window shown in Figure 4-16 will be displayed.

DekoCast Technical Reference And Service Guide

35

Page 36

Chapter 4: Troubleshooting

Figure 4-16: Save Results Window

3. Type a Filename in the Filename area and a brief description of the problem.

When typing a filename for the Save Results file, make sure to use an extension such as .txt

(an example would be: testfailed.txt as a filename). If you know thew TARGA card’ s serial

number, include when typing a brief description of the problem.

Important: When typing a brief description of the problem do no use the <Enter> key on your

keyboard. The <Enter> key will cause the Save Results window to unexpectedly close.

4. Click the “Save” button.

The Save Results file will be saved in the same folder where the I-O Diagnostic test is

located on the DekoCast Workstation. Pinnacle Systems Technical Support may request

that you send this file to them. An example of a saved T est Results file is shown in Figure 4-

17.

Figure 4-17: Example of a saved Test Results file

5. Contact Pinnacle Systems Technical Support.

Pinnacle Systems Technical Support will provide you instructions on the procedure to

obtain a replacement TARGA card. Contact information can be found in “Appendix A:

Pinnacle Systems Technical Support.”

36

DekoCast Technical Reference And Service Guide

Page 37

Chapter 4: Troubleshooting

Deko Manifest Utility

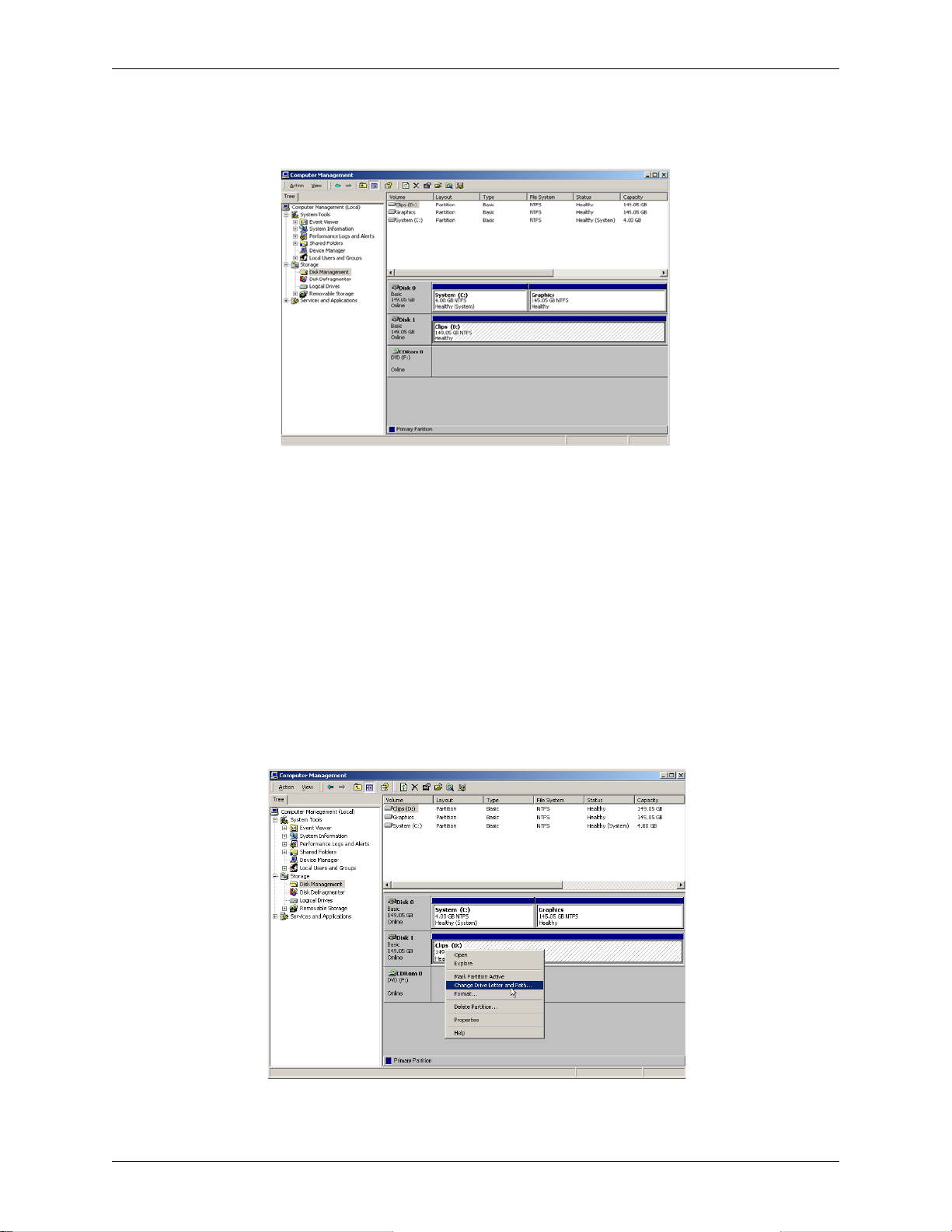

The Deko Manifest test provides a view of the of software components within the DekoCast

workstation. This test compares the registered software components with the official record of a

software release and looks for mismatches. This is useful in identifying workstation software

components that may have become corrupt, or software that may be incompatible with DekoCast

software. This test is also useful in identifying configuration problems that may have occurred in

a DekoCast workstation.

Important: This is a test that should only be used with Pinnacle Systems Customer Support supervision.

Customer Support personnel will be able to properly analyze the results of this test, and then determine the

steps necessary to solve the problem being experienced with the workstation.

Deko Manifest Test Procedure

The following steps should be followed to performed the Deko Manifest Utility test:

1. Turn on the DekoCast Workstation.

Only the Windows OS should be running. If any other programs are running on the

workstation, then you should exit out of those programs.

Important: If your workstation is corrupted to the point where it will not boot up when turned on,

contact Pinnacle Systems Technical Support. Contact information can be found in Appendix A.

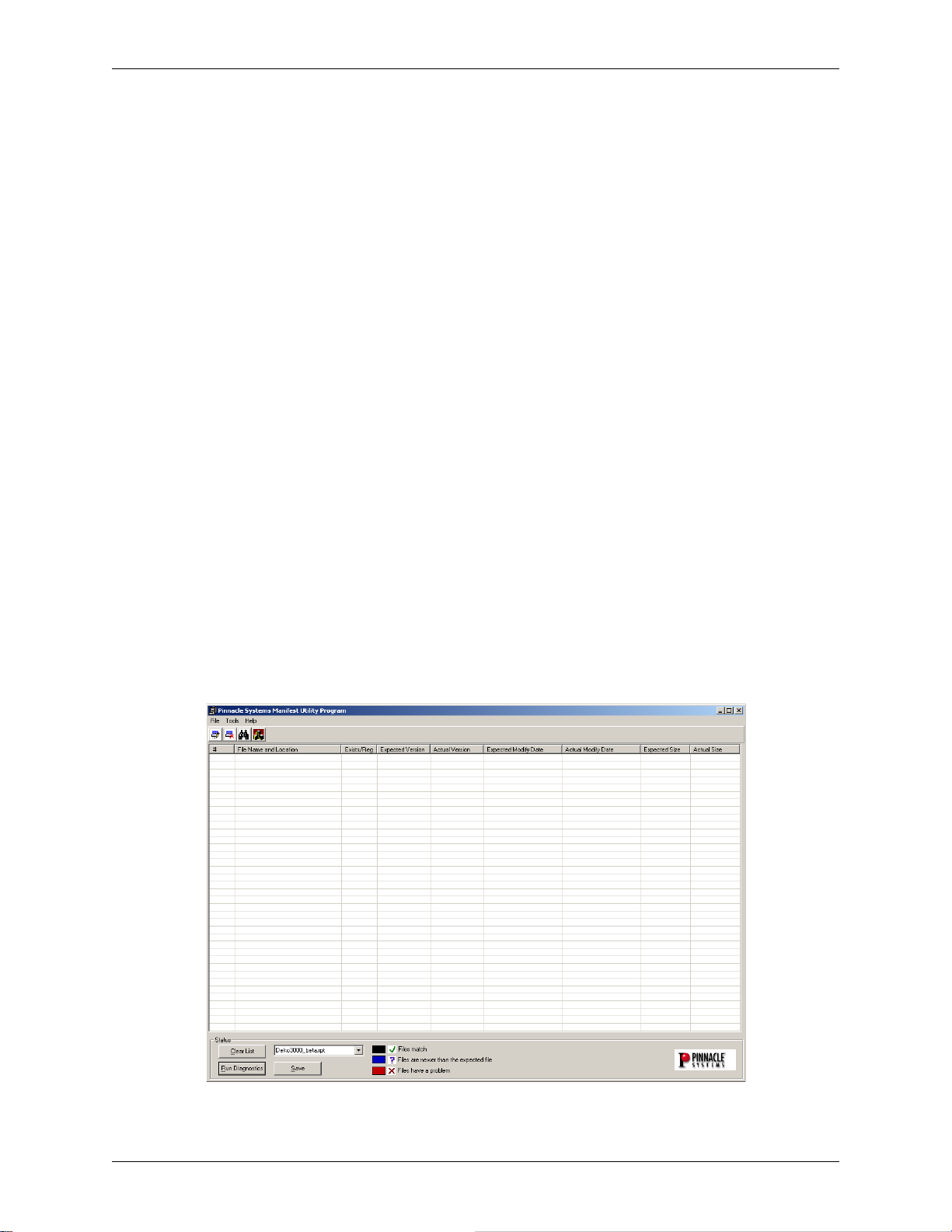

2. Start the Deko Manifest Utility software program.

Navigate the following path to the Deko Manifest software program:

Start >> Programs >> DekoCast >> Diagnostic Tools

Then click the program “DekoManifestUtility” to open it. A Window similar to that shown in

Figure 4-18 should be displayed.

Figure 4-18: Initial start-up screen of Manifest Utility Test

DekoCast Technical Reference And Service Guide

37

Page 38

Chapter 4: Troubleshooting

3. Select the set of software components that are to be tested.

From the pull down on the bottom part of the Manifest Utility start-up screen, select the set

of software components that are to be selected. Refer to Figure 4-19. The choices are

“DekoCast” and “Manifest.”

• DekoCast -- This choice will compare the DekoCast software programs on the workstation being

tested to the official record of the Pinnacle Systems release for the DekoCast software.

• Manifest -- This choice will compare the software programs on the workstation being tested to

the official record of the Pinnacle Systems release for the software.

Figure 4-19: Software components selection for Manifest Utility test

4. Click the “Run Diagnostics” button on the Manifest Utility program window.

Clicking the “Run Diagnostics program will cause the comparison test for the selected

workstation components to be made. For the DekoCast components, a window similar to

that shown in Figure 4-20 will be displayed.

Figure 4-20: Example results from Manifest Utility program

A window similar to that shown in Figure 4-20 will be displayed if the test is run for the

software components.

38

DekoCast Technical Reference And Service Guide

Page 39

Chapter 4: Troubleshooting

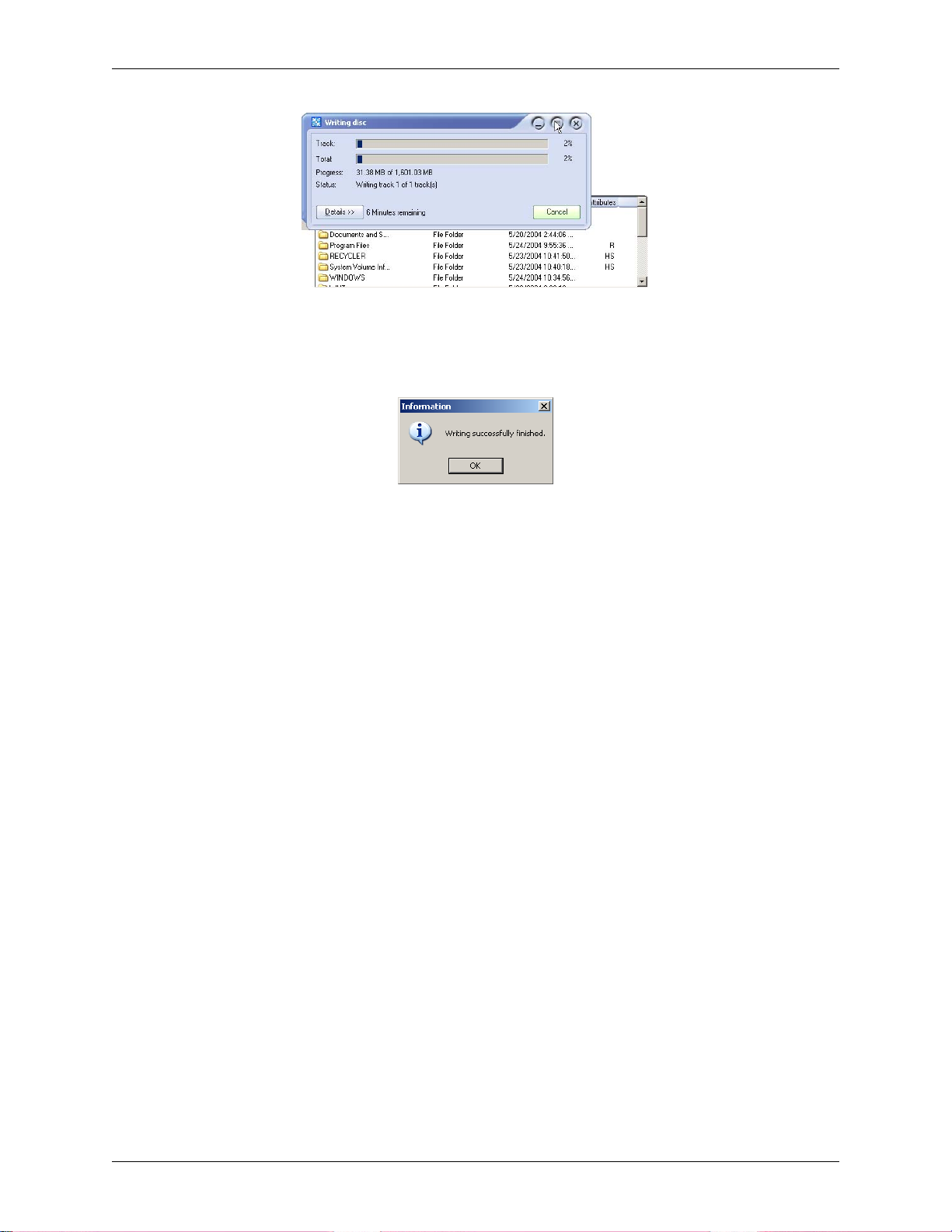

5. Save the results of the test.

Pinnacle Systems Customer Support will either ask to be sent a copy of the file, or go over

the results of the test with you over the phone. Therefore save the results of the test by

clicking the “Save” button on the Manifest Utility program window to capture the window

and save the results. When the “Save” button is clicked, a “Save File As...” window similar

to that shown in Figure 4-21 will be displayed.

Figure 4-21: Example File Save As Window

From the “Save in” pull down at the top upper left of the File Save As window, select the

location that the result of the Deko Manifest test will be saved. Refer to Figure 4-22.

Figure 4-22: Selecting saved location for test results

The file will be saved as an Internet Explorer.html file in the location that you indicated.

DekoCast Technical Reference And Service Guide

39

Page 40

Chapter 4: Troubleshooting

6. Click the “Clear List” button to test the other set of software components listed in the

Deko Manifest screen pull-down list.

Click on the “Clear List” button to refresh the Manifest Utility window so that it looks

similar to what is shown in Figure 4-23.

Figure 4-23: Manifest Utility window refreshed with “Clear List” button

7. Select the other set of software components listed in the Deko Manifest screen pulldown list.

From the pull down on the bottom part of the Manifest Utility start-up screen, select the

other set of software components (i.e., the one not previously tested). Refer to Figure 4-19.

Your choice will either be “DekoCast” or Manifest.

8. Perform Steps 4 and 5 listed above to complete testing.

Once the second set of file components file has been tested and saved, Deko Manifest

Utility testing is completed. Follow the instructions given to you by Pinnacle Systems

Customer Support in order to get the saved files to them.

Interpreting Deko Manifest Test Results

The Deko Manifest Utility test compares the registered software components on the workstation

being tested with the official record of a software release. Files that match are indicated with a

green check mark and normal black text. Files that are newer on the workstation than what the

official release record shows are indicated with a blue “?” and blue text. Files that have a problem

are indicated with a red “x” and red text. Refer to Figure 4-24.

40

DekoCast Technical Reference And Service Guide

Page 41

Chapter 4: Troubleshooting

Figure 4-24: Example Deko Manifest results with possible problems

Important: It does not necessarily mean that the DekoCast workstation being tested is malfunctioning

just because the results of a Deko Manifest test may have blue or red files indicated. In fact, some

workstations are suppose to have files indicated this way. This is why it is absolutely imperative that a

Pinnacle Systems Customer Support representative interprets the test results and recommends to you how

to proceed. This is also why the Internet Explorer .html file of the Deko Manifest results saved in the

procedures above must be sent to Customer Support. Contact information can be found in “Appendix A:

Pinnacle Systems Technical Support.”

DekoCast Technical Reference And Service Guide

41

Page 42

Chapter 4: Troubleshooting

42

DekoCast Technical Reference And Service Guide

Page 43

Chapter 5: System Maintenance

Contents

This Chapter describes how to remove and replace components diagnosed to have failed in the

DekoCast Workstation. System recovery procedures are also given for cases when the entire

DekoCast operating system must be replace on or restored onto a DekoCast workstation. Please

note that DekoCast Workstation components should only be replaced if you are directed to do so

by a Pinnacle Customer Support representative.

This Chapter contains the following sections:

• Replacing Workstation Components

• System Recovery Procedures

• Configuring A New “System” Hard Drive

• Configuring A New “Media” Hard Drive

DekoCast Technical Reference And Service Guide

43

Page 44

Chapter 5: System Maintenance

Replacing Workstation Components

Only the components inside of a DekoCast Workstation that are listed below are considered user

replaceable by non-Pinnacle Systems personnel:

• TARGA Card(s)

• Daria Bypass Card

• RS-422 Card

• SVGA Card

•Hard Drives

• Power Supply

•Fan

• DVD/CD Drive And Floppy Drive

The physical location of each component listed above for a DekoCast Workstation is shown in

Figure 5-1.

Fan

Hard Drives

Floppy Drive

CD-ROM Drive

TARGA Cards

Daria Bypass Card

RS-422 Card

SVGA Card

Workstation

Support Brace

Power Supplies

Figure 5-1: Replaceable components within a DekoCast Workstation

Any components not listed above that needs to be replaced within a DekoCast W orkstation should

only be replaced by a qualified Pinnacle Systems service engineer.

44

DekoCast Technical Reference And Service Guide

Page 45

Chapter 5: System Maintenance

Replacing A TARGA Card

Important: Remove a TARGA card only if directed to do so by a Pinnacle Systems Customer Support

representative.

There is one TARGA card within a DekoCast Workstation. Usually, it is the I/O Diagnostic

application (refer to Chapter 4: Troubleshooting) that confirms the TARGA card needs to be

replaced. Refer to Figure 5-1 for the TARGA card location, and Figure 5-2 for TARGA card

identification.

Figure 5-2: TARGA Card

1. Shut down the computer and turn off the monitor.

Shut down the computer by going to the Start menu and selecting Shut Down (Start menu

>> Shut Down). Turn off the monitor after you are sure the computer has powered down.

Important: Do not attempt to open the computer while the computer is turned on. If you think the

computer is in sleep mode press the power button in front of the computer to wake it, and then shut

down the computer.

2. Remove all cables from the back of the computer, and let the computer cool down.

Unplugging the power cord and cables helps to ensure that no power is running on the

motherboard, which reduces the risk of damage to your equipment. W ait 5 minutes to allow

the computer’s internal components to cool.

3. Discharge static electricity that you may have on your clothes or body.

Use the Anti-Static Wrist Strap that is provided with your new TARGA card. Also, touch

the metal part of the power supply to discharge any static electric charge that you might be

carrying.

4. Remove the top cover from the computer.

Use a Phillips-head (+) screwdriver to remove the screws attaching the top cover to the

computer. Then remove the cover from the computer.

DekoCast Technical Reference And Service Guide

45

Page 46

Chapter 5: System Maintenance

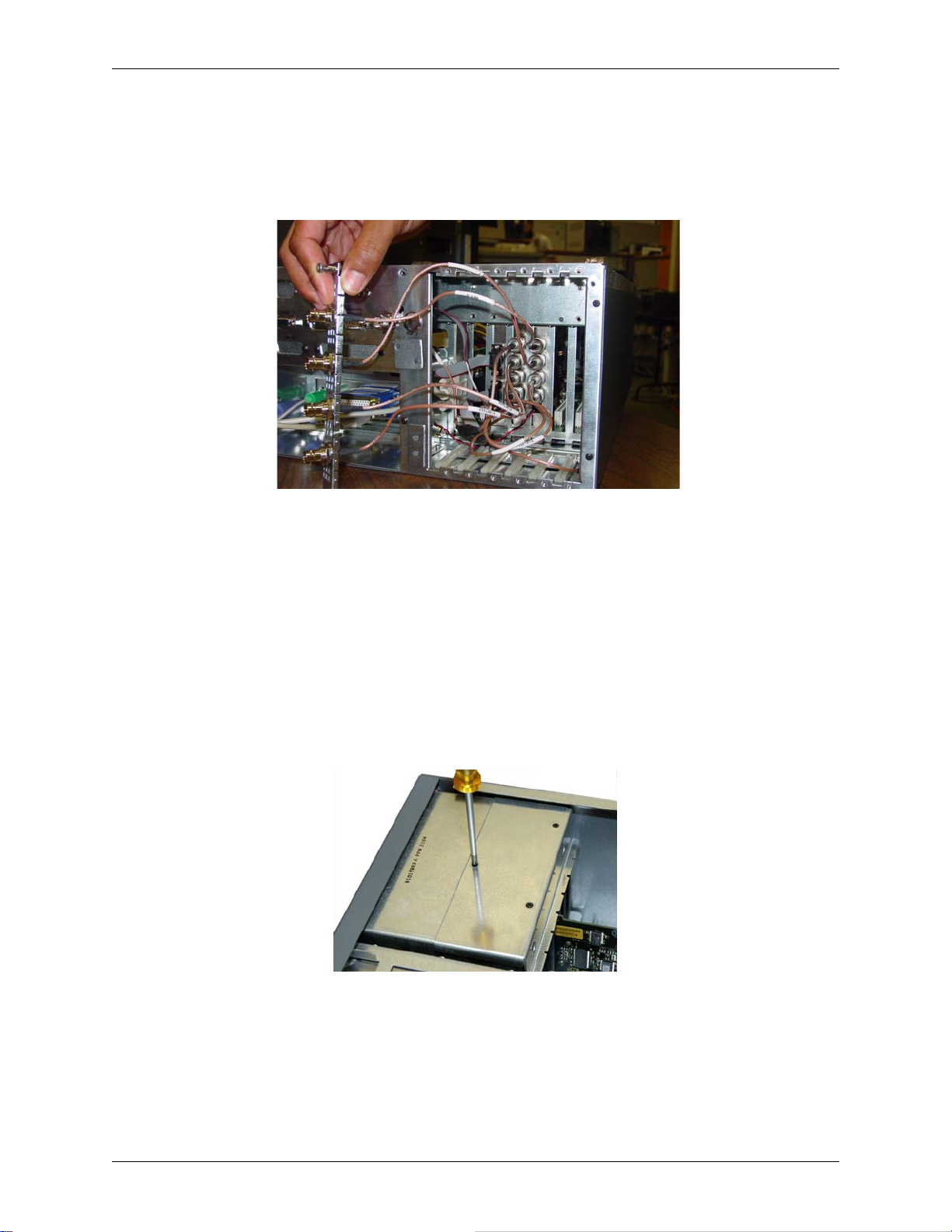

5. Remove all of the PCI slot back-panel access plates at the rear of the computer.

Unscrew the two spring screws that hold each plate in place, and then pry each plate from

the back of the computer. Note that internal BNC cables run from the back of the

workstation’s back-panel access plate for the TARGA card. Refer to Figure 5-3.

Figure 5-3: BNC I/O Connection Plate with internal BNC cables

Remove from the TARGA card the BNC cables coming from the workstation’s back-panel

access plate for the TARGA card.

6. Remove all remaining BNC cables from the TARGA card.

Remove all of the remaining BNC cables from the TARGA card (including the REF BNC

cable if it is used).

7. Remove the Fan Cover.

Refer to Figure 5-4. Unscrew the 3 retaining screws on top of the fan housing that holds the

fan’s cover in place. Then remove the fan cover and put it aside.

Figure 5-4: Fan Cover Retaining Screws

8. Remove the Workstation Support Brace.

The Workstation Support Brace lies across the workstation just above the TARGA card and

other workstation cards. Refer to Figure 5-1. There are two screws on each end of the brace

that must be unscrewed so that the support brace can be removed from the workstation.

46

DekoCast Technical Reference And Service Guide

Page 47

Chapter 5: System Maintenance

9. Remove retaining screw and pull the TARGA card from the PCI slot.

Unscrew the retaining screw that secures the TARGA card’s bracket in place. Save the

screw because it will be used with the new card. Firmly lift the TARGA card from its slot

by pulling upwards while using a gentle lengthwise rocking motion, and set the card aside.

10. Remove the new TARGA card from its antistatic bag.

Make sure you are grounded via the antistatic wrist strap. Handle the card by its edges and

by its metal bracket, and avoid touching the connector pins on the bottom of the card. If a

black handle is connected to the TARGA card, remove the handle so that the card looks

similar to that shown in Figure 5-2.

11. Insert the new TARGA card into the expansion slot.

Note: The same expansion slot that the damaged card was pulled from should be used.

With the bracket toward the open access port, align the connector on the bottom of the

card directly over the slot. Then push down and gently rock the card lengthwise until the

card is firmly seated. When pushed into the slot the TARGA card may catch as if it were

in place, so gently continue to exert pressure until it “seats” again. The gold slot

connectors on the card are barely visible when the card is completely installed.