Page 1

T5/T5HO, T8 & LED AC-to-Grid Mount Installation .............. 2-3

T5/T5HO, T8 & LED AC-to-JB Mount Installation ................ 4-5

T5/T5HO, T8 & LED AC-to-ST Mount Installation ................ 6-7

T5/T5HO, T8 & LED AC-to-Fixture ................................... 8-10

T5/T5HO, T8 & LED PP-to-JB Mount Installation ............ 11-12

T5/T5HO, T8 & LED PP-to-ST Mount Installation ............ 13-14

T5/T5HO, T8 & LED PP-to-Fixture ................................. 15-17

T5/T5HO, T8 & LED Surface Mount Installation .............. 18-20

T5/T5HO, T8 & LED Wall Mount Installation ................... 21-23

Lens Detail ................................................................... 24-25

EDGE

EX33

EX44

INSTALLATION

INSTRUCTIONS

Page 2

EDGE

EX33

EX44

T5/T5HO, T8 & LED

AC-TO-GRID MOUNT INSTALLATION

Page 3

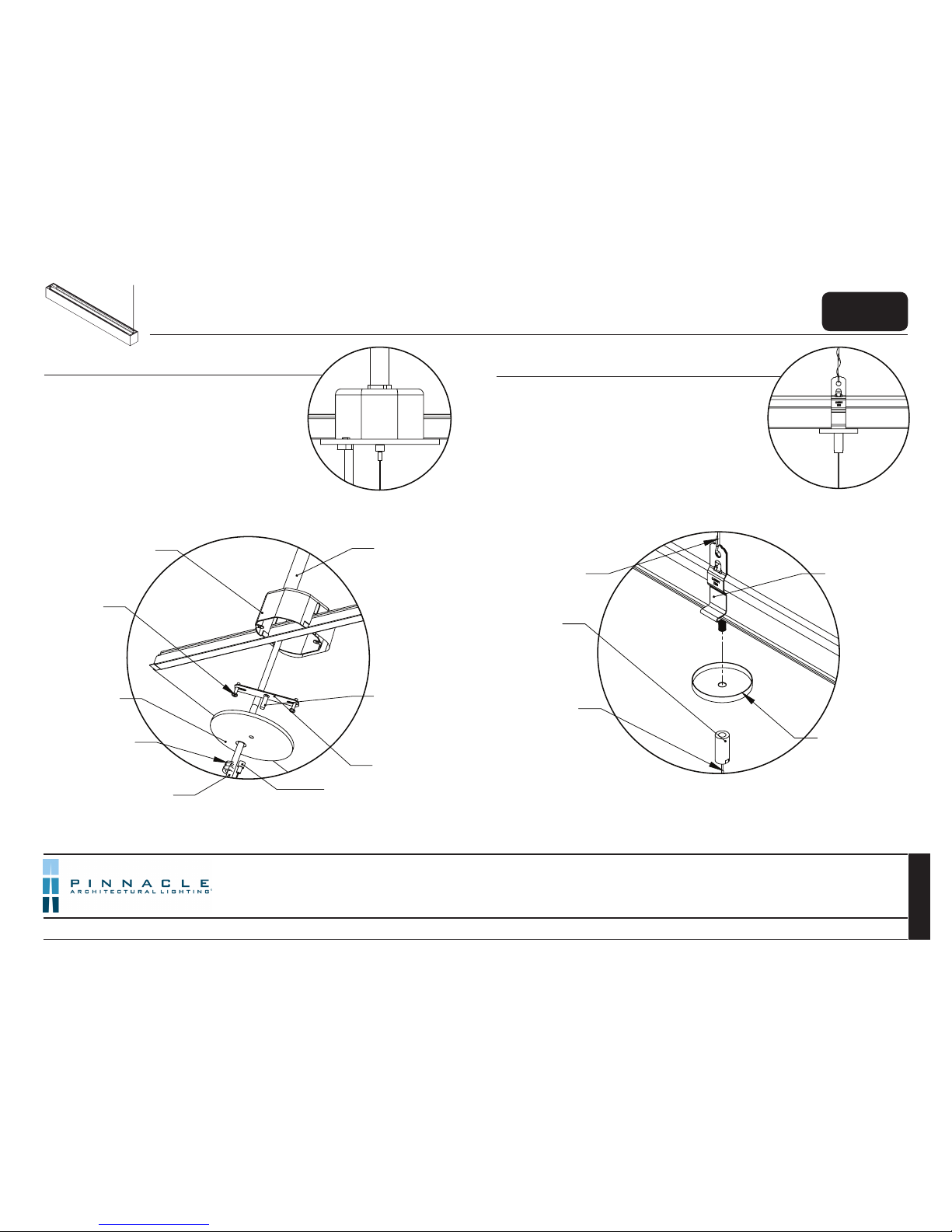

4 - Octagonal

Junction Box

5” Power Canopy

Strain Relief

18ga. SJT Cord

Cross-Bar

Conduit and Fittings

(by others)

1/4-20 Stud

#8 Junction

Box Screws

IDS Clip

Tie-Off to structure

2” Non-Power Canopy

Aircraft Cable

Coupler

Coupler

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

T5/T5HO/T8/LED

Step 2:

Non Power Mount

Step 1:

Power at Ceiling

1. Layout mounting/ junction box locations. Begin row

with fixture label at first mounting point.

2. Install junction box onto T-Bar ceiling. Tie box off to

structure. Install conduit from building power

3. Thread 1/4-20 stud to crossbar for power. mounts.

Install crossbar to junction box.

4. Run SJT cord through canopy, make necessary power

connections, secure using strain relief.

5. Feed aircraft cable through coupler.

6. Secure canopy to crossbar bolts using aircraft cable

coupler.

1. Install IDS clips for non-power mounts. Tie off to structure.

2. Feed aircraft cable through coupler.

3. Secure canopy to IDS clip using aircraft cable coupler.

AC - to - Grid Mount

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

EdgeEX33_44_Booklet_January 2017

3 of 25

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

AC cables with damage, bends, kinks, fraying, or knots must be discarded and replaced with new components. Never install a fixture where the AC cable is more than 5 degrees from perpendicular to the fixture. Fixtures are never to be raised by the cables (instead, lift the fixture up and adjust the cable position). Overtightening of hardware on grippers can damage AC cables. Never

exert force down onto the top of the fixture once it is hanging by safety cables. Never cut safety cables prior to installation. The first zip tie on the SJT and AC cables below the ceiling/canopy

must be no closer than 12” from the ceiling/canopy

Page 4

EDGE

EX33

EX44

T5/T5HO, T8 & LED

AC-TO-JB MOUNT INSTALLATION

Page 5

4 - Octagonal

Junction Box

(by others)

5

” Power Canopy

Strain Relief

18ga. SJT Cord

Cross-Bar

Conduit and Fittings

(by others)

1/4-20 Stud

#8 Junction

Box Screws

1/4-20 Stud

(by others)

2” Non-Power

Canopy

Aircraft Cable

Coupler

*

Stud sits 1/2”

Below Ceiling Plane

Coupler

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

Step 2:

Non Power Mount

Step 1:

Power at Ceiling

1. Layout mounting/ junction box locations. Begin row

with fixture label at first mounting point.

2. Thread 1/4-20 stud to crossbar for power mounts.

3. Install crossbar to 4-octagonal junction box.

4. Run SJT cord through canopy and into junction box,

secure with strain relief.

5. Make all necessary wiring connections.

6. Feed aircraft cable through coupler, secure canopy to

crossbar bolt using coupler.

1. Install 1/4-20 stud for non-power mounts (1/2” below

ceiling plane).

2. Feed aircraft cable through coupler.

3. Secure canopy to bolt using coupler.

AC - to - JB Mount

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

5 of 25

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

AC cables with damage, bends, kinks, fraying, or knots must be discarded and replaced with new components. Never install a fixture where the AC cable is more than 5 degrees from perpendicular to the fixture. Fixtures are never to be raised by the cables (instead, lift the fixture up and adjust the cable position). Overtightening of hardware on grippers can damage AC cables. Never

exert force down onto the top of the fixture once it is hanging by safety cables. Never cut safety cables prior to installation. The first zip tie on the SJT and AC cables below the ceiling/canopy

must be no closer than 12” from the ceiling/canopy

Page 6

EDGE

EX33

EX44

T5/T5HO, T8 & LED

AC-TO-ST MOUNT INSTALLATION

Page 7

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

Step 2:

Non Power Mount

Step 1:

Power at Ceiling

1. Layout mounting/ junction box locations. Begin row

with fixture label at first mounting point.

2. Install 4-octagonal junction box to structure adjacent to

power feed mount locations.

3. Attach crossbar to junction box.

4. Run SJT power cord through canopy and into junction

box. Secure using provided strain relief.

5. Make necessary power connections.

6. Feed Aircraft cable through coupler and secure canopy

to junction using coupler (provided).

1. Install 1/4-20 studs to structure at all mounting points

(3/4” below ceiling plane.)

2. Feed aircraft cable through coupler (if applicable).

5. Secure coupler assembly to 1/4-20 bolt or stud.

AC - to - ST Mount

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

7 of 25

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

AC cables with damage, bends, kinks, fraying, or knots must be discarded and replaced with new components. Never install a fixture where the AC cable is more than 5 degrees from perpendicular to the fixture. Fixtures are never to be raised by the cables (instead, lift the fixture up and adjust the cable position). Overtightening of hardware on grippers can damage AC cables. Never

exert force down onto the top of the fixture once it is hanging by safety cables. Never cut safety cables prior to installation. The first zip tie on the SJT and AC cables below the ceiling/canopy

must be no closer than 12” from the ceiling/canopy

4 - Octagonal

Junction Box

(by others)

5” Power Canopy

Strain Relief

18ga. SJT Cord

Cross-Bar

Conduit and Fittings

(by others)

1/4-20 Stud

#8 Junction

Box Screws

Coupler

Aircraft Cable

*

Stud sits 1/2”

Below Ceiling Plane

1/4-20 Stud

(by others)

Aircraft Cable

Coupler

2” Non-Power

Canopy

Page 8

EDGE

EX33

EX44

T5/T5HO, T8 & LED

AC-TO-FIXTURE INSTALLATION

Page 9

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

1. Attach #8-32 screw to gripper through slot.

2. Slide aircraft cable through gripper.

3. Adjust gripper side to side to level fixture then tighten.

4. Repeat process for each subsequent fixture.

5. Re-level previous fixtures as necessary.

Step 3:

AC Mounting (Indirect)

T5/T5HO/T8/LED

AC - to - Fixture Mount

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

9 of 25

EdgeEX33_44_Booklet_January 2017

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Slot

#8-32 Screw

Mount Spacing

Aircraft Cable - Example Rows

Mount Spacing

47-1/4”, 95-1/4”,

143-1/4”

Mount Spacing

47-1/4”, 95-1/4”,

143-1/4”

48, 96, 144”

Mount Spacing

Individual Fixture First Fixture Consecutive Fixtures

Gripper

Adjustable Cable

Page 10

End Trim

(2 per section)

Quick Connects

#8-32x1-1/8” Bolt

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

1. Install End Trim after louver installation.

Two (2) per 4’ section

Three (3) per 8’ section

Four (4) per 12’ section

1. Install first fixture with two (2) mounting points.

2. Subsequent fixtures use one (1) mount.

3. Install two (2) #8-32 bolt into each fixture as shown.

4. Raise adjoining fixture and slip bolt heads through key-hole slot.

5. Attach mounting to fixture as previously shown.

6. Make necessary wiring connections between fixtures ensuring all wires are

properly matched.

7. Tighten the previously installed #8-32x1-1/8” (1/2 turn past hand tight) to complete joining and create ground.

Step 5:

Joining Fixtures

1. Install end plates prior to lens/louver installation.

2. Place against end of fixture and secure using two (2) #6-32

nuts.

Step 6:

Finishing

EX33 Louver End Trim

EDGE

EX33

EX44

T5/T5HO/T8/LED

AC - to - Fixture Mount

© 2017 Pinnacle Architectural Lighting

10 of 25

EdgeEX33_44_Booklet_January 2017

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 11

EDGE

EX33

EX44

T5/T5HO, T8 & LED

PP-TO-JB MOUNT INSTALLATION

Page 12

4 - Octagonal

Junction Box

(by others)

5” Slip Canopy

Conduit and Fittings

(by others)

Pendant

Cross-Bar

(3/8 IP)

3/8 IP Pendant Pipe

#8 Junction Box

Screws (by others)

4 - Octagonal

Junction Box

(by others)

5” Slip Canopy

Pendant

Cross-Bar

(3/8 IP)

3/8 IP Pendant Pipe

#8 Junction Box

Screws (by others)

Set Screw

Set Screw

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

PP - to - JB Mount

Step 2:

Non Power Mount

Step 1:

Power at Ceiling

1. Install 4-Octagonal Junction boxes to structure at all

mounting locations (see spacing on page 2). Begin row

with fixture label at first mounting point.

2. Install conduit from building power to J-Box.

3. Install crossbar to J-Box

4. Feed slip canopy over pendant and secure pendant

to crossbar.

5. Feed power from J-Box through pendant and out

leaving 12” for fixture wiring.

6. Make all necessary wiring connections.

1. Attach 4-Octagonal Junction boxes to structure at all

mounting locations.

2. Install crossbar to J-Box.

3. Slide slip canopy over pendant.

4. Rotate pendant onto crossbar.

5. Slide canopy up to ceiling level and secure with set

screw.

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

12 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 13

EDGE

EX33

EX44

T5/T5HO, T8 & LED

PP-TO-ST MOUNT INSTALLATION

Page 14

4 - Octagonal

Junction Box

(by others)

Conduit and Fittings

(by others)

Pendant Crossbar (3/8 IP)

#8 Junction Box Screws

(by others)

5” Slip Canopy

Set Screw

4 - Octagonal

Junction Box

(by others)

Pendant Crossbar (3/8 IP)

#8 Junction Box Screws

(by others)

5” Slip Canopy

Set Screw

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

PP - to - ST Mount

Step 2:

Non Power Mount

Step 1:

Power at Ceiling

1. Install 4-Octagonal Junction boxes to structure at all

mounting locations.(see spacing on page 2). Begin row with

fixture label at first mounting point.

2. Install conduit from building power to J-Box.

3. Install crossbar to J-Box

4. Feed slip canopy over pendant and secure pendant to

crossbar.

5. Feed power from J-Box through pendant and out leaving 12” for fixture wiring.

6. Make all necessary wiring connections.

1. Attach 4-Octagonal Junction boxes to structure at all

mounting locations.

2. Install crossbar to J-Box.

3. Slide slip canopy over pendant.

4. Rotate pendant onto crossbar.

5. Slide canopy up to ceiling level and secure with set

screw.

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

14 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 15

EDGE

EX33

EX44

T5/T5HO, T8 & LED

PP-TO-FIXTURE INSTALLATION

Page 16

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

First Fixture

48”, 96”, 144”

Spacing

48”, 96”, 144”

Spacing

Consecutive Fixtures

Pendant - Example Rows

Mount Spacing

43-1/2”, 91-1/2”,

139-1/2”

Mount Spacing

43-1/2”, 91-1/2”,

139-1/2”

Individual Fixture

Cross bar

Nut

Pendant Pipe

Fixture Power

Wires

Building Power

Wires

Step 3:

PP Mounting

Step 4:

Making the connections

1. Pull wires through pendant pipe.

2. Make necessary wiring connections, ensuring all wires are

properly matched.

3. Recess wires back into housing.

(Note: UL label side has stripped wires and ground lead.)

1. Attach pendant pipe to fixture. Two (2) mounts for first fixture in

row/ individual, one (1) mount at opposite end for every fixture after.

2. Tighten down Nut to secure pendant pipe to fixture.

3. If power side mount run power wires into housing through pendant pipe.

(Note: Once run is mounted cover any unused knock outs)

PP - to - ST Mount

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

16 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 17

End Trim

Joining Hardware

Quick Connects

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

1. Install first fixture with two (2) mounting points.

2. Subsequent fixtures use one (1) mount.

3. Install two (2) #8-32 joining hardware as shown below.

4. Raise adjoining fixture and slip bolt heads through key-hole slot.

5. Attach mounting to fixture as previously shown.

6. Make necessary wiring connections between fixtures ensuring all wires are

properly matched.

7. Tighten the previously installed #8-32x1-1/8” (1/2 turn past hand tight) to complete joining and create ground.

Step 5:

Joining Fixtures

1. Install end plates prior to lens/louver installation.

2. Place against end of fixture and secure using two (2) #6-32

nuts.

Step 6:

Finishing

1. Install End Trim after louver installation.

Two (2) per 4’ section.

Three (3) per 8’ section

Four (4) per 12’ section

EX33 Louver End Trim

PP - to - ST Mount

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

17 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 18

EDGE

EX33

EX44

T5/T5HO, T8 & LED

SURFACE MOUNT INSTALLATION

Page 19

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

1. Remove top plug from both ends of beginning of run fixture(s) and

on end of continuous fixture(s)

2. Remove lens/ louver options from fixture(s).

3. Remove reflector from housing by removing reflector screws.

4. Feed necessary through wires out of top access hole.

1. Install junction box (by others) with crossbar (by others) into ceiling.

2. Mount fixture to crossbar using a nipple (by others).

3. Feed wires through nipple and connect to building power ensuring all

wires are properly matched.

4. Subsequent non power locations mount to structure.

Surface Mount Instructions

Step 1:

Fixture Prep

Step 2:

Mounting and Power

Crossbar

(by others)

Junction Box

(by others - size according

to fixture width)

Nipple 1/4” x 1”

(by others)

1/4” Nut

(byu others)

EX33 width = 2-7/8”

EX44 width = 4-7/16”

Plug

Hole Size = 7/8”

3/8” IP

Reflector

Lens

Reflector

Screws

Through wire

If MR16 Unit

2-1/4”

91-1/2”

2-1/4”

2-1/4” 2-1/4”

43-1/2”

48”

Individual Spacing

96”

8’ 8’ 8’

First Fixture

91-1/2”

96” Spacing 96” Spacing

Mount Spacing Example Rows

End Plates Not Included

Fixture Lenghts: 48”, 96”, 144” (add 6” per MR16)

First/ Individual Fixture

Mount Spacing (C-to-C)

4’ = 43-1/2”

8’ = 91-1/2”

12’ = 139-1/2”

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

19 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 20

End Trim

(2 per section)

Quick Connects

#8-32x1-1/8” Bolt

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

1. Install End Trim after louver installation.

Two (2) per 4’ section

Three (3) per 8’ section

Four (4) per 12’ section

1. Install first fixture with two (2) mounting points.

2. Subsequent fixtures use one (1) mount.

3. Install two (2) #8-32 bolt into each fixture as shown.

4. Raise adjoining fixture and slip bolt heads through key-hole slot.

5. Attach mounting to fixture as previously shown.

6. Make necessary wiring connections between fixtures ensuring all wires are

properly matched.

7. Tighten the previously installed #8-32x1-1/8” (1/2 turn past hand tight) to complete joining and create ground.

Step 3:

Joining Fixtures

1. Install end plates prior to lens/louver installation.

2. Place against end of fixture and secure using two (2) #6-32

nuts.

Step 4:

Finishing

EX33 Louver End Trim

Surface Mount Instructions

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

20 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 21

EDGE

EX33

EX44

T5/T5HO, T8 & LED

WALL MOUNT INSTALLATION

Page 22

Wall Mount

Screw/ Washer

Fixture Side

Mounting Bracket

6-7/16”

5-1/4”

1-5/16”

3-1/4”

2-7/16”

Step 2:

Power Mount

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

Step 1:

Wall Bracket

1. Attach wall side bracket to structure via mounting

hardware (by others).

2. If power side, mount bracket in line with 2x4 junction

box (by others).

3. Bring power in through junction box.

4. Follow mount spacing on page 2 for additional

mounting points.

(Note: See page 2 for additional mount dimensions)

1. To power fixture attach building power to fixture power

wires using push nuts.

2. Recess connections into junction box.

3. Attach fixture to wall bracket as shown.

4. Make necessary adjustments laterally prior to tightening

wall mount screw.

(Note: See page 2 for additional mount dimensions)

Step 3:

Joining Fixtures

Step 4:

Finishing

1. Install joining kit hardware.

2. Slip adjacent fixture’s mounting hardware through the

keyhole slots on the end plates.

3. Make wiring connections between fixtures, and recess

wires into one of the fixtures.

4. Tighten joining hardware.

1. Install end caps.

2. Place against end of fixture and secure using two (2)

#8-32 screws.

Wall Mount Instructions

1. Install End Trim after louver installation.

Two (2) per 4’ section.

Three (3) per 8’ section

Four (4) per 12’ section

EX33 Louver End Trim

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

22 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 23

88”

96”

Wall

Fixture

7’-4” Center to Center of Bracket (first fixture)

2 Mounting Brackets

8’ Center to Center of Bracket (continuous fixture)

1 Mounting Bracket

1/2”

7/8”

1-1/16”

7/8”

2-1/8”

(Mounted in Center)

3/8”

(Mounted in Center)

D

C

A

B

A

B

C

D

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568 www.pinnacle-ltg.com

First/ Independent Fixture Mounting Example

Intermediate/ End Fixture Mounting Example

2’-0” Center to center of bracket

3’-0” Center to center of bracket

4’-0” Center to center of bracket

8’-0” Center to center of bracket

12’-0” Center to center of bracket

1’-4” Center to center of bracket

2’-4” Center to center of bracket

3’-4” Center to center of bracket

7’-4” Center to center of bracket

11’-4” Center to center of bracket

24”

36”

48”

96”

144”

16”

28”

40”

88”

136”

Note: Power typically

on left side of fixture.

* *

Wall Mount Instructions

EDGE

EX33

EX44

© 2017 Pinnacle Architectural Lighting

23 of 25

EdgeEX33_44_Booklet_January 2017

T5/T5HO/T8/LED

1. This product must be installed in accordance with applicable installation and electrical codes by a professional familiar with the

construction and operation of the product.

2. Minimum 90ºC supply conductors

3. All electrical connections must be performed by a certified electrician to applicable local and national electrical codes.

4. Fixtures must be mounted directly to structure.

5. The holding strength of AC cables cannot be guaranteed if the cables are damaged in any way.

Return to

Main Menu

Page 24

EDGE

EX33

EX44

LENS

DETAIL

Page 25

© 2017 Pinnacle Architectural Lighting

12655 E. 42nd Ave. #50 Denver, CO 80239 Phone: 303.322.5570 Fax: 303.322.5568

25 of 25

www.pinnacle-ltg.com

Snap In Lens

Lensing detail sheet

Lens Installation Lens Removal

1. Begin at one end of the fixture and insert lens into appropriate position

where it will snap into place.

2. Gradually insert the lens along the length of the fixture, snapping it into

place as you go.

3. If at any point the lens becomes difficult to insert press slightly into the

center of the lens in order to allow for it to flex, temporarily decreasing the

width of the lens.

1. Insert a rigid object approx. 1/16” thick, such as a quarter, into the edge

between the lens and the fixture, approx. 1-2” from the end of the lens.

(6” for regress lens)

2. Using said object, gently pry lens away from fixture until it is released

from the mounting edge.

3. Once the section is released, start at one end of the fixture and pull the

lens out of the fixture.

EdgeEX33_44_Booklet_January 2017

Fixture End

Snap-In Lens

Note: Low temperatures can effect the lens material,

making it brittle. Please allow the lenses to warm

to room temperature before installation.

Approx. 1-2” Away

From Fixture End

Snap-In Lens

Flexed for Installation

Approx. location

to allow for flex

EDGE

Return to

Main Menu

Loading...

Loading...