Pilz PSSuniversal Technical Catalogue

Technical Catalogue

PSSuniversal

Planning Guide

DRAFT

Issue 01/05

PSSuniversal

Contents Page

PSSuniversal system

Basics

System description

Modular structure 1.1-1

Module bus 1.1-2

Structure of module bus 1.1-2

Maximum system expansion 1.1-3

System limits 1.1-3

Local enable principle 1.1-4

Connection labelling on the base modules 1.1-5

Colour marking of connection levels 1.1-5

Separating supplies to form supply groups 1.1-6

Installation

Mounting position 1.2-1

Mounting rail 1.2-1

Module layout 1.2-1

Mounting distances 1.2-2

Installing the head module 1.2-3

Removing the head module 1.2-4

Installing base modules 1.2-5

Removing base modules 1.2-6

Installing an end bracket at the start of the system 1.2-7

Removing an end bracket at the start of the system 1.2-7

Installing a terminating plate and end bracket at the end of the system 1.2-8

Removing a terminating plate and end bracket at the end of the system 1.2-9

Inserting an electronic module 1.2-10

Mechanical coding 1.2-11

Removing an electronic module 1.2-12

Earthing 1.2-13

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1

PSSuniversal

Modules

Head modules

PSSu H SB 2.1-1

PSSu H SB DP 2.1-9

Supply voltage modules

PSSu E F PS 2.2-1

PSSu E F PS1 2.2-11

PSSu E F PS-P 2.2-21

PSSu E F BSW 2.2-31

Digital input/output (standard)

PSSu E S 4DI 2.3-1

PSSu E S 4DO 0.5 2.3-9

PSSu E S 2DO 2 2.3-17

Digital input/output (failsafe)

PSSu E F 4DI 2.4-1

PSSu E F 4DO 0.5 2.4-11

PSSu E F 2DO 2 2.4-21

PSSu E F 2DOR 8 2.4-31

PSSu E F 4DI OZ 2 2.4-43

Voltage distribution

PSSu E PD 2.5-1

Order reference

Module overview

Electronic modules with base modules (screw terminals) 3.1-1

Electronic modules with base modules (cage clamp terminals) 3.1-2

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

System description

Modular structure

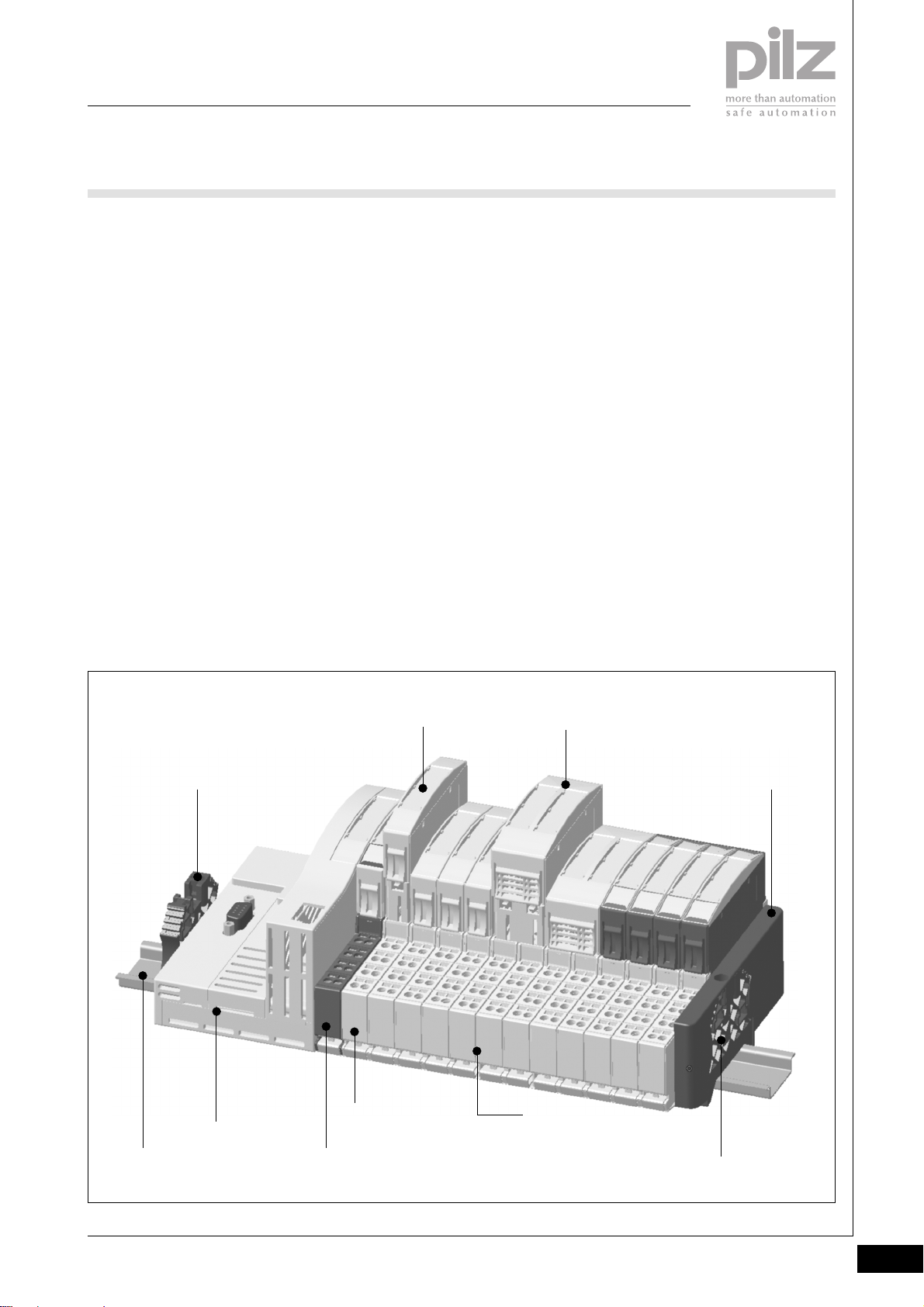

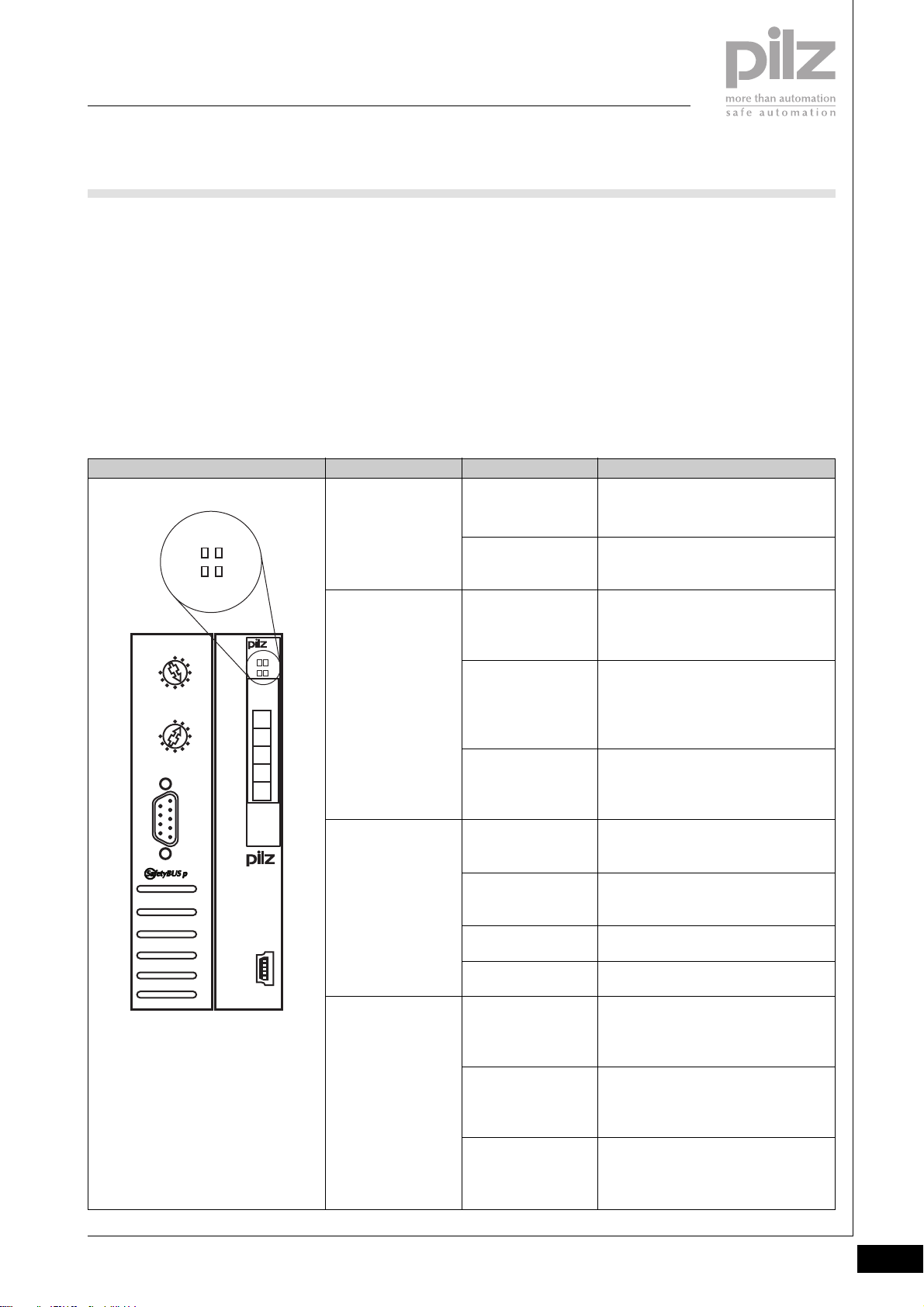

The PSS universal (PSSu) from Pilz is

a modular system for use in the

decentralised periphery of plant and

machinery. A modular PSSu type

system consists of:

` One head module

` At least one supply voltage

module

` Input/output modules for standard

and failsafe applications, which

may be installed in any sequence

` End bracket at the start of the

system to secure the system on

the mounting rail

` Terminating plate with integratable

end bracket at the end of the

system to secure the system on

the mounting rail

Head module

` Connects the sensor/actuator

level for standard applications to

master controllers via various

standard bus systems (e.g.

PROFIBUS)

` Connects the sensor/actuator

level for failsafe applications to

SafetyBUS p

` Co-ordinates the entire process

data traffic for standard and

failsafe applications

` Permits a failsafe output to be

switched via a standard signal,

depending on an enable from a

failsafe signal (local enable

principle)

Supply voltage modules

` Available for various functions

` Consist of an electronic module

and a base module

Input/output modules

` Available for a wide range of

input/output functions

` Consist of an electronic module

and a base module

Base modules

` Carrier units for the supply voltage

and input/output modules

` Used to connect the field wiring

` Available with the following

connection types:

- Cage clamp terminals or

- Screw terminals

Electronic modules

` Are plugged into base modules

` Can be inserted/removed

independently from the base

module

` Determine the function of the

supply voltage or input/output

module

` Communicate with the head

module via the module bus

2

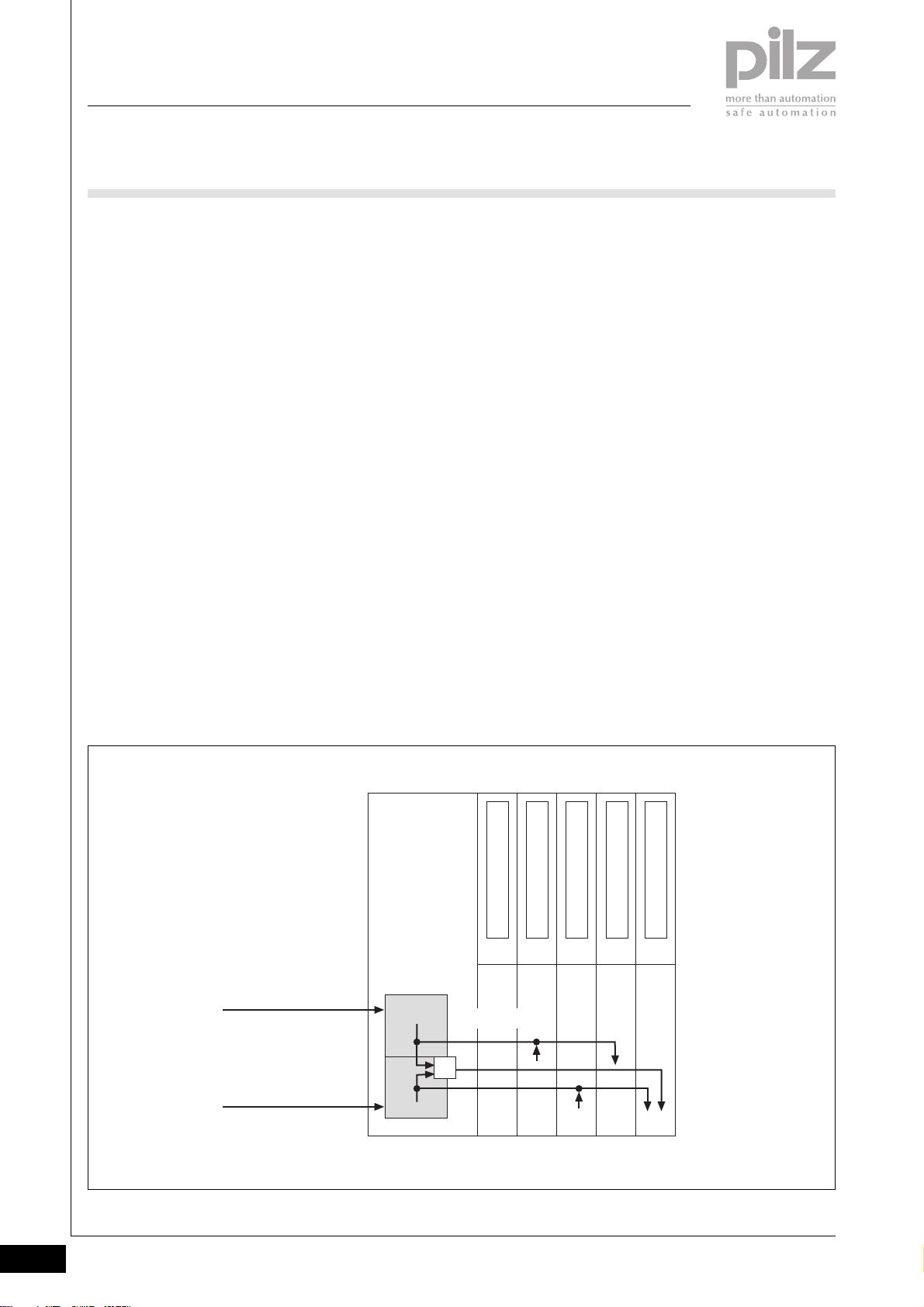

End bracket

Head module

Electronic module

(grid width 1 x 12.6 mm)

Base module

(grid width 1 x 12.6 mm)

Electronic module

(grid width 2 x 12.6 mm)

Terminating plate

Base module

(grid width 2 x 12.6 mm)

Mounting rail

(DIN EN50022)

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Supply voltage module

(electronic module + base module)

End bracket

(integrated into terminating plate)

Status 01/05

1.1-1

PSSuniversal

Basics

System description

Module bus

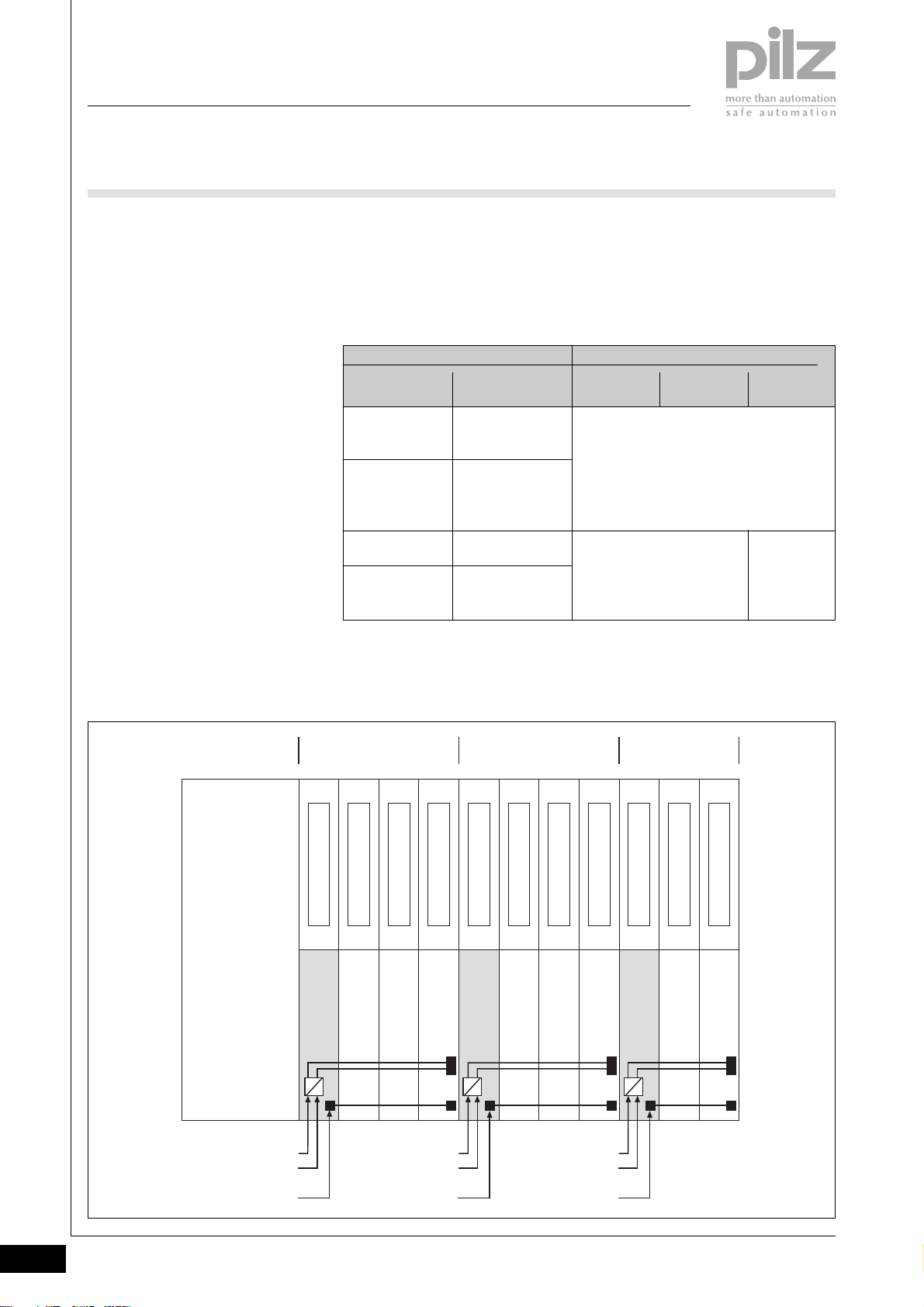

The module bus is formed by

arranging the base modules together

and connecting them via a

mechanical latch.

` Data

2 independent bus systems are

available for FS data and ST data.

The data is processed in the head

module.

` Module supply

Supply for the head module and

the electronic modules. Various

supply voltage modules are

available for different functions

(e.g. voltage refresh, separating

the supply).

` Periphery supply

The supply for the actuators (load)

or input test pulses is provided at

the base module contacts,

depending on the function of the

electronic module. Various supply

voltage modules are available for

different functions.

The connection on the module

bus can be disconnected in order

to form supply groups. In this

case it is necessary to use an

appropriate supply module, which

disconnects the supply (module

supply, periphery supply and Crail supply) to the preceding (lefthand) modules and provides a

new supply to subsequent (righthand) modules.

` C-rail

The C-rail is routed through all the

base modules via the module bus.

The C-rail is an additional power

rail, which is attached to the base

module connections. It is intended

as an option, providing additional

power if required.

Access to the C-rail is available

through the use of base modules

which contain the letter “C” in

their description (e.g. PSSu BP1/8 S). The base module

connections on which the C-rail is

available are marked with a black

bar across the whole connection

level. I/O modules normally route

the C-rail connections on

connection level 3.

If the supply is separated on base

modules containing supply

modules, this is symbolised by the

fact that only the right-hand

connection on the connection

level is marked with a black bar.

CC

C

CC

This is normally connection 24.

Permitted infeed at C-rail:

- PE or

- 0 V or

- Screen or

- - 24 VDC ... + 24 VDC,

max. 10 A

Make sure that the C-rail supply

belongs to the same circuit as the

other base module connections.

1.1-2

Structure of module bus

Module bus

Communication rail

(FS + ST data)

Rail for module supply

Rail for periphery supply

C-rail (cross connection)

Base module Base module

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

System description

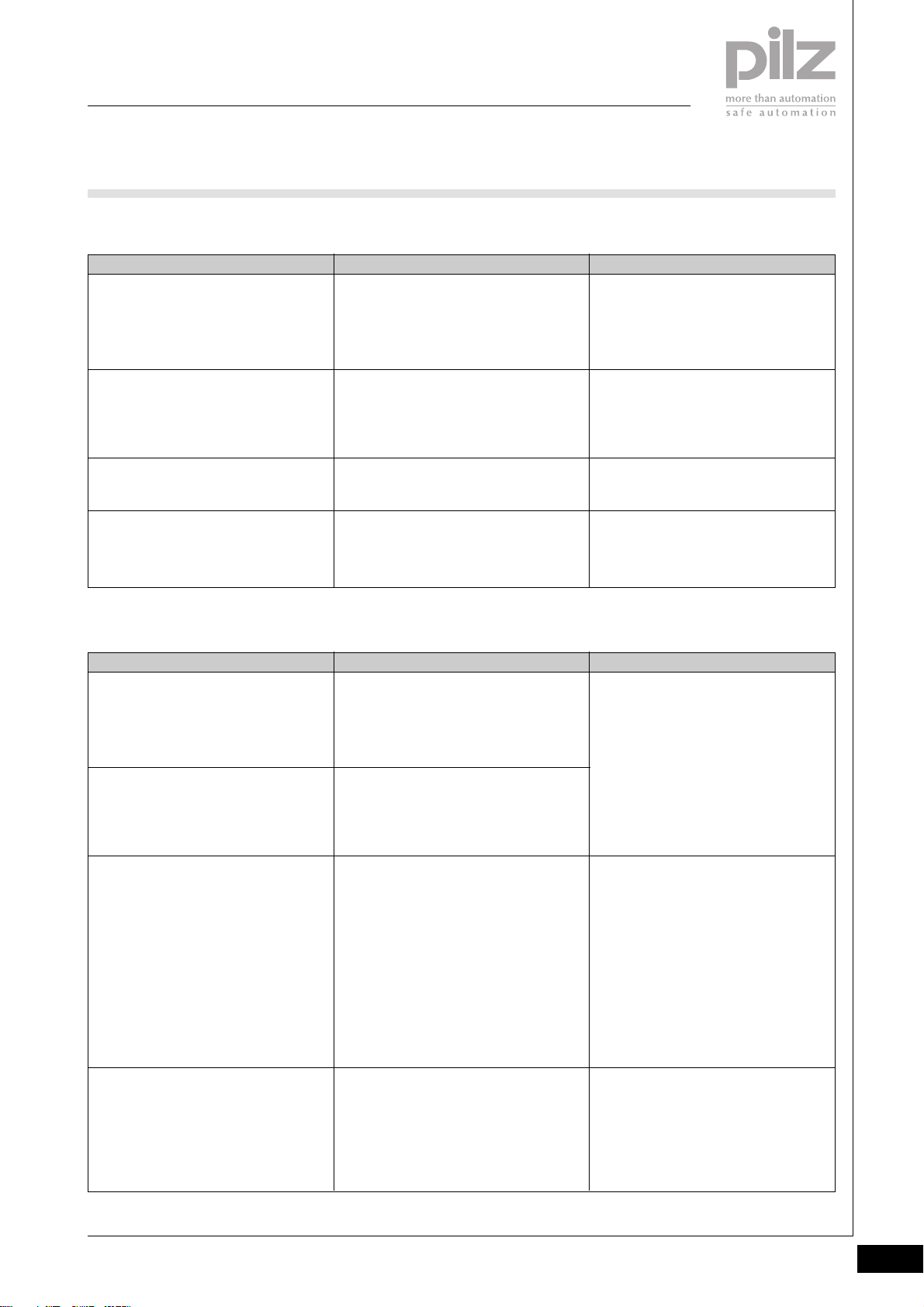

Maximum system expansion

Module type

Input/output modules in total

(identifier: PSSu E F ... / PSSu E S ...)

Input/output modules for

ST applications

(identifier: PSSu E S ...)

Input/output modules for

FS applications

(identifier: PSSu E F ...)

Output modules with

dual-pole outputs for

FS applications

(identifier: PSSu E F ... OZ...)

System limits

Module supply

when supplied via

- PSSu E F PS

Module supply

when supplied via

- PSSu E F PS1

Number of modules per system

Max. 64

Max. 64

Max. 32

Max. 16

Max. current load ExplanationSystem supply

Max. 1.5 A

Max. 2 A

Explanation

Details are valid for designing a PSSu

system with any combination of ST

modules and FS modules, provided all

the following conditions are met.

Details are valid for designing a PSSu

system with ST modules only.

Restrictions may apply, depending on

the standard bus system that is used.

Details are valid for designing a PSSu

system with FS modules only.

Details are valid for designing a PSSu

system with dual-pole FS output

modules only

(e.g. PSSu E F DI OZ 2).

The load is determined by the current

consumption of the head module and

electronic modules that are used. If a

heavier load arises, an additional supply

module must be used to refresh the

module supply. Further details can be

found in the description of the relevant

supply module.

2

Periphery supply

when supplied via

- PSSu E F PS

- PSSu E F PS1

- PSSu E F PS-P

C-rail

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Max. 10 A

Max. 10 A

The module bus rail for periphery supply

can take a max. 10 A load. If a heavier

load arises, an additional supply module

must be used to refresh the periphery

supply. The load is determined by the

current consumption of the sensors/

actuators on the electronic modules that

are used. Further details can be found in

the description of the relevant supply

module.

The C-rail can take a max. 10 A load. If a

heavier load arises, an additional supply

module must be used. Further details

can be found in the description of the

relevant supply module.

Status 01/05

1.1-3

PSSuniversal

Basics

System description

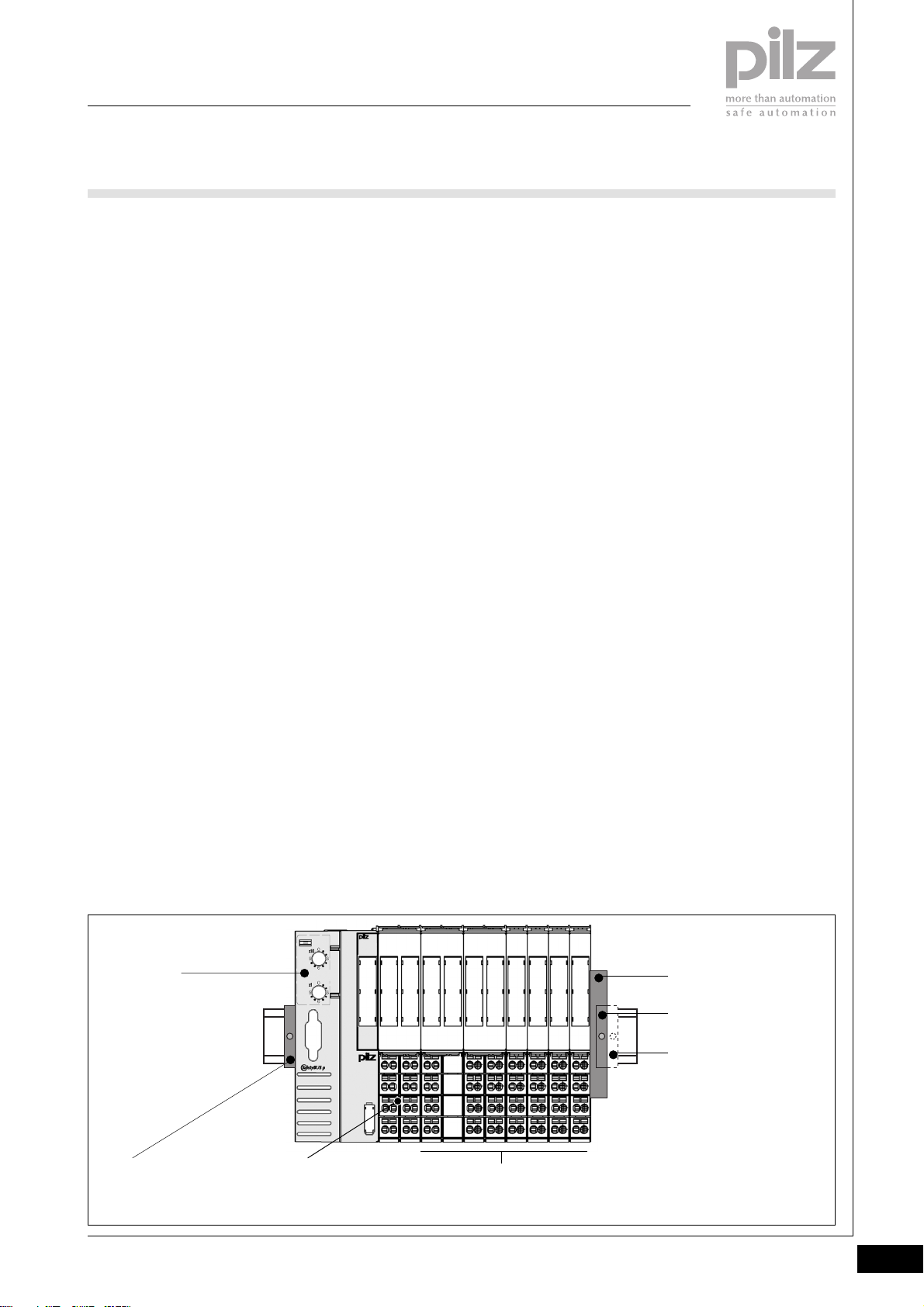

Local enable principle

The new local enable principle

technique means that outputs on

failsafe output modules can now be

switched via a standard bus system

(e.g. PROFIBUS).

Configuration of the local enable

principle

` Via the PSS WIN-PRO system

software

` By configuring FS output modules

for the relevant standard bus

system (e.g. in the case of

Profibus, included in the GSD file)

` By assigning an FS output to a bit

in the ST process image of

outputs (ST-PIO). The FS output

will therefore operate as an enable

output.

` Ability to read the FS inputs via

the standard bus system.

Operation of the local enable

principle

` The configured FS outputs are

driven via a standard bus system.

` Provided the enable output carries

a “1” signal, the configured FS

outputs can be driven via a

standard bus system.

As soon as the enable output

carries a “0” signal, the configured

FS outputs are shut down safely.

Control via the standard bus

system is ignored.

Function model of the local enable

principle

Control via

standard bus system

Control via

SafetyBUS p

ST Data

FS Data

Head Module

Module Bus

&

Power Supply

Input Module (ST)

Output Module (ST)

Input Module (FS)

Output Module (FS)

1.1-4

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

System description

Connection labelling on the base

modules

The connections on the base

modules are indicated via two-digit

numbers. The first digit denotes the

column on the module. The second

digit denotes the connection level

within the PSSu system.

Example:

Colour marking of connection levels

Colour marking of connection levels

The colour marking on the different

connection levels is helpful when it

comes to wiring. Various colour

markers are available to label the

connection levels. For the connection

diagram to remain consistent it

makes sense to arrange I/O modules

of the same type into groups (see

example).

The connection levels are typically

assigned as follows:

` Connection level 1 and 4

On I/O modules, connection levels

1 and 4 typically contain the

module’s inputs or outputs.

Marking in the example:

- Black [3]

` Connection levels 2 and 3

On I/O modules, connection levels

2 and 3 typically contain the

common supplies (+24 VDC, test

pulse outputs, 0 VDC).

Marking in the example:

- Red [1]: +24 VDC/test pulses

- Blue [2]: 0 VDC

2

Head Module

PSSu E F 4DI

Power Supply

2111

2111

2212

2212

2313

2313

2414

2414

Input Modules Output Modules

PSSu E F 2DO 2

PSSu E S 4DI

PSSu E F 4DI

2111

2212

[1] [2]

2313

2414

2111

2212

2313

2414

PSSu E S 4DI

2111

2212

2313

2414

PSSu E F 2DO 2

PSSu E F 4DI

2111

2111

[3]

2212

2212

2313

2313

2414

2414

[3]

PSSu E S 2DO 2

2111

2111

2212

2212

2313

2313

[2][1]

2414

2414

PSSu E F 4DO 0.5

PSSu E S 4DO 0.5

Connection Level 1

2111

2111

Connection Level 2

2212

2212

Connection Level 3

2313

2313

Connection Level 4

2414

2414

[1] : + 24 VDC

[2] : 0 VDC

[3] : Inputs/outputs

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1.1-5

PSSuniversal

Basics

System description

Separating supplies to form supply

groups

Supply groups are formed by

separating the 24 V supply (periphery

supply) and, if necessary, also the

5 V supply (module supply). In this

case it is necessary to use a supply

module that disconnects the supply

(periphery supply, C-rail supply and,

if necessary, the module supply) to

the preceding (left-hand) modules

and provides a new supply to

subsequent (right-hand) modules.

Provided an appropriate base

module is used, in principle any

electronic supply voltage module is

suitable for separating supplies.

Principle:

Formation of supply groups for

periphery supply

In each case you should take note of

the description of the relevant

electronic supply voltage module.

For example, supplies can be

separated on the following modules:

Modules

Electronic module

PSSu E F PS

(no module

buffer)

PSSu E F PS1

(module buffer

for max.

20 modules)

PSSu E F PS-P

PSSu E F BSW

(block switching)

Base module

PSSu BS-R 1/8 S

PSSu BS-R 1/8 C

PSSu BS-R 2/8 S

PSSu BS-R 2/8 C

PSSu BS 1/8 S

PSSu BS 1/8 C

PSSu BS 2/8 S

PSSu BS 2/8 C

Separation of supply

C-rail Periphery

supply

Separation of supply from left-hand

modules and

supply infeed to right-hand modules

Separation of supply from

left-hand modules and

supply infeed to right-hand

modules

Module

supply

No separation

of supply

(5 V potential

looped

through)

Head Module

Periphery Supply 1

(24 V DC)

C-rail

Supply

Supply Group 1 Supply Group 2 Supply Group 3

I/O Module

I/O Module

Power Supply

Power Supply

24 V DC 24 V DC 24 V DC

Periphery Supply 2

(24 V DC)

C-rail

Supply

I/O Module

I/O Module

Power Supply

Periphery Supply 3

(24 V DC)

C-rail

Supply

I/O Module

I/O Module

I/O Module

Power Supply

I/O Module

1.1-6

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

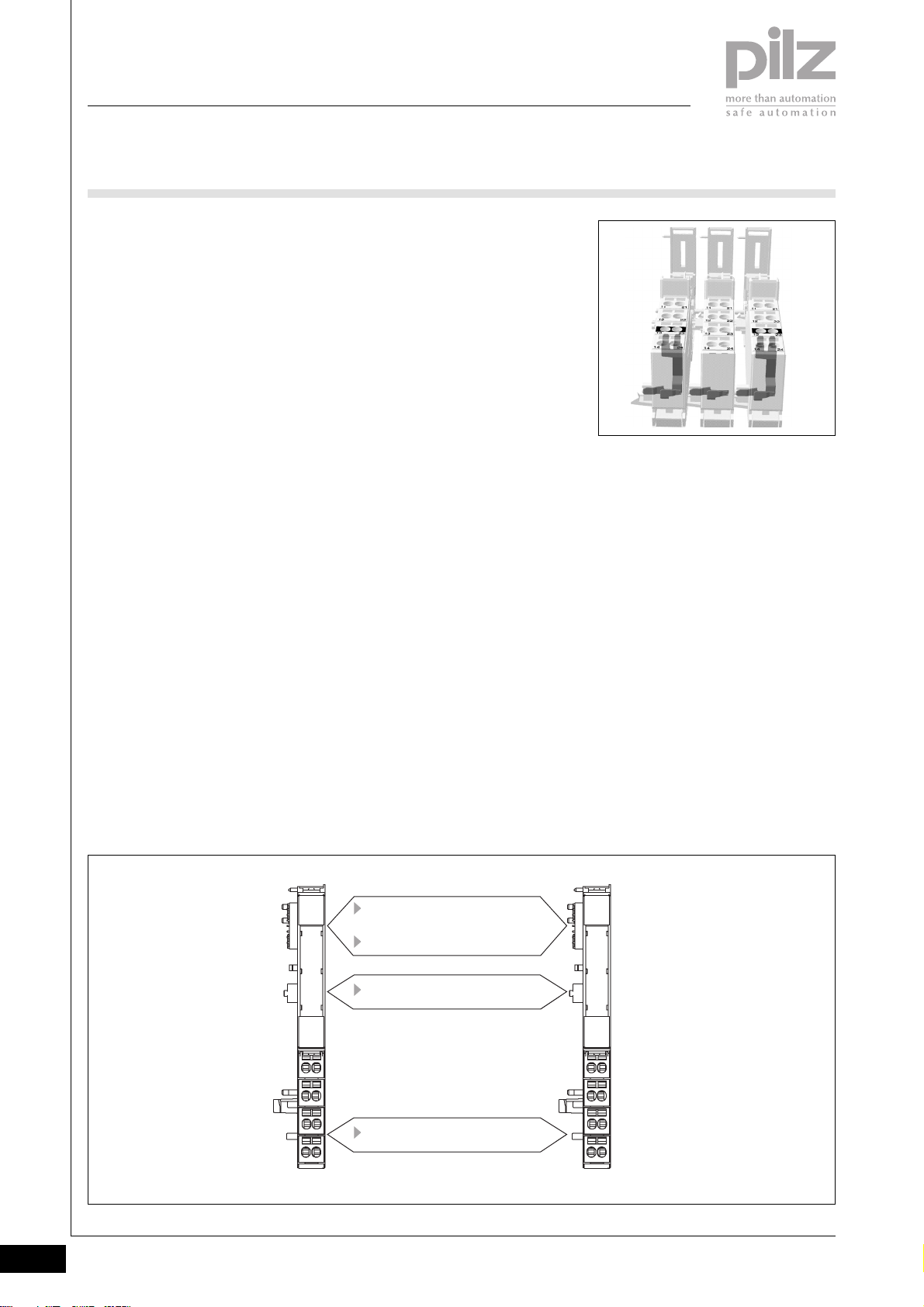

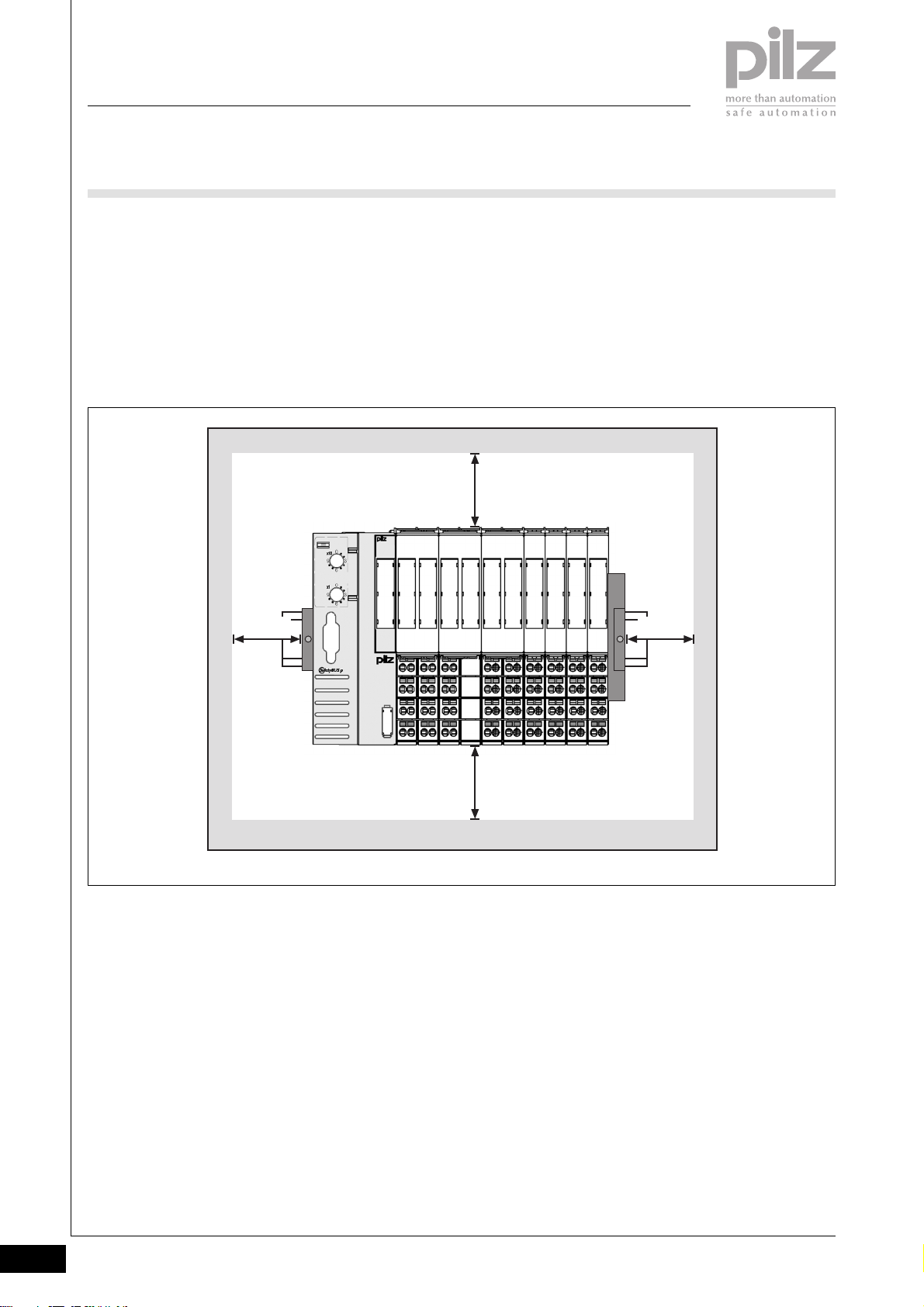

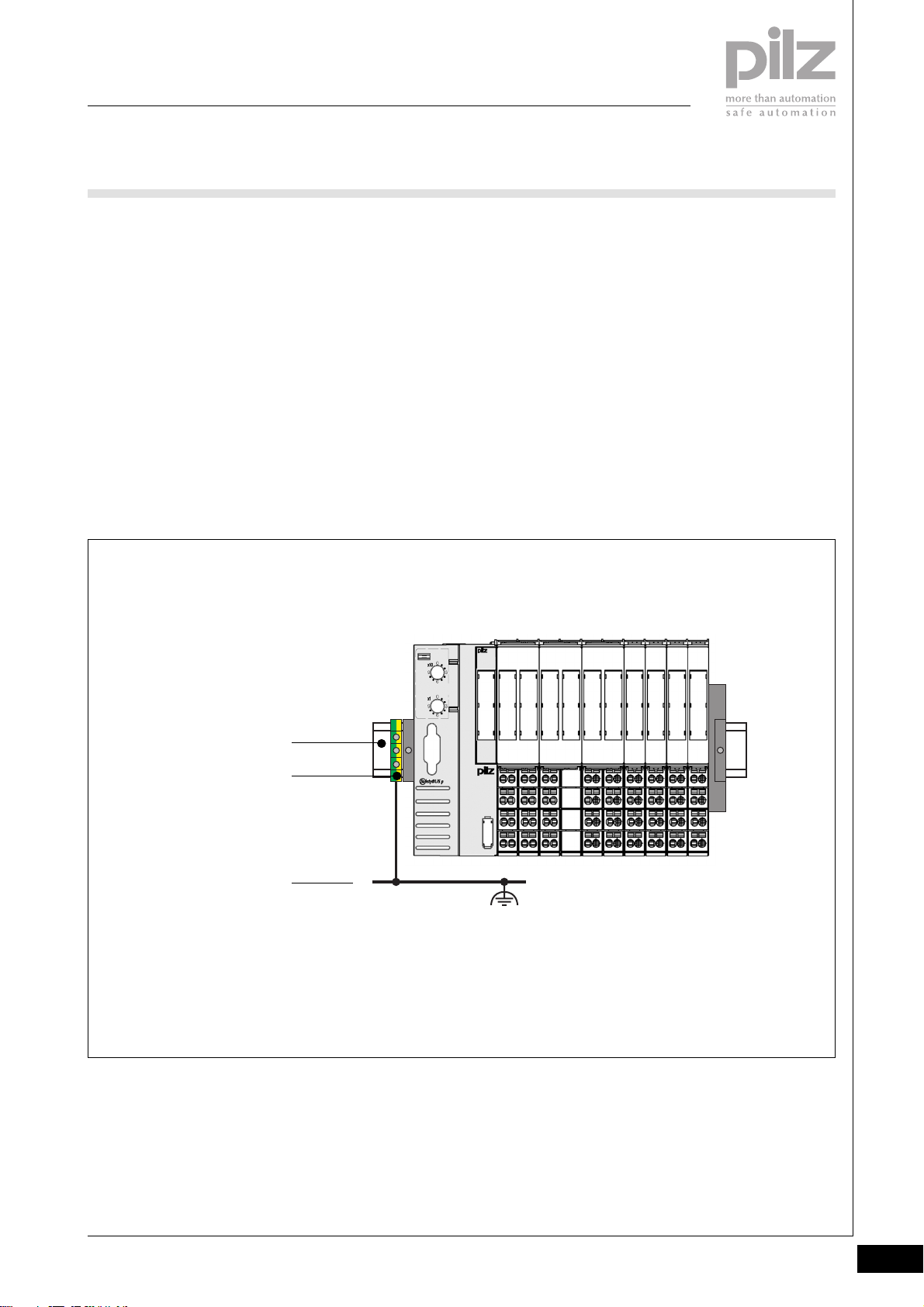

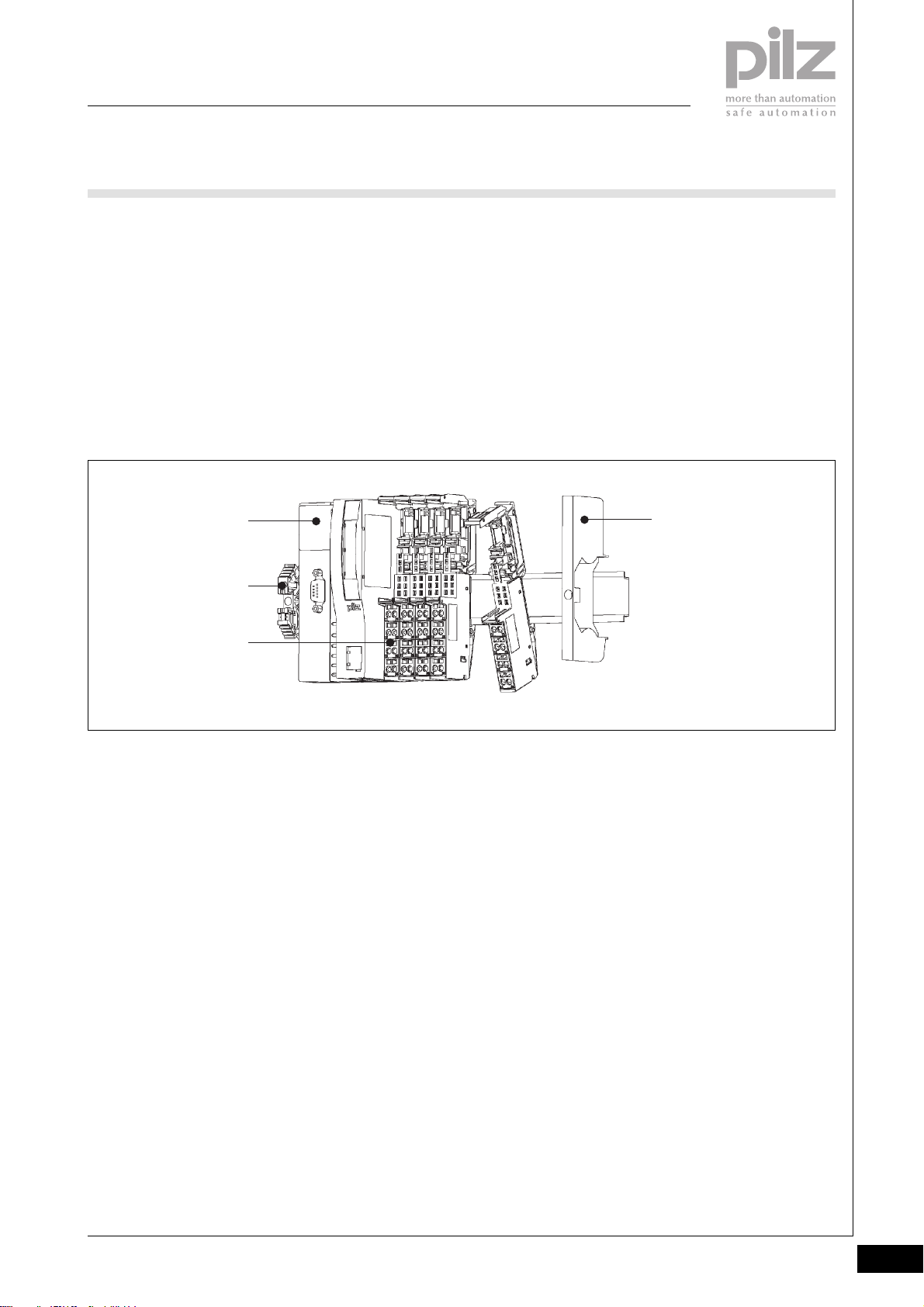

Mounting position

` A PSSu system should preferably

be installed horizontally on a

vertical wall.

` If other mounting positions are

used (e.g. vertical installation),

there will be certain restrictions

with regard to

- Ambient temperature

Optimum upward heat

dissipation can no longer be

guaranteed.

- Vibration and shock stress

There will be increased

requirements on the system

fastenings: use additional

metallic end brackets!

Mounting rail

` A PSSu system is designed to be

installed on a zinc plated DIN rail

in accordance with DIN EN 50022.

Dimensions:

35 x 7.5 mm or 35 x 15 mm

` Where vibration and shock stress

place increased requirements on

the system fastenings, it is

recommended that the mounting

rail is screwed to the mounting

plate approximately every

200 mm.

Module layout

` The first module on a PSSu

system is always a head module.

` A supply voltage module is always

connected to the right of the head

module

- To supply the module electronics to the head module and

subsequent I/O modules

- To provide 24 VDC for the

periphery supply

` Next right it is possible to install

I/O modules for FS and ST

applications.

- The I/O modules (input

modules, output modules) can

be installed in any order.

- I/O modules for FS applications

and ST applications can be

combined as required.

- In various applications it makes

sense to combine specific

modules into groups.

- It is not possible to mix base

modules with screw terminals

and cage clamp terminals.

- The max. number of I/O

modules is determined through

the defined system limits.

` Supply voltage modules may be

required to refresh the supply to

the module electronics. This can

be determined through the

defined system limits.

` To form supply groups, an

additional voltage supply module

is required at the start of each

group. The modules belonging to

the supply group will then follow

to the right.

` The final element in a PSSu

system is always a terminating

plate, containing the bus

terminating resistors.

` Various fastening elements are

used at the start and end of the

system to secure the system on

the mounting rail:

- End bracket at the start of the

system

- Plastic version (standard)

- Metal version

(increased requirements with

regard to vibration and

shock stress)

- End bracket at the end of the

system

- Plastic version (standard)

- Metal version

(increased requirements with

regard to vibration and

shock stress)

2

Head

module

End bracket

(metal version

if necessary)

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Supply voltage module

I/O modules

with supply voltage modules to separate the supplies

if necessary)

Terminating plate

with integrated

End bracket

Additional metal end

bracket if required

Status 01/05

1.2-1

PSSuniversal

Basics

Installation

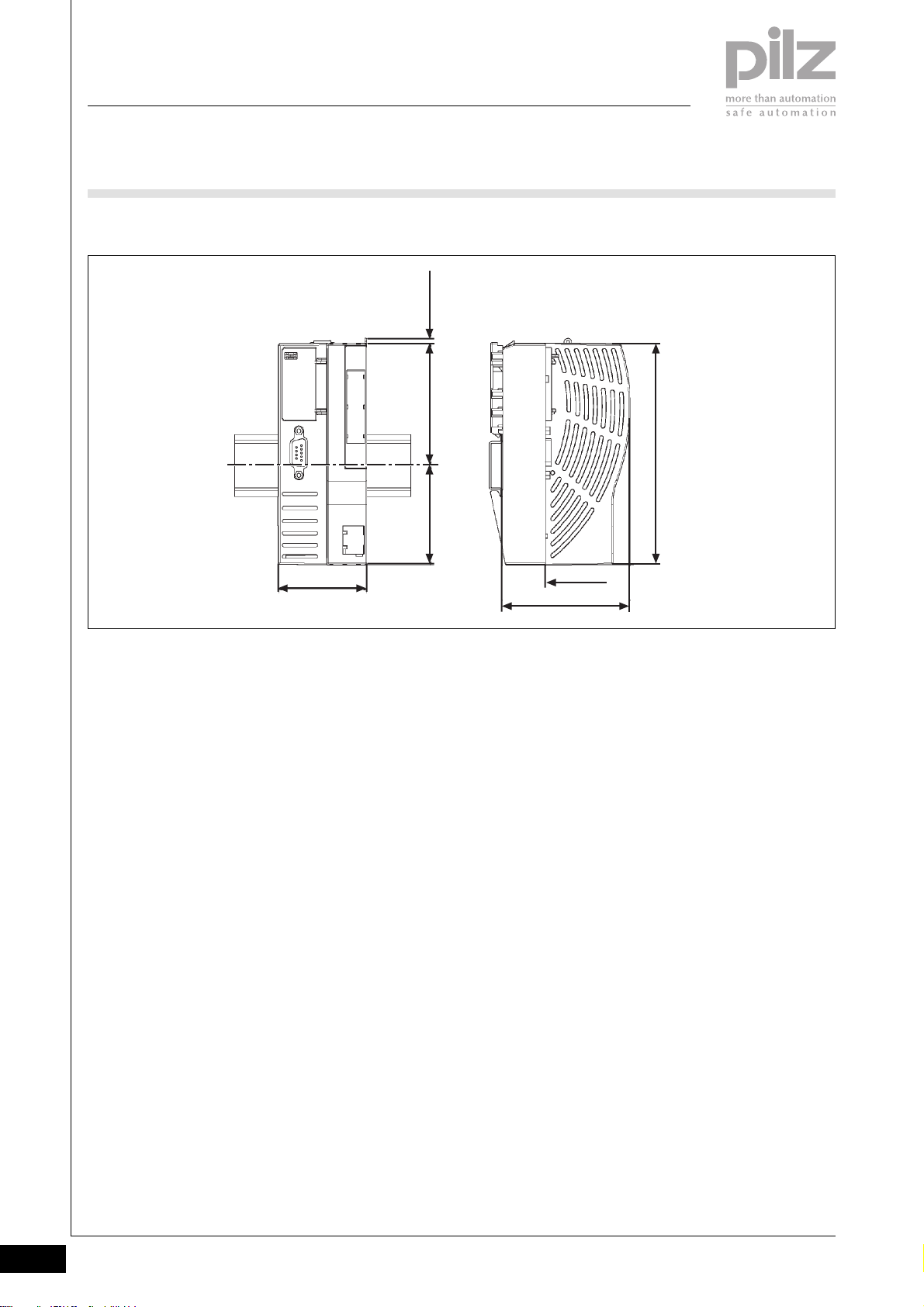

Mounting distances

The values stated in the diagram

below are minimum specifications.

20 mm 20 mm

Appropriate air conditioning may also

be required. The values stated for

ambient temperature must be

maintained. These values can be

found in the technical details for the

individual modules.

35 mm

35 mm

1.2-2

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

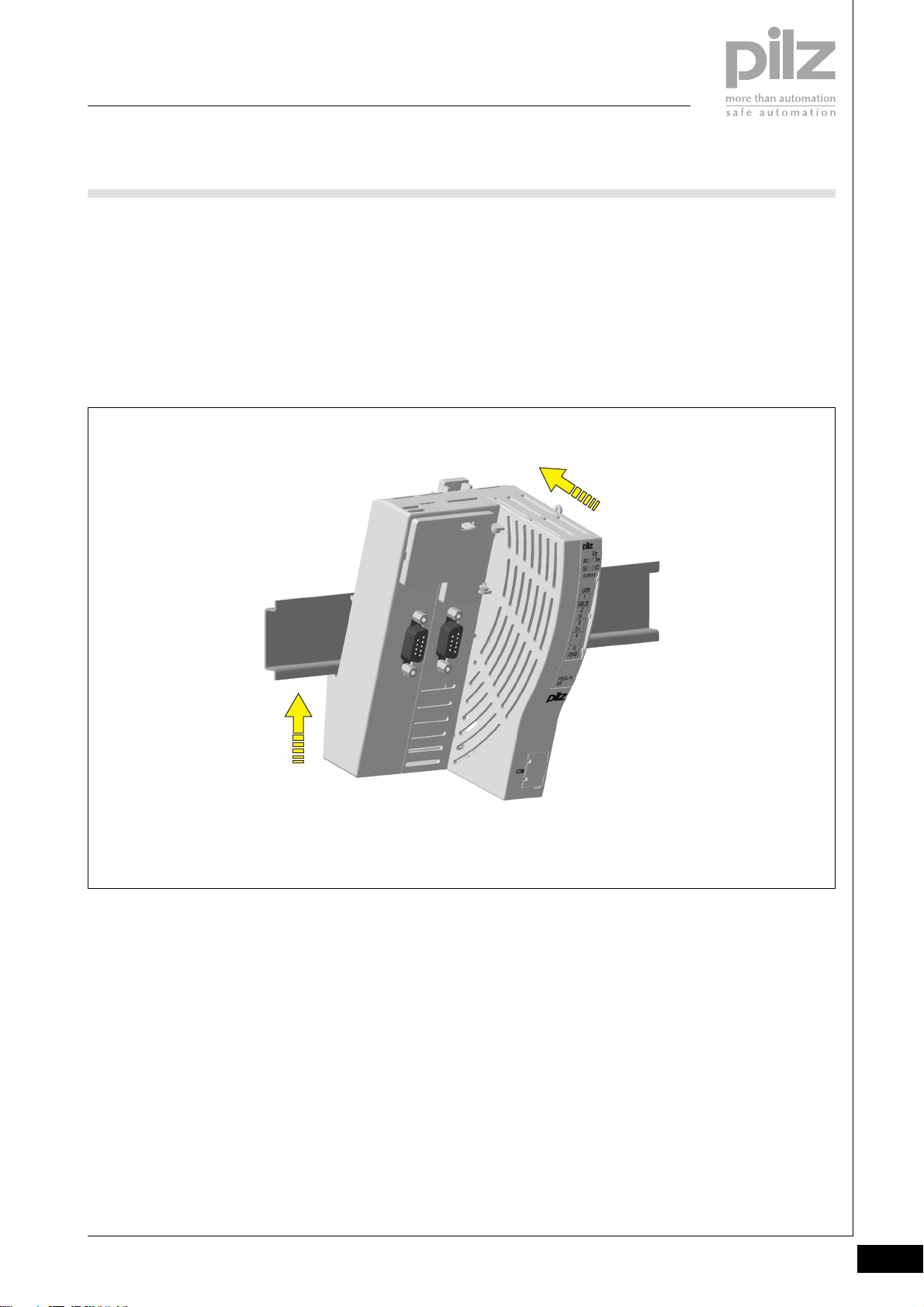

Installing the head module

` Prerequisites:

- The mounting rail must already

be installed.

` Install an appropriate end bracket

to the left of the head module or

leave enough space to install it

later.

` Procedure:

- Slot the groove on the head

module on to the mounting rail

from below [1].

- Push the head module back [2]

until you hear it lock into

position.

2

[2]

[1]

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1.2-3

PSSuniversal

Basics

Installation

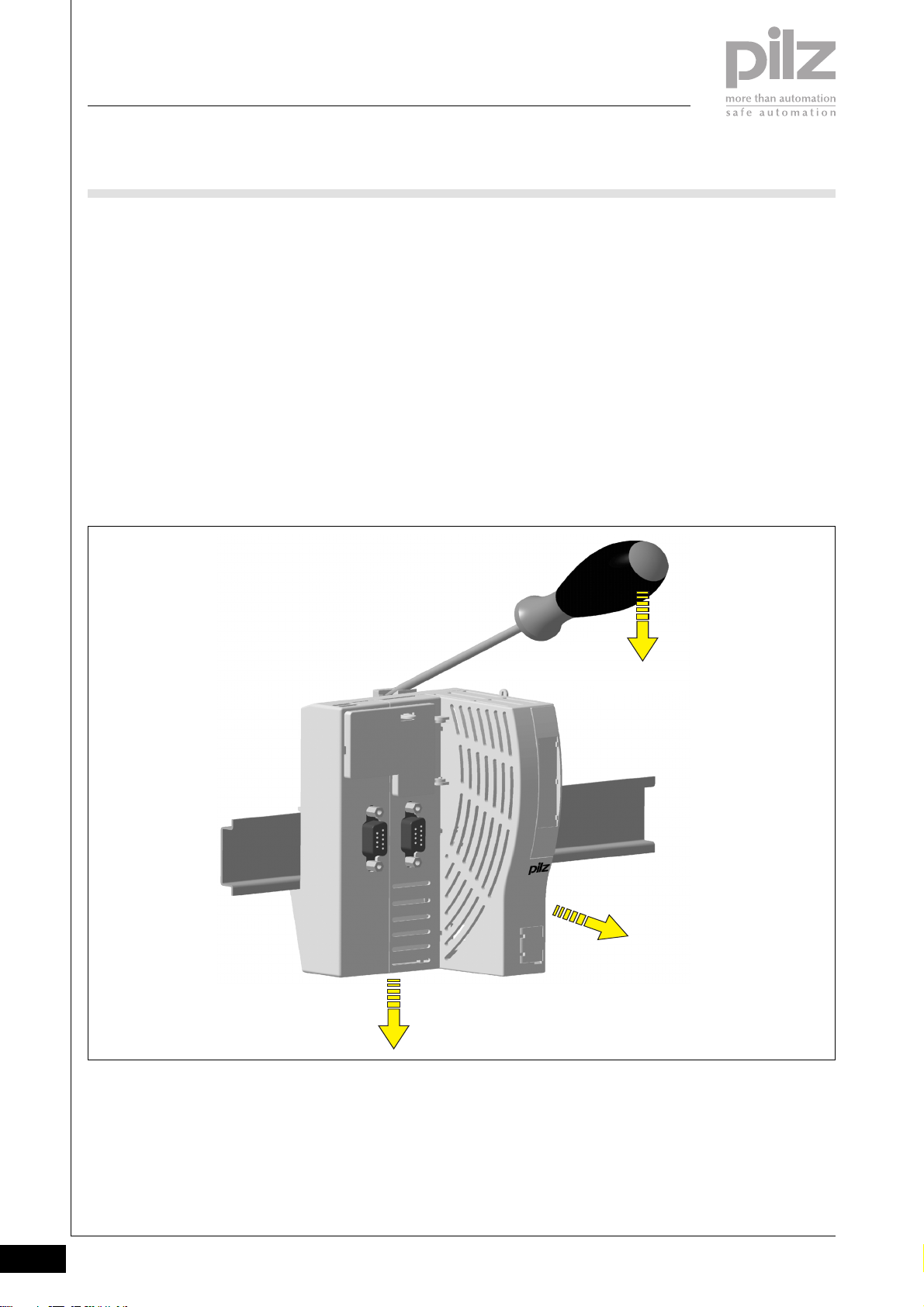

Removing the head module

` Prerequisite:

- The supply voltage must be

switched off

- The bus connections must be

disconnected

- All the wiring must be removed

- All the base modules must have

been moved to the right (min.

30 mm) or have already been

removed.

` Procedure:

- Using a screwdriver, push the

rear locking element [1]

upwards until the locking hook

releases the anchor.

- Pivot the head module and

screw driver forwards [2] and

remove in a downward

direction [3].

[1]

[2]

[3]

1.2-4

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

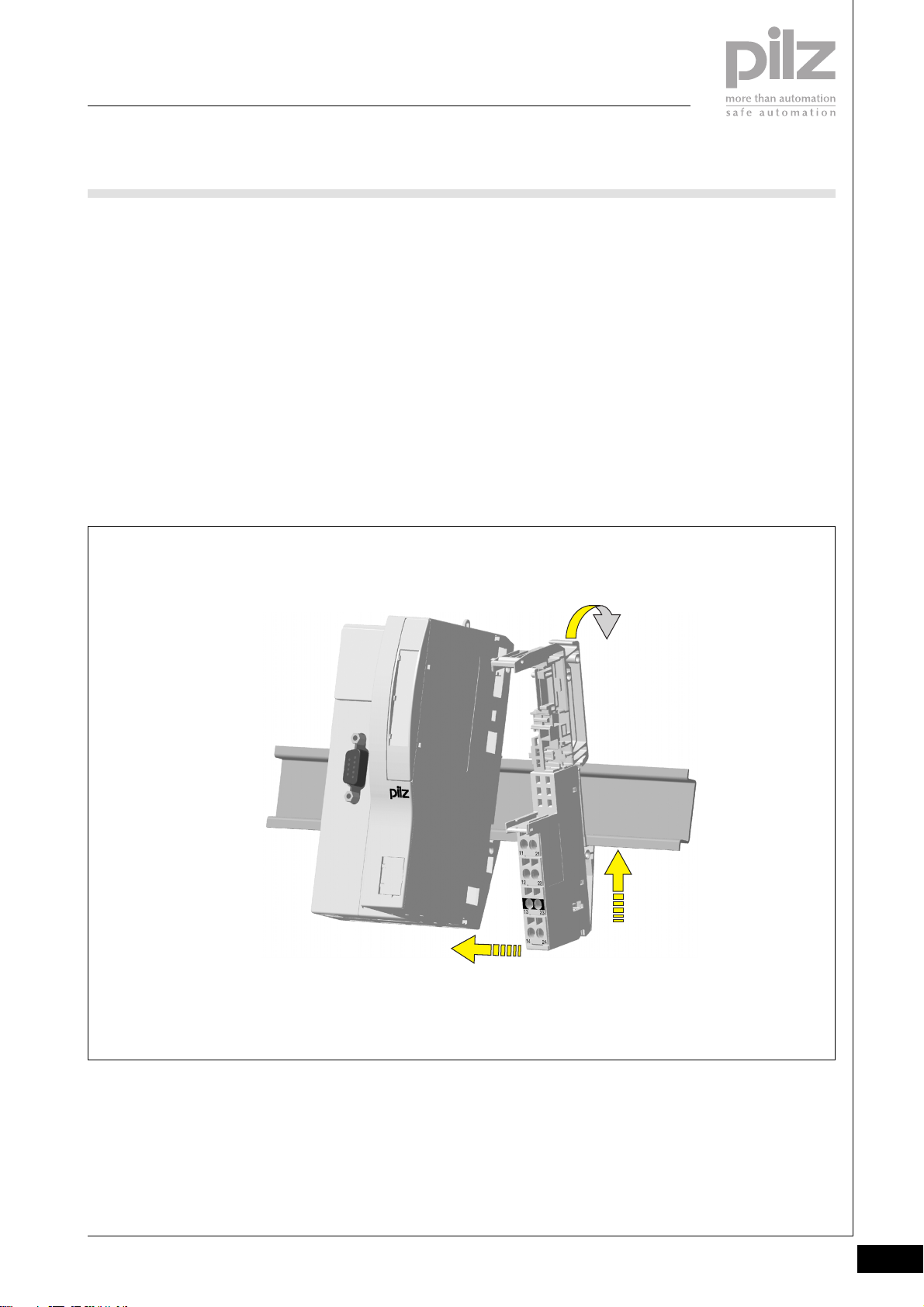

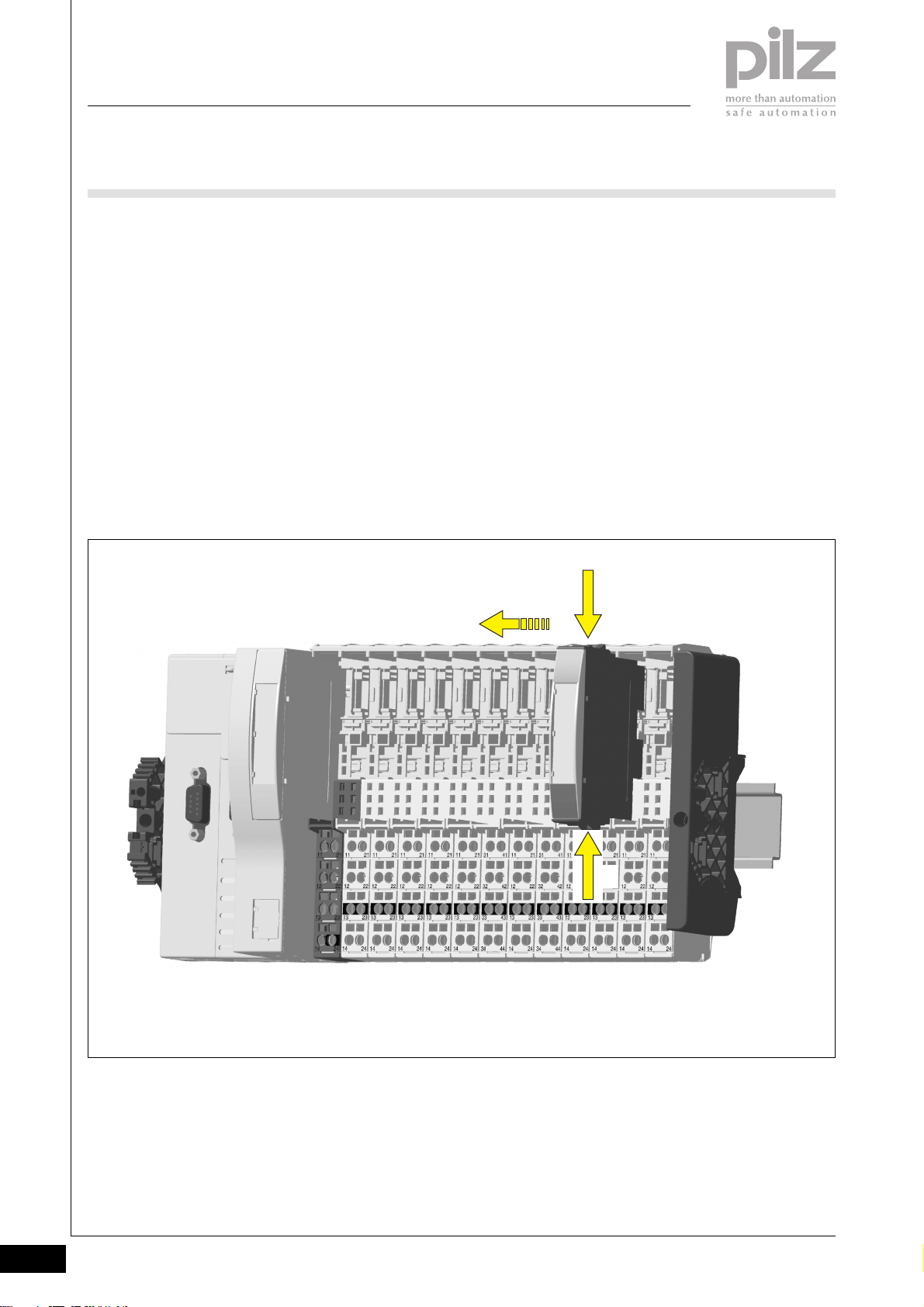

Installing base modules

` Prerequisite: The head module

must already be installed.

` The head module must always be

followed on the right by a base

module that is suitable for an

appropriate supply voltage

module.

` The wiring should preferably be

carried out after the base modules

are installed, but before the

electronic modules are installed.

` Please note:

- For mechanical reasons it is not

possible to mix base modules

with screw terminals and base

modules with cage clamp

terminals.

- All contacts should be

protected from contamination.

` Procedure:

The same procedure applies for all

base modules (e.g. base modules

in grid widths 1 x 12.6 mm, 2 x

12.6 mm).

- Base modules should always

be installed to the right of the

head module.

- Slot the groove on the base

module on to the mounting rail

from below [1].

- Push the base module back [2]

until you hear it lock into

position.

- On the mounting rail, slide the

base module to the left until

you hear the two lateral

mounting hooks on the

adjacent module (head module

or base module) lock into

position [3].

2

[2]

[3]

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

[1]

Status 01/05

1.2-5

PSSuniversal

Basics

Installation

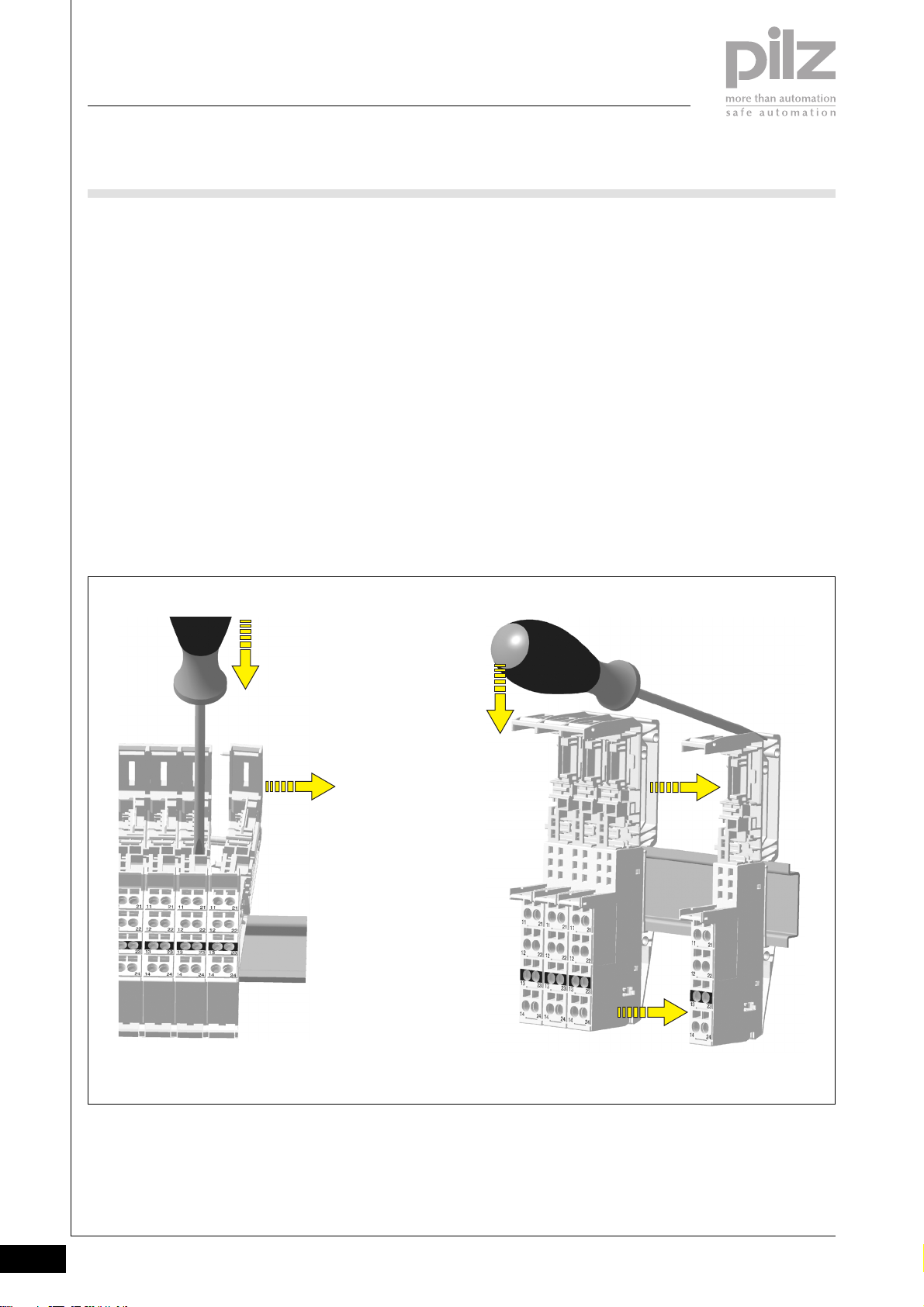

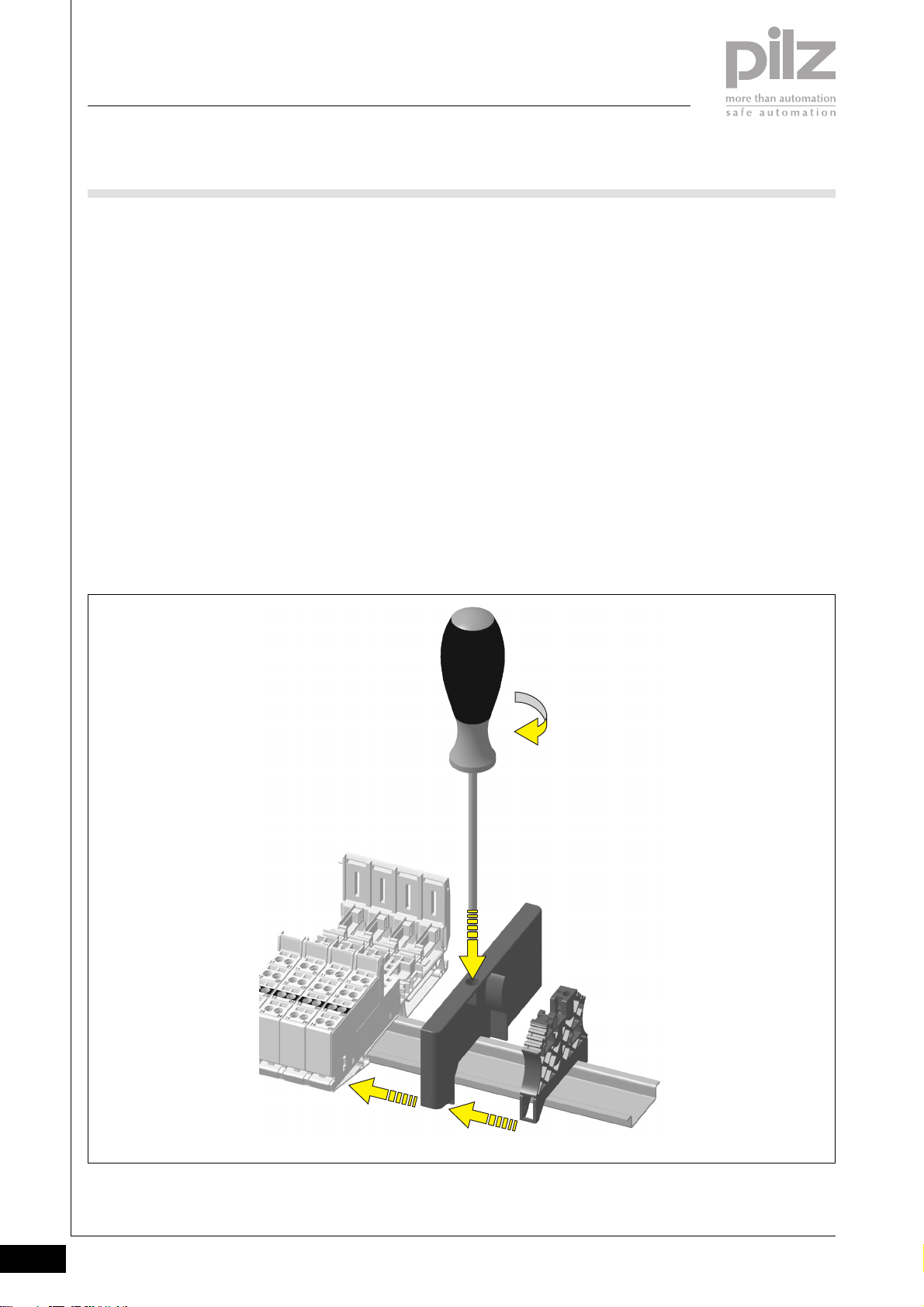

Removing base modules

` Prerequisite:

- The supply voltage on the

corresponding supply module

must be switched off

- All the wiring must be removed

- The electronic module on the

relevant base module must

have been removed, plus the

electronic module on the base

module to the left.

- All the base modules to the

right of the relevant base

module must have been moved

to the right (min. 30 mm) or

have already been removed.

[1]

` Procedure:

The same procedure applies for all

base modules (e.g. base modules

in grid widths 1 x 12.6 mm,

2 x 12.6 mm).

- Insert the screwdriver into the

square opening on the base

module to the left of the

relevant module [1].

- Push the screwdriver

downwards and keep it

pressed down.

- Use the other hand to pull the

base module to the right [2]

until the locking element on the

base module you are removing

is completely free.

- On the mounting rail, slide the

base module to the right [3]

- Using a screwdriver, push the

rear locking element [4]

upwards [5] until the locking

hook releases the anchor.

- Pivot the base module and

screw driver forwards and

remove in a downward

direction.

NOTICE

Modules may be inserted and

removed a maximum of 20 times.

After this point a correct contact can

no longer be guaranteed.

[2]

[5]

[4]

[3]

[3]

1.2-6

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

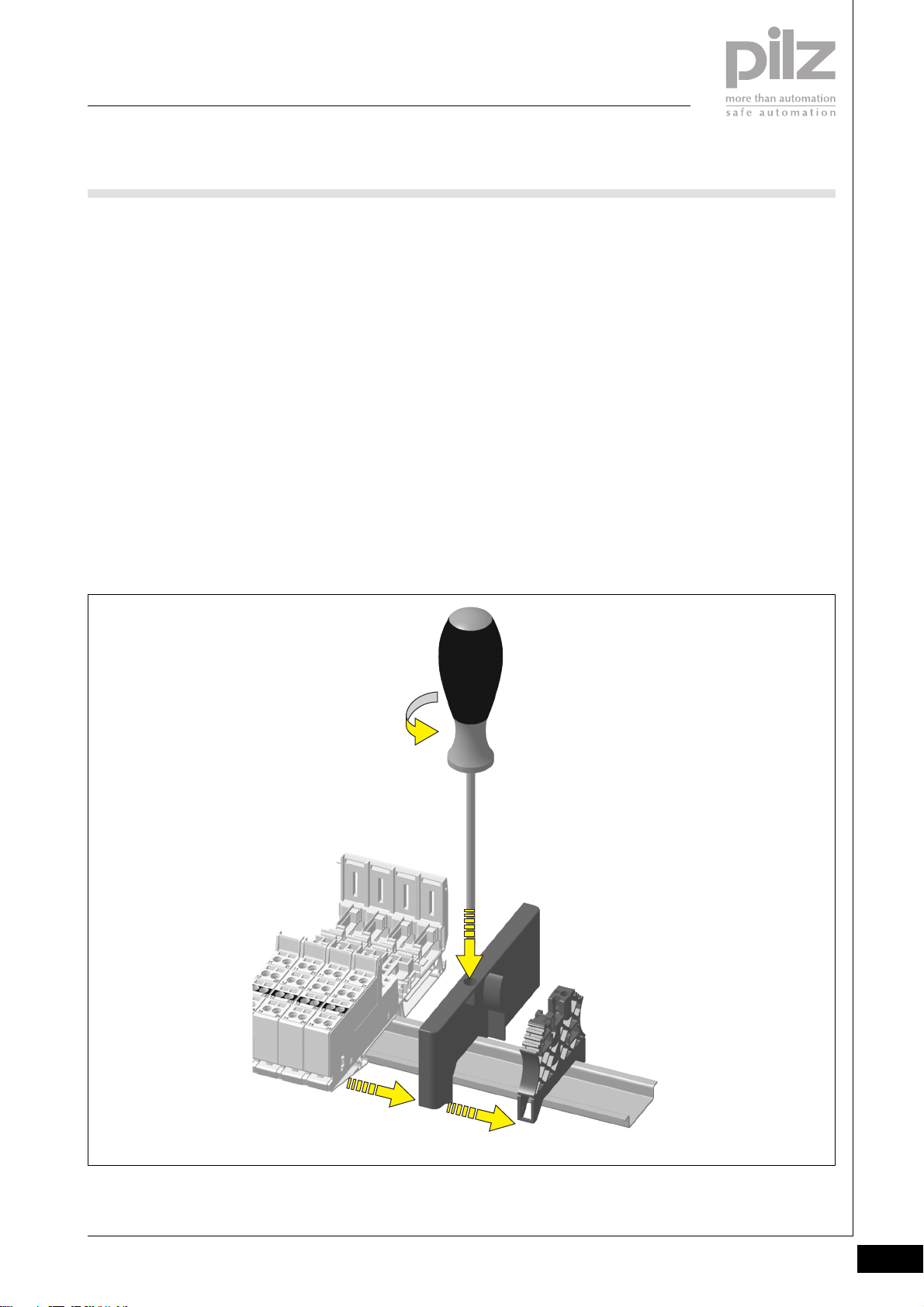

Installing an end bracket at the start

of the system

` Select an end bracket, depending

on the vibration and shock stress

(plastic version/metal version)

` Procedure:

- Use a screwdriver for slottedhead screws (M2).

- Loosen the fixing screw on the

end bracket until the terminals

are far enough apart for the end

bracket to be positioned on the

mounting rail.

[3]

- Place the end bracket on the

mounting rail, to the left of the

head module [1].

- Slide the end bracket up close

to the head module [2]

- Tighten up the end bracket [3].

2

[1]

[2]

Removing an end bracket at the start

of the system

` Procedure:

- Use a screwdriver for slottedhead screws (M2).

- Loosen the fixing screw on the

end bracket until the terminals’

clamping force is lifted.

- Remove the end bracket from

the mounting rail.

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1.2-7

PSSuniversal

Basics

Installation

Installing a terminating plate and end

bracket at the end of the system

` Select an end bracket, depending

on the vibration and shock stress

- Plastic version of end bracket

(integrated into terminating

plate)

- Additional end bracket if

required (metal version)

` Procedure:

- Use a screwdriver for slottedhead screws (M2).

- Attach the terminating plate to

the mounting rail as the final

element on the system [1].

- Loosen the fixing screw on the

end bracket until the terminals

are far enough apart for the end

bracket to be positioned on the

mounting rail.

- Place the end bracket on the

mounting rail, to the right of the

terminating plate [2].

- Slide the end bracket and

terminating plate into each

other [3]

- Slide the terminating plate with

integrated end bracket up to

the final base module as far as

it will go [4]; ensure that contact

is made with the integrated bus

terminating resistors.

- Insert the screwdriver into the

terminating plate [5]

- Tighten up the integrated end

bracket [6].

` If an additional end bracket (metal

version) is required to secure the

system, this additional end

bracket is installed to the right of

the terminating plate.

Procedure:

- Loosen the fixing screw on the

metallic end bracket

- Place the metallic end bracket

on the mounting rail

- Slide the metallic end bracket

up close to the terminating

plate with the integrated end

bracket

- Tighten up the metallic end

bracket

[4]

[6]

[1]

[5]

[2]

[3]

1.2-8

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

Removing a terminating plate and

end bracket at the end of the system

` Procedure:

- Use a screwdriver for slottedhead screws (M2).

- Insert the screwdriver into the

terminating plate [1]

- Loosen the fixing screw on the

end bracket [2].

- Move the terminating plate and

integrated end bracket to the

right [3].

Note: Do not damage the

elements used to connect to

the adjacent base module.

- Loosen the fixing screw on the

end bracket until the terminals’

clamping force is lifted.

- Remove the terminating plate

and integrated end bracket

from the mounting rail.

2

[3]

[2]

[1]

[3]

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1.2-9

PSSuniversal

Basics

Installation

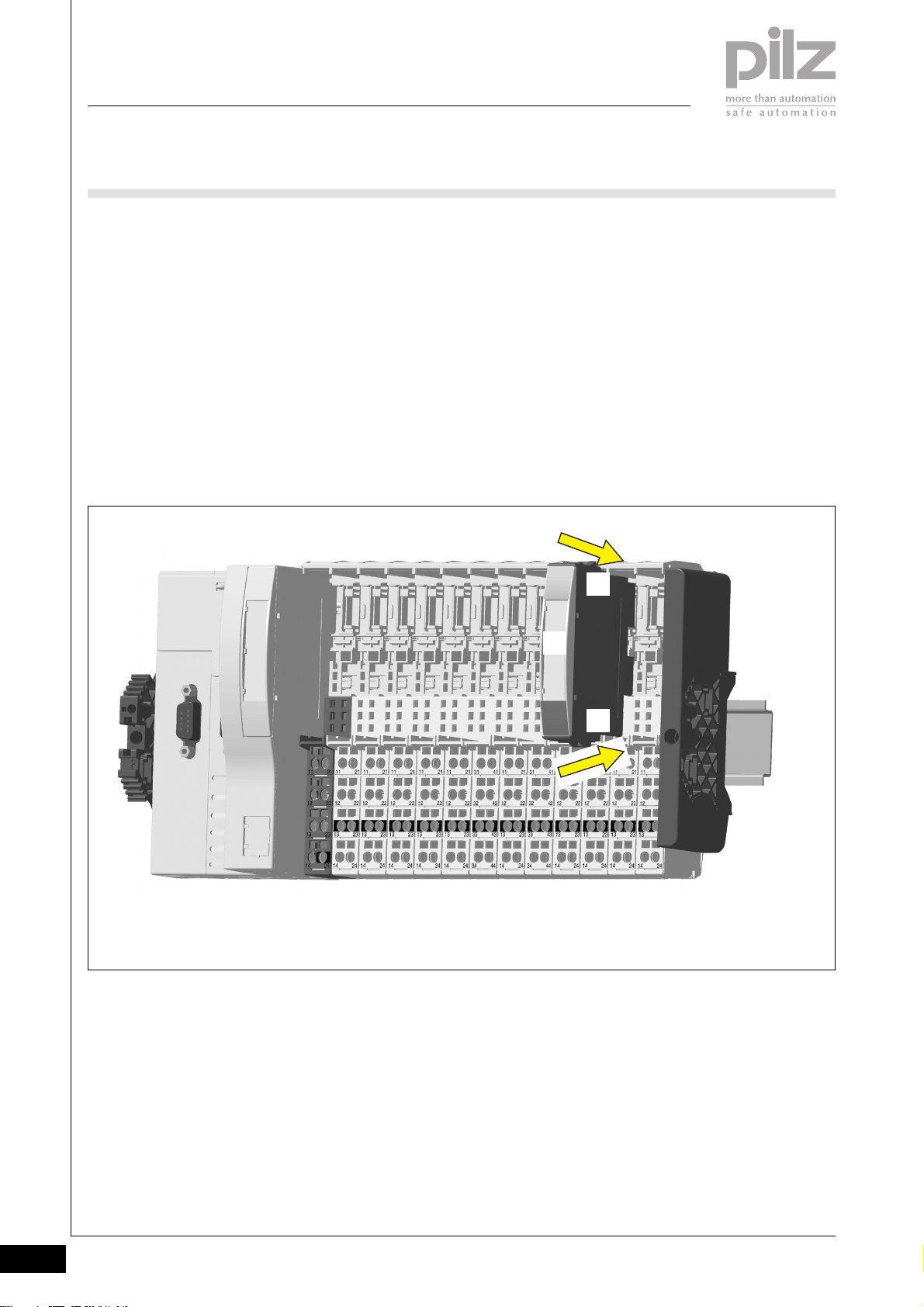

Inserting an electronic module

NOTICE

Modules may be inserted and

removed a maximum of 20 times.

After this point a correct contact can

no longer be guaranteed.

` Electronic modules should only be

plugged into base modules that

are installed and, preferably,

wired.

` Electronic modules with outputs

(output modules) may only be

inserted or removed when the

load is switched off.

If modules are inserted/removed

under load, the possibility of the

PSSu system switching to a safe

condition (STOP condition) cannot

be excluded. The corresponding

I/O-Group (SafetyBUS p) may also

switch to a STOP condition.

[2]

` Procedure:

- The electronic module must

audibly lock into position [1].

- Identify the electronic module

using the labelling strips [2]

[1]

[1]

1.2-10

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

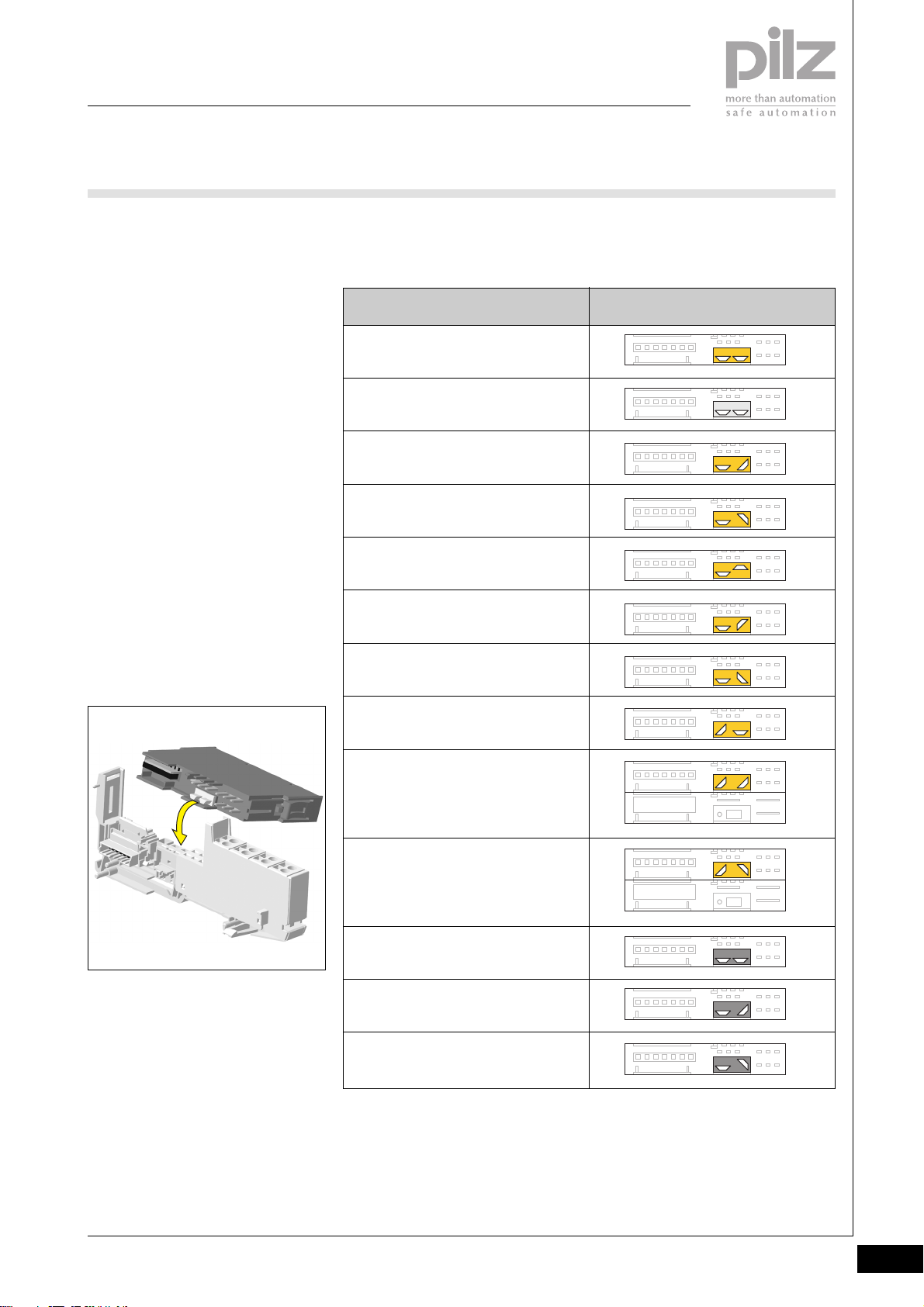

Mechanical coding

Electronic modules have a two-part

coding element. The first time an

electronic module is plugged into a

base module, one part of the coding

element remains on the electronic

module, while its counterpart is fixed

on to the base module.

The coding element is designed to

help prevent plugging errors (e.g.

when exchanging modules).

` Once a base module has been

coded, only electronic modules

with the same coding can be

inserted.

` If a new electronic module is to be

plugged into a base module that

has already been coded, you will

initially need to remove the coding

counterpart on the electronic

module.

Overview of the mechanical coding

elements on electronic modules

Electronic module

PSSu E F PS-P

Coding: yellow, A

PSSu E PD

Coding: light grey, A

PSSu E F PS

Coding: yellow, B

PSSu E F PS1

Coding: yellow, C

PSSu E F 4DI

Coding: yellow, D

PSSu E F 4DO 0.5

Coding: yellow, E

PSSu E F 2DO 2

Coding: yellow, F

Mechanical coding element

(rear view of electronic module)

2

PSSu E F DI OZ 2

Coding: yellow, G

PSSu E F 2DOR 8

Coding: yellow, H

PSSu E F BSW

Coding: yellow, I

PSSu E S 4DI

Coding: dark grey, A

PSSu E S 4DO 0.5

Coding: dark grey, B

PSSu E S 2DO 2

Coding: dark grey, C

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1.2-11

PSSuniversal

Basics

Installation

Removing an electronic module

NOTICE

Ensure that a correct contact is

made. A correct contact can no

longer be guaranteed when modules

have been inserted and removed

more than 20 times.

` Electronic modules with outputs

(output modules) may only be

inserted or removed when the

load is switched off.

If modules are inserted/removed

under load, the possibility of the

PSSu system switching to a safe

condition (STOP condition) cannot

be excluded. The corresponding

I/O-Group (SafetyBUS p) may also

switch to a STOP condition.

[2]

Procedure:

` Press the locking mechanisms [1]

together and at the same time

` Pull out the electronic module [2]

[1]

1.2-12

[1]

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Basics

Installation

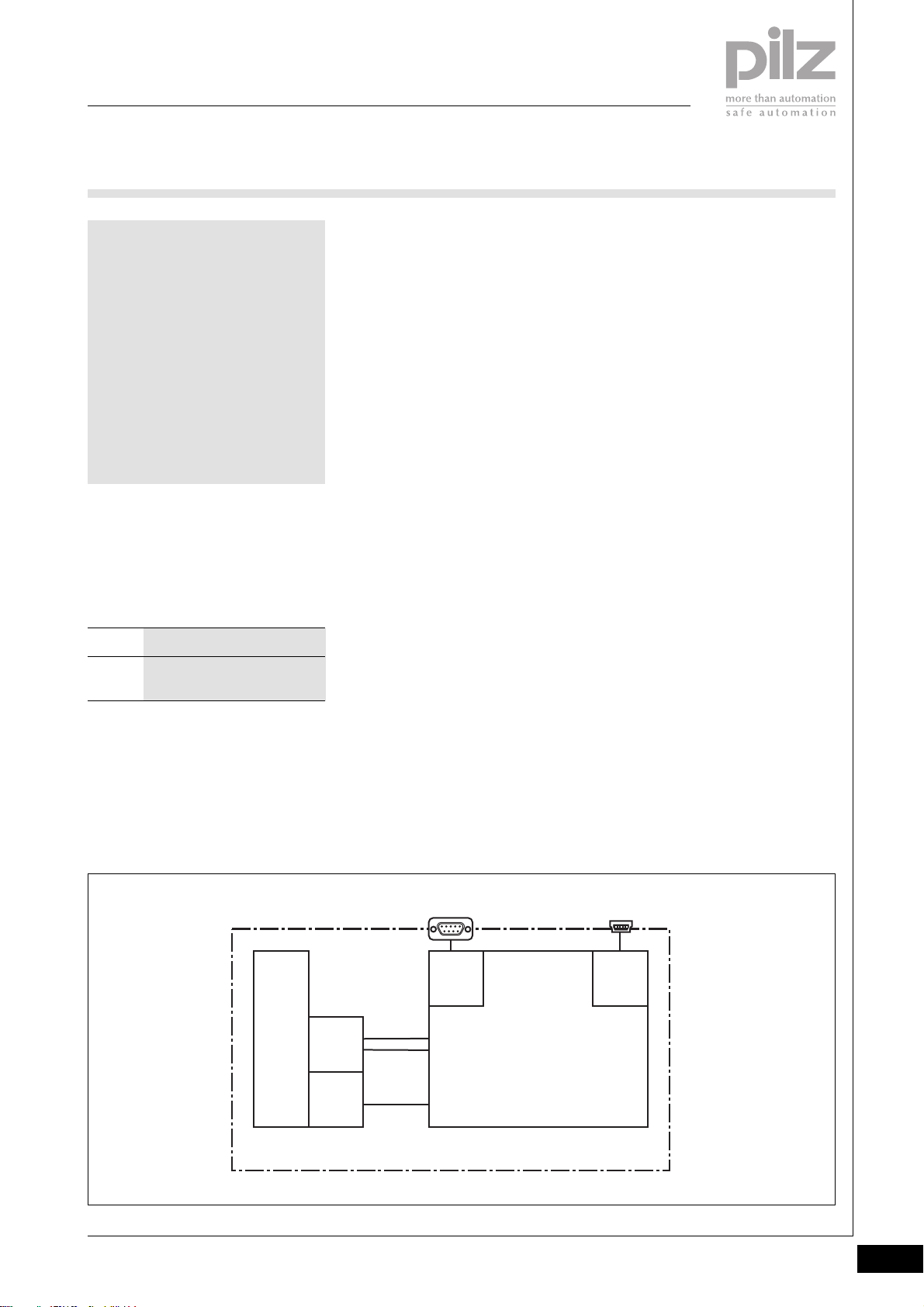

Earthing

When modules are attached to the

mounting rail, contact with the

mounting rail is made via a contact

spring. The mounting rail should be

earthed appropriately.

A special earthing terminal that can

be attached to the mounting rail is

available as an accessory.

2

Mounting rail

Earthing terminal

Functional earth

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

1.2-13

PSSuniversal

Basics

Installation

Notes

1.2-14

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Head modules

PSSu H SB

PSSu H SB

not shown

Head module to connect a PSSu

type system to SafetyBUS p.

Suitable for safety-related functions.

Approvals

PSSu H SB

Module features

` SafetyBUS p interface for

switching failsafe inputs/outputs

via SafetyBUS p

` USB port for PC connection

- Commissioning and service

` LED indicators for:

- System status

- SafetyBUS p status

- USB status

` Electronic modules suitable for

use for input/output:

- All failsafe modules

(identifier: PSSu F...)

Module description

The module meets the requirements

of EN IEC 61508 and EN 954-1

Category 4. The module may be

used to connect the system to

` SafetyBUS p

Safety features

The module meets the following

safety requirements:

` Watchdog for life monitoring

` Protection against over-

temperature

` Safe voltage monitoring

2

Block diagram

In progress

Mo du le Bus

Module

Supply

+ 5 V DC

Data

(FS)

1

659

Data

(FS)

USBSafetyBUS p

1

Firmware

5

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

2.1-1

PSSuniversal

Head modules

PSSu H SB

Function description

` Module supply (5 VDC)

The electronics are supplied via

the module bus.

` SafetyBUS p

The system can be connected to

SafetyBUS p as a SafetyBUS p

subscriber via the SafetyBUS p

interface.

- SafetyBUS p interface: male 9pin D-SUB connector

“SafetyBUS p”

- Ability to connect the Pilz FO

coupler PSS SB SUB-D F0.

- Device address: can be set via

the two rotary switches “SB

ADDRESS”.

Valid device addresses:

32D ... 95D.

- SafetyBUS p status: displayed

via the LEDs “SB” and “I/O”.

Setting the device address for

SafetyBUS p

` USB

For commissioning and service

work, a PSSu system can be

connected to a PC via the USB

port.

- USB port:

Mini-B USB connector “USB”

- USB status: displayed via the

LED “USB”

Rotary switch “SB ADDRESS” Key

“x 10”

“x 1”

Setting the tens

Setting the units

Example: Device address 51

0

x 10

9

SB ADDRESS

x 1

9

3

6

0

3

6

D

2.1-2

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Head modules

PSSu H SB

System configuration for

SafetyBUS p

The system is configured using Pilz

configuration software.

Usb

SB

0

x 10

9

6

SB ADDRESS

0

x 1

9

6

Dev

I/O

3

3

Usb Dev

SB I/O

312 010

USB

1

VBUS

2

D -

3

D +

4

5

G N D

Diagnostics

` The module has various LEDs to

display

- System status

- SafetyBUS p status

- I/O-Group status (SafetyBUS p)

- USB status

(see table below)

LED KeyLED statusHead module

“Usb”

“SB”

Off

Lights green

Off

Flashes green

Lights green

` SafetyBUS p error reaction:

If an error occurs, all the outputs

in the affected I/O-Group are shut

down safely and the I/O-Group

switches to a STOP condition. The

error is entered in the head

module’s error buffer.

2

No data is being exchanged via the

USB port

Data is being exchanged via the USB

port

No contact with SBp

- SBp wiring is faulty or

- MD is not in operation

There is contact with SBp, but the MD

does not recognise the SBp device

- SBp device address is faulty or

- SBp configuration is faulty

There is contact with SBp, the

connection to the MD is running

correctly

PSSu H

SB

USB

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

“Dev”

“I/O”

Off

Lights green

Lights red

Flashes red

Off

Flashes green

Lights green

A PSSu system error is preventing the

PSSu system from starting up

The PSSu system is operating without

error

A PSSu module error has occurred

A PSSu periphery error has occurred

All the I/O-Groups configured on the

SBp device are in a STOP condition

One of the I/O-Groups configured on

the SBp device is in a STOP condition

All the I/O-Groups configured on the

SBp device are in a RUN condition

Status 01/05

2.1-3

PSSuniversal

Head modules

PSSu H SB

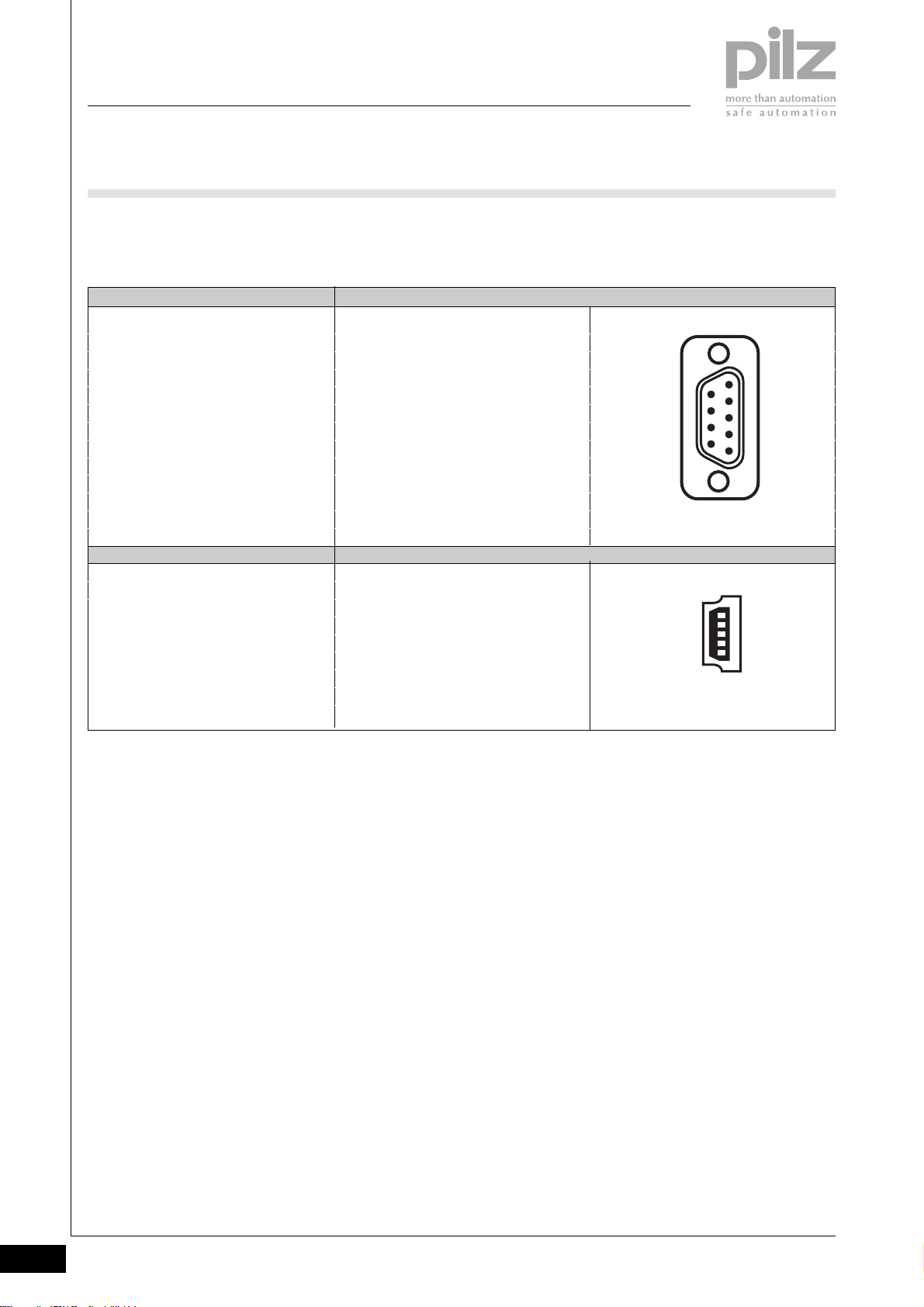

Head module

` Interface assignment

SafetyBUS p Assignment

Male 9-pin D-SUB connector

USB

Mini-B USB connector

1: n.c.

2: CAN_L (brown)

3: CAN_GND (white)

4: n.c.

5: CAN_SHLD

6: n.c.

7: CAN_H (green)

8: Supply voltage for

Pilz FO coupler

9: n.c.

n.c. = not connected

Assignment

1: VBUS +5 VDC

2: D- USB Data3: D+ USB Data+

4: n.c.

5: GND Ground

n.c. = not connected

6

9

1

5

1

5

2.1-4

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Head modules

PSSu H SB

Installation

` Horizontal installation is

preferable!

Vertical installation is possible, but

involves restrictions in terms of

temperature and vibration

resistance.

` Attach the head module to the

mounting rail as the first module

on the system and lock into

position [1].

[1]

[2]

[3]

` Install the appropriate end bracket

on the mounting rail to the left of

the head module [2].

` Always attach an appropriate

supply voltage module to the

mounting rail as the first module

to the right of the head module

and then lock into position [3].

` Secure the final module on the

mounting rail with the appropriate

fixing bracket [4].

2

[4]

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

2.1-5

PSSuniversal

Head modules

PSSu H SB

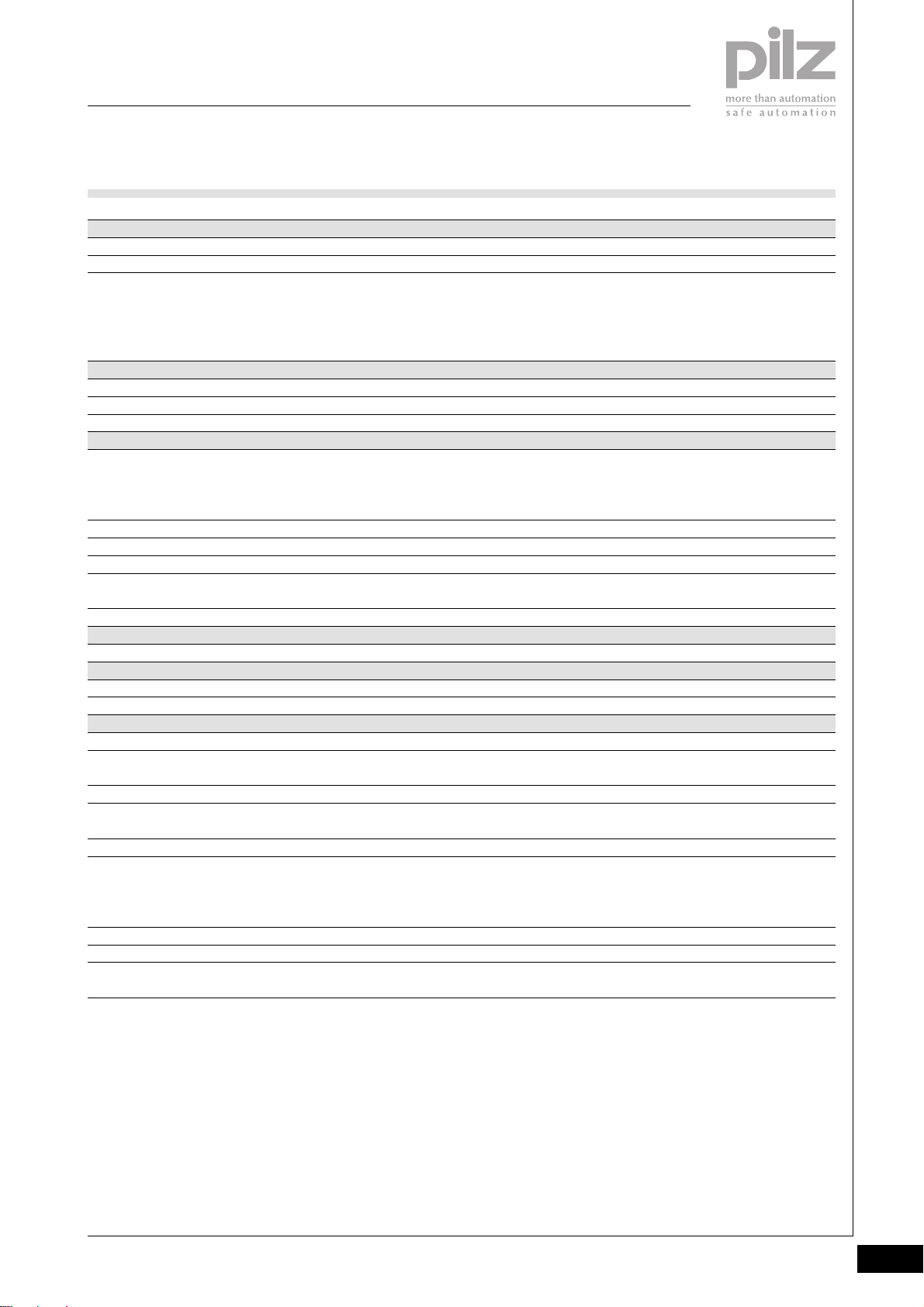

Dimensions

2,8 mm

69,2 mm56,4 mm

125,6 mm

50,2 mm

Using this data sheet

This data sheet is only intended for

use during configuration.

NOTICE

Please refer to the operating

manual during commissioning and

operation.

21,6 mm

72,6 mm

2.1-6

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

PSSuniversal

Head modules

PSSu H SB

Technical details

Function

Application range

Electrical data

Supply voltage from module supply

Current consumption from module supply

Power consumption

SafetyBUS p

Application range

Device address

Transmission rate

Cable runs

Transmission type

Connection

USB

Connection

Mechanical data

Dimensions (H x W x D)

Weight

Environmental data

Protection type (EN 60529, 02/00)

Ambient temperature

(EN 60068-2-14, 11/99)

Storage temperature (EN 60068-2-1/-2, 07/94)

Climatic suitability

(EN 60068-2-78, 10/01)

Condensation

Vibration (EN 60068-2-6, 04/95)

Shock (EN 60068-2-27, 03/93)

Continuous shock (EN 60068-2-29, 04/93)

EMC

PSSu H SB

Modular I/O system for decentralised applications

Failsafe applications conforming to

EN 954-1, 03/97,

DIN V 19 250, 05/94,

DIN VDE 0116, 09/97,

EN IEC 61508, 12/98

5 VDC

≤ 300 mA

1.5 W

Failsafe applications conforming to

EN 954-1, 03/97,

DIN V 19 250, 05/94,

DIN VDE 0116, 09/97

32D ... 95D, selectable

Max. 500 kBit/s

max. 3,500 m

Differential two-wire cable,

Fibre-optic cable via fibre-optic coupler

Male 9-pin D-SUB connector

Mini-B USB connector

128.4 x 50.2 x 72.6 mm

180 g

IP20

0 ... +60 °C

-25 ... +70 °C

93 % r.h. at 40 °C

Not permitted

Frequency range: 10 ... 57 Hz

Amplitude: 0.075 mm

Frequency range: 57 ... 150 Hz

Acceleration: 1g

15g, 11 ms

10g, 16 ms

EN 61000-6-2, 08/02

EN 61000-6-4, 08/02

2

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Status 01/05

2.1-7

Loading...

Loading...