PicoVNA™ 106

Vector Network Analyzer

User's Guide

pv106ug r1

Distribution in the UK & Ireland

Lambda Photometrics Limited

Lambda House Batford Mill

Harpenden Herts AL5 5BZ

Distribution in the UK & Ireland

Lambda Photometrics Limited

Lambda House Batford Mill

Harpenden Herts AL5 5BZ

United Kingdom

E: info@lambdaphoto.co.uk

W: www.lambdaphoto.co.uk

T: +44 (0)1582 764334

F: +44 (0)1582 712084

United Kingdom

E: info@lambdaphoto.co.uk

W: www.lambdaphoto.co.uk

T: +44 (0)1582 764334

F: +44 (0)1582 712084

I

Contents

1 Safety ................................................................................................................................... 1

1 Symbols .................................................................................................................................................. 1

2 Maximum input/output ranges .............................................................................................................. 1

3 Grounding ............................................................................................................................................... 2

4 External connections .............................................................................................................................. 3

5 Environment ............................................................................................................................................ 3

6 Care of the product ................................................................................................................................ 4

2 Quick start guide ................................................................................................................. 5

1 Installing the software ........................................................................................................................... 5

2 Loading the calibration kit(s) ................................................................................................................. 5

3 Setting up calibration parameters ......................................................................................................... 6

4 Setting up display parameters ............................................................................................................... 6

5 Calibration tips ....................................................................................................................................... 7

6 Running in demo mode .......................................................................................................................... 7

Contents

3 Description .......................................................................................................................... 8

4 Vector network analyzer basics ...................................................................................... 10

1 Introduction .......................................................................................................................................... 10

2 Structure of the VNA ............................................................................................................................ 10

3 Measurement ....................................................................................................................................... 11

4 S-parameters ........................................................................................................................................ 11

5 Displaying measurements ................................................................................................................... 14

6 Calibration and error correction .......................................................................................................... 14

7 Other measurements ........................................................................................................................... 15

1 Reflection parameters ............................................................................................................. 15

2 Transmission parameters ....................................................................................................... 15

3 Phase ........................................................................................................................................ 16

4 Group delay .............................................................................................................................. 16

5 Gain compression .................................................................................................................... 17

6 AM to PM conversion .............................................................................................................. 17

7 Time domain reflectometry (TDR) .......................................................................................... 17

5 Getting started .................................................................................................................. 22

1 Minimum requirements ....................................................................................................................... 22

2 Software installation ............................................................................................................................ 22

1 Typical error messages ........................................................................................................... 22

3 Switching on the VNA .......................................................................................................................... 23

4 Calibration kit parameters ................................................................................................................... 23

1 Insertable DUT ......................................................................................................................... 24

2 Non-insertable DUT .................................................................................................................. 24

3 Open circuit model ................................................................................................................... 24

4 Short circuit model ................................................................................................................... 24

© 2017 Pico Technologypv106ug r1

5 Short and open without models .............................................................................................. 24

6 Calibration kit editor ................................................................................................................ 24

7 Using a matched termination with poor return loss or unmodeled short and open ............ 25

6 Operation ........................................................................................................................... 27

1 The PicoVNA 2 main window .............................................................................................................. 27

1 Display setup ............................................................................................................................ 27

2 Data markers ............................................................................................................................ 29

3 Measurement enhancement ................................................................................................... 31

4 Memory facility ........................................................................................................................ 34

5 Limit lines facility ..................................................................................................................... 35

6 Status panel ............................................................................................................................. 36

7 Triggered sweep ...................................................................................................................... 37

8 Sweep trigger output ............................................................................................................... 37

9 Measurement start / stop ....................................................................................................... 37

10 PC data link interruption ........................................................................................................ 37

2 Calibration ............................................................................................................................................ 38

1 Changing the frequency sweep settings without recalibrating ............................................. 40

2 Calibration steps for S11 measurements ............................................................................... 41

3 Calibration steps for S21 measurements ............................................................................... 41

4 Calibration steps for S11 and S21 measurements ................................................................ 41

5 Calibration steps for all S-parameters measurements (insertable DUT) ............................. 42

6 Calibration steps for all S-parameters measurements (non-insertable DUT) ...................... 42

7 Calibration for best dynamic range – minimizing the effect of crosstalk ............................ 43

3 Measurements ..................................................................................................................................... 44

1 Return loss ............................................................................................................................... 44

2 Insertion loss / gain ................................................................................................................. 45

3 Complete 2-port measurement ............................................................................................... 45

4 Group delay .............................................................................................................................. 46

5 Time domain measurements .................................................................................................. 46

6 Reverse measurements on two port devices ......................................................................... 50

7 Powering active devices using the built-in bias-Ts ................................................................ 51

4 Reference plane extension and de-embedding .................................................................................. 51

5 Saving data ........................................................................................................................................... 54

6 Loading data ......................................................................................................................................... 54

7 Plotting graphics .................................................................................................................................. 55

8 Saving graphics .................................................................................................................................... 55

9 Signal generator utility ......................................................................................................................... 56

10 Output power at the 1 dB gain compression point utility ................................................................ 56

11 AM to PM conversion utility .............................................................................................................. 58

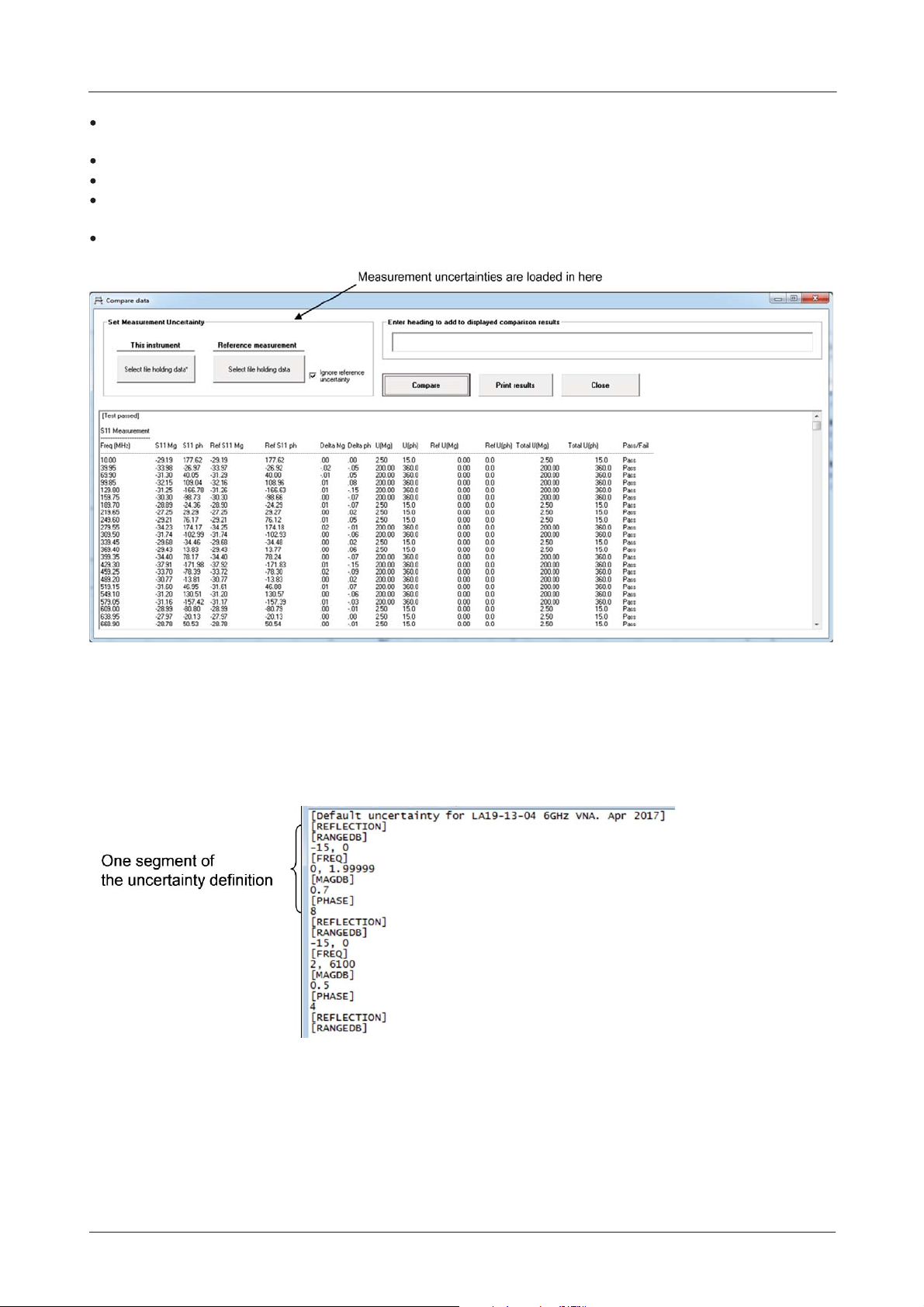

12 Compare data utility ........................................................................................................................... 59

13 Closing down the software ................................................................................................................ 61

IIPicoVNA 106 6 GHz Vector Network Analyzer

7 Performance verification and maintenance ................................................................... 62

1 Measurement uncertainty .................................................................................................................... 62

© 2017 Pico Technology pv106ug r1

III

2 Routine maintenance ........................................................................................................................... 63

Contents

8 Performance specification .............................................................................................. 64

9 Troubleshooting guide ..................................................................................................... 68

10 Warranty .......................................................................................................................... 70

Index ..................................................................................................................................... 71

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 1

1 Safety

To prevent possible electrical shock, fire, personal injury, or damage to the product, carefully read this safety

information before attempting to install or use the product. In addition, follow all generally accepted safety

practices and procedures for working with and near electricity.

This instrument has been designed to meet the requirements of EN61010-1 (Safety Requirements for

Electrical Equipment for Measurement, Control and Laboratory Use) and is intended only for indoor use in a

Pollution Degree 1 environment (no pollution, or only dry non-conductive pollution) in the temperature range

15 °C to 35 °C, 20 % to 80 % relative humidity (non-condensing).

The following safety descriptions are found throughout this guide:

A WARNING identifies conditions or practices that could result in injury or death.

A CAUTION identifies conditions or practices that could result in damage to the product or equipment to

which it is connected.

WARNING

To prevent injury or death use the product only as instructed and use only the power supply

provided. Protection provided by the product may be impaired if used in a manner not specified

by the manufacturer.

1.1 Symbols

These safety and electrical symbols may appear on the product or in this guide.

Symbol Description

Earth (ground) terminal

This terminal can be used to make a measurement ground

connection. It is not a safety or protective earth.

Chassis terminal

Possibility of electric shock

CAUTION

Appearance on the product indicates a need to read these

safety instructions.

Do not dispose of this product as unsorted municipal waste.

1.2 Maximum input/output ranges

WARNING

To prevent electric shock, do not attempt to measure or apply signal levels outside the

specified maxima below.

© 2017 Pico Technology pv106ug r1

Safety2

The table below indicates the maximum voltage of the outputs and the overvoltage protection range for

each input on the VNA. The overvoltage protection ranges are the maximum voltages that can be applied

without damaging the instrument.

Connector Maximum operating voltage

(output or input)

Ports 1 and 2 +10 dBm (about 710 mV RMS) +20 dBm (about 2.2 V RMS)

Bias tees 1 and 2 ±15 V DC 250 mA

Trigger and reference in ±6 V pk

Trigger and reference out 0 V to +5 V Do not apply a voltage

WARNING

Signals exceeding the voltage limits in the table below are defined as "hazardous live" by EN

61010.

Signal voltage limits of EN61010

± 70 V DC 33 V AC RMS ± 46.7 V pk max.

WARNING

To avoid equipment damage and possible injury, do not operate the instrument outside its rated

supply voltages or environmental range.

CAUTION

Exceeding the overvoltage protection range on any connector can cause permanent damage to

the instrument and other connected equipment.

Overvoltage or overcurrent

protection

CAUTION

To prevent permanent damage, do not apply an input voltage to the trigger or reference output

of the VNA.

1.3 Grounding

WARNING

The instrument's ground connection through the USB cable is for functional purposes only. The

instrument does not have a protective safety ground.

WARNING

To prevent injury or death, never connect the ground of an input or output (chassis) to any

electrical power source. To prevent personal injury or death, use a voltmeter to check that there

is no significant AC or DC voltage between the instrument's ground and the point to which you

intend to connect it.

CAUTION

Applying a voltage to the ground input is likely to cause permanent damage to the instrument,

the attached computer, and other equipment.

CAUTION

To prevent measurement degradation caused by poor grounding, always use the high-quality

USB cable supplied with the instrument.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 3

1.4 External connections

WARNING

To prevent injury or death, only use the adaptor supplied with the product. This is approved for

the voltage and plug configuration in your country.

Power supply options and ratings

Ext DC power supply

Model name USB connection

Voltage Current Total power

USB 2.0.

PicoVNA 106

WARNING

Containment of radio frequencies

The instrument contains a swept or CW radio frequency signal source (300 kHz to 6.02 GHz at

+6 dBm max.) The instrument and supplied accessories are designed to contain and not radiate

(or be susceptible to) radio frequencies that could interfere with the operation of other

equipment or radio control and communications. To prevent injury or death, connect only to

appropriately specified connectors, cables, accessories and test devices, and do not connect to

an antenna except within approved test facilities or under otherwise controlled conditions.

Compatible with

USB3.0.

12 to 15 V DC 1.85 A pk 22 W

1.5 Environment

WARNING

To prevent injury or death, do not use the VNA in wet or damp conditions, or near explosive gas

or vapor.

CAUTION

To prevent damage, always use and store your VNA in appropriate environments.

Storage Operating

Temperature –20 °C to +50 °C +15 °C to +35 °C

Humidity Up to 80% RH (non-condensing) Up to 80% RH (non-condensing)

Altitude 2000 m

Pollution degree 2

CAUTION

Do not block the air vents at the back or underside of the instrument as overheating will

damage.

Do not insert any objects through the air vents as internal interference will cause damage.

© 2017 Pico Technology pv106ug r1

Safety4

1.6 Care of the product

The product and accessories contain no user-serviceable parts. Repair, servicing and calibration require

specialized test equipment and must only be performed by Pico Technology or an approved service provider.

There may be a charge for these services unless covered by the Pico warranty.

WARNING

To prevent injury or death, do not use the product if it appears to be damaged in any way, and

stop use immediately if you are concerned by any abnormal behavior.

CAUTION

To prevent damage to the device or connected equipment, do not tamper with or disassemble

the instrument, case parts, connectors, or accessories.

When cleaning the product, use a soft cloth dampened with a solution of mild soap or detergent

in water. Do not allow liquids to enter the instrument's casing.

WARNING

To avoid equipment damage, do not block the ventilation ports on the instrument.

CAUTION

Take care to avoid mechanical stress or tight bend radii for all connected leads, including all

coaxial leads and connectors. Mishandling will cause deformation of sidewalls, and will

degrade performance. In particular, note that test port leads should not be formed to tighter

than 5 cm (2") bend radius.

To prevent measurement errors and extend the useful life of test leads and accessory

connectors, ensure that liquid and particulate contaminants cannot enter. Always fit the dust

caps provided and use the correct torque when tightening. Pico recommends: 1 Nm (8.85 inch

lb) for supplied and all stainless steel connectors, or 0.452 Nm (4.0 inch-lb) when a brass or

gold-plated connector is interfaced.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 5

2 Quick start guide

2.1 Installing the software

Obtain the PicoVNA 2 software installer from the disk supplied or from www.picotech.com/downloads.

Run the installer (right-click and Run as administrator) and ensure that the installation was successful.

Connect the PicoVNA 106 unit to the computer and wait while Windows automatically installs the driver.

In case of difficulties, refer to Software installation

for more details.

2.2 Loading the calibration kit(s)

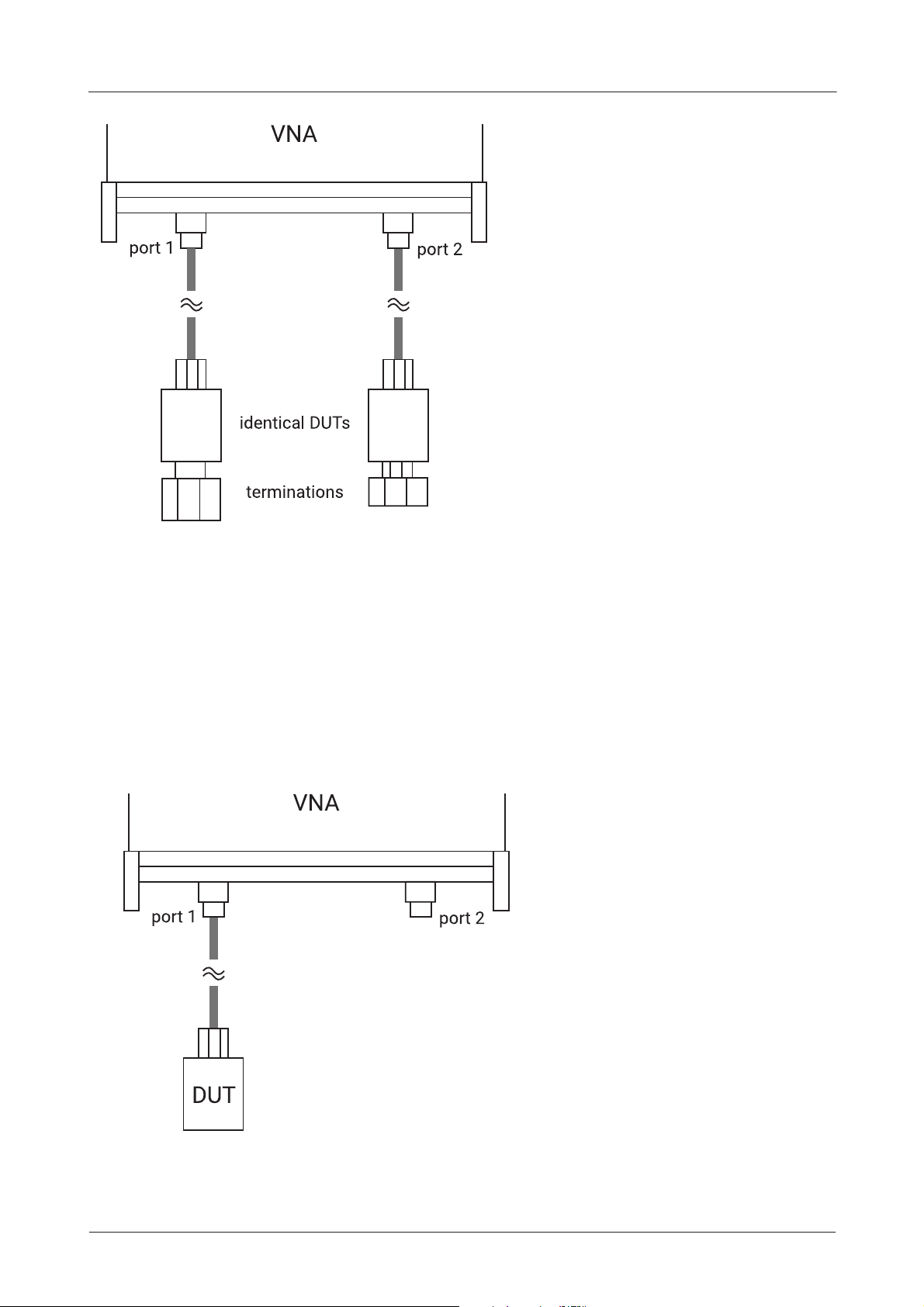

If the device to be tested is ‘insertable’ (one female and one male connector), two kits are required.

Otherwise a single kit is required. See diagrams below:

Run the PicoVNA 2 software

In the main menu, select Tools > Calibration kit

Click Load P1 kit, select the data for your Port 1 kit and then click Apply

Click Load P2 kit, select the data for your Port 2 kit and then click Apply

Select the calibration kit(s) required depending on the device to be tested.

Note: if testing a non-insertable DUT with, for example, female connectors, use a single female kit for ports 1

and 2.

© 2017 Pico Technology pv106ug r1

2.3 Setting up calibration parameters

Click Calibration to open the Calibration window:

Quick start guide6

2.4 Setting up display parameters

Click Display in the main window to open the Display Set Up window:

When finished, click Start in the main window to begin measurements

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 7

2.5 Calibration tips

The bandwidth setting used during calibration largely determines the available dynamic range during the

measurement. The table below shows suggested bandwidth and power settings to use during calibration for

different types of measurement.

Measurement Calibration

bandwidth

Fastest speed 10 kHz None +0 dBm Set bandwidth to 140 kHz during measurement

Best accuracy and

~100dB dynamic range

General use, fast speed,

~90dB dynamic range

Best dynamic range 10 Hz None +6 dBm Leave bandwidth unchanged during measurement.

100 Hz None –3 dBm Set bandwidth to 100 Hz during measurement

1 kHz None +0 dBm Set bandwidth to 1 kHz during measurement

Calibration

averaging

Calibration

power

Comments

Refer to “Calibration for best dynamic range –

minimizing the effect of crosstalk”.

2.6 Running in demo mode

Demo mode allows you to explore the user interface software without the need to have an instrument

running.

To enter demo mode, run the PicoVNA 2 software with no instrument connected.

Click Go to demo in the dialog that appears.

PicoVNA 2 will then offer you a selection of demonstration measurements.

© 2017 Pico Technology pv106ug r1

Description8

3 Description

The PicoVNA 106 is a PC-driven vector network analyzer capable of operation over the range of 300 kHz to 6

GHz. It can perform direct measurements of forward and reverse parameters with up to 118 dB of dynamic

range. The test frequency can be set with a resolution of 10 Hz or less. A simplified block diagram of the

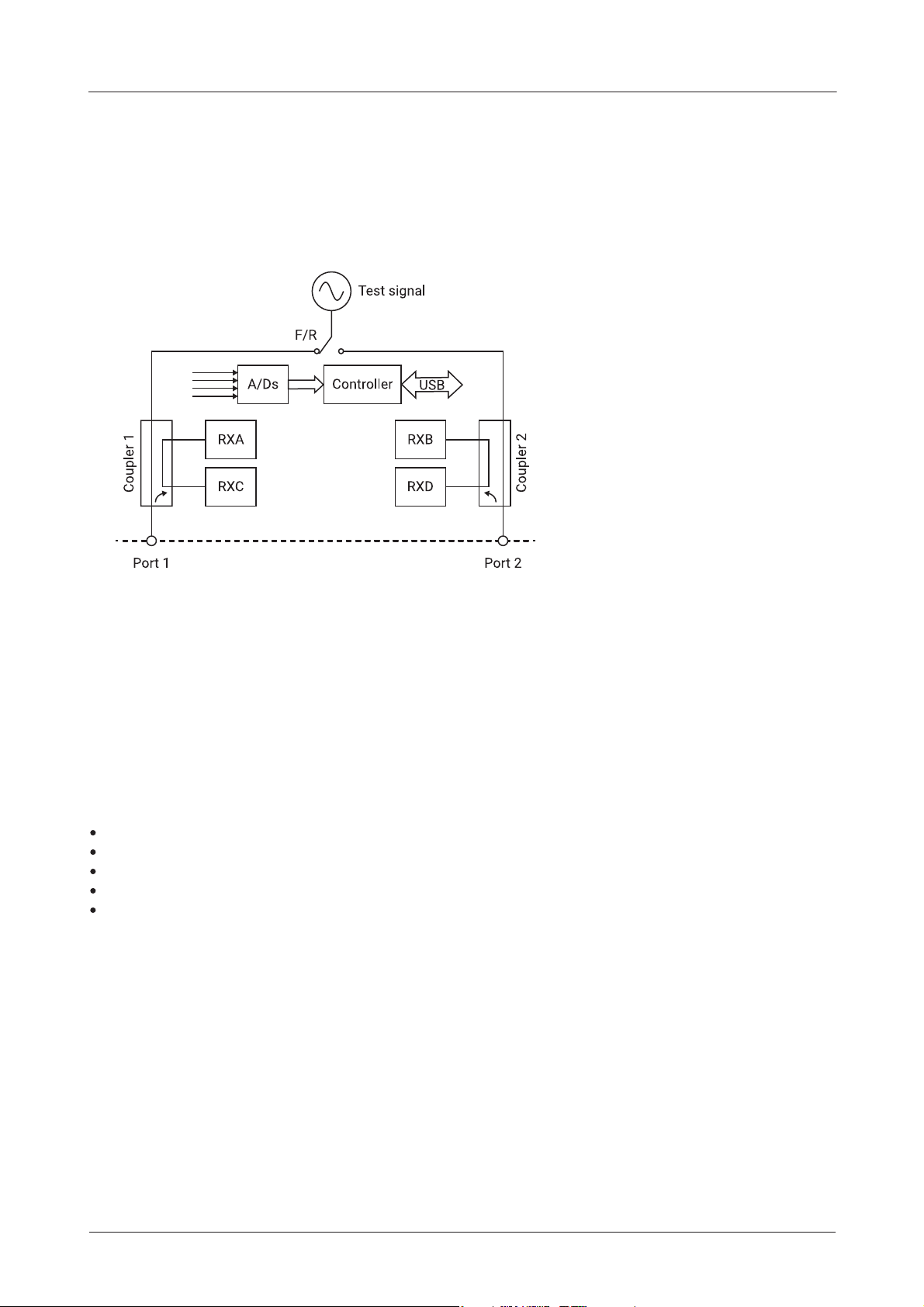

instrument is shown below:

Simplified block diagram of the PicoVNA 106

The architecture is based on a four-receiver ("Quad RX") arrangement using a bandwidth of up to 140 kHz.

Couplers 1 and 2 are wideband RF bridge components which provide the necessary directivity in both

directions. Signal detection is by means of analog-to-digital converters used to sample the IF signal. The

sample data is processed by the embedded controller to yield the I and Q components. The detection

system operates with an IF of 1.3 MHz and employs a patented circuit technique to yield fast speeds with

very low trace noise.

The instrument's software runs on a personal computer and communication with the instrument is through

the USB interface. The software carries out the mathematical processing and allows the display of

measured parameters in many forms, including:

frequency domain

time domain

de-embedding utility

measuring output power at the 1 dB gain compression point

measuring AM to PM conversion

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 9

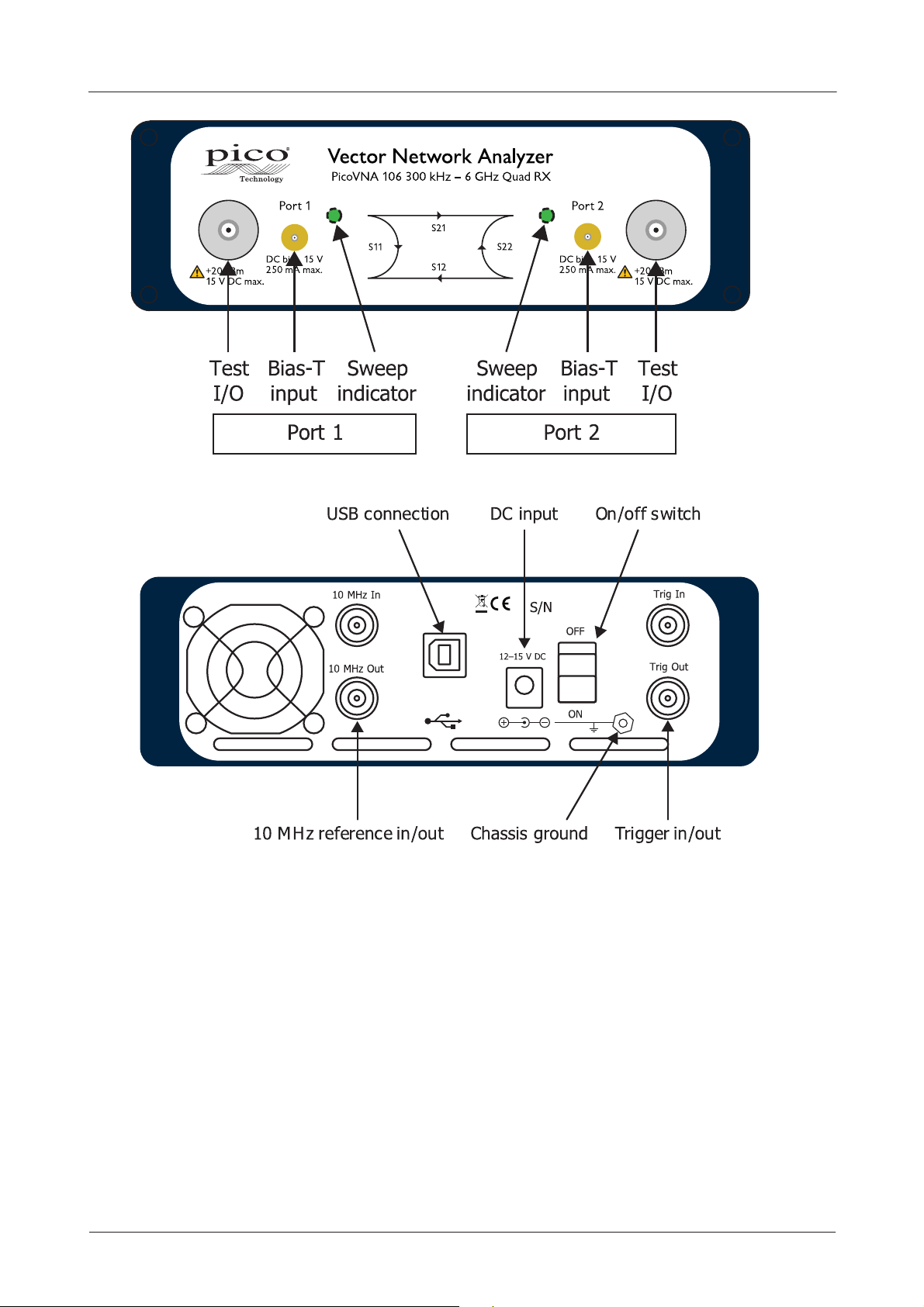

Front panel of the PicoVNA 106

Back panel of the PicoVNA 106

© 2017 Pico Technology pv106ug r1

Vector network analyzer basics10

4 Vector network analyzer basics

4.1 Introduction

A vector network analyzer is used to measure the performance of circuits or networks such as amplifiers,

filters, attenuators, cables and antennas. It does this by applying a test signal to the network to be tested,

measuring the reflected and transmitted signals and comparing them to the test signal. The vector network

analyzer measures both the magnitude and phase of these signals.

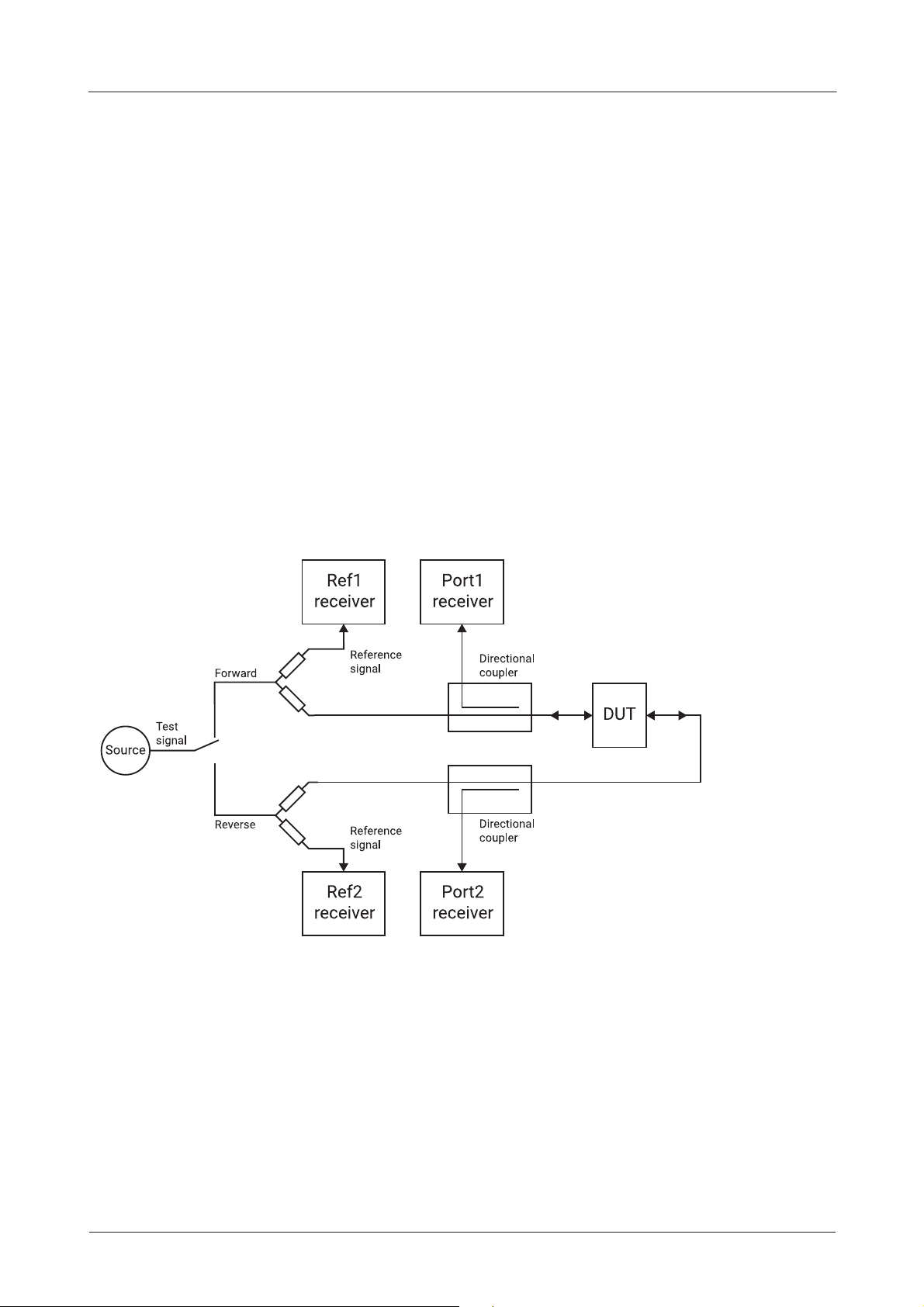

4.2 Structure of the VNA

The VNA consists of a tunable RF source, the output of which is split into two paths. The signal feeds to the

couplers are each measured by their respective reference receivers through power dividers. In the forward

mode, the test signal is passed through a directional coupler or directional bridge before being applied to the

DUT. The directional output of the coupler, which selects only signals reflected from the input of the DUT, is

connected to the Port1 receiver where the signal’s magnitude and phase are measured. The rest of the

signal, the portion that is not reflected from the input, passes through the DUT to the Port2 receiver where its

magnitude and phase are measured. The measurements at the Port1 and Port2 receivers are referenced to

the measurements made by the Ref1 and Ref2 receivers so that any variations due to the source are

removed. The Ref1 and Ref2 receivers also provide a reference for the measurement of phase.

Simplified vector network analyzer block diagram

In reverse mode, the test signal is applied to the output of the DUT, and the Port2 receiver is used to

measure the reflection from the output port of the DUT while the Port1 receiver measures the reverse

transmission through the DUT.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 11

4.3 Measurement

Vector network analyzers have the capability to measure phase as well as magnitude. This is important for

fully characterizing a device or network either for verifying performance or for generating models for design

and simulation. Knowledge of the phase of the reflection coefficient is particularly important for matching

systems for maximum power transfer. For complex impedances the maximum power is transferred when

the load impedance is the complex conjugate of the source impedance (see figure).

Matching a load for maximum power transfer

Measurement of phase in resonators and other components is important in designing oscillators. In

feedback oscillators, oscillation occurs when the phase shift round the loop is a multiple of 360° and the

gain is unity. It is important that these loop conditions are met as close as possible to the center frequency

of the resonant element to ensure stable oscillation and good phase noise performance.

The ability to measure phase is also important for determining phase distortion in a network. Phase

distortion can be important in both analog and digital systems. In digital transmission systems, where the

constellation depends on both amplitude and phase, any distortion of phase can have serious effects on the

errors detected.

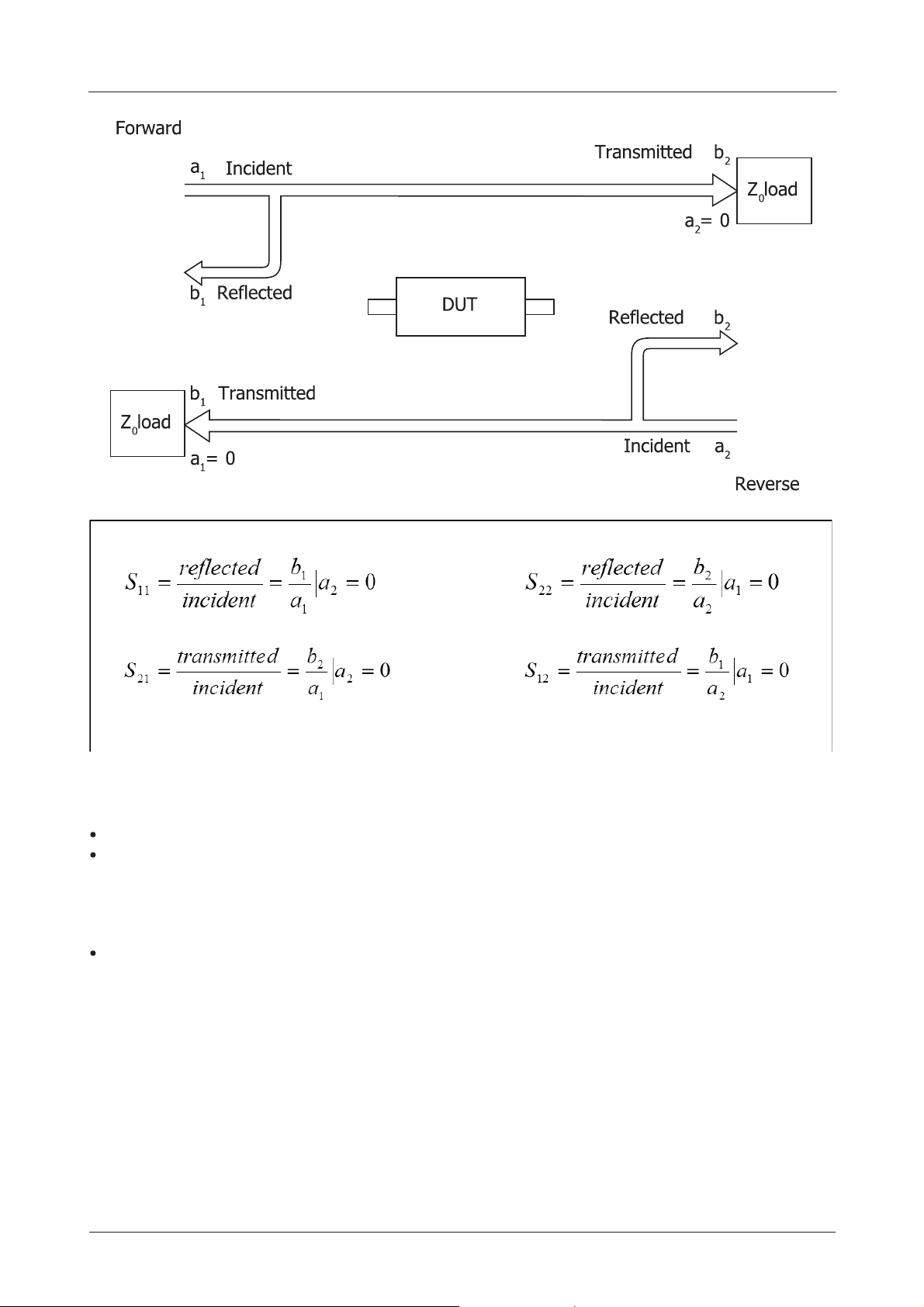

4.4 S-parameters

The basic measurements made by the vector network analyzer are S (scattering) parameters. Other

parameters such as H, Y and Z parameters may all be deduced from the S-parameters if required. The

reason for measuring S-parameters is that they are made under conditions that are easy to produce at RF.

Other parameters require the measurement of currents and voltages, which is difficult at high frequencies.

They may also require open circuits or short circuits that can be difficult to achieve at high frequencies, and

may also be damaging to the device under test or may cause oscillation.

Forward S-parameters are determined by measuring the magnitude and phase of the incident, reflected and

transmitted signals with the output terminated with a load that is equal to the characteristic impedance of

the test system (see figure below).

© 2017 Pico Technology pv106ug r1

Vector network analyzer basics12

S-parameters definition

The measured parameters are presented in a file similar to the one below. The format is as follows:

Header lines: these start with a ! symbol and give general information such as time and date.

Format line: this starts with a # symbol and gives information about the format of the data.

o First field gives the frequency units, in this case MHz

o Second field indicates the parameters measured, in this case S-parameters

o Third field indicates the format of the measurement, in this case MA meaning magnitude and angle.

Others formats are RI, meaning real and imaginary, and DB, meaning log magnitude and angle.

Data lines. The number of columns of data depends on the parameters that have been measured.

o A 1-port measurement measures the reflected signal from the device under test and usually produces

three columns. If the format is MA (magnitude and angle), the first column is the measurement

frequency, the second is the magnitude of S

second column is the real part of S

and the third column is the imaginary part of S11.

11

and the third is the angle of S11. If the format is RI, the

11

o When a reflection and transmission measurement is made there are five columns of data. Column 1

is the measurement frequency, columns 2 and 3 contain S

imaginary data, and columns 4 and 5 contain S

magnitude and angle or real and imaginary data.

21

magnitude and angle or real and

11

o If a full 2-port measurement is made, there will be nine columns of data. Column 1 contains frequency

information, columns 2 and 3 S

data, 4 and 5 S21 data, 6 and 7 S12 data, and 8 and 9 S22 data.

11

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 13

The PicoVNA 106 can generate full set of 2-port parameters but you can choose to export either 1-port .s1p

or full 2-port .s2p S-parameter files to suit most RF and microwave circuit simulators.

Part of a typical 2-port S-parameter file is shown below. The header shows that the frequency units are MHz,

the data format is Magnitude and Angle and the system impedance is 50 Ω. Column 1 shows frequency, 2

and 3 S

! 06/09/2005 15:47:34

! Ref Plane: 0.000 mm

# MHZ S MA R 50

!

3 0.00776 16.96 0.99337 -3.56 0.99324 -3.53 0.00768 12.97

17.985 0.01447 19.99 0.9892 -20.80 0.98985 -20.72 0.01519 15.23

32.97 0.01595 20.45 0.98614 -37.96 0.98657 -37.95 0.01704 6.40

47.955 0.01955 28.95 0.98309 -55.15 0.98337 -55.10 0.018 1.75

62.94 0.02775 24.98 0.98058 -72.29 0.98096 -72.29 0.0199 -6.07

77.925 0.03666 11.76 0.97874 -89.46 0.9803 -89.45 0.02169 -23.06

92.91 0.04159 -6.32 0.97748 -106.62 0.9786 -106.62 0.01981 -48.43

107.895 0.0426 -24.79 0.97492 -123.77 0.97579 -123.89 0.01424 -87.79

122.88 0.0396 -41.35 0.97265 -141.25 0.97269 -141.30 0.00997 -166.81

137.865 0.03451 -52.96 0.96988 -158.65 0.96994 -158.76 0.01877 113.15

152.85 0.03134 -56.07 0.96825 -176.27 0.96858 -176.28 0.03353 69.81

167.835 0.03451 -57.72 0.96686 166.10 0.96612 165.99 0.04901 34.83

182.82 0.04435 -67.59 0.9639 148.18 0.96361 148.21 0.06131 1.42

197.805 0.05636 -86.28 0.96186 130.15 0.96153 130.06 0.07102 -33.33

212.79 0.06878 -110.45 0.95978 111.82 0.95996 111.90 0.07736 -69.57

227.775 0.08035 -136.14 0.9557 93.50 0.9568 93.41 0.08303 -107.21

242.76 0.09099 -161.24 0.95229 74.84 0.95274 74.89 0.08943 -144.34

257.745 0.10183 175.34 0.94707 56.03 0.94755 55.95 0.09906 -179.63

, 4 and 5 S21, 6 and 7 S12, and 8 and 9 S22.

11

© 2017 Pico Technology pv106ug r1

Vector network analyzer basics14

4.5 Displaying measurements

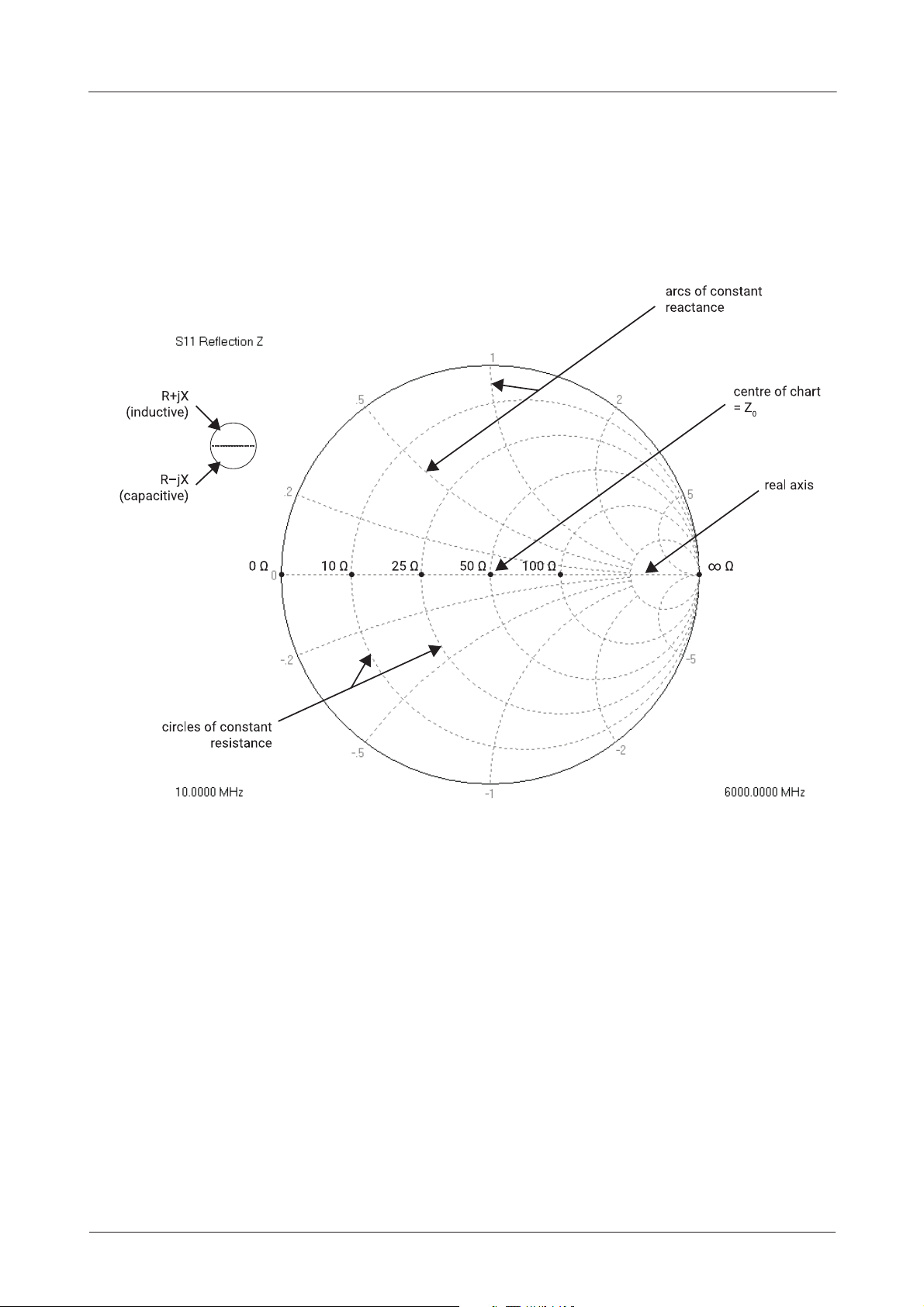

Input and output parameters, S11 and S22, are often displayed on a polar plot or a Smith chart. The polar plot

shows the result in terms of the complex reflection coefficient, but impedance cannot be directly read off

the chart. The Smith chart maps the complex impedance plane onto a polar plot. All values of reactance and

all positive values of resistance, from 0 to ∞, fall within the outer circle. This has the advantage that

impedance values can be read directly from the chart.

The Smith chart

4.6 Calibration and error correction

Before accurate measurements can be made, the network analyzer needs to be calibrated. In the calibration

process, well-defined standards are measured and the results of these measurements are used to correct

for imperfections in the hardware. The most common calibration method, SOLT (short, open, load, through),

uses four known standards: a short circuit, an open circuit, a load matched to the system impedance, and a

through line. These standards are usually contained in a calibration kit and their characteristics are stored

on the controlling PC in a Cal Kit definition file. Analyzers such as the PicoVNA 106 that have a full Sparameter test set can measure and correct all 12 systematic error terms.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 15

(

Six key sources of errors in forward measurement.

Another six sources exist in the reverse measurement

not shown).

4.7 Other measurements

S-parameters are the fundamental measurement performed by the network analyzer, but many other

parameters may be derived from these including H, Y and Z parameters.

4.7.1 Reflection parameters

The input reflection coefficient Γ can be obtained directly from S11:

ρ is the magnitude of the reflection coefficient i.e. the magnitude of S

ρ = |S11|

Sometimes ρ is expressed in logarithmic terms as return loss:

return loss = –20 log(ρ)

VSWR can also be derived:

VSWR definition

11:

4.7.2 Transmission parameters

Transmission coefficient T is defined as the transmitted voltage divided by the incident voltage. This is the

same as S

© 2017 Pico Technology pv106ug r1

.

21

Vector network analyzer basics16

If T is less than 1, there is loss in the DUT, which is usually referred to as insertion loss and expressed in

decibels. A negative sign is included in the equation so that the insertion loss is quoted as a positive value:

If T is greater than 1, the DUT has gain, which is also normally expressed in decibels:

4.7.3 Phase

The phase behavior of networks can be very important, especially in digital transmission systems. The raw

phase measurement is not always easy to interpret as it has a linear phase increment superimposed on it

due to the electrical length of the DUT. Using the reference plane function the electrical length of the DUT

can be removed leaving the residual phase characteristics of the device.

Operation on phase data to yield underlying characteristics

4.7.4 Group delay

Another useful measurement of phase is group delay. Group delay is a measure of the time it takes a signal

to pass through a network versus frequency. It is calculated by differentiating the phase response of the

device with respect to frequency, i.e. the rate of change of phase with frequency:

The linear portion of phase is converted to a constant value typically, though not always, representing the

average time for a signal to transit the device. Differences from the constant value represent deviations from

linear phase. Variations in group delay will cause phase distortion as a signal passes through the circuit.

When measuring group delay the aperture must be specified. Aperture is the frequency step size used in the

differentiation. A small aperture will give more resolution but the displayed trace will be noisy. A larger

aperture effectively averages the noise but reduces the resolution.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 17

4.7.5 Gain compression

The 1 dB gain compression point of amplifiers and other active devices can be measured using the power

sweep. The small signal gain of the amplifier is determined at low input power, then the power is increased

and the point at which the gain has fallen by 1 dB is noted.

The 1 dB gain compression is often used to quote output power capability

4.7.6 AM to PM conversion

Another parameter that can be measured with the VNA is AM to PM conversion. This is a form of signal

distortion where fluctuations in the amplitude of a signal produce corresponding fluctuations in the phase of

the signal. This type of distortion can have serious effects in digital modulation schemes where both

amplitude and phase accuracy are important. Errors in either phase or amplitude cause errors in the

constellation diagram.

4.7.7 Time domain reflectometry (TDR)

Time domain reflectometry is a useful technique for measuring the impedance of transmission lines and for

determining the position of any discontinuities due to connectors or damage. The network analyzer can

determine the time domain response to a step input from a broad band frequency sweep at harmonically

related frequencies. An inverse Fourier Transform is performed on the reflected frequency data (S

the impulse response in the time domain. The impulse response is then integrated to give the step

response. Reflected components of the step excitation show the type of discontinuity and the distance from

the calibration plane.

A similar technique is used to derive a TDT (Time Domain Transmission) signal from the transmitted signal

data (S

provides a more detailed treatment of TDR and TDT.

). This can be used to measure the rise time of amplifiers, filters and other networks. The following

21

) to give

11

© 2017 Pico Technology pv106ug r1

Vector network analyzer basics18

4.7.7.1 Traditional TDR

The traditional TDR consists of a step source and sampling oscilloscope (see figure below). A step signal is

generated and applied to a load. Depending on the value of the load, some of the signal may be reflected

back to the source. The signals are measured in the time domain by the sampling scope. By measuring the

ratio of the input voltage to the reflected voltage, the impedance of the load can be determined. Also, by

observing the position in time when the reflections arrive, it is possible to determine the distance to

impedance discontinuities.

Traditional TDR setup

4.7.7.1.1 Example: shorted 50 ohm transmission line

Simplified representation of the response of a shorted line.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 19

For a transmission line with a short circuit (figure above) the incident signal sees the characteristic

impedance of the line so the scope measures Ei. The incident signal travels along the line to the short circuit

where it is reflected back 180° out of phase. This reflected wave travels back along the line canceling out the

incident wave until it is terminated by the impedance of the source. When the reflected signal reaches the

scope the signal measured by the scope goes to zero as the incident wave has been canceled by the

reflection. The result measured by the scope is a pulse of magnitude Ei and duration that corresponds to the

time it takes the signal to pass down the line to the short and back again. If the velocity of the signal is

known, the length of the line can be calculated:

where v is the velocity of the signal in the transmission line, t is the measured pulse width and d is the length

of the transmission line.

4.7.7.1.2 Example: open-circuited 50 ohm transmission line

Simplified representation of the response of a open line

In the case of the open circuit transmission line (figure above) the reflected signal is in phase with the

incident signal, so the reflected signal combines with the incident signal to produce an output at the scope

that is twice the incident signal. Again, the distance d can be calculated if the velocity of the signal is known.

4.7.7.1.3 Example: resistively terminated 50 ohm transmission line

Simplified representation of the response of a resistively terminated line

© 2017 Pico Technology pv106ug r1

Vector network analyzer basics20

4.7.7.1.4 Reactive terminations and discontinuities

Reactive elements can also be determined by their response. Inductive terminations produce a positive

pulse. Capacitive terminations produce a negative pulse.

Simplified representation of the response of a reactively terminated line

Similarly, the position and type of discontinuity in a cable, due to connectors or damage, can be determined.

A positive pulse indicates a connector that is inductive or damage to a cable, such as a removal of part of

the outer screen. A negative-going pulse indicates a connector with too much capacitance or damage to the

cable, such as being crushed.

Simplified representation of the response of a line discontinuity

4.7.7.2 Time domain from frequency domain

An alternative to traditional TDR is where the time domain response is determined from the frequency

domain using an Inverse Fast Fourier Transform (IFFT). Several methods are available for extracting time

domain information from the frequency domain. The main methods are lowpass and bandpass.

4.7.7.2.1 Lowpass method

The lowpass method can produce results that are similar to the traditional TDR measurements made with a

time domain reflectometer using a step signal, and can also compute the response to an impulse. It

provides both magnitude and phase information and gives the best time resolution. However, it requires that

the circuit is DC-coupled. This is the method supported by the PicoVNA 106.

The lowpass method uses an Inverse Fourier Transform to determine the impulse response in the time

domain from the reflection coefficient measured in the frequency domain. The DC component is

extrapolated from the low-frequency data to provide a phase reference. Alternatively, if the DC termination is

known it can be entered manually. Once the impulse response is computed, the step response may be

determined from the time integral of the impulse response. In the step response mode the trace is similar to

that of a TDR, except that there is no step at t = 0. When the time domain response is derived from the

frequency information the value at t = 0 is the impedance of the transmission line or load immediately

following the calibration plane. The value is referenced to 50 Ω, the characteristic impedance of the system.

For example, an open circuit would appear as a value of +1 unit relative to the reference value and a short

circuit would appear as a value of –1 unit relative to the reference value (see example TDR plots above).

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 21

To facilitate the use of the Inverse Fourier Transform to compute the time domain response, the samples in

the frequency domain must be harmonically related and consist of 2

in the PicoVNA 106 makes available special 512, 1024, 2048 and 4096-frequency-point calibrations with a

stop frequency of up to 6000 MHz. The resulting alias-free range is a function of the number of frequency

points (N) and the total frequency span. It is given by the expression:

So, the available ranges on the PicoVNA 106 are approximately 100 ns, 171 ns, 341 ns and 683 ns.

The transform returns twice the number of points of the calibration in the time domain. Therefore the above

ranges provide time resolutions of approximately 98ps to 84ps.

n

points. For this reason, the TDR facility

4.7.7.2.2 Bandpass method

The bandpass method provides only magnitude information so it is not possible to distinguish between

inductive and capacitive reactances. Also, the time resolution is only half as good as in the lowpass mode.

However, the method can be used for circuits where there is no DC path and hence is suitable for ACcoupled circuits such as bandpass filters. This method is not currently supported by the PicoVNA 106.

4.7.7.3 Windowing

The bandwidth of the network analyzer is limited by the frequency range, so the frequency domain data will

be truncated at the bandwidth of the analyzer. Also the analyzer gathers data at discrete frequencies. The

result of the sampled nature of the data and the truncation in the frequency domain is to produce a sin(x)/x

response when transformed to the time domain. This appears as ringing on both the displayed impulse

response and the step response. To overcome this problem, a technique known as windowing can be

applied to the frequency domain data before implementing the Inverse Fourier Transform.

The windowing function progressively reduces the data values to zero as the edge of the frequency band is

approached, thus minimizing the effect of the discontinuities. When the modified data is transformed, the

ringing is reduced or removed depending on the selected windowing function. However, the windowing

function reduces the bandwidth and so increases the width of the pulse in impulse response mode and

slows the edge in step response mode. A balance must be made between the width of the pulse, or speed of

the edge, and the amount of ringing to be able to determine closely spaced discontinuities. The PicoVNA

106 allows you to choose a rectangular window (no bandwidth reduction), a Hanning window (raised

cosine), or a Kaiser–Bessel window. The order of the Kaiser–Bessel window is configurable.

4.7.7.4 Aliasing

The sampled nature of the data means it is subject to the effects of aliasing. The result is repetition of timedomain response at the effective sampling rate in the frequency domain. This limits the maximum time

delay and hence maximum cable length that can be observed. In the PicoVNA 106 this is 683ns

(approximately 138m of cable).

© 2017 Pico Technology pv106ug r1

Getting started22

5 Getting started

Refer to the Quick Start Guide above for initial instructions, then return here for more detail.

5.1 Minimum requirements

The recommended minimum requirements to operate the VNA are as follows.

PC or laptop

Pentium 4 (2 GHz) or equivalent

2 GB of RAM

200 MB of hard disk storage available on the C: partition

Windows 7, 8 or 10

Minimum display resolution of 1280 x 720

USB port

The performance of the software is influenced by the performance of the PC and video adaptor installed in

it. It is important that an adaptor with good graphics performance is used. As a general guide, it is

recommended that an adaptor with at least 64 MB of memory is used.

5.2 Software installation

Follow the Quick Start Guide to install the software from the disk or from www.picotech.com. The installer

will copy the program and the USB driver to your computer. You need administrative privileges in order to run

the installer.

The installer creates a support directory at C:\User\Public\Documents\PicoVNA2. This directory contains

the following files:

xxx-log.txt The status log file. ‘xxx’ is the serial number

DefCal.cal Default calibration data (last used calibration)

UsersGuide.pdf This User's Guide

Support\ Folder with data files to support the software

5.2.1 Typical error messages

On Windows 7 machines it is common to see the following error message:

It is safe to click Ignore to continue the installation.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 23

5.3 Switching on the VNA

When the VNA is powered on, the front-panel channel activity indicators will flash to indicate that the

controller has started correctly.

5.4 Calibration kit parameters

The minimum requirements to carry out a 12-term calibration (full error correction) depend on the device to

be tested. For example, the most accurate calibration is for ‘insertable’ devices, and this requires a total of

six standards: three of the four in each of the male and female cal standards.

An ‘insertable’ device is one that has connectors of different sexes at its ports. On the other hand, a

calibration for a non-insertable device can be carried out using only three standards by using the “unknown

through” calibration method.

The calibration kits parameters can be inspected using the Calibration Kit Parameters window (see below)

found under the Tools menu. From this the kit editor can be launched to modify and create new kits as

discussed later in the section.

The ‘unknown thru’ calibration method only requires that the ‘thru’ adaptor be reciprocal: that is, have S

.

S

12

=

21

Calibration Kit window. The short/open offsets are in mm in air.

© 2017 Pico Technology pv106ug r1

Getting started24

5.4.1 Insertable DUT

Open circuit (2 pieces, one male and one female)

Short circuit (2 pieces, one male and one female)

Matched termination (2 pieces, one male and one female)

Through connection test cable(s)

For insertable DUTs the requirement is for two calibration kits, one of each sex. Generally, it is required that

the matched termination should be of good quality and, as a guide, should have a return loss of better than

40 dB. However, the PicoVNA 106 allows terminations with relatively poor return loss values to be used and

still maintain good accuracy. This is discussed in Using a matched termination

.

5.4.2 Non-insertable DUT

Open circuit (1 piece)

Short circuit (1 piece)

Matched termination (1 piece)

Either a characterized through connection adaptor (1 piece) or any uncharacterized reciprocal adaptor

Through connection test cable(s)

For non-insertable DUTs only a single calibration kit is required. In addition, a reciprocal but otherwise

unknown through adaptor, or a fully characterized through adaptor, is required. These are supplied with all

Pico standard kits.

5.4.3 Open circuit model

The open circuit capacitance model used is described by the equation below, where Freq is the operating

frequency. Generally, with typical open circuit standards, the effect is small, amounting to no more than a

few degrees of phase shift at 6 GHz.

= C0 + C1Freq + C2Freq2 + C3Freq

C

open

In addition, an offset length (sometimes referred to as offset delay) can be entered as well as the loss of the

offset line.

3

5.4.4 Short circuit model

The short circuit inductance is modeled by an inductance component and in addition, a non-zero offset

length can be entered together with the loss of the offset line.

5.4.5 Short and open without models

The PicoVNA 106 supports short and open standards defined by data only. In this case the data is supplied

in the form of a 201-frequency-points table. Each frequency point has three comma-separated entries:

frequency (in MHz), real part of the reflection coefficient and the imaginary part of the reflection coefficient.

5.4.6 Calibration kit editor

As already mentioned, the calibration kit editor can be used to create or edit an existing calibration kit. The

figure below shows the editor window. A typical example is to create a new kit using an existing kit as a

template to speed the process. So, the process would be to first load the existing calibration kit from the

Calibration Kit Parameters

required. Finally, click Save Kit to save the new kit under a new name.

window. Type the new kit name in the name box and modify the parameters as

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 25

In the above example, if the existing kit loaded had load data or through data and you want to replace this

with new data, uncheck the appropriate box and then re-check it.

Calibration Kit Editor

The calibration kits optionally supplied with the PicoVNA 106 provide an economical solution while retaining

good measurement accuracy. They are supplied with SMA or precision PC3.5 (SMA-compatible) connectors.

Refer to the PicoVNA 106 Data Sheet for details.

5.4.7 Using a matched termination with poor return loss or

unmodeled short and open

A successful calibration can be carried out without the need for a good-quality matched load. In order to

retain accuracy, it is necessary to provide the instrument with accurate performance data of the matched

load to be used. The data needs to be in a fixed format thus:

Frequency (MHz)

1.0 -1.7265E-03 7.7777E-05

30.995 -1.6588E-03 3.3093E-04

60.99 -1.4761E-03 5.9003E-04

90.985 -1.4653E-03 1.0253E-03

120.98 -1.3841E-03 1.2608E-03

150.975 -1.1924E-03 1.5800E-03

240.96 -1.0884E-03 1.9085E-03

300.95 -8.7216E-04 2.1355E-03

330.945 -7.0326E-04 2.4109E-03

360.94 -5.7006E-04 2.6790E-03

S11 (real)

S11 (imaginary)

There must be 201 data lines. Typically these should

cover the band 1MHz to 6.00GHz. No empty or

comment lines are allowed.

Table: format for characteristics of matched load

In the case when the models for the open and short are not known, it is possible to enter measured data in

the same format as shown above. This approach can give good results if the open and short can be

measured accurately, particularly at the higher frequencies where it is usually difficult to model components

accurately.

When supplied, the data for the through connection adaptor must be in the format shown below. The data

must be a full set of S-parameters with no empty or comment lines. It is recommended that the data spans

the full frequency range from 1 MHz to 6000 MHz.

© 2017 Pico Technology pv106ug r1

Getting started26

Freq (MHz) S11r S11i S21r S21i S12r S12i S22r S22i

0.3 1.1450E-04 -1.0852E-04 0.9965E-01 -1.0394E-03 9.9947E-01 -7.4717E-04 1.0723E-04 4.9711E-05

40.3 2.9307E-04 1.9923E-04 9.9973E-01 -1.0241E-02 9.9934E-01 -1.0505E-02 2.0715E-04 2.0814E-04

80.3 4.1774E-04 4.3168E-04 9.9922E-01 -1.9672E-02 9.9927E-01 -1.9668E-02 2.8195E-04 2.8897E-04

120.3 5.3415E-04 5.7609E-04 9.9898E-01 -2.9165E-02 9.9855E-01 -2.8852E-02 4.0525E-04 2.8043E-04

160.3 7.1924E-04 6.4942E-04 9.9883E-01 -2.9165E-02 9.9855E-01 -2.8852E-02 4.0646E-04 2.8133E-04

200.3 7.8941E-04 7.5903E-04 9.9834E-01 -3.8214E-02 9.9846E-01 -3.8128E-02 5.4323E-04 2.2344E-04

240.3 9.9069E-04 7.8162E-04 9.9792E-01 -5.7033E-02 9.9758E-01 -4.7805E-02 5.7273E-04 2.9411E-04

280.3 1.0791E-03 8.0397E-04 9.9715E-01 -6.6419E-02 9.9699E-01 -6.5967E-02 5.7191E-04 2.6551E-04

320.3 1.2779E-03 8.5429E-04 9.9648E-01 -7.5557E-02 9.9625E-01 -7.5449E-02 6.3081E-04 2.9580E-04

...

and so on, to a total of 201 frequency points

Table: Format for the characteristics of the through connector. These must be a full set of S-parameters

(real and imaginary).

To add matched load, short and open, or through adaptor data to a calibration kit, follow the steps below:

Load kit using the Kit Editor (see Calibration Kit)

Check the Load Data Available box and similarly the boxes for the Thru and Short and Open circuits in the

Kit Editor parameters window.

If the existing kit already has load, short and open, or through data, uncheck and recheck the appropriate

box. If this is not done, the existing data will be kept and copied to the new kit.

If needed, manually enter the rest of the kit parameters. Ensure that the correct offset is entered.

Click Save Kit

When prompted, select the data file containing the matched load or the through adaptor data in the format

shown above.

Save the kit for future use by clicking the Save Kit button (see Calibration Kit).

Note: When a kit is loaded, any available matched load or through adaptor data that is associated with the

kit will be automatically loaded.

The calibration kits available for the PicoVNA 106 come complete with matched load, short and open, and

through adaptor data. Copy these files to your computer for easy access.

It is critically important that the correct kit data, with the correct serial number, is loaded.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 27

6 Operation

The PicoVNA 2 software allows you to program the measurement parameters and plots the measurement

results in real time. The main window includes a status panel that displays information including calibration

status, frequency sweep step size and sweep status. The Help menu includes a copy of this manual.

6.1 The PicoVNA 2 main window

The PicoVNA 2 main window is shown below. It is dominated by a large graphics area where the

measurement results are plotted together with the readout of the markers. One, two or four plots can be

displayed simultaneously. The plots can be configured to display the desired measurements.

User interface window

6.1.1 Display setup

Setting up the display is carried out through the Display Set Up window which is called up from the main

window by clicking Display. The window is shown below. The typical sequence to set up the display is as

follows:

Set the number of channels to be displayed by clicking the appropriate radio button under Display

Channels

Select the desired active channel from the drop-down list (can also be selected by clicking on a marker in

the main window on the desired display channel)

© 2017 Pico Technology pv106ug r1

Operation28

y

Select the channel to set up by clicking the appropriate radio button under Select

Choose the desired parameter to display on this channel from the drop-down list under Parameter / Graph

Type

Choose the desired graph type from the drop-down list under Parameter / Graph Type

Select the vertical axis values from the Vertical Axis section. Optionally, click Autoscale to automatically

set the sensitivity and reference values. Note that reference position 1 is at the top (see second figure

below).

Click Apply to apply the selected values

Repeat the above steps for each display needed

Note: The Active Channel must be one of the displayed channels.

The Display Set Up window is used to set up the measurements displa

Display graph parameters

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 29

The colors of the main graphics display can be changed to suit individual preferences. This can be done by

selecting the Color Scheme item from the Tools menu. To set a color, click the color preview box next to

the item name.

Once you have set up a color scheme, you can save and recall it as a Cal and Status setting using the File

menu.

Editing graph parameters using the mouse

The figure above shows how the mouse can be used to quickly adjust reference position, reference value

and vertical scale sensitivity.for the graph. Drag the indicated values up and down to adjust, or type a new

value where the cursor indicates.

6.1.2 Data markers

It is possible to display up to eight markers on each display. They are set up by clicking on the Markers

button (see figure below). There are four possible marker modes as follows:

Active marker: The active marker is the marker used for comparison when the delta marker mode (switched

on by selecting a reference marker) is on. One of the displayed markers must be chosen as the active

marker.

Reference marker: The reference marker causes the delta marker mode to be switched on. The value

difference between the active marker and the reference markers is shown on the right hand marker display

panel.

Fixed marker: A fixed marker cannot be moved and its position is not updated with subsequent

measurement values. It provide a fixed reference point. Only a reference marker can be made a fixed

marker. Once a marker is fixed, it cannot be moved until it is unfixed.

Normal marker: The value of a normal marker is displayed on the right-hand marker readout panel and in

lower resolution readouts below each measurement plot.

Any marker (except a fixed marker) can be moved to a new position by left clicking on it (on any displayed

channel) and dragging it to a new position.

© 2017 Pico Technology pv106ug r1

Operation30

The markers set up form provides a Peak / Minimum Search facility. This places marker 1 at either the peak

or minimum value on the displayed trace on the active channel when the corresponding Find button is

pressed.

The Markers Set Up dialog is used to display measurement markers

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 31

Change the marker type by right-clicking on any marker on the active channel. Note that only the reference

marker can be fixed.

The peak / minimum search facility provides a means of placing additional markers to indicate the 3 or 6 dB

bandwidth. If either the 3 dB or 6 dB band box are selected, then clicking Find will place markers 2 and 3 on

the frequency points either side of marker 1 which are 3 dB or 6 dB relative to it. Note that for best accuracy

a sufficient number of sweep points should be used. This will ensure a fine enough resolution to allow

accurate determination of the band points.

6.1.3 Measurement enhancement

The measurement enhancement options are displayed (see figure below) by clicking Enhancement in the

main UI window. The options available are as follows.

Averages (1 to 255, on a point by point basis)

Trace Smoothing (0 to 10%)

Bandwidth (140 kHz to 10 Hz)

Port 1 Level (+6 dBm to –20 dBm, 0.1 dB resolution)

CW sweep time per point (500 to 65 000 μs/point)

Reference Plane Extension (manual entry or automatic)

Effective dielectric constant of device under test (manual entry to correct plane extension values)

De-embedding (specify embedding networks at ports 1 and or 2)

© 2017 Pico Technology pv106ug r1

Impedance conversion for devices that are not 50 Ω

Operation32

The measurement enhancement window

The Bandwidth setting refers to the receiver bandwidth. Maximum sweep speed is achieved with the highest

(140 kHz) setting. On the other hand, the widest dynamic range (lowest noise floor) is achieved with the

lowest value, 10 Hz. Note that the bandwidth setting used during calibration determines the maximum

dynamic range achievable during measurements. So, consider this when carrying out a calibration. For

example, if you need to carry out measurement over more than, say 90 dB dynamic range, then use a 500 Hz

or less bandwidth setting when calibrating.

The Port 1 Level sets the test signal level. The default value is +3 dBm as this gives best overall

measurement accuracy. However, it may be necessary, particularly when measuring active devices (e.g.

amplifiers) to reduce the test level. For maximum dynamic range, then use the highest power setting. For

best measurement accuracy it is recommended that the calibration is carried out at the same test level as it

is intended to use for the measurement. Whenever the test level is different to that used for the calibration, a

‘?’ will be added to the calibration status indicator on the Status Panel (Fig. 6.1)

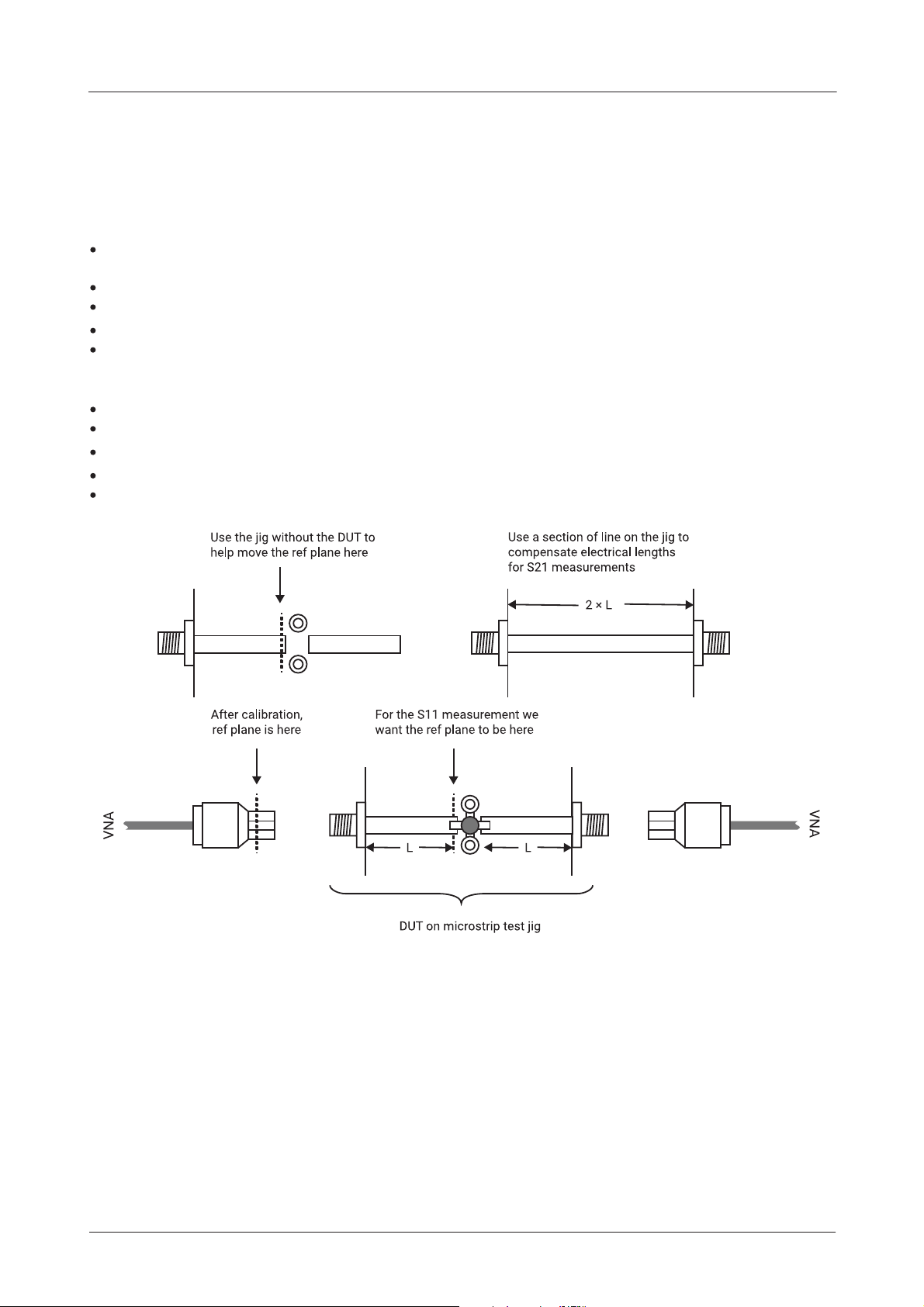

The Reference Plane facility allows the reference plane of each parameter measurement to be arbitrarily

moved away from the calibration plane. The value entered applies to the measurement parameter (S

or S22) displayed on the active channel. Note that the same plane value will be used for all other

S

12

11

, S21,

measurements on that same parameter regardless if they are on the active channel or not.

The Auto Reference automatically moves the reference plane. It uses the measurement on the active

channel. This feature is particularly useful, for example, when measuring microstrip devices and it is

necessary to remove the effect of the connecting input and output lines. It takes the effective dielectic

constant value entered to correct the displayed value. Refer to Reference plane extension and de-embedding

for more details.

Note: The reference plane must be at 0 mm for the Auto Ref function to work correctly. Also, Enhancement

window changes only take place when the instrument is sweeping.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 33

The Effective Dielectric of the device under test can be entered so that the displayed Reference Plane

extension values (shown on the Enhancement Window) are corrected accordingly when the Auto Ref button

is clicked. The default value is 1.0 and the maximum value allowed is 50.0.

Note: The reference plane extension value shown in the main window

on the markers display panel on the

right is the reference plane extension as shown in the Enhancement window.

The de-embedding facility is explained in detail in Reference plane extension and de-embedding.

The System Z

Conversion facility allows measurements, which are always taken in 50 Ω, to be converted to

0

another impedance selected by the user. This feature can be useful, for example, for measuring 75 Ω

devices. The value of Z

entered must be real (purely resistive) and must be within the range of 10 Ω to 200

0

Ω. Whenever this facility is selected, an indicator is displayed on the top right corner of the graphics display

as shown in the second figure below. Note that when requested, impedance conversion will performed on

the live measurement and any stored memory trace.

There are two possible ways of using the System Z

Conversion facility. For example, 75 Ω devices can be

0

measured using the techniques illustrated below.

Possible techniques for measuring 75 Ω devices.

Impedance matching pads can be used to measure a connectorized device.

A discrete device mounted on a 50 Ω test jig is somewhat simpler to measure.

The steps necessary for each of the two techniques illustrated in the figure above are as follows:

75 Ω device with connectors

i. Connect 50 Ω to 75 Ω impedance matching networks (e.g. matching pads) at the ends of the cables

connected to ports 1 and 2.

ii. In the Enhancement window, check the Convert System Zo box

iii. Check External Zo match to indicate external matching networks in use

iv. Enter 75 in the Convert System Zo value box and click Apply

v. Proceed to calibrate using a 75 Ω calibration kit

vi. Connect the DUT and start the measurement

75 Ω device mounted on 50 Ω test jig

i. In the Enhancement window, uncheck the Convert System Zo box

ii. Calibrate at the ends of the test cables using a 50 Ω calibration kit

iii. Apply de-embedding to remove test jig effects. See Calibration kit

for some suggestions.

iv. In the Enhancement window, check the Convert System Zo box

© 2017 Pico Technology pv106ug r1

Operation34

y

v. Uncheck the External Zo match box (in this case mathematical impedance conversion is done by the

software)

vi. Enter 75 in the Convert System Zo value box and click Apply

vii. Connect the DUT and start the measurement

System impedance chosen is displayed on the top right corner

Note: S-parameters are interrelated, so, when using the Z

matching networks) without a full set of S-parameters available (e.g. only an S

conversion facility (and no external impedance

0

calibration) the program

11

will assume values for the unavailable parameters as shown in the following table. A warning will be

displayed in such cases.

S

11

S

12

S

21

S

22

10–6, j0.0 10–6, j0.0 10–6, j0.0 10–6, j0.0

Table: Values assumed for parameters not available during Z0 conversion

6.1.4 Memory facility

The current displayed data on each channel can be stored in memory. Also, each channel can be stored

independently of all others. The Memory Set Up window is used to store the data and this window can be

displayed by clicking Memory in the main window.

The Memory Set Up window is used to store data into memor

Once the data is stored, it can be displayed by clicking Display Data and Memory in the main window.

There are three vector math functions available: sum, subtraction and division. The selected function is used

when you select the Display Memory Math function on the main window.

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 35

The trace hold is used to store the maximum or minimum values on the memory trace. Trace hold is not

available when group delay is displayed.

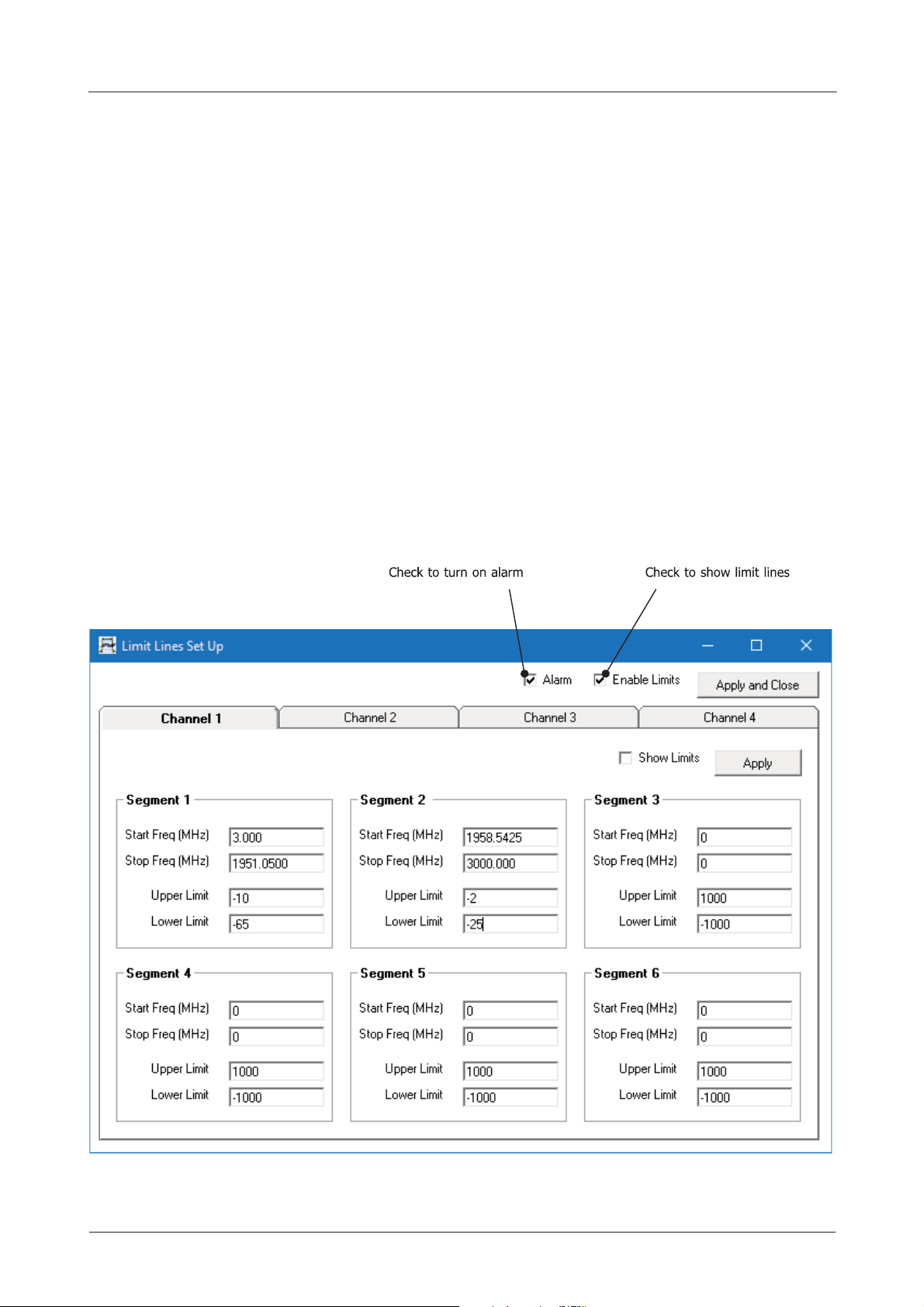

6.1.5 Limit lines facility

The limit lines facility allows six segments to be defined for each displayed graph. By taking advantage of

the overlapping capability (see below) a maximum of 11 segments can be created The set up window,

shown below, is displayed by clicking Limit Lines in the main window.

Overlapping segments

All valid segments entered are loaded in sequence (i.e. segment 1 first) with the each segment loaded

having priority over the previous segment. This feature allows overlapping segments to be loaded. For

example, if segment 1 is specified to cover, say, 400 to 800 MHz, then a second segment can be specified to

a section of this band, for example, 500 to 600 MHz. This would result in a total of three segments—that is,

400 to 500, 500 to 600 and 600 to 800 MHz—even though only two were specified. An example of a complex

11-segment template is shown in the first plot below.

Alarm

An alarm facility is provided with the limit lines. This provides audible warning during a sweep if any

measurement exceeds the limits set. A visible indication of the last measurement and measurement

channel in error is provided on the status panel where normally the calibration type is displayed. In addition a

symbol is drawn on the trace indicating the last error point detected as shown in the second plot below. The

alarm is available for all graph types except Smith plots.

The Limit Lines Set Up allows at least six segments per graph

© 2017 Pico Technology pv106ug r1

Complex Limit Lines templates are possible by overlapping segments

Operation36

Limit Lines failure graphical visual indicator

6.1.6 Status panel

The status panel in the main window provides useful information as follows:

Instrument serial number

Calibration status (S11, S21, S11 + S21, 12 terms or U/T). A question mark indicates that the test power has

been changed from that used for calibration

Test signal power. This is the Port 1 signal level

Sweep status. Indicates whether instrument is sweeping

Frequency step. Step size of sweep

Sweep points. Number of points in programmed sweep.

Limit Lines alarm if any measurement exceed the set limits (temporarily replaces Calibration status)

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 37

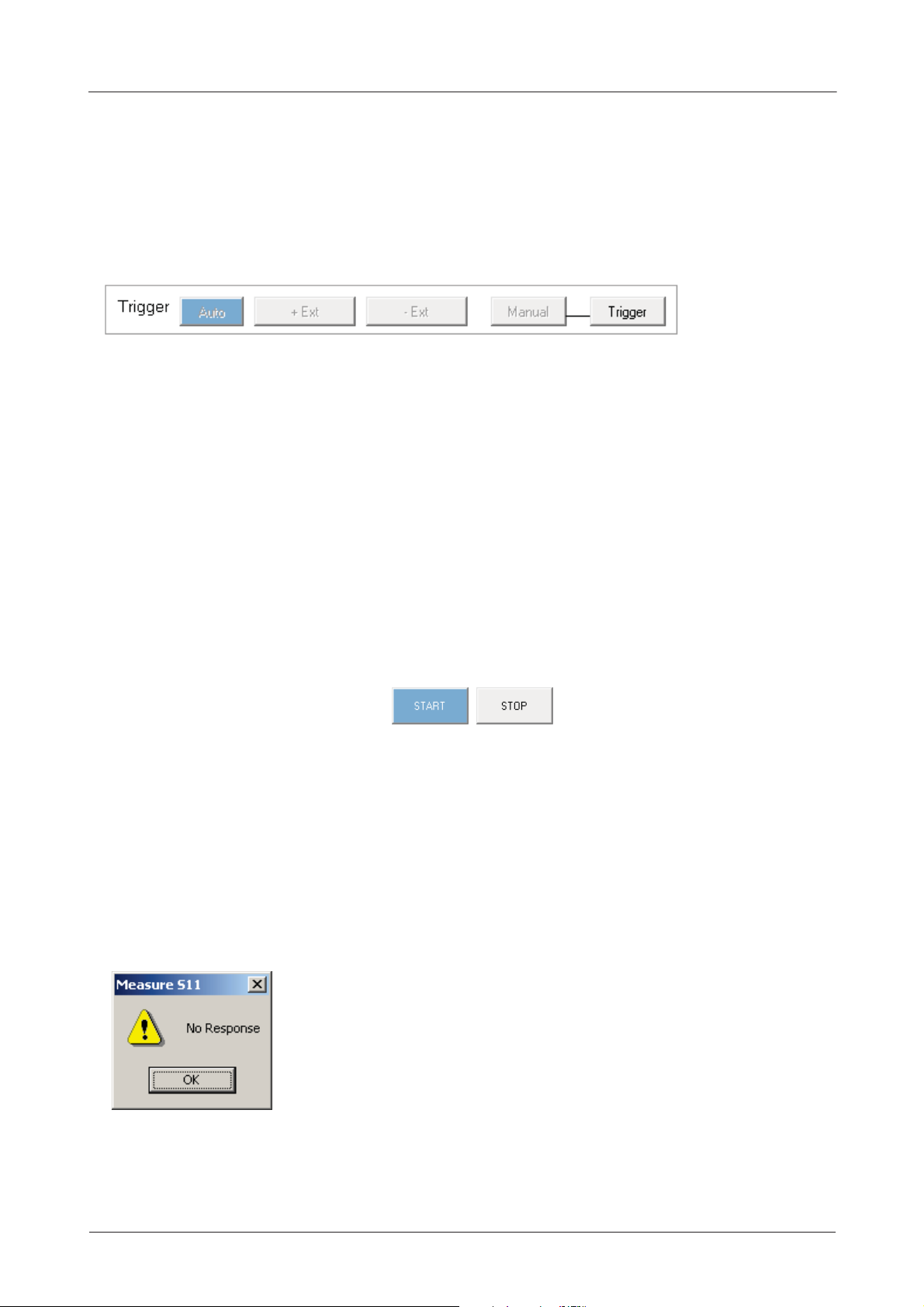

6.1.7 Triggered sweep

It is possible to synchronize each measurement sweep to an external trigger. Simply click the appropriate

radio button in the main window and ensure that a trigger signal is connected to the instrument’s rear panel

Trigger terminal.

The instrument supports either positive or negative edge trigger depending on the radio button selected on

the main panel. The input impedance is 10 kΩ.

Trigger selection radio button on main panel

When the Manual trigger option is selected, the instrument will wait until the Manual button is pressed

before starting a sweep.

6.1.8 Sweep trigger output

The rear panel Trigger Output terminal provides a 3 V logic output with the rising edge synchronized to the

start of the measurement sweep. The signal goes to 0 V at the end of the sweep. The output resistance is

about 500 Ω.

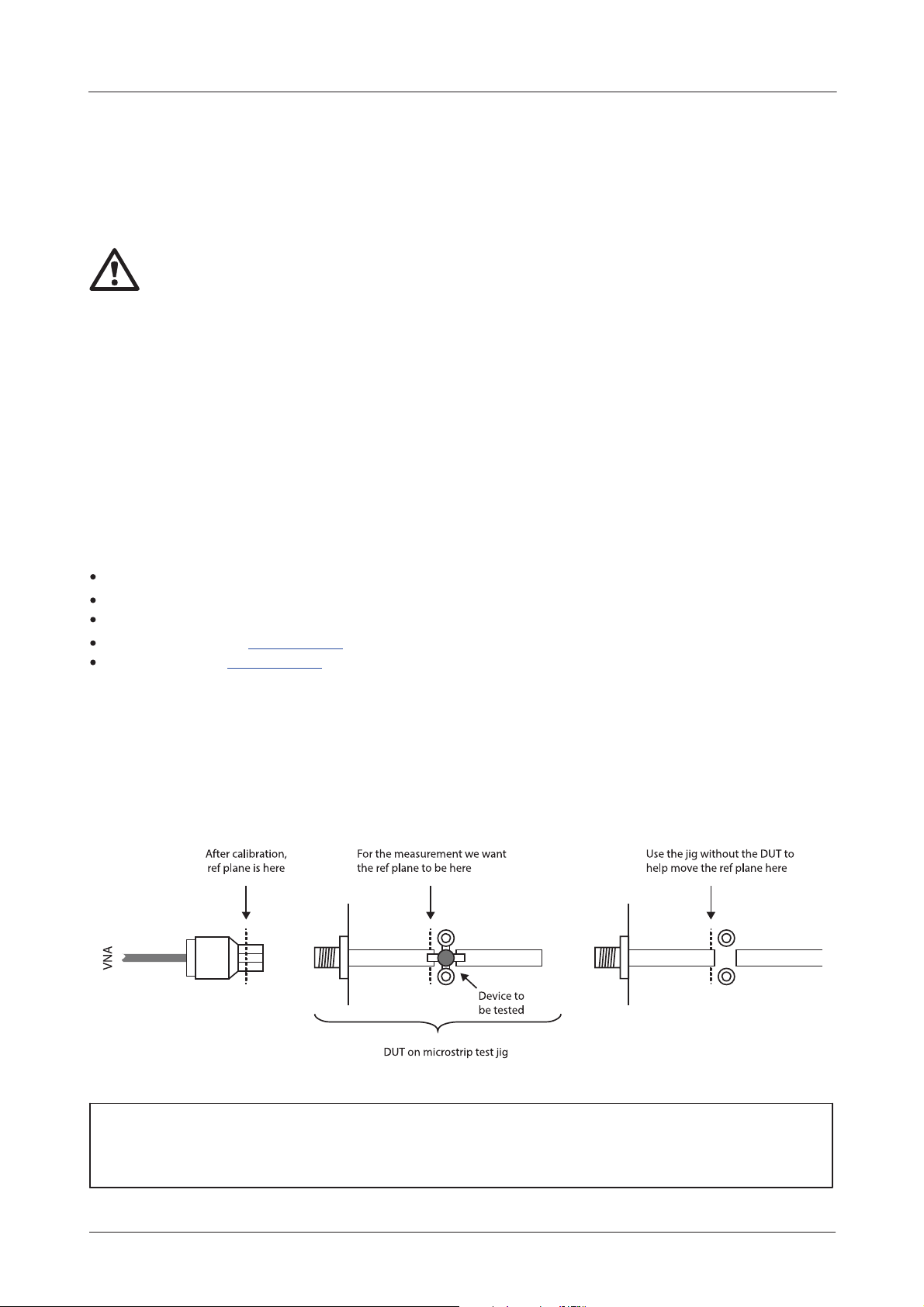

6.1.9 Measurement start / stop

The measurement Start / Stop buttons (see figure) are used to start or stop the instrument’s sweep mode

(measurement mode). This is necessary as functions which require reprogramming the instrument can only

take place when the instrument is idle. The instrument status is shown in the Status Panel as described in

the previous section.

The Start / Stop Measurement buttons control the sweep status

Note that when the sweep is stopped, the test signal frequency is held at the frequency point at the time the

stop command is received by the instrument. In the case of triggered sweep, by default, at the end of the

sweep, the frequency is held at the last frequency point until the next sweep trigger event is received. This

can be changed from the Tools > Diagnostics menu.

6.1.10 PC data link interruption

The data flow between the VNA and its controlling PC can be interrupted by external factors. If the software

cannot restore the link, a message similar to this will appear:

Warning message when the link with the PC is interrupted

In such a case:

© 2017 Pico Technology pv106ug r1

Operation38

p

Restart the software using the selection in the drop-down menu under Tools

Switch the VNA off and on again (using the switch on the back) when prompted to do so

Wait until the front panel lights have stopped flashing

Click OK to complete the software restart

Recalibrate the instrument

You should rarely see a ‘No Response’ message. If it happens often, check that the PC is not running other

applications and that the VNA software is not running as a background task when the sweep is on.

6.2 Calibration

The instrument must be calibrated before any measurements can be carried out. This is done by loading a

previous calibration (see File menu) or carrying a fresh calibration by clicking Calibration in the main

window, which brings up the Calibration window as shown here:

Instrument calibration is carried out through the Calibration window. Before starting calibration select the

referred enhancement settings (bandwidth and averages).

Note: The frequency sweep is set by entering the start, stop and selecting the number of sweep points.

Alternatively, by entering the centre frequency and span after clicking on the Centre/Span format option

box.

The table below summarizes the calibration types available together with the standards required to

complete the calibration. For best overall accuracy, particularly when measuring low isolation devices with

poor return loss values, a 12-term calibration should be performed.

Minimum

calibration

standards

required

S

11

Matched load

Open

Short

S

21

Through

connection

Termination (see

text)

S11 + S

21

Matched load

Open

Short

Through connection

12 terms (insertable

DUT)

Matched load (x 2)

Open ( x 2)

Short (x 2)

Through cable

12 terms or 8 terms*

(non-insertable DUT)

Matched load (x 1)

Open ( x 1)

Short (x 1)

Through adaptor (x

1)

Through cable

© 2017 Pico Technologypv106ug r1

PicoVNA 106 6 GHz Vector Network Analyzer 39

Measurement

capability

S

11

S11 using 3term error

correction

S

21

Frequency