1

www.phywe.com, © All rights reserved 13607-99 / 0317

Operating instructions

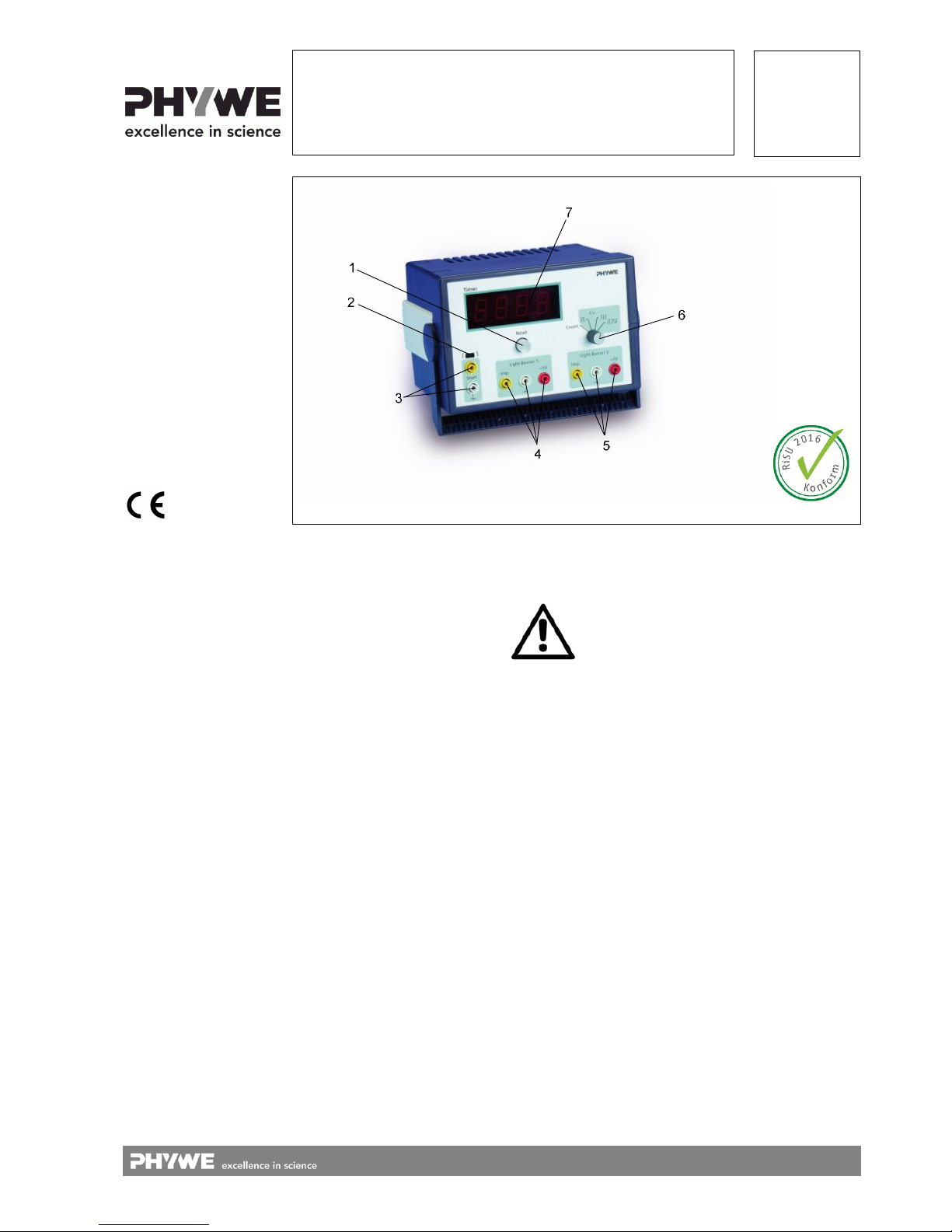

Fig. 1: Timer 2-1, 13607-99

Timer 2-1

13607-99

PHYWE Systeme GmbH & Co. KG

Robert-Bosch-Breite 10

D–37079 Göttingen

Telefon +49 (0) 551 604–0

Fax +49 (0) 551 604–107

E-mail info@phywe.de

Internet www.phywe.com

The unit complies

with the corresponding EU guidelines.

TABLE OF CONTENTS

1 SAEFTY PRECAUTIONS

2 PURPOSE AND DESCRIPTION

3 EXPLANATION OF THE SYMBOLS

4 FUNCTIONAL AND OPERATING ELEMENTS

5 HANDLING

6 NOTES ON OPERATION

7 TECHNICAL DATA

8 SCOPE OF DELIVERY

9 LIST OF EQUIPMENT

10 WASTE DISPOSAL

1 SAEFTY PRECAUTIONS

Carefully read these operating instructions completely be-

fore operating this instrument. This is necessary to avoid

damage to it, as well as for user-safety.

Check that your mains supply voltage corresponds to that

given on the type plate fixed to the instrument.

Install the instrument so that the on/off switch and the

mains connecting plug are easily accessible. Do not

cover the ventilation slits.

Take care that no liquids or objects enter in through the

ventilation slots.

Only use the instrument in dry rooms in which there is no

risk of explosion.

Only use the instrument for the purpose for which it was

designed.

Protect the instrument from dust, moisture and vapours.

Only clean it in voltage-free state with a slightly

moistened, lint-free cloth. Aggressive cleaning agents and

solvents are unsuitable.

Do not operate if there are visible signs of damage to the

unit, the connection cord or the measuring lines.

Do not open the unit.

Do not connect any devices to the unit other than the

ones that are intended for this purpose.

Only use the power supply that is supplied with the unit

(Order.-No. 12651-99).

Attention!

2

www.phywe.com, © All rights reserved 13607-99 / 0317

2 PURPOSE AND DESCRIPTION

The chronometer Timer 2-1 has a 4-digit digital display and

has been specially designed for use in student experiments

and demonstrative teacher experiments. The starting and

stopping of the built-in timer piece, as well as counting, is effected by the opening and closing of electrical circuits, across

light barriers or other TTL signal sources.

Many and various experimental requirements can be fulfilled

with the 4 different operating modes that the Timer 2-1 makes

available for track experiments, for the measurement of the

time of revolution of a turning movement, for the direct measurement of the period of a full swing of a mechanical pendulum and for the counting of events.

3 EXPLANATION OF THE SYMBOLS

The safety isolating transformer and safe

isolation in accordance with

DIN EN 61558-2-16 of the connected power supply unit 12651-99 ensure that the

regulations for safety at schools (Richtlinien für Sicherheit im Unterricht (RiSU)) in

line with the recommendation of the Standing Conference of the Ministers of Education and Cultural Affairs of the Länder in the Federal Republic of Germany are

fulfilled.

4 FUNCTIONAL AND OPERATING ELEMENTS

The instrument is fitted in an impact-resistant plastic housing,

the single carrying handle of which can be swung down to act

as an inclining prop. Four rubber feet ensure slip-resistance

and standing stability. The instrument can be stacked with

other instruments that have the same type of housing, whereby the rubber feet fit into pan-shaped depressions in the instrument housing below to provide increased security against

displacement. The inclined housing position is only permissible for the top housing in a stack. The power supply unit (article no. 12651-99) that is standardly supplied with the instrument serves to connect it to the AC-mains when it is connected to the back of the instrument via the instrument connecting

plug. All other functional and operating elements are to be

found at the front of the instrument (see Fig. 1).

1 Reset button

for resetting the display to zero and to restore readiness for

measurement prior to each new measurement.

2 Slide switch

or selection of the trigger signal edge for the input Start; position : Start of measurement by the rising edge of a TTLpulse (enabling of a light barrier) or by opening the electrical

connection between the sockets of the corresponding input;

position : Start of measurement by the descending edge of

a TTL-pulse (interrupting of a light barrier) or by closing the

electrical connection between the sockets of the corresponding input.

Note: Should no external trigger be connected to the Start

socket, then the slide switch should be in the position ,

as otherwise the instrument will not operate as expected

in all operating modes.

3 Start pair of sockets

or starting time measurement in operating modes

and ; (see section 4 for a description of the operating

modes). The signal can hereby be generated through a light

barrier or a mechanical starter by the opening or closing of an

external contact.

4, 5 Connecting socket for fork light barriers

for the operation of two fork light barriers. The light barriers

are supplied with a 5 VDC operating voltage. Control input

sockets (Imp.) serve to start and/or stop a time measurement

according to the operating mode that has been selected with

switch 6. The reference terminal for each control input socket

is the socket marked "Mass". The mode of action of the control inputs is dependent on the selected operating mode (see

section 4).

6 Rotary switch

for the selection of one of the 4 available operating modes

(see section 4).

7 Digital display

for the display of times measured within the range from 0.000

to 9.999 s, or of the number of counts of events from 0 to

9999.

8 Gate LED

when this LED lights up, it shows that a time measurement

and the internal clock have been started. This function is most

helpful in indicating an inadvertent triggering of timer 2 - 1.

5 HANDLING

When the operating voltage is applied, a press on the reset

button makes the timer ready for use. The operating mode

that is most suitable for the experiment that is to be carried

out is to be selected from described in section 4. Control instruments must be connected to the control input of the timer

for time measurements to be started and stopped. Select the

most suitable of these from the List of Equipment. Should instruments that are not in the list to be connected, first check

that their control signals correspond to the TTLNorm.

An automatic repeat-lock ensures that no measured time value can be unintentionally overwritten. To regain readiness for

a new measurement, press the reset button to put back the

display. A running measurement can be stopped at any time

with the reset button.

Description of the operating modes

Rotary switch 6 allows one of the four available operating

modes to be selected. Graphic symbols on the front plate

mark the switch positions.

For all operating modes, first select the one wanted with

rotary switch 6, then press the reset button. The previous

operating mode is only brought to an end after this is

done.

5.1 Pulse counting

— Turn rotary switch 6 to the "Count" position.

— Press the reset button.

The display shows readiness for measurement with 0000.

A light barrier at the "Light Barrier 1" connection now counts

the number of shadings.

5.2 Measurement of the time period during shading

— Turn rotary switch 6 to the „ “ position.

— Press the reset button.

After the pressing of the reset button, the display shows two

decimal points which confirm readiness for measurement.

3

www.phywe.com, © All rights reserved 13607-99 / 0317

The shading period of a light barrier that is connected either at

"Light Barrier 1" or at "Light Barrier 2" is measured and displayed. Two light barriers can also be simultaneously connected. The shading time of the light barrier that is first interrupted is then measured.

Measurement range: 0 to 9.999 s. Renewed measurement

possible, but only after first pressing the reset button.

5.3 Measurement of the time period between the start of

two shadings

— Turn rotary switch 6 to the " " position.

— Press the reset button.

After the pressing of the reset button, the display shows three

decimal points which confirm readiness for measurement.

The time period between two shadings is measured and displayed. This operating mode is particularly suitable for track

experiments to determine the time that a car takes to travel

the distance between two light barriers.

Alternatively, the timer can be started by a signal at the "Start"

input according to the selected signal edge and be stopped by

the shading of a connected light barrier. Measurement range

0 to 9.999 s. Renewed measurement possible, but only after

first pressing the reset button.

5.4 Measurement of the time period between the start of

the first and the third shadings

— Turn rotary switch 6 to the „ “ position.

— Press the reset button.

After the pressing of the reset button, the display shows four

decimal points which confirm readiness for measurement.

The time period between the first and third shading is measured and displayed. This enables, for example, the complete

period of swing of a pendulum to be measured with one light

barrier. It is hereby of no importance which light barrier input

is used. The time between the beginning of the first and the

third shading is displayed, regardless of with which light barrier the shadings occur.

Alternatively, the timer is started by a signal at the "Start" input according to the selected signal edge and stopped at the

beginning of the second shading of a connected light barrier.

Measurement range 0 to 9.999 s. Renewed measurement

possible, but only after first pressing the reset button.

6 NOTES ON OPERATION

This high-quality instrument fulfills all of the

technical requirements that are complied in

current EC guidelines. The characteristics of

this product qualify it for the CE mark.

This instrument is only to be put into operation under specialist supervision in a controlled electromagnetic environment in

research, educational and training facilities (schools, universities, institutes and laboratories).

This means no mobile phones etc. are to be used in the near

vicinity. The individual connecting leads must not be longer

than 2 m.

The Instrument can be influenced by electromagnetic charges

and other electromagnetic phenomena in such way, that it

works no longer within the given specifications. The following

measures reduce or prevent disturbing influences: Avoid carpeted floor ensure potential equalization, perform the experiments on conductive and grounded surfaces, use screenings

and screened cables and do not work with high frequency

emitters ( radios, mobile phones etc.) in the immediate vicinity. After a total blackout, carry out a "Reset" (new start) of the

complete system.

7 TECHNICAL DATA

Operating temperature range 5-40°C

Relative humidity <80 %

Control Start/Stop) by electrical cir-

cuits (contact closure/contact

opening or level acc. To TTLNorm)

Digital display 4-Digit LED display, digit

height 19 mm

Time measurement Measuring range

0,000...9,999 s

resolution1 ms

Pulse counting Measurement range 0…9999

pulses

Limiting frequency 1 kHz,

shading period > 500 μs

Operating voltage (Stabilized) 5 V±5%

(suitable power supply

5 VDC/2.4 A, 13900-99

standardly supplied)

Power consumption 1.8 VA

Supply connector Connecting socket for hollow

plug, diam. 2.1 mm at the

back of the instrument

5 VDC/350 mA

Overvoltage and reverse up to max. 12 V

polarity protection

Housing dimensions (mm) 206 × 130 × 160 (W, H, D)

Weight approx. 920 g

8 SCOPE OF DELIVERY

Timer 2-1 13607-99

Power supply 5 VDC/4 A 12651-99

9 LIST OF EQUIPMENT

The timer can only be used in combination with suitable control instruments that can be connected to its inputs. All instruments are suitable that open or close a switch contact or supply an electrical pulse and conform to TTL-Norm. The following list provides a selection of instruments that can be connected to inputs 3, 4 and 5:

Falling sphere apparatus 02502-88

Holding device with cable release 02417-04

Starter system, mechanical with release 11202-13

Fork light barrier, compact 11207-20

Push button switch, circuit closing 06039-00

10 WASTE DISPOSAL

The packaging mainly consists of environmentally-friendly

materials that should be returned to the local recycling stations.

PHYWE Systeme GmbH & Co. KG

Customer Service

Robert-Bosch-Breite 10

D–37079 Göttingen

Germany

Telephone +49 (0) 551 604-274

Fax +49 (0) 551 604-246

Do not dispose of this product with normal

household waste. If this unit needs to be

disposed of, please return it to the address

that is stated below for proper disposal.

Loading...

Loading...