Page 1

Radioline Wireless transmission system for

serial interfaces and I/O signals

User manual

Page 2

User manual

Radioline Wireless transmission system for

serial interfaces and I/O signals

2017-01-10

Designation:

Revision:

This user manual is valid for:

Wireless modules: Order No.

RAD-2400-IFS 2901541

RAD-868-IFS 2904909

RAD-2400-IFS-JP 2702863

I/O extension modules:

RAD-AI4-IFS 2901537

RAD-PT100-4-IFS 2904035

RAD-AO4-IFS 2901538

RAD-DI4-IFS 2901535

UM EN RAD-...-IFS

02

RAD-DI8-IFS 2901539

RAD-DOR4-IFS 2901536

RAD-DO8-IFS 2902811

RAD-DAIO6-IFS 2901533

PHOENIX CONTACT 105542_en_02

Page 3

Please observe the following notes

User group of this manual

The use of products described in this manual is oriented exclusively to qualified electricians

or persons instructed by them, who are familiar with applicable standards and other

regulations regarding electrical engineering and, in particular, the relevant safety concepts.

Explanation of symbols used and signal words

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety measures that follow this symbol to avoid possible

injury or death.

There are three different categories of personal injury that are indicated with a

signal word.

DANGER This indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING This indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION This indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

This symbol together with the signal word NOTE and the accompanying text

alert the reader to a situation which may cause damage or malfunction to the

device, hardware/software, or surrounding property.

This symbol and the accompanying text provide the reader with additional

information or refer to detailed sources of information.

How to contact us

Internet Up-to-date information on Phoenix Contact products and our Terms and Conditions can be

found on the Internet at:

phoenixcontact.com

Make sure you always use the latest documentation.

It can be downloaded at:

phoenixcontact.net/products

Subsidiaries If there are any problems that cannot be solved using the documentation, please contact

your Phoenix Contact subsidiary.

Subsidiary contact information is available at phoenixcontact.com

Published by PHOENIX CONTACT GmbH & Co. KG

Flachsmarktstraße 8

32825 Blomberg

GERMANY

Should you have any suggestions or recommendations for improvement of the contents and

layout of our manuals, please send your comments to:

tecdoc@phoenixcontact.com

.

PHOENIX CONTACT

Page 4

Please observe the following notes

General terms and conditions of use for technical documentation

Phoenix Contact reserves the right to alter, correct, and/or improve the technical

documentation and the products described in the technical documentation at its own

discretion and without giving prior notice, insofar as this is reasonable for the user. The

same applies to any technical changes that serve the purpose of technical progress.

The receipt of technical documentation (in particular user documentation) does not

constitute any further duty on the part of Phoenix Contact to furnish information on

modifications to products and/or technical documentation. You are responsible to verify the

suitability and intended use of the products in your specific application, in particular with

regard to observing the applicable standards and regulations. All information made

available in the technical data is supplied without any accompanying guarantee, whether

expressly mentioned, implied or tacitly assumed.

In general, the provisions of the current standard Terms and Conditions of Phoenix Contact

apply exclusively, in particular as concerns any warranty liability.

This manual, including all illustrations contained herein, is copyright protected. Any

changes to the contents or the publication of extracts of this document is prohibited.

Phoenix Contact reserves the right to register its own intellectual property rights for the

product identifications of Phoenix Contact products th at are u sed here. R egistr ati on of su ch

intellectual property rights by third parties is prohibited.

Other product identifications may be afforded legal protection, even where they may not be

indicated as such.

PHOENIX CONTACT

Page 5

Table of contents

1 Technical data for the wireless modules ....................................................................................9

2 For your safety .........................................................................................................................17

2.1 Intended use........................................................................................................17

2.2 Installation notes..................................................................................................18

2.3 Installation in Zone 2............................................................................................19

2.4 Notes for individual I/O extension modules..........................................................21

2.5 UL notes (RAD-2400-IFS only)............................................................................ 21

2.6 FCC and Industry Canada (RAD-2400-IFS only).................................................22

3 Short description ......................................................................................................................23

3.1 Wireless modules................................................................................................23

3.2 Firmware versions ...............................................................................................24

3.3 I/O extension modules.........................................................................................25

4 Installation ................................................................................................................................27

4.1 Wireless module structure...................................................................................27

4.2 Basic circuit diagram ...........................................................................................28

4.3 Mounting and removal.........................................................................................28

4.4 Connecting cables...............................................................................................30

4.5 Connecting the power supply ..............................................................................31

4.6 Serial interfaces...................................................................................................32

4.7 Connecting the antenna ......................................................................................35

5 Configuration and startup .........................................................................................................37

5.1 Default settings of the wireless module ...............................................................37

5.2 Operating mode of the wireless module ..............................................................39

5.3 Setting the address of the wireless module using the thumbwheel...................... 42

5.4 Configuration via CONFSTICK............................................................................42

5.5 Copying device settings via a memory stick ........................................................44

5.6 Configuration via PSI-CONF software.................................................................45

5.7 Diagnostics on the wireless module .................................................................... 51

5.8 Diagnostics via PSI-CONF software....................................................................56

5.9 Starting up I/O extension modules.......................................................................59

5.10 Startup time of the wireless station......................................................................61

6 Serial data mode ......................................................................................................................63

6.1 Frame-based data transmission..........................................................................65

105542_en_02 PHOENIX CONTACT 5

Page 6

RAD-...-IFS

7 PLC/Modbus RTU mode ..........................................................................................................67

7.1 Configuration via PSI-CONF software.................................................................67

7.2 Addressing I/O extension modules......................................................................68

7.3 Watchdog............................................................................................................69

7.4 Modbus function codes .......................................................................................70

7.5 Module type and error code registers for I/O extension modules.........................71

7.6 Modbus memory map..........................................................................................72

7.7 Error codes and formats for analog input and output values................................87

8 Description of I/O extension modules ......................................................................................89

8.1 RAD-AI4-IFS - analog extension module with four inputs ....................................89

8.2 RAD-PT100-4-IFS - extension module with four temperature inputs ...................93

8.3 RAD-AO4-IFS - analog extension module with four outputs.............................. 100

8.4 RAD-DI4-IFS - digital extension module with four inputs ...................................104

8.5 RAD-DI8-IFS - digital extension module with eight inputs..................................108

8.6 RAD-DOR4-IFS - digital extension module with four outputs.............................113

8.7 RAD-DO8-IFS - digital extension module with eight outputs..............................117

8.8 RAD-DAIO6-IFS - analog/digital extension module with six channels ............... 122

9 Planning wireless systems .....................................................................................................127

9.1 Delay time .........................................................................................................127

9.2 Pulse transmission ............................................................................................129

9.3 Trusted Wireless 2.0..........................................................................................129

9.4 RF bands...........................................................................................................133

9.5 Planning wireless paths.....................................................................................134

9.6 Practical test......................................................................................................134

9.7 Selecting antenna cables and antennas............................................................135

9.8 Installing antennas.............................................................................................136

9.9 Level and attenuation of wireless modules and accessories .............................139

9.10 Free space path loss .........................................................................................141

9.11 Propagation of radio waves...............................................................................143

9.12 Fresnel zone......................................................................................................146

9.13 Range................................................................................................................148

9.14 Equivalent isotropically radiated power (EIRP)..................................................149

9.15 System calculation in free space .......................................................................150

9.16 Practical examples ............................................................................................151

6

PHOENIX CONTACT 105542_en_02

Page 7

Table of contents

10 Detecting and removing errors ...............................................................................................153

10.1 Loopback test during serial data transmission...................................................159

A Technical appendix.................................................................................................................161

A 1 Typical combinations of antennas and adapter cables ...................................... 161

A 2 Control box for wireless systems.......................................................................175

A 3 PROFIBUS connections....................................................................................176

A 4 Configuration.....................................................................................................178

B Appendixes.............................................................................................................................189

B 1 List of figures .....................................................................................................189

B 2 List of tables ......................................................................................................193

B 3 Index..................................................................................................................195

105542_en_02 PHOENIX CONTACT 7

Page 8

RAD-...-IFS

8

PHOENIX CONTACT 105542_en_02

Page 9

Technical data for the wireless modules

1 Technical data for the wireless modules

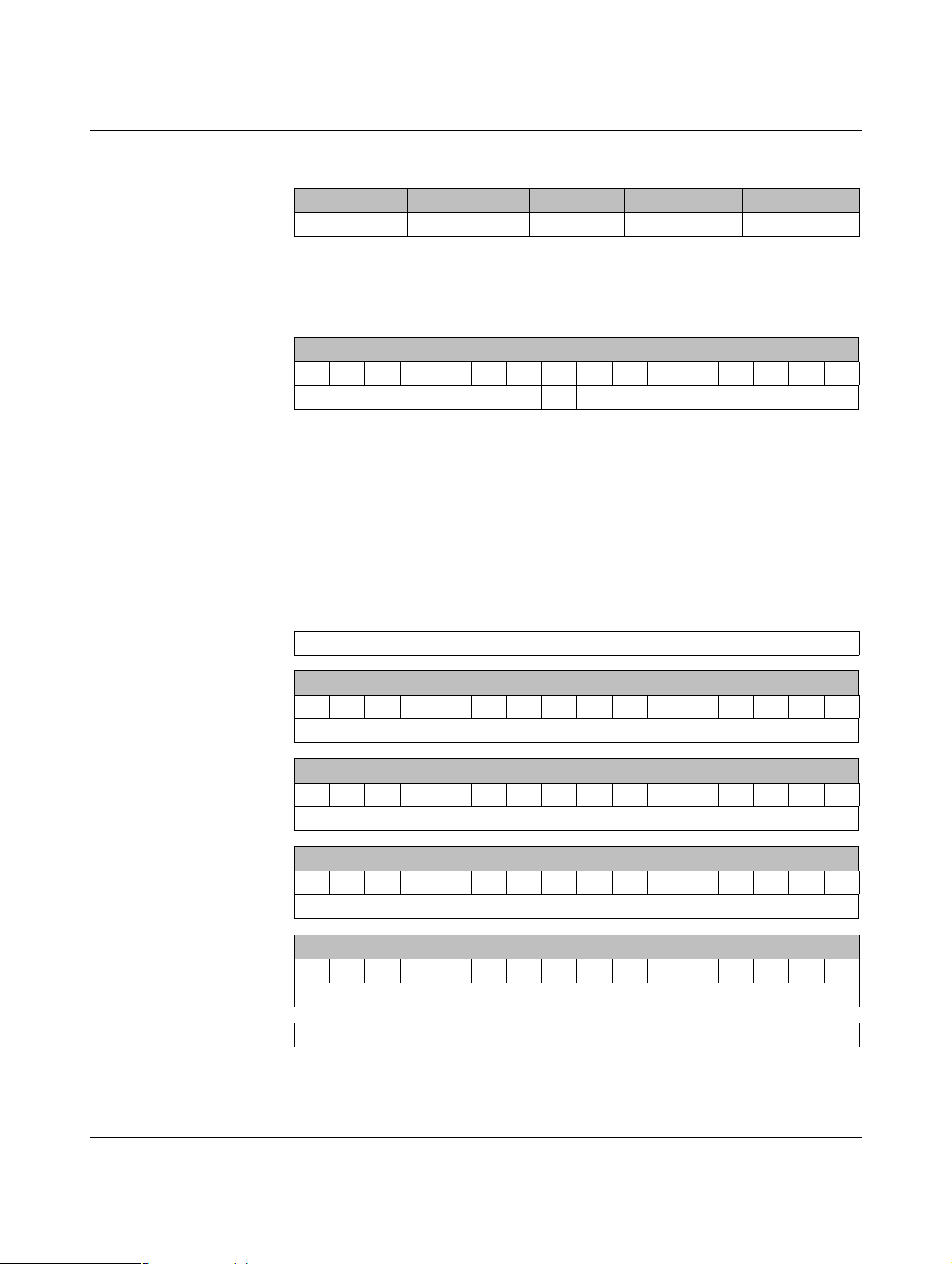

Description Ty p e Order No. Pcs./Pkt.

2400 MHz wireless transceiver with RS-232, RS-485 2-wire interface, can

be extended with I/O extension modules, with screw connection, antenna

connection: RSMA (female), incl. DIN rail connector, without antenna

868 MHz wireless transceiver with RS-232, RS-485 2-wire interface, can

be extended with I/O extension modules, with screw connection, antenna

connection: RSMA (female), incl. DIN rail connector, without antenna

2400 MHz wireless transceiver for operation in Japan, with RS-232,

RS-485 2-wire interface, can be extended with I/O extension modules, with

screw connection, antenna connection: RSMA (female), incl. DIN rail connector, without antenna (no ATEX, IECEx or UL approval)

Accessories

RS-485 front module Ty p e Order No. Pcs./Pkt.

Multipoint multiplexer for RS-485 bus system, can be extended with I/O extension modules. Can be used as Modbus/RTU bus coupler or combined

with Radioline wireless system, screw connection. Up to 99 stations, incl.

DIN rail connector

Extension modules Ty p e Order No. Pcs./Pkt.

Analog I/O extension module with 4 analog current inputs

(0/4 mA ... 20 mA), with screw connection, incl. DIN rail connector

Temperature I/O extension module with 4 Pt 100 inputs

(-50°C … +250°C), with screw connection, incl. DIN rail connector

Analog I/O extension module with 4 analog current/voltage outputs

(0/4 mA ... 20 mA, 0 V ... 10 V), with screw connection, incl. DIN rail connector

Digital I/O extension module with 4 digital inputs (0 V ... 250 V AC/DC),

with screw connection, incl. DIN rail connector

Digital I/O extension module with 8 digital inputs (0 V ... 30.5 V DC) or

2 pulse inputs (0 Hz ... 100 Hz), with screw connection, incl. DIN rail connector

Digital I/O extension module with 4 digital relay outputs (6 A,

250 V AC/24 V DC), with screw connection, incl. DIN rail connector

Digital I/O extension module with 8 digital transistor outputs

(30.5 V DC/200 mA), with screw connection, incl. DIN rail connector

Analog/digital I/O extension module with 2 digital inputs/outputs

(0 V ... 250 V AC/DC) and 1 analog input (0/4 mA ... 20 mA) and output

(0/4 mA ... 20 mA, 0 V ... 10 V), with screw connection, incl. DIN rail connector

RAD-2400-IFS 2901541 1

RAD-868-IFS 2904909 1

RAD-2400-IFS-JP 2702863 1

RAD-RS485-IFS 2702184 1

RAD-AI4-IFS 2901537 1

RAD-PT100-4-IFS 2904035 1

RAD-AO4-IFS 2901538 1

RAD-DI4-IFS 2901535 1

RAD-DI8-IFS 2901539 1

RAD-DOR4-IFS 2901536 1

RAD-DO8-IFS 2902811 1

RAD-DAIO6-IFS 2901533 1

105542_en_02 PHOENIX CONTACT 9

Page 10

RAD-...-IFS

Mounting and configuration Ty p e Order No. Pcs./Pkt.

DIN rail connector for DIN rail power supply, gold-plated contacts, for

DIN rail mounting, 5-pos.

Shield connection clamp for applying the shield on busbars SKS 8-SNS35 3062786 10

Memory stick for saving individual configuration data for the Radioline wire-

less module

USB data cable (USB-A to IFS connector) for communicating between PCs

and PHOENIX CONTACT devices with an IFS data port, e.g.,

RAD-2400-IFS. Energy supply for diagnostics and configuration via the

USB port of the PC. Cable length: 2 m

Vulcanizing sealing tape for external protection of adapters, cable connections, etc. against the effects of weather, roll length: 3 m

ME 17,5 TBUS 1,5/ 5-ST-3,81 GN 2709561 10

RAD-MEMORY 2902828 1

RAD-CABLE-USB 2903447 1

RAD-TAPE-SV-19-3 2903182 1

CONFSTICKS 2.4 GHz Ty p e Order No. Pcs./Pkt.

CONFSTICK for easy and safe network addressing for the 2.4 GHz Radioline wireless module (RAD-2400-IFS), unique network ID, RF band 3

CONFSTICK for easy and safe network addressing for the 2.4 GHz Radioline wireless module (RAD-2400-IFS), unique network ID, RF band 5

CONFSTICK for easy and safe network addressing for the 2.4 GHz Radioline wireless module (RAD-2400-IFS), unique network ID, RF band 7

RAD-CONF-RF3 2902814 1

RAD-CONF-RF5 2902815 1

RAD-CONF-RF7 2902816 1

CONFSTICK 868 MHz Ty p e Order No. Pcs./Pkt.

CONFSTICK for easy and safe network addressing for the 868 MHz

Radioline wireless module (RAD-868-IFS), unique network ID, RF band 1

RAD-868-CONF-RF1 2702197 1

2.4 GHz antennas Ty p e Order No. Pcs./Pkt.

Omnidirectional antenna, 2.4 GHz, 2 dBi, linear vertical, 1.5 m cable,

RSMA (male), IP65, 50 Ω impedance

Omnidirectional antenna with protection against vandalism, 2.4 GHz,

3 dBi gain, IP55 degree of protection, 1.5 m cable length,

RSMA (male) connection, h/v 360°/85° opening angle

Appropriate mounting material is available for wall mounting.

Omnidirectional antenna, 2.4 GHz, 6 dBi, linear vertical, h/v 360°/30°

opening angle, N (female), IP55, incl. mounting bracket and mast clips for

45 mm ... 100 mm diameter, stainless steel, ATEX/IECEx approval

Omnidirectional antenna, 2.4 GHz, 6 dBi, linear vertical, h/v 360°/20°

opening angle, N (female), IP65, seawater-resistant

Omnidirectional antenna, 2.4 GHz, 9 dBi, linear vertical, N (female), IP65,

50 Ω impedance

Directional antenna , 2.4/5 GHz, 9 dBi, linear vertical, N (female), IP67, incl.

mounting bracket and mast clips for 25 mm ... 85 mm diameter, stainless

steel, ATEX/IECEx approval

Parabolic antenna, IP65 degree of protection, 19 dBi gain, linear vertical,

N (female) connection, 50 Ω impedance, h/v 17°/11° opening angle

RAD-ISM-2400-ANT-OMNI-2-1-RSMA 2701362 1

RAD-ISM-2400-ANT-VAN-3-0-RSMA 2701358 1

RAD-ISM-2400-ANT-OMNI-6-0 2885919 1

RAD-2400-ANT-OMNI-6-0-SW 2903219 1

RAD-ISM-2400-ANT-OMNI-9-0 2867623 1

ANT-DIR-2459-01 2701186 1

RAD-ISM-2400-ANT-PAR-19-0 2867885 1

10

PHOENIX CONTACT 105542_en_02

Page 11

Technical data for the wireless modules

868 MHz antennas Ty p e Order No. Pcs./Pkt.

Omnidirectional antenna, 868 MHz, 4 dBi, linear vertical, N (female),

h/v 360°/30° opening angle, IP67, seawater-resistant, incl. mounting

bracket and mast clips for 30 mm ... 45 mm diameter, stainless steel,

ATEX/IECEx approval

Omnidirectional antenna, 868/900 MHz, 2 dBi, linear vertical polarization,

N (female), IP66

Directional antenna, 868 MHz, 3.5 dBi, circular polarized, N (female), IP67,

incl. mounting bracket and mast clips for 25 mm ... 85 mm diameter,

stainless steel, ATEX/IECEx approval

Yagi directional antenna, 868/900 MHz, 8.5 dBi, IP65 degree of protection,

linear vertical polarization, 0.6 m cable length, N (female) connection

Yagi directional antenna, 868/900 MHz, 12.15 dBi, IP65 degree of protection, linear vertical polarization, 0.6 m cable length, N (female) connection

ANT-OMNI-868-01 2702136 1

RAD-900-ANT-OMNI-2-N 2904802 1

ANT-DIR-868-01 2702137 1

RAD-ISM-900-ANT-YAGI-6.5-N 2867814 1

RAD-ISM-900-ANT-YAGI-10-N 5606614 1

Antenna cables and adapters Ty p e Order No. Pcs./Pkt.

Adapter cable as control cabinet feed-through,

N (female) -> RSMA (male), 50 Ω impedance, 0.5 m length

Antenna cable, 0.5 m length, N (male) -> RSMA (male), 50 Ω impedance RAD-PIG-RSMA/N-0.5 2903263 1

Antenna cable, 1 m length, N (male) -> RSMA (male), 50 Ω impedance RAD-PIG-RSMA/N-1 2903264 1

Antenna cable, 2 m length, N (male) -> RSMA (male), 50 Ω impedance RAD-PIG-RSMA/N-2 2903265 1

Antenna cable, 3 m length, N (male) -> RSMA (male), 50 Ω impedance RAD-PIG-RSMA/N-3 2903266 1

Antenna cable, 5 m length, N (male) -> RSMA (male), 50 Ω impedance RAD-PIG-RSMA/N-5 2702140 1

Antenna cable as accessory for leaky wave cable, 0.5 m length,

N (male) -> N (male), attenuation approximately 0.93 dB at 2.4 GHz and

1.6dB at 5GHz

For RAD-2400-IFS: attachment plug with Lambda/4 technology as surge

protection for coaxial signal interfaces. Connection: N connectors

(socket/socket)

For RAD-868-IFS: attachment plug with Lambda/4 technology as surge

protection for coaxial signal interfaces. Connection: N connectors

(socket/socket)

Adapter, N (female) -> N (female) RAD-ADP-N/F-N/F 2867843 1

Adapter, RSMA (male) -> RSMA (female) 90°; insertion loss <0.3 dB at

2.4 GHz

Antenna barrier for installation in Ex Zone 2, separates and transmits

HF signals with intrinsic safety (Ex i) to an antenna in Zone 0, 1 or 2,

0.7 GHz ... 6 GHz frequency range, N (female) -> N (female), ATEX/IECEx

approval

2-way distributor for antenna signals (antenna splitter), N connection

(socket) at the two upper ends and N connection (socket) at the lower end

Antenna cable, 3 m length, N (male) -> N (male), 50 Ω impedance RAD-CAB-EF393- 3M 2867649 1

Antenna cable, 5 m length, N (male) -> N (male), 50 Ω impedance RAD-CAB-EF393- 5M 2867652 1

Antenna cable, 10 m length, N (male) -> N (male), 50 Ω impedance RAD-CAB-EF393-10M 2867665 1

Antenna cable, 15 m length, N (male) -> N (male), 50 Ω impedance RAD-CAB-EF393-15M 2885634 1

RAD-PIG-EF316-N-RSMA 2701402 1

FL LCX PIG-EF142-N-N 2700677 1

CN-LAMBDA/4-5.9-BB 2838490 1

CN-LAMBDA/4-2.2-BB 2800024 1

RAD-ADP-RSMA/M-RSMA/F-90 2904790 1

BAR-ANT-N-N-EX 2702198 1

RAD-SPL-2-N/N 2702293 1

105542_en_02 PHOENIX CONTACT 11

Page 12

RAD-...-IFS

17,5

99

114,5

17,5

99

114,5

Energy supply Ty p e Order No. Pcs./Pkt.

24 V/100 Wp solar system for worldwide use. Consisting of a solar panel,

prewired control cabinet with charge controller, solar batteries, fuses,

surge protection, and mounting material (incl. mast clips).

24 V/200 Wp solar system for worldwide use. Consisting of a solar panel,

prewired control cabinet with charge controller, solar battery, fuses, surge

protection, and mounting material (incl. mast clips).

DIN rail power supply unit, primary-switched, narrow design,

output: 24 V DC/1.5 A

RAD-SOL-SET-24-100 2885472 1

RAD-SOL-SET-24-200 2917722 1

MINI-SYS-PS-100-240AC/24DC/1.5 2866983 1

Control box Ty p e Order No. Pcs./Pkt.

Control box for robust construction of wireless systems for industrial applications, IP65, 25 x 18 x 13 cm, polycarbonate material, gray, drilled, incl.

DIN rail, plugs, and screw connections, without devices

FL RUGGED BOX 2701204 1

Dimensions (nominal sizes in mm)

Dimensions W / H / D 17.5 mm / 99 mm / 114.5 mm

General data

Overvoltage category II

Degree of protection IP20

Pollution degree 2

Housing design PA 6.6 FR, green

Flammability rating UL 94 V0

Supply

Supply voltage range 19.2 V DC ... 30.5 V DC

Maximum current consumption ≤65 mA (at 24 V DC, at 25°C, stand-alone)

Transient surge protection Yes

12

PHOENIX CONTACT 105542_en_02

≤6 A (at 24 V DC, with DIN rail connector at full capacity)

Page 13

Technical data for the wireless modules

System limits RAD-2400-IFS... RAD-868-IFS

Wireless module

Number of supported devices

Number of possible extension modules

Wireless network

I/O data mode

Serial data mode

PLC/Modbus RTU mode

≤250 (addressing via PSI-CONF software)

≤99 (addressing via thumbwheel)

≤32 (per wireless module)

≤99 (I/O extension modules per wireless network, serial interface deactivated)

0 (no I/O extension modules can be used)

≤99 (access to I/O extension modules via Modbus/RTU protocol)

≤99 (per wireless network)

≤32 (per wireless module)

Wireless interface RAD-2400-IFS... RAD-868-IFS

Antenna connection method RSMA (female)

Direction Bidirectional

Frequency 2.4 GHz 868 MHz

Frequency range 2.4002 GHz ... 2.4785 GHz 869.4 MHz ... 869.65 MHz

Number of channel groups 8 14

Number of channels per group 55 Channel distance 1.3 MHz 30 kHz

Data transmission rate (adjustable) 16 kbps

Receiver sensitivity -106.00 dBm (16 kbps)

Transmission power ≤20 dBm (outside of Europe, adjust-

Safety 128-bit data encryption

Operating mode I/O data (default setting, configuration via thumbwheel)

125 kbps

250 kbps

-96.00 dBm (125 kbps)

-93.00 dBm (250 kbps)

able via software)

≤19 dBm (Europe, adjustable via soft-

ware, depends on the data rate)

≤18 dBm (default setting)

Serial data (activation and configuration via PSI-CONF software)

PLC/Modbus RTU mode (activation and configuration via PSI-CONF software)

(depending on the network structure

and data transmission rate)

1.2 kbps

9.6 kbps

19.2 kbps

60 kbps

120 kbps

-122 dBm (1.2 kbps)

-114 dBm (9.6 kbps)

-111 dBm (19.2 kbps)

-104 dBm (60 kbps)

-103 dBm (120 kbps)

≤27 dBm (default setting, adjustable)

RS-232 interface

Connection method COMBICON plug-in screw terminal block

Connection technology 3-wire

Data rate 0.3 kbps ... 115.2 kbps

RS-485 interface

Connection method COMBICON plug-in screw terminal block

Connection technology 2-wire

Data rate 0.3 kbps ... 187.5 kbps

Termination resistor (can be switched on via DIP switches) 390 Ω

105542_en_02 PHOENIX CONTACT 13

150 Ω

390 Ω

Page 14

RAD-...-IFS

Configuration interface

Connection method S-PORT (socket)

RSSI output

Number of outputs 1

Voltage output signal 0 V ... 3 V

RF link relay output

Number of outputs 1

Contact type Changeover contact

Contact material PdRu, gold-plated

Maximum switching voltage 30 V AC/DC / 60 V DC

Maximum switching current 500 mA (30 V AC/DC) / 300 mA (60 V DC)

Electrical service life 5 x 105 switching cycles with 0.5 A at 30 V DC

Connection data

Connection method Screw connection

Conductor cross section solid 0.2 mm² ... 2.5 mm²

Conductor cross section flexible 0.2 mm² ... 2.5 mm²

Conductor cross section AWG/kcmil 24 ... 14

Stripping length 7 mm

Tightening torque 0.6 Nm

Status indicators

Status indicators Green LED (supply voltage, PWR)

Green LED (bus communication, DAT)

Red LED (I/O error, ERR)

3 x green, 1 x yellow LED (LED bar graph for receive quality, RSSI)

Green LED (RS-232/RS-485 receive data, RX)

Green LED (RS-232/RS-485 transmit data, TX)

Ambient conditions

Ambient temperature (operation) -40°C ... 70°C (>55°C derating)

Ambient temperature (storage/transport) -40°C ... 85°C

Permissible humidity (operation) 20% ... 85%

Permissible humidity (storage/transport) 20% ... 85%

Altitude 2000 m

Vibration (operation) According to IEC 60068-2-6: 5g, 10 Hz ... 150 Hz

Shock 16g, 11 ms

-40°F ... 158°F (>131°F derating)

-40°F ... 185°F

Approvals RAD-2400-IFS RAD-868-IFS RAD-2400-IFS-JP

CE conformity R&TTE Directive 1999/5/EC No

ATEX II 3 G Ex nA nC IIC T4 Gc (IBExU 15 ATEX B008 X) No

IECEx Ex nA nC IIC T4 Gc (IECEx IBE 13.0019X) No

FCC FCC Directive Part

ISC ISC Directive RSS 210 No No

UL, USA/Canada UL 508 Listed, Class I,

15.247

Div. 2, Groups A, B, C, D

T4A

Class I, Zone 2, IIC T4

No No

No No

14

PHOENIX CONTACT 105542_en_02

Page 15

Technical data for the wireless modules

Conformity RAD-2400-IFS RAD-868-IFS

Effective use of the radio spectrum according to EN 300328 EN 300220-2

Noise immunity according to EN 61000-6-2

Noise emission according to EN 61000-6-4

Electrical safety according to EN 60950-1

Operating conditions for the extended temperature range (+55°C ... 70°C)

No function restrictions for the extended temperature range if you keep a minimum spacing of 17.5 mm between the modules. The minimum spacing is the width of a DIN rail connector.

Otherwise please observe the following restrictions. Individual operating conditions available on request.

RAD-DAIO6-IFS (2901533):

Do not use the analog loop power output (PWR1).

Only use the analog voltage output (U1).

Do not use more than two of the four possible digital inputs and outputs.

105542_en_02 PHOENIX CONTACT 15

Page 16

RAD-...-IFS

RAD-DOR4-IFS (2901536):

Maximum switching current: 1 A per channel

RAD-AI4-IFS (2901537):

Make sure that no more than 40 mA in total is drawn from loop power outputs

... PWR4.

PWR

1

RAD-AO4-IFS (2901538):

Only use the analog voltage output (0 V ... 10 V).

16

PHOENIX CONTACT 105542_en_02

Page 17

2For your safety

We recommend that you read this user manual before starting up the Radioline wireless

system. Keep this user manual in a place where it is accessible to all users at all times.

The screenshots shown in this user manual may differ from your software version.

2.1 Intended use

The devices are designed for use in industrial environments.

The Radioline wireless system is a Class A item of equipment and may cause radio interfer-

ence in residential areas. In this case, the operator may be required to implement appropriate measures and to pay the costs incurred as a result.

Operation of the wireless system is only permitted if accessories available from

Phoenix Contact are used. The use of other accessory components could invalidate the operating license. You can find the approved accessories for this wireless system listed with

the product at phoenixcontact.net/products

2.1.1 RAD-2400-IFS wireless module

For your safety

.

For the country registrations, please visit phoenixcontact.net/product/2901541.

The RAD-2400-IFS devices comply with R&TTE equipment class 1, with the following

usage restrictions according to ERC Recommendation 70-03:

Norway The device must not be operated within 20 km of the Ny Ålesund town cen-

ter.

Turkey The device may only be operated with Phoenix Contact antennas in accor-

dance with the “Short Range Radio Devices (SRD) Regulations” Gazette

No. 26464 dated March 16, 2007.

Please note that, in combination with antennas, the maximum permissible transmission

power may be exceeded. In this case, set the transmission power via the software (see

“Transmission power” on page 46).

Install the wireless module at least 1 m away from other devices using the 2.4 GHz frequency band (e.g., WLAN, Bluetooth, microwave ovens). Otherwise, both the link quality

and the data transmission speed will be reduced.

2.1.2 RAD-868-IFS wireless module

The RAD-868-IFS wireless module is only approved for use in Europe and South Africa.

105542_en_02 PHOENIX CONTACT 17

Page 18

RAD-...-IFS

Japanese Radio Law and Japanese Telecommunications Business Law Compliance

The device is granted pursuant to the Japanese Radio Law ( ) and the

Japanese Telecommunications Business Law ( ).

This device should not be modified (otherwise the granted designation number will

become invalid.

WARNING: Risk of electric shock

During operation, certain parts of the devices may carry hazardous voltages. Disregarding this warning may

result in serious personal injury and/or damage to equipment.

– Provide a switch/circuit breaker close to the device, which is labeled as the disconnect device for this de-

vice or the entire control cabinet.

– Provide overcurrent protection (I ≤ 6 A) in the installation.

– Disconnect the device from all power sources during maintenance work and configuration (for SELV or

PELV circuits the device can remain connected).

– The housing of the device provides basic insulation against the neighboring devices for 300 V

rms

. If several devices are installed next to each other, this must be taken into consideration and additional insulation

may have to be installed. If the neighboring device is equipped with basic insulation, no additional insulation is required.

2.1.3 RAD-2400-IFS-JP wireless module

The RAD-2400-IFS-JP wireless module is only approved for use in Japan.

The RAD-2400-IFS-JP wireless module does not have ATEX approval. It is not suitable

for use in potentially explosive areas. Only install the wireless module in the safe area.

Install the wireless module at least 1 m away from other devices using the 2.4 GHz frequency band (e.g., WLAN, Bluetooth, microwave ovens). Otherwise, both the link quality

and the data transmission speed will be reduced.

2.2 Installation notes

• RAD-2400-IFS and RAD-868-IFS only: Phoenix Contact hereby declares that this

wireless system complies with the basic requirements and other relevant regulations

specified in Directive 1999/5/EC.

• RAD-2400-IFS and RAD-868-IFS only: The category 3 device is suitable for installation in Zone 2 potentially explosive areas. It meets the requirements of EN 600790:2012+A11:2013 and EN 60079-15:2010.

• Installation, operation, and maintenance must be carried out by qualified electricians.

Follow the installation instructions as described.

• When installing and operating the device, the applicable regulations and safety directives (including national safety directives), as well as the general codes of practice,

must be observed. The technical data is provided in the packing slip and on the certificates (conformity assessment, additional approvals where applicable).

18

PHOENIX CONTACT 105542_en_02

Page 19

For your safety

• Do not open or modify the device. Do not repair the device yourself; replace it with an

equivalent device instead. Repairs may only be carried out by the manufacturer. The

manufacturer is not liable for damage resulting from noncompliance.

• The IP20 degree of protection (IEC 60529/EN 60529) of the device is intended for use

in a clean and dry environment. Do not subject the device to mechanical and/or thermal

loads that exceed the specified limits.

• To protect the device against mechanical or electrical damage, install it in suitable

housing with an appropriate degree of protection according to IEC 60529.

• The device complies with the EMC regulations for industrial areas (EMC class A).

When used in residential areas, the device may cause radio interference.

• Only specified devices from Phoenix Contact may be connected to the 12-pos.

S-PORT interface.

• This device is not designed for use in atmospheres with a risk of dust explosions.

• If dust is present, the device must be installed in suitable approved housing, taking the

surface temperature of the housing into consideration.

2.3 Installation in Zone 2

WARNING: Explosion hazard when used in potentially explosive areas

Make sure that the following notes and instructions are observed.

The RAD-2400-IFS-JP wireless module does not have ATEX approval. It is not suitable

for use in potentially explosive areas. Only install this wireless module in the safe area.

• Observe the specified conditions for use in potentially explosive areas. Install the device in suitable approved housing (with at least IP54 degree of protection) that meets

the requirements of EN 60079-15. Also observe the requirements of EN 60079-14.

• Only connect devices to the supply and signal circuits in Zone 2 that are suitable for operation in Ex Zone 2 and for the conditions at the installation location.

• In potentially explosive areas, only snap the device onto or off the DIN rail connector

and connect/disconnect cables when the power is disconnected.

• The switches of the device that can be accessed may only be actuated when the power

supply to the device is disconnected.

• The device must be stopped and immediately removed from the Ex area if it is damaged, was subjected to an impermissible load, stored incorrectly or if it malfunctions.

• Ensure that the radiated wireless power is neither bundled (focused) by the antenna itself nor by any inserts in the environment of the antenna, and that it cannot enter neighboring Zones 1 or 0. Please refer to the technical data for the transmission power.

• The HF cable to the antenna must be suitable for the ambient conditions. Install the cable so that it is protected against mechanical damage, corrosion, chemical stress, and

negative effects from heat or UV radiation. The same applies to the antenna which is

connected to the cable and which functions as a cable termination.

• The antenna must meet the requirements of EN 60079-0 with regard to housing and

electrostatic charge. Otherwise install the antenna in housing that meets the requirements of EN 60079-0 and EN 60079-15 and has at least IP54 degree of protection

(EN 60529).

105542_en_02 PHOENIX CONTACT 19

Page 20

RAD-...-IFS

Notes for antennas

• Only use antennas approved for the Ex area (see Section “Accessories” on page 9).

• The intrinsically safe antennas support universal communication in various HF areas.

The antennas are intended for use in potentially explosive areas that require

1G equipment. Connection is via antenna barriers (Order No. 2702198) with separate

approval as intrinsically safe equipment.

• Observe the safety notes in the documentation for the respective antenna.

20

PHOENIX CONTACT 105542_en_02

Page 21

For your safety

2.4 Notes for individual I/O extension modules

For RAD-DI4-IFS, RAD-DOR4-IFS, RAD-DAIO6-IFS

WARNING: Risk of electric shock

Use the same phase for digital inputs and outputs. The isolating voltage between the individual channels must not exceed 300 V.

For RAD-AO4-IFS

Use either the current or voltage output at every analog channel.

2.5 UL notes (RAD-2400-IFS only)

For RAD-2400-IFS wireless module

INDUSTRIAL CONTROL EQUIPMENT FOR HAZARDOUS LOCATIONS 45FP

A This equipment is suitable for use in ClassI, Zone2, IIC T4 and ClassI, Division2,

Groups A, B, C, D T4A hazardous locations or non-hazardous locations only.

B WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UN-

LESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

C WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR CLASS 1, DIVISION 2.

D These devices are open-type devices that are to be installed in an enclosure suit-

able for the environment that is only accessible with the use of a tool.

E WARNING - Exposure to some chemicals may degrade the sealing properties of

materials used in relays within this device.

F WARNING - EXPLOSION HAZARD - S-PORT IS FOR MAINTENANCE AND

PROGRAMMING ONLY AND SHOULD ONLY BE USED WHEN THE AREA IS

KNOWN TO BE NON-HAZARDOUS.

For the I/O extension modules

INDUSTRIAL CONTROL EQUIPMENT FOR HAZARDOUS LOCATIONS 45FP

A This equipment is suitable for use in ClassI, Zone2, IIC T4 and ClassI, Division2,

Groups A, B, C, D T4A hazardous locations or non-hazardous locations only.

B WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UN-

LESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

C WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IM-

PAIR SUITABILITY FOR CLASS 1, DIVISION 2.

D These devices are open-type devices that are to be installed in an enclosure suitable

for the environment that is only accessible with the use of a tool.

E WARNING - Exposure to some chemicals may degrade the sealing properties of ma-

terials used in relays within this device.

105542_en_02 PHOENIX CONTACT 21

Page 22

RAD-...-IFS

2.6 FCC and Industry Canada (RAD-2400-IFS only)

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions:

This device may not cause harmful interference. This device must accept any interference

received, including interference that may cause undesired operation.

NOTE: Interference

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case, the user will be required to correct the interference at his own expense.

Any changes or modifications not explicitly approved by PhoenixContact could cause the

device to cease to comply with FCC rules Part 15, and thus void the user's authority to operate the equipment.

Radio frequency exposure:

The device contains a radio transmitter and receiver. During communication the device re-

ceives and transmits radio frequency (RF) electromagnetic fields (microwaves) in the frequency range of 2400 MHz to 2483.5 MHz.

RF Exposure Statement:

This equipment should be installed and operated with a minimum distance of 20 cm be-

tween the radiator and your body.

This transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

This device contains:

FCC ID: YG3RAD2400A

Industry Canada (IC)

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may

cause undesired operation of the device.

This device has been designed to operate with an antenna having a maximum gain of 9 dBi.

Having a higher gain is strictly prohibited per regulations of Industry Canada. The required

antenna impedance is 50 ohms.

To reduce potential radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (EIRP) is not more than that

permitted for successful communication.

This device contains:

IC certificate: 4720B-RAD2400A

22

PHOENIX CONTACT 105542_en_02

Page 23

3 Short description

Wireless communication is based on Trusted Wireless 2.0 technology. The wireless modules meet the high requirements for interference-free data transmission through, among

other things, the use of the frequency-hopping spread spectrum (FHSS) method and

128-bit data encryption (AES).

Wireless modules Frequency band

RAD-2400-IFS, RAD-2400-IFS-JP License-free 2.4 GHz ISM band

RAD-868-IFS 868 MHz ISM band, license-free in Europe

3.1 Wireless modules

In addition to an RS-232 and RS-485 2-wire interface, the wireless modules support the option of directly connecting up to 32 I/O extension modules in the station structure via the DIN

rail connector.

Addressing of the wireless modules and I/O mapping of the extension modules is carried

out quickly and easily by means of the thumbwheel on the front. You can use the yellow

thumbwheel on the wireless module to set the RAD ID and the white thumbwheel on the extension modules to set the I/O MAP address. Programming knowledge is not required. You

can easily start up the wireless network without the need for software.

In addition, the wireless network can be extended with up to 98 RS-485 stations

(RAD-RS485-IFS, Order No. 2702184). I/O data can therefore be distributed across various media using the thumbwheel.

The PSI-CONF configuration and diagnostic software for special functions and diagnostic

options of the wireless module is available free of charge.

Short description

Features

– Flexible network applications: I/O data, serial data, PLC/Modbus RTU mode

– Adjustable data rates for the wireless interface

– Easy point-to-point or network structures (star, mesh)

– Yellow thumbwheel for unique addressing of wireless modules in the wireless network

– Integrated RS-232 and RS-485 interface

– Can be extended with up to 32 I/O modules per station via DIN rail connector (hot-

swappable)

– 128-bit AES data encryption and authentication

– Unique network addressing via plug-in configuration memory (RAD-CONF) for secure,

parallel operation of multiple networks with different RF bands

– Data rates and ranges can be configured using the PSI-CONF software

– International approvals

– Installation in Ex Zone 2 (RAD-2400-IFS and RAD-868-IFS only)

–Can be combined with RS-485 stations

The RAD-RS485-IFS RS-485 front module is not described in this user manual. For additional information, visit phoenixcontact.com/product/2702184.

105542_en_02 PHOENIX CONTACT 23

Page 24

RAD-...-IFS

3.2 Firmware versions

Make sure that all the wireless modules in a network have the same firmware version.

Where possible, always use the latest firmware.

You can download the latest firmware free of charge at phoenixcontact.net/products

Table 3-1 Firmware versions

Function As of firmware version ...

RAD-2400-IFS RAD-868-IFS

Initial version 1.00 1.00

PLC/Modbus RTU mode 1.30 1.00

Support for I/O extension modules

RAD-DI8-IFS and RAD-DO8-IFS

Support for RAD-PT100-4-IFS 1.50 1.00

Support for ETSI EN 300328: V1.8.1 1.60 Support for RS-485 front module

RAD-RS485-IFS

1.40 1.00

1.70 1.70

.

24

PHOENIX CONTACT 105542_en_02

Page 25

Short description

3.3 I/O extension modules

Various I/O extension modules are available for setting up the wireless system quickly and

easily. You can therefore adapt the number and type of signals to the respective application.

Features

– White thumbwheel for easy and tool-free assignment of device pairs (I/O mapping)

– Modular structure via DIN rail connector (hot-swappable)

– Depending on the module: channel-to-channel electrical isolation

– Depending on the module: analog inputs or outputs

(0/4 mA ... 20 mA / 16-bit resolution / <0.1% accuracy)

– Depending on the module: digital wide-range inputs or outputs (0 V ... 250 V AC/DC)

– DIP switches for HOLD/RESET behavior of outputs

– Loop power function for passive sensors

For a detailed description of the available I/O extension modules, refer to the pages listed

below:

Table 3-2 Overview of I/O extension modules

Module type Designation Order

No.

Analog 4 analog inputs RAD-AI4-IFS 2901537 89

4 Pt 100 inputs RAD-PT100-4-IFS 2904035 93

4 analog outputs RAD-AO4-IFS 2901538 100

Digital 4 digital inputs RAD-DI4-IFS 2901535 104

Analog/

digital

8 digital inputs or 2 pulse

inputs

4 digital relay outputs RAD-DOR4-IFS 2901536 113

8 digital transistor outputs RAD-DO8-IFS 2902811 117

1 analog input/output,

2 digital wide-range

inputs/outputs

RAD-DI8-IFS 2901539 108

RAD-DAIO6-IFS 2901533 122

From

page

105542_en_02 PHOENIX CONTACT 25

Page 26

RAD-...-IFS

26

PHOENIX CONTACT 105542_en_02

Page 27

4 Installation

+

2

4

V

R

S

S

I+

R

S

S

I

-

A

N

T

C

O

M

1

N

O

1

N

C

1

R

X

T

X

G

N

D

D

(

A

)

D

(

B

)

Reset

RAD-ID

RAD-2400-IFS

S.PORT

8

8

PW

R

D

A

T

E

R

R

R

X

TX

0

V

+

2

4

V

0

V

R

S

S

I+

R

S

S

I

-

2

1

3

4

5

7

6

9

11

12

17

16

13

15

14

10

8

Installation

4.1 Wireless module structure

Figure 4-1 Wireless module structure

Item Te rm i n a l

Designation

block

1 RSMA antenna connection (socket)

2 2.1/2.2 Test output RSSI (0 V ... 3 V DC) for evaluation of the wireless signal

strength

3 1.1/1.2 Device supply (+24 V DC, GND)

4 S-PORT (12-pos. programming interface)

5 Yellow thumbwheel for setting the RAD ID

6SET button

7 Connection option for DIN rail connector

8DIN rail

9 Metal foot catch for DIN rail fixing

10 4.1/4.2 Connection terminal blocks for RS-485 interface

11 5.1/5.2/5.3 Connection terminal blocks for RS-232 interface

12 6.1/6.2/6.3 Relay output with floating changeover contact (RF link relay)

13 Status LED (RX/TX) for RS-232/RS-485 serial interface

14 LED bar graph for displaying the wireless signal strength

15 ERR status LED, red (communication error)

16 DAT status LED, green (bus communication)

17 PWR status LED, green (supply voltage)

105542_en_02 PHOENIX CONTACT 27

Page 28

RAD-...-IFS

RF

5.1

5.2

5.3

RX

TX

RS232

GND

4.1

4.2

D(A)

D(B)

RS485

RAD-ID

S-Port

1.2

1.1

+24 V

0 V

2.1

2.2

RSSI+

RSSI-

U

IFS

IFS

µC

6.1

6.2

6.3

NC

1

NO

1

COM

1

DC

DC

4.2 Basic circuit diagram

Figure 4-2 Basic circuit diagram for the wireless module

4.3 Mounting and removal

You can connect up to 32 different I/O extension modules to each wireless module via the

DIN rail connector. Data is transmitted and power is supplied to the I/O extension modules

via the bus foot.

When using the device in a connection station, use the supplied 17.5 mm DIN rail connector. Only use the DIN rail connector in conjunction with 24 V DC devices.

– Mount the wireless module to the left and the I/O extension modules only to the right

of the wireless module.

– The individual extension modules can be arranged in any order.

– 2.4 GHz wireless modules only: install the wireless module at least 1 m away from

other devices using the 2.4 GHz frequency band (e.g., WLAN, Bluetooth, microwave

ovens). Otherwise, both the link quality and the data transmission speed will be re-

duced.

28

PHOENIX CONTACT 105542_en_02

Figure 4-3 Radioline connection station with up to 32 I/O extension modules

Page 29

Installation

A

B

C

DE

Figure 4-4 Mounting and removal

Mounting a connection station with DIN rail connectors:

• To form a connection station, connect the DIN rail connectors together.

• Push the connected DIN rail connectors onto the DIN rail.

• Place the device onto the DIN rail from above (see Figure 4-4, D). Make sure that the

device and DIN rail connector are aligned correctly.

• Holding the device by the housing cover, carefully push the device towards the mounting surface so that the device bus connector is securely fixed onto the DIN rail connector.

• Once the snap-on foot snaps onto the DIN rail, check that it is fixed securely. The device

is only mechanically secured via the DIN rail.

• Connect the desired number of I/O extension modules to the wireless module via the

DIN rail connector.

• In order to meet the requirements for the protection class, install the device in suitable

housing.

• During startup, check that the device is operating, wired, and marked correctly.

• A connection can be established between two DIN rail connectors using MINI

COMBICON connectors:

– MC 1,5/5-ST-3,81 (socket, 1803604)

– IMC 1,5/5-ST-3,81 (pin, 1857919)

Device replacement is also possible during operation when outside the Ex area.

105542_en_02 PHOENIX CONTACT 29

Removal

• Use a suitable screwdriver to release the locking mechanism on the snap-on foot of the

device (see Figure 4-4, E).

• Hold onto the device by the housing cover and carefully tilt it upwards.

• Carefully lift the device off the DIN rail connector and the DIN rail.

Page 30

RAD-...-IFS

A

B

8

8

PWR

DAT

ERR

4.4 Connecting cables

Figure 4-5 Connecting cables

For easy installation, it is also possible to pull the screw terminal block out of the device

and to re-insert it after having connected the cables.

• Fit the litz wires with ferrules. Permissible cable cross section: 0.2 mm2... 2.5 mm

2

• Insert the wire with ferrule into the corresponding connection terminal block.

• Use a screwdriver to tighten the screw in the opening above the connection terminal

block. Tightening torque: 0.6 Nm.

30

PHOENIX CONTACT 105542_en_02

Page 31

Installation

+

2

4

V

R

S

S

I

+

R

S

S

I

-

A

N

T

C

O

M

1

N

O

1

N

C

1

R

X

T

X

G

N

D

D

(

A

)

D

(

B

)

Reset

RAD-ID

RAD-2400-IFS

S.PO

RT

8

8

PWR

DA

T

ERR

R

X TX

0

V

1

.1

1

.2

R

S

S

I

+

R

S

S

I-

MINI SYS POWE

R

OUT DC 24 V 1,5 A

DC

OK

2

4

V

1

3

1

4

2

4

V

0

V

0

V

IN AC 100-240V

L NC N(-)

+

2

4

V

R

S

S

I+

R

S

S

I-

A

N

T

C

O

M

1

N

O

1

N

C

1

R

X

T

X

G

N

D

D

(A

)

D

(

B

)

Reset

RAD-ID

RAD-2400-IFS

S.PORT

8

8

PW

R

DA

T

ERR

RX TX

0

V

+

2

4

V

0

V

R

S

S

I+

R

S

S

I-

4.5 Connecting the power supply

Via screw terminal blocks

Connect a DC voltage source (19.2 V ... 30.5 V DC) to the wireless module. The nominal

voltage is 24 V DC. Supply voltage to the device via terminal blocks 1.1 (24V) and 1.2(0V).

In the case of a connection station, it is sufficient to supply the first device in the group.

Figure 4-6 Connecting the power supply

In order to prevent damage to the wireless module, we recommend installing a surge protective device. Make sure the wiring between the surge protective device and the wireless

module is as short as possible. Please also observe the manufacturer’s specifications.

With a system power supply via the bus foot

If DIN rail connectors are used, you can use the MINI-SYS-PS 100-240AC/24DC/1.5 system power supply (Order No. 2866983). Connect the system power supply using two DIN

rail connectors to the left of the device.

Figure 4-7 Supply via system power supply

– Parallel supply via the screw terminal blocks and with a system power supply via the

bus foot is not possible.

– For redundant supply, you can connect a second MINI-SYS-PS 100-

240AC/24DC/1.5 system power supply.

105542_en_02 PHOENIX CONTACT 31

Page 32

RAD-...-IFS

4.6 Serial interfaces

The wireless modules have one RS-232 interface and one RS-485 2-wire interface. Connect the I/O device to the wireless module via the corresponding interface.

– Activate and configure the RS-232 or RS-485 interface using the PSI-CONF software

(from page 45 onwards).

– You can only use one interface per wireless module. Parallel operation of both inter-

faces is not possible.

4.6.1 Shielding of the RS-485 bus cable

• Connect the overall shielding braid of the RS-485 bus cable correctly via an external

shield connection clamp (e.g,. SKS 8-SNS35, Order No. 3062786).

NOTE: Damage to the interface

If the shielding has been connected incorrectly, permanent, external disturbing pulses

may damage the interface.

Observe the polarity of the RS-485 2-wire cable and make sure that the shielding is connected correctly.

Choose the type of the overall shielding braid according to the expected interference:

– Firstly, connect the shield on one side. This suppresses electrical fields.

– To suppress disturbances caused by alternating magnetic fields, connect the shield on

both sides. When doing so, ground loops must be taken into consideration. Galvanic

disturbances along the reference potential can interfere with the useful signal, and the

shielding effect is reduced.

– If several devices are connected to a single bus, the shield must be connected to each

device (e.g., by means of clamps).

– Connect the bus shield to a central PE point using short, low-impedance connections

with a large surface area (e.g., by means of shield connection clamps).

32

PHOENIX CONTACT 105542_en_02

Page 33

Installation

+24V

RSS

I+RSS

I-

ANT

C

O

M

1

N

O

1

N

C

1

R

X

T

X

G

N

D

D

(A

)

D

(B

)

Reset

RAD-ID

RAD-2400-IF

S

S.PORT

8

8

P

W

R

DAT

ERR

RX

TX

0V

+

2

4

V

R

S

S

I

+

RS

S

I

-

0

V

1.2 1.1

2.22.1

6.36.2

5.35.2

6.1

5.1

4.2

4.1

D

C

D

C

I

F

S

I

FS

R

F

S

-

P

o

r

t

R

A

D

ID

0

1

RS

4

8

5

R

s

2

3

2

0

V

+

2

4

V

RS

S

I

RS

S

I+

N

C

1

N

O

1

C

O

M

1

G

N

D

T

X

R

X

D

(

B

)

D

(

A

)

μC

O

F

F

O

N

DIP S

1

2 1

RS

485

Term

inate

“O

FF

“ OF

F

OFF

RS

485

Term

ina

te

“ON“ ON

ON

2 1

F

la

c

hs

m

ar

kts

tr

a

ße

8

3

28

2

5 B

lom

b

er

g

G

erm

a

n

y

R

AD

-2400

-IF

S

O

r

d._

No

.:29

01

541

c 12

X

II 3 G

Ex nA n

C

IIC

T4 G

c X

2 1

OFF

ON

D(B)

D(A)

+

-

RS-485

COMBICON

D(B) + (4.2)

D(A) - (4.1)

4.6.2 Terminating the RS-485 bus cable

The wireless modules are operated on a 2-wire bus cable. RS-485 bus connections must

be terminated at both ends with a 390/150/390 termination network.

• Depending on the position of the device on the RS-485 bus cable, activate or deactivate

the termination network.

Table 4-1 DIP switches 1 and 2: termination network

DIP switches

Device position Te rmi na t io n ne t wo r k 1 2

RS-485 termination device On ON ON

RS-485 device Off OFF OFF

Figure 4-8 DIP switches

4.6.3 RS-485 pin assignment

In RS-485 mode, you can create a network with several I/O devices. Use a twisted pair bus

cable to connect the I/O devices. Fit this bus cable with a termination network at the two furthest points.

• Connect the single wires of the data cable to the COMBICON plug-in screw terminal

block (Figure 4-1, item 10).

• Make sure the signal assignment is correct.

Figure 4-9 RS-485 interface pin assignment

105542_en_02 PHOENIX CONTACT 33

Page 34

RAD-...-IFS

COMBICON

RX (5.1)

TX (5.2)

GND (5.3)

D-SUB-9

RX (2)

TX (3)

GND (5)

PLC (DCE)

RS-232

COMBICON

RX (5.1)

TX (5.2)

GND (5.3)

D-SUB-9

RX (2)

TX (3)

GND (5)

PC (DTE)

RS-232

4.6.4 RS-232 pin assignment

In RS-232 mode, point-to-point connections can be established.

– The RS-232 interface of the wireless module is of DTE type (Data Terminal Equip-

ment). This means that terminal point 5.2 (Tx) is always used to transmit and terminal

point 5.1 (Rx) is always used to receive.

– Only connect the wireless module to devices which meet the requirements of

EN 60950.

According to the standard, you can connect a DCE device (Data Communication Equipment) to the RS-232 interface using a 1:1 cable (Figure 4-10). It is also possible to connect

a DTE device using a crossed cable (Figure 4-11).

Figure 4-10 RS-232 interface pin assignment (DTE - DCE)

Figure 4-11 RS-232 interface pin assignment (DTE - DTE)

If you are not sure whether the device to be connected is of DTE or DCE type, you can also

measure the voltage. Measure the voltage between Tx and GND in the idle state:

– Voltage of approximately -5 V: DTE device

– Voltage of approximately 0 V: DCE device

34

PHOENIX CONTACT 105542_en_02

Page 35

Installation

+

2

4

V

0

V

R

S

S

I+

R

S

S

I-

A

B

+24V

RSS

I+

RSS

I-

AN

T

CO

M

1

N

O

1

N

C

1

RX

TX GND

D(A) D(

B)

Reset

RAD-ID

RAD-2400-IFS

S.PORT

8

8

P

W

R

D

AT

ER

R

R

X

T

X

0V

4.7 Connecting the antenna

The wireless module has an RSMA antenna socket for an external antenna. Various installation examples can be found under “Typical combinations of antennas and adapter cables”

on page 161.

– Install the antenna outside the control cabinet or building.

– Please also observe the installation instructions for the antenna as well as Section

“For your safety” on page 17.

– For information on the transmission power, refer to “Transmission power” on

page 46.

Figure 4-12 Connecting the antenna

105542_en_02 PHOENIX CONTACT 35

Page 36

RAD-...-IFS

36

PHOENIX CONTACT 105542_en_02

Page 37

5 Configuration and startup

5.1 Default settings of the wireless module

All wireless modules are configured to the same default settings when delivered or following

a reset at a later stage.

Table 5-1 Default settings of the wireless module

Parameter Setting

Operating mode I/O data (wire in/wire out)

Wireless interface

Net ID 127

RF band 4 2

Encryption OFF

Network structure Mesh

Device type Repeater/slave

Blacklisting WLAN channel 6 Data rate of the wireless

interface

Receive preamplifier Activated Transmission power 18 dBm 20 dBm 27 dBm

Configuration and startup

RAD-2400-IFS RAD-2400-IFS-JP RAD-868-IFS

125 kbps 9.6 kbps

By default upon delivery, the receive preamplifier is activated. The transmission power is

set so that the devices can cover the greatest possible distances. Therefore, if the devices

are operated directly next to one another the receiver may become overloaded. In this

case, remove the antennas, increase the distance between the devices and antennas or

reduce the transmission power using the PSI-CONF software.

105542_en_02 PHOENIX CONTACT 37

Page 38

RAD-...-IFS

5.1.1 Resetting to the default settings

The device can be reset to the default settings either manually or using the PSI-CONF software.

Manual reset

• Disconnect the device from the supply voltage.

• Hold down the SET button located on the front of the device and switch the supply volt-

age on.

• Hold down the SET button until the DAT LED flashes.

Reset via PSI-CONF software

• In the device selection area, select “Wireless, RAD-2400-IFS” or “Wireless,

RAD-868-IFS”.

• Select “Local Device”.

• Select “Set device to factory default configuration”.

5.1.2 Firmware update

You can download the latest firmware free of charge at phoenixcontact.net/products

You can update the firmware using the PSI-CONF software. The device is reset to the default settings after a firmware update.

• In the device selection area, select “Wireless, RAD-2400-IFS” or “Wireless,

RAD-868-IFS”.

• Select “Update firmware”.

.

38

PHOENIX CONTACT 105542_en_02

Page 39

Configuration and startup

5.2 Operating mode of the wireless module

The Radioline wireless system offers three different options for signal and data transmission:

Table 5-2 Operating mode

Operating mode Configuration

I/O data mode Default setting, configuration only possible via thumbwheel

Serial data mode

PLC/Modbus RTU mode

You can select only one operating mode. It is not possible to simultaneously transmit

I/O signals and serial data.

If the wireless system is operated in an environment where other networks are also present,

e.g., additional Radioline networks, then a configuration memory can be used (see “Configuration via CONFSTICK” on page 42). Extended settings of the wireless modules can also

be configured using the PSI-CONF software (from page 45 onwards).

5.2.1 I/O data mode

Configuration via PSI-CONF software

Figure 5-1 I/O data mode

By default upon delivery, all wireless modules are in I/O data mode. For simple I/O-to-I/O

applications with extension modules, you can easily set the addresses using the thumbwheel. You can therefore establish a wireless connection to other wireless modules without

any programming effort (see “Setting the address of the wireless module using the thumbwheel” on page 42 and “Setting the address of the extension modules via the thumbwheel”

on page 60).

105542_en_02 PHOENIX CONTACT 39

Page 40

RAD-...-IFS

RS-485 RS-485 RS-485

RS-485

RAD-2400-IF

S

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

0

1

SET

D(A)

D(B)

RX

COM

1

TX

NO

2

GND

NC

1

+24V

RSSI

+

0V

ANT

RSSI

-

RAD-D

AIO6-IFS

IO-MAP

OFF ON

DIP-1

1

2

3

4

PWR

DAT

ERR

DO4

DO3

DO2

DO1

DI1L

DI2L

DI1H

DI2H

DI1

DI2

UL1 +I1 -I1

U1 I1

1

COM1

COM2

NO1

NO2

NC1

NC2

1 2

RAD-DOR4-IF

S

8 8

IO-MAP

PWR

DAT

ERR

DO4

DO3

DO2

DO1

OFF ON

DIP-1

1

2

3

4

COM1

NO1

NC1

COM2

NO2

NC2

COM3

NO3

NC3

COM4

NO4

NC4

RAD-AO4-IFS

PWR

DAT

ERR

2 2

IO-MAP

OFF ON

DIP-1

1

2

3

4

U1U2I1

I2 2

1

U3U4I3

I4 4

3

RAD-DI4-IF

S

DI1L

DI2L

DI1H

DI2H

DI1

DI2

PWR

DAT

ERR

DI4

DI3

DI2

DI1

DI3L

DI4L

DI3H

DI4H

DI3

DI4

7 7

IO-MAP

RAD-2400-IF

S

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

0

3

SET

D(A)

D(B)

RX

COM

1

TX

NO

2

GND

NC

1

+24V

RSSI

+

0V

ANT

RSSI

-

RAD-DOR4-IF

S

8 8

IO-MAP

PWR

DAT

ERR

DO4

DO3

DO2

DO1

OFF ON

DIP-1

1

2

3

4

COM1

NO1

NC1

COM2

NO2

NC2

COM3

NO3

NC3

COM4

NO4

NC4

RAD-AO4-IFS

PWR

DAT

ERR

2 2

IO-MAP

OFF ON

DIP-1

1

2

3

4

U1U2I1

I2 2

1

U3U4I3

I4 4

3

RAD-2400-IF

S

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

0

4

SET

D(A)

D(B)

RX

COM

1

TX

NO

2

GND

NC

1

+24V

RSSI

+

0V

ANT

RSSI

-

RAD-DI4-IF

S

DI1L

DI2L

DI1H

DI2H

DI1

DI2

PWR

DAT

ERR

DI4

DI3

DI2

DI1

DI3L

DI4L

DI3H

DI4H

DI3

DI4

8 8

IO-MAP

RAD-AI4-IFS

PWR

DAT

ERR

2 2

IO-MAP

OFF ON

DIP-1

1

2

3

4

Pwr1

Pwr2

+I1

+I2

-I1

-I2

Pwr3

Pwr4

+I3

+I4

-I3

-I4

RAD-2400-IF

S

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

0

2

SET

D(A)

D(B)

RX

COM

1

TX

NO

2

GND

NC

1

+24V

RSSI

+

0V

ANT

RSSI

-

RAD-DOR4-IF

S

8 8

IO-MAP

PWR

DAT

ERR

DO4

DO3

DO2

DO1

OFF ON

DIP-1

1

2

3

4

COM1

NO1

NC1

COM2

NO2

NC2

COM3

NO3

NC3

COM4

NO4

NC4

RAD-DAIO6-IFS

IO-MAP

OFF ON

DIP-1

1

2

3

4

PWR

DAT

ERR

DO4

DO3

DO2

DO1

DI1L

DI2L

DI1H

DI2H

DI1

DI2

UL1 +I1 -I1

U1 I1

1

COM1

COM2

NO1

NO2

NC1

NC2

1 2

RAD-RS485-IFS

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

LINK

0

5

SET

D(A)

D(B)

COM

1

NO1

NC1

+24V

0V

RAD-DOR4-IF

S

7 7

IO-MAP

PWR

DAT

ERR

DO4

DO3

DO2

DO1

OFF ON

DIP-1

1

2

3

4

COM1

NO1

NC1

COM2

NO2

NC2

COM3

NO3

NC3

COM4

NO4

NC4

RAD-AO4-IFS

PWR

DAT

ERR

4 4

IO-MAP

OFF ON

DIP-1

1

2

3

4

U1U2I1

I2 2

1

U3U4I3

I4 4

3

RAD-RS485-IFS

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

LINK

0

6

SET

D(A)

D(B)

COM

1

NO1

NC1

+24V

0V

RAD-DOR4-IF

S

7 7

IO-MAP

PWR

DAT

ERR

DO4

DO3

DO2

DO1

OFF ON

DIP-1

1

2

3

4

COM1

NO1

NC1

COM2

NO2

NC2

COM3

NO3

NC3

COM4

NO4

NC4

RAD-AO4-IFS

PWR

DAT

ERR

4 4

IO-MAP

OFF ON

DIP-1

1

2

3

4

U1U2I1

I2 2

1

U3U4I3

I4 4

3

RAD-RS485-IFS

RAD-ID

S-PORT

PWR

DAT

ERR

RXTX

LINK

0

7

SET

D(A)

D(B)

COM

1

NO1

NC1

+24V

0V

RAD-DOR4-IF

S

7 7

IO-MAP

PWR

DAT

ERR

DO4

DO3

DO2

DO1

OFF ON

DIP-1

1

2

3

4

COM1

NO1

NC1

COM2

NO2

NC2

COM3

NO3

NC3

COM4

NO4

NC4

RAD-AO4-IFS

PWR

DAT

ERR

4 4

IO-MAP

OFF ON

DIP-1

1

2

3

4

U1U2I1

I2 2

1

U3U4I3

I4 4

3

RS-485 front module

The RAD-RS485-IFS RS-485 front module for I/O extension modules allows Radioline stations to be operated via a 2-wire RS-485 bus system. The front module can be extended

with up to 32 I/O extension modules via the DIN rail connector.

You can connect Radioline RS-485 stations to a Radioline master wireless module and

thereby extend the wireless network. All devices in the wireless network and in the RS-485

network form one system. All stations are addressed uniquely using the yellow thumbwheel.

The I/O signals can be distributed easily between all stations, regardless of the medium

used.

40

PHOENIX CONTACT 105542_en_02

Figure 5-2 I/O-to-I/O, wireless, and RS-485

The RAD-RS485-IFS RS-485 front module is not described in this user manual. For additional information, visit phoenixcontact.com/product/2702184

.

Page 41

Configuration and startup

5.2.2 Serial data mode

Figure 5-3 Serial data mode

In serial data mode, multiple controllers or serial I/O devices are networked quickly and easily using wireless technology. In this way, serial RS-232 or RS-485 cables can be replaced.

You need to configure each wireless module using the PSI-CONF software (from page 45

onwards).

5.2.3 PLC/Modbus RTU mode

Figure 5-4 PLC/Modbus RTU mode

You can connect the I/O extension modules to the controller directly via the integrated

RS-232 and RS-485 interface by means of wireless communication. In PLC/Modbus RTU