Page 1

User Manual

Hardware and Firmware User Manual for the

FL IL 24 BK / FL IL 24 BK-PAC

Ethernet/Inline Bus Coupler

Designation:

Order No.:

FL IL 24 BK-PAC UM E

90 14 20 5

Page 2

Page 3

Factory Line

User Manual

Hardware and Firmware User Manual

FL IL 24 BK / FL IL 24 BK-PAC Ethernet/Inline Bus Coupler

Designation:

Revision:

Order No.:

This user manual is valid for:

FL IL 24 BK

FL IL 24 BK-PAC

FL IL 24 BK-PAC UM E

05

90 14 20 5

© Phoenix Contact 09/2004

615605

Page 4

Page 5

Please Observe the Following Notes:

In order to ensure the safe use of your device, we recommend that you read this

manual carefully. The following notes provide information on how to use this manual.

Requirements of the User Group

The use of products described in this manual is oriented exclusively to qualified

electricians or persons instructed by them, who are familiar with applicable national

standards. Phoenix Contact assumes no liability for erroneous handling or damage

to products from Phoenix Contact or external products resulting from disregard of

information contained in this manual.

Explanation of Symbols Used

The note symbol informs you of conditions that must strictly be observed to

achieve error-free operation. It also gives you tips and advice on the efficient use

of hardware and on software optimization to save you extra work.

The attention symbol refers to an operating procedure which, if not carefully followed, could result in damage to equipment or personal injury.

615605

The text symbol refers to detailed sources of information (manuals, data sheets,

literature, etc.) on the subject matter, product, etc. This text also provides helpful

information for the orientation in the manual.

Page 6

FL IL 24 BK-PAC UM E

Statement of Legal Authority

This manual, including all illustrations contained herein, is copyright protected. Use

of this manual by any third party deviating from the copyright provision is forbidden.

Reproduction, translation, or electronic or photographic archiving or alteration requires the express written consent of Phoenix Contact. Violators are liable for

damages.

Phoenix Contact reserves the right to make any technical changes that serve the

purpose of technical progress.

Phoenix Contact reserves all rights in the case of patent award or listing of a registered design. Third-party products are always named without reference to patent

rights. The existence of such rights shall not be excluded.

Warning

The FL IL 24 BK(-PAC) module is designed exclusively for SELV operation according to IEC 60950/EN 60950/VDE 0805.

Shielding

The shielding ground of the twisted pair cables that can be connected is electrically connected with the socket. When connecting network segments, avoid

ground loops, potential transfers, and voltage equalization currents using the

braided shield.

ESD

The modules are fitted with electrostatically sensitive components. Exposure to

electric fields or charge imbalance may damage or adversely affect the life of the

modules.

The following safety equipment must be used when using electrostatically

sensitive modules:

Create an electrical equipotential bonding between yourself and your surroundings, e.g., using an ESD wristband, which is connected to the grounded DIN rail

to which the module will be connected.

Housing

Only authorized Phoenix Contact personnel are permitted to open the housing.

615605

Page 7

About This Manual

Purpose of this manual This manual illustrates how to configure an Ethernet/Inline station to meet applica-

tion requirements.

Who should use this

manual

Related documentation For specific information on the individual Inline terminals see the corresponding ter-

Latest documentation

on the Internet

Use this manual if you are responsible for configuring and installing an Ethernet/Inline station. This manual is written based on the assumption that the reader possesses basic knowledge about Inline systems.

minal-specific data sheets.

Make sure you always use the latest documentation. Changes in or additional information on present documentation can be found on the Internet at

www.phoenixcontact.com

daily. You can also contact us by sending an e-mail to

factoryline-service@phoenixcontact.com.

or www.factoryline.de. The homepages are updated

615605

Page 8

FL IL 24 BK-PAC UM E

Orientation in this

manual

This user manual

includes

Validity of

documentation

For easy orientation when looking for specific information the manual offers the following help:

– The manual starts with the main table of contents that gives you an overview

of all manual topics.

– Each manual section starts with an overview of the section topics.

– On the left side of the pages within the sections you will see the topics that are

covered in the section.

– In the Appendix you will find a list of figures and a list of tables.

In the first section you are introduced to Inline basics and general information that

applies to all terminals or terminal groups of the Inline product range. Topics are,

for example:

– Overview of the Inline product groups

– Terminal structure

– Terminal installation and wiring

– Common technical data

Phoenix Contact reserves the right to make any technical extensions and changes

to the system that serve the purpose of technical progress. Up to the time that a

new manual revision is published, any updates or changes will be documented on

the Internet at www.phoenixcontact.com

or www.factoryline.de.

615605

Page 9

Table of Contents

1 FL IL 24 BK(-PAC)........................................................................................................ 1-3

1.1 General Functions ..................................................................................1-3

1.1.1 Product Description ................................................................1-3

1.2 Structure of the FL IL 24 BK(-PAC) Bus Coupler ...................................1-5

1.2.1 Local Status and Diagnostic Indicators ...................................1-6

1.3 Connecting the Supply Voltage ..............................................................1-7

1.4 Connector Assignment........................................................................... 1-8

1.5 Supported Inline Modules....................................................................... 1-9

1.6 Basic Structure of Low-Level Signal Modules ...................................... 1-16

1.6.1 Electronics Base ...................................................................1-17

1.6.2 Connectors ...........................................................................1-17

1.7 Function Identification and Labeling.....................................................1-21

1.8 Dimensions of Low-Level Signal Modules............................................ 1-24

1.9 Electrical Potential and Data Routing ...................................................1-27

1.10 Circuits Within an Inline Station and Provision

of the Supply Voltages..........................................................................1-29

1.10.1 Supply of the Ethernet Bus Coupler .....................................1-30

1.10.2 Logic Circuit U

1.10.3 Analog Circuit U

1.10.4 Main Circuit U

1.10.5 Segment Circuit .................................................................... 1-33

1.11 Voltage Concept...................................................................................1-35

1.12 Diagnostic and status indicators........................................................... 1-42

1.12.1 LEDs on the Ethernet Bus Coupler ....................................... 1-42

1.12.2 Indicators on the Supply Terminal ........................................1-44

1.12.3 Indicators on the Input/Output Modules ................................1-45

1.12.4 Indicators on Other Inline Modules ....................................... 1-46

1.13 Mounting/Removing Modules and Connecting Cables.........................1-47

1.13.1 Installation Instructions .........................................................1-47

1.13.2 Mounting and Removing Inline Modules ...............................1-47

1.13.3 Mounting ............................................................................... 1-48

1.13.4 Removing .............................................................................. 1-50

1.13.5 Replacing a Fuse ..................................................................1-52

L .......................................................................................

ANA ...............................................................................

M .......................................................................................

1-30

1-31

1-32

615605 i

Page 10

Table of Contents

1.14 Grounding an Inline Station .................................................................. 1-54

1.14.1 Shielding an Inline Station ....................................................1-56

1.14.2 Shielding Analog Sensors and Actuators ............................. 1-56

1.15 Connecting Cables ............................................................................... 1-59

1.15.1 Connecting Unshielded Cables ............................................ 1-59

1.15.2 Connecting Shielded Cables Using the Shield Connector ... 1-61

1.16 Connecting the Voltage Supply ............................................................1-64

1.16.1 Power Terminal Supply ......................................................... 1-64

1.16.2 Provision of the Segment Voltage Supply

at Power Terminals ............................................................... 1-65

1.16.3 Demands on the Power Supply Units ................................... 1-65

1.17 Connecting Sensors and Actuators...................................................... 1-66

1.17.1 Connection Methods for Sensors and Actuators ..................1-66

1.17.2 Connection Examples for Digital I/O Modules ...................... 1-67

2 Startup/Operation ......................................................................................................... 2-3

2.1 Default Upon Delivery/Default Settings .................................................. 2-3

2.2 Firmware Start........................................................................................ 2-3

2.3 Transmitting BootP Requests.................................................................2-4

2.4 Assigning an IP Address Using the Factory Manager............................ 2-4

2.4.1 BootP ......................................................................................2-4

2.5 Manual Addition of Devices Using The Factory Manager ...................... 2-5

2.6 Selecting IP Addresses ..........................................................................2-5

2.6.1 Possible Address Combinations .............................................2-7

2.6.2 Subnet Masks .........................................................................2-8

2.6.3 Structure of the Subnet Mask ................................................. 2-8

2.7 Web-Based Management.....................................................................2-10

2.7.1 Calling Web-Based Management (WBM) ............................. 2-10

2.7.2 Structure of the Web Pages ..................................................2-11

2.7.3 Layout of the Web Pages ..................................................... 2-11

2.7.4 Password Protection ............................................................. 2-12

2.7.5 Process Data Access Via XML ............................................. 2-12

2.8 Firmware Update.................................................................................. 2-17

2.8.1 Firmware Update Using The Factory Manager .....................2-17

ii 615605

Page 11

FL IL 24 BK-PAC UM E

2.9 Firmware Update Using Web-Based Management (WBM)

Without Factory Manager.....................................................................2-19

2.9.1 Trap Generation .................................................................... 2-19

2.9.2 Representation of Traps in the Factory Manager ................. 2-19

2.9.3 FL IL 24 BK(-PAC) Traps ......................................................2-20

2.9.4 Defining the Trap Manager ...................................................2-20

2.10 Factory Line I/O Configurator ...............................................................2-21

2.10.1 Factory Line I/O Browser ......................................................2-21

2.10.2 OPC Configurator .................................................................2-22

2.11 Management Information Base - MIB................................................... 2-24

2.11.1 Standard MIBs: ..................................................................... 2-24

2.12 Interface Group (1.3.6.1.2.1.2) .............................................................2-25

2.12.1 Private MIBs ......................................................................... 2-30

2.13 Meaning of the 7-Segment Display ......................................................2-44

3 Driver Software............................................................................................................. 3-3

3.1 Documentation ....................................................................................... 3-3

3.1.1 Hardware and Firmware User Manual .................................... 3-3

3.2 Software Structure..................................................................................3-3

3.2.1 Ethernet/Inline Bus Coupler Firmware .................................... 3-4

3.2.2 Driver Software ....................................................................... 3-4

3.3 Support and Driver Update.....................................................................3-5

3.4 Transfer of I/O Data................................................................................3-6

3.4.1 Position of the Process Data (Example) ................................. 3-7

3.5 Startup Behavior of the Bus Coupler...................................................... 3-8

3.5.1 Plug & Play Mode ...................................................................3-8

3.5.2 Expert Mode ...........................................................................3-9

3.5.3 Possible Combinations of the Modes ..................................... 3-9

3.5.4 Startup Diagrams of the Bus Coupler ................................... 3-10

3.5.5 Changing and Starting a Configuration in P&P Mode ........... 3-12

3.6 Changing a Reference Configuration Using the Software....................3-13

3.6.1 Effects of Expert Mode .........................................................3-13

3.6.2 Changing a Reference Configuration ...................................3-13

3.7 Description of the Device Driver Interface (DDI) Introduction............... 3-15

3.7.1 Overview ...............................................................................3-15

3.7.2 Working Method of the Device Driver Interface ....................3-16

3.7.3 Description and Functions of the

Device Driver Interface .........................................................3-18

615605 iii

Page 12

Table of Contents

3.8 Monitoring Functions............................................................................3-33

3.8.1 Process Data Monitoring/

Process Data Watchdog ....................................................... 3-35

3.8.2 Connection Monitoring (Host Checking) ............................... 3-37

3.8.3 Data Interface (DTI) Monitoring ............................................ 3-40

3.8.4 I/O Fault Response Mode ..................................................... 3-44

3.8.5 Treatment of the NetFail Signal/Testing With

ETH_SetNetFail .................................................................... 3-46

3.9 IN Process Data Monitoring.................................................................. 3-52

3.10 Notification Mode.................................................................................. 3-56

3.11 Programming Support Macros..............................................................3-58

3.11.1 Introduction ........................................................................... 3-58

3.12 Description of the Macros..................................................................... 3-60

3.12.1 Macros for Converting the Data Block of a Command ..........3-61

3.12.2 Macros for Converting the Data Block of a Message ............ 3-63

3.12.3 Macros for Converting Input Data .........................................3-65

3.12.4 Macros for Converting Output Data ......................................3-66

3.13 Diagnostic Options for Driver Software ................................................ 3-68

3.13.1 Introduction ........................................................................... 3-68

3.14 Positive Messages................................................................................ 3-69

3.15 Error Messages....................................................................................3-70

3.15.1 General Error Messages .......................................................3-70

3.15.2 Error Messages When Opening a Data Channel .................. 3-72

3.15.3 Error Messages When Transmitting

Messages/Commands ..........................................................3-73

3.15.4 Error Messages When Transmitting Process Data ............... 3-75

3.16 Example Program................................................................................. 3-78

3.16.1 Demo Structure Startup ........................................................ 3-78

3.16.2 Example Program Source Code ...........................................3-80

4 Firmware Services........................................................................................................ 4-3

4.1 Overview.................................................................................................4-3

4.1.1 Services Available in Both Operating Modes ..........................4-3

4.1.2 Services Available Only in Expert Mode ................................. 4-4

4.2 Notes on Service Descriptions ...............................................................4-4

4.2.1 "Name_of_the_Service" Service .............................................4-5

4.3 Services for Parameterizing the Controller Board ..................................4-7

4.3.1 "Control_Parameterization" Service ........................................ 4-7

iv 615605

Page 13

FL IL 24 BK-PAC UM E

4.3.2 "Set_Value" Service ................................................................4-9

4.3.3 "Read_Value" Service ........................................................... 4-11

4.3.4 "Initiate_Load_Configuration" Service ..................................4-13

4.3.5 "Load_Configuration" Service ............................................... 4-15

4.3.6 "Terminate_Load_Configuration" Service ............................. 4-18

4.3.7 "Read_Configuration" Service .............................................. 4-20

4.3.8 "Complete_Read_Configuration" Service ............................. 4-26

4.3.9 "Delete_Configuration" Service ............................................. 4-29

4.3.10 "Create_Configuration" Service ............................................4-30

4.3.11 "Activate_Configuration" Service ..........................................4-32

4.3.12 "Control_Device_Function" Service ...................................... 4-34

4.3.13 "Reset_Controller_Board" Service ........................................4-36

4.4 Services for Direct INTERBUS Access ................................................4-38

4.4.1 "Start_Data_Transfer" Service .............................................. 4-38

4.4.2 "Alarm_Stop" Service ............................................................ 4-40

4.5 Diagnostic Services.............................................................................. 4-41

4.5.1 "Get_Error_Info" Service ....................................................... 4-41

4.5.2 "Get_Version_Info" Service .................................................. 4-47

4.6 Error Messages for Firmware Services ................................................ 4-50

4.6.1 Overview ...............................................................................4-50

4.6.2 Positive Messages ................................................................ 4-51

4.6.3 Error Messages ....................................................................4-51

5 PCP Communication .................................................................................................... 5-3

5.1 Transmission of Parameter Data............................................................5-3

5.1.1 PCP Configuration in the Web-Based Management ............... 5-4

5.1.2 Configuration of the PCP PDU Size ....................................... 5-4

5.2 Supported PCP Commands................................................................... 5-5

6 Modbus/TCP Protocol ..................................................................................................6-3

6.1 Modbus Protocol.....................................................................................6-3

6.1.1 Modbus Connections ..............................................................6-3

6.1.2 Modbus Port ...........................................................................6-4

6.1.3 Modbus Conformance Classes ............................................... 6-4

6.1.4 Modbus Message Format .......................................................6-4

6.1.5 Modbus Byte Order ................................................................. 6-4

6.1.6 Modbus Bit Order .................................................................... 6-5

6.2 Modbus Function Codes.........................................................................6-5

615605 v

Page 14

Table of Contents

6.3 Modbus Table......................................................................................... 6-5

6.3.1 Dynamic Modbus/TCP Process Data Table ........................... 6-6

6.3.2 Example: Location of the Input/Output Data ........................... 6-7

6.3.3 Location of the Process Data in Dynamic Tables ................... 6-8

6.4 Applicable Functions .............................................................................. 6-9

6.5 Supported Function Codes.....................................................................6-9

6.5.1 Read Multiple Registers ........................................................ 6-10

6.5.2 Write Multiple Registers ........................................................ 6-11

6.5.3 Read Coils ............................................................................ 6-12

6.5.4 Read Input Discretes ............................................................6-13

6.5.5 Read Input Registers ............................................................6-14

6.5.6 Write Coils ............................................................................6-15

6.5.7 Write Single Register ............................................................6-16

6.5.8 Read Exception Status ......................................................... 6-17

6.5.9 Exception Status Data Format .............................................. 6-17

6.5.10 Exception Responses ........................................................... 6-18

6.5.11 Write Multiple Coils ............................................................... 6-19

6.5.12 Read/Write Register .............................................................6-20

6.6 Reserved Registers for

Command and Status Words ...............................................................6-22

6.6.1 Command Word .................................................................... 6-22

6.6.2 Status Word ..........................................................................6-23

6.6.3 Diagnostics Using the Analog Input Table ............................ 6-23

6.6.4 Fault Table ............................................................................ 6-24

6.7 Monitoring............................................................................................. 6-25

6.8 Modbus Monitoring............................................................................... 6-26

6.9 I/O Fault Response Mode..................................................................... 6-26

6.9.1 Power Up Table ....................................................................6-27

6.9.2 Connection Monitoring Table ................................................ 6-28

6.10 Modbus/TCP PCP Registers ................................................................ 6-30

7 Technical Data.............................................................................................................. 7-3

7.1 Ordering Data....................................................................................... 7-11

vi 615605

Page 15

Section 1

This section provides information about

– the basic structure of low-level signal modules

– the assignment and meaning of the diagnostic and status indicators on the va-

rious Inline modules

– potential and data routing

– housing dimensions and labeling options for the modules

– general information on the module circuit diagrams

FL IL 24 BK(-PAC)............................................................................................................ 1-3

1.1 General Functions ..................................................................................1-3

1.1.1 Product Description .................................................................1-3

1.2 Structure of the FL IL 24 BK(-PAC) Bus Coupler ...................................1-5

1.2.1 Local Status and Diagnostic Indicators....................................1-6

1.3 Connecting the Supply Voltage ..............................................................1-7

1.4 Connector Assignment........................................................................... 1-8

1.5 Supported Inline Modules....................................................................... 1-9

1.6 Basic Structure of Low-Level Signal Modules ...................................... 1-16

1.6.1 Electronics Base....................................................................1-17

1.6.2 Connectors ............................................................................1-17

1.7 Function Identification and Labeling.....................................................1-21

1.8 Dimensions of Low-Level Signal Modules............................................ 1-24

1.9 Electrical Potential and Data Routing ...................................................1-27

1.10 Circuits Within an Inline Station and Provision of the

Supply Voltages....................................................................................1-29

1.10.1 Supply of the Ethernet Bus Coupler ...................................... 1-30

1.10.2 Logic Circuit U

1.10.3 Analog Circuit U

1.10.4 Main Circuit U

1.10.5 Segment Circuit ..................................................................... 1-33

1.11 Voltage Concept...................................................................................1-35

1.12 Diagnostic and status indicators........................................................... 1-42

1.12.1 LEDs on the Ethernet Bus Coupler........................................ 1-42

1.12.2 Indicators on the Supply Terminal ......................................... 1-44

1.12.3 Indicators on the Input/Output Modules................................. 1-45

1.12.4 Indicators on Other Inline Modules ........................................ 1-46

615605 1-1

L ........................................................................................

ANA................................................................................

M ........................................................................................

1-30

1-31

1-32

Page 16

FL IL 24 BK-PAC UM E

1.13 Mounting/Removing Modules and Connecting Cables.........................1-47

1.13.1 Installation Instructions ..........................................................1-47

1.13.2 Mounting and Removing Inline Modules................................1-47

1.13.3 Mounting................................................................................ 1-48

1.13.4 Removing...............................................................................1-50

1.13.5 Replacing a Fuse...................................................................1-52

1.14 Grounding an Inline Station .................................................................. 1-54

1.14.1 Shielding an Inline Station .....................................................1-56

1.14.2 Shielding Analog Sensors and Actuators .............................. 1-56

1.15 Connecting Cables ............................................................................... 1-59

1.15.1 Connecting Unshielded Cables ............................................. 1-59

1.15.2 Connecting Shielded Cables Using the Shield Connector .... 1-61

1.16 Connecting the Voltage Supply ............................................................1-64

1.16.1 Power Terminal Supply.......................................................... 1-64

1.16.2 Provision of the Segment Voltage Supply at

Power Terminals.................................................................... 1-65

1.16.3 Demands on the Power Supply Units....................................1-65

1.17 Connecting Sensors and Actuators...................................................... 1-66

1.17.1 Connection Methods for Sensors and Actuators ................... 1-66

1.17.2 Connection Examples for Digital I/O Modules ....................... 1-67

1-2 615605

Page 17

1 FL IL 24 BK(-PAC)

1.1 General Functions

1.1.1 Product Description

Ethernet/Inline bus coupler

Features

– Ethernet coupler for the Inline I/O system

– Ethernet TCP/IP

- 10/100 Base-T(X)

- Management via SNMP

- Integrated web server

– Modbus/TCP protocol

– DDI (Device Driver Interface) protocol software interface

– Up to 63 additional Inline modules can be connected (process data channel)

up to eight PCP modules can be connected

– Flexible installation system for Ethernet

– IP parameter setting via BootP, web-based management (WBM) or SNMP

– Driver software for Sun Solaris/Windows NT/2000

– Software interface kit for other Unix systems

FL IL 24 BK(-PAC)

Applications

– Connection of sensors/actuators via Ethernet

Exchange of Inline process data via Ethernet using a Unix workstation or a

Windows NT/2000 computer.

615605 1-3

Page 18

FL IL 24 BK-PAC UM E

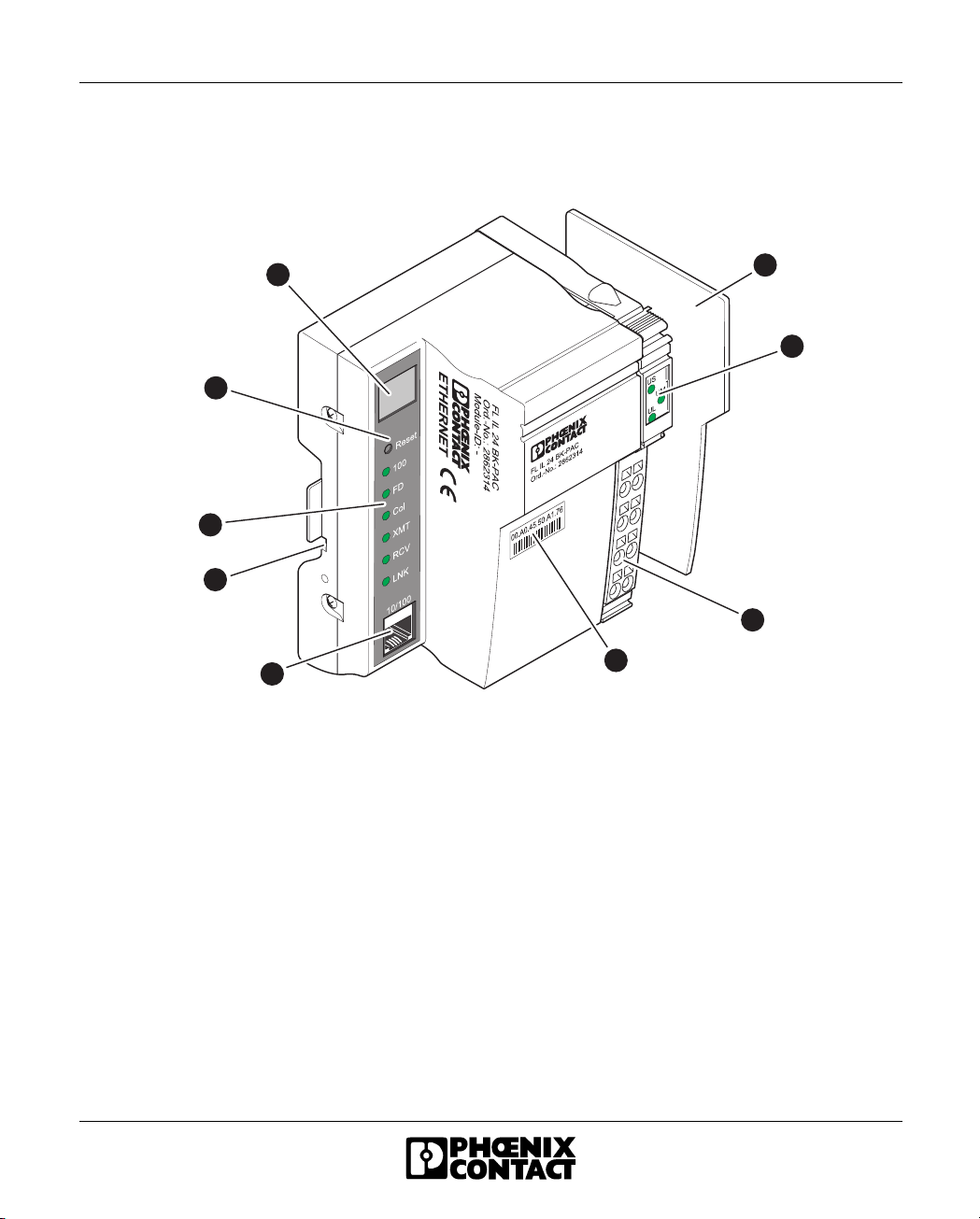

Front view of the FL IL 24 BK(-PAC)

F L I L 2 4 B K - P A C

R E S E T

O r d . - N o . : 2 8 6 2 3 1 4

U S

U M

U L

1 0 0

F D

0 0 . A 0 . 4 5 . 5 0 . A 1 . 7 7

C O L

X M T

R C V

L I N K

1 0 / 1 0 0

Figure 1-1 Front view of the FL IL 24 BK(-PAC)

1 2

1

2

3

4

6 1 5 5 0 0 0 2

1

2

3

4

1-4 615605

Page 19

FL IL 24 BK(-PAC)

1.2 Structure of the FL IL 24 BK(-PAC)

Bus Coupler

9

1

2

8

7

6

3

5

Figure 1-2 Structure of the FL IL 24 BK(-PAC) bus coupler

The bus coupler has the following components:

1 End plate to protect the last Inline module

2 Inline diagnostic indicators

3 24 V DC supply and functional earth ground connector

(not supplied as standard - order as an accessory)

4 MAC address in clear text and as a barcode

5 Ethernet interface (twisted pair cables in RJ45 format)

6 Two FE contacts for grounding the bus coupler using a DIN rail

(on the back of the module)

7 Ethernet status and diagnostic indicators

8 Reset button

9 7-segment display for the device status (Ethernet communication unit)

4

615605 1-5

Page 20

FL IL 24 BK-PAC UM E

1.2.1 Local Status and Diagnostic Indicators

Table 1-1 Local status and diagnostic indicators

Des. Color Status Meaning

Module Electronics

UL Green ON 24 V supply, 7 V communications power/interface supply present

OFF 24 V supply, 7 V communications power/interface supply not present

UM Green ON 24 V main circuit supply present

OFF 24 V main circuit supply not present

US Green ON 24 V segment supply present

OFF 24 V segment supply not present

Ethernet Port

100 Green ON Operation at 100 Mbps

OFF Operation at 10 Mbps (if LNK LED active)

FD Green ON Data transmission in full duplex mode

OFF Data transmission in half duplex mode (if LNK LED active)

COL Red ON Collision of data telegrams

OFF Transmission of telegrams without a collision (if LNK LED active)

XMT Green ON Data telegrams are being sent

OFF Data telegrams are not being sent

RCV Yellow ON Data telegrams are being received

OFF Data telegrams are not being received

LNK Green ON Physical network connection ready to operate

OFF Physical network connection interrupted or not present

Reset button

The reset button is on the front plate. When the reset button is pressed the bus

coupler is completely initialized and booted. Inline system outputs are reset and

inputs are not read.

1-6 615605

Page 21

1.3 Connecting the Supply Voltage

The module is operated using a +24 V DC SELV.

Typical Connection of the Supply Voltage

U S

U M

U L

I n t e r n a l j u m p e r

( i n t h e m o d u l e )

1 2

1

1

2

2

+

3

3

-

S G N D

4

4

1 0 0

F D

C O L

X M T

R C V

L I N K

1 0 / 1 0 0

R E S E T

F L I L 2 4 B K - P A C

O r d . - N o . : 2 8 6 2 3 1 4

U

L G N D

B K

FL IL 24 BK(-PAC)

+

U

S

+

-

U

M

-

6 1 5 5 1 0 1 1

Figure 1-3 Typical connection of the supply voltage

615605 1-7

Page 22

FL IL 24 BK-PAC UM E

1.4 Connector Assignment

Table 1-2 Connector assignment

Termina l

Assignment/Power Connector Wire Color/Remark

Point/

Connector

1.1 24 V DC

)

(U

S

1.2 24 V DC

(U

BK

2.1, 2.2 24 V DC

24 V segment supply The supplied voltage is directly led to the potential jumper.

24 V supply The communications power for the bus coupler and the

)

Main voltage The main voltage is routed to the local bus devices via the

(UM)

1.3 LGND Reference potential

logic ground for U

BK

2.3 SGND Reference potential

and U

for U

S

M

1.4, 2.4 FE Functional earth

ground (FE)

connected local bus devices is generated from this power.

The 24 V analog power (U

) for the local bus devices is

ANA

also generated.

potential jumpers.

The potential is the reference ground for the communications

power U

BK

.

The reference potential is directly led to the potential jumper

and is, at the same time, ground reference for the main and

segment supply.

The functional earth ground must be connected to the 24 V

DC supply/functional earth ground connection. The contacts

are directly connected to the potential jumper and FE springs

on the bottom of the housing. The terminal is grounded when

it is snapped onto a grounded DIN rail. Functional earth

ground is only used to discharge interference.

The GND potential jumper carries the total current from the main and segment

circuits. The total current must not exceed the maximum current carrying capacity

of the potential jumper (8 A). If the 8 A limit is reached at one of the potential

jumpers U

, UM, and GND during configuration, a new power terminal must be

S

used.

Functional earth ground must be connected through the 24 V DC supply/

functional earth ground connection.

1-8 615605

Page 23

FL IL 24 BK(-PAC)

1.5 Supported Inline Modules

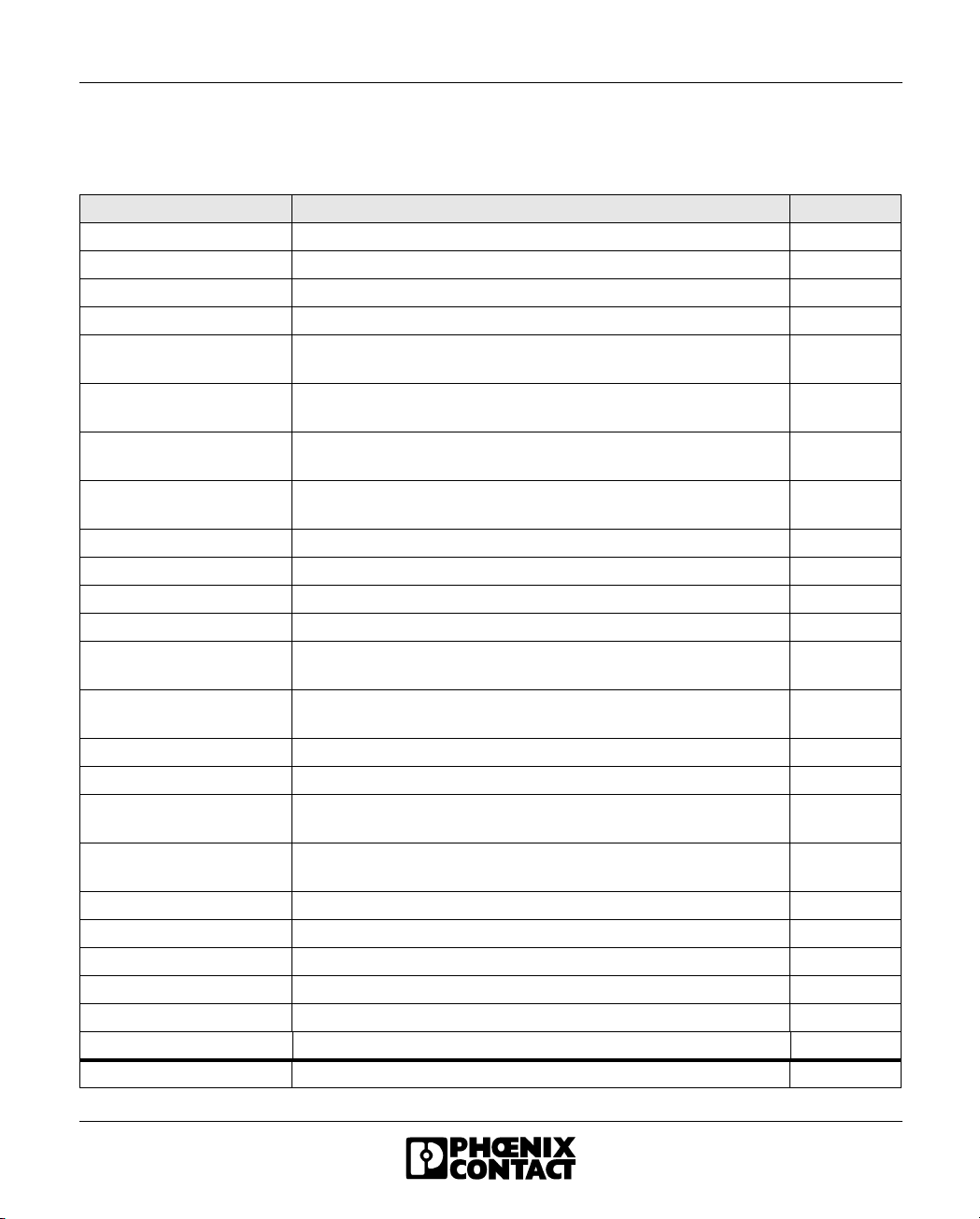

Table 1-3 Digital Input/Output Modules

Designation Properties Order No.

IB IL 24 DI 2 2 inputs, 4-wire termination, 24 V DC 27 26 20 1

IB IL 24 DI 2-PAC 2 inputs, 4-wire termination, 24 V DC 28 61 22 1

IB IL 24 DI 2-NPN 2 inputs with negative logic, 4-wire termination, 24 V DC 27 40 11 2

IB IL 24 DI 2-NPN-PAC 2 inputs with negative logic, 4-wire termination, 24 V DC 28 61 48 3

IB IL 24 EDI 2 2 inputs, 4-wire termination, with electronic overload protection

and diagnostics

IB IL 24 EDI 2-PAC 2 inputs, 4-wire termination, with electronic overload protection

and diagnostics

IB IL 24 EDI 2-DESINA 2 inputs, 4-wire termination according to Desina specification, with

electronic overload protection and diagnostics

IB IL 24

EDI 2-DESINA-PAC

IB IL 24 DI 4 4 inputs, 3-wire termination, 24 V DC 27 26 21 4

IB IL 24 DI 4-PAC 4 inputs, 3-wire termination, 24 V DC 28 61 23 4

IB IL 24 DI 8 8 inputs, 4-wire termination, 24 V DC 27 26 22 7

IB IL 24 DI 8-PAC 8 inputs, 4-wire termination, 24 V DC 28 61 24 7

IB IL 24 DI 8 T2 8 inputs, 4-wire termination, 24 V DC,

IB IL 24 DI 8 T2-PAC 8 inputs, 4-wire termination, 24 V DC,

IB IL 24 DI 16 16 inputs, 3-wire termination, 24 V DC 27 26 23 0

IB IL 24 DI 16-PAC 16 inputs, 3-wire termination, 24 V DC 28 61 25 0

IB IL 24 DI 16-NPN 16 inputs with negative logic,

IB IL 24 DI 16-NPN-PAC 16 inputs with negative logic, 3-wire termination,

IB IL 24 DI 32/HD 32 inputs, 1-wire termination, 24 V DC 28 60 78 5

IB IL 24 DI 32/HD-PAC 32 inputs, 1-wire termination, 24 V DC 28 62 83 5

IB IL 120 DI 1 1 input, 3-wire termination, 120 V AC 28 36 70 6

IB IL 120 DI 1-PAC 1 input, 3-wire termination, 120 V AC 28 61 91 7

IB IL 230 DI 1 1 input, 3-wire termination, 230 V AC 27 40 34 2

IB IL 230 DI 1-PAC 1 input, 3-wire termination, 230 V AC 28 61 54 8

IB IL 24 DO 2 2 outputs, 500 mA, 4-wire termination, 24 V DC 27 40 10 6

2 inputs, 4-wire termination according to Desina specification, with

electronic overload protection and diagnostics

according to EN 61131-2 Type 2

according to EN 61131-2 Type 2

3-wire termination, 24 V DC

24 V DC

27 42 60 9

28 61 62 9

27 40 32 6

28 61 52 2

28 60 43 9

28 62 20 4

28 63 51 7

28 63 52 0

615605 1-9

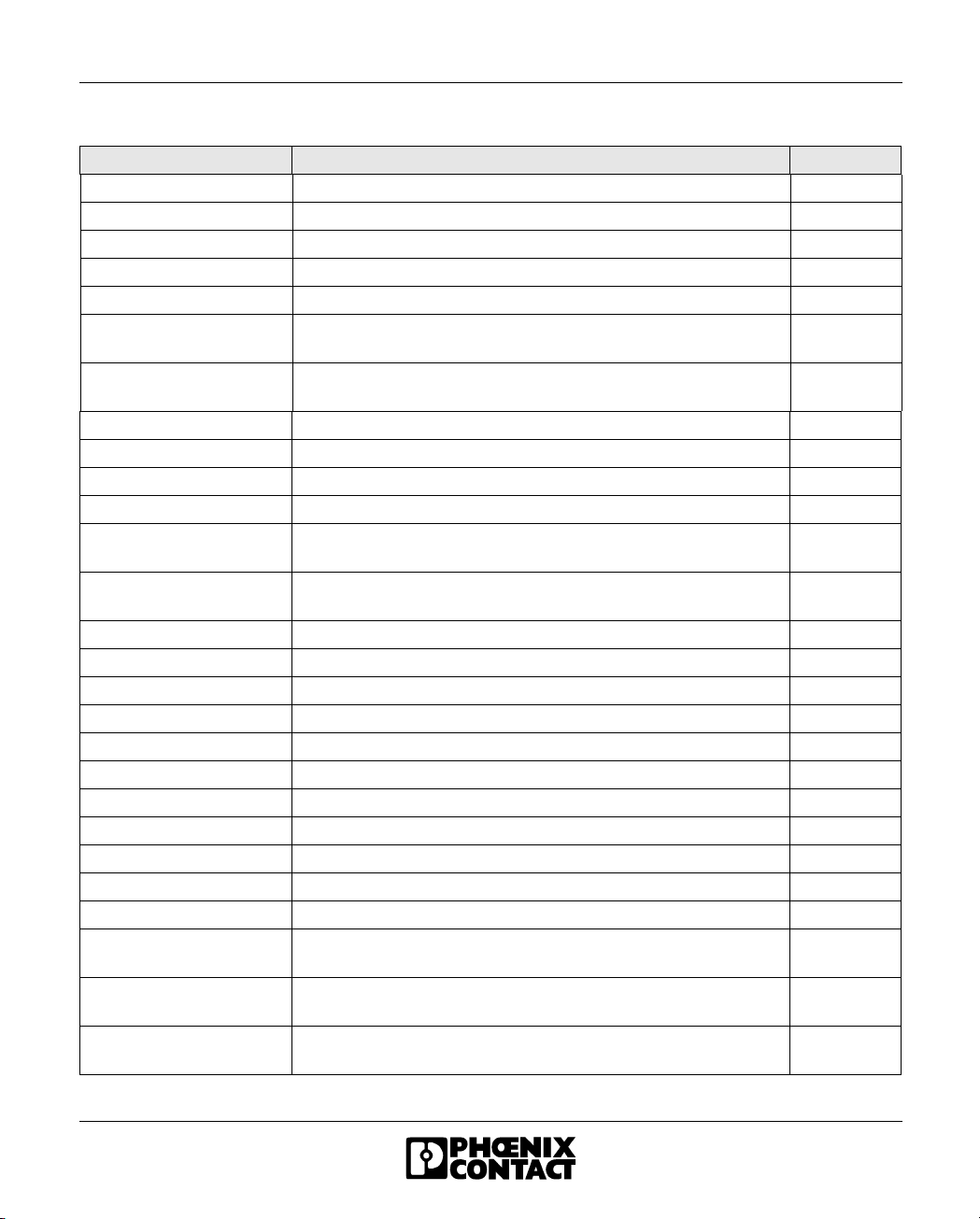

Page 24

FL IL 24 BK-PAC UM E

Table 1-3 Digital Input/Output Modules

Designation (Contd.) Properties Order No.

IB IL 24 DO 2-PAC 2 outputs, 500 mA, 4-wire termination, 24 V DC 28 61 47 0

IB IL 24 DO 2-2A 2 outputs, 2 A, 4-wire termination, 24 V DC 27 26 24 3

IB IL 24 DO 2-2A-PAC 2 outputs, 2 A, 4-wire termination, 24 V DC 28 61 26 3

IB IL 24 DO 2-NPN 2 outputs with negative logic, 500 mA, 4-wire termination, 24 V DC 27 40 11 9

IB IL 24 DO 2-NPN-PAC 2 outputs with negative logic, 500 mA, 4-wire termination, 24 V DC 28 61 49 6

IB IL 24 EDO 2 2 outputs, 500 mA, 4-wire termination, 24 V DC, extended

diagnostics, configurable outputs

IB IL 24 EDO 2-PAC 2 outputs, 500 mA, 4-wire termination, 24 V DC, extended

diagnostics, configurable outputs

IB IL 24 DO 4 4 outputs, 500 mA, 3-wire termination, 24 V DC 27 26 25 6

IB IL 24 DO 4-PAC 4 outputs, 500 mA, 3-wire termination, 24 V DC 28 61 27 6

IB IL 24 DO 8 8 outputs, 500 mA, 4-wire termination, 24 V DC 27 26 26 9

IB IL 24 DO 8-PAC 8 outputs, 500 mA, 4-wire termination, 24 V DC 28 61 28 9

IB IL 24 DO 8-NPN 8 outputs with negative logic, 500 mA,

4-wire termination, 24 V DC

IB IL 24 DO 8-NPN-PAC 8 outputs with negative logic, 500 mA,

4-wire termination, 24 V DC

IB IL 24 DO 8-2A 8 outputs, 2 A, 4-wire termination, 24 V DC 27 42 11 7

IB IL 24 DO 8-2A-PAC 8 outputs, 2 A, 4-wire termination, 24 V DC 28 61 60 3

IB IL 24 DO 16 16 outputs, 500 mA, 3-wire termination, 24 V DC 27 26 27 2

IB IL 24 DO 16-PAC 16 outputs, 500 mA, 3-wire termination, 24 V DC 28 61 29 2

IB IL 24 DO 32/HD 32 outputs, 500 mA, 1-wire termination, 24 V DC 28 60 93 4

IB IL 24 DO 32/HD-PAC 32 outputs, 500 mA, 1-wire termination, 24 V DC 28 62 82 2

IB IL DO 1 AC 1 output, 12 V - 253 V AC, 500 mA, 3-wire termination 28 36 74 8

IB IL DO 1 AC-PAC 1 output, 12 V - 253 V AC, 500 mA, 3-wire termination 28 61 92 0

IB IL DO 4 AC-1A 1 output, 12 V - 253 V AC, 1 A, 3-wire termination 27 42 69 6

IB IL DO 4 AC-1A-PAC 1 output, 12 V - 253 V AC, 1 A, 3-wire termination 28 61 65 8

IB IL 24/230 DOR 1/W 1 SPDT relay contact, 5 V - 253 V AC, 3 A 28 36 43 4

IB IL 24/230 DOR 1/W-

PAC

IB IL 24/230 DOR 1/W-PC 1 SPDT relay contact, 5 V - 253 V AC, 3 A, for inductive and

IB IL 24/230 DOR 1/WPC-PAC

1 SPDT relay contact, 5 V - 253 V AC, 3 A 28 61 88 1

capacitive loads

1 SPDT relay contact, 5 V - 253 V AC, 3 A, for inductive and

capacitive loads

27 42 59 9

28 61 61 6

28 63 54 6

28 63 53 3

28 60 40 0

28 62 17 8

1-10 615605

Page 25

FL IL 24 BK(-PAC)

Table 1-3 Digital Input/Output Modules

Designation (Contd.) Properties Order No.

IB IL 24/230 DOR 4/W 4 SPDT relay contacts, 5 V - 253 V AC, 3 A 28 36 42 1

IB IL 24/230 DOR 4/W-

4 SPDT relay contacts, 5 V - 253 V AC, 3 A 28 61 87 8

PAC

IB IL 24/230 DOR 4/W-PC 4 SPDT relay contacts, 5 V - 253 V AC, 3 A, for inductive and

28 60 41 3

capacitive loads

IB IL 24/230 DOR 4/W-

PC-PAC

4 SPDT relay contacts, 5 V - 253 V AC, 3 A, for inductive and

capacitive loads

28 62 18 1

IB IL 24/48 DOR/2W 2 SPDT relay contacts, 5 V - 50 V AC, 5 V - 120 V DC, 2 A 28 62 97 4

IB IL 24/48 DOR/2W-PAC 2 SPDT relay contacts, 5 V - 50 V AC, 5 V - 120 V DC, 2 A 28 63 11 9

Table 1-4 Analog input/output modules

Designation Properties Order No.

IB IL AI 2/4-20 2 inputs, 2-wire termination, 24 V DC, 0 -10 V, ±10 V,

28 60 44 2

0 - 20 mA, 4 - 20 mA, ±20 mA

IB IL AI 2/4-20-PAC 2 inputs, 2-wire termination, 24 V DC, 0 -10 V, ±10 V,

28 62 21 7

0 - 20 mA, 4 - 20 mA, ±20 mA

IB IL AI 2/SF 2 inputs, 2-wire termination, 24 V DC, 0 -10 V, ±10 V,

27 26 28 5

0 - 20 mA, 4 - 20 mA, ±20 mA, 0 - 40 mA, ±40 mA

IB IL AI 2/SF-PAC 2 inputs, 2-wire termination, 24 V DC, 0 -10 V, ±10 V,

28 61 30 2

0 - 20 mA, 4 - 20 mA, ±20 mA, 0 - 40 mA, ±40 mA

IB IL AI 2/SF-230 2 inputs, 2-wire termination, 24 V DC, 0 -10 V, ±10 V,

27 40 81 8

0 - 20 mA, 4 - 20 mA, ±20 mA, 0 - 40 mA, ±40 mA, 230 Hz

IB IL AI 2/SF-230-PAC 2 inputs, 2-wire termination, 24 V DC, 0 -10 V, ±10 V,

28 61 57 7

0 - 20 mA, 4 - 20 mA, ±20 mA, 0 - 40 mA, ±40 mA, 230 Hz

IB IL AI 8/SF 8 inputs, 2-wire termination, 24 V DC, 0 - 5 V, 0 - 10 V, ±10 V, 0 -

27 27 83 1

25 V, 0 - 20 mA, 4 - 20 mA, ±20 mA, 0 - 40 mA

IB IL AI 8/SF-PAC 8 inputs, 2-wire termination, 24 V DC, 0 - 5 V, 0 - 10 V, ±10 V, 0 -

28 61 41 2

25 V, 0 - 20 mA, 4 - 20 mA, ±20 mA, 0 - 40 mA

IB IL AI 8/IS 8 inputs, 3-wire termination, 24 V DC, 0 - 20 mA,

27 42 74 8

4 - 20 mA, ±20 mA, 0 - 40 mA, ±40 mA

IB IL AI 8/IS-PAC 8 inputs, 3-wire termination, 24 V DC, 0 - 20 mA,

28 61 66 1

4 - 20 mA, ±20 mA, 0 - 40 mA, ±40 mA

IB IL AI 2-HART 2 inputs, 2-wire termination 24 V DC, 0 - 25 mA, 4 - 20 mA, HART

28 60 26 4

functionality, HART protocol transmission

IB IL AI 2-HART-PAC 2 inputs, 2-wire termination 24 V DC, 0 - 25 mA, 4 - 20 mA, HART

28 62 14 9

functionality, HART protocol transmission

615605 1-11

Page 26

FL IL 24 BK-PAC UM E

Table 1-4 Analog input/output modules

Designation (Contd.) Properties Order No.

IB IL TEMP 2 RTD 2 inputs, 4-wire termination, 16 bits, resistance sensors 27 26 30 8

IB IL TEMP 2 RTD-PAC 2 inputs, 4-wire termination, 16 bits, resistance sensors 28 61 32 8

IB IL TEMP 2 RTD/300 2 inputs, 4-wire termination, 16 bits, resistance sensors 27 40 76 6

IB IL TEMP 2 RTD/300-

PAC

IB IL TEMP 2 UTH 2 inputs, 2-wire termination, 16 bits, thermocouples 27 27 76 3

IB IL TEMP 2 UTH-PAC 2 inputs, 2-wire termination, 16 bits, thermocouples 28 61 38 6

IB IL TEMPCON RTD Multi-channel temperature controller, 6 inputs/6 outputs 28 19 24 4

IB IL TEMPCON RTD-

PAC

IB IL TEMPCON UTH 8 inputs, 8 outputs, controller functions 28 19 31 2

IB IL TEMPCON UTH-

PAC

IB IL AO 1/SF 1 output, 2-wire termination, 24 V DC, 0-20 mA,

IB IL AO 1/SF-PAC 1 output, 2-wire termination, 24 V DC, 0-20 mA,

IB IL AO 1/U/SF 1 output, 2-wire termination, 24 V DC, 0-10 V 27 27 77 6

IB IL AO 1/U/SF-PAC 1 output, 2-wire termination, 24 V DC, 0-10 V 28 61 39 9

IB IL AO 2/SF 2 outputs, 2-wire termination, 24 V DC, 0-20 mA,

IB IL AO 2/SF-PAC 2 outputs, 2-wire termination, 24 V DC, 0-20 mA,

IB IL AO 2/U/BP 2 outputs, 2-wire termination, 24 V DC, 0 - 10 V, ±10 V 27 32 73 2

IB IL AO 2/U/BP-PAC 2 outputs, 2-wire termination, 24 V DC, 0 - 10 V, ±10 V 28 61 46 7

2 inputs, 4-wire termination, 16 bits, resistance sensors 28 61 55 1

Multi-channel temperature controller, 6 inputs/6 outputs 28 61 77 1

8 inputs, 8 outputs, controller functions 28 61 80 7

27 26 29 8

4-20 mA, 0-10 V

28 61 31 5

4-20 mA, 0-10 V

28 62 80 6

4-20 mA, 0-10 V

28 63 08 3

4-20 mA, 0-10 V

Table 1-5 Special function modules

Designation Properties Order No.

IB IL SSI 1 absolute encoder input, 4 digital inputs, 4 digital outputs, 500

mA, 3-wire termination, 24 V DC

IB IL SSI-PAC 1 absolute encoder input, 4 digital inputs, 4 digital outputs, 500

mA, 3-wire termination, 24 V DC

IB IL SSI-IN 1 absolute encoder input, 24 V DC 28 19 30 9

IB IL SSI-IN-PAC 1 absolute encoder input, 24 V DC 28 19 57 4

1-12 615605

28 36 34 0

28 61 86 5

Page 27

FL IL 24 BK(-PAC)

Table 1-5 Special function modules

Designation Properties Order No.

IB IL INC 1 incremental encoder input, 4 digital inputs, 4 digital outputs, 500

28 36 32 4

mA, 3-wire termination, 24 V DC

IB IL INC-PAC 1 incremental encoder input, 4 digital inputs, 4 digital outputs, 500

28 61 84 9

mA, 3-wire termination, 24 V DC

IB IL INC-IN 1 incremental encoder input with square-wave signal, 1 digital

28 19 22 8

signal for reference signal, 2 digital inputs, 24 V DC

IB IL INC-IN-PAC 1 incremental encoder input with square-wave signal, 1 digital

28 61 75 5

signal for reference signal, 2 digital inputs, 24 V DC

IB IL CNT 1 counter input, 1 control input, 1 digital output, 500 mA, 3-wire

28 36 33 7

termination, 24 V DC

IB IL CNT-PAC 1 counter input, 1 control input, 1 digital output, 500 mA, 3-wire

28 61 85 2

termination, 24 V DC

IB IL IMPULSE IN 1 input for magnetostrictive length measuring systems with pulse

28 19 23 1

interface

IB IL IMPULSE IN-PAC 1 input for magnetostrictive length measuring systems with pulse

28 61 85 2

interface

IB IL POS 200 Inline positioning control 28 19 33 8

IB IL POS 200-PAC Inline positioning control including accessories 28 61 82 3

IB IL RS 232 Terminal for serial data transmission via RS 232 27 27 34 9

IB IL RS 232-PAC Terminal for serial data transmission via RS 232 28 61 35 7

IB IL RS 485/422 Terminal for serial data transmission via RS 485/422 28 36 79 3

IB IL RS 485/422-PAC Terminal for serial data transmission via RS 485/422 28 61 93 3

ASI MA IB IL AS-i/master 27 41 28 8

Table 1-6 Motor terminal blocks

Designation Properties Order No.

IB IL 24 TC Thermistor terminal 27 27 41 7

IB IL 24 TC-PAC Thermistor terminal 28 61 36 0

IB IL 400 ELR 1-3A Electronic direct starter, 1.5 kW (2.01 hp), 400 V AC 27 27 35 2

IB IL 400 ELR R-3A Electronic reversing-load starter, 1.5 kW (2.01 hp), 400 V AC 27 27 37 8

IB IL 400 MLR 1-8A Electromechanical direct starter, 3.7 kW (4.96 hp), 400 V AC 27 27 36 5

IB IL DC AR 48/10A Servo amplifier for DC motors with brushgears 28 19 28 6

IB IL EC AR 48/10A Servo amplifier for DC motor without brushgears (EC motor) 28 19 25 7

615605 1-13

Page 28

FL IL 24 BK-PAC UM E

Table 1-6 Motor terminal blocks

Designation Properties Order No.

IB IL EC AR 48/10A-PAC Servo amplifier for DC motor without brushgears (EC motor) 28 19 58 7

IB IL PWM/2 Terminal for pulse width modulation and frequency modulation or

stepper motor control, 2 outputs for 5 V or 24 V

IB IL PWM/2-PAC Terminal for pulse width modulation and frequency modulation or

stepper motor control, 2 outputs for 5 V or 24 V

Table 1-7 Power and segment terminals

Designation Properties Order No.

IB IL 24 PRW IN Power terminal, 24 V DC 27 26 31 1

IB IL 24 PRW IN-PAC Power terminal, 24 V DC 28 61 33 1

IB IL 24 PRW IN/F Power terminal, 24 V DC with fuse 27 27 90 9

IB IL 24 PRW IN/F-PAC Power terminal, 24 V DC with fuse 28 61 43 8

IB IL 24 PRW IN/F-D Power terminal, 24 V DC with fuse and diagnostics 28 36 66 7

IB IL 24 PRW IN/F-D-PAC Power terminal, 24 V DC with fuse and diagnostics 28 61 89 4

IB IL 24 PRW IN/2-F Power terminal, 24 V DC with fuse 28 60 01 5

IB IL 24 PRW IN/2-F-PAC Power terminal, 24 V DC with fuse 28 62 13 6

IB IL 24 PRW IN/2-F-D Power terminal, 24 V DC with fuse and diagnostics 28 60 28 0

IB IL 24 PRW IN/2-F-D-

PAC

IB IL 24 PWR IN/M Power terminal, 24 V DC 28 61 02 7

IB IL 24 PWR IN/R Power terminal, 24 V DC 27 42 76 4

IB IL 24 PWR IN/R-PAC Power terminal, 24 V DC 28 61 67 4

IB IL 120 PRW IN Power terminal, 120 V AC with fuse 27 31 70 4

IB IL 120 PRW IN-PAC Power terminal, 120 V AC with fuse 28 61 45 4

IB IL 230 PRW IN Power terminal, 230 V AC with fuse 27 40 33 9

IB IL 230 PRW IN-PAC Power terminal, 230 V AC with fuse 28 61 53 5

IB IL 24 SEG Segment terminal, 24 V DC 27 26 32 4

IB IL 24 SEG-PAC Segment terminal, 24 V DC 28 61 34 4

IB IL 24 SEG/F Segment terminal, 24 V DC with fuse 27 27 74 7

IB IL 24 SEG/F-PAC Segment terminal, 24 V DC with fuse 28 61 37 3

IB IL 24 SEG/F-D Segment terminal, 24 V DC with fuse and diagnostics 28 36 68 3

IB IL 24 SEG/F-D-PAC Segment terminal, 24 V DC with fuse and diagnostics 28 61 90 4

IB IL 24 SEG-ELF Segment terminal, 24 V DC with electronic fuse 27 27 78 9

Power terminal, 24 V DC with fuse and diagnostics 28 62 15 2

27 42 61 2

28 61 63 2

1-14 615605

Page 29

FL IL 24 BK(-PAC)

Table 1-7 Power and segment terminals

Designation Properties Order No.

IB IL 24 SEG-ELF-PAC Segment terminal, 24 V DC with electronic fuse 28 61 40 9

IB IL PD GND Terminal for GND potential distribution 28 63 06 7

IB IL PD GND-PAC Terminal for potential distribution (GND) 28 62 99 0

IB IL PD 24V Terminal for potential distribution (main voltage) 28 63 05 4

IB IL PD 24V-PAC Terminal for potential distribution (main voltage) 28 62 98 7

Table 1-8 Safety

Designation Properties Order No.

IB IL 24 SAFE 1 Safety terminal with 2 N/O contacts 27 40 78 2

IB IL 24 SAFE 1-PAC Safety terminal with 2 N/O contacts 28 61 56 4

IB IL 400 SAFE 2 Safety terminal with 3 N/O contacts and 1 N/C contact, 200 V AC

27 40 79 5

to 600 V AC

Table 1-9 Controller / CPU

Designation Properties Order No.

ILC 200 UNI Inline Controller with INTERBUS local bus interface 27 30 90 9

ILC 200 UNI-PAC Inline Controller with INTERBUS local bus interface 28 62 29 1

IB IL 332-128 Inline CPU 28 19 13 4

IB IL 332-128-PAC Inline CPU 28 61 73 9

IB IL 332-256 Inline-CPU with 256 kbytes RAM, 1 MB flash, serial interface 28 19 32 5

IB IL 332-256-PAC Inline-CPU with 256 kbytes RAM, 1 MB flash, serial interface 28 61 81 0

615605 1-15

Page 30

FL IL 24 BK-PAC UM E

B a c k

c o n n e c t o r s h a f t l a t c h

D i a g n o s t i c a n d s t a t u s

i n d i c a t o r s

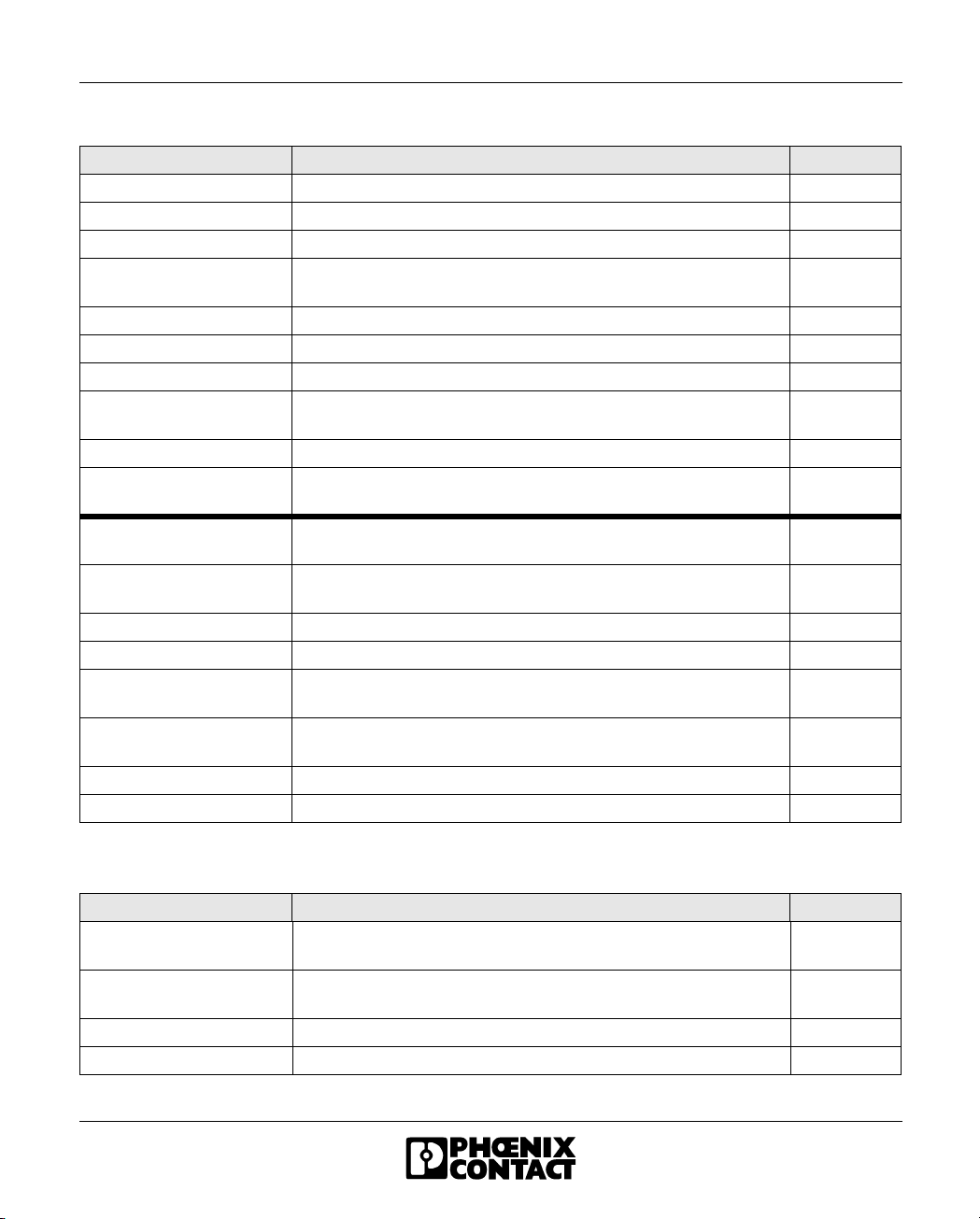

1.6 Basic Structure of Low-Level Signal Modules

Regardless of the function and the design width, an Inline low-level signal module

consists of the electronics base (or base for short) and the plug-in connector (or

connector for short).

Z B F M l a b e l i n g f i e l d f o r c o n n e c t o r

T r a n s p a r e n t f i e l d

A t t a c h m e n t f o r l a b e l i n g f i e l d

Z B F M l a b e l i n g f i e l d f o r s i g n a l 1 / 2

S i g n a l t e r m i n a l s 1 / 2

V o l t a g e t e r m i n a l s

F E o r s i g n a l t e r m i n a l s 3 / 4

F u n c t i o n c o l o r c o d i n g

B a c k

s n a p - o n m e c h a n i s m

Z B F M l a b e l i n g f i e l d

f o r m o d u l e i d e n t i f i c a t i o n

E l e c t r o n i c s b a s e

D a t a r o u t i n g

P o t e n t i a l r o u t i n g

Z B F M l a b e l i n g f i e l d f o r s i g n a l 3 / 4

C o n n e c t o r

F r o n t

c o n n e c t o r s h a f t l a t c h

S l o t c o d i n g

F r o n t

s n a p - o n m e c h a n i s m

L a t c h f o r

D I N r a i l

F e a t h e r k e y f o r

k e y / f e a t h e r k e y c o n n e c t i o n

5 5 2 0 A 0 3 3

Figure 1-4 Basic structure of an Inline module

The most important components shown in Figure 1-4 are described in sections

"Electronics Base" on page 1-17 and "Connectors" on page 1-17.

ZBFM: Zack marker strips, flat

(see also Section "Function Identification and Labeling" on

page 1-21)

The components required for labeling are listed in the Phoenix Contact

"CLIPLINE" catalog.

1-16 615605

Page 31

FL IL 24 BK(-PAC)

1.6.1 Electronics Base

The electronics base holds the entire electronics for the Inline module and the

potential and data routing.

Design widths The electronics bases for low-level signal modules are available in a width of 8

terminal points (8-slot terminal) or 2 terminal points (2-slot terminal). Exceptions are

combinations of these two basic terminal widths (see also Section "Dimensions of

Low-Level Signal Modules" on page 1-24).

1.6.2 Connectors

The I/O or supply voltages are connected using a pluggable connector.

Advantages This pluggable connection offers the following advantages:

– Simple exchange of module electronics for servicing. There is no need to

remove the wiring.

– Different connectors can be used on one electronics base, depending on your

requirements.

Connector width Regardless of the width of the electronics base, the connectors have a width of two

terminal points. This means that you must plug 1 connector on a 2-slot base, 2

connectors on a 4-slot base, and 4 connectors on an 8-slot base.

Connector types The following connector types are available:

1

Figure 1-5 Inline connector types

615605 1-17

2

3

6 1 5 6 0 0 1 0

Page 32

FL IL 24 BK-PAC UM E

1 Standard connector

The green standard connector is used for the connection of two signals in

4-wire technology (e.g., digital I/O signals).

The black standard connector is used for supply terminals. The adjacent

contacts are jumpered internally (see Figure 1-6 on page 1-19).

2 Shield connector

This green connector is used for signals connected using shielded cables

(e.g., analog I/O signals).

FE or shielding is connected via a shield connection clamp rather than via a

terminal point.

3 Extended double signal connector

This green connector is used for the connection of four signals in 3-wire

technology (e.g., digital I/O signals).

Connector

identification

All connectors are offered with and without color print. The connectors with color

print (marked with CP in the Order Designation) have terminal points that are colorcoded according to their functions.

The following colors indicate the signals of the terminal points:

Table 1-10 Terminal point color-coding

Color Terminal Point Signal

Red +

Blue -

Green/yellow Functional earth ground

1-18 615605

Page 33

Internal structure of the

connectors

A B C

FL IL 24 BK(-PAC)

D

1 2

1

1

2

2

3

3

4

4

1 2

1

1

2

2

3

3

4

4

1 2

1

1

2

2

3

3

4

4

1 2

1

2

3

4

565

1

2

3

4

6

6 1 5 6 0 0 1 1

Figure 1-6 Internal structure of the connectors

A Green connector for I/O connection

B Black connector for supply terminals

C Shield connector for analog terminals

D Double signal connector for I/O connection

Jumpered terminal points already integrated in the connectors are shown in

Figure 1-6.

The shield connector is jumpered through the shield connection. All other

connectors are jumpered through terminal point connection.

To avoid a malfunction, only snap a connector on a terminal that is appropriate

for this connection. Refer to the module-specific data sheet to select the correct

connectors.

The black connector must not be placed on a module for which a double signal

connector is to be used. Mixing this up leads to a short circuit between two signal

terminal points (1.4 - 2.4).

Only snap black connectors onto a supply terminal.

When the terminal points are jumpered in the black connector, power is carried

through the jumpering in the connector and not through the printed circuit board

of the module.

615605 1-19

Page 34

FL IL 24 BK-PAC UM E

Connector keying You can prevent mismatching of connectors by keying the base and the connector.

A

1

2

1

1

Figure 1-7 Connector keying

• Plug a keying profile (disc) into the keyway in the base (1) and turn it away from

the small plate (2) (Figure 1-7, detail A).

• Use a diagonal cutter to cut off the keying tab from the connector (Figure 1-7,

detail B).

Now, only the base and connector with the same keying will fit together (Figure 1-7,

detail C).

B

1

C

1

6 1 5 6 0 0 1 2

1-20 615605

Page 35

FL IL 24 BK(-PAC)

1.7 Function Identification and Labeling

Function identification The modules are color-coded to enable visual identification of the functions (1 in

Figure 1-8).

.

1

5 5 2 0 A 0 7 5

Figure 1-8 Function identification

The following colors indicate the functions:

Table 1-11 Module color-coding

Color Function of the Module

Light blue Digital input 24 V DC area

Pink Digital output 24 V DC area

Blue Digital input 120/230 V AC area

Red Digital output 120/230 V AC area

Green Analog input

Yellow Analog output

Orange Fieldbus coupler, special function modules

Black Power terminal/segment terminal

Connector

The color-coding of the terminal points is described on page 1-18.

identification

615605 1-21

Page 36

FL IL 24 BK-PAC UM E

Labeling/

Terminal point numbering is illustrated using the example of an 8-slot module.

terminal numbering

1 . 1

1 . 2

1 . 3

1 . 4

X . Y

1

2 3

1

2

1

2

3

4

2 . 1

1

2 . 2

2

2 . 3

3

2 . 4

4

1 2

1 2

1

1

1

2

2

2

3

3

3

4

4

4

4

1 2

1 2

1

1

1

1

1

2

2

2

2

2

3

3

3

3

4

4

3

4

4

4

1

2

3

4

5 5 2 0 A 0 3 5

Figure 1-9 Terminal point numbering

Slot/connector The slots (connectors) on a base are numbered consecutively (1 in Figure 1-9).

This numbering is not shown on the actual module.

Terminal point The terminal points on each connector are marked X.Y.

X is the number of the terminal point row on the connector. It is indicated above the

terminal point row (2 in Figure 1-9).

Y is the terminal point number in a row. It is directly indicated on the terminal point

(3 in Figure 1-9).

The precise designation for a connection point is thus specified by the slot and

terminal point. The highlighted terminal point (4 in Figure 1-9) would be numbered

as follows: slot 3, terminal point 2.3.

Additional labeling In addition to this module marking, you can identify the slots, terminal points, and

connections using marker strips and labeling fields.

1-22 615605

Page 37

FL IL 24 BK(-PAC)

1

6

Figure 1-10 Labeling of modules

3

2

4

5

5 5 2 0 A 0 3 6

Various options are available for labeling the slots and terminal points:

1 Each connector can be labeled individually with Zack marker strips.

2 / 3 Another option is to use a large labeling field. This labeling field is available

in two widths, either as a labeling field covering one connector (2) or as a

labeling field covering four connectors (3). You can label each channel

individually with free text. On the upper connector head there is a keyway

for attaching this labeling field. The labeling field can be tilted up and down.

In each end position there is a small latch which ensures that the labeling

field remains in place.

4 / 5 Each signal can be labeled individually using Zack markers. On a double

signal connector, the upper keyway (4) is designed for labeling signals 1/2

and the lower keyway (5) is for signals 3/4.

6 On the electronics base each slot can be labeled individually using Zack

markers. These markers are covered when a connector is plugged in.

615605 1-23

Page 38

FL IL 24 BK-PAC UM E

Using the markers on the connector and on the electronics base, you can clearly

assign both connector and slot.

The components required for labeling are listed in the Phoenix Contact

"CLIPLINE" catalog.

1.8 Dimensions of Low-Level Signal Modules

Today, small I/O stations are frequently installed in 80 mm (3.150 in.) standard

control boxes. Inline modules are designed so that they can be used in this type of

control box.

The housing dimensions of a module are determined by the dimensions of the

electronics base and the dimensions of the connector.

The electronics bases of the low-level signal modules are available in three design

widths (12.2 mm [0.480 in], 24.4 mm [0.961 in.] and 48.8 mm [1.921 in.]).

It accepts either one, two, or four 12.2 mm (0.480 in.) wide connectors.

When a connector is plugged in, each terminal depth is 71.5 mm (2.815 in.).

The height of the module depends on the connector used. The connectors are

available in three different versions (see Figure 1-14).

2-slot housing

7 1 . 5 m m ( 2 . 8 1 5 " )

1 2 0 m m ( 4 . 7 2 4 " )

1 2 . 2 m m

( 0 . 4 8 0 " )

5 5 2 0 1 0 2 3

Figure 1-11 Dimensions of the electronics bases (2-slot housing)

1-24 615605

Page 39

FL IL 24 BK(-PAC)

4-slot housing

8-slot housing

7 1 . 5 m m ( 2 . 8 1 5 " )

1 2 0 m m ( 4 . 7 2 4 " )

2 4 . 4 m m

( 0 . 9 6 1 " )

5 5 2 0 1 0 2 2

Figure 1-12 Dimensions of the electronics bases (4-slot housing)

7 1 . 5 m m ( 2 . 8 1 5 " )

1 2 0 m m ( 4 . 7 2 4 " )

4 8 . 8 m m

( 1 . 9 2 1 " )

5 5 2 0 1 0 2 4

Figure 1-13 Dimensions of the electronics bases (8-slot housing)

615605 1-25

Page 40

FL IL 24 BK-PAC UM E

Connector

A B C

1 2

1

1

2

2

3

1 1 2 . 4 m m ( 4 . 4 2 5 " )

3

4

4

1 3 2 m m ( 5 . 1 9 7 " )

1 2

1

1

2

2

3

3

4

4

1 3 7 m m ( 5 . 3 9 4 " )

1 2 . 2 m m

( 0 . 4 8 0 " )

1 2 . 2 m m

( 0 . 4 8 0 " )

1 2

1

2

3

4

565

1

2

3

4

6

1 2 . 2 m m

( 0 . 4 8 0 " )

5 5 2 0 0 0 5 8

Figure 1-14 Connector dimensions

Key:

A Standard connector

B Shield connector

C Extended double signal connector

The depth of the connector does not influence the overall depth of the module.

1-26 615605

Page 41

FL IL 24 BK(-PAC)

1.9 Electrical Potential and Data Routing

An important feature of the INTERBUS Inline and Ethernet/Inline bus coupler

product ranges is their internal potential routing system. The electrical connection

between the individual station devices is created automatically when the station is

installed. When the individual station devices are connected, a power rail is created

for the relevant circuit. It is created mechanically through the interlocking of knife

and featherkey contacts on the adjacent modules.

A special segment circuit eliminates the need for additional external potential

jumpering to neighboring modules.

Two independent circuits are created in one station: the logic circuit and the I/O

circuit.

1 2 3

4 5 6 7

9

Figure 1-15 Potential and data routing

a b c

8

6 1 5 6 0 0 1 7

615605 1-27

Page 42

FL IL 24 BK-PAC UM E

Table 1-12 Potential jumper (see Figure 1-15)

No. Function Meaning

1 FE FE Functional earth ground

2 SGND SGND Ground of segment supply and main supply

324 V U

424 V U

M

S

Supply for main circuit (with overload protection, if necessary)

Supply for segment circuit (with overload protection, if necessary)

This jumper does not exist in the120/230 V AC power levels.

5LGNDU

624 V U

7 7.5 V U

L-

ANA

L+

Ground of communications power and I/O supply for analog modules

I/O supply for analog modules

Supply for module electronics

(9) FE spring FE contact to DIN rail

The GND potential jumper carries the total current from the main and segment

circuits. The total current must not exceed the maximum current carrying capacity

of the potential jumper (8 A). If the 8 A limit is reached at one of the potential

jumpers U

, UM, and GND during configuration, a new power terminal must be

S

used.

The FE potential jumper must be connected via terminal point 1.4 or 2.4 at the

Ethernet bus coupler to a grounding terminal (see Figure 1-9). The FE potential

jumper is led through all of the modules and connected via the FE spring to the

grounded DIN rail of every supply terminal.

Table 1-13 Data jumper (see Figure 1-15)

No. Function Meaning

8a DI1 Local bus signal (Data IN)

8b DO1 Local bus signal (Data OUT)

8c DCLK Clock signal, local bus

1-28 615605

Page 43

FL IL 24 BK(-PAC)

1.10 Circuits Within an Inline Station and Provision

of the Supply Voltages

There are several circuits within an Inline station. These are automatically set up

when the modules have been properly installed. The voltages of the different

circuits are supplied to the connected modules via the potential jumpers.

Please refer to the module-specific data sheet for the circuit to which the I/O

circuit of a special module is to be connected.

Load capacity of the

jumper contacts

Observe the maximum current carrying capacity of the jumper contacts on the side

for each circuit. The load capacities for all potential jumpers are given in the

following sections.

The arrangement of the potential jumpers can be found in Section "Electrical

Potential and Data Routing" on page 1-27.

For voltage connection, please refer to the notes given in the module-specific

data sheets.

615605 1-29

Page 44

FL IL 24 BK-PAC UM E

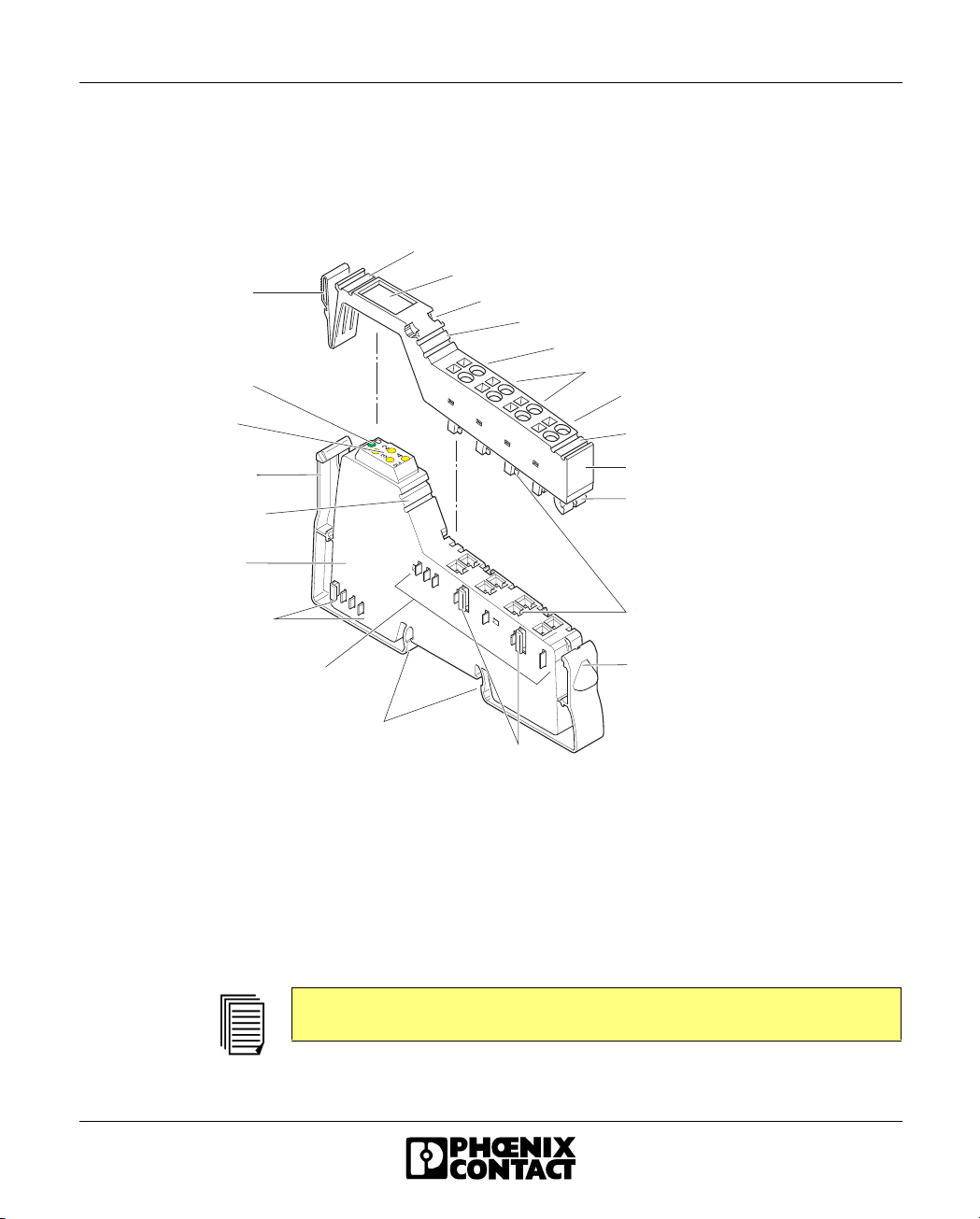

1.10.1 Supply of the Ethernet Bus Coupler

The supply voltage UBK and the segment voltage US must be connected to the

Ethernet bus coupler. From the supply voltage U

(7.5 V) and the supply of the modules for analog signals U

U

L

internally generated. The segment voltage is used to supply the sensors and

actuators.

F L I L 2 4 B K - P A C

O r d . - N o . : 2 8 6 2 3 1 4

R E S E T

1 0 0

F D

C O L

X M T

L G N D

U

B K

+

-

R C V

L I N K

1 0 / 1 0 0

, the voltages for the logic circuit

BK

U S

U M

U L

1 2

1

2

3

4

I n t e r n a l j u m p e r

( i n t h e m o d u l e )

1

2

+

3

-

S G N D

4

U

ANA

+

-

M

(24 V) are

U

S

6 1 5 5 1 0 1 1

Figure 1-16 Typical connection of the supply voltage

1.10.2 Logic Circuit U

L

The logic circuit with communications power UL starts at the bus coupler, is led

through all modules of a station and cannot be supplied via another supply terminal.

Function The logic circuit provides the communications power for all modules in the station.

Voltage The voltage in this circuit is 7.5 V DC.

1-30 615605

Page 45

FL IL 24 BK(-PAC)

Provision of U

L

The communications power UL is generated from the supply voltage UBK of the bus

coupler.

The communications power is not electrically isolated from the 24 V input voltage

for the bus coupler.

Current carrying

The maximum current carrying capacity of UL is 2 A.

capacity

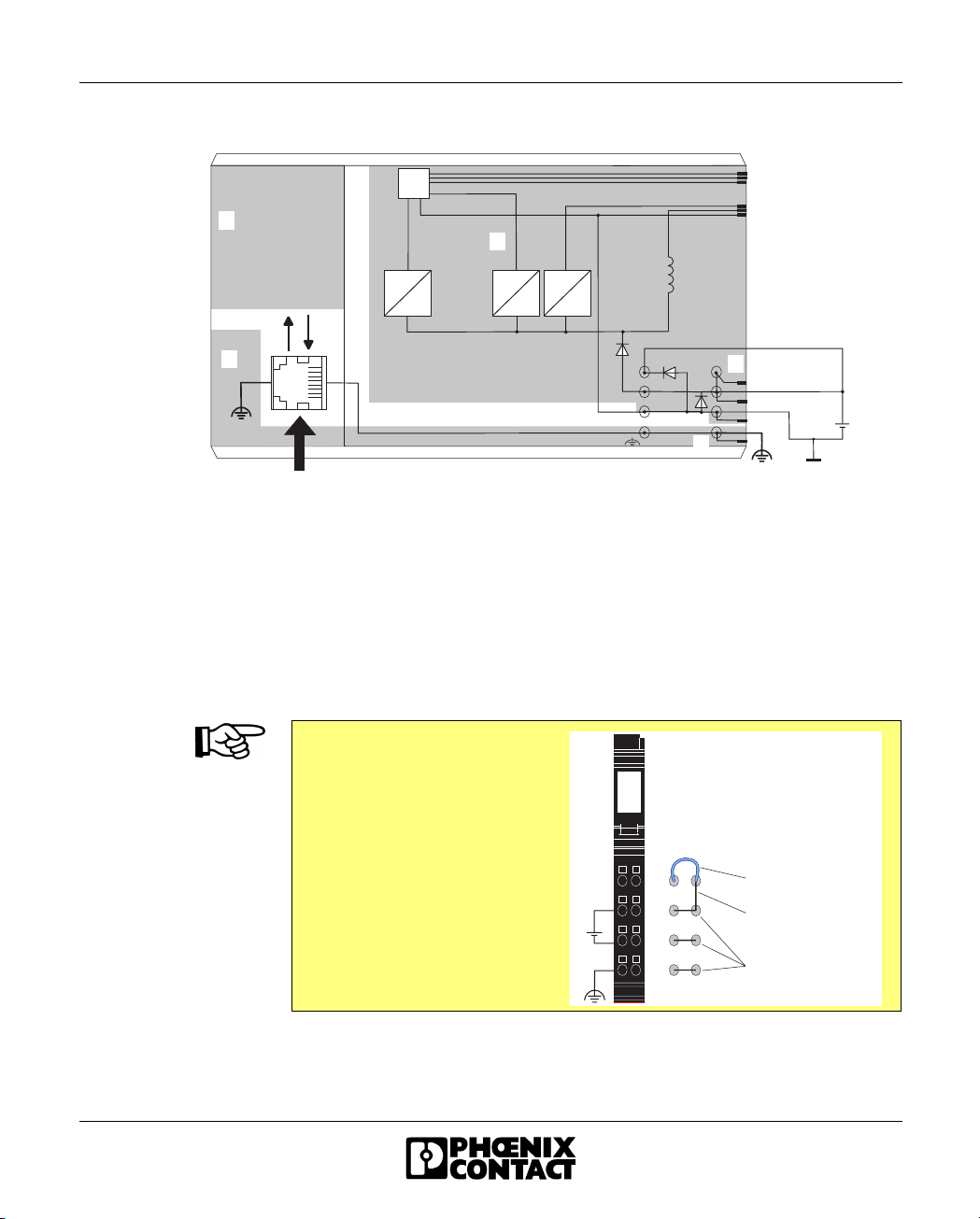

1.10.3 Analog Circuit U

ANA

The analog circuit with the supply for the analog modules (also referred to as analog

voltage) U

an Inline station. Power cannot be supplied by the supply terminals. U

electrically isolated from U

is supplied at the bus coupler and is led through all the modules in

ANA

ANA

BK

.

is not

Function The module I/O devices for analog signals are supplied from the analog circuit.

Voltage The voltage in this circuit is 24 V.

Provision of U

ANA

The analog voltage U

is generated from the main voltage UBK of the bus

ANA

coupler.

Current carrying

The maximum current carrying capacity of U

ANA

is 0.5 A.

capacity

F L I L 2 4 B K - P A C

P W R I N

S E G / F

U

U

G N D L

L

A N A

U

S

U

M

U

M

6 1 5 6 0 0 0 1

Figure 1-17 Logic and analog circuit

FL IL 24 BK-PAC Ethernet bus coupler

PWR IN Power terminal

SEG/F Segment terminal with fuse as an example of a segment

terminal

615605 1-31

Page 46

FL IL 24 BK-PAC UM E

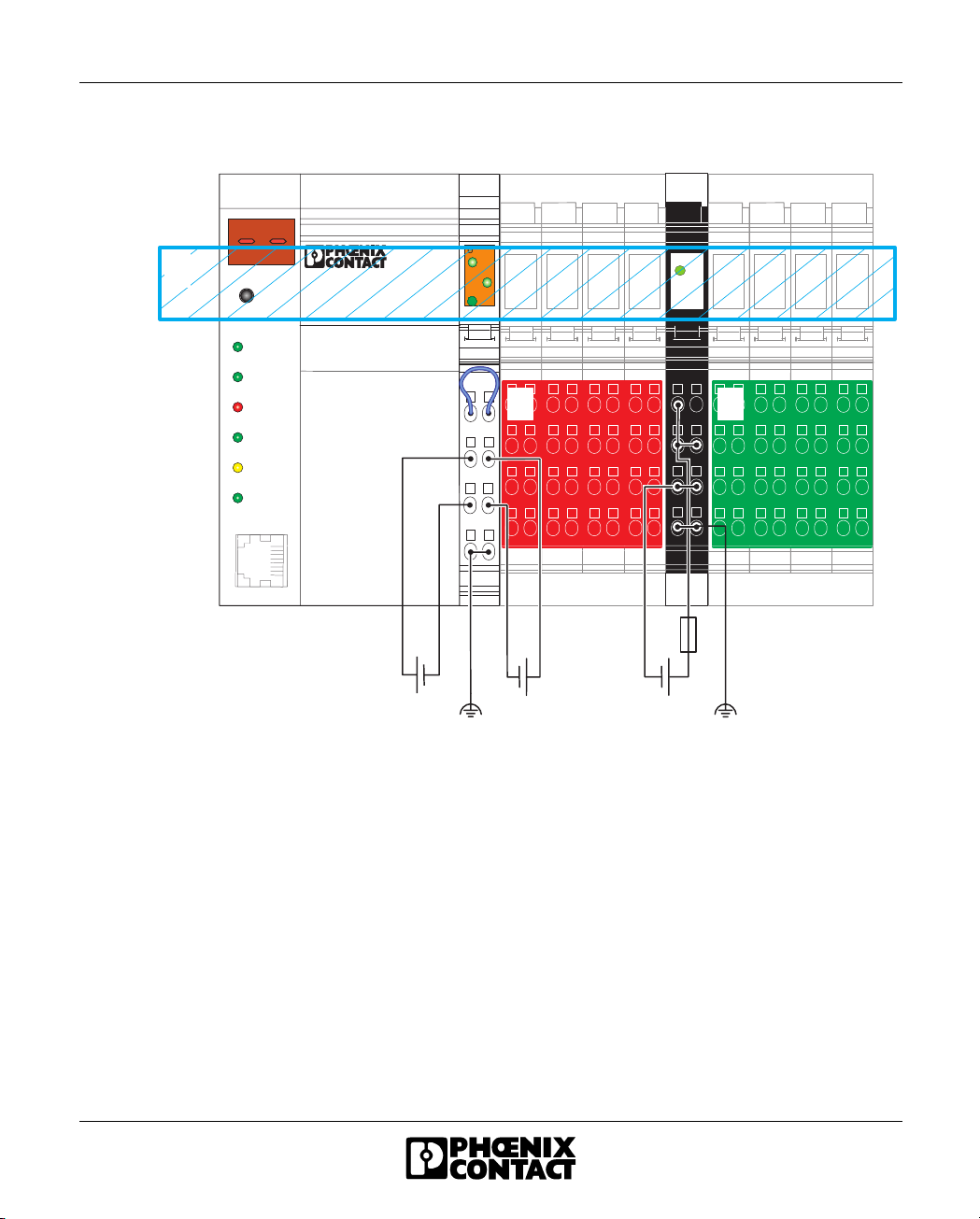

1.10.4 Main Circuit U

M

The main circuit with the main voltage UM starts at the bus coupler or a power

terminal and is led through all subsequent modules until it reaches the next power

terminal. A new circuit that is electrically isolated from the previous one begins at

the next power terminal.

Several power terminals can be used within one station.

Function Several independent segments can be created within the main circuit. The main

circuit provides the main voltage for these segments. For example, a separate

supply for the actuators can be provided in this way.

Voltage

The maximum voltage in this circuit is 24 V DC. UM can only be a maximum of

Current carrying

capacity

250 V AC

The maximum current carrying capacity is 8 A (total current with the segment

circuit). If the limit value of the common GND potential jumper for U

reached (total current of U

when using special PWR-IN modules.

and UM), a new power terminal must be used.

S

F L I L 2 4 B K - P A C

P W R I N

S E G / F

and US is

M

U

L

U

A N A

G N D L

U

S

U

M

U

M

U

M

6 1 5 6 0 0 0 2

Figure 1-18 Main circuit

FL IL 24 BK-PAC Ethernet bus coupler

PWR IN Power terminal

SEG/F Segment terminal with fuse as an example of a segment

terminal

Provision of U

M

In the simplest case, the main voltage UM can be supplied at the bus coupler. In this

case it is 24 V DC.

1-32 615605

Page 47

FL IL 24 BK(-PAC)

The main voltage UM can also be supplied via a power terminal. A power terminal

must be used if:

1 Different voltage areas (e.g., 120 V AC) are to be created.

2 Electrical isolation is to be created.

3 The maximum current carrying capacity of a potential jumper (UM, US or GND,

total current of U

and UM) is reached.

S

1.10.5 Segment Circuit

The segment circuit or auxiliary circuit with the segment voltage US starts at the

Ethernet bus coupler or a supply terminal (power terminal or segment terminal) and

is led through all subsequent modules until it reaches the next supply terminal.

Function You can use several segment terminals within a main circuit, and in this way

segment the main circuit. It has the same reference ground as the main circuit. This

means that circuits with different fuses can be created within the station without

external cross wiring.

Voltage The voltage in this circuit should not exceed 24 V DC.

Current carrying

capacity

The current carrying capacity is 8 A, maximum (total current with the main circuit).

If the limit value of the common potential jumper for U

current of U

and UM), a new power terminal must be used.

S

and/or US is reached (total

M

615605 1-33

Page 48

FL IL 24 BK-PAC UM E

Generation of U

S

There are various ways of providing the segment voltage US:

1 You can supply the segment voltage at the Ethernet/Inline bus coupler or a

power terminal.

2 You can tap the segment voltage from the main voltage at the Ethernet/Inline

bus coupler or a power terminal using a jumper or a switch.

3 You can use a segment terminal with a fuse. Within this terminal the segment

voltage is automatically tapped from the main power.

4 You can use a segment terminal without a fuse and tap the segment voltage

from the main voltage using a jumper or a switch.

With 120 V/230 V AC voltage levels, segments cannot be created. In this case,

only the main circuit is used.

F L I L 2 4 B K - P A C P W R I N

USU

M

U

M

S E G / F

6 1 5 6 0 0 0 3

U

L

U

A N A

G N D L

U

S

U

M

Figure 1-19 Segment circuit

FL IL 24 BK(-PAC) Ethernet/Inline bus coupler

PWR IN Power terminal

SEG/F Segment terminal with fuse as an example of a

segment terminal

1-34 615605

Page 49

FL IL 24 BK(-PAC)

1.11 Voltage Concept

The Ethernet bus coupler and the Inline local bus system have a defined voltage

and grounding concept.