Page 1

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

WARNING – Shut off AC power to branch

circuits to which units will be connected. All

wiring should be per N.E.C. Articles 501-4(b)

and local codes.

To maintain warranty, equipment with batteries

must be installed or placed on charge within

prescribed period after shipment.

TMFIC/ZMFIC

Series Damp Location

200-450W Emergency Luminaire

DAMP LOCATION LISTED 0°-40°C

INSTALLATION AND

OPERATING

INSTRUCTIONS

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety

precautions should always be followed, including

the following:

READ AND FOLLOW ALL

SAFETY INSTRUCTIONS

All servicing should be performed by qualified

personnel only.

Equipment should be mounted in locations and at

heights where it will not be readily subjected to

tampering by unauthorized personnel.

The use of accessory equipment not recommended

by the manufacturer may cause an unsafe condition.

Do not use this equipment for other than intended

use.

Suitable for use in damp locations 0°-40°C.

Do not let supply cords touch hot surfaces.

Do not mount near gas or electric heaters.

CAUTION: Halogen cycle lamp(s) are used in

this equipment. To avoid shattering: Do not

operate lamp in excess of rated voltage, protect

lamp against abrasion and scratches and against

liquids when lamp is operating, dispose of lamp

with care.

Halogen cycle lamps operate at high temperatures.

Do not store or place flammable materials near

lamp.

CAUTION: “To avoid electrical overload, total

connected lamp load (factory and field installed)

should not exceed output rating”.

SAVE THESE

INSTRUCTIONS

Page 2

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

GENERAL INSTRUCTIONS

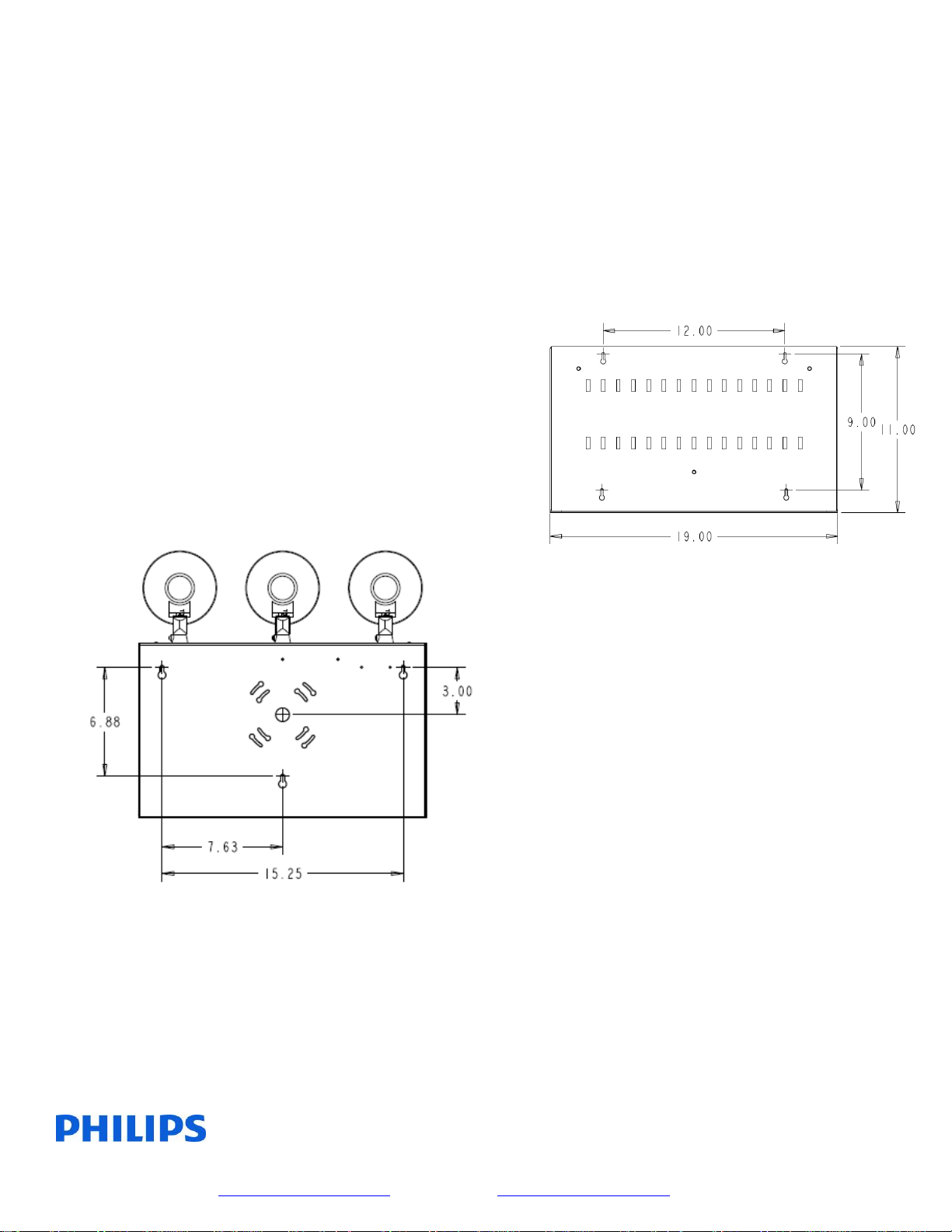

Direct Wall Mount Installation

1) Begin the installation process by securing

the unit less battery. Three slotted vertical

keyway knockouts in the housing (see

Figure 1) are to be used to attach the

housing to independent anchor supports.

Use three ¼” toggle bolts (supplied by

others) to secure the unit to drywall. If

mounting to hollow concrete masonry, a

minimum of two toggle bolts must be used.

When using wall recessed wiring, The

slotted, circular keyways can be used to

secure the housing to a standard junction

box for wiring purposes only. Run the wires

through center hole of housing in

preparation for unit wiring. For surface

conduit wiring, there are a total of six

knockouts which can be used for service

entrance and exit.

OPTIONAL MOUNTING SHELF FOR

COLUMN, POLE OR I-BEAM

1) If the unit is to be mounted to poles,

columns or I-Beams, use the optional

mounting shelf kit and strapping kit (ordered

separately).

2) If mounting shelf is to be used for wall

mounting, there are four (4) slotted vertical

keyways (see Figure 2) available. Use ¼”

toggle bolts (supplied by others) for

installation.

Figure 2

3) Once mounting shelf is installed, the unit is

ready for installation.

4) Place unit on shelf less batteries and secure

with three (3) securing screws (provided

with mounting shelf) to shelf threaded

inserts.

INSTALLING BATTERIES

1. Units ship without batteries installed. Unit

batteries are shipped separately. Battery

wiring harnesses are already connected to

PCB assembly. Connection of harness to

Figure 1

batteries is required.

2. Install and wire batteries as appropriate.

(See Page 7 for battery configurations)

3. Tighten straps to secure batteries inside unit.

Page 3

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

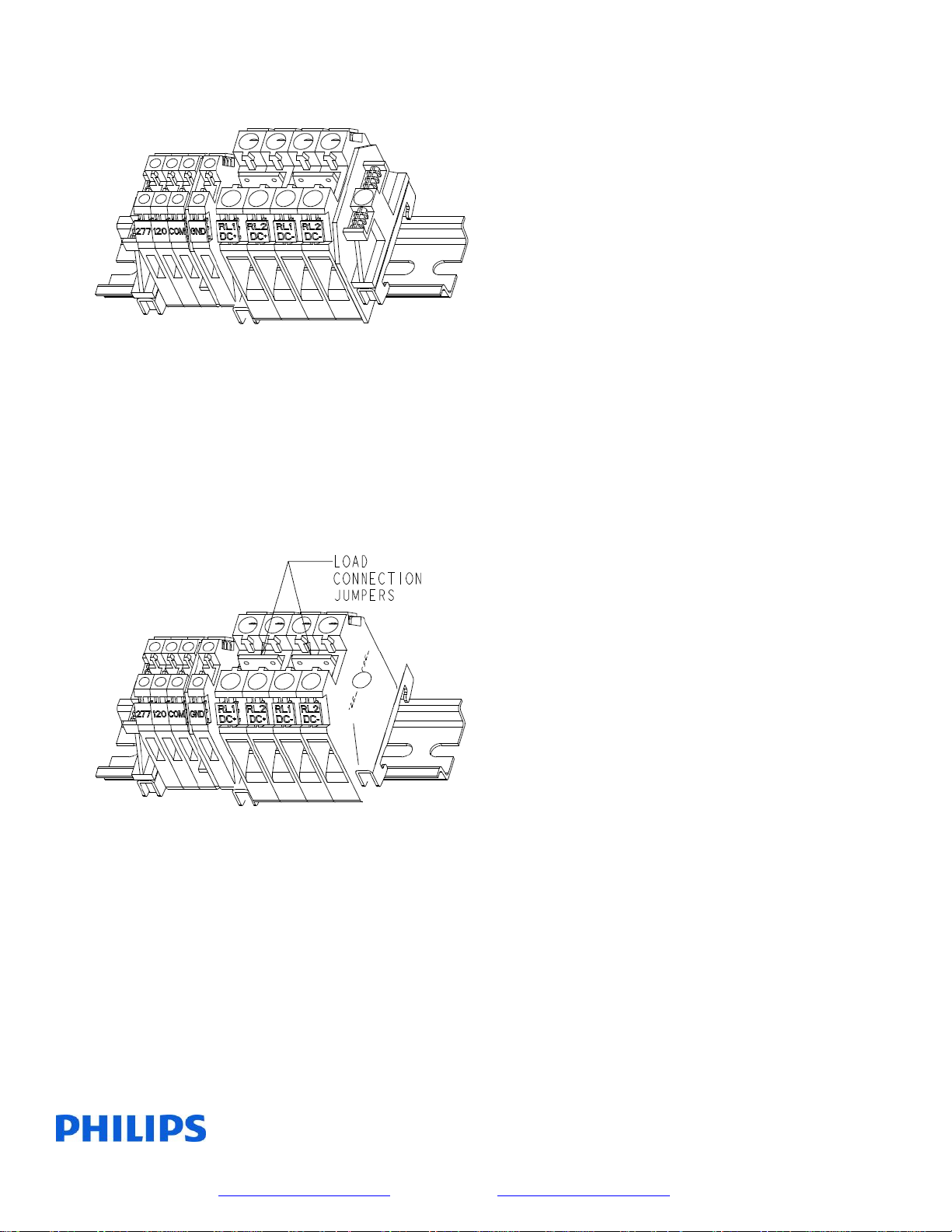

AC SERVICE

HOOKUP INSTRUCTIONS

Standard Units:

Connect AC service to unit terminal block.

The unit is pre-wired to accept 120 or 277

VAC. Insert AC service leads and ground

wire to appropriately labeled terminal(s).

Tighten.

REMOTE LAMP CONNECTION

1. A terminal block for the remote lamp loads

is provided for easy installation. Two

terminals are available for DC+ and DCeach. Units ship from the factory with load

connection jumpers installed on both DC+

and DC-. This parallels the load among the

unit RL1+ and RL2+ output load fuses.

Using the jumpers ensures that the total load

of the unit is evenly distributed.

REMOTE LOADS WITH LOAD

CONNECTION JUMPERS INSTALLED

(SMALLER REMOTE LOAD REQUIREMENTS)

1. When using the jumpers, simply subtract the

internal lamp total wattage from the unit

total wattage and the remainder is the

available total remote load capacity.

Balancing of RL1 and RL2 is not required as

the jumpers perform the remote load

balancing.

2. When figuring total load, include the

wattage of the internal lamps if applicable

and do not exceed unit total wattage

capability.

3. EXAMPLE:

A 200 watt unit with three (3) 12 watt

lamps connected has 164 watts of remote

load capability.

REMOTE LOADS REQUIRING

SEPARATE FUSING

(LARGER REMOTE LOAD REQUIREMENTS)

1. When it is necessary to independently fuse

each set of remote lamp loads, removal of

the load connection jumpers is required.

2. Removal of the load connection jumpers is

accomplished unscrewing and removing the

jumper itself.

3. The terminals are marked RL1 DC+, RL2

DC+, RL1 DC- and RL2 DC-. The terminal

blocks are capable of accepting up to #6

wire.

Balancing of the remote lamp loads among

RL1 and RL2 is now a consideration and

must be planned ahead of time.

Page 4

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

Determination of allowable RL1 and RL2

maximum capacity depends on whether the

unit is configured as a two or three internal

head unit as the remote load PCB fuses are

shared with the internal lamps.

The schematic below illustrates the PCB

load routing of the unit where L1+, L2+ and

L3+ represent internal lamp loads and RL1+

and RL2+ are the remote lamp loads:

4. Determining allowable remote lamp loads

for RL1 and RL2:

- For two head units, subtract twice the lamp

wattage rating from the unit total available

power. Equally divide the remaining

capacity between RL1 and RL2.

- For three head units, internal lamp 1 and

internal lamp 3 are on the RL1 fused circuit.

Internal lamp 2 is connected to the RL2

fused circuit.

For RL1 circuit, subtract twice the internal

lamp rating from half the unit wattage and

the remainder is the available remote load

capacity.

For RL2 circuit, subtract one internal lamp

wattage from half the unit wattage and the

remainder is the RL2 remote capacity.

Example:

A 300 watt unit is configured with 3 internal

12 watt heads. The total available wattages

for RL1 and RL2 are calculated as follows:

RL1 Max Watts = (Unit Wattage / 2) – (2 * Internal

Lamp Wattage)

= (300/2) - (2*12)

= 150 – 24

= 126 (Watts)

RL2 Max Watts = (Unit Wattage / 2) – (1 * Internal

Lamp Wattage)

= (300/2) – (1*12)

= 150 – 12

= 138 (Watts)

Ensure total unit load (including internal

lamps) does not exceed unit rating including

internal lamp loads.

COMPLETING UNIT INSTALLATION

1. Adjust head(s) to illuminate desired area(s).

2. Close cover and latch. Ensure electrical

wires and membrane switch cable remain

inside unit and that the cover does not pinch

wires when closed. Hand tighten the two

thumb screws to finalize cover closure.

Page 5

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

Self Diagnostic System Operation – Emergency Light or EXIT Sign Products

Normal Power Up Sequence

At power up the red and green LED indicators will alternately flash for one to two seconds. Next the product will execute

a “Power Up Quick Test” causing the green LED indicator to flash rapidly. If any faults are detected during the “Power Up

Quick Test” these will be evident by a flashing red LED indicator. If the audible diagnostic option has been ordered, the

flashing red LED will be accompanied by a simultaneous beeping tone. (Note: A continuous rapid alternating Red/Green

flash with rapid beeping tone indicates 277V applied to 120V input lead. TURN OFF POWER IMMEDIATELY!)

Emergency Operation

Emergency operation occurs when AC power fails. The product remains in emergency operation until AC power is

restored or battery capacity is depleted. During emergency operation both red and green LED indicators are disabled.

User Interface

Green LED indicator

Slow Flash/Continuous ON = AC power present; normal operating condition

Rapid Flash = product performing an automatic or manually initiated diagnostic test

Red LED indicator

Single Flash = battery fault

Two Flashes = lamp failure (light bar failure – EXIT signs)

Three Flashes = charger fault

Four Flashes = transfer fault

(If more than one fault condition is present simultaneously, the red LED will flash the indication pattern for each

fault independently then repeat the cycle.)

Pushbutton Test Switch

Long Press (longer than 0.5sec) transfers product to emergency operation during time the button is

pressed.

Short Press initiates self diagnostic activities as follows:

One Press cancels diagnostic test presently running.

Two Presses starts a one minute diagnostic test.

Three Presses starts a 90 minute diagnostic test.

Four Presses conducts a lamp load calibration (emergency light products only).

Seven Presses initiates a system reset.

(Note: the microprocessor will allow up to seven, one minute diagnostic tests within the first 24 hours of

operation. Allow 24 hours of charging before performing any long duration testing.)

Buzzer (optional)– Sounds in unison with the flashing red LED if a fault condition is present. Buzzer may be

silenced for up to 196 hours by a short press of either the test switch or the optional IR remote control device

“silence” button. Correcting fault condition will cancel fault notification. Lamp failure indication requires a

manually activated diagnostic test after lamp replacement to cancel notification.

IR Remote Control (optional)- is a hand held device that allows remote activation of diagnostic testing and

silencing of the optional buzzer during fault conditions.

Page 6

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

Page 7

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

Philips Lighting Canada Ltd.

281 Hillmount Road,

Markham ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

9140053386 February 2016

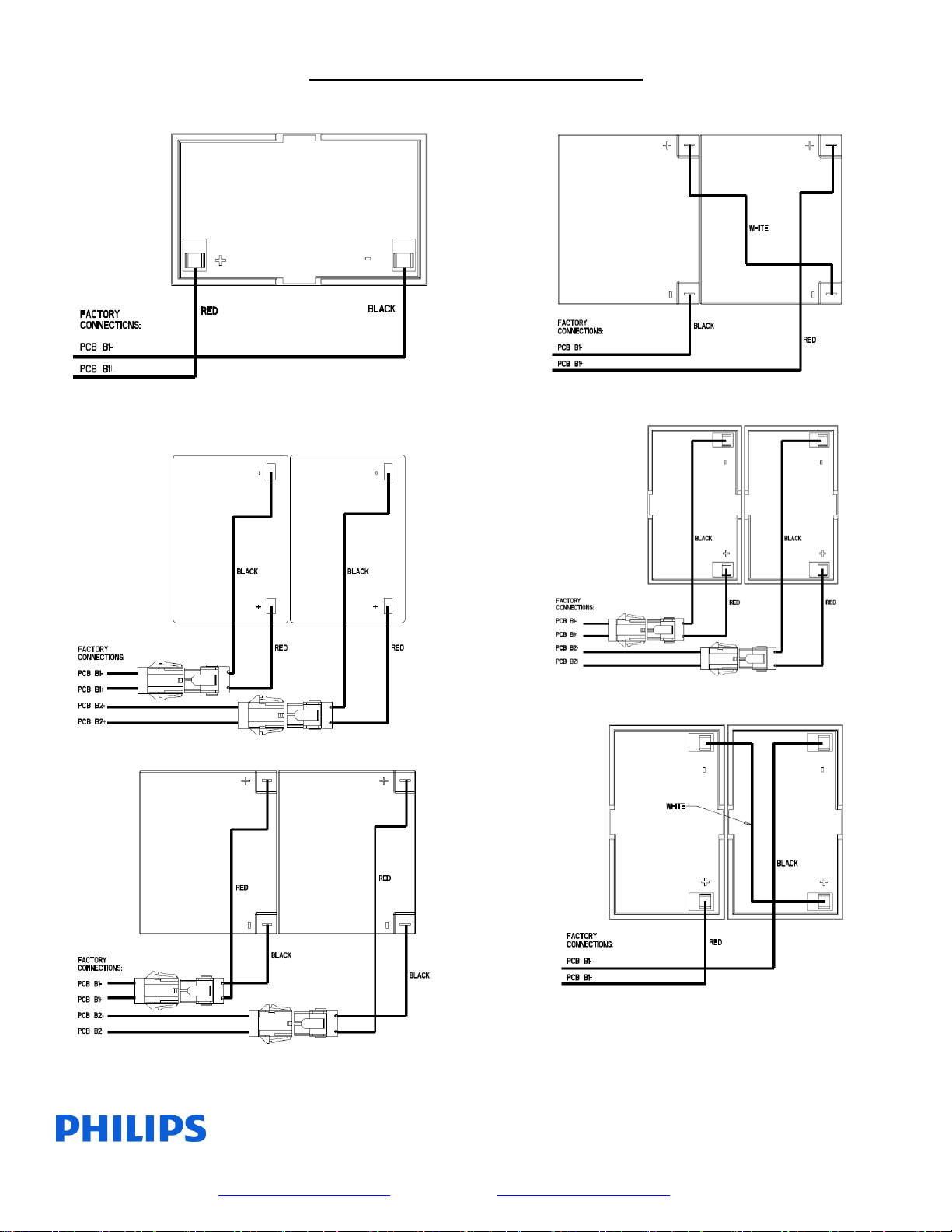

BATTERY HOOKUP DIAGRAMS

12V 200W

12V 250W

24V 300W

12V 450W

12V 300W

24V 450W

Loading...

Loading...