Page 1

UM10107

P89LPC915/916/917

8-bit microcontrollers with two-clock 80C51 core and 8-bit A/D

Rev. 01 — 15 July 2004 User manual

Document information

Info Content

Keywords P89LPC915, P89LPC916, P89LPC917

Abstract Technical information for the P89LPC915, P89LPC916, and P89LPC917

devices.

Page 2

Philips Semiconductors

Revision history

Rev Date Description

01 20040715 Initial version (9397 750 13316).

UM10107

P89LPC915/916/917 User manual

Contact information

For additional information, please visit: http://www.semiconductors.philips.com

For sales office addresses, please send an email to: sales.addresses@www.semiconductors.philips.com

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 2 of 125

Page 3

Philips Semiconductors

1. Introduction

The P89LPC915/916/917 are single-chip microcontrollers designed for applications

demanding high-integration, low cost solutions over a wide range of performance

requirements. The P89LPC915/916/917 is based on a high performance processor

architecture that executes instructions in two to four clocks, six times the rate of standard

80C51 devices. Many system-level functions have been incorporated into the

P89LPC915/916/917 in order to reduce component count, board space, and system cost.

1.1 Logic symbols

VDDV

UM10107

P89LPC915/916/917 User manual

SS

KBI0

KBI1

KBI2

KBI3

KBI4

KBI5

DAC1

AD10

AD11

AD12

AD13

CLKIN

Fig 1. P89LPC915 logic symbol.

KBI1

KBI2

KBI3

KBI4

KBI5

DAC1

AD10

AD11

AD12

AD13

CLKIN

CMP2

CIN2B

CIN2A

CIN1B

CIN1A

CMPREF

CIN2B

CIN2A

CIN1B

CIN1A

CMPREF

PORT 0

PORT 0

P89LPC915

002aaa828

V

V

DD

SS

P89LPC916

002aaa829

PORT 1

PORT 1

PORT 2

TxD

RxD

T0

INT0

INT1

RST

TxD

RxD

T0

INT0

RST

MOSI

MISO

SS

SPICLK

SCL

SDA

SCL

SDA

Fig 2. P89LPC916 logic symbol.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 3 of 125

Page 4

Philips Semiconductors

C

1

UM10107

P89LPC915/916/917 User manual

V

V

DD

SS

KBI0

KBI1

KBI2

KBI3

KBI4

KBI5

KBI7

DAC1

AD10

AD11

AD12

AD13

CLKIN

CLKOUT

Fig 3. P89LPC917 logic symbol.

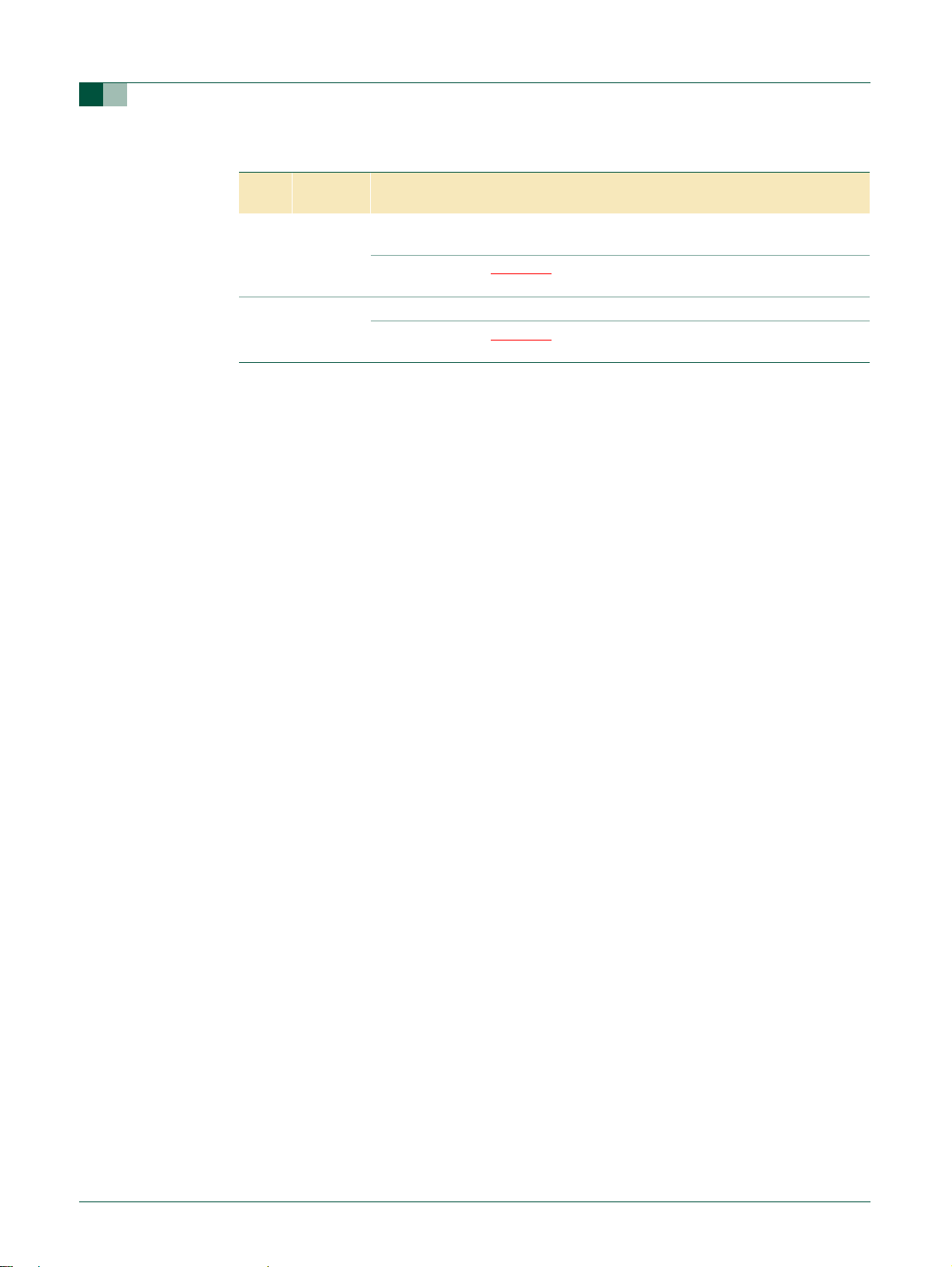

1.2 Product comparison

Table 1 highlights the differences between these devices. For a complete list of device

features, please refer to the P89LPC915/916/917 data sheet.

Table 1: Product comparison

Type

number

P89LPC915 X - - - X 6

P89LPC916 - X - - - 5

P89LPC917 X - X X X 7

1.3 Pin Configuration

CMP2

CIN2B

CIN2A

CIN1B

CIN1A

CMPREF

T1

Comp 2

output

PORT 0

P89LPC917

002aaa830

SPI T1 PWM

output

TxD

PORT 1

PORT 2

RxD

T0

INT0

INT1

RST

SCL

SDA

CLKOUT INT1 KBI

002aaa825

14

13

12

11

P0.5/CMPREF/KBI5/CLKIN

10

DD

9

IN2B/KBI1/AD10/P0.1 P0.2/CIN2A/KBI2/AD11

KBI0/CMP2/P0.0 P0.3/CIN1B/KBI3/AD12

RST/P1.5 P0.4/CIN1A/KBI4/AD13/DAC

INT1/P1.4 V

SDA/INT0/P1.3 P1.0/TXD

SCL/T0/P1.2 P1.1/RXD

1

2

3

V

SS

LPC915

4

5

6

7 8

Fig 4. P89LPC915 TSSOP14 pin configuration.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 4 of 125

Page 5

Philips Semiconductors

UM10107

P89LPC915/916/917 User manual

CIN2B/KBI1/AD10/P0.1 P0.2/CIN2A/KBI2/AD11

SS/P2.4 P0.3/CIN1B/KB13/AD12

RST/P1.5 P0.4/CIN1A/KBI4/AD13/DAC1

MISO/P2.3 V

MOSI/P2.2 P2.5/SPICLK

SDA/INT0/P1.3 P1.0/TXD

SCL/T0/P1.2 P1.1/RXD

1

2

3

V

4

SS

LPC916

5

6

7

8

002aaa826

Fig 5. P89LPC916 TSSOP16 pin configuration.

CIN2B/KBI1/AD10/P0.1 P0.2/CIN2A/KBI2/AD11

KBI0/CMP2/P0.0 P0.3/CIN1B/KB13/AD12

RST/P1.5 P0.4/CIN1A/KBI4/AD13/DAC1

MOSI/P2.2 V

INT1/P1.4 P0.7/T1/KBI7/CLKOUT

SDA/INT0/P1.3 P1.0/TXD

SCL/T0/P1.2 P1.1/RXD

1

2

3

V

4

SS

LPC917

5

6

7

8

002aaa827

Fig 6. P89LPC917 TSSOP pin configuration.

16

15

14

13

P0.5/CMPREF/KBI5/CLKIN

12

DD

11

10

9

16

15

14

13

P0.5/CMPREF/KBI5/CLKIN

12

DD

11

10

9

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 5 of 125

Page 6

Philips Semiconductors

Ta ble 2: P89LPC915 pin description

Symbol Pin Type Description

P0.0 to P0.5 1, 2, 11,

12, 13, 14

2 I/O P0.0 — Port 0 bit 0.

1 I/O P0.1 — Port 0 bit 1.

14 I/O P0.2 — Port 0 bit 2.

13 I/O P0.3 — Port 0 bit 3.

12 I/O P0.4 — Port 0 bit 4.

11 I/O P0.5 — Port 0 bit 5.

I/O Port 0: Port 0 is a 6-bit I/O port with user-configurable outputs. During reset Port 0

latches are configured in the input only mode with the internal pull-up disabled. The

operation of Port0 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 5.1

The Keypad Interrupt feature operates with Port 0 pins.

All pins have Schmitt triggered inputs.

Port 0 also provides various special functions as described below:

I CMP2 — Comparator 2 output.

I KBI0 — Keyboard input 0.

I CIN2B — Comparator 2 positive input B.

I KBI1 — Keyboard input 1.

I AD10 — A/D channel 1, input 0

I CIN2A — Comparator 2 positive input A.

I KBI2 — Keyboard input 2.

I AD11 — A/D channel 1, input 1

I CIN1B — Comparator 1 positive input B.

I KBI3 — Keyboard input 3.

I AD12 — A/D channel 1, input 2.

I CIN1A — Comparator 1 positive input A.

I KBI4 — Keyboard input 4.

I AD13 — A/D channel 1, input 3.

O DAC1 — Digital to analog converter 1 output.

I CMPREF — Comparator reference (negative) input.

I KBI5 — Keyboard input 5.

I CLKIN — External clock i nput.

UM10107

P89LPC915/916/917 User manual

for details.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 6 of 125

Page 7

Philips Semiconductors

Ta ble 2: P89LPC915 pin description

Symbol Pin Type Description

P1.0 to P1.5 3, 5, 6, 7,

8, 9

9 I/O P1.0 — Port 1 bit 0

8 I/O P1.1 — Port 1 bit 0

7 I/O P1.2 — Port 1 bit 2. (Open drain when used as an output.)

6 I/O P1.3 — Port 1 bit 2. (Open drain when used as an output.)

5 I/O P1.4 — Port 1 bit 2.

3IP1.5 — Port 1 bit 5. (Input only.)

V

SS

V

DD

4IGround: 0 V reference.

10 I Power Supply: This is the power supply voltage for normal operation as well as Idle

I/O

(P1.2);

I(P1.5)

O TxD — Serial port transmitter data.

I RxD — Serial port receiver dat a .

I/O T0 — Timer/counter 0 external count input, overflow output, or PWM output.

I/O SCL — I

I/O INT0

I/O SDA — I

I/O INT1

I RST

Port 1: Port 1 is a 6-bit I/O port with user-configurable outputs. During reset Port 1

latches are configured in the input only mode with the internal pull-up disabled. The

operation of the inputs and outputs depends upon the port configuration selected.

Refer to Section 5.1

input only.

All pins have Schmitt triggered inputs.

Port 1 also provides various special functions as described below:

2

— External interrupt 0 input.

2

— External interrupt 1input.

— External Reset input during power-on or if selected via UCFG1. When

functioning as a reset input a LOW on this pin resets the microcontroller, causing I/O

ports and peripherals to take on their default states, and the processor begins

execution at address 0. Also used during a power-on sequence to force In-System

Programming mode.

and Power-down modes.

UM10107

P89LPC915/916/917 User manual

for details. P1.2 is an o pen drai n whe n used as an outpu t. P1. 5 is

C serial clock input/output.

C serial data input/output.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 7 of 125

Page 8

Philips Semiconductors

Ta ble 3: P89LPC916 pin description

Symbol Pin Type Description

P0.1 to P0.5 1, 13, 14,

15, 16

1 I/O P0.1 — Port 0 bit 1.

16 I/O P0.2 — Port 0 bit 2.

15 I/O P0.3 — Port 0 bit 3.

14 I/O P0.4 — Port 0 bit 4.

13 I/O P0.5 — Port 0 bit 5.

I/O Port 0: Port 0 is a 5-bit I/O port with user-configurable outputs. During reset Port 0

latches are configured in the input only mode with the internal pull-up disabled. The

operation of Port0 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 5.1

The Keypad Interrupt feature operates with Port 0 pins.

All pins have Schmitt triggered inputs.

Port 0 also provides various special functions as described below:

I CIN2B — Comparator 2 positive input B.

I KBI1 — Keyboard input 1.

I AD10 — A/D channel 1, input 0

I CIN2A — Comparator 2 positive input A.

I KBI2 — Keyboard input 2.

I AD11 — A/D channel 1, input 1

I CIN1B — Comparator 1 positive input B.

I KBI3 — Keyboard input 3.

I AD12 — A/D channel 1, input 2.

I CIN1A — Comparator 1 positive input A.

I KBI4 — Keyboard input 4.

I AD13 — A/D channel 1, input 3.

O DAC1 — Digital to analog converter 1 output.

I CMPREF — Comparator reference (negative) input.

I KBI5 — Keyboard input 5.

I CLKIN — External clock i nput.

UM10107

P89LPC915/916/917 User manual

for details.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 8 of 125

Page 9

Philips Semiconductors

UM10107

P89LPC915/916/917 User manual

Ta ble 3: P89LPC916 pin description

Symbol Pin Type Description

P1.0 to P1.3,

P1.5

P2.2 to P2.5 2, 5, 6, 11 I/O Port 2: Port 2 is a 4-bit I/O port having user-configurable output types. During reset

V

SS

V

DD

3, 7, 8, 9, 10I/O

(P1.2);

I(P1.5)

10 I/O P1.0 — Port 1 bit 0

O TxD — Serial port transmitter data.

9 I/O P1.1 — Port 1 bit 0

I RxD — Serial port receiver dat a .

8 I/O P1.2 — Port 1 bit 2. (Open drain when used as an output.)

I/O T0 — Timer/counter 0 external count input, overflow output, or PWM output.

I/O SCL — I

7 I/O P1.3 — Port 1 bit 2. (Open drain when used as an output.)

I/O INT0

I/O SDA — I

3IP1.5 — Port 1 bit 5. (Input only.)

I RST

6 I/O P2.2 — Port 2 bit 2.

O MOSI — SPI master out slave in. When configured as a master this pin is an output.

5 I/O P2.3 — Port 2 bit 3.

I MISO — SPI master in slave out. When configured as a master this pin is an input.

2 I/O P2.4 — Port 2 bit 4.

I/O SS

11 I/O P2.5 — Port 2 bit 5.

I/O SPICLK — When configured as a master this pin is an output. When configured as a

4IGround: 0 V reference.

12 I Power Supply: This is the power supply voltage for normal operation as well as Idle

Port 1: Port 1 is a 5-bit I/O port with user-configurable outputs. During reset Port 1

latches are configured in the input only mode with the internal pull-up disabled. The

operation of the P1. 2 input and output s de pends upon the port c onf iguration selected.

Refer to Section 5.1

input only.

All pins have Schmitt triggered inputs.

Port 1 also provides various special functions as described below:

2

C serial clock input/output.

— External interrupt 0 input.

2

C serial data input/output.

— External Reset input during power-on or if selected via UCFG1. When

functioning as a reset input a LOW on this pin resets the microcontroller, causing I/O

ports and peripherals to take on their default states, and the processor begins

execution at address 0. Also used during a power-on sequence to force In-System

Programming mode.

Port 1 latches are configured in th e input only mode with the i nternal pull-up disabled.

The operation of the P2 input and outputs depends upon the port configuration

selected. Refer to Section 5.1

All pins have Schmitt triggered inputs.

Port 2 also provides various special functions as described below:

When configured as a slave, this pin is an input.

When configured as a slave, this pin is an output.

— SPI Slave select.

slave, this pin is an input.

and Power-down modes.

for details. P1.2 is an o pen drai n whe n used as an outpu t. P1. 5 is

for details.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 9 of 125

Page 10

Philips Semiconductors

Ta ble 4: P89LPC917 pin description

Symbol Pin Type Description

P0.0 to P0.5,

P0.7

1, 2, 11,

13, 14, 15,

16

2 I/O P0.0 — Port 0 bit 0.

1 I/O P0.1 — Port 0 bit 1.

16 I/O P0.2 — Port 0 bit 2.

15 I/O P0.3 — Port 0 bit 3.

14 I/O P0.4 — Port 0 bit 4.

13 I/O P0.5 — Port 0 bit 5.

11 I/O P0.7 — Port 0 bit 7.

I/O Port 0: Port 0 is a 7-bit I/O port with user-configurable outputs. During reset Port 0

latches are configured in the input only mode with the internal pull-up disabled. The

operation of Port 0 pins as inputs and outputs depends upon the port configuration

selected. Each port pin is configured independently. Refer to Section 5.1

The Keypad Interrupt feature operates with Port 0 pins.

All pins have Schmitt triggered inputs.

Port 0 also provides various special functions as described below:

I CMP2 — Comparator 2 output.

I KBI0 — Keyboard input 0.

I CIN2B — Comparator 2 positive input B.

I KBI1 — Keyboard input 1.

I AD10 — A/D channel 1, input 0

I CIN2A — Comparator 2 positive input A.

I KBI2 — Keyboard input 2.

I AD11 — A/D channel 1, input 1

I CIN1B — Comparator 1 positive input B.

I KBI3 — Keyboard input 3.

I AD12 — A/D channel 1, input 2.

I CIN1A — Comparator 1 positive input A.

I KBI4 — Keyboard input 4.

I AD13 — A/D channel 1, input 3.

O DAC1 — Digital to analog converter 1 output.

I CMPREF — Comparator reference (negative) input.

I KBI5 — Keyboard input 5.

I CLKIN — External clock input.

I T1 — Timer/counter 1 external count input, overflow output, or PWM output.

I KBI7 — Keyboard input 7.

I CLKOUT — Clock output.

UM10107

P89LPC915/916/917 User manual

for details.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 10 of 125

Page 11

Philips Semiconductors

UM10107

P89LPC915/916/917 User manual

Ta ble 4: P89LPC917 pin description

Symbol Pin Type Description

P1.0 to P1.5 3, 6, 7, 8,

9, 10

10 I/O P1.0 — Port 1 bit 0.

9 I/O P1.1 — Port 1 bit 1.

8 I/O P1.2 — Port 1 bit 2. (Open drain when used as an output.)

7 I/O P1.3 — Port 1 bit 3. (Open drain when used as an output.)

6 I/O P1.4 — Port 1 bit 4.

3IP1.5 — Port 1 bit 5. (Input only.)

P2.2 5 I/O Port 2: Port 2.2 is a single-bit I/O port with a user-configurable output. During reset

V

SS

V

DD

4IGround: 0 V reference.

12 I Power Supply: This is the power supply v olt age fo r norma l ope ration as w ell as Id le

I/O

(P1.0:4);

I(P1.5)

O TxD — Serial port transmitter data.

I RxD — Serial port receiver data.

I/O T0 — Timer/counter 0 external count input, overflow, or PWM output.

I/O SCL — I

I/O INT0

I/O SDA — I

I/O INT1

I RST

Port 1: Port 1 is a 6-bit I/O port with user-configurable outputs. During reset Port 1

latches are configured in the input only mode with the internal pull-up disabled. The

operation of the outputs depends upon the port configuration selected. Refer to

Section 5.1

input only.

All pins have Schmitt triggered inputs.

Port 1 also provides various special functions as described below:

functioning as a reset input a LOW on thi s pin reset s t he mi crocon trolle r, causing I /O

ports and peripherals to take on their default states, and the processor begins

execution at address 0. Also used during a power-on sequence to force In-System

Programming mode.

the Port 2.2 latch is configured in the input only mode with the internal pull-up

disabled. The operation of the output depends upon the port configuration selected.

Refer to Section 5.1

This pin has a Schmitt triggered i nput.

and Power-down modes.

for details. P1.2 and P1.3 are open drain when used as outputs. P1.5 is

2

C serial clock input/output.

— External interrupt 0 input.

2

C serial data input/output.

— External interrupt 1input.

— External Reset input during power-on or if selected via UCFG1. When

and details.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 11 of 125

Page 12

Philips Semiconductors

UM10107

P89LPC915/916/917 User manual

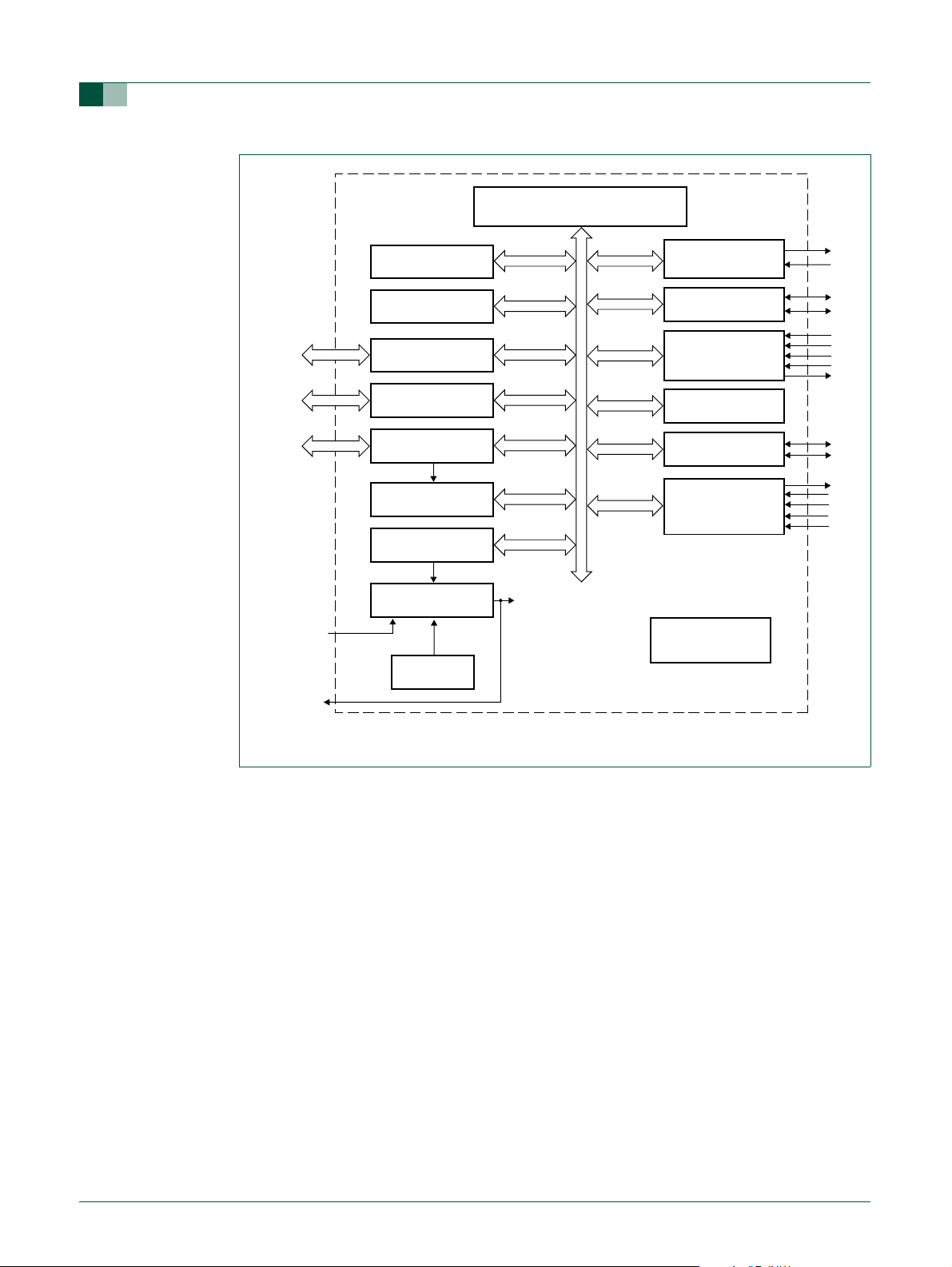

external

clock

input

P89LPC915

2 kB

CODE FLASH

256-BYTE

DATA RAM

PORT 1

CONFIGURABLE I/Os

PORT 0

CONFIGURABLE I/Os

KEYPAD

INTERRUPT

WATCHDOG TIMER

AND OSCILLATOR

PROGRAMMABLE

OSCILLATOR DIVIDER

ON-CHIP RC

OSCILLATOR

HIGH PERFORMANCE

ACCELERATED 2-CLOCK 80C51 CPU

INTERNAL

BUS

CPU

CLOCK

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

UART

I2C

ADC1/DAC1

REAL-TIME CLOCK/

SYSTEM TIMER

TIMER 0

TIMER 1

ANALOG

COMPARATORS

Fig 7. P89LPC915 block diagram.

002aaa822

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 12 of 125

Page 13

Philips Semiconductors

UM10107

P89LPC915/916/917 User manual

external

clock

input

P89LPC916

2 kB

CODE FLASH

256-BYTE

DATA RAM

PORT 2

CONFIGURABLE I/Os

PORT 1

CONFIGURABLE I/Os

PORT 0

CONFIGURABLE I/Os

KEYPAD

INTERRUPT

WATCHDOG TIMER

AND OSCILLATOR

PROGRAMMABLE

OSCILLATOR DIVIDER

ON-CHIP RC

OSCILLATOR

HIGH PERFORMANCE

ACCELERATED 2-CLOCK 80C51 CPU

INTERNAL

BUS

CPU

CLOCK

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

UART

I2C

ADC1/DAC1

SPI

REAL-TIME CLOCK/

SYSTEM TIMER

TIMER 0

TIMER 1

ANALOG

COMPARATORS

Fig 8. P89LPC916 block diagram.

002aaa823

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 13 of 125

Page 14

Philips Semiconductors

UM10107

P89LPC915/916/917 User manual

external

clock

input

CLKOUT

P89LPC917

2 kB

CODE FLASH

256-BYTE

DATA RAM

PORT 2

CONFIGURABLE I/Os

PORT 1

CONFIGURABLE I/Os

PORT 0

CONFIGURABLE I/Os

KEYPAD

INTERRUPT

WATCHDOG TIMER

AND OSCILLATOR

PROGRAMMABLE

OSCILLATOR DIVIDER

ON-CHIP RC

OSCILLATOR

HIGH PERFORMANCE

ACCELERATED 2-CLOCK 80C51 CPU

INTERNAL

BUS

CPU

CLOCK

POWER MONITOR

(POWER-ON RESET,

BROWNOUT RESET)

UART

I2C

ADC1/DAC1

REAL-TIME CLOCK/

SYSTEM TIMER

TIMER 0

TIMER 1

ANALOG

COMPARATORS

002aaa824

Fig 9. P89LPC917 block diagram.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 14 of 125

Page 15

Philips Semiconductors

1.4 Special function registers

Remark: Special Function Registers (SFRs) accesses are restricted in the following

ways:

• User must not attempt to access any SFR locations not defined.

• Accesses to any defined SFR locations must be strictly for the functions for the SFRs.

• SFR bits labeled ‘-’, ‘0’ or ‘1’ can only be written and read as follows:

– ‘-’ Unless otherwise specif ied, must be written with ‘0’, but can return any value

– ‘0’ must be written with ‘0’, and will return a ‘0’ when read.

– ‘1’ must be written with ‘1’, and will return a ‘1’ when read.

UM10107

P89LPC915/916/917 User manual

when read (even if it was written with ‘0’). It is a reserved bit and may be used in

future derivatives.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 15 of 125

Page 16

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 16 of 125

Table 5: P89LPC915 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

ACC* Accumulator E0H 00 00000000

ADCON1 A/D control register 1 97H ENBI1 ENADCI1TMM1 EDGE1 ADCI1 ENADC1 ADCS11 ADCS10 00 00000000

ADINSA/D input select A3HADI13ADI12ADI11ADI10----0000000000

ADMODAA/D mode registerA C0HBNDI1BURST1SCC1SCAN1----0000000000

ADMODB A/D mode register B A1H CLK2 CLK1 CLK0 - ENDAC1 - BSA1 - 00 000x0000

AD1BH A/D_1 boundary high register C4H FF 11111111

AD1BL A/D_1 boundary low register BCH 00 00000000

AD1DAT0 A/D_1 data register 0 D5H 00 00000000

AD1DAT1 A/D_1 data register 1 D6H 00 00000000

AD1DAT2 A/D_1 data register 2 D7H 00 00000000

AD1DAT3 A/D_1 data register 3 F5H 00 00000000

AUXR1 Auxiliary function register A2H CLKLP EBRR - ENT0 SRST 0 - DPS 00 000000x0

B* B register F0H 00 00000000

BRGR0

BRGR1

BRGCON Baud rate generator control BDH - - - - - - SBRGS BRGEN 00

CMP1 Comparator 1 control register ACH - - CE1 CP1 CN1 - CO1 CMF1 00

CMP2 Comparator 2 control register ADH - - CE2 CP2 CN2 OE2 CO2 CMF2 00

DIVM CPU clock divide-by-M

DPTR Data pointer (2 bytes)

DPH Data pointer high 83H 00 00000000

DPL Data pointer low 82H 00 00000000

FMADRH Program Flash address high E7H - - - - - - 00 00000000

FMADRL Program Flash address low E6H 00 00000000

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

Bit addressE7E6E5E4E3E2E1E0

Bit addressF7F6F5F4F3F2F1F0

[2]

Baud rate generator rate low BEH 00 00000000

[2]

Baud rate generator rate high BFH 00 00000000

95H 00 00000000

control

MSB LSB Hex Binary

[2]

[1]

[1]

xxxxxx00

xx000000

xx000000

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 17

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 17 of 125

Table 5: P89LPC915 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

FMCON Program Flash Control

FMDATA Program Flash data E5H 00 00000000

I2ADR I2C slave address register DBH I2ADR.6 I2ADR.5 I2ADR.4 I2ADR.3 I2ADR.2 I2ADR.1 I2ADR.0 GC 00 00000000

I2CON* I

I2DAT I

I2SCLH Serial clock generator/SCL

I2SCLL Serial clock generator/SCL

I2STAT I

IEN0* Interrupt enable 0 A8H EA EWDRT EBO ES/ESR ET1 EX1 ET0 EX0 00 00000000

IEN1* Interrupt enable 1 E8H EAD EST - - - EC EKBI EI2C 00

IP0* Interrupt priority 0 B8H - PWDRT PBO PS/PSR PT1 PX1 PT0 PX0 00

IP0H Interrupt priority 0 high B7H - PWDRTHPBOH PSH/

IP1* Interrupt priority 1 F8H PAD PST - - - PC PKBI PI2C 00

IP1H Interrupt priority 1 high F7H PADH PSTH - - - PCH PKBIH PI2CH 00

KBCON Keypad control register 94H - - - - - - PATN

KBMASK Keypad interrupt mask

KBPATN Keypad pattern register 93H FF 11111111

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

E4H BUSY - - - HVA HVE SV OI 70 01110000

(Read)

Program Flash Control (Write) FMCMD.7FMCMD.6FMCMD.5FMCMD.4FMCMD.3FMCMD.2FMCMD.1FMCMD.

Bit addressDFDEDDDCDBDAD9 D8

2

C control register D8H - I2EN STA STO SI AA - CRSEL 00 x00000x0

2

C data register DAH

DDH 00 00000000

duty cycle register high

DCH 00 00000000

duty cycle register low

2

C status r egister D 9H ST A.4 STA.3 STA.2 STA.1 STA.0 0 0 0 F8 11111000

Bit addressAFAEADACABAAA9 A8

Bit addressEFEEEDECEBEAE9 E8

Bit addressBFBEBDBCBBBAB9 B8

Bit addressFFFEFDFCFBFAF9F8

86H 00 00000000

register

Bit address8786858483828180

MSB LSB Hex Binary

0

[1]

[1]

PT1H PX1H PT0H PX0H 00

[1]

PSRH

[1]

[1]

KBIF 00

[1]

_SEL

00x00000

x0000000

x0000000

00x00000

00x00000

xxxxxx00

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 18

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 18 of 125

Table 5: P89LPC915 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

P0* Port 0 80H - - CMPREF

P1* Port 1 90H - - RST

P0M1 Port 0 output mode 1 84H - - (P0M1.5) (P0M1.4) (P0M1.3) (P0M1.2) (P0M1.1) (P0M1.0) FF

P0M2 Port 0 output mode 2 85H - - (P0M2.5) (P0M2.4) (P0M2.3) (P0M2.2) (P0M2.1) (P0M2.0) 00

P1M1 Port 1 output mode 1 91H - - - (P1M1.4) (P1M1.3) (P1M1.2) (P1M1.1) (P1M1.0) D3

P1M2 Port 1 output mode 2 92H - - - (P1M2.4) (P1M2.3) (P1M2.2) (P1M2.1) (P1M2.0) 00

PCON Power control register 87H SMOD1 SMOD0 BOPD BOI GF1 GF0 PMOD1 PMOD0 00 00000000

PCONA Power control register A B5H RTCPD - VCPD ADPD I2PD - SPD - 00

PSW* Program status word D0H CY AC F0 RS1 RS0 OV F1 P 00 00000000

PT0AD Port 0 digital input disable F6H - - PT0AD.5 PT0AD.4 PT0AD.3 PT0AD.2 PT0AD.1 - 00 xx00000x

RSTSRC Reset source register DFH - - BOF POF R_BK R_WD R_SF R_EX

RTCCON Real-time clock control D1H RTCF RTCS1 RTCS0 - - - ERTC RTCEN 60

RTCH Real-time clock register high D2H 00

RTCL Real-time clock register low D3H 00

SADDR Serial port address register A9H 00 00000000

SADEN Serial port address enable B9H 00 00000000

SBUF Serial Port data buffer register 99H xx xxxxxxxx

SCON* Serial port control 98H SM0/FE SM1 SM2 REN TB8 RB8 TI RI 00 00000000

SSTAT Serial port extended status

SP Stack pointer 81H 07 00000111

TAMODTimer0 and 1 auxiliary mode8FH-------T0M200xxx0xxx0

TCON* Timer 0 and 1 control 88H TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0 00 00000000

TH0 Timer 0 high 8CH 00 00000000

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

Bit address9796959493929190

Bit addressD7D6D5D4D3D2D1D0

Bit address9F9E9D9C9B9A99 98

BAH DBMOD INTLO CIDIS DBISEL FE BR OE STINT 00 00000000

register

Bit address8F8E8D8C8B8A89 88

MSB LSB Hex Binary

/KBI5

CIN1A

/KBI4

CIN1B

/KBI3

INT1 INT0/

SDA

CIN2A

/KBI2

CIN2B

/KBI1

CMP2

/KBI0

T0/SCL RXD TXD

[1]

[1]

[1]

[1]

[1]

[1][6]

[6]

[6]

[1]

[1]

11111111

00000000

11x1xx11

00x0xx00

00000000

[3]

011xxx00

00000000

00000000

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 19

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 19 of 125

Table 5: P89LPC915 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

TH1 Timer 1 high 8DH 00 00000000

TL0 Timer 0 low 8AH 00 00000000

TL1 Timer 1 low 8BH 00 00000000

TMOD Timer 0 and 1 mode 89H T1GATE T1C/T

TRIM Internal oscillator trim register 96H RCCLK - TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

WDCON Watchdog control register A7H PRE2 PRE1 PRE0 - - WDRUN WDTOF WDCLK

WDL Watchdog load C1H FF 11111111

WFEED1 Watchdog feed 1 C2H

WFEED2 Watchdog feed 2 C3H

[1] All ports are in input only (high impedance) state after power-up.

[2] BRGR1 and BRGR0 must only be written if BRGEN in BRGCON SFR is logic 0. If any are written while BRGEN = 1, the result is unpredictable.

[3] The RSTSRC register reflects the cause of the P89LPC915/916/917 reset. Upon a power-up reset, all reset source flags are cleared except POF and BOF; the power-on reset

[4] After reset, the value is 111001x1, i.e., PRE[2:0] are all logic 1, WDRUN = 1 and WDCLK = 1. WDTOF bit is logic 1 after Watchdog reset and is logic 0 after power-on reset. Other

[5] On power-on reset, the TRIM SFR is initialized with a factory preprogrammed value. Other resets will not cause initialization of the TRIM register.

[6] The only reset source that affects these SFRs is power-on reset

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

value is xx110000.

resets will not affect WDTOF.

MSB LSB Hex Binary

T1M1 T1M0 T0GATE T0C/T T0M1 T0M0 00 00000000

Philips Semiconductors

[5] [6]

[4] [6]

P89LPC915/916/917 User manual

UM10107

Page 20

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 20 of 125

Table 6: P89LPC916 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

ACC* Accumulator E0H 00 00000000

ADCON1 A/D control register 1 97H ENBI1 ENADCI1TMM1 EDGE1 ADCI1 ENADC1 ADCS11 ADCS10 00 00000000

ADINSA/D input select A3HADI13ADI12ADI11ADI10----0000000000

ADMODAA/D mode registerA C0HBNDI1BURST1SCC1SCAN1----0000000000

ADMODB A/D mode register B A1H CLK2 CLK1 CLK0 - ENDAC1 - BSA1 - 00 000x0000

AD1BH A/D_1 boundary HIGH

AD1BL A/D_1 boundary LOW

AD1DAT0 A/D_1 data register 0 D5H 00 00000000

AD1DAT1 A/D_1 data register 1 D6H 00 00000000

AD1DAT2 A/D_1 data register 2 D7H 00 00000000

AD1DAT3 A/D_1 data register 3 F5H 00 00000000

AUXR1 Auxiliary function register A2H CLKLP EBRR - ENT0 SRST 0 - DPS 00 000000x0

B* B register F0H 00 00000000

BRGR0

BRGR1

BRGCON Baud rate generator control BDH - - - - - - SBRGS BRGEN 00

CMP1 Comparator 1 control register ACH - - CE1 CP1 CN1 - CO1 CMF1 00

CMP2 Comparator 2 control register ADH - - CE2 CP2 CN2 OE2 CO2 CMF2 00 xx000000

DIVM CPU clock divide-by-M

DPTR Data pointer (2 bytes)

DPH Data pointer HIGH 83H 00 00000000

DPL Data pointer LOW 82H 00 00000000

FMADRH Program Flash address HIGH E7H - - - - - - 00 00000000

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

register

register

[2]

Baud rate generator rate

LOW

[2]

Baud rate generator rate

HIGH

control

addr.

Bit addressE7E6E5E4E3E2E1E0

C4H FF 11111111

BCH 00 00000000

Bit addressF7F6F5F4F3F2F1F0

BEH 00 00000000

BFH 00 00000000

95H 00 00000000

MSB LSB Hex Binary

[2]

[1]

xxxxxx00

xx000000

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 21

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 21 of 125

Table 6: P89LPC916 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

FMADRL Program Flash address LOW E6H 00 00000000

FMCON Program Flash Control

FMDATA Program Flash data E5H 00 00000000

I2ADR I

I2CON* I

I2DAT I

I2SCLH Serial clock generator/SCL

I2SCLL Serial clock generator/SCL

I2STAT I

IEN0* Interrupt enable 0 A8H EA EWDRT EBO ES/ESR ET1 - ET0 EX0 00 00000000

IEN1* Interrupt enable 1 E8H EAD EST - - ESPI EC EKBI EI2C 00

IP0* Interrupt priority 0 B8H - PWDRT PBO PS/PSR PT1 - PT0 PX0 00

IP0H Interrupt priority 0 HIGH B7H - PWDRTHPBOH PSH/

IP1* Interrupt priority 1 F8H PAD PST - - PSPI PC PKBI PI2C 00

IP1H Interrupt priority 1 HIGH F7H PADH PSTH - - PSPIH PCH PKBIH PI2CH 00

KBCON Keypad control register 94H - - - - - - PATN

KBMASK Keypad interrupt mask

KBPATN Keypad pattern register 93H FF 11111111

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

E4H BUSY - - - HVA HVE SV OI 70 01110000

(Read)

Program Flash Control (Write) FMCMD.7FMCMD.6FMCMD.5FMCMD.4FMCMD.3FMCMD.2FMCMD.1FMCMD.

2

C slave address register DBH I2ADR.6 I2ADR.5 I2ADR.4 I2ADR.3 I2ADR.2 I2ADR.1 I2ADR.0 GC 00 00000000

Bit addressDFDEDDDCDBDAD9 D8

2

C control register D8H - I2EN STA STO SI AA - CRSEL 00 x00000x0

2

C data register DAH

DDH 00 00000000

duty cycle register HIGH

DCH 00 00000000

duty cycle register LOW

2

C status r egister D 9H ST A.4 STA.3 STA.2 STA.1 STA.0 0 0 0 F8 11111000

Bit addressAFAEADACABAAA9 A8

Bit addressEFEEEDECEBEAE9 E8

Bit addressBFBEBDBCBBBAB9 B8

Bit addressFFFEFDFCFBFAF9F8

86H 00 00000000

register

MSB LSB Hex Binary

0

[1]

[1]

PT1H - PT0H PX0H 00

[1]

PSRH

[1]

[1]

KBIF 00

[1]

_SEL

00x00000

x0000000

x0000000

00x00000

00x00000

xxxxxx00

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 22

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 22 of 125

Table 6: P89LPC916 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

P0* Port 0 80H - - CMPREF

P1* Port 1 90H - - RST

P2* Port 2 A0H - - SPICLK SS

P0M1 Port 0 output mode 1 84H - - (P0M1.5) (P0M1.4) (P0M1.3) (P0M1.2) (P0M1.1) - FF

P0M2 Port 0 output mode 2 85H - - (P0M2.5) (P0M2.4) (P0M2.3) (P0M2.2) (P0M2.1) - 00

P1M1 Port 1 output mode 1 91H - - - - (P1M1.3) (P1M1.2) (P1M1.1) (P1M1.0) D3

P1M2 Port 1 output mode 2 92H - - - - (P1M2.3) (P1M2.2) (P1M2.1) (P1M2.0) 00

P2M1 Port 2 output mode 1 A4H - - (P2M1.5) (P2M1.4) (P2M1.3) (P2M1.2) - - FF

P2M2 Port 2 output mode 2 A5H - - (P2M2.5) (P2M2.4) (P2M2.3) (P2M2.2) - - 00

PCON Power control register 87H SMOD1 SMOD0 BOPD BOI GF1 GF0 PMOD1 PMOD0 00 00000000

PCONA Power control register A B5H RTCPD - VCPD ADPD I2PD SPPD SPD - 00

PSW* Program status word D0H CY AC F0 RS1 RS0 OV F1 P 00 00000000

PT0AD Port 0 digital input disable F6H - - PT0AD.5 PT0AD.4 PT0AD.3 PT0AD.2 PT0AD.1 - 00 xx00000x

RSTSRC Reset source register DFH - - BOF POF R_BK R_WD R_SF R_EX

RTCCON Real-time clock control D1H RTCF RTCS1 RTCS0 - - - ERTC RTCEN 60

RTCH Real-time clock register HIGH D2H 00

RTCL Real-time clock register LOW D3H 00

SADDR Serial port address register A9H 00 00000000

SADEN Serial port address enable B9H 00 00000000

SBUF Serial Port data buffer register 99H xx xxxxxxxx

SCON* Serial port control 98H SM0/FE SM1 SM2 REN TB8 RB8 TI RI 00 00000000

SSTAT Serial port extended status

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

Bit address8786858483828180

Bit address9796959493929190

Bit address9796959493929190

Bit addressD7D6D5D4D3D2D1D0

Bit address9F9E9D9C9B9A99 98

BAH DBMOD INTLO CIDIS DBISEL FE BR OE STINT 00 00000000

register

MSB LSB Hex Binary

/KBI5

CIN1A

/KBI4

- INT0/

CIN1B

/KBI3

CIN2A

/KBI2

CIN2B

/KBI1

T0/SCL RXD TXD

SDA

MISO MOSI - -

-

[1]

[1]

[1]

[1]

[1]

[1]

[1]

[1][6]

[6]

[6]

[1]

[1]

[1]

11111111

00000000

11x1xx11

00x0xx00

11111111

00000000

00000000

[3]

011xxx00

00000000

00000000

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 23

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 23 of 125

Table 6: P89LPC916 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

SP Stack pointer 81H 07 00000111

SPCTL SPI control register E2H SSIG SPEN DORD MSTR CPOL CPHA SPR1 SPR0 04 00000100

SPSTAT SPI status register E1H SPIF WCOL - -----0000xxxxxx

SPDAT SPI data register E3H 00 00000000

TAMODTimer0 and 1 auxiliary mode8FH-------T0M200xxx0xxx0

TCON* Timer 0 and 1 control 88H TF1 TR1 TF0 TR0 - - IE0 IT0 00 00000000

TH0 Timer 0 HIGH 8CH 00 00000000

TH1 Timer 1 HIGH 8DH 00 00000000

TL0 Timer 0 LOW 8AH 00 00000000

TL1 Timer 1 LOW 8BH 00 00000000

TMOD Timer 0 and 1 mode 89H T1GATE T1C/T

TRIM Internal oscillator trim register 96H RCCLK - TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

WDCON Watchdog control register A7H PRE2 PRE1 PRE0 - - WDRUN WDTOF WDCLK

WDL Watchdog load C1H FF 11111111

WFEED1 Watchdog feed 1 C2H

WFEED2 Watchdog feed 2 C3H

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

Bit address8F8E8D8C8B8A89 88

MSB LSB Hex Binary

T1M1 T1M0 T0GATE T0C/T T0M1 T0M0 00 00000000

[5] [6]

[4] [6]

Philips Semiconductors

[1] All ports are in input only (high impedance) state after power-up.

[2] BRGR1 and BRGR0 must only be written if BRGEN in BRGCON SFR is logic 0. If any are written while BRGEN = 1, the result is unpredictable.

[3] The RSTSRC register reflects the cause of the P89LPC915/916/917 reset. Upon a power-up reset, all reset source flags are cleared except POF and BOF; the power-on reset

value is xx110000.

[4] After reset, the value is 111001x1, i.e., PRE[2:0] are all logic 1, WDRUN = 1 and WDCLK = 1. WDTOF bit is logic 1 after Watchdog reset and is logic 0 after power-on reset. Other

resets will not affect WDTOF.

[5] On power-on reset, the TRIM SFR is initialized with a factory preprogrammed value. Other resets will not cause initialization of the TRIM register.

[6] The only reset source that affects these SFRs is power-on reset.

P89LPC915/916/917 User manual

UM10107

Page 24

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 24 of 125

Table 7: P89LPC917 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

ACC* Accumulator E0H 00 00000000

ADCON1 A/D control register 1 97H ENBI1 ENADCI1TMM1 EDGE1 ADCI1 ENADC1 ADCS11 ADCS10 00 00000000

ADINSA/D input select A3HADI13ADI12ADI11ADI10----0000000000

ADMODAA/D mode registerA C0HBNDI1BURST1SCC1SCAN1----0000000000

ADMODB A/D mode register B A1H CLK2 CLK1 CLK0 - ENDAC1 - BSA1 - 00 000x0000

AD1BH A/D_1 boundary HIGH

AD1BL A/D_1 boundary LOW

AD1DAT0 A/D_1 data register 0 D5H 00 00000000

AD1DAT1 A/D_1 data register 1 D6H 00 00000000

AD1DAT2 A/D_1 data register 2 D7H 00 00000000

AD1DAT3 A/D_1 data register 3 F5H 00 00000000

AUXR1 Auxiliary function register A2H CLKLP EBRR ENT1 ENT0 SRST 0 - DPS 00 000000x0

B* B register F0H 00 00000000

BRGR0

BRGR1

BRGCON Baud rate generator control BDH - - - - - - SBRGS BRGEN 00

CMP1 Comparator 1 control register ACH - - CE1 CP1 CN1 - CO1 CMF1 00

CMP2 Comparator 2 control register ADH - - CE2 CP2 CN2 OE2 CO2 CMF2 00

DIVM CPU clock divide-by-M

DPTR Data pointer (2 bytes)

DPH Data pointer HIGH 83H 00 00000000

DPL Data pointer LOW 82H 00 00000000

FMADRH Program Flash address HIGH E7H - - - - - - 00 00000000

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

register

register

[2]

Baud rate generator rate

LOW

[2]

Baud rate generator rate

HIGH

control

addr.

Bit addressE7E6E5E4E3E2E1E0

C4H FF 11111111

BCH 00 00000000

Bit addressF7F6F5F4F3F2F1F0

BEH 00 00000000

BFH 00 00000000

95H 00 00000000

MSB LSB Hex Binary

[2]

[1]

[1]

xxxxxx00

xx000000

xx000000

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 25

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 25 of 125

Table 7: P89LPC917 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

FMADRL Program Flash address LOW E6H 00 00000000

FMCON Program Flash Control

FMDATA Program Flash data E5H 00 00000000

I2ADR I

I2CON* I

I2DAT I

I2SCLH Serial clock generator/SCL

I2SCLL Serial clock generator/SCL

I2STAT I

IEN0* Interrupt enable 0 A8H EA EWDRT EBO ES/ESR ET1 EX1 ET0 EX0 00 00000000

IEN1* Interrupt enable 1 E8H EAD EST - - - EC EKBI EI2C 00

IP0* Interrupt priority 0 B8H - PWDRT PBO PS/PSR PT1 PX1 PT0 PX0 00

IP0H Interrupt priority 0 HIGH B7H - PWDRTHPBOH PSH/

IP1* Interrupt priority 1 F8H PAD PST - - - PC PKBI PI2C 00

IP1H Interrupt priority 1 HIGH F7H PADH PSTH - - - PCH PKBIH PI2CH 00

KBCON Keypad control register 94H - - - - - - PATN

KBMASK Keypad interrupt mask

KBPATN Keypad pattern register 93H FF 11111111

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

E4H BUSY - - - HVA HVE SV OI 70 01110000

(Read)

Program Flash Control (Write) FMCMD.7FMCMD.6FMCMD.5FMCMD.4FMCMD.3FMCMD.2FMCMD.1FMCMD.

2

C slave address register DBH I2ADR.6 I2ADR.5 I2ADR.4 I2ADR.3 I2ADR.2 I2ADR.1 I2ADR.0 GC 00 00000000

Bit addressDFDEDDDCDBDAD9 D8

2

C control register D8H - I2EN STA STO SI AA - CRSEL 00 x00000x0

2

C data register DAH

DDH 00 00000000

duty cycle register HIGH

DCH 00 00000000

duty cycle register LOW

2

C status r egister D 9H ST A.4 STA.3 STA.2 STA.1 STA.0 0 0 0 F8 11111000

Bit addressAFAEADACABAAA9 A8

Bit addressEFEEEDECEBEAE9 E8

Bit addressBFBEBDBCBBBAB9 B8

Bit addressFFFEFDFCFBFAF9F8

86H 00 00000000

register

MSB LSB Hex Binary

0

[1]

[1]

PT1H PX1H PT0H PX0H 00

[1]

PSRH

[1]

[1]

KBIF 00

[1]

_SEL

00x00000

x0000000

x0000000

00x00000

00x00000

xxxxxx00

Philips Semiconductors

P89LPC915/916/917 User manual

UM10107

Page 26

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 26 of 125

Table 7: P89LPC917 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

P0* Port 0 80H T1/KBI7/

P1* Port 1 90H - - RST

P0M1 Port 0 output mode 1 84H (P0M1.7) - (P0M1.5) (P0M1.4) (P0M1.3) (P0M1.2) (P0M1.1) (P0M1.0) FF

P0M2 Port 0 output mode 2 85H (P0M2.7) - (P0M2.5) (P0M2.4) (P0M2.3) (P0M2.2) (P0M2.1) (P0M2.0) 00

P1M1 Port 1 output mode 1 91H - - - (P1M1.4) (P1M1.3) (P1M1.2) (P1M1.1) (P1M1.0) D3

P1M2 Port 1 output mode 2 92H - - - (P1M2.4) (P1M2.3) (P1M2.2) (P1M2.1) (P1M2.0) 00

PCON Power control register 87H SMOD1 SMOD0 BOPD BOI GF1 GF0 PMOD1 PMOD0 00 00000000

PCONA Power control register A B5H RTCPD - VCPD ADPD I2PD - SPD - 00

PSW* Program status word D0H CY AC F0 RS1 RS0 OV F1 P 00 00000000

PT0AD Port 0 digital input disable F6H - - PT0AD.5 PT0AD.4 PT0AD.3 PT0AD.2 PT0AD.1 - 00 xx00000x

RSTSRC Reset source register DFH - - BOF POF R_BK R_WD R_SF R_EX

RTCCON Real-time clock control D1H RTCF RTCS1 RTCS0 - - - ERTC RTCEN 60

RTCH Real-time clock register HIGH D2H 00

RTCL Real-time clock register LOW D3H 00

SADDR Serial port address register A9H 00 00000000

SADEN Serial port address enable B9H 00 00000000

SBUF Serial Port data buffer register 99H xx xxxxxxxx

SCON* Serial port control 98H SM0/FE SM1 SM2 REN TB8 RB8 TI RI 00 00000000

SSTAT Serial port extended status

SP Stack pointer 81H 07 00000111

TAMOD Timer 0 and 1 auxiliary mode 8FH - - - T1M2 - - - T0M2 00 xxx0xxx0

TCON* Timer 0 and 1 control 88H TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0 00 00000000

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

Bit address8786858483828180

Bit address9796959493929190

Bit addressD7D6D5D4D3D2D1D0

Bit address9F9E9D9C9B9A99 98

BAH DBMOD INTLO CIDIS DBISEL FE BR OE STINT 00 00000000

register

Bit address8F8E8D8C8B8A89 88

MSB LSB Hex Binary

-CMPREF

CLKOUT

/KBI5

CIN1A

/KBI4

CIN1B

/KBI3

INT1 INT0/

SDA

CIN2A

/KBI2

CIN2B

/KBI1

CMP2

/KBI0

T0/SCL RXD TXD

[1]

[1]

[1]

[1]

[1]

[1][6]

[6]

[6]

Philips Semiconductors

[1]

[1]

11111111

00000000

11x1xx11

00x0xx00

00000000

[3]

011xxx00

00000000

00000000

P89LPC915/916/917 User manual

UM10107

Page 27

xxxxxxxxxxxxxxxx xxxxx xxxxxxx xxxxxxxxxxx xxxxxxxx xxxx xxx x x x xxxxxxxx xxxxxxxxxxxxxx xxxxxxxx xxx xxxxxxxxxxxx xxxx xx xx xxxx x

xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 27 of 125

Table 7: P89LPC917 Special function registers

* indicates SFRs that are bit addressable.

Name Description SFR

TH0 Timer 0 HIGH 8CH 00 00000000

TH1 Timer 1 HIGH 8DH 00 00000000

TL0 Timer 0 LOW 8AH 00 00000000

TL1 Timer 1 LOW 8BH 00 00000000

TMOD Timer 0 and 1 mode 89H T1GATE T1C/T

TRIM Internal oscillator trim register 96H RCCLK ENCLK TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

WDCON Watchdog control register A7H PRE2 PRE1 PRE0 - - WDRUN WDTOF WDCLK

WDL Watchdog load C1H FF 11111111

WFEED1 Watchdog feed 1 C2H

WFEED2 Watchdog feed 2 C3H

[1] All ports are in input only (high impedance) state after power-up.

[2] BRGR1 and BRGR0 must only be written if BRGEN in BRGCON SFR is logic 0. If any are written while BRGEN = 1, the result is unpredictable.

[3] The RSTSRC register reflects the cause of the P89LPC915/916/917 reset. Upon a power-up reset, all reset source flags are cleared except POF and BOF; the power-on reset

[4] After reset, the value is 111001x1, i.e., PRE[2:0] are all logic 1, WDRUN = 1 and WDCLK = 1. WDTOF bit is logic 1 after Watchdog reset and is logic 0 after power-on reset. Other

[5] On power-on reset, the TRIM SFR is initialized with a factory preprogrammed value. Other resets will not cause initialization of the TRIM register.

[6] The only reset source that affects these SFRs is power-on reset.

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

Bit functions and addresses Reset value

addr.

value is xx110000.

resets will not affect WDTOF.

MSB LSB Hex Binary

T1M1 T1M0 T0GATE T0C/T T0M1 T0M0 00 00000000

Philips Semiconductors

[5] [6]

[4] [6]

P89LPC915/916/917 User manual

UM10107

Page 28

Philips Semiconductors

3

1.5 Memory organization

07FFh

0700h

06FFh

0600h

05FFh

0500h

04FFh

0400h

03FFh

0300h

02FFh

0200h

01FFh

0100h

00FFh

000h

SECTOR 7

SECTOR 6

SECTOR 5

SECTOR 4

SECTOR 3

SECTOR 2

SECTOR 1

SECTOR 0

2 kB Flash code

memory space

SPECIAL FUNCTION

REGISTERS

(DIRECTLY ADDRESSABLE)

UM10107

P89LPC915/916/917 User manual

IDATA (incl. DATA)

128 BYTES ON-CHIP

DATA MEMORY (STACK

AND INDIR. ADDR.)

DATA

128 BYTES ON-CHIP

DATA MEMORY (STACK,

DIRECT AND INDIR. ADDR.)

4 REG. BANKS R[7:0]

data memory

(DATA, IDATA)

FFh

80h

7Fh

00h

002aaa91

Fig 10. P89LPC915/916/917 memory map.

The various P89LPC915/916/917 memory spaces are as follows:

DAT A — 128 bytes of internal data memory space (00h:7Fh) accessed via direct or

indirect addressing, using instruction other than MOVX and MOVC. All or part of the Stack

may be in this area.

IDAT A — Indirect Data. 256 bytes of internal data memory space (00h:FFh) accessed via

indirect addressing using instructions other than MOVX and MOVC. All or part of the

Stack may be in this area. This area includes the DATA area and the 128 bytes

immediately above it.

SFR — Special Function Registers. Selected CPU registers and peripheral control and

status registers, accessible only via direct addressing.

CODE — 64 kB of Code memory space, accessed as part of program execution and via

the MOVC instruction. The P89LPC915/916/917 has 2 kB of on-chip Code memory.

Table 8: Data RAM arrangement

Type Data RAM Size (bytes)

DA TA Directly and indirectly addressab le memo ry 128

IDATA Indirectly addressable memory 256

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 28 of 125

Page 29

Philips Semiconductors

2. Clocks

2.1 Enhanced CPU

The P89LPC915/916/917 uses an enhanced 80C51 CPU which runs at six times the

speed of standard 80C51 devices. A machine cycle consists of two CPU clock cycles, and

most instructions execute in one or two machine cycles.

2.2 Clock definit ions

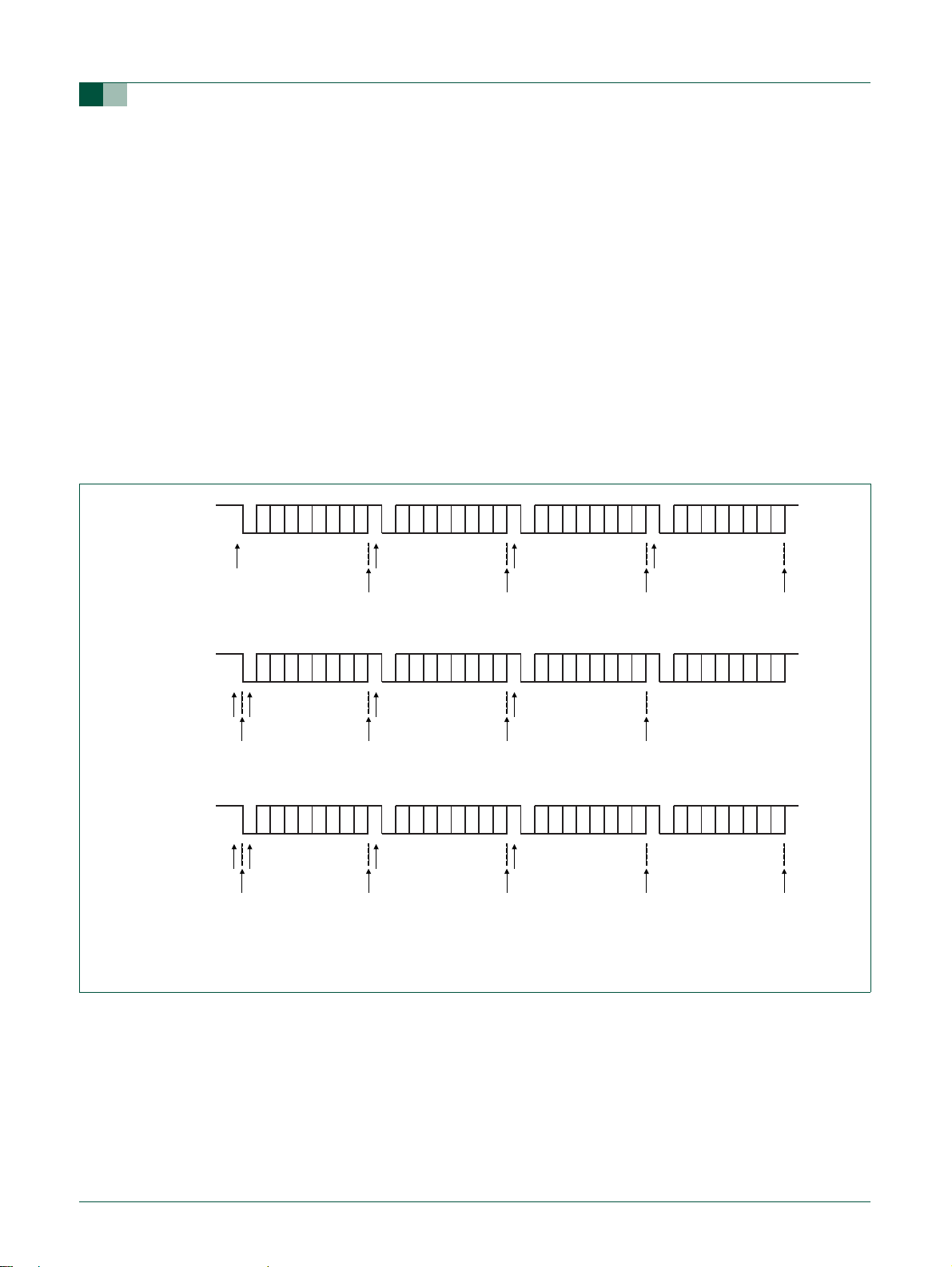

The P89LPC915/916/917 device has several internal clocks as defined below:

OSCCLK — Input to the DIVM clock divider. OSCCLK is selected from one of three clock

sources and can also be optionally divided to a slower frequency (see Figure 11

Section 2.8 “

OSCCLK frequency.

CCLK — CPU clock; output of the DIVM clock divider. There are two CCLK cycles per

machine cycle, and most instructions are executed in one to two machine cycles (two or

four CCLK cycles).

RCCLK — The internal 7.373 MHz RC oscillator output.

PCLK — Clock for the various peripheral devices and is

P89LPC915/916/917 User manual

CPU Clock (CCLK) modification: DIVM register”). Note: f

CCLK

e

.

2

UM10107

and

is defined as the

osc

The P89LPC915/916/917 provides user-selectable oscillator options. This allows

optimization for a range of needs from high precision to lowest possible cost. These

options are configured when the FLASH is programmed and include an on-chip watchdog

oscillator, an on-chip RC oscillator, or an external clock source.

2.3 Clock output (P89LPC917)

The P89LPC917 supports a user-selectable clock output function on the CLKOUT pin.

This allows external devices to synchronize to the P89LPC917. This output is enabled by

the ENCLK bit in the TRIM register.

The frequency of this clock output is

in Idle mode, it may be turned off prior to entering Idle, saving additional power. Note: on

reset, the TRIM SFR is initialized with a factory preprogrammed value. Therefore when

setting or clearing the ENCLK bit, the user should retain the contents of bits 5:0 of the

TRIM register. This can be done by reading the contents of the TRIM register (into the

ACC for example), modifying bit 6, and writing this result back into the TRIM register.

Alternatively, the ‘ANL direct’ or ‘ORL direct’ instructions can be used to clear or set bit 6

of the TRIM register.

1

e

that of the CCLK. If the clock output is not needed

2

2.4 On-chip RC oscillator option

The P89LPC915/916/917 has a TRIM register that can be used to tune the frequency of

the RC oscillator. During reset, the TRIM value is initialized to a factory pre-programmed

value to adjust the oscillator frequency to 7.373 MHz, r 1 %. (Note: the initial value is

better than 1 %; please refer to the P89LPC915/916/917 data sheet for behavior over

temperature). End user applications can write to the TRIM register to adjust the on-chip

RC oscillator to other frequencies. Increasing the TRIM value will decrease the oscillator

frequency.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 29 of 125

Page 30

Philips Semiconductors

Table 9: On-chip RC oscillator trim register (TRIM - address 96h) bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol RCCLK ENCLK TRIM.5 TRIM.4 TRIM.3 TRIM.2 TRIM.1 TRIM.0

Reset 0 0 Bits 5:0 loaded with factory stored value during reset.

Table 10: On-chip RC oscillator trim register (TRIM - address 96h) bit description

Bit Symbol Description

0 TRIM.0 Trim value. Determines the frequency of the internal RC oscillator. During

1TRIM.1

2TRIM.2

3TRIM.3

4TRIM.4

5TRIM.5

6 ENCLK when = 1,

7 RCCLK when = 1, selects the RC Oscillator output as the CPU clock (CCLK)

UM10107

P89LPC915/916/917 User manual

reset, these bits are loaded wi th a stored factory calibra tion value. When w riting

to either bit 6 or bit 7 of this register, care should be taken to preserve the

current TRIM value by reading this register, modifying bits 6 or 7 as required,

and writing the result to this register.

CCLK

e

is output on the XTAL2 pin provide d the cryst al osci llator is no t

being used.

2

2.5 Watchdog oscillator option

The watchdog has a separate oscillator which has a frequency of 400 kHz. This oscillator

can be used to save power when a high clock frequency is not needed.

2.6 External clock input option

In this configuration, the processor clock is derived from an external source driving the

P0.5 pin. The rate may be from 0 Hz up to 12 MHz.

RTCS1:0

CLKIN

RC

OSCILLATOR

(7.3728 MHz)

WATCHDOG

OSCILLATOR

(400 kHz)

RCCLK

XCLK

OSCCLK

DIVM

PCLK

RCCLK

CCLK

÷2

PCLK

peripheral clock

RTC

CPU

ADC1/DAC1

WDT

CLKOUT

BAUD RATE

GENERATOR

UART

TIMERS 1 AND 0

I2C

SPI

(P89LPC916)

002aaa831

Fig 11. Block diagram of oscillator control.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 30 of 125

Page 31

Philips Semiconductors

2.7 Oscillator Clock (OSCCLK) wake-up delay

The P89LPC915/916/917 has an internal wake-up timer that delays the clock until it

stabilizes. This delay is 224 OSCCLK cycles plus 60 Ps to 100 Ps.

2.8 CPU Clock (CCLK) modification: DIVM register

The OSCCLK frequency can be divided down, by an integer, up to 510 times by

configuring a dividing register, DIVM, to provide CCLK. This produces the CCLK

frequency using the following formula:

UM10107

P89LPC915/916/917 User manual

Where: f

Since N ranges from 0 to 255, the CCLK frequency can be in the range of f

(for N =0, CCLK = f

This feature makes it possible to temporarily run the CPU at a lower rate, reducing power

consumption. By dividing the clock, the CPU can retain the ability to respond to events

other than those that can cause interrupts (i.e. events that allow exiting the Idle mode) by

executing its normal program at a lower rate. This can often result in lower power

consumption than in Idle mode. The value of DIVM may be changed by the program at

any time without interrupting code execution.

2.9 Low power select

The P89LPC915/916/917 is designed to run at 12 MHz (CCLK) maximum. However, if

CCLK is 8 MHz or slower, the CLKLP SFR bit (AUXR1.7) can be set to a logic 1 to lower

the power consumption further. On any reset, CLKLP is logic 0 allowing highest

performance. This bit can then be set in software if CCLK is running at 8 MHz or slower.

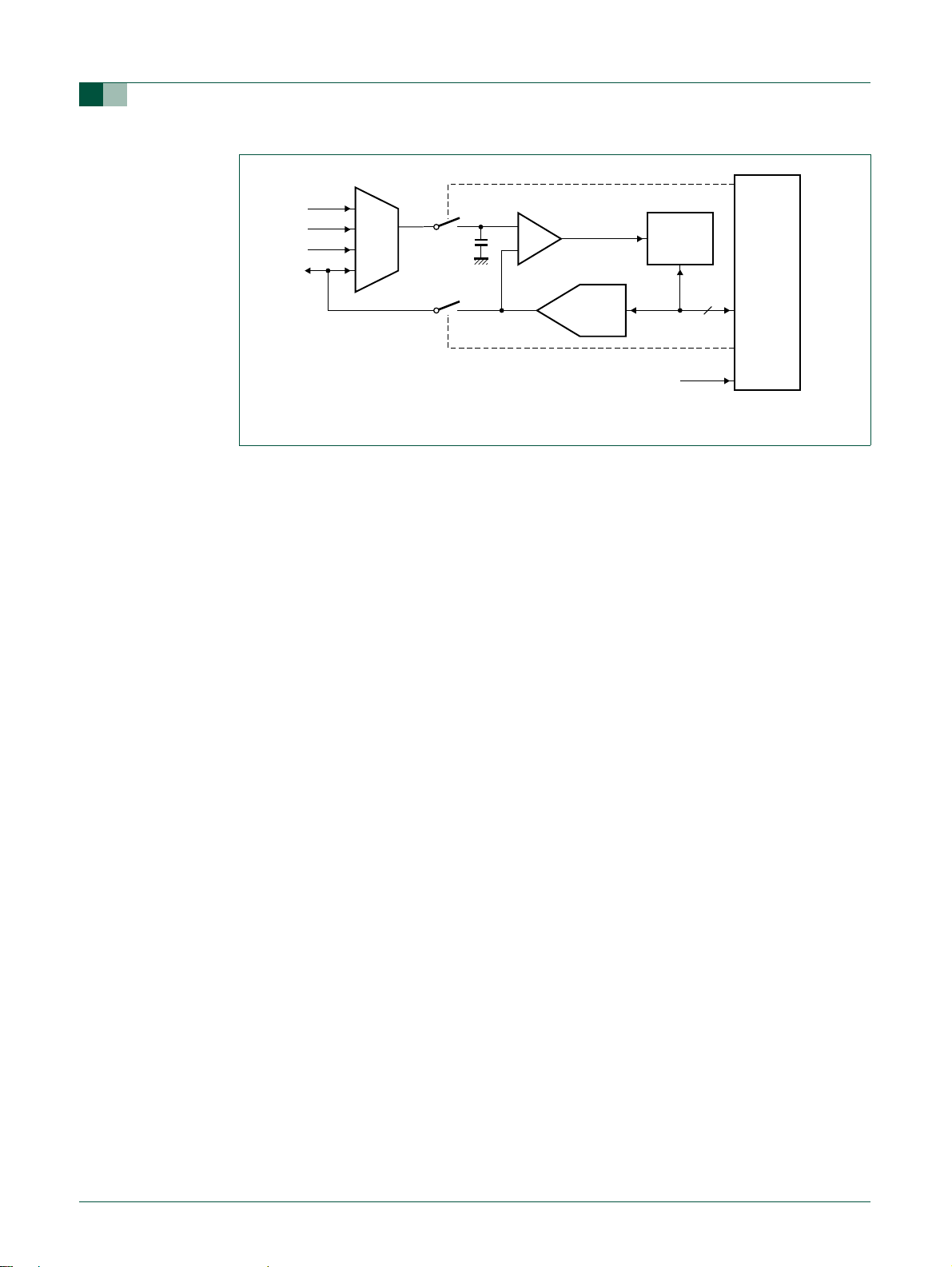

3. A/D converter

The P89LPC915/916/917 has an 8-bit, 4-channel, multiplexed successive approximation

analog-to-digital converter module (ADC1) and one DAC module (DAC1). A block

diagram of the A/D converter is shown in Figure 12

multiplexer which feeds a sample and hold circuit providing an input signal to one of two

comparator inputs. The control logic in combination with the successive approximation

register (SAR) drives a digital-to-analog converter which provides the other input to the

comparator. The output of the comparator is fed to the SAR.

CCLK frequency = f

is the frequency of OSCCLK, N is the value of DIVM.

osc

osc

osc

).

/ (2N)

to f

osc

. The A/D consists of a 4-input

osc

/510.

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 31 of 125

Page 32

Philips Semiconductors

Fig 12. A/D converter block diagram.

3.1 Features

• An 8-bit, 4-channel, multiplexed input, successive approximation A/D converter.

• Four A/D result registers.

• Six operating modes

– Fixed channel, single conversion mode

– Fixed channel, continuous conversion mode

– Auto sc an , sing le co nve r si on mode

– Auto scan, continuous conversion mode

– Dual ch anne l, con t in uou s con ve rsi on mode

– Single step mode

• Three conversion start modes

– Timer triggered start

– Start immediately

– Edge triggered

• 8-bit conversion time of t 3.9 Ps at an ADC clock of 3.3 MHz

• Interrupt or polled operation

• Boundary limits interrupt

• DAC output to a port pin with high output impedance

• Clock divider

• Power-down mode

INPUT

MUX

COMP

+

–

UM10107

P89LPC915/916/917 User manual

SAR

CONTROL

LOGIC

DAC1

CCLK

8

002aaa783

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 32 of 125

Page 33

Philips Semiconductors

3.2 A/D operating modes

3.2.1 Fixed channel, single conversion mode

A single input channel can be selected for conversion. A single conversion will be

performed and the result placed in the result register which corresponds to the selected

input channel (See Table 11

conversion completes. The input channel is selected in the ADINS register. This mode is

selected by setting the SCAN1 bit in the ADMODA register.

Table 11: Input channels and Result registers for fixed channel single, auto scan single,

Result register Input channel Result register Input channel

AD1DAT0 AD10 AD1DAT2 AD12

AD1DAT1 AD11 AD1DAT3 AD13

3.2.2 Fixed channel, continuous conversion mode

A single input channel can be selected for continuous conversion. The results of the

conversions will be sequentially placed in the four result registers Table 12

enabled, will be generated after every four conversions. Additional conversion results will

again cycle through the four result registers, overwriting the previous results. Continuous

conversions continue until terminated by the user. This mode is selected by setting the

SCC1 bit in the ADMODA register.

UM10107

P89LPC915/916/917 User manual

). An interrupt, if enabled, will be generated after the

and autoscan continuous conversion modes.

. An interr up t, i f

3.2.3 Auto scan, single conversion mode

Any combination of the four input channels can be selected for conversion by setting a

channel’s respective bit in the ADINS register. The channels are converted from LSB to

MSB order (in ADINS). A single conversion of each selected input will be performed and

the result placed in the result register which corresponds to the selected input channel

(See Table 11

). An interrupt, if enabled, will be generated after all selected channels have

been converted. If only a single channel is selected this is equivalent to single channel,

single conversion mode. This mode is selected by setting the SCAN1 bit in the ADMODA

register.

T able 12: Result registers and conversion results for fixed channel, c ontinuous convers ion

mode.

Result register Contains

AD1DAT0 Selected channel, first conversion result

AD1DAT1 Selected channel, second conversion result

AD1DAT2 Selected channel, third conversion result

AD1DAT3 Selected channel, forth conversion result

3.2.4 Auto scan, continuous conversion mode

Any combination of the four input channels can be selected for conversion by setting a

channel’s respective bit in the ADINS register. The channels are converted from LSB to

MSB order (in ADINS). A conversion of each selected input will be performed and the

result placed in the result register which corresponds to the selected input channel (See

Table 11

converted. The process will repeat starting with the first selected channel. Additional

). An interrupt, if enabled, will be generated after all selected channels have been

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 33 of 125

Page 34

Philips Semiconductors

conversion results will again cycle through the result registers of the selected channels,

overwriting the previous results. Continuous conversions continue until terminated by the

user. This mode is selected by setting the BURST1 bit in the ADMODA register.

3.2.5 Dual channel, continuous conversion mode

Any combination of two of the four input channels can be selected for conversion. The

result of the conversion of the first channel is placed in the first result register. The result

of the conversion of the second channel is placed in the second result register. The first

channel is again converted and its result stored in the third result register. The second

channel is again converted and its result placed in the fourth result register (See

Table 13

conversions per channel). This mode is selected by setting the SCC1 bit in the ADMODA

register.

Table 13: Result registers and conversion results for dual channel, continuous conversion

Result register Contains

AD1DA T 0 First channel, first conversion resul t

AD1DAT1 Second channel, first conversion result

AD1DAT2 First channel, second conversion resu lt

AD1DAT3 Second channel, second conversion result

UM10107

P89LPC915/916/917 User manual

). An interrupt is generated, if enabled, after every set of four conversions (two

mode.

3.2.6 Single step

This special mode allows ‘single-stepping’ in an auto scan conversion mode. Any

combination of the four input channels can be selected for conversion. After each channel

is converted, an interrupt is generated, if enabled, and the A/D waits for the next start

condition. The result of each channel is placed in the result register which corresponds to

the selected input channel (See Table 11

mode is selected by clearing the BURST1, SCC1, and SCAN1 bits in the ADMODA

register.

3.2.7 Conversion mode selection bits

The A/D uses three bits in ADMODA to select the conversion mode. These mode bits are

summarized in Table 14

combinations shown, ar e undef ined.

Table 14: Conversion mode bits.

BURST1 SCC1 Scan1 ADC1 conversion

0 0 0 single step 0 0 0 single step

0 0 1 fixed channel,

0 1 0 fixed channel,

1 0 0 auto scan,

, below. Combinations of the three bits, other than the

mode

single

auto scan, single auto scan, single

continuous

dual channel,

continuous

continuous

). May be used with any of the start modes. This

BURST0 SCC0 Scan0 ADC0 conversion

mode

0 0 1 fixed channel,

single

0 1 0 fixed channel,

continuous

dual channel,

continuous

1 0 0 auto scan,

continuous

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 34 of 125

Page 35

Philips Semiconductors

3.3 T rigger modes

3.3.1 Timer triggered start

An A/D conversion is started by the overflow of Timer 0. Once a conversion has started,

additional Timer 0 triggers are ignored until the conversion has completed. The Timer

triggered start mode is available in all A/D operating modes. This mode is selected by the

TMM1 bit and the ADCS11 and ADCS10 bits (See Table 16

3.3.2 Start immediately

Programming this mode immediately starts a conversion. This start mode is available in all

A/D operating modes. This mode is selected by setting the ADCS11 and ADCS10 bits in

the ADCON1 register (See Table 16

3.3.3 Edge triggered

An A/D conversion is started by rising or falling edge of P1.4. Once a conversion has

started, additional edge triggers are ignored until the conversion has completed. The edge

triggered start mode is available in all A/D operating modes. This mode is selected by

setting the ADCS11 and ADCS10 bits in the ADCON1 register (See Table 16

UM10107

P89LPC915/916/917 User manual

).

).

).

3.3.4 Boundary limits interrupt

The A/D converter has both a high and low boundary limit register. After the four MSBs

have been converted, these four bits are compared with the four MSBs of the boundary

high and low registers. If the four MSBs of the conversion are outside the limit an interrupt

will be generated, if enabled. If the conversion result is within the limits, the boundary

limits will again be compared after all 8 bits have been converted. An interrupt will be

generated, if enabled, if the result is outside the boundary limits. The boundary limit may

be disabled by clearing the boundary limit interrupt enable.

3.4 DAC output to a port pin with high impedance

The AD0DAT3 register is used to hold the value fed to the DAC. After a value has been

written to AD0DAT3 the DAC output will appear on the DAC0 pin. The DAC output is

enabled by the ENDAC0 bit in the ADMODB register (See Table 20

3.5 Clock divider

The A/D converter requires that its internal clock source be in the range of 500 kHz to

3.3 MHz to maintain accuracy. A programmable clock divider that divides the clock from 1

to 8 is provided for this purpose (See Table 20

).

3.6 I/O pins used with A/D converter functions

The analog input pins used with for the A/D converter have a digital input and output

function. In order to give the best analog performance, pins that are being used with the

ADC or DAC should have their digital outputs and inputs disabled and have the 5 V

tolerance disconnected. Digital outputs are disabled by putting the port pins into the

Input-only mode as described in the Port Configurations section (see Table 28

).

).

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 35 of 125

Page 36

Philips Semiconductors

Digital inputs will be disconnected automatically from these pins when the pin has been

selected by setting its corresponding bit in the ADINS register and the A/D or DAC has

been enabled. Pins selected in ADINS will be 3 V tolerant provided that the A/D is enabled

and the device is not in power-down, otherwise the pin will remain 5 V tolerant.

3.7 Power-down and idle mode

In idle mode the A/D converter, if enabled, will continue to function and can cause the

device to exit idle mode when the conversion is completed if the A/D interrupt is enabled.

In Power-down mode or Total power-down mode, the A/D does not function. If the A/D is

enabled, it will consume power. Power can be reduced by disabling the A/D.

Table 15: A/D Control register 1 (ADCON1 - address 97h) bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol ENBI1 ENADCI1TMM1 EDGE1 ADCI1 ENADC1 ADCS11 ADCS10

Reset00000000

Table 16: A/D Control register 1 (ADCON1 - address 97h) bit description

Bit Symbol Description

0 ADCS10 A/D start mode bits [11:10]:

1 ADCS11

2 ENADC1 Enable A/D channel 1. When set = 1, enables ADC1. Must also be

3 ADCI1 A/D Conversion complete Interrupt 1. Set when an y c onvers io n or

4 EDGE1 When = 0, an Edge conversion start is triggered by a falling edge

5 TMM1 Timer Trigger mode 1. Selects either stop mode (TMM1= 0) or

6 ENADCI1 Enable A/D Conversion com plete Interrupt 1. When s et, will ca use

7 ENBI1 Enable A/D boundary interrup t 1. Whe n set, will c ause a n inte rrupt

UM10107

P89LPC915/916/917 User manual

00 — Timer T r igg er mo de whe n TM M1= 1. Conversions starts on

overflow of Timer 0. Stop mode when TMM1 = 0, no start occurs.

01 — Immediate Start mode. Conversions starts immediately.

10 — Edge Trigger mode. Conversion starts when edge condition

defined by bit EDGE1 occurs.

set for D/A operation of this channel.

set of multiple conversions has completed. Cleared by software.

on P1.4. When = 1, an Edge conversion start is trig gered by a

rising edge on P1.4.

timer trigger mode (TMM1= 1) when the ADCS11 and ADCS10

bits = 00.

an interrupt if the ADCI1 flag is set and the A/D interrupt is

enabled.

if the boundary i nte rrupt 1 flag, BNDI1, is set a nd the A/D i nterrupt

is enabled.

Table 17: A/D Mode Register A (ADMODA - address C0h) bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol BNBI1 BURST1 SCC1 SCAN1 - - - Reset00000000

9397 750 13316 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

User manual Rev. 01 — 15 July 2004 36 of 125

Page 37

Philips Semiconductors

Table 18: A/D Mode Register A (ADMODA - address C0h) bit description

Bit Symbol Description

0:3 - reserved

4 SCAN1 when = 1, selects single conv ers io n mod e (auto scan or fixed

5 SCC1 when = 1, selects fixed channel, continuous conversion mode for

6 BURST1 when = 1, selects auto scan, continuous conv ersion mode for

7 BNBI1 ADC1 boundary interrupt flag. Whe n set, indic ate s that the

Table 19: A/D Mode Register B (ADMODB - address A1h) bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol CLK2 CLK1 CLK0 - ENDAC1-- BSA1 -

Reset00000000

UM10107

P89LPC915/916/917 User manual

channel) for ADC1

ADC1

ADC1