Philips TDA8000 Datasheet

INTEGRATED CIRCUITS

DATA SH EET

TDA8000; TDA8000T

Smart card interface

Product specification

Supersedes data of 1995 Feb 01

File under Integrated Circuits, IC02

1996 Dec 12

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

FEATURES

• Two protected I/O lines

• VCC regulation (5 V ±4%, 100 mA max. with controlled

rise and fall times)

• VPP generation (12.5, 15 or 21 V ±2.5%, 50 mA max.

APPLICATIONS

• Pay TV

• Telematics

• Cashless payment

• Multipurpose card-readers, etc.

programmable by two bits, with controlled rise and fall

times)

• Clock generation (up to 8 MHz)

• Short-circuit, thermal and card extraction protections

• Two voltage supervisors (digital and analog supplies)

• Automatic activation and deactivation sequences via an

independent internal clock

• Enhanced ESD protections on card connections

(4 kV min.)

• ISO 7816 approval.

GENERAL DESCRIPTION

The TDA8000 is a complete, low-cost analog interface

which can be positioned between a smart card or a

memory card (ISO 7816) and a microcontroller. It is

approved for banking, telecom and pay TV applications.

The complete supply, protection and control functions are

realized with only a few external components, which

makes the TDA8000 very attractive for consumer

applications. Application suggestions and support is

available on request (see examples in

Chapter “Application information”).

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DD

I

DD

supply voltage 6.7 − 18 V

supply current idle mode; VDD=12V − 25 − mA

active modes; unloaded − 32 − mA

V

th2

V

CC

I

CC

V

H

I

PP

, t

t

de

act

threshold voltage on V

SUP

card supply voltage 4.8 5.0 5.2 V

card supply current −−−100 mA

high voltage supply for V

PP

programming current read mode; VPP=5V −−−50 mA

write mode; V

>5V −−−50 mA

PP

deactivation/activation cycle

4.5 − 4.68 V

−−30 V

−−500 µs

duration

P

tot

continuous total power

dissipation

TDA8000; T

see Fig.10

TDA8000T; T

amb

amb

= +70 °C;

= +70 °C;

−−2W

−−0.92 W

see Fig.11

T

amb

operating ambient temperature 0 − +70 °C

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION VERSION

PACKAGE

TDA8000 DIP28 plastic dual in-line package; 28 leads (600 mil) SOT117-1

TDA8000T SO28 plastic small outline package; 28 leads; body width 7.5 mm SOT136-1

1996 Dec 12 2

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

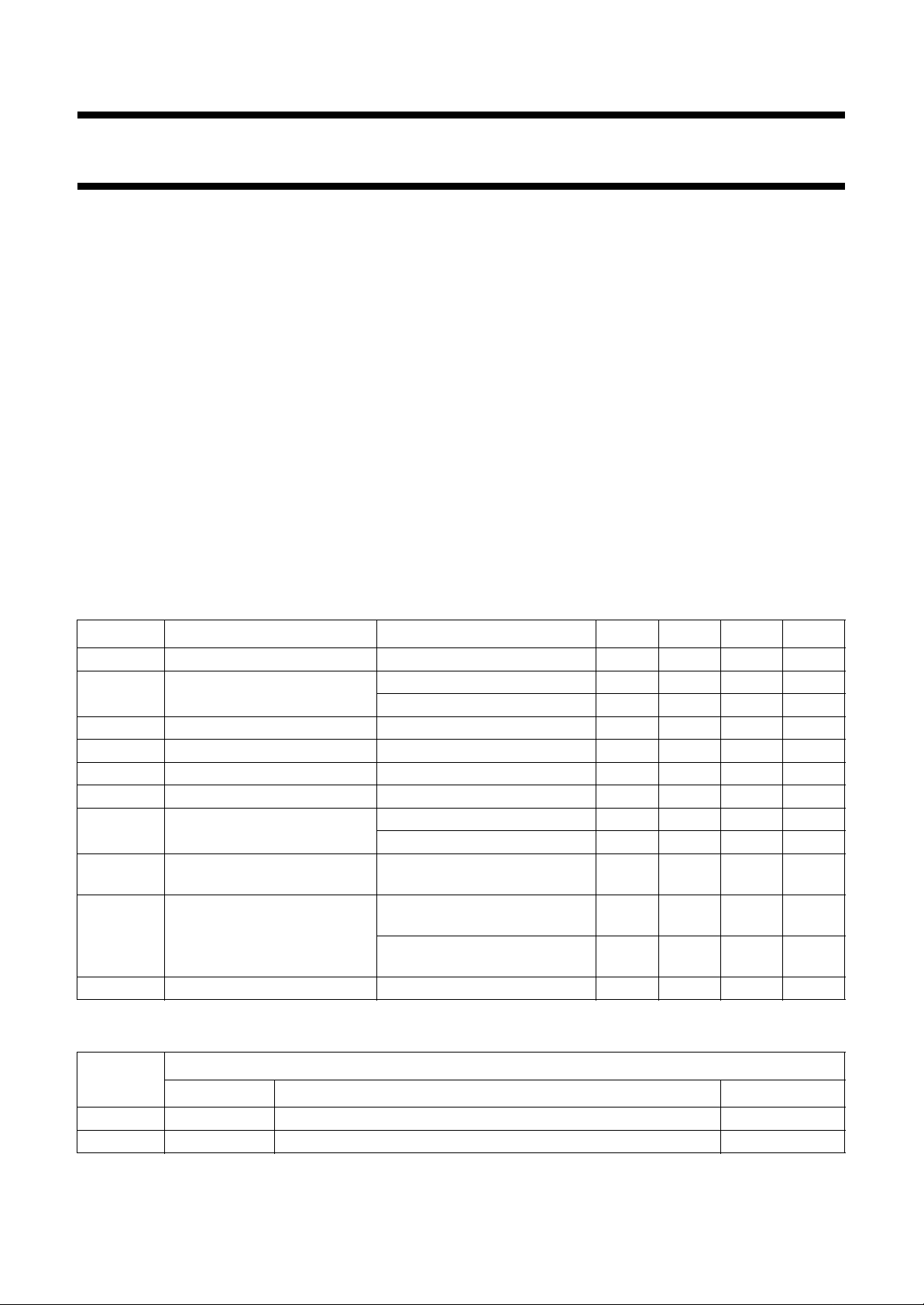

BLOCK DIAGRAM

handbook, full pagewidth

ALARM

ALARM

I/O1(µC)

I/O2(µC)

RSTIN

OFF

START

WRITE

CLKDIV

CLKOUT

17

18

28

27

26

19

20

21

23

25

AND

ENABLE

V

DD

MAIN

SUPPLY

V

SUP

SUPERVISOR

DELAY

15 16 13 12

VOLTAGE

PROTECTIONS

TDA8000

LOGIC

PROTECTIONS

INTERNAL

CLOCK

CLOCK

CIRCUITRY

GENERATOR

ENABLE

V

CC

CLOCK

GND

22

CVNC

3

I/O1

2

I/O2

4

RST

9

PRES

8

PRES

14

V

CC

5

CLK

PSEL1

PSEL2

6

7

OSCILLATOR

124 11

XTAL

CLKIN

Fig.1 Block diagram.

1996 Dec 12 3

V

PP

GENERATOR

V

H

10

MBH810

V

PP

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

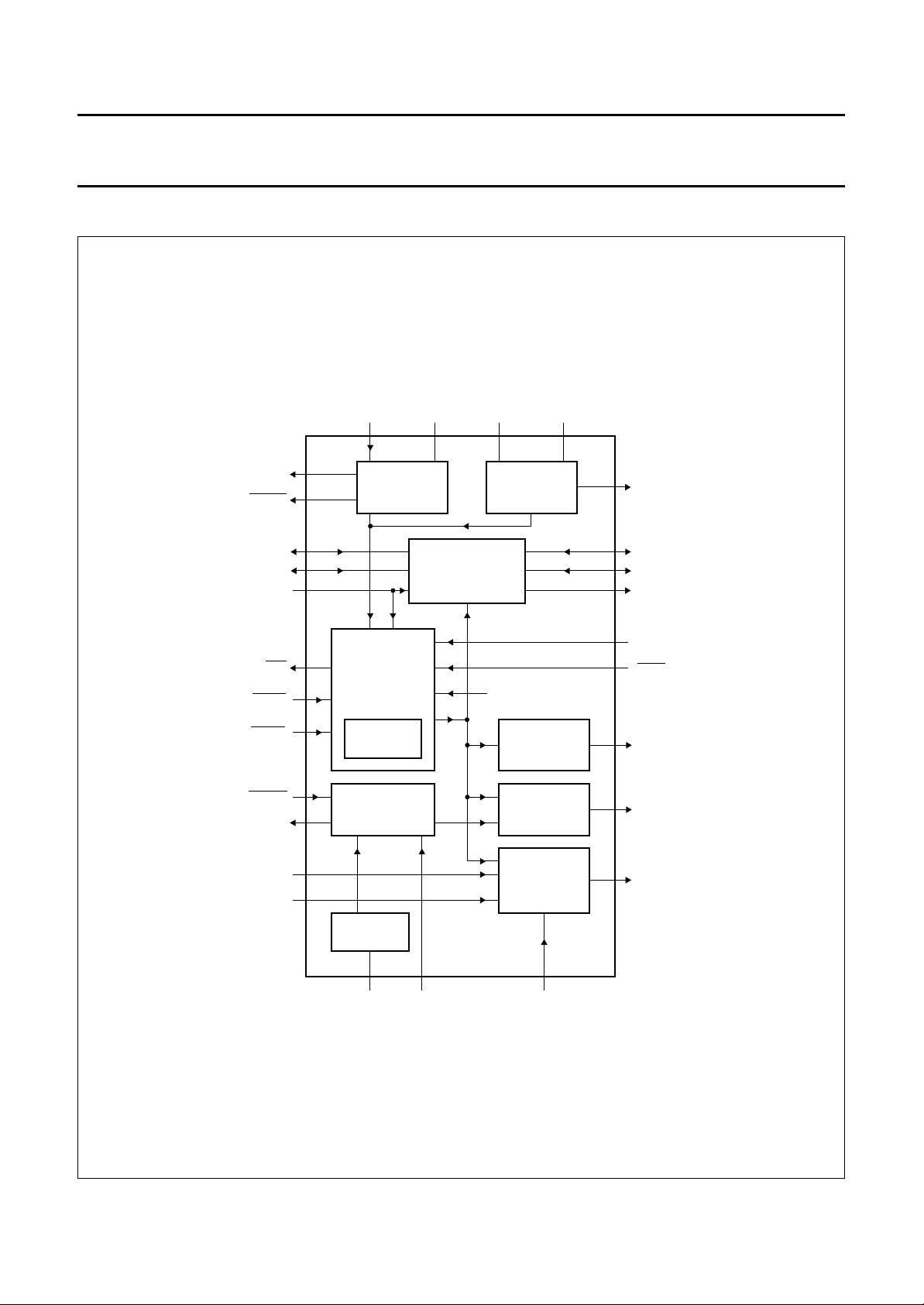

PINNING

SYMBOL PIN DESCRIPTION

XTAL 1 crystal connection

I/O2 2 data line to/from the card

I/O1 3 data line to/from the card

RST 4 card reset output

CLK 5 clock output to the card

PSEL1 6 programming voltage selection input (see Table 1)

PSEL2 7 programming voltage selection input (see Table 1)

PRES 8 card presence contact input (active LOW)

PRES 9 card presence contact input (active HIGH)

V

PP

V

H

10 card programming voltage output

11 high voltage supply for VPP generation

GND 12 ground

V

V

V

DD

CC

SUP

13 positive supply voltage

14 card supply output voltage

15 voltage supervisor input

DELAY 16 external capacitor connection for delayed reset timing

ALARM 17 open-collector reset output for the microcontroller (active

HIGH)

ALARM 18 open-collector reset output for the microcontroller (active

LOW)

OFF 19 interrupt output to the microcontroller (active LOW)

START 20 microcontroller input for starting session (active LOW)

WRITE 21 control input for applying programming voltage to the card

(active LOW)

CVNC 22 internally generated 5 V reference, present when V

DD

is

on; to be decoupled externally (47 nF)

CLKDIV 23 input for dividing/not dividing the CLKOUT frequency by

two (active LOW)

CLKIN 24 external clock signal input

CLKOUT 25 clock output to the microcontroller, or another TDA8000

RSTIN 26 card reset input from the microcontroller (active HIGH)

I/O2(µC) 27 data line to/from the microcontroller; must not be left

open-circuit, tie to CVNC if not used

I/O1(µC) 28 data line to/from the microcontroller; must not be left

open-circuit, tie to CVNC if not used

page

XTAL

I/O2

I/O1

RST

CLK

PSEL1

PSEL2

PRES

PRES

V

PP

V

GND

V

DD

V

CC

H

1

2

3

4

5

6

7

TDA8000T

8

9

10

11

12

13

14

TDA8000

Fig.2 Pin configuration.

MBH809

28

27

26

25

24

23

22

21

20

19

18

17

16

15

I/O1(µC)

I/O2(µC)

RSTIN

CLKOUT

CLKIN

CLKDIV

CVNC

WRITE

START

OFF

ALARM

ALARM

DELAY

V

SUP

1996 Dec 12 4

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

FUNCTIONAL DESCRIPTION

Power supply

The circuit operates within a supply voltage range of

6.7 to 18 V. V

and GND are the supply pins. All card

DD

contacts remain inactive during power-up or power-down,

provided VDD does not rise or fall too fast (0.5 V/ms typ.).

P

OWER-UP

The logic part is powered first and is in the reset condition

until VDD reaches V

reaches V

OWER-DOWN

P

th4+Vhys4

When VDD falls below V

. The sequencer is blocked until V

th1

.

, an automatic deactivation of

th4

DD

the contacts is performed.

Voltage supervisor

This block surveys the 5 V supply of the microcontroller

) in order to deliver a defined reset pulse and to avoid

(V

SUP

any transients on card contacts during power-up or

power-down of V

SUP

.

The voltage supervisor remains active even if VDD is

powered-down.

OWER-UP

P

As long as V

is below V

SUP

th2+Vhys2

the capacitor C

DEL

connected to the pin DELAY, will be discharged. When

V

rises to the threshold level, C

SUP

will be recharged.

DEL

ALARM and ALARM remain active, and the sequencer is

blocked until the voltage on the pin DELAY reaches V

OWER-DOWN (see Fig.3)

P

If V

falls below V

SUP

th2

, C

will be discharged, ALARM

DEL

th3

andALARM become active, and an automatic deactivation

of the contacts is performed.

Clock circuitry (see Fig.4) The clock signal (CLK) can be applied to the card by two

different methods:

1. Generation by a crystal oscillator: the crystal

(3 to 11 MHz) is connected to pin XTAL. Its frequency

is divided by two.

2. Use of a signal frequency already present in the

system and connected to the pin CLKIN (up to 8 MHz).

Pin XTAL has to be connected to GND via a 1 kΩ

resistor. In this event, the CLKOUT signal remains

LOW.

In both events the signal is buffered and enabled.

Pin CLKOUT may be used to clock a microcontroller.

The signal (

1

⁄2f

or f

xtal

if CLKDIV is HIGH) is available

xtal

when the circuit is powered up.

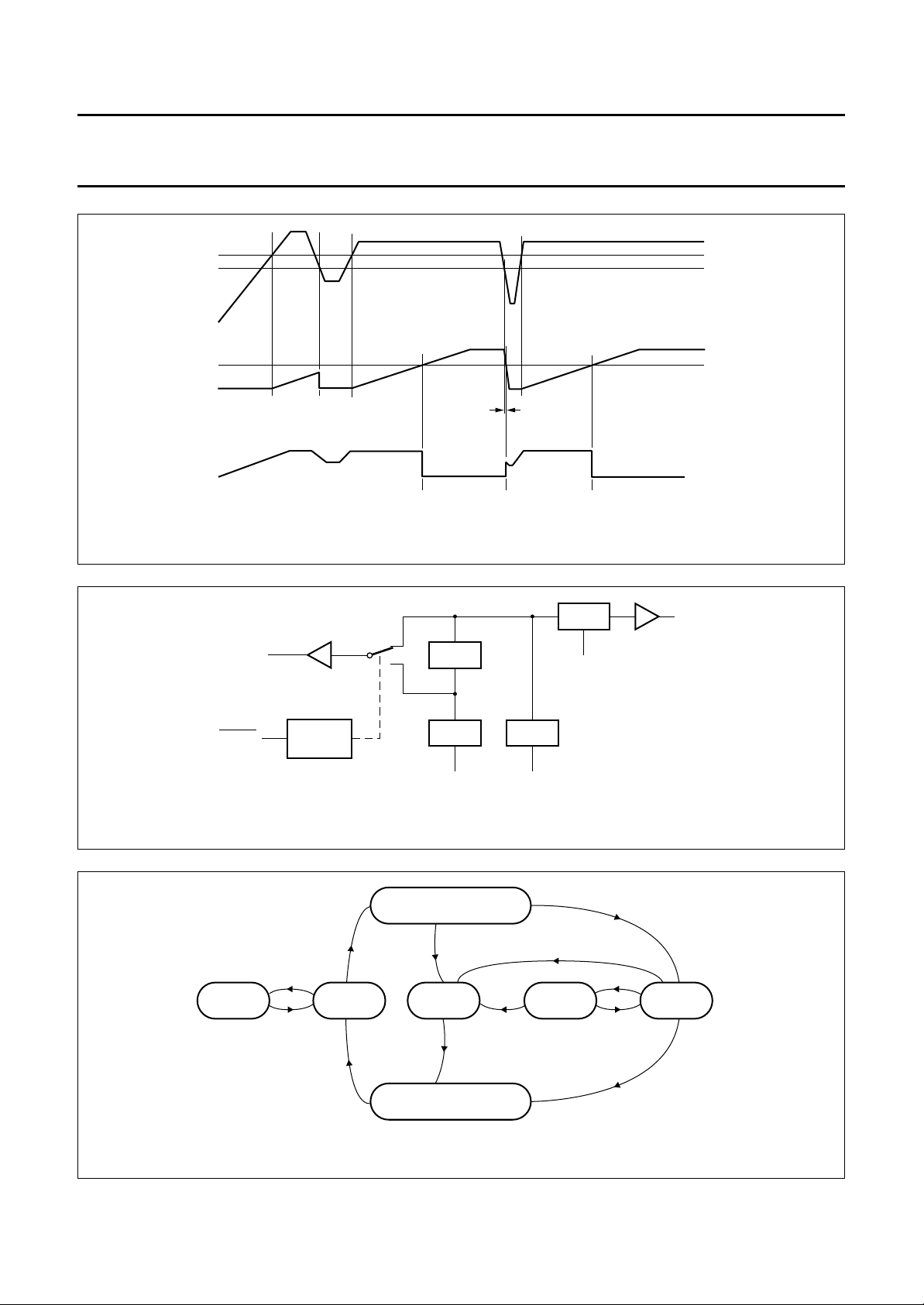

State diagram

Once activated, the circuit has six possible modes of

operation:

• Idle

• Activation

• Read

• Write

• Deactivation

• Fault.

Figure 5 shows how these modes are accessible.

DLE MODE

I

After reset, the circuit enters the IDLE state. A minimum

number of circuits are active while waiting for the

microcontroller to start a session:

• All card contacts are inactive

• Voltage generators are stopped

• Oscillator is running, providing CLKOUT

• Voltage supervisor is active

,

• Pins I/O1(µC) and I/O2(µC) are high impedance.

The OFF line is HIGH if a card is present (PRES and

PRES active) and LOW if a card is not present.

.

CTIVATION SEQUENCE

A

From the IDLE mode, the circuit enters the ACTIVATION

mode when the microcontroller sets the START line

(active LOW). The I/O(µC) signals must not be LOW.

The internal circuitry is activated, the internal clock starts

and the following ISO 7816 sequence is performed:

1. VCC rises from 0 to 5 V

2. I/Os are enabled

3. VPP rises from 0 to 5 V

4. No change

5. CLK is enabled

6. RST is enabled.

The typical time interval between two steps is 32 µs for the

first two steps and 64 µs for the other three. Timing is

derived from the internal clock (see Fig.6).

1996 Dec 12 5

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

Between steps 3 and 5, a HIGH level on pin RSTIN allows

the CLK signal to be applied to the card. This feature

facilitates a precise count of CLK periods while waiting for

the card to respond to a reset.

After step 5, RSTIN has no further action on CLK.

After step 6, RST is set to the complementary value of

RSTIN.

EAD MODE

R

When the activation sequence is completed and, after the

card has replied to its Answer-to-Reset, theTDA8000

enters the READ mode. Data is exchanged between the

card and the microcontroller via the I/O lines.

When it is required to write to the internal memory of the

card, the circuit is set to the WRITE mode by the

microcontroller.

Cards with EPROM memory require a programming

voltage (V

GENERATION

V

PP

PP

).

The circuit supports cards with VPP of 12.5, 15 or 21 V.

The selection of P is achieved by PSEL1 and PSEL2

according to Table 1.

DEACTIVATION SEQUENCE (see Fig.8)

When the session is completed, the microcontroller sets

the START line to its HIGH state.

The circuit then executes an automatic deactivation

sequence by counting back the sequencer:

1. Card reset (RST falls to LOW)

2. CLK is stopped

3. No change

4. VPP falls to 0 V

5. I/O1(µC) and I/O2(µC) become high impedance

6. V

falls to 0 V.

CC

The circuit returns to the IDLE mode on the next rising

edge of the sequencer clock.

P

ROTECTIONS

Main fault conditions are monitored by the circuit:

• Short-circuit on V

• Short-circuit on V

CC

PP

• Over current on I/Os

• Card extraction during transaction

• Overheating problem.

Table 1 Card programming voltage selection

PSEL1 PSEL2

PROGRAMMING

VOLTAGE P

LOW LOW 5

LOW HIGH 12.5

HIGH LOW 15

HIGH HIGH 21

In order to respect the ISO7816 slopes, the circuit

generates V

by charging and discharging an internal

PP

capacitor. The voltage on this capacitor is then amplified

by a power stage gain of 5, powered via an external supply

[30 V (max.)].

pin V

H

RITE MODE (see Fig.7)

W

When the microcontroller sets the WRITE line (active

LOW), the circuit enters the WRITE mode. VPP rises from

5 V to the selected value with a typical slew rate of 1 V/µs.

When the write operation is completed, the microcontroller

returns the WRITE line to its HIGH state, and VPP falls

back to 5 V with the same slew rate.

When one of these fault conditions is detected, the circuit

pulls the interrupt line OFF to its active LOW state and

returns to the FAULT mode.

AULT MODE (see Fig.9)

F

When a fault condition is written to the microcontroller via

the OFF line, the circuit initiates a deactivation sequence.

After the deactivation sequence has been completed, the

OFF line is reset to its HIGH state when the microcontroller

has reset the START line HIGH, except if the fault

condition was due to a card extraction.

Note

The two other causes of emergency deactivation (Power

failure detected on V

DD

or V

) do not act upon OFF.

SUP

WRITE has no action outside a session.

1996 Dec 12 6

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

handbook, full pagewidth

V

V

DELAY

ALARM

handbook, full pagewidth

SUP

Fig.3 ALARM and DELAY as a function of V

CLKOUT

÷ 2

V

+ V

th2

hys2

V

th2

V

th3

t

d

MGG818

(C

SUP

fixes the pulse width).

DEL

ENABLE

ENCLK

CLK

handbook, full pagewidth

CLKDIV

INPUT

IDLE

OSC INPUT

XTAL CLKIN

Fig.4 Clock circuitry.

ACTIVATION

FAULT READWRITEPDOWN

DEACTIVATION

Fig.5 State diagram.

MGG819

MGG820

1996 Dec 12 7

Philips Semiconductors Product specification

Smart card interface TDA8000; TDA8000T

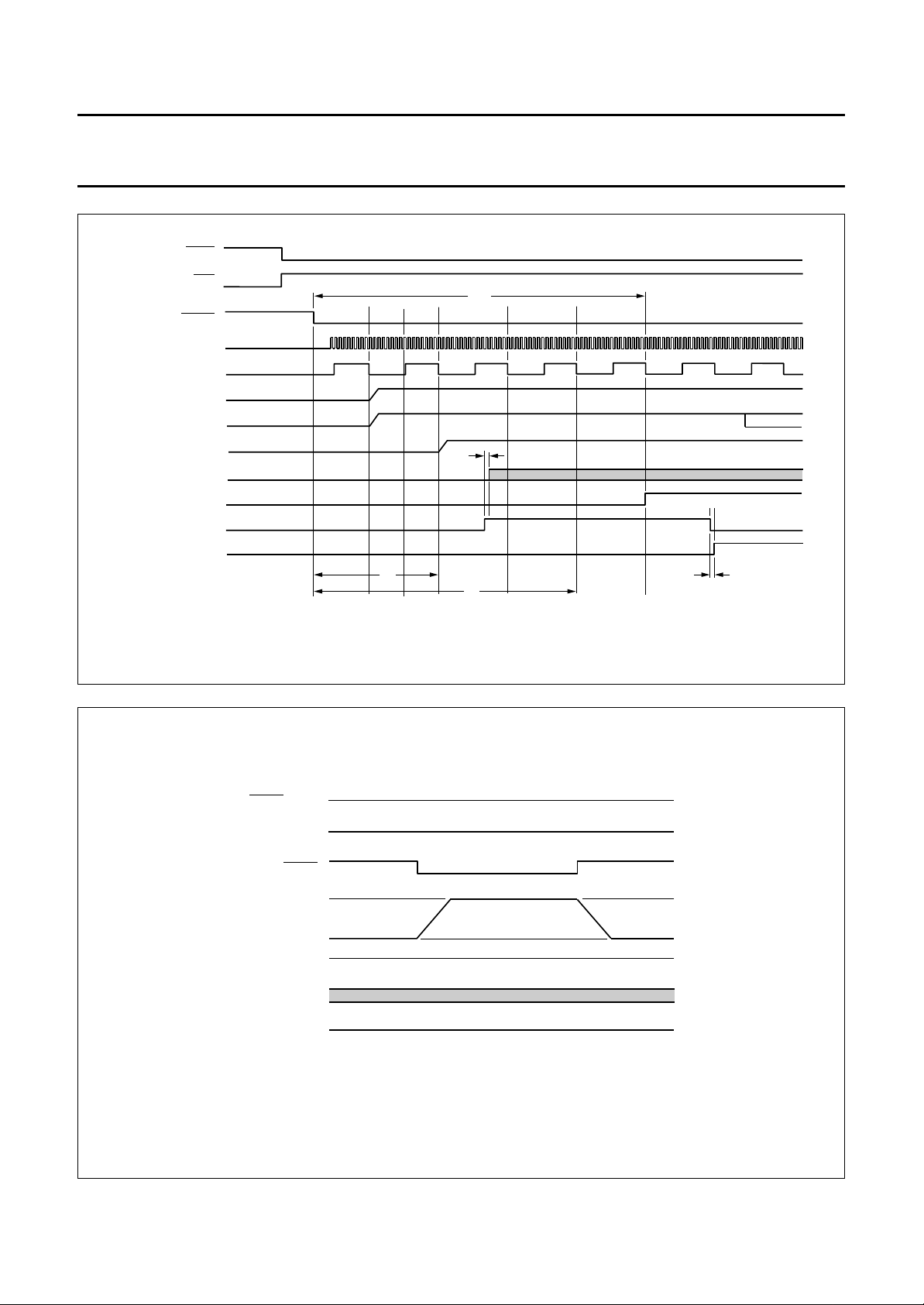

handbook, full pagewidth

INTERNAL CLOCK

SEQUENCER CLOCK

ENABLE RESET

PRES

OFF

START

V

CC

I/O

V

PP

CLK

RSTIN

RST

INTERNAL

t

act

t

d(clk)

t

3

123 4 5 6

t

5

Fig.6 Activation sequence.

t

RST

MGG821

handbook, full pagewidth

START (LOW)

VCC (+5 V)

WRITE

(P)

(+5 V)

VPP (0 V)

CLK

RST (HIGH)

Fig.7 Read/Write; Read mode.

1996 Dec 12 8

MGG822

Loading...

Loading...