Philips TDA5341 Datasheet

INTEGRATED CIRCUITS

DATA SH EET

TDA5341

Brushless DC motor and VCM drive

circuit with speed control

Product specification

File under Integrated Circuits, IC11

1997 Jul 10

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

with speed control

FEATURES

• Full-wave commutation (using push-pull output stages)

without position sensors

• Built-in start-up circuitry

• Three push-pull MOS outputs:

– 1 A output current

– Low voltage drop

– Built-in current limiter

• Thermal protection

• General purpose operational amplifier

• Reset generator

• Motor brake facility

• Actuator driver (H-bridge current-controlled)

• Power-down detector

• Automatic park and brake procedure

• Adjustable park voltage

• Sleep mode

• Speed control with Frequency-Locked Loop (FLL)

• Serial port

• Friction reduction prior to spin-up.

APPLICATIONS

• Hard Disk Drive (HDD).

GENERAL DESCRIPTION

The TDA5341 is a BiCMOS integrated circuit used to drive

brushless DC motors in full-wave mode. The device

senses the rotor position using an EMF sensing technique

and is ideally suited as a drive circuit for a hard disk drive

motor.

The TDA5341 also includes a Voice Coil Motor driver

(VCM), reset and park facilities and an accurate speed

regulator. In addition, a serial port facilitates the control of

the device.

TDA5341

QUICK REFERENCE DATA

Measured over full voltage and temperature range.

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

DD

I

oMOT

R

DS(MOT)

I

oACT

R

DS(ACT)

ORDERING INFORMATION

TYPE

NUMBER

TDA5341G LQFP64

general supply voltage for logic and power 4.5 5.0 5.25 V

motor output current 1.3 1.6 1.9 A

motor output resistance − 1.1 1.56 Ω

actuator output current 0.7 1.1 1.4 A

actuator output resistance − 2.0 2.5 Ω

PACKAGE

NAME DESCRIPTION VERSION

plastic low profile quad flat package; 64 leads; body 10 × 10 × 1.4 mm

SOT314-2

1997 Jul 10 2

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

with speed control

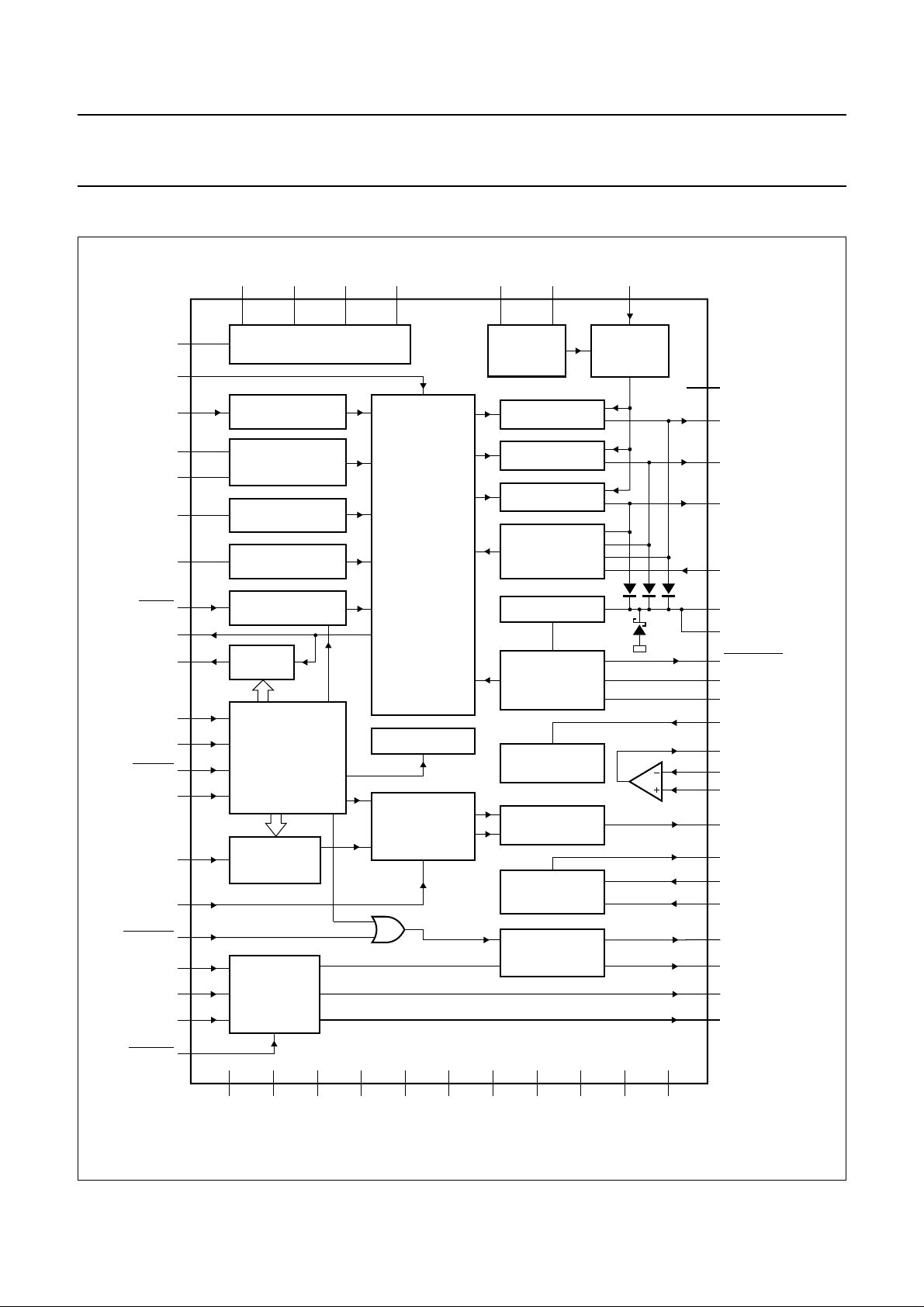

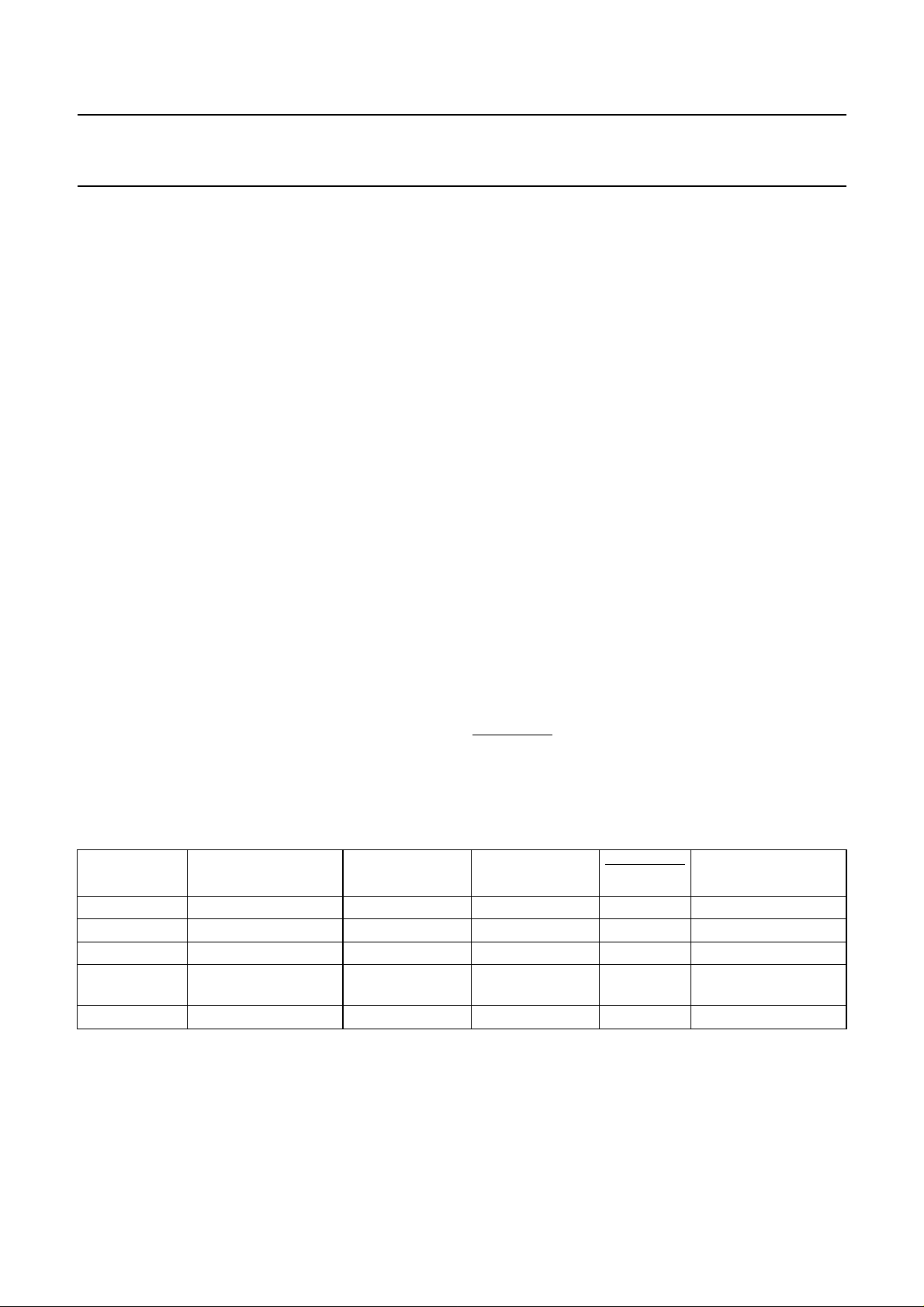

BLOCK DIAGRAM

handbook, full pagewidth

CAPCP

FREDENA

TESTIN

CAPCDM

CAPCDS

CAPTI

CAPST

BRAKE

FG

FMOT

CLOCK

DATA

ENABLE

RESET

ROSC

DPULSE

RETRACT

V

CMIN1

V

CMIN2

V

ref

GAINSEL

CAPXA

27

9

12

18

19

2

1

11

10

58

39

38

42

57

48

35

30

33

34

36

15

CAPXB

UPPER VOLTAGE

THERMAL

SWITCH

ADAPTIVE

COMMUTATION

DELAY

TIMING

OSCILLATOR

START

OSCILLATOR

BRAKE

CONTROLLER

POLES

DIVIDER

SERIAL

PORT

PROGRAMMING

FREQUENCY

DIVIDER

VCM

PREAMPLIFIER

50 14 55 31 49 17

CAPYA

CONVERTER

CAPYB

COMMUTATION

AND

OUTPUT

DRIVING

LOGIC

brake

BAND GAP 1

sleep

fill

DIGITAL

FREQUENCY

COMPARATOR

park

CNTRL

CAPCPC

222463625961

CONTROL

AMPLIFIER

POWER 1

POWER 2

POWER 3

COMPARATORS

BAND GAP 2

UNDER-VOLTAGE

DETECTOR

BRAKE

AFTER PARK

CHARGE

PUMP

SENSE

AMPLIFIER

VCM

H-BRIDGE

CURRENT

LIMIT

CONTROL

TDA5341

25 64 40 16 41

ILIM

TDA5341

23

20

PRESET

60

MOT1

8

MOT2

21

MOT3

7

MOT0

3

CLAMP1

26

CLAMP2

43

RESETOUT

44

UVDIN1

54

UVDIN2

46

BRAKEDELAY

4

AMPOUT

5

AMPIN−

6

AMPIN+

32

FILTER

53

SENSEOUT

52

SENSEIN+

51

SENSEIN−

37

VCM+

45

VCM−

28

FB1

29

FB2

V

EEDVEE1VEE2VEE3VEE4VEEVDD1VDD2VDD3VDDVDDD

Fig.1 Block diagram.

1997 Jul 10 3

MGE817

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

TDA5341

with speed control

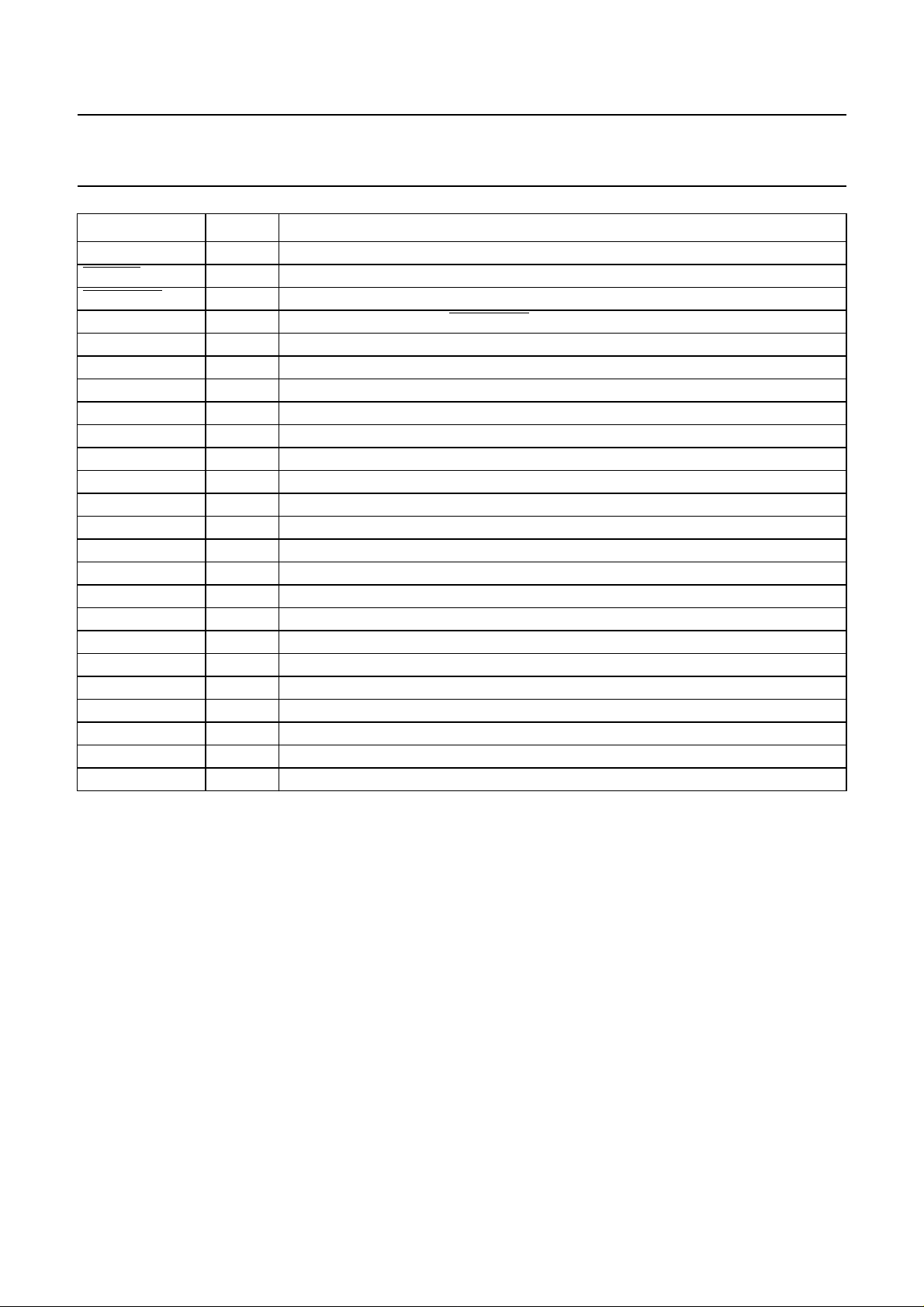

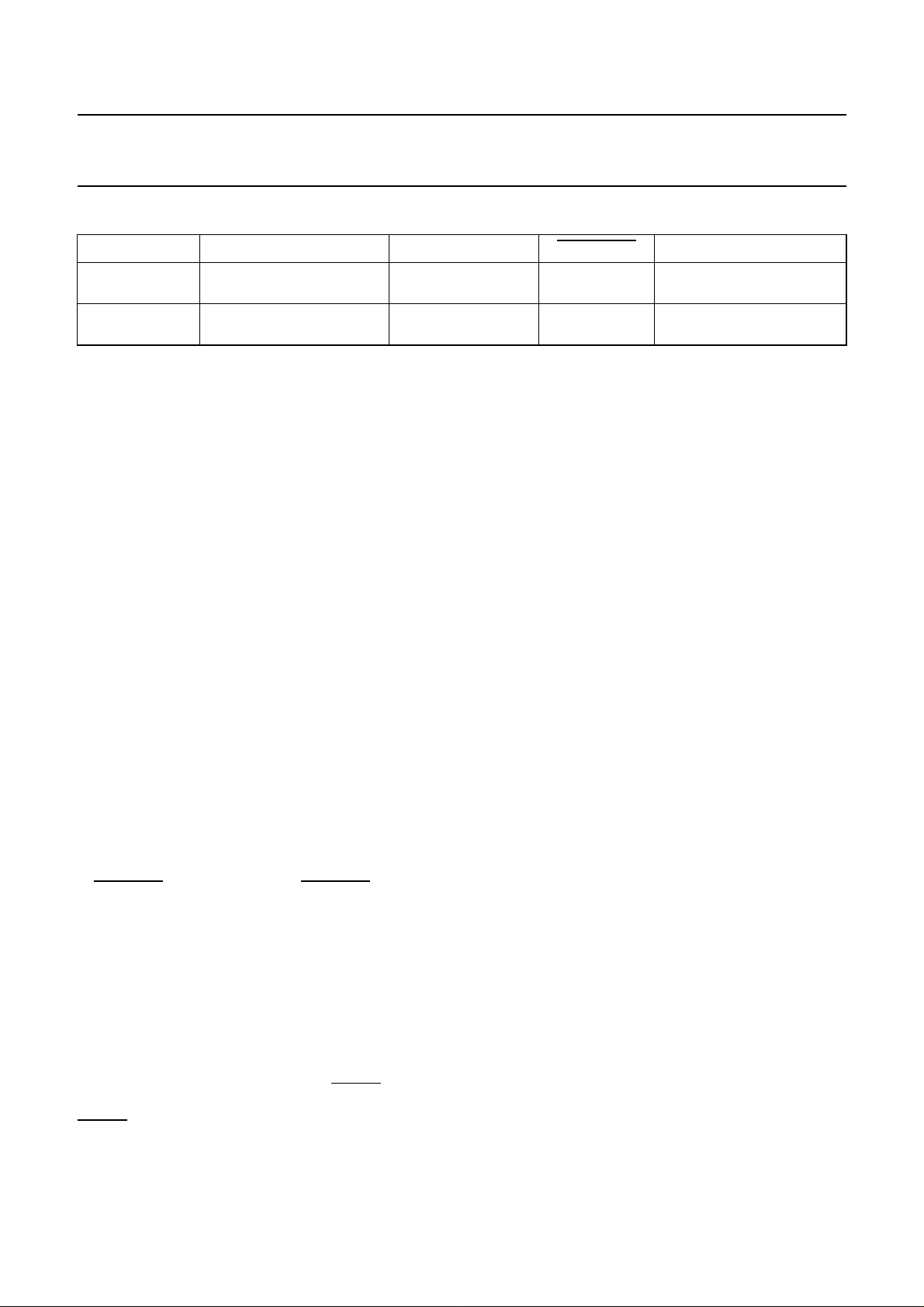

PINNING

SYMBOL PIN DESCRIPTION

CAPST 1 external capacitor for starting oscillator

CAPTI 2 external capacitor for timer circuit

CLAMP1 3 external capacitor used to park the heads; must be externally connected to CLAMP2

AMPOUT 4 uncommitted operational amplifier output

AMPIN− 5 uncommitted operational amplifier invert input

AMPIN+ 6 uncommitted operational amplifier direct input

MOT0 7 motor centre tap input

MOT2 8 motor driver output 2

FREDENA 9 friction reduction mode enable input (active HIGH)

FG 10 frequency generator (tacho) output

BRAKE 11 brake input command (active LOW)

TESTIN 12 test input for power output switch-off (active HIGH)

TP1 13 test purpose 1 (should be left open-circuit)

V

EE1

GAINSEL 15 VCM gain adjustment input (switch ON when GAINSEL is LOW)

V

DD

V

EE

CAPCDM 18 external capacitor for adaptive commutation delay (master)

CAPCDS 19 external capacitor for adaptive commutation delay (slave)

PRESET 20 set the motor drivers into a fixed state: MOT1 = F (floating), MOT2 = L, MOT3 = H

MOT3 21 motor driver output 3

CAPCPC 22 frequency compensation of the current control

ILIM 23 current limit control input

CNTRL 24 motor control

V

DD1

CLAMP2 26 external capacitor used to park the heads; must be externally connected to CLAMP1

CAPCP 27 external capacitor for the charge pump output

FB1 28 output of the VCM preamplifiers

FB2 29 switchable output of the VCM preamplifier

RETRACT 30 park input command (active LOW)

V

EE3

FILTER 32 charge pump output to be connected to an external filter

V

CMIN1

V

CMIN2

DPULSE 35 data pulse input of the frequency comparator of the speed control

V

ref

VCM+ 37 positive output of the VCM amplifier

DATA 38 input data of the serial port (active HIGH)

CLOCK 39 clock input signal to shift DATA into SERIALIN register (active HIGH)

V

DD3

14 ground for the spindle motor drivers

16 general power supply

17 general ground

25 power supply 1 for the spindle motor drivers

31 ground 3 for the actuator driver

33 VCM voltage control input

34 switchable VCM voltage control input

36 voltage reference input

40 power supply 3 for the actuator driver

1997 Jul 10 4

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

TDA5341

with speed control

SYMBOL PIN DESCRIPTION

V

DDD

ENABLE 42 enable input; enables the serial port, i.e. allows DATA to be shifted in (active LOW)

RESETOUT 43 under-voltage detector output flag (active LOW)

UVDIN1 44 external capacitor for the

VCM− 45 negative output of the VCM amplifier

BRAKEDELAY 46 delay control input for brake after park

TP2 47 test purpose 2 (should be left open-circuit)

ROSC 48 reference oscillator input for motor speed control

V

EE4

V

EED

SENSEIN− 51 inverting input of the VCM sense amplifier

SENSEN+ 52 non-inverting input of the VCM sense amplifier

SENSEOUT 53 output of the VCM sense amplifier

UVDIN2 54 external voltage reference for the under-voltage detector

V

EE2

TP3 56 test purpose 3 (should be left open-circuit)

RESET 57 reset input; forces all bits of the SERIALIN register to 0 (active HIGH)

FMOT 58 tachometer output (one pulse per mechanical revolution)

CAPXB 59 external capacitor for the charge pump output

MOT1 60 motor driver output 1

CAPXA 61 external capacitor for the charge pump output

CAPYA 62 external capacitor for the charge pump output

CAPYB 63 external capacitor for the charge pump output

V

DD2

41 digital power supply

RESETOUT duration

49 ground 4 for the actuator driver

50 digital ground

55 ground 2 for the spindle motor drivers

64 power supply for the spindle motor drivers

1997 Jul 10 5

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

with speed control

handbook, full pagewidth

DD2

CAPYB

CAPST

CAPTI

CLAMP1

AMPOUT

AMPIN−

AMPIN+

MOT0

MOT2

FREDENA

FG

BRAKE

TESTIN

TP1

V

EE1

GAINSEL

V

DD

V

64

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

EE

V

CAPYA

63

62

18

19

CAPCDS

CAPCDM

CAPXA

MOT1

61

60

20

21

MOT3

PRESET

FMOT

CAPXB

59

58

TDA5341

22

23

ILIM

CAPCPC

RESET

57

24

CNTRL

TP3

56

25

DD1

V

EE2

V

UVDIN2

55

54

26

27

CAPCP

CLAMP2

SENSEIN+

SENSEOUT

53

52

28

29

FB2

FB1

EED

SENSEIN−

V

51

50

30

31

EE3

V

RETRACT

EE4

V

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

FILTER

TDA5341

ROSC

TP2

BRAKEDELAY

VCM−

UVDIN1

RESETOUT

ENABLE

V

DDD

V

DD3

CLOCK

DATA

VCM+

V

ref

DPULSE

V

CMIN2

V

CMIN1

MGE816

Fig.2 Pinning diagram.

1997 Jul 10 6

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

with speed control

FUNCTIONAL DESCRIPTION

The TDA5341 offers a sensorless three-phase motor

full-wave drive function. The device also offers protected

outputs capable of handling high currents and can be used

with star or delta connected motors.

The TDA5341 can easily be adapted for different motors

and applications.

The TDA5341 offers the following features:

• Sensorless commutation by using the motor EMF

• Built-in start-up circuit

• Optimum commutation, independent of motor type or

motor loading

• Built-in flyback diodes

• Three-phase full-wave drive

• High output current (1.3 A)

• Low MOS R

• Outputs protected by current limitation and thermal

protection of each output transistor

• Low current consumption

• Additional uncommitted operational amplifier

• H-bridge actuator driver current controlled with an

external series sense resistor

• Automatic retract procedure

• Adjustable park voltage

• Sleep mode

• Automatic brake (after park) procedure

DSon

(1 Ω)

TDA5341

• Speed control based on FLL technique

• Serial port DATAIN (24 bits)

• Friction reduction prior to spin-up.

TDA5341 modes description

The TDA5341 can be used in two main modes, depending

on whether they are controlled or not.

The ‘controlled modes’ (user commands) are executed by

the TDA5341 without delay or priority treatment, either by

software via the serial port or by hardware. BRAKE is a

hardware command whereas RETRACT can be controlled

in both ways. If it is preferable to control the heads parking

via the serial bus, the equivalent pin can be left

open-circuit.

The sleep mode is controlled by software only; it results

from the combination of the spindle and actuator being

disabled. The spindle is turned off by bit SPINDLE

DISABLE, whereas the actuator is disabled towards bit

VCM DISABLE of the serial port (see Section “Serial

port”). In addition, a special spin-up mode can be activated

in the event of high head stiction

The ‘uncontrolled modes’ only result from different failures

caused by either a too high internal temperature or an

abnormally low power voltage, which will cause the

actuator to retract and, after the spindle, to brake.

The output signals mainly affected by those failures are

RESETOUT, MOT1, 2 and 3, VCM+ and VCM−. This is

summarised in Tables 1 and 2.

Table 1 Summary of controlled modes

HARDWARE/

SOFTWARE

Software spindle disable high impedance high impedance HIGH spindle off

Software VCM disable not affected high impedance HIGH spindle on; VCM off

Hardware brake LOW not affected HIGH spindle coils ground

Software/

hardware

Hardware friction reduction − not affected HIGH heads in vibration

1997 Jul 10 7

MODE MOT1, 2 AND 3

retract not affected VCM− = 0.65 V;

VCM+ AND

VCM−

VCM+=0V

RESETOUT EFFECT

HIGH heads parked

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

with speed control

Table 2 Summary of uncontrolled modes

FAILURE MOT1, 2 AND 3 VCM+ AND VCM− RESETOUT EFFECT

Thermal

shut-down

Voltage

shut-down

Controlled modes

S

PINDLE DISABLE

The spindle circuitry is switched off when bit 23 (SPINDLE

DISABLE) of the serial port is pulled HIGH. In that mode,

the reference band gap generator is cut off so that all

internal current sources are disabled. Both the spindle and

actuator outputs will be set to the high impedance state

because the upper converter is also turned off.

It should be noted that the uncommitted operational

amplifier is also disabled in that mode.

VCM

DISABLE

The actuator will be disabled when bit 22 (VCM DISABLE)

is set to logic 1; the spindle circuitry is not affected in that

mode. The retract circuitry also remains active, so that the

heads can be parked although the VCM is disabled. In that

mode, the current consumption can be reduced by ±4 mA.

high impedance → LOW VCM− = 0.65 V;

VCM+ = 0 V

high impedance → LOW VCM− = 0.65 V;

VCM+ = 0 V

RICTION REDUCTION

F

Pulling FREDENA HIGH activates the friction reduction

mode of the TDA5341. In that mode, a clock signal fed via

pin TESTIN will cause the MOT outputs to sequentially

switch-on and switch-off at the same frequency and, as a

result, generate an AC spindle torque high enough to

overcome the head stiction.

Before start-up, the head stiction might be higher than

normal due to condensation between the head(s) and the

disk(s). Normal spin-up is not possible when this friction

torque is higher than the start-up torque of the spindle

motor. Spin-up is then only possible after friction has been

reduced by breaking the head(s) free. Bringing a static

friction system into mechanical resonance is an effective

method to break static friction head(s) free.

The resonance frequency is:

f

res

1

×=

------ -

2π

LOW automatic park and brake

LOW automatic park and brake

C

0.5

--- -

J

TDA5341

S

LEEP MODE

The sleep mode is obtained by pulling both the SPINDLE

and VCM DISABLE bits of the serial port HIGH. The power

monitor circuitry only remains active in sleep mode.

ETRACT

R

Retract is activated by pulling either bit 21 (PARK) HIGH

or RETRACT (pin 30) LOW. WhenRETRACT is set LOW,

a voltage of 0.65 V is applied to pin VCM− for parking.

It should be noted that the park voltage can be made

adjustable by changing one of the interconnect masks.

Accordingly, some different voltages, varying from

0.2 to 1.2 V, can quickly be obtained on customer

demand. This mode does not affect the control of the

spindle rotation.

B

RAKE MODE

The brake mode is activated by pulling BRAKE (pin 11)

LOW. When a voltage of less than 0.8 V is applied to pin

BRAKE, the 3 motor outputs are short-circuited to ground,

which results in a quick reduction of the speed until the

motor stops completely.

Where:

C = Stiffness of the head-spring(s) in direction of disk(s)

rotation, (N/m)

2

J = Inertia of the disk(s), (kg/m

).

The external clock input frequency must be:

f

clk

6

------ -

2π

C

0.5

×=

--- -

J

A burst of n × 6 clock pulse will bring the system into

resonance and break the heads free (n > 2). Once the

heads have been broken free, the normal spin-up

procedure can be applied.

It should be noted that the clock frequency must be smaller

than 40000/CAPCDM (nF).

1997 Jul 10 8

Philips Semiconductors Product specification

Brushless DC motor and VCM drive circuit

with speed control

Uncontrolled modes

P

OWER SHUT-DOWN

If the power supply decreases to less than the voltage

threshold determined by the ratio between R1 and R2

connected to UVDIN2 (see Fig.8) (for more than 1 µs), the

TDA5341 will issue a reset (RESETOUT goes LOW) and

the following operation will start:

• Firstly, the MOT outputs are switched to the high

impedance state so as to get back the rectified EMF

issued from the motor itself. At the same time, the

voltage upper converter is cut off in order to preserve the

voltage on the charge pump capacitance at CAPCP.

The energy supplied in that way is then used to park the

heads in a safe position

• Secondly, after a certain period of time, depending on

the RC constant of the device connected to

BRAKEDELAY, the lower MOS drivers will be turned on

in order to stop the motor completely.

TDA5341

The system will only function when the EMF voltage from

the motor is present. Consequently, a start oscillator is

provided that will generate commutation pulses when no

zero-crossings in the motor voltage are available.

A timing function is incorporated into the device for internal

timing and for timing of the reverse rotation detection.

The TDA5341 also contains a control amplifier, directly

driving output amplifiers.

The TDA5341 also provides access to the user of some of

its internal test modes. Firstly, a PRESET mode can be

used for prepositioning the three motor output drivers into

a fixed state. By pulling pin PRESET to 0.75 V above V

MOT3 goes HIGH, MOT2 goes LOW and MOT1 goes to

the high impedance state.

In addition, when TESTIN is pulled HIGH (provided that

FREDENA is LOW), the 3 motor output drivers are

switched off. It should be noted that RESETOUT goes

LOW in that particular event.

DD

,

T

HERMAL SHUT-DOWN

Should the temperature of the chip exceed +140 ±10 °C, a

shut-down operation will also be processed. The actions

described for power shut-down will be sequenced in the

same manner.

PINDLE SECTION (see Fig.1)

S

Full-wave driving of a three-phase motor requires three

push-pull output stages. In each of the six possible states

two outputs are active, one sourcing current and one

sinking current. The third output presents a high

impedance to the motor which enables measurement of

the motor EMF in the corresponding motor coil by the EMF

comparator at each output. The commutation logic is

responsible for control of the output transistors and

selection of the correct EMF comparator.

The zero-crossing in the motor EMF (detected by the

comparator selected by the commutation logic) is used to

calculate the correct moment for the next commutation, i.e.

the change to the next output state. The delay is calculated

(depending on the motor loading) by the adaptive

commutation delay block.

Because of high inductive loading the output stages

contain flyback diodes. The output stages are also

protected by a current limiting circuit and by thermal

protection of the six output transistors.

The zero-crossings can be used to provide speed

information such as the tacho signal (FG).

Adjustments

The system has been designed in such a way that the

tolerances of the application components are not critical.

However, the approximate values of the following

components must still be determined:

• The start capacitor; this determines the frequency of the

start oscillator

• The two capacitors in the adaptive commutation delay

circuit; these are important in determining the optimum

moment for commutation, depending on the type and

loading of the motor

• The timing capacitor; this provides the system with its

timing signals.

The start capacitor (CAPST)

This capacitor determines the frequency of the start

oscillator. It is charged and discharged, with a current of

5.5 µA, from 0.05 to 2.2 V and back to 0.05 V. The time

taken to complete one cycle is given by:

t

= (0.78 × C); where C is given in µF.

start

The start oscillator is reset by a commutation pulse and so

is only active when the system is in the start-up mode.

A pulse from the start oscillator will cause the outputs to

change to the next state (torque in the motor). If the

movement of the motor generates enough EMF the

TDA5341 will run the motor.

1997 Jul 10 9

Loading...

Loading...