philips TC5.1L CB Service Manual

Color Television Chassis

TC5.1L

CB

H_17510_000.eps

021107

Contents Page

1. Technical Specifications, Connections and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 6

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 7

6. Block Diagrams, Test Point Overviews, and

Waveforms

Chassis Block Diagram 9

7. Circuit Diagrams and CBA Layouts Diagram CBA

Main Board 01-29PT6457/44-MA1 10 12

Main Board 01-29PT6457/55-MA1 11 12

CRT Panel 13 14

Side I/O Panel 40-TB59PH-SIA1XG 14

Layout Front IR Panel 40-TB59PH-FBB1XG 14

Layout BTSC Panel 40-TB59PH-MPB1XG 14

8. Alignments 15

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 18

10. Spare Parts List 24

11. Revision List 27

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by WS 0770 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17510

EN 2 TC5.1L CB1.

Technical Specifications, Connections and Chassis Overview

1. Technical Specifications, Connections and Chassis Overview

1.1 Technical Specifications

Tuning - technology : PLL

Tuning - presets/channels : 181

Freq Bands : Full-Cable

TV Systems Off Air/ Cable : NTSC M (3.58 - 4.5)

TV Systems Multi : NTSC

Mains voltage : 180-240V

(29PT6457/44)

: 100-120V

: (29PT6457/55)

Mains frequency : 50/60Hz

Power consumption : 90W (29PT6457/44)

Standby Power consumption : <3W (29PT6457/44)

Sound Systems : BTCS SAP

Audio output (RMS) : 2x5W

Scan Modes : 4:3

Sound Features : AVL, Mute

Sound Control : 4 sound modes

Menu Languages : American English,

Clock/Timer Function : Sleep timer

Terrestrial Antenna in : 75 Ohm (F type)

1.2 Connection overview

1.2.1 Connections

: 95W (29PT6457/55)

: <1W (29PT6457/55)

: Balance

: Bass Boost

: Treble Boost,

: Volume

French, Spanish

Figure 1-2 Rear audio and video connections

Cinch: Video CVBS - Out, Audio - Out

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm kq

PP

/10 kohm kq

RMS

/ 10 kohm kq

RMS

Cinch: Video YUV- In

Gn - Video Y 1 V

Bu - Video U 0.7 V

Rd - Video V 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

G_16340_002.eps

100306

G_16340_001.eps

100306

Figure 1-1 Aerial connection

Aerial - In

- - F-type Coax, 75 ohm D

H_17480_008.eps

050707

Figure 1-3 Side audio and video connections

S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Technical Specifications, Connections and Chassis Overview

1.3 Chassis Overview

See Chapter 10, Parts List.

EN 3TC5.1L CB 1.

EN 4 TC5.1L CB2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current flows. In particular this is valid

for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function, to prevent the cord from touching the CRT,

hot components, or heat sinks.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the “general repair instruction” noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

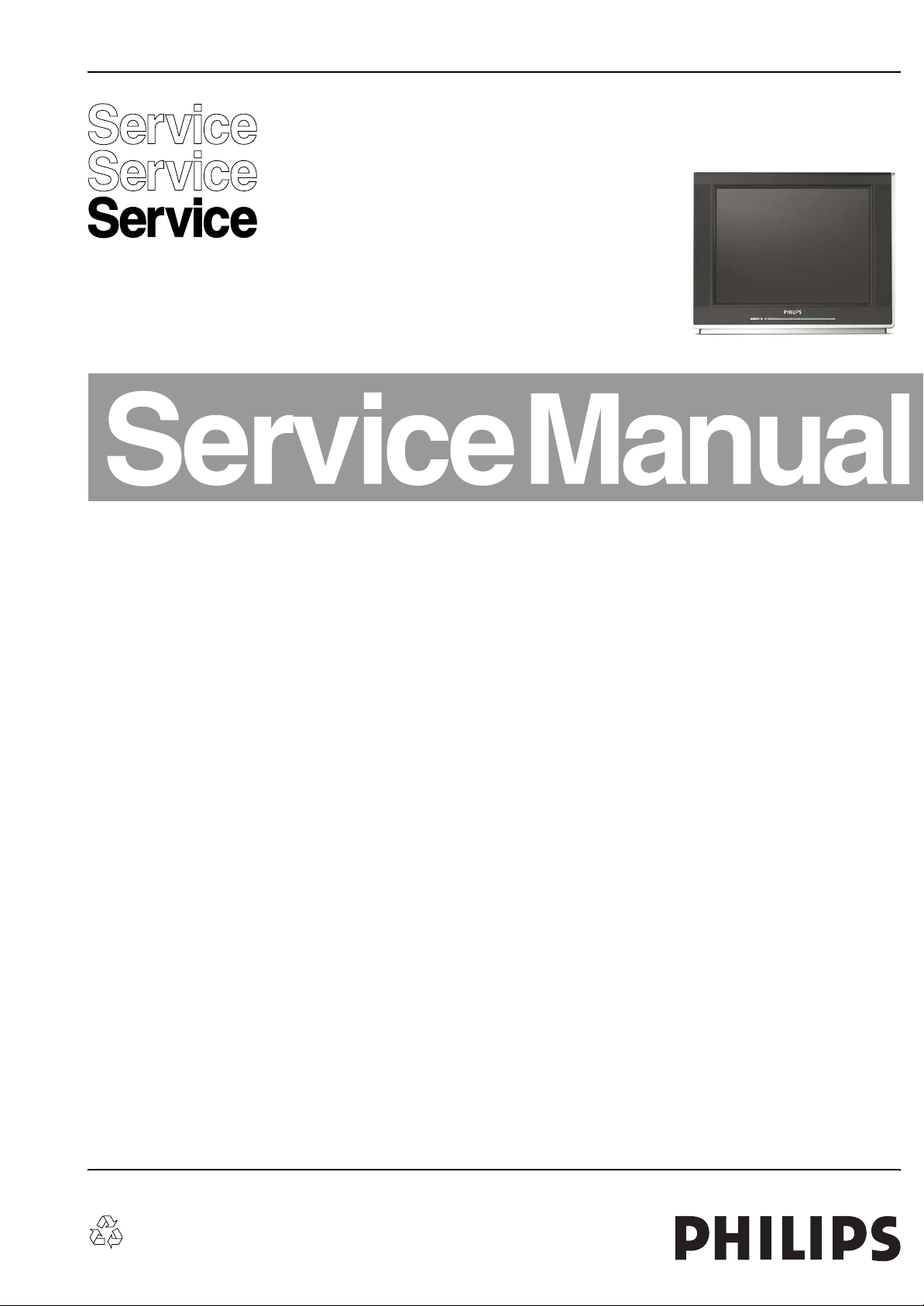

picture tube, use the method shown in figure “Discharge

picture tube”, to discharge the picture tube. Use a high

voltage probe and a multi-meter (position V

until the meter reading is 0 V (after approx. 30 s).

V

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and prevents circuits

from becoming unstable.

2.4 Notes

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

). Discharge

DC

E_06532_007.eps

250304

Safety Instructions, Warnings, and Notes

EN 5TC5.1L CB 2.

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.4.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

-9

), or pico-farads (p= x10

-12

2.4.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

MODEL :

-6

),

).

PROD.NO:

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

32PF9968/10

AG 1A0617 000001

Figure 2-2 Serial number example

MADE IN BELGIUM

220-240V 50/60Hz

~

128W

VHF+S+H+UHF

BJ3.0E LA

S

E_06532_024.eps

130606

P

b

Figure 2-3 Lead-free logo

Device Removal

As is the case with any component that is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature. A

uniform temperature reduces the risk of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has been shown to

result in problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighboring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clean the solder-joint from old tin and re-solder with new

tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

EN 6 TC5.1L CB3.

Directions for Use

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.4.5 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering the

correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.4.6 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

4. Mechanical Instructions

See Chapter 10, Parts List.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

5.1 Trouble Shooting

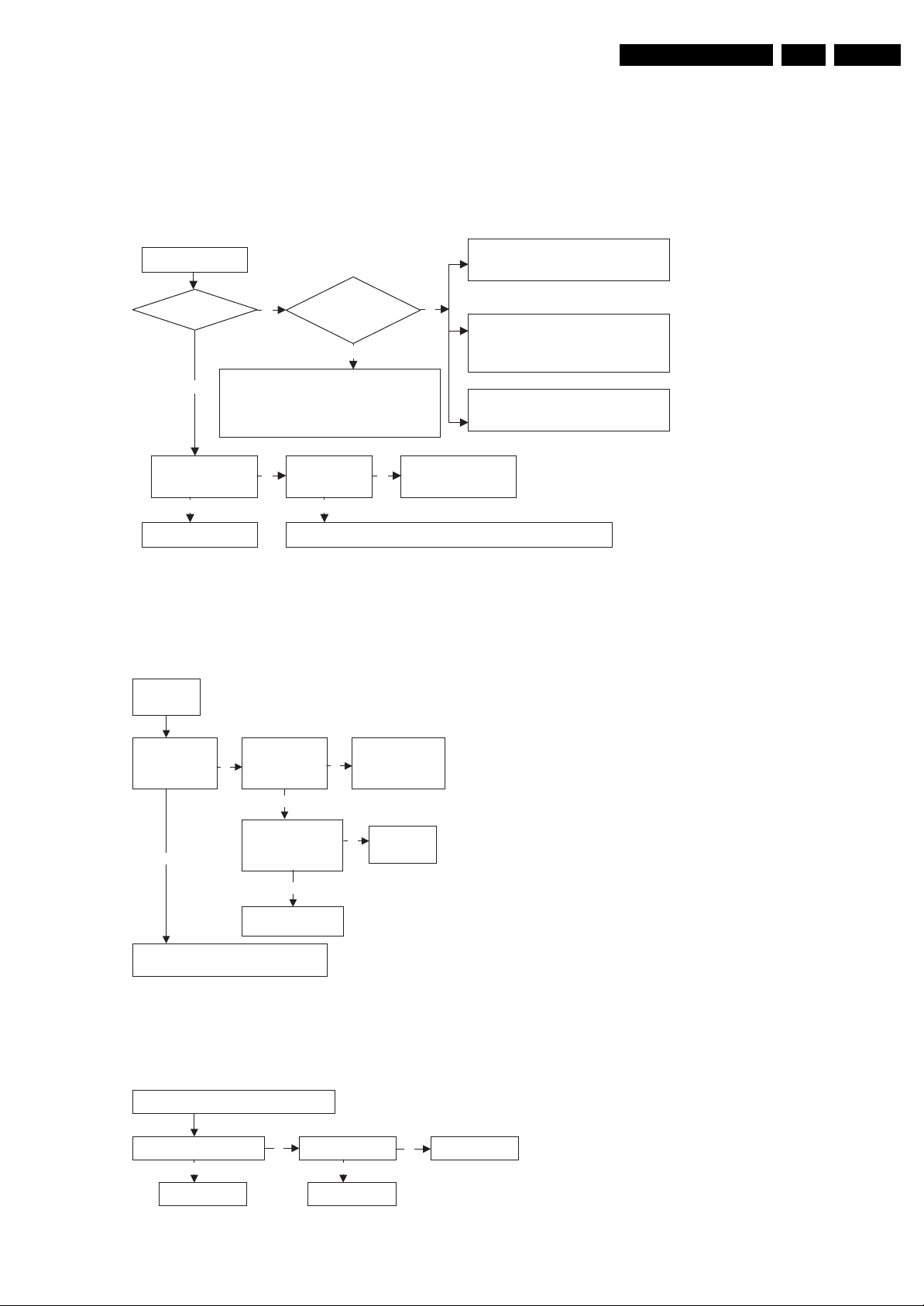

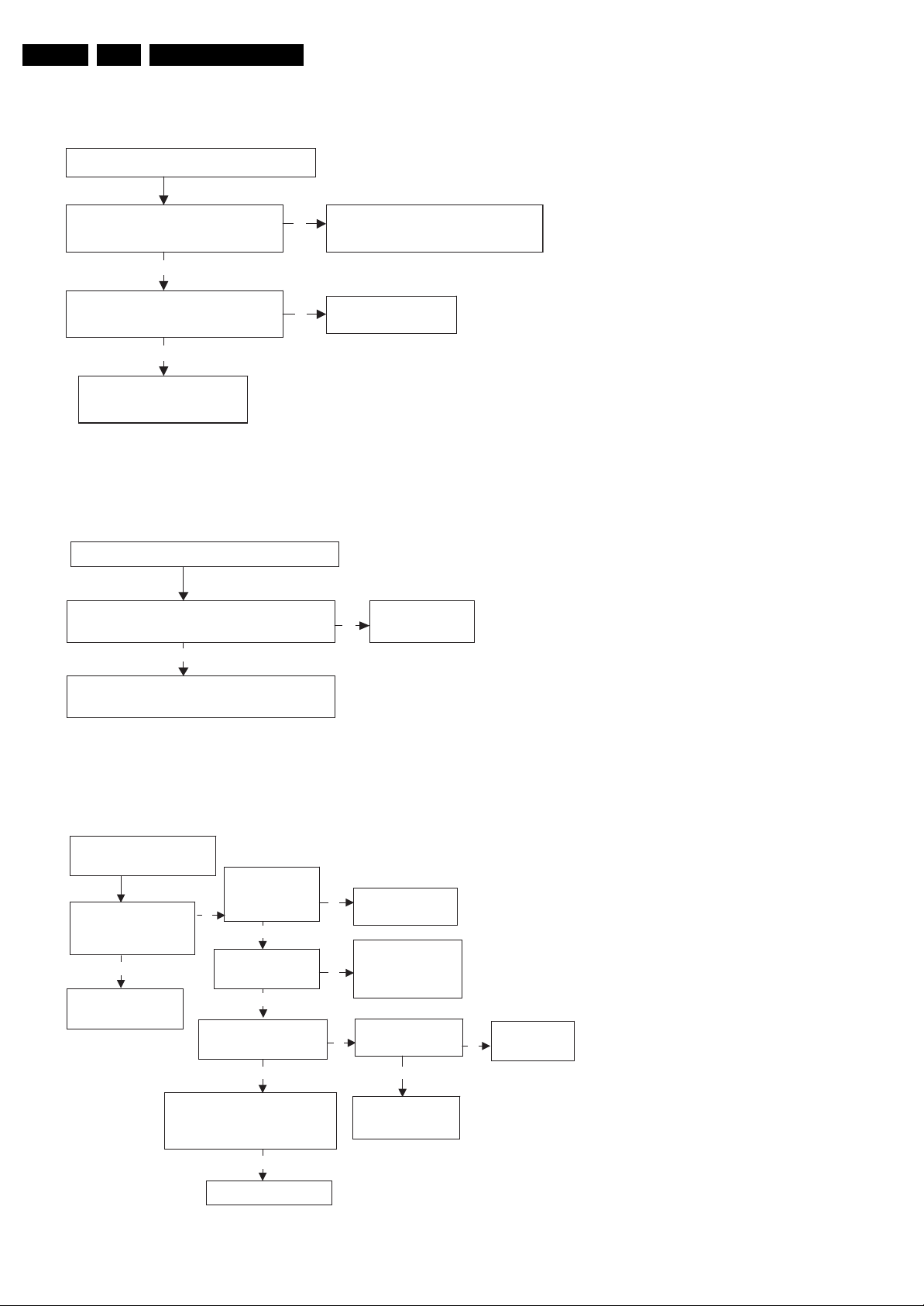

5.1.1 Can not Power On

EN 7TC5.1L CB 5.

Can not Power On

Fuse OK?

(1) Check if B+ shorted to earth.

(2) To check whether D822 and R821 are

N

(3) To check whether D823 and R823 are

Is it IC801 Pin 1

shorted to earth?

Y

Check/Replace IC801

5.1.2 No Raster, Sound OK

No Raster

Sound OK

Check B+,

Y Y

turnoff.

turnoff. And whether C836 shorted.

+12V, Ok?

N

Is DB801 OK?

NN

Y

Check the components such as C801, C802, C806, C807 and C815

Is power supply for IC101 correct?

If not, check Q820, Q821, Q007, Q008,

D001

Check Horizontal Scan circuit:

Check H-Vcc and H-out of IC 101

Check Q401, T401 and Q411

Check standby circuit: Check Pin64 of

IC101, Check Q825, Q824, Q823, Q822.

Replace DB801

Figure 5-1 Can not Power On

G_16340_004.eps

100306

Is the power

supply of Q401

and Q411 ok?

N

To check whether R404, C401, T401,

Q401, R422 are ok?

Check Pin 13

(H-OUT) voltage

ok?

Y

Is there any shorted

in the scan part of

the circuit?

Change IC101

Y

N

Y

N

5.1.3 Raster OK, Sound OK, No TV/AV picture

Raster OK, Sound OK, No TV/AV picture

Check whether Q917 is

ok?

N

Replace Q917

Y Y

Replace C238

N

Check each

output voltage of

FBT

Change the

shorted part.

G_16340_005.eps

100306

Figure 5-2 No Raster, Sound OK

Change IC901 Check C238, ok?

G_16340_008.eps

100306

Figure 5-3 Raster OK, Sound OK, No TV/AV picture

EN 8 TC5.1L CB5.

5.1.4 Raster OK, Sound OK, No AV picture

Raster OK, Sound OK, No AV picture

Service Modes, Error Codes, and Fault Finding

Is the signal waveform at Pin 12 and

Pin 14 of IC901 right?

Y

Check Q917, Q918, Q919, ok?

N

Replace the fail component.

5.1.5 Raster OK, Sound OK, No TV picture

Raster OK, Sound OK, No TV picture

Is the signal waveform at Pin 15 of IC901

right?

N

To check whether R903, C903, R902

N

and R905, C908, R908 are ok?

Replace IC901

Y

G_16340_006.eps

100306

Figure 5-4 Raster OK, Sound OK, No AV picture

Replace

IC901

Y

Check R234, Q204, R235, C229

5.1.6 No picture, dense noise dots

No picture, dense noise

dots

Is the antenna feed line

or the adapter broken?

Y

Handing the antenna

fault

N

Is the signal at Pin SCL,

SDA of tuner ok?

Check signal at P5, P57, P58,

P59, and P60 of IC101 and

replace the abnormal relative

circuit

Figure 5-5 Raster OK, Sound OK, No TV picture

Is the signal at

Pin41, Pin42 of

IC101 ok?

N

Is the signal at IF

pin of the tuner ok?

N

N N

Y

Check/Replace

Y

IC101

Check the relative

circuit of Q101,

Y

Z141 etc

Is the supply

voltage of tuner ok?

Y

Check/Replace

IC201, IC202,

D101.

G_16340_007.eps

100306

Check/Replace

Tuner

Y

Check EEPROM

G_16340_009.eps

Figure 5-6 No picture, dense noise dots

100306

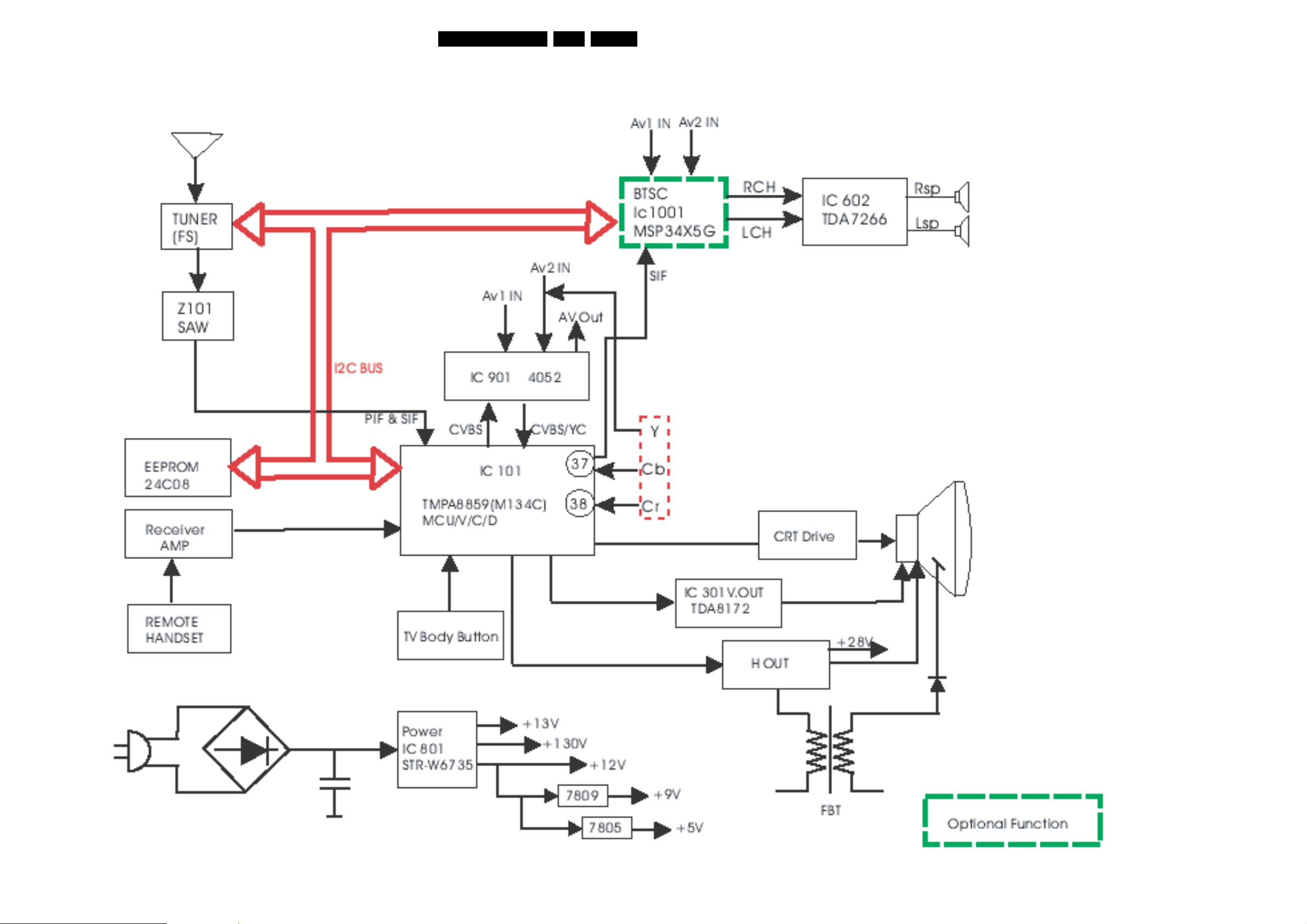

Block Diagrams, Test Point Overviews, and Waveforms

6. Block Diagrams, Test Point Overviews, and Waveforms

Chassis Block Diagram

EN 9TC5.1L CB 6.

* /44 sets use STR-W6756

H_17510_009.eps

021107

Loading...

Loading...