Philips TC5.1L Service Manual

Color Television Chassis

TC5.1L

CB

H_17510_000.eps

021107

Contents Page

1. Technical Specifications, Connections and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 6

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 7

6. Block Diagrams, Test Point Overviews, and

Waveforms

Chassis Block Diagram 9

7. Circuit Diagrams and CBA Layouts Diagram CBA

Main Board 01-29PT6457/44-MA1 10 12

Main Board 01-29PT6457/55-MA1 11 12

CRT Panel 13 14

Side I/O Panel 40-TB59PH-SIA1XG 14

Layout Front IR Panel 40-TB59PH-FBB1XG 14

Technical Specifications, Connections and Chassis Overview

EN 2 TC5.1L CB1.

1. Technical Specifications, Connections and Chassis Overview

1.1 Technical Specifications

Tuning - technology : PLL

Tuning - presets/channels : 181

Freq Bands : Full-Cable

TV Systems Off Air/ Cable : NTSC M (3.58 - 4.5)

TV Systems Multi : NTSC

Mains voltage : 180-240V

(29PT6457/44)

: 100-120V

: (29PT6457/55)

Mains frequency : 50/60Hz

Power consumption : 90W (29PT6457/44)

: 95W (29PT6457/55)

Standby Power consumption : <3W (29PT6457/44)

: <1W (29PT6457/55)

Sound Systems : BTCS SAP

Audio output (RMS) : 2x5W

Scan Modes : 4:3

Sound Features : AVL, Mute

Sound Control : 4 sound modes

: Balance

: Bass Boost

: Treble Boost,

: Volume

Menu Languages : American English,

French, Spanish

Clock/Timer Function : Sleep timer

Terrestrial Antenna in : 75 Ohm (F type)

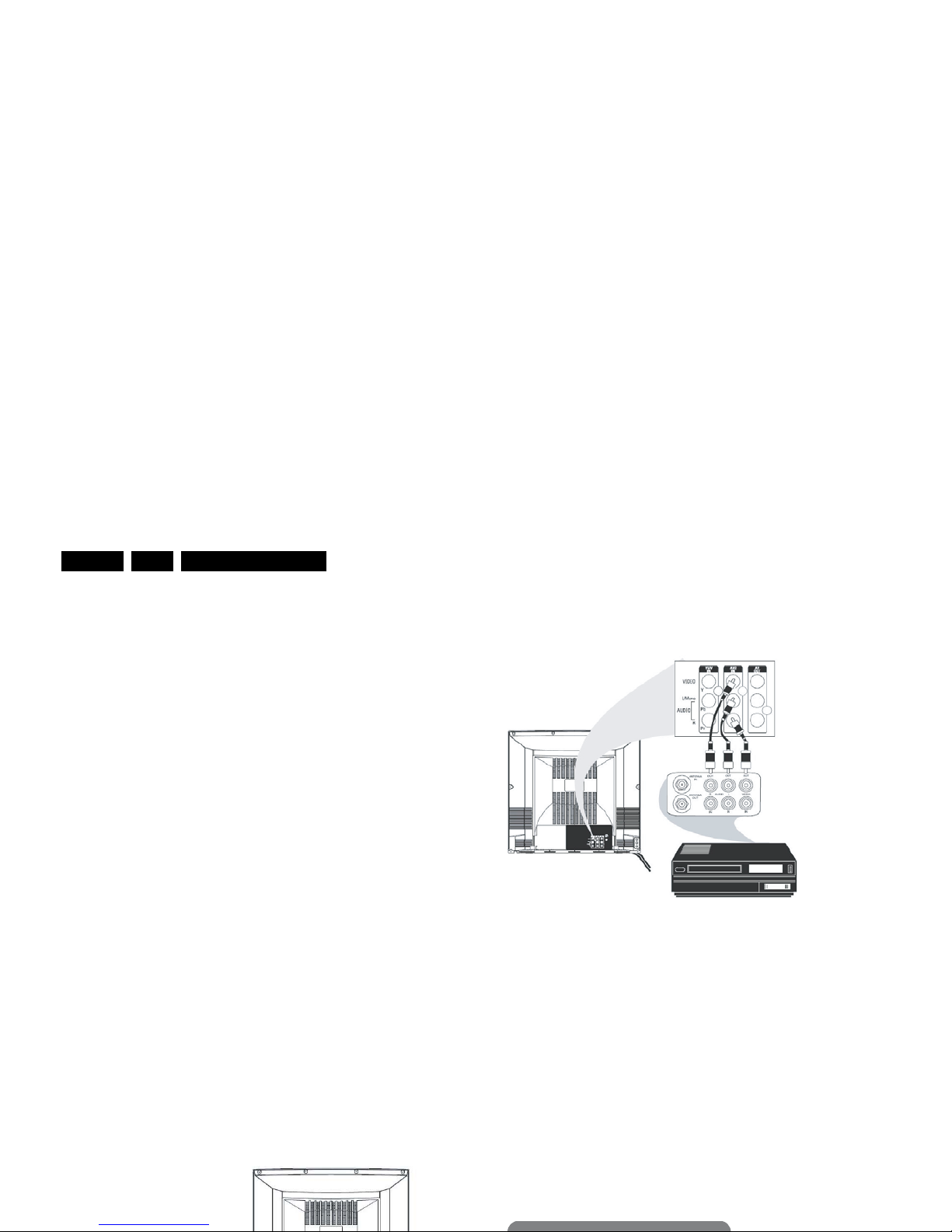

1.2 Connection overview

1.2.1 Connections

Figure 1-2 Rear audio and video connections

Cinch: Video CVBS - Out, Audio - Out

Ye - Video CVBS 1 V

PP

/ 75 ohm kq

Wh - Audio L 0.5 V

RMS

/10 kohm kq

Rd - Audio R 0.5 V

RMS

/ 10 kohm kq

Cinch: Video YUV- In

Gn - Video Y 1 V

PP

/ 75 ohm jq

Bu - Video U 0.7 V

PP

/ 75 ohm jq

Rd - Video V 0.7 V

PP

/ 75 ohm jq

Cinch: Audio - Out

Rd - Audio - R 0.5 V

RMS

/ 10 kohm kq

Wh - Audio - L 0.5 V

RMS

/ 10 kohm kq

G_16340_002.eps

100306

Technical Specifications, Connections and Chassis Overview

EN 3TC5.1L CB 1.

1.3 Chassis Overview

See Chapter 10, Parts List.

Safety Instructions, Warnings, and Notes

EN 4 TC5.1L CB2.

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current flows. In particular this is valid

for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

1. Perform the “general repair instruction” noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

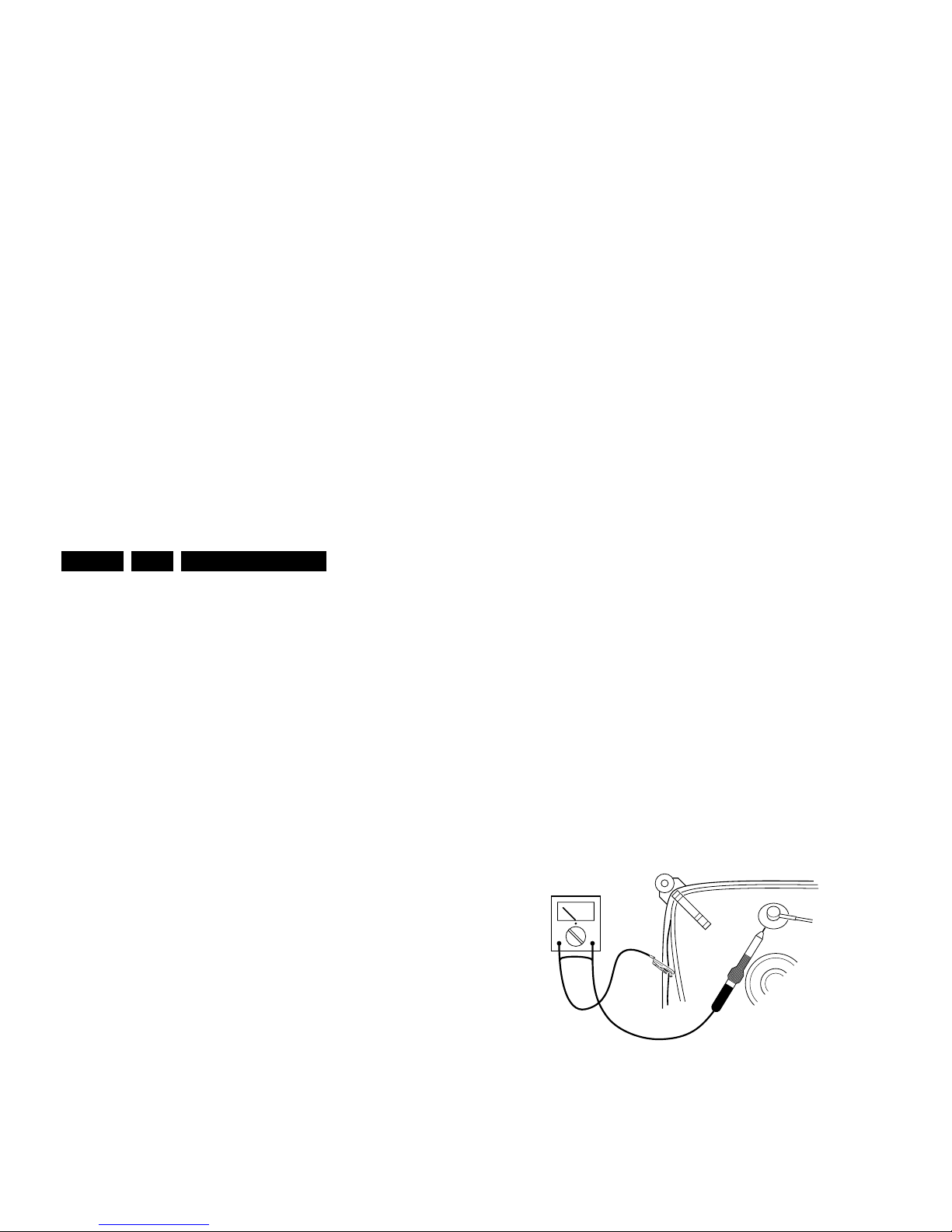

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in figure “Discharge

picture tube”, to discharge the picture tube. Use a high

voltage probe and a multi-meter (position V

DC

). Discharge

until the meter reading is 0 V (after approx. 30 s).

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

V

E_06532_007.eps

250304

Safety Instructions, Warnings, and Notes

EN 5TC5.1L CB 2.

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.4.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= x10

-6

),

nano-farads (n= x10

-9

), or pico-farads (p= x10

-12

).

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device Removal

As is the case with any component that is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature. A

uniform temperature reduces the risk of warping the PWB.

To do this, we recommend that the board is heated until it is

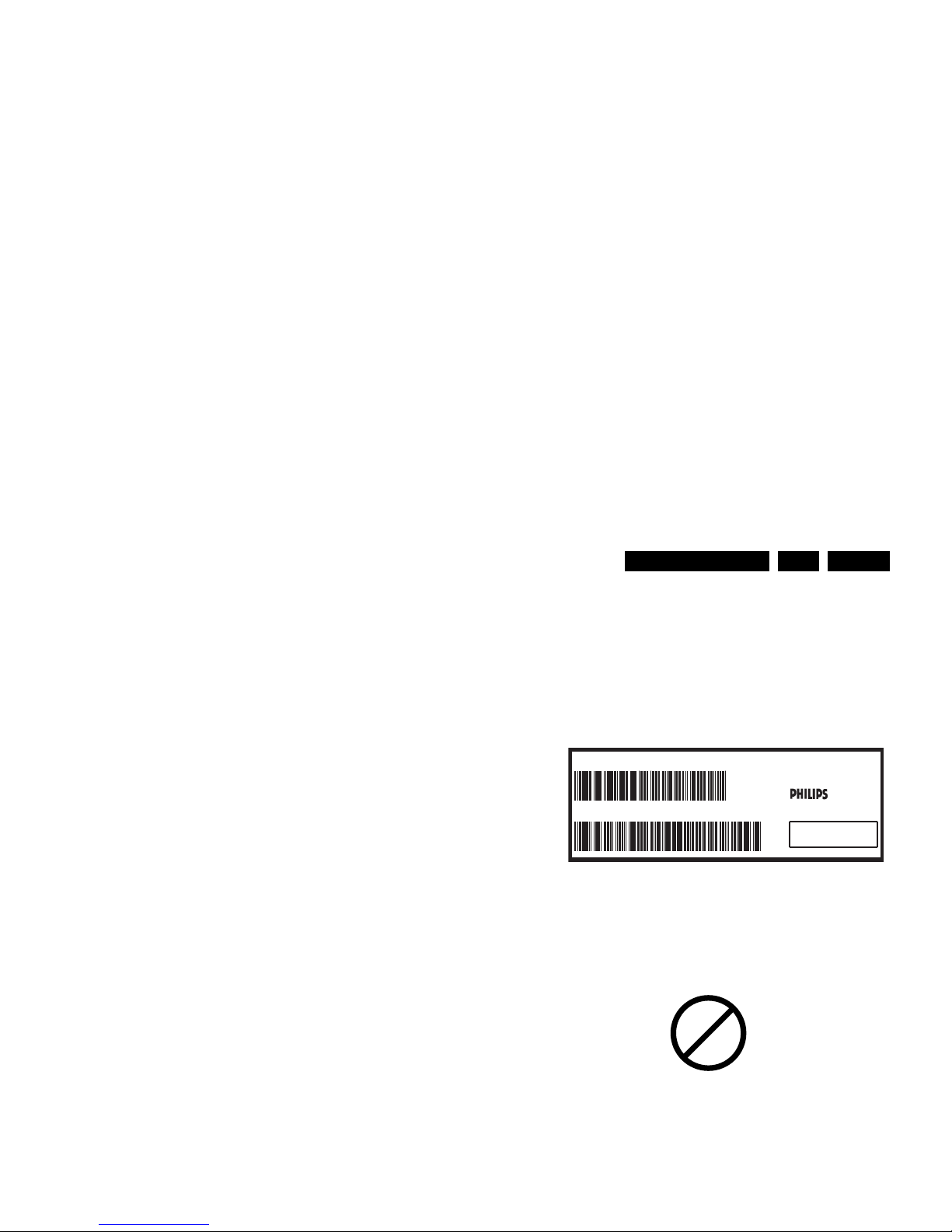

2.4.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

Figure 2-2 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

Figure 2-3 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

E_06532_024.eps

130606

MODEL :

PROD.NO:

~

S

32PF9968/10

MADE IN BELGIUM

220-240V 50/60Hz

128W

AG 1A0617 000001

VHF+S+H+UHF

BJ3.0E LA

P

b

Directions for Use

EN 6 TC5.1L CB3.

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.4.5 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering the

correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.4.6 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Service Modes, Error Codes, and Fault Finding

EN 7TC5.1L CB 5.

5. Service Modes, Error Codes, and Fault Finding

5.1 Trouble Shooting

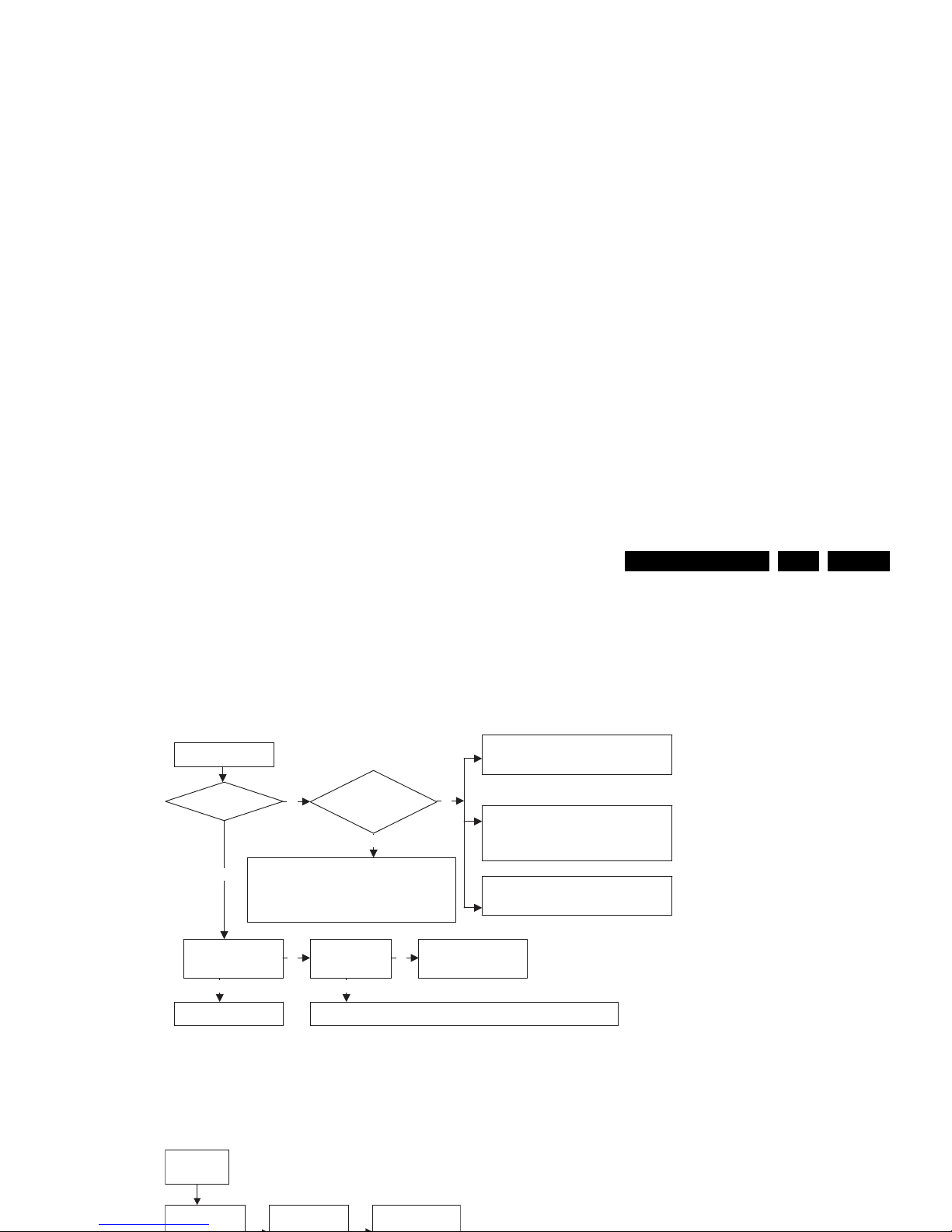

5.1.1 Can not Power On

Figure 5-1 Can not Power On

5.1.2 No Raster, Sound OK

G_16340_004.eps

100306

Can not Power On

Fuse OK?

Check B+,

+12V, Ok?

Is power supply for IC101 correct?

If not, check Q820, Q821, Q007, Q008,

D001

Check standby circuit: Check Pin64 of

IC101, Check Q825, Q824, Q823, Q822.

Check Horizontal Scan circuit:

Check H-Vcc and H-out of IC 101

Check Q401, T401 and Q411

(1) Check if B+ shorted to earth.

(2) To check whether D822 and R821 are

turnoff.

(3) To check whether D823 and R823 are

turnoff. And whether C836 shorted.

Is it IC801 Pin 1

shorted to earth?

Is DB801 OK?

Check the components such as C801, C802, C806, C807 and C815

Replace DB801

Check/Replace IC801

Y Y

Y

NN

N

N

Y

Is the power

supply of Q401

Check Pin 13

(H-OUT) voltage

Check each

output voltage of

No Raster

Sound OK

Service Modes, Error Codes, and Fault Finding

EN 8 TC5.1L CB5.

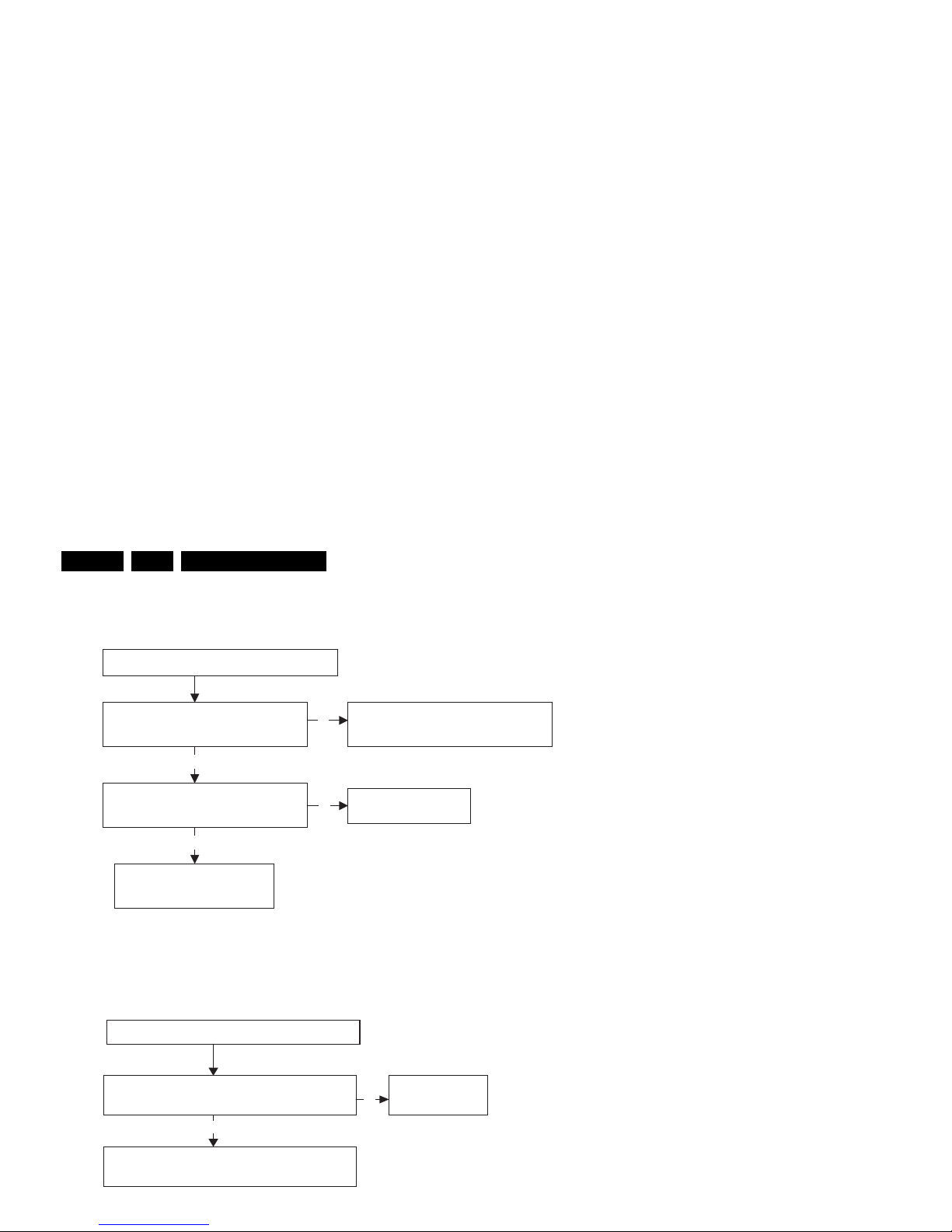

5.1.4 Raster OK, Sound OK, No AV picture

Figure 5-4 Raster OK, Sound OK, No AV picture

5.1.5 Raster OK, Sound OK, No TV picture

Figure 5-5 Raster OK, Sound OK, No TV picture

G_16340_006.eps

100306

To check whether R903, C903, R902

and R905, C908, R908 are ok?

Is the signal waveform at Pin 12 and

Pin 14 of IC901 right?

Raster OK, Sound OK, No AV picture

Replace IC901

Check Q917, Q918, Q919, ok?

Replace the fail component.

Y

N

N

Y

G_16340_007.eps

100306

Replace

IC901

Is the signal waveform at Pin 15 of IC901

right?

Raster OK, Sound OK, No TV picture

Check R234, Q204, R235, C229

N

Y

Block Diagrams, Test Point Overviews, and Waveforms

EN 9TC5.1L CB 6.

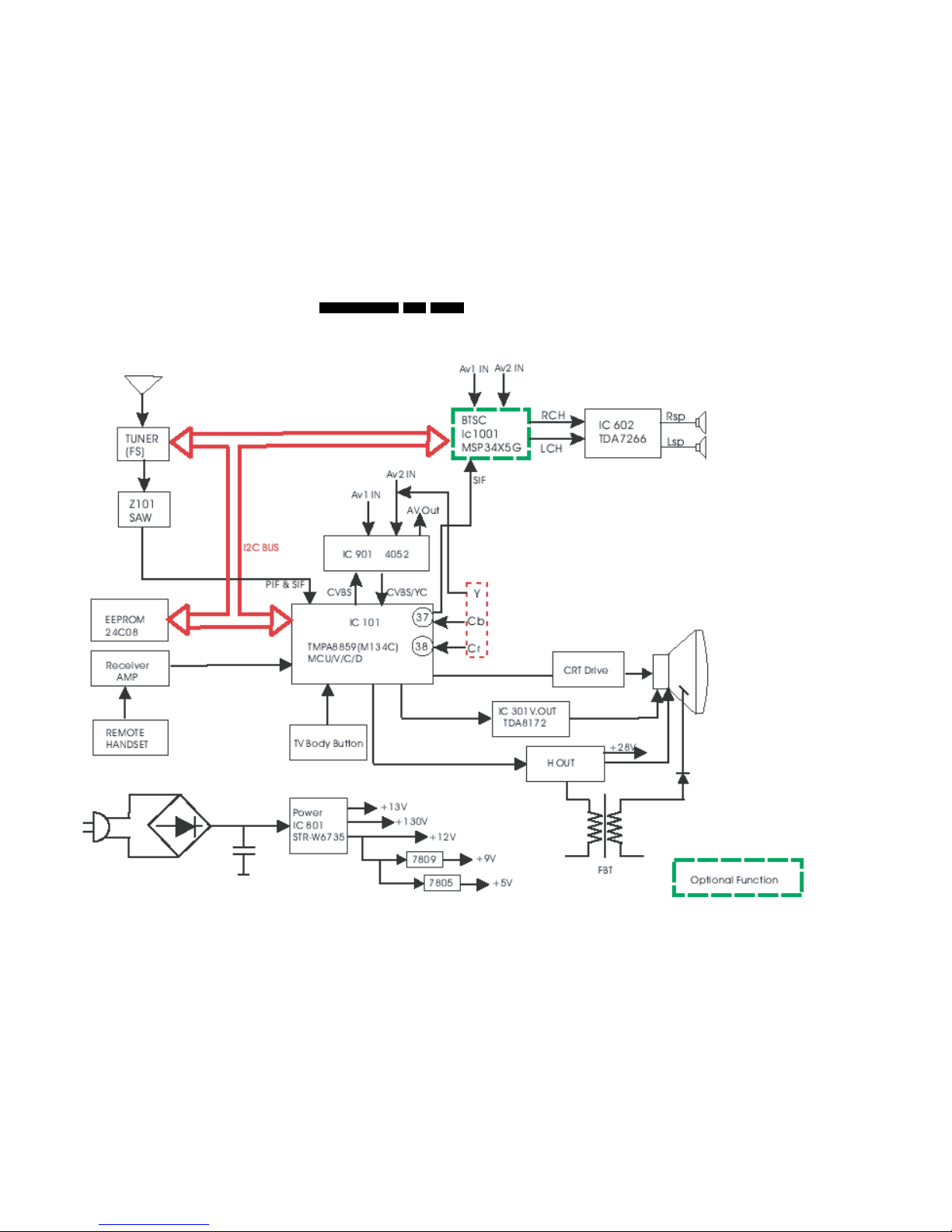

6. Block Diagrams, Test Point Overviews, and Waveforms

Chassis Block Diagram

H_17510_009.eps

021107

* /44 sets use STR-W6756

Loading...

Loading...