Page 1

SureSigns VS4

Vital Signs Monitor

Release A.06

English

Service Guide

Page 2

Page 3

SureSigns VS4

Vital Signs Monitor

SERVICE GUIDE

Release A.06

English

Page 4

Notice

Proprietary Information

This document contains proprietary information, which is protected by copyright.

Copyright

© 2015 Koninklijke Philips N.V., All Rights Reserved

Trademark Acknowledgments

SureSigns is a registered trademark of Koninklijke Philips N.V. Other product names may be

trademarks of their respective owners.

This software is based in part on the work of the Independent JPEG Group.

Manufacturer

Philips Medical Systems

3000 Minuteman Road

Andover, MA 01810-1085

(978) 687-1501

Document Number

4535 645 72701

Warranty Disclaimer

The information contained in this document is subject to change without notice. Philips Medical

Systems makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Philips Medical

Systems shall not be liable for errors contained herein or for incidental or consequential damages

in connection with the furnishing, performance, or use of this material.

Printing History

New editions of this document incorporate all material updated since the previous edition. Update

packages may be issued between editions and contain replacement and additional pages to be

merged by a revision date at the bottom of the page. Pages that are rearranged due to changes on

a previous page are not considered revised.

The documentation printing date and part number indicate its current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates that are incorporated at

reprint do not cause the date to change.) The document part number changes when extensive

technical changes are incorporated.

First Edition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . October 2015

ii SureSigns VS4 Service Guide

Page 5

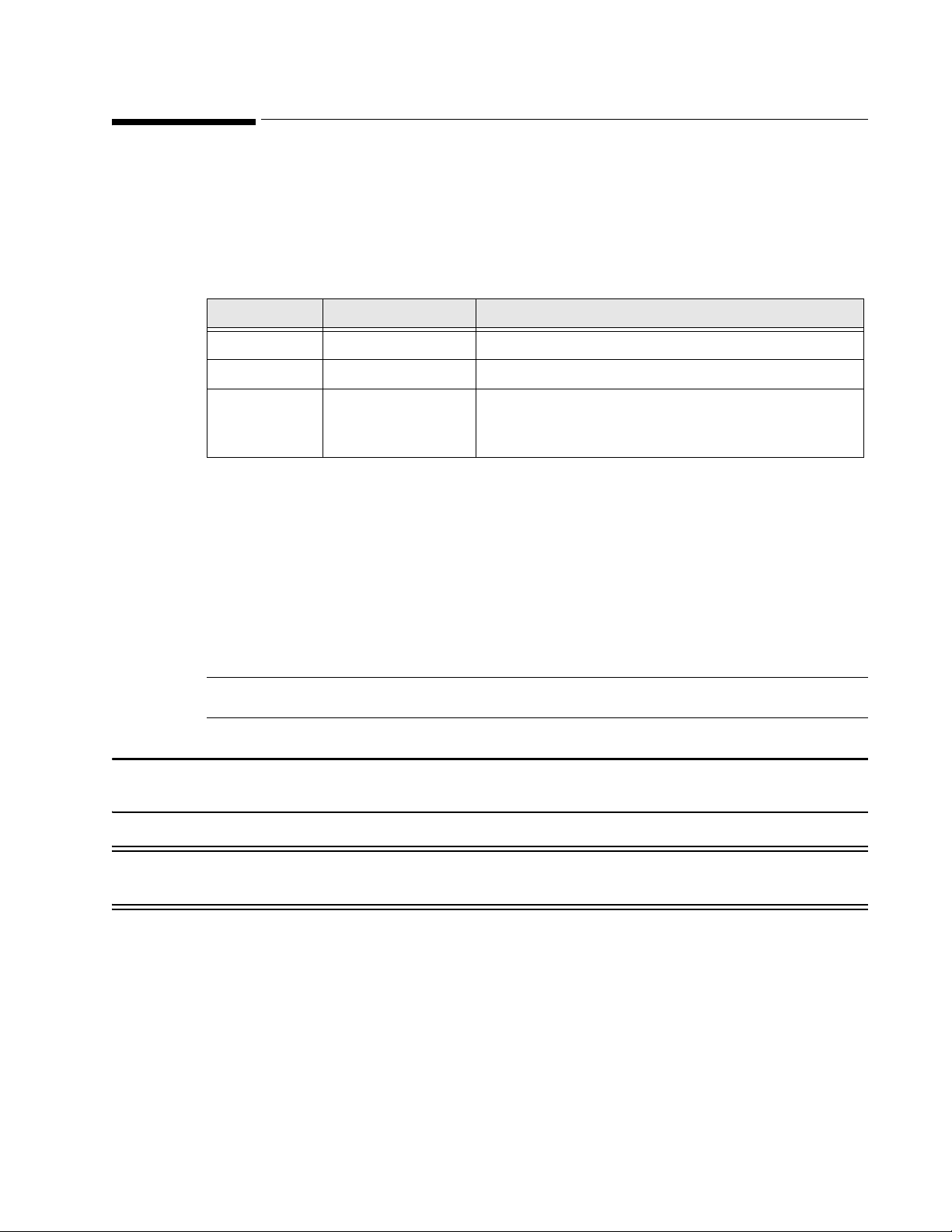

Conventions

This section describes the conventions used in this guide.

Text Formatting

The following typographical conventions are used in this guide.

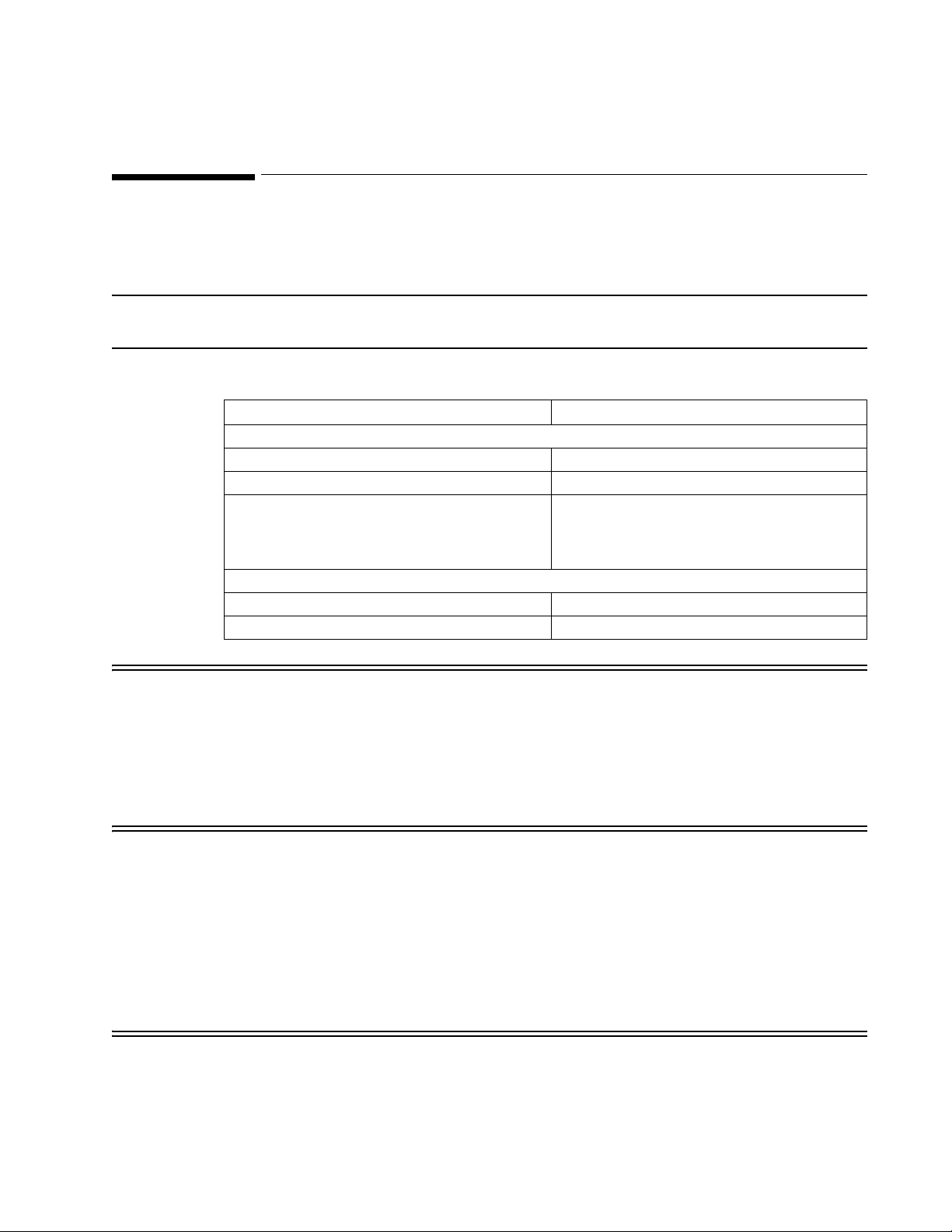

Typeface Usage Example

Bold System keys Press the Main Screen key.

Special bold User interface text Open the System Menu.

Italic Variables,

ocument titles

d

• <product name>-<hardware

configuration>-<software version>.cfg

• SureSigns VM Series Instructions for Use

Decimal Points

Because the SureSigns monitor uses a period (.) to indicate a decimal point in decimal numbers (for

example, 10.0), all decimal numbers in this guide use a period as a decimal point. Commas are not

used as decimal points.

Notes, Cautions, and Warnings

The guide uses the following conventions for Notes, Cautions, and Warnings.

Note — A Note calls attention to an important point in the text.

Caution A Caution calls attention to a condition or possible situation that could damage or destroy the

product or the user’s work.

Warning A Warning calls attention to a condition or possible situation that could cause injury to the user

and/or patient.

SureSigns VS4 Service Guide iii

Page 6

Explanation of Symbols

40°C

-20°C

90%

15%

90%

15%

0123

1014 hPA

708 hPA

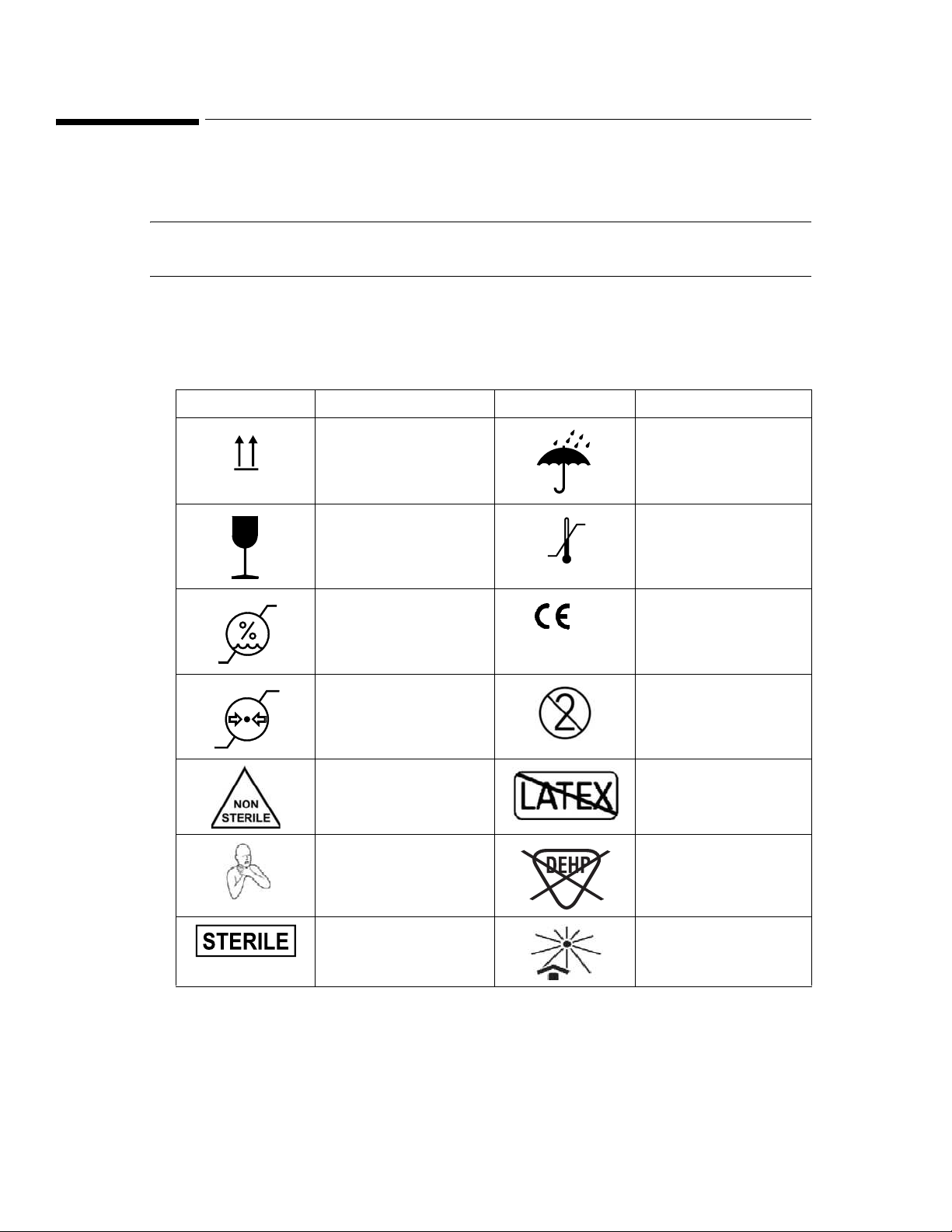

This section explains the symbols that appear on the monitor and its packaging

Packaging

Note — The symbols that appear on your monitor depend on the monitor model and its

configured options.

The following symbols appear on the monitor’s packaging:.

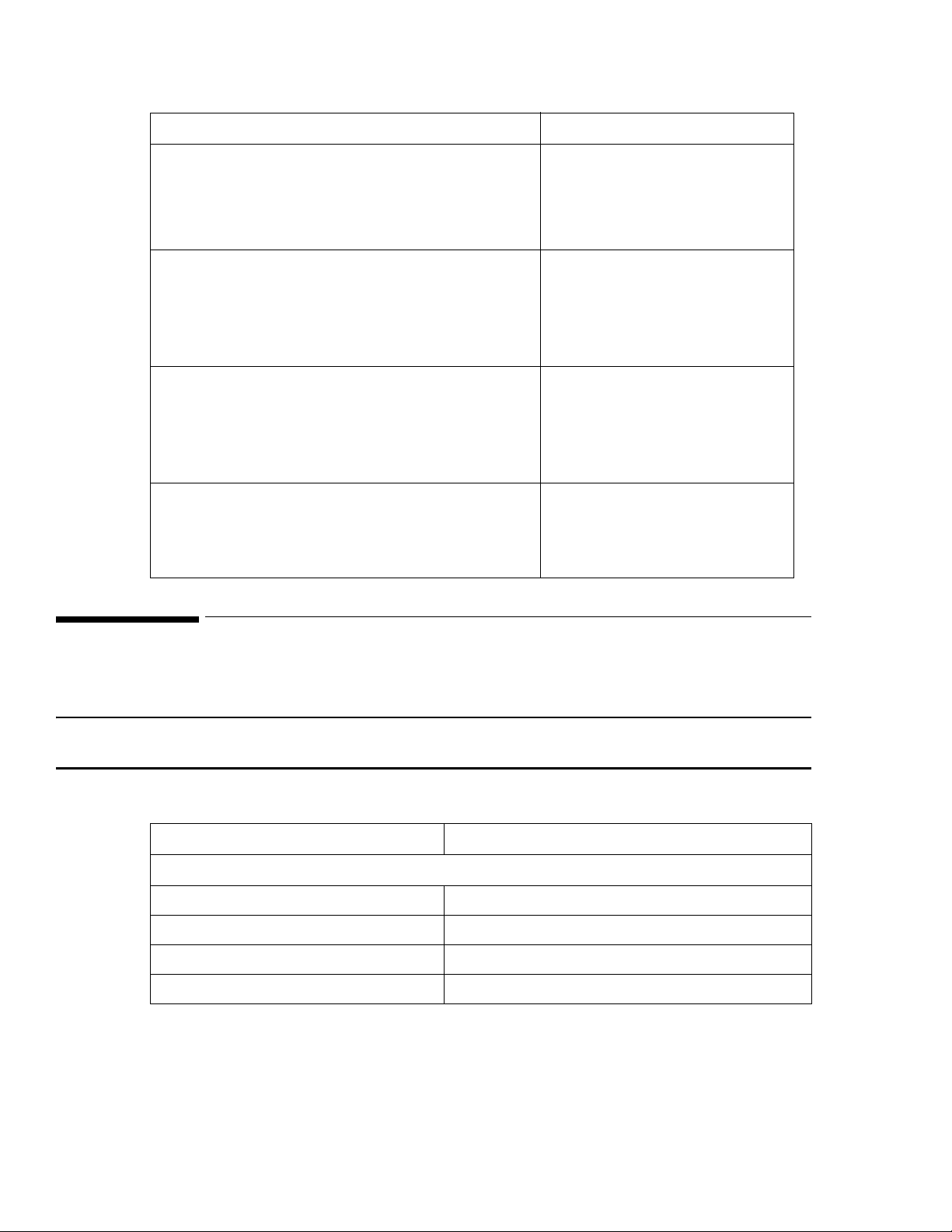

Symbol Description Symbol Description

Keep upright Keep dry

Fragile, handle with

care

Humidity limitation

Atmospheric pressure

limitation

Temperature limitation

CE marking

Single Use

Non-Sterile No Latex

Choking Hazard DEHP-free

Sterile Keep out of sun

iv SureSigns VS4 Service Guide

Page 7

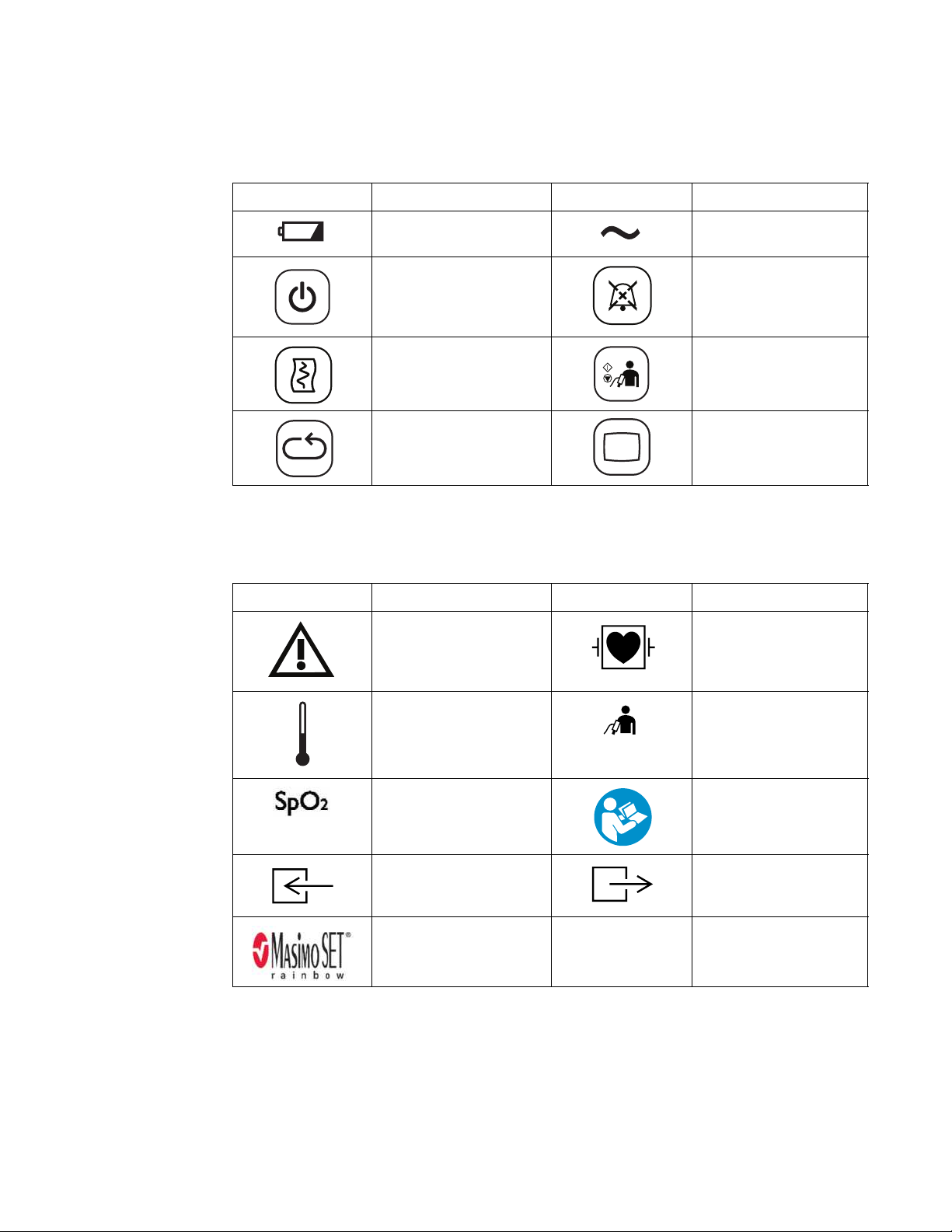

User-Control Symbols

The following symbols appear on and near the user-control buttons on the front of the monitor:.

Symbol Description Symbol Description

Battery charging LED AC Power LED

On/Standby key Alarm Silence key

Print key NBP key

NBP Interval key Main Screen key

Measurement Connector Symbols

The following symbols appear next to the measurement connectors on the side of the monitor:.

Symbol Description Symbol Description

Caution, consult

accompanying

documents

Temperature connector NBP connector

SpO2 connector Follow Instructions for

CO2 input connector CO2 output connector

Masimo SET® (red and

black symbol)

Defibrillator Proof Type

CF applied part

Use (Blue safety

symbol)

SureSigns VS4 Service Guide v

Page 8

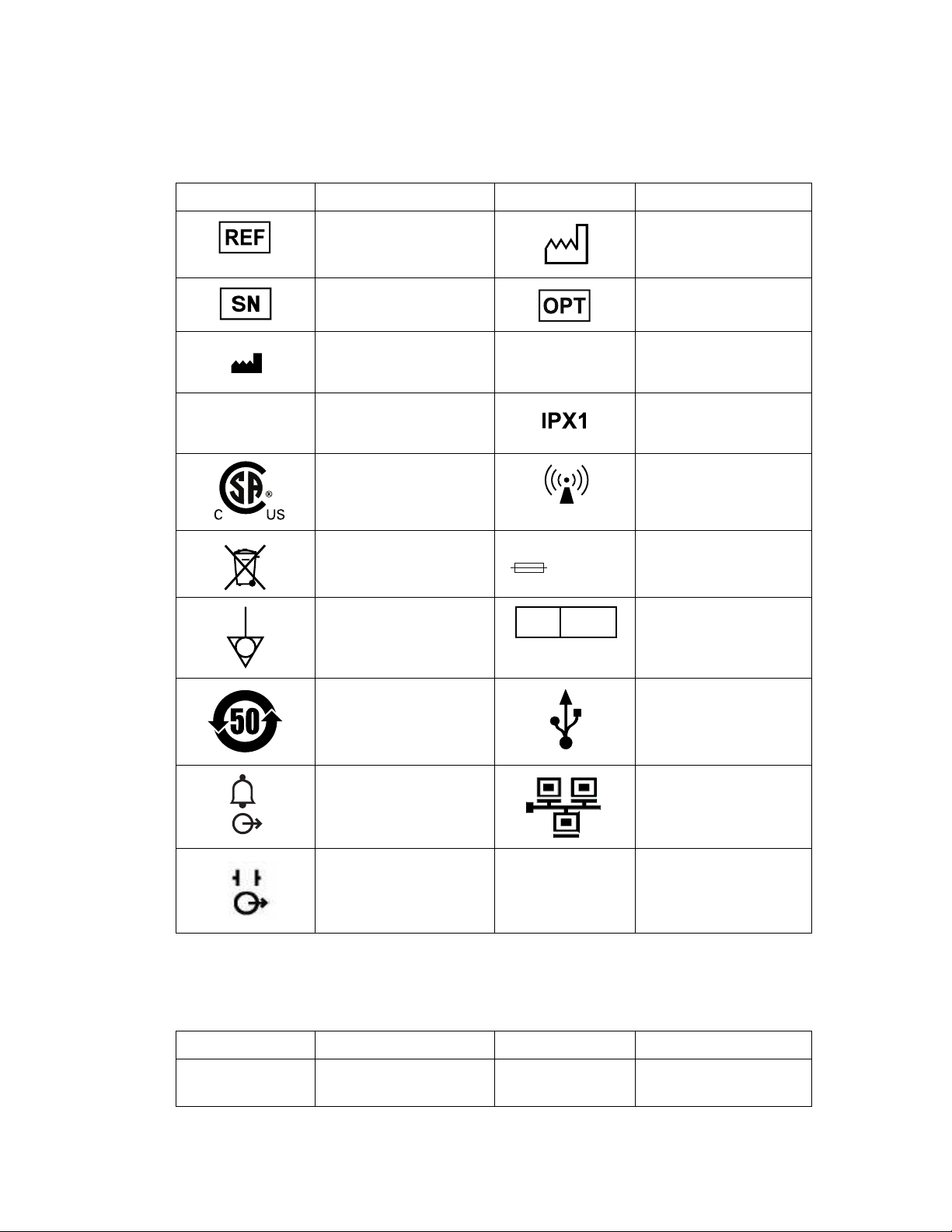

Rear Panel Label Symbols

Rx only

ICES-001

100-240V ~ 50/60Hz 120VA

T1.6A 250V

EC REP

FCC ID

IC ID

The following symbols appear on the rear panel label of the monitor:.

Symbol Description Symbol Description

Catalog number Date of manufacture

Date of first calibration

Serial number Option number

Manufacturer’s Name

and Address

Canadian ISM

requirement

CSA mark RF Interference

Compliance with WEEE

standard

Equipotential

grounding post

EUFP

(Environmentally

frie

ndly

use period - China)

Nurse call connector Ethernet port

Prescription Use Only

(US Federal Law)

Ingress protection to

vertically falling water

drops

Input power and fuse

rating

Authorized EU

Representative

USB port

Radio Symbols

vi SureSigns VS4 Service Guide

ECG Out port

This port is not

av

ailable for use.

The following symbols are available when the monitor uses the radio accessory:

Symbol Description Symbol Description

FCC label for radio

Industry Canada label

for radio

Page 9

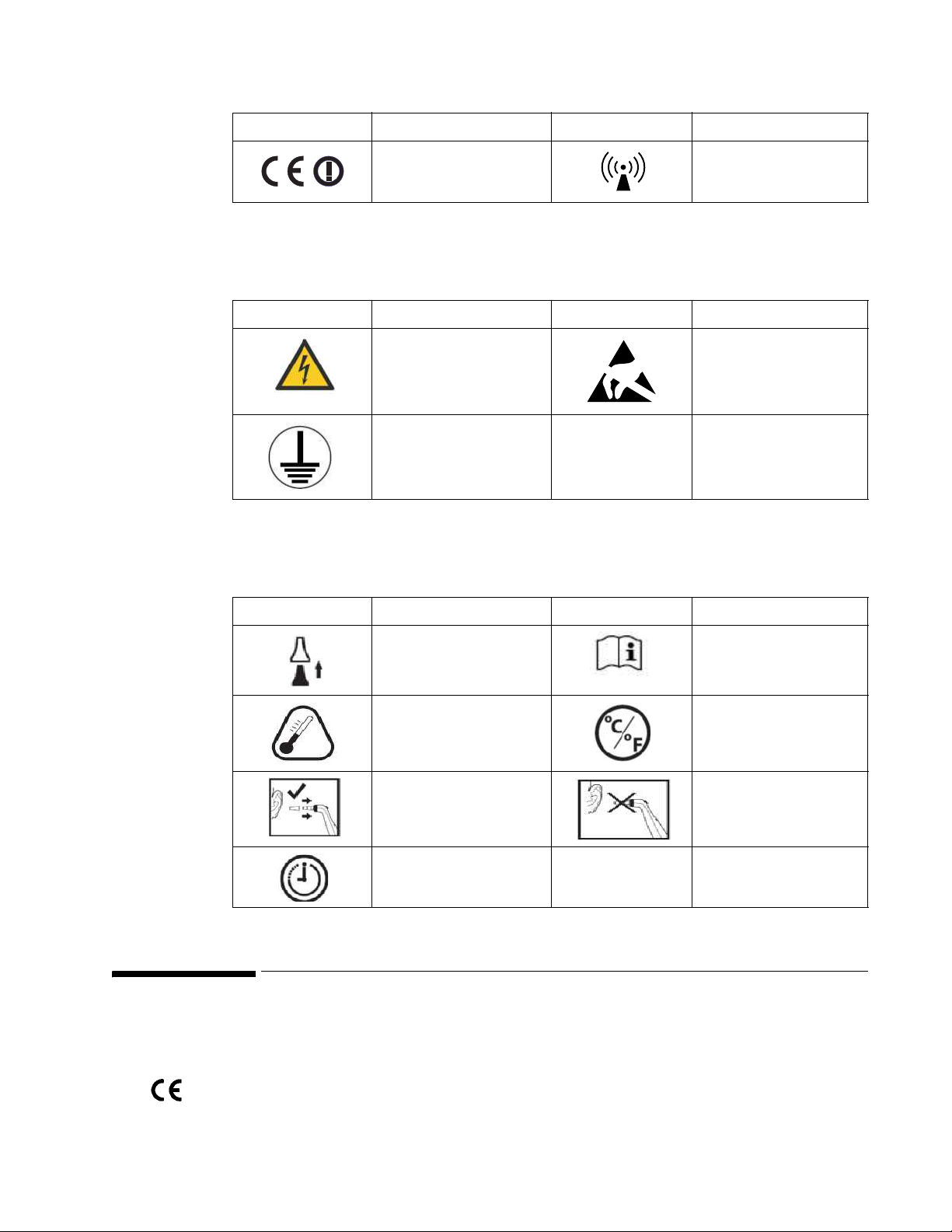

0123

Symbol Description Symbol Description

Internal Symbols

The following symbols are located inside the monitor::

Symbol Description Symbol Description

Side Mount Accessories

The following symbols are located on the side mount:

CE marking and

ier for radio

identif

Dangerous voltage

(Yellow safety symbol)

Protective earth ground

RF Interference

Electrostatic sensitive

device handling

Symbol Description Symbol Description

Eject key Consult instructions for

Scan key

Probe cover installed Probe cover not

Timer key

Regulatory and Safety Specifications

Declaration

use

°C/°

F key

installed

The SureSigns VS4 monitor is a Class IIb device and complies with the requirements of the Council

Directive 93/42/EEC of 14 June 1993 concerning medical devices and carries CE-marking

accordingly.

SureSigns VS4 Service Guide vii

Page 10

The radio device used in the SureSigns VS4 vital signs monitors are in compliance with the essential

requirements and other relevant provisions of Directive 1999/5/EC (Radio Equipment and

Telecommunications Terminal Equipment Directive).

Authorized EU Representative

Philips Medizin Systeme Böblingen GmbH

Hewlett-Packard Str. 2

71034 Böblingen

Germany

Australia Sponsor

Philips Healthcare

65 Epping Road, North Ryde

NSW, Australia 2113

Rx Only

Caution United States Federal Law restricts this device to sale by or on the order of a physician.

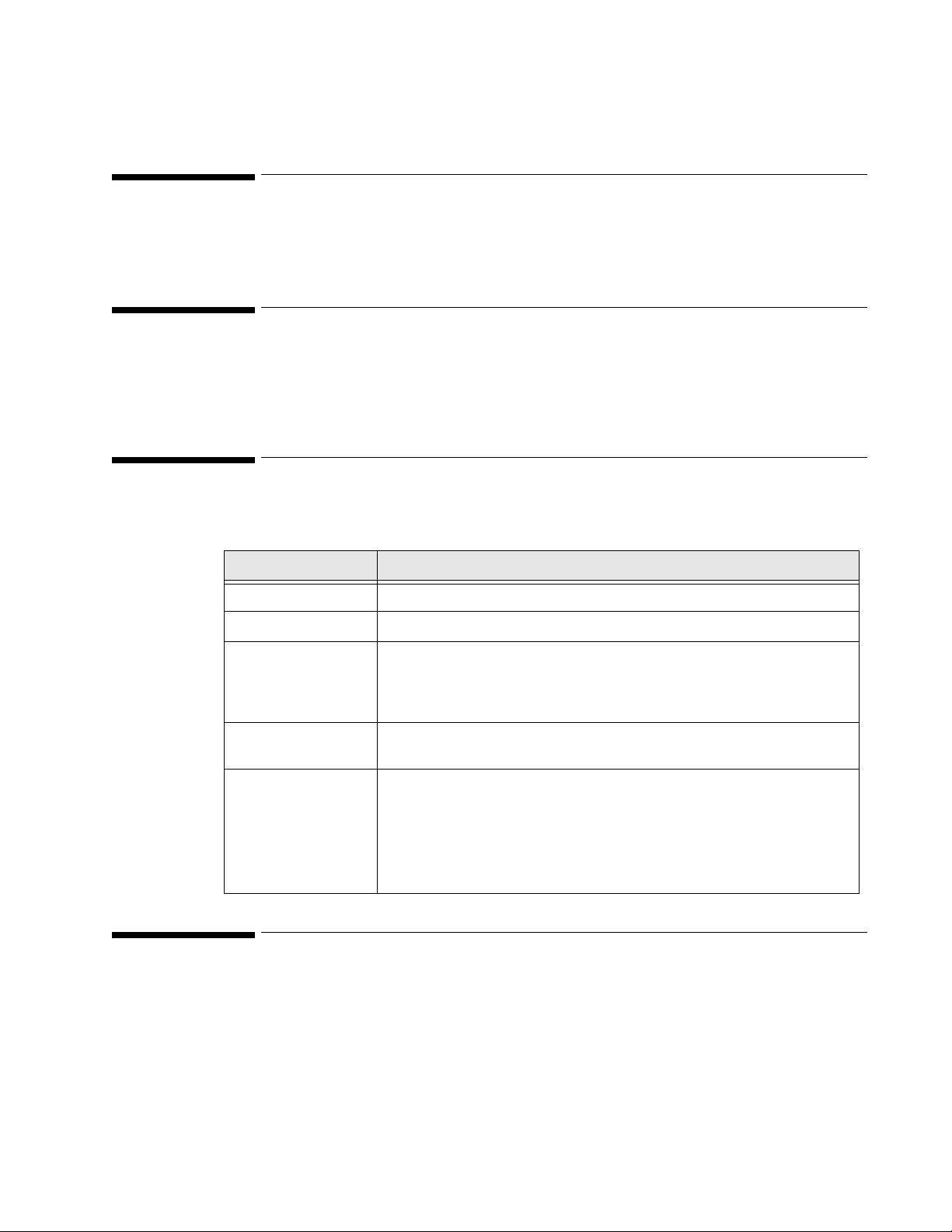

Safety Standards

Parameter Specification

IEC 60601-1:2005 +CORR. 1 (2006) + CORR. 2 (2007)

IEC 60601-1-2:2007 (R2012)

IEC 80601-2-30:2009, IEC 60601-1-6:2010,

IEC 60601-1-8:2006

IEC 60601-2-49:2011, ISO 80601-2-55:2011

ISO 80601-2-56:2009, ISO 80601-2-61:2011

Protection Class Class I, internally powered equipment, per IEC 60601-1

Degree of Protection Type CF defibrillator-proof: per IEC 60601-1

Mode of Operation Continuous

Protection Against Hazards of

Ignition of Flammable

Anaesthetic Mixtures

Equipment is not suitable for use in the presence of a flammable

anaesthetic mixture with air or oxygen or nitrous oxide, per IEC

60601-1

viii SureSigns VS4 Service Guide

Page 11

Contents

1. Overview

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Navigation Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SureSigns VS4 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Performing Routine Maintenance

Recommended Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Routine Safety and Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cleaning and Disinfecting the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Maintaining the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

About the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Viewing Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Reconditioning the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Battery Messages and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Technical Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

3. Performance Verification Testing

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Testing and Inspection Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Recommended Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Test Recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Accessing the System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Accessing the System Admin Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

System Admin Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Enabling Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Upgrading the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Registering for Software Upgrades from Philips InCenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Performing Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Accessing the System Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Accessing Maintenance Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Visual Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Alarms Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

SpO

2

CO2 Calibration Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Gas Measurement Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

CO

2

Calibrating the CO

NBP Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

NBP Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

NBP Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Pneumatic Leakage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Predictive Temperature Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Tympanic Temperature Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Enclosure Leakage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Expected Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Expected Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Ground Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Expected Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2

SureSigns VS4 Service Guide

Contents-1

Page 12

Patient Leakage Current With Mains Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Expected Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Nurse Call Relay Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Calibrating the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

4. Troubleshooting

When You Cannot Correct a Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Viewing System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Diagnosing a Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Start-up and Power Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Troubleshooting Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Power Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Display Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Alarm Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

NBP Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Temperature Measurement Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Measurement Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

SpO

2

Measurement Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

etCO

2

Navigation Wheel, Touch Screen, and Key Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Recorder Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Nurse Call Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

USB Hub Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Security Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Running System Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Running the Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Testing the Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Testing the Navigation Wheel and Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Testing the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Testing the Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Testing the Battery LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Viewing and Resetting Tracked Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Resetting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Viewing, Printing, and Exporting the Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Clearing Patient Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

5. Repairing the Monitor

Disassembling the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Tools Required for Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Shutting Down the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Removing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Reinstalling the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Removing a Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Removing the Predictive Temperature Module and Probe Cover Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Reinstalling the Predictive Temperature Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Removing the Tympanic Temperature Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Removing the Temporal Temperature Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Removing the CO

Separating the Front and Rear Case Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Removing the Faceplate or Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Removing the Main Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Removing the Fan and Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Replacing the Handle O-Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Contents-2

SureSigns VS4 Service Guide

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

2

Reassembling the Front and Rear Cases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Removing the Main Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

Reinstalling the Main Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Page 13

Removing the Front End Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Replacing the SpO2 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Determining the Type of SpO2 Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Removing the Philips SpO

Removing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Removing the Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Resetting the Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Setting the System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Removing the NBP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Removing the NBP Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Removing the AC Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

Removing the Communications (LAN) Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Removing the Battery Connector Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Removing the LCD Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Removing the Navigation Wheel Assembly Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Removing the Touch Screen Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Removing the Wireless Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Removing the Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

2

6. Replacement Parts and Assembly Drawings

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Power Cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

A. Theory of Operation

Block Diagram Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Main Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Front End Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Communications (LAN) Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Nurse Call Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Front Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Navigation Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

NBP Assembly and Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Philips SpO

Masimo SpO2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Predictive Temperature Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Predictive Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Monitored Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Tympanic Temperature Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Temporal Temperature Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

2

B. Electromagnetic Compatibility

Instructions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Reducing Electromagnetic Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Restrictions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Emissions and Immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Guidance and Manufacturer’s Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Recommended Separation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

SureSigns VS4 Service Guide

Contents-3

Page 14

Contents-4

SureSigns VS4 Service Guide

Page 15

Intended Audience

This guide is for biomedical engineers or technicians responsible for troubleshooting, repairing,

and maintaining Philips patient monitoring systems.

About This Guide

This guide includes information about current hardware. For information about earlier versions of

the hardware, see an earlier version of the Service Guide on the SureSigns VS3 and VS4 Service

Documentation CD.

Navigation Controls

The following table describes how to use the navigation controls on the SureSigns® VS4 monitor:

1

Overview

Action Description

Select Touch a button, menu, or list item on

Press Press a front panel key

Enter data using

the nume

keypad and

keyboard

Select or clear

check boxes

Scroll Touch the list and drag your finger to scro

ric

Touch the item to display the numeric keypad or the keyboard. Touch

the values, and then touch OK to close the keypad or keyboard.

Touch a check box to select or clear it.

Up or Down arrows to display the next or previous page in the list.

(You can also use the wheel to scroll and select items in the list.)

A scroll bar to the right of the list indicates the current location in the

list.

Touch an item to select it.

SureSigns VS4 Documentation

SureSigns VS4 documentation includes:

the touch screen to select it.

or press the wheel.

ll up and down. Touch the

• SureS

• SureSigns VS4 Instructions f

igns VS4 Installation and Configuration Guide: Provides instructions for unpacking,

installing, and connecting all hardware. Includes initial testing and configuration

procedures. Also includes instructions for returning the monitor.

or Use: Provides information for day to day operation of the

monitor. Also includes safety information, monitor specifications, and a list of compatible

accessories.

Overview

SureSigns VS4 Service Guide 1-1

Page 16

SureSigns VS4 Documentation

• SureSigns VS4 Quick Card: Provides brief descriptions of commonly used functions.

• SureSigns VS4 Service Guide: Provides instructions for repairing and testing the monitor.

Includes assembly diagrams, spare parts lists and troubleshooting information.

• SureSigns VS4 Data Export Guide: Provides detailed information about the HL7 data export

feature, including HL7 message syntax and procedures for exporting HL7 data from the

monitor.

• SureSigns VS4 Network Configuration Guide: Provides instructions for configuring your

monitor to connect to a network using a wired LAN connection, a wireless LAN connection, or

an RS-232 serial adapter.

• SureSigns VS4 QuickCapture Configuration Guide: Provides instructions for configuring the

QuickCapture feature on the monitor. Includes information about defining the set of

observations and assessments, creating a file to import that information into the monitor, and

mapping the exported data to an EHR.

• SureSigns VS4 QuickAlerts Configuration Guide: Provides instructions for planning and

configuring the QuickAlerts feature on the SureSigns VS4 monitor. Includes information about

defining the set of alert messages, creating a file to import that information into the monitor,

and mapping the exported data to an EHR.

Overview

1-2 SureSigns VS4 Service Guide

Page 17

Performing Routine Maintenance

Recommended Frequency

Perform the maintenance procedures at the recommended frequency shown in the following

table.

2

Caution The frequency recommendations in the following table do not supersede local requirements.

Always perform locally required testing in addition to the testing in this chapter.

Maintenance Procedure Frequency

Routine Safety and Operational Checks

• Visual Inspection of exterior for damage Before use.

• Inspection of labels for legibility Before use.

Cleaning and Disinfecting According to your institution’s policy or

between each patient. For complete

cleaning instructions, see the Instructions for

Use provided with your monitor.

Maintaining the Battery

• Charging As needed.

• Reconditioning When the Max Error is 10% or greater.

Warning The monitor must be connected to a three-wire, grounded hospital-grade receptacle. Do not

remove the grounding connector from the power plug or use extensions cords or adapters of

any type.

If there is any doubt about the integrity of the protective earth conductor arrangement,

operate the device on internal battery power until the AC power supply protective conductor

is fully functional.

Measure the device's leakage current whenever an external device is connected to the serial

port. Leakage current must not exceed 100 microamperes. See “Safety Tests” on page 3-22.

Warning MR-unsafe!

Do not expose the device to a magnetic resonance (MR) environment.

• The device may present a risk of projectile injury due to the presence of ferromagnetic

materials which can be attracted by the MR magnet core.

• Thermal injury and burns may occur due to the metal components of the device which can

heat during MR scanning.

• The device may generate artifacts in the MR image.

• The device may not function properly due to the strong magnetic and radio frequency

fields generated by the MR scanner.

Performing Routine Maintenance

SureSigns VS4 Service Guide 2-1

Page 18

Routine Safety and Operational Checks

Routine Safety and Operational Checks

Philips recommends that you regularly:

• Visually inspect the monitor exterior for damage.

• Ensure the vents are free of dust.

• Inspect the monitor labels for legibility.

If the labels on the rear case are not legible, you must replace the rear case. If the serial

number label is not legible, you must return the monitor for label replacement. For detailed

information, see “Visual Test” on page 3-13.

Philips recommends that you perform certain test and verification checks at least once a year and

after each repair. For complete information about performing verification testing and checks, see

Chapter 3, “Performance Verification Testing.”

Cleaning and Disinfecting the Monitor

To clean or disinfect your monitor, use only cleaning agents approved by Philips. For complete

cleaning instructions, see the Instructions for Use provided with your monitor.

Maintaining the Battery

About the Battery

The rechargeable lithium ion battery used in the monitor is a smart battery with built-in circuitry

that communicates battery status information to the monitor. Battery power lasts a minimum of

four hours of continuous monitoring with no printing and one NBP measurement every 15 minutes.

Observe these guidelines:

• If a battery shows damage or signs of leakage, replace it immediately.

• Never use a faulty battery in the monitor.

• Never dispose of the battery in a normal waste container.

• Never leave a battery inside the monitor if it is not used for a long period of time.

• Never store a battery that is more than 50% charged.

Note — For information about the battery status indicators, see the Instructions for Use provided

with your monitor.

Viewing Battery Information

As a battery ages, its capacity decreases and the battery status indicator becomes increasingly less

accurate, relative to the total number of charges and discharges. Select the Battery Info button to

display information about the battery.

Performing Routine Maintenance

2-2 SureSigns VS4 Service Guide

Page 19

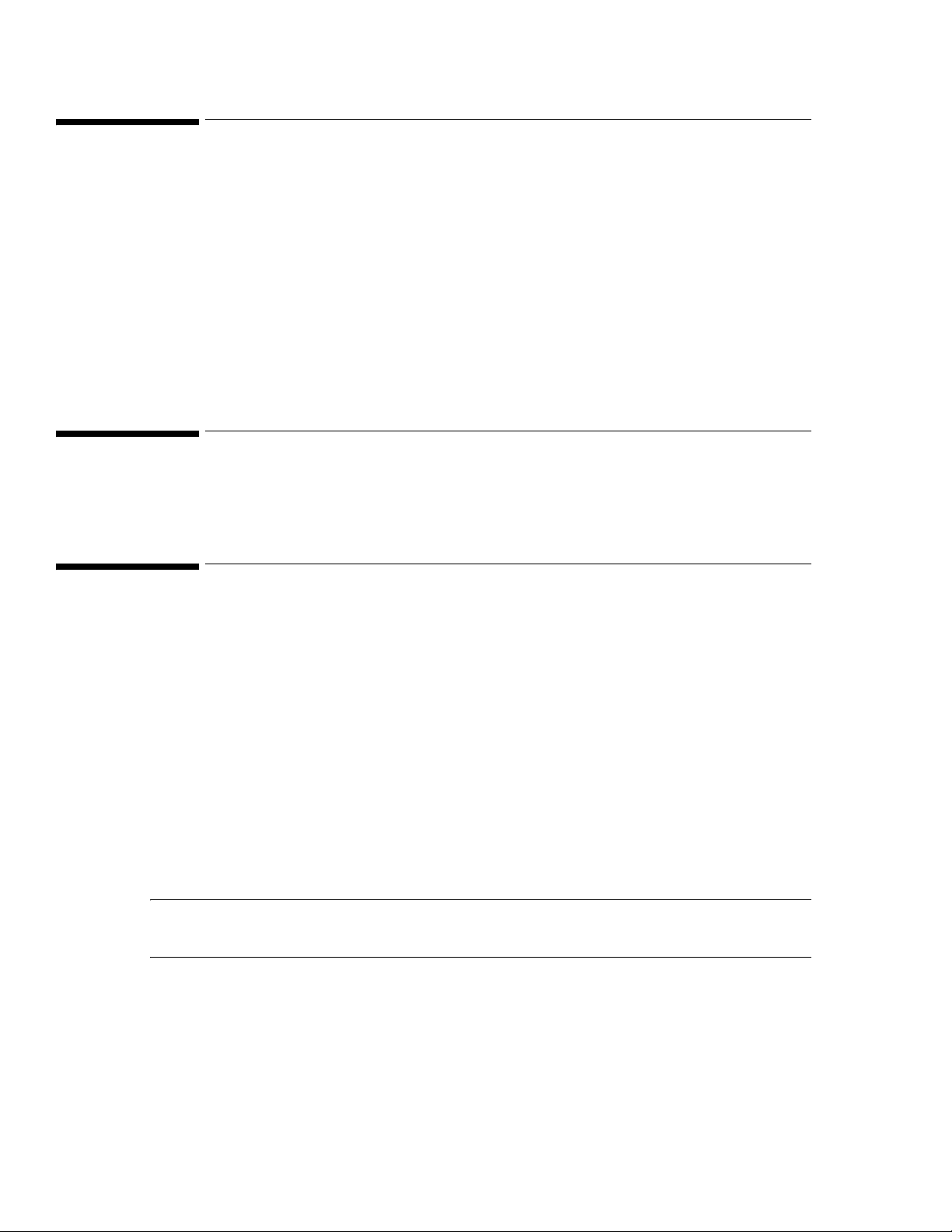

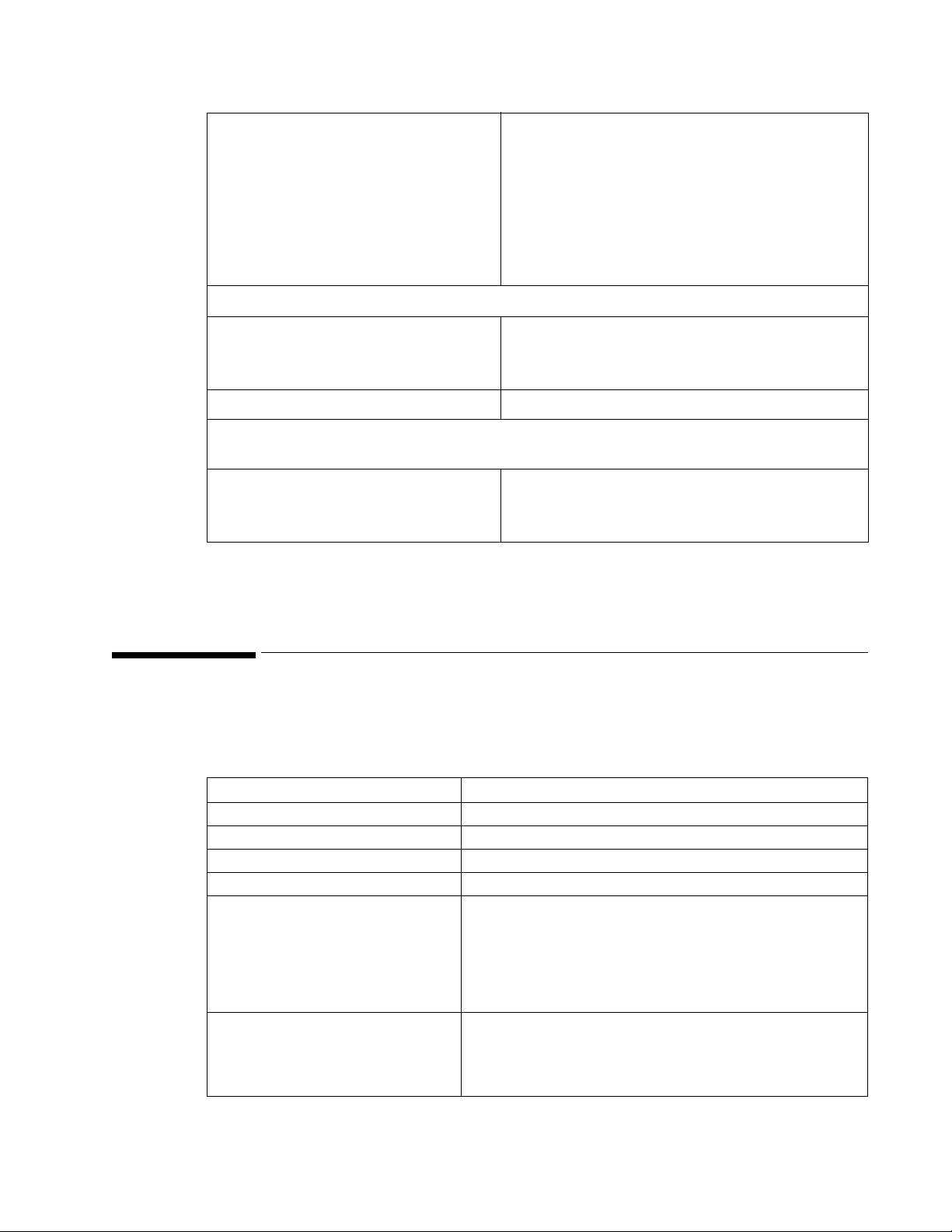

To view information about the battery:

Battery Info

06/27/13

95

Manufact. Date

Cycle Count

2%Max Error

ReturnRecondition

EONEMOLI

LION

Manufacturer

Chemistry

#17403Serial Number:

99%

97%

Relative Charge

Absolute Charge

E013RBattery Name

12503 (mV)Voltage

664 (mA)Current

299.50 (K) 26.50(C)Temperature

7100 (mAH)Full Capacity

7200 (mAH)Design Capacity

Parameter

Value

Step

Maintaining the Battery

1 Open the Sy

on page 3-11.

2 Select the

Battery Info button.

The Battery Info window opens.

stem Diagnostics Menu. See “Accessing the System Diagnostics Menu”

The Battery Info

including:

Note — If the message, No data from battery. Please see Service Guide. appears,

you must reseat the battery. For detailed information, see “Removing the Battery”

on page 5-3.

3 To view the entire list of results, select the list to

window provides detailed information about battery capacity and charging status,

• Cycle Count: The number of full charge and discharge cycles calculated by the battery.

• Max Error: The expected margin of error in the state of the charge calculation. The Max Error

value is the difference between the Relative Charge value and the Absolute Charge value.

• Relative Charge: The predicted remaining battery capacity, expressed as a percentage of Full

Capacity. The value in the Relative Charge field decreases as the battery ages. The Battery

Status icon

is a graphic representation of the Relative Charge.

• Absolute Charge: The predicted remaining battery capacity, expressed as a percentage of

Design Capacity.

ll Capacity: The predicted capacity of the battery when it is fully charged. The value in the

• Fu

Full Capacity field decreases as the battery ages. The difference between the value in the

Full Capacity field and the value in the Design Capacity field is an indication of battery

condition.

sign Capacity: The capacity of a new battery.

• De

activate scrolling.

Performing Routine Maintenance

SureSigns VS4 Service Guide 2-3

Page 20

Maintaining the Battery

Reconditioning the Battery

Reconditioning the battery reduces the Max Error value, and in turn, increases the accuracy of the

Relative Charge. Philips recommends that you condition the battery by fully discharging and

recharging it when the Max Error is 10% or greater.

Step

1 Open the Battery Info window.

2 Disconnect the monitor from

3 Select Recon

The Relative Charge percentage will decrease to 0%.

4 When the monitor shuts down, connect the monitor to the power source and allow

the ba

5 Repeat step 1 through step 4.

Note — If the battery does not recharge after four reconditioning cycles, replace it.

Replacing the Battery

Replace the battery if the following conditions occur:

• After reconditioning, if the monitor operates for less than one hour on a fully charged battery

before the low battery (Low Batt) alarm occurs, or

•The Max Error cannot be brought <= 8% after several recondition cycles, or

•The Full Capacity is 50% or less of the Design Capacity.

For information about replacing the battery, see “Removing the Battery” on page 5-3.

See “Viewing Battery Information” on page 2-2.

the power source.

dition.

ttery to recharge to 100%.

Warning Dispose of used batteries in an environmentally responsible manner. Do not dispose of the

battery in normal waste containers. Consult your hospital administrator to find out about local

arrangements.

Battery Messages and Alarms

The condition of the battery is reported by technical alarms and error codes.

Technical Alarms

The following battery technical alarms appear in the message area:

• Low Batt — Remaining battery power is less than 30%.

• E

xtreme Low Batt — Remaining battery power is less than 21%.

Error Codes

An error code (for example, 257 System Error, indicating Battery charger power failure) appears in

the Error Log. To view the Error Log, see “Viewing, Printing, and Exporting the Error Log” on

page 4-38. For a complete list of error codes and actions

Performing Routine Maintenance

2-4 SureSigns VS4 Service Guide

to take, see Chapter 4, “Troubleshooting.”

Page 21

Overview

3

Performance Verification Testing

This chapter includes the following information:

• Testing and inspection guidelines

• Recommended frequency of performance tests

• Test procedures following monitor repair or during routine maintenance

• NBP calibration procedure

If the monitor fails any test, it must be repaired before it is returned to use.

Note — The procedures in this chapter assume knowledge of basic monitor operation. For

details about using the monitor, see the Instructions for Use provided with your

monitor.

Testing and Inspection Guidelines

The following table lists the tests that Philips requires that you complete after performing

monitor repairs or upgrading the software.

For information about routine maintenance procedures, see Chapter 2, “Performing Routine

Maintenance.”

For information about repair procedures, see Chapter 5, “Repairing the Monitor.”

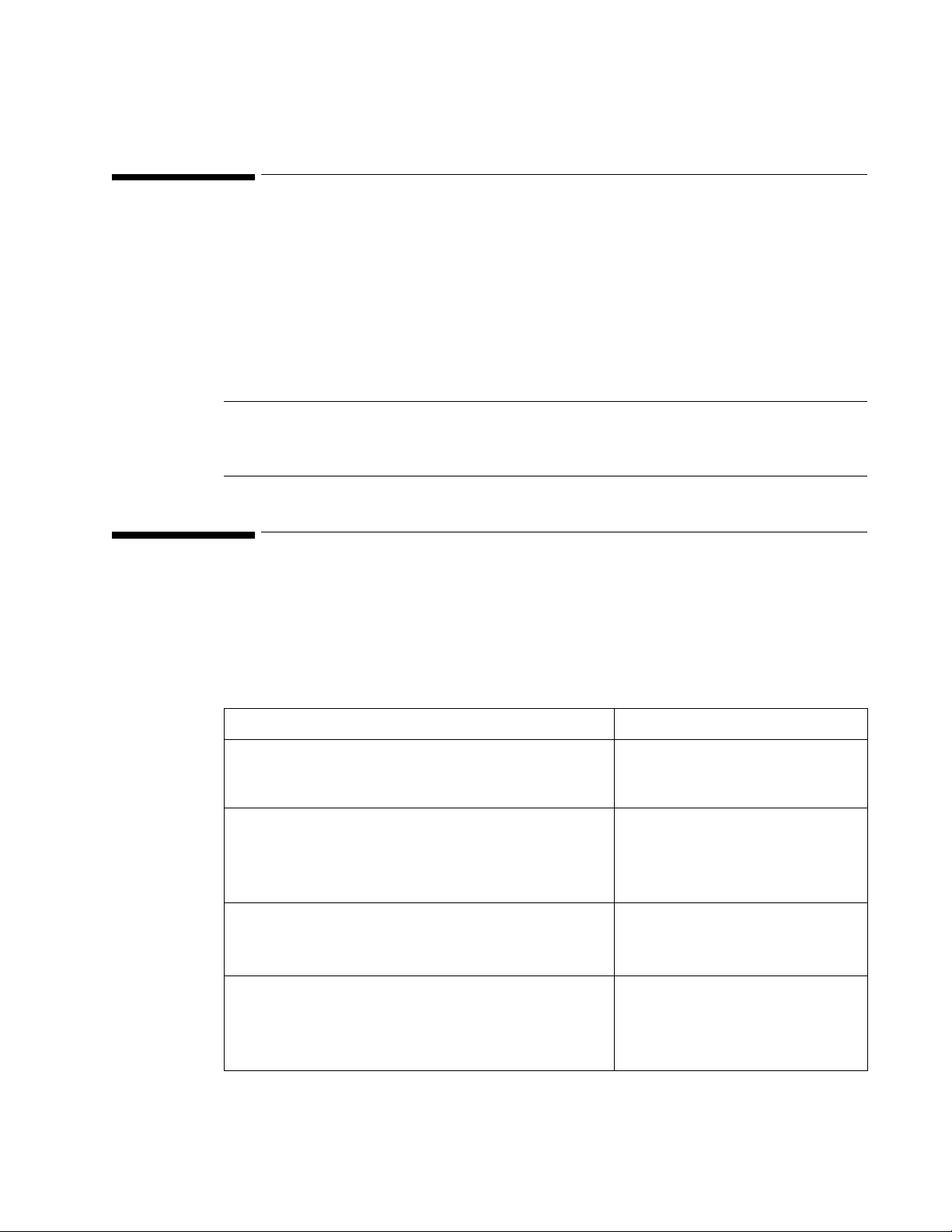

After Complete These Tests

Upgrading the software • Power-on self test

Opening the monitor for any reason • Power-on self test

Replacing any internal parts (except NBP parts, SpO2

board)

Replacing the NBP module or parts • Power-on self test

• Verify that your system

settings are preserved

• Alarms test

• Pneumatic leakage test

• All safety tests

• Power-on self test

• Pneumatic leakage test

• All safety tests

• NBP test

• Pneumatic leakage test

• All safety tests

Performance Verification Testing

SureSigns VS4 Service Guide 3-1

Page 22

Recommended Frequency

After Complete These Tests

Replacing the Philips SpO2 board

Note — Monitors with the Masimo SpO

board must

2

be returned to Philips for Masimo SpO2 board

replacement. Contact the Philips Customer Care Center

or your local Philips representative.

• Power-on self test

•SpO

2

• Pneumatic leakage test

• All safety tests

Replacing the temperature module • Power-on self test

• Alarms test

• Pneumatic leakage test

• All safety tests

• Temperature test

Replacing the LCD • Power-on self test

• Alarms test

• Pneumatic leakage test

• All safety tests

• Touch Screen Calibration

Replacing the CO2 module • Power-on

•CO2 calibration

• Pneumatic leakage

• All safety tests

Recommended Frequency

Perform the test procedures at the recommended frequency outlined in the following table.

Caution The frequency recommendations in the following table do not supersede local requirements.

Always perform locally required testing in addition to the testing outlined in the table.

Suggested Testing Frequency

Preventive Maintenance

NBP calibration Once every two years.

Battery reconditioning When the Max Error is 10% or greater.

Tympanic temperature calibration

Temporal Temperature calibration

1

2

Once a year.

Once a year.

Performance Verification Testing

3-2 SureSigns VS4 Service Guide

Page 23

Required Test Equipment

CO2 calibration • First calibration at 1,200 hours of use or after

one year, whichever comes sooner.

• After the first calibration, once a year or after

4,000 hours, whichever comes sooner.

• After any repairs or the replacement of any

parts.

Replace the entire CO2 module after 20,000 hours

of use.

Performance

• Predictive temperature accuracy

• NBP accuracy test

•SpO

2

• Nurse call relay3 Once every two years.

Safety

In accordance with IEC 60601-1

• Enclosure leakage current

• Ground integrity

• Patient leakage current

1.

Requires a Covidien calibration module. For more information, see “Tympanic Temperature Test” on

page 3-22.

2.

Requires an Exergen calibration module.

3.

When used as part of facility protocols.

Required Test Equipment

The following table lists the additional test equipment that you need to perform each of the tests in

this chapter. Many of these tests also use the standard accessories that are shipped with the mo

monitor..

Once every two years, or if you suspect the

measurement is incorrect.

Once a year or after repairs where the monitor has

been opened (front and back separated) or the

monitor has been damaged by impact.

To Perform This Test You Need This Test Equipment

“Visual Test” on page 3-13 None

“Power-On Self Test” on page 3-13 None

“Alarms Test” on page 3-14 NBP cuff and hose

“SpO2 Test” on page 3-14 Adult SpO2 transducer

“CO2 Calibration Test” on

page 3-15

“NBP Test” on page 3-17 • A reference manometer (including hand pump and

• Electronic flowmeter, M1026-60144

• Gas calibration equipment:

– Cal 1 gas 15210-64010 (5% CO2)

– Cal gas flow regulator M2267A

– Cal tube 13907A

valve) with an accuracy 0.2%

• An expansion chamber (volume 250 ml ± 10%)

• Appropriate tubing

Performance Verification Testing

SureSigns VS4 Service Guide 3-3

Page 24

Test Recording

To Perform This Test You Need This Test Equipment

“Predictive Temperature Test” on

page 3-21

“Safety Tests” on page 3-19 A multimeter

“Nurse Call Relay Test” on

page 3-25

Test Recording

Authorized Philips personnel report test results back to Philips to add to the product development

database. Hospital personnel, however, do not need to report results.

The following table describes what to record on the service record after you complete the tests in

this chapter.

Note — P = pass, F = fail, X = measured value as defined in tests in this chapter.

• SureSigns temperature probe

• SureSigns Temperature Calibration Key (part number

4535 640 33691)

• A patient simulator

• An ohmmeter

• A phono connector

Test What to record

Visual V:P or V:F

Power-On PO:P or PO:F

NBP NBP:P/X1/X2/X3 or

NBP:F/X1/X2/X3

CO

2

SpO

2

Safety S(1): P/X1/X2 or

CO2 cal:P or CO2 cal:F

SpO2:P or SpO2:F

S(2): P/X1 or

S(3): P/X1 or S(3): F/X1

Accessing the System Menu

Use the System Menu to configure the monitor, view system information, shut down the monitor,

and access the System Admin Menu. For more information about using the System Menu to

configure the monitor, see the Instructions for Use or the Installation and Configuration Guide

provided with your monitor.

To access the Sy

stem Menu:

S(1):F/X1/X2

S(2): F/X1

• Select the System button.

The Sy

stem Menu appears.

Performance Verification Testing

3-4 SureSigns VS4 Service Guide

Page 25

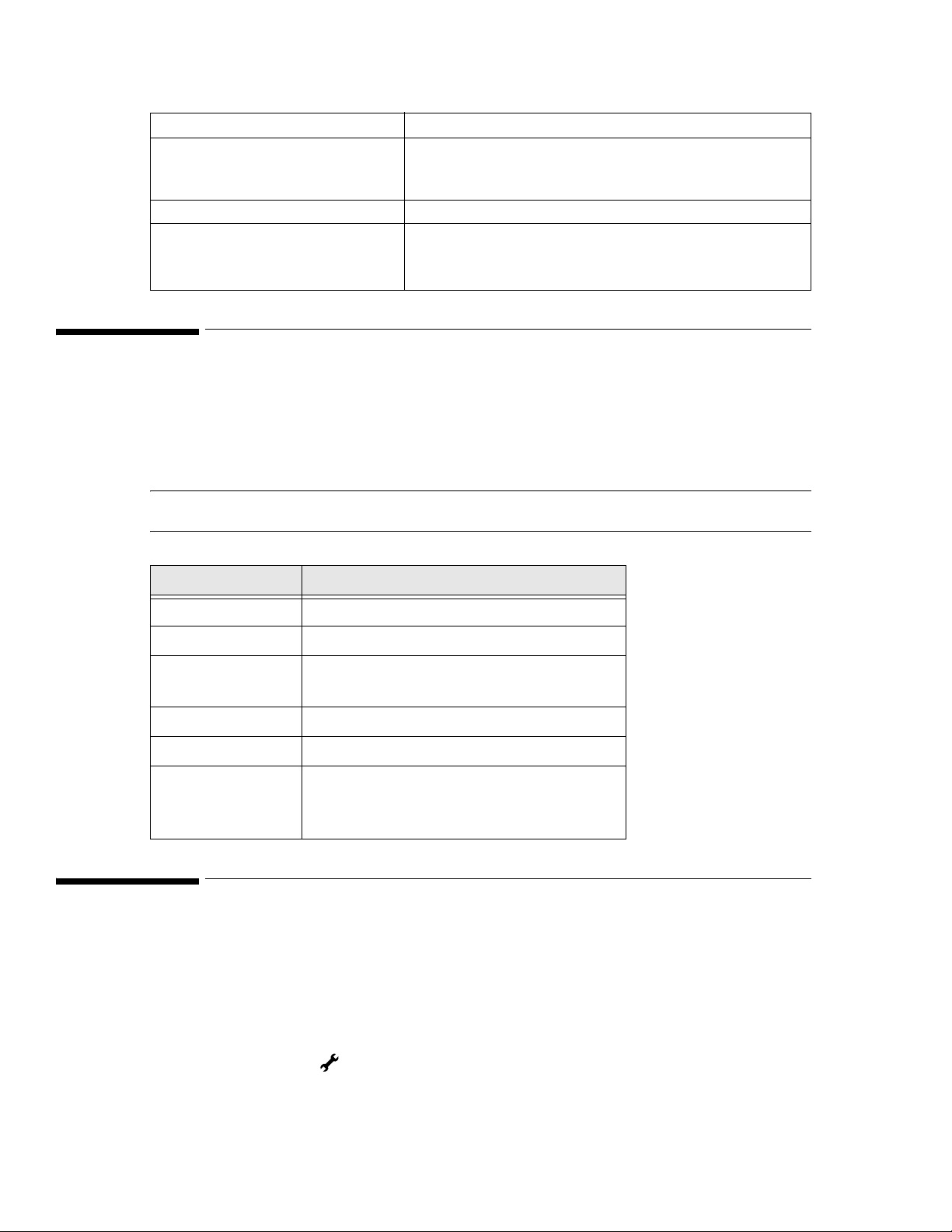

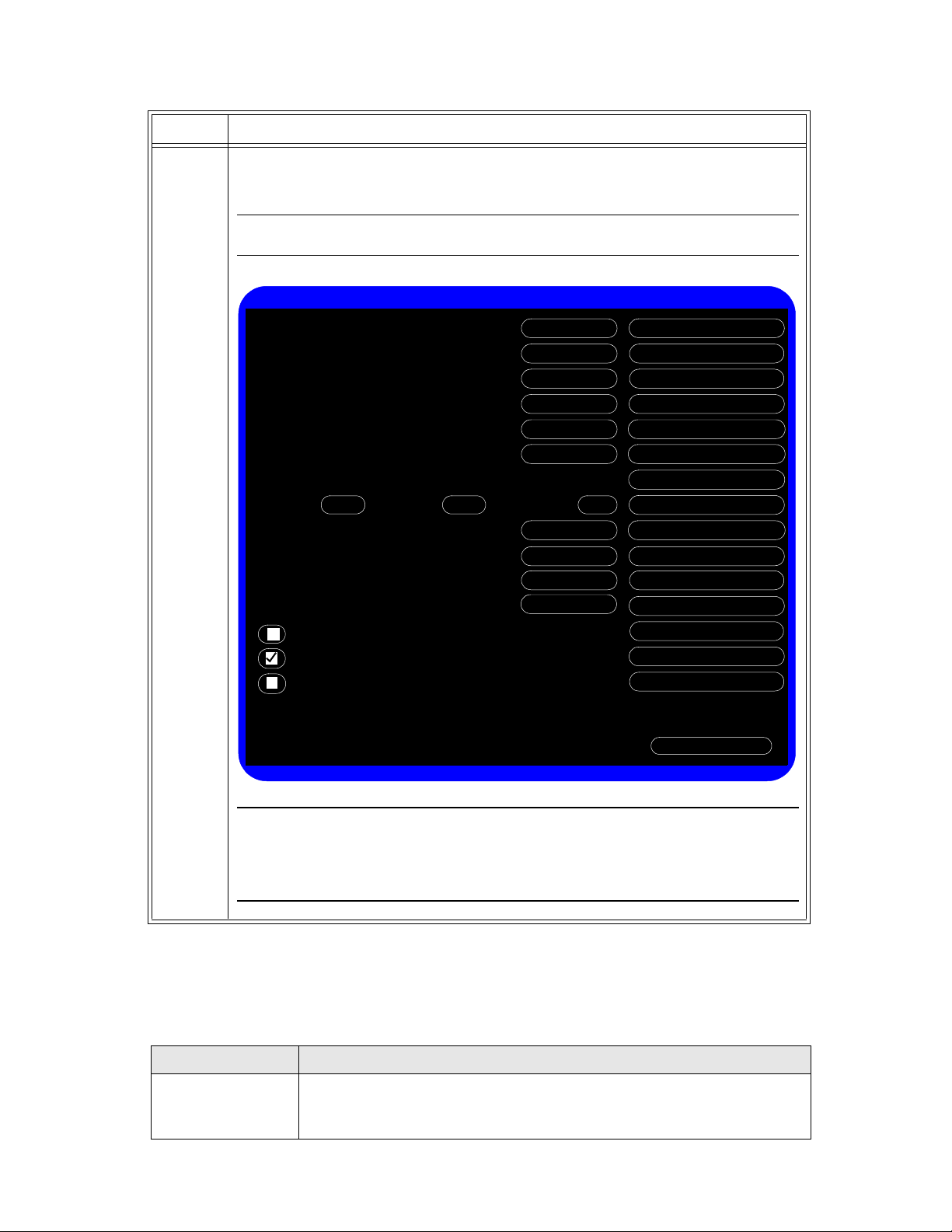

Accessing the System Admin Menu

System Menu

Recorder Speed:

Waveform Print:

Date Format:

Serial Number:

Main Screen

25.0 mm/s

Hardware ID:

Software Version:

Configuration:

LAN MAC Address:

LAN IP Address:

Language:

USL0000001

6 - 00 - A7

A.04.52

VS4 SpO2-P Temp-T NBP-P

00-09-FB-13-4B-3C

0.0.0.0

English

Display Time:

20 seconds

Yes

Default Patient Type:

Recorder Wireless CO2-S

USL0000001

Monitor Name:

mm/dd/yyyy

Adult

System Admin

Brightness

Lock Touch Screen

Shutdown

WLAN MAC Address:

WLAN IP Address:

00-17-23-A1-84-B2

0.0.0.0

Accessing the System Admin Menu

You can use the System Admin Menu to configure password-protected functions of the monitor,

including Demo Mode, system diagnostics, and upgrading the software. For more information

about using the System Admin Menu to configure the monitor, see the Installation and

Configuration Guide provided with your monitor.

Notes

•The System Admin Menu is password-protected, and should only be accessed by

qualified service personnel.

• The procedures in this guide use the default Administrator password, 215. To improve

the security of the monitor settings, you can change the administrator password after

you install the monitor. For more information about changing the password, see the

Installation and Configuration Guide provided with your monitor.

To access the System Admin Menu:

Step

1 In the System Menu, select the System Admin button.

2 In the window that appears, enter the Administrator password, 215, or the password

defined by your institution and select OK.

Performance Verification Testing

SureSigns VS4 Service Guide 3-5

Page 26

Accessing the System Admin Menu

System Admin Menu

Language:

English

Diagnostics

Return

Default Initial NBP Inflation Pressure:

Adult:

Auto Suspend:

Neonate:

Pediatric:

Demo Mode

100160 140

Upgrade Software

Export Settings

Import Settings

Off

Default NBP Interval:

Default Save Measurements to Record:

Default Blue Probe Site:

2 minutes

Auto Save Patient Record:

1 minute

Patient ID Settings

Align Interval to Clock:

No

QuickCapture

Data Export

Oral

QuickAlerts

Date/Time Settings

Large Battery Icon

On

Security

QuickCheck

QuickNBP

LAN

Wireless

Line Frequency:

60 Hz

Default Alarm Settings

Dashboard

Masimo Pulse Smart Tone:

Off

Masimo RRa Freshness Timeout:

15 Minutes

Step

3 Select OK.

The System Admin Menu opens.

Note — Masimo settings appear only if the Masimo SpO

module is installed.

2

Caution

The System Admin Menu remains unlocked for 1 minute after you close it. This

allows you to open the menu again without having to re-enter the password. Do

not leave the monitor unattended during the unlock time.

System Admin Menu Options

The following table describes the System Admin Menu options that are explained in this guide. All

other options on the menu are explained in the Installation and Configuration Guide and the

Network Configuration Guide provided with your monitor.

Option Description

Demo Mode Demo Mode allows the monitor to be demonstrated without actually

Performance Verification Testing

3-6 SureSigns VS4 Service Guide

monitoring parameters.

For more information, see “Enabling Demo Mode” on page 3-7.

Page 27

Option Description

Diagnostics Opens the System Diagnostics menu. Monitoring is suspended while this

Upgrade Software Opens the Upgrade Software menu.

Enabling Demo Mode

Accessing the System Admin Menu

menu is open.

Note — This button is unavailable when the monitor is running in Demo

mode.

For more information, see “Performing Verification Tests” on page 3-11.

For more information, see “Upgrading the Software” on page 3-8.

Warning Do not connect a patient to a monitor running in Demo mode. Values represented in Demo mode

do not represent measurements from a patient connected to the monitor, and may lead to

incorrect diagnoses.

Demo mode is used for demonstrating the monitor without monitoring parameters. Demo mode

simulates all patient parameters and generates alarms when alarm settings are exceeded.

By default, the check box is cleared.

Caution Entering Demo mode clears the patient data.

Note — You cannot access the System Diagnostics menu when the monitor is in Demo mode.

To put the monitor in Demo mode:

Step

1 Open the System Admin Menu. See “Accessing the System Admin Menu” on

page 3-5.

2 Select the Demo Mode check box.

3 Select the Return button.

4 Select Yes.

The monitor enters Demo mode and clears all patient data and ** DEMO ** is

displayed.

Performance Verification Testing

SureSigns VS4 Service Guide 3-7

Page 28

Upgrading the Software

Step

5 To exit Demo mode, press the On/Standby key to turn off the monitor.

The monitor clears all simulated patient data.

Upgrading the Software

Use the following procedure to upgrade the system software with a USB flash drive. When you

upgrade the software, the monitor saves all of the system settings, including the System Admin

Menu settings, the Error log, and the patient list.

Before you place an upgraded monitor back into se

establishes a protocol to train users about any changes in the functionality of the monitor resulting

from the software upgrade.

rvice, Philips recommends that your facility

Registering for Software Upgrades from Philips InCenter

You can download a software upgrade from Philips InCenter, which requires an active registration

and password.

Before you register, obtain the serial number of the monitor you plan to include in your registration.

The serial number is located on the product identification label on the rear of case of the monitor.

To register:

Step

1 Access the Philips InCenter website at incenter.medical.philips.com.

2 Click Ne

3 Under Software Updates, click

registration.

The Sure

4 Enter your personal information and answer the questions, and then click Submit.

After your information is processed, an ema

sent to the email address you entered. It may take 24 to 48 hours to receive the

email.

ed Help?.

Click here for SureSigns patient monitor account

Signs InCenter Registration Form appears.

il with temporary login information is

Note — Philips recommends using a SanDisk

upgrades.

Caution Before you upgrade the software, you can back up the system settings by exporting the current

configuration settings or by recording them on the worksheets. For worksheets and more

information, see the Installation and Configuration Guide provided with your monitor.

Do not downgrade the software to an earlier version, because it may cause hardware

incompatibility and loss of system settings and patient records. The current software version is

displayed on the start-up screen and the System Menu. For more information, see “Viewing

System Information” on page 4-1.

When you upgrade the software:

Performance Verification Testing

3-8 SureSigns VS4 Service Guide

®

or Kingston® USB flash drive for software

Page 29

Upgrading the Software

• Charge the battery before upgrading the software.

• Never perform a software upgrade with the monitor connected to a patient.

• Disconnect any USB peripherals.

• Do not upgrade software through a USB hub.

• If the USB port has a clamp in place, you may need to remove the clamp to ensure that the

USB flash drive can be inserted completely into the USB port.

After the upgrade starts:

• Do not unplug the monitor.

• Do not remove the USB flash drive.

• Do not press any keys.

If the upgrade is inadvertently interrupted and the main board data is lost, replace the main

board. For more information, see “Removing the Main Board” on page 5-33.

To perform a software upgrade:

Step

1 Connect the monitor to AC power and power up the monitor.

Note — Your monitor must be connected to AC power and have a fully charged

battery before upgrading the software.

2 Insert the USB flash drive with the software upgrade into the USB port on the

back of the monitor.

Note — The software upgrade folder must be located in the top directory of the

USB flash drive.

3 Open the System Admin Menu. See “Accessing the System Admin Menu” on

page 3-5.

Performance Verification Testing

SureSigns VS4 Service Guide 3-9

Page 30

Upgrading the Software

Upgrade Software

Current Version:

Return

Upgrade

A.05.24

A.05.25

New Version:

WARNING: Battery should be charged before upgrading software. Do no unplug the

monitor, remove the USB flash drive, or press any keys after the upgrade process begins.

Any user interaction during the upgrade may cause the upgrade to fail and adversely

affect monitor performance.

Step

4 Select the Upgrade Software button.

The monitor searches for a valid software image on the USB flash drive, and then

displays the software image information in the Upgrade Software window.

If the monitor cannot find a valid software image, the screen returns to the

System Admin Menu.

5 Select the Upgrade Software button to start the upgrade.

The Upgrade in Progress indicator increments while the upgrade is in progress.

When the upgrade is complete, the Checking Memory CRC and Upgrade

Successful messages appear.

After the software upgrade, the monitor automatically shuts down and restarts.

6 Remove the USB flash drive.

7 Before placing the monitor back in service, perform the following:

• Power-on self test. See “Power-On Self Test” on page 3-13.

• Verify that your system settings are as expected.

Performance Verification Testing

3-10 SureSigns VS4 Service Guide

Page 31

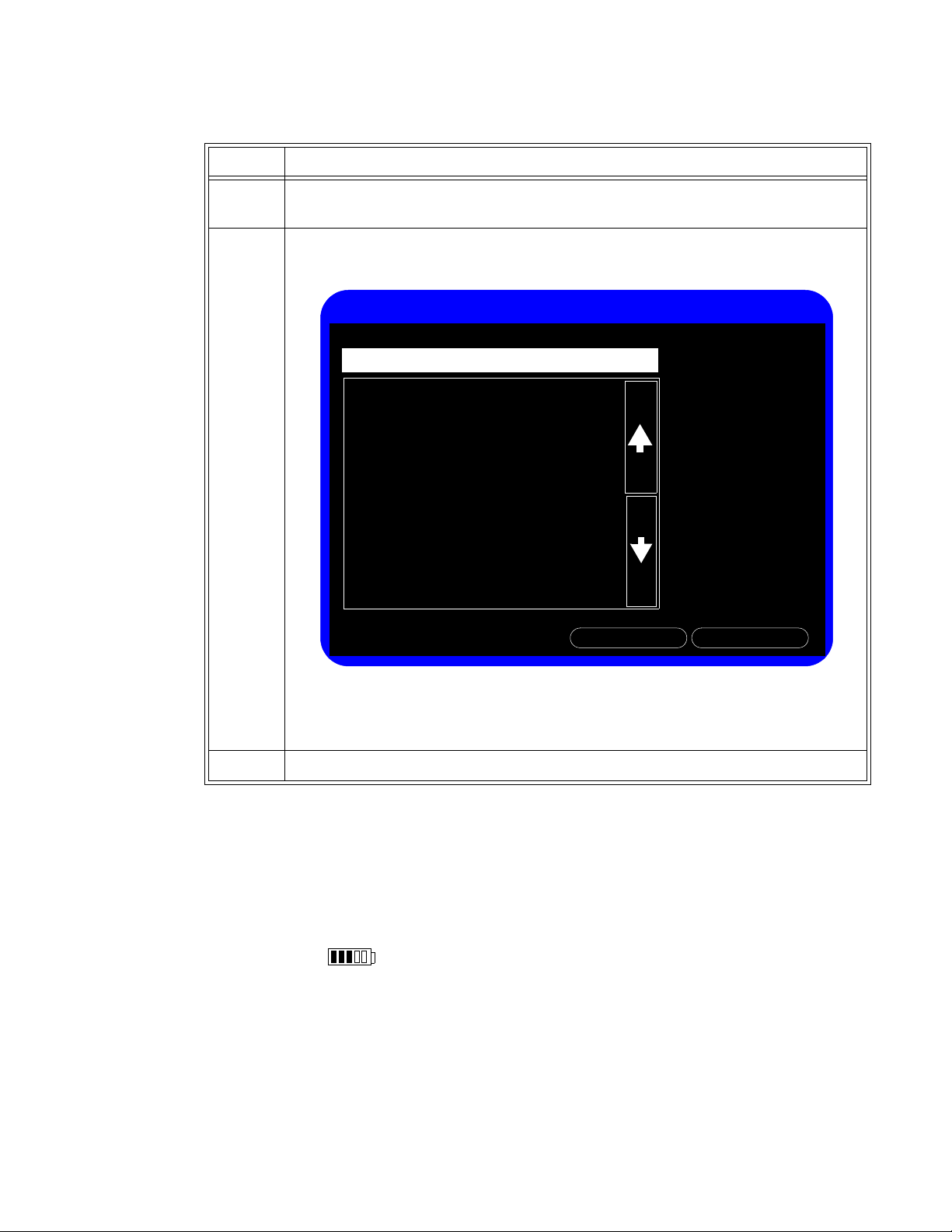

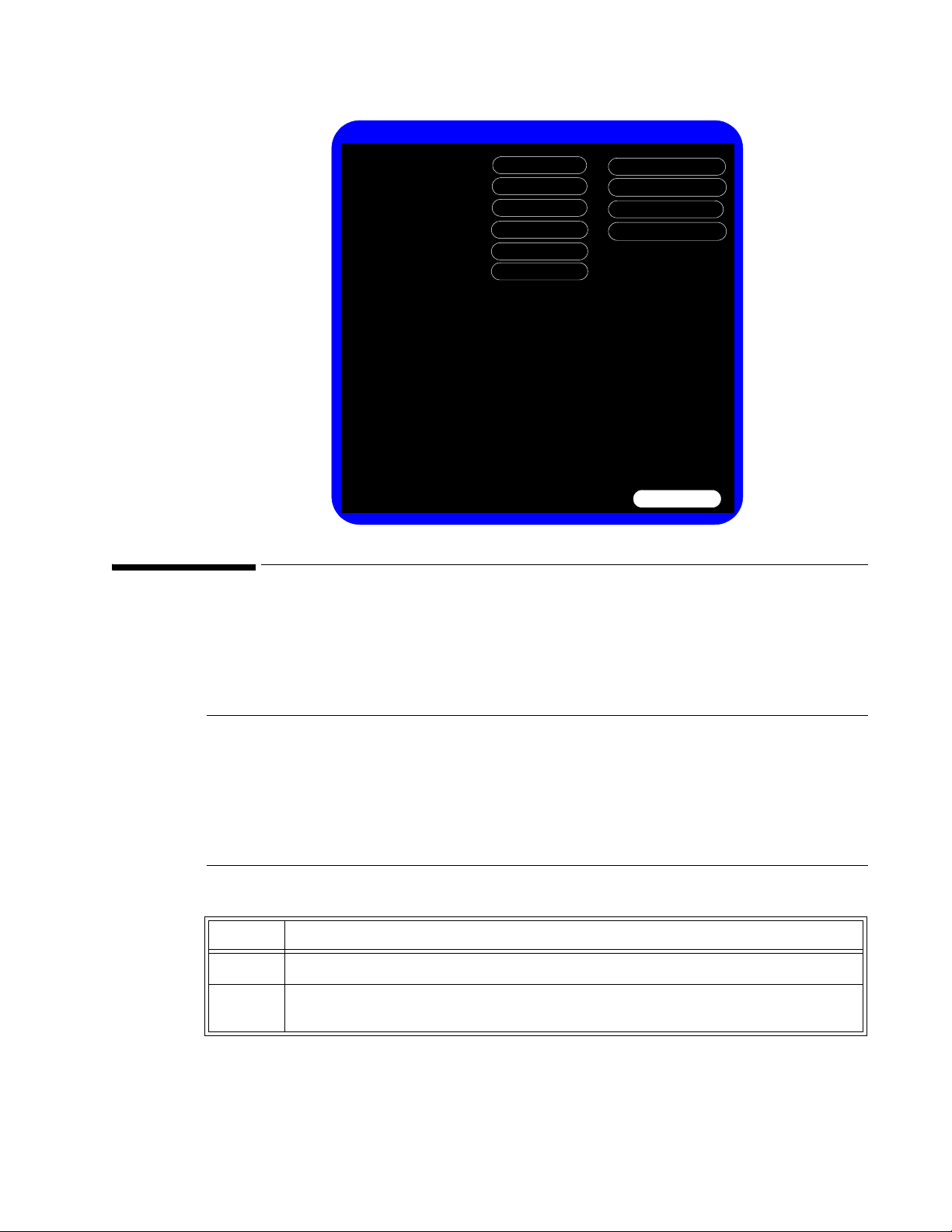

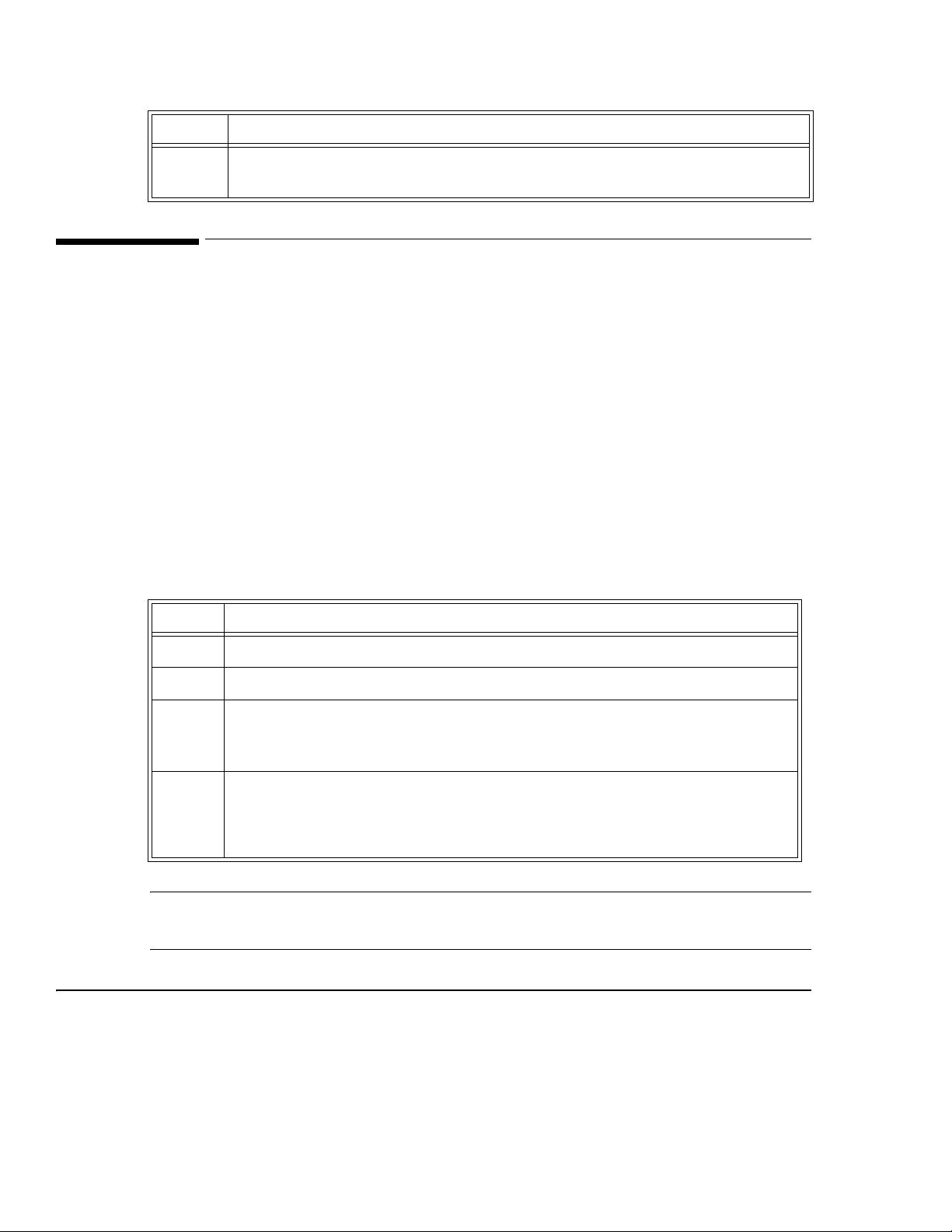

Performing Verification Tests

System Diagnostics

Monitoring Suspended

NBP Cycle Count: 44

LCD Usage Hours: 23.1

Return

Error Log

Self Test

Recorder Test

Battery Info

Keys Test

Display Test

Audio Test

LED Test

Errors: 0

Touch Screen Calibration

Network Test

Maintenance >>

Some of the verification tests require using the System Diagnostics menu or the Maintenance

options. When you open the System Diagnostics menu, monitoring is suspended and

measurements stop.

Notes

• The Charging LED does not show battery status while the System Diagnostics menu is

open.

•The System Diagnostics menu is not available when the monitor is in Demo mode.

Accessing the System Diagnostics Menu

Use the System Diagnostics Menu to track component usage hours and perform the system

diagnostic and verification tests.

Performing Verification Tests

Note — You cannot access the System Diagnostics menu when the monitor is in Demo mode.

To access the System Diagnostics menu:

Step

1 Open the System Admin Menu. See “Accessing the System Admin Menu” on

page 3-5.

2 Select the Diagnostics button.

The System Diagnostics menu appears.

Performance Verification Testing

SureSigns VS4 Service Guide 3-11

Page 32

Performing Verification Tests

System Diagnostics

Monitoring Suspended

NBP Cycle Count: 44

LCD Usage Hours: 23.1

Return

Error Log

Self Test

Recorder Test

Battery Info

Keys Test

Display Test

Audio Test

LED Test

Errors: 0

Touch Screen Calibration

Network Test

Configuration

Reset

Reset

Reset

Reset S/N

NBP Test

Clear Data

Step

3 To access the options under the Maintenance >> button, see “Accessing

Maintenance Options” on page 3-12.

Accessing Maintenance Options

You must enter an additional password to access the Maintenance options. Only trained biomedical

engineers or support personnel should access the Maintenance options.

To access the Maintenance options in the System Diagnostics menu:

Step

1 Open the System

Diagnostics menu. See “Accessing the System Diagnostics Menu”

on page 3-11.

2 Select the Maintenance >> but

ton.

3 In the window that appears, enter the password, 129.

The Sy

stem Diagnostics menu displays additional options.

Note — Masimo SpO

and CO2 settings appear only if those modules are

2

installed.

Performance Verification Testing

3-12 SureSigns VS4 Service Guide

Page 33

Visual Test

To perform the visual test:

Visual Test

Step

1 Inspect the system for obvious signs of dama

breakage.

2 Check all external cables and accessories for

wrong connections.

3 Ensure that all markings a

If the labels on the rear case are not legible, replace the rear case. If the serial

number label is not legible, contact the Philips Customer Care Center or your local

Philips representative to return the monitor for label replacement.

4 Check for any obstructions to mechanical parts.

The expected test result is that the system

obstruction.

Note — Philips employees record this value as V:P or V:F.

Power-On Self Test

To perform the power-on self test:

Step

1 Connect the monitor to an AC power source.

ge; for example, cracks, cuts, or

damage; for example, cuts, kinks,

nd labeling are legible.

has no obvious signs of damage or

2 Press the

3 Make sure that the monitor powers up successfully as

sequence:

• The screen displays color bars for about five seconds.

• The LCD turns off for three seconds,

• The Philips screen appears for one second, and a startup tone

• The main screen appears.

The expected result is that the monitor starts up and displays the main screen. For

de

Power Sequences” on page 4-2.

If the LEDs do not function as expected, see “Power Problems” on page 4-4.

If the display does not function as expected, se

“Display Problems” on page 4-6.

If you do not hear a startup tone, or the monitor displays the Speaker Malfunc error

message, see “Error Codes” on page 4-13.

On/Standby key to power up the monitor.

and the charging LED lights.

tailed information about the start-up and power sequences, see “Start-up and

e “Power Problems” on page 4-4 or

Note — Philips employees record this value as PO:P or PO:F.

Performance Verification Testing

SureSigns VS4 Service Guide 3-13

described in the following

sounds.

Page 34

Alarms Test

Alarms Test

The following test allows you to verify that the visual and audio alarms are working.

To perform this test, you need an NBP cuff and hose.

To test the alarms:

Step

1 With the monitor turned on, make sure that all alarms are enabled (the monitor is not

in Audio Pause or Audio Off mode).

2 Make sure the NBP alarm is enabled (the crossed bell icon does not appear in the

NBP numeric pane).

3 Connect the NBP hose to the NBP input connector, but do not place the cuff on your

arm.

4 Press the NBP key on the front panel.

5 Wait for the NBP module to cycle and check that an NBP error message appears and

an alarm tone sounds.

SpO2 Test

6 If you do not get the results in step 5, see “NBP Problems” on page 4-6.

The following procedure tests the performance of the SpO2 measurement and alarm.

To perform this test, you need an adult SpO2 sensor.

To perform the SpO2 test:

Step

1 Connect an adult SpO

red LED in the sensor is lit.

2 Connect the other end of the sensor to your finger.

3 Verify that the SpO

not, try the test again with a patient simulator.

4 If you still do not get the results in step 3, see “SpO2 Measurement Problems”

page 4-9.

sensor to the SpO2 connector on the monitor. Ensure that the

2

value displayed on the monitor is between 95% and 100%. If it is

2

on

Caution A functional tester cannot be used to assess the accuracy of a pulse oximeter monitor.

3-14 SureSigns VS4 Service Guide

However, if there is independent demonstration that a particular calibration curve is accurate

for the combination of a pulse oximeter monitor and a pulse oximeter sensor, then a functional

tester can measure the contribution of a monitor to the total error of a monitor/sensor system.

The functional tester can then measure how accurately a particular pulse oximeter monitor is

reproducing that calibration curve.

Performance Verification Testing

Page 35

CO2 Calibration Test

This test checks the calibration of the Microstream CO2 gas measurement. The CO2 calibration test

is required after the first 1,200 hours of use or one year, whichever comes sooner. After the first

calibration, calibrate after 4,000 hours of continuous use or every year, whichever comes sooner.

In addition, perform the calibration tests when the instrument is repaired or when parts are

replaced.

CO

Calibration Test

2

Note — Replace the CO

Caution If the initial calibration is performed before 720 hours of use, the module resets to require the

next calibration after 1,200 hours instead of after 4,000 hours.

This test uses calibration equipment that you can order. Refer to the documentation accompanying

the calibration equipment for more details.

module after 20,000 hours of use.

2

Warning A monitor that is not calibrated at the recommended intervals may provide inaccurate results.

Dispose of empty or partially empty calibration gas containers in accordance with the

manufacturer’s instructions and local regulations.

Required Test Equipment

• Electronic flowmeter, M1026-60144

• Gas calibration equipment:

– Cal 1 gas 15210-64010 (5% CO2)

– Cal gas flow regulator M2267A

– Cal tube 13907A

CO2 Gas Measurement Calibration Check

To check the calibration of the CO2 gas measurement:

Step

1 Ensure that the CO2 module is not in Standby mode (when the monitor is in Display

Waveform mode, Standby is displayed in the CO2 waveform pane).

If necessary, turn on the CO2 module by opening the CO2 Menu and setting

Hardware: to On.

CO2

2 Open the Maintenance options in the System Diagnostics menu. See “Accessing

Maintenance Options” on page 3-12.

Performance Verification Testing

SureSigns VS4 Service Guide 3-15

Page 36

CO2 Calibration Test

Last Calibration Date:

CO2 Usage Time:

Hours to Calibration:

Hours to Service:

757

3243

19,243

CO2 Test

Return

CO2 (mmHg):

Start Calibration Check

Stop Calibration Check

Start Calibration

Stop Calibration

2009/5/18 18:21

1035

18965

Last Calibration Date:

CO2 Usage Time:

Hours to Calibration:

Hours to Service:

0

Firmware Version:

Hardware Version:

5.01

2.31

3 Select the CO2 Test button.

The CO2 Test menu appears.

4 Connect one end of the sampling line to the CO2 inlet on the monitor and leave the

5 In the CO2 Test menu, select Start Calibration Check.

6 Connect the other end of the sampling line to the gas controller equipment inlet with

7 Open the valve on the gas controller equipment to allow 5% CO2 gas to flow into the

8 Select OK in the confirmation window to begin checking the calibration.

Calibrating the CO2 Module

9 If the module is not in calibration, an error message appears. Calibrate the module.

10 Turn off the flow of gas and select Return in the CO2 Test menu. Press the wheel to

other end unconnected.

A message to connect the gas to the CO2 module appears.

a 5% gas concentration.

monitor.

Note — The calibration check can take up to one minute to complete. The monitor

checks the calibration and when the calibration check completes, the CO2 Test

window displays a message. For example:

CO2 calibration check successful. CO2 rate: 5.1.

“Calibrating the CO2 Module” on page 3-16.

See

exit the test.

Caution Because the monitor uses the current date and time as the calibration date and time, ensure

3-16 SureSigns VS4 Service Guide

that the system date and time is set correctly.

Performance Verification Testing

Page 37

NBP Test

Note — The monitor always displays the CO

menu.

To calibrate the CO2 module:

module’s operating (usage) time in the CO2 Test

2

Note — Do not perform the initial calibration before 720 hours of use. If the initial calibration is

performed before 720 hours of use, the module will reset, and then require its next

calibration after 1,200 hours, instead of after 4,000 hours.

Step

1 Connect one end of the sampling line (if not already connected) to the CO2 inlet on

the monitor and leave the other end unconnected.

2 In the CO2 Test menu, select Start Calibration.

A confirmation window appears telling you to

3 Connect the other end of the sampling line to the

a 5% gas concentration.

4 Open the valve on the gas controller equipment to allow 5% CO2 gas to flow into the

monitor.

connect the gas to the CO2 module.

gas controller equipment inlet with

NBP Test

5 Select OK i

The monitor begins calibrating the CO

when complete.

n the confirmation window to begin calibrating.

module and displays the calibration value

2

Note — The calibration process can take up to one minute to complete.

6 Turn off the flow of

exit the test.

7 If the calibration is successful, the Last Calibration Date and Hours to Calibration in

the CO2 Test menu reset. To check this, re-open the CO2 Test menu.

8 If the module is not able to calibrate itself, an error

CO

module. See “Removing the CO2 Module” on page 5-15.

2

These tests check the performance of the non-invasive blood pressure measurement:

• NBP accuracy

• NBP calibration procedure (if required)

• NBP pneumatic leakage

To perform these tests, you need:

gas and select Return in the CO2 Test menu. Press the wheel to

message appears. Replace the

• A reference manometer (includes hand pump and valve), accuracy 0.2% of reading

• An expansion chamber (volume 250 ml

• Appropriate tubing

10%)

Performance Verification Testing

SureSigns VS4 Service Guide 3-17

Page 38

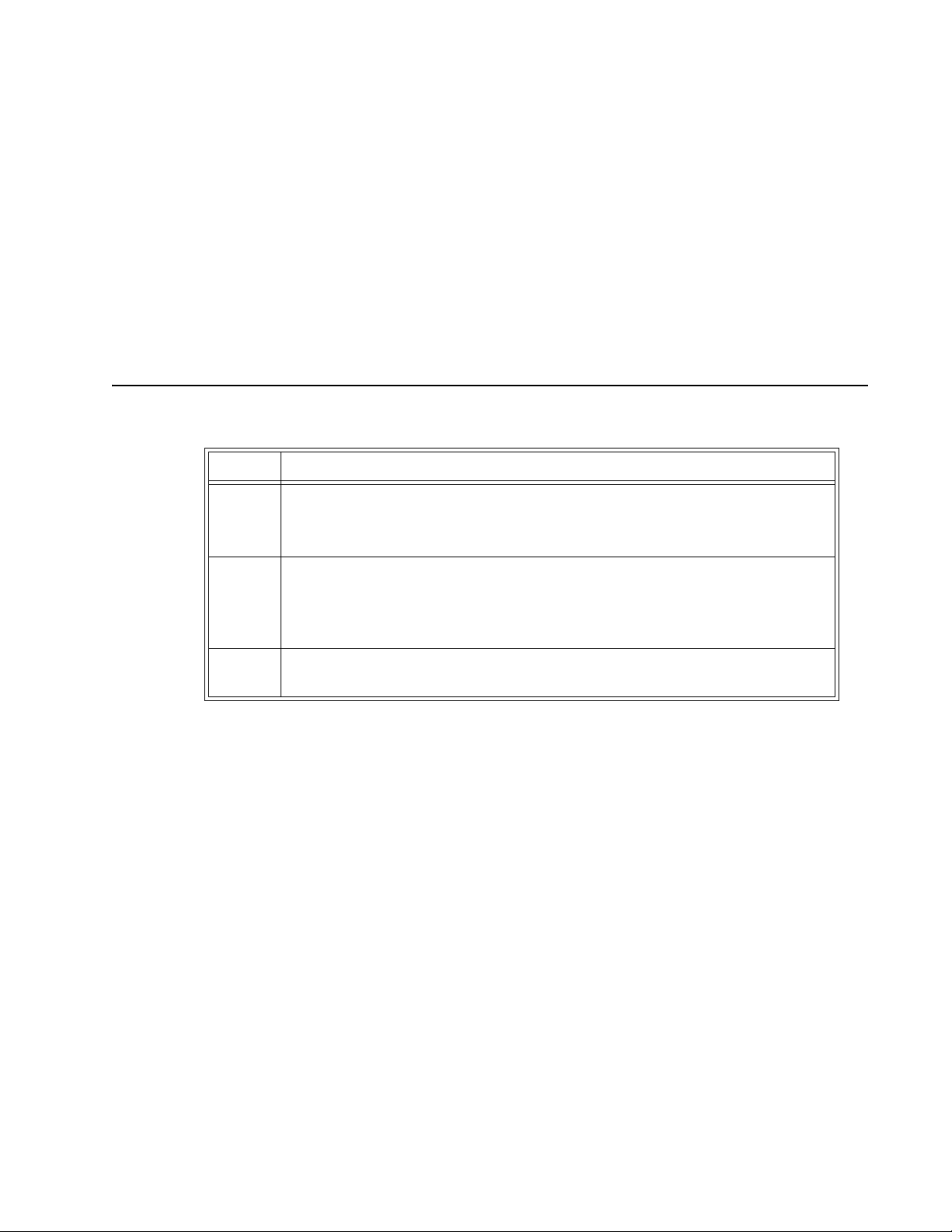

NBP Test

SureSigns VM Patient Monitor

Expansion chamber MonitorManometer

NBP Accuracy

Note — Philips recommends that you do not test NBP accuracy with a simulator.

To test the NBP accuracy:

Step

1 Connect the manometer and the pump with tubing to the NBP connector on the

monitor.

2 Connect the tubing to the expansion chamber (250 ml cylinder).

3 Open the Maintenance options in the System Diagnostics menu. See “Accessing

Maintenance Options” on page 3-12.

Performance Verification Testing

3-18 SureSigns VS4 Service Guide

Page 39

Step

NBP Test

Pressure (mmHg):

Return

Start Static Pressure Test

NBP Calibration

Firmware version: 0.33

4 Select NBP Test.

The NBP Test menu appears.

NBP Test

10 Select the Stop Static Pressure Test button to stop the test.

5 Select the Start Static Pressure Test button to start the test.

6 Squeeze the manometer pump and apply a pressure of 280 mmHg.

7 Wait 10 seconds for the pressure to stabilize. Note the pressure displayed in the NBP

Test menu. The value should be 280 mmHg 3 mmHg.

Note — Philips employees record this value as X1.

8 Squeeze the manometer pump to apply a pressure of 150 mmHg to the monitor.

9 Wait 10 seconds for the pressure to stabilize. Note the pressure displayed in the NBP