Page 1

technical note

Philips Magnetic Products

Philips

Components

SMD Coil Formers and Cores

Page 2

Philips Magnetic Products

1

Contents

Introduction 3

Ferrite Material Properties 6

Range Overview 7

E5.3/2.7/2 8

E6.3/2.9/2 10

EFD10 12

EFD12 14

EFD15 16

EFD20 18

EP7 20

ER9.5 22

ER11 24

RM4/I 26

RM5/I 28

RM6S/I 30

RM6S/ILP 32

Tag plate TGPS-9 34

SMD Coil Formers

and Cores

Page 3

Philips Magnetic Products

2

Range of SMD accessories and cores

Page 4

Philips Magnetic Products

3

Introduction

With its new range of surface-mount coil formers, Philips

Components offers a real solution to circuit designers

wishing to take maximum advantage of surface-mount

technology in their designs.

The trend toward full surface-mount technology has been

hampered by the problems of introducing inductive

components (inductors and transformers for example) in

surface-mount execution.

These devices, consisting of cores, coil-formers and

windings held together by clips, were not easily converted

to surface-mount versions, and former designs, based on

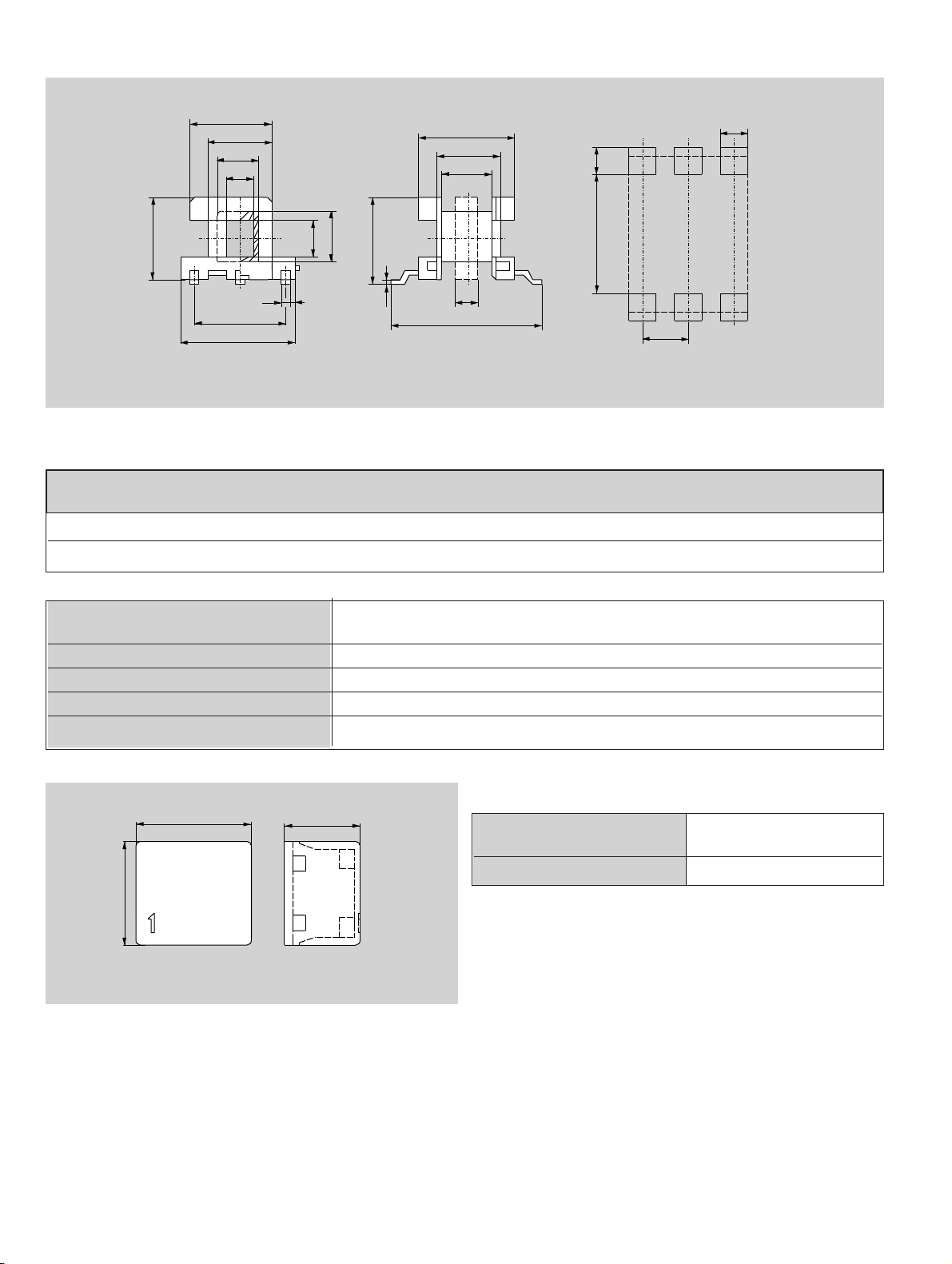

"gull-wing" terminations (see Fig.1) have not been entirely

satisfactory.

Disadvantages of "gull-wing" pins

In particular, tensions introduced by the winding wire,

which is wrapped around the upper part of the gull-wing

terminations, can severely degrade the coplanarity of the

solder pads. The use of thin wire windings is a partial

solution to this problem but this introduces limitations on

coil design. Furthermore, during soldering of the winding

wire to the termination, spillage of solder onto the solder

pad can further degrade coplanarity. However, for very

small coil formers gull-wing pins are the only possible

design due to space limitations. For small to medium sized

coil formers there is a better solution: U-pins.

Fig.1 The “gull-wing” design.

> 0.1 mm

Page 5

Philips Magnetic Products

4

Advantages of the U-pin design

The introduction of Philips' new range of surface-mount,

coil formers, however, solves all these problems. These

feature "U-pin" terminations (Fig.2) securely embedded in

the plastic coil former body. These pins are thicker and

wider than most gull-wing pins and therefore stronger.

The solder pads, located beneath the plastic body and in

contact with it, form a rigid structure with a guaranteed

coplanarity of less than 0.1 mm, according to

IEC 191-2Q.

The upper part of the U-pins protrude from the plastic

body and offer a large area on which to terminate the

windings. Since these are physically separated from the

solder pads, tension introduced by the winding wire will

not affect coplanarity, and neither will solder used to attach

the winding wires spill onto the solder pads. The contact

surface of the pads is also much larger than typical gullwing solder pads, making them ideal for these relatively

heavy components.

Moreover, with this design, the thickness of the winding

wire is no longer a limitation, allowing circuit designers far

more freedom in their choice of wire.

High-grade plastic

The coil former body is of high-grade liquid-crystal

polymer (LCP) offering excellent thermal stability. The

body is exceptionally tough and can withstand soldering

temperatures up to 350

o

C and operating temperatures up

to 180

o

C.

Excellent ferrites

In combination with Philips' extensive range of ferrite

cores, these new coil formers provide surface-mount

solutions in a host of applications from wide-band signal

transformers to power transformers.

When assembled with windings, coil-formers, cores and a

newly-designed clip with a flat upper surface (ideal for

vacuum pickup), the products can easily be inserted by a

pick and place assembly line.

clean solder pads

Fig.2 The U-pin design

< 0.1 mm

Page 6

Philips Magnetic Products

5

Page 7

Philips Magnetic Products

6

Initial permeability µ

i

-f = ≤10 kHz, B < 0.1mT, 1800 900 ∼80 4700 10000 12000

T = 25 oC

Saturation flux density B

s

mT f = 10 kHz, T = 25

o

C ∼500 ∼450 ∼330 ∼360 ∼360 ∼400

at Field strength H A/m 3000 3000 3000 250 250 250

Remanence B

r

mT T = 25

o

C ∼150 ∼150 ∼200 ∼100 ∼80 ∼100

Coercivity H

c

A/m T = 25

o

C ∼15 ∼60 ∼170 ∼10 ∼5 ∼4

Power loss density P

v

kW/m

3

f = 25kHz, B = 200mT 70 - - - -

(typical, sine wave f = 100kHz, B = 100mT 50 200 - - -

excitation) f = 500kHz, B = 50mT 180 180 - - -

f = 1MHz, B = 30mT 300 140 300 - f = 3MHz, B = 10mT - 240 150 - -

Curie temperature T

c

o

C-≥200 ≥220 ≥260 ≥125 ≥125 ≥130

Resistivity (DC) ρΩm T = 25 oC ∼2 ∼10 ∼10

5

∼1 ∼0.5 ∼0.5

Density g/cm

3

T = 25

o

C ∼4.8 ∼4.7 ∼4.6 ∼4.8 ∼4.9 ∼4.9

Ferrite material properties

PARAMETER SYMBOL UNIT TEST CONDITIONS 3F3 3F4 4F1 3E4 3E5 3E6

Page 8

Philips Magnetic Products

7

Range overview

Core Type Core materials SMD

3F3 3F4 3E4 3E5 3E6 coil former

E5.3/2.7/2

E6.3/2.9/2

EFD10

EFD12

EFD15

EFD20

EP7

ER9.5

ER11

RM4/I

RM5/I

RM6/I

RM6/ILP

EFD assembly

Page 9

Philips Magnetic Products

8

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless (CrNi) steel

Clamping force ∼ 5N

Type number CLM-E5.3/2

Fig. 1 SMD coil former for E5.3/2.7/2

Fig. 2 Clamp for E5.3/2.7/2

E5.3/2.7/2

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 6 1.5 2.6 12.6 CPHS E5.3/2-1S-6P

262

× 0.6 2 × 1.0 13 CPHS E5.3/2-2S-6P

Fig. 3 Cover for E5.3/2.7/2

Cover material Liquid crystal polymer

(LCP)

Type number COV-E5.3/2

Cover data

4.7 max.

3.6

2.3

1.5

± 0.1

±0.1

+0.1

0

+0.1

2.15

0

3.7

-0,15

2.6min.

0

0

-0.1

2.9

4.9max.

1.65.5

1.2

0.6

3.7

5.3max. 7.85max.

0.25

0.5

4.9

1.85

1.5

5.8

6

4.8 max

1.6 max4.8 max

Page 10

Philips Magnetic Products

9

Σ (l/A) core factor (C1) 5.13 mm

-1

V

e

effective volume 31.4 mm

3

l

e

effective length 12.7 mm

A

e

effective area 2.5 mm

2

A

min

minimum area 2.3 mm

2

m mass of core half ∼0.08 g

3F3 265 ±25% ∼1080 ∼0 E5.3/2.7/2-3F3

3F4 165 ±25% ∼675 ∼0 E5.3/2.7/2-3F4

3E5 1400 +40/-30% ∼5700 ∼0 E5.3/2.7/2-3E5

3E6 1600 +40/-30% ∼6520 ∼0 E5.3/2.7/2-3E6

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core halves for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 300 ≤ 0.005 ≤ 0.008 - 3F4 ≥ 250 - - ≤ 0.006 ≤ 0.010

Fig. 3 E5.3/2.7/2 core half

E5.3/2.7/2

±0.05

2.65

+0.1

1.9

0

2

0

-0.1

3.8

1.4

5.25

+0.2

0

0

-0.1

±

0.1

Page 11

Philips Magnetic Products

10

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Cover material Liquid crystal polymer

(LCP)

Type number COV-

E6.3/2

Fig. 1 SMD coil former for E6.3/2.9/2

Fig. 2 Cover for E6.3/2.9/2

E6.3/2.9/2

Winding data

Coil former data

Cover data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 6 1.62 2.7 12.8 CPHS-E6.3/2-1S-6P

262 × 0.45 2 × 0.75 12.8 CPHS-E6.3/2-2S-6P

4.7max.

4.4

± 0.08

3.5

2.3 ± 0.05

+0.1

1.5

0

5.08

6.4 max.

5.5

0

3.5

- 0.1

2.7 min.

+0.1

0

±0.05

2.1

2.9

5 max.

0.6

0.25

1.2

8.6 max.

1.66.5

2.54

1.6

7.7 max

5.1 max.

6.9 max

Page 12

Philips Magnetic Products

11

Σ (l/A) core factor (C1) 3.67 mm

-1

V

e

effective volume 40.6 mm

3

l

e

effective length 12.2 mm

A

e

effective area 3.3 mm

2

A

min

minimum area 2.6 mm

2

m mass of core half ∼0.12 g

3F3 360 ±25% ∼ 1050 ∼0 E6.3/2.9/2-3F3

3F4 225 ±25% ∼ 660 ∼0 E6.3/2.9/2-3F4

3E5 1700 +40/-30% ∼ 4960 ∼0 E6.3/2.9/2-3E5

3E6 2100 +40/-30% ∼ 6130 ∼0 E6.3/2.9/2-3E6

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core halves for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 300 ≤ 0.007 ≤ 0.010 −−

3F4 ≥ 250 - −≤ 0.008 ≤ 0.013

Fig. 3 E6.3/2.9/2 core half

E6.3/2.9/2

+ 0.2

3.6

0

0

1.4

- 0.1

0

+ 0.1

0

- 0.1

1.85

2.9

0

6.3

- 0.25

0

-0,1

2

Page 13

Philips Magnetic Products

12

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clamp material stainless(CrNi) steel

Clamping force ∼ 15N

Type number CLM-EFD10

Fig. 1 SMD coil former for EFD10

Fig. 2 Clamp for EFD10

EFD10

Winding data

Coil former data

Clamp data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 8 4.2 6.05 14.8 CPHS-EFD10-1S-8P

2.8

11

1.8

3

MBW122

0.8

7.3-0.15

5.7-0.1

4.8+0.1

3

9

11.7max.

1.6+0.1

2.5-0.1

5.4max.0.3

1.8

7.1-0.15

6.05min.

12

14.7max.

0.3

2

12 - 0.3

9.4

2.5

10 - 0.3

10.5

± 0.2

88

4

MBW128

Page 14

Philips Magnetic Products

13

5.2 ± 0.1

Σ (l/A) core factor (C1) 3.29 mm

-1

V

e

effective volume 171 mm

3

l

e

effective length 23.7 mm

A

e

effective area 7.2 mm

2

A

min

minimum area 6.5 mm

2

m mass of core half ∼0.45 g

3F3 25±5% ∼ 66 ∼540 EFD10-3F3-A25-S

40±8% ∼ 105 ∼300 EFD10-3F3-A40-S

63±10% ∼ 165 ∼170 EFD10-3F3-A63-S

500±25% ∼ 1290 ∼0 EFD10-3F3-S

3F4 25±5% ∼ 66 ∼520 EFD10-3F4-A25-S

40±8% ∼ 105 ∼280 EFD10-3F4-A40-S

63±10% ∼ 165 ∼150 EFD10-3F4-A63-S

280±25% ∼ 730 ∼0 EFD10-3F4-S

3E4 1400 +40/-30% ∼ 3670 ∼ 0 EFD10-3E4-S

3E5 2000 +40/-30% ∼ 5240 ∼ 0 EFD10-3E5-S

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.02 ≤ 0.035 −−

3F4 ≥ 250 −−≤ 0.034 ≤ 0.055

Fig. 3 EFD10 core half

EFD10

3.75 ± 0.15

10.5 ± 0.3

7.65 ± 0.25

4.55 ± 0.15

2.7 ± 0.1

MBW131

0.2

1.45 ± 0.05

Page 15

Philips Magnetic Products

14

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clamp material stainless(CrNi) steel

Clamping force ∼ 20N

Type number CLM-EFD12

Fig. 1 SMD coil former for EFD12

Fig. 2 clamp for EFD12

EFD12

Winding data

Coil former data

Clamp data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 8 6.5 7.65 18.6 CPHS-EFD12-1S-8P

2.812.5

1.8

3

MBW123

8.65-0.15

6.55-0.1

5.65+0.1

0.8

9

13.7max.

3.1-0.1

2.2+0.1

6.2max.

0.3

1.8

8.7-0.15

7.65min.

0.3

13.4

16.2max. 23

14 - 0.3

11.5

2.5

12 - 0.3

12.5

± 0.2

9.410.5

4

MBW129

Page 16

Philips Magnetic Products

15

6.2 ± 0.1

Σ (l/A) core factor (C1) 2.50 mm

-1

V

e

effective volume 325 mm

3

l

e

effective length 28.5 mm

A

e

effective area 11.4 mm

2

A

min

minimum area 10.7 mm

2

m mass of core half ∼0.9 g

3F3 40±5% ∼ 80 ∼490 EFD12-3F3-A40-S

63±8% ∼ 125 ∼280 EFD12-3F3-A63-S

100±10% ∼ 200 ∼160 EFD12-3F3-A100-S

700±25% ∼ 1370 ∼0 EFD12-3F3-S

3F4 40±5% ∼ 80 ∼470 EFD12-3F4-A40-S

63±8% ∼ 125 ∼260 EFD12-3F4-A63-S

100±10% ∼ 200 ∼140 EFD12-3F4-A100-S

380±25% ∼ 760 ∼0 EFD12-3F4-S

3E4 1900 +40/-30% ∼ 3780 ∼ 0 EFD12-3E4-S

3E5 2800 +40/-30% ∼ 5570 ∼ 0 EFD12-3E5-S

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.04 ≤ 0.065 −−

3F4 ≥ 250 −−≤ 0.065 ≤ 0.11

Fig. 3 EFD12 core half

EFD12

4.55 ± 0.15

3.5 ± 0.1

12.5 ± 0.3

9 ± 0.25

5.4 ± 0.15

MBW132

0.2

2 ± 0.1

Page 17

Philips Magnetic Products

16

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless(CrNi) steel

Clamping force ∼ 12.5N each

Type number CLI-EFD15

Fig. 1 SMD coil former for EFD15

Fig. 2 Clip for EFD15

EFD15

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm2) (mm) of turn (mm)

1 8 16.7 9.15 25.6 CPHS-EFD15-1S-8P

Fig. 2 Clamp for EFD15

Clamp material stainless(CrNi) steel

Clamping force ∼ 25N

Type number CLM-EFD15

Clamp data

10.55 - 0.15

6.65 - 0.1

5.55+0.1

10.4 - 0.15

9.15 min

0.3

2

2.8

15

3.75

11.25

16.7 max

3.7 - 0.1

2.6 + 0.1

0.3 7.5 max

1.8

161

18.7 max

2

3.75

MBW143

5

4.5

19

13.3

MBW144

2.6

0

16.5

-0.3

13.5

12

4

±0.2

14.3

±0.2

15

12.5

4

Page 18

Philips Magnetic Products

17

5.5 ± 0.25

Σ (l/A) core factor (C1) 2.27 mm

-1

V

e

effective volume 510 mm

3

l

e

effective length 34.0 mm

A

e

effective area 15.0 mm

2

A

min

minimum area 12.2 mm

2

m mass of core half ∼1.4 g

3F3 63±5% ∼ 115 ∼350 EFD15-3F3-A63-S

100±8% ∼ 180 ∼170 EFD15-3F3-A100-S

160±10% ∼ 290 ∼100 EFD15-3F3-A160-S

780±25% ∼ 1400 ∼0 EFD15-3F3-S

3F4 63±5% ∼ 115 ∼350 EFD15-3F4-A63-S

100±8% ∼ 180 ∼160 EFD15-3F4-A100-S

160±10% ∼ 290 ∼90 EFD15-3F4-A160-S

400±25% ∼ 720 ∼0 EFD15-3F4-S

3E4 2000 +40/-30% ∼ 3610 ∼ 0 EFD15-3E4-S

3E5 ≥ 2500 ≥ 4510 ∼ 0 EFD15-3E5-S

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.06 ≤ 0.10 −−

3F4 ≥ 250 −−≤ 0.10 ≤ 0.16

Fig. 3 EFD15 core half

EFD15

7.5 ± 0.15

15 ± 0.4

11 ± 0.35

5.3 ± 0.15

4.65 ± 0.15

2.4 ± 0.1

MBW145

0.2

Page 19

Philips Magnetic Products

18

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless(CrNi) steel

Clamping force ∼ 20N each

Type number CLI-EFD20

Fig. 1 SMD coil former for EFD20

Fig. 2 Clip for EFD20

EFD20

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 10 27.7 13.5 34.1 CPHS-EFD20-1S-10P

Fig. 2 Clamp for EFD20

Clamp material stainless(CrNi) steel

Clamping force ∼ 30N

Type number CLM-EFD20

Clamp data

14.8 - 0.2

10.5 - 0.15

9.2 + 0.1

5 -0.1

9.5 max

14.8-0.2

13.5 min

0.3

2

2.8

20

7.5 ±0.05

1

15 ± 0.05

21.7 max

3.9 + 0.1

0.3

1.8

21

23.7 max

2

3.75

MBW148

5

24

18.3

6

MBW146

4

0

21.5

19.3

- 0.3

18.5

17

4.7

±0.2

20

17.5

±0.2

4

Page 20

Philips Magnetic Products

19

7.7 ± 0.25

Σ (l/A) core factor (C1) 1,52 mm

-1

V

e

effective volume 1460 mm

3

l

e

effective length 47.0 mm

A

e

effective area 31.0 mm

2

A

min

minimum area 29.0 mm

2

m mass of core half ∼3.5 g

3F3 63±3% ∼ 75 ∼500 EFD20-3F3-E63-S

100±3% ∼ 120 ∼240 EFD20-3F3-A100-S

160±5% ∼ 195 ∼140 EFD20-3F3-A160-S

250±8% ∼ 300 ∼90 EFD20-3F3-A250-S

315±10% ∼ 425 ∼65 EFD20-3F3-A315-S

1200±25% ∼ 1450 ∼0 EFD20-3F3

3F4 63±3% ∼ 75 ∼500 EFD20-3F4-E63-S

100±3% ∼ 120 ∼240 EFD20-3F4-A100-S

160±5% ∼ 195 ∼140 EFD20-3F4-A160-S

250±8% ∼ 300 ∼90 EFD20-3F4-A250-S

315±10% ∼ 425 ∼65 EFD20-3F4-A315-S

650±25% ∼ 785 ∼0 EFD20-3F4

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core halves/sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.17 ≤ 0.28 −−

3F4 ≥ 300 −−≤ 0.44 ≤ 0.50

Fig. 3 EFD20 core half

EFD20

10 ± 0.15

20 ± 0.55

15.4 ± 0.5

8.9 ± 0.2

6.65 ± 0.15

3.6 ± 0.15

MBW147

0.17

Page 21

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless(CrNi) steel

Clamping force ∼ 22N

Type number CLI-EP7

Fig. 1 SMD coil former for EP7

Fig. 2 clip for EP7

EP7

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm2) (mm) of turn (mm)

1 6 4.7 3.9 17.9 CPHS-EP7-1S-6P

Philips Magnetic Products

20

7-0.1

4.5-0.1

3.5+0.1

4.9-0.1

3.9min.

1.8

2.8

0.8

3

6

9.2max.

0.3

7.3max.

7.151.8

9.85max.

0.3

2

6

3

MBW124

9

MBW130

4

9.4+0,2

4.3

6.9-0.3

0.25

Page 22

7.2 + 0.4

Σ (l/A) core factor (C1) 1.45 mm

-1

V

e

effective volume 165 mm

3

l

e

effective length 15.5 mm

A

e

effective area 10.7 mm

2

A

min

minimum area 8.55 mm

2

m mass of core set ∼0.8 g

3F3 25±3% ∼ 30 ∼790 EP7-3F3-E25

40±3% ∼ 48 ∼440 EP7-3F3-A40

63±3% ∼ 76 ∼260 EP7-3F3-A63

100±3% ∼ 121 ∼150 EP7-3F3-A100

160±5% ∼ 193 ∼85 EP7-3F3-A160

1000±25% ∼ 1210 ∼0 EP7-3F3

3F4 100±3% ∼ 121 ∼150 EP7-3F4-A100

160±5% ∼ 193 ∼85 EP7-3F4-A160

600±25% ∼ 730 ∼0 EP7-3F4

3E5 5200 +40/-30% ∼ 6300 ∼0 EP7-3E5

3E6 5800 +40/-30% ∼ 7000 ∼0 EP7-3E6

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.02 ≤ 0.035 −−

3F4 ≥ 250 −−≤ 0.033 ≤ 0.053

Fig. 3 EP7 core set

EP7

Philips Magnetic Products

21

3.4 - 0.2

6.5 - 0.3

1.7 ± 0.1

5 + 0.4

7.5 - 0.2

9.4 - 0.4

MBW133

Page 23

Philips Magnetic Products

22

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clamp material stainless(CrNi)steel

Clamping force ∼ 20N

Type number CLM-ER9.5

Fig. 1 SMD coil former for ER9.5

Fig. 2 clamp for ER9.5

ER9.5

Winding data

Coil former data

Clamp data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 8 2.8 2.05 18.4 CPVS-ER9.5-1S-8P

2.05 min.

7.3± 0,1ø

4.45± 0.08ø

3.6±0.08ø

8.1

11.7max.

2.95± 0.1

4.4 max.

0.25

0.7

8.6 max.

2

6

1.6

10

2

1.6

4

9.8

5.5

Page 24

Philips Magnetic Products

23

Σ (l/A) core factor (C1) 1.67 mm

-1

V

e

effective volume 120 mm

3

l

e

effective length 14.2 mm

A

e

effective area 8.47 mm

2

A

min

minimum area 7.60 mm

2

m mass of core half ∼0.35 g

3F3 850±25% ∼ 1145 ∼0 ER9.5-3F3-S

3F4 525±25% ∼ 700 ∼0 ER9.5-3F4-S

3E5 3600 +40/-30% ∼ 4780 ∼0 ER9.5-3E5-S

3E6 4800 +40/-30% ∼ 6380 ∼0 ER9.5-3E6-S

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 300 ≤ 0.015 ≤ 0.025 −−

3F4 ≥ 250 −−≤ 0.024 ≤ 0.038

Fig. 3 ER9.5 core half

ER9.5

0

3.5

9.5

7.1

7.5

- 0.2

0

- 0.3

+ 0.2

0

+ 0.25

0

0

+0.15

1.6

2.45 ±0.05

0

- 0.2

5

Page 25

Philips Magnetic Products

24

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless(CrNi) steel

Clamping force ∼ 25N

Type number CLM-ER11

Fig. 1 SMD coil former for ER11

Fig. 2 clamp for ER11

ER11

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 10 2.8 1.85 21.6 CPVS-ER11-1S-10P

+0.1

8.5

-0.2ø

5.3± 0.1ø

4.5± 0.1ø

2.8± 0.1

4.4 max.

10.6 max.

1.610

1.6

1.85 min.

9.2

12.35max.

0.25

0.7

4

8

2

4.4

11.5

5.6

Page 26

Philips Magnetic Products

25

Σ (l/A) core factor (C1) 1.23 mm

-1

V

e

effective volume 174 mm

3

l

e

effective length 14.7 mm

A

e

effective area 11.9 mm

2

A

min

minimum area 10.3 mm

2

m mass of core half ∼0.5 g

3F3 1200±25% ∼ 1170 ∼0 ER11-3F3-S

3F4 725±25% ∼ 710 ∼0 ER11-3F4-S

3E5 5000 +40/-30% ∼ 4890 ∼0 ER11-3E5-S

3E6 6700 +40/-30% ∼ 6560 ∼0 ER11-3E6-S

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

Properties of core sets under power conditions

3F3 ≥ 300 ≤ 0.025 ≤ 0.040 −−

3F4 ≥ 250 −−≤ 0.035 ≤ 0.056

Fig. 3 ER11 core half

ER11

0

4.25

0

± 0.05

+0.15

1.5

2.45

0

- 0.2

6

- 0.25

0

11

- 0.35

+0.2

8

0

+0.3

8.7

0

Page 27

Philips Magnetic Products

26

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless steel

Clamping force ∼5 N each

Type number CLI-RM4/5

Fig. 1 SMD coil former for RM4/I

Fig. 2 Clip for RM4/I

RM4/I

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 6 8.4 5.75 19.8 CPVS-RM4-1S-6P

7.85-0.15ø

4.9-0.1ø

4+0.1ø

0.4

2

2.88.5

3.75

MBW125

8.8 max

0.3

7.5

10.65 max

6.8-0.1

(5.7 min)

1

7

11.15 max

2

1.8

2.1

9.3

22

R

8.2

Page 28

Philips Magnetic Products

27

2.5

Σ (l/A) core factor (C1) 1.69 mm

-1

V

e

effective volume 322 mm

3

l

e

effective length 23.3 mm

A

e

effective area 13.8 mm

2

A

min

minimum area 11.5 mm

2

m mass of core set ∼1.7 g

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Properties of core sets under power conditions

3F3 ≥ 300 ≤ 0.05 ≤ 0.07 −−

3F4 ≥ 250 −−≤ 0.065 ≤ 0.11

Fig. 3 RM4/I core set

RM4/I

3F3 100±3% ∼ 134 ∼ 170 RM4/I-3F3-A100

160±3% ∼ 215 ∼ 100 RM4/I-3F3-A160

250±10% ∼ 336 ∼ 50 RM4/I-3F3-A250

950±25% ∼ 1280 ∼0 RM4/I-3F3

3F4 100±3% ∼ 134 ∼ 150 RM4/I-3F4-A100

160±3% ∼ 215 ∼ 80 RM4/I-3F4-A160

250±10% ∼ 336 ∼ 40 RM4/I-3F4-A250

560±25% ∼ 750 ∼0 RM4/I-3F4

3E5 3500 +40/-30% ∼ 4700 ∼0 RM4/I-3E5

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

4.6 - 0.2

> 5.8

11 - 0.5

3.9 - 0.2ø

9.8 - 0.4

9 ± 0.25

ø 7.95 + 0.4

7 + 0.4

MBW134

10.4 ± 0.1

Page 29

Philips Magnetic Products

28

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless (CrNi)steel

Clamping force ∼5 N each

Type number CLI-RM4/5

Fig. 1 SMD coil former for RM5/I

Fig. 2 Clip for RM5/I

RM5/I

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 8 9.8 4.9 24.9 CPVS-RM5-1S-8P

ø

ø

ø

10.1

5.9

+0.1

5

0

0

− 0.1

0

− 0.15

0.9

0.4

2.8

11.2

3.75

2

8.45 max.

0.3

3.75

11.25

14.25 max.

6.1

4.9 min.

1

14.9 max.

2

1.8

2.1

9.3

22

R

8.2

Page 30

Philips Magnetic Products

29

2.5

Σ (l/A) core factor (C1) 0.935 mm

-1

V

e

effective volume 574 mm

3

l

e

effective length 23.2 mm

A

e

effective area 24.8 mm

2

A

min

minimum area 18.1 mm

2

m mass of core set ∼3.3 g

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.08 ≤ 0.11 −−

3F4 ≥ 250 −−≤ 0.11 ≤ 0.20

Fig. 3 RM5/I core set

RM5/I

3F3 100±3% ∼ 74 ∼ 300 RM5/I-3F3-A100

160±3% ∼ 119 ∼ 160 RM5/I-3F3-A160

250±3% ∼ 186 ∼ 90 RM5/I-3F3-A250

1700±25% ∼ 1270 ∼0 RM5/I-3F3

3F4 100±3% ∼ 74 ∼ 300 RM5/I-3F4-A100

160±3% ∼ 119 ∼ 160 RM5/I-3F4-A160

250±3% ∼ 186 ∼ 90 RM5/I-3F4-A250

1000±25% ∼ 750 ∼0 RM5/I-3F4

3E5 6700 +40/-30% ∼ 4980 ∼0 RM5/I-3E5

3E6 9500 +40/-30% ∼ 7050 ∼0 RM5/I-3E6

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

6.8 - 0.4

9.1 ± 0.25

> 6

14.6 - 0,6

4.9 - 0.2ø

12.3 - 0.5

6.3 + 0.4

10.4 ± 0.1

ø 10.2 + 0.4

MBW135

Page 31

Philips Magnetic Products

30

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless (CrNi) steel

Clamping force ∼10 N each

Type number CLI-RM6

Fig. 1 SMD coil former for RM6S/I

Fig. 2 Clip for RM6S/I

RM6S/I

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 8 14 6.25 31 CPVS-RM6S-1S-8P

12.3-0.25ø

7.55-0.15ø

6.5+0.15ø

0.56.25 min

2

10.5 max0.3 2.2

5

12.5

15.7 max

7.9-0.1

1

17.45 max

2

13.7 2.8

1.814.7

3.75

5

3.75

MBW127

2.3

11.7

R

30

MBW138

9.45

Page 32

Philips Magnetic Products

31

8.2 - 0.4

Σ (l/A) core factor (C1) 0.784 mm

-1

V

e

effective volume 1090 mm

3

l

e

effective length 29.2 mm

A

e

effective area 37.0 mm

2

A

min

minimum area 31.2 mm

2

m mass of core set ∼4.9 g

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Properties of core sets under power conditions

3F3 ≥ 315 ≤ 0.14 ≤ 0.20 −−

3F4 ≥ 250 −−≤ 0.22 ≤ 0.35

Fig. 3 RM6S/I core set

RM6S/I

3F3 63±3% ∼ 39 ∼ 950 RM6S/I-3F3-A63

100±3% ∼ 62 ∼ 500 RM6S/I-3F3-A100

160±3% ∼ 100 ∼ 300 RM6S/I-3F3-A160

250±3% ∼ 156 ∼ 150 RM6S/I-3F3-A250

2150±25% ∼ 1350 ∼0 RM6S/I-3F3

3F4 63±3% ∼ 39 ∼ 950 RM6S/I-3F4-A63

100±3% ∼ 62 ∼ 500 RM6S/I-3F4-A100

160±3% ∼ 100 ∼ 300 RM6S/I-3F4-A160

250±3% ∼ 156 ∼ 150 RM6S/I-3F4-A250

1250±25% ∼ 780 ∼0 RM6S/I-3F4

3E5 8600 +40/-30% ∼ 5370 ∼0 RM6S/I-3E5

3E6 12500 +40/-30% ∼ 6200 ∼0 RM6S/I-3E6

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

2.8

10.35 ± 0.25

> 8.8

17.9 - 0.7

ø 6.4 - 0.2

14.7 - 0.6

8 + 0.4

12.4 ± 0.1

ø 12.4 + 0.5

MBW136

Page 33

Philips Magnetic Products

32

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Clip material stainless (CrNi) steel

Clamping force ∼10 N each

Type number CLI-RM6/LP

Fig. 1 SMD coil former for RM6S/ILP

Fig. 2 Clip for RM6S/ILP

RM6S/ILP

Winding data

Coil former data

Clip data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

1 8 6.4 2.8 min 31.0 CPVS-RM6S/LP-1S-8P

2

5

3.75

MBW142

2.2

0.3 7.0 max

12.3 - 0.25ø

7.55 - 0.15ø

6.5 +0.15ø

5

12.5

15.7 max

1

0.5

4.4 - 0.1

2.8 min

14.7 1.8

17.45 max

2.813.7

2

3.75

2.3

7.5

16

R

5.95

Page 34

Philips Magnetic Products

33

8.2 - 0.4

Σ (l/A) core factor (C1) 0.580 mm

-1

V

e

effective volume 820 mm

3

l

e

effective length 21.8 mm

A

e

effective area 37.5 mm

2

A

min

minimum area 31.2 mm

2

m mass of core set ∼4.2 g

B(mT) at Core loss at Core loss at Core loss at Core loss at

Grade H = 250 A/m f = 100 kHz f = 400 kHz f = 1MHz f = 3MHz

f = 25kHz B = 100mT B = 50mT B = 30mT B = 10mT

T = 100 oC T = 100 oC T = 100 oC T = 100 oC T = 100 oC

Effective core parameters

symbol parameter value unit

Properties of core sets under power conditions

3F3 ≥ 300 ≤ 0.10 ≤ 0.15 −−

3F4 ≥ 250 −−≤ 0.16 ≤ 0.26

Fig. 3 RM6S/ILP core set

RM6S/ILP

3F3 2700±25% ∼ 1250 ∼ 0 RM6S/ILP-3F3

3F4 1600±25% ∼ 740 ∼ 0 RM6S/ILP-3F4

3E5 10500 +40/-30% ∼ 4850 ∼0 RM6S/ILP-3E5

3E6 15000 +40/-30% ∼ 6930 ∼0 RM6S/ILP-3E6

Core sets for general purpose transformers and power applications

Grade A

L

(nH) µ

e

Airgap (µm) Type number

2.8

> 8.8

17.9 - 0.7

ø 6.4 - 0.2

14.7 - 0.6

4.5 + 0.4

6.84 ± 0.25

ø 12.4 +0.5

9 - 0.2

MBW140

Page 35

Philips Magnetic Products

34

Coil former material Liquid crystal polymer (LCP), glass reinforced, flame retardant in accordance

with UL94V-0.

Solder pad material Copper-tin alloy (CuSn), tin-lead alloy (SnPb) plated

Maximum operating temperature 155 oC, IEC 85 class F

Resistance to soldering heat “IEC 68-2-20” part2, test Tb, method 1B: 350 oC, 3.5s.

Solderability “IEC 68-2-20” part2, test Ta, method 1: 235

o

C, 2s

Cover material Polyamide (PA4.6)

glass reinforced, flame retardant

in accordance with UL94V-0.

Maximum operating 130 oC, IEC 85 class B

temperature

Type number COV-9

Fig. 1 Tag plate for 9mm ring cores.

Fig. 2 Cover for TGPS-9

TGPS-9

Winding data

Coil former data

Cover data

Number of Number of Winding area Winding width Average length Type number

sections solder pads (mm

2

) (mm) of turn (mm)

- 8 - - - TGPS-9

14.7max.

10.8 min.

13 max.

3

9

0.8

1.75max.

12

1.8

0.3

1.8

2.8

11

2

˚

45

3

0.6(4x)

±0.1

11

11.7 max 0.6

6 max.

Page 36

Philips Magnetic Products

35

Σ (l/A) core factor (C1) 5.17 mm

-1

V

e

effective volume 102 mm

3

l

e

effective length 22.9 mm

A

e

effective area 4.44 mm

2

m mass of core ∼ 0.5 g

Effective core parameters

symbol parameter value unit

Fig. 3 TN9/6/3 ring core

3F3 440 ±25% ∼ 1800 blue TN9/6/3-3F3

3E5

1)

2070 ±30% ∼ 8500 yellow/white TL9/6/3-3E5

3E6

2)

2435 ±30% ∼ 10000 purple/white TC9/6/3-3E6

Ring core data

Grade A

L

(nH) µ

e

Colour code Type number

TN9/6/3

Note

1. Ring cores in 3E5 are lacquered and therefore have different dimensions: OD = 9.3±0.4 mm, ID = 5.75±0.3mm, H = 3.25±0.3mm.

2. Ring cores in 3E6 are coated with parylene and therefore have different dimensions: OD = 9.0±0.2 mm, ID = 6.0±0.2mm, H = 3.0±0.15mm.

9.4 ± 0.3

5.5 ± 0.3

3.4 ± 0.3

Page 37

Philips

Components

Philips Components - a worldwide company

Australia: Philips Components Pty Ltd., NORTH RYDE,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Österreichische Philips Industrie GmbH, WIEN,

Tel. +43 1 60 101 12 41, Fax. +43 1 60 101 12 11

Belarus: Philips Office Belarus, MINSK,

Tel. +375 172 200 924/733, Fax. +375 172 200 773

Benelux: Philips Nederland B.V., EINDHOVEN, NL,

Tel. +31 40 2783 749, Fax. +31 40 2788 399

Brazil: Philips Components, SÃO PAULO,

Tel. +55 11 821 2333, Fax. +55 11 829 1849

Canada: Philips Electronics Ltd., SCARBOROUGH,

Tel. +1 416 292 5161, Fax. +1 416 754 6248

China: Philips Company, SHANGHAI,

Tel. +86 21 6354 1088, Fax. +86 21 6354 1060

Denmark: Philips Components A/S, COPENHAGEN S,

Tel. +45 3329 3333, Fax. +45 3329 3905

Finland: Philips Components, ESPOO,

Tel. +358 9 615 800, Fax. +358 9 615 80510

France: Philips Composants, SURESNES,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6493

Germany: Philips Components GmbH, HAMBURG,

Tel. +49 40 2489-0, Fax. +49 40 2489 1400

Greece: Philips Hellas S.A., TAVROS,

Tel. +30 1 4894 339/+30 1 4894 239, Fax. +30 1 4814 240

Hong Kong: Philips Hong Kong, KOWLOON,

Tel. +852 2784 3000, Fax. +852 2784 3003

India: Philips India Ltd., MUMBAI,

Tel. +91 22 4930 311, Fax. +91 22 4930 966/4950 304

Indonesia: P.T. Philips Development Corp., JAKARTA,

Tel. +62 21 794 0040, Fax. +62 21 794 0080

Ireland: Philips Electronics (Ireland) Ltd., DUBLIN,

Tel. +353 1 7640 203, Fax. +353 1 7640 210

Israel: Rapac Electronics Ltd., TEL AVIV,

Tel. +972 3 6450 444, Fax. +972 3 6491 007

Italy: Philips Components S.r.l., MILANO,

Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Japan Ltd., TOKYO,

Tel. +81 3 3740 5135, Fax. +81 3 3740 5035

Korea (Republic of): Philips Electronics (Korea) Ltd., SEOUL,

Tel. +82 2 709 1472, Fax. +82 2 709 1480

Malaysia: Philips Malaysia SDN Berhad,

Components Division, PULAU PINANG,

Tel. +60 3 750 5213, Fax. +60 3 757 4880

Mexico: Philips Components, EL PASO, U.S.A.,

Tel. +52 915 772 4020, Fax. +52 915 772 4332

New Zealand: Philips New Zealand Ltd., AUCKLAND,

Tel. +64 9 815 4000, Fax. +64 9 849 7811

Norway: Norsk A/S Philips, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Pakistan: Philips Electrical Industries of Pakistan Ltd., KARACHI,

Tel. +92 21 587 4641-49, Fax. +92 21 577 035/+92 21 587 4546

Philippines: Philips Semiconductors Philippines Inc.,

METRO MANILA, Tel. +63 2 816 6345, Fax. +63 2 817 3474

Poland: Philips Poland Sp. z.o.o., WARSZAWA,

Tel. +48 22 612 2594, Fax. +48 22 612 2327

Portugal: Philips Portuguesa S.A.,

Philips Components: LINDA-A-VELHA,

Tel. +351 1 416 3160/416 3333, Fax. +351 1 416 3174/416 3366

Russia: Philips Russia, MOSCOW,

Tel. +7 95 755 6918, Fax. +7 95 755 6919

Singapore: Philips Singapore Pte Ltd., SINGAPORE,

Tel. +65 350 2000, Fax. +65 355 1758

South Africa: S.A. Philips Pty Ltd., JOHANNESBURG,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

Spain: Philips Components, BARCELONA,

Tel. +34 93 301 63 12, Fax. +34 93 301 42 43

Sweden: Philips Components AB, STOCKHOLM,

Tel. +46 8 5985 2000, Fax. +46 8 5985 2745

Switzerland: Philips Components AG, ZÜRICH,

Tel. +41 1 488 22 11, Fax. +41 1 481 7730

Taiwan: Philips Taiwan Ltd., TAIPEI,

Tel. +886 2 2134 2900, Fax. +886 2 2134 2929

Thailand: Philips Electronics (Thailand) Ltd., BANGKOK,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Türk Philips Ticaret A.S., GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

United Kingdom: Philips Components Ltd., DORKING,

Tel. +44 1306 512 000, Fax. +44 1306 512 345

United States:

• Display Components, ANN ARBOR, MI,

Tel. +1 734 996 9400, Fax. +1 734 761 2776

• Magnetic Products, SAUGERTIES, NY,

Tel. +1 914 246 2811, Fax. +1 914 246 0487

• Passive Components, SAN JOSE, CA,

Tel. +1 408 570 5600, Fax. +1 408 570 5700

Yugoslavia (Federal Republic of): Philips Components, BELGRADE,

Tel. +381 11 625 344/373,Fax. +381 11 635 777

Internet:

• Display Components: www.dc.comp.philips.com

• Passive Components: www.passives.comp.philips.com

For all other countries apply to:

Philips Components, Building BF-1, P.O. Box 218, 5600 MD EINDHOVEN,

The Netherlands, Fax. +31-40-27 23 903.

COB20 Philips Electronics N.V. 1998

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the

copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to

be accurate and reliable and may be changed without notice. No liability will be accepted by the publisher

for any consequence of its use. Publication thereof does not convey nor imply any license under patent- or

other industrial or intellectual property rights.

Printed in The Netherlands xxxx xxx xxxxx Date of release: 11/98

Printed in The Netherlands 9398 237 50011 Date of release: 6/97

Page 38

Magnetic Products NAFTA Sales Offices

Alabama Over and Over, Inc., Charlotte, NC (708) 583-9100

Alaska Eclipse Marketing Group, Redmond, WA (206) 885-6991

Arizona Harper and Two, Tempe, AZ (602) 804-1290

Arkansas Philips Components, Willoughby, OH (440) 269-8585

California - Northern Criterion Sales, Santa Clara, CA (408) 988-6300

California - Southern Harper and Two, Signal Hill, CA (801) 264-8050

Colorado Philips Components, Willoughby, OH (440) 269-8585

Connecticut Philips Components, Woburn, MA (617) 932-4748

Deleware Philips Components, Woburn, MA (617) 932-4748

Florida Over and Over, Charlotte, NC (704) 583-9100

Georgia Over and Over, Charlotte, NC (704) 583-9100

Hawaii Harper and Two, Signal Hill, CA (310) 424-3030

Idaho - Northern Eclipse Marketing Group, Redmond, WA (206) 885-6991

Idaho - Southern Electrodyne, Inc., Salt Lake City, UT (801) 264-8050

Illinois - Northern Philips Components, Willoughby, OH (440) 269-8585

Illinois - Quad Cities Lorenz Sales, Cedar Rapids, IA (319) 377-4666

Illinois - Southern Lorenz Sales, St. Louis, MO (314) 997-4558

Indiana - Northern Corrao Marsh, Fort Wayne, IN (219) 482-2725

Indiana - Central and Southern Corrao Marsh, Green eld, IN (317) 462-4446

Iowa - All except Quad Cities Lorenz Sales, Cedar Rapids, IA (319) 377-4666

Kansas - Northeast Lorenz Sales, Overland Park, KS (913) 469-1312

Kansas - All except Northeast Lorenz Sales, Wichita, KS (316) 721-0500

Kentucky Corrao Marsh, Green eld, IN (317) 462-4446

Louisiana Philips Components, Willoughby, OH (440) 269-8585

Maine Philips Components, Woburn, MA (617) 932-4748

Maryland Philips Components, Willoughby, OH (440) 269-8585

Massachusetts Philips Components, Woburn, MA (617) 932-4748

Michigan Philips Components, Willoughby, OH (440) 269-8585

Minnesota Electronic Component Sales, Minneapolis, MN (612) 946-9510

Mississippi Over and Over, Charlotte, NC (704) 583-9100

Missouri - Eastern Lorenz Sales, St. Louis, MO (314) 997-4558

Missouri - Western Lorenz Sales, Overland Park, KS (913) 469-1312

Montana Electrodyne, Inc., Salt Lake City, UT (801) 264-8050

Nebraska Lorenz Sales, Cedar Rapids, IA (319) 377-4666

Nevada - Central and Northern Criterion Sales, Santa Clara, CA (408) 988-6300

Nevada - Sourthern Harper and Two, Tempe, AZ (602) 804-1290

New Hampshire Philips Components, Woburn, MA (617) 932-4748

New Jersey Philips Components, Woburn, MA (617) 932-4748

New Mexico Harper and Two, Tempe, AZ (602) 804-1290

New York - Western Philips Components, Willoughby, OH (440) 269-8585

New York - All other Philips Components, Woburn, MA (617) 932-4748

North Carlolina Over and Over, Charlotte, NC (704) 583-9100

North Dakota Electronic Component Sales, Minneapolis, MN (612) 946-9510

Ohio Philips Components, Willoughby, OH (440) 269-8585

Oklahoma Philips Components, Willoughby, OH (440) 269-8585

Oregon Eclipse Marketing Group, Beaverton, OR (503) 642-1661

Pennsylvania - Western Philips Components, Willoughby, OH (440) 269-8585

Pennsylvania - Eastern Philips Components, Woburn, MA (617) 932-4748

Rhode Island Philips Components, Woburn, MA (617) 932-4748

South Carolina Over and Over, Charlotte, NC (704) 583-9100

South Dakota Electronic Component Sales, Minneapolis, MN (612) 946-9510

Tennesse Over and Over, Charlotte, NC (704) 583-9100

Texas Philips Components, Willoughby, OH (440) 269-8585

Utah Electrodyne, Inc., Salt Lake City, UT (801) 264-8050

Vermont Philips Components, Woburn, MA (617) 932-4748

Virginia Philips Components, Willoughby, OH (440) 269-8585

Washington Eclipse Marketing Group, Redmond, WA (206) 885-6991

Washington DC Philips Components, Willoughby, OH (440) 269-8585

West Virginia Philips Components, Willoughby, OH (440) 269-8585

Wisconsin Philips Components, Willoughby, OH (440) 269-8585

Wyoming Electrodyne, Inc., Salt Lake City, UT (801) 264-8050

Canada Philips Components, Scarborough, ON (416) 292-5161

Mexico Philips Components, El Paso, TX (915) 772-4020

Puerto Rico Max Anderson Co., Caperra Heights, PR (809) 783-6544

Virgin Islands Max Anderson Co., Caperra Heights, PR (809) 783-6544

Loading...

Loading...