Page 1

Philips Medical Systems DMC GmbH

Replacement kit

for rel. 2 generators

9890 000 61323

Rotor Control HS

SERVICE MANUAL

742

UNIT

File this documentation in manual: OPTIMUS section 8 “SERVICE INFORMATION”

DMC Hamburg

Printed in Hamburg, Federal Republic of Germany

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

4512 984 22433 REV AA 1

titel _repl_roc o

Page 2

SERVICE MANUAL -- UNIT

Replacement kit Rotor Control HS Rel. 2

Replacement kit Rotor Control HS

for rel. 2 generators

Type No: 9890 000 61323

In case there are any questions concerning this manual,

please send this LOPAD via fax to 49/(0)40/5078 2481

File: RK_RoCo_HS_rel2_22433AA

Author: Th. Frenschek

List of pages and drawings (LOPAD) Manual Order No: 4512 984 22433

released: 10/2003

1

2

3...7 (03.0)

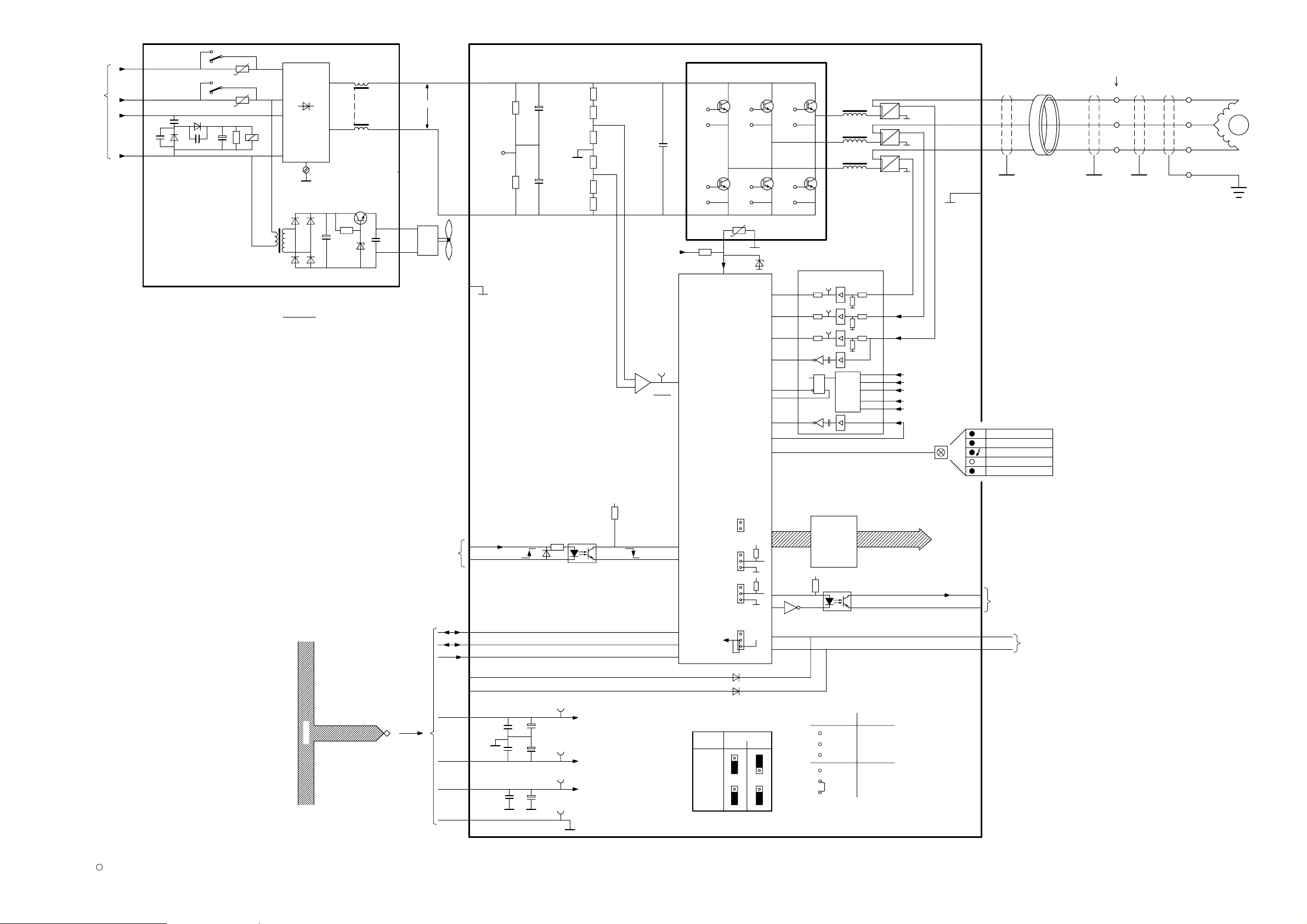

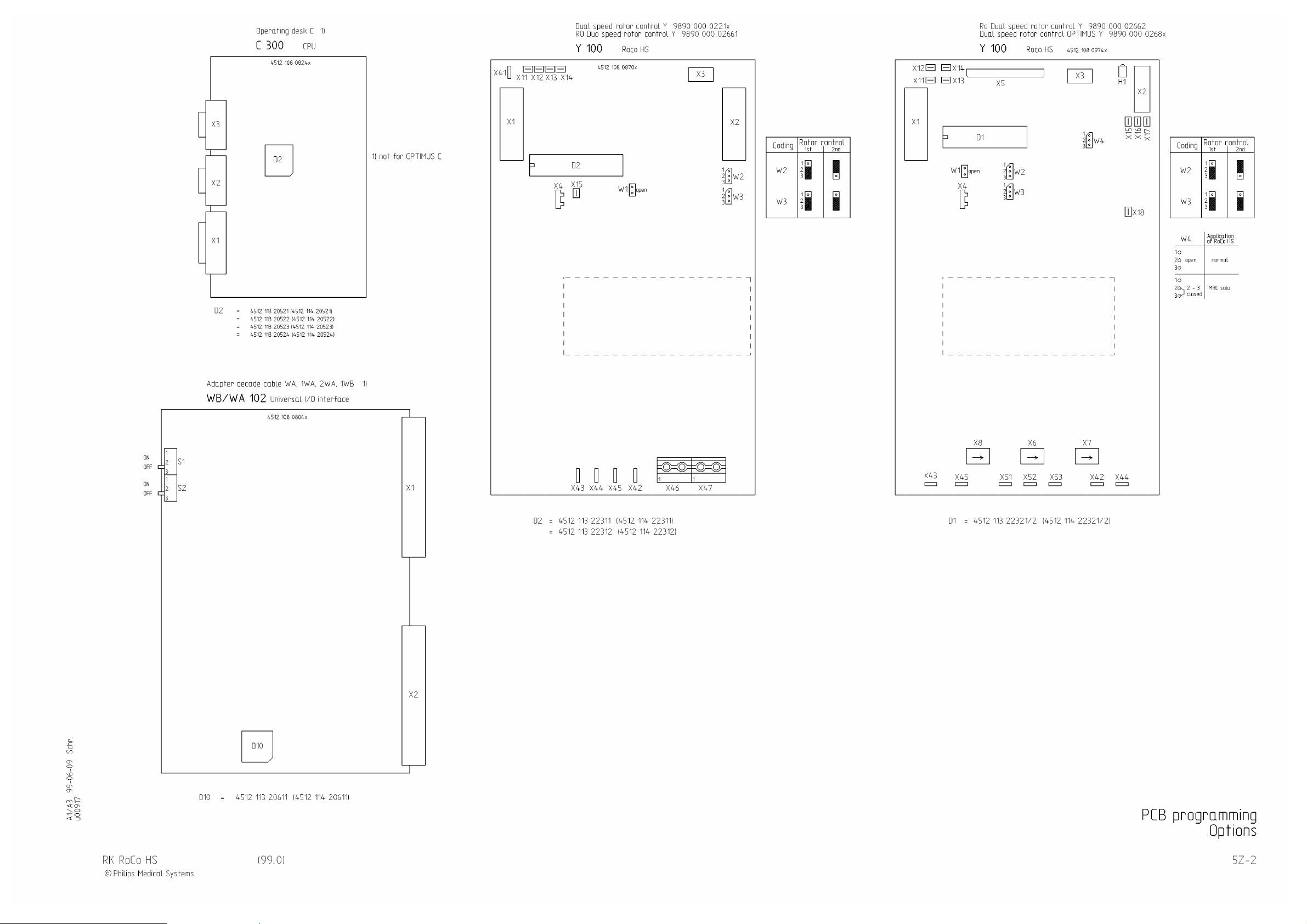

Z1-13.2 (c/00.0) A3 RK RoCo HS

5Z--2 (99.0) A3 RK RoCo HS

_____________________________

2

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

4512 984 22433 REV AA

rk_roc o_HS_rel2_22433_l opad

Page 3

Replacement kit rotor control HS rel. 2

1. Introduction

This document describes the detailed replacement procedure for the rotor control unit.

Additional stator inductance measurements are described to detect stator inductance problems which can lead to

rotor control failures.

2. Compatibility

Rotor control HS 9890 000 02212 4512 104 71401/2/3/4/5

OPTIMUS RAD 9890 000 02001 release ≤ 2.x

3. Scope of delivery

Rotor control HS unit replacement kit 9890 000 6132x

comprising

-- Rotor control HS 4512 104 7410x

including software 4512 1 13 22341

-- This manual 4512 984 22433AA

4. Tools

-- Standard tool set

-- Service PC with XRGScope

-- Inductivity measuring device to be obtained locally

or to be ordered at SL Hamburg (4512 101 77141)

5. Service reliability information

Permanently interested in quality improvement of the PMS products, we depend on information from the field.

Therefore, please send us the current generator logfile information.

Please download the generator errorlog logfile.

The filename must express the generator serial number and generator release.

e.g. ”23960234.tdl” for Rel. 2.3 and serial number 960234.

Send this file to:

Carsten Mais, Test & Integration Generators, PMS Hamburg,

as attachment to E-Mail.

E-Mail:

Carsten.Mais@philips.com

RK RoCo HS rel.2 (03.0) 3

rk_roc o_HS_rel2_030

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 4

Replacement kit rotor control HS rel. 2

6. Stator inductance test

This test is suitable to detect internal stator coil shortcircuits.

Depending on the location of a possible shortcircuit (number of shorted wires), the resistance of the coil still shows

a value within tolerance but the inductivity is out of tolerance. This leads to an increased stator current and can

destroy the rotor control unit.

SRO-Stator

(mH)

101 202

U

stator link wire

--10% +10%

U--V 101/103 –

= 1–2 ¶

51,7 57 62,7

SRO/RO

107/109

V--W208/210 –

202/204

= 2–3 ¶

30,6 34 37,4

V

W

109 210

-- Stator links not removed.

-- Stator wires U--V--W disconnected.

This check can be performed with a low--cost inductance measuring device to be obtained locally or to be ordered

at the SL Hamburg with the 12NC 4512 101 77141.

Please send the measuring results including the tube type and serial number together with generator serial number

and customer/site data to:

Dietmar Morgenstern Service Innovation

Tubes

Email: dietmar.morgenstern@philips.com

or to

Help Xray Hamburg

Email: Helpdesk.Xray

.Hamburg@philips.com

.

.

e.g.

XYZ hospital, Town, Country

SRO 25 50 serial number 89123 – 654123

Generator Optimus 50 970023

Inductance:

U--V = 56; V--W = 35

Appreciate your help and many thanks in advance.

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

RK RoCo HS rel.2(03.0)4

rk_roc o_HS_rel2_030

Page 5

Replacement kit rotor control HS rel. 2

7. Replacement procedure

Caution

Switch the generator off and disconnect it completely from mains with earth-leackage breaker or mains

switch!

7.1. Remove old RoCo unit

S Remove the data cable from back panel EZX 51 and leave it with the old RoCo unit.

S Disconnect the stator wires from the terminal EX 1100 (single tube generator).

In case Tube switch unit EWG is present:

S Remove plug EY 100 X3, it will be used again

later.

S Disconnect stator cable Y100 – EWG at EWG K11:1 :2 :3 and leave it with the old RoCo unit.

S Remove the mains wires from ENF3: T1 :T2 :T3 and ENX 1102 and leave them with the old RoCo unit.

S Remove the RoCo unit completely from the

generator.

7.2. Install the new RoCo unit

S Install the new unit into the generator.

S Connect the mains wires at ENF3: T1 :T2 :T3 and ground wire to ENX 1102.

S In case Tube switch unit EWG is present:

S Establish stator cable of RoCo unit at EWG K11: 1 :2 :3.

S Reestablish plug EY 100 X3.

Single tube generator

S Connect the stator cable to the terminal EX 1100 (U-V-W) and cable of RoCo unit likewise.

Make sure the screen of the stator cable is properly connected to ground.

S Relieve the tension on the stator cable with a cable tie.

EX1100

Note

-- Use screened cables. Connect the screen to

earth at both ends. (0722 215 02054)

-- Do not mix up the phases, otherwise

components of the rotor control may be

destroyed.

UVW

cable tie

terminal

rotor control

S Connect the data cable at EZX51.

for screen

tube

S Tighten all cables and wires with cable ties.

S Check that the start up and brake function of the tube works normal.

In case rotation prolongation is programmed: Once started with PREP, the anode keeps rotating for 30 s after

the last let go of the PREP position as long as no exposure has been switched. The tube finally stops if an

exposure has been switched or after 30 s or if any of the desk buttons have been activated.

RK RoCo HS rel.2 (03.0) 5

rk_roc o_HS_rel2_030

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 6

Replacement kit rotor control HS rel. 2

8. Documentation changes

S Exchange the drawings Z1--13.2 and 5Z--2 in service manual OPTIMUS RAD.

9. Return procedure

Due to the fact that no upgrade (or repair) to a new unit is possible this kit is not declared as ”EU” (Exchangable

Unit) therefore we only need the upgrade information to update the generator installed base database. Please send

the last page with all information we asked to the mentioned address.

S The old rotor control unit and cables are to be disposed of in a safe way in accordance with local safety

regulations.

S Fill out next page and send fax to mentioned address.

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

RK RoCo HS rel.2(03.0)6

rk_roc o_HS_rel2_030

Page 7

Replacement kit rotor control HS rel. 2

Fax message

H

Philips Medical Systems DMC GmbH

To: Günther Kramm Philips Medical Systems F ax: +494050781611

Service Innovation generators

Email: Guenther.Kramm@philips.com

From: Tel. :

Fax:

No. of pages:

(incl. cover sheet)

1

please copy

locally

Ref. : Date:

Subject: Rotor Control HS replacement feedback information

Release 2

HOSPITAL / ADDRESS :

LOCATION / FW SITE NO.: SALES ORDER NO. / OA NO.:

Generator PEI : 9 8 9 0 0 0 0 0 2 0 0 1

Generator Serial Number :

Rotor Control HS PCB Barcode # :

Completed per instruction on

BRANCH

REGION /

DEALER :

SIGNATURE CUSTOMER SUPPORT ENGINEER DATE

JOB NO. / SERVICE INCIDENT NO.:

DATE

SERVICE UNIT /

SERVICE AREA NO.:

RK RoCo HS rel.2 (03.0) 7

rk_roc o_HS_rel2_030

E

2003 Philips Medical Systems

ALL RIGHTS RESERVED

Page 8

Dual speed rotor control

blkX9:3

generator CAN high active

generator CAN low active

Current phase n

input voltage intermediate voltage

negative intermediate (voltage)

phase current (phase) U

phase voltage (phase) U

positive intermediate (voltage)

rotor control stator 2

rotor control stator 3

short circuit clear

short circuit detection

not used

(c/00.0)

~

from ENF3

3 400V

Power supply

00-09-04 Schr.

RK RoCo HS

OPTIMUS RF Z1-13.2

Z1-13.2

c

Philips Medical Systems

A1/A3

READY GND

RCST2/

READY C = MRCRD

RCST3/

Rotor control

Start

2

IGBT modul

Start __ HI/

-

Rotor control HS

4512 108 0974.

+5V

GND

m

47

47

37

W

V

No. 1...12

X2:2

X2:1

EY100

normal

MRC Solo

Tube extension,

switch over of stator contactors

X3:1

X3:2

Application

of RoCo HS

W

V

PH U CU

951

10 6 2 X52 V

11

12

X53 W

84

IM U

X18

CU U1

CU U1

IGBT - Modul

L3

12

L2

X2

K1

14

21

22

X1

L1

K1

24

X51 U

SH

3 windings

X3

L2

ring core

PO IM

P+

U

5

18

X7

V

4

CU W1

PO

11

X43

NG

X6

560V DC

X7

3

A

5

X8

V

4

3

A

W

Uref=+5V

2K15

X42

X4:1

X16

CU V

NG IM

CU U1

CU V1

CU W1

Measurement protection

CU V1

1

2

3

3

W2

Coding

W3

W1

1

W2

2

3

1

W3

1st 2nd

1

W4

2)

9,3A/V

3

open

1

2 - 3

2

closed

3

1

2

L1

6

X2:4

m

X1:12

X1:13

X11

X12

X14

-15V

X4

N

rdX9:1

T2

EZX51

XRG-BUS

100

X15

CU U

STATUS

SDN/

SDCL/

PH U VO

Driver

1)

1) ignore W1

U

Computer

control

N-

NTC

X4:3

X17

9,3A/V

9,3A/V

CU W

TMP I6BT

decoupling

+

Logic

and

Trigger

2

W4

with

galvanic

2

3

1

3

10K 10K

NN1

START HIX2:3

-

N IM

X41

GND

X44

reset Fu

M1

positive

negative

+

-

-

Selftest

Ready

Watch dog error

not used

open

+

2)

+5V

MRC SOLO

+

mode:

address:

1V

142,5V

+

-

+15V VDD

H1

-15V VEE

CU W1

CU V1

U PHASE

CAN-announcement

U

or

tube extension

EY

9890 000 0268x

EY200

RoCo Rectifier

>

4512 108 09604-

Mnemonics

CAN H

CAN L

CU n

IM U

NG

NG IM

PH U CU

PH U VO

PO

PO IM

RC ST 2/

RC ST 3/

RESET C/

SDCL/

SDN/

X13

CAN H

CAN L

+15V

RESET C/

X1:3

X1:2

X1:10

X1:7

m

X1:8

X1:4

X1:5

X1:6

.

.

.

X1:11

M

X1:17

terminal EX1100

RO/SRO tubes

U

V

4

15 5

V

X45

X6

6

L2

6

3

L3

16

A

A1

Filter and

K1

rectifier

A2

Direction of blow of fan M1: down

Page 9

Loading...

Loading...