Page 1

Colour Television Chassis

VE8

Q529.1A

LA

VE8

I_17670_000.eps

230408

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 6

3. Directions for Use 7

4. Mechanical Instructions 8

5. Service Modes, Error Codes, and Fault Finding 12

6. Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram 42"-47" (VE8) 33

Wiring Diagram 52" (VE8) 34

Block Diagram Main Display Supply (42") 35

Block Diagram Video 36

Block Diagram Audio 37

Block Diagram Control & Clock Signals 38

SSB: Test Points (Top Side) 39

SSB: Test Points (Bottom Side) 40

I2C IC Overview 41

Supply Lines Overview 42

7. Circuit Diagrams and PWB Layouts Drawing PWB

Main Power Supply IPB 42: Stby, MF (A1)43 46-47

Main Power Supply IPB 42: HV Inverter (A2)44 46-47

Main Power Supply IPB 42: DC / DC (A3) 45 46-47

Small Signal Board (B01-B10) 48-100 104-113

SSB: SRP List Explanation 101

SSB: SRP List Part 1 102

SSB: SRP List Part 2 103

IR & LED Panel (VE) (J)114 115

Light Guide Panel (L) 116 117

8. Alignments 119

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 122

Abbreviation List 130

IC Data Sheets 133

10. Spare Parts List 141

11. Revision List 141

©

Copyright 2008 Koninklijke Philips Electronics N.V.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by EL 0864 BU TV Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 17670

Page 2

EN 2 Q529.1A LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 42" (107 cm), 16:9

: 47" (120 cm), 16:9

: 52" (132 cm), 16:9

Resolution (H × V pixels) : 1920 × 1080

Min. light output (cd/m

Min. contrast ratio : 30000:1 (42" and 47")

Max. response time (ms) : 2

Viewing angle (H × V degrees) : 176 × 176

Tuning system : PLL

TV Colour systems : PAL B/G, D/K, I

Video playback : NTSC

Tuner bands : UHF, VHF, S, Hyper

Supported video formats

- 60 Hz : 480i

- 60 Hz : 480p

- 50 Hz : 576i

- 50 Hz : 576p

- 50/60 Hz : 720p

- 50/60 Hz : 1080i

- 24/25/30/50/60 Hz : 1080p

Supported computer formats:

- 60 Hz : 640 × 480

- 60 Hz : 800 × 600

- 60 Hz : 1024 × 768

- 60 Hz : 1280 × 768

- 60 Hz : 1360 × 768

- 60 Hz : 1920 × 1080i

- 60 Hz : 1920 × 1080p

Presets/channels : 100/125 presets

Tuner bands : VHF

2

) : 500

: 450 (52")

: 55000:1 (52")

: SECAM B/G, D/K, L/L’

: DVB-T COFDM 2K/

: PAL

: SECAM

: UHF

: S-band

: Hyper-band

8K, MPEG4 (optional)

: JPEG

USB input : USB1.1 (12 Mbps)

Network : DLNA PC Network

1.1.4 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50 / 60

Ambient conditions:

- Temperature range (°C) : +5 to +35

Power consumption (values are indicative)

- Normal operation (W) : ≈ 232 (42")

- Standby (W) : < 0.15

Dimensions (W × H × D in mm) : 1054 × 658 × 100

Weight (kg) : 22.7 (42")

) : 220 - 240 ±10%

AC

: USB2.0 (480 Mbps)

link

: 90% R.H.

: ≈ 275 (47")

: ≈ 275 (52")

(42")

:1157× 752 × 117

(47")

:1300× 803 × 127

(52")

: 35.0 (47")

: 43.0 (52")

1.1.2 Sound

Sound systems : FM-stereo B/G

Maximum power (W

1.1.3 Multimedia

Supported formats : Slideshow.alb files

):2 × 15

RMS

: NICAM B/G, D/K, I, L

: AV Stereo

: Virtual Dolby Digital

: BBE

: MPEG1

: MPEG2

:MP3

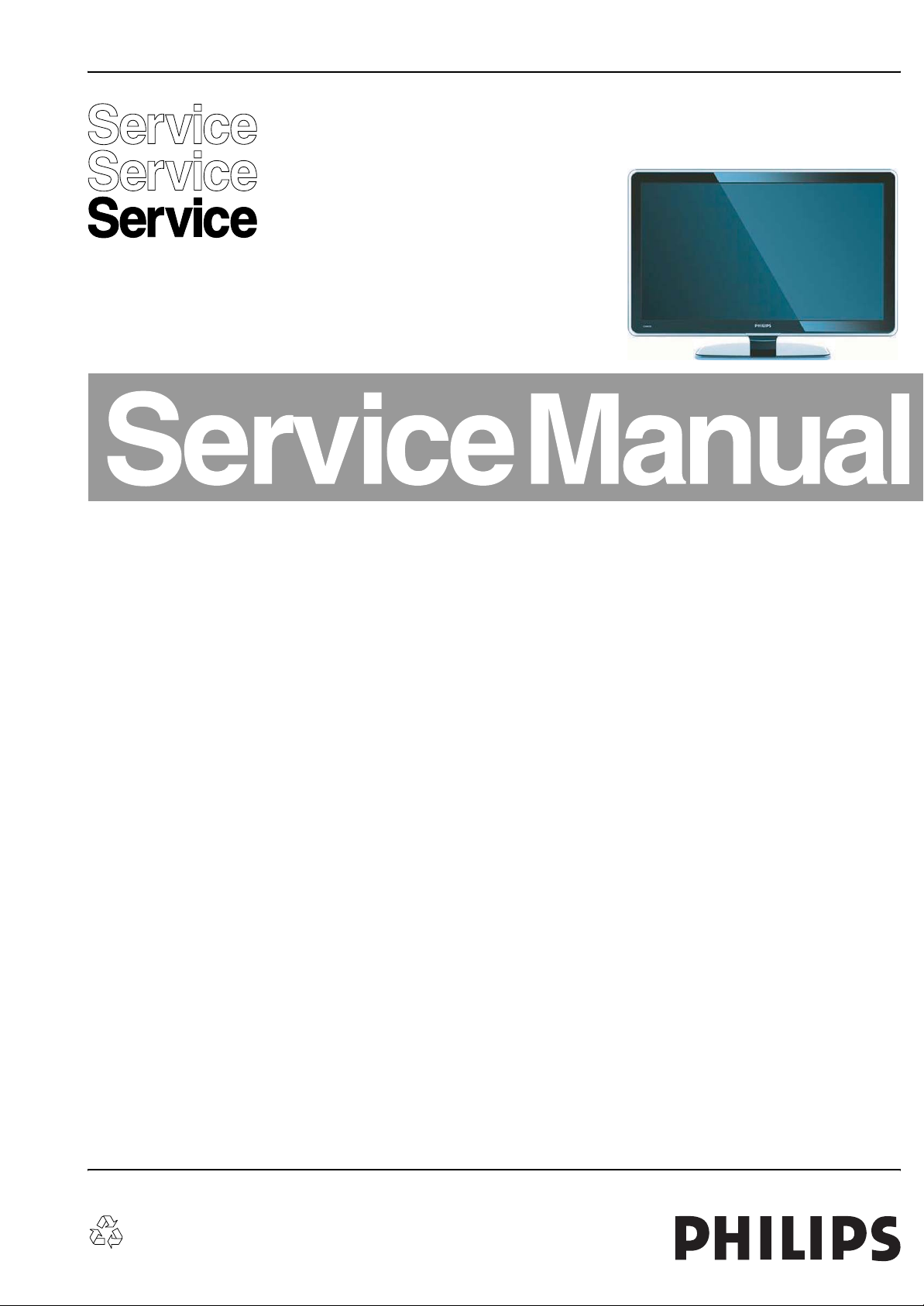

Page 3

Technical Specifications, Connections, and Chassis Overview

EN 3Q529.1A LA 1.

1.2 Connections

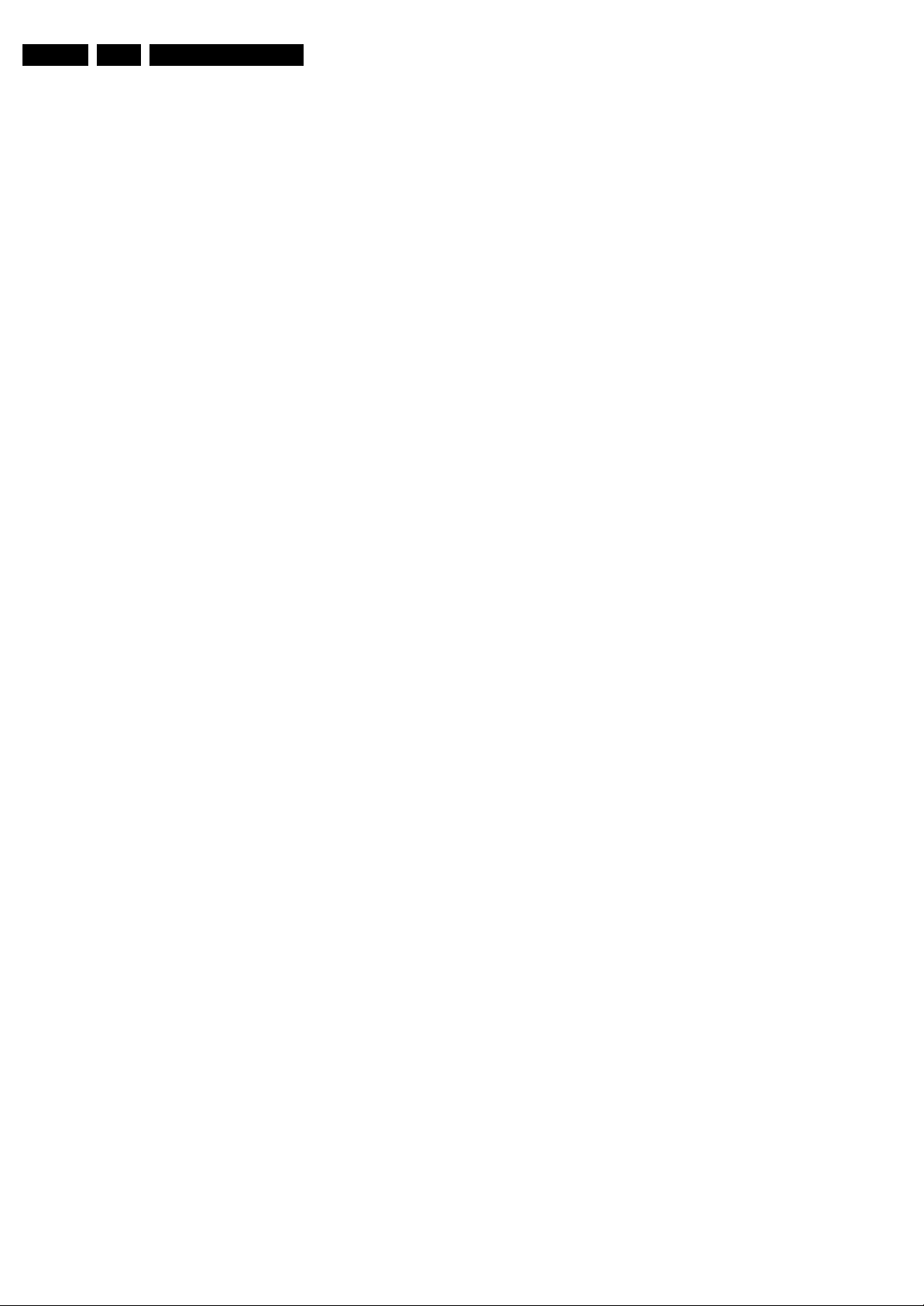

5. USB 2.0

1 2 3 4

E_06532_022.eps

300904

Figure 1-2 USB (type A)

1-+5V k

2 -Data (-) jk

3 -Data (+) jk

4 -Ground Gnd H

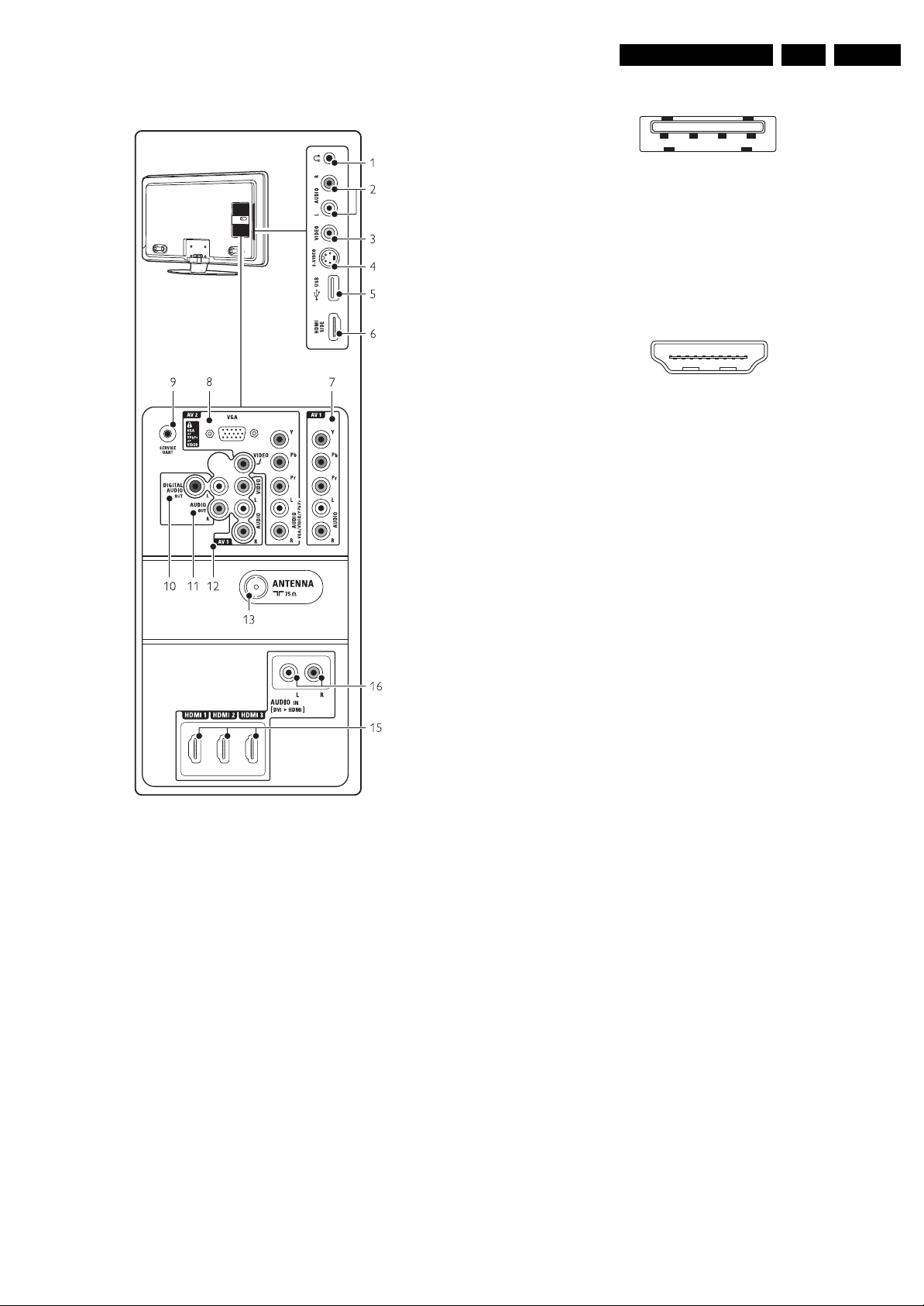

6. HDMI: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 -D2+ Data channel j

2-Shield Gnd H

3 -D2- Data channel j

4 -D1+ Data channel j

5-Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8-Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

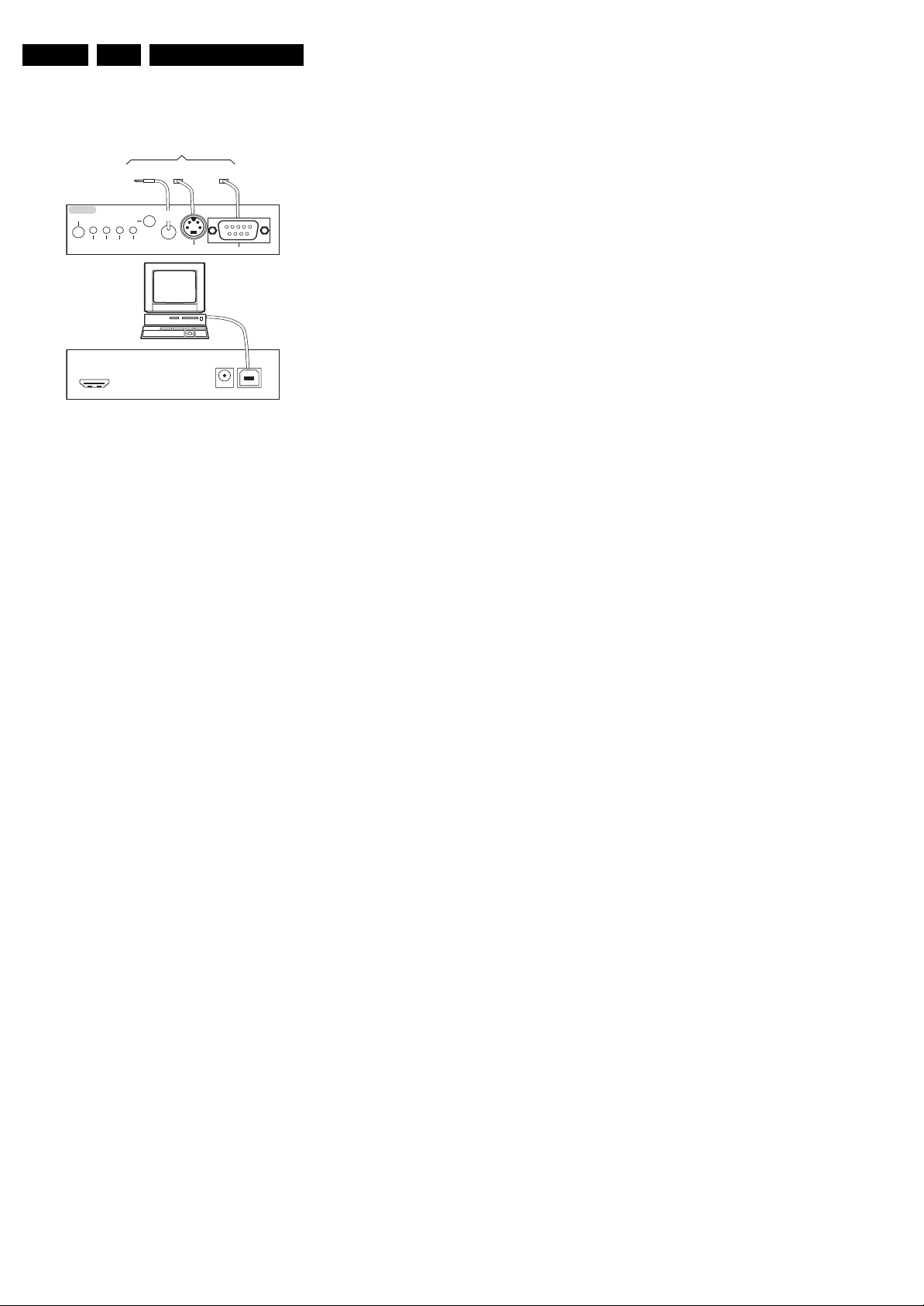

I_17670_001.eps

290408

Figure 1-1 Connection overview

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green,

Gy= Grey, Rd= Red, Wh= White, Ye= Yellow.

1.2.1 Side Connections

1. Headphone (Output)

Bk - Headphone 32 - 600 ohm / 10 mW ot

2, 3. Cinch: Video CVBS - In, Audio - In

Rd - Audio R 0.5 V

Wh - Audio L 0.5 V

Ye - Video CVBS 1 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

4. S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 -Video Y 1 V

4 -Video C 0.3 V

/ 75 ohm j

PP

/ 75 ohm j

PP

Page 4

EN 4 Q529.1A LA1.

Technical Specifications, Connections, and Chassis Overview

1.2.2 Rear Connections

7. AV1: Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

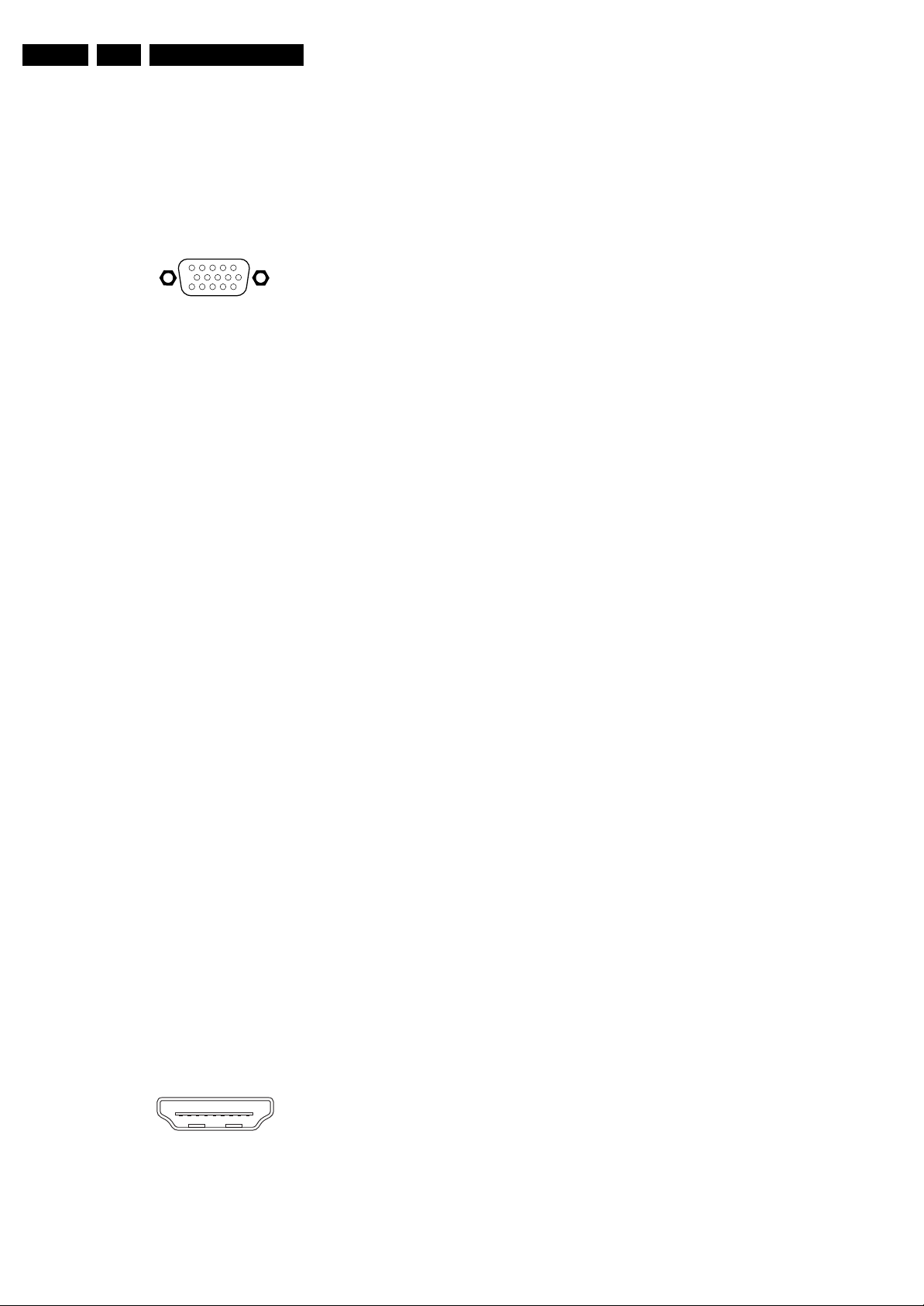

8. AV2: VGA: Video RGB - In

1

5

6

11

10

15

E_06532_002.eps

050404

Figure 1-4 VGA Connector

1 -Video Red 0.7 V

2 -Video Green 0.7 V

3 -Video Blue 0.7 V

4-n.c.

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

5 -Ground Gnd H

6 -Ground Red Gnd H

7 -Ground Green Gnd H

8 -Ground Blue Gnd H

9-+5V

10 - Ground Sync Gnd H

DC

+5 V j

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

4 -D1+ Data channel j

5-Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8-Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

16. Cinch: Audio - In

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

8. AV2: Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

9. Service Connector (UART)

1 -Ground Gnd H

2 -UART_TX Transmit k

3 -UART_RX Receive j

10. AV3: Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

/ 75 ohm kq

PP

11. AV3: Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

12. AV3: Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

13. Aerial - In

- - IEC-type (EU) Coax, 75 ohm D

15. HDMI 1, 2 & 3 Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-5 HDMI (type A) connector

1 -D2+ Data channel j

2-Shield Gnd H

3 -D2- Data channel j

Page 5

Technical Specifications, Connections, and Chassis Overview

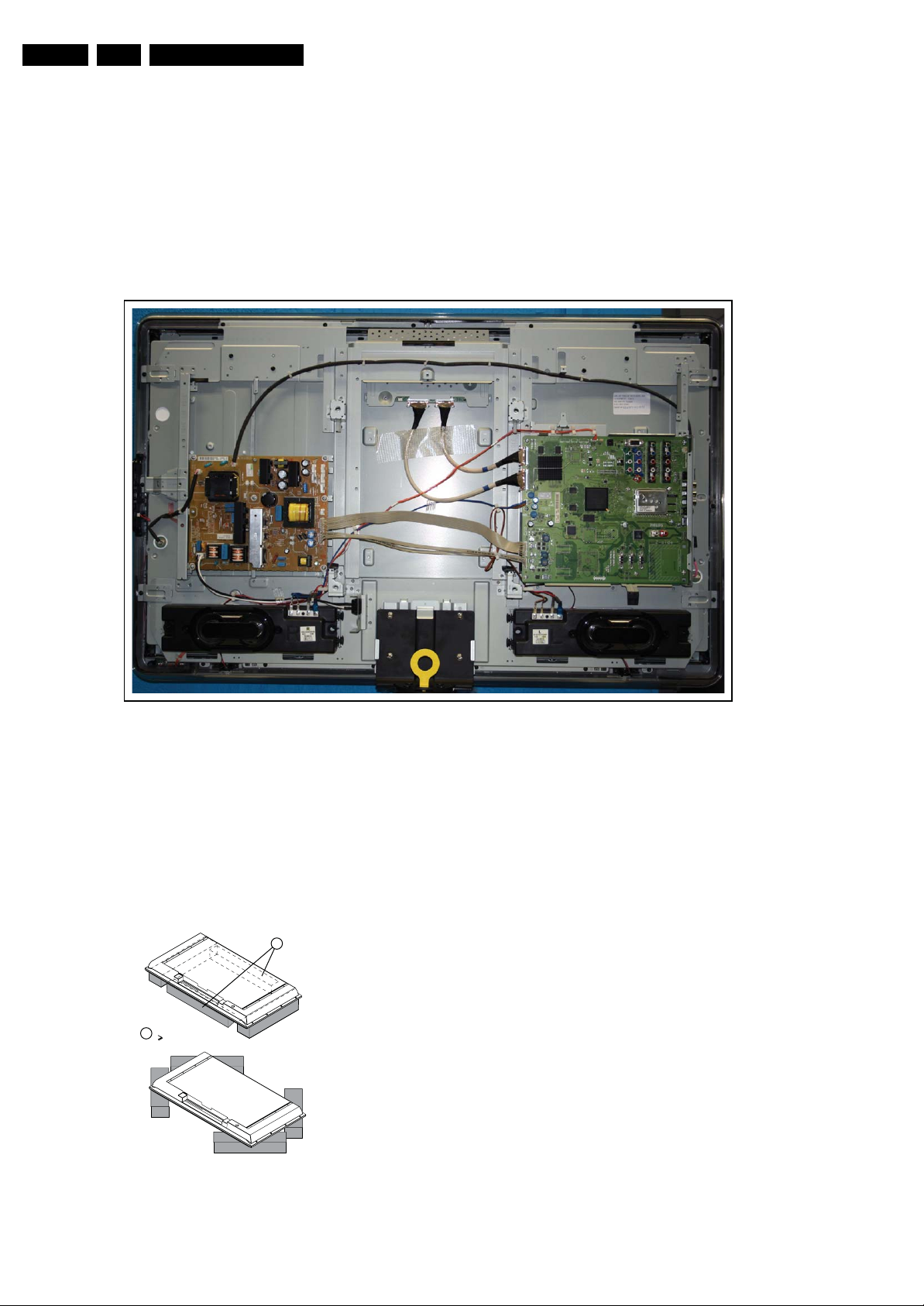

1.3 Chassis Overview

MAIN

A

SUPPLY PANEL

EN 5Q529.1A LA 1.

KEYBOARD CONTROL

E

PA NE L

IR & LED PANEL

J

Figure 1-6 PWB/CBA locations

SMALL SIGNAL

BOARD

LIGHT GUIDE

PA NE L

I_17670_002.eps

B

L

290408

Page 6

EN 6 Q529.1A LA2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic”, “Virtual Dolby Digital” and the “doubleD symbol”, are trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ = × 10

nano-farads (n = × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

-9

), or pico-farads (p = × 10

-12

-6

),

).

Page 7

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Directions for Use

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

220-240V 50/60Hz

VHF+S+H+UHF

S

Figure 2-1 Serial number (example)

2.3.6 Board Level Repair (BLR) or Component Level Repair

(CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

EN 7Q529.1A LA 3.

MADE IN BELGIUM

~

128W

BJ3.0E LA

E_06532_024.eps

260308

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 8

EN 8 Q529.1A LA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal VE8 Styling

4.4 Set Re-assembly.

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging (see figure “Rear cover”).

• Foam bars (created for Service).

4.2.1 Foam Bars

1

Required for sets

1

42"

Figure 4-1 Cable dressing

I_17670_003.eps

280408

bars” for details. Sets with a display of 42" and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, the screen can

be monitored.

E_06532_018.eps

171106

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

Page 9

Mechanical Instructions

EN 9Q529.1A LA 4.

4.3 Assy/Panel Removal VE8 Styling

Note: the following disassembly-instructions apply to the

European sets. Small deviations with the AP sets occur.

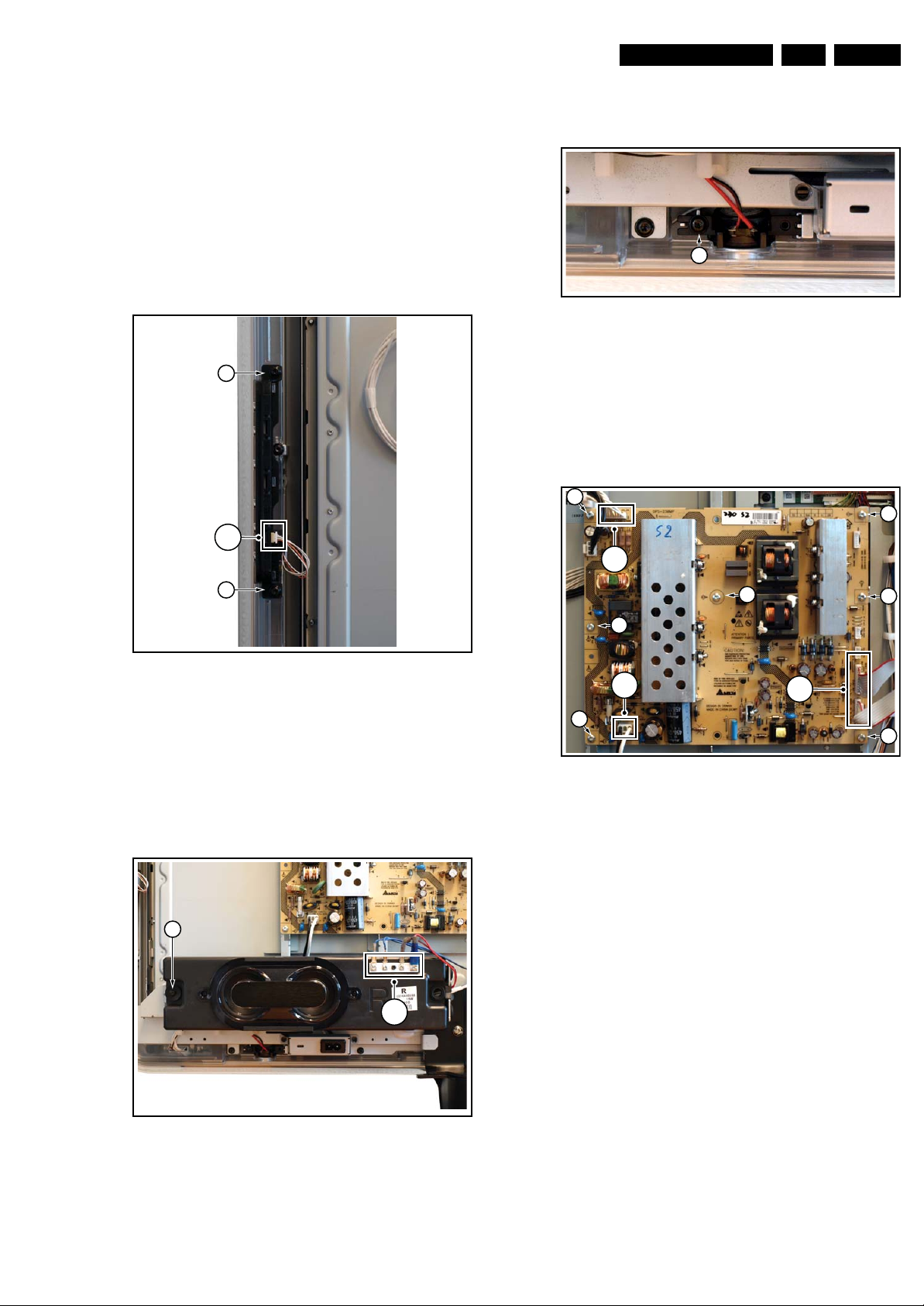

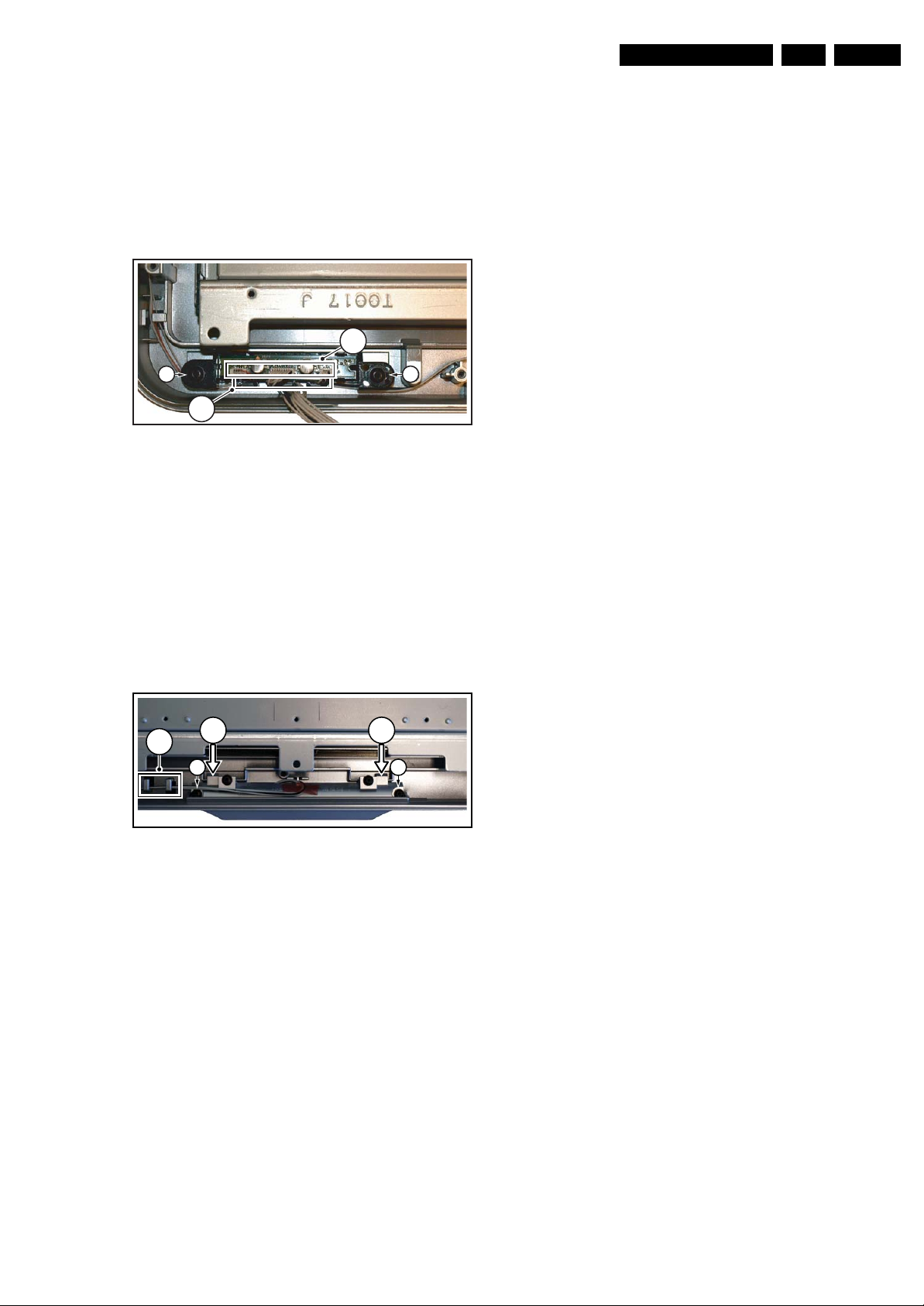

4.3.1 Key Board

Refer to next figure for details.

1. Unplug the key board connector [1] from the IR & LED

board.

2. Remove the screws [2].

3. Lift the unit and take it out of the set.

When defective, replace the whole unit.

2

1

1. Remove the bass-midrange speaker as described earlier.

2. Remove the screw [1] and lift the whole unit from the set.

When defective, replace the whole unit.

1

Figure 4-5 Tweeters

4.3.4 Display Supply Panel

Refer to next figure for details.

1. Unplug the connectors [1].

2. Remove the fixation screws [2].

3. Take the board out.

2

1

I_17660_112.eps

130308

2

2

Figure 4-3 Key Board

4.3.2 Bass-midrange Speakers

Refer to next figure for details.

1. Release the speaker connectors [1] from unit.

2. Remove the screw [1] and lift the whole unit from the set.

Take the speakers out together with their casing. When

defective, replace the whole unit.

2

I_17660_110.eps

130308

1

2

2

1

2

2x

(

2

Figure 4-6 Display Supply Panel

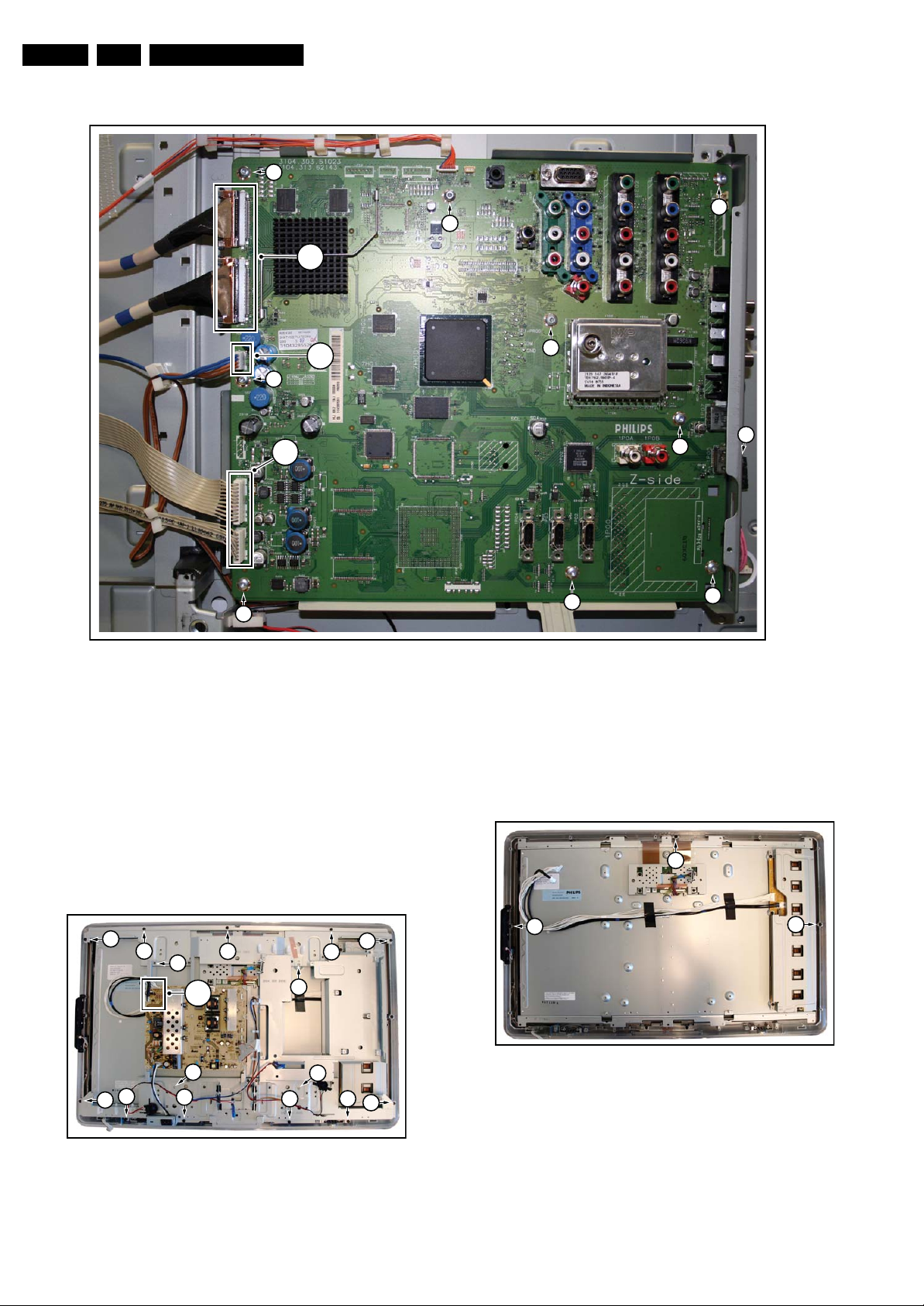

4.3.5 Small Signal Board (SSB)

Refer to next figure for details.

Caution: it is mandatory to remount all different screws at their

original position during re-assembly. Failure to do so may result

in damaging the SSB.

1. Unplug the LVDS connector(s) [1].

Caution: be careful, as this is a very fragile connector!

2. Unplug the connectors [2].

3. Remove the screw [3] from the side I/O cover.

4. Remove the fixation screws [4].

5. The SSB can now be taken out of the set.

)

I_17660_113.eps

2

2

130308

Figure 4-4 Bass-midrange Speaker

4.3.3 Tweeters

Refer to next figure for details.

I_17660_111.eps

130308

Page 10

EN 10 Q529.1A LA4.

Mechanical Instructions

4

1

2x

)

(

4

4

4

2

2x

)

(

4

4.3.6 LCD Panel

Refer to next figure for details.

1. Remove the SSB as described earlier.

2. Remove the Bass-midrange speakers as described earlier.

3. Remove the Tweeters as described earlier.

4. Unplug the connectors [1].

5. Remove the fixation screws [2].

6. Remove the fixation screws [3].

7. Lift out the sub frame.

8. The LCD panel can now be lifted from the front cabinet.

When defective, replace the whole unit.

2

Figure 4-7 Small Signal Board

4.3.7 Rim

4

4

4

I_17670_004.eps

3

4

280408

Refer to next figure for details.

1. Do all steps as described in the removal of the LCD panel

except the last step.

2. Remove the screws [1], and take out the rim.

1

2

2

3

2

2

2

1

2x

)

(

3

3

3

2

2

2

22

2

I_17660_115.eps

130308

Figure 4-9 Rim

1

1

I_17660_116.eps

130308

Figure 4-8 LCD Panel

Page 11

4.3.8 IR & LED Board

Refer to next figure for details.

1. Do all steps as described in the removal of the Rim.

2. Remove screws [1] and lift the IR & LED Board from the

front cover.

3. Lift the board and take it out of the set.

4. Release the cables from the cable clamps.

5. Unplug the connectors [2].

When defective, replace the whole unit.

2

3x)

(

Mechanical Instructions

EN 11Q529.1A LA 4.

1

2

Figure 4-10 IR & LED Board

4.3.9 Lightguide

Refer to next figure for details.

1. Do all steps as described in the removal of the Rim.

2. Release the cables from the cable clamps [1].

3. Remove screws [2] and lift the lightguide from the front

cover.

4. Release the board by pushing up the clamps in the

direction of the arrows [3].

5. Remove the unit from the front cover.

When defective, replace the whole unit.

1

3 3

2 2

1

I_17660_117.eps

290408

Figure 4-11 Lightguide

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure “Cable

dressing”.

• Pay special attention not to damage the EMC foams on the

SSB shields. Ensure that EMC foams are mounted

correctly.

I_17660_118.eps

140308

Page 12

EN 12 Q529.1A LA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Stepwise Start-up

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Fault Finding and Repair Tips

5.9 Software Upgrading

5.1 Test Points

As most signals are digital, it will be difficult to measure

waveforms with a standard oscilloscope. However, several key

ICs are capable of generating test patterns, which can be

controlled via ComPair. In this way it is possible to determine

which part is defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default mode (SDM) and Service Alignment Mode

(SAM) offers several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between the call centre and the customer.

This chassis also offers the option of using ComPair, a

hardware interface between a computer and the TV chassis. It

offers the abilities of structured troubleshooting, error code

reading, and software version read-out for all chassis.

(see also section “5.4.1 ComPair”).

5.2.1 Service Default Mode (SDM)

– Skip/blank of non-favourite pre-sets.

How to Activate SDM

For this chassis there are two kinds of SDM: an analog SDM

and a digital SDM. Tuning will happen according table “SDM

Default Settings”.

• Analog SDM: use the standard RC-transmitter and key in

the code “062596”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it “off”, push the “MENU”

button again.

• Digital SDM: use the standard RC-transmitter and key in

the code “062593”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it “off”, push the “MENU”

button again.

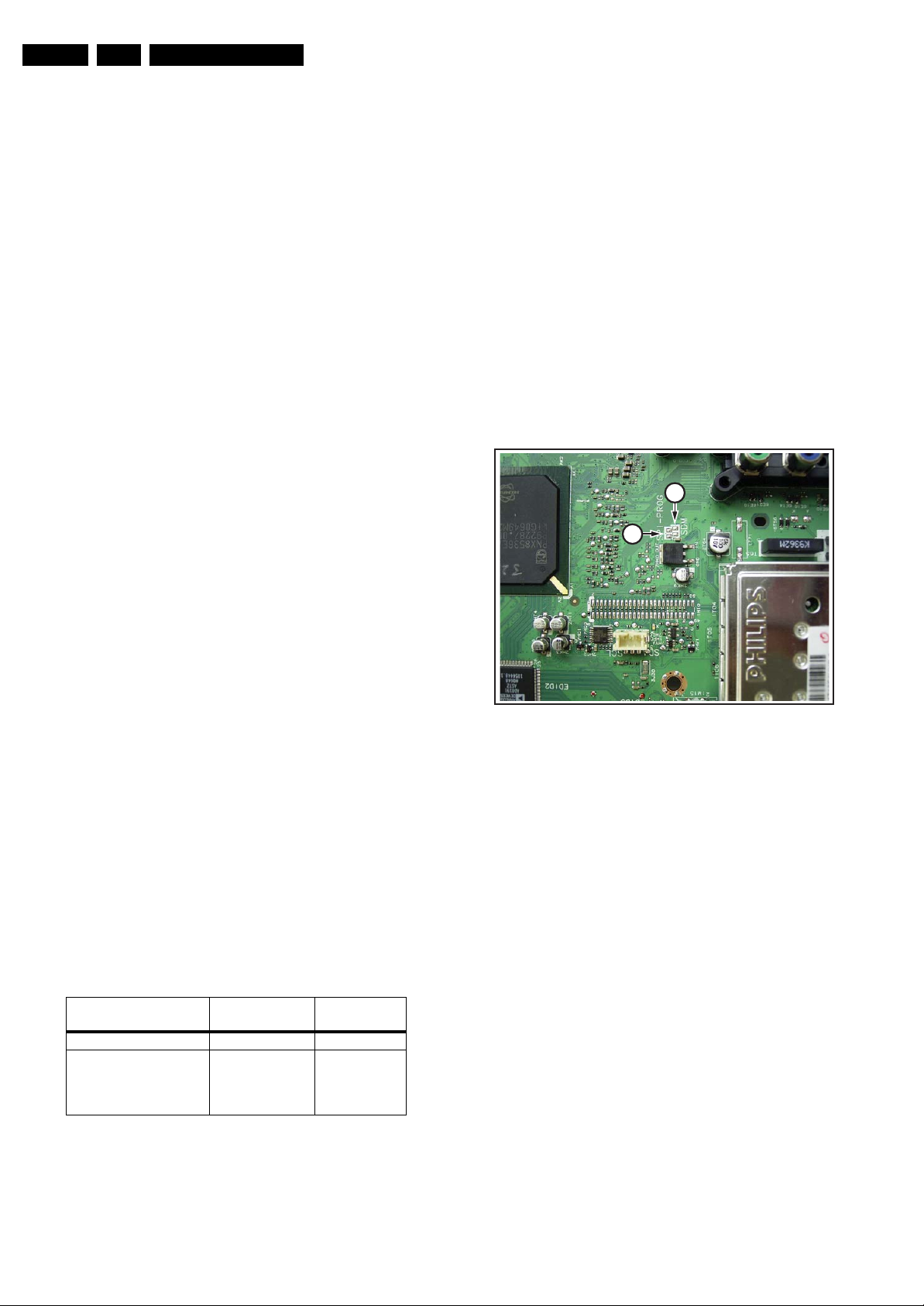

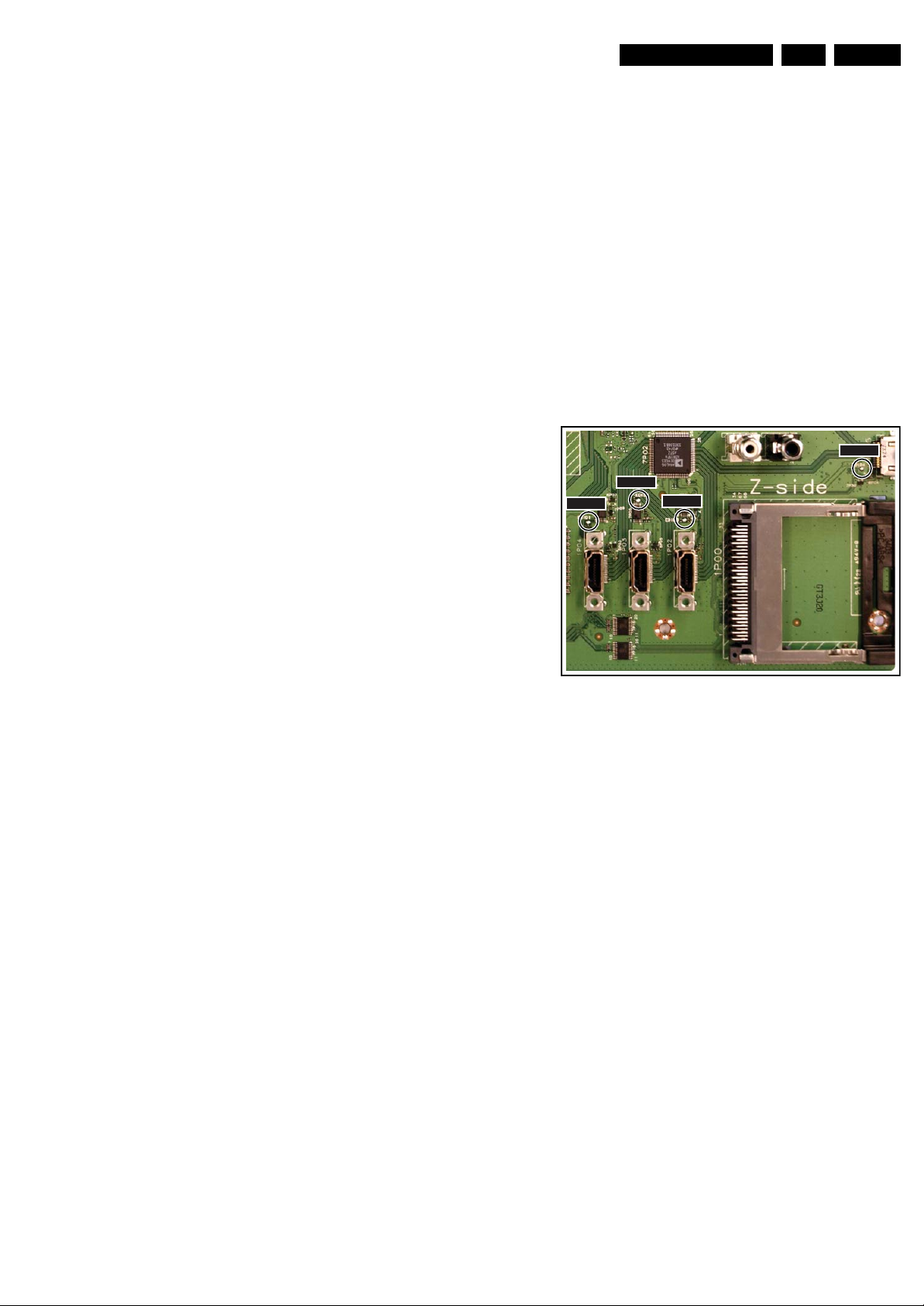

• Analog SDM can also be activated by shorting for a

moment the two solder pads (see figure “Service mode

pads”) on the SSB, with the indication “SDM”.

1

2

H_16770_100.eps

130707

Figure 5-1 Service mode pads

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections detected by stand-by

processor and make the TV start up to the step just before

protection (a sort of automatic stepwise start up). See

section “5.3 Stepwise Start-up”.

• To start the blinking LED procedure where only layer 2

errors are displayed. (see also section “5.5 Error Codes”)

Specifications

Table 5-1 SDM default settings

Default

Region Freq. (MHz)

Europe, AP(PAL/Multi) 475.25 PAL B/G

Europe, AP DVB-T 546.00 PID

Video: 0B 06 PID

PCR: 0B 06 PID

Audio: 0B 07

• All picture settings at 50% (brightness, colour, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

– Picture mute (blue mute or black mute).

– Automatic volume levelling (AVL).

system

DVB-T

After activating this mode, “SDM” will appear in the upper right

corner of the screen (when a picture is available).

How to Navigate

When the “MENU” button is pressed on the RC transmitter, the

set will toggle between the SDM and the normal user menu

(with the SDM mode still active in the background).

How to Exit SDM

Use one of the following methods:

• Switch the set to STAND-BY via the RC-transmitter.

• Via a standard customer RC-transmitter: key in “00”sequence.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

How to Activate SAM

Via a standard RC transmitter: key in the code “062596”

directly followed by the “INFO” button. After activating SAM

with this method a service warning will appear on the screen,

continue by pressing the red button on the RC.

Page 13

Service Modes, Error Codes, and Fault Finding

Contents of SAM:

• Hardware Info.

– A. SW Version. Displays the software version of the

main software (example: Q591A-1.2.3.4 =

AAAAB_X.Y.W.Z).

• AAAA= the chassis name.

• B= the region: A= AP, E= EU, L= LatAm, U = US.

For AP sets it is possible that the Europe software

version is used.

• X.Y.W.Z= the software version, where X is the

main version number (different numbers are not

compatible with one another) and Y.W.Z is the sub

version number (a higher number is always

compatible with a lower number).

– B. SBY PROC Version. Displays the software version

of the stand-by processor.

– C. Production Code. Displays the production code of

the TV, this is the serial number as printed on the back

of the TV set. Note that if an NVM is replaced or is

initialized after corruption, this production code has to

be re-written to NVM. ComPair will foresee in a

possibility to do this.

• Operation Hours. Displays the accumulated total of

operation hours (not the stand-by hours). Every time the

TV is switched “on/off”, 0.5 hours is added to this number.

• Errors (followed by maximum 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see section “5.5 Error Codes”).

• Reset Error Buffer. When “cursor right” (or the “OK

button) is pressed and then the “OK” button is pressed, the

error buffer is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu.

• Dealer Options. Extra features for the dealers.

• Options. Extra features for Service. For more info

regarding option codes, see chapter 8 “Alignments”.

Note that if the option code numbers are changed, these

have to be confirmed with pressing the “OK” button before

the options are stored. Otherwise changes will be lost.

• Initialize NVM. The moment the processor recognizes a

corrupted NVM, the “initialize NVM” line will be highlighted.

Now, two things can be done (dependent of the service

instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initializing. This will give

the Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialize the NVM.

Note: When the NVM is corrupted, or replaced, there is a high

possibility that no picture appears because the display code is

not correct. So, before initializing the NVM via the SAM, a

picture is necessary and therefore the correct display option

has to be entered. Refer to chapter 8 “Alignments” for details.

To adapt this option, it’s advised to use ComPair (the correct

HEX values for the options can be found in chapter 8

“Alignments”) or a method via a standard RC (described

below).

Changing the display option via a standard RC: Key in the

code “062598” directly followed by the “MENU” button and

“XXX” (where XXX is the 3 digit decimal display code as

mentioned in table “Option code overview” in chapter 8

“Alignments”). Make sure to key in all three digits, also the

leading zero’s. If the above action is successful, the front LED

will go out as an indication that the RC sequence was correct.

After the display option is changed in the NVM, the TV will go

to the Stand-by mode. If the NVM was corrupted or empty

before this action, it will be initialized first (loaded with default

values). This initializing can take up to 20 seconds.

EN 13Q529.1A LA 5.

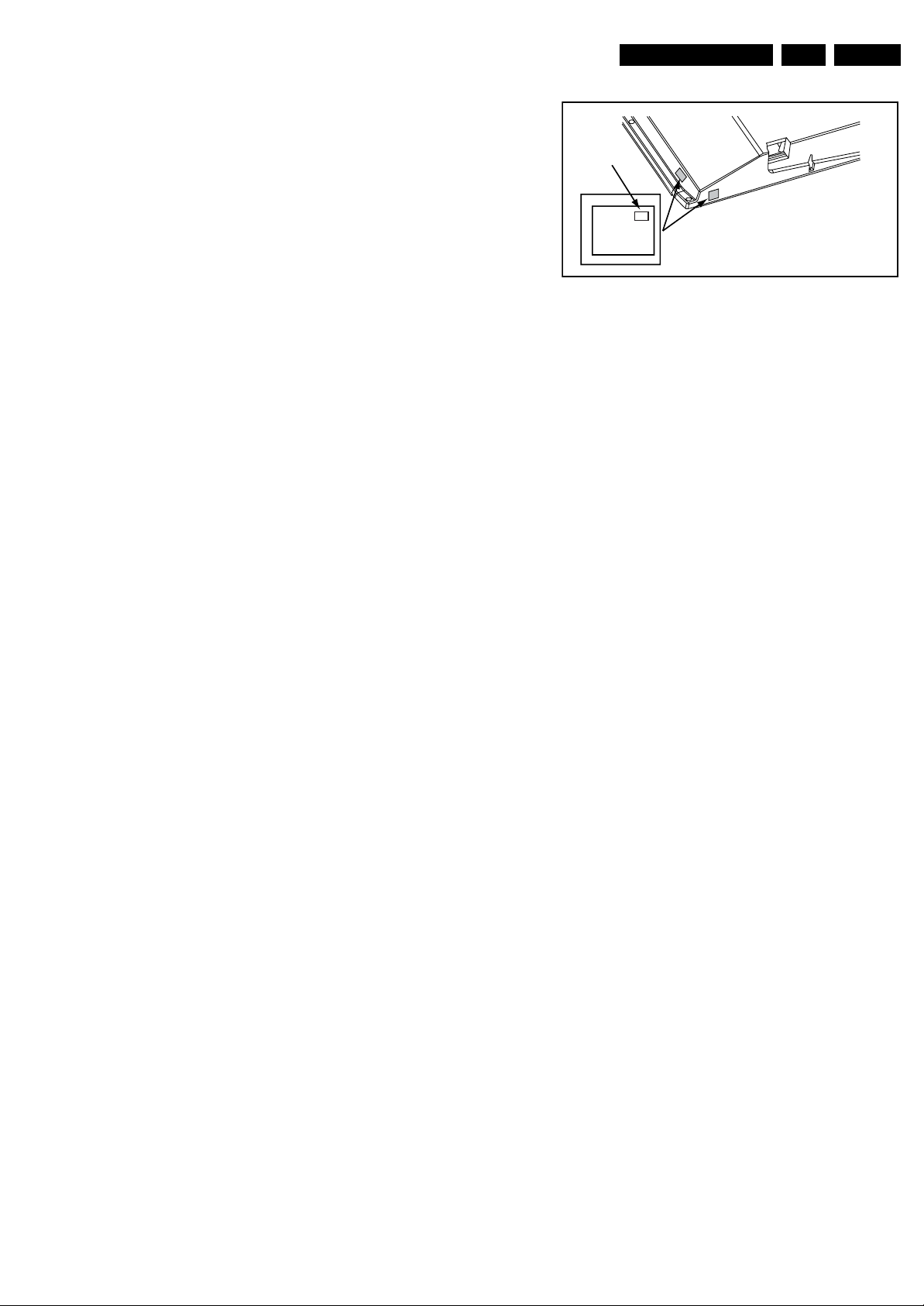

Display Option

Code

39mm

040

PHILIPS

MODEL:

32PF9968/10

27mm

PROD.SERIAL NO:

AG 1A0620 000001

(CTN Sticker)

E_06532_038.eps

240108

Figure 5-2 Location of Display Option Code sticker

• Store - go right. All options and alignments are stored

when pressing “cursor right” (or the “OK” button) and then

the “OK”-button.

• SW Maintenance.

– SW Events. Not useful for Service purposes. In case

of specific software problems, the development

department can ask for this info.

– HW Events. Not useful for Service purposes. In case

of specific software problems, the development

department can ask for this info.

• Test settings. For development purposes only.

• Upload to USB. To upload several settings from the TV to

an USB stick, which is connected to the SSB. The items are

“Channel list”, “Personal settings”, “Option codes”,

“Display-related alignments” and “History list”. First a

directory “repair\” has to be created in the root of the USB

stick. To upload the settings select each item separately,

press “cursor right” (or the “OK button), confirm with “OK”

and wait until “Done” appears. In case the download to the

USB stick was not successful “Failure” will appear. In this

case, check if the USB stick is connected properly and if

the directory “repair” is present in the root of the USB stick.

Now the settings are stored onto the USB stick and can be

used to download onto another TV or other SSB.

Uploading is of course only possible if the software is

running and if a picture is available. This method is created

to be able to save the customer’s TV settings and to store

them into another SSB.

• Download to USB. To download several settings from the

USB stick to the TV. Same way of working as with

uploading. To make sure that the download of the channel

list from USB to the TV is executed properly, it is necessary

to restart the TV and tune to a valid preset if necessary.

Note: The “History list item” can not be downloaded from

USB to the TV. This is a “read-only” item. In case of

specific problems, the development department can ask

for this info.

• Development file versions. Not useful for Service

purposes, this information is only used by the development

department.

How to Navigate

• In SAM, the menu items can be selected with the

“CURSOR UP/DOWN” key (or the scroll wheel) on the RCtransmitter. The selected item will be highlighted. When not

all menu items fit on the screen, move the “CURSOR UP/

DOWN” key to display the next/previous menu items.

• With the “CURSOR LEFT/RIGHT” keys (or the scroll

wheel), it is possible to:

– (De) activate the selected menu item.

– (De) activate the selected sub menu.

• With the “OK” key, it is possible to activate the selected

action.

How to Exit SAM

Use one of the following methods:

• Press the “MENU” button on the RC-transmitter.

Page 14

EN 14 Q529.1A LA5.

Service Modes, Error Codes, and Fault Finding

• Switch the set to STAND-BY via the RC-transmitter.

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Helpdesk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

When in this chassis CSM is activated, a testpattern will be

displayed during 5 seconds (1 second Blue, 1 second Green

and 1 second Red, then again 1 second Blue and 1 second

Green). This test pattern is generated by the PNX5100. So if

this test pattern is shown, it could be determined that the back

end video chain (PNX5100, LVDS, and display) of the SSB is

working.

To determine if the MPEG4-circuit is working (in case of an

MPEG4-set), push the “MUTE” button during CSM to display

another test pattern. This is a forced input selection to make

sure the test pattern is visible. If this test pattern is not shown,

it is possible that the settings are not correct (for instance in

SAM the MPEG4-option is “NOT PRESENT”). The display of

this test pattern is a toggle function, pressing the “MUTE” key

again removes this test pattern.

When CSM is activated and there is a USB stick connected to

the TV, the software will dump the complete CSM content to the

USB stick. The file (Csm.txt) will be saved in the root of the USB

stick. This info can be handy if no information is displayed.

Also when CSM is activated, the layer 1 error is displayed via

blinking LED. Only the latest error is displayed. (see also

section “5.5 Error Codes”).

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to Navigate

By means of the “CURSOR-DOWN/UP” knob (or the scroll

wheel) on the RC-transmitter, can be navigated through the

menus.

Contents of CSM

The contents are reduced to 3 pages: General, Software

versions and Quality items. The group names itself are not

shown anywhere in the CSM menu.

• 12NC SSB. Gives an identification of the SSB as stored in

NVM. Note that if an NVM is replaced or is initialized after

corruption, this identification number has to be re-written to

NVM. ComPair will foresee in a possibility to do this. This

identification number is the 12nc number of the SSB.

• 12NC display. Shows the 12NC of the display

• 12NC supply. Shows the 12NC of the supply.

• 12NC “bolt-on”.

module.

Software versions

• Current main SW. Displays the built-in main software

version. In case of field problems related to software,

software can be upgraded. As this software is consumer

upgradeable, it will also be published on the Internet.

Example: Q591E_1.2.3.4

• Standby SW. Displays the built-in stand-by processor

software version. Upgrading this software will be possible

via ComPair or via USB (see chapter Software upgrade).

Example: STDBY_3.0.1.2.

• MOP ambient light SW. Displays the MOP ambient light

EPLD SW.

• MPEG4 software. Displays the MPEG4 software (optional

for sets with MPEG4).

• PNX5100 boot NVM. Displays the SW-version that is used

in the PNX5100 boot NVM.

Quality items

• Signal quality. Poor / average /good

• Child lock. Not active / active. This is a combined item for

locks. If any lock (Preset lock, child lock, lock after or

parental lock) is active, the item shall show “active”.

• Table channel changed. This item is for development

purpose, it will be defined later.

• Key missing. This is a combined item for keys. The keys

have a separate bit and the sum is displayed in decimal

value.

– HDMI key valid = 001

– MAC key valid = 010

Important remark here : due to a software bug, the

MAC key is missing and not valid when “2” is displayed

in CSM.So, if for instance the HDMI and MAC keys are

both valid, the decimal value in CSM “1” is displayed

and not “3”.

– BDS key valid = 100

If 3 keys are valid the value: “5” is displayed(should be

“7” but due to the software bug).

• CI slot present. If the common interface module is

detected the result will be “YES”, else “NO”.

• HDMI input format. The detected input format of the

HDMI.

• HDMI audio input stream. The HDMI audio input stream

is displayed: present / not present.

• HDMI video input stream. The HDMI video input stream

is displayed: present / not present.

Shows the 12NC of the “BOLT-ON”-

General

• Set Type. This information is very helpful for a helpdesk/

workshop as reference for further diagnosis. In this way, it

is not necessary for the customer to look at the rear of the

TV-set. Note that if an NVM is replaced or is initialized after

corruption, this set type has to be re-written to NVM.

ComPair will foresee in a possibility to do this.

• Production Code. Displays the production code (the serial

number) of the TV. Note that if an NVM is replaced or is

initialized after corruption, this production code has to be

re-written to NVM. ComPair will foresee a in possibility to

do this.

• Installed date. Indicates the date of the first installation of

the TV. This date is acquired via time extraction.

• Options 1. Gives the option codes of option group 1 as set

in SAM (Service Alignment Mode).

• Options 2. Gives the option codes of option group 2 as set

in SAM (Service Alignment Mode).

How to Exit CSM

Press “MENU” on the RC-transmitter.

Page 15

Service Modes, Error Codes, and Fault Finding

EN 15Q529.1A LA 5.

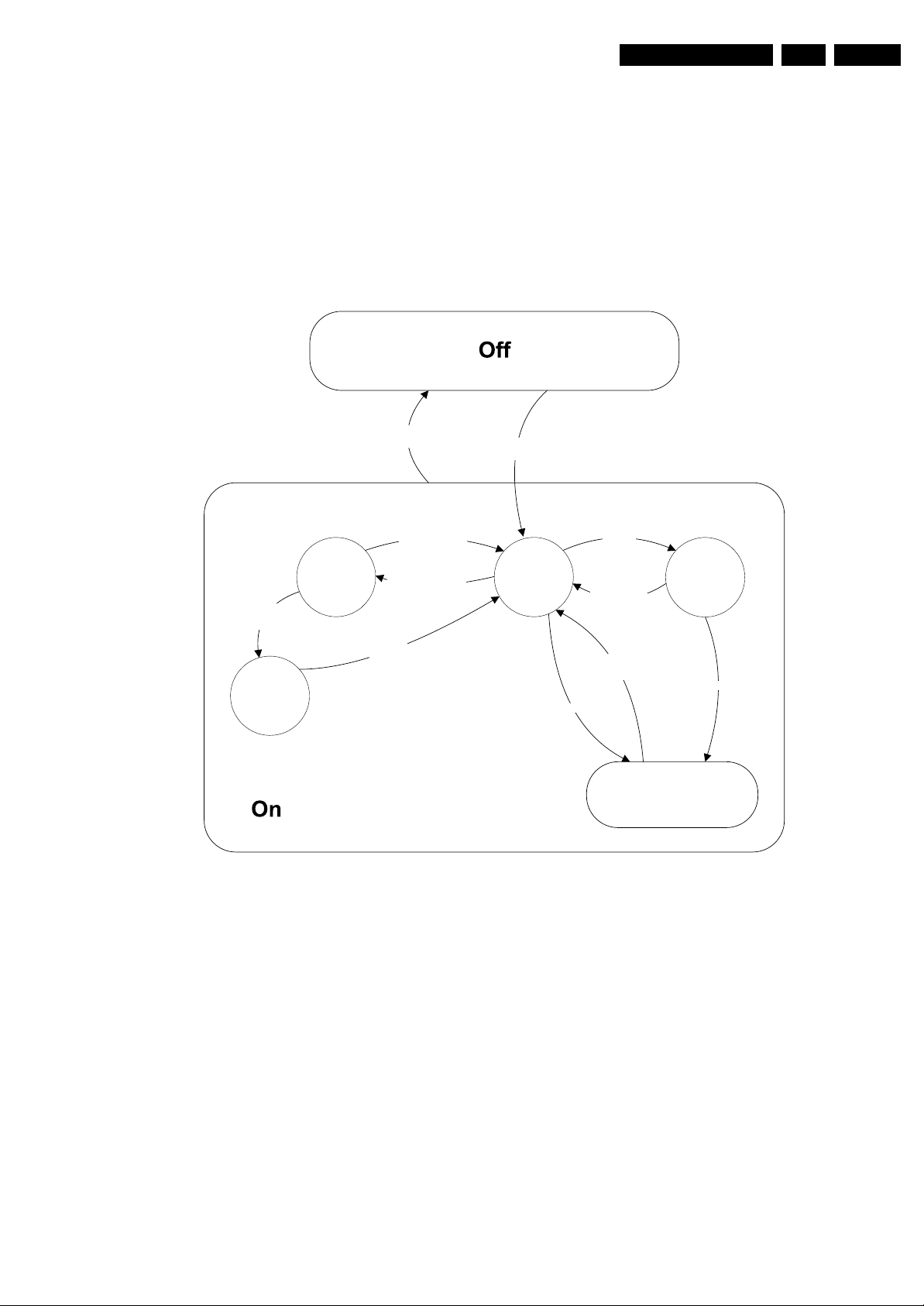

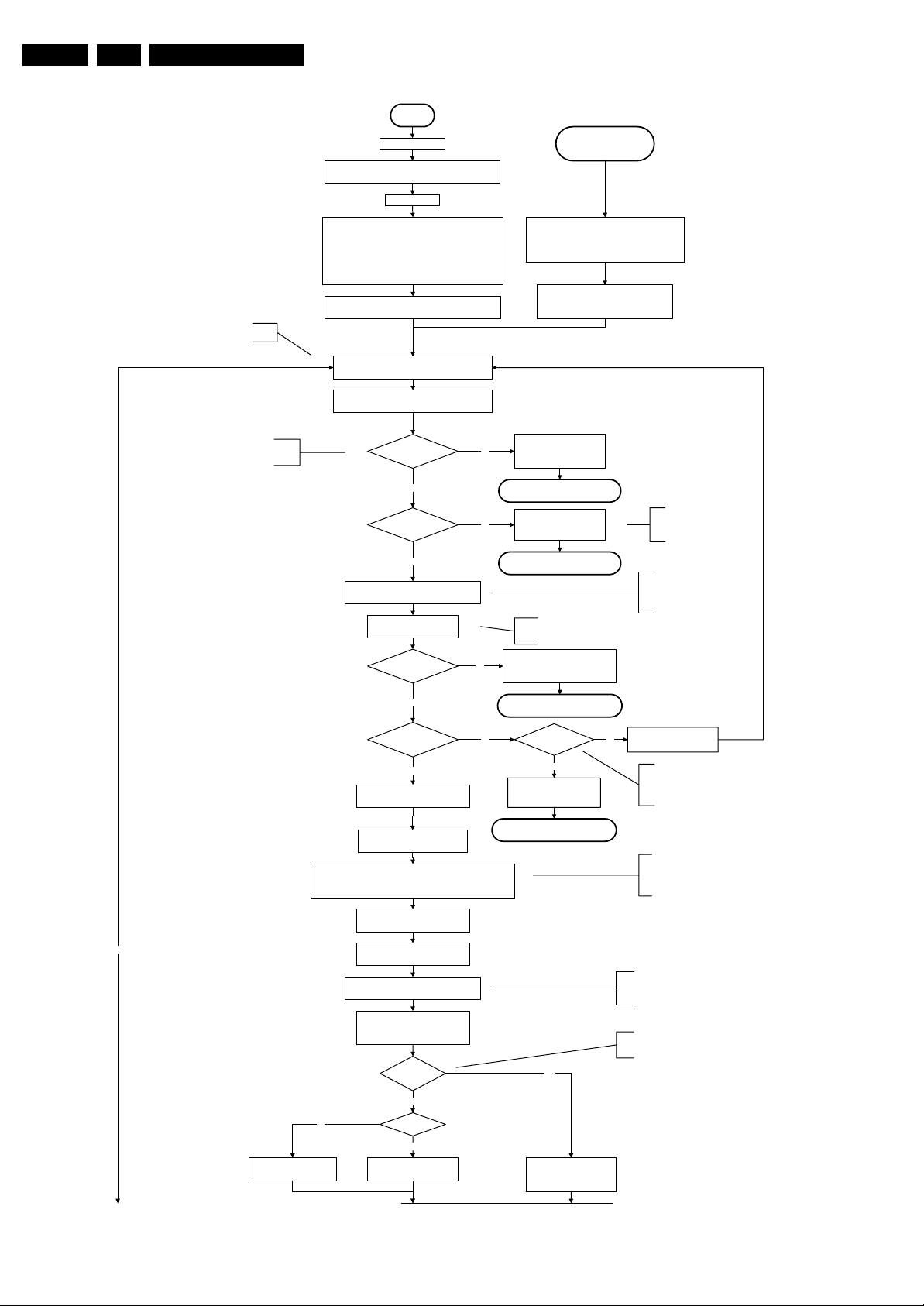

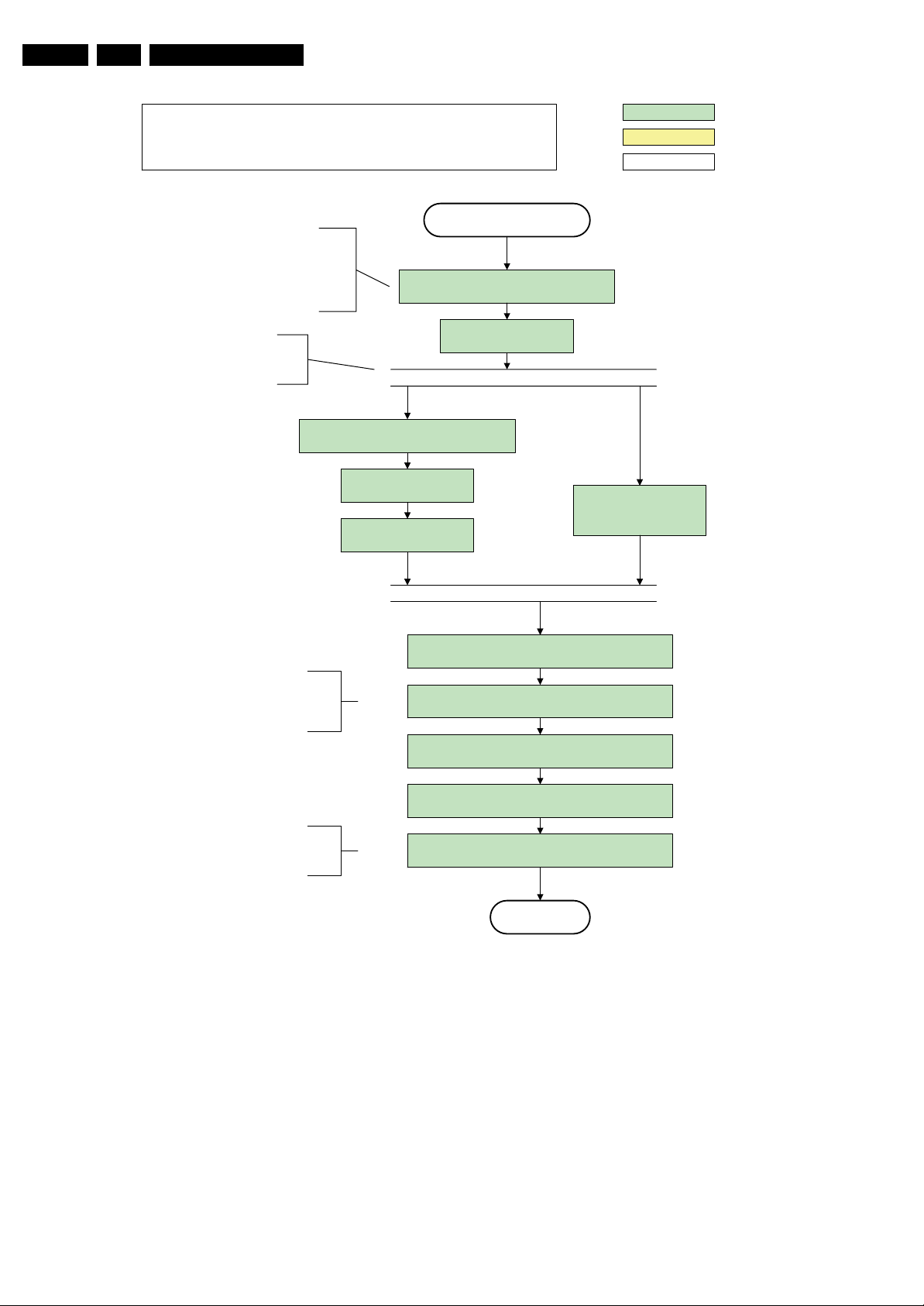

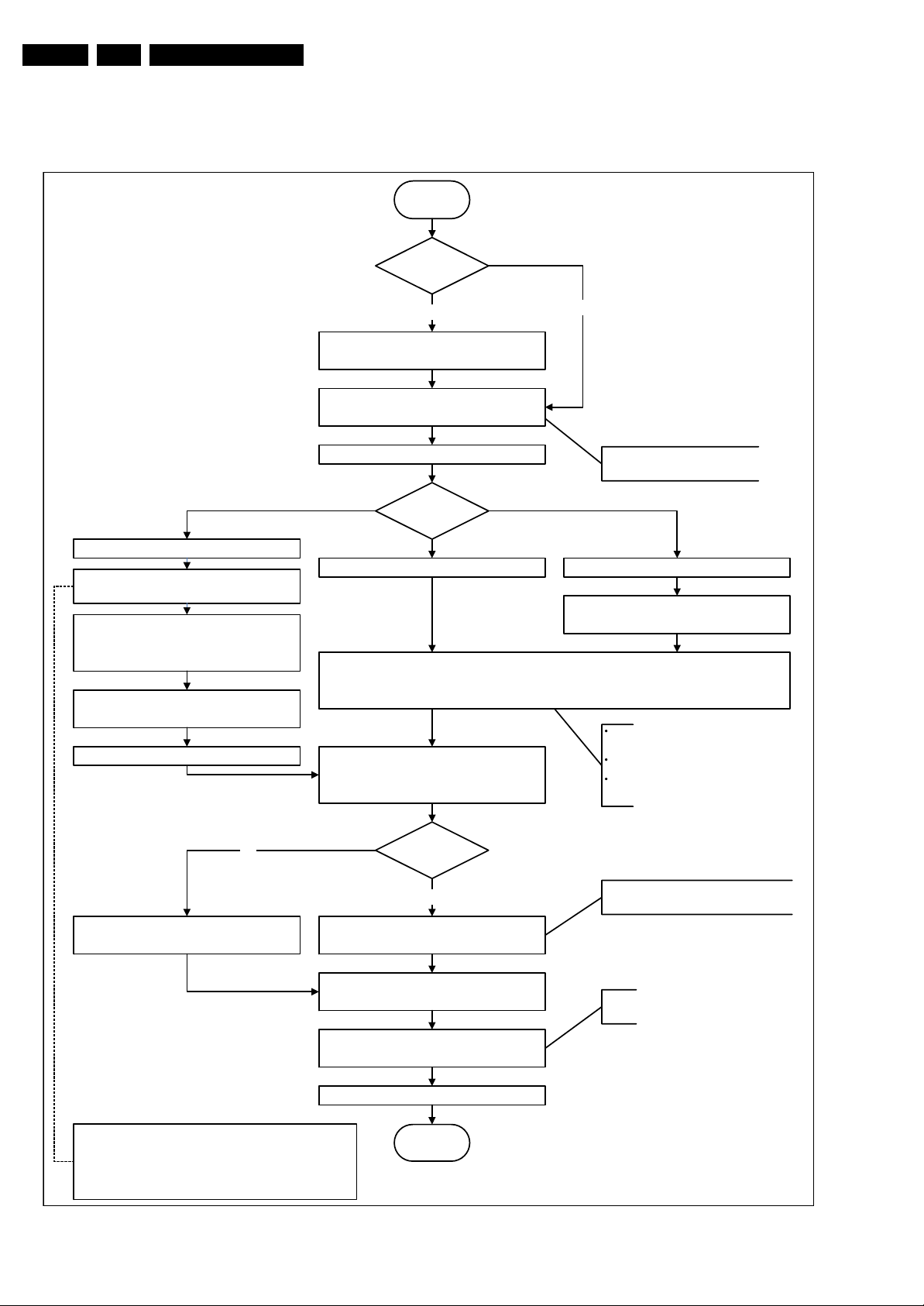

5.3 Stepwise Start-up

When the TV is in a protection state due to an error detected by

stand-by software (error blinking is displayed) and SDM is

activated via shortcutting the pins on the SSB, the TV starts up

until it reaches the situation just before protection. So, this is a

kind of automatic stepwise start-up. In combination with the

start-up diagrams below, you can see which supplies are

present at a certain moment. Important to know is, that if e.g.

the 3V3 detection fails and thus error layer 2 = 18 is blinking

while the TV is restarted via SDM, the Stand-by Processor will

enable the 3V3, but the TV set will not go to protection now.

The TV will stay in this situation until it is reset (Mains/AC

Power supply interrupted). Caution: in case the start up in this

St by

-Tact switch Pushed

-last status is hibernate

after mains ON

Tact switch

Hibernate

Mains

off

-WakeUp requested

-Acquisition needed

-No data Acquisition

required

-ta ct SW pushed

-last status i s hibernate

after mains ON

pushed

Mains

on

Semi

St by

mode with a faulty FET 7U08 is done, you can destroy all IC’s

supplied by the +3V3, due to overvoltage (12V on 3V3-line). It

is recommended to measure first the FET 7U08 or others

FET’s on shortcircuit before activating SDM via the service

pads.

The abbreviations “SP” and “MP” in the figures stand for:

• SP: protection or error detected by the Stand-by

Processor.

• MP: protection or error detected by the MIPS Main

Processor.

WakeUp

requested

Active

- St by requested

-tact SW pushed

WakeUp

requested

(SDM)

GoToProtection

GoToProtection

Figure 5-3 Transition diagram

Protection

I_17660_124.eps

140308

Page 16

EN 16 Q529.1A LA5.

Important remark; the appearance of the +12V

will start the +1V2 DCDC converter automatically

Service Modes, Error Codes, and Fault Finding

Off

Mains is app lied

Standby Supply starts running.

All standby supply voltages become available .

st-by µ P resets

Initialise I/O pins of the st-by µP:

- Switch reset-AVCLOW (reset state)

- Switch WP-NandFlash LOW (protected)

- Switch reset-system LOW (reset state)

- Switch reset-5100 LOW (reset state)

- Switch reset-Ethernet LOW (reset state)

- Switch reset-ST7100 LOW (reset state)

- keep reset-NVM high, Audio-reset and Audio-Mute-Up HIGH

start keyboard scanning, RC detection. Wake up reasons are

Switch ON Platform and display supply by switching

+12V, +/-12Vs, AL and Bolt-on power

is switched on, followed by the +1V2 DCDC converter

off.

LOW the Standby line.

Stand by or

Protection

If the protection state was left by short circuiting the

SDM pins, detection of a protection condition during

startup will stall the startup. Protection conditions in a

playing set will be ignored. The protection mode will

not be entered.

- Switch Audio-Reset high.

It is low in the standby mode if the standby

mode lasted longer than 10s.

Detect2 should be polled on the standard 40ms

interval and startup should be continued when

detect2 becomes high.

Switch LOW the RESET-NVM line to allow access to NVM. (Add a

2ms delay before trying to address the NVM to allow correct NVM

initialization, this is not issue in this setup, the delay is automatically

No

No

Release AVC system r eset

Feed warm boot script

To I_17660_125b.eps To I_17660_125b.eps

Detect2 high received

within 1 second?

Yes

Supply-fault I/O

High?

Yes

Enable the DCDC converter for +3V3 and

+5V. (EN ABLE-3V3)

Wait 50ms

Supply-fault I/O

High?

yes

Detect-1 I/O line

High?

Yes

Enable the supply fault detection

algorithm

Set I²C slave address

of Standby µP to (A0h)

covered by the architectural setup)

Switch HIGH the WP-NandFlash to

allow access to NAND Flash

Release Reset-PNX5100.

PNX5100 will start b ooting.

Wait 10ms (minimum) to allow the bootscript

of the PNX5100 to configure the PCI arbiter

Detect EJTAG debug probe

(pulling pin of the probe interface to

ground by inserting EJTAG probe)

EJTAG probe

connected ?

No

Cold boot?

Yes

Relea se AVC system r eset

Feed cold boot script

No

No

No

No

Power-OK er ror:

Layer1: 3

Layer2: 16

Enter protection

1V2 DCDC or class D error:

Layer1: 2

Layer2: 19

Enter protection

Delay of 50ms needed because of the latency of the detect-1 circuit.

This delay is also needed for the PNX5100. The reset of the

PNX5100 should only be released 10ms after powering the IC.

3V3 / 5V DCDC or class D error:

Layer1: 2

Layer2: 11

Enter protection

Detect -2 I/ O line

High?

Yes

Voltage output error:

Layer1: 2

Layer2: 18

Enter protection

Yes

Release AVC system r eset

Feed initializing boot script

disable alive mechanism

The supply-fault line is a

combination of the DCDC

converters and the audio

protection line.

This enables the +3V3 and

+5V converter. As a result,

also +5V-tuner, +2V5, +1V8PNX8541 and +1V8-PNX5100

become available.

Disable 3V3, switch standby

No

line high and wait 4 seconds

Added to make the system more robust to

power dips during startup. At this point the

regular supply fault detection algorithm which

normally detects power dips is not up and

running yet.

This will a llow access to NVM a nd

NAND FLASH and can not be done

earlier because the FLASH needs to

be in Write Protect as long as the

supplies are not available.

Before PNX8541 boots, the PNX5100 should have

set its PCI arbiter (bootscript command). To allow

this, approx. 1ms is needed. This 1ms is extended

to 10ms to also give some relaxation to the supplies.

An EJTAG probe (e.g. WindPower ICE probe) can

be connected for Linux Kernel debugging

purposes.

I_17660_125a.eps

140308

Figure 5-4 “Off” to “Semi Stand-by” flowchart (part 1)

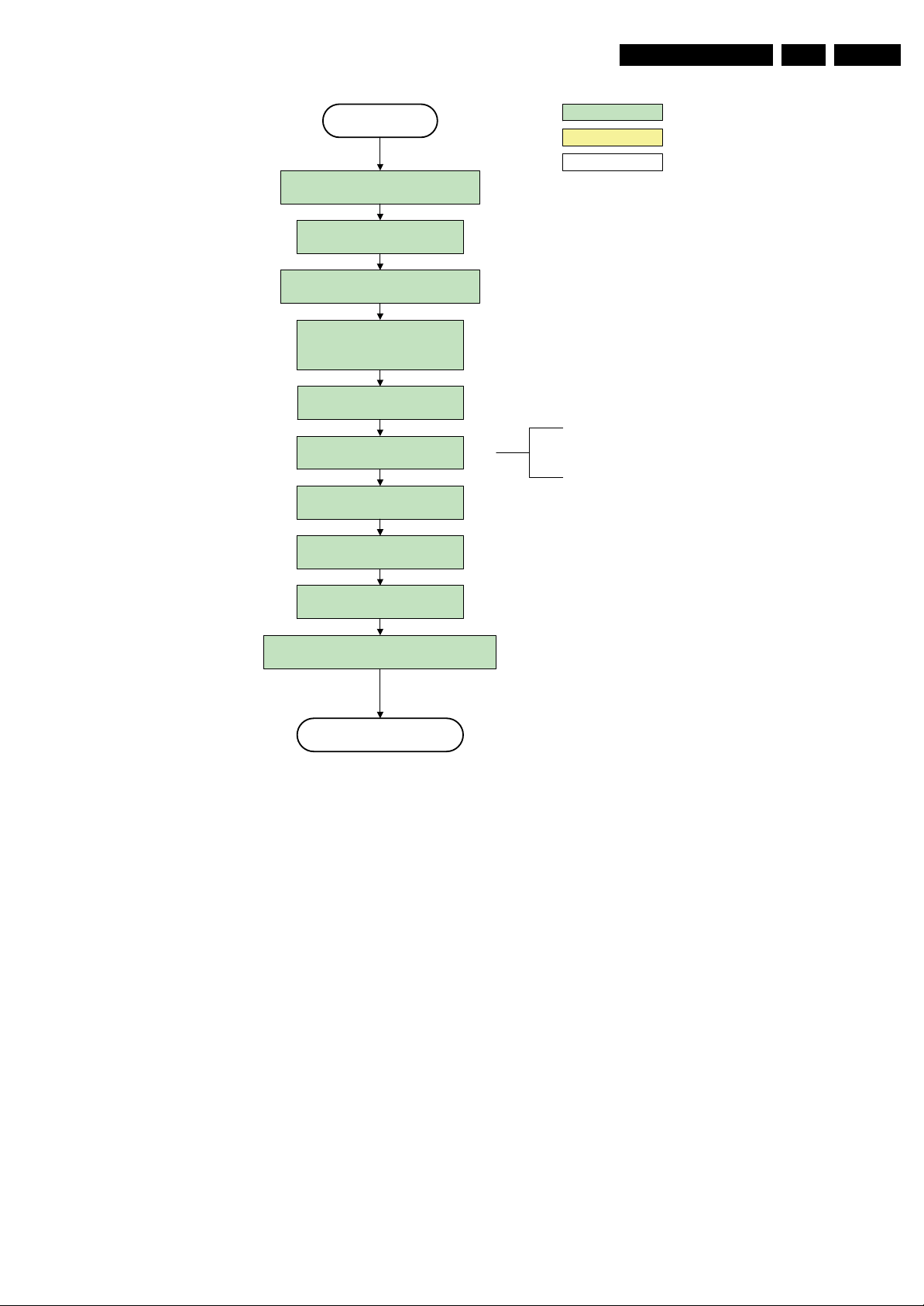

Page 17

Service Modes, Error Codes, and Fault Finding

From I_17660_125a.eps From I_17660_125a.eps

EN 17Q529.1A LA 5.

No

3-th try?

Yes

Blink Code as

error code

Reset- system is connected to USB

4to1HDMI Mux and channel decoder.

This cannot be done through the bootscript,

the I/O is on the standby µP

Timing need to be updated if

more mature info is available.

Code =

Layer1: 2

Layer2: 15

Switch AVC PNX85 41

in reset (active low )

Wait 10ms

Switch the NVM reset

line HIGH.

Disable all supply related protections and

switch off the +3V3 +5V DC/DC converter.

Wait 5ms

switch off the remaining DC/DC

converters

Switch Standby

I/O line high.

-reset,

No

Code =

Layer1: 2

Layer2: 53

No

Reset-system is switched HIGH by the

AVC at the end of the bootscript

AVC releases Reset-Ethernet when the

end of the AVC boot-script is detected

Reset-Audio and Audio-Mute-Up are

switched by MIPS code later on in the

Set I²C slave address

of Standby µP to (60h)

RPC start (comm. protocol)

No

image transfer succeeded

No

Enable Alive check mechanism

MIPS reads the wake up reason

Switch on the display in case of a LED backlight

display by sending the TurnOnDisplay(1) (I²C)

command to the PNX5100

Download firmware into the channel

startup process

Bootscript ready

in 1250 ms?

Yes

Flash to Ram

within 30s?

Yes

SW initializatio n

succeeded

within 20s?

Yes

from standby µP.

Initialize audio

decoder

Reset-syst em is switched HIGH by the

AVC at the end of the bootscript

AVC releases Reset-Ethernet when the

end of the AVC boot-script is detected

Reset-Audio and Audio-Mute-Up are

switched by MIPS code later on in the

startup process

Timing needs to

be updated if more

mature info is

available.

Timing needs to be

updated if more

matur e info is

available.

Wait until AVC starts to

communicate

In case of a LED backlight display, a LED DIM panel is

present which is fed by the Vdisplay. To power the LED DIM

Panel, the Vdisplay switch driven by the PNX5100 must be

closed. The display startup sequence is taken care of by the

LED DIM panel.

STi7100AliveFailedError

and generate fast cold reboot

eventually followed by a cold

Alive

polling

NOK

Log SW event

reboot.

Release reset MPEG4 module:

BOLT-ON-IO: High

MPEG4 module will start booting

autonomously.

Wait 3000 ms

POR polling positive?

yes

Start alive IIC polling

mechanism

No

POR polling positive?yes

bootSTi7100PorFailure:

and generate cold boot

Log SW event:

STi7100PorFailure

Wait 200 ms

No

Log HW error

Layer1: 2

Layer2: 38

Enter protection

Third try? No

Yes

Log channel decoder error:

Layer1: 2

Layer2: 37

Downloaded

successfully ?

Yes

initialize tuner, Master IF and channel

decoder

Initiali ze source sele ction

Initialize video processing IC's

initialize AutoTV by triggering CHS AutoTV Init interface

Initialize Ambilight with Lights off.

Semi-Standby

Figure 5-5 “Off” to “Semi Stand-by” flowchart (part 2)

I_17660_125b.eps

140308

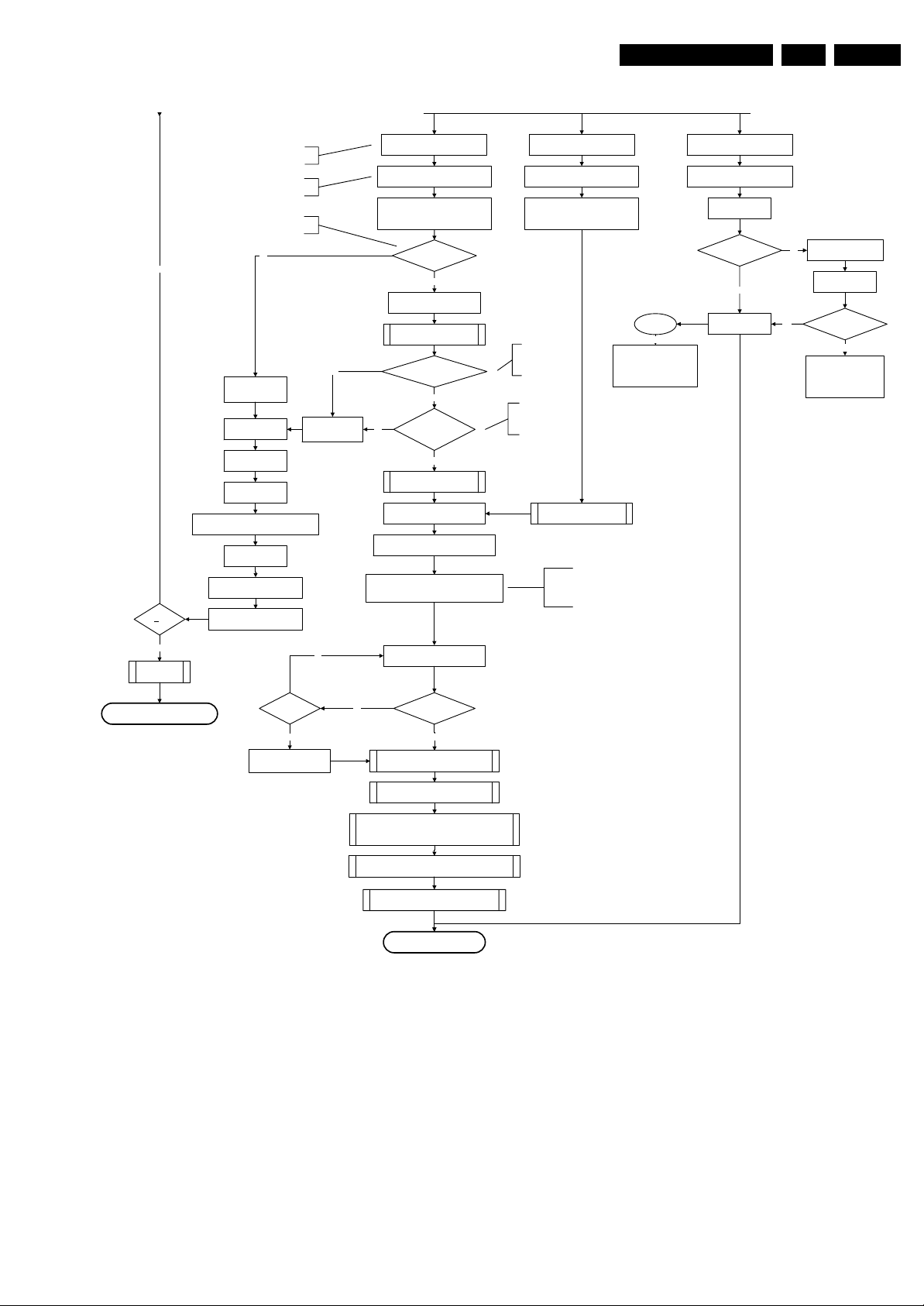

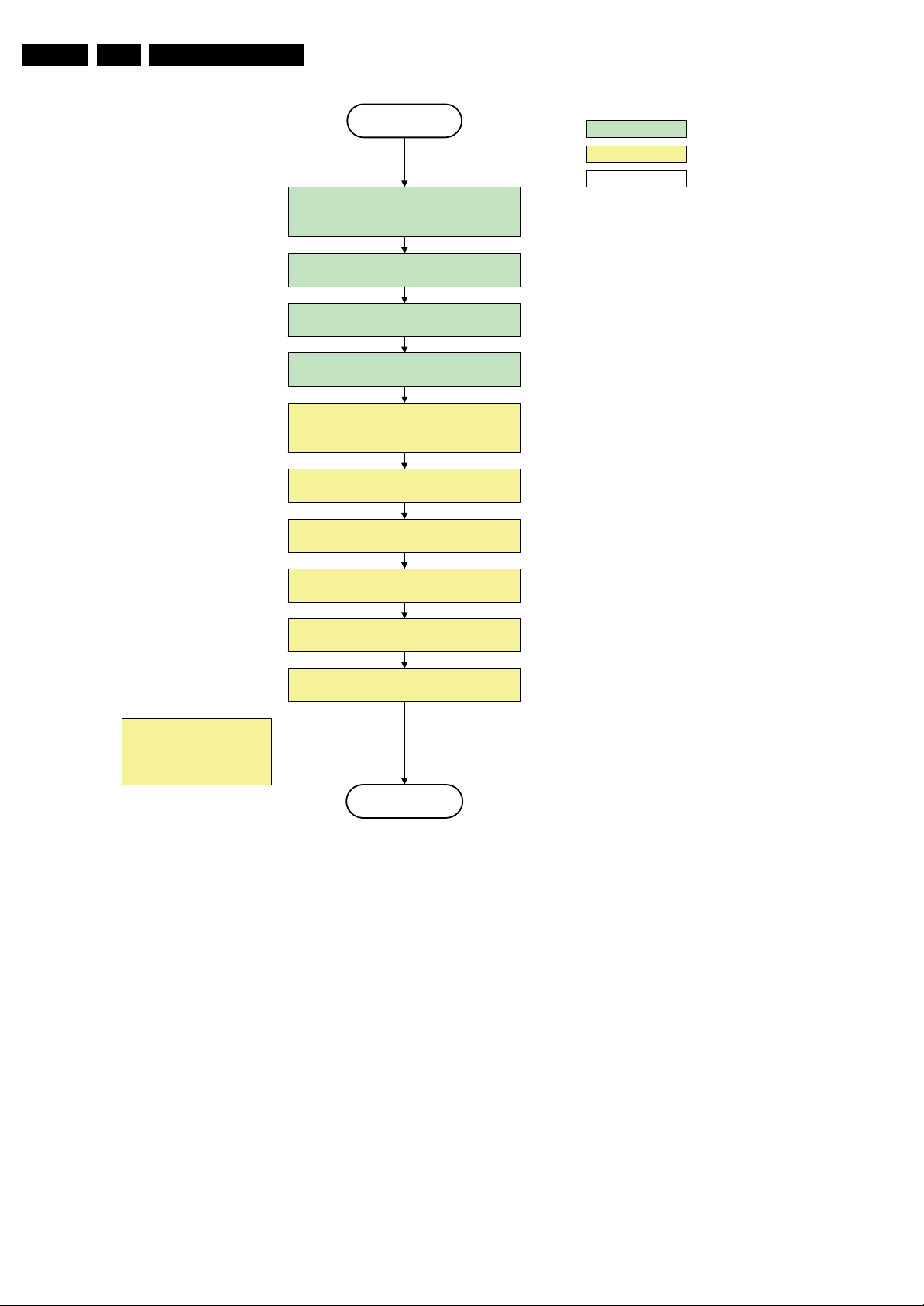

Page 18

EN 18 Q529.1A LA5.

Service Modes, Error Codes, and Fault Finding

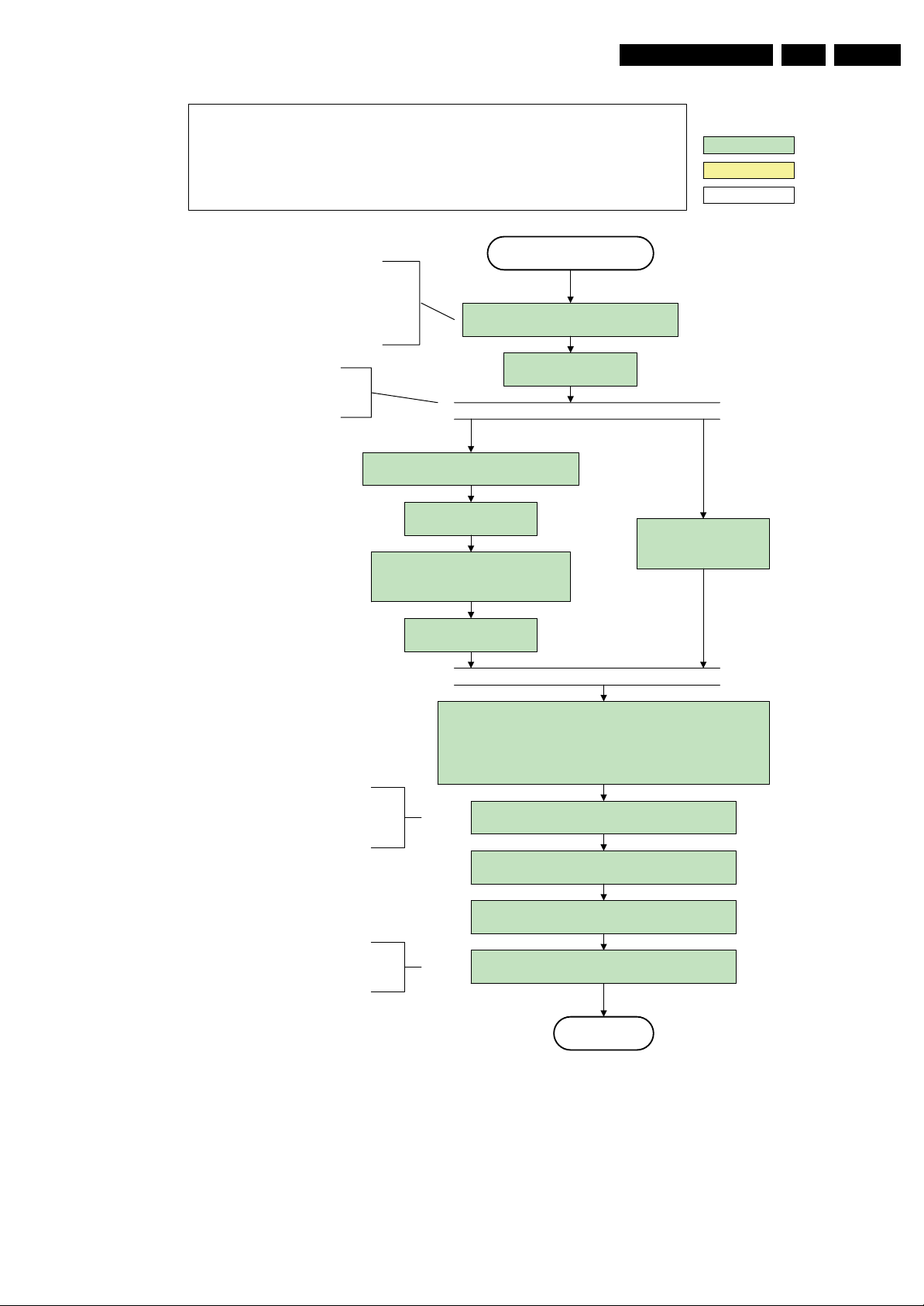

Constraints taken into account:

- Display may only be started when valid LVDS output clock can be delivered by the AVC .

- Between 5 and 50 ms after power is supplied, display should receive valid lvds clock .

- minimum wait time to switch on the lamp after power up is 200ms.

action holder: AVC

action holder: St-by

autonomous action

The assumption here is that a fast toggle (<2s)

can only happen during ON-> SEMI ->ON. In

these states, the AVC is st ill active and can

provide the 2s delay. If the t ransition ON-> SEMI-

>STBY -> SEMI ->ON can b e made in less than 2s,

the semi -> stby transition has to be delayed

CPipe already generates a valid output

clock in t he semi -stand by state : display

startup can start immediately when leaving

The timings to be used in

combination with the PanelON

comman d for this specific d isplay

The higher level requirement is that audio and

video should be demuted without transient

effects and that the audio should be demuted

maximum 1s before or at the same time as the

until the requirement is met.

the semi-standby state.

TurnOnDisplay(1) (I²C) command to the PN X5100

unblanking of the video.

Semi Standby

Wait until previous on-state is left more than 2

seconds ago. (to prevent LCD display problems)

Assert RGB video blanking

Switch on the display by sending the

wait 250ms (min. = 200ms)

Switch on LCD backlight

(Lamp-ON)

Wait until valid and stable audio and video, corresponding to

the requested output is delivered by the AVC.

Switch Audio -Reset low and wait 5ms

Release audio mute and wait 100ms before any other audio

handling is done (e.g. volume change)

and audio mute

Initialize audio and video

processing IC's and functions

according needed use case.

The higher level requirement is that the

ambilig ht functionality m ay not be switched on

before the backlight is turned on in case the

set contains a CE IPB inverter supply.

Figure 5-6 “Semi Stand-by” to “Active” flowchart

unblank the video.

Switch on the Ambilight functionality according the last status

settings.

Active

I_17660_126.eps

140308

Page 19

Service Modes, Error Codes, and Fault Finding

Constraints taken into account:

- Display may only be started when valid LVDS output clock can be delivered by the AVC.

- Between 5 and 50 ms after power is supplied, display should receive valid lvds clock .

- minimum wait time to switch on the lamp after power up is 200ms.

- To have a reliable operation of the backlight, the backlight should be driven with a PWM duty cycle of 100%

during the first second. Only after this first one or two seconds, the PWM may be set to the required output level

(Note that the PWM output should be present before the backlight is switched on). To minimize the artefacts, the

picture should only be unblanked after these first seconds.

EN 19Q529.1A LA 5.

action holder: AVC

action holder: St-by

autonomous action

The assumption here is that a fast toggle (<2s)

can only happen during ON->SEMI ->ON. In

these states, the AVC is st ill active and can

provide t he 2s delay. If the transition ON -> SEMI-

->STBY-> SEMI -> ON can be made in less than 2s,

the semi -> stby transition has to be delayed

CPipe already generates a valid output

clock in t he semi -standby state: display

startup can start immediately when leaving

until the requirement is met.

the semi-standby state.

TurnOnDisplay(1) (I²C) command to the PNX5100

Switch on the display by sending the

Switch off the dimming backlight feature, set

the BOOST control to nominal and make sure

Semi Standby

Wait until previous on-state is left more than 2

seconds ago. (to prevent LCD display problems)

Assert RGB video blanking

wait 250ms (min. = 200ms)

PWM output is set to 100%

Switch on LC D backlig ht

(Lamp-ON)

and audio mute

Initialize audio and video

processing IC's and functions

according needed use case.

The higher level requirement is that audio and

video should be demuted without transient

effects and that the audio should be demuted

maximum 1s before or at the same time as the

unblanking of the video.

The higher level requirement is that the

ambilig ht fun ctionality may not b e switched on

before the backlight is turned on in case the

set contains a CE IPB inverter supply.

Figure 5-7 “Semi Stand-by” to “Active” flowchart LCD with preheat

Wait until valid and stable audio and video, corresponding to the requested

[the backlight PWM has been on for 1s (internal inverter LPL displays

OR the backlight PWM has been on for 2s (external inverter LPL displays)] .

Release audio mute and wait 100ms before any other audio

handling is done (e.g. volume change)

Restore dimming backlight feature, PWM and BOOST output

Switch on the Ambilight functionality according the last status

output is delivered by the AVC

Switch Audio-Reset low and wait 5ms

AND

and unblank the video.

settings.

Active

I_17660_127.eps

140308

Page 20

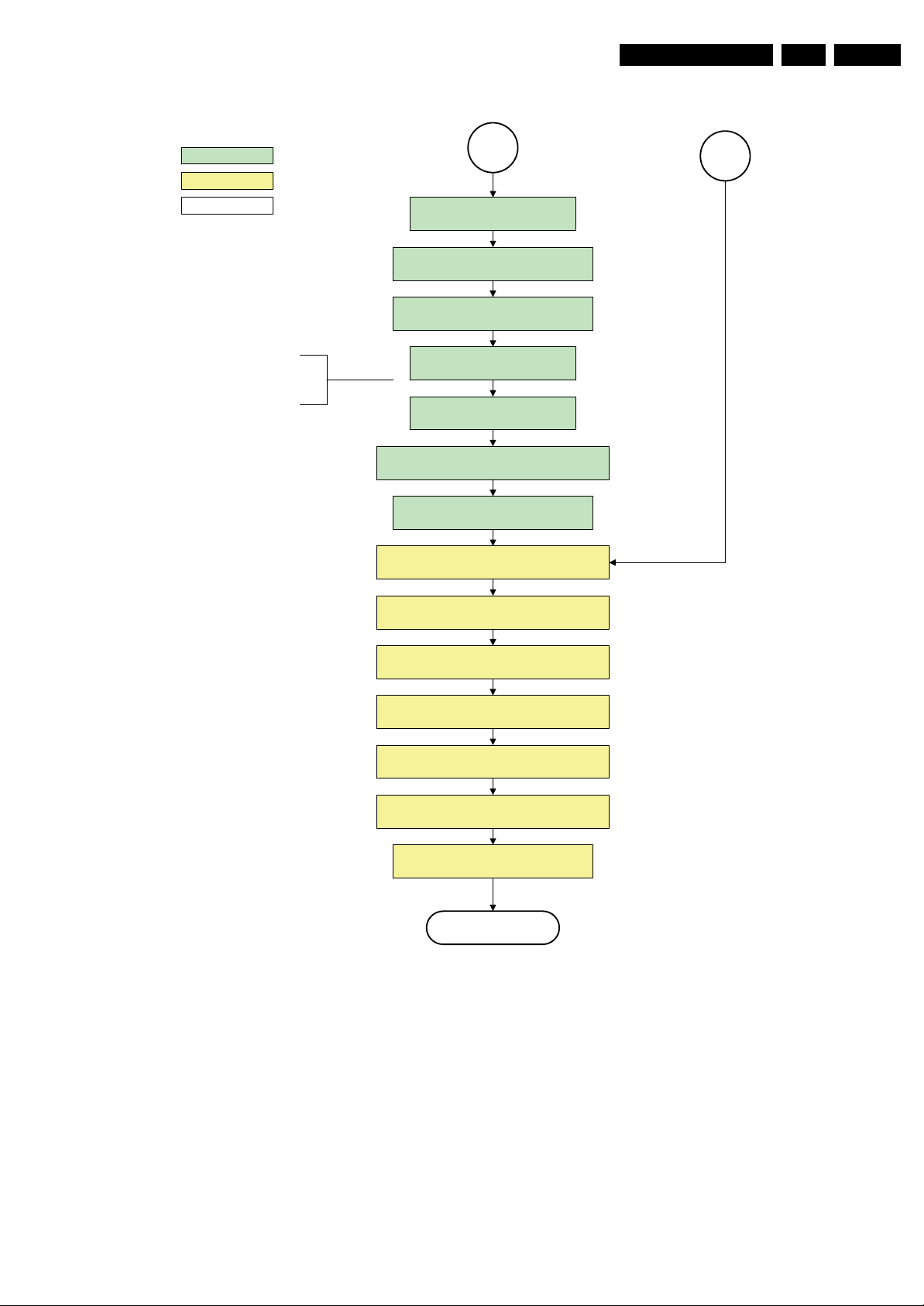

EN 20 Q529.1A LA5.

Service Modes, Error Codes, and Fault Finding

Constraints taken into account:

- Display may only be started when valid LVDS output clock can be delivered by the AVC.

- Between 5 and 50 ms after power is supplied, display should receive valid lvds clock .

- minimum wait time to switch on the lamp after power up is 200ms.

Semi Standby

The assumption here is that a fast toggle (<2s)

can only happen during ON-> SEMI -> ON. In

these states, the AVC is still act ive and can

provide the 2s delay. If the transit ion ON -> SEMI-

>STBY->SEMI->ON can be made in less than 2s,

the semi -> stby transition has to be delayed

CPipe already generates a valid output

clock in t he semi -standby state : display

startup can start immediately when leaving

until the requirement is met.

the semi-standby state.

Switch on the display by sending the OUTPUTENABLE (I²C) command to the LED DIM panel

wait 250ms (min. = 200ms)

Switch on LC D backlig ht

Wait until previous on-state is left more than 2

seconds ago. (to prevent LCD display problems)

Assert RGB video blanking

TBC in def. spec

(Lamp-ON)

and audio mute

action holder: AVC

action holder: St-by

autonomous action

Initialize audio and video

processing IC's and functions

according needed use case.

The higher level requirement is that audio and

video should be demuted without transient

effects and that the audio should be demuted

maximum 1s before or at the same time as the

ambilig ht fun ctionality may not b e switched on

unblanking of the video.

The higher level requirement is that the

before the backlight is turned on in case the

set contains a CE IPB inverter supply.

Figure 5-8 “Semi Stand-by” to “Active” flowchart (LED backlight)

Wait until valid and stable audio and video, corresponding to

the requested output is delivered by the AVC.

Switch Audio -Reset low and wait 5ms

Release audio mute and wait 100ms before any other audio

handling is done (e.g. volume change)

unblank the video.

Switch on the Ambilight functionality according the last status

settings.

Active

I_17660_128.eps

140308

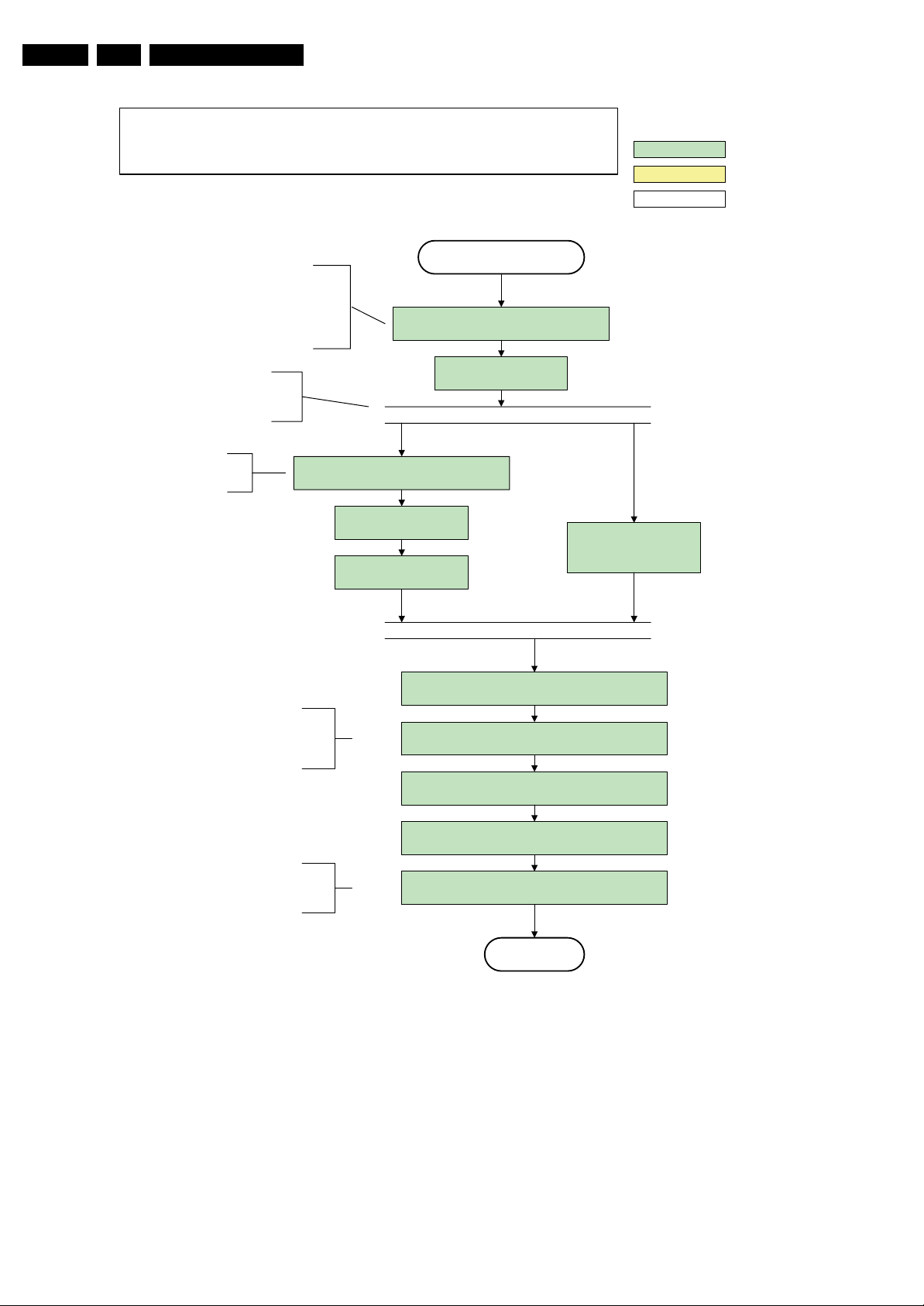

Page 21

Service Modes, Error Codes, and Fault Finding

EN 21Q529.1A LA 5.

Active

Mute all sound outputs via softmute

Wait 100ms

Set main amplifier mute (I/O: audio-mute)

Force ext audio outputs to ground

(I/O: audio reset)

And wait 5ms

switch o ff Ambilig ht

Wait until Ambilight has faded out

(fixed wait time of x s)

switch off LCD backlight

Mute all video outputs

action holder: AVC

action holder: St-by

autonomous action

The higher level requirement is that the

backlight may not be switched off before the

ambilight functionality is turned off in case the

set contains a CE IPB inverter supply.

Wait 25 0ms (min . = 200ms)

Switch off the display by sending the

TurnOnDisplay(0) (I²C) command to the PNX5100

Semi Standby

Figure 5-9 “Active” to “Semi Stand-by” flowchart (LCD non DFI)

I_17660_129.eps

140308

Page 22

EN 22 Q529.1A LA5.

Service Modes, Error Codes, and Fault Finding

Semi Stand by

If ambientlight functionality was used in semi -standby

(lampadaire mode), switch off ambient light

Delay transition until ramping down of ambient light is

transfer Wake up reasons to the Stand by µP.

Switch Memories to self-refresh (this creates a more

stable condition when switching off the power).

Switch AVC syste m in re set sta te

finished. *)

Switch reset-PNX5100 LOW

Switch reset-ST7100 LOW

Switch Reset-Ethernet LOW

Wait 10ms

Switch the NVM reset line HIGH

Switch het WP-Nandflash LOW

action holder: MIPS

action holder: St-by

autonomous action

*) If this is not performed and the set is

switched to standby when the switch off of

the ambilights is still ongoing , the lights will

switch off abruptly when the supply is cut.

Important remark:

release reset audio 10 sec after

entering standb y to save power

Disable all supply related protections and switch off

the DC/DC converters (ENABLE-3V3)

Wait 5ms

Switch OFF all supplies by swit ching HI GH the

Standby I/O line

Stand by

Figure 5-10 “Semi Stand-by” to “Stand-by” flowchart

I_17660_130.eps

140308

Page 23

Service Modes, Error Codes, and Fault Finding

EN 23Q529.1A LA 5.

action holder: MIPS

action holder: St-by

autonomous action

If needed to speed up this transition,

this block could be omitted. This is

depending on the outcome of the

safety investig ations .

MP

Log the appropriate err or and

set stand-by flag in NVM

Redefine wake up reasons for protection

state and transfer to stand-by µP.

Switch off LCD lamp supply

Wait 250ms (min. = 200ms)

Switch off LVDS signal

Switch off 12V LCD supply within a time frame of

min. 0.5ms to max. 50ms after LVDS switch off.

Ask stand-by µP to enter protection state

Switch AVC in r eset state

SP

Figure 5-11 “To Protection State” flowchart

5.4 Service Tools

5.4.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. and offers the following:

1. ComPair helps to quickly get an understanding on how to

repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. No

knowledge on I

because ComPair takes care of this.

2

C or UART commands is necessary,

Wait 10ms

Switch the NVM reset line HIGH.

Disable all supply related protections and switch off

the +1V8 and the +3V3 DC/DC converter.

Wait 5ms

Switch OFF all supplies by switching HIGH the

Flash the Protection-LED in order to indicate

Standby I/O line.

protection state* (*): This can be the standby LED or the ON LED

Protection

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software up possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The ComPair II interface box is connected to the PC via an

USB cable. For the TV chassis, the ComPair interface box and

the TV communicate via a bi-directional cable via the service

connector(s).

The ComPair fault finding program is able to determine the

problem of the defective television, by a combination of

automatic diagnostics and an interactive question/answer

procedure.

depending on the availability in the set

I_17660_131.eps

140308

Page 24

EN 24 Q529.1A LA5.

Service Modes, Error Codes, and Fault Finding

How to Connect

This is described in the chassis fault finding database in

ComPair.

TO TV

TO

UART SERVICE

I2C SERVICE

CONNECTOR

CONNECTOR

2

C

I

PC

ComPair II Developed by Philips Brugge

Optional power

5V DC

TO

RS232 /UART

E_06532_036.eps

150208

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

HDMI

I

TO

UART SERVICE

CONNECTOR

Multi

function

RC out

2

C only

Figure 5-12 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• Software is available via internet:

http://www.atyourservice.ce.philips.com

• ComPair UART interface cable for Q52x.x.

(using 3.5 mm Mini Jack connector): 3104 311 12742.

Note: While encounting problems, contact the local support

desk.

5.4.2 Memory and Audio Test

With this tool you can test the memory of the PNX8541, as well if the PNX5100 is enabled and audio-testing.

What is needed?

– An USB-stick.

– “TESTSCRIPT Q529” (3104 337 05021). Downloadable

from the Philips Service website from the section “Software

for Service only”.

– A ComPair/service cable (3104 311 12742)

Procedure

Create a directory “JETTFILES” under the root of the USB-stick

– Place “MemoryTestPNX8635.bin” and “autojett.bin”

(available in “TESTSCRIPT Q529”) under the directory

“JETTFILES”

– Install the computer program “BOARDTESTLOGGER”

(available in “TESTSCRIPT Q529”) on the PC

– Connect a “ComPair/service”-cable from the service-

connector in the set to the COM1-port of the PC

– Start-up the program “BOARDTESTLOGGER” and select

“COM1”

– Put the USB stick into the TV and startup the TV while

pressing the “i+”-button on a Philips DVD RC6 remote

control (it’s also possible to use a TV remote in “DVD”mode)

– On the PC the memory test is shown now. This is also

visible on the TV screen.

– In “BOARDTESTLOGGER” an option “Send extra UART

command” can be found where you can select “AUD1”.

This command generates hear test tones of 200, 400,

1000, 2000, 3000, 5000, 8 000 and 12500Hz.

5.4.3 LVDS Tool

Support of the LVDS Tool has been discontinued.

5.5 Error Codes

5.5.1 Introduction

The error code buffer contains all detected errors since the last

time the buffer was erased. The buffer is written from left to

right, new errors are logged at the left side, and all other errors

shift one position to the right.

When an error occurs, it is added to the list of errors, provided

the list is not full. When an error occurs and the error buffer is

full, then the new error is not added, and the error buffer stays

intact (history is maintained).

To prevent that an occasional error stays in the list forever, the

error is removed from the list after more than 50 hrs. of

operation.

When multiple errors occur (errors occurred within a short time

span), there is a high probability that there is some relation

between them.

New in this chassis is the way errors can be displayed:

• There is a simple blinking LED procedure for board level

repair (home repair) so called LAYER 1 errors next to the

existing errors which are LAYER 2 errors.(see table 5-2

error code overview).

– LAYER 1 errors are one digit errors.

– LAYER 2 errors are 2 digit errors.

• In protection mode.

– From consumer mode: LAYER 1.

– From SDM mode: LAYER 2.

• Fatal errors, if I2C bus is blocked and the set reboots,

CSM and SAM are not selectable.

– From consumer mode: LAYER 1.

– From SDM mode: LAYER 2.

Important remark:

For all errors detected by MIPS which are fatal =>

rebooting of the TV set (reboot starts after LAYER error

1 blinking), one should short the solder paths at startup from the power OFF state by mains interruption and

not via the power button to trigger the SDM via the

hardware pins.

• In CSM mode

– When entering CSM: error LAYER 1 will be displayed

by blinking LED. Only the latest error is shown.

• In SDM mode

– When SDM is entered via Remote Control code or the

hardware pins, LAYER 2 is displayed via blinking LED.

• In the ON state

– In “Display error mode”, set with the RC commands

“mute_06250X _OK” LAYER 2 errors are displayed via

blinking LED.

• Error display on screen.

– In CSM no error codes are displayed on screen.

– In SAM the complete error list is shown.

Basically there are three kinds of errors:

• Errors detected by the Stand-by software which lead to

protection. These errors will always lead to protection and

an automatic start of the blinking LED LAYER error 1.

(see section “5.6 The Blinking LED Procedure”).

• Errors detected by the Stand-by software which not

lead to protection. In this case the front LED should blink

the involved error. See also section “5.5 Error Codes, 5.5.4

Error Buffer, Extra Info”. Note that it can take up several

minutes before the TV starts blinking the error (e.g. LAYER

error 1 = 2, LAYER error 2 = 15 or 53).

Page 25

Service Modes, Error Codes, and Fault Finding

• Errors detected by main software (MIPS). In this case

the error will be logged into the error buffer and can be read

out via ComPair, via blinking LED method LAYER error 12, or in case picture is visible, via SAM.

5.5.2 How to Read the Error Buffer

Use one of the following methods:

• On screen via the SAM (only when a picture is visible).

E.g.:

– 00 00 00 00 00: No errors detected

– 23 00 00 00 00: Error code 23 is the last and only

detected error.

– 37 23 00 00 00: Error code 23 was first detected and

error code 37 is the last detected error.

– Note that no protection errors can be logged in the

error buffer.

• Via the blinking LED procedure. See section 5.5.3 How to

Clear the Error Buffer.

•Via ComPair.

5.5.3 How to Clear the Error Buffer

Use one of the following methods:

• By activation of the “RESET ERROR BUFFER” command

in the SAM menu.

• With a normal RC, key in sequence “MUTE” followed by

“062599” and “OK”.

• If the content of the error buffer has not changed for 50+

hours, it resets automatically.

EN 25Q529.1A LA 5.

5.5.4 Error Buffer

In case of non-intermittent faults, clear the error buffer before

starting to repair (before clearing the buffer, write down the

content, as this history can give significant information). This to

ensure that old error codes are no longer present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

code and not the actual cause (e.g. a fault in the protection

detection circuitry can also lead to a protection).

There are several mechanisms of error detection:

• Via error bits in the status registers of ICs.

• Via polling on I/O pins going to the stand-by processor.

• Via sensing of analog values on the stand-by processor or

the PNX8541.

• Via a “not acknowledge” of an I

Take notice that some errors need several minutes before they

start blinking or before they will be logged. So in case of

problems wait 2 minutes from start-up onwards, and then

check if the front LED is blinking or if an error is logged.

2

C communication.

Page 26

EN 26 Q529.1A LA5.

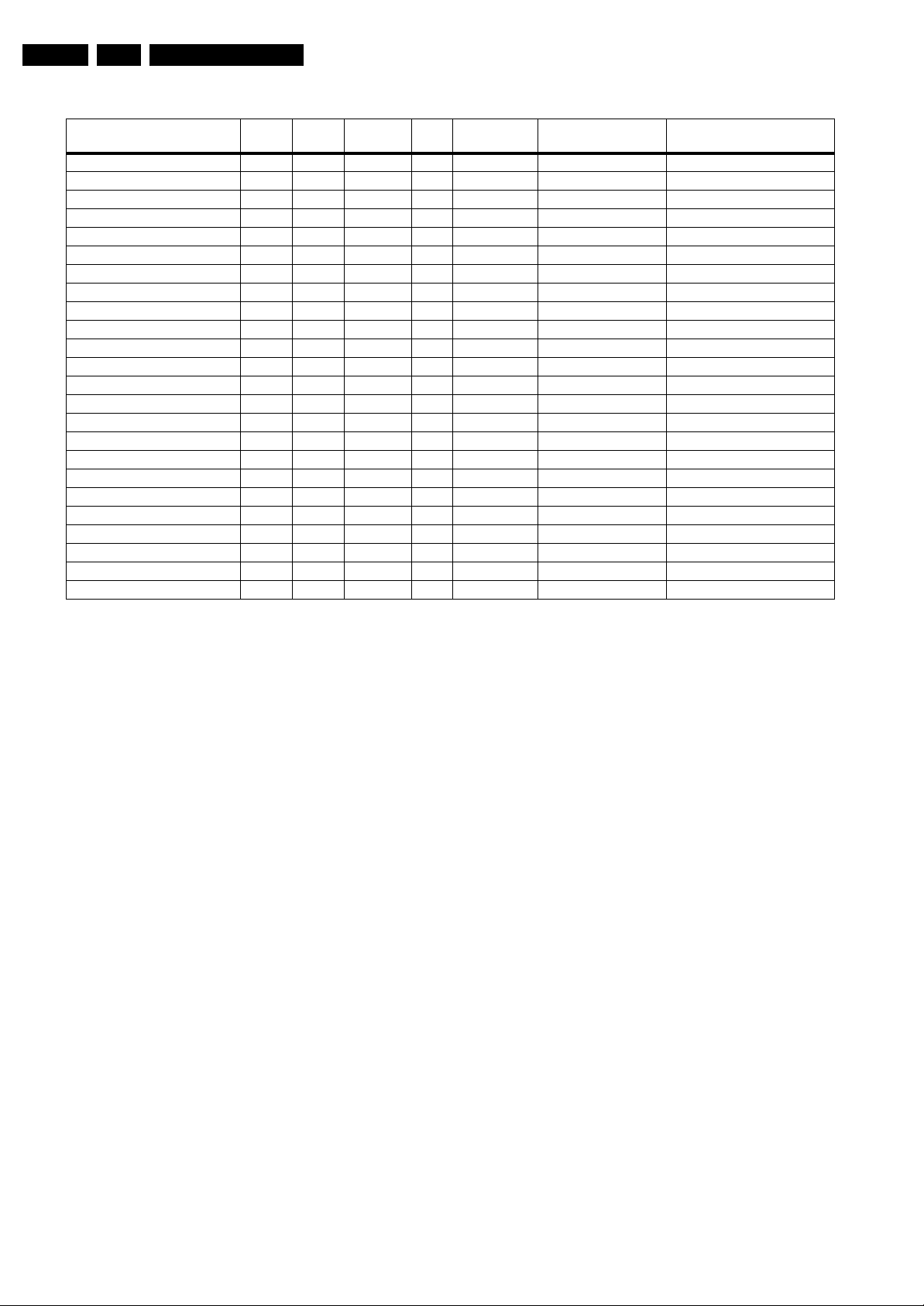

Table 5-2 Error code overview

Service Modes, Error Codes, and Fault Finding

Description Layer 1 Layer 2

2

C3 2 13 MIPS E BL / EB SCL/D-SSB SSB

I

2

C4 5 14 MIPS E BL / EB SCL/D-DISP Display (LED back light only)

I

by

PNX doesn’t boot (HW cause) 2 15 Stby µP E BL PNX8541 I

Monitored

Error/

Error Buffer/

Prot

Blinking LED Device Defective Board

2

C blocked SSB

12V 3 16 Stby µP P BL / Supply

1V2, 3V3, 5V to low 2 18 Stby µP P BL / SSB

1V2 or Class D 2 19 Stby µP P BL / SSB

3V3/5V DCDC to high 2 11 Stby µP P BL / SSB

PNX 5100 2 21 MIPS E EB PNX5100 SSB

HDMI mux 2 23 MIPS E EB AD8197A SSB

2

C switch 2 24 MIPS E EB PCA9540 SSB

I

Master IF 2 26 MIPS E EB TDA9898 SSB

FPGA Ambilight 2 28 MIPS E EB / SSB

Tuner 2 34 MIPS E EB UV1783S/TD1716 SSB

Channel Decoder DVB-T 2 37 MIPS E EB TDA10048 SSB

ST7100 2 38 MIPS E EB ST7100 SSB

MHP 6 39 MIPS E EB / MHP module

Fan I2C expander 7 41 MIPS E EB PCA9533 FAN module

T° sensor 7 42 MIPS E EB LM 75 T° sensor

FAN 1 7 43 MIPS E EB FAN

FAN 2 7 44 MIPS E EB FAN

main NVM 2 / MIPS E X STM24C128 SSB

Channel decoder DVB-C 2 48 MIPS E EB TDA 10023 SSB

PNX doesn’t boot (SW cause) 2 53 Stby µP E BL PNX8541 SSB

Display (only LED back light) 5 64 MIPS E BL / EB Display

Extra Info

• Rebooting. When a TV is constantly rebooting due to

internal problems, most of the time no errors will be logged

or blinked. This rebooting can be recognized via a ComPair

interface and Hyperterminal (for Hyperterminal settings,

see section “5.8 Fault Finding and Repair Tips, 5.8.6

Logging). It’s shown that the loggings which are generated

by the main software keep continuing. In this case

diagnose has to be done via ComPair.

• Error 11 (3V3/5V too high). This protection can occur

during start up (LAYER error 1 = 2). Be careful to overrule

this protection via SDM for the reason supply related

devices can be possibly destroyed here.

• Error 13 (I

2

C bus 3 blocked). At the time of release of this

manual, this error was not working as expected. Current

situation: when this error occurs, the TV will constantly

reboot due to the blocked bus. The best way for further

diagnosis here, is to use ComPair.

• Error 15 (PNX8541 doesn’t boot). Indicates that the main

processor was not able to read his bootscript. This error will

point to a hardware problem around the PNX8541

(supplies not OK, PNX 8541 completely dead, I

between PNX and Stand-by Processor broken, etc...).

When error 15 occurs it is also possible that I

blocked (NVM). I

2

C2 can be indicated in the schematics as

2

C link

2

C2 bus is