Philips Q522.1HE Schematic

Colour Television Chassis

18440_000_090205.eps

090226

Q522.1HE

LA

Contents Page Contents Page

1. Revision List 2

2. Technical Specifications, Directions for Use, and

Connections 2

3. Precautions, Notes, and Abbreviation List 6

4. Mechanical Instructions 10

5. Service Modes, Error Codes, and Fault Finding 25

6. Alignments 46

7. Circuit Descriptions 52

8. IC Data Sheets 54

9. Block Diagrams

Wiring Diagram 26" with Smartcard (ME8) 67

Wiring Diagram 32" with Smartcard (ME8) 68

Wiring Diagram 37" with Smartcard (ME8) 69

Wiring Diagram 42" with Smartcard (ME8) 70

Block Diagram Video 71

Block Diagram Audio 72

Block Diagram Control & Clock Signals 73

I2C IC Overview 74

Supply Lines Overview 75

10. Circuit Diagrams and PWB Lats Drawing PWB

SSB: DC / DC 3V3 1V2

SSB: Main Tuner (B03) 79 121-122

SSB: PNX8541: Stand-by Controller (B04) 88 121-122

SSB: Dual LVDS (B05) 104 121-122

SSB: Pacific 3: LVDS (B06) 105 121-122

SSB: Analog I/O: Scart 1 & 2 (B07) 108 121-122

SSB: Digital I/O: USB Connector + Control(B08) 112 121-122

SSB: Digital I/O: PCMCIA Interf. & Buffer (B10) 115 121-122

SSB: Class-D (B10) 117 121-122

SSB: SRP List Explanation 118

SSB: SRP List Part 1 119

SSB: SRP List Part 2 120

DC / DC Converter Panel (DC) 123 123

iBoard (Part 2) (HC02) 125 127

©

Copyright 2009 Koninklijke Philips Electronics N.V.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

(B02) 76 121-122

iBoard: SRP List Part 1 126

Keyboard Control Panel (E) 128 128

IR & LED Panel (J) 129 130

System Interface Panel 131 132

Switch Panel (SP01) 133 134

Published by MB/CC 0972 BU TV Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 18681

2009-Dec-04

EN 2 Q522.1HE LA1.

Revision List

1. Revision List

Manual xxxx xxx xxxx.0

• First release.

Manual xxxx xxx xxxx.1

• Layout improvements.

• Chapter 5: Added information on VSecure self-test

procedure.

• Chapter 10: Added schematics and layouts for the IR/LED

panel and the Keyboard.

2. Technical Specifications, Directions for Use, and Connections

Index of this chapter:

2.1 Technical Specifications

2.2 Directions for Use

2.4 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

2.1 Technical Specifications

For on-line product support please use the links in Table 2-1.

Here is product information available, as well as getting started,

user manuals, frequently asked questions and software &

drivers.

Table 2-1 Described Model numbers

CTN Styling Published in:

26HFL5870D/10

32HFL5870D/10

37HFL5880D/10

42HFL5880D/10

P&S 3122 785 18680

P&S 3122 785 18680

P&S 3122 785 18680

P&S 3122 785 18680

2.2 Directions for Use

Directions for use can be downloaded from the following

websites:

http://www.philips.com/support

http://www.p4c.philips.com

2009-Dec-04

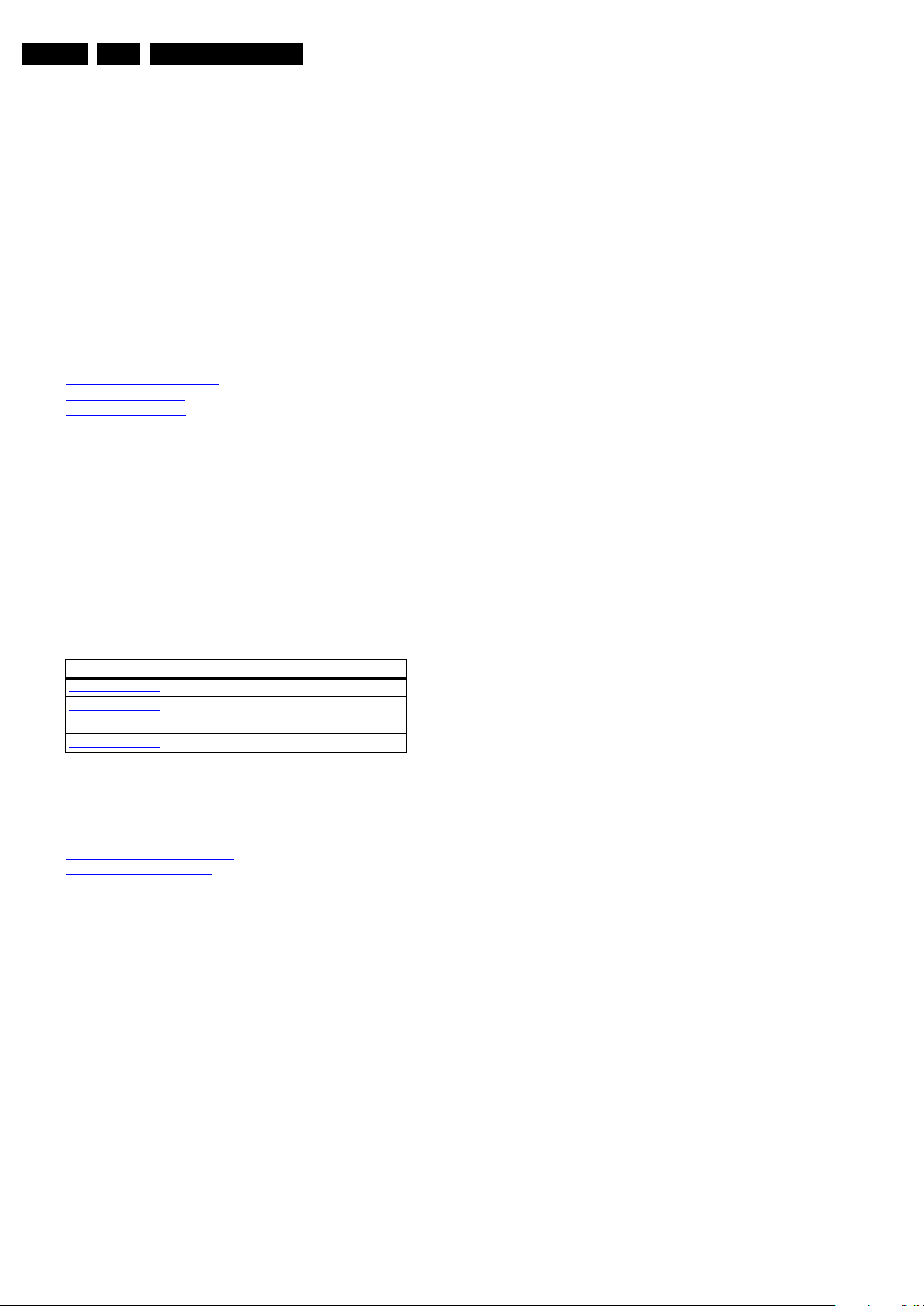

Technical Specifications, Directions for Use, and Connections

AUDIO OUT

SERV. U

SPDIF

OUT

L

R

AUDIO IN

HDMI 1

AUDIO IN:

LEFT / RIGHT

HDMI 1 / DVI

HDMI 2 / DVI

HDMI 3 / DVI

EXT 2

(RGB/CVBS)

EXT 3

EXT 1

(RGB/CVBS)

HDMI 2

L

Pr

Pb

Y

R

TV ANTENNA

75X

18680_001_090820.eps

090820

REAR

CONNECTIONS

SIDE

CONN.

SMART CARD

INTERFACE

2.3 Connections

EN 3Q522.1HE LA 2.

Figure 2-1 Connection overview

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, Ye= Yellow.

2009-Dec-04

EN 4 Q522.1HE LA2.

1 2 3 4

10000_022_090121.eps

090121

10000_017_090121.eps

090428

19

1

18 2

Technical Specifications, Directions for Use, and Connections

2.3.1 Side Connections

Smart Card Interface: Data Video - In/Out

17

1

10000_044_090121.eps

32

16

090121

Figure 2-2 Smart-card Connector

1 - 3V3 (1) +3.3 V k

2 - Ground power Gnd H

3 - 12V (1) +12 V j

4 - Ground I

2

C Gnd H

5 - IR data Data j

6 - POR (2) Signal j

7 - TV Clock (3) Clock Signal k

8 - Data in (3) Data j

9 - Data out (3) Data k

10 - 5V (1) +5 V j

11 - H-sync Signal k

12 - V-sync Signal k

13 - Gnd CVBS in Gnd H

14 - SCL (4) DDC clock jk

15 - SDA (4) DDC data jk

16 - Reserved

17 - B_Pb in (5) Blue in Signal j

18 - G_Y in (5) Green in Signal j

19 - R_Pr in (5) Red in Signal j

20 - FBL in (5) Signal j

21 - Gnd CVBS out Gnd H

22 - CVBS out (6) 1 V

/ 75 W j

PP

23 - Reserved

24 - Reserved

25 - Reserved

26 - Gnd Audio in Gnd H

27 - Audio R 0.5 V

28 - Audio L 0.5 V

29 - Audio R 0.5 V

30 - Audio L/Mono in 0.5 V

31 - Video CVBS/Yin 1 V

32 - C in 0.7 V

/ 1 kW k

RMS

/ 1 kW k

RMS

/ 10 kW j

RMS

/ 10 kW j

RMS

/ 75 W j

PP

/ 75 W j

PP

1. Pin 1, 3, 10: maximum current limits 1.5A for 3.3V, 1.0A for

5V, and 0.6A for 12V. Total power may not exceed 10W.

2. Pin 6: Bidirectional POR. TV will reset the system card

(active low) when mains is switched “off” to “on”. DCM can

reset iTV controller by pulling POR low for 150 ms.

3. Pin 7, 8, 9: SPI bus global (either I2C bus or SPI at any one

time, not simultaneously).

4. Pin 14, 15: I2C bus (either I2C bus or SPI at any one time,

not simultaneously).

5. Pin 17, 18, 19, 20: RGB+FBL applicable only for full field

insertion and not for OSD. For CVI input, only applicable for

1fH.

6. Pin 22: CVBS_terr_out when switching from analog RF to

SCART. Composite video out when switch from DVB-T to

SCART.

Head phone (Output)

Bk - Head phone 32 - 600 ohm / 10 mW ot

USB2.0

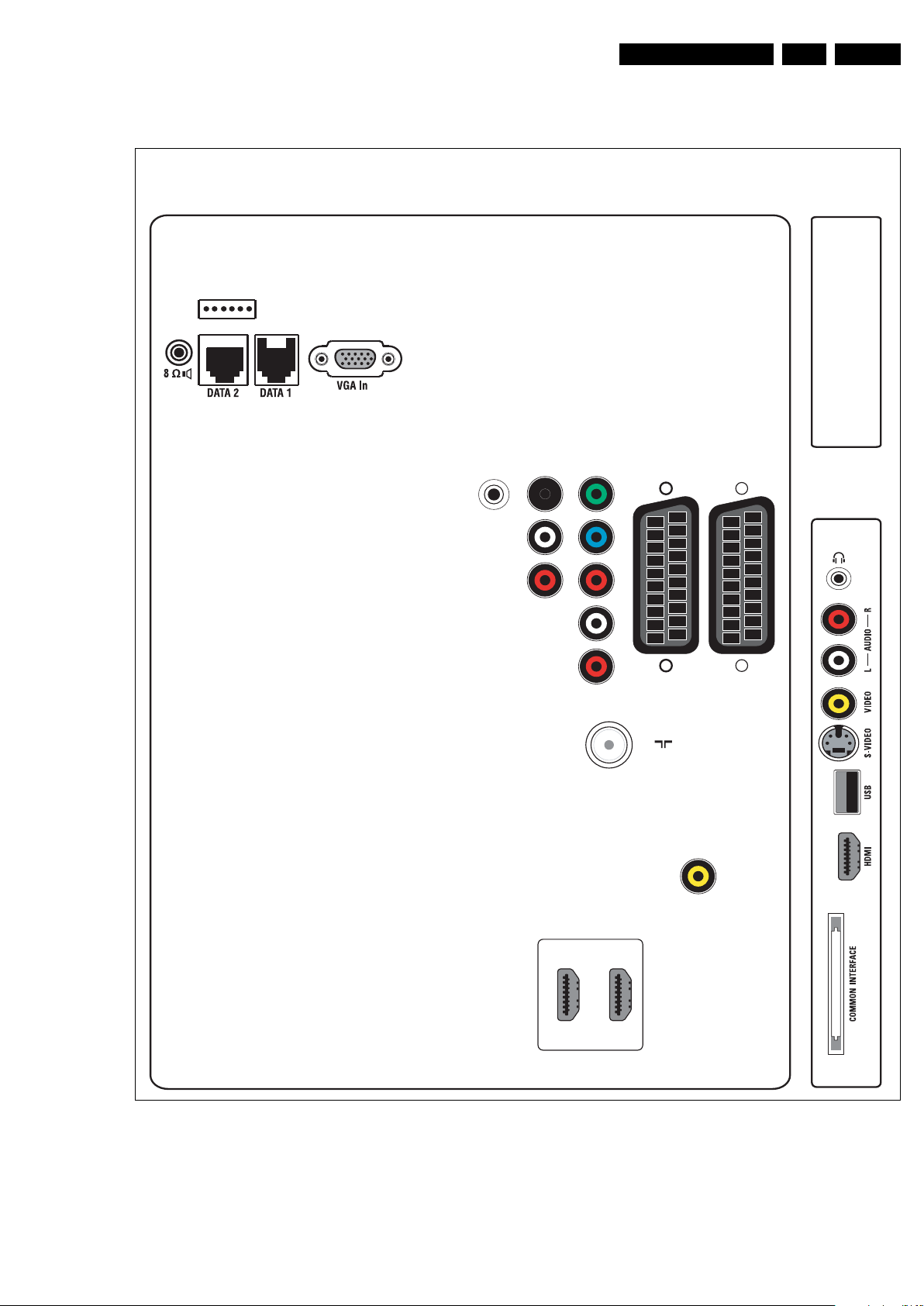

Figure 2-3 USB (type A)

1-+5V k

2 - Data (-) jk

3 - Data (+) jk

4 - Ground Gnd H

HDMI: Digital Video, Digital Audio - In

Figure 2-4 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - Easylink CEC jk

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

Common Interface

68p - See diagram B09A jk

2.3.2 Rear Connections

Mini Jack: Bathroom speaker (Output)

Bk - Bathroom speaker 8 W / 1 W o

RJ48 DATA2 (Xpress Box/Set Top Box- In/Out)

1 - +12V +12V/1W k

2 - Gnd Gnd H

3 - Reserved

4 - Reserved

5 - TXD232 Signal

6 - RXD232 Signal

7 - IR-OUT/SDA Signal k

8 - POR Signal k

9 - CVBS_out Signal k

10 - Gnd CVBS_out Gnd H

Cinch: Video CVBS - In, Audio - In

Rd - Audio R 0.5 V

Wh - Audio L 0.5 V

Ye - Video CVBS 1 V

S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

2009-Dec-04

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

RJ12 DATA1 (SmartCard XPress Box)

Configure via communication menu

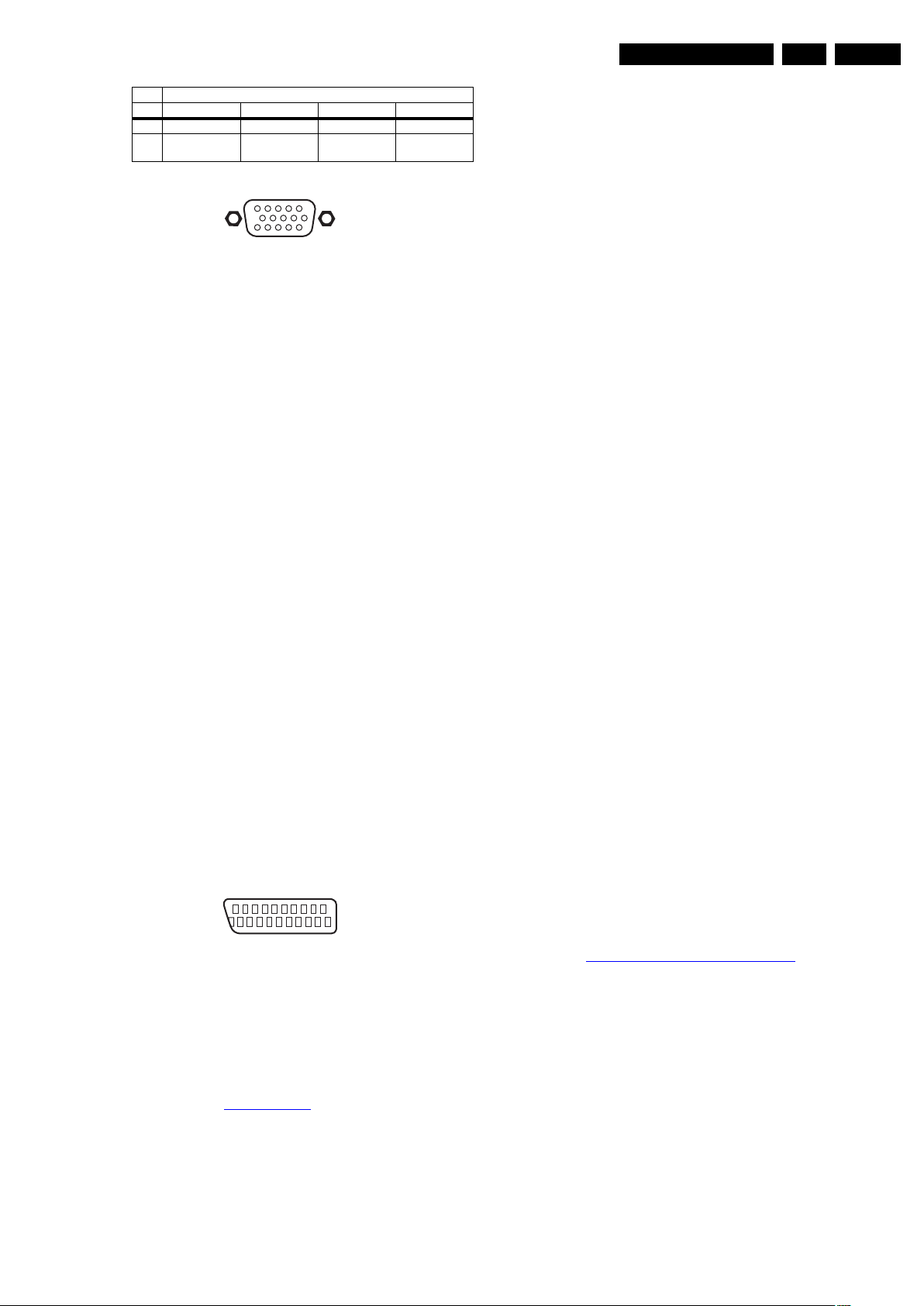

Pins SP-SPI SP-Serial XP SP-I2C HM-Link

1 SP Clock, 5V,

active low

2 SP Data In, 5V,

active high

3 Reserved Reserved Reserved Reserved

4 SP Data Out, 5V,

active low

Tx_ 5V,

active low

Rx_5V,

active low

Not use Not use Status

SCL, 5V,

active low

Use pin 7 RJ45

for SDA, 5V

active low

LED Ctrl

IR in to TV, 5V,

active low

Technical Specifications, Directions for Use, and Connections

1

6

10

11

5

15

10000_002_090121.eps

090127

21

20

1

2

10000_001_090121.eps

090121

EN 5Q522.1HE LA 2.

Configure via communication menu

Pins SP-SPI SP-Serial XP SP-I2C HM-Link

5 Gnd Gnd Gnd Gnd

6 IR Out,

open collector

IR Out,

open collector

IR Out,

open collector

IR from RC, 5V,

active low

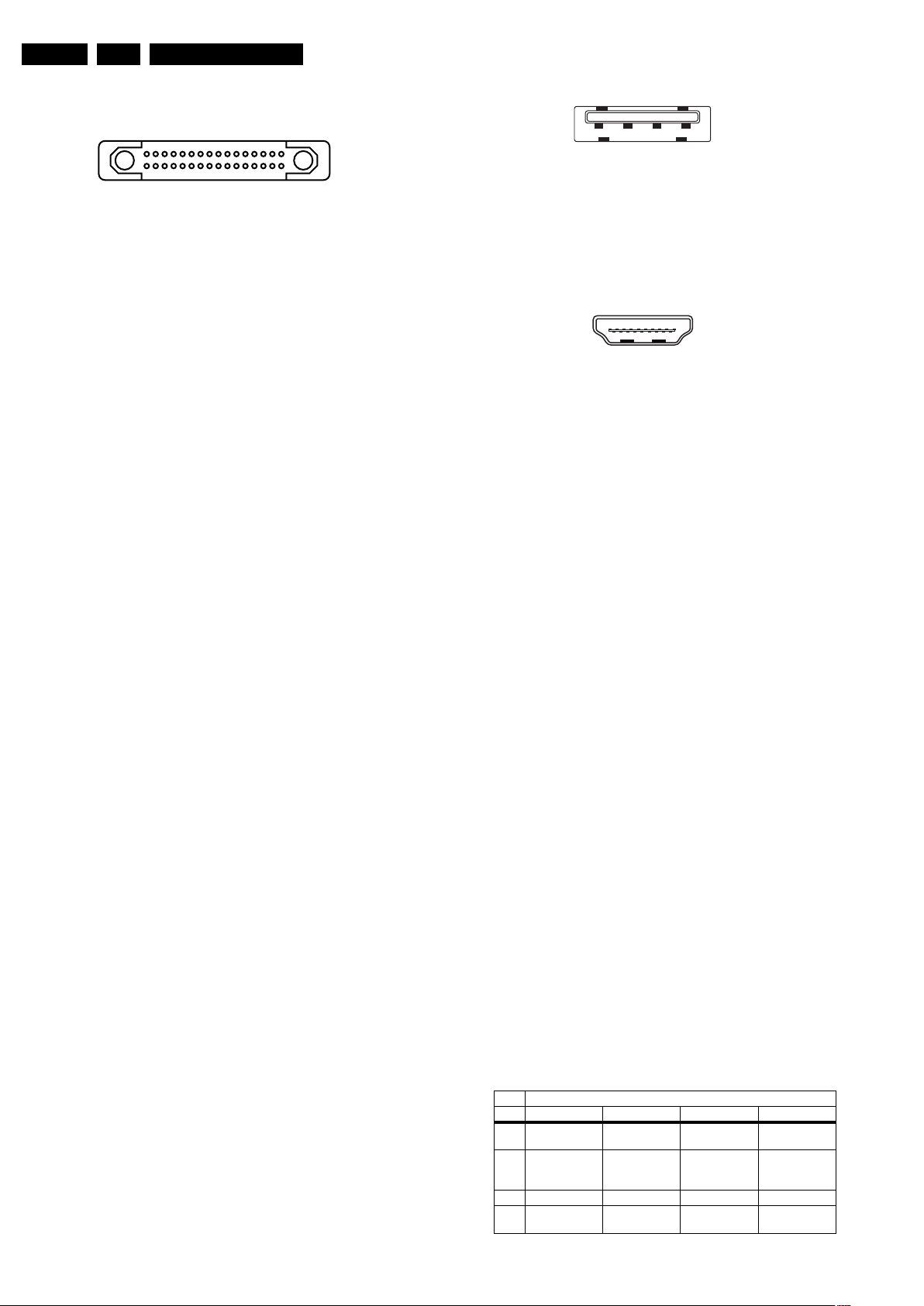

VGA: Video RGB - In

Figure 2-5 VGA Connector

1 - Video Red 0.7 V

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

/ 75 W j

PP

/ 75 W j

PP

/ 75 W j

PP

4 - Sense Gnd H

5 - Ground Gnd H

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

9-+5V

+5 V (EDID NVM) j

DC

10 - Ground Sync Gnd H

11 - Sense Gnd H

12 - Bi-directional data EDID I2C data jk

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - Data clock EDID I2C clock jk

Service Connector (UART)

1 - Ground Gnd H

2 - UART_TX Transmit k

3 - UART_RX Receive j

Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

/ 75 ohm kq

PP

Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

EXT3: Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

EXT1: Video RGB - In (*), CVBS - In/Out, Audio - In/Out

3 - Audio L 0.5 V

4 - Ground Audio Gnd H

/ 1 kohm k

RMS

5 - Ground Blue Gnd H

6 - Audio L 0.5 V

7 - Video Blue (*) 0.7 V

/ 10 kohm j

RMS

/ 75 ohm j

PP

8 - Function Select 0 - 2 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9 - Ground Green Gnd H

10 - n.c.

11 - Video Green (*) 0.7 V

/ 75 ohm j

PP

12 - n.c.

13 - Ground Red Gnd H

14 - Ground P50 Gnd H

15 - Video Red (*) 0.7 V

16 - Status/FBL 0 - 0.4 V: INT

/ 75 ohm j

PP

1 - 3 V: EXT / 75 ohm j

17 - Ground Video Gnd H

18 - Ground FBL Gnd H

19 - Video CVBS 1 V

20 - Video CVBS 1 V

21 - Shield Gnd H

/ 75 ohm k

PP

/ 75 ohm j

PP

(*) Only when Cardslot is disabled in “Communication” menu.

EXT2: Video YPbPr - In, CVBS - In/Out, Audio - In/Out

1 - Audio R 0.5 V

2 - Audio R 0.5 V

3 - Audio L 0.5 V

4 - Ground Audio Gnd H

/ 1 kohm k

RMS

/ 10 kohm j

RMS

/ 1 kohm k

RMS

5 - Ground Pb Gnd H

6 - Audio L 0.5 V

7 - Video Pb 0.7 V

8 - Function Select 0 - 2 V: INT

/ 10 kohm j

RMS

/ 75 ohm j

PP

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9 - Ground Y Gnd H

10 - n.c.

11 - Video Y 0.7 V

12 - n.c.

/ 75 ohm j

PP

13 - Ground Pr Gnd H

14 - Ground P50 Gnd H

15 - Video Pr 0.7 V

16 - Status/FBL 0 - 0.4 V: INT

/ 75 ohm j

PP

1 - 3 V: EXT / 75 ohm j

17 - Ground Video Gnd H

18 - Ground FBL Gnd H

19 - Video CVBS 1 V

20 - Video CVBS 1 V

21 - Shield Gnd H

/ 75 ohm k

PP

/ 75 ohm j

PP

Aerial - In

- - IEC-type (EU) Coax, 75 ohm D

Figure 2-6 SCART connector

1 - Audio R 0.5 V

2 - Audio R 0.5 V

/ 1 kohm k

RMS

/ 10 kohm j

RMS

2.4 Chassis Overview

Refer to chapter Block Diagrams for PWB/CBA locations.

HDMI 1 & 2 Digital Video, Digital Audio - In

See HDMI: Digital Video, Digital Audio - In

Mini Jack: HDMI/DVI Audio - In

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

2009-Dec-04

EN 6 Q522.1HE LA3.

Precautions, Notes, and Abbreviation List

3. Precautions, Notes, and Abbreviation List

Index of this chapter:

3.1 Safety Instructions

3.2 Warnings

3.3 Notes

3.4 Abbreviation List

3.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard. Of de set

ontploft!

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

picture carrier at 475.25 MHz for PAL, or 61.25 MHz for

NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

3.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kΩ).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220 Ω).

• All capacitor values are given in micro-farads (μ=× 10

nano-farads (n =× 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed on the Philips

Spare Parts Web Portal.

3.3.3 Spare Parts

For the latest spare part overview, consult your Philips Spare

Part web portal.

3.3.4 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: http://www.atyourservice-magazine.com

“Magazine”, then go to “Repair downloads”. Here you will find

Information on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile.

Where applicable and available, this profile is added to the IC

Data Sheet information section in this manual.

-9

), or pico-farads (p =× 10

. Select

-12

-6

),

).

3.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

3.3 Notes

3.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode with a colour bar signal and stereo

sound (L: 3 kHz, R: 1 kHz unless stated otherwise) and

3.3.5 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin. If lead-free solder paste is

required, please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2009-Dec-04

Precautions, Notes, and Abbreviation List

10000_024_090121.eps

090121

MODEL :

PROD.NO:

~

S

32PF9968/10

MADE IN BELGIUM

220-240V 50/60Hz

128W

AG 1A0617 000001

VHF+S+H+UHF

BJ3.0E LA

EN 7Q522.1HE LA 3.

3.3.6 Alternative BOM identification

It should be noted that on the European Service website,

“Alternative BOM” is referred to as “Design variant”.

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Figure 3-1 Serial number (example)

3.3.7 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

3.3.8 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3.4 Abbreviation List

0/6/12 SCART switch control signal on A/V

board. 0 = loop through (AUX to TV),

6 = play 16 : 9 format, 12 = play 4 : 3

format

AARA Automatic Aspect Ratio Adaptation:

algorithm that adapts aspect ratio to

remove horizontal black bars; keeps

the original aspect ratio

ACI Automatic Channel Installation:

algorithm that installs TV channels

directly from a cable network by

means of a predefined TXT page

ADC Analogue to Digital Converter

AFC Automatic Frequency Control: control

signal used to tune to the correct

frequency

AGC Automatic Gain Control: algorithm that

controls the video input of the feature

box

AM Amplitude Modulation

AP Asia Pacific

AR Aspect Ratio: 4 by 3 or 16 by 9

ASF Auto Screen Fit: algorithm that adapts

aspect ratio to remove horizontal black

bars without discarding video

information

ATSC Advanced Television Systems

Committee, the digital TV standard in

the USA

ATV See Auto TV

Auto TV A hardware and software control

system that measures picture content,

and adapts image parameters in a

dynamic way

AV External Audio Video

AVC Audio Video Controller

AVIP Audio Video Input Processor

B/G Monochrome TV system. Sound

carrier distance is 5.5 MHz

BDS Business Display Solutions (iTV)

BLR Board-Level Repair

BTSC Broadcast Television Standard

Committee. Multiplex FM stereo sound

system, originating from the USA and

used e.g. in LATAM and AP-NTSC

countries

B-TXT Blue TeleteXT

C Centre channel (audio)

CEC Consumer Electronics Control bus:

remote control bus on HDMI

connections

CL Constant Level: audio output to

connect with an external amplifier

CLR Component Level Repair

ComPair Computer aided rePair

CP Connected Planet / Copy Protection

CSM Customer Service Mode

CTI Color Transient Improvement:

manipulates steepness of chroma

transients

CVBS Composite Video Blanking and

Synchronization

DAC Digital to Analogue Converter

DBE Dynamic Bass Enhancement: extra

low frequency amplification

DCM Data Communication Module. Also

referred to as System Card or

Smartcard (for iTV).

DDC See “E-DDC”

D/K Monochrome TV system. Sound

carrier distance is 6.5 MHz

DFI Dynamic Frame Insertion

2009-Dec-04

EN 8 Q522.1HE LA3.

Precautions, Notes, and Abbreviation List

DFU Directions For Use: owner's manual

DMR Digital Media Reader: card reader

DMSD Digital Multi Standard Decoding

DNM Digital Natural Motion

DNR Digital Noise Reduction: noise

reduction feature of the set

DRAM Dynamic RAM

DRM Digital Rights Management

DSP Digital Signal Processing

DST Dealer Service Tool: special remote

control designed for service

technicians

DTCP Digital Transmission Content

Protection; A protocol for protecting

digital audio/video content that is

traversing a high speed serial bus,

such as IEEE-1394

DVB-C Digital Video Broadcast - Cable

DVB-T Digital Video Broadcast - Terrestrial

DVD Digital Versatile Disc

DVI(-d) Digital Visual Interface (d= digital only)

E-DDC Enhanced Display Data Channel

(VESA standard for communication

channel and display). Using E-DDC,

the video source can read the EDID

information form the display.

EDID Extended Display Identification Data

(VESA standard)

EEPROM Electrically Erasable and

Programmable Read Only Memory

EMI Electro Magnetic Interference

EPG Electronic Program Guide

EPLD Erasable Programmable Logic Device

EU Europe

EXT EXTernal (source), entering the set by

SCART or by cinches (jacks)

FDS Full Dual Screen (same as FDW)

FDW Full Dual Window (same as FDS)

FLASH FLASH memory

FM Field Memory or Frequency

Modulation

FPGA Field-Programmable Gate Array

FTV Flat TeleVision

Gb/s Giga bits per second

G-TXT Green TeleteXT

H H_sync to the module

HD High Definition

HDD Hard Disk Drive

HDCP High-bandwidth Digital Content

Protection: A “key” encoded into the

HDMI/DVI signal that prevents video

data piracy. If a source is HDCP coded

and connected via HDMI/DVI without

the proper HDCP decoding, the

picture is put into a “snow vision” mode

or changed to a low resolution. For

normal content distribution the source

and the display device must be

enabled for HDCP “software key”

decoding.

HDMI High Definition Multimedia Interface

HP HeadPhone

I Monochrome TV system. Sound

2

I

C Inter IC bus

2

I

D Inter IC Data bus

2

I

S Inter IC Sound bus

carrier distance is 6.0 MHz

IF Intermediate Frequency

IR Infra Red

IRQ Interrupt Request

ITU-656 The ITU Radio communication Sector

(ITU-R) is a standards body

subcommittee of the International

Telecommunication Union relating to

radio communication. ITU-656 (a.k.a.

SDI), is a digitized video format used

for broadcast grade video.

Uncompressed digital component or

digital composite signals can be used.

The SDI signal is self-synchronizing,

uses 8 bit or 10 bit data words, and has

a maximum data rate of 270 Mbit/s,

with a minimum bandwidth of 135

MHz.

ITV Institutional TeleVision; TV sets for

hotels, hospitals etc.

LS Last Status; The settings last chosen

by the customer and read and stored

in RAM or in the NVM. They are called

at start-up of the set to configure it

according to the customer's

preferences

LATAM Latin America

LCD Liquid Crystal Display

LED Light Emitting Diode

L/L' Monochrome TV system. Sound

carrier distance is 6.5 MHz. L' is Band

I, L is all bands except for Band I

LPL LG.Philips LCD (supplier)

LS Loudspeaker

LVDS Low Voltage Differential Signalling

Mbps Mega bits per second

M/N Monochrome TV system. Sound

carrier distance is 4.5 MHz

MHEG Part of a set of international standards

related to the presentation of

multimedia information, standardised

by the Multimedia and Hypermedia

Experts Group. It is commonly used as

a language to describe interactive

television services

MIPS Microprocessor without Interlocked

Pipeline-Stages; A RISC-based

microprocessor

MOP Matrix Output Processor

MOSFET Metal Oxide Silicon Field Effect

Transistor, switching device

MPEG Motion Pictures Experts Group

MPIF Multi Platform InterFace

MUTE MUTE Line

MTV Mainstream TV: TV-mode with

Consumer TV features enabled (iTV)

NC Not Connected

NICAM Near Instantaneous Compounded

Audio Multiplexing. This is a digital

sound system, mainly used in Europe.

NTC Negative Temperature Coefficient,

non-linear resistor

NTSC National Television Standard

Committee. Color system mainly used

in North America and Japan. Color

carrier NTSC M/N= 3.579545 MHz,

NTSC 4.43= 4.433619 MHz (this is a

VCR norm, it is not transmitted off-air)

NVM Non-Volatile Memory: IC containing

TV related data such as alignments

O/C Open Circuit

OSD On Screen Display

OAD Over the Air Download. Method of

software upgrade via RF transmission.

Upgrade software is broadcasted in

TS with TV channels.

OTC On screen display Teletext and

Control; also called Artistic (SAA5800)

P50 Project 50: communication protocol

between TV and peripherals

PAL Phase Alternating Line. Color system

mainly used in West Europe (color

carrier= 4.433619 MHz) and South

America (color carrier PAL M=

2009-Dec-04

Precautions, Notes, and Abbreviation List

EN 9Q522.1HE LA 3.

3.575612 MHz and PAL N= 3.582056

MHz)

PCB Printed Circuit Board (same as “PWB”)

PCM Pulse Code Modulation

PDP Plasma Display Panel

PFC Power Factor Corrector (or Pre-

conditioner)

PIP Picture In Picture

PLL Phase Locked Loop. Used for e.g.

FST tuning systems. The customer

can give directly the desired frequency

POD Point Of Deployment: a removable

CAM module, implementing the CA

system for a host (e.g. a TV-set)

POR Power On Reset, signal to reset the uP

PTC Positive Temperature Coefficient,

non-linear resistor

PWB Printed Wiring Board (same as “PCB”)

PWM Pulse Width Modulation

QRC Quasi Resonant Converter

QTNR Quality Temporal Noise Reduction

QVCP Quality Video Composition Processor

RAM Random Access Memory

RGB Red, Green, and Blue. The primary

color signals for TV. By mixing levels

of R, G, and B, all colors (Y/C) are

reproduced.

RC Remote Control

RC5 / RC6 Signal protocol from the remote

control receiver

RESET RESET signal

ROM Read Only Memory

RSDS Reduced Swing Differential Signalling

data interface

R-TXT Red TeleteXT

SAM Service Alignment Mode

S/C Short Circuit

SCART Syndicat des Constructeurs

d'Appareils Radiorécepteurs et

SCL Serial Clock I

Téléviseurs

SCL-F CLock Signal on Fast I

SD Standard Definition

SDA Serial Data I

SDA-F DAta Signal on Fast I

2

C

2

C bus

2

C

2

C bus

SDI Serial Digital Interface, see “ITU-656”

SDRAM Synchronous DRAM

SECAM SEequence Couleur Avec Mémoire.

Color system mainly used in France

and East Europe. Color carriers=

4.406250 MHz and 4.250000 MHz

SIF Sound Intermediate Frequency

SMPS Switched Mode Power Supply

SoC System on Chip

SOG Sync On Green

SOPS Self Oscillating Power Supply

SPI Serial Peripheral Interface bus; a 4-

wire synchronous serial data link

standard

S/PDIF Sony Philips Digital InterFace

SRAM Static RAM

SRP Service Reference Protocol

SSB Small Signal Board

SSC Spread Spectrum Clocking, used to

reduce the effects of EMI

STB Set Top Box

STBY STand-BY

SVGA 800 × 600 (4:3)

SVHS Super Video Home System

SW Software

SWAN Spatial temporal Weighted Averaging

Noise reduction

SXGA 1 280 × 1024

TFT Thin Film Transistor

THD Total Harmonic Distortion

TMDS Transmission Minimized Differential

Signalling

TS Transport Stream

TXT TeleteXT

TXT-DW Dual Window with TeleteXT

UI User Interface

uP Microprocessor

UXGA 1600 × 1200 (4:3)

V V-sync to the module

VESA Video Electronics Standards

Association

VGA 640 × 480 (4:3)

VL Variable Level out: processed audio

output toward external amplifier

VSB Vestigial Side Band; modulation

method

WYSIWYR What You See Is What You Record:

record selection that follows main

picture and sound

WXGA 1280 × 768 (15:9)

XTAL Quartz crystal

XGA 1024 × 768 (4:3)

Y Luminance signal

Y/C Luminance (Y) and Chrominance (C)

signal

YPbPr Component video. Luminance and

scaled color difference signals (B-Y

and R-Y)

YUV Component video

2009-Dec-04

EN 10 Q522.1HE LA4.

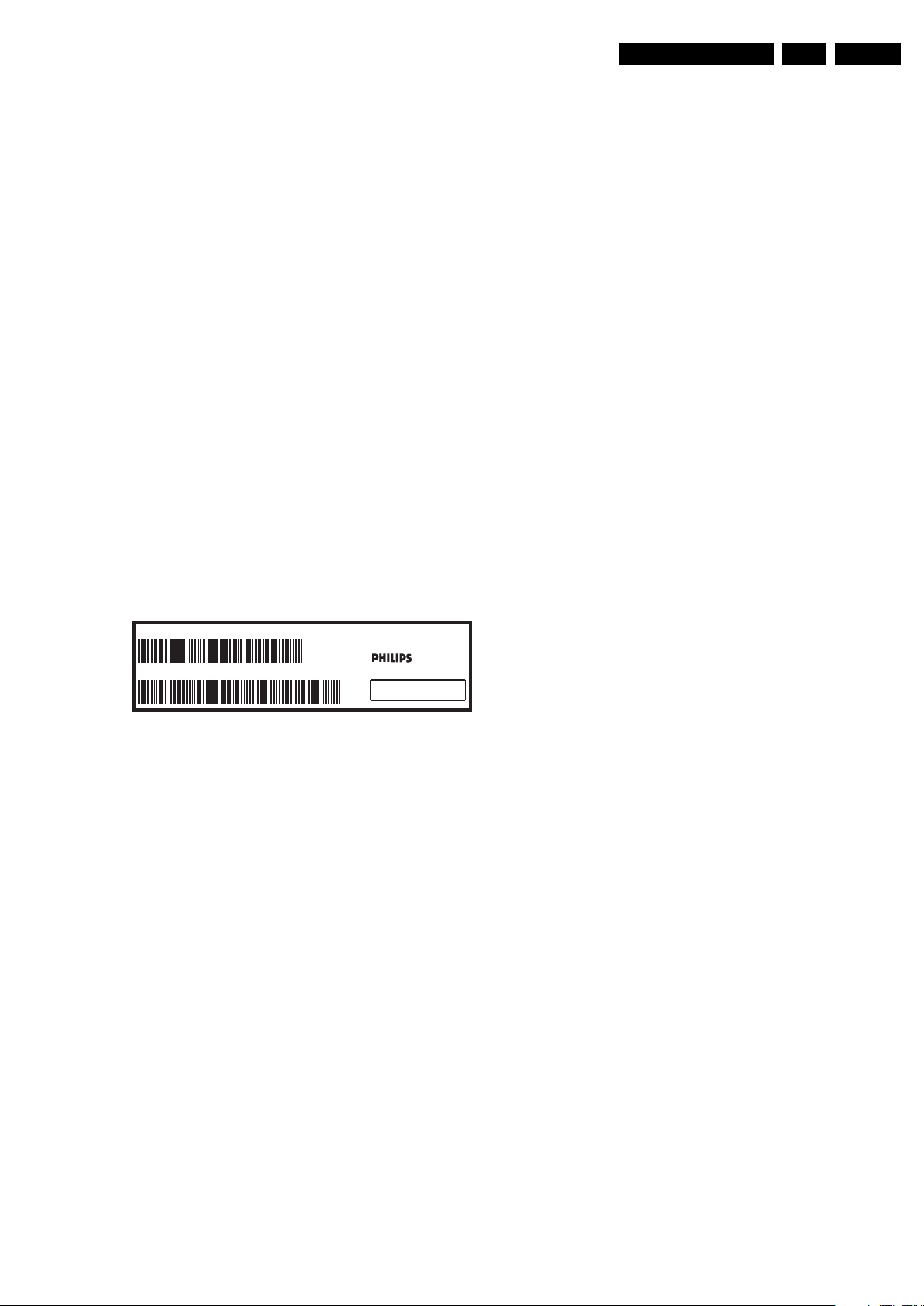

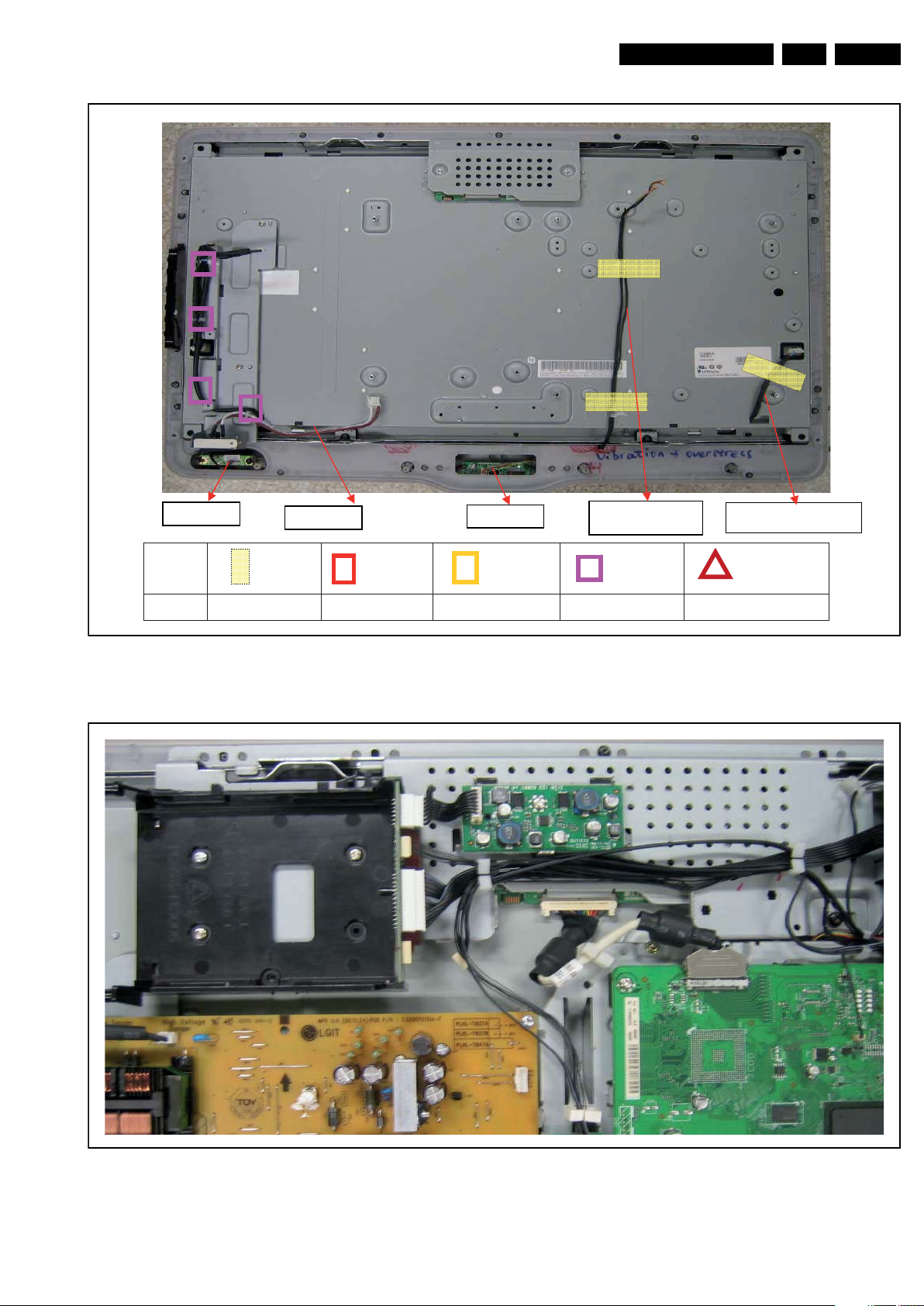

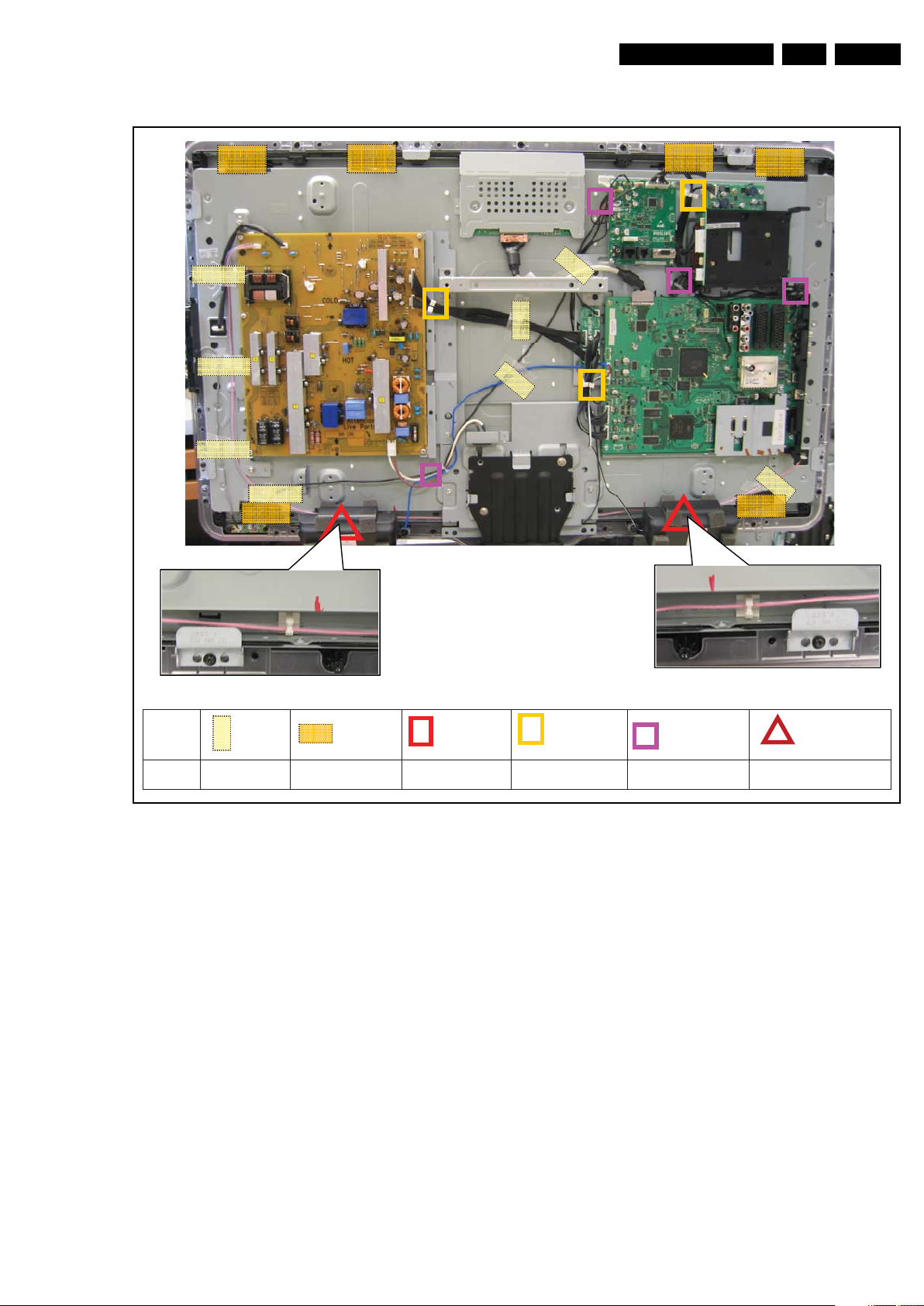

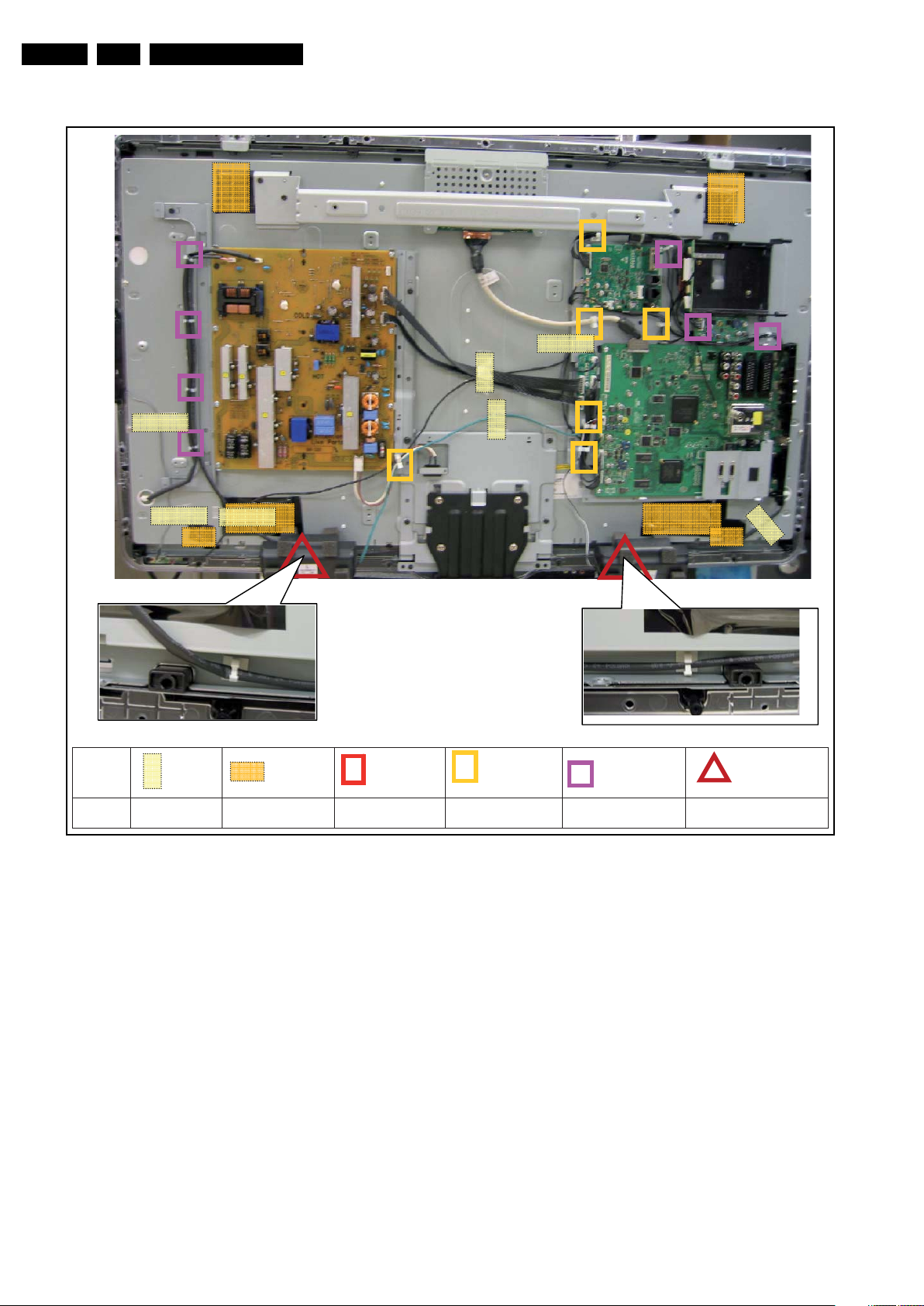

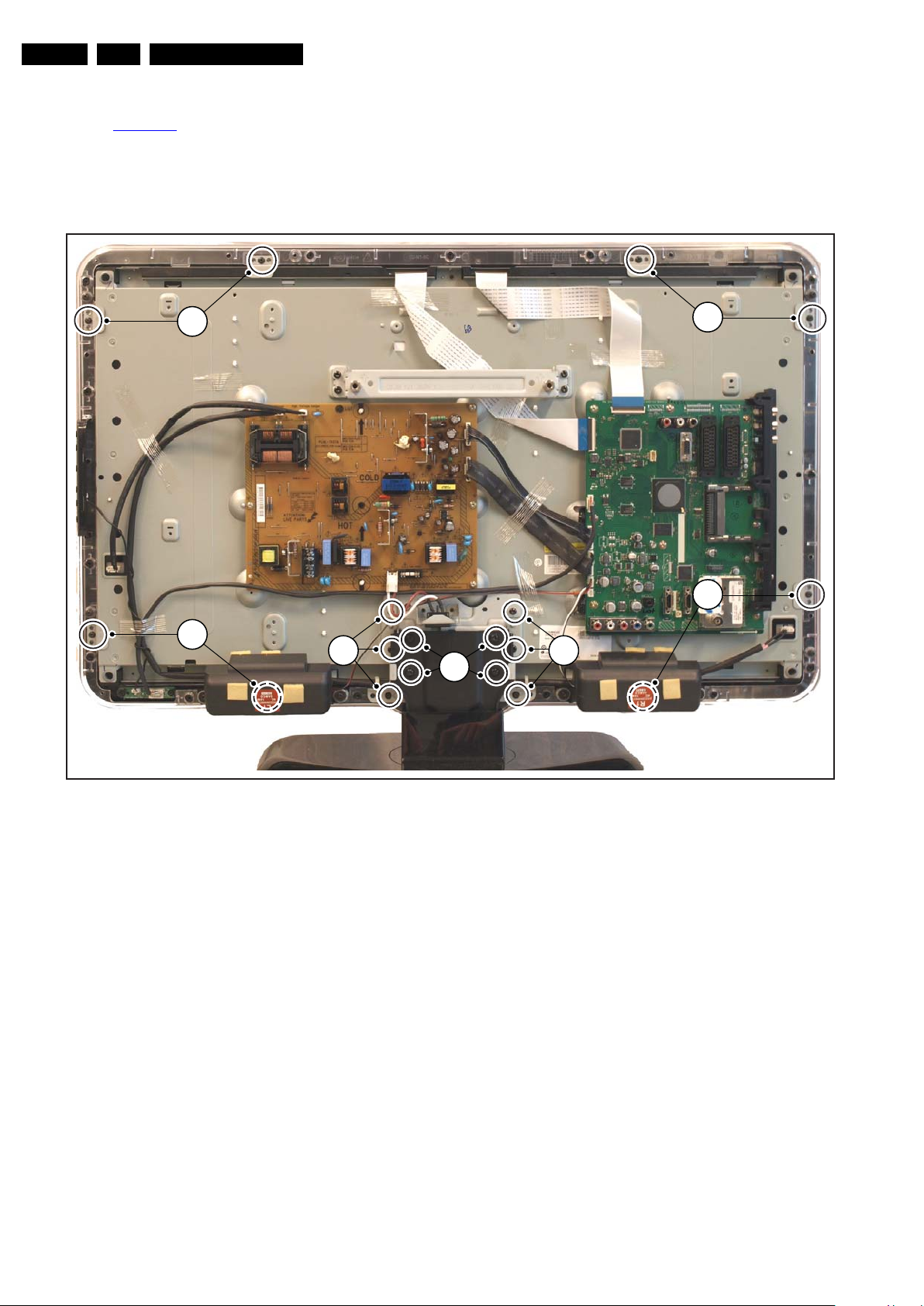

18680_100_090820.eps

090820

Type Tape

Saddle

(L)

Saddle

(M)

Saddle

(S)

Saddle

(Adhesive)

Qty 0 0 5 8 0

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.1.1 Cable dressing 26HFL5870D/10

4.1.2 Cable dressing 32HFL5870D/10

4.1.3 Cable dressing 37HFL5880D/10

4.1.4 Cable dressing 42HFL5880D/10

4.2 Service Positions

4.3 Assy/Panel Removal

4.1 Cable Dressing

4.1.1 Cable dressing 26HFL5870D/10

4.4 Set Re-assembly

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

Figure 4-1 Overview 26HFL5870D/10

2009-Dec-04

Mechanical Instructions

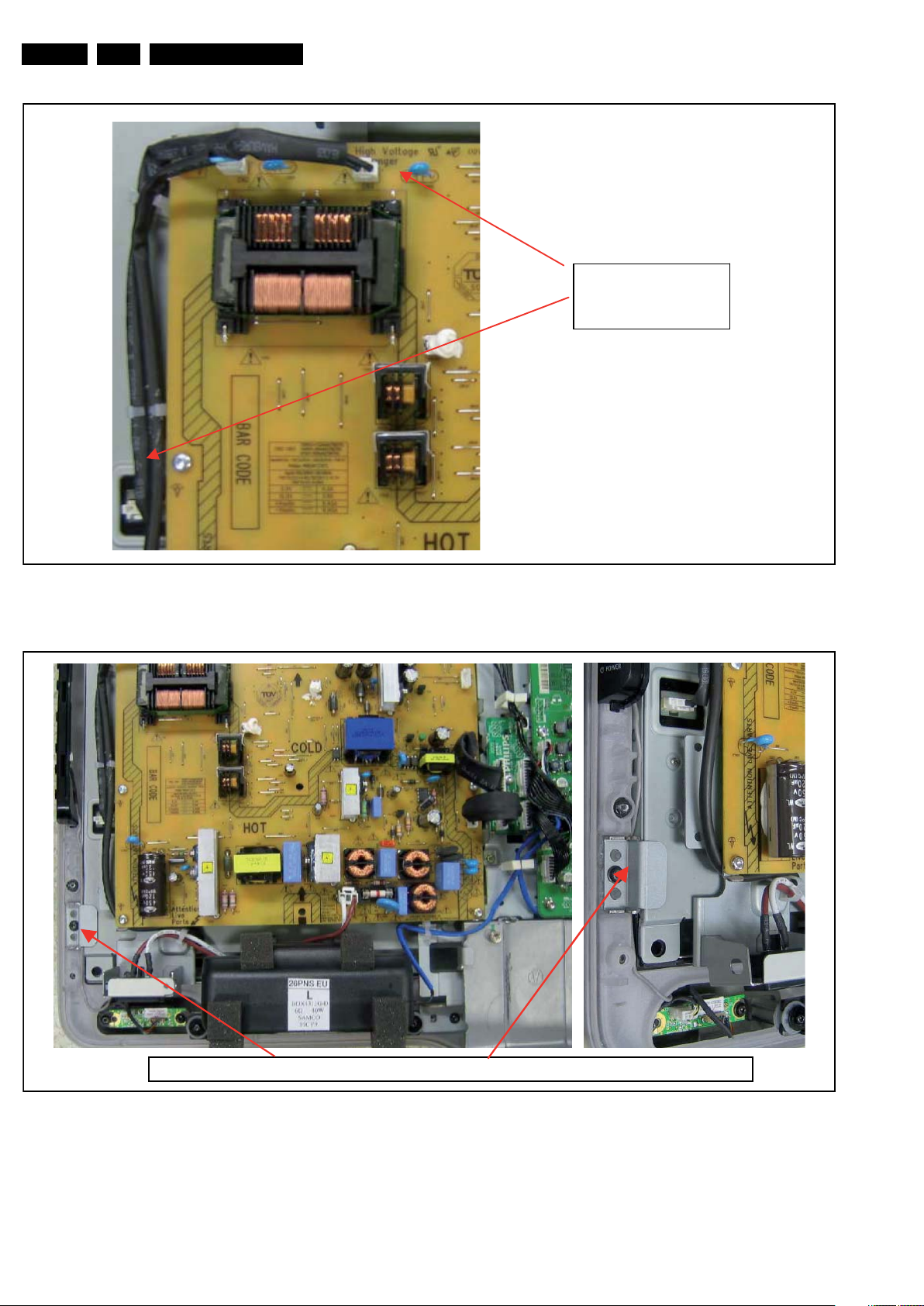

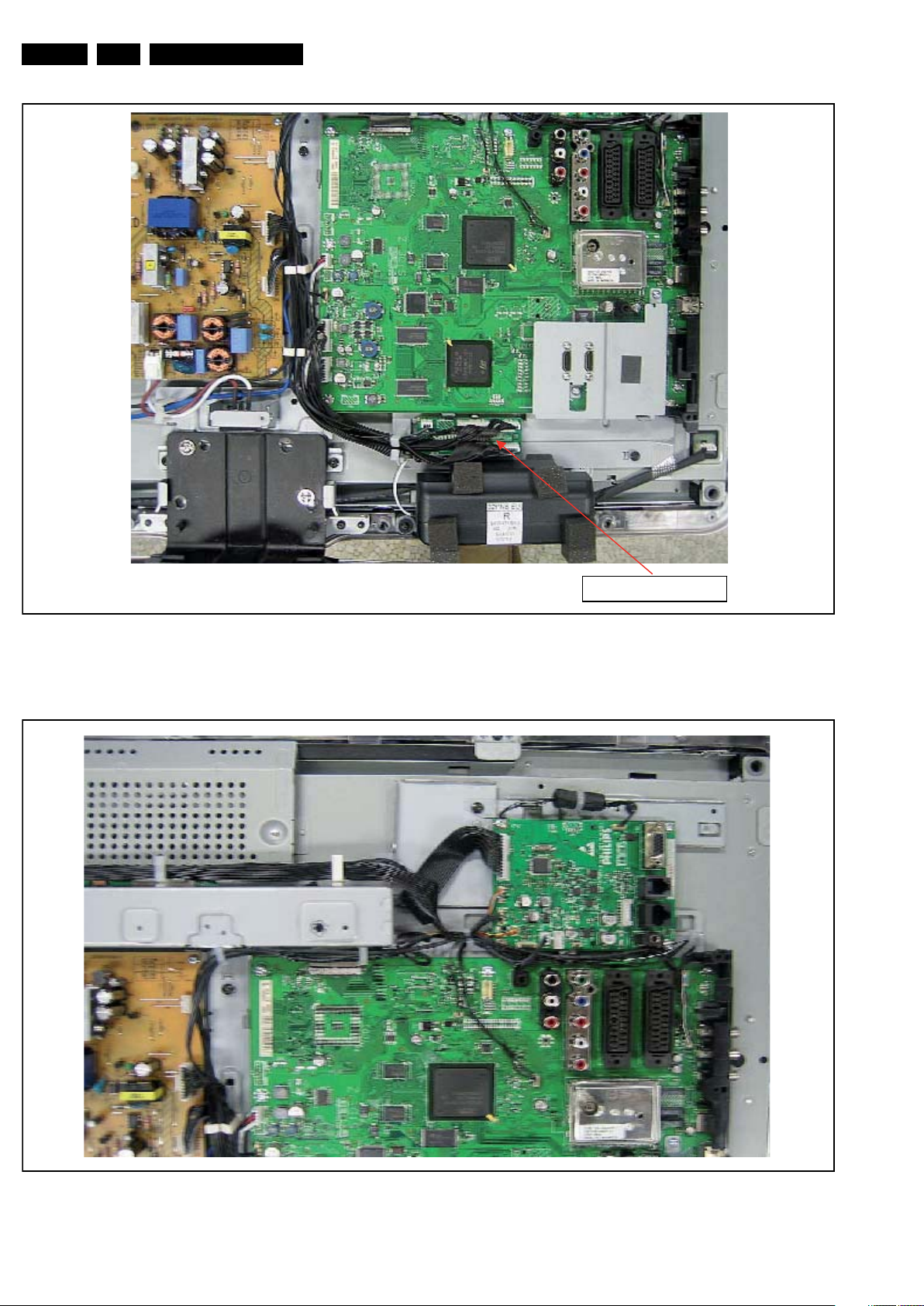

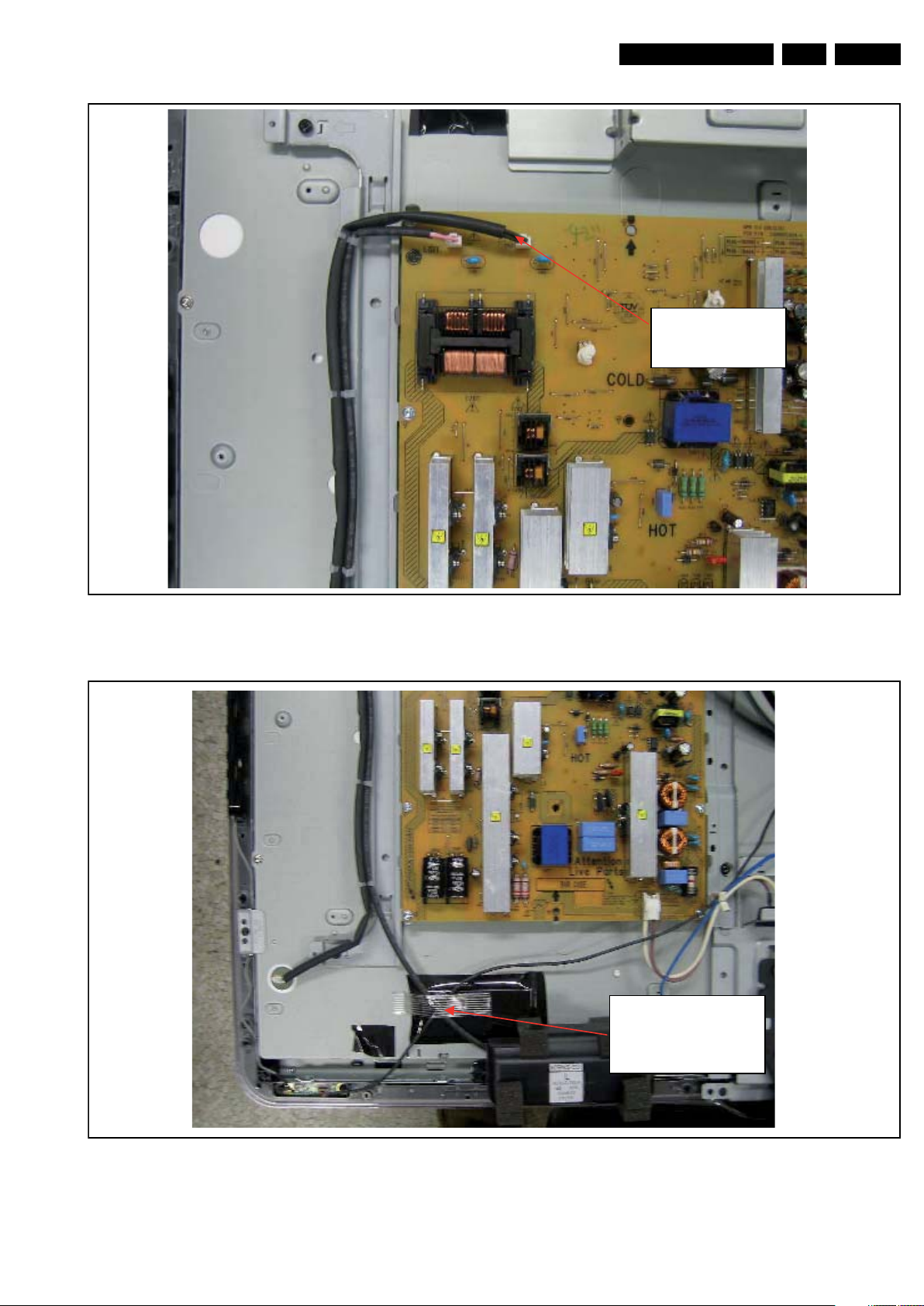

18680_101_090820.eps

091201

Type Tape

Saddle

(L)

Saddle

(M)

Saddle

(S)

Saddle

(Adhesive)

Qty 3 0 0 4 0

Ac inlet wire

Lcd clock

IRled pnl

IRled and lcd

clock cable

HV cable that comes

with lcd

p

anel

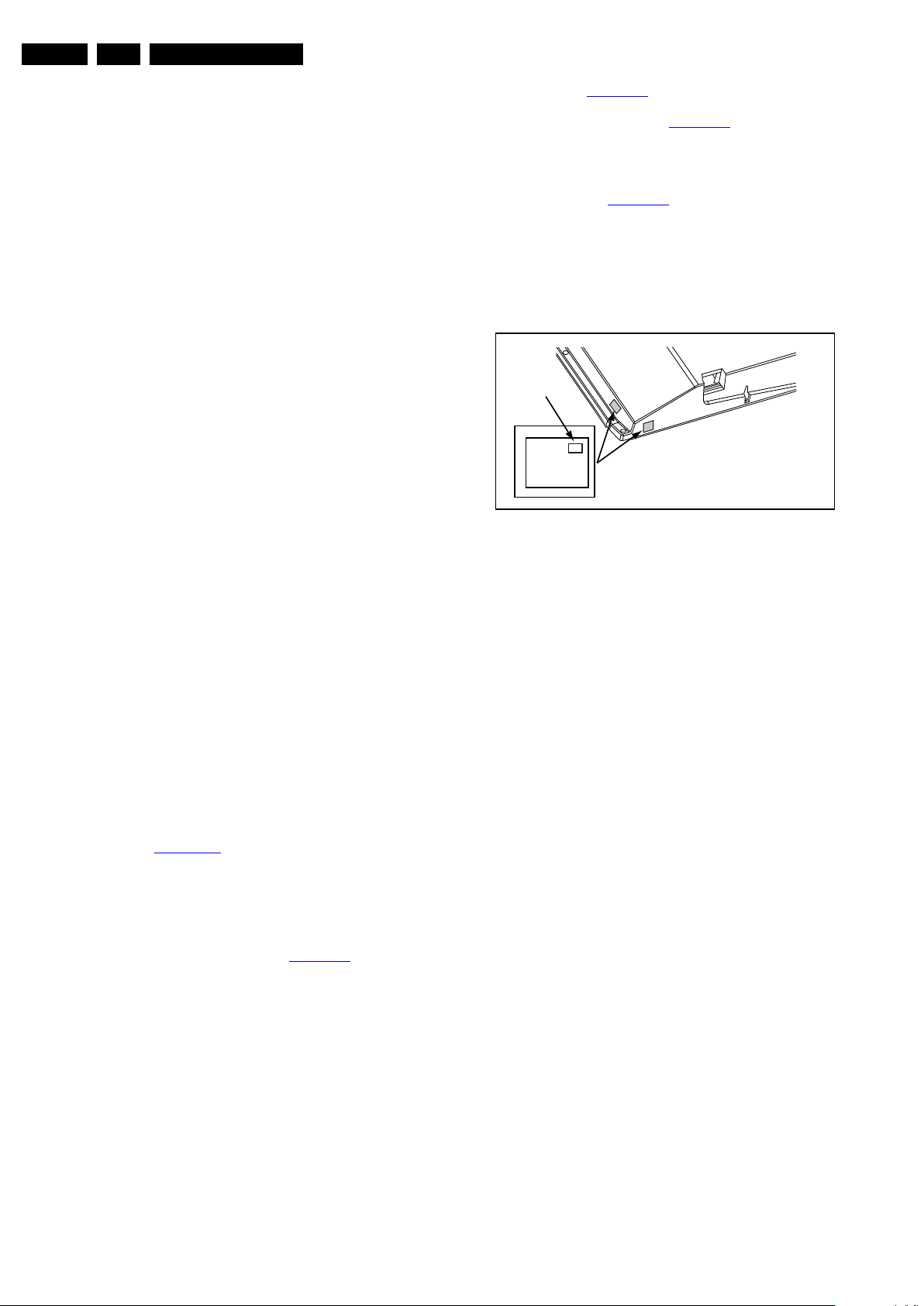

18680_105_090820.eps

091201

EN 11Q522.1HE LA 4.

Figure 4-2 Panel HV cable taping of 26HFL5870D/10

Figure 4-3 Top left + LVDS 26HFL5870D/10

2009-Dec-04

EN 12 Q522.1HE LA4.

18680_102_090820.eps

091130

Shorter HV cable

plugs on the inside

connector

Mechanical Instructions

Figure 4-4 Middle left 26HFL5870D/10

Keyboard cable hold by panel stop, done only for 26” due to space constraint

2009-Dec-04

Figure 4-5 Bottom left 26HFL5870D/10

18680_103_090820.eps

091130

Mechanical Instructions

18680_104_090820.eps

091130

EN 13Q522.1HE LA 4.

Figure 4-6 Top right 26HFL5870D/10

2009-Dec-04

EN 14 Q522.1HE LA4.

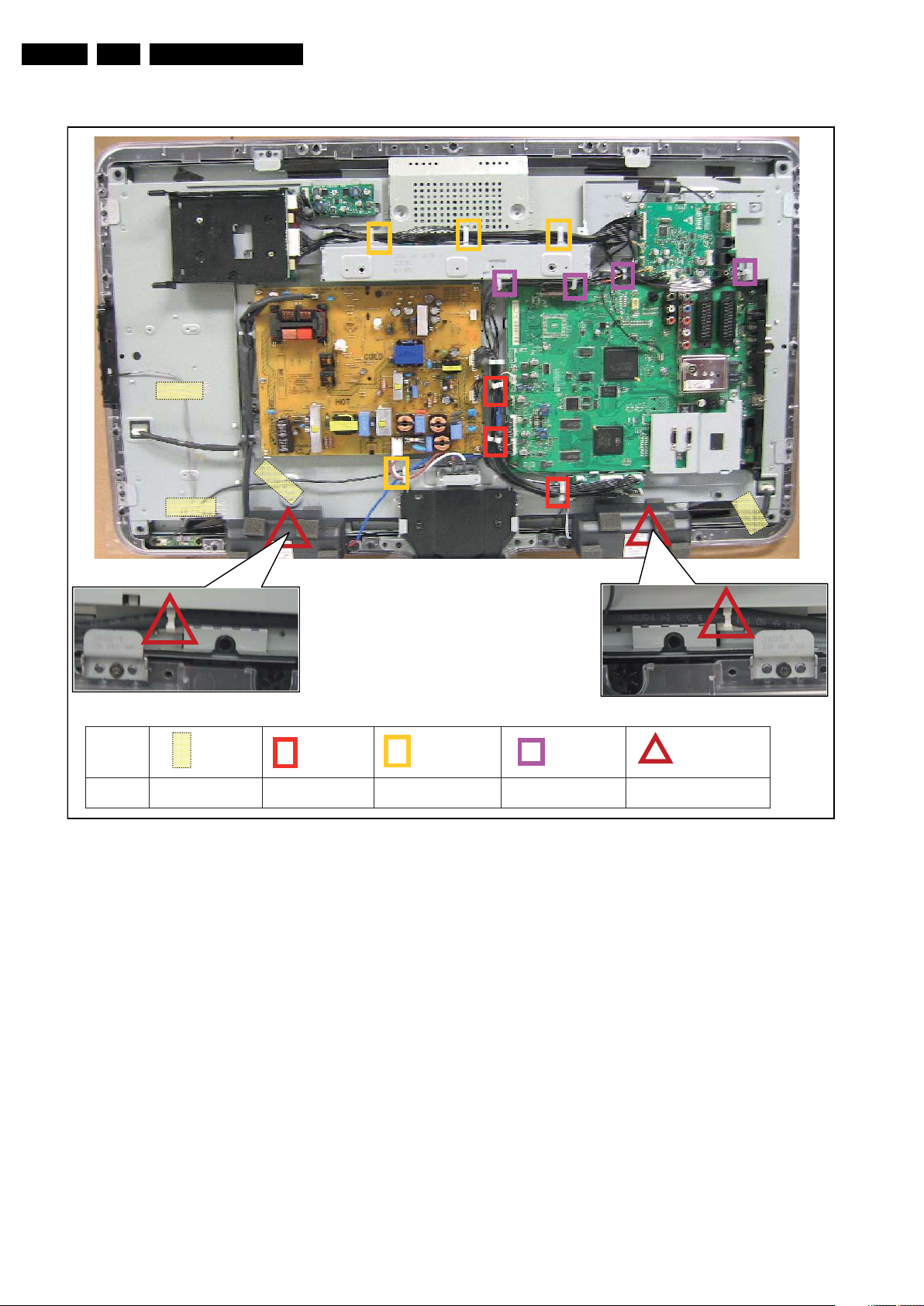

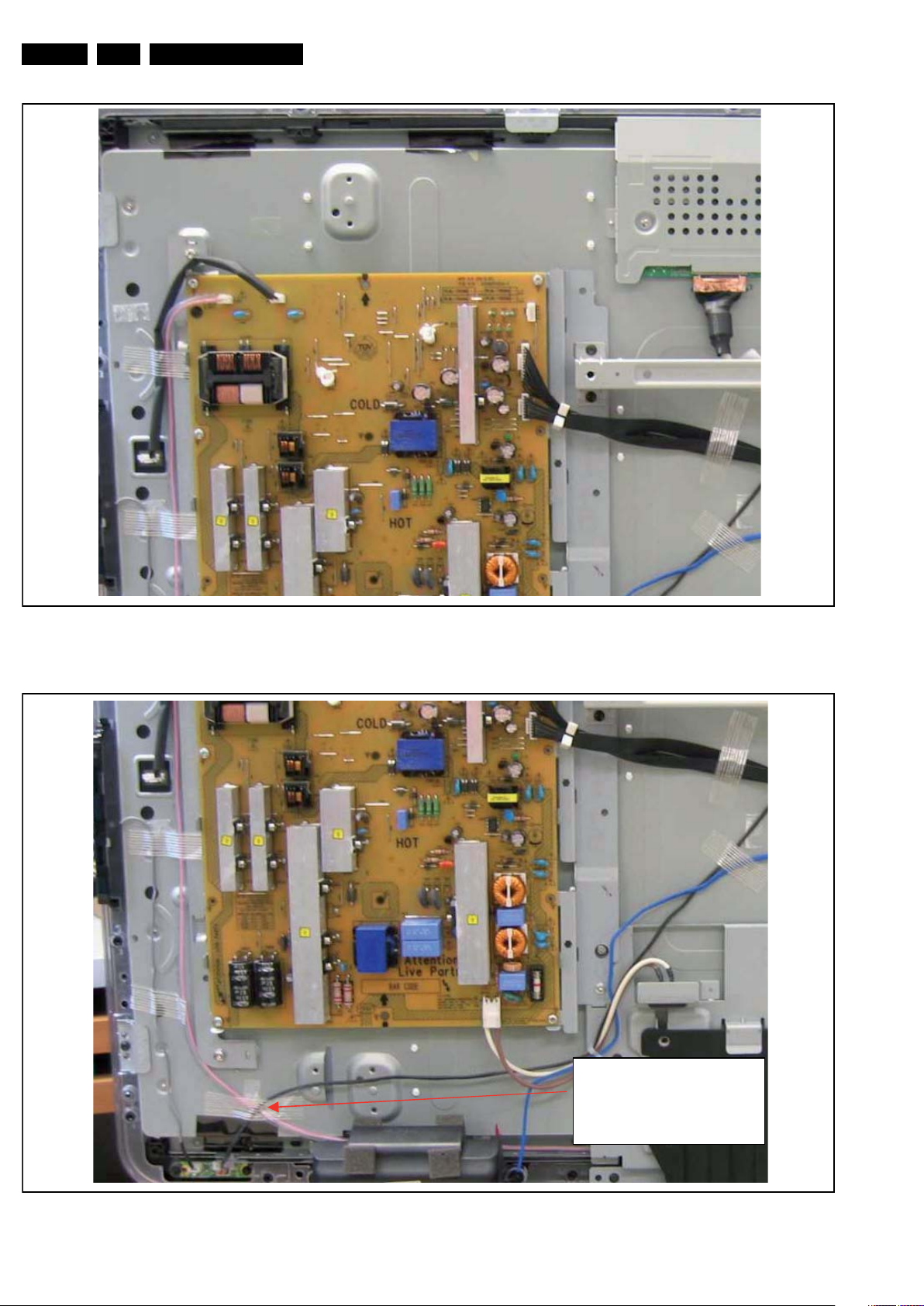

Type Tape

Saddle

(L)

Saddle

(M)

Saddle

(S)

Saddle

(Adhesive)

Qty 4 3 4 4 2

HV cable is routed under the speaker

box assy in the grovee of lcd panel

using adhesive saddle

18680_110_090820.eps

090820

4.1.2 Cable dressing 32HFL5870D/10

Mechanical Instructions

Figure 4-7 Overview 32HFL5870D/10

2009-Dec-04

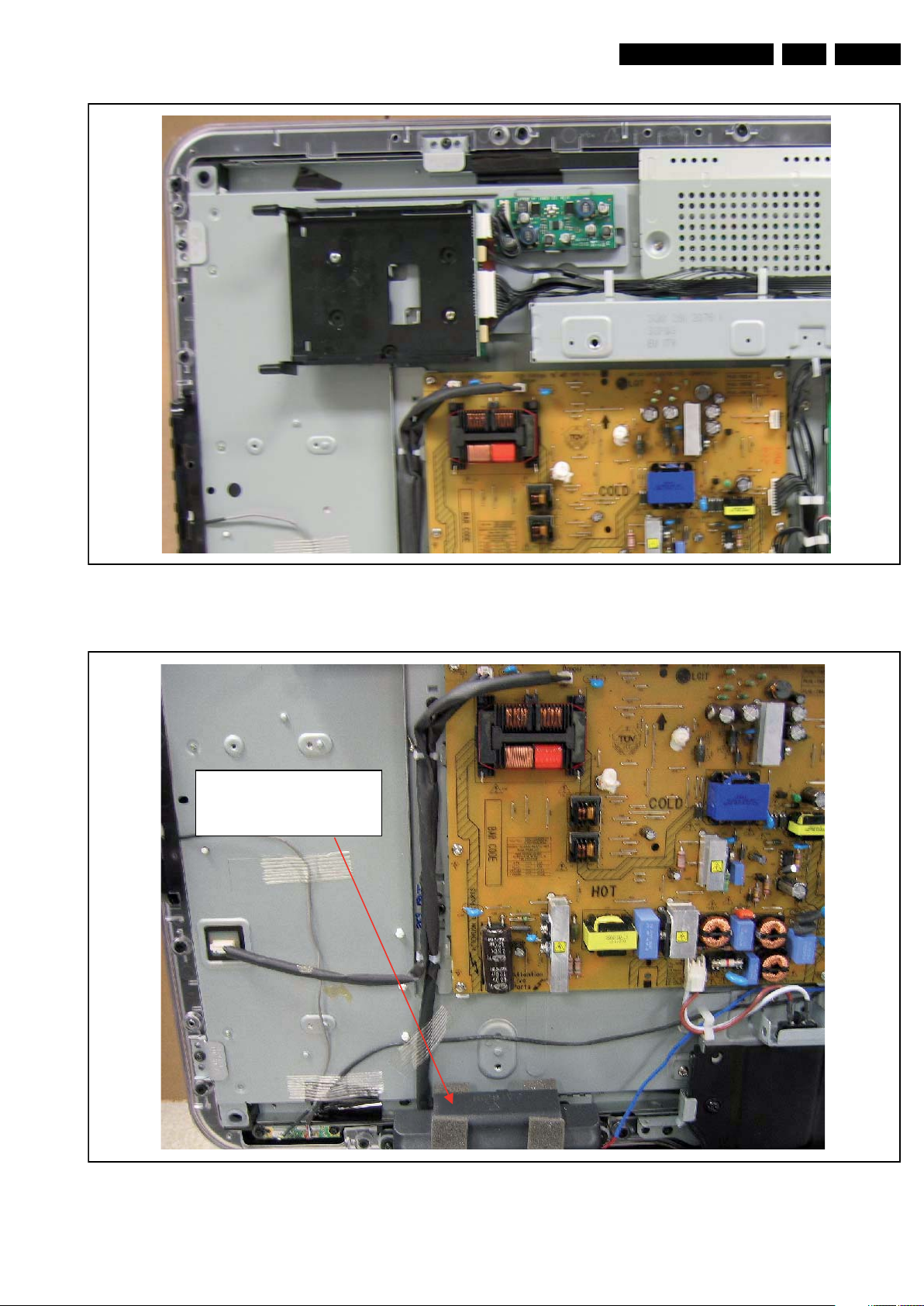

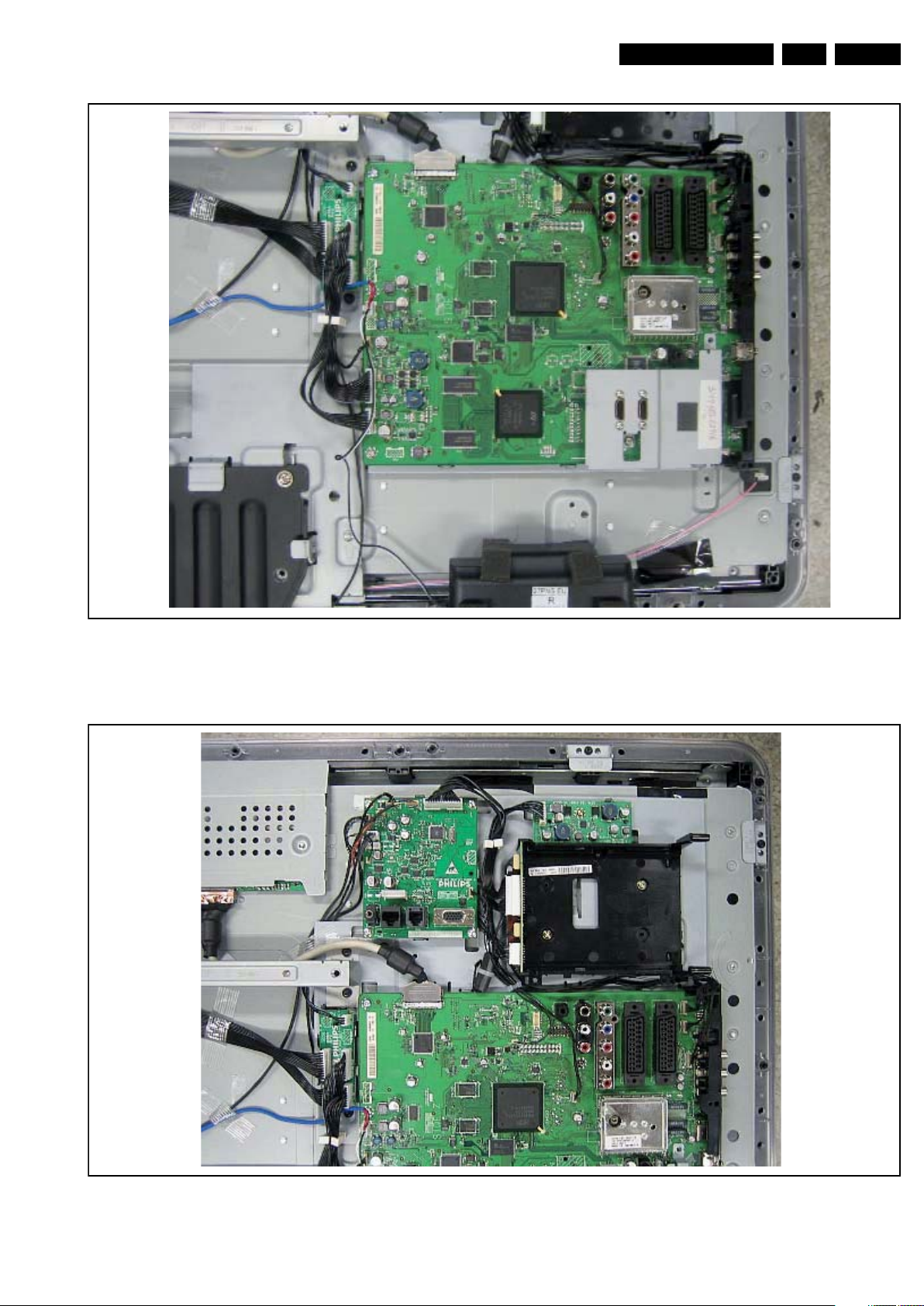

Mechanical Instructions

18680_112_090820.eps

091201

1

8680_111_090820.eps

091201

IR/LED cable cross HV

cable at right angle to

minimize interference

EN 15Q522.1HE LA 4.

Figure 4-8 Top left 32HFL5870D/10

Figure 4-9 Bottom left 32HFL5870D/10

2009-Dec-04

EN 16 Q522.1HE LA4.

18680_114_090820.eps

091201

12V Switch panel

18680_113_090820.eps

091201

Mechanical Instructions

Figure 4-10 Bottom right 32HFL5870D/10

2009-Dec-04

Figure 4-11 Top right 32HFL5870D/10

4.1.3 Cable dressing 37HFL5880D/10

Type Tape

Black

tape

Saddle

(L)

Saddle

(M)

Saddle

(S)

Saddle

(Adhesive)

Qty 7 6 0 3

4

2

HV cable is routed under the

speaker box assy in the groove of

LCD panel using adhesive saddle

18680_120_090821.eps

090821

Mechanical Instructions

EN 17Q522.1HE LA 4.

Figure 4-12 Overview 37HFL5880D/10

2009-Dec-04

EN 18 Q522.1HE LA4.

18680_122_090821.eps

091201

1

8680_121_090821.eps

091201

IR/LED and HV cable

crosses at right angle

to minimize

interference

Mechanical Instructions

Figure 4-13 Top left 37HFL5880D/10

2009-Dec-04

Figure 4-14 Bottom left 37HFL5880D/10

Mechanical Instructions

18680_124_090821.eps

091201

18680_123_090821.eps

091201

EN 19Q522.1HE LA 4.

Figure 4-15 Bottom right 37HFL5880D/10

Figure 4-16 Top right 37HFL5880D/10

2009-Dec-04

EN 20 Q522.1HE LA4.

Type Tape

Black

tape

Saddle

(L)

Saddle

(M)

Saddle

(S)

Saddle

(Adhesive)

Qty 7 6 0 6

7

2

HV cable is routed under the

speaker box assy in the groove of

LCD panel using adhesive saddle

18680_130_090821.eps

091201

4.1.4 Cable dressing 42HFL5880D/10

Mechanical Instructions

Figure 4-17 Overview 42HFL5880D/10

2009-Dec-04

Mechanical Instructions

18680_132_090821.eps

091201

Short HV cable

insert on

the inside

18680_131_090821.eps

091201

IR/LED cable cross

HV cable at 90

degree to prevent

EN 21Q522.1HE LA 4.

Figure 4-18 Top left 42HFL5880D/10

Figure 4-19 Bottom left 42HFL5880D/10

2009-Dec-04

EN 22 Q522.1HE LA4.

18680_134_090821.eps

091201

1

8680_133_090821.eps

091201

Mechanical Instructions

Figure 4-20 Bottom right 42HFL5880D/10

2009-Dec-04

Figure 4-21 Top right 42HFL5880D/10

Mechanical Instructions

10000_018_090121.eps

090121

1

Required for sets

42"

1

EN 23Q522.1HE LA 4.

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging.

• Foam bars (created for Service).

4.2.1 Foam Bars

4.3.2 Speakers

Each speaker unit is mounted with two screws. A sticker on the

the unit indicates if it is the right (“R”) or left (“L”) box, seen from

the backside of the set. Speakers are firing downwards.

When defective, replace the whole unit.

4.3.3 IR/LED Panel

1. Unplug the connectors leading to the SSB and Keyboard.

2. Remove the fixation screws.

3. Lift the panel and take it out.

When defective, replace the whole unit.

4.3.4 Clock unit (not for 42-inch model)

1. Remove the TV stand.

2. Remove the subframe/bracket that holds the stand.

3. Unscrew the clock panel via the holes in the flare.

4. Loosen the flare by partly unscrewing the two brackets

underneath the speakers.

5. Now lift the flare and take the clock panel out.

6. Unplug the cable.

When defective, replace the whole unit.

4.3.5 Keyboard Control Panel

1. Unplug the Keyboard connector from the IR/LED panel.

2. Release the clamp on the top side.

3. Lift the unit and take it out (it hinges at the bottom).

When defective, replace the whole unit.

Figure 4-22 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See Figure 4-22

details. Sets with a display of 42" and larger, require four foam

bars [1]. Ensure that the foam bars are always supporting the

cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, the screen can

be monitored.

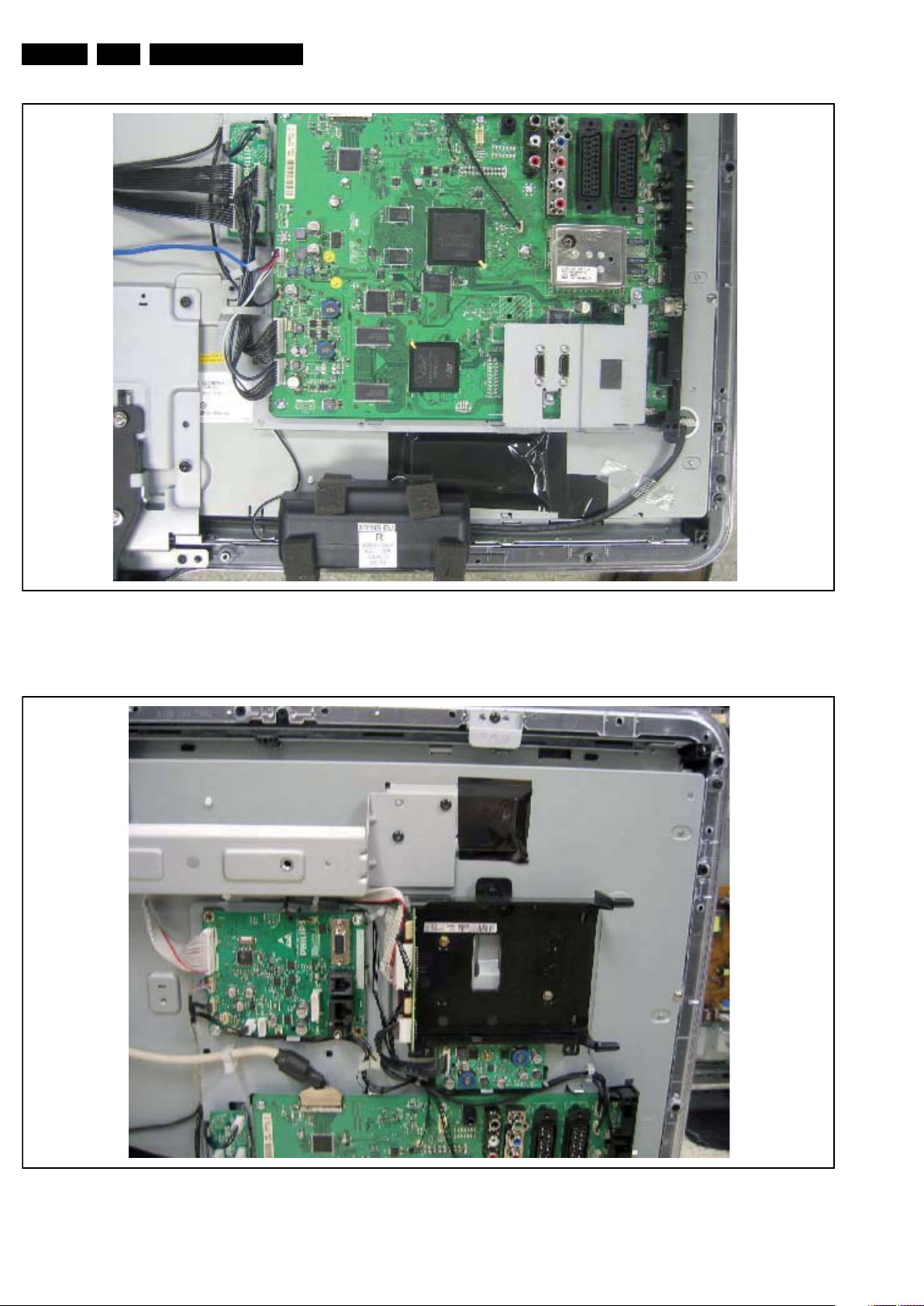

4.3 Assy/Panel Removal

4.3.1 Rear Cover

Warning: Disconnect the mains power cord before you remove

the rear cover.

Note: it is not necessary to remove the stand while removing

the rear cover.

1. Remove all screws of the rear cover.

2. Lift the rear cover from the TV. Make sure that wires and

flat coils are not damaged while lifting the rear cover from

the set.

for

4.3.6 iBoard Panel

1. Unplug all connectors.

2. Remove the screws that hold the panel and take the panel

out.

4.3.7 DC/DC Converter Panel

1. Unplug the connector.

2. Remove the screw and take the panel out.

When defective, replace the whole unit.

4.3.8 12V Switch Panel

1. Unplug all connectors.

2. Remove the screw that holds the panel and take the panel

out.

When defective, replace the whole unit.

4.3.9 Main Supply Panel

1. Unplug all connectors.

2. Remove the fixation screws.

3. Take the panel out.

When defective, replace the whole unit.

4.3.10 Small Signal Board (SSB)

Caution: It is mandatory to remount screws at their original

position during re-assembly. Failure to do so may result in

damaging the SSB.

1. Unplug all connectors. Be careful with the fragile LVDS

connector(s)!

2. Remove all screws that secure the panel.

3. The SSB can now be taken out of the set, together with the

side cover.

4. To remove the side cover, remove the screw in the middle

of the cover, release the notch at the head phone

connector, and pull the cover sidewards from the SSB.

2009-Dec-04

EN 24 Q522.1HE LA4.

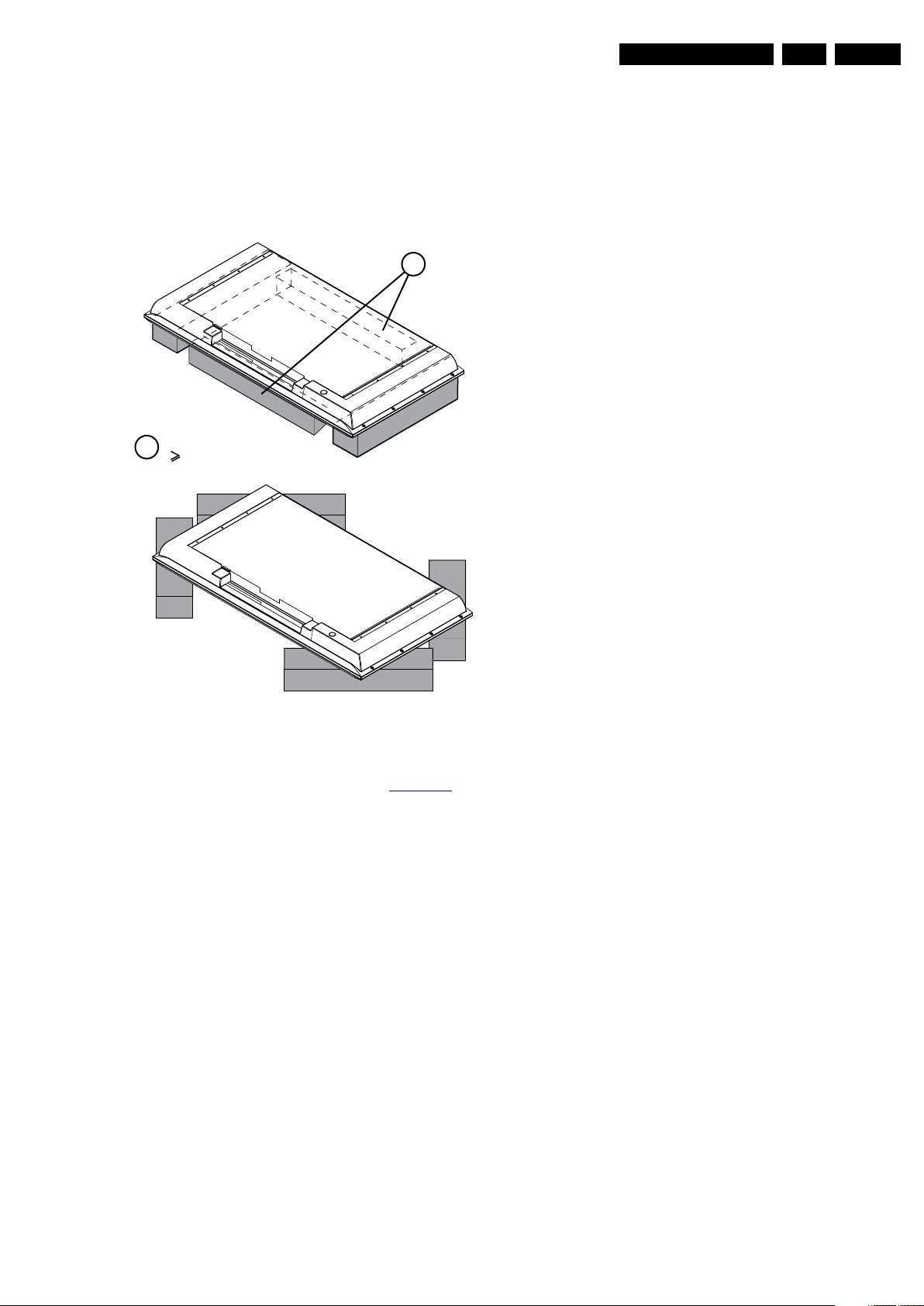

18440_103_090223.eps

090709

1

2

3

3

3

3

2

Mechanical Instructions

4.3.11 LCD Panel

Refer to Figure 4-23

(slightly) different mechanical construction (some have the

panels directly mounted on the LCD display, others use

brackets), we only describe one model. Disassembly method of

other LCD panels is similar to the one described below (see

also cable dressing pictures for more details).

for details. As every screen size has a

1. Unplug all connectors.

2. Remove all panels as earlier described.

3. Remove the speakers as earlier described.

4. Remove the stand [1].

5. Remove all subframes from the LCD panel (e.g. [2]).

6. Remove the brackets [3] that secure the LCD Panel.

7. The LCD panel can now be lifted from the front cabinet.

Figure 4-23 LCD Panel removal (example model without iTV panels)

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position.

See Cable Dressing pictures.

• Pay special attention not to damage the EMC foams in the

set. Ensure that EMC foams are mounted correctly.

2009-Dec-04

Service Modes, Error Codes, and Fault Finding

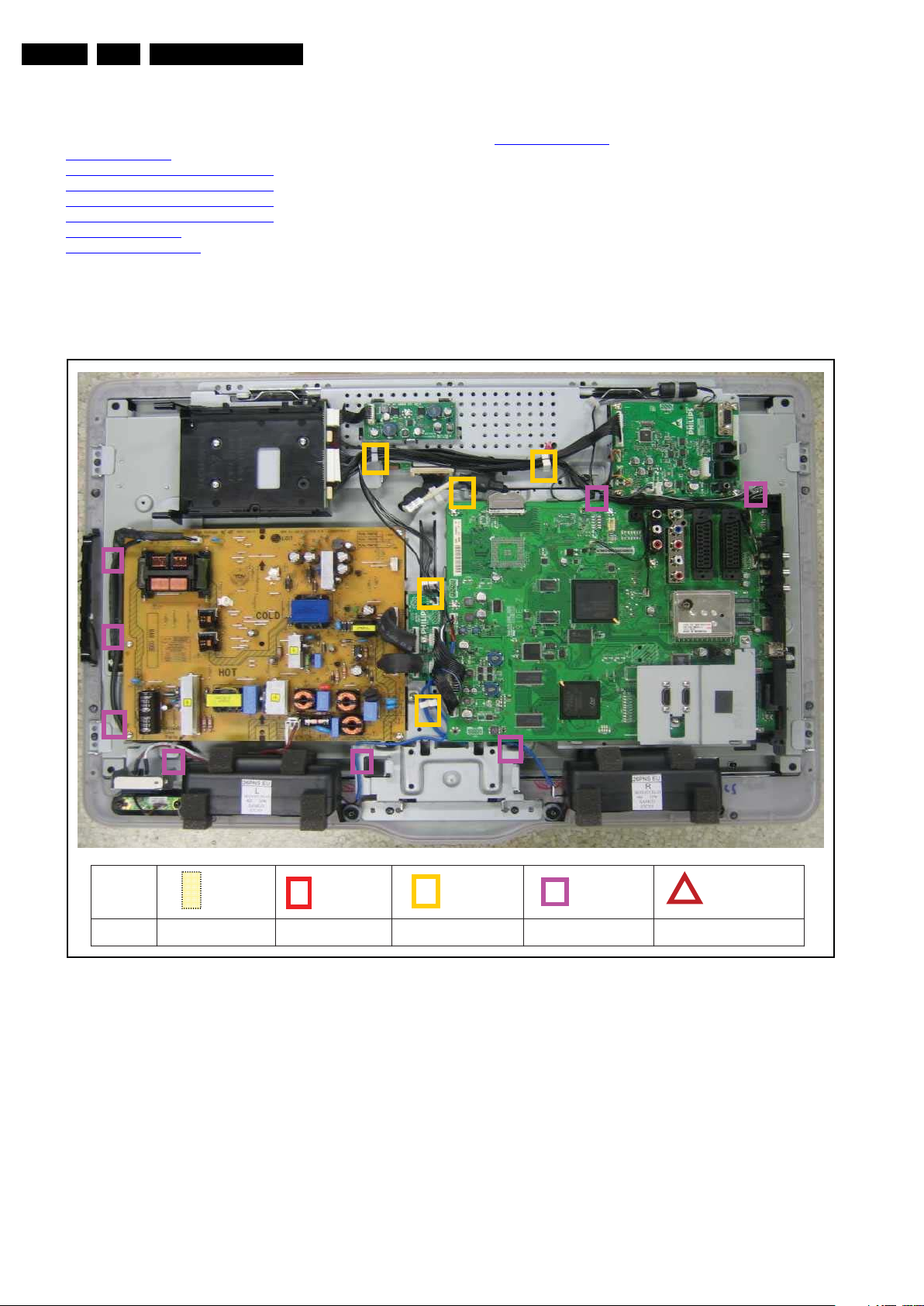

18680_201_090825.eps

090825

2

SPI

1

SDM1SDM

5. Service Modes, Error Codes, and Fault Finding

EN 25Q522.1HE LA 5.

Index of this chapter:

5.1 Test Points

5.2 Hotel mode

5.3 Service Modes

5.4 Stepwise Start-up

5.5 Service Tools

5.6 Error Codes

5.7 The Blinking LED Procedure

5.8 Protections

5.9 Fault Finding and Repair Tips

5.10 Software Upgrading

5.1 Test Points

As most signals are digital, it will be difficult to measure

waveforms with a standard oscilloscope. However, several key

ICs are capable of generating test patterns, which can be

controlled via ComPair. In this way it is possible to determine

which part is defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Hotel mode

Before the service modes can be activated, the set needs to be

switched into normal consumer mode (MTV-Mode) first. Use

an iTV setup remote control (type: RC2573/01, 12nc:

3139 228 88782) to key in the code ‘024995’ (slowly) directly

followed by the MENU button. The text messages “TV Is Now

In MTV Mode” and “Please Do A Cold Start!” appears on the

screen. Disconnect the set for a few seconds from the mains

supply, reconnect the set to the mains supply again. The set is

now in the normal consumer mode (MTV-Mode).

After repair, place the set into hotel mode (iTV-Mode) again.

Key-in the same code on the remote control as described

above. The text message “TV Is Now In ITV Mode” appears. A

cold start must be performed as described above. The set is

now in the hotel mode (iTV-Mode) again.

Specifications

Table 5-1 SDM default settings

Default

Region Freq. (MHz)

Europe, AP(PAL/Multi) 475.25 PAL B/G

Europe, AP DVB-T 546.00 PID

Video: 0B 06 PID

PCR: 0B 06 PID

Audio: 0B 07

• All picture settings at 50% (brightness, colour, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

– Picture mute (blue mute or black mute).

– Automatic volume levelling (AVL).

– Skip/blank of non-favourite pre-sets.

How to Activate SDM

For this chassis there are two kinds of SDM: an analogue SDM

and a digital SDM. Tuning will happen according table “SDM

Default Settings”.

• Analogue SDM: use the standard RC-transmitter and key

in the code “062596”, directly followed by the “MENU”

button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it “off”, push the “MENU”

button again.

• Digital SDM: use the standard RC-transmitter and key in

the code “062593”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it “off”, push the “MENU”

button again.

• Analogue SDM can also be activated by shorting for a

moment the two solder pads [1] (see Figure 5-1

SSB, with the indication “SDM”. Activation can be

performed in all modes, except when the set has a problem

with the Stand-by Processor.

system

DVB-T

) on the

5.3 Service Modes

Service Default mode (SDM) and Service Alignment Mode

(SAM) offers several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between the call centre and the customer.

This chassis also offers the option of using ComPair, a

hardware interface between a computer and the TV chassis. It

offers the abilities of structured troubleshooting, error code

reading, and software version read-out for all chassis.

(see also section ComPair

5.3.1 Service Default Mode (SDM)

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections detected by stand-by

processor and make the TV start up to the step just before

protection (a sort of automatic stepwise start up). See

section Stepwise Start-up

• To override SW protections detected by MIPS. See also

section Error Codes

• To start the blinking LED procedure (not valid for

protections detected by stand-by software).

).

.

.

Figure 5-1 Service mode pads

After activating this mode, “SDM” will appear in the upper right

corner of the screen.

How to Navigate

By pressing the “MENU” button on the RC transmitter, the set

will toggle between the SDM and the normal user menu (with

the SDM mode still active in the background).

2009-Dec-04

EN 26 Q522.1HE LA5.

PHILIPS

MODEL:

32PF9968/10

PROD.SERIAL NO:

AG 1A0620 000001

040

39mm

27mm

(CTN Sticker)

Display Option

Code

E_06532_038.eps

240108

Service Modes, Error Codes, and Fault Finding

How to Exit SDM

Use one of the following methods:

• Switch the set to STAND-BY via the RC-transmitter.

• Via a standard customer RC-transmitter: key in “00”sequence.

5.3.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

How to Activate SAM

Via a standard RC transmitter: key in the code “062596”

directly followed by the “INFO/i+” button. After activating SAM

with this method a service warning will appear on the screen,

to continue press the red button on the RC.

Contents of SAM:

• Hardware Info.

– A. SW Version. Displays the software version of the

main software (example: Q53HE-1.2.3.4 =

AAAAB_X.Y.W.Z).

• AAAA= the chassis name.

• B= the region: A= AP, E= EU, L= LatAm, U = US.

For AP sets it is possible that the Europe software

version is used.

• X.Y.W.Z= the software version, where X is the

main version number (different numbers are not

compatible with one another) and Y.W.Z is the sub

version number (a higher number is always

compatible with a lower number).

– B. SBY PROC Version. Displays the software version

of the stand-by processor.

– C. Production Code. Displays the production code of

the TV, this is the serial number as printed on the back

of the TV set. Note that if an NVM is replaced or is

initialized after corruption, this production code has to

be re-written to NVM. ComPair will foresee in a

possibility to do this.

• Operation Hours. Displays the accumulated total of

operation hours (not the stand-by hours). Every time the

TV is switched “on/off”, 0.5 hours is added to this number.

• Errors (followed by maximal 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see section Error Codes

• Reset Error Buffer. By pressing “cursor right” (or the “OK

button) and then the “OK” button, the error buffer is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu.

• Dealer Options. Extra features for the dealers.

• Options. Extra features for Service. For more info

regarding option codes, see chapter Alignments

Note that if the option code numbers are changed, it has to

be confirmed with the “OK” button before storing the

options. Otherwise any changes will be lost.

• Initialise NVM. The moment the processor recognizes a

corrupted NVM, the “initialize NVM” line will be highlighted.

Now, two options are available (dependent of the service

instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initializing. This will give

the Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialize the NVM.

Note: When NVM is corrupted, or the NVM has been replaced,

there is a high possibility that the set will not display a picture

anymore because the display code is not correct. So, before

initializing the NVM via the SAM, the set should display a

picture and therefore the correct display option is a necessity.

2009-Dec-04

Refer to chapter Alignments

for details. To adapt this option,

the ComPair tool can be used (the correct HEX values for the

options can be found in chapter Alignments

) or a method via a

standard RC (described below).

Changing the display option via a standard RC: Key in the

code “062598” directly followed by the “MENU” button and

“XXX”, where XXX is the 3 digit decimal display code (see table

Table 6-3 in chapter Alignments

, or sticker on the side/bottom

of the cabinet). Make sure to key in all three digits, also the

leading zero’s. If the above action is successful, the front LED

will go out as an indication that the RC sequence was correct.

After the display option is changed in the NVM, the TV will go

to the Stand-by mode. If the NVM was corrupted or empty

before this action, it will be initialized first (loaded with default

values). This initializing can take up to 20 seconds.

Figure 5-2 Location of Display Option Code sticker

• Store - go right. All options and alignments are stored

when pressing “cursor right” (or the “OK” button) and then

the “OK”-button.

• SW Maintenance.

– SW Events. Not useful for Service purposes. In case

of specific software problems, the development

department can ask for this information.

– HW Events. Not useful for Service purposes. In case

of specific software problems, the development

department can ask for this info.

• Test settings. For development purposes only.

• Upload to USB. To upload several settings from the TV to

a USB stick, which is connected to the Side I/O. The items

are “Channel list”, “Personal settings”, “Option codes”,

“Display-related alignments” and “History list”. First a

directory “repair” has to be created in the root of the USB

stick. To upload the settings each item has to be selected

).

separately, press “cursor right” (or the “OK button), confirm

with “OK” and wait until “Done” appears. In case the

download to the USB stick was not successful “Failure” will

appear. In this case, check if the USB stick is connected

properly and if the directory “repair” is present in the root of

the USB stick. Now the settings are stored onto the USB

stick and can be used to download onto another TV or

.

other SSB. Uploading is of course only possible if the

software is running and the set is displaying a picture. This

method is created to be able to save the customer’s TV

settings and to store them into another SSB.

• Download from USB. To download several settings from

the USB stick to the TV. Same way of working as with

uploading. To make sure that the download of the channel

list from USB to the TV is executed properly, it is necessary

to restart the TV and tune to a valid preset if necessary.

Note: The “History list item” can not be downloaded from

USB to the TV. This is a “read-only” item. In case of specific

problems, the development department can ask for this

info.

How to Navigate

• In SAM, menu items can be selected with the “CURSOR

UP/DOWN” key on the RC-transmitter. The selected item

will be highlighted. When not all menu items fit on the

Service Modes, Error Codes, and Fault Finding

EN 27Q522.1HE LA 5.

screen, move the “CURSOR UP/DOWN” key to display the

next/previous menu items.

• With the “CURSOR LEFT/RIGHT” keys, it is possible to:

– (De) activate the selected menu item.

– (De) activate the selected sub menu.

• With the “OK” key, it is possible to activate the selected

action.

How to Exit SAM

Use one of the following methods:

• Press the “MENU” button on the RC-transmitter.

• Switch the set to STAND-BY via the RC-transmitter.

5.3.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Help desk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

When in this chassis CSM is activated, a colour bar test pattern

will be visible for 5 seconds. This test pattern is generated by

the Pacific3. So if this test pattern is displayed, the correct

running of the back end video chain (Pacific3, LVDS, and

display) can be determined. In case of a set with DFI panel, an

extra test picture is generated. A Pacific3 test picture for 3

seconds and then the DFI EPLD test picture for another 3

seconds will be generated. With this extra test picture it is

possible to determine if the DFI panel is working properly.

Also new in this chassis: when CSM is activated and there is a

USB stick connected to the TV, the software will dump the

complete CSM content to the USB stick. The file (Csm.txt) will

be saved in the root of the USB stick. This information can be

useful if the set is not displaying a picture.

Another new item in this chassis is when CSM is activated, the

complete error-buffer content will be shown via the blinking

LED procedure.

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to Navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter, can be navigated through the menus.

Contents of CSM

• Set Type. This information is very helpful for a help

desk/workshop as reference for further diagnosis. In this

way, it is not necessary for the customer to look at the rear

of the TV-set. Note that if an NVM is replaced or is

initialized after corruption, this set type has to be re-written

to NVM. ComPair will foresee in a possibility to do this.

• Production Code. Displays the production code (the serial

number) of the TV. Note that if an NVM is replaced or is

initialized after corruption, this production code has to be

re-written to NVM. ComPair will foresee a in possibility to

do this.

• Code 1. Gives the last five errors of the error buffer. As

soon as the built-in diagnose software has detected an

error, the buffer is adapted. The last occurred error is

displayed on the leftmost position. Each error code is

displayed as a 2-digit number. When less than 10 errors

occur, the rest of the buffer is empty (00). See also section

Error Codes

• Code 2. Gives the first five errors of the error buffer. See

also section Error Codes

for a description.

for a description.

• Options 1. Gives the option codes of option group 1 as set

in SAM (Service Alignment Mode).

• Options 2. Gives the option codes of option group 2 as set

in SAM (Service Alignment Mode).

• 12NC SSB. Gives an identification of the SSB as stored in

NVM. Note that if an NVM is replaced or is initialized after

corruption, this identification number has to be re-written to

NVM. ComPair will foresee in a possibility to do this. This

identification number consists of 14 characters and is built

up as follows:

- Seven last characters of the 12NC of the SSB itself.

- the serial number of the SSB, which consists of seven

digits. Both can be found on a sticker on the PWB of the

SSB itself. The format of the identification number is then

as follows: <last seven characters of 12NC of SSB><serial

number of SSB> (total fourteen characters).

• Installed date. Indicates the date of the first installation of

the TV. This date is acquired via time extraction.

• Digital Natural Motion. Gives the status of the Digital

Natural Motion setting as set by the customer. Remark: a

customer can choose between “OFF”, “MINIMUM” and

“MAXIMUM”, but in CSM this item will only show “OFF” or

“ON” (“ON” in case the customer has chosen “MINIMUM”

or “MAXIMUM”)

• Pixel Plus. Gives the last status of the Perfect Pixel HD

setting, as set by the customer. Possible values are “ON”

and “OFF”. See DFU on how to change this item.

• DNR. Gives the last status of the Noise reduction setting,

as set by the customer. Possible values are “OFF”,

“MINIMUM”, “MEDIUM” and “MAXIMUM”. See DFU on

how to change this item.

• Noise Figure. Gives an indication of the signal quality for

the selected transmitter. Possible values are “BAD”,

“AVERAGE”, “GOOD“ and “DIGITAL”. In case of a digital

channel, this item will never indicate: “BAD”, “GOOD” or

“AVERAGE” but only displays “DIGITAL”.

• 12NC Display. Shows the 12NC of the display.

• MPEG4 (blue to toggle).

• Head phone Volume. Gives the last status of the head

phone volume, as set by the customer. The value can vary

from 0 (volume is minimum) to 100 (volume is maximum).

See DFU on how to change this item.

• Surround Mode. Indicates the by the customer selected

sound mode (or automatically chosen mode). Possible

values are “STEREO” and “VIRTUAL DOLBY

SURROUND”. It can also have been selected

automatically by signalling bits (internal software). See

DFU on how to change this item.

• AVL. Indicates the last status of AVL (Automatic Volume

Level) as set by the customer: See DFU on how to change

this item.

• Delta Volume. Indicates the last status of the delta volume

for the selected preset as set by the customer: from “-12”

to “+12”. See DFU on how to change this item.

• Volume. Indicates the last status of the volume for the

selected preset as set by the customer: from “0” to “100”.

See DFU on how to change this item.

• Balance. Indicates the last status of the balance for the

selected preset as set by the customer: from “-10” to “+10”.

See DFU on how to change this item.

• Preset Lock. Indicates if the selected preset has a child

lock: “LOCKED” or “UNLOCKED”. See DFU on how to

change this item.

• Child Lock. Indicates the status of the Child lock. See DFU

on how to change this item.

• Lock After. Indicates at what time the channel lock is set:

“OFF” or e.g. “18:45” (lock time). See DFU on how to

change this item.

• Parental Rating Lock. Indicates the “Parental rating” as

set by the customer. See DFU on how to change this item.

• Parental Rating Status. Indicates the “Parental rating” as

transmitted by the broadcaster (if applicable). If the

2009-Dec-04

EN 28 Q522.1HE LA5.

parental rating status is indicating a higher age then the

parental rating lock as set by the customer, the child lock

code will be needed to enter.

• On timer. Indicates if the “On timer” is set “ON” or “OFF”

and when it is set to “ON”, also start time, start day and

program number is displayed. See DFU on how to change

this item.

• Location. Gives the last status of the location setting as

set via the installation menu. Possible values are “SHOP”

and “HOME”. If the location is set to “SHOP”, several

settings are fixed. So for a customer location must be set

to “HOME”. Can be changed via the installation menu (see

also DFU).

• HDMI Key Validity. Indicates if the HDMI keys (or HDCP

keys) are valid or not. In case these keys are not valid and

the customer wants to make use of the HDMI functionality,

the SSB has to be replaced.

• Tuner Frequency. Indicates the frequency the transmitter

is tuned to.

• TV System. Gives information about the video system of

the selected transmitter. In case a DVBT signal is received

this item will also show ATSC.

– BG: PAL BG signal received

– DK: PAL DK signal received

– L/La: SECAM L/La signal received

– I: PAL I signal received

– M: NTSC M signal received

– ATSC: ATSC signal received

– DVB: DVBT signal received

Service Modes, Error Codes, and Fault Finding

• 12NC One Zip SW. Displays the 12NC number of the onezip file as it is used for programming software in production.

In this one-zip file all below software versions can be found.

• Initial Main SW. Displays the main software version which

was initially loaded by the factory.

• Current Main SW. Displays the built-in main software

version. In case of field problems related to software,

software can be upgraded. As this software is consumer

upgradeable, it will also be published on the Internet.

Example: Q582E_1.2.3.4.

• Flash Utils SW. Displays the software version of the

software which contains all necessary components of the

download application. To program this software, EJTAG

tooling is needed. Example: Q582E_1.2.3.4.

• Stand-by SW. Displays the built-in stand-by processor

software version. Upgrading this software will be possible

via ComPair or via USB. Example: STDBY_3.0.1.2.

• MOP SW. Only applicable for US. At the time of release of

this manual, there was still a problem with this item, and

some rubbish was displayed. Ignore this.

• Pacific 3 Flash SW (if applicable). Displays the Pacific 3

software version.

• NVM Version. Displays the NVM version as programmed

by factory.

• Display Parameters. for development purposes only.

• Private PQ Parameters. for development purposes only.

• Public PQ Parameters. for development purposes only.

• Ambilight Parameters. for development purposes only.

• Acoustics Parameters. for development purposes only.

• DFI Software (if applicable). Displays the DFI EPLD

software version.

•

DFI Ambilight software (if applicable). Displays the DFI

ambilight EPLD software version.

• MPEG4 software. Displays the MPEG4 software version.

How to Exit CSM

Press “MENU” on the RC-transmitter.

2009-Dec-04

Service Modes, Error Codes, and Fault Finding

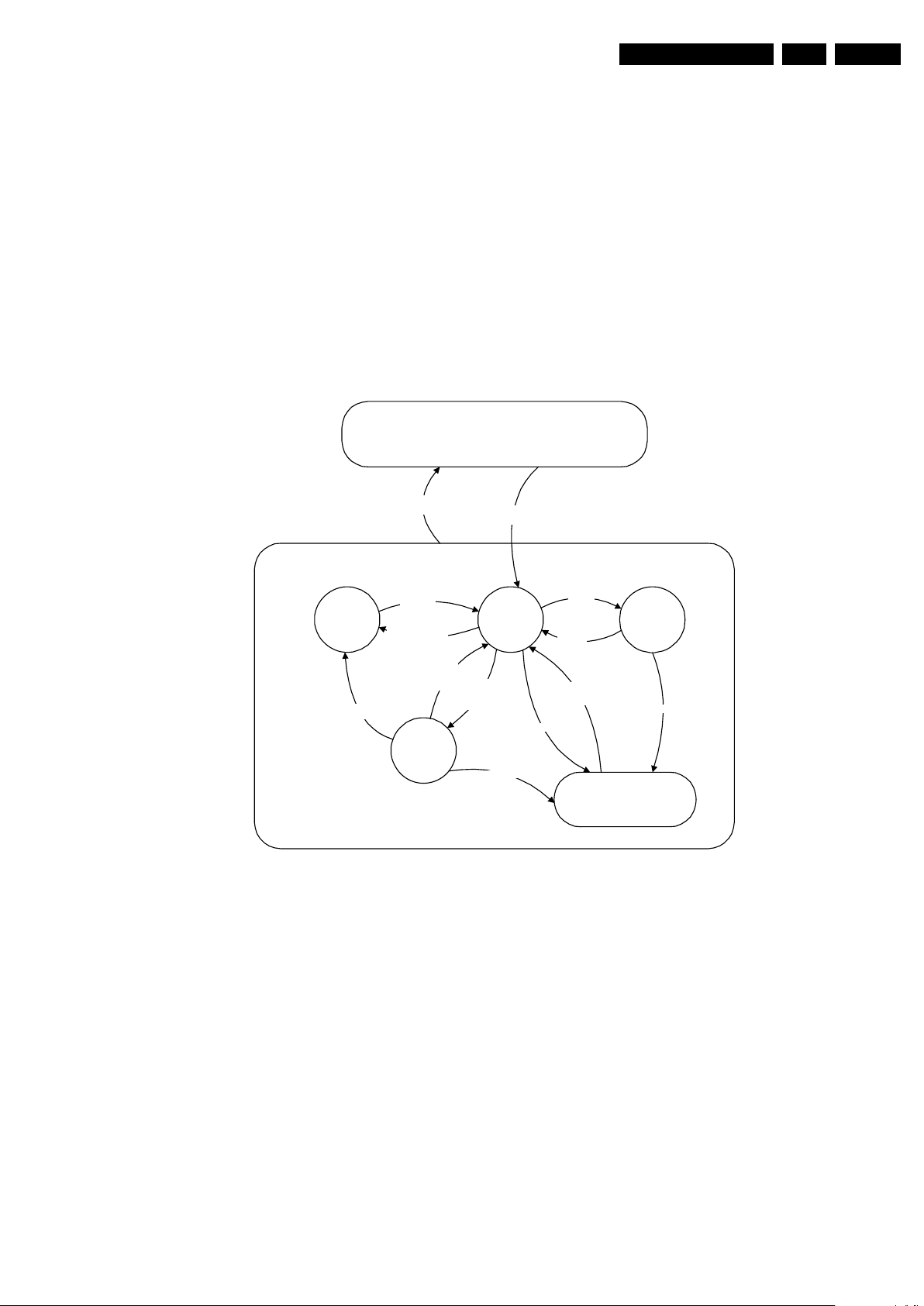

H_17650_093.eps

180108

On

Active

Semi

St by

St by

(Off St by)

Off

Mains

on

Mains

off

GoToProtection

- WakeUp

requested

- Acquisition

needed

- No data Acquisition

required

and no POD present

- tact SW pushed

- St by

requested

- tact SW

pushed

WakeUp

requeste

d

Protection

WakeUp

requeste

d

GoToProtection

POD

St by

No d ata

Acquisition

required and

POD pre sent

- POD Card removed

- tact SW pushed

GoToProtection

- WakeUp

requested

- Acquisition

needed

For POD should be read Common Interface (CI)

EN 29Q522.1HE LA 5.

5.4 Stepwise Start-up

There are two possible situations: one for protections detected

by the stand-by software and one for protections detected by

the main software.

When the TV is in a protection state due to an error detected by

stand-by software (and thus blinking an error) and SDM is

activated via short-circuiting the pins on the SSB, the TV starts

up until it reaches the situation just before protection. So, this

is a kind of automatic stepwise start-up. In combination with the

start-up diagrams below, you can see which supplies are

present at a certain moment. Important to know is, that if e.g.

the 3V3 detection fails (and thus error 8 is blinking) and the TV

is restarted via SDM, the Stand-by Processor will enable the

3V3, but will not go to protection now. The TV will stay in this

situation until it is reset (Mains/AC Power supply interrupted).

Caution: in case the start up in this mode with a faulty FET

7U08 is done, you can destroy all ICs supplied by the +3V3,

due to over-voltage. It is recommended to measure first the

FET 7U08 on short-circuit before activating SDM via the

service pads.

When the TV is in protection state due to an error detected by

main software (MIPS protection) and SDM is activated via

short-cutting the service pads on the SSB, the TV starts up and

ignores the error.

In this chassis, only error “63” (power-ok) is a MIPS protection

and already displays the failure via blinking LED.

The abbreviations “SP” and “MP” in the figures stand for:

• SP: protection or error detected by the Stand-by

Processor.

• MP: protection or error detected by the MIPS Main

Processor.

Figure 5-3 Transition diagram

2009-Dec-04

EN 30 Q522.1HE LA5.

All I/O lines have a High default state:

- Switch P NX85x x in re set (act ive LOW).

- Keep the Audio-reset high.

- NVM power line is high, no NVM communication possible.

Off

Standby Supply starts running.

All stand by supply volta ges become a vailable .

st-b y µP resets

action holder: MIPS

autonomous action

action holder: St-by

Stand by or

Protection

Mains is ap plied

- Switch Audio-Reset high.

It is low in the standby mode if the standby

mode lasted longer than 10s.

No

Yes

SP

“5V 12V supply” error

detect-5V-12V received within

2900 ms after POD-mode I/O

line toggle?

No

SP

Yes

Detection

received within

250 ms after enable-3V3

toggle?

+5V, and +12V are switched on

No

SUPPLY-F AULT I/O line

is High ?

Switch ON Platform and display supply by switching LOW the

POD-MODE an d the ON-MODE I/O lines.

Initialise I/O pins of the st-by µP, start keyboard scanning, RC

detection. Wake up reasons are off.

If the protection state was left by short circuiting the

SDM pins, detection of a protection condition during

startup will stall the startup. Protection conditions in a

playing se t will be ignor ed. Th e protect ion mode will

not be entered.

PDPGO line is high (either HW wise in a non FHP set or

because of the stby µP r eset in an F HP set) which will star t the

FHP PDP.

Wait 50ms and the n start pollin g the dete ct-

5V-12V every 40ms.

The a vailability of the supplies is checked through detect

signals going to the st-by µP. These signals are available

for +12V and +5V (combined as AND function, called

detect-5V-12V) and for +1V2 and +3V3 (combined as

AND function, called detect-1V2-2V5-3V). A low to high

transition of the signals should occur within a certain time

after toggling the standby line. If an observer is detected

before the time-out elapses, of course, the process

should continue in order to minimize start up time.

No separate enable is present

for the +1V8 supply in the

TV522.

Only one detect line is present

in the TV522: it detects +1V2

and +3V3

100

ms is recommended by the

PNX

85xx

spec

.

The supply fault line is an OR

function of DCDC, DCDC5050

and POD /CI supply sw itch.

Display sup ply is switched on

through the ON-mode I/O line

activate +5V/+12V supply

detection algorithm. See CHS protections.

Off/Stby to Semi

Enable the +1V2 supply (ENABLE-1V2 )

Wait 100m s

Enable the supply for

+1.8V and +3. 3V (ENABLE-3V3)

Start polling the detect-1V2-2V5-3V3

every 40ms

1V2 2V5 3V3 DCDC error

Activate supply detection algorithms for DC-

DC outputs

Wait 20ms

Supply fault error

H_17650_094a.eps

090826

Service Modes, Error Codes, and Fault Finding

Figure 5-4 “Off” to “Semi Stand-by” flowchart (part 1)

2009-Dec-04

Loading...

Loading...