Page 1

I N S T R U C T I O N M A N U A L

Plasma Swivel Stand

PSS-2000BR/SS)

The Plasma Swivel Stand (PSS-2000) is available in black

(PSS-2000BR) or silver (PSS-2000SS) to securely mount

your large flat panel display. A stylish solution for residential,

commercial and business applications, the PSS-200 provides a wide variety of features for most table top installations.

Features include +/-45 degrees of swivel, free standing with

bolt down capability for permanent installation or security,

infinite height adjustment of 5” and two cable options for

ease of installation. The PSS-2000 swivel feature offers

optional stops at +/-15 degrees, 25 degrees or 35 degrees.

The infinite height adjustment of 5” allows for different screen

heights up to 32 inches and cables may extend from the ba ck

of the display or be routed through an access hole in the middle of the stand.

The PSS-2000 uses Chief’s exclusive Q-Latch™ Mounting

System for easy installation, stable mounting and quick

release. A video conferencing shelf, aesthetic cover kit, and

Q-clamps for added security are available.

BEFORE YOU BEGIN

• CAUTION: To prevent damage to the stand, which could affect or void the Factory warranty, thoroughly

study all instructions and illustrations before you begin to install or operate the unit. Pay particular attention to the “Important Precautions” on Page 1.

• The maximum weight to be installed on the PSS is 150 pounds (68.36 Kg)

• If you have any questions about this assembly, contact Chief Manufacturing at 1-800-582-6480 or 952-582-6480.

CHIEF MANUFACTURING INC.

1-800-582-6480 952-894-6280 FAX 952-894-6918

8401 EAGLE CREEK PARKWAY, STE. 700

SAVAGE, MINNESOTA 55378 USA

PART NO. 8800-000039 (Rev. D)

©2004 Chief Manufacturing

www.chiefmfg.com

09-05

Page 2

Instruction Manual Swivel Stand

IMPORTANT WARNINGS and CAUTIONS!

WARNING: A WARNING alerts you to the possibility of serious injury or death if you do not follow the instructions.

CAUTION: A CAUTION alerts you to the possibility of damage or destruction of equipment if you do not follow the corre-

sponding instructions.

• WARNING:Improper installation can result in serious personal injury! Make sure that the structural members can

support a redundant weight factor five times the total weight of the equipment: if not, reinforce the structure before installing the table stand.

• WARNING:Be aware also of the potential for personal injury or damage to the unit if it is not adequately mounted.

• CAUTION: Inspect the unit for shipping damage.

• CAUTION: Do not use cleanser or harsh cleaning agents on displays.

TOOLS REQUIRED FOR INSTALLATION

• Phillips screwdriver

NOTE: Other tools may be required depending on the

method of installation.

CONTENTS

INSPECT PARTS BEFORE ASSEMBLY ......... 2

DISPLAY PREPARATION PROCEDURES ..... 3

STAND ASSEMBLY PROCEDURES ............... 3

DISPLAY INSTALLATION PROCEDURES ... 5

STAND ADJUSTMENT PROCEDURES .......... 5

STAND ANCHORING PROCEDURES ............ 6

CABLE MANAGEMENT .................................. 6

1

Page 3

Instruction Manual Swivel Stand

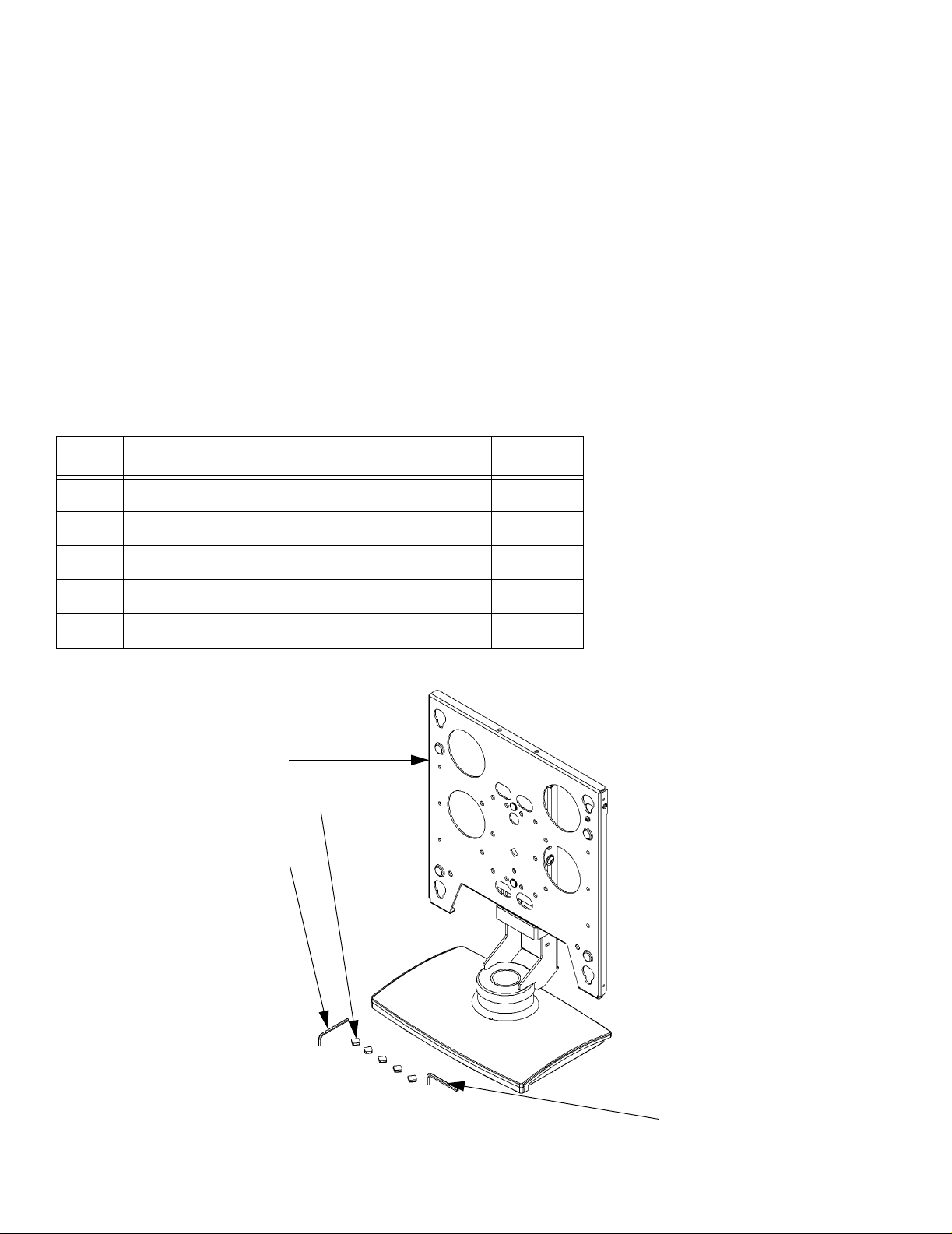

INSPECT PARTS BEFORE ASSEMBLY

Remove and Inspect the Stand

1. Open shipping container , remove unit from cont ainer , and

remove wooden shipping base.

2. Carefully inspect the stand for shipping damage. If any

damage is apparent, call your carrier claims agent and do

not continue with the assembly procedure until the carrier

has reviewed the damage.

NOTE:

Read all assembly instructions before start-

ing assembly.

3. Carefully inspect all components for damage (See

able 1 and Figure 1).

Table 1:

Item # Description Quantity

10 Stand Assembly 1

20 Bumper, rubber 5

30 Wrench, Allen, 3/16” 1

40 Wrench, Allen, 5/32” 1

50 Template, paper (Not Shown) 1

10

20

30

40

Figure 1. Parts

2

Page 4

Instruction Manual Swivel Stand

DISPLAY PREPARATION PROCEDURES

Prepare the display for installation as follows:

1. Install the PSB bracket (shipped with the PSS) on your

display according to the instructions included in PSB

bracket package.

STAND ASSEMBLY PROCEDURES

Free Standing (not anchored) Applications Only:

NOTE: Do not perform this step if you are going to anchor

the stand to a surface.

1. Install five rubber bumpers on the bottom of the stand

(see Figure 1).

Display Measuring 30 Inches or Smaller In Height:

NOTE: Stand comes assembled for displays 30” in height or

less and lowered to its minimum height for shipment.

1. Loosen the four height adjustment screws and raise the

slide to its maximum height (see Figure 2).

2. Secure the slide in place by tightening the four height

adjustment screws.

Display Measuring More Than 30 Inches In Height:

1. Remove the slide from the base by removing four height

adjustment screws (see Figure 3).

2. Remove the front plate from the slide by removing two

nuts securing the front plate (see Figure 3).

Attach rubber bumpers here

Figure 1. Free Standing Installations Only

Adjust height using these screws

3. Install the front plate in the upper mounting holes of slide

and secure using the two nuts removed in the previous

step (see Figure 4).

4. Install the slide on the base using the four height adjust-

ment screws (see Figure 3).

5. Raise the slide to its maximum height (see Figure 2).

6. Secure the slide in place by tightening the four height

adjustment screws.

Figure 2. Height Adjustment

3

Page 5

Instruction Manual Swivel Stand

Height Adj.

Screws

Slide

Front Plate

Nuts

Figure 3. Stand Assembly

Flag in down

(lowered)

Nuts

Holes used for displays measuring

less than 30 Inches Tall

Reattach front plate using these holes

position

Figure 4. For displays Taller Than 30 Inches

4

Page 6

Instruction Manual Swivel Stand

DISPLAY INSTALLATION PROCEDURES

Install the display as follows:

1. Make sure the latching flag of the stand is in the open

(lowered) position (see Figure 4).

2. Align the mounting buttons of the PSB bracket, installed

on your display, with the teardrop slots in the mounting

plate of the stand.

3. Lower the display into place and raise the latching flag to

secure the display. If the latching flag will not engage

completely, the display is not properly mounted. Make

sure the mounting buttons rest at the bottom of the teardrop slots.

STAND ADJUSTMENT PROCEDURES

Adjust display height as follows:

CAUTION: Displays are fragile. Allowing the display to drop to

the bottom of stand travel may result in damage to the display.

1. While holding the display in place, loosen the four height

adjustment screws (see Figure 2).

2. Position the display to the desired height.

3. Tighten the four height adjustment screws (see Figure 2).

Adjust stand tension as follows:

1. With the display secured to the stand assembly, check

swivel tension.

Adjust swivel tension using these screws

Figure 5. Tension Adjustment Screws

Select swivel stop by inserting

10-24 X 1/2” Phillips head screw

in one of these holes

2. If tension adjustment is necessary, slightly tighten or

loosen adjustment screws on stand assembly (see Figure 5).

3. Repeat Step 1 and Step 2 as necessary.

Adjust stand swivel stop as follows:

1. If desired, insert the 10-24 X 1/2” Phillips head cap screw

in one of the three swivel stop holes (15, 25 or 35

degrees) in the base of the stand (see Figure 6).

Figure 6. Swivel Stops (15, 25 or 35 Degrees)

5

Page 7

Instruction Manual Swivel Stand

STAND ANCHORING PROCEDURES

NOTE: Due to the wide variety of anchoring options, hard-

ware is not provided.

Anchor stand follows:

1. Select a suitable location for anchoring, allowing for room

for swivel and access for cabling.

2. Using the template provided, drill anchoring holes for the

four 1/4-20 X 1/2” tapped holes (see Figure 7).

3. If routing cables through mounting surface, Use the template provided and drill the cable access hole in the

mounting surface.

CABLE MANAGEMENT

Install cables as follows:

1. Attach cabling to flat panel display.

2. Route cables in one of three ways:

a. down the back of the display (open),

1/4-20 X 1/2” Tapped holes

Figure 7. Anchoring Hole Locations

b. through the center post of the stand and out the bot-

tom of the stand in the back,

c. through the center post of the stand and through a

hole in the mounting surface.

6

Loading...

Loading...