Page 1

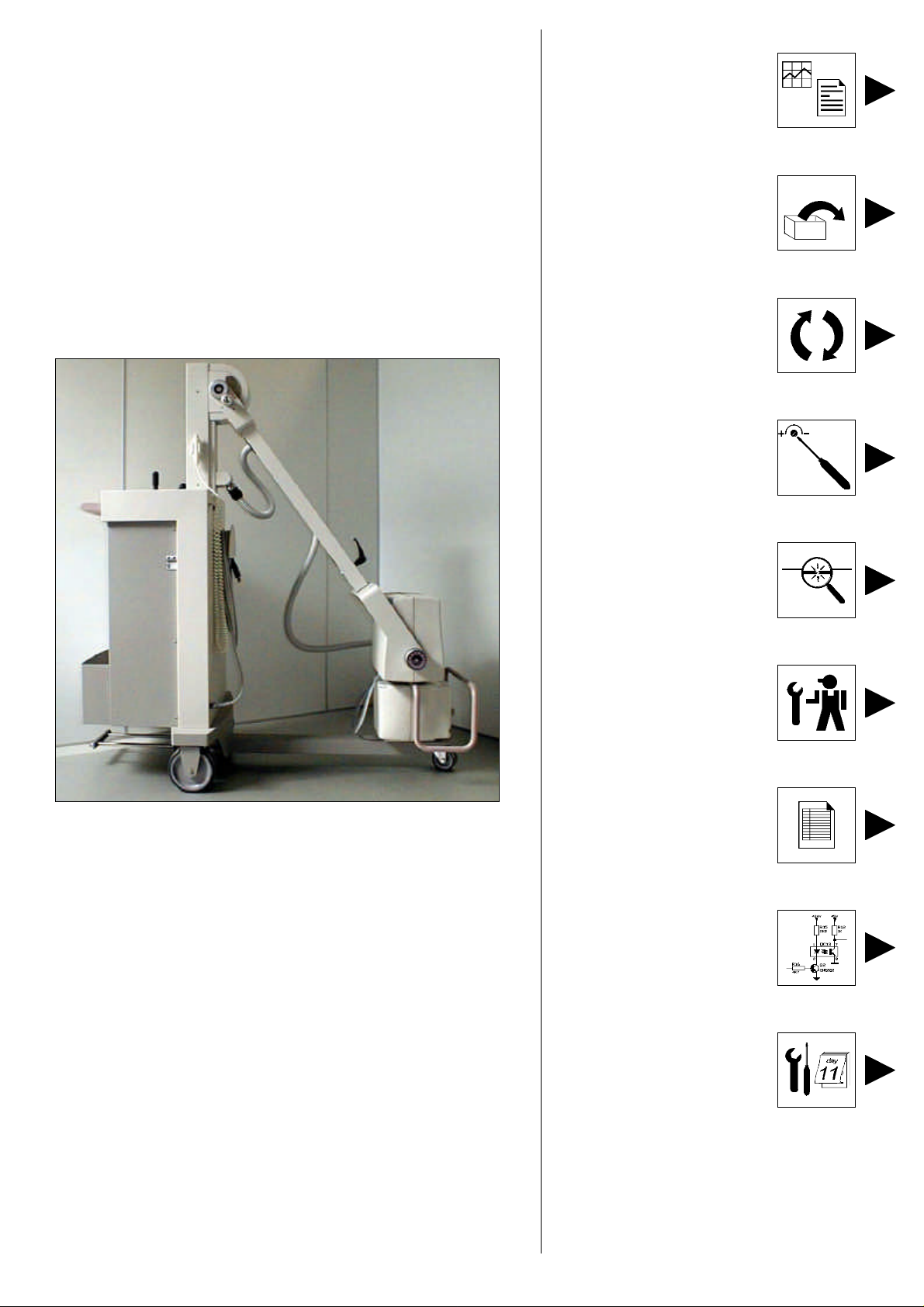

PRACTIX 100 PLUS

1.Technical data &

labels

code: W3004_Rev0

SERVICE MANUAL

2. Installation &

Acceptance

code: W3006_Rev0

3. Replacement

code: W3010_Rev0

4. Adjustments

code: W3012_Rev0

5. Faults finding

code: W3014_Rev0

Practix 100 plus

PMS 12NC: 9890-010-81791

Date:

Service manual

PMS 12NC: 4512-984-22741

File name: W3000_Rev1.doc

6. Service information

code:W3016_Rev0

7. Parts list

code: W3018_Rev1

8. Electrical drawings

code: W3020_Rev0

9. Programmed

maintenance

code: W3022_Rev0

****

Page 2

PRACTIX 100 PLUS

TECHNICAL DATA &

LABELS

[File: W3004_Rev0.doc]

Page 3

PRACTIX 100 plus Technical data & labels

SUMMARY

TECHNICAL DATA 2

Electrical characteristics...................................................................................................................... 2

Radiological characteristics.................................................................................................................. 2

Monobloc........................................................................................................................................... 3

Collimator.......................................................................................................................................... 3

Environmental data ............................................................................................................................ 3

Operative modes................................................................................................................................ 4

Functionality ...................................................................................................................................... 4

Accessories and options...................................................................................................................... 4

Mechanical characteristics................................................................................................................... 5

Unit volume sizes ............................................................................................................................... 6

MHF 2011 Monobloc........................................................................................................................... 7

Tube characteristics............................................................................................................................ 8

LABELS 10

STANDARDS AND DIRECTIVES COMPLIANCE 11

[File: W3004_Rev0.doc] 1/12

Page 4

PRACTIX 100 plus Technical data & labels

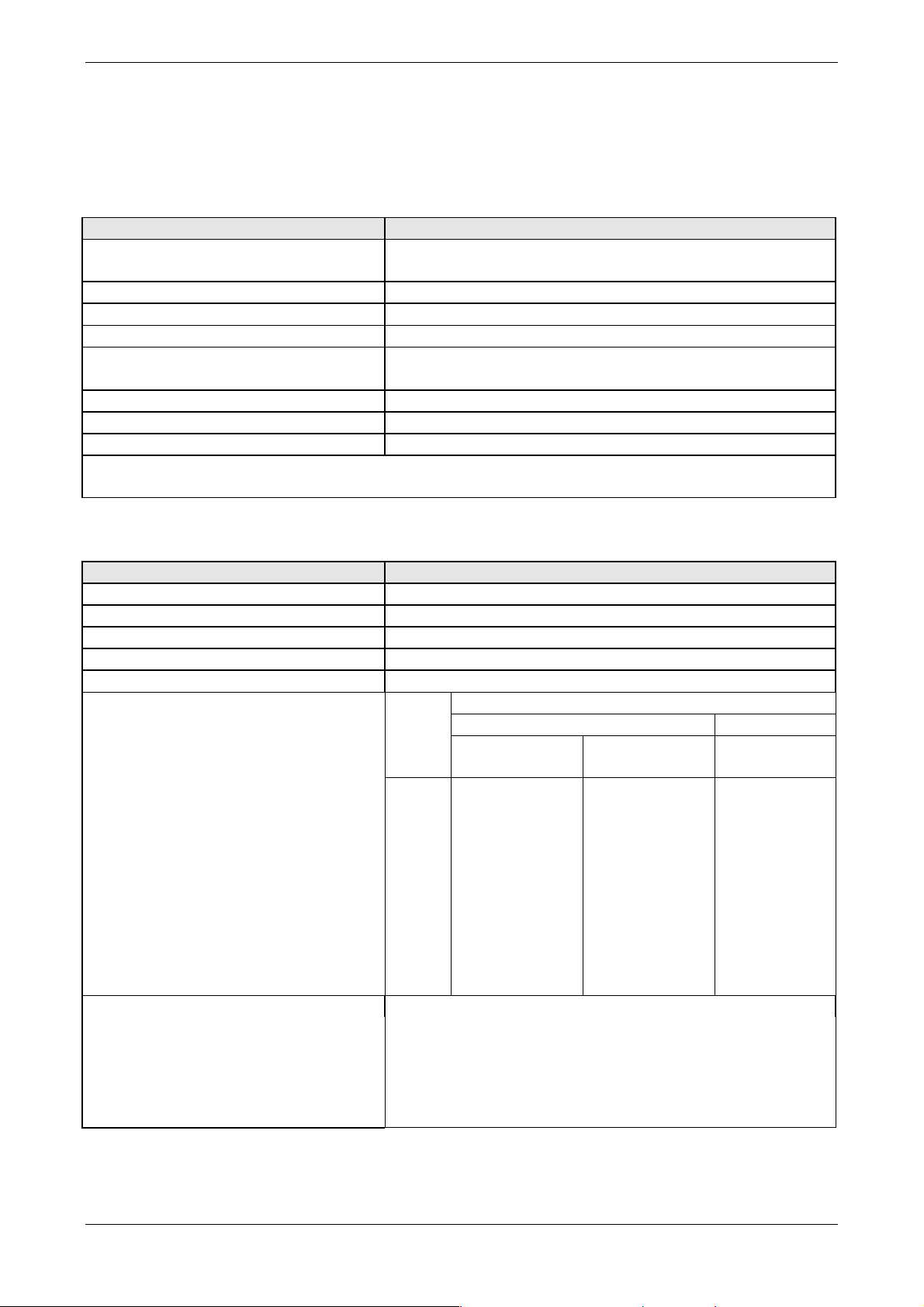

TECHNICAL DATA

Electrical characteristics

Description Data

Voltage

Frequency

Absorbed current

Line compensation

Line resistance

Standard plug

Classification

Use conditions

The unit is not suitable to the use where danger of mixtures inflammable with air or nitrous oxide

exists.

115/230Vac ±10% Standard monophase with automatic

unit predisposition in function of the mains line

50/60Hz standard

9A max. peak in radiography @ 230Vac

Automatic

<1Ω @230Vac

< 1Ω @115Vac

16A @230Vac

Class I, applied parts type B

Continuos functioning with intermitting load

Radiological characteristics

Description Data

Generator power in DC current

Inverter frequency

Max. Ripple

Rise time

kV Range

mA range

@115/230Vac

mAs range in function of kV

@115/230Vac

11kW @100Kv

20kHz

<1% @100kV

<2ms @100kV

40 ÷ 125kVp in step of 1kV

kV

40 140mA 70mA 70mA

50 140mA 70mA 70mA

60 130mA 65mA 65mA

70 125mA 63mA 63mA

80 120mA 60mA 60mA

90 115mA 58mA 58mA

100 110mA 55mA 55mA

110 90mA 45mA 45mA

120 80mA 40mA 40mA

125 75mA 38mA 38mA

0,2 ÷÷ 125mAs in 57 steps with 12,5% inc.

From:

mAs>0,63 mAs<0,63

(t<100ms)

MODE1

40 ÷ 42kV 0,2 ÷ 125mAs

43 ÷ 62kV 0,2 ÷ 100mAs

63 ÷ 72kV 0,2 ÷ 80mAs

73 ÷ 102kV 0,2 ÷ 63mAs

103 ÷ 125kV 0,2 ÷ 50mAs

mA

(t>100ms)

MODE2

MODE2

[File: W3004_Rev0.doc] 2/12

Page 5

PRACTIX 100 plus Technical data & labels

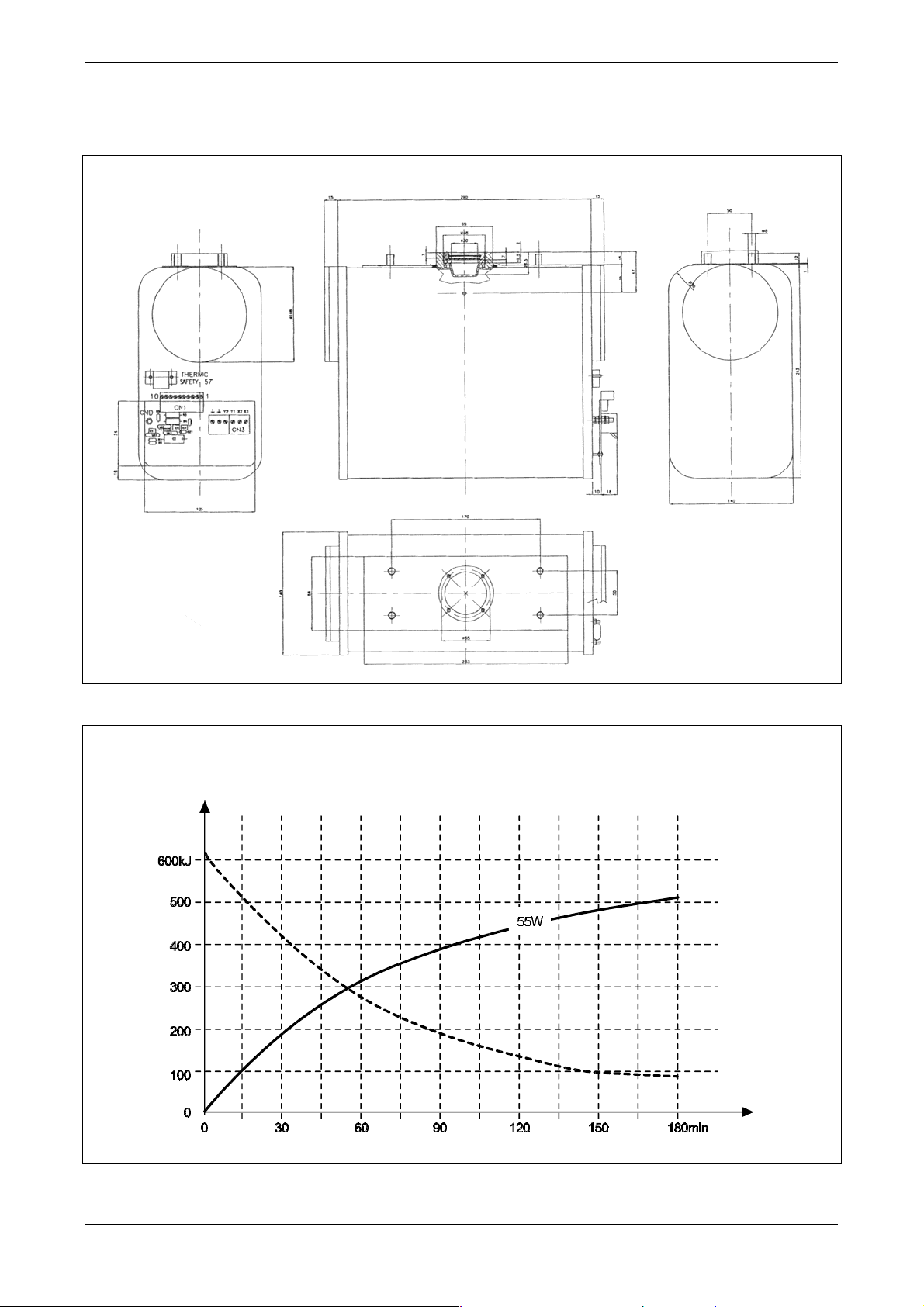

Monobloc

Description Data

Monobloc type

Weight

X-ray tube type

Anode

Focus nominal extension according to IEC 336

Nominal anodic power (for 1 sec.)

Anode thermal capacity

Anode disk diameter

Anode inclination

Max. continuos thermal dissipation of the anode

Max. anode cooling speed

Monobloc thermal capacity

Max. continuos thermal dissipation of monobloc

Total filtration

Leakage radiation

Loading, heating, and cooling curves

H.V. transformer isolation

MHF 2011

19kg.

IAE X20P

Rotating (2850rpm @ 50Hz) (3400rpm @ 60Hz)

0.8mm small focus

11kW small focus

50kJ (67kHU)

64mm

17,5°

175W

13kJ/min (17,5kHU/min)

600kJ (800kHU)

55W

2.7mm Al

<1mGy/h second IEC 601-1-3

Please refer to the enclosed diagrams

Oil bath

Collimator

Description Data

Type, brand and model

Collimation

Brightness source

Field covering

Brightness intensity

Contrast ratio

Focus film distance measure

Inherent filtration

Rotation

Weight

Accessories

Manual with internal luminous source (Ralco P 232)

Square field, multilayers

Halogen lamp 12V 100W with temporized ignition of approx. 30s

43 x 43cm at focus film distance of 1m

160lux at focus film distance of 1m

4:1

Extractable Meter

2mm Al

±130°

8.4Kg.

Predisposition of the ionization chamber insertion

Environmental data

Description Normal use Transport and warehouse

Temperature

Relative humidity

Pressure

From +10°C to +40°C From -25°C to +70°C

From 30% to 75% not condensing From 10% to 90% not condensing

From 700 to 1060hPa From 500 to 1060hPa

[File: W3004_Rev0.doc] 3/12

Page 6

PRACTIX 100 plus Technical data & labels

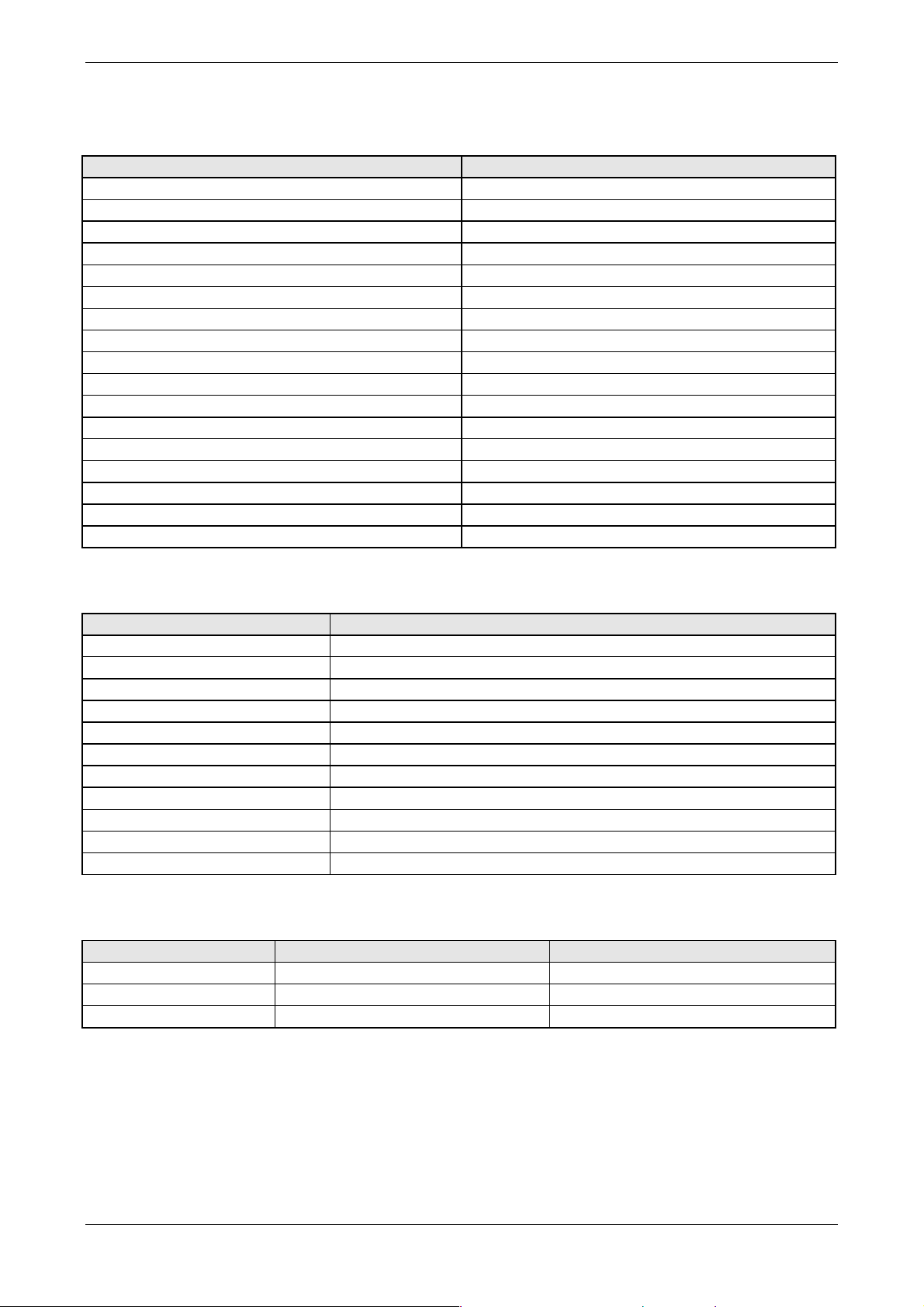

Operative modes

Mode Characteristic Performances

Radiography

Working Mode At 2 points with kV and mAs setting

APR Anatomic Mode Memorization of 32 exams, (4 programs,

each of 8 exam) available in the 4 selectable

languages

Small focus in any operating status 0,8mm

kV variation range

mA variation range @115/230Vac

mAs variation range @115/230Vac

Times range @115/230Vac

Exposure control Constant kV and mA during the whole

Use coefficient (duty cycle) 1:40

40 ÷ 125kV in step of 1kV

38 ÷ 140mA associated in automatic to kV

0,2 ÷ 125mAs in 57 steps with 12,5%

increases

0,0025 ÷ 2s in function of the set mAs

exposure

Functionality

Description Data

User’s interface

Selectable languages

Radiography control

Safeties

Keyboard with display (alphanumeric LCD, 4 lines x 20 characters) for

every operating parameter and message of eventual anomalies.

Service program for faults finding.

Microcontroller management.

English, French, German and Spanish, by a configuration program.

Push-button with extractendible cable. It’s shown the use of last kV value

set in manual mode or APR.

Upon the ignition the unit is set in manual mode with default values.

Filament current.

Monobloc temperature.

Max. load exceeded.

Max. kV or H.V. fault.

Memory data check.

Microcontroller auto test

Accessories and options

Description 12NC

X-ray control with extendible cable

Infrared X-ray control, model RAYMOTE III

Ionizing chamber dosimeter, model DIAMENTOR PX

4512-535-39761 Standard

9890-010-82071 Optional

9890-010-81141 Optional

[File: W3004_Rev0.doc] 4/12

Page 7

PRACTIX 100 plus Technical data & labels

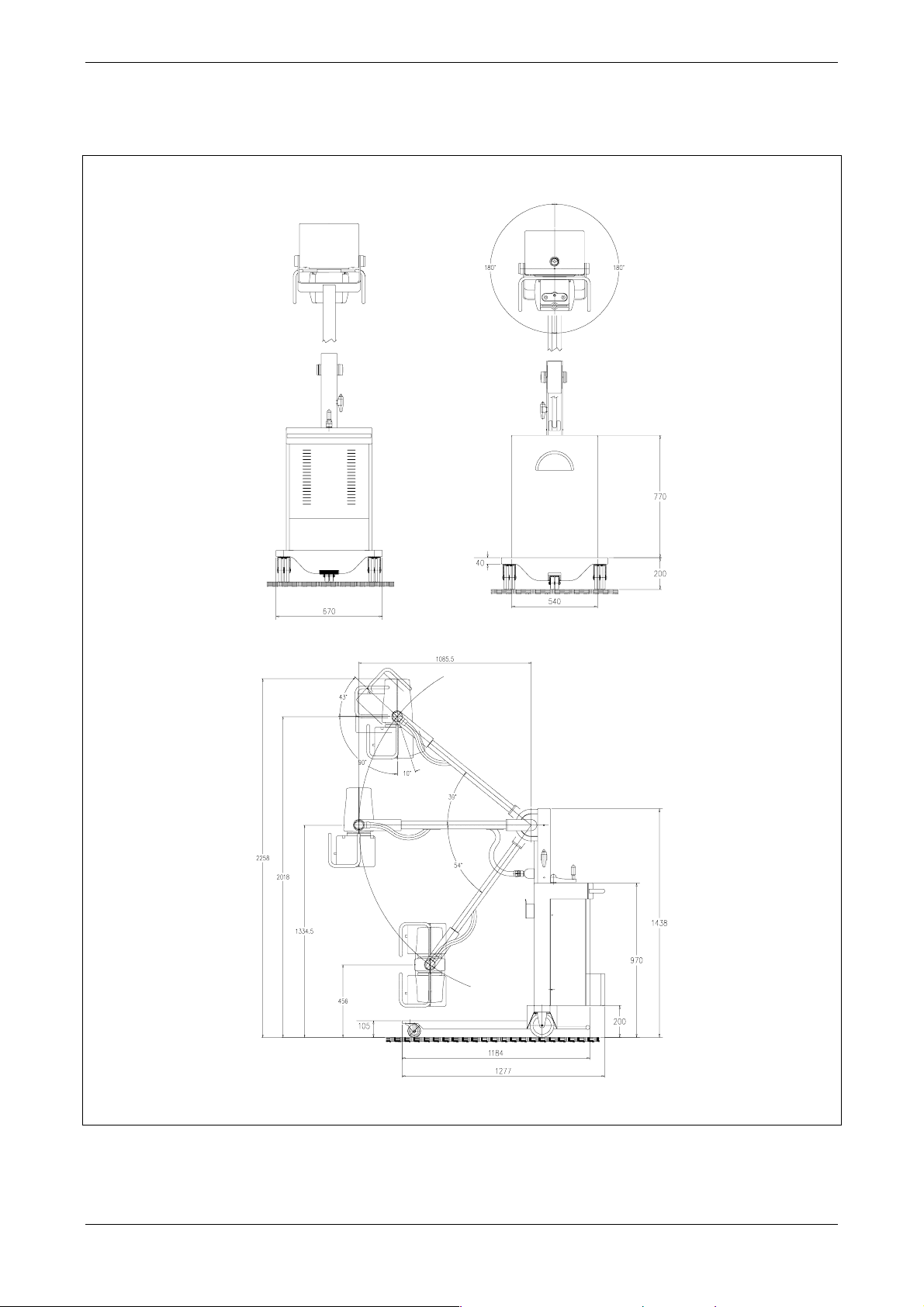

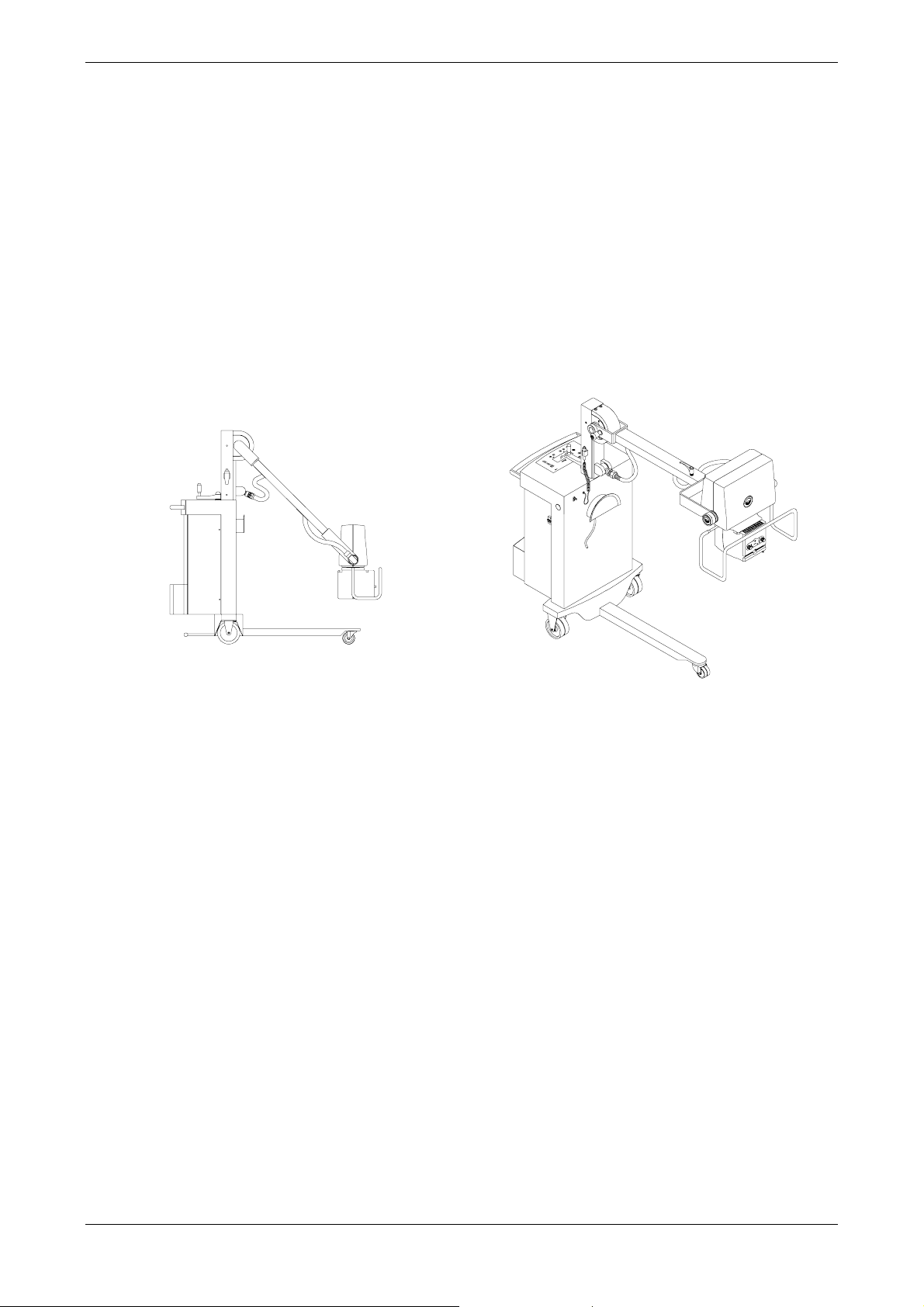

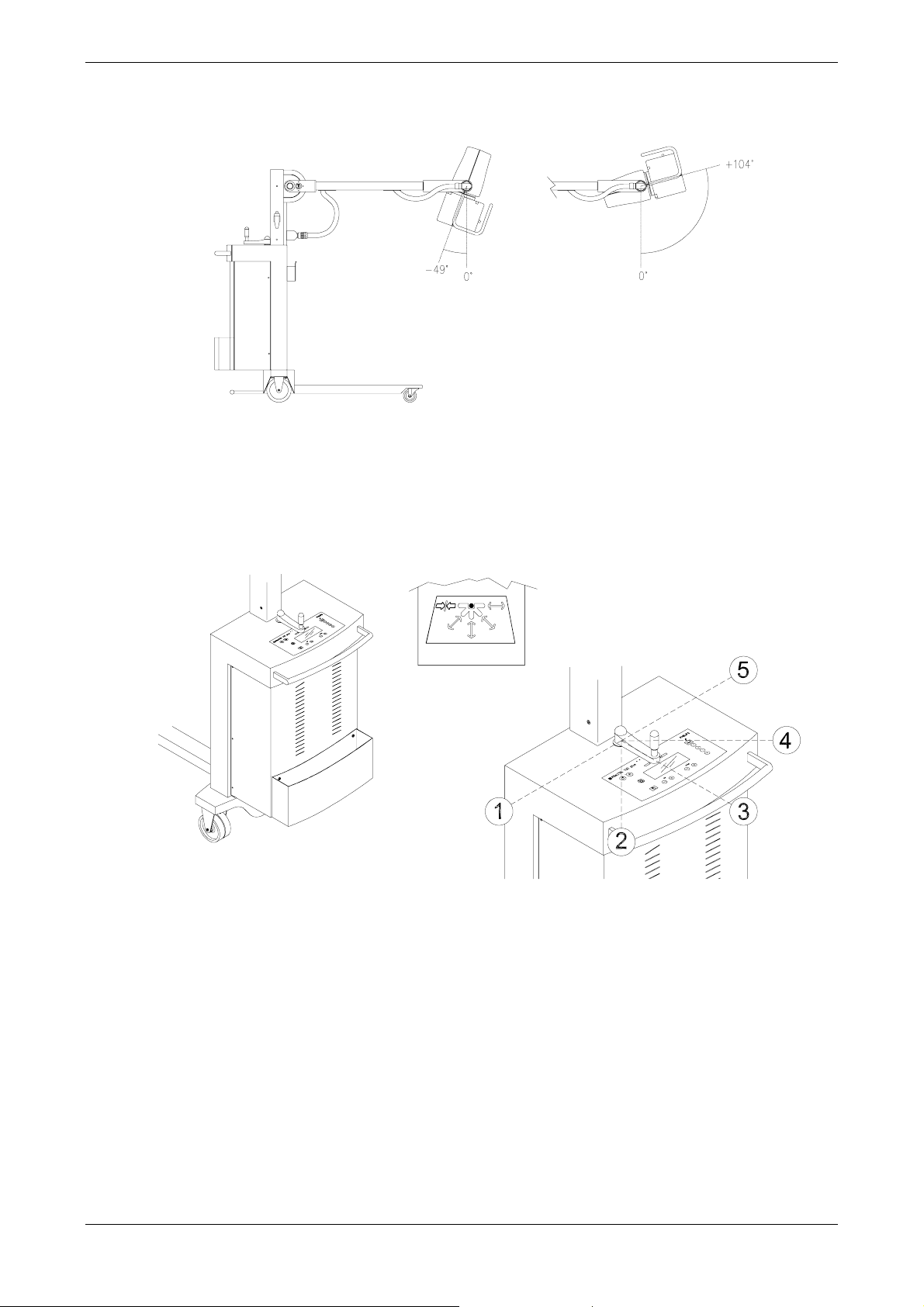

Mechanical characteristics

Description Data

Weight

Max. width

Length in transport position

Max. height in transport position

Max. height with arm at the max. extension

Control console height

Focus-floor distance

Arm rotation around the vertical axis

Monobloc rotation around the arm axis

Monobloc rotation around its axis

Max. height of the unit front leg

Cassette holder

Movement

Wheels diameter

Please refer to the drawing enclosed

170kg approx.

670mm

1277mm

1438mm

2258mm

970mm

456 ÷ 2018mm

n.d.

±180°

153° (+104° ÷ -49° towards the vertical axis)

105mm

5 cassettes, 35 x 43cm format

Manual.

Double front swiveling wheel.

Double rear wheels driven by the handle placed

on the unit stand near the console.

Stationary brake activation by the same handle

for the rear wheels driving.

Tilting pedal (obstacles over passing).

Rear: double wheel 150mm width 30mm

Front: double wheel 80mm width 25mm

[File: W3004_Rev0.doc] 5/12

Page 8

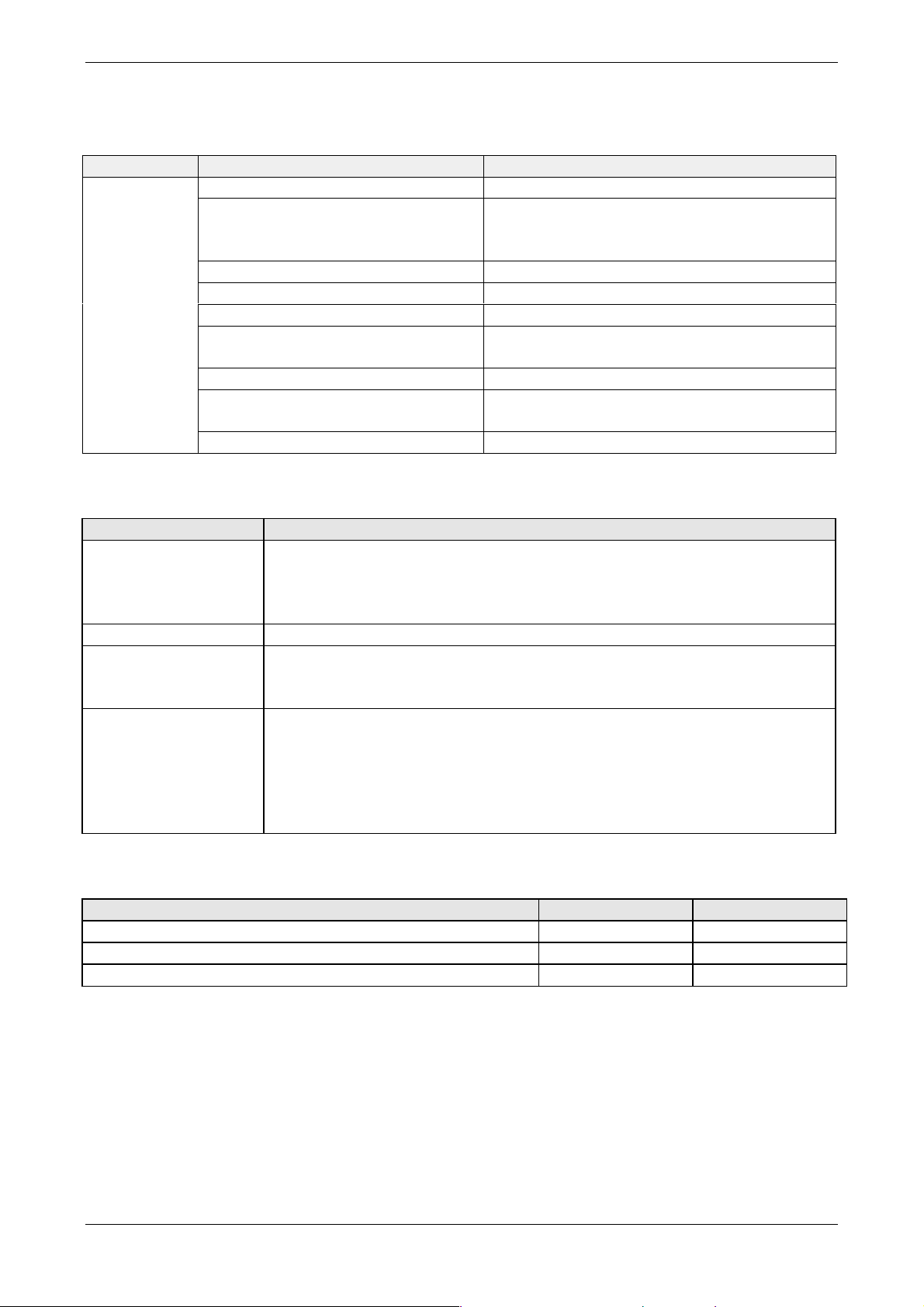

Unit volume sizes

PRACTIX 100 plus Technical data & labels

[File: W3004_Rev0.doc] 6/12

Page 9

MHF 2011 Monobloc

PRACTIX 100 plus Technical data & labels

Sizes

Monobloc cooling and heating curves

Stored energy (kJ) / Time (min)

[File: W3004_Rev0.doc] 7/12

Page 10

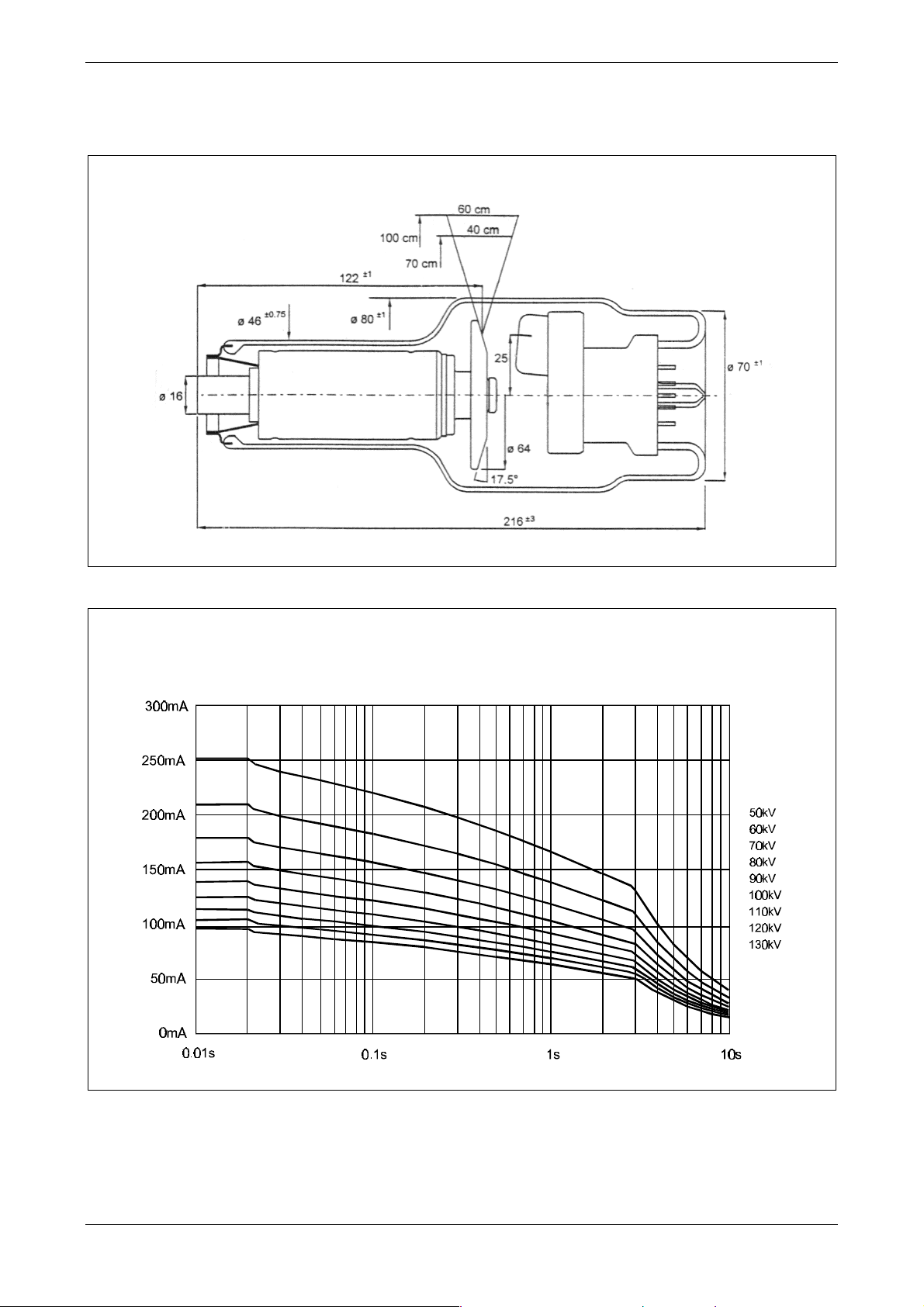

Tube characteristics

PRACTIX 100 plus Technical data & labels

Sizes

Single load rating

0.8 - 3~ - 3000min

-1

Tube current (mA) / Time. (sec)

[File: W3004_Rev0.doc] 8/12

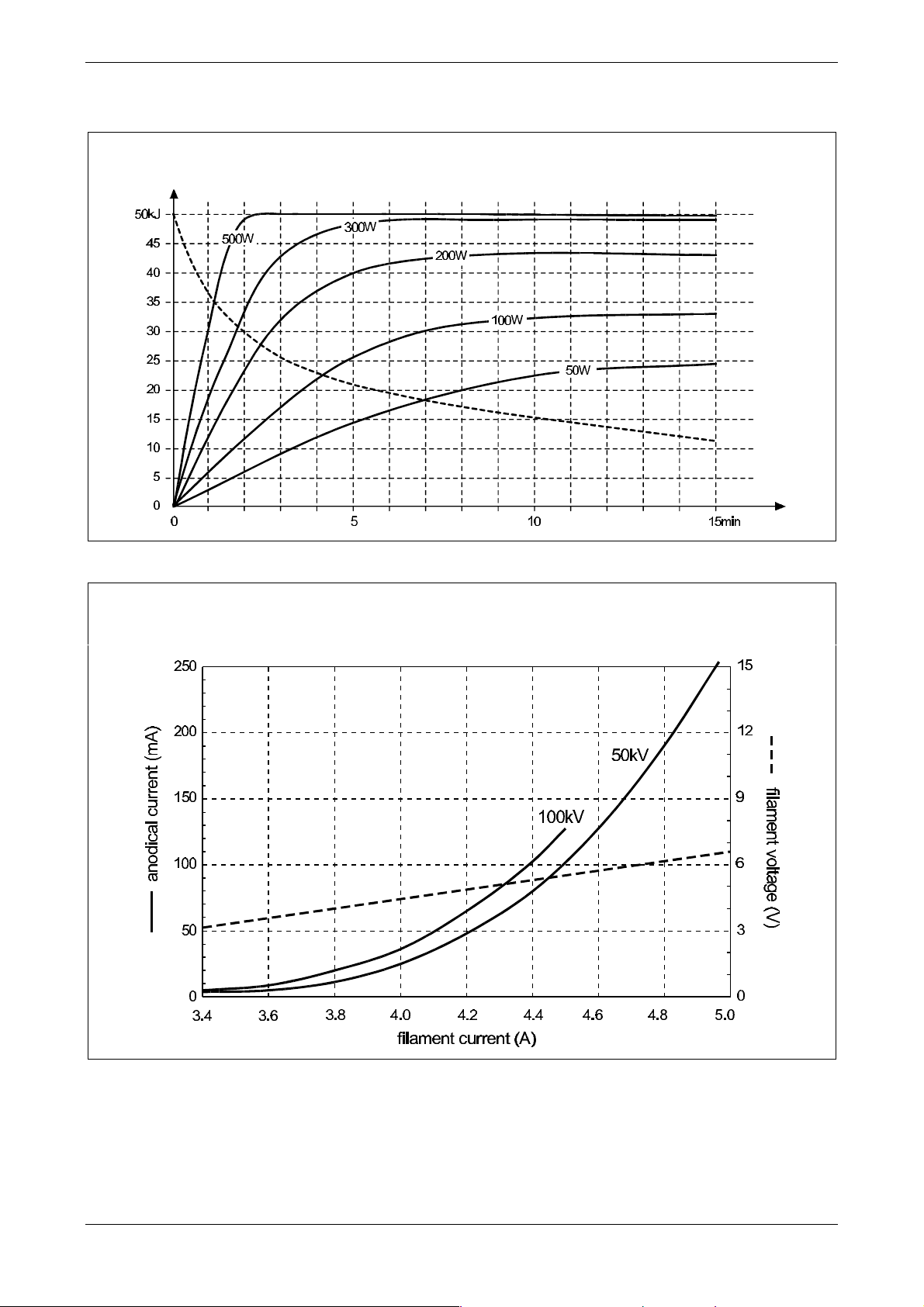

Page 11

PRACTIX 100 plus Technical data & labels

Anodical cooling and warming curves

Stored energy (kJ) / Time (min)

Filament emission curve

Filament current / Anodical current (mA)

Filament current / Filament voltage (V)

[File: W3004_Rev0.doc] 9/12

Page 12

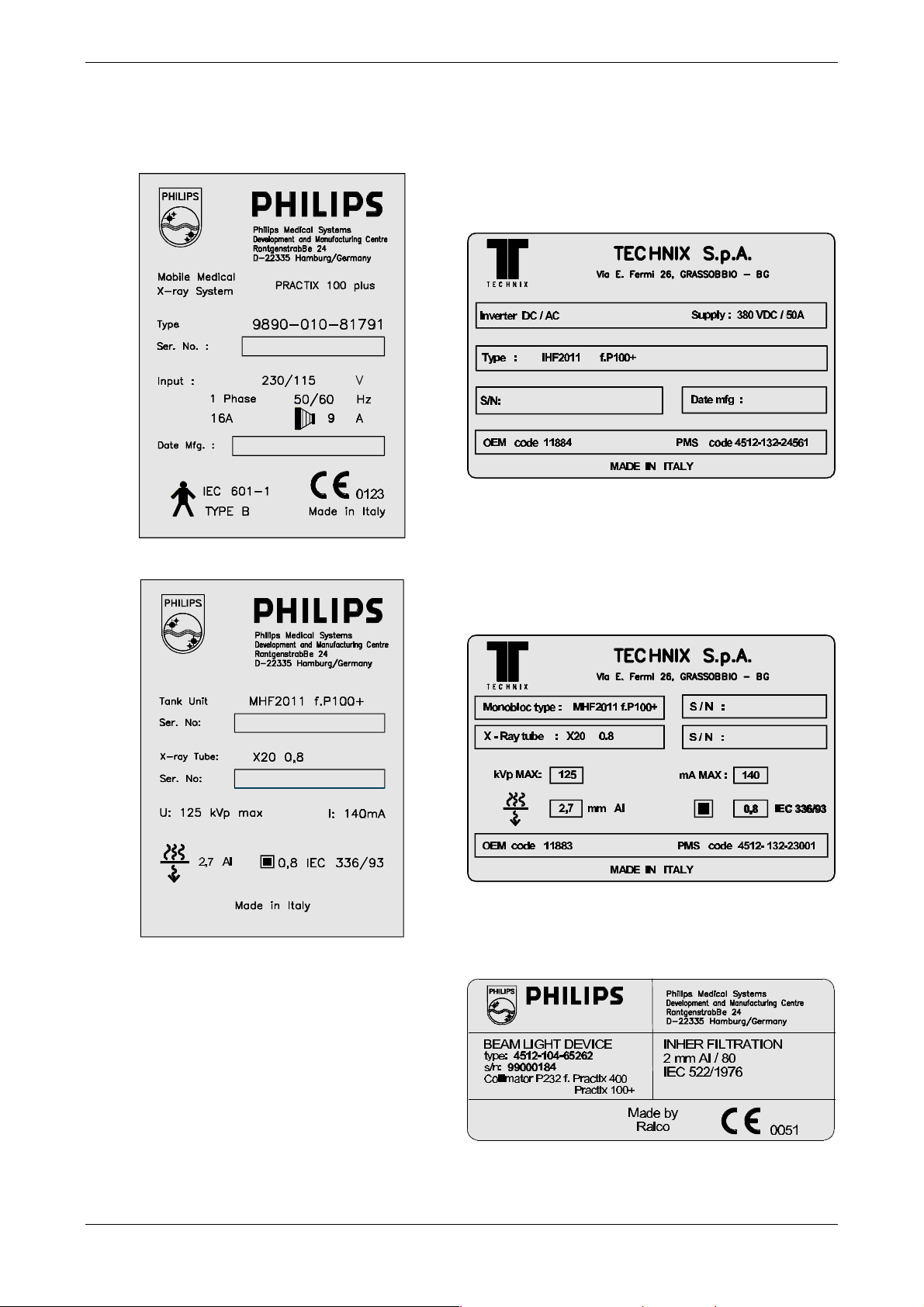

LABELS

PRACTIX 100 plus Technical data & labels

inverter label

unit label

monobloc external label

monobloc internal label

collimator label

[File: W3004_Rev0.doc] 10/12

Page 13

PRACTIX 100 plus Technical data & labels

STANDARDS AND DIRECTIVES COMPLIANCE

Reference Description

MDD 93/42/EEC

89/336/EEC

EN IEC 60601-1

EN IEC 60601-1-2

EN IEC 60601-1-3

EN IEC 60601-1-4

EN IEC 60601-2-7

EN IEC 60601-2-28

EN 1441

IEC 336

UL 187

FDA

CDHR

CSA

Medical Devices Directive (CE mark)

Electromagnetic compatibility

Medical devices safety

Electromagnetic compatibility

Protection against ionizing radiation

Software safety

High voltage generators

X-ray tube assemblies – housing

Risk analysis

X-ray tubes focus

USA standard

USA standard

USA standard

Canada standard

[File: W3004_Rev0.doc] 11/12

Page 14

PRACTIX 100 plus Technical data & labels

DOCUMENT STATUS

Rev. Date Page/s Modifiction description

0 Document approval

1

2

3

4

5

[File: W3004_Rev0.doc] 12/12

Page 15

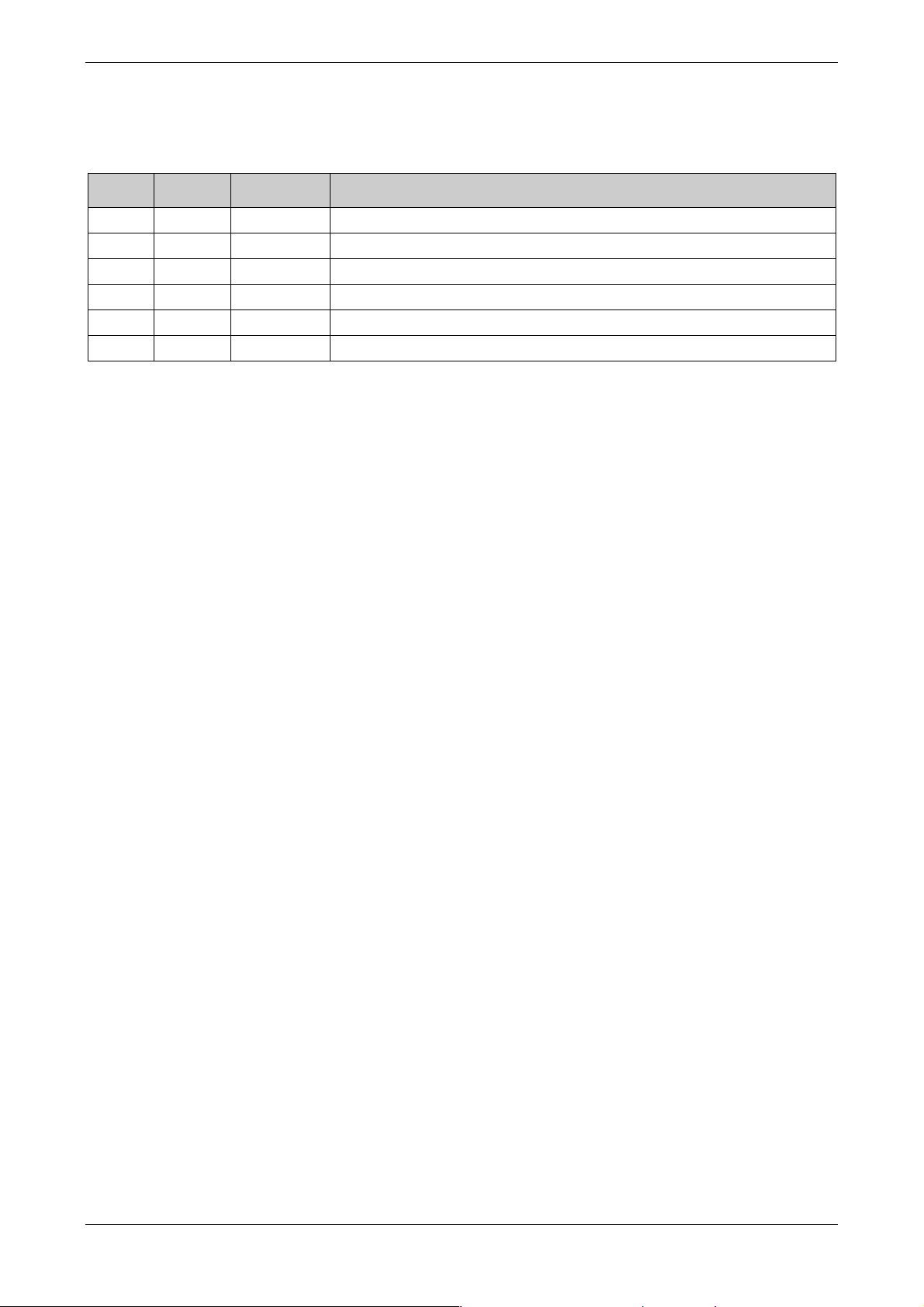

PRACTIX 100 PLUS

INSTALLATION &

ACCEPTANCE

[File: W3006_Rev0.doc]

Page 16

PRACTIX 100 plus Installation & Acceptance

SUMMARY

HOW TO PROCEED 2

PRELIMINARY INFORMATION 3

UNIT UNPACKING 4

Unpacking procedure.......................................................................................................................... 4

Packing and content description.......................................................................................................... 7

SIGHT CHECK OF THE UNIT INTEGRITY 8

PRELIMINARY KNOWLEDGES 8

MECHANICAL TESTS 9

UNIT SUPPLY 11

Preliminary operations...................................................................................................................... 11

Mains connection.............................................................................................................................. 11

ELECTRICAL TESTS (NO IRRADIATION) 12

Ignition - Start up - Ready ................................................................................................................ 12

Collimator check............................................................................................................................... 12

Data setting and preparation check ................................................................................................... 12

TUBE PREPARATION 13

ACCURACY TEST 14

Output data check............................................................................................................................ 14

X-ray irradiation field check............................................................................................................... 15

UNIT CONFIGURATION 16

Default configuration........................................................................................................................ 16

Customer’s configuration .................................................................................................................. 16

Configuration sheet...................................................................................................................... 17

Configuration ................................................................................................................................... 18

Date and time setting....................................................................................................................... 18

[File: W3006_Rev0.doc] 1 / 19

Page 17

PRACTIX 100 plus Installation & Acceptance

HOW TO PROCEED

For the proper and safe unit installation please follow, step by step, the INSTALLATION

SHEET. Proceed with the next operation ONLY once the previous steps have been properly

completed.

INSTALLATION SHEET

1. Preliminary knowledges and information KK yes KK no

2. Unpacking and content verification KK yes KK no

3. Sight check of the unit integrity * KK yes KK no

4. Reading of the chapter “Service information” KK yes KK no

5. Mechanical tests* KK yes KK no

6. Check of the unit compatibility with mains KK yes KK no

7. Electrical tests (do not perform x-ray)* KK yes KK no

8. X-ray tube preparation* KK yes KK no

9. X-ray tests* KK yes KK no

10. Request of data configuration to the user KK yes KK no

11. Unit configuration KK yes KK no

☺☺

12. Now the unit is ready for the use

!!EUREKA!!

* Acceptance phase

[File: W3006_Rev0.doc] 2 / 19

Page 18

PRACTIX 100 plus Installation & Acceptance

PRELIMINARY INFORMATION

This unit has been assembled and checked in factory following methods certified both for

production and testing. The same methods are in compliance with the most recent international

Standards and with the European Directive for Medical Devices (93/42 CEE).

During checking phase it is draught a Test Report including the following information is draught:

• Output data accuracy (kV-mA-time) test

• Light field X-ray field conformity test

• Electrical safety (PE resistance and leaked currents)

To ensure the unit safety and efficiency even during the transport between firm and user, some

tests and functional checks are required. It is necessary to perform those tests upon installation.

To check the output data, therefore kV and X-ray time measurements, the use of non-invasive

tools is required. Should tools be not available, check these values on the unit display directly (see

next pages).

Perform what described in this chapter, even if additional and specific acceptance

tests are required

(i.e. by hospital or Government).

DO NOT PERFORM HAZARDOUS OPERATIONS

ELECTICAL SHOCK DANGER

Even if the mains plug is disconnected a dangerous voltage can be

present inside the unit in case the

completely discharged.

capacitors battery is not

PERFORM THE DISCHARGE PROCEDURE

Before removing the Plexiglas protection or performing any

operation on Capacitors Battery, Power Unit

Circuits and Monobloc it is necessary to discharge the capacitors

battery.

THE DISCHARG

“Faults finding”.

E PROCEDURE IS DESCRIBED IN THE CHAPTER

, Inverter Power

[File: W3006_Rev0.doc] 3 / 19

Page 19

PRACTIX 100 plus Installation & Acceptance

UNIT UNPACKING

Unpacking procedure

This procedure requires a two operators intervention. For its performance, it is necessary to

use a fork key ø17mm to remove clamps and a screwdriver to remove the packing screws.

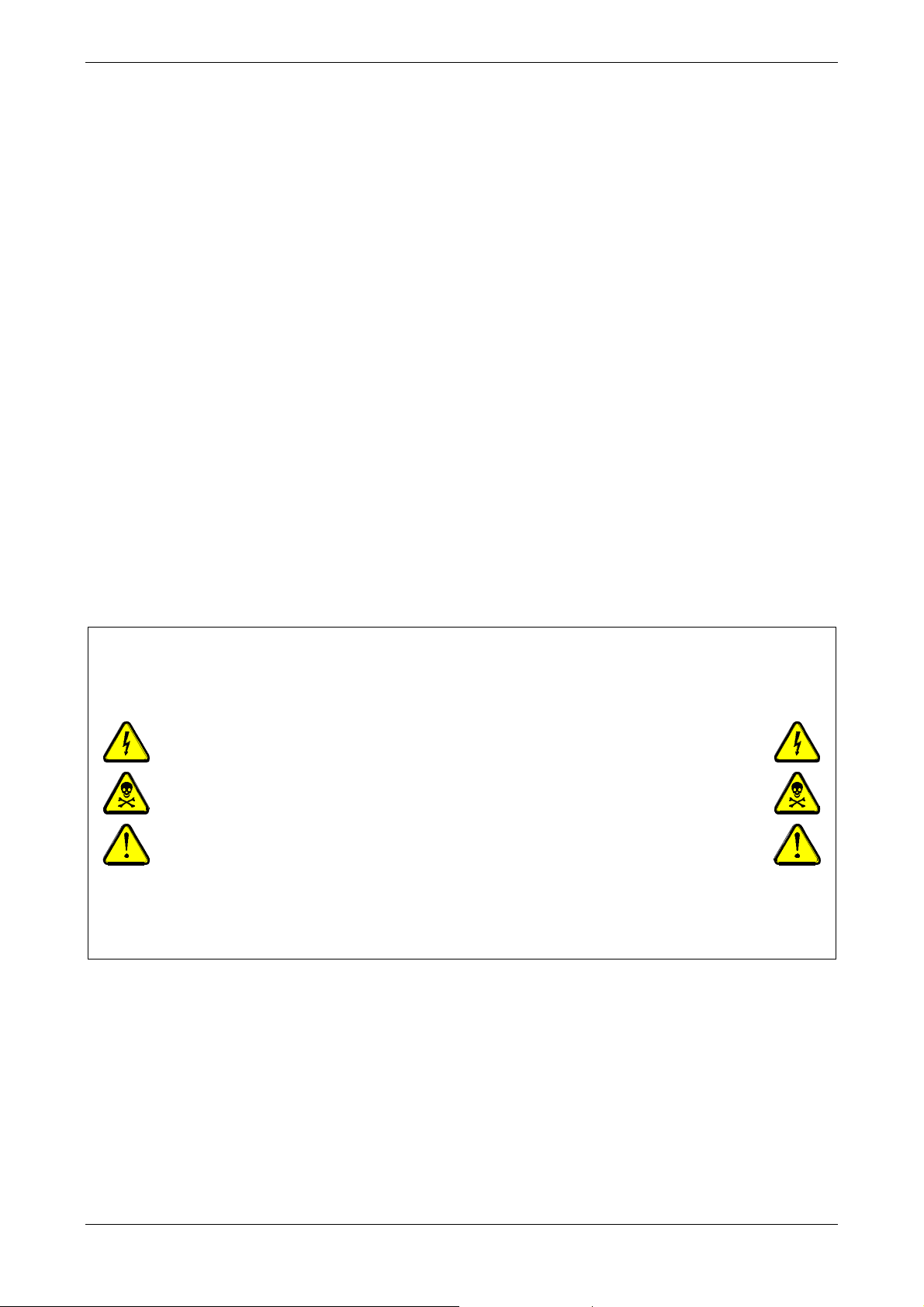

1.

Remove the packing cover.

2. Loosen the nuts which fix the clamps and remove the arm belt.

[File: W3006_Rev0.doc] 4 / 19

Page 20

PRACTIX 100 plus Installation & Acceptance

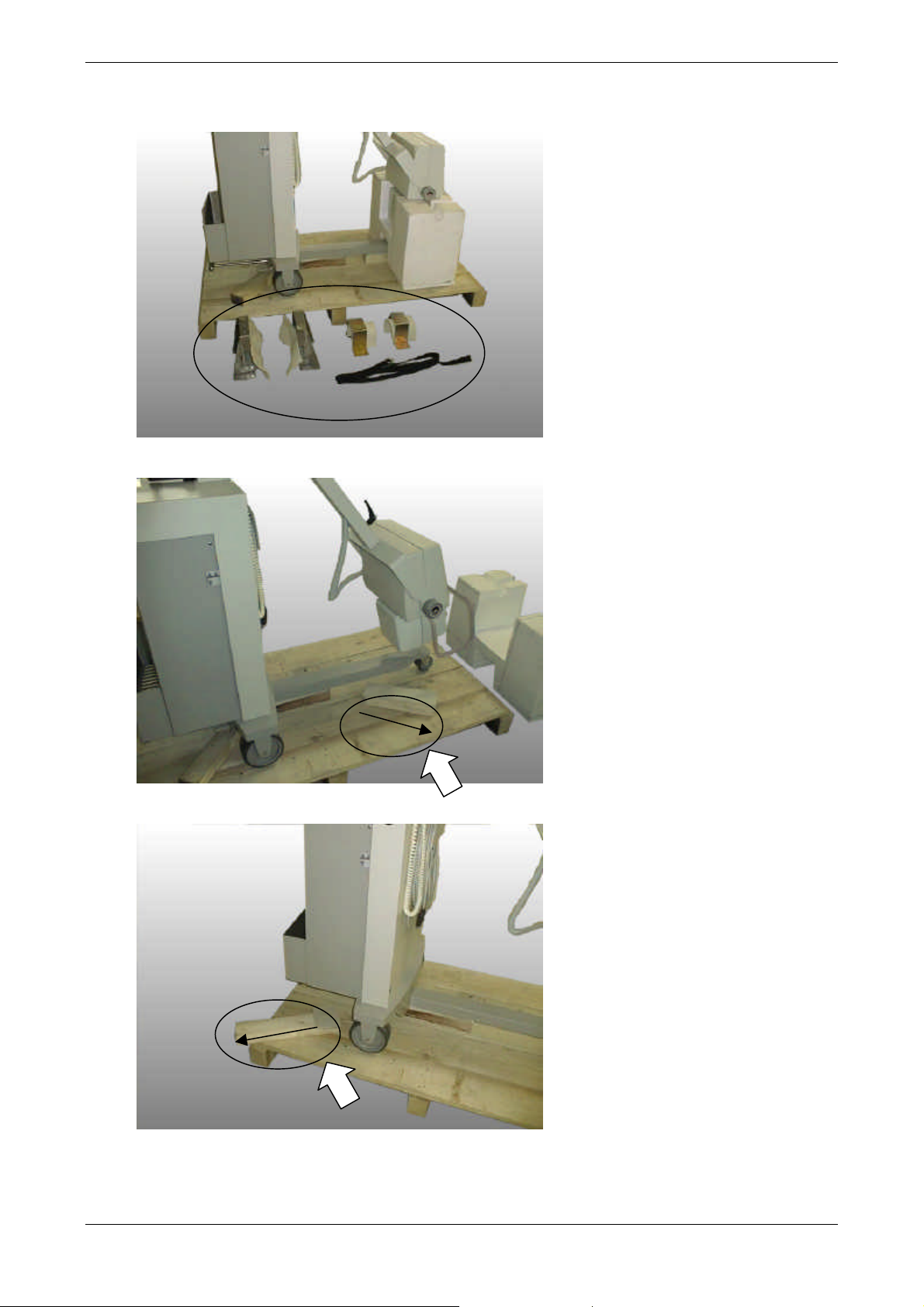

3. Remove every clamp.

4. Remove the polystyrene protecting the monobloc and the anterior wood block .

5. Remove the posterior wood block.

[File: W3006_Rev0.doc] 5 / 19

Page 21

PRACTIX 100 plus Installation & Acceptance

6. Act on the tilting lever and arise the unit frontal part, remove the central wood block.

7. Then, by using the skid, operate very carefully and remove the unit from the pallet.

[File: W3006_Rev0.doc] 6 / 19

Page 22

PRACTIX 100 plus Installation & Acceptance

Packing and content description

The packing includes:

q.ty description TX cod. 12NC

1 PRACTIX 100 plus 62915 9890-010-81791

Manuals

1 User’s manual in English language 4512-109-23042

1 User’s manual in German language 4512-109-23041

1 User’s manual in French language 4512-109-23043

1 User’s manual in Spanish language 4512-109-23044

1 Service manual (english) X3000 4512-984-22741

Paints

1 Touch kit paints composed by: 62428 4512-535-39211

1 Gray SF8758

1 Pink SF8582

1 Mushroom SF6998

Parts

1 Spare parts set composed by: 62918 4512-132-23131

1 Halogen lamp 12V - 100W 11449 4512-535-38731

1 Fuse 5x20 T 250mA / 250V 11361 4512-132-23141

1 Fuse 5x20 T 500mA / 250V 11288 4512-535-37301

1 Fuse 5x20 T 1A / 250V 11289 4512-535-37291

2 Fuse 5x20 T 4A / 250V 11292 4512-535-37331

1 Fuse 5x20 T 10A / 250V 11150 4512-535-37271

2 Ceramic extrafast fuse 10x38 20A - gR/ 600V 11917 4512-132-23151

2 Extrafast fuse 63A - ETF / 660V 11456 4512-132-23161

4 Support for board locking EHCBS - 6 (h=10mm) 11872 4512-132-24361

2 Support for board locking EHCBS - 16 (h=25mm) 11867 4512-132-23181

4 Cables medium clip 150x3,6mm 11234 4512-535-23191

[File: W3006_Rev0.doc] 7 / 19

Page 23

PRACTIX 100 plus Installation & Acceptance

SIGHT CHECK OF THE UNIT INTEGRITY

After the unpacking phase perform the following checks:

1. Labels

2. Covers painting

3. Keyboard

4.

Collimator and monobloc

5. Handles

6. Mains cable

7. X-ray button and button cable

8. Generator-monobloc-collimator connecting cable

PRELIMINARY KNOWLEDGES

Before proceeding with the unit installation the technician has to carefully read the chapter

“Service information”

. It includes several useful information to perform the installation properly.

[File: W3006_Rev0.doc] 8 / 19

Page 24

MECHANICAL TESTS

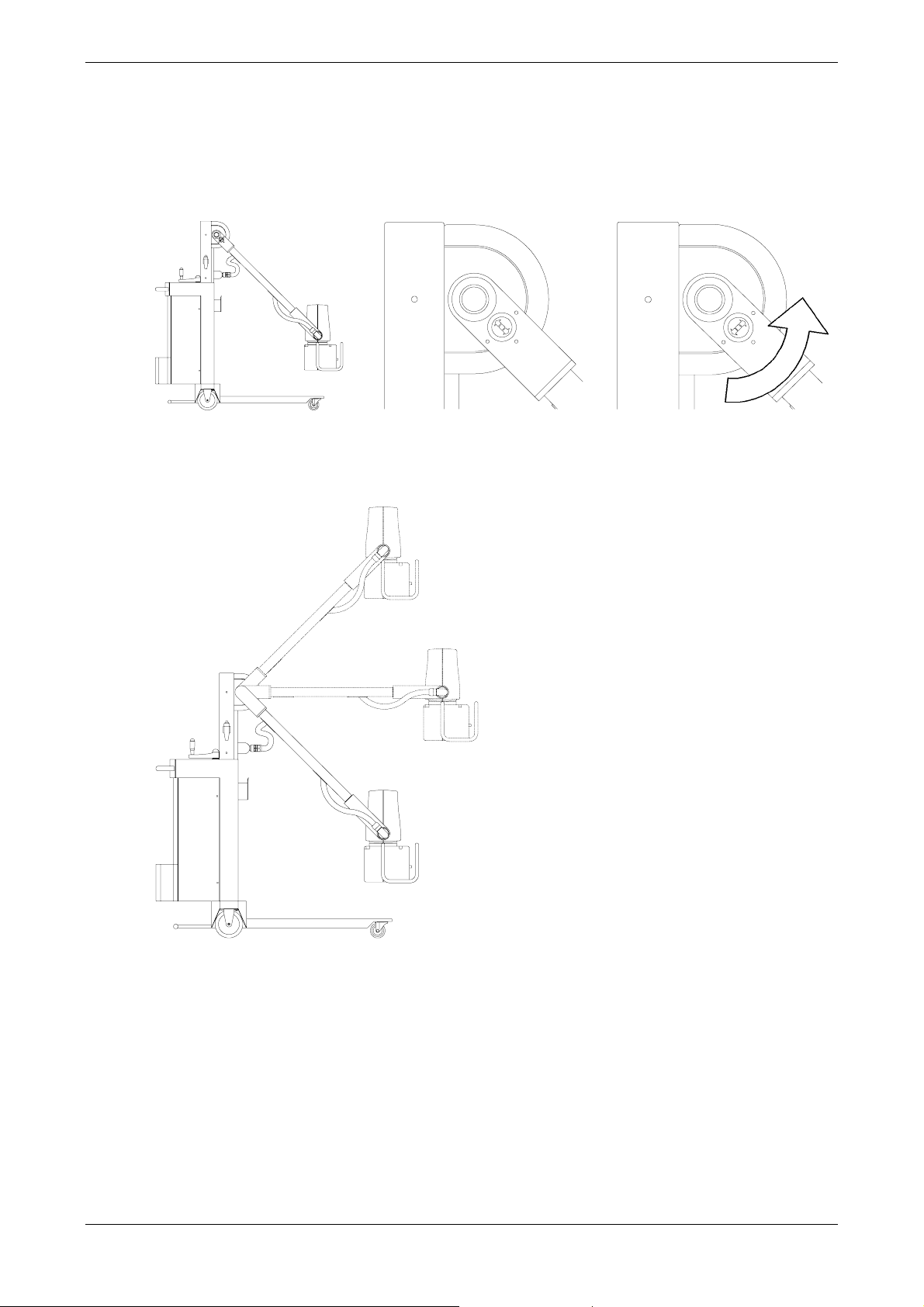

Move the unit from the parking condition (unlock the arm) by pulling and rotating (90°.) the release

1.

pawl.

parking position locked arm unlocked arm

Check the arm movement and balancing in every operative position, as shown in the picture.

2.

PRACTIX 100 plus Installation & Acceptance

[File: W3006_Rev0.doc] 9 / 19

Page 25

PRACTIX 100 plus Installation & Acceptance

Check the monobloc group balancing and rotation towards the longitudinal axis.

3.

Unlock the monobloc brake and check the monobloc group rotation (±180°) around the horizontal

4.

axis. Furthermore check the right gonimeter indication.

Check the proper collimator rotation around his vertical axis (±135°).

5.

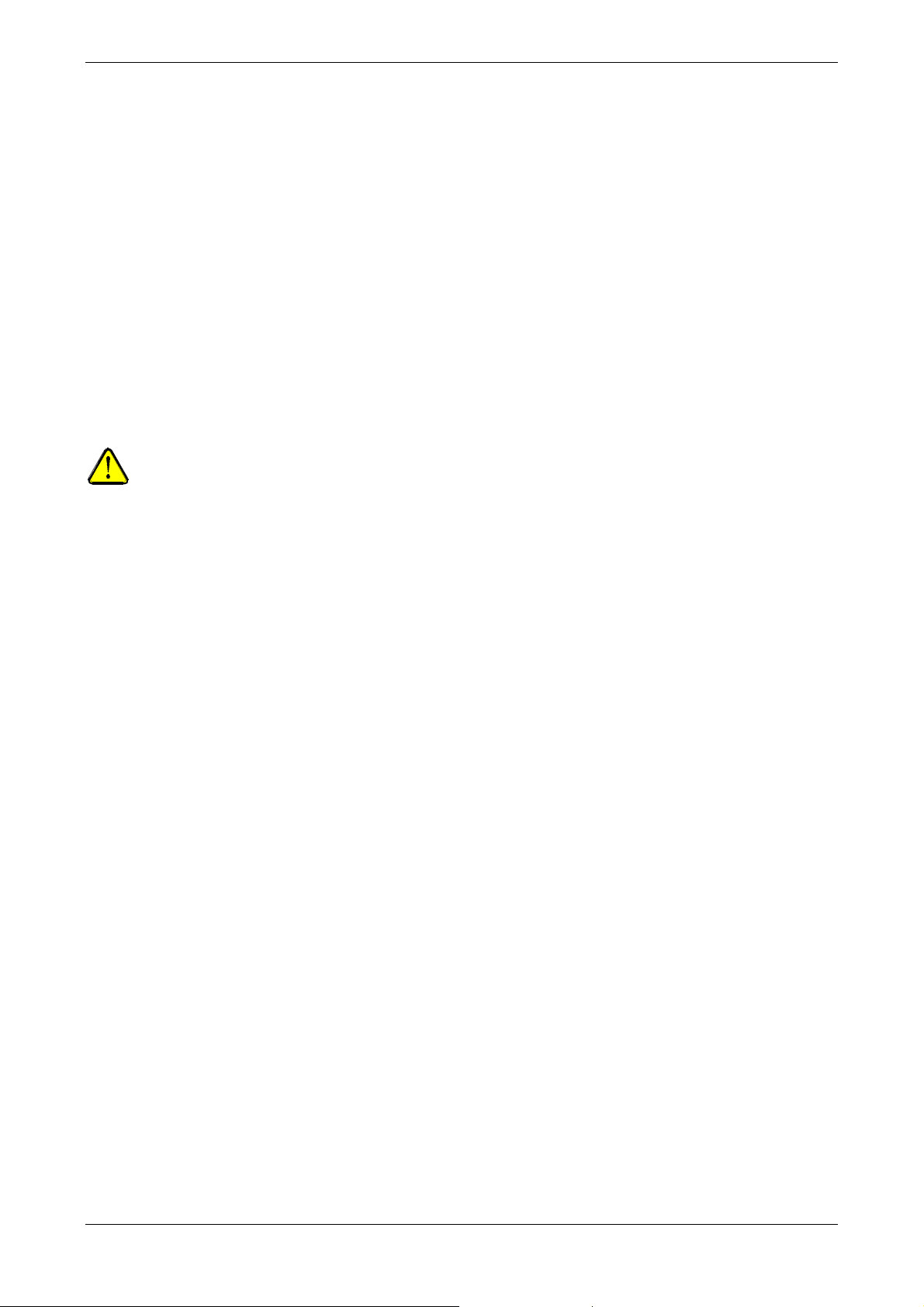

Check the stationary brake and the directional handle.

6.

Place the handle in the following positions (refer to the label attached on the arm column) and check

the proper functioning:

• pos. 1: brake ON

• pos. 2: oblique left-right motion

• pos. 3: backward-forward motion

• pos. 4: oblique right-left motion

• pos. 5: left-right motion

[File: W3006_Rev0.doc] 10 / 19

Page 26

PRACTIX 100 plus Installation & Acceptance

UNIT SUPPLY

Preliminary operations

The Practix 100 plus automatically adapts to the mains.

The unit performances do not depend on mains voltage (115V or 230V).

Only the anode starting time and, as a consequence, the preparation time, depend on the mains

voltage (0,8s @230Vac - 1,6s @115Vac). These parameters are automatically set by the unit.

Before connecting the unit to the mains check the following:

1. mains voltage..........................................115V or 230V (±10%) monophase

2. mains frequency......................................50Hz or 60Hz

3. available power.......................................3kW (16A max)

4. mains plug with earth connection

Before connecting the mains make sure that the PLUG IS GROUNDED.

Mains connection

Then it’s possible to connect the unit to the mains.

The mains voltage presence is indicated by the turning ON of the yellow led placed aside the ON

button. Should the led be OFF, make sure that the automatic switch is turned ON.

[File: W3006_Rev0.doc] 11 / 19

Page 27

PRACTIX 100 plus Installation & Acceptance

ELECTRICAL TESTS (NO IRRADIATION)

Never perform an exposure in this phase. It may be dangerous for the unit

integrity.

Ignition - Start up - Ready

1. Turn the unit ON (press the ON button) and follow step by step the Start up sequence,

checking its proper performing (refer to chapter “Service information”).

2. If no problem is detected the display will show the message “READY” after the Start up phase.

Collimator check

1. Completely open the collimator blades.

2. Press the COLLIMATOR button located on the keyboard (or on teh same collimator), turn the

collimator lamp on and check its proper functioning (approx 30s long).

Data setting and preparation check

1. Verify the functioning of the kV and mAs increase/decrease buttons.

2. Perform X-ray preparation (just press the first step of the button for 3s at least) and check the

proper anode rotation.

3. Upon the button release, check the anode proper braking.

[File: W3006_Rev0.doc] 12 / 19

Page 28

TUBE PREPARATION

Warning: X-ray presence, use proper protections.

PRACTIX 100 plus Installation & Acceptance

Arrange the tube for X-ray performing the Warm-up (

procedure (kV step-up). Perform these procedures with the TUBE SEASONING program (refer to

SERVICE MODE, chapt. “Service information”).

At Start up, after a long inactivity period (3 months or more) the display will show “TUBE

SEASONING” message. Therefore, it’s necessary to proceed with the TUBE SEASONING program

(refer to SERVICE MODE, chapt. “Service information”).

After the seasoning DO NOT perform any exposure. Let the monobloc cool down for 8

minutes at least.

Warm

sub-procedure) and the

kVup

sub-

[File: W3006_Rev0.doc] 13 / 19

Page 29

PRACTIX 100 plus Installation & Acceptance

ACCURACY TEST

Output data check

Warning: X-ray presence, use proper protections.

Place in the X-ray field a non-invasive tool for the kV and X-ray time measurements according to

what indicated in the tool manual.

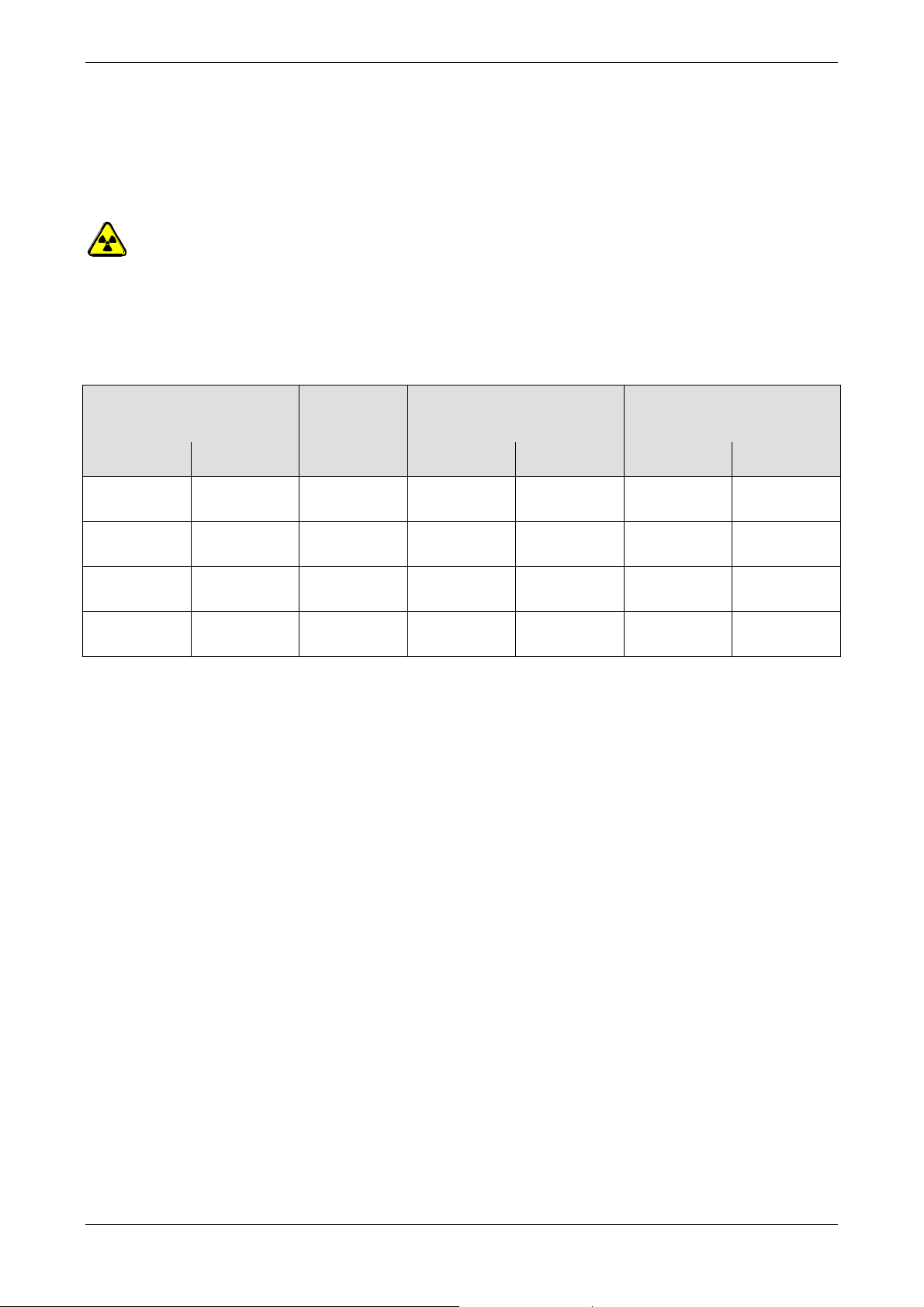

Perform the exposures listed in this table and verify that the measured values are in the allowed

limits.

Set data output

kV mAs [ms] kV time [ms] kV time [ms]

60 12,5 96 ............ ............ 57 - 63 91 - 101

80 12,5 104 ............ ............ 76 - 84 98 -109

80 63 950 ............ ............ 76 - 84 902 - 998

100 11 100 ............ ............ 95 -105 95 - 105

Without the tool:

• it’s possible to check the X-ray time on the unit display directly; this is automatically displayed

after every exposure;

• it’s possible to check the kV (and anodic current) from the SERVICE MODE, by the TEST KV-

mA option, as described in the chapter “Service information ”.

Theorical

time

Measured value

Acceptance limit data

output

[File: W3006_Rev0.doc] 14 / 19

Page 30

PRACTIX 100 plus Installation & Acceptance

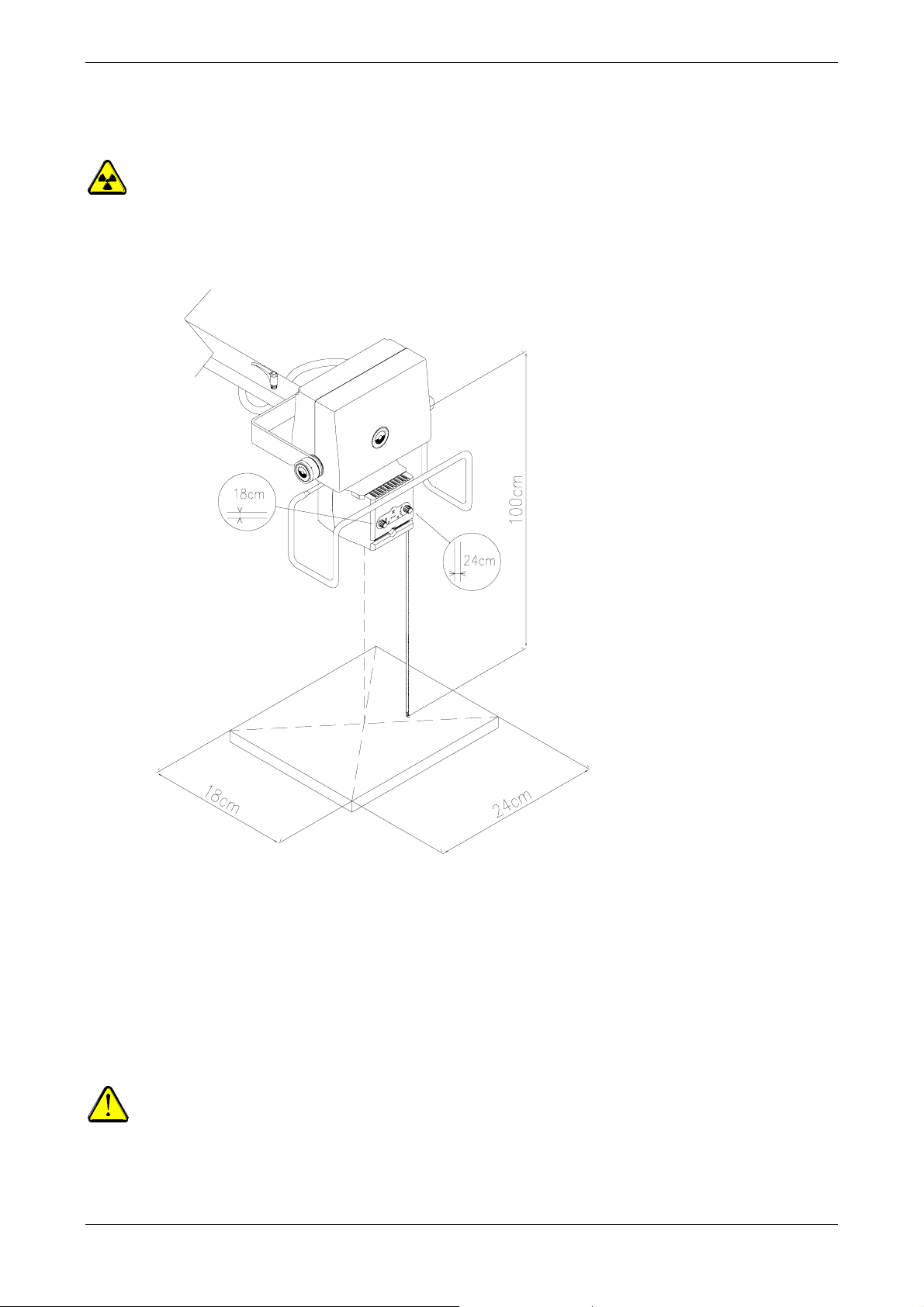

X-ray irradiation field check

Warning: X-ray presence, use proper protections.

This test verifies the correspondence between collimator light and X-ray field.

Place under the collimator, at 1m from the focus, a 18x24 cassette with film.

1.

Press the COLLIMATOR button (both on collimator and keyboard); the lamp will be ON for approx.

2.

30s.

Rotate the handles placed on the collimator and adjust the shutters opening, in order to light the

3.

whole surface of the cassette.

Perform an exposure (i.e. 63kV/10mAs) and check the proper irradiaton of the film (at least within

4.

the requested tolerance).

The X-ray data/parameters vary in function of the cassette type.

As alternative to the cassette it’s possible to use a fluorescent, graduated, high persistence

screen (field position analyzer).

[File: W3006_Rev0.doc] 15 / 19

Page 31

PRACTIX 100 plus Installation & Acceptance

UNIT CONFIGURATION

Default configuration

The unit has been set as follows:

PARAMETER DEFAULT DISPLAY

Maximum kV

(MAX. KV)

Start up kV

(START KV)

Start up mAs

(START mAs)

Language

(LANGUAGE)

APR data storing

(APR mem.)

Starter brake

(SARTER BRAKE)

Dosimeter

(DOSIMETER)

Buzzer

(BUZZER)

Date and time

(DATE-TIME)

125kV 125

63kV 63

4mAs 4

English ENG

disenabled OFF

enabled ON

not present OFF

enabled ON

Rome time zone

(GMT+1.00h)

Customer’s configuration

The user has to be aware of the different working possibilities of the unit, thus to choose the most

convenient and suitable configuration.

Before proceeding it is necessary to fill out, together with the user, the CONFIGURATION SHEET

(see the next page).

[File: W3006_Rev0.doc] 16 / 19

Page 32

PRACTIX 100 plus Installation & Acceptance

Configuration sheet

Unit: PRACTIX 100 plus s/n°:

Place of installation: Date of installation:

Dept: Date of maintenance:

Maximum kV value.

(please, choose between 40 and 125)

kV value at start up.

(please, choose between 40 and the maximum kV value)

……………….kV

……………….kV

mAs value at start up.

……………….mAs

Messages language.

(choose among English, Spanish, French and German)

Availability to store APR values modified by the operator.

Disenablation of the anode braking.

Dosimeter presence.

(available on request)

Disenablation of beeper.

User’s signature: Technician’s signature:

K yes K no

K yes K no

K yes K no

K yes K no

……………….

[File: W3006_Rev0.doc] 17 / 19

Page 33

PRACTIX 100 plus Installation & Acceptance

Configuration

Now it’s possible to set the unit with the values indicated in the CONFIGURATION SHEET. By

SERVICE MODE activate the CONFIG function (see the chapter “Service information”) and modify

the parameters.

Please note that, with the service technician’s intervention, it will be always possible to modify the

configuration parameters.

Date and time setting

Set date and time, follow the DATE-TIME procedure (please refer to SEVICE MODE, described in

the chapter “Service information”).

With the service technician’s intervention, it will be always possible to modify the

configuration parameters.

[File: W3006_Rev0.doc] 18 / 19

Page 34

PRACTIX 100 plus Installation & Acceptance

DOCUMENT STATUS

Rev. Date Page/s Modification description

0 Document approval

1

2

3

4

5

[File: W3006_Rev0.doc] 19 / 19

Page 35

PRACTIX 100 PLUS

REPLACEMENT

[File: W3010_Rev0.doc]

Page 36

PRACTIX 100 plus Replacement

SUMMARY

PROCEDURES DESCRIPTION 1

Electrical parts replacement ................................................................................................................1

Mechanical parts replacement............................................................................................................. 2

Lamp replacement.........................................................................................................................2

Monobloc replacement................................................................................................................... 5

Collimator dismounting .................................................................................................................. 9

PROCEDURES DESCRIPTION

Electrical parts replacement

Should a fault or a malfunctioning be detected, it is advisable to replace the boards (and not to

repair them). The boards provided will be already tested and adjusted.

In case of any adjustment, please refer to the chapter “Adjustments”.

[File: W3010_Rev0.doc] 1 / 12

Page 37

PRACTIX 100 plus Replacement

Mechanical parts replacement

Lamp replacement

WARNING: Before proceeding make sure of the lamp bracket, lamp and socket cooling.

Danger of fingers burning!!.

1. Disconnect the mains.

Block the unit brakes.

Park the arm in the lowered position and activate the safety brake.

2. Remove the filters holder slides (4 screws).

3. Remove the rear cover (2 screws). Pay attention to wires.

Remove the handles (2 hexagonal, ø2mm).

Remove the top of the extractable meter (1 screw).

Disconnect the clamp of the lamp button (2 screws, no polarity) placed on the collimator side.

[File: W3010_Rev0.doc] 2 / 12

Page 38

PRACTIX 100 plus Replacement

4. Remove the front cover (pay attention not to break the extractable meter).

5. Remove the 4 screws of the front cover (2 long, 2 short).

Remove the second front cover (very carefully, this is not an easy operation).

[File: W3010_Rev0.doc] 3 / 12

Page 39

PRACTIX 100 plus Replacement

6. Remove the 2 screws and the spacers of the lamp protection cover.

7.

Do not touch the lamp, socket or lamp bracket with fingers. These could be very hot and

cause severe burns.

EVEN IF COLD, NEVER TOUCH THE LAMP WITH UNPROTECTED HANDS!!

Carefully remove the faulty lamp.

Replace the lamp with a new one type:

PHILIPS PROJECTION LAMP

Type 7023

FCR A1/215

12V 100W GY6.35

cod. 3222 617 51621 or 7222 613 32021

or equivalent

8. Make sure that the lamp pins are completely inserted in the lamp-holder.

9. Follow the foregoing steps from the bottom to re-mount the collimator assembly.

10. Before remounting the handles close both shutters and adjust the handle indicators.

[File: W3010_Rev0.doc] 4 / 12

Page 40

Monobloc replacement

This procedure can cause severe and serious damages to unit and/or operators.

Act VERY CAREFULLY while

How to arrange the unit for the replacement.

1.

Disconnect the unit from the mains.

Block the unit brakes.

Park the arm in horizontal position.

Properly stretch a stout belt or a rope

front leg. Make sure that the rope cannot slide towards the arm pivot. To perform this operation,

tightly bind the rope between the blocking handle for the rotation and the monobloc stirrup.

Furthermore, check that the rope is well stretched.

IMPORTANT: When the monobloc is removed from its support, a force at the arm

extremity directed to the

PRACTIX 100 plus Replacement

performing any operation.

(resisting to 100kgf/1000N at least) between arm and

top, will be present (of approx. 40kgf/400N).

[File: W3010_Rev0.doc] 5 / 12

Page 41

PRACTIX 100 plus Replacement

How to remove the monobloc cover.

2.

Remove the 2 protective cups and loosen the 2 screws placed in the upper part of the monobloc

cover.

Loosen the 4 screws placed in the lower part of the cover.

Remove the 2 covers.

[File: W3010_Rev0.doc] 6 / 12

Page 42

PRACTIX 100 plus Replacement

How to remove the monobloc.

3.

Loosen the 4 lateral screws and remove the monobloc cover support.

Disconnect the supply and signal cables from the monobloc: the connection is performed by tearing

clamps. No tool is required, except for the ground conductor.

ATTENTION: the following step is the most dangerous. The rope will be subjected

to a sudden tension of

stout the arm could arise suddenly, causin

several kgf (>60kgf); if rope and hitches are not properly

g really severe damages for the

operators around and the unit. Before removing the monobloc, it is adv

carefully stretch the rope as much as possible, so that it will be subjected to

fewer stresse

s.

Loosen the 4 nuts with plain and Grower washers which fix the monobloc to the support. This way,

the monobloc is completely free and, acting very carefully, can be removed.

For any reason, DO NOT REMOVE or UN-STRECTH the rope.

In this status the unit might be really dangerou

s, therefore, operate thus to let

the unit as less as possible in such condition.

None, except the tech

nician who will re-mount the monobloc, must approach the

unit.

Do not let the unit unguarded.

isable to

[File: W3010_Rev0.doc] 7 / 12

Page 43

PRACTIX 100 plus Replacement

How to re-mount the monobloc.

4.

Place the monobloc on the support.

Grip the 4 nuts by plain and Grower washers, in order to fix the monobloc to the support and make

sure that these are well gripped.

Connect to the monobloc the supply and signal cables: the connection is performed by tearing

clamps. No tool is required, except for the ground conductor.

Re-mount the monobloc cover support and grip the 4 lateral screws.

How to re-mount the monobloc cover.

5.

Re-mount the 2 covers.

Grip the 4 screws placed in the lower part of the cover.

Grip the 2 screws placed in the upper part of the monobloc cover.

Re-insert the 2 protective cups.

How to arrange the unit to the functioning.

6.

Make sure that the monobloc is well fixed.

Remove the rope ONLY after checking that it is not under tension anymore.

Perform the x-ray tube calibration (see the corresponding par.).

Perform the X-ray beam centering with the rotating adapter (see the corresponding par.).

Check the proper correspondence between X-ray beam and light field of the collimator.

[File: W3010_Rev0.doc] 8 / 12

Page 44

Collimator dismounting

Disconnect the unit from the mains.

1.

Block the unit brakes.

Park the arm in the lowered position and activate the safety brake.

Rotate upwards the monobloc/collimator group.

PRACTIX 100 plus Replacement

Remove the filters holder slides (4 screws).

2.

[File: W3010_Rev0.doc] 9 / 12

Page 45

PRACTIX 100 plus Replacement

Remove the rear cover (2 screws). Pay attention to wires.

3.

Disconnect the cables from the 4 clamps.

4.

Remove the cable clamp (fork wrench ø6mm) and withdraw the cable carefully.

signal cable clamp

lamp order (1) black 1

--2

+V1 (12V DC 9A) (3) brown 3

0V1 (4) blue 4

GND (2) yellow/green GND

[File: W3010_Rev0.doc] 10 / 12

Page 46

Withdraw the cable from the hole on the rear cover.

5.

PRACTIX 100 plus Replacement

6.

If the arm has not been previously blocked it may arise suddenly!!

Loosen the 4 grub-screws in the upper part of the collimator (warning: do not let the collimator fall).

[File: W3010_Rev0.doc] 11 / 12

Page 47

PRACTIX 100 plus Replacement

DOCUMENT STATUS

Rev. Date Page/s Modification description

0 Document approval

1

2

3

4

5

[File: W3010_Rev0.doc] 12 / 12

Page 48

PRACTIX 100 PLUS

ADJUSTMENTS

[File: W3012_Rev0.doc]

Page 49

PRACTIX 100 plus Adjustments

SUMMARY

ELECTRICAL ADJUSTMENTS 2

X-ray tube calibration ......................................................................................................................... 2

Trimmers...........................................................................................................................................2

MECHANICAL ADJUSTMENT 4

Collimator.......................................................................................................................................... 4

Alignment between X-ray beam and rotating adapter....................................................................... 4

Arm balancing adjustment.............................................................................................................. 7

Adjustment of the arm balancing clutch...............................................................................................8

Adjustment of the fork-monobloc clutch............................................................................................... 9

[File: W3012_Rev0.doc] 1/10

Page 50

PRACTIX 100 plus Adjustments

ELECTRICAL ADJUSTMENTS

The most important electrical adjustments are performed by the SERVICE MODE (see the

corresponding chapter). Therefore, it’s possible to modify the operating parameters even if the

unit cover is closed (risks and times are reduced).

The adjustments that require the cover removing are already performed by the manufacturer

during the unit checking and, usually, must not be re-performed.

X-ray tube calibration

See the chapt. “Service information” SERVICE MODE TUBE CALIBRATION option.

Trimmers

Every trimmer is properly set in factory. Regulations can be performed only if strictly

necessary. Un-proper regulations may be dangerous.

(CW= clockwise rotation, CCW= counterclockwise rotation)

Board Trimmer Value Test Point Function

B1

Keyboard

P1 - -

CW Increases the LCD contrast

Board Trimmer Value Test Point Function

B4

Charger

P1 25kHz TP4

P2

P3 6,80V max TP6

P4 6,9V max TP5

6µs

TP4 CCW Increases the Dead Time

CCW Increases the charger converter

working frequency

Sets the capacitors battery voltage

(Vc=680V)

CW Increases V

Reference voltage for capacitors supervisor

circuits.

CW Anticipates the safety circuit

intervention time

Board Trimmer Value Test Point Function

B5

Chopper

Control

P1 20kHz TP5

P2 -7,5V TP2

P3 -5,5V TP3

CW Increases the chopper working

frequency

Sets the Chopper output voltage to 375V.

CW Increases the output voltage.

Sets the Chopper max. output current to

55A.

CCW Decreases the Chopper max output

current

.

C

[File: W3012_Rev0.doc] 2/10

Page 51

PRACTIX 100 plus Adjustments

Board Trimmer Value Test Point Function

B7

Filament

*

ONLY FOR FACTORY TEST

P2*

P3 17kHz TP2

P4*

0÷4V

0÷7V

TP3 FIL DAC OUT simulation trimmer: enabled if

B4-JP2 is in “b-c” position.

CW Increases.

CCW Increases the filament working

frequency

TP1 mA SET signal simulation trimmer: enabled

if B4-JP3 is in “b-c” position (1V=20mA).

CW To increase.

Perform B11 board trimmers regulation with XR ENABLE and XR ORDER signals enabled, but

without high level power. Discharge the capacitors battery (procedure described in the chapter

“Fault finding” ) and remove the inverter feeding fuses B6-F1 and F2.

Board Trimmer Value Test Point Function

B11

Inverter

Control

P1 10,0Vmax TP3 Max output voltage of the error amp. (10V)

P2 16,6kHz IC9-1 Sets the inverter working frequency.

On IC9-1 a symmetrical square wave with

60µs period has to be measured.

P3 6,25Vmax TP4 Sets the max. kV SET voltage

(6,25V=125kV).

P4 25µs IC13-1 Sets the first IGBT “on” time.

The impulse is high active for 25µs.

P5

25µs

IC13-8 Sets the second IGBT “on” time.

The impulse is high active for 25µs.

[File: W3012_Rev0.doc] 3/10

Page 52

PRACTIX 100 plus Adjustments

MECHANICAL ADJUSTMENT

Collimator

Alignment between X-ray beam and rotating adapter

Warning: X-ray presence, use proper protections.

This adjustment has to be performed only in case of monobloc, rotating adapter or handle

replacement.

In order to obtain a proper balancing of X-ray source, anode and variable position of the rotating

adapter, perform the following operations:

1. Turn the unit OFF and park the arm in the lowered position, then upwards rotate the monobloc with

collimator.

2. Remove the collimator (see the corresponding chapter).

3. Mount the centering tool on the rotating adapter.

For this operation, plug the centering tool and rotate it until the 4 holes on the tool are aligned with

the 4 fixing bolts of the rotating adapter.

Unlock the arm and rotate the centering tool downwards.

4.

[File: W3012_Rev0.doc] 4/10

Page 53

PRACTIX 100 plus Adjustments

5. Turn the unit ON and wait for the “READY” signal.

6. Take all the radioprotective precautions, then set 60kV/10mAs and perform an exposure.

7. Expose the film and measure P and Q distances.

When the P and Q distances are lower than 1mm, the collimator is centered on the tube and no readjustment is needed.

[File: W3012_Rev0.doc] 5/10

Page 54

PRACTIX 100 plus Adjustments

8. If, on the basis of the measurement on the film, the rotating adapter is not centered, loosen the four

bolts which fix the rotating adapter to the tube, then move the rotating adapter and repeat

exposures on the film until the tolerance achieved is less than 1mm.

9. Switch the unit OFF.

10. Grip the four bolts which fix the rotating adapter and remove the centering tool.

11. Re-mount the collimator (see the corresponding chapter).

[File: W3012_Rev0.doc] 6/10

Page 55

PRACTIX 100 plus Adjustments

Arm balancing adjustment

The ideal weight balancing must be obtained with the arm in horizontal position.

The spring nut for the arm balancing is accessible from the bottom of the unit.

Its adjustment must be performed with a Ø19mm fix spanner.

The procedure is as follows:

1. Completely loosen the arm balancing clutch (see the following paragraph)

2. Completely arise the arm.

The hexagonal nut of the balancing spring is accessible from the bottom of the central column.

3. With a fixed spanner (Ø19mm) rotate the nut as follows:

• turn counterclockwise in order to increase the balancing compensation (if the arm goes down)

• turn clockwise in order to decrease the balancing compensation (if the arm goes up)

4. Adjust the arm balancing clutch (see the next paragraph)

[File: W3012_Rev0.doc] 7/10

Page 56

PRACTIX 100 plus Adjustments

Adjustment of the arm balancing clutch

The clutch function is to keep the arm in the wished position even if the proper balancing is not

exact.

Usually, the clutch is completely loosened during the weight balancing procedure, and then is

gripped until the arm is balanced in every position (even with the arm completely arose or

lowered) and the movement is perfectly smooth and regular.

To adjust the clutch:

1. Remove the cup that covers the clutch with a small screwdriver acting on the edge.

2. Using the special tool to adjustment the clutch and rotate the rod.

• Rotate counterclockwise to loosen the clutch.

• Rotate clockwise to grip the clutch.

3. Once the adjustment is performed, re-mount the plastic cup.

[File: W3012_Rev0.doc] 8/10

Page 57

PRACTIX 100 plus Adjustments

Adjustment of the fork-monobloc clutch

The clutch adjustment is necessary to obtain a smooth movement and to keep the monobloc in

the wished position.

In case the monobloc does not keep the wished position grip the clutch.

To adjust the clutch:

1. By means of a hexagonal male wrench loosen the 3 grub screws and remove the goniometer.

2. Using the special tool for the clutch adjustment, rotate the rod.

• Rotate counterclockwise to loosen the clutch.

• Rotate clockwise to grip the clutch.

3. Once the adjustment is performed, re-mount the plastic cup.

[File: W3012_Rev0.doc] 9/10

Page 58

PRACTIX 100 plus Adjustments

DOCUMENT STATUS

Rev. Date Page/s Modification description

0 Document approval

1

2

3

4

5

[File: W3012_Rev0.doc] 10/10

Page 59

PRACTIX 100 PLUS

FAULTS FINDING

[File: W3014_Rev0.doc]

Page 60

PRACTIX 100 plus Faults finding

SUMMARY

BOARDS POSITION 2

TROUBLESHOOTING GUIDE 3

Non-displayed faults........................................................................................................................... 3

Displayed faults .................................................................................................................................. 4

DESCRIPTION 8

Signals............................................................................................................................................... 8

Leds................................................................................................................................................ 16

Test point ........................................................................................................................................ 19

Fuses............................................................................................................................................... 22

Jumpers........................................................................................................................................... 23

Relays ............................................................................................................................................. 24

Timing diagrams............................................................................................................................... 25

Chopper IGBT driver.................................................................................................................... 25

Inverter IGBT drivers................................................................................................................... 25

CAPACITORS BATTERY 26

Description....................................................................................................................................... 26

Charging time.............................................................................................................................. 27

Natural discharging time .............................................................................................................. 27

Forced discharging time............................................................................................................... 27

Capacitors discharge procedure.................................................................................................... 28

DO NOT PERFORM HAZARDOUS OPERATIONS

ELECTICAL SHOCK DANGER

Even if the mains plug is disconnected a dangerous voltage can be

present inside the unit, if the capa

citors battery is not completely

discharged.

PERFORM THE DISCHARGE PROCEDURE

Before performing any operation on Capacitors Battery, Power Unit

and on the Inverter power circuits i

capacitors battery.

THE DISCHARGE PROCEDURE IS DESCRIBED AT THE END OF

CHAPTER.

t is necessary to discharge the

THIS

[File: W3014_Rev0.doc] 1/30

Page 61

BOARDS POSITION

&

R

PRACTIX 100 plus Faults finding

B1 - OPERATO

INTERF. BOARD

B9 - RELEASE MODE

SWITCH BOARD

S1 - POWER SUPPLY

(AC-DC)

inverter

IHF2011

B3 - IGNITION

STARTER BOARD

resist. R1

line switch SWL1

mains filter FT1

B7 - FILAMENT BOARD

S2 - POWER SUPPLY

(DC-DC)

B8 - HANDSWITCH

BOARD

B6 - POWER CHOPPER BOARD

B5 - CONTROL

CHOPPER BOARD

B2 - MANAGEMENT

PROCESSOR BOARD

B4 - CHARGER BOARD

cond. elect. C1

capacitors battery

inductor L1

capacitors battery

[File: W3014_Rev0.doc] 2/30

Page 62

PRACTIX 100 plus Faults finding

TROUBLESHOOTING GUIDE

Should a fault or a malfunctioning be detected, it is advisable to replace the boards (and not to

repair them). The boards provided will be already tested and adjusted.

In case of any adjustment, please refer to the chapter “Adjustments”.

Non-displayed faults

Problem Likely causes Remedy Point to Check

Check that the automatic main switch

placed on the right side of the unit is in

“I” position.

It is impossible to

turn the unit ON.

The MAINS signal

(yellow led) near

the ON push

button is OFF.

It is impossible to

perform X-ray.

The READY signal

(green led) on

panel is OFF.

Collimator lamp

doesn’t light up.

The unit is ON but

LCD is OFF.

a) Automatic main switch in “0”

position.

b) Leak of mains voltage.

c) Faulty power supply plug.

d) Faulty S1 power supplier.

In stand-by phase the voltage to

the capacitors battery is lower

than 600V.

Usually a branch of the capacitors

battery has exceeded 350V, the

CHARGER may not be properly

supplied or faulty.

The lamp fuse is burnt or the

lamp filament is interrupted.

a) B2 board (MPB) faulty or not

feeded.

b) B1 board (OIB) or LCD are

faulty.

Ensure the presence of the mains

voltage to the power supply socket.

Ensure that the mains voltage is present

inside the unit, the led Ld1 on B3 board

should be lighting up.

Check the S1-F1 fuse integrity as well as

its output voltage.

Check the B3-F5 fuse integrity, it feeds

the ignition circuit.

Check on B4 Charger board the

following:

- F2 fuse

- +VC FAULT and -VC FAULT signals

- CHARGER ENABLE signal

- DISABLE signal

B3-Ld6 led has to be ON. When OFF the

B3-F6 is faulty.

If the fuse is functioning properly,

replace the halogen lamp in the

collimator.

WARNING. Never handle the lamp glass

bulb with un-protected hands. In case of

accidental contact immediately wash

with water and soap, then dry with a

clean cloth.

Check on B2 board the following:

- the 5Vm voltage presence

- the efficiency of the flat cable CF1

connection between MPB and OIB.

SWL1“I”

B3-Ld1ON

S1-F1

B3-Tp1/Tp2 =13,2V

B3-F5

B4-F2

B4-Ld1OFF

B4-Ld2OFF

B2-Ld27ON

B4-Ld5ON

B4-Ld6ON

B4-Ld7ON

B3-Ld6ON

B3-F6

Collimator lamp.

B2-Tp1/Tp25Vm

B2-CF1

[File: W3014_Rev0.doc] 3/30

Page 63

Displayed faults

PRACTIX 100 plus Faults finding

Message on

Display

HAND SWITCH

ERR

V2 FAULT

CALL SERVICE

V3 FAULT

CALL SERVICE

POWER FAULT

CALL SERVICE

CHOPPER FAULT

Likely causes Remedy Point to Check

Upon the ignition the HS PRE

and/or HS RAD control is already

present.

The Handswitch might be faulty.

Lack of V2 power supply. S2

supplier is faulty, or the

Hardware safety circuit

intervention occurs.

Lack of V3 power supply.

The supplying fuses of the Power

Unit are burst or the S3 power

supplier is faulty.

A) Generated by CHARGER

FAULT (B4-Ld1 or Ld2 ON).

In the Capacitors Battery (CB)

there is an unbalancing between

the positive and negative

branches. Maybe a capacitor is

discharging, faulty, or a fuse

burst. Usually if the capacitor is

faulty, the fuse as a

consequence, burns.

B) CB has not achieved 650V

within approx. 120s from the

ignition.

Usually a capacitors battery

branch has exceeded 350V, or

the CHARGER is not supplied or

faulty.

C) Generated by CHOPPER

FAULT (B5-Ld2 ON).

The Chopper output voltage

exceeded 400V. The IGBT driver

circuit or the IGBT itself could be

faulty.

Chopper device error.

It is generated in preparation

phase if CHOPPER output is lower

than 320V (B5-Ld1 OFF).

Check the Handswitch functioning and

the integrity of its cable.

Ld17 and Ld18 leds, connected to the

MPB inputs, should be OFF without

controlling the Handswitch. If ON

replace the Handswitch.

If mounted, please check the optional IR

REMOTE CONTROL.

Check the fuse of S2 supplier.

Check on B2 board (MPB) the following:

- V2 OK signal

- CPU RUNNING signal.

Check on B3 board (I&S) the following:

- F1 and F2 fuses.

Check on Charger B4 board the

following:

- mains voltage presence,

- 320 VL continuos voltage,

- F1 fuse.

Before operating, make sure

that each capacitor is totally discharged

(see the end of this chapter).

If the voltage to the capacitors leads is

< than 280V, the corresponding green

led is OFF.

Check the integrity of the protection

fuses of every capacitor.

Check on the B4 Charger board the

following:

- F2 fuse

- +VC FAULT and -VC FAULT signals

- CHARGER ENABLE signal

- DISABLE signal

Enable X-ray preparation, and

check on B5 the following:

- CHARGER ENABLE signal

- VSET signal

- VFEED signal

- IGBT DRIVER signal

Check that there is not a short

circuit between Collector and Emitter of

the IGBT mounted on B6 board.

Enable X-ray preparation, and on

B5, check the following:

- CHOPPER ENABLE signal

- VSET signal

- IGBT DRIVER signal

HS PREB2-Ld18

HS RADB2-Ld17

S2-F1

B2-Ld1ON

B2-Ld19ON

B2-Ld4OFF

B3-F1 & F2

B4-Ld10ON

B4-F1

B4-Ld1OFF

B4-Ld2OFF

CB (1/2 left):

Ld1÷6ON

F1÷6

CB (2/2 right):

Ld1÷6ON

F1÷6

B4-F2

B4-Ld1OFF

B4-Ld2OFF

B2-Ld27ON

B4-Ld5ON

B4-Ld6ON

B4-Ld7ON

B2-Ld27ON

B5-Tp2-7,6Vmax

B5-Tp61V=50V

B5-TP12 / TP11

B2-Ld29ON

B5-Tp2-7,6Vmax

B5-TP12 / TP11

[File: W3014_Rev0.doc] 4/30

Page 64

PRACTIX 100 plus Faults finding

Message on

Display

STARTER

INTERLOCK

FILAMENT

CALL SERVICE

LACK OF X-RAY

Likely causes Remedy Point to Check

If during preparation phase the

start-current of the anode is not

sufficient or missing, no STARTER

READY signal is present (B3-Ld5

is OFF)

Min. safety current intervention

(green led B7-Ld2 OFF).

Filament current is absent or

lower than 220mA.

Likely causes:

a) Faulty filament fuse

b) Faulty filament board

c) Faulty DAC circuit on B3

board

d) Discontinued filament

Max. safety current intervention

(red led B7-Ld1ON).

The filament current has

exceeded for a while the

maximum allowed value

(>480mA).

Likely causes:

a) Faulty filament board

b) Faulty DAC circuit on B3

board

The kV value has not reached the

85% of the set value in the first

10ms of exposures, or there is

not high voltage.

Likely causes:

a) The inverter doesn’t send

kV>85% signal.

b) Chopper and Inverter

protective fuses are

discontinuos.

Check the following:

- integrity of B3-F3 and F4 fuses

- efficiency of the connection

between the B3 board and the

stator turns.

- STARTER ENABLE signal

- B3-K3 relay excitation

- STARTER RUN signal

Check on B7 board the

following:

- F1 fuse.

- the integrity of connection between

the board (B7-CM10) and the

filament (B10-CP2).

- ±15V2 supplier

- FIL DAC OUT signal (in standby=2,5V)

- FIL SET signal (in st.by = 3,5V)

- FIL CUR signal (1V=50mA)

- mA SET signal (1V=20mA)

Perform an exposure and

check the KV>85% signal presence on

the boards:

B11-Ld1ON

B2-Ld11ON

If the leds won’t light up discharge the

capacitors battery and check the B6-F1

and B6-F2 extra fast fuses integrity.

B3-F3 & F4

B3-CM3/CM4

B2-Ld22

B3-K3

B2-Ld20

B7-F1

B7-Tp5, Tp9, TP4

B7-Tp3

B7-Tp7

B7-Tp8

B7-Tp1

B11-Ld1

B2-Ld11

B6-F1 & F2

INVERTER KV

ERROR

a) High voltage circuit in the Xray assembly is unbalanced or kV

feed-back is not present during

an exposure or it is out of range.

The red led B11-Ld3 is on.

b) During X-ray emission the kV

decrease under 85%. The

Inverter missing the kV>85%

(during emission B11-Ld1 turns

OFF).

c) During X-ray emission the kV

increase over 110% of set value

(software control on TUBE KV

analog signal).

[File: W3014_Rev0.doc] 5/30

Perform an exposure and check on

the Inverter B11 board the following:

- KV FEED signal (1V = 20kV)

- the KV+ and kV- signals balancing

- kV>85% signal

- TUBE KV signal (1V = 20kV)

B11-Tp1

B11-Tp5 e Tp6

B11-Ld1ON

B2-Tp6

Page 65

PRACTIX 100 plus Faults finding

Message on

Display

INVERTER

OVERLOAD

INVERTER FAULT

MAX TIME

DATA ERR.

CALL SERVICE

ERR. TUBE CALIB.

CALL SERVICE

TUBE SEASONING

Likely causes Remedy Point to Check

Inverter current absorption is too

high (Ipk>300A).

Red led B11-Ld4 lights up.

Monobloc fault or too high

anodical current.

IGBT drivers error.

B11-Ld5 red led lights up.

The max exposure time (2s) has

been achieved.

XR ORDER circuit (X-ray order is

always ON) or the filament

control one (anodic mA too low)

might be faulty.

Checksum data error, memory

error. The EEPROM memory B2IC21 is faulty.

Data in the memory are out of

range. These could be wrong or

the EEPROM B2-IC21 faulty.

After a long period of un-use (3

months or more) it’s necessary to

perform the X-ray tube

seasoning, in order to avoid any

damage.

in preparation phase check on B7

board the following signals:

- FIL DAC OUT

- mA SET

- FIL CUR

in radiography phase

- ANODIC mA

- mA STABILIZATION

Perform an exposure. Replace the

Inverter if the fault persists.

Check that the B2-Ld24 led (XR ORDER

signal) is ON only during the X-ray time.

Check the anodic mA value; if umproper, check the following on B7 board:

- FIL DAC OUT signal

- mA SET signal

- FIL CUR signal

- mA STABILIZATION signal

Replace the B2-IC21 IC.

Perform the tube calibration, if the error

persists please replace B2-IC21 IC.

Perform the tube seasoning.

B7-Tp3

B7-Tp1 (1V=20mA)

B7-Tp8 (1V=100mA)

B11-Tp8 (1V=20mA)

B2-Ld26

B2-Ld24OFF

B11-Tp8 (1V=20mA)

B7-Tp3

B7-Tp1 (1V=20mA)

B7-Tp8 (1V=100mA)

B2-Ld26

[File: W3014_Rev0.doc] 6/30

Page 66

PRACTIX 100 plus Faults finding

Message on

Display

INACTIVE

Dosimeter

NOT OK

Likely causes Remedy Point to Check

The dosimeter chamber is active

but MPB does not recognize it.

The chamber is active but the

feedback pulses are out of range.

Check the following:

- the connection efficiency between

MPB board and DOSIMETER

- the 15Vd supply presence

- the TEST SIGNAL presence (B2-

Ld32 high active for 1s) at start-up.

Check the efficiency of the connection

between MPB board and DOSIMETER.

S2-7/8

B2-Ld32

215 < PULS > 275

[File: W3014_Rev0.doc] 7/30

Page 67

PRACTIX 100 plus Faults finding

DESCRIPTION

Signals

Power supplies signals

Mnemonic Signal description Path

MAIN SUPPLY

+V1

+12V1

± 15V2

Vd

Vm

VL

115V±10% mains voltage or 230V±10%, 50/60Hz. It is

connected to the ac/dc S1 power supplier and, through the

B3-K1 relay, to the Power Unit. The voltage presence is

indicated by the green led B3-Ld1.

The S1 power supplier generates the +V1 power supply

(13Vdc), it is present even if the unit is OFF. It supplies the

insertion circuit, the collimator and dc/dc S2 power

supplier. If voltage is present, the green led placed on the

keyboard near the “on” key, lights up.

This voltage is referred to GND.

The +V1 voltage supplies the B3-Q1-E transistor. Upon the

unit ignition, the Q1-C transistor transfers the +12V1=

(+V1- Vcesat) voltage to the starter checking circuits.

Furthermore, it supplies the Handswitch and the Infrared

Handswitch optional accessory.

The V2 power supply (±15Vdc) is generated by the S2

power supplier and is present upon the unit turning ON.

This voltage supplies the Hardware safety circuits and if no

fault is present, through the B2-K2 relay, also the Filament

and Inverter checking circuits and some in/out circuit on

MPB are supplied.

+15Vd power supply for dosimeter; generated by S2 and

not referred to GND.

+5Vm power supply for CPU; generated by S2 and not

referred to GND.

Rectified and filtrated mains voltage for the (320Vdc)

Charger and Filament power supply.

Its presence is indicated by the green led B4-Ld10.

ATTENTION! Circuits are not isolated from the mains,

(LIVE) danger of severe electrical shock.

Plug Filter B3 B4

S1 B3 Collimator

S1 B3

S2 B2

S2 B2 Dosimeter

S2 B5

Line B3 B4 B7

Ignition signals

Mnemonic Signal description Path

ON

OFF

S2 ENABLE

LINE 115

ON control by keyboard.

OFF control by keyboard.

Enabling signal for S2 power supplier. It is present with

the unit in “on” status.

It indicates to MPB if the unit is supplied at 230V or at

115V, in order to fix the start time and brake time of the

rotating anode.

Vrete=230V B3-Ld2=ON time=0,8s

Vrete=115V B3-Ld2=OFF time=1,6s

Trip point=150V

[File: W3014_Rev0.doc] 8/30

B1 B3

B1 B3

B3 S2

B3 B5

Page 68

PRACTIX 100 plus Faults finding

Hardware safety signals

Mnemonic Signal description Path

V2 OK

CPU RUNNING

MAX XR TIME

High active signal. In case of unbalancing between the V2

pos. and neg. the signal is missing, the red led B2-Ld2

lights up and the “V2 FAULT CALL SERVICE” alarm is

displayed. For safety reasons, the B2-K1/K2 relays are

disexcited, taking off the V1voltage to the X-ray key, ±V2

power supply to Inverter and Filament and the V3 to the

Charger/Chopper control signals. To reset the safety

status, turn the unit OFF.

High active signal. If the program blocks the signal is

missing and the red led B2-Ld4 lights up. For safety

reasons, the B2-K1/K2 relays are unexcited, taking off the

V1voltage to the X-ray key, ±V2 power supply to Inverter

and Filament and the V3 to the Charger/Chopper control

signals. To reset the safety status, turn the unit OFF.

Low active signal. In case the exposure time is > 2,1s (Red

led B2-Ld3 ON), the hardware safety blocks the unit

functioning. For safety reasons, the B2-K1/K2 relays are

unexcited, taking off the V1 voltage to X-ray key, ±V2

power supply to Inverter and Filament and V3 to the

Charger/Chopper control signals. To reset the safety

status, turn the unit OFF.

B2

B2

B2

X-ray control signals

Mnemonic Signal description Path

HS COM

HS PRE

HS RAD

THERMAL SAFETY

REALISE MODE

SWITCH

Handswitch +12V1power supply. It is selected by the

hardware safety circuit through the B2-K2 relay.

X-ray preparation request of the “dead man” type.

(Yellow led B2-Ld18 ON).

X-ray request of the “dead man” type. (Yellow led B2-Ld17

ON).

It is active with the medium temperature > 57°C of the

monobloc (Yellow led B2-Ld6 OFF).

Its intervention let the eventual current exposure complete,

then the “HOT TUBE” message is displayed and any other

X-ray request is blocked, until the monobloc returns to a

lower temperature.

Slide switch at two positions that allows the selection of the

X-ray request; Handswitch or Infrared remote control.

The mounting in series of the Infrared remote control is

not foreseen.

HS B8 B3-B2

HS B8 B3-B2

HS B8 B3-B2

B3 Monob B3 B2

B9

[File: W3014_Rev0.doc] 9/30

Page 69

PRACTIX 100 plus Faults finding

Charger signals

Mnemonic Signal description Path

V3

Vc

+VC

-VC

V3 OK

CHARGER ENABLE

CHARGER FAULT

BAT DISC

VBAT

RES

DISABLE

CHARGER OFF

STOP

±15V3 power supply for the Chopper and Charger checking

circuits. Voltages presence is indicated by the green led B4Ld9 (+) and B4-Ld8 (-). This voltage is referred to GND.

Voltage to the capacitor battery leads (±350Vc); the 0Vc is

connected to GND.

ATTENTION! If capacitors haven’t been discharged this

voltage is present even if the unit is OFF and unplugged.

The natural discharge requires approx.3h. the capacitor

charging status is indicated by the green led B4-Ld3

(branch +) and B4-Ld4 (branch -), that light up to 35V

voltage per each branch. It’s possible to discharge the

battery instantaneously operating by the keyboard

(SERVICE MODE DIAGNOSTIC menu CAPACITORS

option) or pressing the red button B4-PB1 for a while.

ATTENTION! Before operating on the Power Unit verify, by

means of a Voltmeter, that every capacitor is completely

discharged. Do not perform risky operations. Dangers of

severe electrical shock even if the unit is OFF.

Voltages feedback of the capacitors battery positive and

negative branches. They are also used in the unbalancing

circuit and voltage max safety. The unbalancing is

indicated by the red leds B4-Ld1(+) and B4-Ld2 (-).

It is generated by the ±15V3 supply voltage supervisor. In

case the V3 power supplier is faulty, the green led B4-Ld11

is OFF and the “V3 FAULT CALL SERVICE” alarm is

displayed.

Capacitors charge enable signal. It is generated by MPB

upon the “start up test” end, and disappears during X-ray.

High active when the voltage of a capacitor battery branch

is higher then 350Vc. If it is active the capacitor charge is

blocked via hardware and “POWER FAULT CALL SERVICE”

is displayed.

For safety reasons, the Chopper Fault signal trigs the

capacitors battery discharge.

The discharge can be also activated by keyboard in

SERVICE MODE DIAGNOSTIC menu CAPACITORS

option. The lighting up of the red led B4-Ld12 indicates the

discharging circuit trig.

Analogic signal for the battery voltage measurement in

1/100 format in the 0-7V range. It is converted into

frequency on MPB (1V2kHz), to indicate the battery

voltage.

Initial active low reset. It is generated upon the ignition

and blocks the battery charge for approx.500ms.

When high active it blocks the converter for the battery

charge. The yellow led B4-Ld5 is OFF.

Generated when the capacitor battery reaches the

requested charging value. (±340Vc). Its typical hysteresis is

of 5Vc. The signal is low active.

Safety signal generated by a chopper fault condition or a

battery discharge. The signal is active and permanent. To

deactivate it, turn the unit OFF and ON again.

B4

B4 Cap.Bat B5

B4

B4 B2

B2 B4

B4 B2

B2 B4

B4 B2

B4

B4

B4

B4

[File: W3014_Rev0.doc] 10/30

Page 70

PRACTIX 100 plus Faults finding

Charger signals

Mnemonic Signal description Path

+VC FAULT

-VC FAULT

SCR ON

High active safety signals. The capacitor charge is blocked

when the voltage of a battery branch is more than 350V.

(the checking circuit of the charge could be faulty or an

unbalancing between the positive and negative branches of

the battery has happened). The intervention is indicated by

red leds B4-Ld1(+) or B4-Ld2 (-) and the “POWER FAULT”

alarm is displayed. To reset the block, turn the unit OFF

and ON again.

Safety signal. It is active if the discharging thyristor B4-TH2

is “on”, in this status the battery is blocked. The charge is

automatically enabled when TH2 returns in “off” status.

B4

B4

Control Chopper & Chopper signals

Mnemonic Signal description Path

V3

±15V mains voltage for the Charger and Chopper checking

circuits. This voltage is referred to GND.

B4 B5

Va

CHOPPER ENABLE

CHOPPER READY

CHOPPER FAULT

ISET

VSET

EN

IEA

VEA

SEA

FAULT

±13V mains voltage for the IGBT driver.

It is generated from a dc/dc of +15V3.

ATTENTION! this voltage is NOT referred to ground but

connected to Vc. Danger of electrical shock.

This signal is generated by MBP for the Chopper

enablation. In stand-by status the chopper output voltage

is kept at 320Vdc max. During preparation, or X-ray, it

reaches 380Vdc max.

This signal is high active when the chopper output voltage

is more than 320V. To allow X-rays the signal must be

active.

High active high signal. If, and anytime, the Chopper

output voltage is >400V, the signal is generated, blocking

the Chopper and Charger functioning. For safety reasons,

the capacitor battery discharge is automatically trigged.

The ”POWER FAULT CALL SERVICE” alarm is displayed.

Setting of the max. output current from the Chopper in

1V10A (B5-TP3) format. Typical value: 50A.

Setting of the max output voltage from the Chopper in

1V50V (B5-TP2) format. Typical value: 370V.

In case of high signal, the error amplifier outputs and the

PWM circuit output are activated.

Output signal of the current error amplifier.

Output signal of the voltage error amplifier.

Sum signal of the error amplifiers. If the signal is at low

level, the Chopper power transistor is interdicted.

Equal to the “Chopper fault” signal, but low active. It

blocks the transfer of the PWM signal to the IGBT Driver.

B5

B2 B4 B5

B5 B4 B2

B5 B4 B2

B5

B5

B5

B5

B5

B5

B5

[File: W3014_Rev0.doc] 11/30

Page 71

PRACTIX 100 plus Faults finding

Starter signals

Mnemonic Signal description Path

STARTER ENABLE

STARTER RUN

STARTER BRAKE

STARTER READY

PRINC

SHIFT

COM

Safety signal generated by high active MPB. It controls the

B3-K3 relay, that selects the TH1/TH2 Triac and the mains

stator.

The relay is controlled so that its contacts always close and

open in “zero power” status, therefore with “off” Triacs.

Generated by the high active MPB that, by means of TH1

and TH2 Triac, let the rotating anode stator run.

The start time is fixed by the mains voltage and controlled

by MPB: 230V0,8sec; 115V1,6sec.

Generated by high active MPB guiding the TH2 Triac.TH2

supplies only in half wave the stator main wrapping, aimed

to block the anode during the rotation.

The brake time is fixed by the mains voltage and controlled

by MPB 230V0,8sec; 115V1,6sec.

Braking can be disenabled in set up phase.

(SERVICE MODE SETUP menu Brake OFF).

High active signal (B3-Ld5 ON), present during the

whole starting phase, if currents flowing in the stator are

higher than the pre-fixed minimum. If currents do not

exceed the minimum fixed, the “STARTER INTERLOOK”

alarm is displayed.

Principal winding (R=20Ω).

ATTENTION! Danger of electrical shock, mains voltage.

Shift winding (R=50Ω).

ATTENTION! Danger of electrical shock, mains voltage.

Common windings.

ATTENTION! Danger of electrical shock, mains voltage.

B2 B3

B2 B3

B2 B3

B3 B2

B3 Monobloc

B3 Monobloc

B3 Monobloc

[File: W3014_Rev0.doc] 12/30

Page 72

Label Signal description Path

VL

FIL DAC OUT

FIL SET

FIL CUR

mA SET

ANODIC mA

mA STABILIZATION

FILAMENT READY

PRACTIX 100 plus Faults finding

Filament signals

Rectified and filtrated mains voltage (320Vdc) to supply the

filament and its power circuit (half bridge). The fuse B7-F1

of 1A selects it. Attention! Mains voltage circuits. Danger

of electrical shock.

Voltage generated by MPB for the filament ignition. In

stand by its value is +2V. In preparation, it is in function of

the kV and mAs set parameters and can reach +4V.

Control voltage for the filament ignition with the

1V100mA format. Its value is determined by the FIL DAC

OUT voltage added to 1V.

[ V FIL SET = V FIL DAC OUT + 1 ]

Voltage proportional to the filament current with 1V50mA

format. Its max filament current is of approx. 480mA.

Voltage generated by MBP comprised between +3,7V at

+7,0V. It is sent to the automatic adjustment circuit of the

anodic current, as reference voltage. Its value is in function

of the set kV and mAs parameters; the correspondence is

1V20mA.

Voltage generated by the tube anodic current; the

correspondence is 1V20mA, between 0 and 7V. This

signal is sent to the filament, as feedback, for the mA

adjustment and to MPB for the mAs counting, therefore it

determines the exposure block.

High active signal generated by MPB. It enables the circuit

of the automatic adjustment for the anodic current. For

safety reasons it is cut from the Handswitch and is active

only during X-ray.

This signal is high active (B7-Ld2 ON) if the filament

current is comprised between 220mA and 480mA. A

current out of range blocks the unit functioning and the

“FILAMENT CALL SERVICE” alarm is displayed. If the alarm

has been generated by a current > than 480mA the red led

B7-Ld1 lights up and stores the intervention of the max.

current safety. This safety intervention excites the B7-K1

relay, cutting the filament, to protect it from over-current.

To reset the safety status, turn the unit OFF.

Line B3 B4 B7

B2 B7

B2 B7

B2

B2 B7

Monob B11 B2

B7

B2 B7

B7 B2