Philips Power Semiconductor Service Manual

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

CHAPTER 2

Switched Mode Power Supplies

2.1 Using Power Semiconductors in Switched Mode Topologies

(including transistor selection guides)

2.2 Output Rectification

2.3 Design Examples

2.4 Magnetics Design

2.5 Resonant Power Supplies

103

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Using Power Semiconductors in Switched Mode Topologies

105

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

2.1.1 An Introduction to Switched Mode Power Supply

Topologies

Formanyyearstheworldof power supply designhas seen

a gradual movement away from the use of linear power

suppliestothemorepracticalswitchedmodepower supply

(S.M.P.S.). The linear power supply contains a mains

transformer and a dissipative seriesregulator. Thismeans

the supply has extremely large and heavy 50/60 Hz

transformers, and also very poor power conversion

efficiencies,both seriousdrawbacks. Typical efficienciesof

30% are standard for a linear. This compares with

efficiencies of between 70 and 80%, currently available

using S.M.P.S. designs.

Furthermore,by employing high switching frequencies, the

sizes of the power transformer and associated filtering

components in the S.M.P.S. are dramatically reduced in

comparison to the linear. For example, an S.M.P.S.

operating at 20kHz produces a 4 times reduction in

component size, and this increases to about 8 times at

100kHz and above. This means an S.M.P.S. design can

producevery compactand lightweightsupplies.This isnow

an essential requirement for the majority of electronic

systems.The supply must slot into an ever shrinking space

left for it by electronic system designers.

Outline

At the heart of theconverter is the highfrequency inverter

section, where the input supply is chopped at very high

frequencies(20to200kHzusingpresenttechnologies) then

filtered and smoothed to produce dc outputs. The circuit

configuration which determines how the power is

transferred is called the TOPOLOGY of the S.M.P.S.,and

is an extremely important part of the design process. The

topology consists of an arrangement of transformer,

inductors, capacitors and power semiconductors (bipolar

or MOSFET power transistors andpower rectifiers).

Presently, there is a very wide choice of topologies

available, each one having its own particular advantages

and disadvantages, making it suitable for specific power

supply applications. Basic operation, advantages,

drawbacks and most common areas of use for the most

commontopologies arediscussed inthe followingsections.

A selection guide to the Philips range of power

semiconductors (including bipolars, MOSFETs and

rectifiers) suitable for usein S.M.P.S. applications isgiven

at the end of each section.

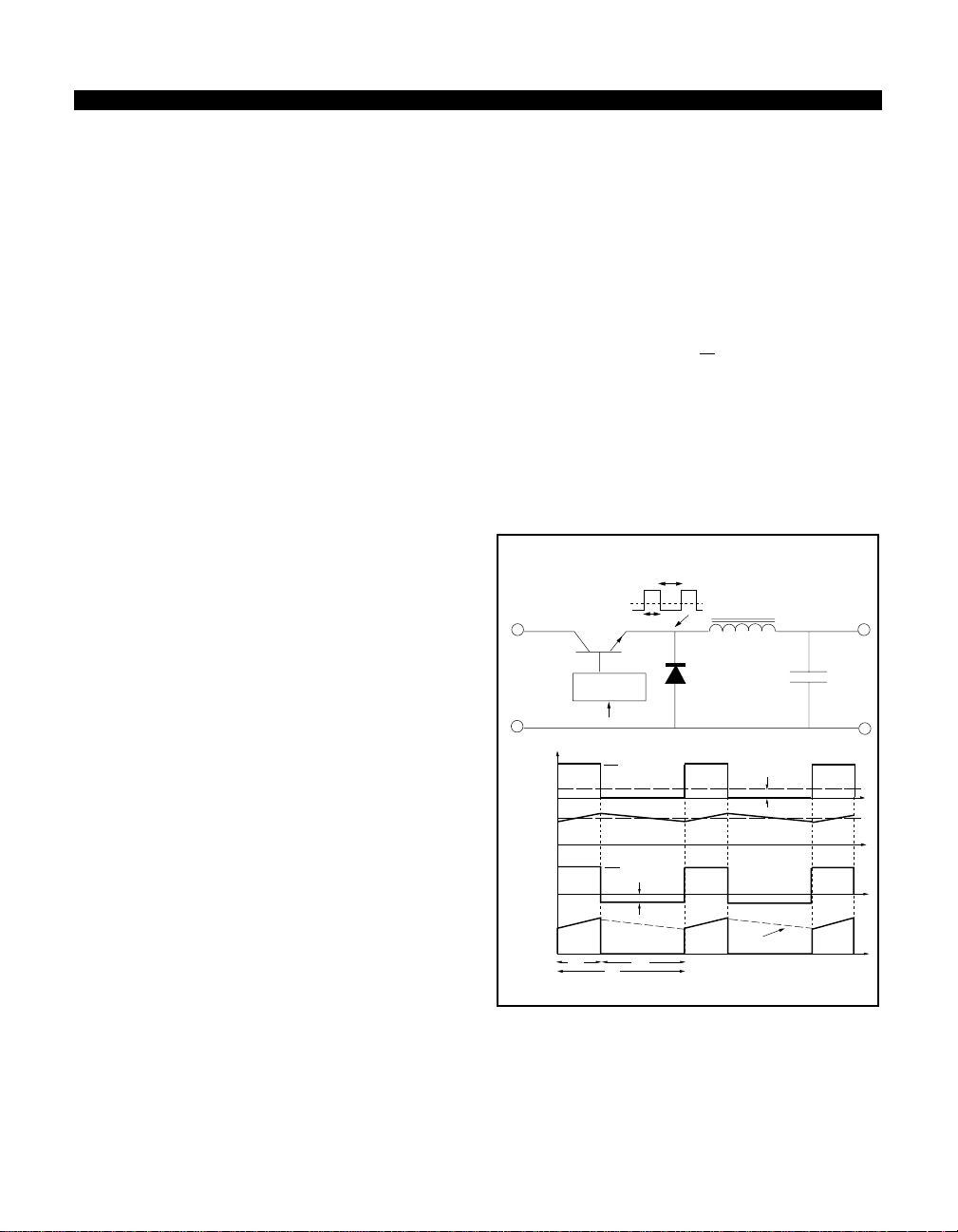

(1) Basic switched mode supply circuit.

An S.M.P.S. can be a fairly complicated circuit, as can be

seen from the block diagram shown in Fig. 1. (This

configuration assumes a 50/60Hz mains input supply is

used.) The ac supply is first rectified, and then filtered by

the input reservoir capacitor to produce a rough dc input

supply. This level can fluctuate widely due to variations in

the mains. In addition the capacitance on the input has to

be fairly large to hold up the supply in case of a severe

droop in the mains. (The S.M.P.S. can also be configured

tooperate fromany suitable dcinput, in thiscase thesupply

is called a dc to dc converter.)

ac input

supply

Input rectification

and filtering

duty cycle

High

Frequency

switch

mosfet or

control

bipolar

T

control

circuitry

Power

Transformer

PWM

OSC

Output rectification

and filtering

Vref

Fig. 1. Basic switched mode power supply block diagram.

107

dc output

voltage

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Theunregulated dc isfed directly to the central block of the

supply, the high frequency power switching section. Fast

switchingpowersemiconductordevices suchas MOSFETs

and Bipolars are driven on and off, and switch the input

voltage across the primary of the power transformer. The

drive pulses are normally fixed frequency (20 to 200kHz)

and variable duty cycle. Hence, a voltage pulse train of

suitable magnitude and duty ratio appears on the

transformer secondaries. This voltage pulse train is

appropriately rectified, and then smoothed by the output

filter, which is either a capacitor or capacitor / inductor

arrangement, depending upon the topology used. This

transferofpowerhas tobe carriedout withthelowest losses

possible, to maintain efficiency. Thus, optimum design of

thepassive andmagnetic components, andselection ofthe

correct power semiconductors is critical.

Regulation of the output to provide a stabilised dc supply

is carried out by the control / feedback block. Generally,

mostS.M.P.S. systemsoperateon a fixed frequency pulse

width modulation basis, where the duration of the on time

ofthe drive to the power switch is varied on acyclebycycle

basis. This compensates for changes in the input supply

and output load. The output voltage is compared to an

accurate reference supply, and theerror voltageproduced

by the comparator is used by dedicated control logic to

terminatethedrivepulsetothe mainpower switch/switches

atthe correct instance. Correctly designed, this will provide

a very stable dc outputsupply.

It is essential that delays in the control loop are kept to a

minimum,otherwisestabilityproblemswouldoccur. Hence,

veryhigh speed components must be selected forthe loop.

In transformer-coupled supplies, in order to keep the

isolation barrier intact, some type of electronic isolation is

required in the feedback. Thisis usually achievedby using

asmall pulse transformer or anopto-isolator,hence adding

to the component count.

In most applications, the S.M.P.S. topology contains a

power transformer. This provides isolation, voltagescaling

through the turns ratio, and the ability to provide multiple

outputs. However, there are non-isolated topologies

(without transformers) such as the buck and the boost

converters, where the power processing is achieved by

inductive energy transfer alone. All of the more complex

arrangements are based on thesenon-isolated types.

(2) Non-Isolated converters.

The majority of the topologies used in today’s converters

are all derived from the following three non-isolated

versions called the buck, the boost and the buck-boost.

These are the simplest configurations possible, and have

the lowest component count, requiring only one inductor,

capacitor, transistor and diode to generate their single

output.If isolation between theinputand output is required,

a transformer must be includedbefore the converter.

(a) The Buck converter.

The forward converter family which includes thepush-pull

and bridge types, are all based on the buck converter,

shown in Fig. 2. Its operation is straightforward. When

switch TR1 is turned on, the input voltage is applied to

inductor L1 and power is delivered to the output. Inductor

current also builds up according to Faraday’s law shown

below:-

dI

V =L

dt

When the switch is turned off, the voltage across the

inductor reverses and freewheel diode D1 becomes

forwardbiased.Thisallows theenergystoredin theinductor

tobe deliveredto theoutput. Thiscontinuous currentis then

smoothedby outputcapacitor Co. Typical buck waveforms

are also shown in Fig. 2.

toff

T = ton + toff

Vin

Applied

voltage

Inductor

current

Inductor

voltage

TR1

current

v

A

0

I

L

0

V

L

0

Iin

0

ton toff

TR1

CONTROL

CIRCUIT

ton

Vo

Vin

Vin - Vo

Vo

T

Fig. 2 Buck Regulator (step-down).

The LC filter has an averaging effect on the applied

pulsating input, producinga smoothdc output voltageand

current, with very small ripple components superimposed.

The average voltage/sec across the inductor over a

complete switching cycle must equal zero in the steady

state. (The same applies toall ofthe regulatorsthat willbe

discussed.)

L1

D1

Vo

I

D

Continuous mode

Vo

Co

Io

t

t

t

t

108

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Neglecting circuit losses, the average voltage at the input

side of the inductor is VinD, while Vois the output side

voltage. Thus, in the steady state, for the average voltage

acrossthe inductor to bezero, the basic dcequation ofthe

buck is simply:-

V

o

= D

V

i

D is the transistor switch duty cycle, defined as the

conduction time divided by one switching period, usually

expressed in the form shownbelow:-

t

on

; where T =t

D =

T

on+toff

Thus,thebuck isa stepdowntype, wherethe outputvoltage

isalwayslower thantheinput.(Since Dnever reachesone.)

Output voltage regulation is provided by varying the duty

cycle of the switch. The LC arrangement provides very

effective filtering of the inductor current. Hence, the buck

and its derivatives all have very low output ripple

characteristics. The buck is normally always operated in

continuous mode ( inductor current never falls to zero)

where peak currents are lower, and the smoothing

capacitor requirements are smaller. There are no major

control problems with the continuous mode buck.

(b) The Boost Converter.

Operation of another fundamental regulator, the boost,

shown in Fig. 3 is more complex than the buck. When the

switch is on,diode D1 is reversebiased, and Vinis applied

across inductor, L1. Current builds up in the inductor to a

peak value, either from zero current in a discontinuous

mode, or an initial value in the continuousmode. When the

switch turns off, the voltage across L1 reverses, causing

thevoltage at the diode to rise above the input voltage.The

diodethen conductsthe energy stored inthe inductor, plus

energy direct from the supply to the smoothing capacitor

and load. Hence, Vois always greater than Vin, making this

a stepup converter. For continuous mode operation, the

boost dc equation is obtained by a similar process as for

the buck, and is givenbelow:-

V

1

o

=

V

1− D

i

Again, the output only depends upon the input and duty

cycle.Thus, by controlling the duty cycle, outputregulation

is achieved.

From the boost waveforms shown in Fig. 3, it is clear that

thecurrent supplied to the output smoothingcapacitor from

the converter is the diode current, which will always be

discontinuous. This means that the output capacitor must

be large, with a low equivalent series resistance (e.s.r) to

produce a relatively acceptable output ripple. This is in

contrast to the buck output capacitor requirements

describedearlier.Ontheother hand,the boostinput current

is the continuous inductor current, and this provides low

input ripple characteristics. The boost is very popular for

capacitive load applications such as photo-flashers and

batterychargers.Furthermore, thecontinuous inputcurrent

makestheboost apopularchoice asapre-regulator,placed

before the main converter. The main functions being to

regulate the input supply, and to greatly improve the line

powerfactor. This requirementhas become very important

in recent years, in a concertedeffort to improve the power

factor of the mains supplies.

TR1

CONTINUOUS MODE

D1

Vo

Co

t

I

in

t

Io

t

t

Vin

TR1

voltage

Inductor

current

Diode

current

TR1

current

V

ce

0

I

L

0

I

D

0

0

Vo

CONTROL

CIRCUIT

Vo

ton toff

T

L1

Fig. 3 Boost Regulator (step-up).

If the boost is used in discontinuous mode, the peak

transistor and diode currentswill behigher, andthe output

capacitor will need to be doubled in size to achieve the

sameoutput rippleas in continuousmode. Furthermore, in

discontinuous operation, the output voltage also becomes

dependent on the load, resulting in poorerload regulation.

Unfortunately, there are major control and regulation

problems with the boost when operated in continuous

mode. The pseudo LC filter effectively causes a complex

second order characteristic in the small signal (control)

response. In the discontinuous mode, the energy in the

inductorat the startof each cycle is zero. Thisremoves the

inductancefrom the small signalresponse, leaving only the

output capacitance effect. This produces a much simpler

response, which is far easierto compensate and control.

109

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

(c) The Buck-Boost Regulator

(Non-isolated Flyback).

Thevery popular flyback converter(see section 5(a)) is not

actually derived solely from the boost. The flyback only

delivers stored inductor energy during the switch off-time.

The boost, however, also delivers energy from the input.

The flyback is actually based on a combined topology of

the previous two, called the buck-boost or non isolated

flyback regulator. This topology isshown in Fig. 4.

Vin

Vo

TR1

CONTROL

CIRCUIT

Step up / down Polarity inversion

D1

L1

Fig. 4 Buck-Boost (Flyback) Regulator.

When the switch ison, thediode isreverse biased andthe

inputis connectedacrossthe inductor,whichstores energy

as previously explained. At turn-off, the inductor voltage

reverses and the stored energy is then passed to the

capacitor and load through the forward biased rectifier

diode.

-Vo

Co

The waveforms are similar to the boost except that the

transistorswitch now has to support thesum of Vinand Vo

across it. Clearly, both the input and output currents must

be discontinuous. There is also a polarity inversion, the

output voltage generated is negative with respect to the

input. Close inspection reveals that the continuous mode

dc transfer function is asshown below:-

V

D

o

=

V

1− D

i

Observation shows that the value of the switch duty ratio,

D canbe selected such that the output voltage can either

be higher or lower than the input voltage. This gives the

converter the flexibility to either step up or step down the

supply.

Thisregulator also suffers from the same continuous mode

control problems as the boost, and discontinuous modeis

usually favoured.

Since both input and output currents are pulsating, low

ripple levels are very difficult to achieve using the

buck-boost. Very large outputfilter capacitorsare needed,

typically up to 8 timesthat of a buck regulator.

The transistor switch also needs to be ableto conduct the

highpeakcurrent,aswellas supportingthehigher summed

voltage.Theflyback regulator(buck-boost) topologyplaces

the most stress on the transistor. The rectifier diode also

hasto carry high peak currentsandso the r.m.s conduction

losses will be higher thanthose of the buck.

110

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

(3) Transformers in S.M.P.S. converters.

The non-isolated versions have very limited use, such as

dc-dcregulators onlycapable of producing asingle output.

Theoutput range is also limited by the input and dutycycle.

The addition of a transformer removes most of these

constraints and provides a converter with the following

advantages:-

1) Input to output isolation is provided. This is normally

alwaysnecessaryfor 220/ 110V mainsapplications, where

a degree of safety isprovided for the outputs.

2) The transformer turns ratio can be selected to provide

outputs widely different from the input; non-isolated

versions are limited to a range of approximately 5 times.

By selecting the correct turns ratio, the duty cycle of the

converter can also be optimised and the peak currents

flowing minimised. The polarity of each output is also

selectable, dependent upon the polarity of the secondary

w.r.t the primary.

3) Multiple outputs are very easily obtained, simply by

adding more secondary windings tothe transformer.

There are some disadvantages withtransformers, suchas

theiradditional size,weight and powerloss. Thegeneration

of voltage spikes due to leakageinductance may alsobe a

problem.

Theisolatedconverters tobecovered aresplitintotwo main

categories, called asymmetrical and symmetrical

converters, depending upon how the transformer is

operated.

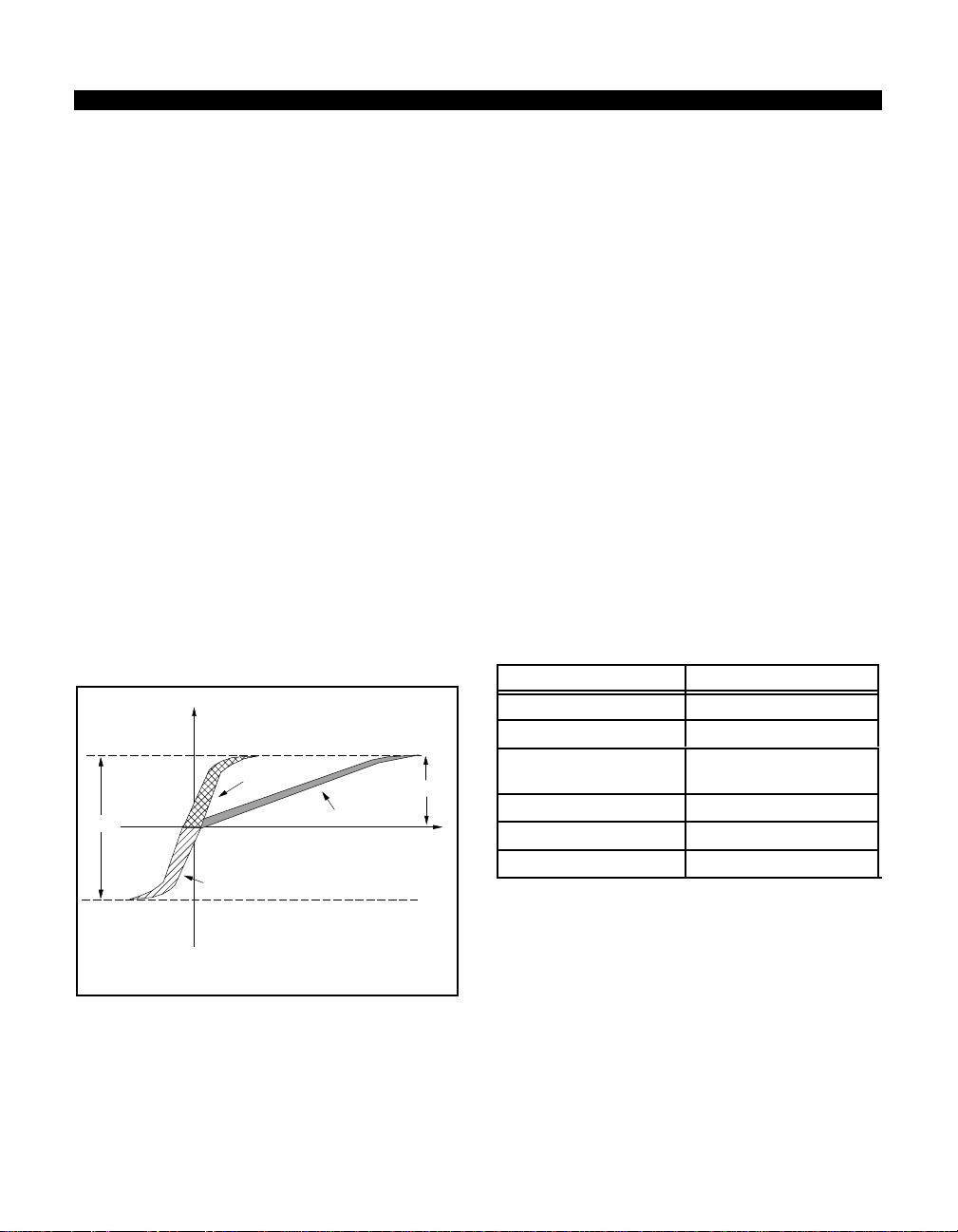

B

asymmetrical

converters

forward

symmetrical

converters

2Bs

Fig. 5 Comparative core usage of asymmetrical and

symmetrical converters.

converter

symmetrical

converters

available

flux swing

flyback

converter

Bs

H

Inasymmetrical convertersthemagnetic operatingpoint of

the transformer is always in one quadrant i.e the flux and

the magnetic field never changes sign. Thecore has to be

reseteachcycle toavoid saturation, meaning that only half

of the usable flux is ever exploited. This can be seen in

Fig. 5, which shows the operating mode of eachconverter.

The flyback and forward converter are both asymmetrical

types.Thediagramalso indicatesthat theflyback converter

is operated at a lower permeability (B/H) and lower

inductance than the others. This is because the flyback

transformeractuallystoresalloftheenergy beforedumping

into the load, hence an air gap is required to store this

energyand avoidcoresaturation. Theair gap hastheeffect

of reducing the overall permeability of the core. All of the

other converters have true transformer action and ideally

store no energy, hence, noair gap is needed.

Inthesymmetrical converterswhichalways requirean even

number of transistor switches, the full available flux swing

in both quadrants of the B / H loop is used, thus utilising

the core much more effectively. Symmetrical converters

cantherefore producemore power thantheir asymmetrical

cousins. The 3 major symmetrical topologies used in

practiceare thepush-pull, the half-bridgeand thefull bridge

types.

Table 1 outlines the typical maximum output power

available from each topology using present day

technologies:-

Converter Topology Typical max output power

Flyback 200W

Forward 300W

Two transistor forward / 400W

flyback

Push-pull 500W

Half-Bridge 1000W

Full-Bridge >1000W

Table 1. Converter output power range.

Manyother topologies exist, butthe types outlined in Table

1 are by far the most commonly used in present S.M.P.S.

designs. Each is now looked at in more detail, with a

selection guide for the most suitable Philips power

semiconductors included.

111

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

(4) Selection of the power

semiconductors.

The Power Transistor.

The two mostcommon power semiconductorsused in the

S.M.P.S.arethe Bipolartransistorand thepowerMOSFET.

The Bipolar transistor is normally limited to use at

frequencies up to 30kHz, due to switching loss. However,

it has very low on-state losses and is a relatively cheap

device, making it the most suitable for lower frequency

applications.The MOSFETis selected forhigher frequency

operation because of its very fast switching speeds,

resulting in low (frequency dependent) switching losses.

The driving of the MOSFET is also far simpler and less

expensive than thatrequired for theBipolar. However, the

on-state losses of the MOSFET are far higher than the

Bipolar, and they are also usually more expensive. The

selection of which particular device to use is normally a

compromise between the cost, and the performance

required.

(i) Voltage limiting value:After deciding uponwhether to use a Bipolar orMOSFET,

the next step in deciding upon a suitable type is by the

correct selection of the transistor voltage. For transformer

coupled topologies, the maximum voltage developed

across the device is normally at turn-off.This willbe either

half,fullordoublethemagnitude ofthe inputsupply voltage,

dependent upon the topology used. There may also be a

significant voltage spike due to transformer leakage

inductance that must be included. The transistor must

safely withstand these worst case values withoutbreaking

down. Hence, for a bipolar device, a suitably high V

must be selected, and for a MOSFET, a suitably high

V

.Atpresent 1750V is themaximum blocking voltage

BR(DSS)

available for power Bipolars,and a maximum of 1000V for

power MOSFETs.

The selection guides assume that a rectified220V or 110V

mainsinput is used. The maximum dc link voltages that will

be produced for these conditions are 385V and 190V

respectively.Thesevalues arethe inputvoltage levelsused

to select the correct devicevoltage rating.

(ii) Current limiting value:The Bipolar device has a very low voltage drop across it

during conduction, which is relatively constant within the

rated current range. Hence, for maximum utilisation of a

bipolar transistor, it should be run close to its I

This gives a good compromise between cost, drive

requirements and switching. The maximum current for a

particularthroughputpower iscalculated for each topology

Csat

ces(max)

value.

using simple equations. These equations are listed in the

appropriatesections,andthe levelsobtainedused toselect

a suitable Bipolar device.

The MOSFET device operatesdifferently from the bipolar

in that the voltage developed across it (hence, transistor

dissipation) is dependent upon the current flowingand the

device "on-resistance" which is variable with temperature.

Hence, the optimum MOSFET for a given converter can

onlybechosen onthe basisthatthedevicemust notexceed

a certain percentageof throughput (output) power.(In this

selection a 5% loss in the MOSFET was assumed). A set

of equations used to estimate the correct MOSFET R

DS(on)

valuefor a particular power level has been derived foreach

topology. These equations are included in Appendix A at

the end of the paper. The value of RDS(on) obtained was

then used to select a suitable MOSFET device for each

requirement.

NOTE! This method assumes negligible switching losses

in the MOSFET. However for frequencies above 50kHz,

switching losses become increasingly significant.

Rectifiers

Two types of output rectifier are specified from the Philips

range. For very low output voltages below 10V it is

necessarytohaveanextremely lowrectifierforwardvoltage

drop,VF,inorder tokeep converterefficiency high.Schottky

typesare specifiedhere,since theyhave verylowVFvalues

(typically 0.5V). The Schottky also has negligible switching

losses and can be used at very high frequencies.

Unfortunately,theverylowVFoftheSchottkyis lostathigher

reverseblocking voltages (typicallyabove100V ) and other

diode types become more suitable. This means that the

Schottky is normally reserved for useon outputsup to 20V

or so.

Note. A suitable guideline in selecting the correct rectifier

reversevoltageis toensurethedevice willblock 4to6times

theoutputvoltageitisusedtoprovide(depends ontopology

and whether rugged devices arebeing used).

For higher voltage outputs the most suitable rectifier is the

fastrecovery epitaxial diode (FRED). This device has been

optimised for use in high frequency rectification. Its

characteristics include low VF(approx. 1V) with very fast

and efficient switching characteristics. The FRED has

reverse voltage blocking capabilities up to 800V. They are

therefore suitable for use in outputs from 10 to 200V.

Therectifier devices specified in each selection guide were

chosenashaving thecorrectvoltage limitingvalue andhigh

enoughcurrent handling capability for theparticular output

power specified. (A single outputis assumed).

112

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

(5) Standard isolated topologies.

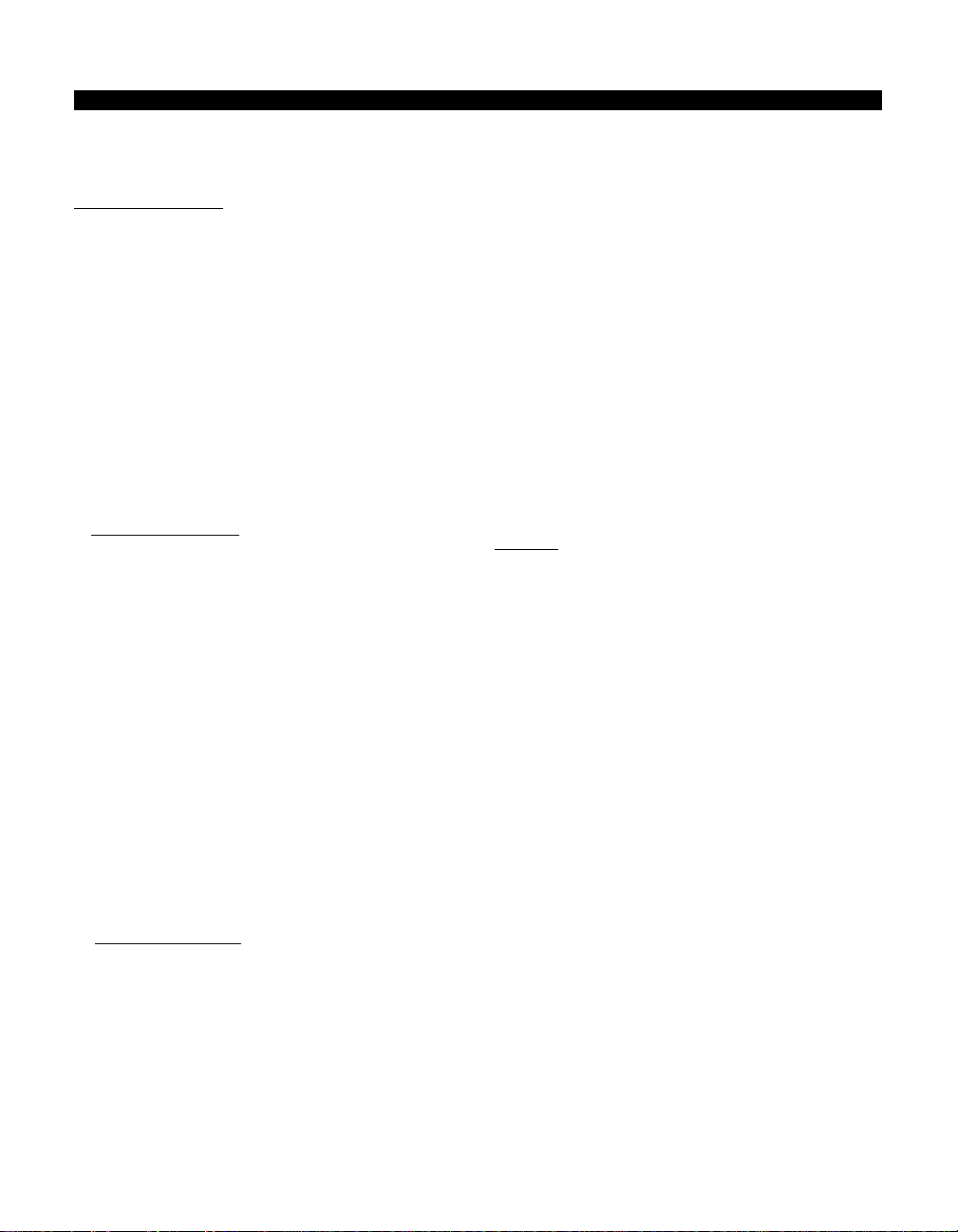

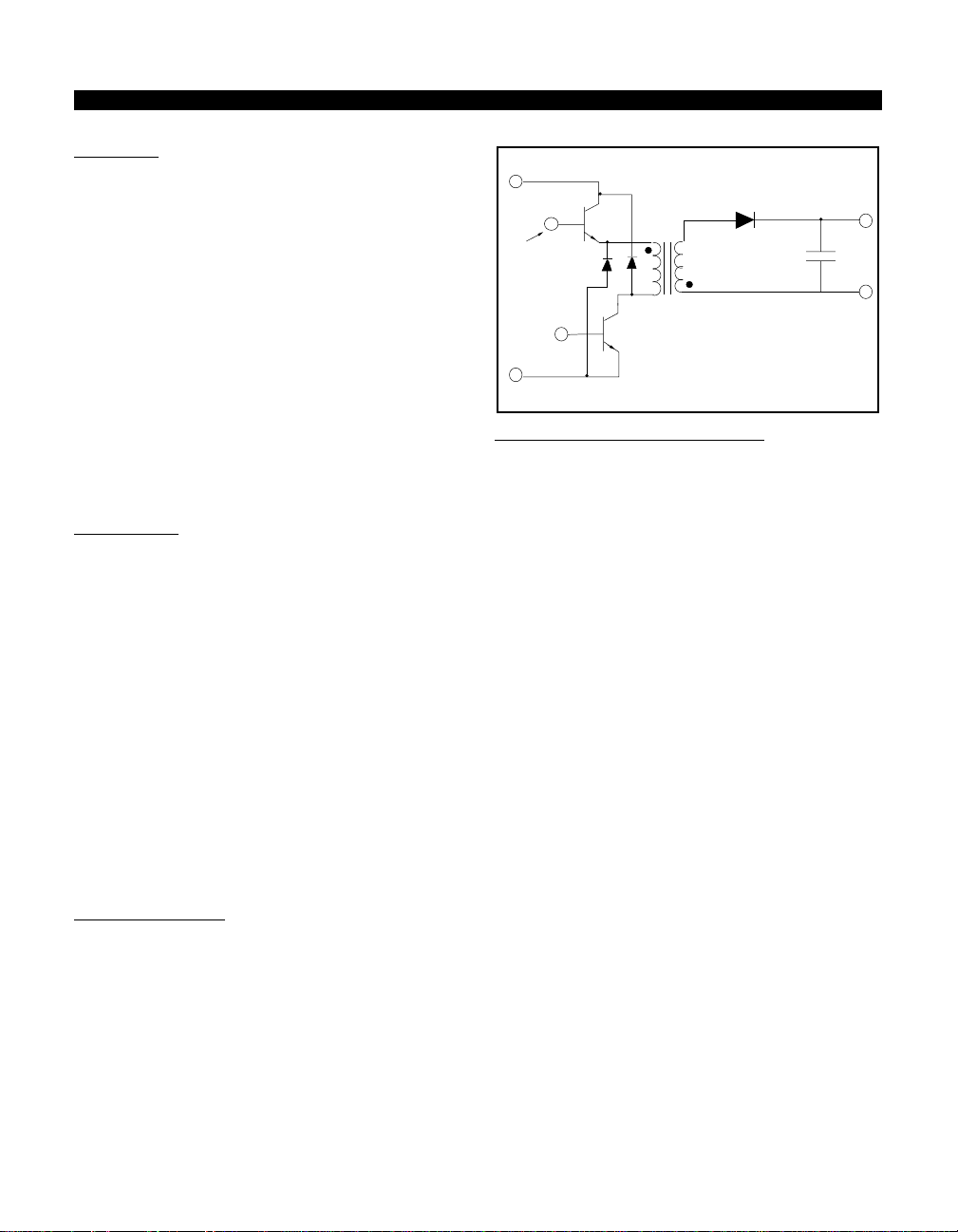

(a) The Flyback converter.

Operation

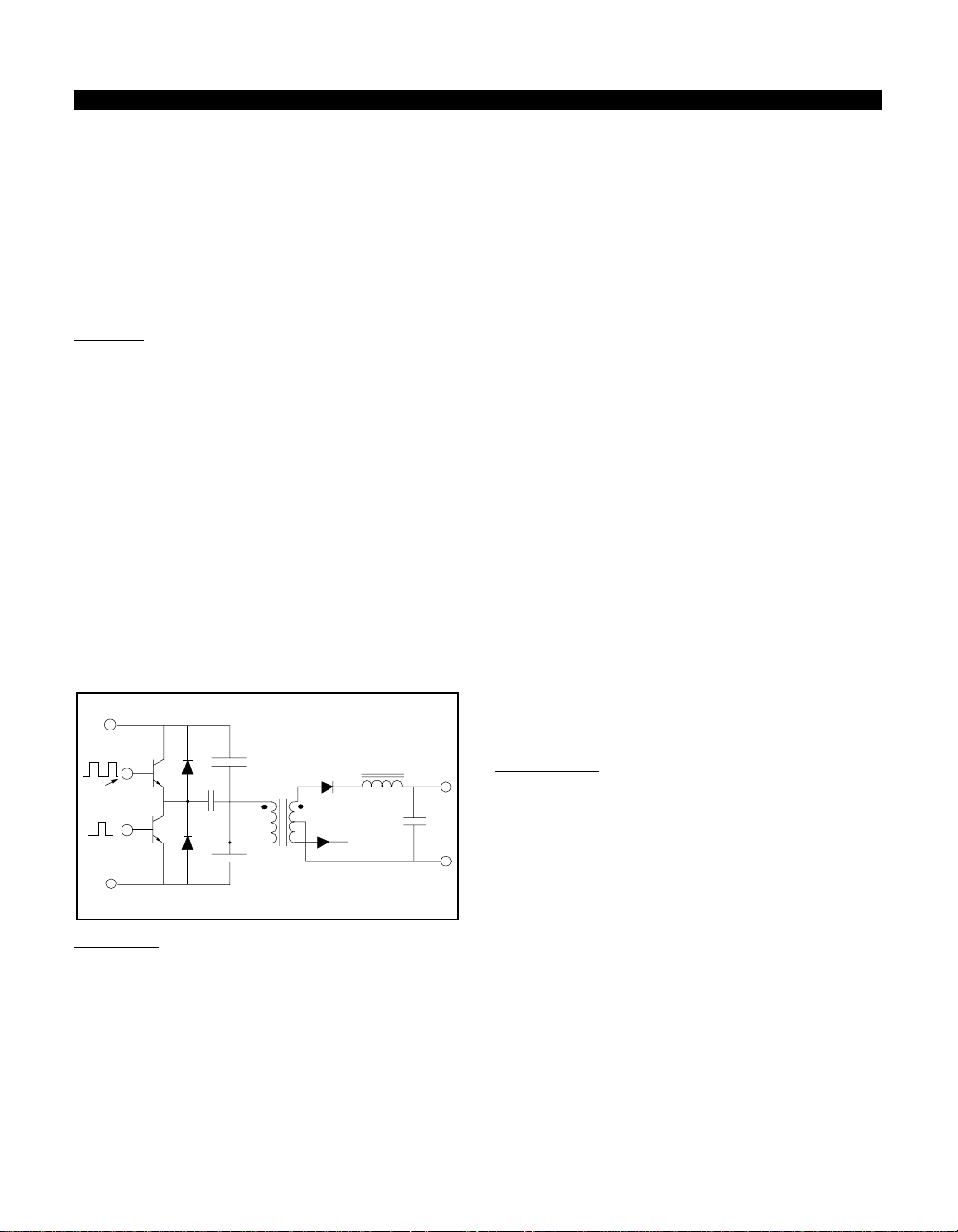

Of all the isolated converters, by far the simplest is the

single-ended flyback converter shown in Fig. 6.The use of

a single transistor switch means that the transformer can

only be driven unipolar (asymmetrical). This results in a

largecore size. The flyback, which is anisolated version of

the buck-boost, does not in truth contain a transformer but

a coupled inductor arrangement. When the transistor is

turned on, current builds up in the primary and energy is

storedin the core, this energy is thenreleased to the output

circuitthroughthe secondary when the switch is turned off.

(A normal transformer such as the types used in the buck

derived topologies couples the energy directly during

transistor on-time, ideally storing noenergy).

D1

TR1

Ip = Vin.ton/Lp

(discontinuous)

n2

T

T1

n:1

Isec = Idiode

leakage

inductance

spike

Vin

Discontinuous

Vin

Primary

current

current

Switch

voltage

sec

I

P

I

sw

0

I

S

I

D

0

Vce

or

Vds

0

Vin + Vo n1

ton toff

Fig. 6 Flyback converter circuit and waveforms.

The polarity of the windings is such that the output diode

blocks during the transistor on time. When the transistor

turns off, the secondary voltage reverses, maintaining a

constant flux in the core and forcing secondary current to

flow through the diode to the output load. The magnitude

Vo

Co

of the peak secondary current is the peak primary current

reached at transistor turn-off reflected through the turns

ratio, thus maintaining a constant Ampere-turn balance.

The fact that all of the output power of the flyback has to

be stored in thecore as 1/2LI2energy means thatthe core

size and cost will be much greater than in the other

topologies, where only the core excitation (magnetisation)

energy, which is normallysmall, isstored. This, in addition

to the initial poor unipolar core utilisation, means that the

transformer bulk is one of the major drawbacks of the

flyback converter.

Inorder toobtain sufficientlyhigh stored energy,theflyback

primary inductance has to be significantly lower than

required for a true transformer, since high peak currents

areneeded. This is normally achieved bygappingthe core.

Thegap reduces the inductance,andmost of thehighpeak

energy is then stored in thegap, thusavoiding transformer

saturation.

When the transistor turns off, the output voltage is back

reflectedthroughthetransformertotheprimaryand inmany

cases this can be nearly as high as the supply voltage.

There is also a voltage spike at turn-off due to the stored

energy in the transformer leakage inductance.This means

that the transistor must be capable of blocking

approximately twice the supply voltage plus the leakage

spike. Hence, for a 220V ac application where the dc link

canbe upto 385V, thetransistor voltage limitingvaluemust

lie between 800 and 1000V.

Using a 1000V Bipolar transistor such as the BUT11A or

BUW13Aallows a switching frequencyof 30kHz to be used

at output powers up to 200Watts.

MOSFETs with 800V and 1000V limiting values can also

beused,suchas theBUK456-800Awhichcansupply100W

t

atswitching frequencies anywhereupto 300kHz.Although

the MOSFET can be switched much faster and has lower

switching losses , it does suffer from significant on-state

t

losses, especially in the higher voltage devices when

compared to the bipolars. Anoutline of suitable transistors

and output rectifiers for different input and power levels

using the flyback is given in Table 2.

t

Onewayofremovingthe transformerleakage voltagespike

is to add a clamp winding as shown in Fig. 8. This allows

the leakage energy to be returned to the input instead of

stressing the transistor. The diode is always placed at the

high voltage end so that the clamp winding capacitance

does not interfere with the transistor turn-oncurrent spike,

whichwould happen if the diode was connected toground.

This clamp is optional and depends on the designer’s

particular requirements.

113

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Advantages.

The action of the flyback means that the secondary

inductance is in series with the output diode when current

is delivered to the load; i.e driven from a current source.

This means that no filter inductor is needed in the output

circuit. Hence, each output requires only one diode and

output filter capacitor. This means the flyback is the ideal

choiceforgeneratinglow cost,multipleoutput supplies.The

crossregulationobtained usingmultiple outputsis alsovery

good (load changes on one output have little effect on the

others) because of the absence ofthe output choke, which

degrades this dynamic performance.

Theflybackisalso ideallysuited for generatinghigh voltage

outputs.If a buck type LC filter was used to generate a high

voltage, a very large inductancevalue wouldbe neededto

reduce the ripple current levels sufficiently to achieve the

continuous mode operationrequired. This restriction does

not apply to theflyback, since itdoes notrequire anoutput

inductance for successful operation.

Disadvantages.

From the flyback waveforms in Fig. 6 it is clear that the

output capacitor is only supplied during the transistor off

time. This means that the capacitor has to smooth a

pulsatingoutput current which has higher peak values than

the continuous output current that would be producedin a

forward converter, for example. In order to achieve low

outputripple, very large output capacitorsare needed,with

very low equivalent series resistance (e.s.r). It can be

shown that at the same frequency, an LC filter is

approximately 8 times more effective at ripple reduction

than a capacitor alone. Hence, flybacks have inherently

much higher output ripples than other topologies. This,

togetherwiththe higherpeak currents, largecapacitors and

transformers, limits the flyback to lower output power

applications in the 20 to 200W range. (It should be noted

that at higher voltages, the required output voltage ripple

magnitudes are not normally as stringent, and this means

that the e.s.r requirement andhence capacitor sizewill not

be as large as expected.)

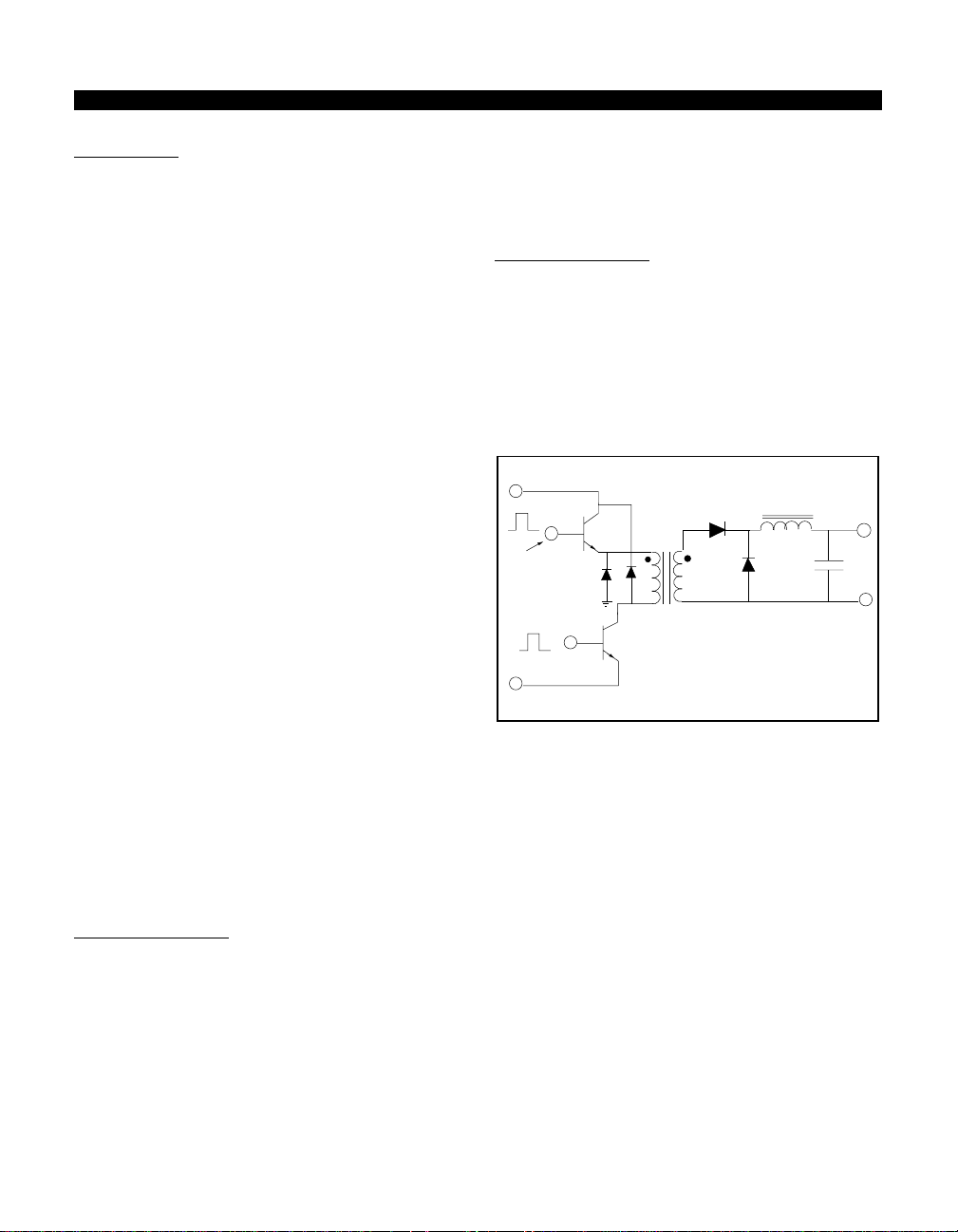

Two transistor flyback.

One possible solution to the 1000V transistor requirement

is the two transistor flyback version shown in Fig. 7. Both

transistorsare switched simultaneously,andall waveforms

are exactly the same, except that the voltageacross each

transistor never exceeds the input voltage. The clamp

winding is now redundant, sincethe two clamp diodes act

to return leakage energy to the input. Two 400 or 500V

devices can now be selected, which will have faster

switching andlower conduction losses. The output power

and switching frequencies can thus be significantly

increased. The drawbacks of the two transistor version are

the extra cost and more complex isolated base drive

needed for the top floating transistor.

Vin

isolated

base

drive

TR2

TR1

T1

n : 1

D1

Fig. 7 Two transistor Flyback.

Continuous Vs Discontinuous operation.

As with the buck-boost, the flyback can operate in both

continuous and discontinuous modes. The waveforms in

Fig. 6 show discontinuous mode operation. In

discontinuous mode, thesecondary current fallsto zero in

each switching period, and all of the energy is removed

from the transformer. In continuous mode there is current

flowing in the coupled inductor at all times, resulting in

trapezoidal current waveforms.

Themain plus of continuous mode is that thepeakcurrents

flowing are only halfthat ofthe discontinuous for the same

output power, hence, lower output ripple is possible.

However, the core size is about 2 to 4 times larger in

continuous mode to achieve the increased inductance

needed to reduce the peakcurrents to achieve continuity.

A further disadvantage of continuous mode is that the

closed loop is far more difficult to control than the

discontinuousmode flyback.(Continuous mode contains a

right hand plane zeroin itsopen loop frequency response,

the discontinuous flyback does not. See Ref[2] for further

explanation.) This means that much more time and effort

is required for continuous mode to design the much more

complicatedcompensationcomponentsneeded toachieve

stability.

There is negligible turn-on dissipation in the transistor in

discontinuous mode, whereas this dissipationcan befairly

high in continuous mode, especially when the additional

effects of the output diodereverse recovery current, which

only occurs in the continuous case, is included. This

normally means that a snubber must be added to protect

the transistor against switch-on stresses.

Oneadvantage ofthe continuous mode isthatits open loop

gain is independentof the output load i.e Voonly depends

uponD and Vinas shown in the dc gainequation at the end

of the section. Continuous mode has excellent open loop

loadregulation, i.e varying the output load will not affect Vo.

Discontinuous mode, on the other-hand, does have a

dependency on theoutput, expressed as RLin the dc gain

equation. Hence, discontinuous mode has a much poorer

114

Vo

Co

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

openloop loadregulation,i.e changing the outputwill affect

Vo. This problem disappears, however, when the control

loop is closed, and the load regulation problem is usually

completely overcome.

Theuse ofcurrentmode control with discontinuous flyback

(where both the primary current and output voltage are

sensed and combined to control the duty cycle) produces

a much improved overall loop regulation, requiring less

closed loop gain.

Although the discontinuous mode has the major

disadvantageofveryhighpeakcurrentsand alarge output

capacitor requirement, it ismuch easierto implement, and

is by far the more common of the two methods used in

present day designs.

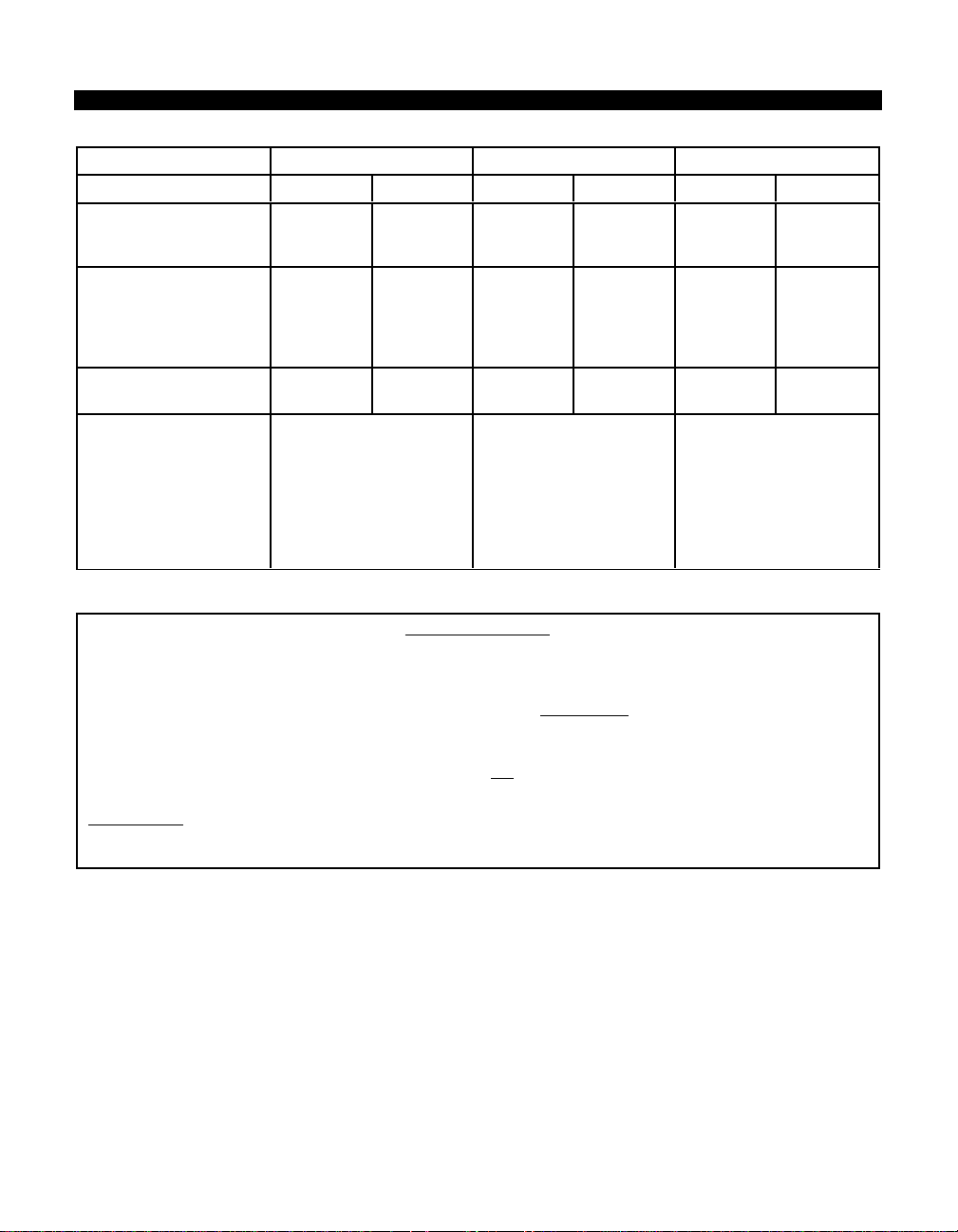

Output power 50W 100W 200W

Line voltage, Vin 110V ac 220V ac 110V ac 220V ac 110V ac 220V ac

Transistor requirements

Max current 2.25A 1.2A 4A 2.5A 8A 4.4A

Max voltage 400V 800V 400V 800V 400V 800V

Bipolar transistors.

TO-220 BUT11 BUX85 BUT12 BUT11A --- BUT12A

Isolated SOT-186 BUT11F BUX85F BUT12F BUT11AF --- BUT12AF

SOT-93 --- --- --- --- BUW13 ---

Isolated SOT-199 --- --- --- --- BUW13F ---

Power MOSFET

TO-220 BUK454-400B BUK454-800A BUK455-400B BUK456-800A --- ---

Isolated SOT-186 BUK444-400B BUK444-800A BUK445-400B BUK446-800A --- ---

SOT-93 --- --- --- --- BUK437-400B BUK438-800A

Output Rectifiers

O/P voltage

5V PBYR1635 PBYR2535CT ---

10V PBYR10100 PBYR20100CT PBYR30100PT

BYW29E-100/150/200 BYV79E-100/150/200 BYV42E-100/150/200

BYV72E-100/150/200

20V PBYR10100 PBYR10100 PBYR20100CT

BYW29E-100/150/200 BYW29E-100/150/200 BYV32E-100/150/200

50V BYV29-300 BYV29-300 BYV29-300

100V BYV29-500 BYV29-500 BYV29-500

Table 2. Recommended Power Semiconductors for single-ended flyback.

Note! The above values are for discontinuous mode. In continuous mode the peak transistor currents are approximately

halved and the output power available is thus increased.

Converter efficiency, η = 80%; Max duty cycle, D

Max transistor voltage, V

Maxtransistorcurrent,IC; ID= 2

dc voltage gain:- (a) continuous (b) Discontinuous

Vin

Vo

= n

D

1− D

or V

= 2V

ce

ds

+ leakage spike

in(max)

η D

max

P

out

maxVmin

= 0.45

Vo

Vin

= D

RLT

2 L

√

P

Applications:- Lowest cost, multiple output supplies in the 20 to 200W range. E.g. mains input T.V. supplies, small

computer supplies, E.H.T. supplies.

115

Flyback

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

(b) The Forward converter.

Operation.

The forward converter is also a single switch isolated

topology, and is shown inFig. 8. Thisis based onthe buck

converter described earlier, with the addition of a

transformer and another diode in the output circuit. The

characteristic LC output filter isclearly present.

In contrast tothe flyback, the forwardconverter has a true

transformer action, where energyis transferred directly to

the output through the inductor during the transistor

on-time. It can be seen that the polarity of the secondary

winding is opposite to that of the flyback, hence allowing

direct current flow through blocking diode D1. During the

on-time, the current flowing causesenergy to bebuilt up in

the output inductor L1. When the transistor turns off, the

secondary voltage reverses, D1 goes from conducting to

blocking mode and the freewheel diode D2 thenbecomes

forwardbiased and provides a path for theinductor current

to continue to flow. This allows the energy stored in L1 to

be released into the load during the transistor off time.

The forward converter is always operated in continuous

mode (in this case the output inductor current), since this

producesverylowpeak inputand output currentsand small

ripple components. Going into discontinuous mode would

greatly increase these values, as well as increasing the

amountof switching noisegenerated. No destabilising right

hand plane zero occurs in the frequency response of the

forwardin continuous mode (as with thebuck). See Ref[2].

This means thatthe control problemsthat existed with the

continuous flyback are not present here. So there are no

realadvantages to be gained by using discontinuous mode

operation for the forward converter.

Advantages.

As can beseen from the waveforms in Fig. 8, the inductor

current IL, which is also the output current, is always

continuous. The magnitude of the ripple component, and

hence the peak secondary current,depends uponthe size

of the output inductor. Therefore, the ripple can be made

relatively small compared to the output current, with the

peak current minimised. This lowripple, continuousoutput

currentis very easyto smooth, and so the requirements for

the output capacitor size, e.s.r and peak current handling

are far smaller than theyare for the flyback.

Since the transformer in this topology transfers energy

directly there is negligible stored energy in the core

compared to the flyback. However, there is a small

magnetisation energy requiredto excite thecore, allowing

it to become an energy transfer medium. This energy is

very small and only a very small primary magnetisation

current is needed. This means that a high primary

inductance is usually suitable, withno need forthe core air

gap required in the flyback. Standard un-gapped ferrite

cores with high permeabilities (2000-3000) are ideal for

providing the high inductance required. Negligible energy

storage means that the forward converter transformer is

considerablysmaller than the flyback, and core loss is also

muchsmaller forthe samethroughput power. However,the

transformer is still operated asymmetrically, which means

that power is only transferred during the switch on-time,

and this poor utilisation means the transformer is still far

bigger than in the symmetrical types.

The transistors have the same voltage rating as the

discontinuous flyback (see disadvantages), but the peak

current required for the same output power is halved, and

this can be seen in the equations given for the forward

converter. This, coupled with the smaller transformer and

outputfilter capacitorrequirements means that the forward

converter is suitable for use at higher output powers than

the flyback can attain,and is normallydesigned tooperate

inthe 100to 400Wrange. Suitable bipolars and MOSFETs

for the forward converter arelisted in Table 3.

Vin

output

Inductor

current

Diode

currents

TR1

current

Vo

TR1

voltage

Imag

Vce

Clamp

winding

necessary

CONTROL

CIRCUIT

0

I

L

0

Id1

0

0

Ip

0

ton toff

D1

D3

Vin

T1

n : 1

TR1

2Vin

Id2

Id3

Is

T

L1

D2

Vo

Co

t

Io

Fig. 8 The Forward converter and waveforms.

t

t

t

t

116

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Disadvantages.

Because of the unipolar switching action of the forward

converter, there is a major problem in how to remove the

core magnetisation energy by the end of each switching

cycle. If this did not happen, there would be a net dc flux

build-up, leadingtocore saturation, and possible transistor

destruction. This magnetisation energy is removed

automatically by the push-pull action of the symmetrical

types. In the flybackthis energy isdumped intothe load at

transistor turn-off. However, there is no such path in the

forward circuit.

Thispath is provided by adding an additionalreset winding

of opposite polarity to the primary. A clampdiode is added,

such that the magnetisation energyis returned to theinput

supply during the transistor off time. The reset winding is

woundbifilarwith the primary to ensure good coupling, and

is normally made tohave thesame numberof turns as the

primary. (The resetwinding wire gauge can be very small,

since it only has to conduct the small magnetisation

current.) The time for the magnetisation energy to fall to

zero is thus the same duration as the transistor on-time.

This means that the maximumtheoretical dutyratio of the

forward converter is 0.5 and after taking into account

switchingdelays,this fallsto 0.45.This limitedcontrol range

isone of the drawbacksof usingthe forward converter. The

waveform of the magnetisation current is also shown in

Fig. 8. The clamp winding in the flyback is optional, but is

always needed in the forwardfor correct operation.

Due to the presence of the reset winding, in order to

maintain volt-sec balancewithin the transformer, the input

voltage is back reflected to the primary from the clamp

winding at transistor turn-off for the duration of the flow of

the magnetisation resetcurrent throughD3. (There is also

a voltage reversal across the secondary winding, and this

is why diode D1 is added to block this voltage from the

output circuit.) This means that the transistor must block

two times Vin during switch-off. The voltage returnsto Vin

after reset has finished, which means transistor turn-on

losses will be smaller. Thetransistors musthave the same

added burden of the voltage rating of the flyback, i.e 400V

for 110V mains and 800Vfor 220V mains applications.

Output diode selection.

The diodes in the output circuit both have to conduct the

full magnitude of the output current. They are also subject

to abrupt changes in current, causing a reverse recovery

spike, particularly in the freewheel diode, D2. This spike

cancauseadditional turn-onswitching lossin thetransistor,

possiblycausing devicefailure in the absence of snubbing.

Thus, very high efficiency, fast trr diodes are required to

minimise conduction losses and to reduce the reverse

recovery spike. These requirements aremet withSchottky

diodes for outputs up to 20V, and fast recovery epitaxial

diodesforhigher voltageoutputs.It isnotnormalfor forward

converter outputs to exceed100V becauseof the need for

a very large output choke, andflybacks arenormally used.

Usually, both rectifiers areincluded ina singlepackage i.e

a dual centre-tap arrangement. The Philips range of

Schottkiesand FREDs which meet these requirements are

also included in Table 3.

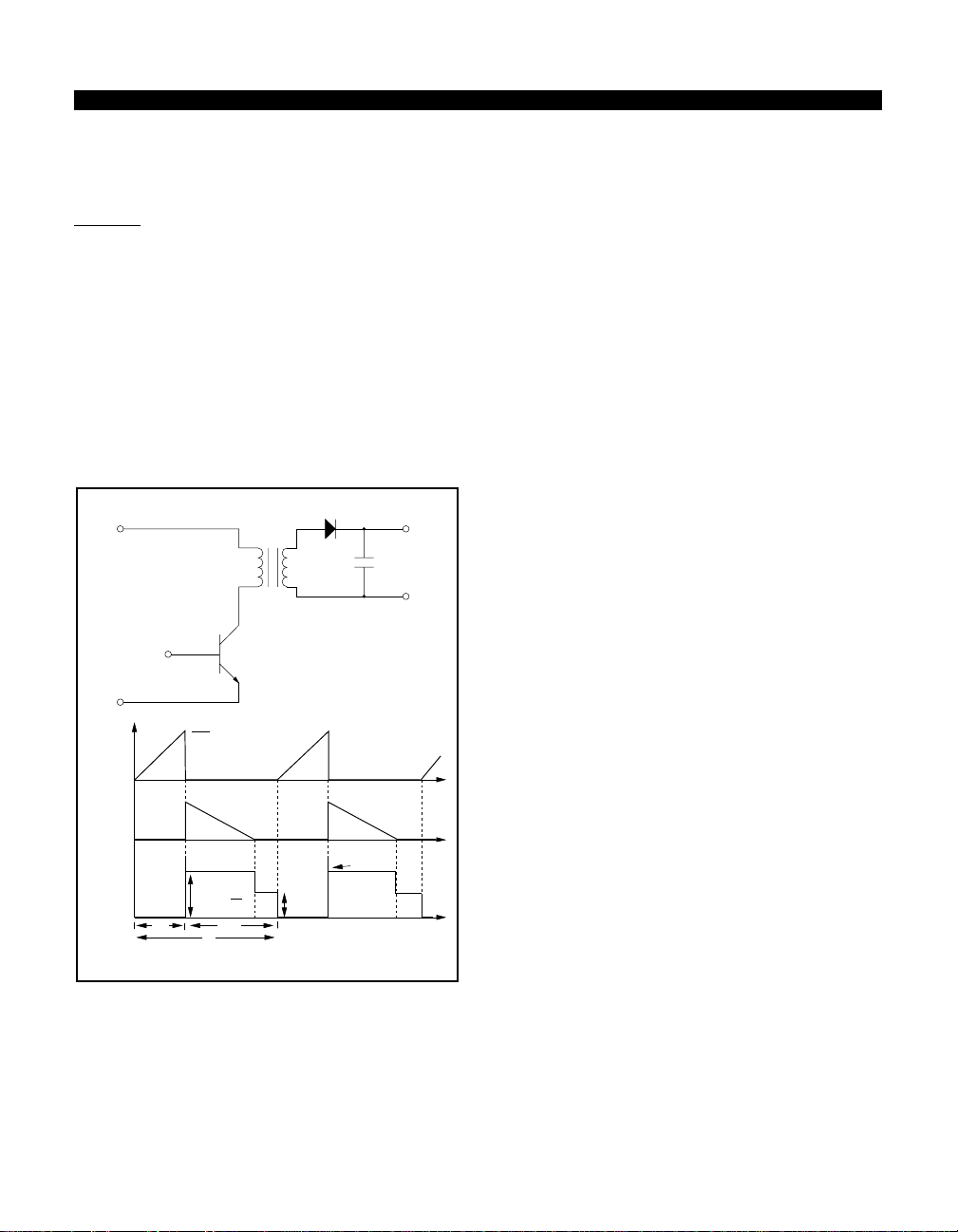

Two transistor forward.

In order to avoid the use of higher voltage transistors, the

two transistor version of the forward can be used. This

circuit, shown in Fig. 9, is very similar to the two transistor

flyback and has the sameadvantages. Thevoltage across

the transistor is again clamped to Vin, allowing the use of

faster more efficient 400 or 500V devices for 220V mains

applications. The magnetisation reset is achieved through

the two clampdiodes, permitting the removalof the clamp

winding.

Vin

L1

isolated

base

drive

TR2

D1

T1

D2

n : 1

TR1

Fig. 9 Two transistor Forward.

The two transistor version is popular for off-line

applications. It provides higher output powers and faster

switching frequencies. The disadvantages are again the

extracost of the higher componentcount, and the needfor

an isolated drive for thetop transistor.

Although this converter has some drawbacks, andutilises

the transformer poorly, itis avery popularselection forthe

power range mentionedabove, and offerssimple drive for

the single switch and cheap component costs. Multiple

output types are very common. The output inductors are

normally wound on a single core, which has the effect of

improving dynamic cross regulation, and if designed

correctly also reduces the output ripple magnitudes even

further. The major advantage of the forward converter is

thevery low output ripple thatcanbe achieved for relatively

small sized LC components. This means that forward

converters are normally used to generate lower voltage,

high current multiple outputs such as 5, 12, 15, 28V from

mains off-line applications, where lower ripple

specifications are normally specified for the outputs. The

high peak currents thatwould occur if a flyback was used

would place an impossible burden on the smoothing

capacitor.

117

Vo

Co

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Output power 100W 200W 300W

Line voltage, Vin 110V ac 220V ac 110V ac 220V ac 110V ac 220V ac

Transistor requirements

Max current 2.25A 1.2A 4A 2.5A 6A 3.3A

Max voltage 400V 800V 400V 800V 400V 800V

Bipolar transistors.

TO-220 BUT11 BUX85 BUT12 BUT11A --- BUT12A

Isolated SOT-186 BUT11F BUX85F BUT12F BUT11AF --- BUT12AF

SOT-93 --- --- --- --- BUW13 ---

Isolated SOT-199 --- --- --- --- BUW13F ---

Power MOSFET

TO-220 BUK454-400B BUK454-800A BUK455-400B BUK456-800A --- ---

Isolated SOT-186 BUK444-400B BUK444-800A BUK445-400B BUK446-800A --- ---

SOT-93 --- --- --- --- BUK437-400B BUK438-800A

Output Rectifiers (dual)

O/P voltage

5V PBYR2535CT --- ---

10V PBYR20100CT PBYR30100PT PBYR30100PT

20V PBYR20100CT PBYR20100CT PBYR20100CT

50V BYT28-300 BYT28-300 BYT28-300

BYV32E-100/150/200 BYV42E-100/150/200 BYV72E-100/150/200

BYV72E100/150/200

BYQ28E-100/150/200 BYV32E-100/150/200 BYV32E-100/150/200

Table 3. Recommended Power Semiconductors for single-ended forward.

Forward

Converter efficiency, η = 80%; Max duty cycle, D

Max transistor voltage, V

Maxtransistorcurrent,IC; ID=

dc voltage gain:-

ce

Vo

Vin

or V

= 2V

ds

η D

= nD

max

in(max)

P

out

maxVmin

= 0.45

Applications:- Low cost, low output ripple, multiple output supplies in the 50 to 400W range. E.g. small computer

supplies, DC/DC converters.

118

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

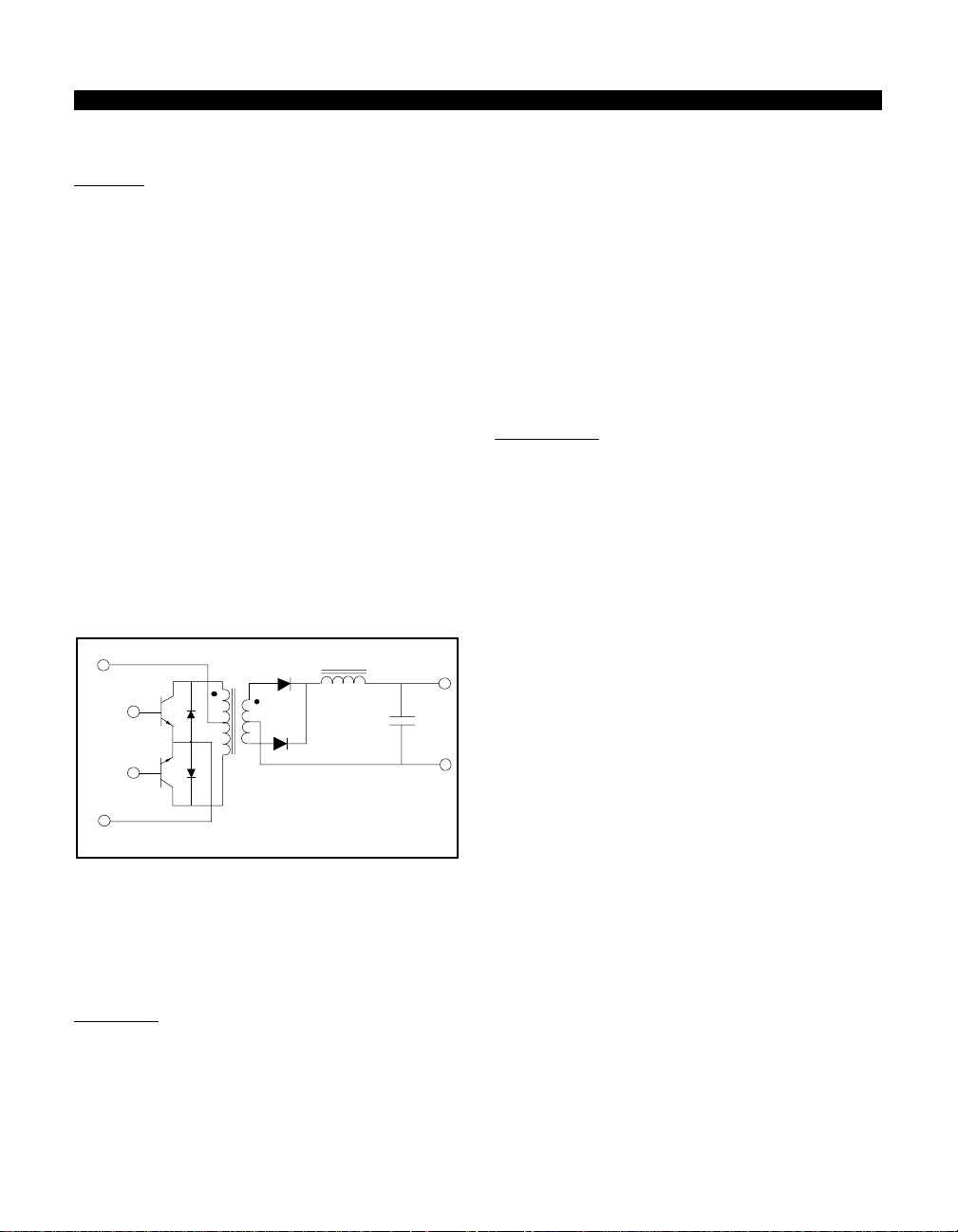

(c) The Push-pull converter.

Operation.

To utilise the transformerflux swingfully, itis necessaryto

operate the core symmetrically as described earlier. This

permits much smaller transformer sizes and provides

higher output powers than possible with the single ended

types. The symmetrical types always require an even

numberof transistor switches. Oneof the best knownofthe

symmetrical types is the push-pull converter shown in

Fig. 10.

The primary is a centre-tapped arrangement and each

transistor switch is driven alternately, driving the

transformerin both directions.The push-pulltransformeris

typically half the size of that for the single ended types,

resulting in a more compact design. This push-pull action

produces natural core resetting during each half cycle,

hence no clamp winding is required. Power is transferred

to the buck type output circuit during each transistor

conduction period. Theduty ratio ofeach switch is usually

less than 0.45. This provides enough dead time to avoid

transistor cross conduction. The power can now be

transferred to the output for up to 90% of the switching

period, hence allowing greaterthroughput power thanwith

the single-ended types. The push-pull configuration is

normally used for output powers in the 100 to500W range.

Vin

TR1

TR2

T1 D1

D2

n : 1

Fig. 10 Push-pull converter.

The bipolar switching action also means that the output

circuitis actually operated at twice the switchingfrequency

ofthepowertransistors, ascanbe seenfromthewaveforms

inFig. 11. Therefore,the outputinductor and capacitor can

be even smaller for similar output ripple levels. Push-pull

converters are thus excellent for high power density, low

ripple outputs.

Advantages.

As stated, the push-pull offers very compact design of the

transformer and output filter, while producing very low

output ripple. So if spaceis a premiumissue, the push-pull

could be suitable. The controlof thepush-pull is similar to

theforward,in thatit isagain basedon thecontinuousmode

L1

Vo

Co

buck. When closing the feedback control loop,

compensation is relatively easy. For multiple outputs, the

same recommendations given for the forward converter

apply.

Clamp diodes are fitted across the transistors, as shown.

Thisallows leakage and magnetisation energytobe simply

channelled back to the supply, reducing stress on the

switches and slightly improving efficiency.

The emitter or source of the power transistors are both at

the same potential in the push-pull configuration, and are

normally referenced to ground. This means that simple

base drive can be used for both, and no costly isolating

drive transformer is required. (Thisis not so for the bridge

types which are discussed latter.)

Disadvantages.

One of the main drawbacks of the push-pull converter is

the fact that each transistor must block twice the input

voltage due to the doubling effect of the centre-tapped

primary,even thoughtwo transistors are used. This occurs

whenonetransistorisoffand theother isconducting. When

both are off, each then blocks the supply voltage, this is

shown in the waveforms in Fig. 11. This means that TWO

expensive,less efficient800 to 1000V transistors would be

required for a 220V off-line application. A selection of

transistors and rectifiers suitable for the push-pull used in

off-line applications is given in Table 4.

Afurther major problem with the push-pull is that it is prone

to flux symmetry imbalance. If the flux swing in each half

cycle is not exactly symmetrical, the volt-sec will not

balance and this will result in transformer saturation,

particularly for high input voltages. Symmetry imbalance

can be caused by different characteristics in the two

transistors such as storage time in a bipolar and different

on-state losses.

The centre-tap arrangement alsomeans that extracopper

isneededforthe primary, and very good coupling between

the two halves is necessary to minimise possible leakage

spikes. It should also benoted that if snubbersare used to

protect the transistors, the design must be very precise

since each tends to interact with the other. This is true for

all symmetrically driven converters.

These disadvantages usually dictate that the push-pull is

normally operated at lower voltage inputs such as 12, 28

or 48V. DC-DC converters found in the automotive and

telecommunication industries are often push-pulldesigns.

At these voltage levels, transformer saturation is easier to

avoid.

Since the push-pull is commonly operated with low dc

voltages,a selectionguide for suitablepower MOSFETs is

alsoincluded for 48 and 96Vapplications, seenin Table 5.

119

S.M.P.S. Power Semiconductor Applications

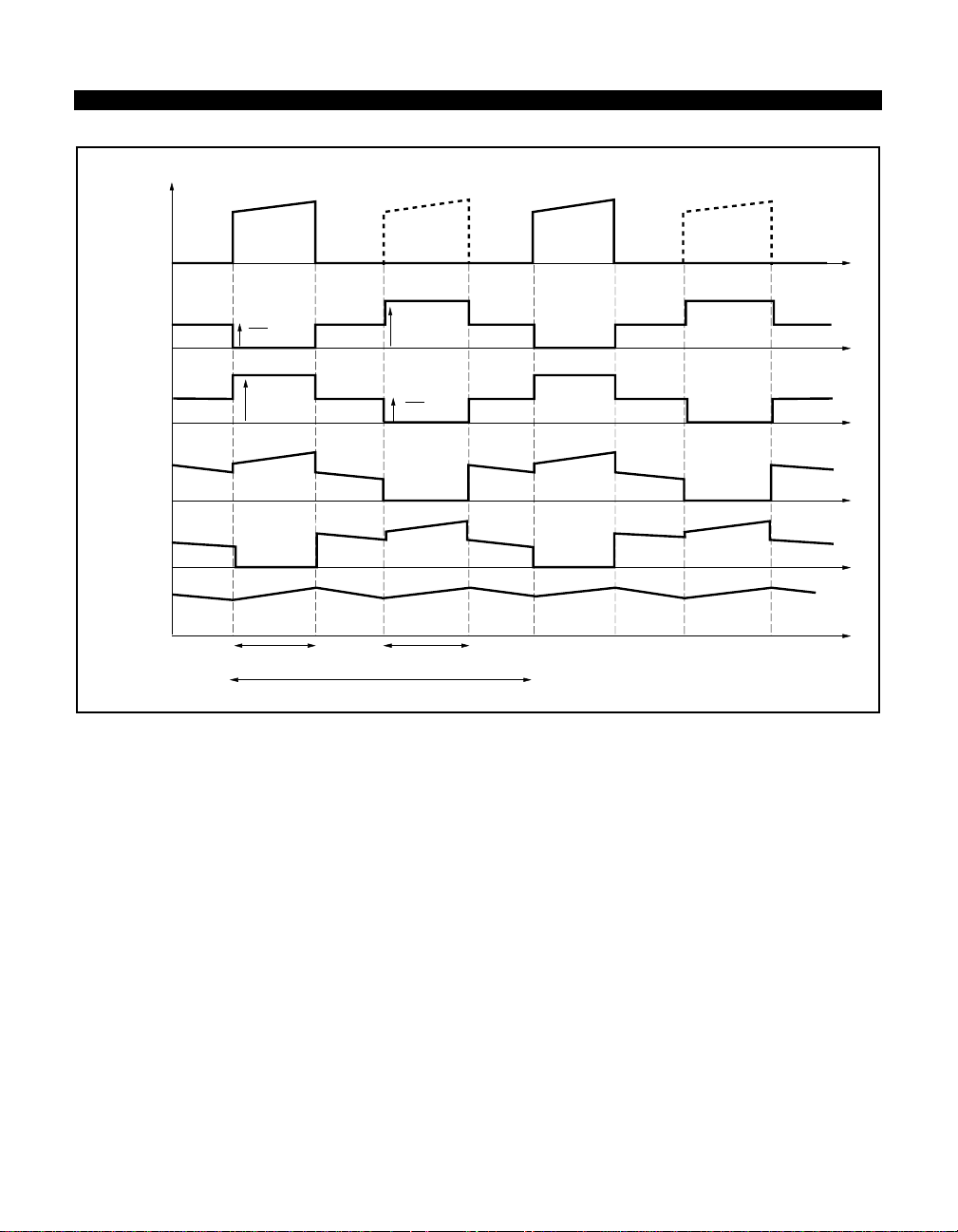

Philips Semiconductors

Current mode control.

The introduction of current mode control circuits has also

benefited the push-pull type. In this type of control, the

primary current is monitored, and any imbalance which

occursiscorrectedona cycle by cycle basis by varying the

duty cycle immediately. Current mode control completely

Transistor

currents

TR1

voltage

TR2

voltage

D1

current

D2

current

output

inductor

current

I

TR1

0

0

0

0

0

0

Vin

2Vin

I

L

ton

12

I

TR2

2Vin

Vin

ton

T

Fig. 11 Push Pull waveforms.

removes the symmetry imbalance problem, and the

possibilities of saturation are minimised. This has meant

thatpush-pull designshave becomemore popular inrecent

years, with some designers even using them in off-line

applications.

t

t

t

t

t

t

120

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

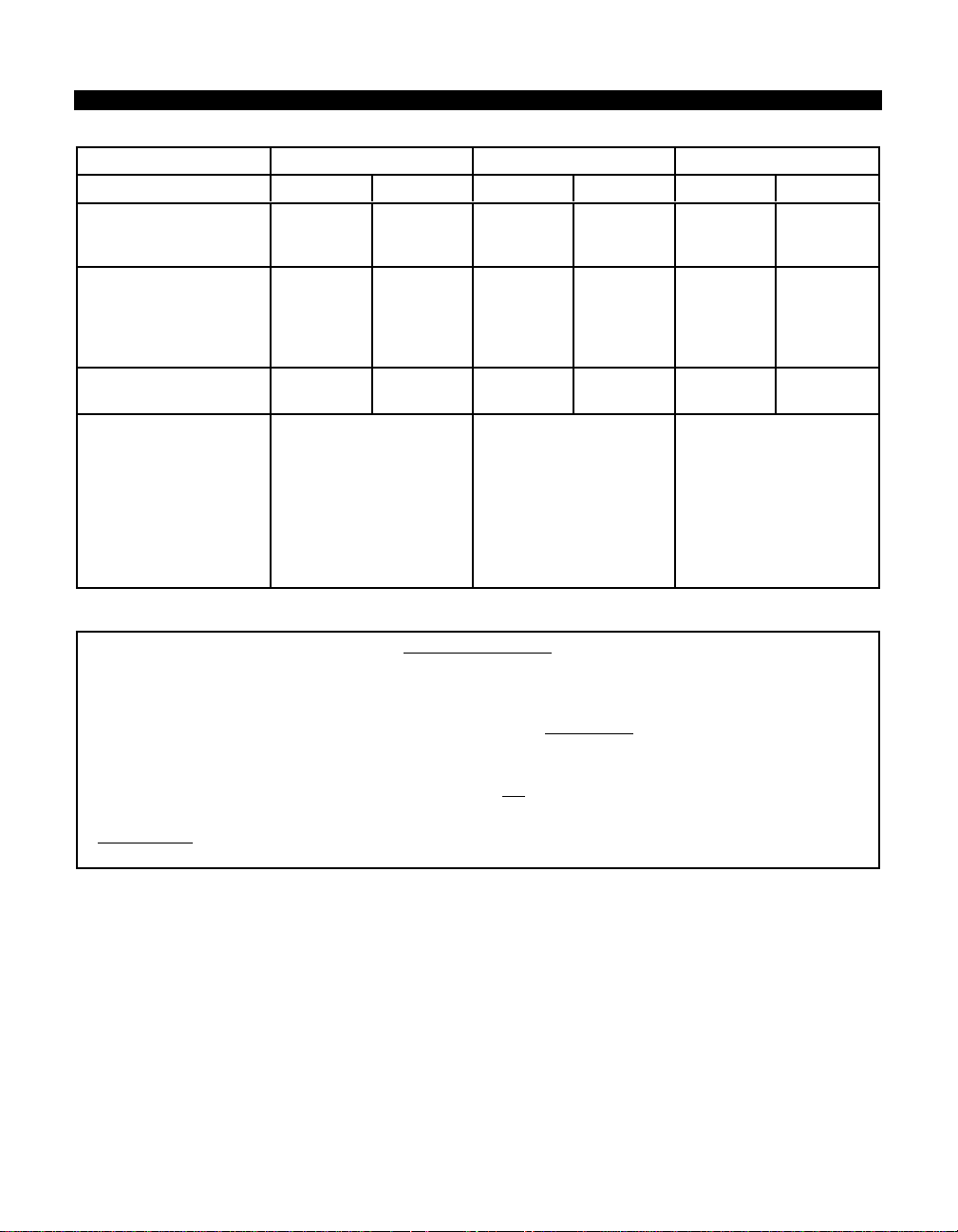

Output power 100W 300W 500W

Line voltage, Vin 110V ac 220V ac 110V ac 220V ac 110V ac 220V ac

Transistor requirements

Max current 1.2A 0.6A 4.8A 3.0A 5.8A 3.1A

Max voltage 400V 800V 400V 800V 400V 800V

Bipolar transistors.

TO-220 BUT11 BUX85 BUT12 BUT11A --- BUT12A

Isolated SOT-186 BUT11F BUX85F BUT12F BUT11AF --- BUT12AF

SOT-93 --- --- --- --- BUW13 ---

Isolated SOT-199 --- --- --- --- BUW13F ---

Power MOSFET

TO-220 BUK454-400B BUK454-800A BUK455-400B BUK456-800A --- ---

Isolated SOT-186 BUK444-400B BUK444-800A BUK445-400B BUK446-800A --- ---

SOT-93 --- --- --- --- BUK437-400B BUK438-800A

Output Rectifiers (dual)

O/P voltage

5V PBYR2535CT --- ---

10V PBYR20100CT PBYR30100PT --20V PBYR20100CT PBYR20100CT PBYR30100PT

50V BYT28-300 BYT28-300 BYV34-300

BYV32E-100/150/200 BYV72E-100/150/200 BYT230PI-200

BYQ28E-100/150/200 BYV32E-100/150/200 BYV42E-100/150/200

BYV72E-100/150/200

Table 4. Recommended Power Semiconductors for off-line Push-pull converter.

Output power 100W 200W 300W

Line voltage, Vin 96V dc 48V dc 96V dc 48V dc 96V dc 48V dc

Power MOSFET

TO-220 BUK455-400B BUK454-200A BUK457-400B BUK456-200B --- ---

Isolated SOT-186 BUK445-400B BUK444-200A BUK437-400B BUK436-200B --- ---

SOT-93 --- --- --- --- BUK437-400B ---

Table 5. Recommended power MOSFETs for lower input voltage push-pull.

Push-Pull converter.

Converter efficiency, η = 80%; Max duty cycle, D

Max transistor voltage, V

Maxtransistorcurrent,IC; ID=

dc voltage gain:-

ce

or V

= 2V

ds

Vo

= 2 nD

Vin

+ leakage spike.

in(max)

P

η D

maxVmin

= 0.9

max

out

Applications:- Compact design, very low output ripple supplies in the 100 to 500W range. More suited to low input

applications. E.g. battery, 28, 40V inputs, high current outputs. Telecommunication supplies.

121

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

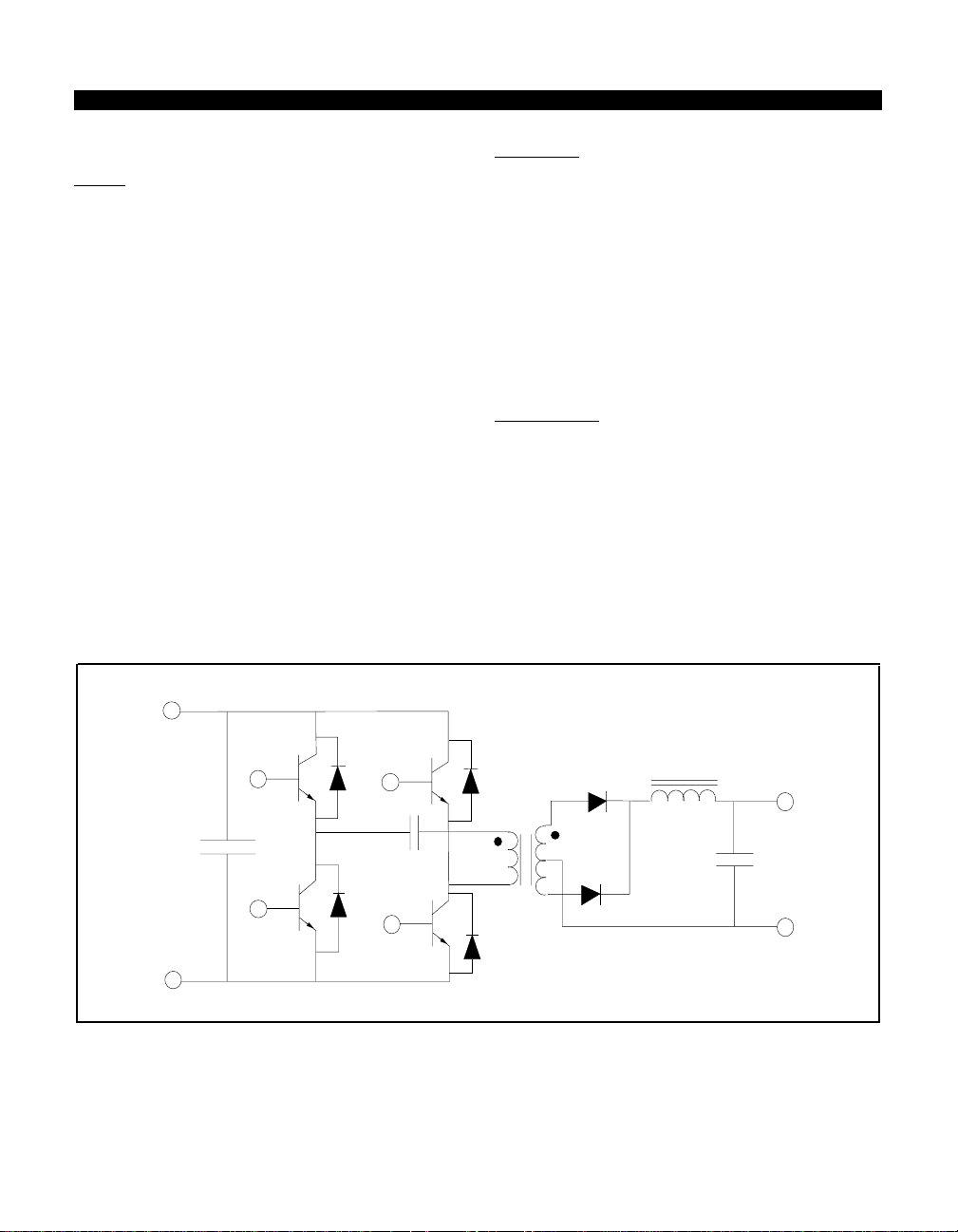

(d) The Half-Bridge.

Of all the symmetrical high power converters, the

half-bridge converter shown inFig. 12 isthe mostpopular.

It is also referred to as the single ended push-pull, and in

principle is a balanced version of the forward converter.

Again it is a derivative of the buck. The Half-Bridge has

some key advantages over the push-pull, which usually

makes it first choice for higher power applications in the

500 to 1000W range.

Operation.

The two mains bulk capacitors C1 and C2 are connected

in series, and an artificial input voltage mid-point is

provided, shown as point A in the diagram. The two

transistorswitches aredriven alternately, andthis connects

eachcapacitor across the single primary windingeach half

cycle. Vin/2 is superimposed symmetrically across the

primaryin a push-pull manner.Power is transferred directly

to the output on each transistor conduction time and a

maximum duty cycle of 90% is available (Some dead time

is required to prevent transistor cross-conduction.) Since

theprimary isdriven in both directions, (naturalreset) a full

wave buck output filter (operating at twice the switching

frequency) rather than a half wave filter is implemented.

This again results in very efficient core utilisation. As can

be seen in Fig. 13, the waveforms are identical to the

push-pull, except that the voltageacross thetransistors is

halved. (The device currentwould be higher for the same

output power.)

Vin

TR1

D3

isolated

drive

needed

D4

TR2

Fig. 12 Half-Bridge converter.

Advantages.

Since both transistors are effectively in series, they never

seegreater than thesupply voltage, Vin.When both are off,

theirvoltages reach anequilibriumpoint of Vin/2.This is half

the voltage rating of the push-pull (although double the

C1

T1

C3

A

C2

D2

n : 1

L1

D1

Vo

Co

current). This means that the half-bridge is particularly

suited to high voltage inputs, such as off-lineapplications.

Forexample, a 220V mains application can use twohigher

speed, higher efficiency 450V transistors instead of the

800V types needed for a push-pull. This allows higher

frequency operation.

Another major advantage over the push-pull is that the

transformer saturation problems due to flux symmetry

imbalance are not a problem. By using a small capacitor

(less than 10µF) any dc build-up of flux in the transformer

isblocked, and onlysymmetrical ac is drawnfrom the input.

The configuration of the half-bridge allowsclamp diodes to

be added across the transistors, shown as D3 and D4 in

Fig. 12. The leakage inductance and magnetisation

energies are dumped straight back into the two input

capacitors, protecting the transistors from dangerous

transients and improving overall efficiency.

A less obvious exclusive advantage of the half-bridge is

that the two series reservoir capacitors already exist, and

this makes it ideal for implementing a voltage doubling

circuit. This permits the useof either110V /220V mainsas

selectable inputs to the supply.

The bridge circuits also have the same advantages over

the single-ended types that the push-pull possesses,

including excellent transformer utilisation, very low output

ripple,andhighoutputpower capabilities.Thelimitingfactor

inthemaximumoutput power availablefrom thehalf-bridge

is the peak current handling capabilities of present day

transistors. 1000W is typically the upper power limit. For

higher output powers thefour switchfull bridgeis normally

used.

Disadvantages.

The need for two 50/60 Hz input capacitors is a drawback

because of their large size. The top transistor must also

have isolated drive, since the gate / base is at a floating

potential. Furthermore, if snubbers are used across the

power transistors, great care must be taken in their design,

since the symmetrical action means that they will interact

with one another. The circuit cost and complexity have

clearlyincreased,and this must be weighed upagainst the

advantagesgained. Inmany cases, this normallyexcludes

the use of the half-bridge at output power levels below

500W.

Suitable transistors and rectifiers for the half-bridge are

given in Table 6.

122

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Transistor

currents

TR1

voltage

TR2

voltage

D1

current

D2

current

output

inductor

current

I

TR1

0

Vin

0

0

0

0

0

2

Vin

I

L

ton

12

I

TR2

t

Vin

t

Vin

2

ton

T

t

t

t

t

Fig. 13 Half-Bridge waveforms.

123

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Output power 300W 500W 750W

Line voltage, Vin 110V ac 220V ac 110V ac 220V ac 110V ac 220V ac

Transistor requirements

Max current 4.9A 2.66A 11.7A 6.25A 17.5A 9.4A

Max voltage 250V 450V 250V 450V 250V 450V

Bipolar transistors.

TO-220 BUT12 BUT11 --- --- --- ---

Isolated SOT-186 BUT12F BUT11F --- --- --- ---

SOT-93 --- --- BUW13 BUW13 --- BUW13

Isolated SOT-199 --- --- BUW13F BUW13F --- BUW13F

Power MOSFET

SOT-93 --- BUK437-500B --- --- --- ---

Output Rectifiers (dual)

O/P voltage

5V --- --- ---

10V PBYR30100PT --- --20V PBYR20100CT PBYR30100PT ---

50V BYT28-300 BYV34-300 BYV34-300

BYV72E-100/150/200

BYV32E-100/150/200 BYV42E-100/150/200

BYV72E-100/150/200

Table 6. Recommended Power Semiconductors for off-line Half-Bridge converter.

Half-Bridge converter.

Converter efficiency, η = 80%; Max duty cycle, D

Max transistor voltage, V

Maxtransistorcurrent,IC; ID= 2

dc voltage gain:-

ce

or V

ds

= V

Vo

Vin

in(max)

η D

= nD

+ leakage spike.

max

P

out

maxVmin

= 0.9

Applications:- High power, up to 1000W. High current, very low output ripple outputs. Well suited for high input

voltage applications. E.g. 110, 220, 440V mains. E.g. Large computer supplies, Lab equipment supplies.

124

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

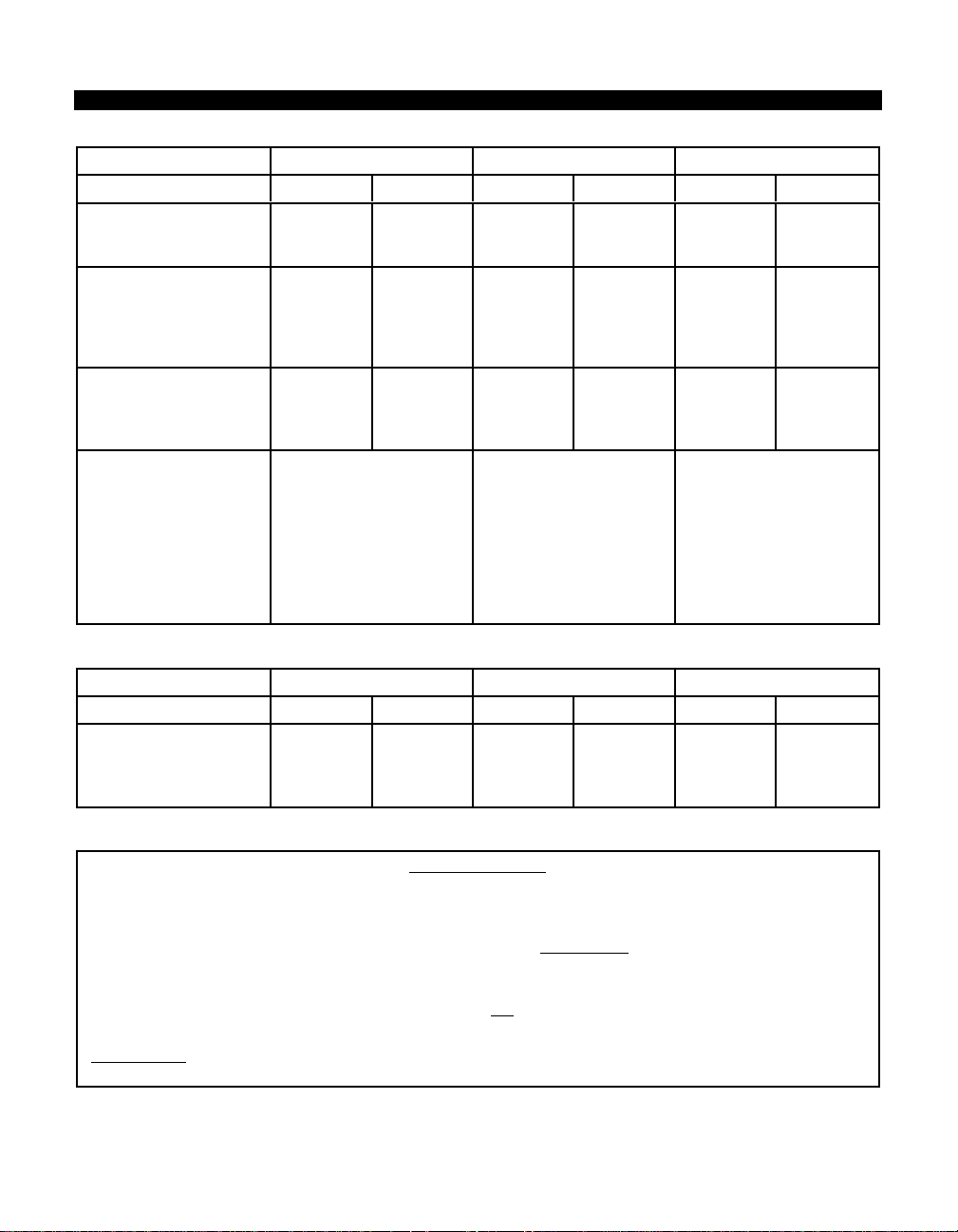

(e) The Full-Bridge.

Outline.

The Full-Bridge converter shown in Fig. 14 is a higher

power version of theHalf-Bridge, andprovides thehighest

output power level of anyof the convertersdiscussed. The

maximum current ratings of the power transistors will

eventually determine the upperlimit ofthe outputpower of

the half-bridge. These levels can be doubled by using the

Full-Bridge, which is obtained by adding another two

transistors and clamp diodes to the Half-Bridge

arrangement.Thetransistors are drivenalternately inpairs,

T1and T3, then T2 and T4. The transformer primary isnow

subjectedtothe fullinputvoltage. Thecurrent levelsflowing

are halved compared to the half-bridge for a given power

level. Hence, the Full-Bridge will double the output power

of the Half-Bridge using the same transistor types.

Thesecondary circuit operates inexactly the samemanner

as the push-pull and half-bridge, also producing very low

ripple outputs at very high current levels. Therefore, the

waveforms for the Full-Bridge are identical to the

Half-Bridge waveforms shown in Fig. 13, except for the

voltage across the primary, which is effectively doubled

(and switch currents halved). This is expressed in the dc

gain and peak current equations, where the factor of two

comes in, compared with the Half-Bridge.

Vin

Advantages.

As stated,the Full-Bridge is ideal for thegeneration of very

high output powerlevels. The increased circuit complexity

normally means that the Full-Bridge is reserved for

applications with power output levels of 1kW and above.

For such high power requirements, designers often select

power Darlingtons, since theirsuperior currentratings and

switching characteristics provide additional performance

and in many cases amore cost effective design.

The Full-Bridge also has the advantage of only requiring

one mains smoothing capacitor compared to two for the

Half-Bridge, hence, saving space. Its other major

advantages are the same asfor the Half-Bridge.

Disadvantages.

Four transistors and clamp diodes are needed instead of

two for the other symmetrical types. Isolated drive for two

floating potential transistors is now required. The

Full-Bridge has the most complex andcostly designof any

oftheconverters discussed,andshould onlybe usedwhere

other types do not meet the requirements. Again, the four

transistor snubbers (if required) must be implemented

carefully to prevent interactions occurringbetween them.

Table 7 gives an outline of the Philips power

semiconductors suitable for use with the Full-Bridge.

C1

* Isolated drive required.

TR1

*

TR2

D3

D4

TR4

*

C2

TR3

D5

D6

D1

T1

D2

L1

Vo

Co

Fig. 14 The Full-Bridge converter.

125

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Output power 500W 1000W 2000W

Line voltage, Vin 110V ac 220V ac 110V ac 220V ac 110V ac 220V ac

Transistor requirements

Max current 5.7A 3.1A 11.5A 6.25A 23.0A 12.5A

Max voltage 250V 450V 250V 450V 250V 450V

Bipolar transistors.

TO-220 BUT12 BUT18 --- --- --- ---

Isolated SOT-186 BUT12F BUT18F --- --- --- ---

SOT-93 --- --- BUW13 BUW13 --- BUW13

Isolated SOT-199 --- --- BUW13F BUW13F --- BUW13F

Power MOSFET

SOT-93 --- BUK438-500B --- --- --- ---

Output Rectifiers (dual)

O/P voltage

5V --- --- --10V --- --- --20V PBYR30100PT --- ---

50V BYV34-300 BYV44-300 ---

Table 7. Recommended Power Semiconductors for the Full-Bridge converter.

BYV42E-100/150/200

BYV72E-100/150/200

Converter efficiency, η = 80%; Max duty cycle, D

Max transistor voltage, V

Maxtransistorcurrent,IC; ID=

dc voltage gain:-

ce

or V

= V

ds

in(max)

Vo

= 2 nD

Vin

+ leakage spike.

P

η D

maxVmin

= 0.9

max

out

Applications:- Very high power, normally above 1000W. Very high current, very low ripple outputs. Well suited for

high input voltage applications. E.g. 110, 220, 440V mains. E.g. Computer Mainframe supplies, Large lab equipment

supplies, Telecomm systems.

Full-Bridge converter.

126

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Conclusion.

The 5 most common S.M.P.S. converter topologies, the

flyback,forward,push-pull,half-bridgeand full-bridgetypes

have been outlined. Each has its own particular operating

characteristics and advantages, which makes it suited to

particular applications.

Theconvertertopologyalsodefinesthevoltageand current

requirements of the power transistors (either MOSFET or

Bipolar).Simpleequations andcalculations used to outline

the requirements ofthe transistors foreach topology have

been presented.

The selection guide fortransistors andrectifiers atthe end

ofeach topologysectionshows some of thePhilips devices

which are ideal for usein S.M.P.S. applications.

References.

(1) Philips MOSFET Selection Guide For S.M.P.S. by

M.J.Humphreys. Philips Power Semiconductor

Applications group, Hazel Grove.

(2) Switch Mode Power Conversion - Basic theory and

design by K.Kit.Sum. (Published by Marcel Dekker

inc.1984)

127

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

Appendix A.

MOSFET throughput power calculations.

Assumptions made:The power loss (Watts) in the transistor due to on-state

losses is 5% of the total throughput (output) power.

Switching losses in the transistor are negligible. N.B. At

frequencies significantly higher than 50kHz the switching

losses may become important.

The device junction temperature, Tjis taken to be 125˚C.

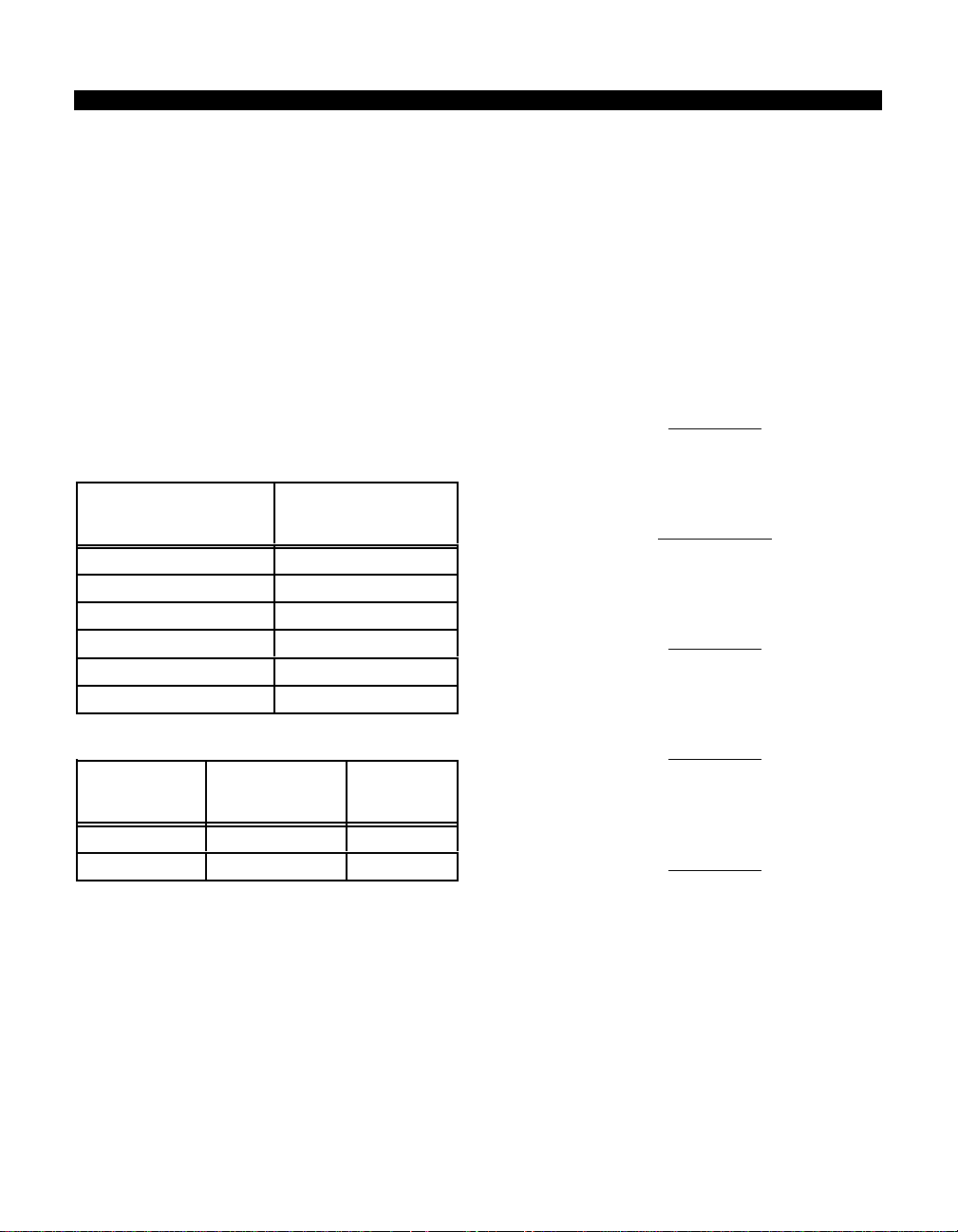

Theratio R

ds(125C˚)/Rds(25˚C)

MOSFET device. Table A1 gives the ratio for the relevant

voltage limiting values.

The value of V

A2.

s(min)

Device voltage limiting R

value. --------

100 1.74

200 1.91

400 1.98

500 2.01

800 2.11

1000 2.15

Table A1. On resistance ratio.

Main input Maximum dc link Minimum dc

voltage voltage link

220 / 240V ac 385V 200V

110 / 120V ac 190V 110V

Table A2. Max and Min dc link voltages for mains inputs.

isdependent on thevoltage of the

for each input value is given in Table

ds(125C)

R

ds(25C)

voltage

Using the following equations, for a given device with a

known R

topology can be calculated.

, the maximum throughput power in each

ds(125˚C)

Where:-

P

= Maximum throughput power.

th(max)

D

= maximum duty cycle.

τ = required transistor efficiency (0.05 ± 0.005)

max

Rds

V

s(min)

= R

(125˚C)

= minimum dc link voltage.

ds(25˚C)

x ratio.

Forward converter.

2

τ×V

×D

s(min)

P

th(max)

D

=

max

= 0.45

R

max

ds(125c)

Flyback Converter.

P

th(max)

3×τ×V

=

D

max

s(min)

4× R

= 0.45

ds(125c)

×D

max

2

Push Pull Converter.

2

τ×V

×D

s(min)

P

th(max)

=

D

= 0.9

max

R

max

ds(125c)

Half Bridge Converter.

2

τ×V

×D

s(min)

P

th(max)

=

4× R

D

= 0.9

max

max

ds(125c)

Full Bridge Converter.

2

τ×V

×D

s(min)

P

th(max)

=

2× R

D

= 0.9

max

max

ds(125c)

128

S.M.P.S. Power Semiconductor Applications

Philips Semiconductors

2.1.2 The Power Supply Designer’s Guide to High Voltage

Transistors

One of the most critical components in power switching

converters is the high voltage transistor. Despite its wide

usage, feedback from power supply designers suggests

that there are several features of high voltage transistors

which are generally not wellunderstood.

This section begins with a straightforward explanation of

the key properties of high voltage transistors. This isdone

byshowing howthe basic technology ofthe transistor leads

toits voltage,current,power and secondbreakdownlimits.

It is also made clear how deviations from conditions

specifiedin thedata book will affect the performance of the

transistor. The final section of the paper gives practical

advicefordesignerson howcircuits mightbe optimisedand

transistor failures avoided.

Introduction

A large amount of useful information about the

characteristics of a given component is provided in the

relevant data book. By using this information, a designer

can usually be sure of choosing the optimum component

for a particular application.

However,if aproblem ariseswiththe completedcircuit, and

a more detailed analysis of the most critical components

becomes necessary, the databook can become a source

of frustration rather than practical assistance. In the data

book,a component is often measured under averyspecific

setofconditions.Very littleissaidabouthowthe component

performance is affected if these conditions are not

reproducedexactlywhenthecomponent isused ina circuit.

There are as many different sets of requirements for high

voltage transistors asthere arecircuits whichmake use of

them. Covering every possible drive and load condition in

the device specification is an impossible task. There is

therefore a real need for any designer using high voltage

transistorstohave anunderstandingof howdeviations from

theconditionsspecified inthe transistordatabook willaffect

the electrical performance of the device, in particular its

limiting values.

Feedbackfrom designersimpliesthatthis informationis not

readily available. The intentionof thisreport istherefore to

provide designers with the information they need in order

tooptimise thereliability oftheir circuits.The characteristics

ofhigh voltage transistors stem from their basic technology

and so it is importantto begin with an overview of this.

HVT technology

Stripping away the encapsulationof the transistor reveals

how the electrical connections are made (see Fig. 1). The

collector is contacted through the back surface of the

transistorchip,which issolderedtothenickel-plated copper

lead frame. For Philips power transistors the lead frame

andthe centreleg are formed froma single pieceof copper,

and so the collector can be accessed through either the

centre leg or any exposed part of the lead frame (eg the

mounting base for TO-220 and SOT-93).

nickel-plated

copper lead

frame

passivated

chip

aluminium

wires

tinned copper

leads

Base Collector Emitter

Fig. 1 High voltage transistor without the plastic case.

The emitter area ofthe transistor is contactedfrom thetop

surfaceof the chip. A thinlayer of aluminium joinsall of the