Page 1

LCD TV

chassis PL9.3

Service Manual

Contents

32” 32PFL6704D/F7 (Serial No. : YA1A**********)

32” 32PFL6704D/F7 (Serial No. : YA1B**********)

42” 42PFL6704D/F7 (Serial No. : YA1A**********)

42” 42PFL6704D/F7 (Serial No. : YA1B**********)

47” 47PFL6704D/F7 (Serial No. : YA1A**********)

47” 47PFL6704D/F7 (Serial No. : YA1B**********)

© 2009 Funai Electric Co., Ltd.

All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated, transcribed,

downloaded or stored in any storage medium, in any form or for any purpose without the express prior written

consent of Funai. Furthermore, any unauthorized commercial distribution of this manual or any revision hereto

is strictly prohibited.

Information in this document is subject to change without notice. Funai reserves the right to change the content

herein without the obligation to notify any person or organization of such changes.

with the design is a registered trademark of Funai Electric Co., Ltd and may not be used in any way

without the express written consent of Funai. All other trademarks used herein remain the exclusive property of

their respective owners. Nothing contained in this manual should be construed as granting, by implication or

otherwise, any license or right to use any of the trademarks displayed herein. Misuse of any trademarks or any

other content in this manual is strictly prohibited. Funai shall aggressively enforce its intellectual property rights

to the fullest extent of the law.

A9PF4UF/A9PH4UF/A9PJ4UF

090410

Page 2

IMPORTANT SAFETY NOTICE

o

Proper service and repair is important to the safe, reliable operation of all

P&F Equipment. The service procedures recommended by P&F and

described in this service manual are effective methods of performing

service operations. Some of these service special tools should be used

when and as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk

of personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to

understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

P&F could not possibly know, evaluate and advice the service trade of all

conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, P&F has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a

service procedure or tool which is not recommended by P&F must first use

all precautions thoroughly so that neither his safety nor the safe operation

of the equipment will be jeopardized by the service method selected.

The LCD panel is manufactured to provide many years of useful life.

Occasionally a few non active pixels may appear as a tiny spec of col

This is not to be considered a defect in the LCD screen.

Page 3

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Service Modes, Error Codes, and Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Schematic Diagrams and CBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Page 4

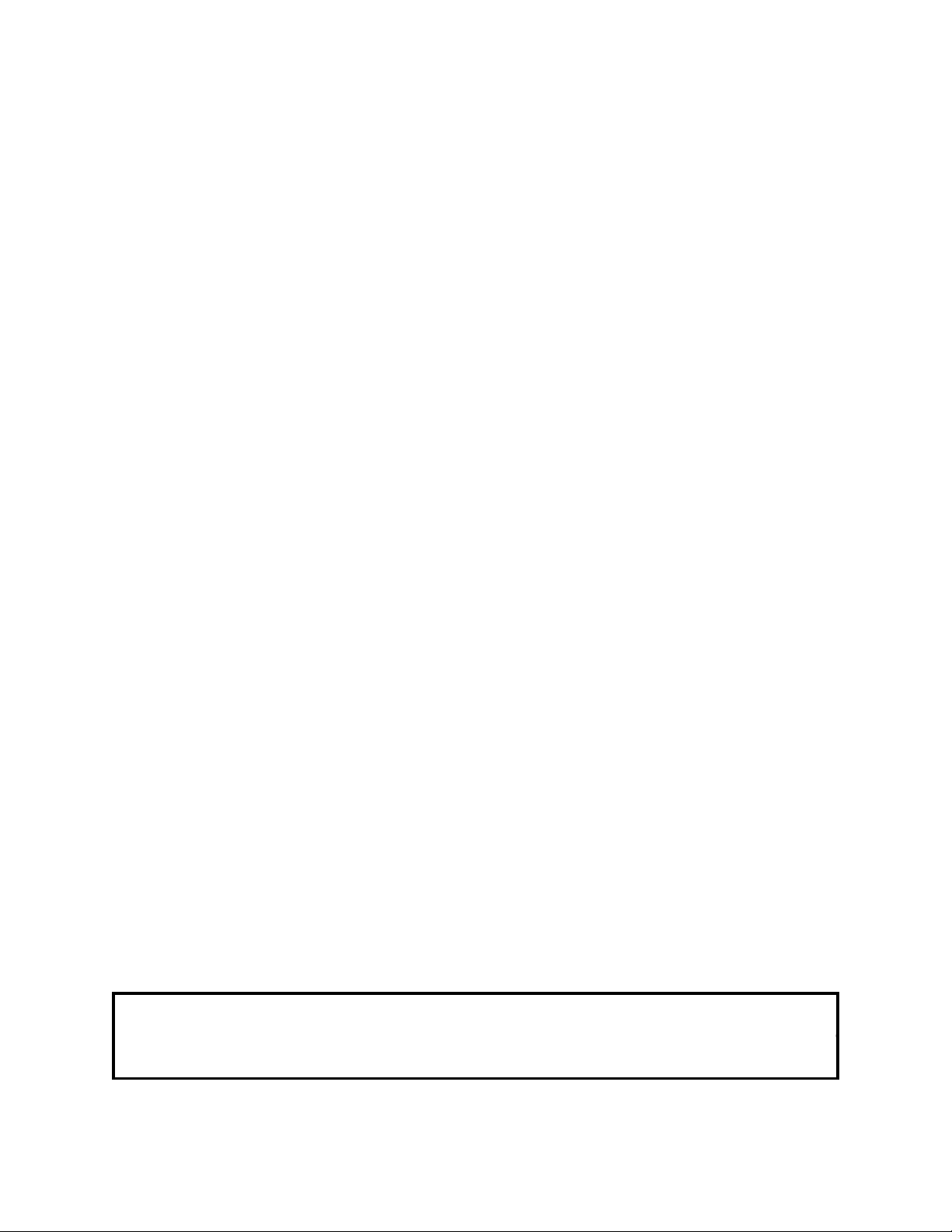

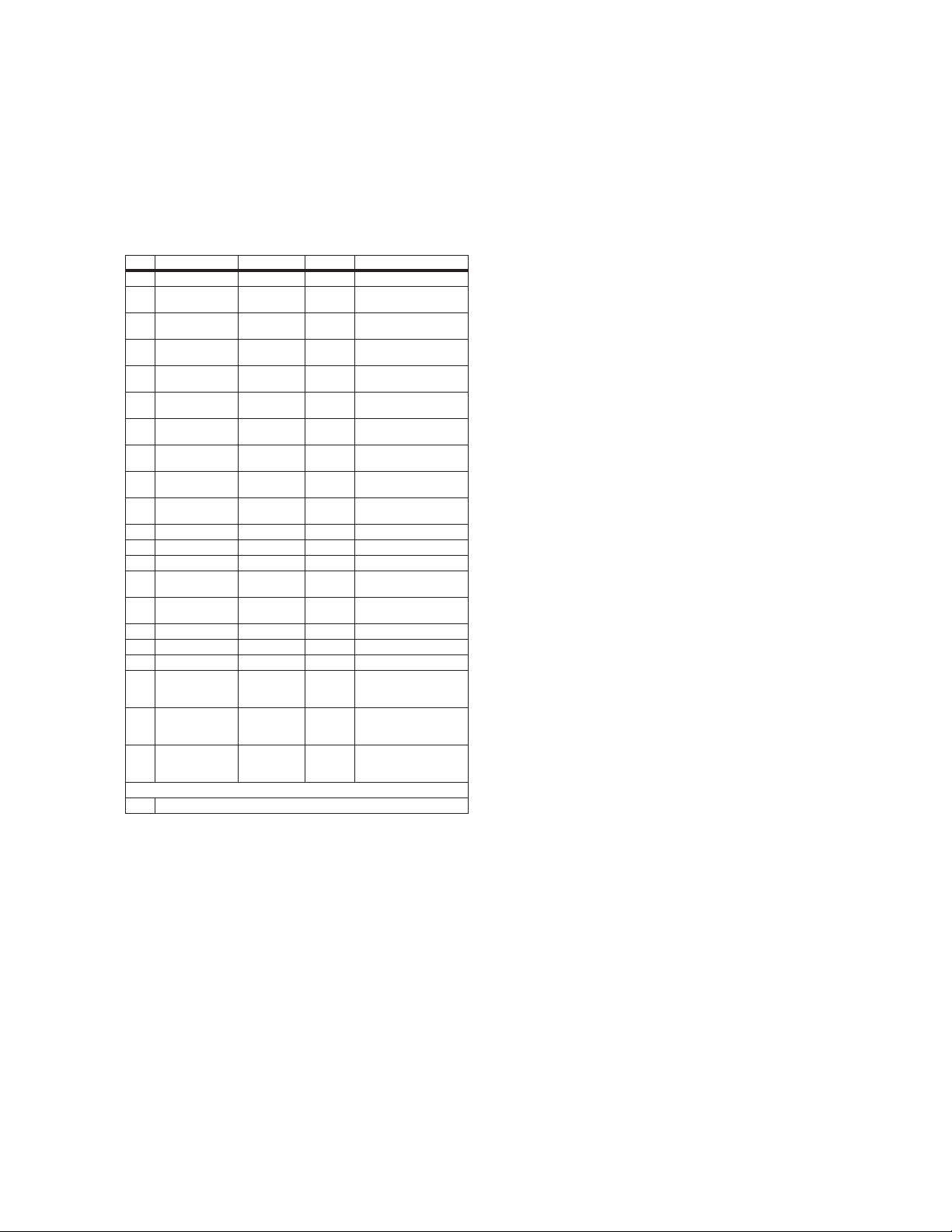

SPECIFICATIONS

< TUNER >

ANT. Input ---------------------- 75 Ω Unbal., F type

Description Band Off air channel (MHz) Cable channel (MHz)

Low Band

1. Channel Coverage

Description System Picture (MHz) Chroma (MHz) Sound (MHz)

2. Intermediate Frequencies NTSC-M 45.75 42.17 41.25

Mid Band

High Band

48.25 to 82.25

175.25 to 224.25

471.25 to 855.25

69.25 to 154.25

161.25 to 439.25

447.25 to 463.25

< LCD PANEL >

Description Condition Unit Nominal Limit

1. Pixel Format

2. Brightness (w / filter) --- cd/m

3. Viewing Angle (CR>20)

Horizontal

Ver t i cal

Horizontal

Ver t i cal

pixels

pixels

°

°

1920

1080

2

500 ---

178

178

---

---

---

---

< VIDEO >

Description Condition Unit Nominal Limit

1. Transient Response --- ns <250 ---

2. Y/C Separation --- dB >20 ---

3. Chroma (3.55 MHz) Suppression --- dB >25 ---

°K

°K

°K

11500

0.276

0.277

9000

0.289

0.291

6500

0.314

0.319

±0.004

±0.004

±0.004

±0.004

±0.004

±0.004

4. Color Temperature

Cool

x

y

Normal

x

y

warm

x

y

< AUDIO >

Description Condition Unit Nominal Limit

1. Distortion at rated Power --- % <10 ---

2. Audio Response Curve -3dB kHz >12.5 ---

---

---

---

1-1 PL9.3SP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for LCD TV

Circuit

1. Before returning an instrument to the

customer, always make a safety check of the

entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are

defective and have been defeated during

servicing. (1) Protective shields are provided

on this chassis to protect both the technician

and the customer. Correctly replace all missing

protective shields, including any removed for

servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the

cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating

fishpapers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or

permit it to be operated without all

protective devices correctly installed and

functioning. Servicers who defeat safety

features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous

voltage. Such openings include, but are not

limited to, (1) spacing between the Liquid

Crystal Panel and the cabinet mask, (2)

excessively wide cabinet ventilation slots, and

(3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug

prongs. Place the instrument AC switch in the

on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch

the other ohmmeter lead in turn to each tuner

antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohm

or greater than 5.2 megohm, an abnormality

exists that must be corrected before the

instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off

position.

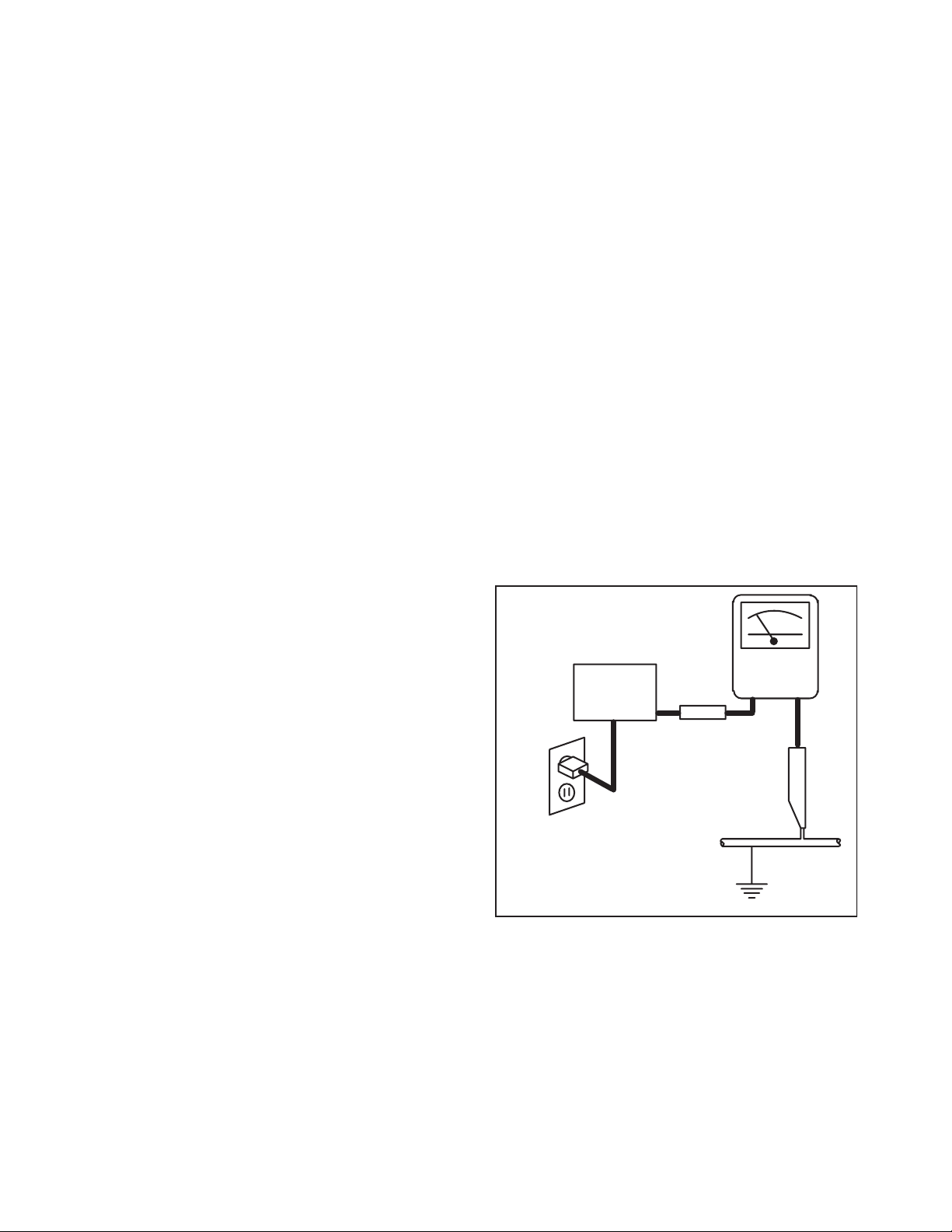

d. Leakage Current Hot Check - With the

instrument completely reassembled, plug the

AC line cord directly into a 120 V AC outlet. (Do

not use an isolation transformer during this

test.) Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI) C101.1

Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on

position and then in the off position, measure

from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the

chassis. Any current measured must not

exceed 0.5 milli-ampere. Reverse the

instrument power cord plug in the outlet and

repeat the test.

READING SHOULD

NOT BE ABOVE 0.5 mA

LEAKAGE

DEVICE

BEING

TESTED

TEST ALL EXPOSED

METAL SURFACES

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR

BEFORE CONNECTING THE ANTENNA OR

ACCESSORIES.

2. Read and comply with all caution and safety-

related notes on or inside the receiver cabinet, on

the receiver chassis, or on the Liquid Crystal

Panel.

CURRENT

TESTER

+

EARTH

GROUND

_

2-1 LTVN_ISP

Page 6

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV

receiver. Design alterations and additions,

including, but not limited to circuit modifications

and the addition of items such as auxiliary audio

and/or video output connections, might alter the

safety characteristics of this receiver and create a

hazard to the user. Any design alterations or

additions will void the manufacturer's warranty and

may make you, the servicer, responsible for

personal injury or property damage resulting

therefrom.

4. Hot Chassis Warning -

a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord and maybe safety-serviced without

an isolation transformer only if the AC power

plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is

inserted correctly, with an AC voltmeter,

measure between the chassis and a known

earth ground. If a voltage reading in excess of

1.0 V is obtained, remove and reinsert the AC

power plug in the opposite polarity and again

measure the voltage potential between the

chassis and a known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground

regardless of the AC plug polarity. This chassis

can be safety-serviced only with an isolation

transformer inserted in the power line between

the receiver and the AC power source, for both

personnel and test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulation material that must not be defeated or

altered.

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high

voltage, and, e. antenna wiring. Always inspect in

all areas for pinched, out of place, or frayed wiring.

Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

7. Product Safety Notice - Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by a # on schematics and in parts lists.

Use of a substitute replacement that does not

have the same safety characteristics as the

recommended replacement part might create

shock, fire, and/or other hazards. The product's

safety is under review continuously and new

instructions are issued whenever appropriate.

Prior to shipment from the factory, our products

are strictly inspected to confirm they comply with

the recognized product safety and electrical codes

of the countries in which they are to be sold.

However, in order to maintain such compliance, it

is equally important to implement the following

precautions when a set is being serviced.

2-2 LTVN_ISP

Page 7

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC supply outlet.

L. When installing parts or assembling the cabinet

parts, be sure to use the proper screws and

tighten certainly.

2-3 LTVN_ISP

Page 8

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and

wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified

values in order to verify compliance with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Region

110 to 130 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

U.S.A. or

Canada

Clearance

Distance (d), (d’)

≥ 3.2 mm

(0.126 inches)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method: (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across both terminals of load Z.

See Fig. 2 and following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Fig. 2

Table 2: Leakage current ratings for selected areas

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

110 to 130 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

U.S.A. or

Canada

0.15 µF CAP. & 1.5 kΩ

RES. Connected in parallel

2-4 LTVN_ISP

i ≤ 0.5 mA rms

Exposed accessible

parts

Page 9

STANDARD NOTES FOR SERVICING

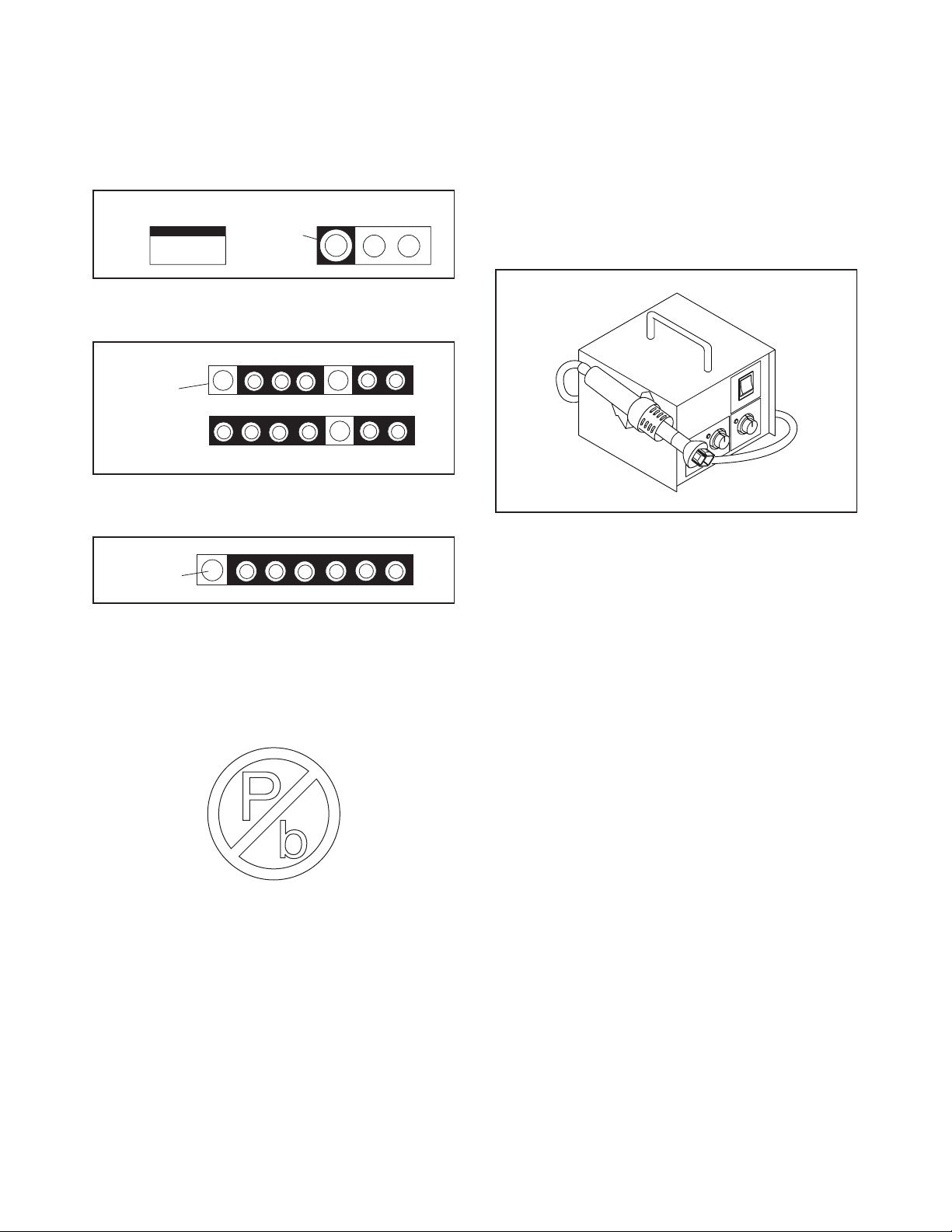

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

Pb free mark will be found on PCBs which use Pb

free solder. (Refer to figure.) For PCBs with Pb free

mark, be sure to use Pb free solder. For PCBs

without Pb free mark, use standard solder.

Pb free mark

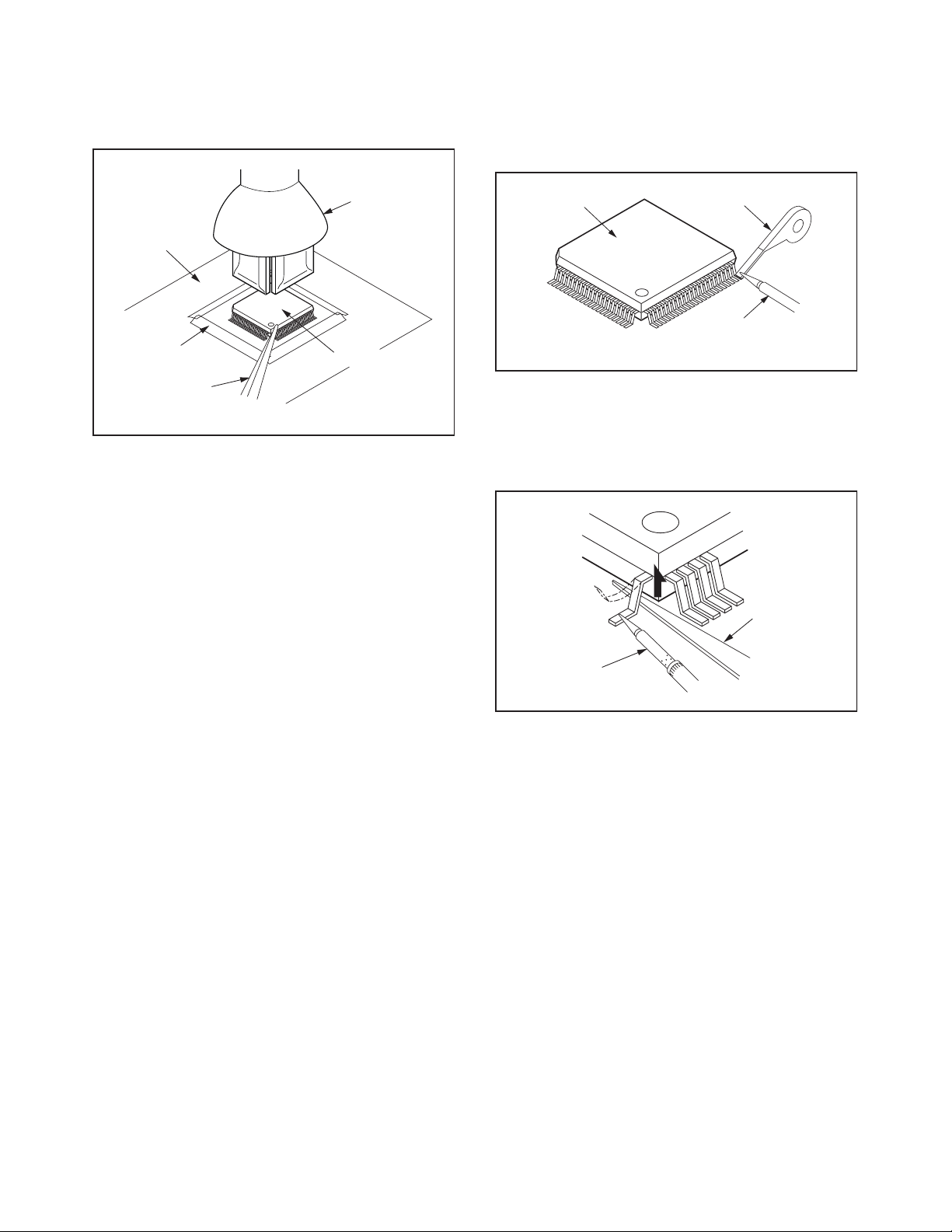

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

3-1 TVN_SN

Page 10

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

3-2 TVN_SN

Page 11

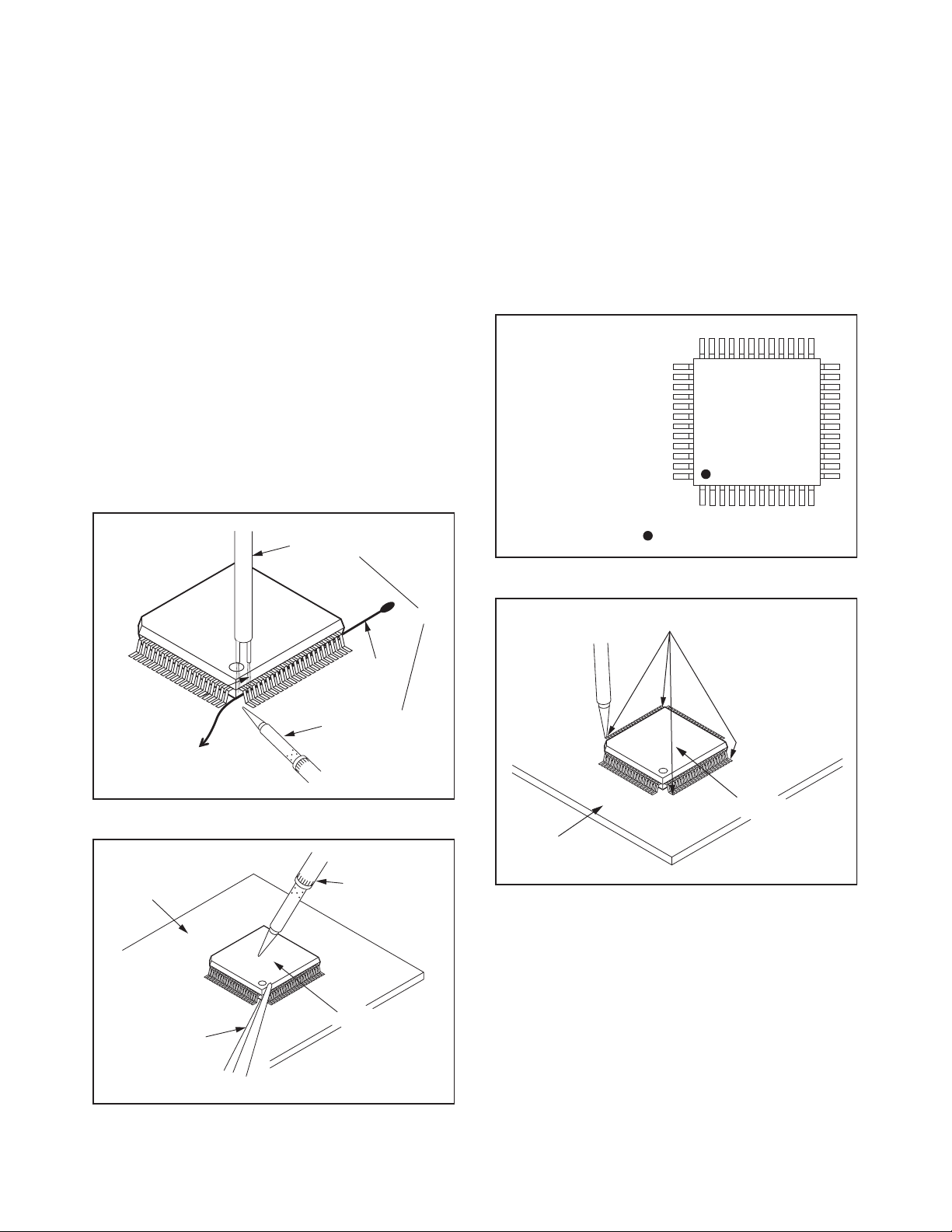

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

3-3 TVN_SN

Page 12

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

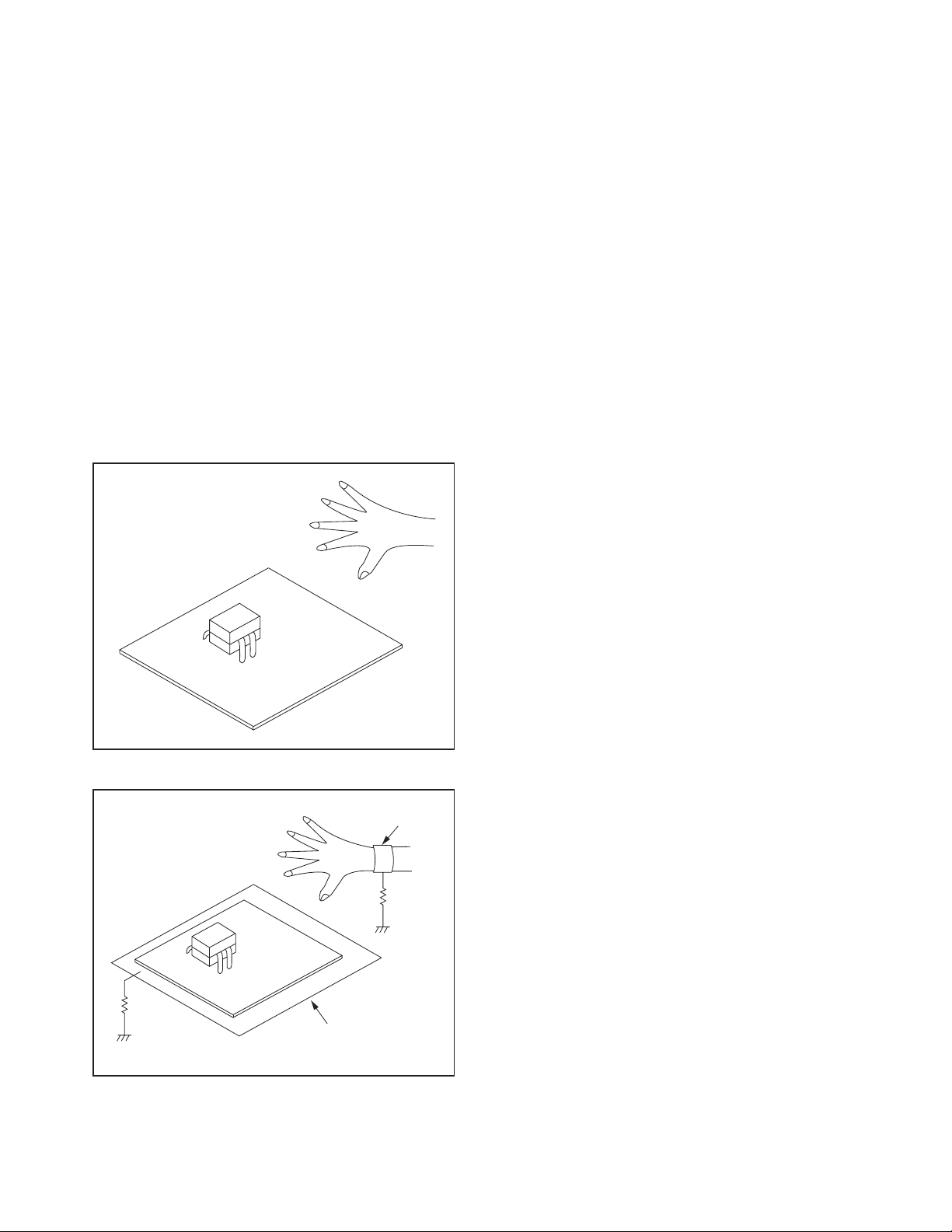

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

3-4 TVN_SN

Page 13

CABINET DISASSEMBLY INSTRUCTIONS

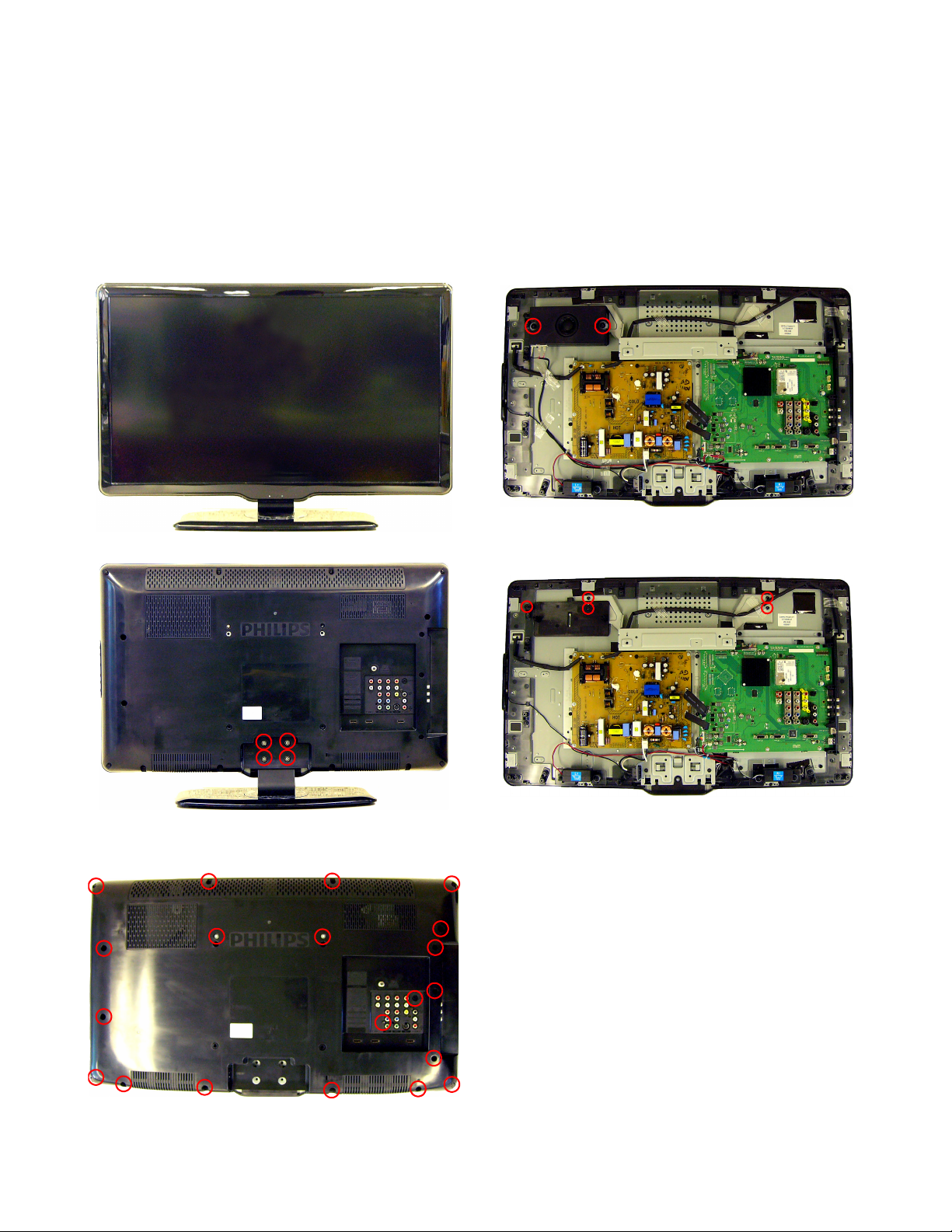

[32PFL6704D/F7]

Notes: 1. Please put your machine on soft material to avoid to scrape panel when you disassemble it.

2. The installation specifications of the part are subject to change without notice.

3. By the difference of the LCD panel, the method of installing each part might be different.

1. Assembly/Panel Removal

Front view

3. Remove the Loudspeaker Box.

Back view

Remove the 2 screws and connector 1736.

1. Remove the stand.

Remove the 4 screws.

2. Remove the Back cover assembly.

Remove the 20 screws.

4. Remove the Woofer Bracket.

Remove the 2 screws.

5. Remove the Top Frame.

Remove the 3 screws.

4-1 PL9.3DC

Page 14

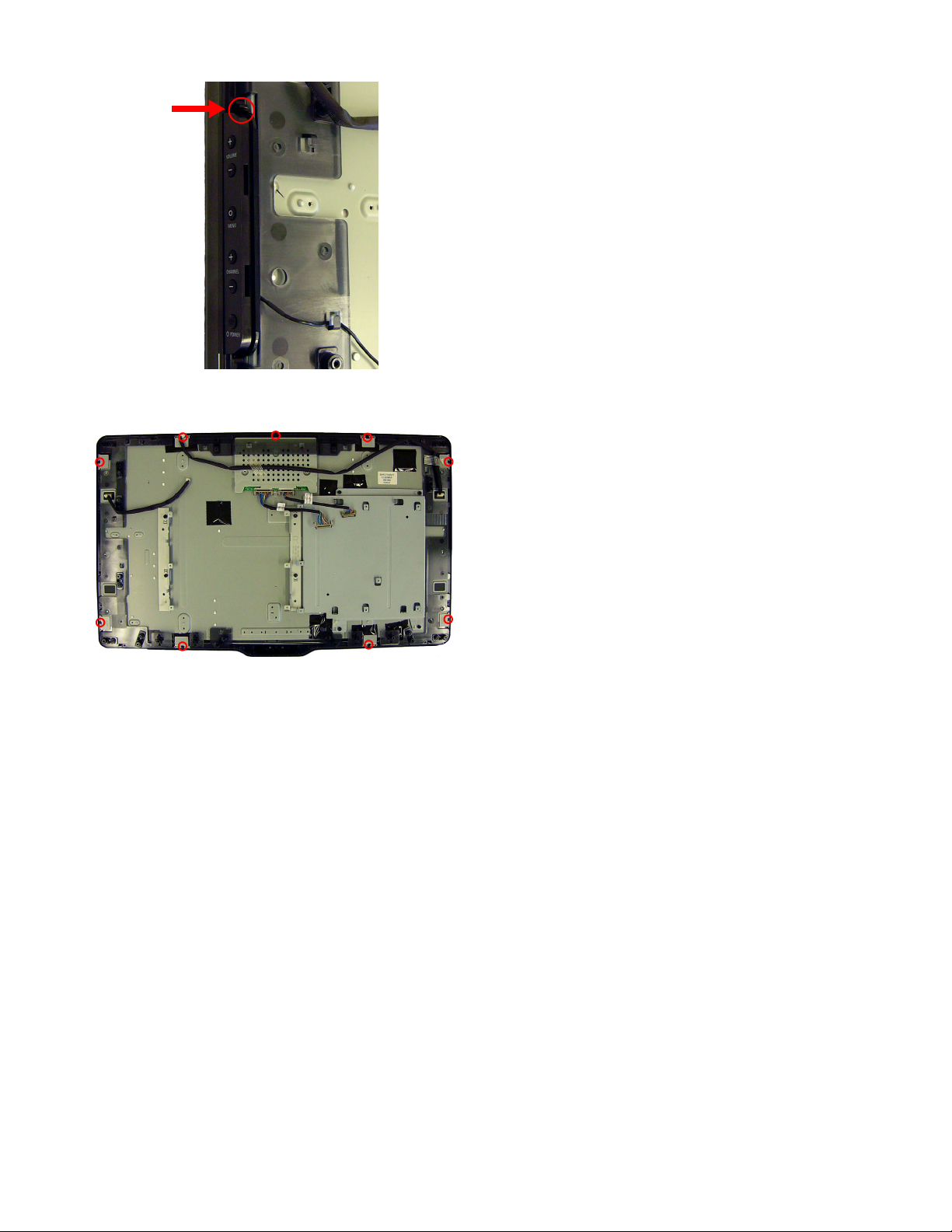

6. Remove the SSB.

Remove the 6 connectors. (1735, 1G50, 1G51,

1M20, 1M95, 1M99)

Remove the 8 screws.

7. Remove the Power supply Module.

Remove the 3 connectors. (CN1, CN2, CN3)

Remove the 6 screws.

8. Remove the Left Loudspeaker.

Remove the 2 screws.

10. Remove the Leading Edge Cover and Stand Plate.

Remove the 6 screws.

11. Remove the Module IR.

Remove the 2 screws and connector J2.

9. Remove the Right Loudspeaker.

Remove the 2 screws.

12. Remove the Light Guide.

4-2 PL9.3DC

Page 15

13. Remove the Module Control Knob.

Release a locking tab.

2. Set Re-assembly

To re-assemble the whole set, execute all processes in

reverse order.

Note: While re-assembling, make sure that all cables

are placed and connected in their original

position.

• The content is different according to the product.

14. Remove the TFT-LCD.

Remove the 9 screws.

4-3 PL9.3DC

Page 16

CABINET DISASSEMBLY INSTRUCTIONS

[42PFL6704D/F7, 47PFL6704D/F7]

Notes: 1. Please put your machine on soft material to avoid to scrape panel when you disassemble it.

2. The installation specifications of the part are subject to change without notice.

3. By the difference of the LCD panel, the method of installing each part might be different.

1. Assembly/Panel Removal

Front view

3. Remove the SSB.

Back view

Remove the 6 connectors. (1735, 1G50, 1G51,

1M20, 1M95, 1M99)

Remove the 8 screws.

4. Remove the Power supply Module.

Remove the 3 connectors. (CN1, CN2, CN3)

Remove the 8 screws.

1. Remove the stand.

Remove the 4 screws.

2. Remove the Back cover assembly.

Remove the 22 screws.

5. Remove the Left Loudspeaker.

Remove the 2 screws.

6. Remove the Right Loudspeaker.

Remove the 2 screws.

4-4 PL9.3DC

Page 17

7. Remove the Leading Edge Cover, PSU Bar Right ,

VESA BKT BTM Right and Stand Plate.

Remove the 10 screws

8. Remove the Module IR.

Remove the 2 screws and connector J2.

10. Remove the TFT-LCD.

Remove the 8 screws.

2. Set Re-assembly

To re-assemble the whole set, execute all processes in

reverse order.

Note: While re-assembling, make sure that all cables

are placed and connected in their original

position.

• The content is different according to the product.

9. Remove the Module Control Knob.

Release a locking tab.

4-5 PL9.3DC

Page 18

SERVICE MODES, ERROR CODES, and FAULT FINDING

1Test Points

In the chassis schematics and layout overviews, the test points

are mentioned. In the schematics, test points are indicated with

“Fxxx” or “Ixxx”, in the layout overviews with a “half-moon” sign.

As most signals are digital, it will be difficult to measure

waveforms with a standard oscilloscope.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Color bar signal.

• Audio: 3 kHz left, 1 kHz right.

2 Se rvice Modes

The Service Mode feature is split into four parts:

• Service Default Mode (SDM).

• Service Alignment Mode (SAM).

• Customer Service Mode (CSM).

• Computer Aided Repair Mode (ComPair).

SDM and SAM offer features, whic

engineer to repair/align a TV set. Some features are:

• A pre-defined situation to ensure measurements can be

made under uniform conditions (SDM).

• Activates the blinking LED procedure for error identification

when no picture is available (SDM).

• The possibility to overrule software protections when SDM

is entered via the Service pins.

• Make alignments (e.g. White Tone), (de)select options,

enter options codes, reset the error buffer (SAM).

• Display information (“SDM”

right corner of screen, error buffer, software version,

operating hours, options

The CSM is a Service Mode that can be enabled by the

consumer. The CSM displays diagnosis information, which the

customer can forward to the dealer or call centre. In CSM

mode, “CSM”, is displayed in the top right corner of the screen.

The information provided in CSM and the purpose of CSM is to:

• Increase the home repair hit rate.

• Decrease the number of nuisance calls.

• Solved customers' problem without home visit.

2.1 General

h can be used by the Service

or “SAM” indication in upper

and option codes, sub menus).

Life Timer

During the life time cycle of the TV set, a timer is kept (called

“Op. Hour”). It counts the normal operation hours (not the

Stand-by hours). The actual value of the timer is displayed in

SDM and SAM in a decimal value. Every two soft-resets

increase the hour by +1. Standby hours are not counted.

Software Identification, Version and Cluster

The software ID, version, and cluster will be shown in the main

menu display of SDM, SAM, and CSM.

The screen will show: “AAAABCD X.YY”, where:

• AAAA

• B

is the chassis name: LC92. (Development chassis)

is the region indication: E= Europe, A= AP/China, U=

NAFTA, L= LATAM.

• C is the display indication: L= LCD, P= Plasma.

• D is the language/feature indication: P= Philips, M=

Magnavox.

• X is the main version number: this is updated with a major

change of specification (incompatible with the previous

software version). Numbering will go from 1 - 9 and A - Z.

– If the main version number changes, the new version

number is written in the NVM.

– If the main version number changes, the default

settings are loaded.

•

is the sub version number: this is updated with a minor

YY

change (backwards compatible with the previous versions)

Numbering will go from 00 - 99.

– If the sub version number changes, the new version

number is written in the NVM.

– If the NVM is fresh, the software identification, version,

and cluster will be written to NVM.

Display Option Code Selection

When after an SSB or display exchange, the display option

code is not set properly, it will result in a TV with “no display”.

Therefore, it is required to set this display option code after

such a repair.

To do so, press the following key sequence on a standard RC

transmitter: “062598"directly followed by MENU and "xxx"

where “xxx” is a 3 digit decimal value of the panel type: see

column “Panel Code” in table “Option Codes OP1...OP7” (ch.

8), or see sticker on the side/bottom of the cabinet. When the

value is accepted and stored in NVM, the set will switch to

Stand-by, to indicate that the process has been completed.

Some items are applicable to all Service Modes or are general.

These are listed below.

Display Option

Code

39mm

040

PHILIPS

MODEL:

2PF9968/10

3

27mm

SERIAL NO:

PROD.

AG 1A0620 000001

(CTN Sticker)

Figure 1 Location of Display Option Code sticker

During this algorithm, the NVM-content must be filtered,

because several items in the NVM are TV-related and not SSBrelated (e.g. Model and Prod. S/N). Therefore, “Model” and

“Prod. S/N” data is changed into “See Type Plate”.

In case a call centre or cons

umer reads “See Type Plate” in

CSM mode, he needs to look to the side/bottom sticker to

identify the set, for further actions.

5-1 PL9.3SM

Page 19

Service Default Mode (SDM)

2.2

Purpose

Set the TV in SDM mode in order to be able to:

• Create a pre-defined setting for measurements to be

made.

• Override software protections.

• Start the blinking LED procedure.

• Read the error buffer.

• Check the life timer.

Specifications

Table 1 SDM default settings

Region Freq. (MHz)

Europe (except France),

AP-PAL/-Multi

NAFTA, AP-NTSC 61.25 (channel 3) NTSC M

ATAL

475.25 PAL B/G

Default syst.

L MACESecnarF

M LAPM

On Screen Menu

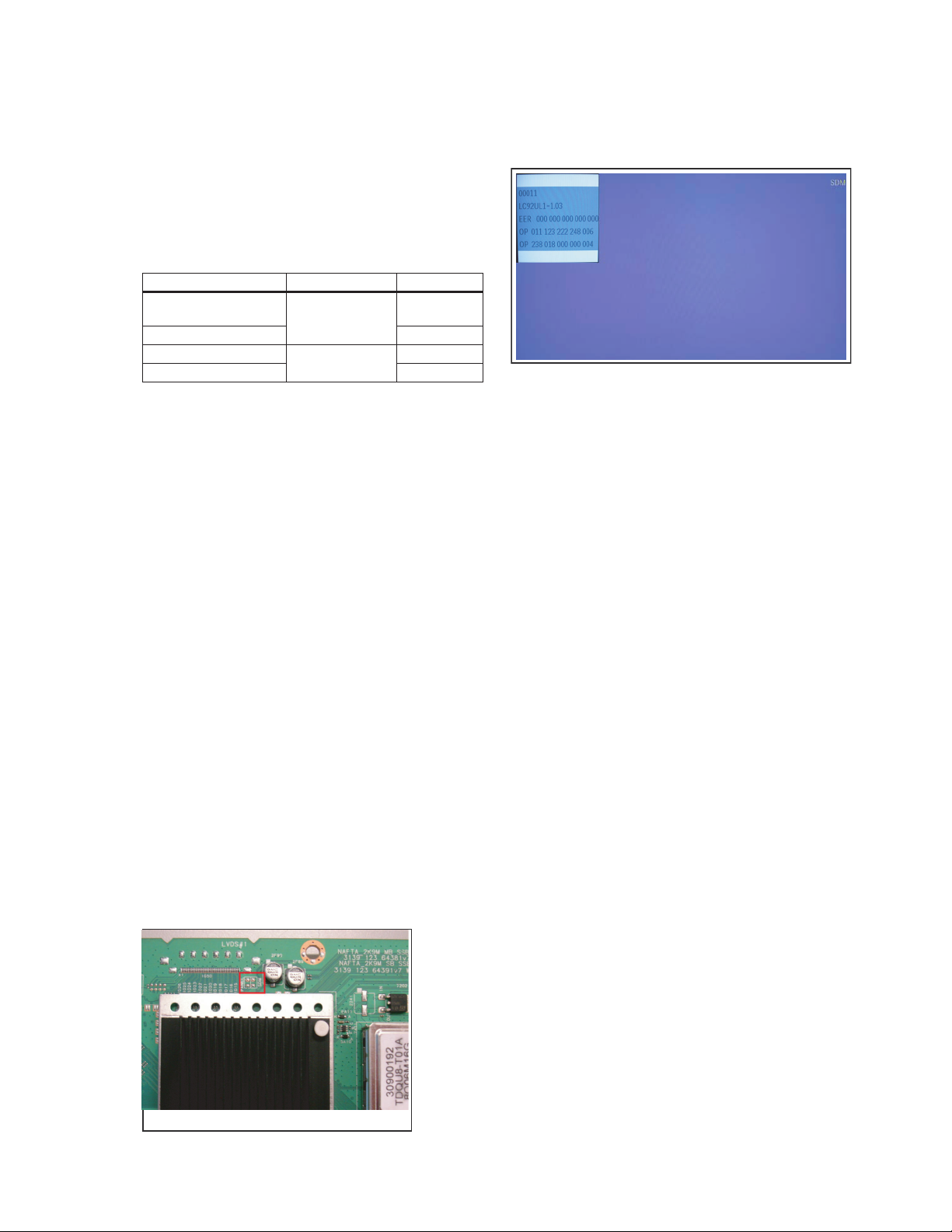

After activating SDM, the following screen is visible, with SDM

in the upper right corner of the screen to indicate that the

television is in Service Default Mode.

Figure 3 SDM menu

• Set linear video and audio settings to 50%, but volume to

25%. Stored user settings are not affected.

• All service-unfriendly modes (if present) are disabled, since

they interfere with diagnosing/repairing a set. These

service unfriendly modes are:

– (Sleep) timer.

– Blue mute/Wall paper.

– Auto switch “off” (when there is no “ident” signal).

– Hotel or hospital mode.

– Child lock or parental lock (manual or via V-chi p).

– Skipping, blanking of “Not favorite”, “Skipped” or

“Locked” presets/channels.

– Automatic storing of Personal Preset or Last Status

settings.

– Automatic user menu time-out (menu switches back/

OFF automatically.

– Auto Volume levelling (AVL).

How to Activate

To activate SDM, use

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU button

(do not allow the display to time out between entries while

keying the sequence).

• Short one of the “Service” jumpers on the TV board during

cold start (see Figures “Service jumper”). Then press the

mains button (remove the short after start-up).

Caution: Activating SDM by shorting “Service” jumpers will

override the DC speaker prot

I2C error (error 4), and the Tr

(error 5). When doing this, the service-technician must

know exactly what he is doing, as it could damage the

television set.

one

of the following methods:

ection (error 1), the General

ident video processor error

Menu explanation:

• HHHHH: Are the operating hours (in decimal).

AAAABCD-X.YY

•

“General” -> “Software Identification, Version, and Cluster”

for the SW name definition.

• EER: Shows all errors detected since the last time the

buffer was erased. Five errors possible.

• OP: Used to read-out the option bytes. See “Options” in the

Alignments section for a detailed description. Ten codes (in

two rows) are possible.

How to Navigate

As this mode is read only, there is not much to navigate. To

switch to other modes, use one of the following methods:

• Command MENU from the user remote will enter the

normal user menu (brightness, contrast, color, etc...) with

“SDM” OSD remaining, and pressing MENU key again will

return to the last status of SDM again.

• To prevent the OSD from interfering with measurements in

SDM, command “OSD” or “i+” (“STATUS” or “INFO” f or

NAFTA and LATAM) from the user remote will toggle the

OSD “on/off” with “SDM” OSD remaining always “on”.

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the OSD/

STATUS/INFO/I+ button to switch to SAM (do not allow the

display to time out between entries while keying the

sequence).

How to Exit

Switch the set to STANDBY by pressing the mains button on

the remote control transmitter or on the television set.

If you switch the television set “off” by removing the mains (i.e.,

unplugging the television), the television set will remain in SDM

when mains is re-applied, and the error buffer is not cleared.

The error buffer will only be cleared when the “clear” command

is used in the SAM menu.

: See paragraph “Service Modes” ->

Figure 2 Service jumper (SSB component side)

Note:

• If the TV is switched “off” by a power interrupt while in SDM,

the TV will show up in the last status of SDM menu as soon

as the power is supplied again. The error buffer will not be

cleared.

• In case the set is in Factory mode by accident (with “F”

displayed on screen), by pressing and hold “VOL-“ and

“CH-” together should leave Factory mode.

5-2 PL9.3SM

Page 20

Service Alignment Mode (SAM)

2.3

Purpose

• To change option settings.

• To display / clear the error code buffer.

• To perform alignments.

Specifications

• Operation hours counter (maximum five digits displayed).

• Software version, error codes, and option settings display.

• Error buffer clearing.

• Option settings.

• Software alignments (White Tone).

• NVM Editor.

• Set the screen mode to full screen (all content on screen is

visible).

How to Activate

To activate SAM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “

STATUS/INFO/I+ button (it depends on region which

button is present on the RC). Do not allow the display to

time out between entries while keying the sequence.

After entering SAM, the following screen is visible, with SAM in

the upper right corner of the screen to indicate that the

television is in Service Alignment Mode.

” directly followed by the OSD/

062596

4.

RGB Align. Used to align the White Tone. See “White

Tone” in the “Alignments” chapter for a detailed

description.

5. NVM Editor. Can be used to change the NVM data in the

television set. See also paragraph “Fault Finding and

Repair Tips” further on.

6.

NVM Copy. Gives the possibility to copy/load the NVM file

to/from an USB stick.

How to Navigate

• In the SAM menu, select menu items with the UP/DOWN

keys on the remote control transmitter. The selected item

will be indicated. When not all

use the UP/DOWN keys to display the next / previous

menu items.

• With the LEFT/RIGHT keys, it is possible to:

– Activate the selected menu item.

– Change the value of the selected menu item.

– Activate the selected sub menu.

• When you press the MENU button twice while in top level

SAM, the set will switch to the normal user menu (with the

SAM mode still active in the background). To return to the

SAM menu press the MENU button.

• The “OSD/STATUS/INFO/i+ ” key from the user remote will

toggle the OSD “on/off” with “SAM” OSD remaining always

“on”.

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU

to switch to SDM (do not allow the display to time out

between entries while keying the sequence).

menu items fit on the screen,

button

Figure 4 SAM menu

Menu explanation:

1. System Information:

Op. Hour. This represents the life timer. The timer

•

counts normal operation hours, but does not count

Stand-by hours.

MAIN SW ID.

•

“General” -> “Software Identification, Version, and

Cluster” for the SW name definition.

• ERROR CODES . Shows all errors detected since the

last time the buffer was erased. Five errors possible.

• OP1 / OP2. Used to read-out the option bytes. See

“Options” in the Alignments section for a detailed

description. Ten codes are possible.

2.

3. Options.. Used to set the option bits. See “Options” in the

Erases the contents of the error buffer. Select the

Clear.

CLEAR menu item and press the MENU RIGHT key. The

content of the error buffer is cleared.

“Alignments” chapter for a detailed description.

See paragraph “Service Modes” ->

How to Store SAM Settings

To store the settings changed in SAM mode (except the

OPTIONS and RGB ALIGN settings), leave the top level SAM

menu by using the POWER button on the remote control

transmitter or the television set. The mentioned exceptions

must be stored separately via the STORE button.

How to Exit

Switch the set to STANDBY by pressing the mains button on

the remote control transmitter or the television set.

Note:

• When the TV is switched “off” by a power interrupt while in

SAM, the TV will show up in “normal operation mode” as

soon as the power is supplied again. The error buffer will

not be cleared.

• In case the set is in Factory mode by accident (with “F”

displayed on screen), by pressing and hold “VOL-“ and

“CH-” together should leave Factory mode.

5-3 PL9.3SM

Page 21

2.4 Customer Service Mode (CSM)

Purpose

The Customer Service Mode shows error codes and

information on the TV’s operation settings. A call centre can

instruct the customer (by telephone) to enter CSM in order to

identify the status of the set. This helps them to diagnose

problems and failures in the TV before making a service call.

The CSM is a read-only mode; therefore, modifications are not

possible in this mode.

Specifications

• Ignore “Service unfriendly modes”.

• Line number for every line (to make CSM language

independent).

• Set the screen mode to full screen (all contents on screen

is visible).

• After leaving the Customer Service Mode, the original

settings are restored.

• Possibility to use

enter the specific channel number on the RC.

How to Activate

To activate CSM, press the following key sequence on a

standard remote control transmitter: “123654” (do not allow the

display to time out between entries while keying the sequence).

Upon entering the Customer Service Mode, the following

screen will appear:

“CH+” or “CH-” for channel surfing, or

Menu Explanation

1. Model Number.

2. Production Serial Number. Product serial no., e.g.

SV1A0805123456 (*). SV= Production center, 1= BOM

code, A= Service version change code, 08= Production

year, 05= Production week, 123456= Serial number.

3. Software Version. Main software cluster and version is

displayed.

4. Option Code 1. Option code information (group 1).

5. Option Code 2. Option code information (group 2).

6. Codes. Error buffer contents.

7.

8. Display.

9. NVM Version. The NVM software version no.

10. PQ Version. PQ (picture quality) data version. This is a

11. Key (HDCP). Indicates if the HDMI keys (or HDCP keys)

12. Digital Signal Quality. Tuner signal condition in

13. Blank.

14. Audio System. Gives information about the audio system

15. HDAU. HDMI audio stream detection. “YES” means audio

16. Video Format. Gives information about the video format of

17. HD SW ID. Shows the HD DNM software version.

18. FPGA SW ID. Shows the FPGA software version (if

19. DFI SW ID. Shows the DFI software version (if present).

20. Standby uP SW ID. Shows the Standby Processor

Indication of the SSB factory ID (= 12nc). (*)

SSB.

subset of the main SW.

are valid or not.

percentage.

of the selected transmitter (MONO/STEREO).

stream detected. “NO” means no audio stream present.

Only displayed when HDMI source is selected.

the selected transmitter (480p30/720p60/1080i50/1080i60,

etc...). Is applicable to both HDMI and CVI sources.

present).

software version.

Type number, e.g. XXPFL6704D/F7

Indication of the display ID (=12 nc). (*)

Figure 5 CSM menu -1- (example)

Figure 6 CSM menu -2- (example)

(*)

If an NVM IC is replaced or initialized, these items must be

re-written to the NVM. ComPair will foresee in a possibility to

do this.

How to Exit

To exit CSM, use one of the following methods:

• Press the MENU button twice on the remote control

transmitter.

• Press the POWER button on the remote control

transmitter.

• Press the POWER button on the television set.

5-4 PL9.3SM

Page 22

3 Error Codes

3.1 Introduction

Error codes are required to indicate failures in the TV set. In

principle a unique error code is available for every:

• Activated protection.

• Failing I2C device.

• General I2C error.

• SDRAM failure.

The last five errors, stored in the NVM, are shown in the

Service menu’s. This is called the error buffer.

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is displayed at the left side and all other errors shift one

position to the right.

An error will be added to the buffer if this error differs from any

error in the buffer. The last found error is displayed on the left.

An error with a designated error code may never lead to a

deadlock situation. This means that it must always be

diagnosable (e.g. error buffer via OSD or blinking LED

procedure, ComPair to read from the NVM).

In case a failure identified by an error code automatically

results in other error codes (cause and effect), only the error

code of the MAIN failure is displayed.

Example: In case of a failure of the I2C bus (CAUSE), the error

code for a “General I2C failure” and “Protection errors” is

displayed. The error codes for the single devices (EFFECT) is

not displayed. All error codes are stored in the same error

buffer (TV’s NVM) except when the NVM itself is defective.

3.2 How to Read the Error Buffer

You can read the error buffer in 3 ways:

• On screen via the SAM/SDM/CSM (if you have a picture).

Example:

– ERROR: 0 0 0 0 0 : No errors detected

– ERROR: 6 0 0 0 0 : Error code 6 is the last and only

detected error

– ERROR: 9 6 0 0 0 : Error code 6 was detected first and

error code 9 is the last detected (newest) error

• Via the blinking LED procedure (when you have no

picture). See “The Blinking LED Procedure”.

•Via ComPair.

5-5 PL9.3SM

Page 23

3.3 Error Codes

4 The Blinking LED Procedure

In case of non-intermittent faults, write down the errors present

in the error buffer and clear the error buffer before you begin

the repair. This ensures that old error codes are no longer

present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

and not the actual cause of the problem (for example, a fault in

the protection detection circuitry can also lead to a protection).

Code Error Description

0 No Error -- -- -- N/A -- -- --

1 DC Protection MT5382

2 +12V Failure WT61P7

3 Stand-by Control-

ler I2C

4 General I2C I2C0 Bus Error Log Communication Error on

5 # MT8280 I2C I2C0 Bus Error Log Communication Error with

6 System NVM I2C I2C0 Bus Protection Communication Error with

7 Tuner Tuner I2C Bus Error Log Communication Error with

8 IF/PLL Demodula-

tor

9 Ambilight FPGA I2C0 Bus Error Log Communication Error with

10 Reserved -- -- -- N/A -- -- --

11 Reserved -- -- -- N/A -- -- --

12 Reserved -- -- -- N/A -- -- --

13 HDMI Switch I2C I2C0 Bus Error Log Communication Error with

14 MT8280 DRAM1 DRAM R/W

15 Reserved -- -- -- N/A -- -- --

16 Reserved -- -- -- N/A -- -- --

17 Reserved -- -- -- N/A -- -- --

18 # Channel Decoder

I2C

19 # Pro Idiom I2C I2C0 Bus Error Log Communication Error with

21 # Bolt-On HDMI

NVM I2C

Detection via: Type

(7A01)

(7E23)

I2C0 Bus Protection Communication Error with

Tu ner I2C Bus Error Log Communication Error with

(7B02/03)

I2C0 Bus Error Log Communication Error with

I2C0 Bus Error Log Communication Error with

Remarks

Protection DC_PROT = Low

Protection POWER_DOWN = Low

WT61P7

I2C0 Bus

MT8280

System NVM

Tuner TDQU

TDA9886

EC2S

Sil9185

Error Log R/W Error with DRAM1 or

DRAM2

MT5112 (reserved for

BDS modules)

Pro Idiom (reserved for

BDS modules)

BDS Bolt-On (reserved for

BDS modules)

4.1 Introduction

The software is capable of identifying different kinds of errors.

Because it is possible that more than one error can occur over

time, an error buffer is available, which is capable of storing the

last five errors that occurred. This is useful if the OSD is not

working properly.

Errors can also be displayed by the blinking LED procedure.

The method is to repeatedly let the front LED pulse with as

many pulses as the error code number, followed by a period of

1.5 seconds in which the LED

is “off”. Then this sequence is

repeated.

Example (1) : error code 4 will result in four times the sequence

LED “on” for 0.25 seconds / LED “off” for 0.25 seconds. After

this sequence, the LED will be “off” for 1.5 seconds. Any RC5

command terminates the sequence. Error code LED blinking is

in red color.

Example (2) : the content of the error buffer is “12 9 6 0 0”

After entering SDM, the following occurs:

• 1 long blink of 5 seconds to start the sequence,

• 12 short blinks followed by a pause of 1.5 seconds,

• 9 short blinks followed by a pause of 1.5 seconds,

• 6 short blinks followed by a pause of 1.5 seconds,

• 1 long blink of 1.5 seconds

to finish the sequence,

• The sequence starts again with 12 short blinks.

4.2 Displaying the Entire Error Buffer

Additionally, the entire error buffer is displayed when Service

Mode “SDM” is entered. In case the TV set is in protection or

Stand-by: The blinking LED procedure sequence (as in SDMmode in normal operation) must be triggered by the following

RC sequence: “MUTE” “062500” “OK ”.

In order to avoid confusion with RC5 signal reception blinking,

this blinking procedure is terminated when a RC5 command is

received.

# If IC/board available.

3.4 How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

• By using the CLEAR command in the SAM menu:

• If the contents of the error buffer have not changed for 50

hours, the error buffer resets automatically.

Note:

If you exit SAM by disconnecting the mains from the

television set, the error buffer is not reset.

5-6 PL9.3SM

Page 24

5 Fault Finding and Repair Tips

Table 2 NVM editor overview

Notes:

• It is assumed that the components are mounted correctly

with correct values and no bad solder joints.

•

any fault finding actions, check if the correct

Before

options are set.

5.1 Software Protections

Most of the protections and errors use either the stand-by or the

micro processor as detection device. Since in these cases,

checking of observers, polling of ADCs, and filtering of input

values are all heavily softwar

e based, these protections are

referred to as software protections.

There are several types of software related protections, solving

a variety of fault conditions:

• Protections related to supplies:

Protections related to breakdown of the safety check

•

check of the 12V.

mechanism. E.g. since the protection detections are done

by means of software, failing of the software will have to

initiate a protection mode since safety cannot be

guaranteed any more.

Remark on the Supply Errors

The detection of a supply dip or

playing of the set does not lead to

supply loss during the normal

a protection, but to a cold

reboot of the set. If the supply is still missing after the reboot,

the TV will go to protection.

Protections during Start-up

During TV start-up, some voltages and IC observers are

actively monitored to be able to optimize the start-up speed,

and to assure good operation of all components. If these

monitors do not respond in a defined way, this indicates a

malfunction of the system and leads to a protection.

5.2 Hardware Protections

The only real hardware protection in

an audio problem) the audio protecti

this chassis is (in case of

on circuit that will trigger

the uP to switch “off” the TV.

Repair Tip

• It is also possible that you have an audio DC protection

because of an interruption in one or both speakers (the DC

voltage that is still on the circuit cannot disappear through

the speakers).

Caution:

(dis)connecting the speaker wires during the ON

state of the TV at high volume can damage the audio

amplifier.

Hex Dec Description

Address 0x000A 10 Existing value

Value 0x0000 0 New value

Store Store?

5.4 Load Default NVM Values

It is possible to download default values automatically into the

NVM in case a blank NVM is placed or when the NVM first 20

address contents are “FF”. After the default values are

downloaded, it is possible to start-up and to start aligning the

TV set. To initiat e a forced default download the following

action has to be performed:

1. Switch “off” the TV set with the mains cord disconnected

from the wall outlet (it does not matter if this is from “Standby” or “Off” situation).

2. Short-circuit the SDM jumpers on the SSB (keep short

circuited).

3. Press “P+” or “CH+” on t

he local keyboard (and keep it

pressed).

4. Reconnect the mains supply to the wall outlet.

5. Release the “P+” or “CH+” when the set is started up and

has entered SDM.

When the downloading has completed successfully, the set

should be into Stand-by, i.e. red LED on.

Alternative method:

It is also possible to upload the default values to the NVM with

ComPair in case the SW is changed, the NVM is replaced with

a new (empty) one, or when the NVM content is corrupted.

After replacing an EEPROM (or with a defective/no EEPROM),

default settings should be used to enable the set to start-up and

allow the Service Default Mode and Service Alignment Mode to

be accessed.

5.5 Display option code

Caution: In case you have replaced the SSB, always check the

display option code in SAM, even if you have picture.

With a wrong display option code it is possible that you have

picture, but that in certain conditions you have unwanted

side-effects.

5.3 NVM Editor

In some cases, it can be convenient if one directly can change

the NVM contents. This can be done with the “NVM Editor” in

SAM mode. With this option, single bytes can be changed.

Caution:

• Do not change these, without understanding the

function of each setting, because incorrect NVM

settings may seriously hamper the correct functioning

of the TV set!

• Always write down the existing NVM settings, before

changing the settings. This will enable you to return to the

original settings, if the new se

ttings turn out to be incorrect.

5-7 PL9.3SM

Page 25

6 Alignments

Note: Figures below can deviate

slightly from the actual

situation, due to the different set executions.

General: The Service Default Mode (SDM) and Service

Alignment Mode (SAM) are described in chapter 5. Menu

navigation is done with the CURSOR UP, DOWN, LE FT or

RIGHT keys of the remote control transmitter.

6.1 General Alignment Conditions

Perform all electrical adjustments under the following

conditions:

• Power supply voltage (depends on region):

– AP-NTSC: 120 V

– AP-PAL-multi: 120 - 230 V

– EU: 230 V

AC

– LATAM-N TSC: 120 - 230 V

– US: 120 V

AC

or 230 V

AC

AC

/ 50 Hz (± 10%).

/ 60 Hz (

AC

± 10%).

/ 50 Hz (± 10%).

AC

/ 50 Hz (± 10%).

/ 50 Hz (

• Connect the set to the mains via an isolation transformer

with low internal resistance.

• Allow the set to warm up for approximately 15 minutes.

• Measure voltages and waveforms in relation to correct

ground (e.g. measure audio signals in relation to

AUDIO_GND).

Caution:

It is not allowed to use heatsinks as ground.

• Test probe: Ri > 10 Mohm, Ci < 20 pF.

• Use an isolated trimmer/screwdriver to perform

alignments.

6.2 Hardware Alignments

There are no hardware alignments foreseen for this chassis.

6.3 Software Alignments

With the software alignments of the Service Alignment Mode

(SAM), the RGB alignments can be performed:

• white tone (warm, normal, cool)

• black level offset

6.3.1 RGB Alignment

Before alignment, in customer menu, choose “Movie” as

predefined picture and sound setting (“Auto Mode” button on

RC). Also in menu “TV menu” > “TV settings” > “Pict ure”, set

• “Active Control” to “Off”

• “Color Enhancement” to “Off”

• “Dynamic Contrast” to “Off”

• “DNR” to “Off”.

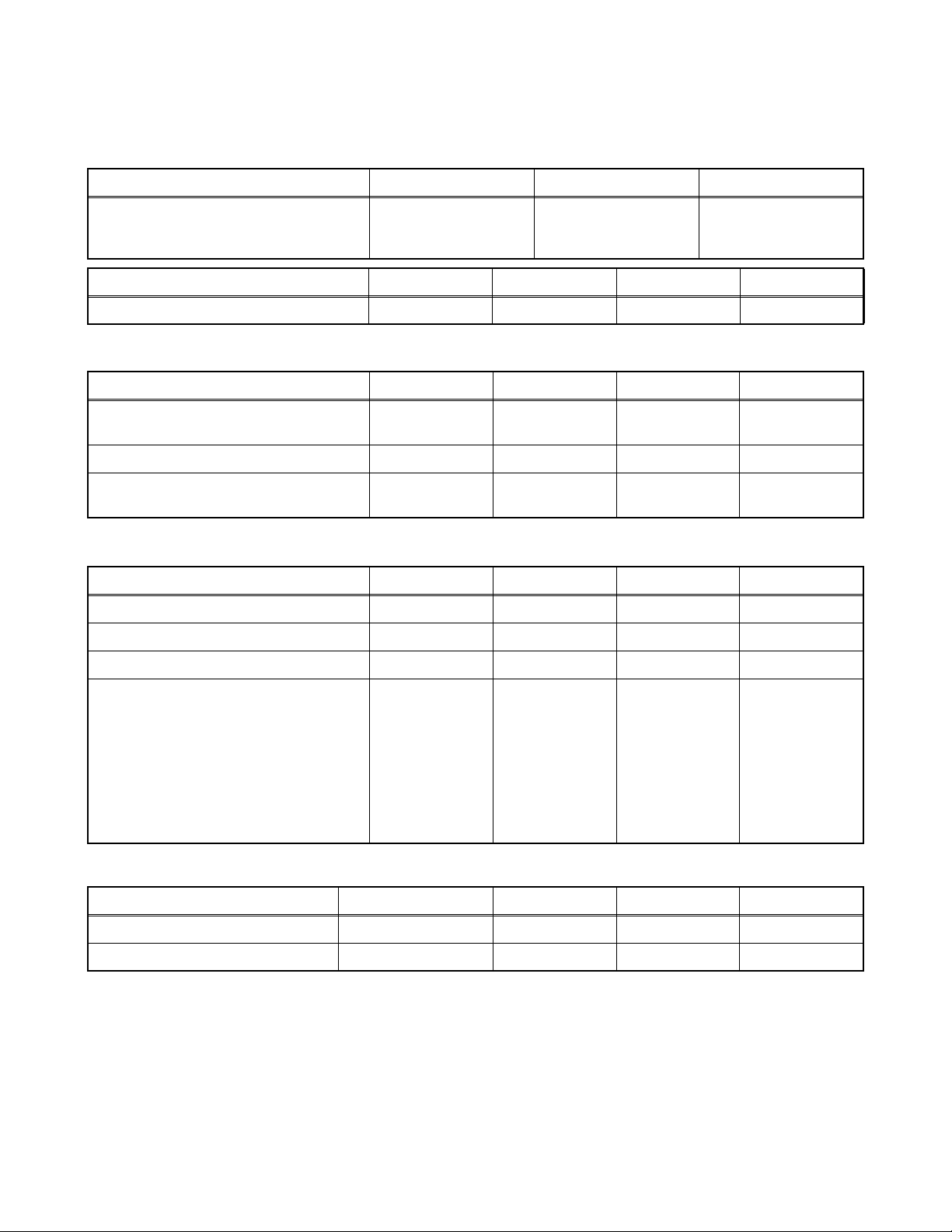

White Tone Alignment:

• Activate SAM

• Select “RGB Align”

• Use a 75% white screen (Fluke 54200) or “Flat73”

(Quantum Data 802BT) as input signal and set the

following values:

– All “R/G/B Gain” values initial to “128” (maximum).

– All “R/G/B Offset” values (blacklevel) to “0”.

In case you have a color analyzer:

• Measure with a calibrated (phosphor- independent) color

analyzer (e.g. Minolta CA-210) in the centre of the screen.

± 10%).

Consequently, the measurement needs to be done in a

dark environment.

• Adjust the correct x,y coordinates (while holding one of the

White point registers R, G or B on “128”) by means of

decreasing the value of one or two other white points to the

correct x,y coordinates (see table “White D alignment

values”). Toler ance: dx: ± 0.004, dy: ± 0.004.

• Repeat this step for the other color Temperatures that need

to be aligned.

• Select “Store” in the “RGB Align” menu to store the aligned

values to the NVM.

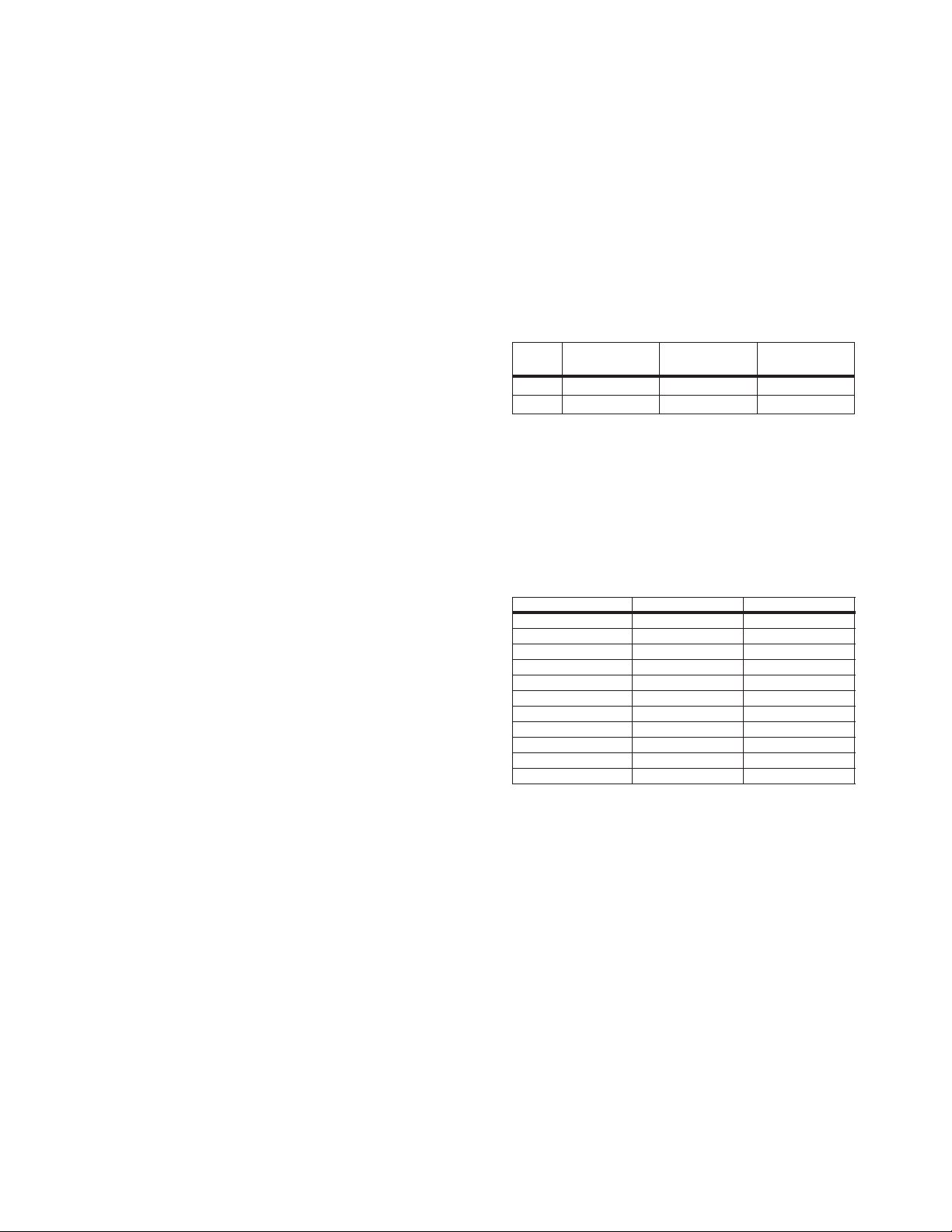

Table 3 White D alignment values

Val ue

Cool

(11500 K)

Normal

(9000 K)

Warm

(6500 K)

x 0.276 0.289 0.314

y 0.277 0.291 0.319

If you do not have a color analyzer, you can use the default

values. This is the next best so

lution. The default values are

average values coming from production (statistics).

• Set the “R/G/B Gain” default values per temperature

according to the values in the “Tint settings” table.

• Select “Store” in the “RGB Align” menu to store the aligned

values to the NVM.

Table 4 Tint settings

t

A

nemngil

WARM_RED 255* 255*

WARM_GREEN 236* 236*

WARM_BLUE 180* 180*

NORMAL_RED 246* 246*

NORMAL_GREEN 248* 248*

NORMAL_BLUE 255* 255*

COOL_RED 210* 210*

COOL_GREEN 226* 226*

COOL_BLUE 255* 255*

"

74"24

Note: *These values were not available at the time of writing,

therefore they come from an early production sample (for

indication only). As soon as the production data become

available, a Service Info or Service Manual update will be

issued via the appropriate channels.

Black Level Offset Alignment

• Activate SAM.

• Select “RGB Align” and choose a temperature.

• For each temperature, the “R/G/B Offset” value should be

set to “0”.

• Select “Store” in the “RGB Align” menu to store the aligned

values to the NVM.

5-8 PL9.3SM

Page 26

6.4.1 Introduction

The microprocessor communicates with a large number of I

ICs in the set. To ensure good communication and to make

digital diagnosis possible, the microprocessor has to know

which ICs to address. The presence/absence of these specific

ICs (or functions) is made known by the option codes.

Notes:

• After changing the option(s), save them with the “Store”

command.

• The new option setting becomes active after the TV is

switched "off" and "on" again with the mains switch (the

NVM is then read again).

6.4.2 How To Set Option Codes

When the NVM is replaced, all options except for the eighth option

indicated as "***" in table 5 will require resetting. To be certain that

the factory settings are reproduced exactly, you must set all numbers

except for the eighth option. You can find the correct option numbers

in table 5 “Option Codes OP1...OP10“ below.

How to Change Options Codes

An option code (or “option byte

”) represents eight different

options (bits). When you change these numbers directly, you

can set all options very quickly. All options are controlled via ten

option bytes (OP1... OPA).

Activate SAM and select “Options”. Now you can select the

option byte (OP#1.. OP#A) with the CURSOR UP/ DOWN

keys, and enter the new 3 digit (decimal) value. For the correct

factory default settings, see the next table “Option code

overview“. The display code will need to be reset when replacing the

SSB. To enter the display code, press 0 6 2 5 9 8 Menu followed by

the three digit display code. The third and fourth digit of the serial

number indicates which panel and display code is used. The option

and display codes are also listed on a label inside the set.

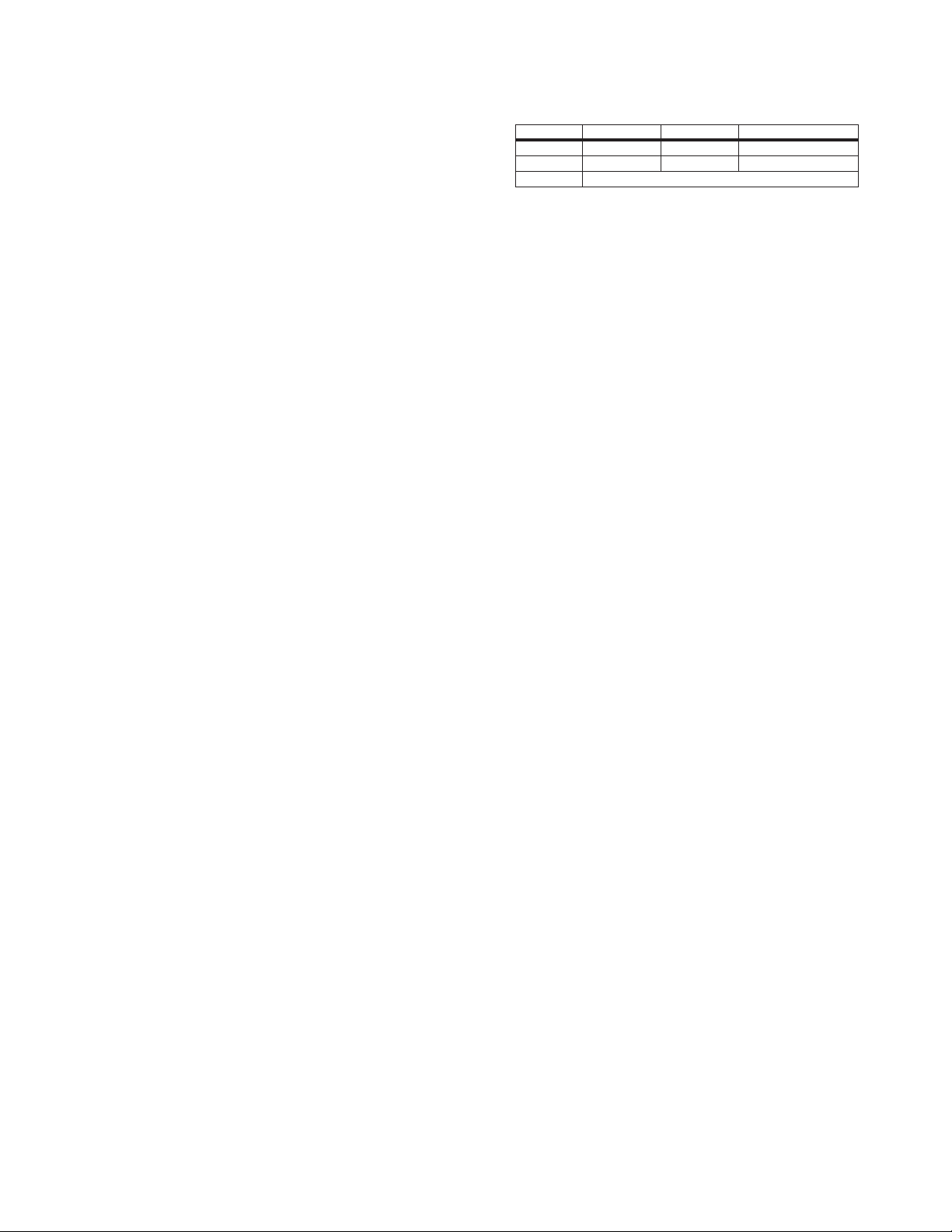

Table 5 Option code overview

CTN

32PFL6704D/F7

42PFL6704D/F7

47PFL6704D/F7

Option Code Display Code Panel

181

075 121 222 248 006 238 054 *** 000 001

075 121 222 248 006 238 054 *** 000 002

075 121 222 248 006 238 054 *** 000 003

TFT-LCD LC320WUF-SBN1

183

TFT-LCD LC420WUF-SBN1

186

TFT-LCD LC470WUF-SBN1

2

C

Note: Display codes are subject to change if the display panel changes

during production. If the serial number is not listed here, refer to the

Screen Diversity code chart on the service website.

The eighth option is not meant to be manipulated or adjusted at all when

reparing the unit;thus, described as "***" in table 5.

5-9 PL9.3SM

Page 27

ELECTRICAL ADJUSTMENT INSTRUCTIONS

Note: Electrical adjustments are required after

replacing circuit components and certain

mechanical parts. It is important to perform

these adjustments only after all repairs and

replacements have been completed.

Also, do not attempt these adjustments unless

the proper equipment is available.

Test Equipment Required

1. NTSC Pattern Generator

2. Remote control unit

3. Color Analyzer

How to set up the service mode:

Service mode:

1. Turn the power on.

2. Press [0], [6], [2], [5], [9], [6] and [Info] buttons on

the remote control unit in the order. The following

screen appears.

"*" differs depending on the models.

SAM

System Information

Clear

Options

RGB Align

NVM Editer

NVM Copy

Op Hour: *****

Main SW ID:*******-*.**

ERR: *** *** *** *** ***

OP1: *** *** *** *** ***

OP2: *** *** *** *** ***

6-1 PL9.3EA

Page 28

The following adjustment normally are not

attempted in the field. Only when

replacing the LCD Panel then adjust as a

preparation.

1. White Balance Adjustment

Purpose: To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

Input Requirements

Input signal: CVBS (NTSC)

Pattern for White Point alignment:

- White 100%

Input Injection Point:

AV1

Alignment Method

1. Operate the unit for more than 12 minutes.

2. Set the color analyzer to the CHROMA mode and

bring the optical receptor to the center on the

LCD-Panel surface after zero point calibration.

Note: The optical receptor must be set

perpendicularly to the LCD Panel surface.

3. Enter the Service mode.

Note: To select menu or change the setting

values, use the Up/Down buttons. To enter the

setting, use the [OK] button or Right button.

4. Press the [MENU] button on the remote control

unit to select “TV Setting”, “Picture”, “Color

temperature” or “Cool” in order and set the “Color

temperature” to “Cool”.

5. Press the [MENU] button on the remote control

unit to return the service mode initial display.

6. Select the “RGB Align” and “Cool” in order and set

the “R offset”, “G offset” and “B offset” to 0.

7. Set the “R Gain”, “G Gain” and “B Gain” to

maximum value.

8. Adjust one or two of the three Red, Green, Blue

Gain to obtain the target “Cool” x,y values as

stated in the Table A keeping at least one of Red,

Green, Blue Gain value at the maximum value.

9. Select “Store” to store selected values into NVM.

10. Change the selection to “Normal” or “Warm” in

step 4 and repeat from step 5.

Table A

Cool X y

Target 0.276 0.277

To le ra nc e

Normal X y

Target 0.289 0.291

To le ra nc e

Warm X y

Target 0.314 0.319

To le ra nc e

±

0.004

±

0.004

±

0.004

±

0.004

±

0.004

±

0.004

6-2 PL9.3EA

Page 29

FIRMWARE RENEWAL MODE

Equipment Required

a. USB memory

b. Remote Control Unit

Firmware Update Procedure

1. Download the *.zip file from the service or

consumer site and extract the autorun.upg file.

2. Load the autorun2k9f.upg file in the root directory

of a USB drive.

3. Turn the TV on.

4. Press [0], [6], [2], [5], [9], [6] and [info] buttons on

the remote control unit in the order. SAM mode

menu screen appears.

5. Press [MENU] button on the remote control unit.

Menu screen appears.

6. Insert the USB drive in the USB port on the TV.

8. When the upgrading process is complete, remove

the USB drive and restart the TV.

USB Port

Rear Cabinet

7. Select Yes and press the OK button on the remote

control unit. If the Software upgrade screen does

not appear, try a different USB drive.

7-1 PL9.3FW

Page 30

FLOW CHART NO.1

No work (LED is off)

TROUBLESHOOTING

Check if power switch is normal.

Ye s

IS 3.3V voltage supplied to Pin(3,5) of 1C02 on the

SSB?

Ye s

IS 3.3V voltage supplied to Pin(1) of 1M95 on the

SSB?

Ye s

Replace SSB.

FLOW CHART NO.2

No raster (picture too dim)

Is 12V voltage supplied to Pin(1,2) of 1M99 and

Pin(6,7,8,9,11) of 1M95 on the SSB?

Ye s

Replace SSB.

FLOW CHART NO.3

No picture

No

No

No

No

Replace Power switch.

Check Module IR.

Replace Power Supply Module.

Replace Power Supply Module.

Is 3.3V voltage supplied to Pin(1) of 1M95 on the

SSB?

Ye s

Check if working voltage each pin of 7116 and each

pin of 7117 on the SSB.

7116 Pin(1,14) 12V

7116 Pin(12) 1.2V

7117 Pin(1,14) 12V

7117 Pin(12) 3.3V

Ye s

Check if clock source 1E07.

Ye s

Check if RGB, clk, H/V and DE signal output 128 bit

TTL.

Ye s

Check line filter on LVDS signal line.

Ye s

Replace LVDS cable.

No

No

No

No

No

Replace Power Supply Module.

Check the circuit around each regulator and

eliminate short and open situation.

Replace 1E07.

Try to replace Flash Rom.

Replace bad line filter.

8-1 A9PH1TR

Page 31

FLOW CHART NO.4

No TV sound

Is audio if signal outputted to Pin(8) of 1203(Tuner) on

the Main SSB?

Ye s

Check 7201.

FLOW CHART NO.5

No remote function

Try another remote control unit.

Ye s

Check IR receiver on the Module IR.

FLOW CHART NO.6

LED and function key poor

Check circuit around ASSY Tact SW and cable between

ASSY Tact SW and SSB.

No

No

Replace 1203(Tuner).

Replace one good remote control unit.

8-2 A9PH1TR

Page 32

BLOCK DIAGRAMS

Set Level System Block Diagram

HV cable

Module

Control

Knob

HV cable

T-con

LVDS

LVDS

LCD Display

Power Supply

Module

Module IR

SSB

AC inlet

Subwoofer

Speaker cable

[With Subwoofer]

Speaker L Speaker R

9-1

PL9.3BL

Page 33

Control Signal Flow Diagram

BACKLIGHT BOOST

IR SENSOR

USB

Service

mode

USB

PANEL

Serial

FLASH

NAND

FLASH

MAIN NVM

RESET

CIRCUIT

HDMI

LIGHT SENSOR

IR

KEYBOARD

LED1

LED2

USB OC

USB PWE

PANEL

SDM

SCL

SDA

LCD PWR ON

SERIAL POCE

FLASH WE

NAND POCE

SYS EEPROM WE

ORESET

HDMI RESET

HDMI CEC

DDC RESET

EDID WE

HDMI HPDD 1...SIDE

+5V HDMI 1...SIDE

DDC SCL HDMI MUX

DDC SDA HDMI MUX

MT5392

PWM DIMMING

BL ON/OFF

PWRDET

STANDBYn

POWER

DOWN

SW MUTE

DC PROT

BIT SELECT

LVDS SELECT

STBY RX/TX

MAIN RX/TX

Inverter

Circuit

+12V

Detection

HP DET

MUTEn

SWITCH

PSU

STANDBY

AUDIO

AMPLIFIER

LVDS

Connector

UART

SERVICE

9-2

PL9.3BL

Page 34

Power Management Diagram

/

/

/

/

y

PSU/iPB : +3V3STBY

To PSU/iPB

To PSU/iPB

To PSU/iPB

PSU/iPB : +12VS

DC_DC

TPS54386

PWP

10uH

10uH

L78M05CDT

10uH

+3V3STBY

/ under 15mA

Stb

PWM

Boost

+12Vdisp

/1000mA

+5V_Tuner

0.17A

+5VS

/ 0.07A

+5V_SW

/ 0.5A

+1V2_SW

/ 500mA

To MT539X

To LCD Panel

To IF Demodulator

To MT539X, USB,

HDMI

To MT539X

DC_DC

TPS54386

PWP

10uH

10uH

DC_DC

ST1S10PH

DC_DC

ST1S10PH

L78M08CDT

3u6H

3u6H

+1V8_SW

/1.75A

+3V3_SW

1.14A

+1V0_MT8281

+1V0_SW

3A

+8V_SW

12mA

To MT539X,

GDDR3, DDR2,

MT828x

To MT539X, HDMi

MUX, Audio DAC,

MT828x

To MT828x

To MT539X

9-3

PL9.3BL

Page 35

SSB 1/12 Schematic Diagram (DC/DC CONVERTER)

SSB 1/12 Schematic Diagram

Parts Location Guide

Ref No. Posi tion Ref No. Posi tion

1188 H16 3130 G3

1190 H15 3131 H6

1191 I14 3132 H3

1192 I13 3133 I7

1194 H13 3134 I1

1195 G13 3135 I7

1198 H15 3136 I3

1M95 C12 3137 I1

1M99 A11 3138 I5

1X08 H14 5112 C5

2119 B13 5113 C2

2120 B13 5114 E6

2121 B13 5115 E3

2122 B13 5116 F3

2124 C6 5117 F6

2125 C2 5118 H3

2126 C2 5119 H6

2127 C3 6110 G3

2128 C6 6111 G6

2129 C6 6112 I6

2130 C7 6113 I3

2131 C7 7101-1 B4

2132 C12 7101-2 C4

2133 D13 7115 E 7

2134 D13 7116 E 5

2135 D13 7117 H4

2136 D13 F110 A12

2137 D13 F111 A12

2138 E3 F112 A12

2139 E4 F113 A12

2140 E6 F114 A12

2141 E8 F115 A12

2142 E4 F116 C5

2143 F5 F117 C12

2144 F4 F118 C12

2145 F2 F119 C12

2146 F7 F120 C12

2148 F5 F121 C12

2149 F3 F122 C12

2150 C5 F 123 D12

2154 F6 F124 E 6

2155 F4 F125 E 8

2156 F7 F126 E 4

2157 G2 F127 F2

2158 G7 F128 F7

2159 G2 F129 H2

2160 G3 F130 H7

2161 H3 F 131 G4

2162 H4 F 132 I 5

2163 H4 F 133 C2

2164 H5 F 134 E 6

2165 H4 I110 C4

2166 I2 I112 C5

2167 I7 I114 F3

2168 I5 I115 F3

2169 I3 I116 F4

2170 I2 I117 F5

2171 I6 I118 F5

2172 I4 I119 F6

2173 I7 I120 F6

2174 I3 I121 F2

2175 I2 I122 F4

2176 I7 I123 F4

3114 A13 I124 F5

3115 C5 I125 H3

3116 C6 I126 H4

3117 C5 I127 H4

3118 C5 I128 H5

3119 F6 I 129 H5

3120 F3 I 130 H6

3121 F7 I 131 H6

3122 F1 I 132 I2

3126 I2 I133 I4

3127 F7 I 134 I5

3128 G1 I 135 I3

3129 G5

SCHEMATIC DIAGRAMS AND CBA

A

B

C

D

E

F

G

H

I

J

K

L

1234

7101-1

1

6

A

SW

2

INH

53

SYNCSWVFB

7101-2

ST1S10PH

10 11

2139

10u

470p

I123

10R

I126

2165 33n

2169

470p

I135

3136

10R

7

VIN

GND

HSPA

8

4

9

VIA

F126

10u

2142

PVDD1 PVDD2

I116

33n2144

213

BOOT1

312

SW1

56

EN1

78

FB1

9

ILIM2

10

I122

SEQ

11

BP

4u7

2155

10u

10u

2162

2163

7117

TPS54386PWP

I127

213

312

56

78

9

10

11

I133

4u7

2172

+1V8_DDR

+5V_SW

+12VS

3134

3137

5113

33R

+12VS

3122

1K5

1%

I121

3128

1K2

1%

F129

4K7

1%

I132

3126

1%

1K8

1K8

1%

F133

10u

10u

2127

2125

2126

5115

10u

F127

2145

2157

2166

2175

5116

10p

RES

RES

100u

10u

10p

2160

2159

6.3V

10p

RES

RES

2170

10u

10p

100u

6.3V

ST1S10PH

10u

2138

100u

16V

I114 I119

3120

1R0

10u

2149

6110

3130

SS34

+12VS_1

2161

100u

16V

RES

I125

3132

5118

1R0

10u

6113

2174

SS34

DC/DC CONVERTER

1

2

3456

56

5112

I110

TPS54386PWP

1

Φ