Philips PDIUSBD12D, PDIUSBD12PW Datasheet

1. Description

PDIUSBD12

USB interface device with parallel bus

Rev. 07 — 27 November 2001 Product data

The PDIUSBD12 is a cost and feature optimized USB device. It is normally used in

microcontroller based systems and communicates with the system microcontroller

over the high-speed general purpose parallel interface. It also supports local DMA

transfer.

This modular approach to implementing a USB interface allows the designer to

choose the optimum system microcontroller from the available wide variety. This

flexibility cuts down the development time, risks, and costs by allowing the use of the

existing architecture and minimize firmware investments. This results in the fastest

way to develop the most cost effective USB peripheral solution.

2. Features

The PDIUSBD12 fully conforms to the

to be compliant with most device class specifications: Imaging Class, Mass Storage

Devices, Communication Devices, Printing Devices, and Human Interface Devices.

As such, the PDIUSBD12 is ideally suited for many peripherals like Printer, Scanner,

External Mass Storage (Zip Drive), Digital Still Camera, etc. It offers an immediate

cost reduction for applications that currently use SCSI implementations.

The PDIUSBD12 low suspend power consumption along with the LazyClock output

allows for easy implementation of equipment that is compliant to the ACPI™,

OnNOW™, and USB power management requirements. The low operating power

allows the implementation of bus powered peripherals.

In addition, it also incorporates features like SoftConnect™, GoodLink™,

programmable clock output, low frequency crystal oscillator, and integration of

termination resistors. All of these features contribute to significant cost savings in the

system implementation and at the same time ease the implementation of advanced

USB functionality into the peripherals.

■ Complies with the

■ High performance USB interface device with integrated SIE, FIFO memory,

transceiver and voltage regulator

■ Compliant with most Device Class specifications

■ High-speed (2 Mbytes/s) parallel interface to any external microcontroller or

microprocessor

■ Fully autonomous DMA operation

■ Integrated 320 bytes of multi-configuration FIFO memory

■ Double buffering scheme for main endpoint increases throughput and eases

real-time data transfer

Universal Serial Bus specification Rev. 1.1

USB specification Rev. 1.1

. It is also designed

Philips Semiconductors

■ Data transfer rates: 1 Mbytes/s achievable in Bulk mode, 1 Mbits/s achievable in

■ Bus-powered capability with very good EMI performance

■ Controllable LazyClock output during suspend

■ Software controllable connection to the USB bus (SoftConnect™)

■ Good USB connection indicator that blinks with traffic (GoodLink™)

■ Programmable clock frequency output

■ Complies with the ACPI, OnNOW and USB power management requirements

■ Internal Power-on reset and low-voltage reset circuit

■ Available in SO28 and TSSOP28 pin packages

■ Full industrial grade operation from −40 to +85 °C

■ Higher than 8 kV in-circuit ESD protection lowers cost of extra components

■ Full-scan design with high fault coverage (>99%) ensures high quality

■ Operation with dual voltages:

■ Multiple interrupt modes to facilitate both bulk and isochronous transfers.

PDIUSBD12

USB interface device with parallel bus

Isochronous mode

3.3 ±0.3 V or extended 5 V supply range of 4.0 to 5.5 V

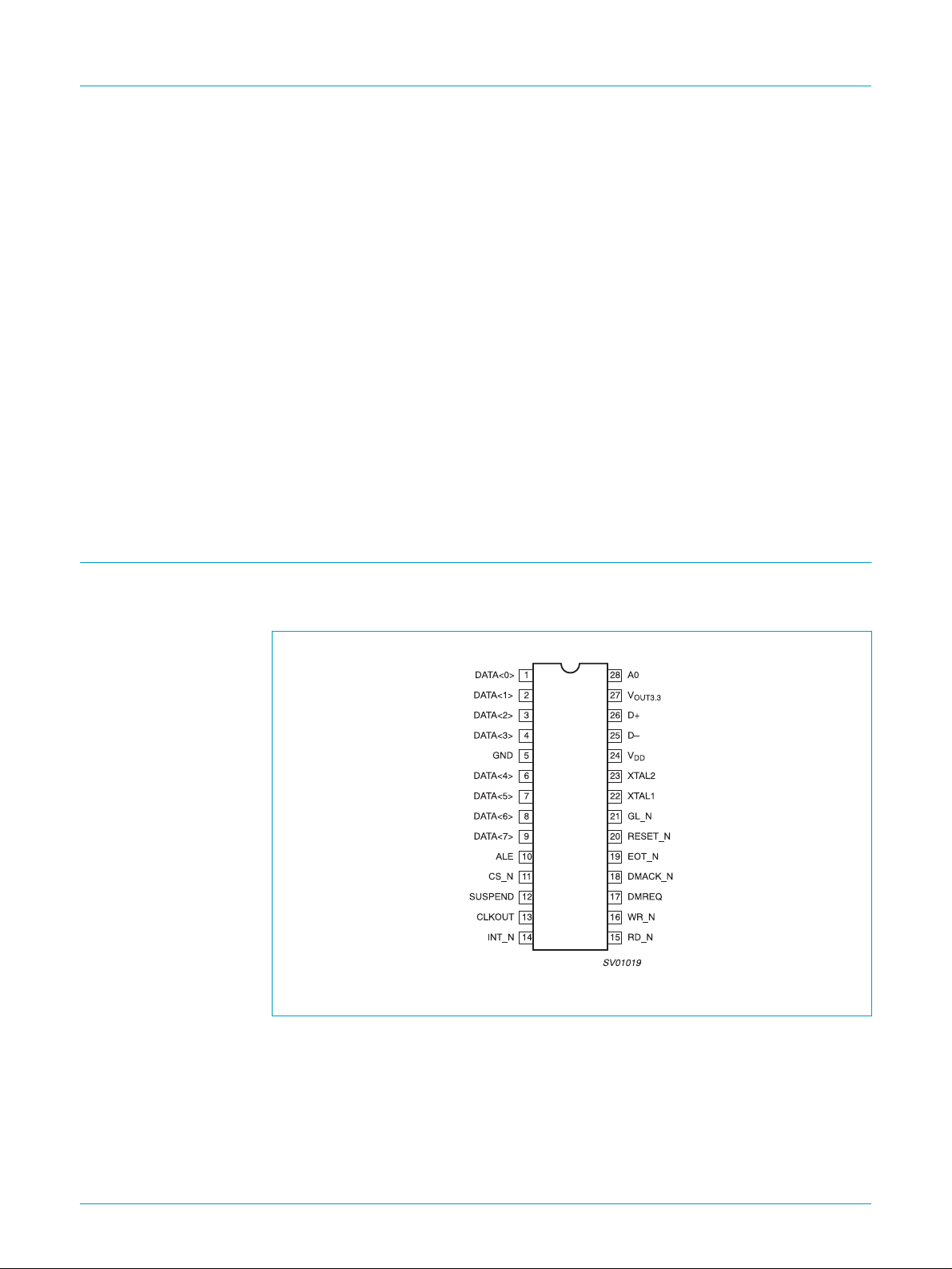

3. Pinning information

3.1 Pinning

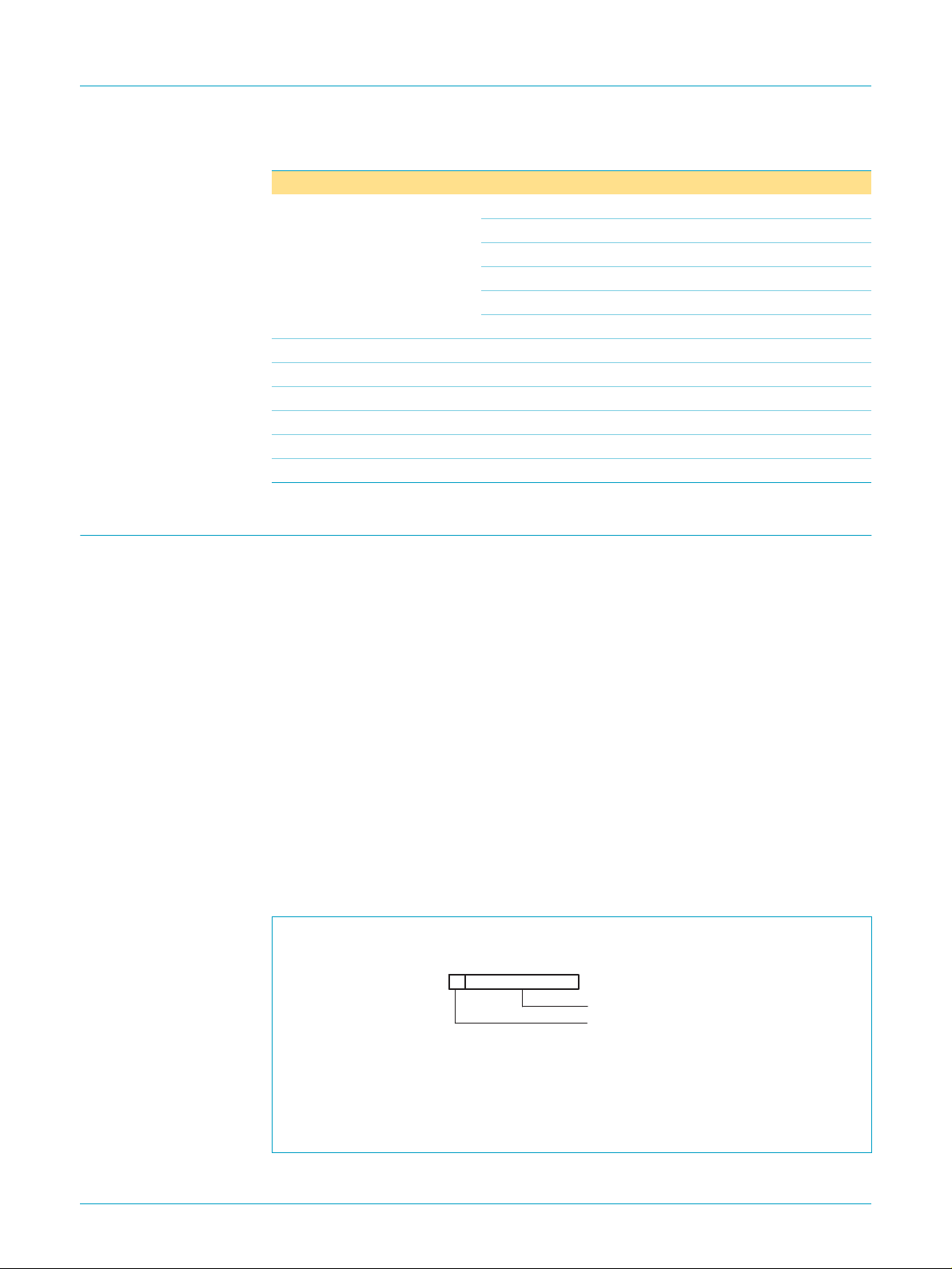

Fig 1. Pin configuration.

9397 750 08969

Product data Rev. 07 — 27 November 2001 2 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

3.2 Pin description

Table 1: Pin description

Symbol Pin Type

DATA <0> 1 IO2 Bit 0 of bidirectional data. Slew-rate controlled.

DATA <1> 2 IO2 Bit 1 of bidirectional data. Slew-rate controlled.

DATA <2> 3 IO2 Bit 2 of bidirectional data. Slew-rate controlled.

DATA <3> 4 IO2 Bit 3 of bidirectional data. Slew-rate controlled.

GND 5 P Ground.

DATA <4> 6 IO2 Bit 4 of bidirectional data. Slew-rate controlled.

DATA <5> 7 IO2 Bit 5 of bidirectional data. Slew-rate controlled.

DATA <6> 8 IO2 Bit 6 of bidirectional data. Slew-rate controlled.

DATA <7> 9 IO2 Bit 7 of bidirectional data. Slew-rate controlled.

ALE 10 I Address Latch Enable. The falling edge is used to close the

CS_N 11 I Chip Select (Active LOW).

SUSPEND 12 I,OD4 Device is in Suspend state.

CLKOUT 13 O2 Programmable Output Clock (slew-rate controlled).

INT_N 14 OD4 Interrupt (Active LOW).

RD_N 15 I Read Strobe (Active LOW).

WR_N 16 I Write Strobe (Active LOW).

DMREQ 17 O4 DMA Request.

DMACK_N 18 I DMA Acknowledge (Active LOW).

EOT_N 19 I End ofDMA Transfer(Active LOW). Double up as V

RESET_N 20 I Reset (Active LOW and asynchronous). Built-in Power-onreset

GL_N 21 OD8 GoodLink LED indicator (Active LOW)

XTAL1 22 I Crystal Connection 1 (6 MHz).

XTAL2 23 O Crystal Connection 2 (6 MHz). If external clock signal, instead

V

CC

D− 25 A USB D− data line.

D+ 26 A USB D+ data line.

USB interface device with parallel bus

[1]

Description

latch of the address information in a multiplexed address/ data

bus. Permanently tied LOW for separate address/ data bus

configuration.

EOT_N is only valid when asserted together with DMACK_N

and either RD_N or WR_N.

circuit present on chip, so pin can be tied HIGH to V

of crystal, is connected to XTAL1, then XTAL2 should be

floated.

24 P Voltage supply (4.0 − 5.5 V).

To operate the IC at 3.3 V, supply 3.3 V to both V

pins.

PDIUSBD12

sensing.

BUS

.

CC

and V

CC

OUT3.3

9397 750 08969

Product data Rev. 07 — 27 November 2001 3 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 1: Pin description

Symbol Pin Type

V

OUT3.3

A0 28 I Address bit. A0 = 1 selects command instruction; A0 = 0 selects

[1] O2 : Output with 2 mA drive

OD4: Output Open Drain with 4 mA drive

OD8: Output Open Drain with 8 mA drive

IO2: Input and Output with 2 mA drive

O4: Output with 4 mA drive.

27 P 3.3 V regulated output. To operate the IC at 3.3 V, supply a

…continued

[1]

Description

3.3 V to both V

the data phase. This bit is a don’t care in a multiplexedaddress

and data bus configuration and should be tied HIGH.

CC

and V

OUT3.3

pins.

4. Ordering information

Table 2: Ordering information

Packages Temperature range Outside North America North America Pkg. Dwg. #

28-pin plastic SO −40 °C to +85 °C PDIUSBD12 D PDIUSBD12 D SOT136-1

28-pin plastic TSSOP −40 °C to +85 °C PDIUSBD12 PW PDIUSBD12PW DH SOT361-1

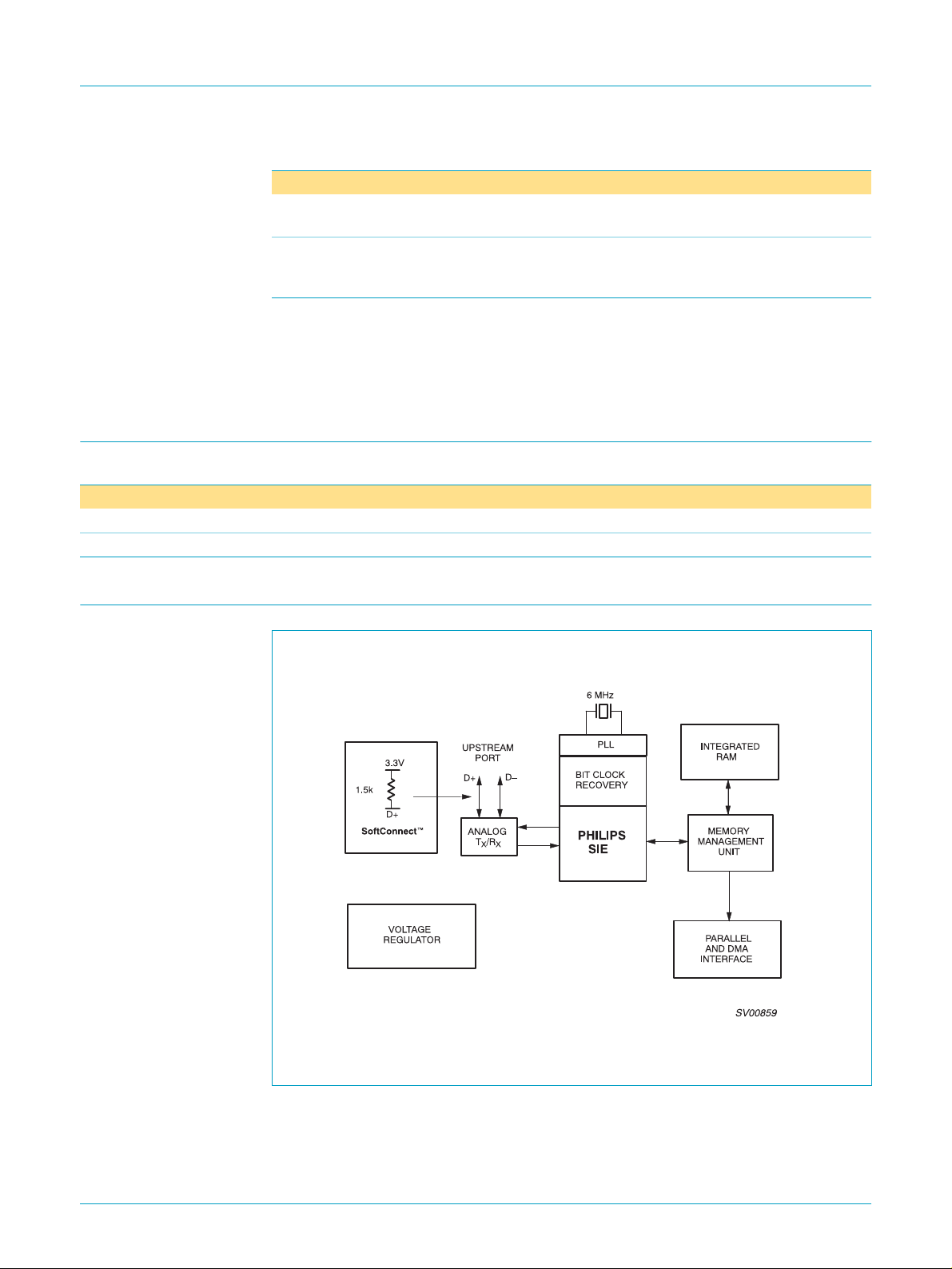

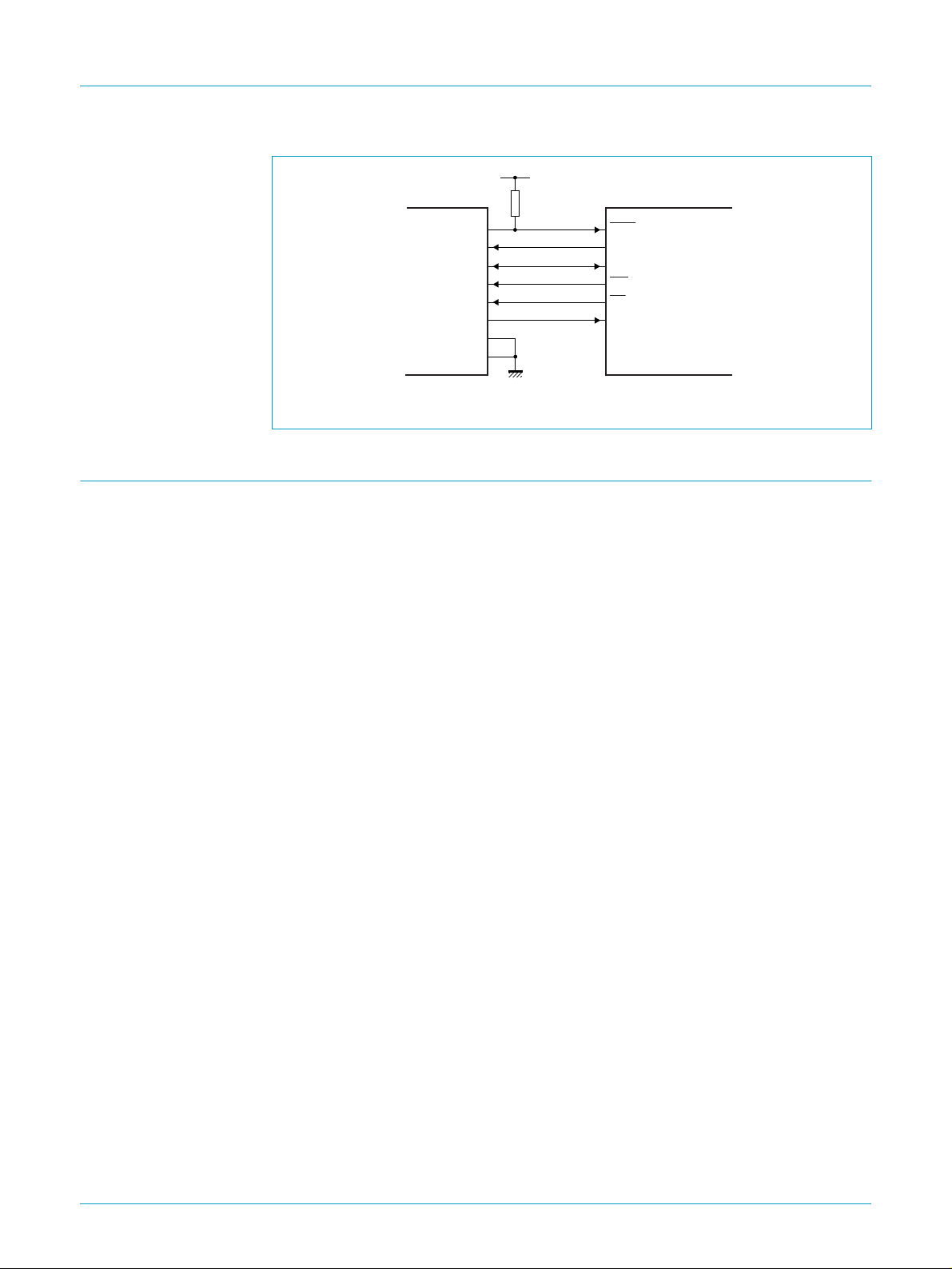

5. Block diagram

This is a conceptual block diagram and does not include each individual signal.

Fig 2. Block diagram.

9397 750 08969

Product data Rev. 07 — 27 November 2001 4 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

6. Functional description

6.1 Analog transceiver

The integrated transceiver interfaces directly to the USB cables through termination

resistors.

6.2 Voltage regulator

A 3.3 V regulator is integrated on-chip to supply the analog transceiver. This voltage

is also provided as an output to connect to the external 1.5 kΩ pull-up resistor.

Alternatively, the PDIUSBD12 provides SoftConnect technology with an integrated

1.5 kΩ pull-up resistor.

6.3 PLL

A 6 MHz to 48 MHz clock multiplier PLL (Phase-Locked Loop) is integrated on-chip.

This allows for the use of a low-cost 6 MHz crystal. EMI is also minimized due to the

lower frequency crystal. No external components are needed for the operation of the

PLL.

PDIUSBD12

USB interface device with parallel bus

6.4 Bit clock recovery

The bit clock recovery circuit recovers the clock from the incoming USB data stream

using 4× oversampling principle. It is able to track jitter and frequency drift specified

by the USB specification.

6.5 Philips Serial Interface Engine (PSIE)

The Philips SIE implements the full USB protocol layer. It is completely hardwired for

speed and needs no firmware intervention. The functions of this block include:

synchronization pattern recognition, parallel/serial conversion, bit stuffing/de-stuffing,

CRC checking/generation, PID verification/generation, address recognition, and

handshake evaluation/generation.

6.6 SoftConnect

The connection to the USB is accomplished by bringing D+ (for high-speed USB

device)HIGH through a 1.5 kΩ pull-up resistor. In the PDIUSBD12, the 1.5 kΩ pull-up

resistor is integrated on-chip and is not connected to VCC by default. The connection

is established through a command sent by the external/system microcontroller. This

allows the system microcontroller to complete its initialization sequence before

deciding to establish connection to the USB. Re-initialization of the USB bus

connection can also be performed without requiring to pull out the cable.

The PDIUSBD12 will check for USB V

established. V

description” for details. Sharing of V

accomplished by using V

open-drain output of the DMA controller pin.

sensing is provided through pin EOT_N. See Section 3.2 “Pin

BUS

voltage as the pull-up voltage for the normally

BUS

availability before the connection can be

BUS

sensing and EOT_N can be easily

BUS

9397 750 08969

Product data Rev. 07 — 27 November 2001 5 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

It should be noted that the tolerance of the internal resistors is higher (25%) than that

specified by the USB specification (5%). However, the overall VSE voltage

specification for the connection can still be met with good margin. The decision to

make sure of this feature lies with the users.

6.7 GoodLink

Good USB connection indication is provided through GoodLink technology. During

enumeration, the LED indicator will blink ON momentarily corresponding to the

enumeration traffic. When the PDIUSBD12 is successfully enumerated and

configured, the LED indicator will be permanently ON. Subsequent successful (with

acknowledgement) transfer to and from the PDIUSBD12 will blink OFF the LED.

During suspend, the LED will be OFF.

This feature provides a user-friendly indicator on the status of the USB device, the

connected hub and the USB traffic. It is a useful field diagnostics tool to isolate faulty

equipment. This feature helps lower field support and hotline costs.

6.8 Memory Management Unit (MMU) and Integrated RAM

PDIUSBD12

USB interface device with parallel bus

The MMU and the integrated RAM buffer the difference in speed between USB,

running in bursts of 12 Mbits/s and the parallel interface to the microcontroller. This

allows the microcontroller to read and write USB packets at its own speed.

6.9 Parallel and DMA Interface

A generic parallel interface is defined for ease-of-use, speed, and allows direct

interfacing to major microcontrollers. To a microcontroller, the PDIUSBD12 appears

as a memory device with 8-bit data bus and 1 address bit (occupying 2 locations).

The PDIUSBD12 supports both multiplexed and non-multiplexed address and data

bus. The PDIUSBD12 also supports DMA (Direct Memory Access) transfer which

allows the main endpoint (endpoint 2) to directly transfer to and from the local shared

memory. Both single-cycle and burst mode DMA transfers are supported.

6.10 Example of parallel interface to an 80C51 microcontroller

In the example shown in Figure 3, the ALE pin is permanently tied LOW to signify a

separate address and data bus configuration. The A0 pin of the PDIUSBD12

connects to any of the 80C51 I/O ports. This port controls the command or data

phase to the PDIUSBD12. The multiplexed address and data bus of the 80C51 can

now be connected directly to the data bus of the PDIUSBD12. The address phase will

be ignored by the PDIUSBD12. The clock input signal of the 80C51 (pin XTAL1) can

be provided by output CLKOUT of the PDIUSBD12.

9397 750 08969

Product data Rev. 07 — 27 November 2001 6 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

7. DMA transfer

PDIUSBD12

INT_N

A0

DATA [7:0

Fig 3. Example of a parallel interface to an 80C51 microcontroller.

]

WR_N

RD_N

CLKOUT

CS_N

ALE

INTO/P3.2

ANY I/O PORT (e.g. P3.3)

P [0.7:0.0]/AD [7:0

WR/P3.6

RD/P3.7

XTAL1

80C51

]

SV00870

Direct Memory Address (DMA) allows an efficient transfer of a block of data between

the host and local shared memory.Using a DMA controller, data transfer between the

PDIUSBD12’s main endpoint (endpoint 2) and local shared memory can happen

autonomously without local CPU intervention.

Preceding any DMA transfer, the local CPU receives from the host the necessary

setup information and programs the DMA controller accordingly. Typically, the DMA

controller is set up for demand transfer mode and the byte count register and the

address counter are programmed with the right values. In this mode, transfers occur

only when the PDIUSBD12 requests them and are terminated when the byte count

register reaches zero. After the DMA controller has been programmed, the DMA

enable bit of the PDIUSBD12 is set by the local CPU to initiate the transfer.

The PDIUSBD12 can be programmed for single-cycle DMA or burst mode DMA. In

single-cycle DMA, the DMREQ pin is deactivated for every single acknowledgement

by the DMACK_N before being re-asserted. In burst mode DMA, the DMREQ pin is

kept active for the number of bursts programmed in the device before going inactive.

This process continues until the PDIUSBD12 receives a DMA termination notice

through pin EOT_N. This will generate an interrupt to notify the local CPU that DMA

operation is completed.

For DMA read operation, the DMREQ pin will only be activated whenever the buffer is

full, signalling that the host has successfully transferred a packet to the PDIUSBD12.

With the double buffering scheme, the host can start filling up the second buffer while

the first buffer is being read out. This parallel processing increases the effective

throughput. When the host does not fill up the buffer completely (less than 64 bytes or

128 bytes for single direction ISO configuration), the DMREQ pin will be deactivated

at the last byte of the buffer regardless of the current DMA burst count. It will be

re-asserted on the next packet with a refreshed DMA burst count.

Similarly, for DMA write operations, the DMREQ pin remains active whenever the

buffer is not full. When the buffer is filled up, the packet is sent over to the host on the

next IN token and DMREQ will be reactivated if the transfer was successful. Also, the

double buffering scheme here will improve throughput. For non-isochronous transfer

(bulk and interrupt), the buffer needs to be completely filled up by the DMA write

9397 750 08969

Product data Rev. 07 — 27 November 2001 7 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

operation before the data is sent to the host. The only exception is at the end of DMA

transfer, when the reception of pin EOT_N will stop DMA write operation and the

buffer content will be sent to the host on the next IN token.

For isochronous transfers, the local CPU and DMA controller have to guarantee that

they are able to sink or source the maximum packet size in one USB frame (1 ms).

The assertion of pin DMACK_N automatically selects the main endpoint (endpoint 2),

regardless of the current selected endpoint. The DMA operation of the PDIUSBD12

can be interleaved with normal I/O access to other endpoints.

DMA operation can be terminated by resetting the DMA enable register bit or the

assertion of EOT_N together with DMACK_N and either RD_N or WR_N.

The PDIUSBD12 supports DMA transfer in single address mode and it can also work

in dual address mode of the DMA controller. In the single address mode, DMA

transfer is done via the DREQ, DMACK_N, EOT_N, WR_N and RD_N control lines.

In the dual address mode, pins DMREQ, DMACK_N and EOT_N are not used;

instead CS_N, WR_N and RD_N control signals are used. The I/O mode Transfer

Protocol of PDIUSBD12 needs to be followed. The source of the DMAC is accessed

during the read cycle and the destination during the write cycle. Transfer needs to be

done in two separate bus cycles, storing the data temporarily in the DMAC.

PDIUSBD12

USB interface device with parallel bus

8. Endpoint description

The PDIUSBD12 endpoints are sufficiently generic to be used by various device

classes ranging from Imaging, Printer, Mass Storage and Communication device

classes. The PDIUSBD12 endpoints can be configured for 4 operating modes

depending on the Set mode command. The 4 modes are:

Mode 0 Non-isochronous transfer (Non-ISO mode)

Mode 1 Isochronous output only transfer (ISO-OUT mode)

Mode 2 Isochronous input only transfer (ISO-IN mode)

Mode 3 Isochronous input and output transfer (ISO-I/O mode).

9397 750 08969

Product data Rev. 07 — 27 November 2001 8 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

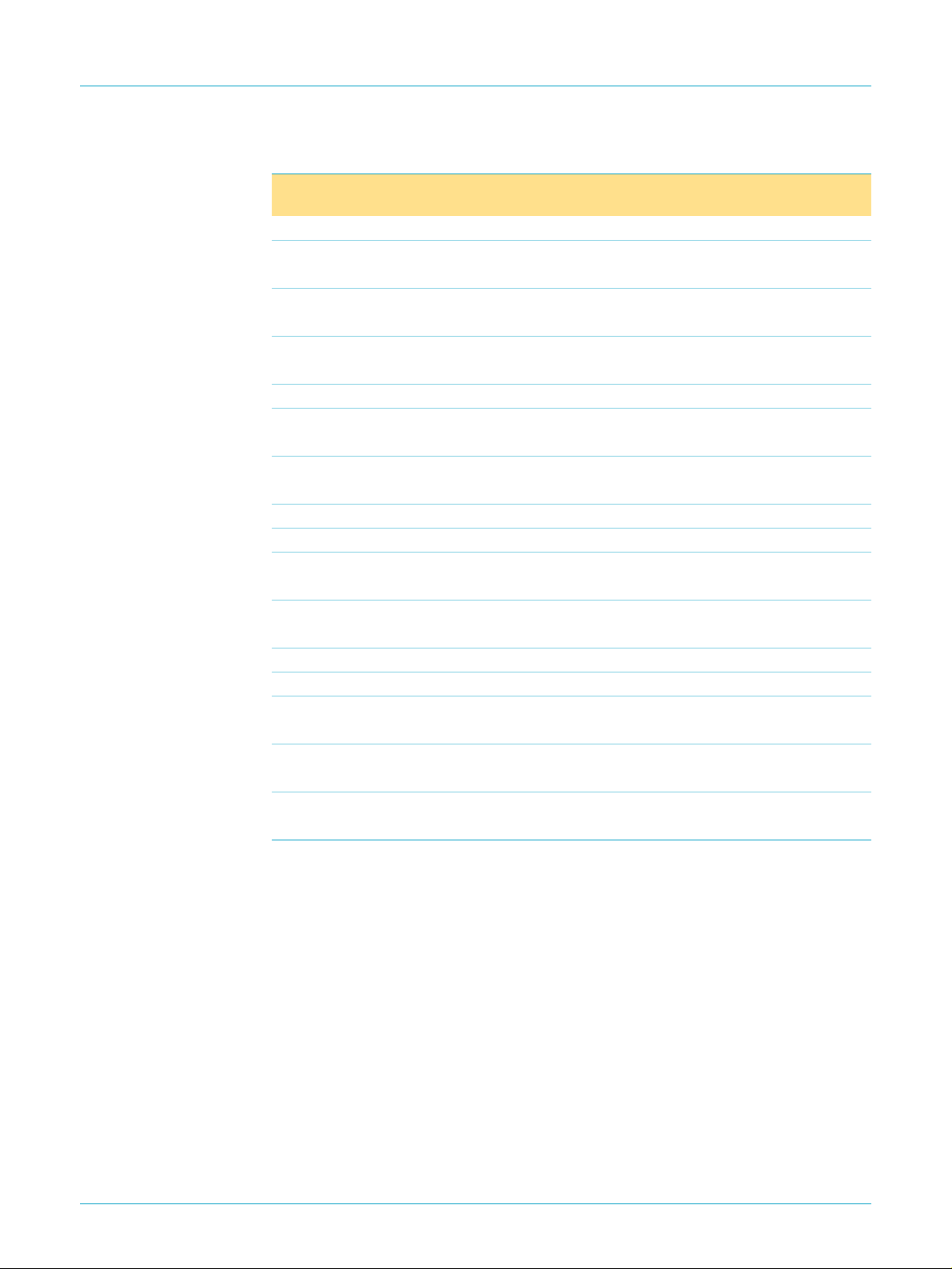

Table 3: Endpoint Configuration

Endpoint

number

Mode 0 (Non-ISO mode)

0 0 Control OUT 16

1 2 Generic

2 4 Generic

Mode 1 (ISO-OUT mode)

0 0 Control OUT 16

1 2 Generic

2 4 Isochronous

Mode 2 (ISO-IN mode)

0 0 Control OUT 16

1 2 Generic

2 5 Isochronous

Mode 3 (ISO-I/O mode)

0 0 Control OUT 16

1 2 Generic

2 4 Isochronous

PDIUSBD12

USB interface device with parallel bus

Endpoint

Transfer type Direction

index

1IN16

[2]

OUT 16

3IN16

[2][3]

OUT 64

5IN64

1IN16

[2]

OUT 16

3IN16

[3]

OUT 128

1IN16

[2]

OUT 16

3IN16

[3]

IN 128

1IN16

[2]

OUT 16

3IN16

[3]

OUT 64

5IN64

[1]

Max. Packet

size (bytes)

[4]

[4]

[4]

[4]

[4]

[4]

[1] IN: input for the USB host; OUT: output from the USB host.

[2] Generic endpoints can be used either as Bulk or Interrupt endpoint.

[3] The main endpoint (endpoint number 2) is double-bufferedto ease synchronization with the real-time

applications and to increase throughput. This endpoint supports DMA access.

[4] Denotes double buffering. The size shown is for a single buffer.

9397 750 08969

Product data Rev. 07 — 27 November 2001 9 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

9. Main endpoint

The main endpoint (endpoint number 2) is the primary endpoint for sinking or

sourcing relatively large amounts of data. It implements the following features to ease

this task:

• Double buffering. This allows parallel operation between USB access and local

CPU access thus increasing throughput. Buffer switching is handled automatically.

This results in transparent buffer operation.

• DMA (Direct Memory Access) operation. This can be interleaved with normal I/O

operation to other endpoints.

• Automatic pointer handling during DMA operation. No local CPU intervention is

necessary when ‘crossing’ the buffer boundary.

• Configurableendpoint for either isochronous transfer or non-isochronous (bulk and

interrupt) transfer.

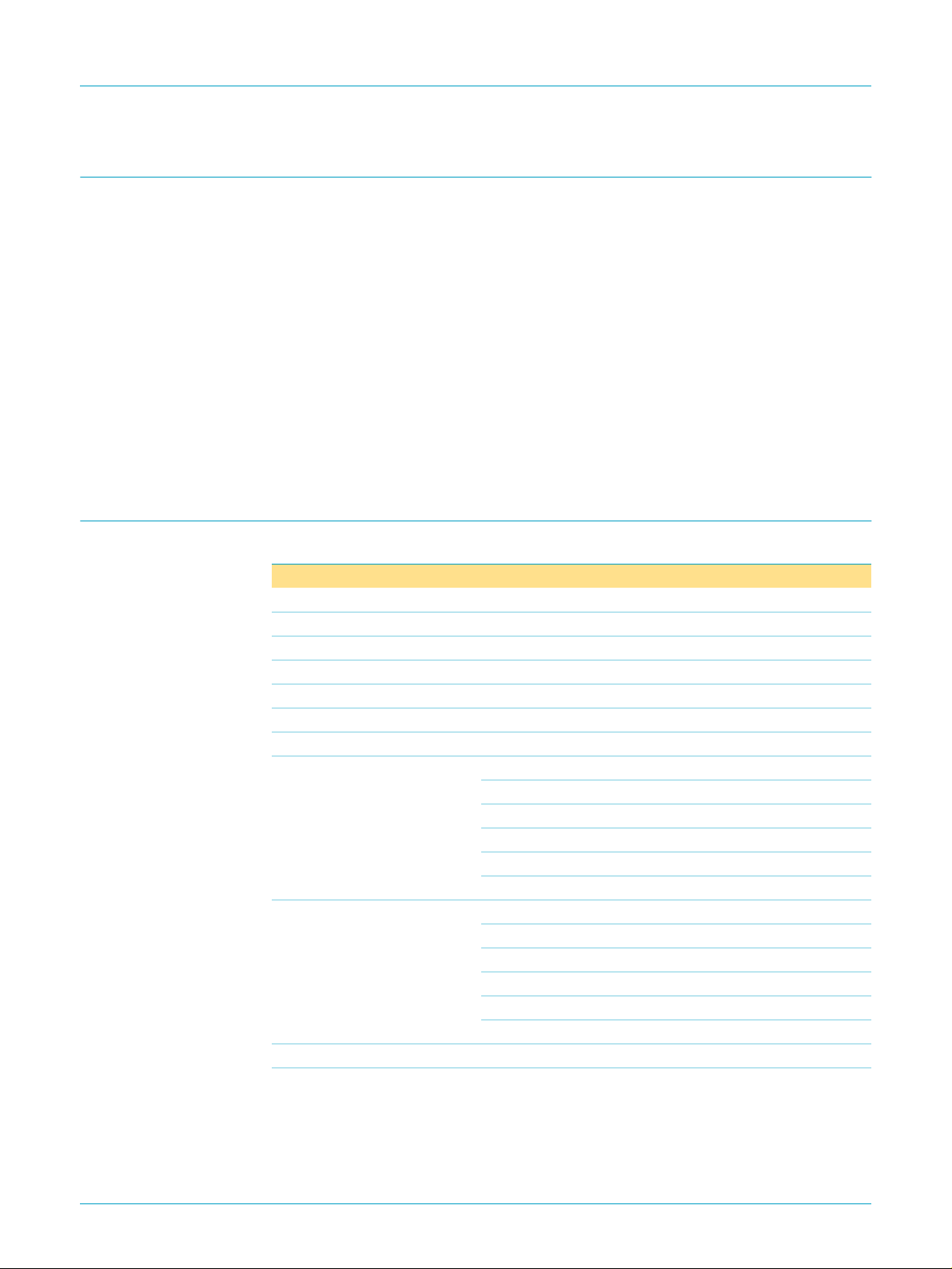

10. Command summary

PDIUSBD12

USB interface device with parallel bus

Table 4: Command summary

Name Destination Code (Hex) Transaction

Initialization commands

Set Address/Enable Device D0 Write 1 byte

Set Endpoint Enable Device D8 Write 1 byte

Set mode Device F3 Write 2 bytes

Set DMA Device FB Write/Read 1 byte

Data flow commands

Read Interrupt Register Device F4 Read 2bytes

Select Endpoint Control OUT 00 Read 1 byte (optional)

Control IN 01 Read 1 byte (optional)

Endpoint 1 OUT 02 Read 1 byte (optional)

Endpoint 1 IN 03 Read 1 byte (optional)

Endpoint 2 OUT 04 Read 1 byte (optional)

Endpoint 2 IN 05 Read 1 byte (optional)

Read Last Transaction Status Control OUT 40 Read 1 byte

Control IN 41 Read 1 byte

Endpoint 1 OUT 42 Read 1 byte

Endpoint 1 IN 43 Read 1 byte

Endpoint 2 OUT 44 Read 1 byte

Endpoint 2 IN 45 Read 1 byte

Read Buffer Selected Endpoint F0 Read nbytes

Write Buffer Selected Endpoint F0 Write n bytes

9397 750 08969

Product data Rev. 07 — 27 November 2001 10 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 4: Command summary

Name Destination Code (Hex) Transaction

Set Endpoint Status Control OUT 40 Write 1 byte

Acknowledge Setup Selected Endpoint F1 None

Clear Buffer Selected Endpoint F2 None

Validate Buffer Selected Endpoint FA None

General commands

Send Resume F6 None

Read Current Frame Number F5 Read 1 or 2 bytes

11. Command description

11.1 Command procedure

There are three basic types of commands: Initialization, Data Flow and General

commands. Respectively, these are used to initialize the function; for data flow

between the function and the host; and some general commands.

…continued

Control IN 41 Write 1 byte

Endpoint 1 OUT 42 Write 1 byte

Endpoint 1 IN 43 Write 1 byte

Endpoint 2 OUT 44 Write 1 byte

Endpoint 2 IN 45 Write 1 byte

11.2 Initialization commands

Initialization commands are used during the enumeration process of the USB

network. These commands are used to enable the function endpoints. They are also

used to set the USB assigned address.

11.2.1 Set Address/Enable

Code (Hex) — D0

Transaction — write 1 byte

This command is used to set the USB assigned address and enable the function.

7654320100

ADDRESS: The value written becomes the address.

ENABLE: A ‘1’ enables this function.

Fig 4. Set Address/Enable command: bit allocation.

000000

POWER ON VALUE

ADDRESS

ENABLE

SV00825

9397 750 08969

Product data Rev. 07 — 27 November 2001 11 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Loading...

Loading...