Philips PDI1394P22 Datasheet

INTEGRATED CIRCUITS

PDI1394P22

3-port physical layer interface

Objective specification 1999 Jul 09

Philips Semiconductors Objective specification

PDI1394P223-port physical layer interface

1.0 FEATURES

•Fully supports provisions of IEEE 1394–1995 Standard for high

performance serial bus and the P1394a supplement (Version 2.0)

•Full P1394a support includes:

– Connection debounce

– Arbitrated short reset

– Multispeed concatenation

– Arbitration acceleration

– Fly-by concatenation

– Port disable/suspend/resume

•Provides three 1394a fully-compliant cable ports at

100/200/400 Megabits per second (Mbits/s)

•Fully compliant with Open HCI requirements

•Cable ports monitor line conditions for active connection to remote

node.

•Power down features to conserve energy in battery-powered

applications include:

– Automatic device power down during suspend

– Device power down terminal

– Link interface disable via LPS

– Inactive ports powered-down

•Logic performs system initialization and arbitration functions

•Encode and decode functions included for data-strobe bit level

encoding

•Incoming data resynchronized to local clock

•Single 3.3 volt supply operation

•Minimum V

of 2.7 V for end-of-wire power-consuming devices

DD

•While unpowered and connected to the bus, will not drive TPBIAS

on a connected port, even if receiving incoming bias voltage on

that port

•Supports extended bias-handshake time for enhanced

1

interoperability with camcorders

•Interface to link-layer controller supports low-cost bus-holder

isolation and optional Annex J electrical isolation

•Data interface to link-layer controller through 2/4/8 parallel lines at

49.152 MHz

•Low-cost 24.576 MHz crystal provides transmit, receive data at

100/200/400 Mbits/s, and link-layer controller clock at 49.152 MHz

•Does not require external filter capacitors for PLL

•Interoperable with link-layer controllers using 3.3 V and 5 V

supplies

•Interoperable with other Physical Layers (PHYs) using 3.3 V and

5 V supplies

•Node power class information signaling for system power

management

•Cable power presence monitoring

•Separate cable bias (TPBIAS) for each port

•Register bits give software control of contender bit, power class

bits, link active bit, and 1394a features

•Fully interoperable with FireWire implementation of IEEE Std 1394

•Function and pin compatible with the Lucent FW803 400 Mbps Phy

2.0 DESCRIPTION

The PDI1394P22 provides the digital and analog transceiver functions

needed to implement a three port node in a cable-based IEEE

1394–1995 and/or 1394a network. Each cable port incorporates two

differential line transceivers. The transceivers include circuitry to

monitor the line conditions as needed for determining connection

status, for initialization and arbitration, and for packet reception and

transmission. The PDI1394P22 is designed to interface with a Link

Layer Controller (LLC), such as the PDI1394L11 or PDI1394L21.

3.0 ORDERING INFORMATION

PACKAGE TEMPERATURE RANGE OUTSIDE NORTH AMERICA NORTH AMERICA PKG. DWG. #

64-pin plastic LQFP 0°C to +70°C PDI1394P22 BD PDI1394P22 BD SOT314-2

1. Implements technology covered by one or more patents of Apple Computer, Incorporated and SGS Thompson, Limited.

1999 Jul 09

2

Philips Semiconductors Objective specification

PDI1394P223-port physical layer interface

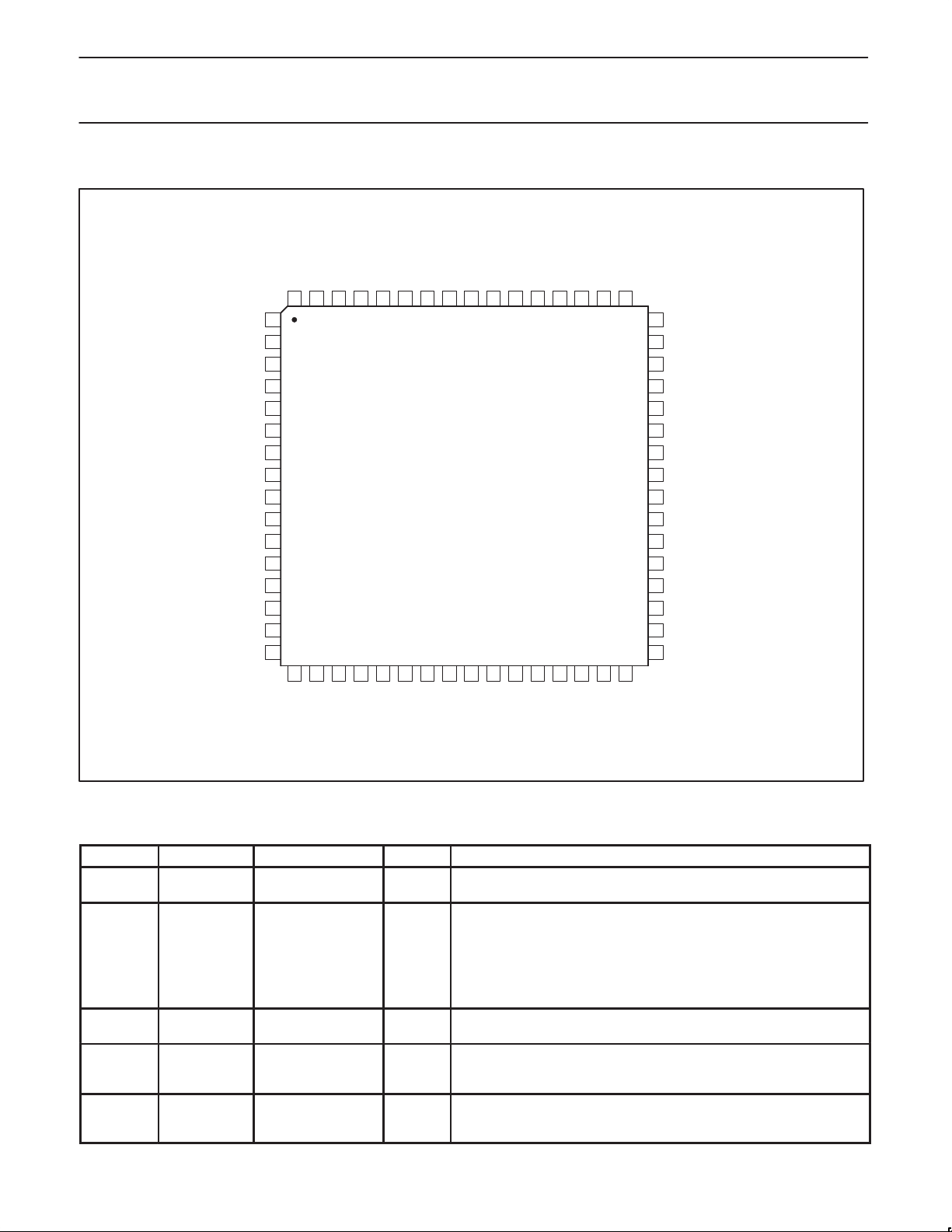

4.0 PIN CONFIGURATION

LREQ

DGND

CTL0

CTL1

DVDD

DGND

CNA

LPS

DGND

SYSCLK

62 61 60 59 58 57 56 55 5464 63 53 52 51 50 49

1

2

3

4

5

D0

6

D1

7

8

D2

9

D3

10

D4

11

D5

12

D6

13

D7

14

15

16

19 20 21 22 23 24 25

DVDD

C/LKON

DVDD

PD

/RESET

PC0

XOXIPLLGND

PLLVDD

PDI1394P22

PC1

PC2

/ISO

CPS

DGND

26 2717 18

DGND

R1

R0

AGND

28 29 30 31 32

DVDD

DVDD

TEST1

AGND

TEST0

AVDD

AVDD

AVDD

AVDD

AGND

AGND

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

TPBIAS2

TPA2+

TPA2–

TPB2+

TPB2–

AVDD

TPBIAS1

TPA1+

TPA1–

TPB1+

TPB1–

TPBIAS0

TPA0+

TPA0–

TPB0+

TPB0–

SV001782

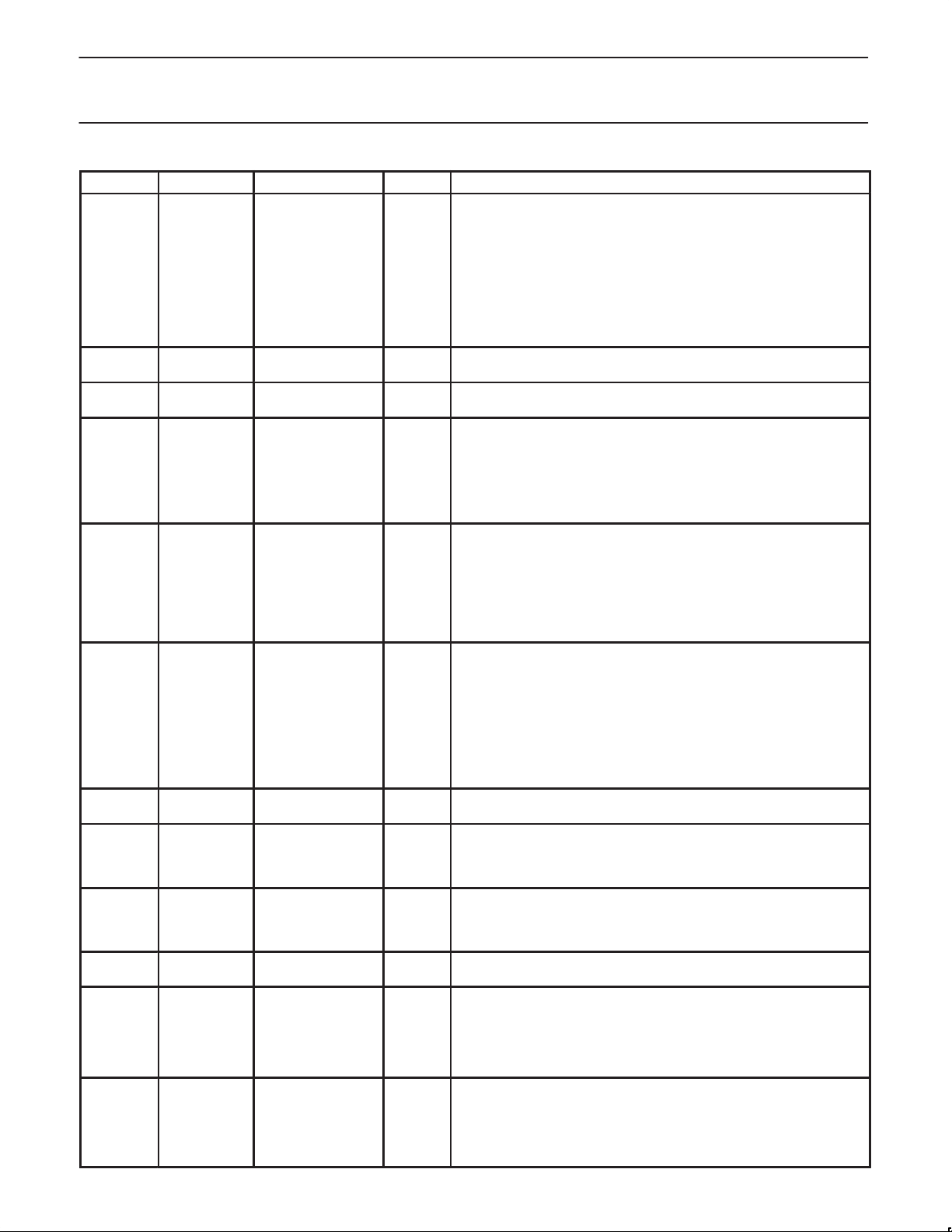

5.0 PIN DESCRIPTION

Name Pin Type Pin Numbers I/O Description

AGND Supply 32, 49, 52, 53 — Analog circuit ground terminals. These terminals should be tied together

AVDD Supply 30, 31, 43, 50, 51 — Analog circuit power terminals. A combination of high frequency

CNA CMOS 15 O Cable Not Active output. This terminal is asserted high when there are

CPS CMOS 24 I Cable Power Status input. This terminal is normally connected to cable

CTL0,

CMOS 5V tol 3, 4 I/O Control I/Os. These bi-directional signals control communication

CTL1

1999 Jul 09

to the low impedance circuit board ground plane.

decoupling capacitors near each terminal are suggested, such as

paralleled 0.1 µF and 0.001 µF. Lower frequency 10 µF filtering

capacitors are also recommended. These supply terminals are

separated from PLL VDD and DVDD internal to the device to provide

noise isolation. They should be tied at a low impedance point on the

circuit board.

no ports receiving incoming bias voltage.

power through a 370–410 kΩ resistor. This circuit drives an internal

comparator that is used to detect the presence of cable power.

between the PDI1394P22 and the LLC. Bus holders are built into

these terminals.

3

Philips Semiconductors Objective specification

PDI1394P223-port physical layer interface

Name DescriptionI/OPin NumbersPin Type

C/LKON CMOS 5V tol 18 I/O Bus Manager Contender programming input and link-on output. On

DGND Supply 2, 14, 25, 56, 64 — Digital circuit ground terminals. These terminals should be tied together

D0–D7 CMOS 5V tol 5, 6, 8, 9, 10, 11,

DVDD Supply 7, 17, 26, 27, 62 — Digital circuit power terminals. A combination of high frequency

/ISO CMOS 23 I Link interface isolation control input. This terminal controls the operation

LPS CMOS 5V tol 16 I Link Power Status input. This terminal is used to monitor the power

LREQ CMOS 5V tol 1 I LLC Request input. The LLC uses this input to initiate a service request

PC0, PC1,

PC2

PD CMOS 5V tol 19 I Power Down input. A logic high on this terminal turns off all internal

PLLGND Supply 58 — PLL circuit ground terminals. These terminals should be tied together to

PLLVDD Supply 57 — PLL circuit power terminals. A combination of high frequency decoupling

/RESET CMOS 5V tol 61 I Logic reset input. Asserting this terminal low resets the internal logic. An

CMOS 5V tol 20, 21, 22 I Power Class programming inputs. On hardware reset, these inputs set

12, 13

I/O Data I/Os. These are bi-directional data signals between the

hardware reset, this terminal is used to set the default value of the

contender status indicated during self-ID. Programming is done by tying

the terminal through a 10kΩ resistor to a high (contender) or low (not

contender). The resistor allows the link-on output to override the input.

Following hardware reset, this terminal is the link-on output, which is

used to notify the LLC to power-up and become active. The link-on

output is a square-wave signal with a period of approximately 163 ns (8

SYSCLK cycles) when active. The link-on output is deasserted low when

the LPS input terminal is active.

to the low impedance circuit board ground plane.

PDI1394P22 and the LLC. Bus holders are built into these terminals.

decoupling capacitors near each terminal are suggested, such as

paralleled 0.1 µF and 0.001 µF. Lower frequency 10 µF filtering

capacitors are also recommended. These supply terminals are

separated from PLL VDD and AVDD internal to the device to provide

noise isolation. They should be tied at a low impedance point on the

circuit board.

of output differentiation logic on the CTL and D terminals. If an optional

isolation barrier of the type described in Annex J of IEEE Std 1394–1395

is implemented between the PDI1394P22 and LLC, the /ISO terminal

should be tied low to enable the differentiation logic. If no isolation barrier

is implemented (direct connection), or bus holder isolation is

implemented, the /ISO terminal should be tied high to disable the

differentiation logic.

status of the LLC, and is connected to either the VDD supplying the link

layer controller through a 1kΩ resistor, or to a pulsed output which is

active when the LLC is powered. The pulsed output is useful when using

an isolation barrier. If this input is low for more than 25 ms, the LLC is

considered powered down. If this input is high for more than 20 ns, the

LLC is considered powered up. If the LLC is powered-down, the

PHY–LLC interface is disabled, and the PDI1394P22 performs only the

basic repeater functions required for network initialization and operation.

Bus holder is built into this terminal.

to the PDI1394P22. Bus holder is built into this terminal.

the default value of the power class indicated during self-ID.

Programming is done by tying the terminals high or low. Refer to

Table 18 for encoding.

circuitry except the cable-active monitor circuits which control the CNA

output. Bus holder is built into this terminal. For more information, refer to

Section 17.3

the low impedance circuit board ground plane.

capacitors near each terminal are suggested, such as paralleled 0.1 µF

and 0.001 µF. Lower frequency 10 µF filtering capacitors are also

recommended. These supply terminals are separated from DVDD and

AVDD internal to the device to provide noise isolation. They should be

tied at a low impedance point on the circuit board.

internal pull-up resistor to VDD is provided so only an external

delay capacitor in parallel with a resistor is required for proper power-up

operation. For more information, refer to Section 17.3. This input is

otherwise a standard logic input, and can also be driven by an

open-drain type driver.

1999 Jul 09

4

Philips Semiconductors Objective specification

gg

gg

PDI1394P223-port physical layer interface

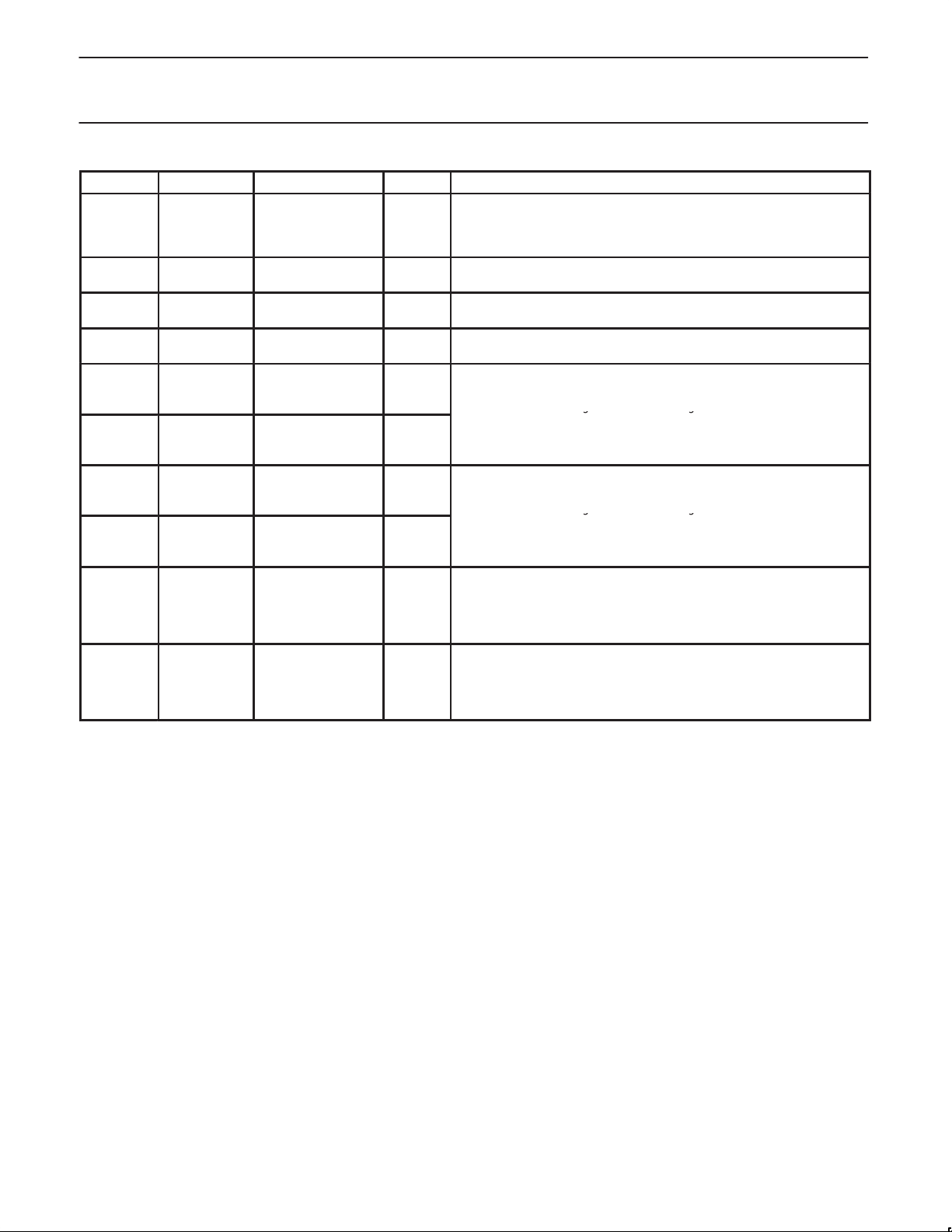

Name DescriptionI/OPin NumbersPin Type

R0, R1 Bias 54, 55 — Current setting resistor terminals. These terminals are connected to

SYSCLK CMOS 63 O System clock output. Provides a 49.152 MHz clock signal, synchronized

TEST0 CMOS 29 I Test control input. This input is used in manufacturing tests of the

TEST1 CMOS 28 I Test control input. This input is used in manufacturing tests of the

TPA0+,

TPA1+,

TPA2+

TPA0–,

TPA1–,

TPA2–

TPB0+,

TPB1+,

TPB2+

TPB0–,

TPB1–,

TPB2–

TPBIAS0,

TPBIAS1,

TPBIAS2

XO, XI Crystal 60, 59 — Crystal oscillator inputs. These terminals connect to a 24.576 MHz

Cable 36, 41, 47 I/O

Cable 35, 40, 46 I/O

Cable 34, 39, 45 I/O

Cable 33, 38, 44 I/O

Cable 37, 42, 48 I/O Twisted-pair bias output. This provides the 1.86V nominal bias voltage

an external resistance to set the internal operating currents and

cable driver output currents. A resistance of 6.34 kΩ ±1% is required to

meet the IEEE Std 1394–1995 output voltage limits.

with data transfers, to the LLC.

PDI1394P22. For normal use, this terminal should be tied to GND.

PDI1394P22. For normal use, this terminal should be tied to GND.

Twisted-pair cable A differential signal terminals. Board traces from each

pair of positive and negative differential signal terminals should be kept

matched and as short as possible to the external load resistors and to

the cable connector.

Twisted-pair cable B differential signal terminals. Board traces from each

pair of positive and negative differential signal terminals should be kept

matched and as short as possible to the external load resistors and to

the cable connector.

needed for proper operation of the twisted-pair cable drivers and

receivers, and for signaling to the remote nodes that there is an active

cable connection. Each of these terminals must be decoupled with a

0.3 µF–1 µF capacitor to ground.

parallel resonant fundamental mode crystal. The optimum values for the

external shunt capacitors are dependent on the specifications of the

crystal used. Can also be driven by an external clock generator (leave

XO unconnected in this case).

1999 Jul 09

5

Philips Semiconductors Objective specification

PDI1394P223-port physical layer interface

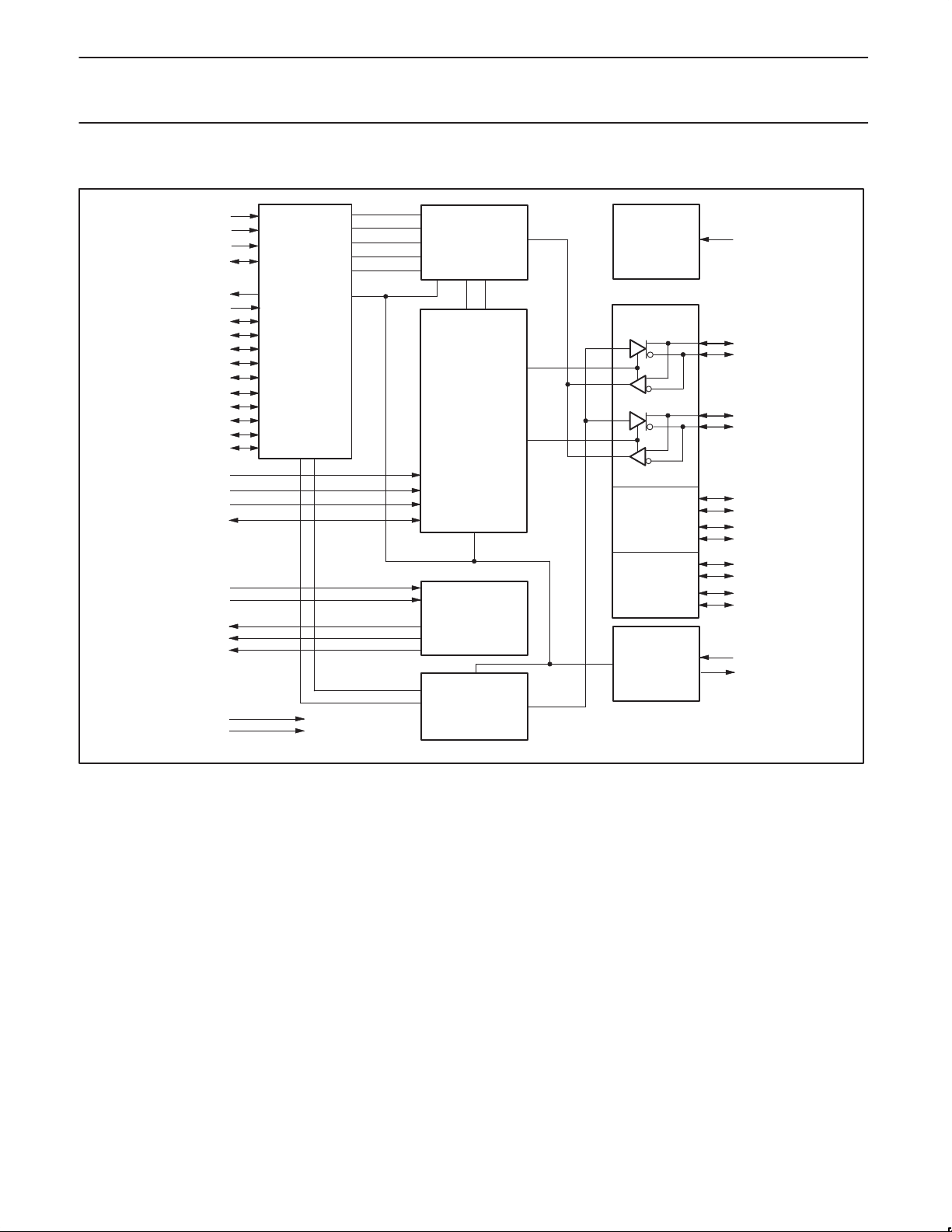

6.0 BLOCK DIAGRAM

CPS

LPS

/ISO

C/LKON

SYSCLK

LREQ

CTL0

CTL1

PC0

PC1

PC2

CNA

TPBIAS0

TPBIAS1

TPBIAS2

PD

/RESET

LINK

INTERFACE

D0

D1

D2

D3

D4

D5

D6

D7

R0

R1

I/O

RECEIVED DATA

DECODER/

RETIMER

ARBITRATION

AND CONTROL

STATE MACHINE

LOGIC

BIAS VOLTAGE

AND

CURRENT

GENERATOR

TRANSMIT

DATA

ENCODER

CABLE POWER

DETECTOR

CABLE PORT 0

CABLE PORT 1

CABLE PORT 2

CRYSTAL

OSCILLATOR,

PLL SYSTEM,

AND CLOCK

GENERATOR

CPS

TPA0+

TPA0–

TPB0+

TPB0–

TPA1+

TPA1–

TPB1+

TPB1–

TPA2+

TPA2–

TPB2+

TPB2–

XI

XO

SV01743

7.0 FUNCTIONAL SPECIFICA TION

The PDI1394P22 requires only an external 24.576 MHz crystal as a

reference. An external clock can be provided instead of a crystal. An

internal oscillator drives an internal phase-locked loop (PLL), which

generates the required 393.216 MHz reference signal. This

reference signal is internally divided to provide the clock signals

used to control transmission of the outbound encoded Strobe and

Data information. A 49.152 MHz clock signal, supplied to the

associated LLC for synchronization of the two chips, is used for

resynchronization of the received data. The Power Down (PD)

function, when enabled by asserting the PD terminal high, stops

operation of the PLL and disables all circuits except the cable bias

detectors at the TPB terminals. The port transmitter circuitry and the

receiver circuitry are also disabled when the port is disabled,

suspended, or disconnected.

The PDI1394P22 supports an optional isolation barrier between

itself and its LLC. When the /ISO input terminal is tied high, the

LLC interface outputs behave normally. When the /ISO terminal is

tied low, internal differentiating logic is enabled, and the outputs are

driven such that they can be coupled through a capacitive or

transformer galvanic isolation barrier as described in

1999 Jul 09

IEEE 1394a

section 5.9.4

. To operate with single capacitor (bus holder) isolation,

the /ISO on the PHY terminal must be tied high.

Data bits to be transmitted through the cable ports are received from

the LLC on two, four or eight parallel paths (depending on the

requested transmission speed). They are latched internally in the

PDI1394P22 in synchronization with the 49.152 MHz system clock.

These bits are combined serially, encoded, and transmitted at

98.304/196.608/392.216 Mbits/s (referred to as S100, S200, and

S400 speed, respectively) as the outbound data-strobe information

stream. During transmission, the encoded data information is

transmitted differentially on the TPB cable pair(s), and the encoded

strobe information is transmitted differentially on the TP A cable

pair(s).

During packet reception the TPA and TPB transmitters of the

receiving cable port are disabled, and the receivers for that port are

enabled. The encoded data information is received on the TPA cable

pair, and the encoded strobe information is received on the TPB

cable pair. The received data-strobe information is decoded to

recover the receive clock signal and the serial data bits. The serial

6

Philips Semiconductors Objective specification

PDI1394P223-port physical layer interface

data bits are split into two-, four- or eight-bit parallel streams

(depending upon the indicated receive speed), resynchronized to

the local 49.152 MHz system clock and sent to the associated LLC.

The received data is also transmitted (repeated) on the other active

(connected) cable ports.

Both the TPA and TPB cable interfaces incorporate dif ferential

comparators to monitor the line states during initialization and

arbitration. The outputs of these comparators are used by the

internal logic to determine the arbitration status. The TPA channel

monitors the incoming cable common-mode voltage. The value of

this common-mode voltage is used during arbitration to set the

speed of the next packet transmission (speed signalling). In addition,

the TPB channel monitors the incoming cable common-mode

voltage on the TPB pair for the presence of the remotely supplied

twisted-pair bias voltage (cable bias detection).

The PDI1394P22 provides a 1.86 V nominal bias voltage at the

TPBIAS terminal for port termination. the PHY contains three

independent TPBIAS circuits. This bias voltage, when seen through

a cable by a remote receiver, indicates the presence of an active

connection. This bias voltage source must be stabilized by an

external filter capacitor of 0.3 µF–1 µF.

The line drivers in the PDI1394P22 operate in a high-impedance

current mode, and are designed to work with external 112 Ω

line-termination resistor networks in order to match the 110 Ω cable

impedance. One network is provided at each end of all twisted-pair

cable. Each network is composed of a pair of series-connected 56 Ω

resistors. The midpoint of the pair of resistors that is directly

connected to the twisted-pair A terminals is connected to its

corresponding TPBIAS voltage terminal. The midpoint of the pair of

resistors that is directly connected to the twisted-pair B terminals is

coupled to ground through a parallel R-C network with recommended

values of 5 kΩ and 220 pF. The values of the external line termination

resistors are designed to meet the standard specifications when

connected in parallel with the internal receiver circuits. An external

resistor connected between the R0 and R1 terminals sets the driver

output current, along with other internal operating currents. This

current setting resistor has a value of 6.34 kΩ ±1%.

When the power supply of the PDI1394P22 is removed while the

twisted-pair cables are connected, the PDI1394P22 transmitter and

receiver circuitry presents a high impedance to the cable in order to

not load the TPBIAS voltage on the other end of the cable.

When the PDI1394P22 is used with one or more of the ports not

brought out to a connector, the twisted-pair terminals of the unused

ports must be terminated for reliable operation. For each unused

port, the TPB+ and TPB– terminals can be tied together and then

pulled to ground, or the TPB+ and TPB– terminals can be connected

to the suggested termination network. The TPA+ and TPA– and

TPBIAS terminals of an unused port can be left unconnected.

The TEST0 and TEST1 terminals are used to set up various

manufacturing test conditions. For normal operation, the TEST0 and

TEST1 terminals should be connected to ground.

Four package terminals, used as inputs to set the default value for

four configuration status bits in the self-ID packet, should be

hard-wired high or low as a function of the equipment design. The

PC0–PC2 terminals are used to indicate the default power-class

status for the node (the need for power from the cable or the ability

to supply power to the cable). See Table 18 for power class

encoding. The C/LKON terminal is used as an input to indicate that

the node is a contender for bus manager.

The PHY supports suspend/resume as defined in the IEEE 1394a

specification. The suspend mechanism allows pairs of directly

connected ports to be placed into a low power state while

maintaining a port-to-port connection between 1394 bus segments.

While in a low power state, a port is unable to transmit or receive

data transaction packets. However, a port in a low power state is

capable of detecting connection status changes and detecting

incoming TPBIAS. When all three ports of the PDI1394P22 are

suspended, all circuits except the bias-detection circuits are

powered down, resulting in significant power savings. The TPBIAS

circuit monitors the value of incoming TPA pair common-mode

voltage when local TPBIAS is inactive. Because this circuit has an

internal current source and the connected node has a current sink,

the monitored value indicates the cable connection status. This

monitor is called connect-detect.

Both the cable bias-detect monitor and TPBIAS connect-detect

monitor are used in suspend/resume signaling and cable connection

detection. For additional details of suspend/resume operation, refer

to the 1394a specification. The use of suspend/resume is

recommended for new designs.

The port transmitter and receiver circuitry is disabled during power

down (when the PD input terminal is asserted high), during reset

(when the /RESET input terminal is asserted low), when no active

cable is connected to the port, or when controlled by the internal

arbitration logic. The port twisted-pair bias voltage circuitry is

disabled during power down, during reset, or when the port is

disabled as commanded by the LLC.

The CNA (cable-not-active) terminal provides a high output when all

twisted-pair cable ports are disconnected, and can be used along

with LPS to determine when to power down the PDI1394P22. The

CNA output is not debounced. In Power Down mode, the CNA

detection circuitry remains enabled.

The LPS (link power status) terminal works with the C/LKON

terminal to manage the power usage in the node. The LPS signal

from the LLC indicates to the PHY that the LLC is powered up and

active. During LLC Power Down mode, as indicated by the LPS

input being low for more than 25 µs, the PDI1394P22 deactivates

the PHY -LLC interface to save power. The PDI1394P22 continues

the necessary repeater function required for network operation

during this low power state.

If the PHY receives a link-on packet from another node, the C/LKON

terminal is activated to output a square-wave signal. The LLC

recognizes this signal, reactivates any powered-down portions of the

LLC, and notifies the PHY of its power-on status via the LPS

terminal. The PHY confirms notification by deactivating the

square-wave signal on the C/LKON terminal, then enables the

PHY -link interface.

1999 Jul 09

7

Philips Semiconductors Objective specification

SYMBOL

PARAMETER

CONDITION

UNIT

Electrostatic discharge

SYMBOL

PARAMETER

MIN

TYP

MAX

UNIT

VDDSuppl

oltage

V

gg,

VIDDifferential input voltage amplitude

V

TPB common-mode input voltage

gg

V

TPB common-mode input voltage

S200 speed signal

V

TPB common-mode input voltage

S400 speed signal

PDI1394P223-port physical layer interface

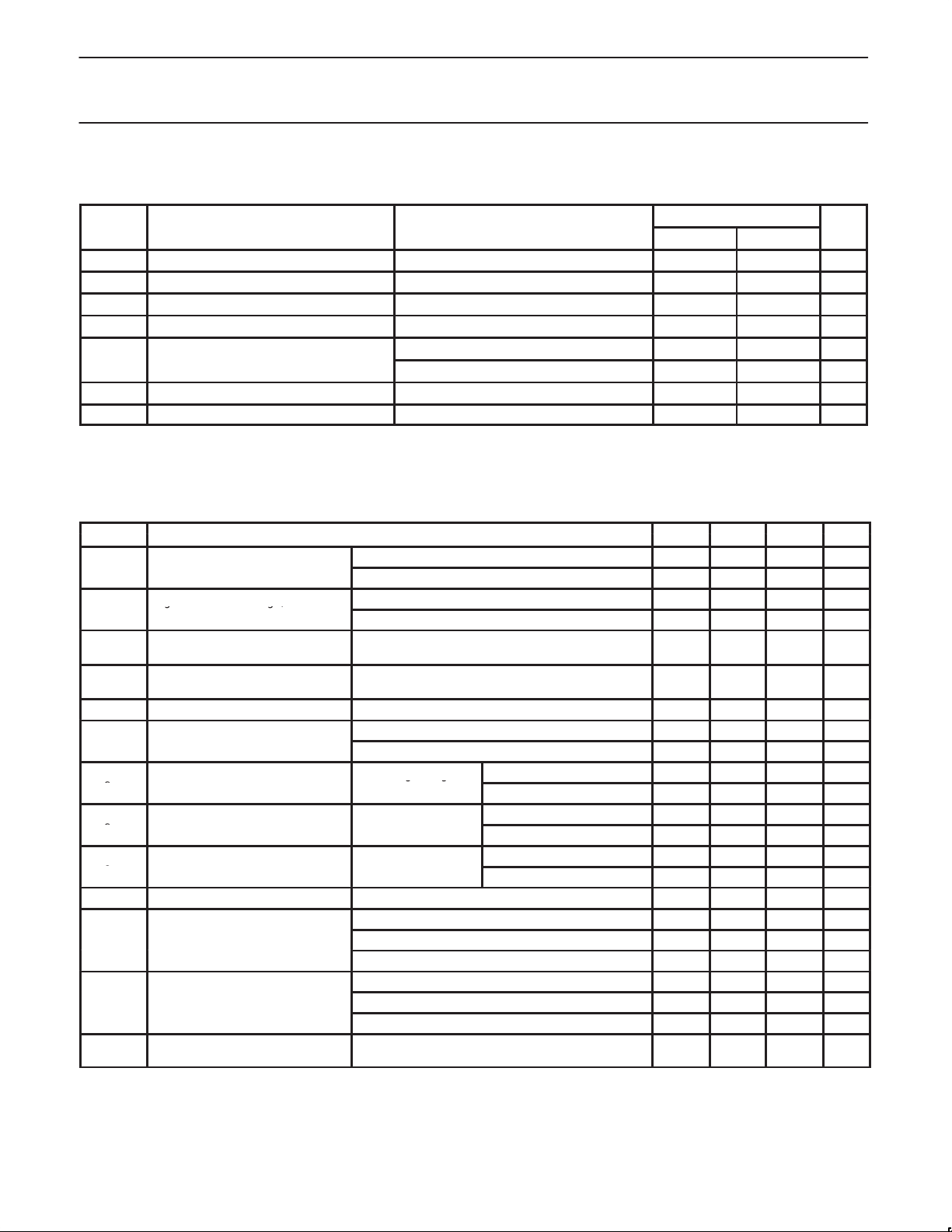

8.0 ABSOLUTE MAXIMUM RATINGS

1

In accordance with the Absolute Maximum Rating System (IEC 134). Voltages are referenced to GND (ground = 0 V).

LIMITS

MIN MAX

V

DC supply voltage –0.5 4.0 V

DD

V

DC input voltage –0.5 VDD+0.5 V

I

VI–5V 5 volt tolerant input voltage range –0.5 5.5 V

V

DC output voltage range at any output –0.5 VDD+0.5 V

O

Human Body Model 2 kV

Machine Model 200 V

T

amb

T

Operating free-air temperature range 0 +70 °C

Storage temperature range –65 +150 °C

stg

NOTE:

1. Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating

Conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability .

9.0 RECOMMENDED OPERATING CONDITIONS

pp

y v

V

IOH/I

IC-100

IC-200

IC-100

t

High-level input voltage, pins

IH

CTLn, Dn, C/LKON

Low-level input voltage, pins

IL

CTLn, Dn, C/LKON

Output current, pins CTLn, Dn,

OL

C/LKON and SYSCLK

I

Output current TPBIAS outputs –6 2.5 mA

O

Power–up reset time Set by capacitor between /RESET pin and GND 2 ms

PU

2

2

p

p

p

p

p

Receive input jitter

Receive input skew

f

XTAL

Crystal or external clock frequency

NOTES:

1. For a node that does not source power to the bus (see Section 4.2.2.2 in the IEEE 1394-1995 standard).

2. C/LKON is only an input when /RESET = 0.

Source power node 3.0 3.3 3.6 V

Non-source power node 2.7

1

3.0 3.6 V

/ISO = VDD, VDD = 2.7 V 2.3 5.5 V

/ISO = VDD, VDD >= 3.0 V 2.6 5.5 V

/ISO = V

DD

0.7 V

VOH = VDD –0.5 V, VOL = 0.5 V –12 12 mA

TPA, TPB cable inputs, during data reception 118 260 mV

TPA, TPB cable inputs, during data arbitration 168 265 mV

Speed signalling off

or S100 speed signal

p

p

Source power node 1.165 2.515 V

Non-source power node 1.165 2.015

1

Source power node 0.935 2.515 V

Non-source power node 0.935 2.015

1

Source power node 0.523 2.515 V

Non-source power node 0.523 2.015

1

TPA, TPB cable inputs, S100 operation 1.08 ns

TPA, TPB cable inputs, S200 operation 0.5 ns

TPA, TPB cable inputs, S400 operation 0.315 ns

Between TPA and TPB cable inputs, S00 operation 0.8 ns

Between TPA and TPB cable inputs, S200 operation 0.55 ns

Between TPA and TPB cable inputs, S400 operation 0.5 ns

Crystal connected according to Figure 8 or external

clock input at pin XI

24.5735 24.576 24.5785 MHz

V

V

V

1999 Jul 09

8

Philips Semiconductors Objective specification

SYMBOL

PARAMETER

TEST CONDITION

UNIT

2

SYMBOL

PARAMETER

TEST CONDITION

UNIT

Z

Differential input impedance

Drivers disabled

Z

Common mode input impedance

Drivers disabled

PDI1394P223-port physical layer interface

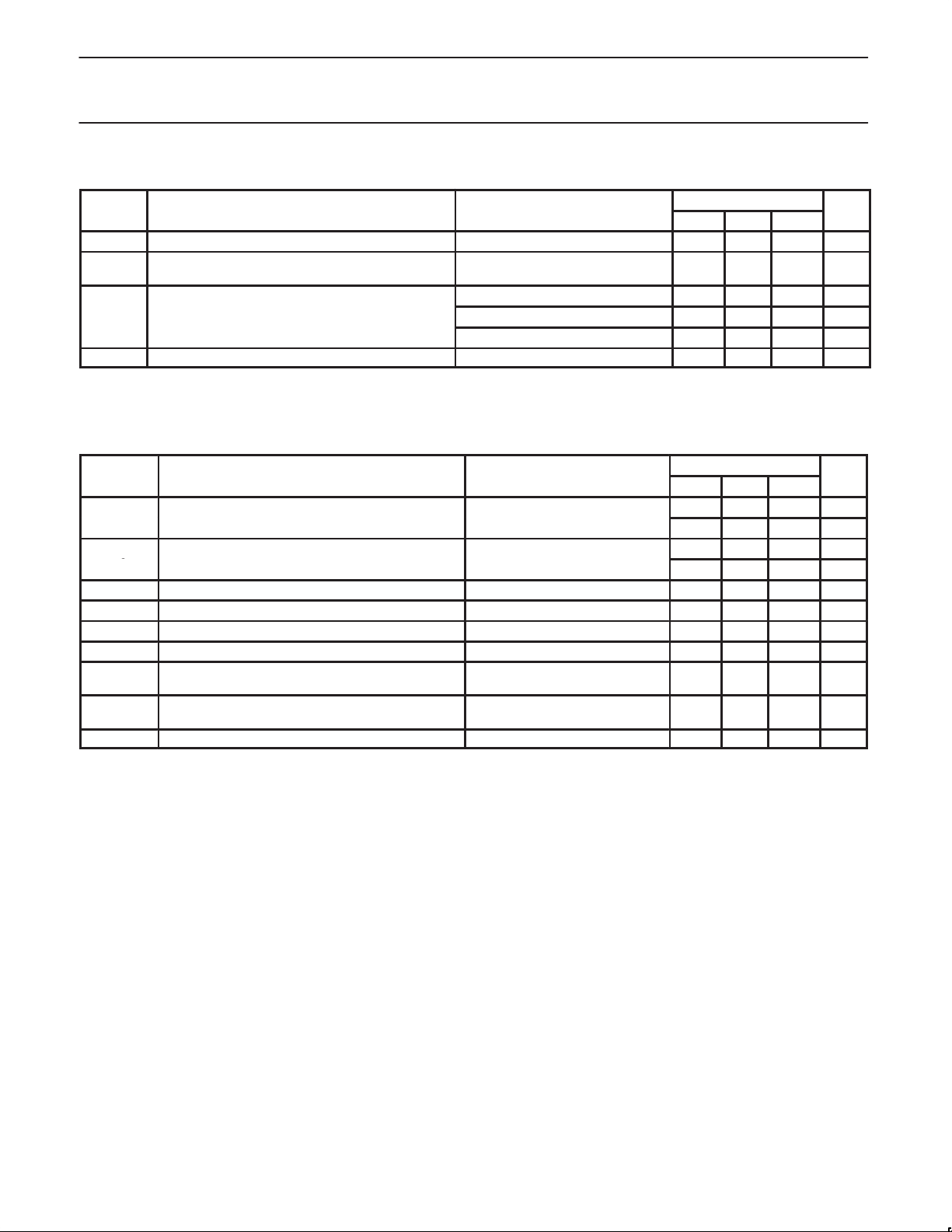

10.0 CABLE DRIVER

LIMITS

MIN TYP MAX

V

I

O(diff)

I

V

OFF

NOTES:

1. Limits defined as algebraic sum of TPA+ and TPA– driver currents. Limits also apply to TPB+ and TPB– algebraic sum of driver currents.

2. Limits defined as absolute limit of each of TPB+ and TPB– driver currents.

11.0 CABLE RECEIVER

V

V

V

V

V

TH–SP200

V

TH–SP400

Differential output voltage 56 Ω load 172 265 mV

OD

Driver Difference current, TP A+, TPA–, TPB+, TPB–

Drivers enabled,

1

speed signaling OFF

–1.05

1

100 Mbit/s speed signaling enabled –0.81 –0.44 mA

Common mode speed signaling current, TPB+, TPB–

SP

200 Mbit/s speed signaling enabled –4.84 –2.53 mA

400 Mbit/s speed signaling enabled –12.4 –8.10 mA

OFF state differential voltage Drivers disabled 20 mV

LIMITS

MIN TYP MAX

ID

IC

TH-R

TH-CB

TH+

TH–

I

CD

p

p

p

p

Receiver input threshold voltage Drivers disabled –30 30 mV

Cable bias detect threshold, TPBn cable inputs Drivers disabled 0.6 1.0 V

Positive arbitration comparator threshold voltage Drivers disabled 89 168 mV

Negative arbitration comparator threshold voltage Drivers disabled –168 –89 mV

Speed signal threshold

Speed signal threshold

TPBIAS–TPA common mode

voltage, drivers disabled

TPBIAS–TPA common mode

voltage, drivers disabled

Connect detect output at TPBIAS pins Drivers disabled 76 µA

10 14

20 kΩ

49 131 mV

314 396 mV

1

0.88

4 pF

24 pF

mA

kΩ

1999 Jul 09

9

Loading...

Loading...