查询PCF2113A供应商查询PCF2113A供应商

INTEGRATED CIRCUITS

DATA SH EET

PCF2113x

LCD controllers/drivers

Product specification

Supersedes data of 1997 Apr 04

File under Integrated Circuits, IC12

2001 Dec 19

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

CONTENTS

1 FEATURES

1.1 Note

2 APPLICATIONS

3 GENERAL DESCRIPTION

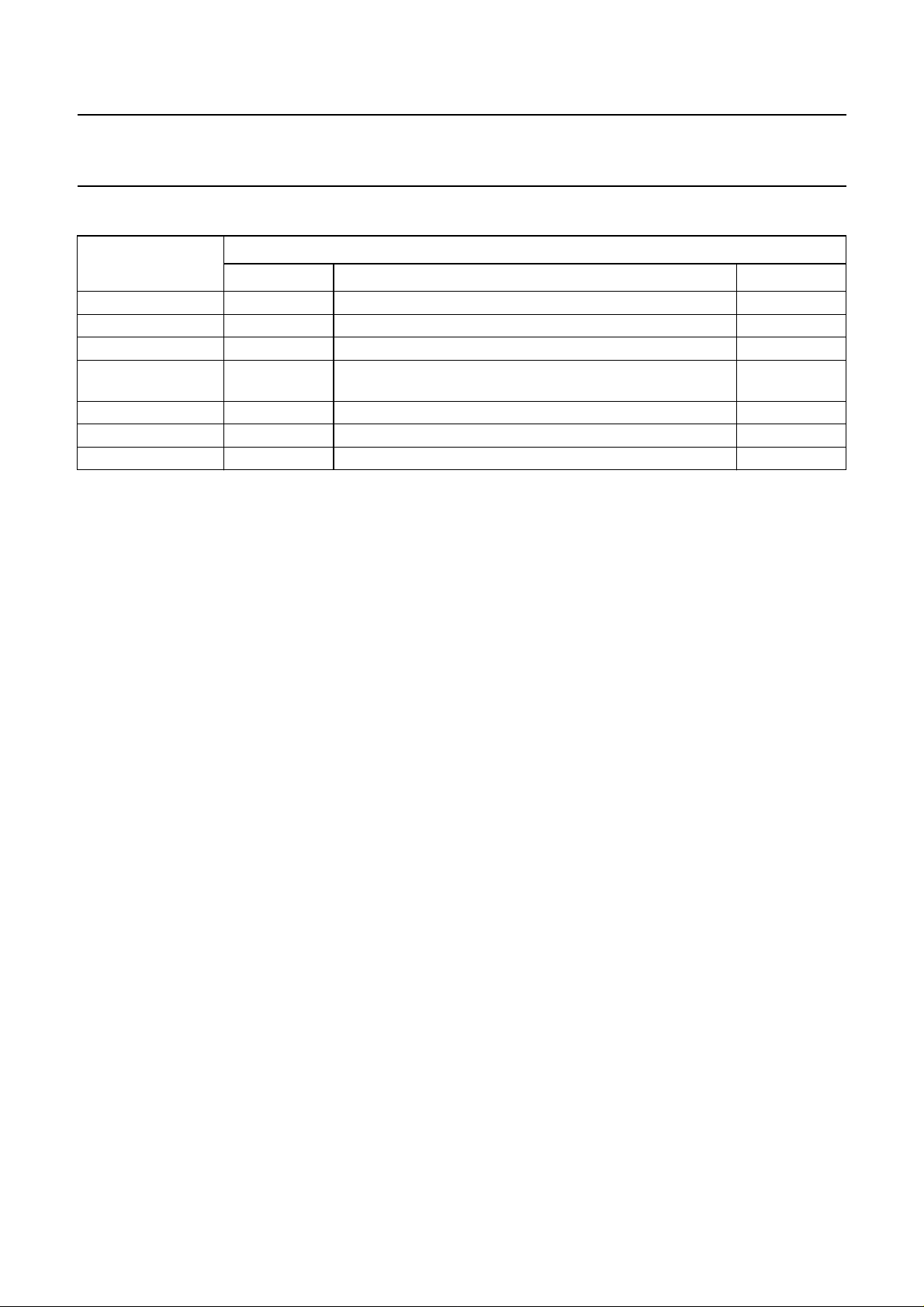

4 ORDERING INFORMATION

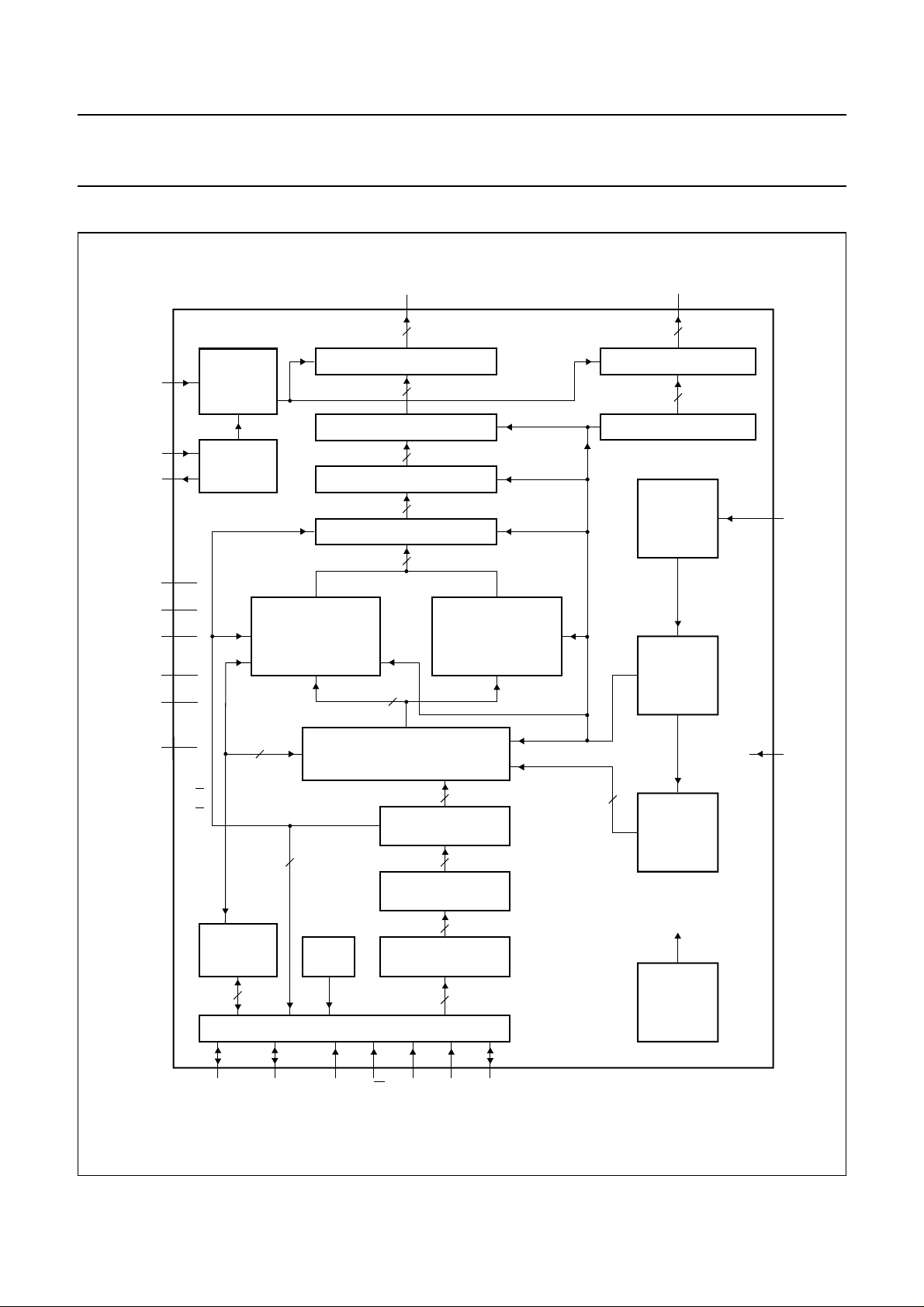

5 BLOCK DIAGRAM

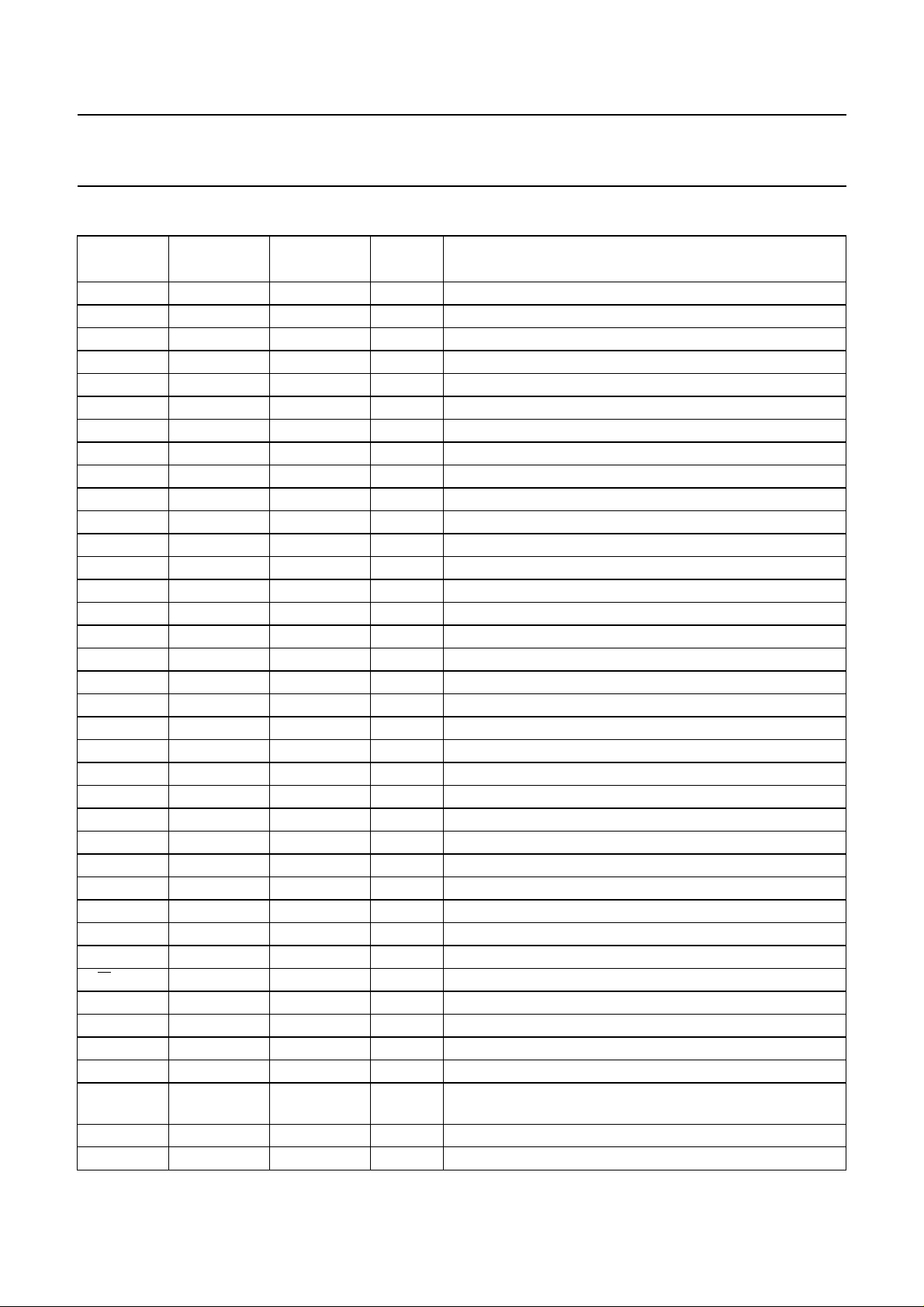

6 PINNING

7 FUNCTIONAL DESCRIPTION

7.1 LCD supply voltage generator

7.2 LCD bias voltage generator

7.3 Oscillator

7.4 External clock

7.5 Power-on reset

7.6 Power-down mode

7.7 Registers

7.8 Busy flag

7.9 Address Counter (AC)

7.10 Display Data RAM (DDRAM)

7.11 Character Generator ROM (CGROM)

7.12 Character Generator RAM (CGRAM)

7.13 Cursor control circuit

7.14 Timing generator

7.15 LCD row and column drivers

7.16 Reset function

8 INSTRUCTIONS

8.1 Clear display

8.2 Return home

8.3 Entry mode set

8.4 Display control (andpartial Power-down mode)

8.5 Cursor or display shift

8.6 Function set

8.7 Set CGRAM address

8.8 Set DDRAM address

8.9 Read busy flag and read address

8.10 Write data to CGRAM or DDRAM

8.11 Read data from CGRAM or DDRAM

9 EXTENDED FUNCTION SET

INSTRUCTIONS AND FEATURES

9.1 New instructions

9.2 Icon control

9.3 Bit IM

9.4 Bit IB

9.5 Direct mode

9.6 Voltage multiplier control

9.7 Screen configuration

9.8 Display configuration

9.9 Temperature control

9.10 Set V

9.11 Reducing current consumption

10 INTERFACES TO MICROCONTROLLER

10.1 Parallel interface

10.2 I2C-bus interface

11 LIMITING VALUES

12 HANDLING INSTRUCTIONS

13 DC CHARACTERISTICS

14 AC CHARACTERISTICS

15 DEVICE PROTECTION CIRCUITS

16 APPLICATION INFORMATION

16.1 General application information

16.2 4-bit operation, 1-line display using internal

16.3 8-bit operation, 1-line display using internal

16.4 8-bit operation, 2-line display

16.5 I2C-bus operation, 1-line display

17 BONDING PAD INFORMATION

18 TRAY INFORMATION

19 PACKAGE OUTLINE

20 SOLDERING

20.1 Introduction to soldering surface mount

20.2 Reflow soldering

20.3 Wave soldering

20.4 Manual soldering

20.5 Suitability of surface mount IC packages for

21 DATA SHEET STATUS

22 DEFINITIONS

23 DISCLAIMERS

24 BARE DIE DISCLAIMER

25 PURCHASE OF PHILIPS I2C COMPONENTS

LCD

reset

reset

packages

wave and reflow soldering methods

2001 Dec 19 2

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

1 FEATURES

• Single-chip LCD controller/driver

• 2-line display of up to 12 characters + 120 icons, or

1-line display of up to 24 characters + 120 icons

• 5 × 7 character format plus cursor; 5 × 8 for kana

(Japanese) and user defined symbols

• Icon mode: reduced current consumption while

displaying

• Icon blink function

• On-chip:

– Configurable 4, 3 or 2 voltage multiplier generating

LCD supply voltage, independent of VDD,

programmable by instruction (external supply also

possible)

– Temperature compensation of on-chip generated

V

: −0.16 to −0.24 %/K (programmable by

LCD

instruction)

– Generation of intermediate LCD bias voltages

– Oscillator requires no external components

(external clock also possible).

• Display data RAM: 80 characters

• Character generator ROM: 240, 5 × 8 characters

• Character generator RAM: 16, 5 × 8 characters;

3 characters used to drive 120 icons, 6 characters used

if icon blink feature is used in application

• 4 or 8-bit parallel bus and 2-wire I2C-bus interface

• CMOS compatible

• 18 row and 60 column outputs

• Multiplex rates 1 : 18 (for normal operation), 1 : 9 (for

single line operation) and 1 : 2 (for icon only mode)

• Uses common 11 code instruction set (extended)

• Logic supply voltage range V

DD1

− V

= 1.8 to 5.5 V

SS1

(chip may be driven with two battery cells)

• V

• Display supply voltage range V

generator supply voltage range

LCD

V

DD2

− V

= 2.2 to 4.0 V

SS2

LCD

− V

= 2.2 to 6.5 V

SS2

• Direct mode to save current consumption for icon mode

and Mux 1 : 9 (depending on V

value and LCD liquid

DD2

properties)

• Very low current consumption (20 to 200 µA):

– Icon mode: <25 µA

– Power-down mode: <2 µA.

1.1 Note

Icon mode is used to save current. When only icons are

displayed, a much lower operating voltage V

LCD

can be

used and the switching frequency of the LCD outputs is

reduced. In most applications it is possible to use VDD as

V

.

LCD

2 APPLICATIONS

• Telecom equipment

• Portable instruments

• Point-of-sale terminals.

3 GENERAL DESCRIPTION

The PCF2113x is a low power CMOS LCD controller and

driver, designed to drive a dot matrix LCD display of 2-line

by 12 or 1-line by 24 characters with 5 × 8 dot format.

All necessary functions for the display are provided in a

single chip, including on-chip generation of LCD bias

voltages, resulting in a minimum of external components

and lower system current consumption. The PCF2113x

interfaces to most microcontrollers via a 4 or 8-bit bus or

via the 2-wire I2C-bus. The chip contains a character

generator and displays alphanumeric and kana

(Japanese) characters. The letter ‘x’ in PCF2113x

characterizes the built-in character set. Various character

sets can be manufactured on request.

2001 Dec 19 3

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

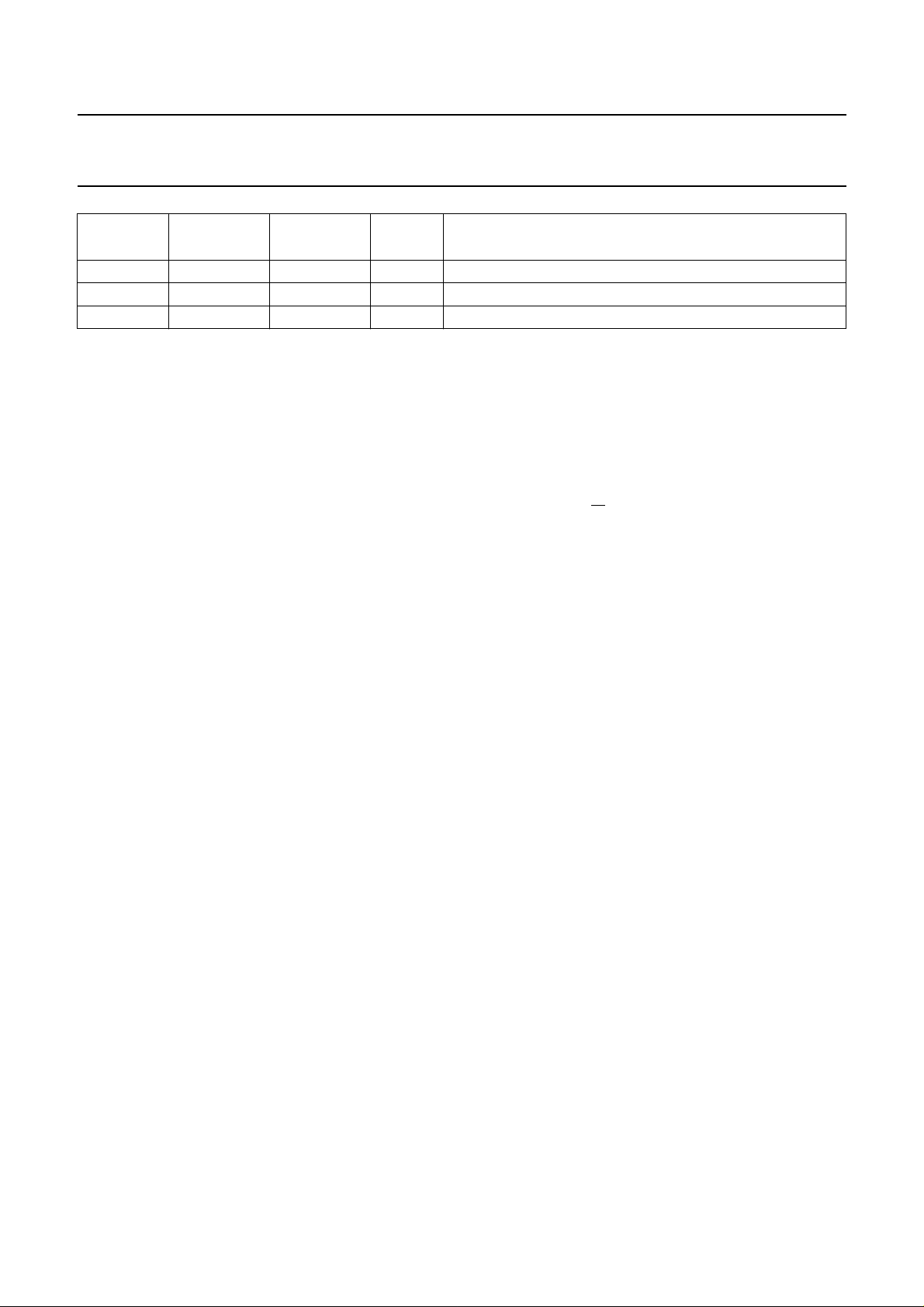

4 ORDERING INFORMATION

TYPE NUMBER

NAME DESCRIPTION VERSION

PCF2113AU/10/F4 − chip on flexible film carrier −

PCF2113DU/10/F4 − chip on flexible film carrier −

PCF2113DU/F4 − chip in tray −

PCF2113DH/F4 LQFP100 plastic low profile quad flat package; 100 leads;

body 14 × 14 × 1.4 mm

PCF2113DU/2/F4 − chip with bumps in tray −

PCF2113EU/2/F4 − chip with bumps in tray −

PCF2113WU/2/F4 − chip with bumps in tray −

PACKAGE

SOT407-1

2001 Dec 19 4

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

5 BLOCK DIAGRAM

handbook, full pagewidth

V

LCD1

V

LCDSENSE

V

LCD2

V

DD1

V

DD2

V

DD3

V

SS1

V

SS2

BIAS

VOLT AGE

GENERATOR

V

LCD

GENERATOR

SHIFT REGISTER 5 × 12 BIT

CURSOR AND DATA CONTROL

CHARACTER

GENERATOR

RAM (128 × 5)

(CGRAM)

16 CHARACTERS

C1 to C60 R1 to R18

60

COLUMN DRIVERS

60

DATA LATCHES

60

5

5

CHARACTER

GENERATOR

ROM

(CGROM)

240 CHARACTERS

8

SHIFT REGISTER 18-BIT

18

ROW DRIVERS

18

OSCILLATOR

TIMING

GENERATOR

OSC

T1

T2

T3

DB0 to DB3/SA0

7

DATA

REGISTER

(DR)

8

DB4 to DB7

DISPLAY DATA RAM

(DDRAM)

80 CHARACTERS/BYTES

ADDRESS COUNTER

BUSY

FLAG

I/O BUFFER

E

R/W

RS

Fig.1 Block diagram.

7

(AC)

77

INSTRUCTION

DECODER

8

INSTRUCTION

REGISTER(IR)

8

SCL

SDA

PD

7

DISPLAY

ADDRESS

COUNTER

PCF2113x

POWER-ON

RESET

MGE990

2001 Dec 19 5

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

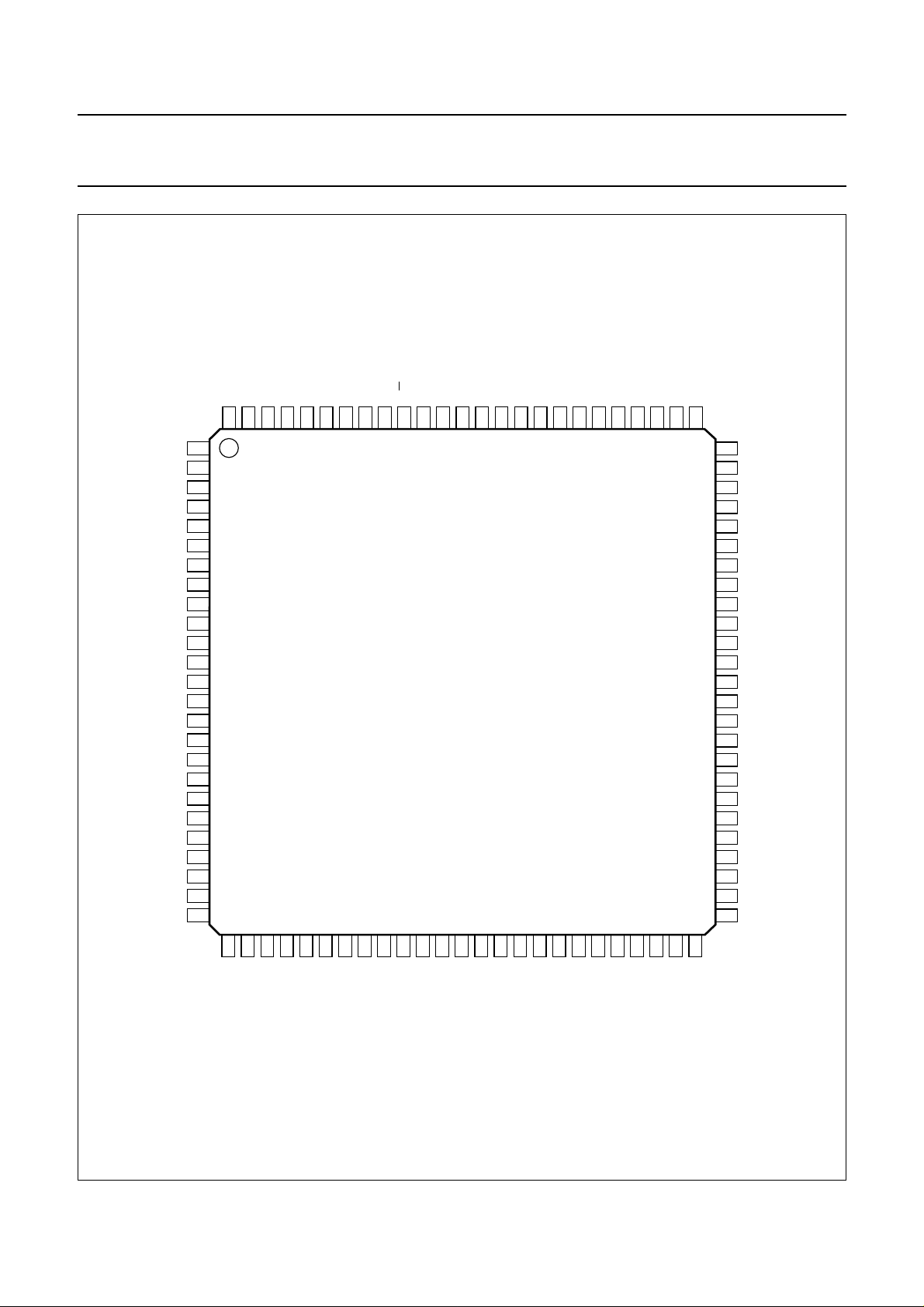

6 PINNING

SYMBOL

V

DD1

PIN

PCF2113DH

PCF2113XU

1 1 P supply voltage 1 for all except V

PAD

(1)

TYPE DESCRIPTION

generator

LCD

OSC 2 2 I oscillator/external clock input; note 2

PD 3 3 I power-down select input; for normal operation PD is LOW

T3 − 4 I test pad; open circuit and not user accessible

T1 4 5 I test pin; must be connected to V

T2 − 6 I test pad; must be connected to V

V

SS1

V

SS2

V

LCD2

V

LCDSENSE

V

LCD1

5 7 P ground 1 for all except V

6 8 P ground 2 for V

79OV

output if V

LCD

− 10 I input (V

LCD

LCD

) for voltage multiplier regulation; notes 3 and 7

LCD

LCD

generator

is generated internally; note 7

8 11 I input for generation of LCD bias levels; note 7

SS1

SS1

generator

R9 to R16 9 to 16 12 to 19 O LCD row driver outputs 9 to 16

R18 17 20 O LCD row driver output 18

C60 to C53 18 to 25 21 to 28 O LCD column driver outputs 60 to 53

dummy pad − 29 −

dummy pad − 30 −

C52 to C28 26 to 50 31 to 55 O LCD column driver outputs 52 to 28

dummy pad − 56 −

dummy pad − 57 −

C27 to C3 51 to 75 58 to 82 O LCD column driver outputs 27 to 3

dummy pad − 83 −

dummy pad − 84 −

C2 76 85 O LCD column driver output 2

C1 77 86 O LCD column driver output 1

R8 to R1 78 to 85 87 to 94 O LCD row driver outputs 8 to 1

R17 86 95 O LCD row driver output 17

SCL 87 96 I I

SDA 88 97 I/O I

2

C-bus serial clock input; note 4

2

C-bus serial data input/output; note 4

E 89 98 I data bus clock input; note 4

RS 90 99 I register select input

R/

W 91 100 I read/write input

DB7 92 101 I/O 8-bit bidirectional data bus bit 7; note 5

DB6 93 102 I/O 8-bit bidirectional data bus bit 6

DB5 94 103 I/O 8-bit bidirectional data bus bit 5

DB4 95 104 I/O 8-bit bidirectional data bus bit 4

DB3/SA0 96 105 I/O 8-bit bidirectional data bus bit 3 or I

2

C-bus address pin;

notes 4 and 5

DB2 97 106 I/O 8-bit bidirectional data bus bit 2

DB1 98 107 I/O 8-bit bidirectional data bus bit 1

2001 Dec 19 6

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

SYMBOL

PIN

PCF2113DH

PCF2113XU

PAD

(1)

TYPE DESCRIPTION

DB0 99 108 I/O 8-bit bidirectional data bus bit 0

V

V

DD2

DD3

100 109 P supply voltage 2 for V

− 110 P supply voltage 3 for V

generator; note 6

LCD

generator; notes 3 and 6

LCD

Notes

1. Bonding pad location information is given in Chapter 17.

2. When the on-chip oscillator is used this pad must be connected to V

DD1

.

3. In the LQFP100 version this signal is connected internally and can not be accessed at any pin.

4. When the I2C-bus is used, the parallel interface pin E must be LOW. In the I2C-bus read mode DB7 to DB0 should

be connected to V

When the parallel bus is used, the pins SCL and SDA must be connected to V

or left open-circuit.

DD1

SS1

or V

; they must not be left

DD1

open-circuit.

When the 4-bit interface is used without reading out from the PCF2113x (R/W is set permanently to logic 0), the

unused ports DB0 to DB4 can either be set to V

SS1

or V

instead of leaving them open-circuit.

DD1

5. DB7 may be used as the busy flag, signalling that internal operations are not yet completed. In 4-bit operations the

four higher order lines DB7 to DB4 are used; DB3 to DB0 must be left open-circuit except for I2C-bus operations

(see note 4).

6. V

7. When V

and V

DD2

LCD

V

is supplied, pin V

LCD

should always be equal.

DD3

is generated internally, pins V

should be left open-circuit to avoid any stray current, pins V

LCD2

LCD1

, V

LCD2

and V

LCDSENSE

must be connected together. When external

LCD1

and V

LCDSENSE

must be

connected together.

2001 Dec 19 7

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

DD2

V

DB0

DB1

DB2

DB3/SA0

DB4

DB5

DB6

DB7

V

V

V

V

LCD2

V

LCD1

DD1

OSC

PD

T1

SS1

SS2

R9

R10

R11

R12

R13

R14

R15

R16

R18

C60

C59

C58

C57

C56

C55

C54

C53

R/WRSE

99989796959493929190898887868584838281

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SDA

PCF2113x

SCL

R17R1R2R3R4

R5

R6R7R8C1C2

8079787776

75

C3

C4

74

C5

73

C6

72

71

C7

C8

70

C9

69

C10

68

67

C11

C12

66

C13

65

C14

64

63

C15

C16

62

C17

61

C18

60

59

C19

C20

58

C21

57

C22

56

55

C23

C24

54

C25

53

C26

52

C27

51

26

C52

C51

C50

31323334353637383940414243444546474849

C49

C47

C46

C45

C44

C43

C42

C48

C41

30

29

28

27

Fig.2 Pin configuration (LQFP100).

2001 Dec 19 8

C40

C39

C38

C37

C36

C35

C34

C33

C32

C31

C30

C29

50

C28

MGE989

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

7 FUNCTIONAL DESCRIPTION

7.1 LCD supply voltage generator

The LCD supply voltage may be generated on-chip. The

V

generator is controlled by two internal 6-bit registers:

LCD

VAand VB. The nominal LCD operating voltage at room

temperature is given by the relationship:

V

OP(nom)

= (integer value of register × 0.08) + 1.82

7.1.1 PROGRAMMING RANGES

Programmed value: 1 to 63. Voltage: 1.90 to 6.86 V.

T

=27°C.

ref

Values producing more than 6.5 V at operating

temperature are not allowed. Operation above this

voltage may damage the device. When programming the

operating voltage the V

tolerance and temperature

LCD

coefficient must be taken into account.

Values below 2.2 V are below the specified operating

range of the chip and are therefore not allowed.

Value 0 for VAand VB switches the generator off

(i.e. VA= 0 in character mode, VB= 0 in icon mode).

Usually register VA is programmed with the voltage for

character mode and register VB with the voltage for icon

mode.

When V

is generated on-chip the V

LCD

pins should be

LCD

decoupled to VSS with a suitable capacitor.

The generated V

temperature compensated. When the V

is independent of VDD and is

LCD

LCD

generator and

the direct mode are switched off, an external voltage may

besupplied at connected pinsV

V

may be higher or lower than V

LCD2

LCD1

andV

DD2

LCD2.VLCD1

.

and

During direct mode (program DM register bit) the internal

V

generator is turned off and the V

LCD

is directly connected to V

DD2

. This reduces the current

output voltage

LCD2

consumption during icon mode and Mux 1 : 9 (depending

on V

The V

value and LCD liquid properties).

DD2

generator ensures that, as long as VDDis in the

LCD

valid range (2.2 to 4 V), the required peak voltage

VOP= 6.5 V can be generated at any time.

7.2 LCD bias voltage generator

The intermediate bias voltages for the LCD display are

also generated on-chip. This removes the need for an

external resistive bias chain and significantly reduces the

system current consumption. The optimum value of V

LCD

depends on the multiplex rate, the LCD threshold voltage

(Vth) and the number of bias levels. Using a 5-level bias

scheme for 1 : 18 maximum rate allows V

LCD

< 5 V for

most LCD liquids. The intermediate bias levels for the

different multiplex rates are shown in Table 1. These bias

levels are automatically set to the given values when

switching to the corresponding multiplex rate.

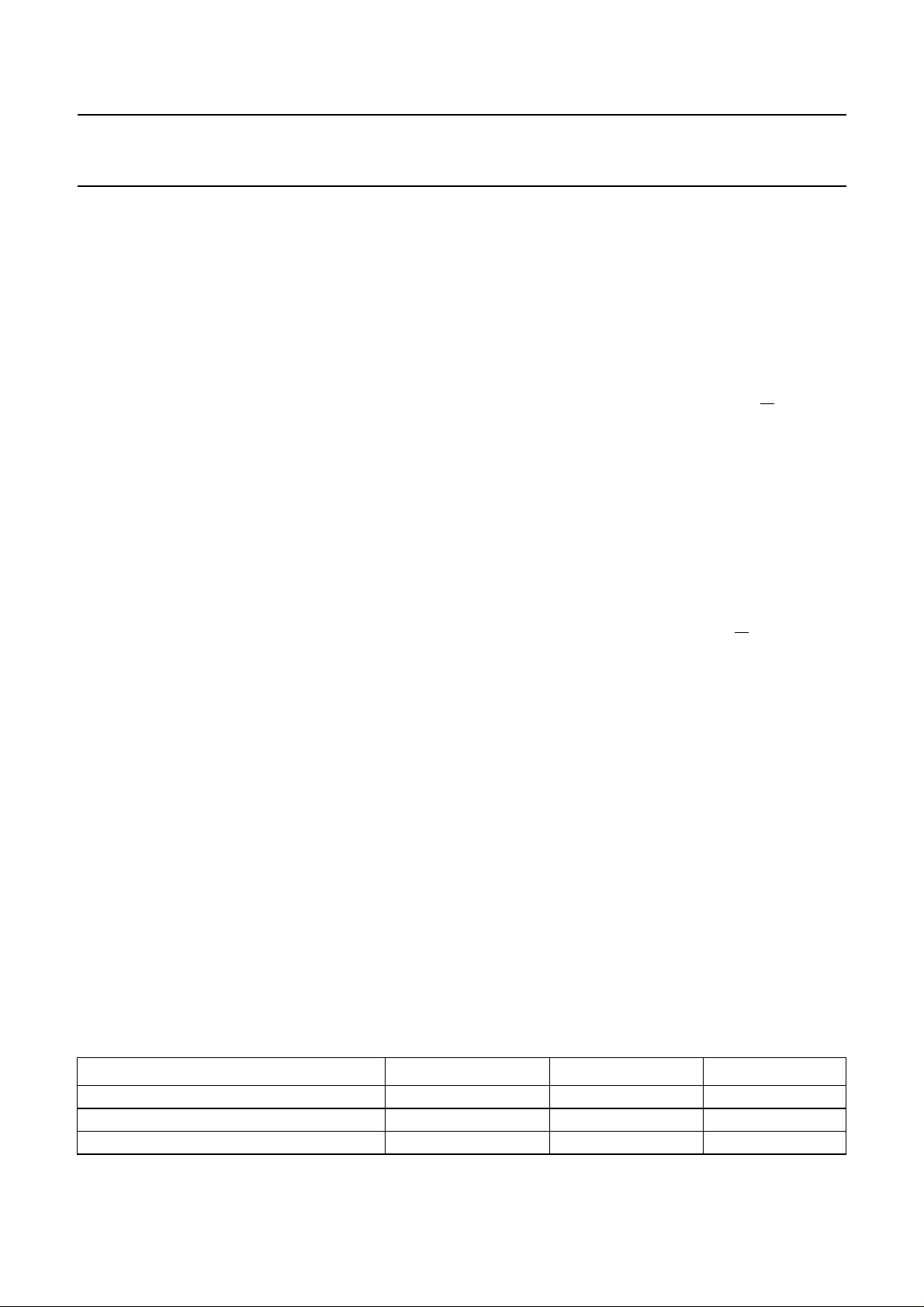

Table 1 Bias levels as a function of multiplex rate; note 1

MULTIPLEX

RATE

1:18 5 V

1:9 5 V

1:2 4 V

NUMBER

OF LEVELS

V

LCD

LCD

LCD

1

V

2

3

/

4

3

/

4

2

/

3

Note

1. The values in the table are given relative to V

− VSS, e.g.3/4means3/4× (V

LCD

2001 Dec 19 9

V

3

1

/

2

1

/

2

2

/

3

V

4

1

/

2

1

/

2

1

/

3

− VSS).

LCD

V

5

1

/

4

1

/

4

1

/

3

V

6

V

SS

V

SS

V

SS

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

7.3 Oscillator

The on-chip oscillator provides the clock signal for the

display system. No external components are required and

the OSC pin must be connected to V

DD1

.

7.4 External clock

If an external clock is to be used this input is at the OSC

pin. The resulting display frame frequency is given by:

f

=

OSC

------------3072

f

frame

Only in the Power-down mode is the clock allowed to be

stopped (OSC connected to V

), otherwise the LCD is

SS

frozen in a DC state.

7.5 Power-on reset

The on-chip Power-on reset block initializes the chip after

power-onor power failure. This isasynchronous reset and

requires 3 oscillator cycles to be executed.

7.6 Power-down mode

Thechip can be putinto Power-down mode byapplying an

external active HIGH level to the PD pin. In Power-down

mode all static currents are switched off (no internal

oscillator, no bias level generation and all LCD outputs are

internally connected to VSS).

During power-down, information in the RAMs and the chip

state are preserved. Instruction execution during

power-down is possible when pin OSC is externally

clocked.

7.7 Registers

The PCF2113x has two 8-bit registers, an Instruction

Register (IR) and a Data Register (DR). The Register

Select (RS) signal determines which register will be

accessed.The instruction register storesinstruction codes

such as ‘display clear’, ‘cursor shift’, and address

information for the Display Data RAM (DDRAM) and

Character Generator RAM (CGRAM).The instruction

register can be written to but not read from by the system

controller.

The data register temporarily stores data to be read from

the DDRAM and CGRAM. When reading, data from the

DDRAM or CGRAM corresponding to the address in the

instruction register is written to the data register prior to

being read by the ‘read data’ instruction.

7.8 Busy flag

The busy flag indicates the internal status of the

PCF2113x. A logic 1 indicates that the chip is busy and

further instructions will not be accepted. The busy flag is

output to pin DB7 when bit RS = 0 and bit R/

W=1.

Instructions should only be written after checking that the

busy flag is at logic 0 or waiting for the required number of

cycles.

7.9 Address Counter (AC)

The address counter assigns addresses to the DDRAM

and CGRAM for reading and writing and is set by the

commands ‘set CGRAM address’ and ‘set DDRAM

address’. After a read/write operation the address counter

is automatically incremented or decremented by 1.

The address counter contents are output to the bus

(DB6 to DB0) when bit RS = 0 and bit R/W=1.

7.10 Display Data RAM (DDRAM)

The DDRAM stores up to 80 characters of display data

represented by 8-bit character codes. RAM locations

which are not used for storing display data can be used as

general purpose RAM. The basic RAM to display

addressing scheme is shown in Fig.3. With no display shift

the characters represented by the codes in the first

24 RAM locations starting at address 00H in line 1 are

displayed. Figures 4 and 5 show the display mapping for

right and left shift respectively.

When data is written to or read from the DDRAM,

wrap-around occurs from the end of one line to the start of

the next line. When the display is shifted each line wraps

around within itself, independently of the others. Thus all

lines are shifted and wrapped around together.

The address ranges and wrap-around operations for the

various modes are shown in Table 2.

Table 2 Address space and wrap-around operation

MODE 1 × 24 2 × 12 1 × 12

Address space 00 to 4F 00 to 27; 40 to 67 00 to 27

Read/write wrap-around (moves to next line) 4F to 00 27 to 40; 67 to 00 27 to 00

Display shift wrap-around (stays within line) 4F to 00 27 to 00; 67 to 40 27 to 00

2001 Dec 19 10

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

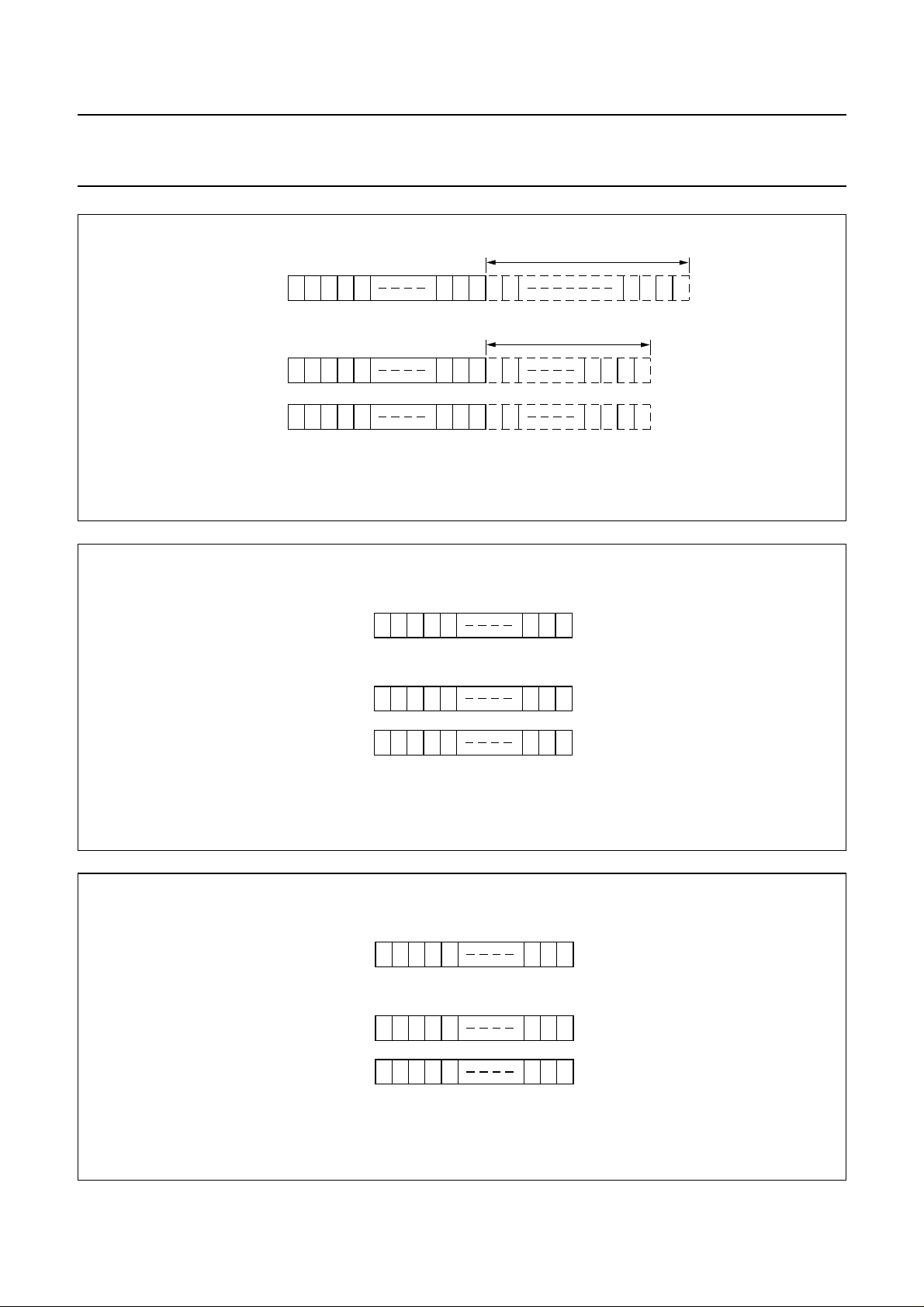

handbook, full pagewidth

display

position

DDRAM

address

1-line display

DDRAM

address

2-line display

handbook, halfpage

12345 222324

non-displayed DDRAM addresses

00 01 02 03 04 15 16 17 18 19 4C 4D 4E 4F

non-displayed DDRAM address

12345 101112

00 01 02 03 04 09 0A 0B 0C 0D 24 25 26 27

line 1

12345 101112

64 65 66 6740 41 42 43 44 49 4A 4B 4C 4D

MGE991

line 2

Fig.3 DDRAM to display mapping; no shift.

display

position

DDRAM

address

1-line display

DDRAM

address

2-line display

1 2 3 4 5 22 23 24

4F 00 01 02 03 14 15 16

1 2 3 4 5 10 11 12

27 00 01 02 03

08 09 0A

1 2 3 4 5 10 11 12

67 40 41 42 43

48 49 4A

MGE992

line 1

line 2

Fig.4 DDRAM to display mapping; right shift.

display

handbook, halfpage

position

DDRAM

address

1 2 3 4 5 22 23 24

01 04 05

02 03 16 17 18

1-line display

1 2 3 4 5 10 11 12

02 03

DDRAM

address

01 04 05

1 2 3 4 5 10 11 12

41 42 43 44 45

2-line display

Fig.5 DDRAM to display mapping; left shift.

2001 Dec 19 11

0A 0B 0C

4A 4B 4C

MGE993

line 1

line 2

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

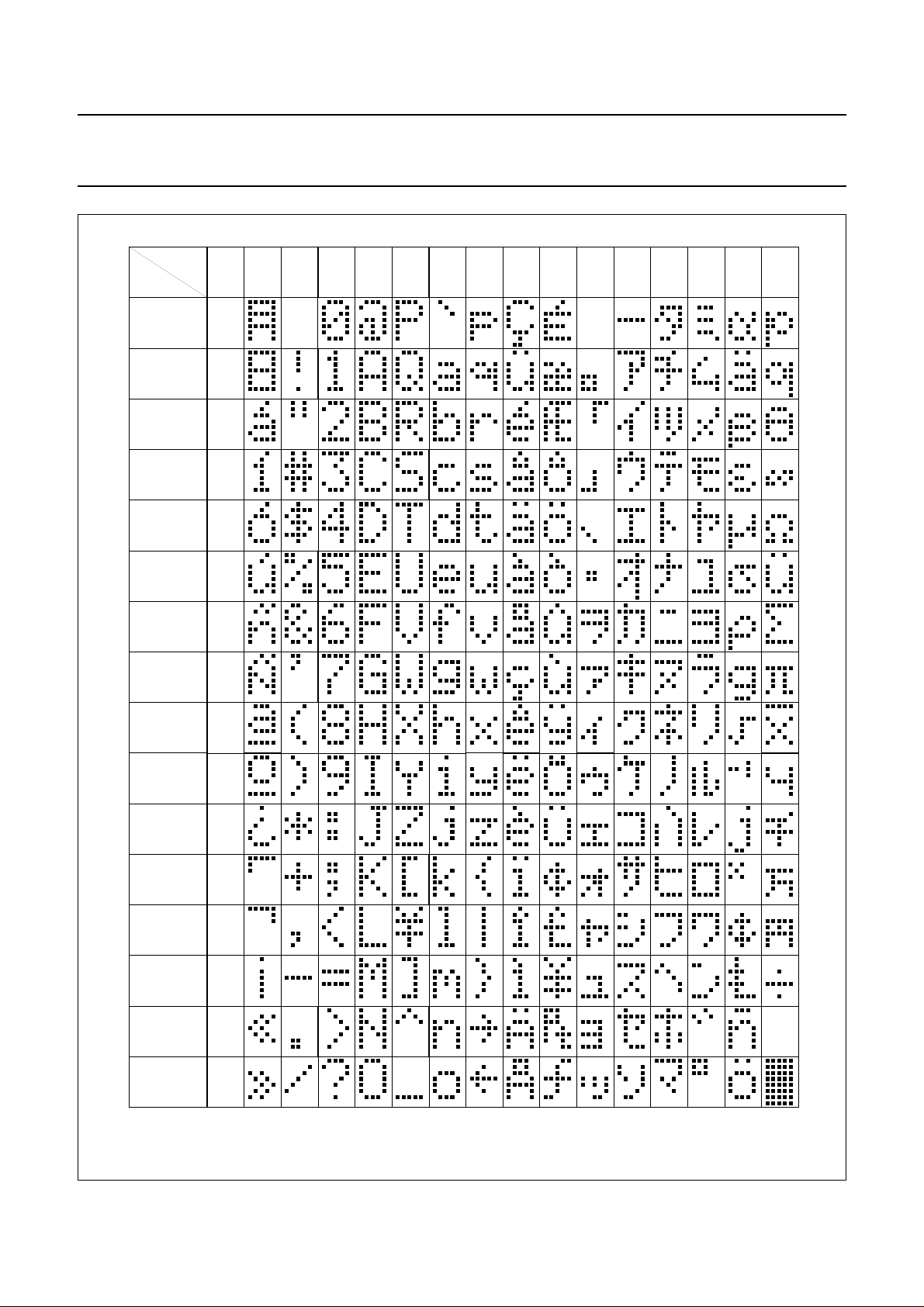

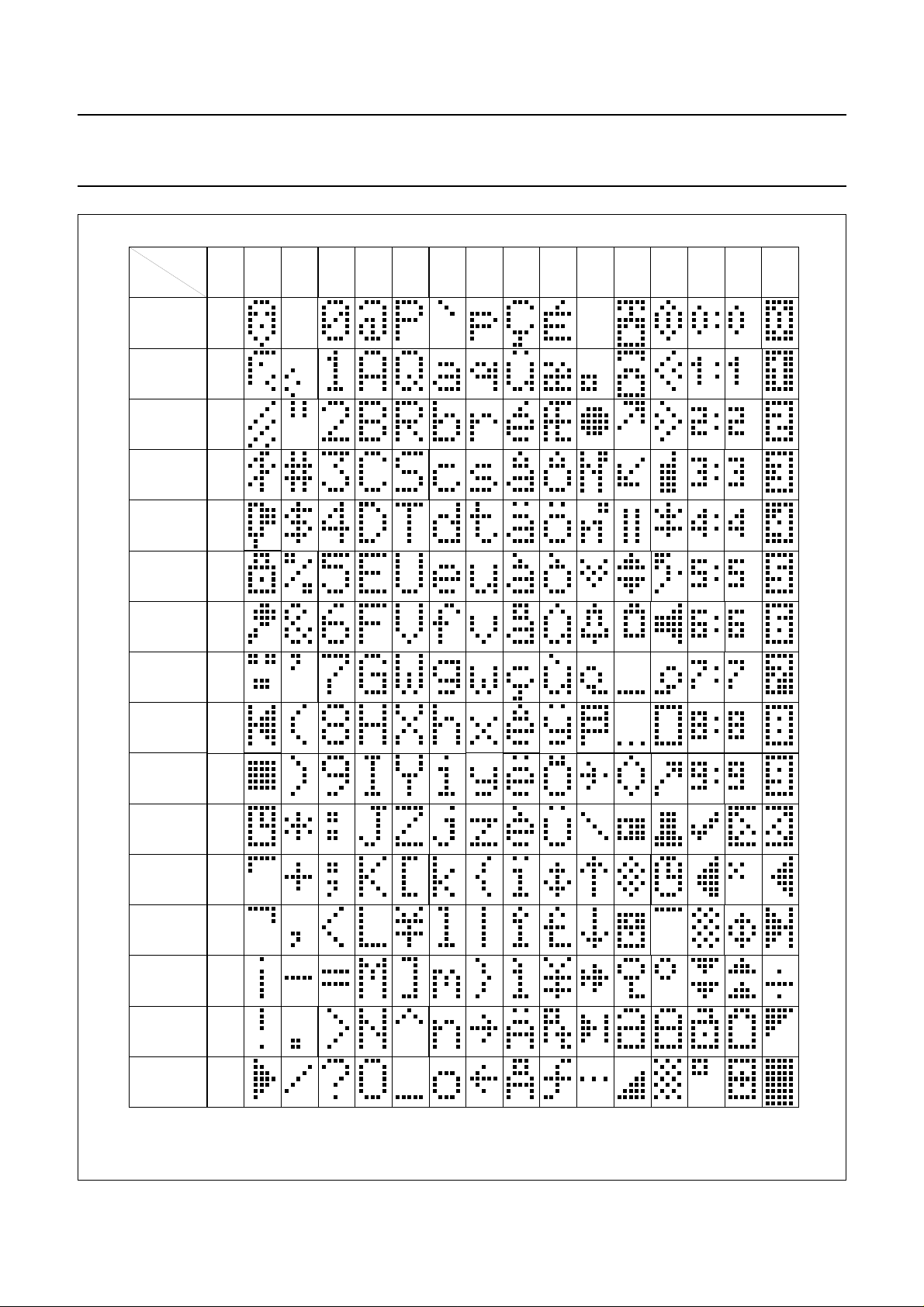

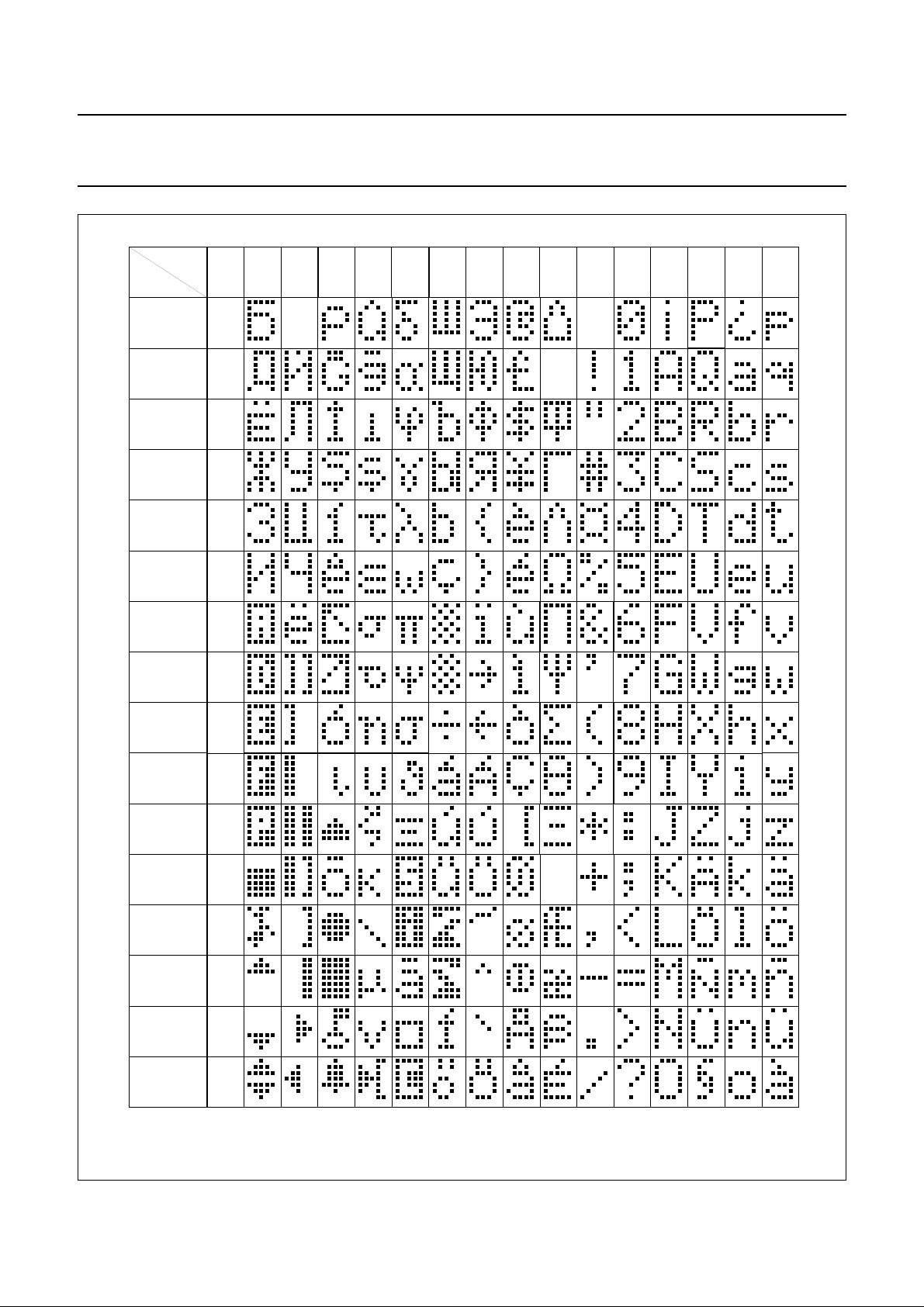

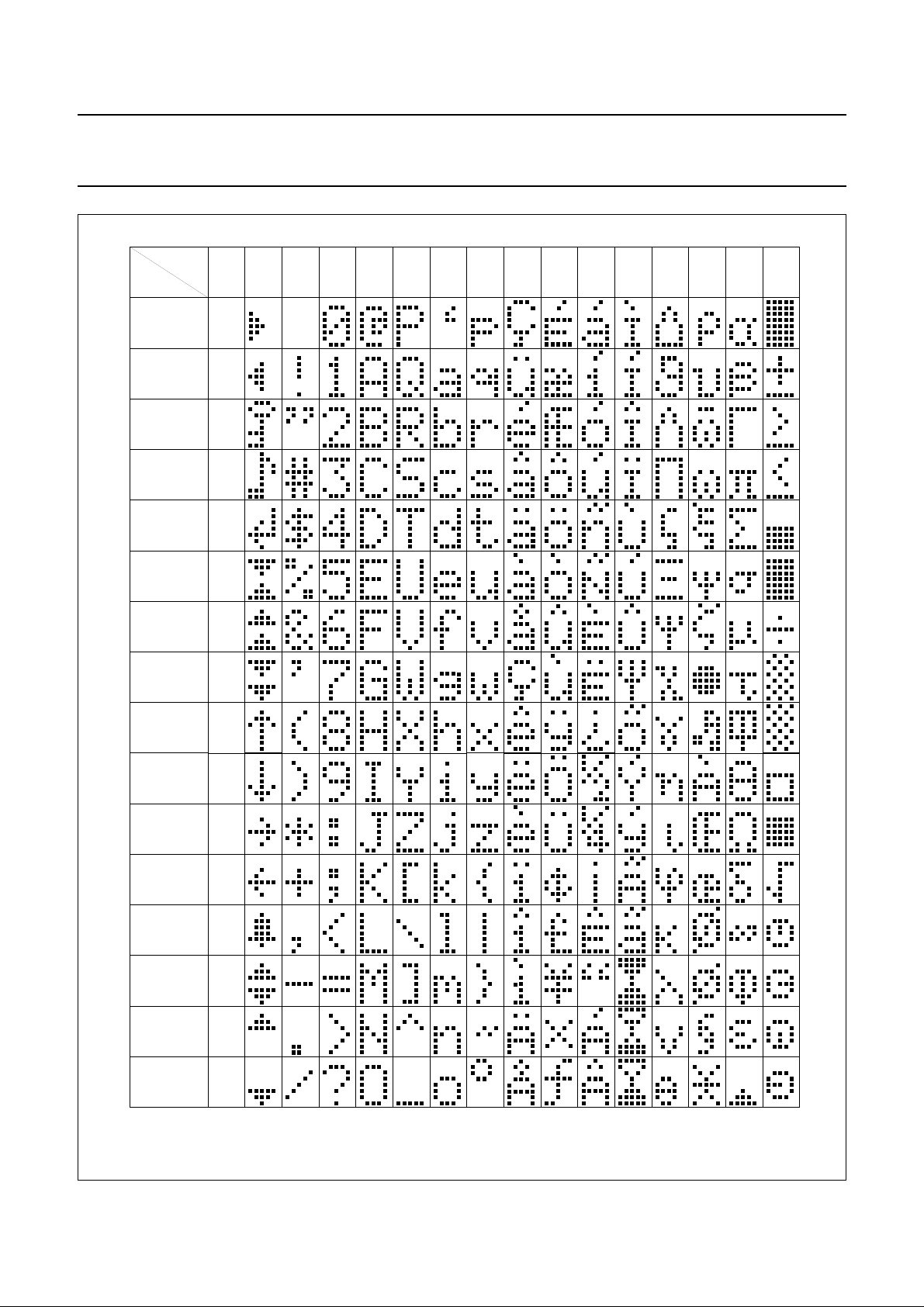

7.11 Character Generator ROM (CGROM)

The CGROM generates 240 character patterns in a

5 × 8 dot format from 8-bit character codes.

Figures 7, 8, 9 and 10 show the character sets that are

currently implemented.

7.12 Character Generator RAM (CGRAM)

Up to 16 user defined characters may be stored in the

CGRAM. Some CGRAM characters (see Fig.16) are also

used to drive icons (6 if icons blink and both icon rows are

used in the application; 3 if no blink but both icon rows are

used in the application; 0 if no icons are driven by the icon

rows). The CGROM and CGRAM use a common address

space, of which the first column is reserved for the

CGRAM (see Fig.7). Figure 11 shows the addressing

principle for the CGRAM.

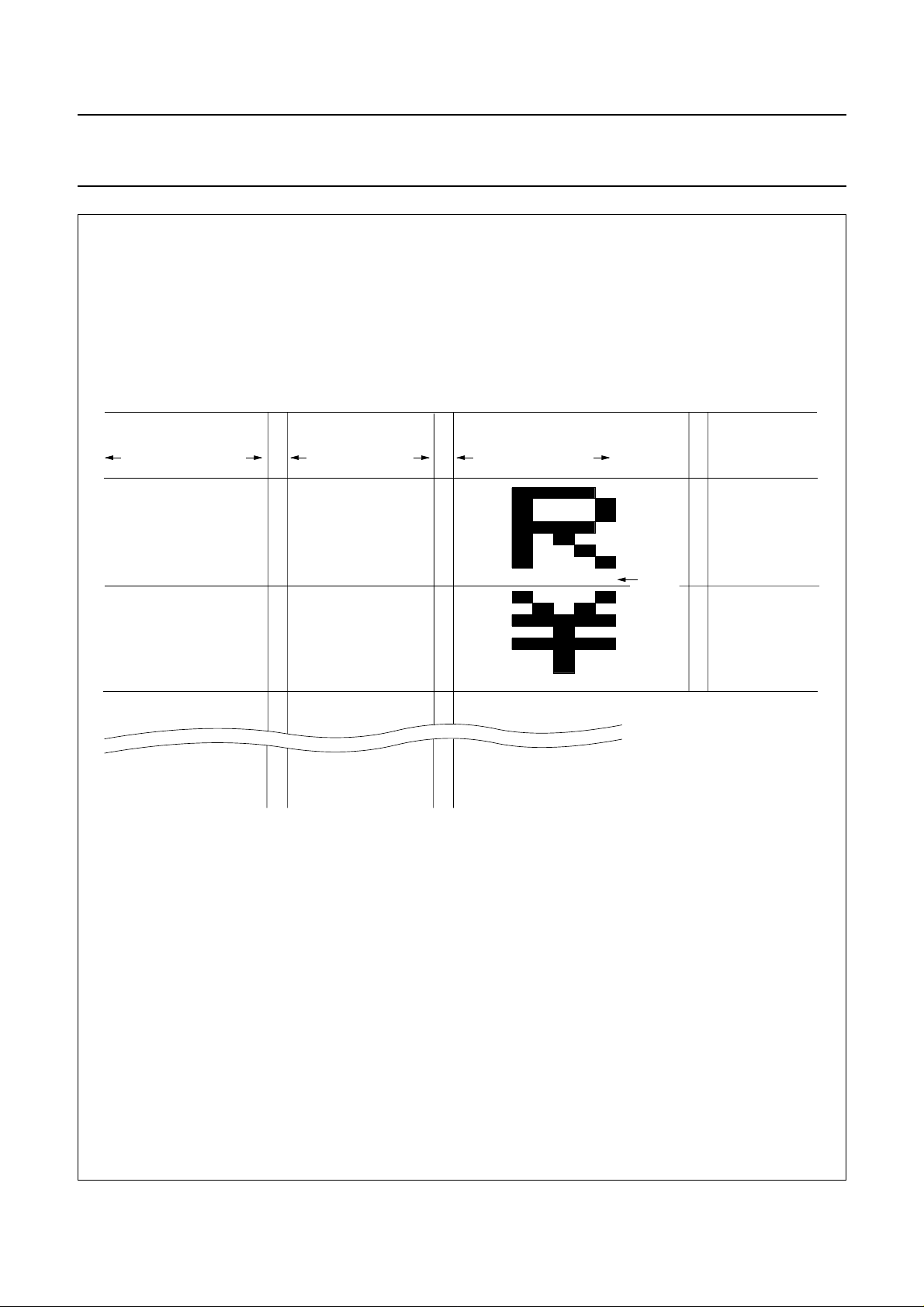

7.13 Cursor control circuit

The cursor control circuit generates the cursor underline

and/or cursor blink as shown in Fig.6 at the DDRAM

address contained in the address counter.

When the address counter contains the CGRAM address

the cursor will be inhibited.

7.14 Timing generator

The timing generator produces the various signals

required to drive the internal circuitry. Internal chip

operation is notdisturbed by operations on thedata buses.

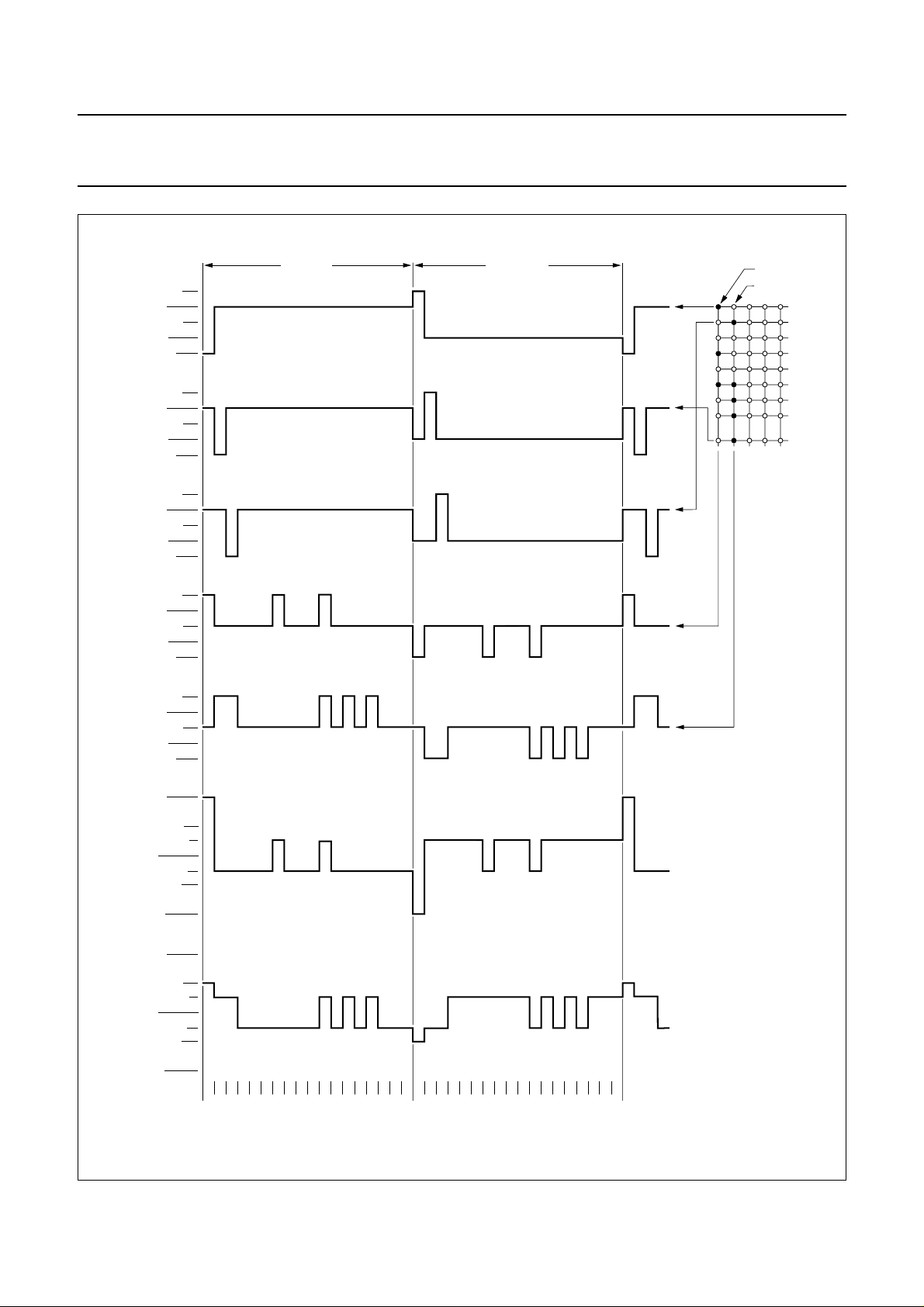

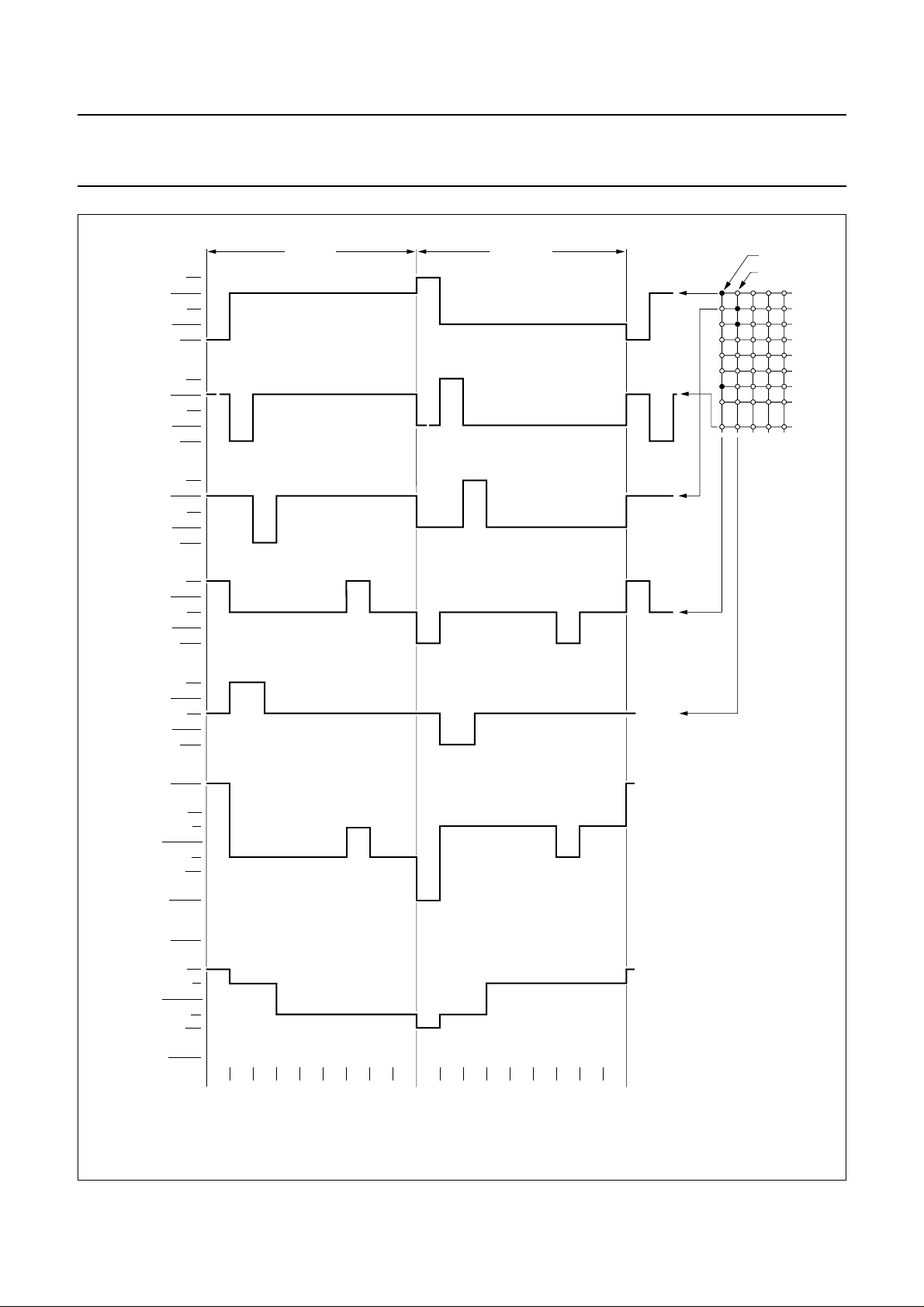

7.15 LCD row and column drivers

The PCF2113x contains 18 row and 60 column drivers,

which connect the appropriate LCD bias voltages in

sequence to the display in accordance with the data to be

displayed. R17 and R18 drive the icon rows.

The bias voltages and the timing are selected

automatically when the number of lines in the display is

selected. Figures 12, 13, 14 and 15 show typical

waveforms. Unused outputs should be left unconnected.

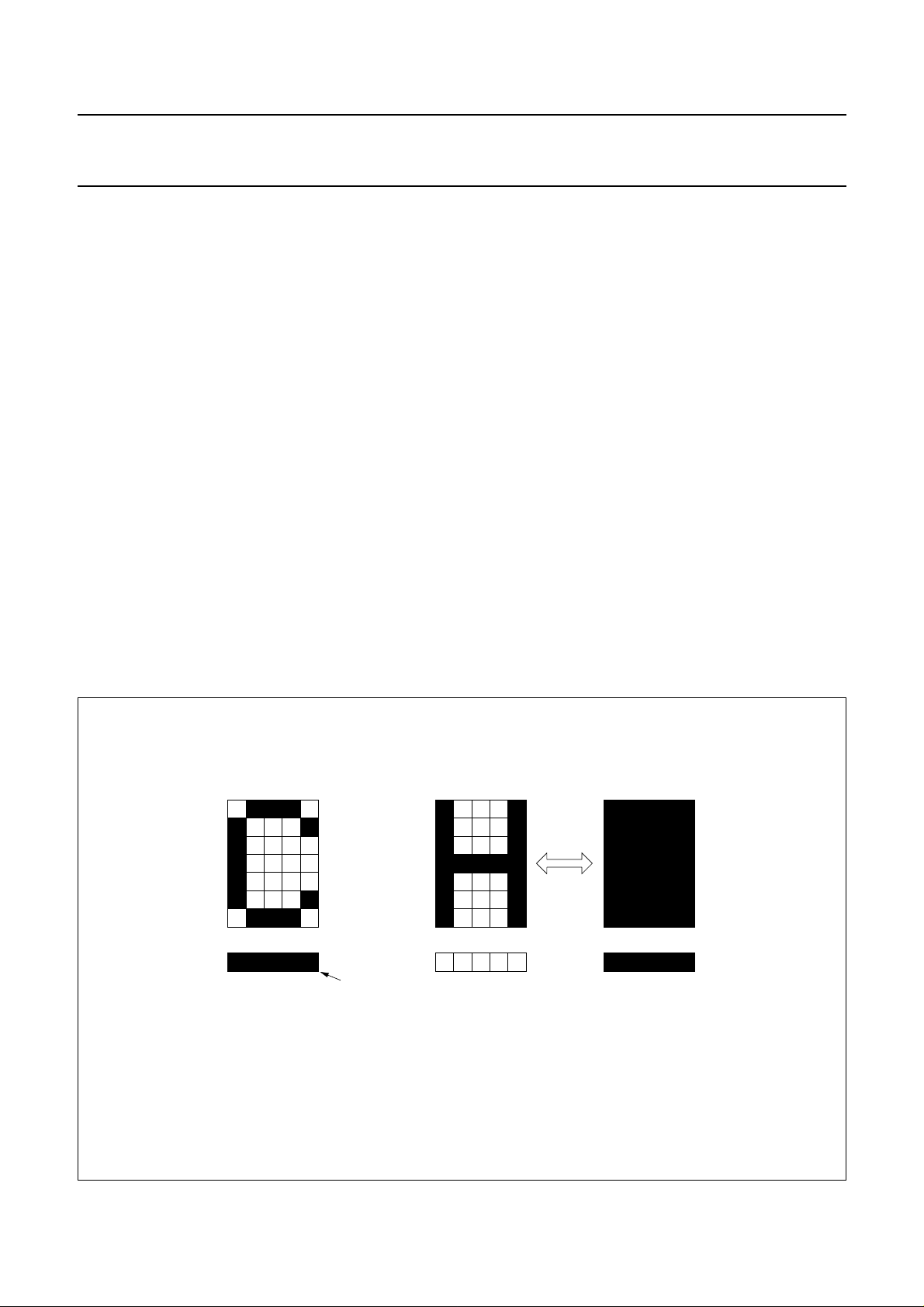

cursor

5 x 7 dot character font alternating display

cursor display example blink display example

Fig.6 Cursor and blink display examples.

2001 Dec 19 12

MGA801

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

lower

4 bits

xxxx 0000

xxxx 0001

xxxx 0010

xxxx 0011

xxxx 0100

xxxx 0101

xxxx 0110

xxxx 0111

upper

4 bits

0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100 1101 1110 1111

1

2

3

4

5

6

7

8

xxxx 1000

xxxx 1001

xxxx 1010

xxxx 1011

xxxx 1100

xxxx 1101

xxxx 1110

xxxx 1111 16

9

10

11

12

13

14

15

MGE994

Fig.7 Character set ‘A’ in CGROM.

2001 Dec 19 13

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

lower

4 bits

xxxx 0000

xxxx 0001

xxxx 0010

xxxx 0011

xxxx 0100

xxxx 0101

xxxx 0110

xxxx 0111

upper

4 bits

0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100 1101 1110 1111

1

2

3

4

5

6

7

8

xxxx 1000

xxxx 1001

xxxx 1010

xxxx 1011

xxxx 1100

xxxx 1101

xxxx 1110

xxxx 1111 16

9

10

11

12

13

14

15

MGD688

Fig.8 Character set ‘D’ in CGROM.

2001 Dec 19 14

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

lower

4 bits

xxxx 0000

xxxx 0001

xxxx 0010

xxxx 0011

xxxx 0100

xxxx 0101

xxxx 0110

xxxx 0111

upper

4 bits

0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100 1101 1110 1111

1

2

3

4

5

6

7

8

xxxx 1000

xxxx 1001

xxxx 1010

xxxx 1011

xxxx 1100

xxxx 1101

xxxx 1110

xxxx 1111 16

9

10

11

12

13

14

15

MGD689

Fig.9 Character set ‘E’ in CGROM.

2001 Dec 19 15

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

lower

4 bits

xxxx 0000

xxxx 0001

xxxx 0010

xxxx 0011

xxxx 0100

xxxx 0101

xxxx 0110

xxxx 0111

upper

4 bits

0000 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100 1101 1110 1111

1

2

3

4

5

6

7

8

xxxx 1000

xxxx 1001

xxxx 1010

xxxx 1011

xxxx 1100

xxxx 1101

xxxx 1110

xxxx 1111 16

9

10

11

12

13

14

15

MGU204

Fig.10 Character set ‘W’ in CGROM.

2001 Dec 19 16

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

character codes

(DDRAM data)

76543210 6543210 43210

higher

order

bits

00000000 0000000 0

00000001 0001

00000010

00001111

00001111

00001111

00001111

lower

order

bits

CGRAM

address

higher

order

bits

010 0000

1

1

1

1

1

1

1

1

1

111

1

1

lower

order

bits

001 000

010 000

011 0

100 0 00

101 00 0

110 000

111 00000

000 000

001 0 0 0

010

100

101 00 00

110 00 00

111 00000

001

1

100

1

101

1

110

1

1

higher

order

bits

character patterns

(CGRAM data)

00 00011

lower

order

bits

character

pattern

example 1

cursor

position

character

pattern

example 2

character code

(CGRAM data)

43210

1

111

1

000

1

000

1111

0010

1

00 01

1

000

1

00

1

000

0

101

1

111

0100

1111

1

01 00

0

010

0

00

0

1

1

0

1

000

1

0

1

0

0

000

MGE995

Character code bits 0 to 3 correspond to CGRAM address bits 3 to 6.

CGRAM address bits 0 to 2 designate the character pattern line position. The 8th line is the cursor position and display is performed by logical ORwith

the cursor. Data in the 8th position will appear in the cursor position.

Character pattern column positions correspond to CGRAM data bits 0 to 4, as shown in this figure.

As shown in Figs 7 and 8, CGRAM character patterns are selected when character code bits 4 to 7 are all logic 0. CGRAM data = logic 1 corresponds

to selection for display.

Only bits 0 to 5 of the CGRAM address are set by the ‘set CGRAM address’ command. Bit 6 can be set using the ‘set DDRAM address’ command in

the valid address range or by using the auto-increment feature during CGRAM write. All bits 0 to 6 can be read using the ‘read busy flag’ and ‘address

counter’ command.

Fig.11 Relationship between CGRAM addresses, data and display patterns.

2001 Dec 19 17

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

V

LCD

V

2

ROW 1

ROW 9

ROW 2

COL1

COL2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

frame n + 1 frame n

state 1 (ON)

state 2 (OFF)

R1

4

R2

R3

R4

R5

R6

R7

R8

4

R9

4

4

4

V

OP

0.5V

OP

0.25V

OP

0 V

state 1

−0.25V

OP

−0.5V

OP

−V

OP

V

OP

0.5V

OP

0.25V

OP

0 V

state 2

−0.25V

OP

−0.5V

OP

−V

OP

123 18123 18

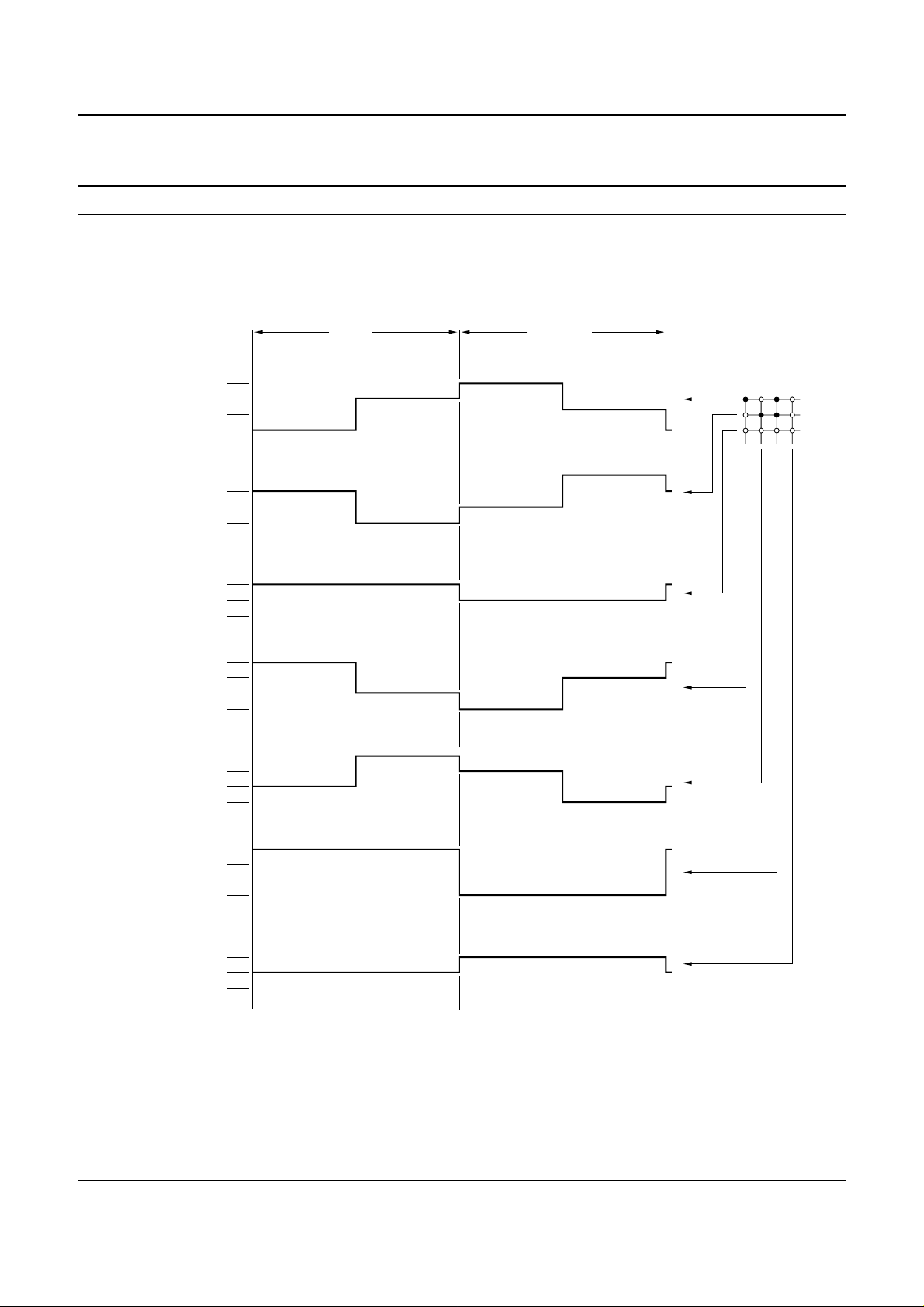

Fig.12 MUX 1 : 18 LCD waveforms; character mode.

2001 Dec 19 18

MGE996

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

V

LCD

V

2

ROW 1

ROW 2

ROW 3

COL1

COL2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

V

LCD

V

2

V3/V

V

5

V

SS

frame n + 1 frame n

state 1 (ON)

state 2 (OFF)

R1

4

R2

R3

R4

R5

R6

R7

R8

4

R9

4

4

4

V

OP

0.5V

OP

0.25V

OP

0 V

state 1

−0.25V

OP

−0.5V

OP

−V

OP

V

OP

0.5V

OP

0.25V

OP

0 V

state 2

−0.25V

OP

−0.5V

OP

−V

OP

123 9123 9

R10 to R18 to be left open.

Fig.13 MUX1:9LCD waveforms; character mode.

2001 Dec 19 19

MGU217

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

ROW 17

ROW 18

ROW 1 to 16

COL 1

ON/OFF

COL 2

OFF

/ON

V

V

V

V

V

LCD

2/3

1/3

V

SS

LCD

2/3

1/3

V

SS

LCD

2/3

1/3

V

SS

LCD

2/3

1/3

V

SS

LCD

2/3

1/3

V

SS

frame n + 1 frame n

only icons are

driven (MUX 1 : 2)

V

LCD

V

2/3

1/3

V

SS

LCD

2/3

1/3

V

SS

COL 3

COL 4

ON/ON

OFF/OFF

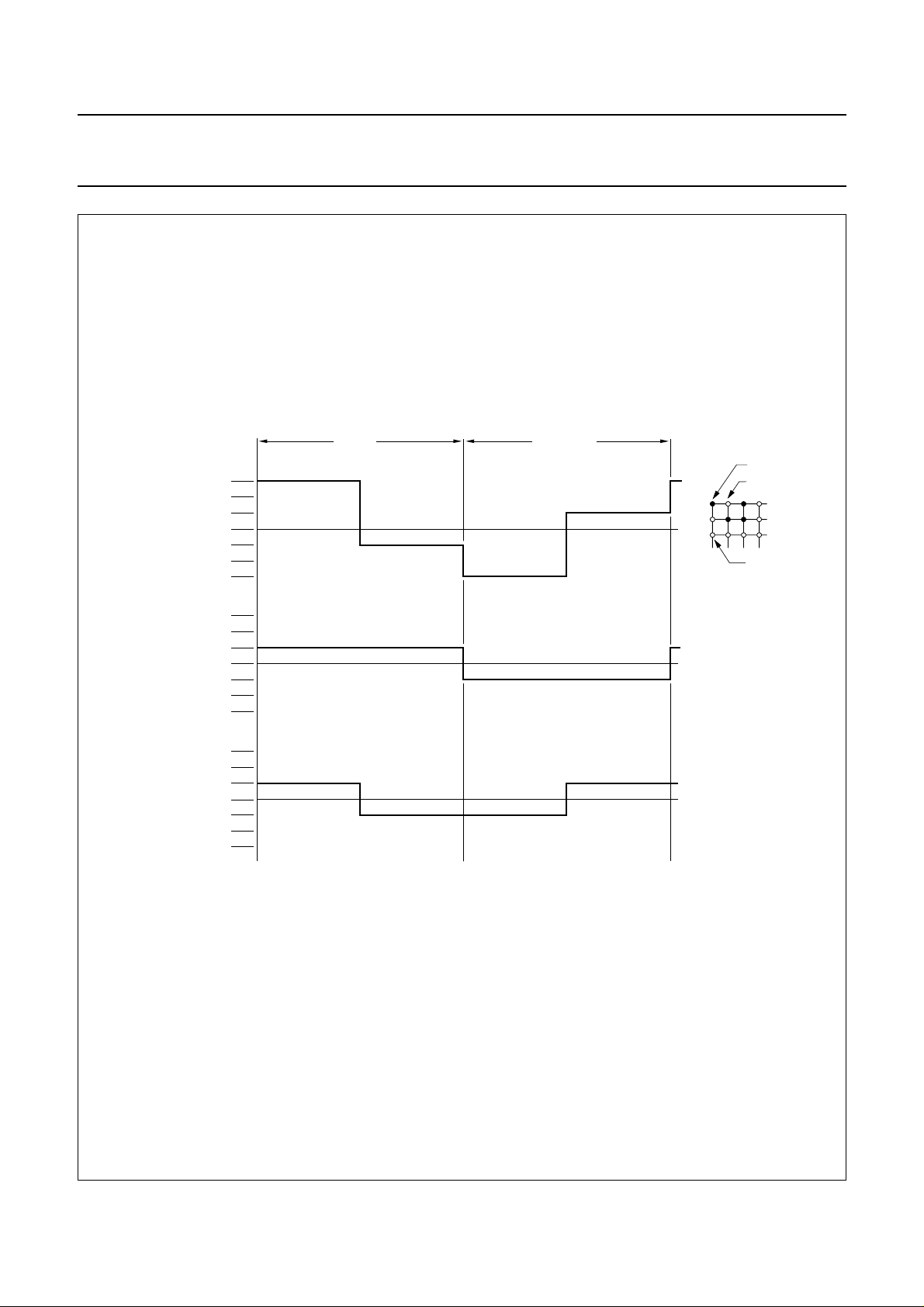

Fig.14 MUX 1 : 2 LCD waveforms; icon mode.

2001 Dec 19 20

MGE997

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

state 1

COL 1 -

ROW 17

state 2

COL 2 -

ROW 17

state 3

COL 1 -

ROW 1 to 16

V

PIXEL

2/3 V

1/3 V

−1/3 V

−2/3 V

−V

2/3 V

1/3 V

−1/3 V

−2/3 V

−V

2/3 V

1/3 V

−1/3 V

−2/3 V

−V

frame n + 1 frame n

state 1 (ON)

V

OP

OP

OP

0

state 2 (OFF)

R17

R18

R1-16

OP

OP

state 3 (OFF)

OP

V

OP

OP

OP

0

OP

OP

OP

V

OP

OP

OP

0

OP

OP

OP

MGE998

V

= 0.745V

ON(rms)

V

OFF(rms)

D

V

ON

------------V

OFF

= 0.333V

2.23==

OP

OP

Fig.15 MUX 1 : 2 LCD waveforms; icon mode.

2001 Dec 19 21

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

7.16 Reset function

The PCF2113x automatically initializes (resets) when power is turned on. The chipexecutes a reset sequence, including

a ‘clear display’, requiring 165 oscillator cycles. After the reset the chip has the state shown in Table 3.

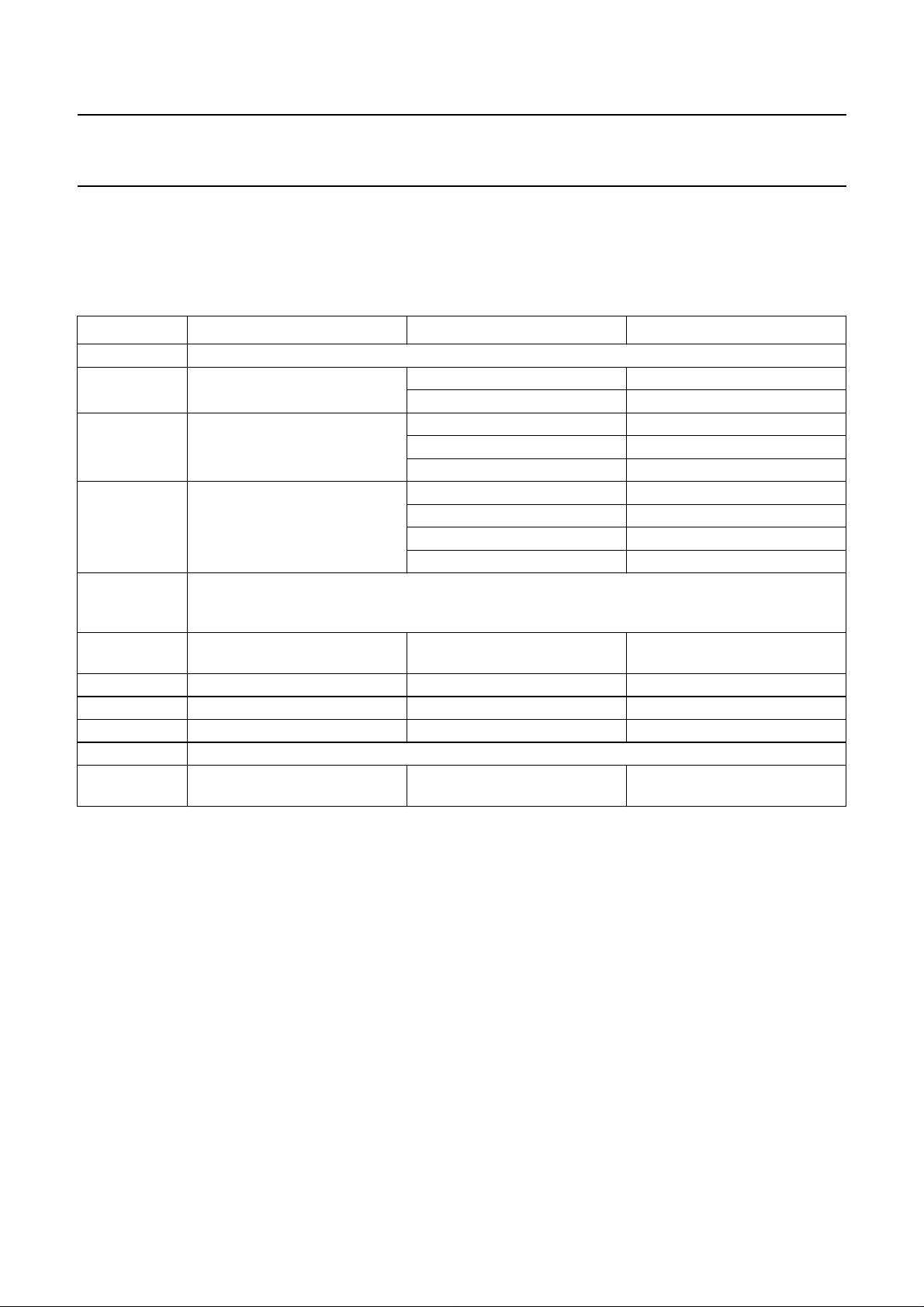

Table 3 State after reset

STEP FUNCTION CONTROL BIT STATE CONDITIONS

1 clear display

2 entry mode set I/D = 1 +1 (increment)

S = 0 no shift

3 display control D = 0 display off

C = 0 cursor off

B = 0 cursor character blink off

4 function set DL = 1 8-bit interface

M = 0 1-line display

H = 0 normal instruction set

SL = 0 MUX 1 : 18 mode

5 default address pointer to DDRAM; the Busy Flag (BF) indicates the busy state (BF = 1) until

initialization ends; the busy state lasts 2 ms; the chip may also be initialized by software;

see Tables 17 and 18

6 icon control IM = 0; IB = 0; DM = 0 icons, icon blink and direct

mode disabled

7 display/screen configuration L = 0; P = 0; Q = 0 default configurations

8V

9 set V

10 I

11 Set HVgen stages S1 = 1; S0 = 0 V

temperature coefficient TC1 = 0; TC2 = 0 default temperature coefficient

LCD

LCD

2

C-bus interface reset

VA= 0; VB=0 V

generator off

LCD

generator voltage

LCD

multiplier set at factor 4

2001 Dec 19 22

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

8 INSTRUCTIONS

OnlytwoPCF2113x registers, the Instruction Register (IR)

and the Data Register (DR) can be directly controlled by

the microcontroller. Before internal operation, control

information is stored temporarily in these registers, to

allow interfacing to various types of microcontrollers which

operate at different speeds or to allow interface to

peripheral control ICs.

The instruction set for I2C-bus commands is given in

Table 4.

The PCF2113x operation is controlled by the instructions

shown in Table 5 together with their execution time.

Details are explained in subsequent sections.

Instructions are of 4 types, those that:

1. Designate PCF2113x functions such as display

format, data length, etcetera.

2. Set internal RAM addresses

3. Perform data transfer with internal RAM

4. Others.

2

Table 4 Instruction set for I

CONTROL BYTE COMMAND BYTE I

CoRS000000DB7DB6DB5DB4DB3DB2DB1DB0note 1

C-bus commands

In normal use, category 3 instructions are used most

frequently. However, automatic incrementing by 1

(or decrementing by 1) of internal RAM addresses after

each data write lessens the microcontroller program load.

The display shift in particular can be performed

concurrently with display data write, enabling the designer

to develop systems in minimum time with maximum

programming efficiency.

During internal operation, no instructions other than the

‘read busy flag’ and ‘read address’ instructions will be

executed.Because the busy flagisset to a logic 1whilean

instructionis being executed, checkto ensure it isa logic 0

before sending the next instruction or wait for the

maximum instruction execution time, as given in Table 5.

An instruction sent while the busy flag is logic 1 will not be

executed.

2

C-BUS COMMANDS

Note

1. R/

W is set together with the slave address.

2001 Dec 19 23

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

CLOCK

REQUIRE

CYCLES

3

lines (M), single line/MUX 1 : 9 (SL) and extended

instruction set control (H)

0

) contents

C

reads the Busy Flag (BF) indicating internal

operating is being performed and reads Address

counter (A

3

165

returns shifted display to original position; DDRAM

address counter

3

contents remain unchanged

3

of display (S); these operations are performed

during data write and read

blink of cursor position character (B); D = 0 (display

off) puts chip into the Power-down mode

3

(R/L) without changing DDRAM contents

3

sets CGRAM address; bit DB6 is to be set by the

command ‘set DDRAM address’; look at the

description of the commands

sets DDRAM address 3

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

Table 5 Instruction set with parallel bus commands

2001 Dec 19 24

INSTRUCTION RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 DESCRIPTION

H=0or1

NOP 0000000000no operation 3

CG

C

000001S/CR/L00moves cursor or shifts display (S/C) to right or left

Cursor/display

shift

0001 A

Set CGRAM

0 1 BF A

Read data 1 1 read data reads data from CGRAM or DDRAM 3

Write data 1 0 write data writes data from CGRAM or DDRAM 3

Function set 00001DL0MSLHsets interface Data Length (DL), number of display

Read busy flag

and address

counter

H=0

Return home 0000000010sets DDRAM address 0 in address counter; also

Clear display 0000000001clears entire display and sets DDRAM address 0 in

Entry mode set 00000001I/DSsets cursor move direction (I/D) and specifies shift

Display control 0000001DCBsets entire display on/off (D), cursor on/off (C) and

address

DD

001 A

Set DDRAM

address

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

CLOCK

REQUIRE

CYCLES

3

Direct Mode (DM)

3

generator voltage multiplier stages

LCD

(S1 = 1 and S0 = 1 not allowed)

(V) 3

B

or V

A

in register V

LCD

W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 DESCRIPTION

INSTRUCTION RS R/

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2001 Dec 19 25

H=1

Reserved 0000000001do not use −

000000001Lset screen configuration (L) 3

Screen

configuration

00000001PQset display configuration, columns (P) and rows (Q) 3

Display

configuration

Icon control 0000001IMIBDMset Icon Mode (IM), Icon Blink (IB),

00000100TC1TC2set Temperature Coefficient (TCx) 3

Temperature

control

0 0 1 V voltage store V

LCD

Set V

Set HVgen stages 00010000S1S0setinternal V

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

Table 6 Explanations of symbols used in Tables 4 and 5.

BIT LOGIC STATE 0 LOGIC STATE 1

Co last control byte; see Table 4 another control byte follows after data/command

DL 4 bits 8 bits

M (noimpact,

if SL = 1)

SL MUX 1 : 18 (1 × 24 or 2 × 12 character display) MUX1:9 (1×12 character display)

H use basic instruction set use extended instruction set

I/D decrement increment

S display freeze display shift

D display off display on

C cursor off cursor on

B cursor character blink off; character at cursor

S/C cursor move display shift

R/L left shift right shift

L (no impact,

if M = 1 or

SL = 1)

P column data: left to right; column data is displayed

Q row data; top to bottom; rowdata is displayedfrom

IM character mode; full display icon mode; only icons displayed

IB icon blink disabled icon blink enabled

DM direct mode disabled direct mode enabled

V set V

1-line by 24 display 2-line by 12 display

cursor character blink on; character at cursor

position does not blink

position blinks

left/right screen: standard connection left/right screen; mirrored connection

1st 12 characters of 24; columns are from 1 to 60 1st 12 characters of 24; columns are from 1 to 60

2nd 12 characters of 24; columns are from 1 to 60 2nd 12 characters of 24; columns are from 60 to 1

column data; right to left; column data is displayed

from 1 to 60

from 60 to 1

row data; bottom to top; row data is displayed

1 to 16 and icon row data is in 17 and 18

A

from 16 to 1 and icon row data is in 18 and 17

set V

B

8.1 Clear display

‘Clear display’ writes character code 20H into all DDRAM

addresses (the character pattern for character code 20H

must be a blank pattern), sets the DDRAM address

counter to logic 0 and returns the display to its original

position, if itwas shifted. Thus, the displaydisappears and

the cursor or blink position goes to the left edge of the

display. Sets entry mode I/D = 1 (increment mode). S of

entry mode does not change.

The instruction ‘clear display’ requires extra execution

time. This may be allowed by checkingthe Busy Flag (BF)

or by waiting until the 165 clock cycles have elapsed.

The lattermust be applied wherenoread-back options are

foreseen, as in some Chip-On-Glass (COG) applications.

2001 Dec 19 26

8.2 Return home

‘Return home’ sets the DDRAM address counterto logic 0

and returns the display to its original position if it was

shifted. DDRAM contents do not change. The cursor or

blink position goes to the left of the first display line.

I/D and S of entry mode do not change.

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

8.3 Entry mode set

8.3.1 BIT I/D

When I/D = 1 (0) the DDRAM or CGRAM address

increments (decrements) by 1 when data is written into or

read from the DDRAM or CGRAM. The cursor or blink

position moves to the right when incremented and to the

left when decremented. The cursor underline and cursor

character blink are inhibited when the CGRAM is

accessed.

8.3.2 BIT S

When S = 1, the entire display shifts either to the right

(I/D = 0)orto the left (I/D = 1) duringaDDRAMwrite. Thus

it appears as if the cursor stands still and the display

moves. The display does not shift when reading from the

DDRAM, or when writing to or reading from the CGRAM.

When S = 0, the display does not shift.

8.4 Display control (and partial Power-down mode)

8.4.1 BIT D

The display is on when D = 1 and off when D = 0. Display

data in the DDRAM is not affected and can be displayed

immediately by setting D = 1.

8.4.3 BIT B

The character indicated by the cursor blinks when B = 1.

The cursor character blink is displayed by switching

between display characters andall dots onwith a period of

f

approximately 1 second, with

f

blink

=

OSC

---------------- 52224

Thecursor underline andthe cursor character blinkcan be

set to display simultaneously.

8.5 Cursor or display shift

‘Cursor/display shift’ moves the cursor position or the

display to the right or left without writing or reading display

data. This function is used to correct a character or move

the cursor through the display. In 2-line displays, the

cursor moves to the next line when it passes the last

position (40)of the line.When the displayed datais shifted

repeatedly all lines shift at the same time; displayed

characters do not shift into the next line.

The Address Counter (AC) content does not change if the

only action performed is shift display, but increments or

decrements with the ‘cursor display shift’.

8.6 Function set

When the display is off (D = 0) the chip is in partial

Power-down mode:

• The LCD outputs are connected to V

SS

• The LCD generator and bias generator are turned off.

Three oscillator cycles are required after sending the

‘display off’ instruction to ensure all outputs are at VSS,

afterwards the oscillator can be stopped. If the oscillator is

running during partial Power-down mode (‘display off’) the

chip can still execute instructions. Even lower current

consumption is obtained by inhibiting the oscillator

(OSC = VSS).

To ensure IDD<1µA, the parallel bus pins DB7 to DB0

should be connected to VDD; pins RS and R/W to VDD or

left open-circuit and pin PD to VDD. Recovery from

Power-down mode: PD back to VSS, if necessary pin OSC

back to VDD and send a ‘display control’ instruction with

D=1.

8.4.2 BIT C

The cursor is displayed when C = 1 and inhibited when

C = 0. Even if the cursor disappears, the display functions

I/D,etcetera, remain in operationduringdisplay data write.

The cursor is displayed using 5 dots in the 8th line (see

Fig.6).

8.6.1 B

IT DL (PARALLEL MODE ONLY)

Sets interface data width. Data is sent or received in bytes

(DB7 to DB0) when DL = 1 or in two nibbles (DB7 to DB4)

when DL = 0. When 4-bit width is selected, data is

transmitted in two cycles using the parallel bus. In a 4-bit

applicationDB3 to DB0shouldbeleftopen-circuit(internal

pull-ups). Hence in the first ‘function set’ instruction after

power-on M, SL and H are set to logic 1. A second

‘function set’ must then be sent (2 nibbles) to set M,

SL and H to their required values.

‘Function set’ from the I2C-bus interface sets the DL bit to

logic 1.

8.6.2 BIT M

Selects either 1-line by 24 display (M = 0) or 2-line by

12 display (M = 1).

8.6.3 BIT SL

Selects MUX 1 : 9, 1-line by 12 display (independent of

M and L). Only rows 1 to 8and 17 are tobe used. All other

rows must be left open-circuit. The DDRAM map is the

same as in the 2-line by 12 display mode, however, the

second line cannot be displayed.

2001 Dec 19 27

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

8.6.4 BIT H

When H = 0 the chip can be programmed via the standard

11 instruction codes used in the PCF2116 and other LCD

controllers.

When H = 1 the extended range of instructions will be

used. These are mainly for controlling the display

configuration and the icons.

8.7 Set CGRAM address

‘Set CGRAM address’ sets bits DB5 to 0 of the CGRAM

address ACG into the address counter (binary A5 to A0).

Data can then be written to or read from the CGRAM.

Attention: the CGRAM address uses the same address

register as the DDRAM address and consists of 7 bits

(binary A6 to A0). With the ‘set CGRAM address’

command, only bits DB5 to DB0 are set. Bit DB6 can be

set using the ‘set DDRAM address’ command first, or by

using the auto-increment feature during CGRAM write. All

bits DB6 to DB0can be read usingthe ‘read busy flag’and

‘read address’ command.

When writing to the lower part of the CGRAM, ensure that

bit DB6of the address is notset(e.g.by an earlier DDRAM

write or read action).

8.8 Set DDRAM address

‘Set DDRAM address’ sets the DDRAM address ADD into

the address counter (binary A6 to A0). Data can then be

written to or read from the DDRAM.

8.9 Read busy flag and read address

8.10 Write data to CGRAM or DDRAM

‘Write data’ writes binary 8-bit data DB7 to DB0 to the

CGRAM or the DDRAM.

Whether the CGRAM or DDRAM is to be written into is

determined by the previous ‘set CGRAM address’ or ‘set

DDRAM address’ command. After writing, the address

automatically increments or decrements by 1, in

accordance with the entry mode. Only bits DB4 to DB0 of

CGRAM data are valid, bits DB7 to DB5 are ‘don’t care’.

8.11 Read data from CGRAM or DDRAM

‘Read data’ reads binary 8-bit data DB7 to DB0 from the

CGRAM or DDRAM.

The most recent ‘set address’ command determines

whether the CGRAM or DDRAM is to be read.

The ‘read data’ instruction gates the content of the Data

Register (DR) to the bus while pin E is HIGH. After pin E

goes LOW again, internal operation increments (or

decrements) the AC and stores RAM data corresponding

to the new AC into the DR.

There are only three instructions that update the data

register:

• ‘Set CGRAM address’

• ‘Set DDRAM address’

• ‘Read data’ from CGRAM or DDRAM.

Other instructions (e.g. ‘write data’, ‘cursor/display shift’,

‘clear display’ and ‘return home’) do not modify the data

register content.

‘Read busy flag and address counter’ read the Busy Flag

(BF) and Address Counter (AC). BF = 1 indicates that an

internal operation is in progress. The next instruction will

not be executed until BF = 0. It is recommended that the

BF status is checked before the next write operation is

executed.

At the same time, the value of the address counter

expressed in binary A6 to A0 is read out. The address

counter is used by both CGRAM and DDRAM, and its

value is determined by the previous instruction.

2001 Dec 19 28

9 EXTENDED FUNCTION SET INSTRUCTIONS AND

FEATURES

9.1 New instructions

H = 1 sets the chip into alternate instruction set mode.

9.2 Icon control

The PCF2113x can drive up to 120 icons. See Fig.16 for

CGRAM to icon mapping.

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

handbook, full pagewidth

icon no. phase ROW/COL character codes CGRAM address CGRAM data

1-5 even 17/1-5 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 0 1

6-10 even 17/6-10 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 0 1 0

11-15 even 17/11-15 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 1 1 1 0

56-60 even 17/56-60 0 0 0 0 0 0 0 1 0 0 0 1 0 1 1 1 1 1 1 1

display:

ROW 17 –

ROW 18 –

COL 1 to 5

12345

61 62 63 64 65

block of 5 columns

7 6 5 4 3 2 1 0

MSB LSB LSB

COL 6 to 10

678910

66 67 68 69 70

6 5 4 3 2 1 0 4 3 2 1 0

MSB MSBLSB

COL 56 to 60

56 57 58 59 60

116 117 118 119 120

MGE999

icon view

61-65 even 18/1-5 0 0 0 0 0 0 0 1 0 0 0 1 1 0 0 1 1 0 0 0

116-120 even 18/56-60 0 0 0 0 0 0 1 0 0 0 1 0 1 1 1 1 1 1 0 1

1-5 odd (blink) 17/1-5 0 0 0 0 0 1 0 0 0 1 0 0 0 0 0 0 0 0 0 0

116-120 odd (blink) 18/56-60 0 0 0 0 0 1 1 0

CGRAM data bit = logic 1 turns the icon on, data bit = logic 0 turns the icon off.

Data in character codes 0 to 3 define the icon state when icon blink is disabled or during the even phase when icon blink is enabled.

Data in character codes 4 to 7 define the icon state during the odd phase when icon blink is enabled (not used for icons when icon blink is disabled).

0 1 1 0 0 1 1 0 0 1 1 0

MGG001

Fig.16 CGRAM to icon mapping.

2001 Dec 19 29

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

9.3 Bit IM

When IM = 0, the chip is in character mode. In the

character mode characters and icons are driven

(MUX 1 : 18). The V

V

voltage programmed in register VA.

LCD

generator, if used, produces the

LCD

When IM = 1, the chip is in icon mode. In the icon mode

only the icons are driven (MUX 1 : 2) and the V

generator, if used, produces the V

voltage as

LCD

LCD

programmed in register VB.

Table 7 Normal/icon mode operation

IM MODE V

0 character mode generates V

1 icon mode generates V

LCD

A

B

9.4 Bit IB

Icon blink control is independent of the cursor/character

blink function.

When IB = 0, the icon blink is disabled. Icon data is stored

in CGRAM character 0 to 2 (3 × 8 × 5 = 120 bits for

120 icons).

When IB = 1, the icon blink is enabled. In this case each

icon is controlled by two bits. Blink consists of two half

phases (corresponding to the cursor on and off phases

called even and odd phases hereafter).

Icon states for the even phase are stored in CGRAM

characters 0 to 2 (3 × 8 × 5 = 120 bits for 120 icons).

These bits also define icon state when icon blink is not

used (see Table 9).

Icon states for the odd phase are stored in CGRAM

character4 to 6(another 120 bits for the 120 icons). When

icon blink is disabled CGRAM characters 4 to 6 may be

used as normal CGRAM characters.

WhenDM = 1, the chipis in direct mode.The internal V

generator is turned off and the V

connected to the V

generator supply voltage V

LCD

output is directly

LCD2

DD2

LCD

.

The direct mode can be used to reduce the current

consumption when the required V

close to the V

supply voltage. This can be the case in

DD2

output voltage is

LCD2

icon mode or in Mux 1:9 (depending on LCD liquid

properties).

9.6 Voltage multiplier control

Bits S1 and S0

A software configurable voltage multiplier is incorporated

in the V

generator and can be set via the ‘Set HVgen

LCD

stages’ command.

The voltage multiplier control can be used to reduce

current consumption by disconnecting internal voltage

multiplier stages, depending on the required V

LCD

output

voltage (see Table 8).

Table 8 S1 and S0 control of voltage multiplier

S1 S0 DESCRIPTION

0 0 set V

generator stages to 1

LCD

(2 x voltage multiplier)

0 1 set V

generator stages to 2

LCD

(3 x voltage multiplier)

1 0 set V

generator stages to 3

LCD

(4 x voltage multiplier)

1 1 do not use

9.7 Screen configuration

Bit L

L = 0: the two halves of a split screen are connected in a

standard way i.e. column 1/61, 2/62 to 60/120; default.

9.5 Direct mode

When DM = 0, thechip is notin the direct mode. Eitherthe

internal V

used to achieve V

generator or an external voltage may be

LCD

.

LCD

L = 1: the two halves of a split screen are connected in a

mirrored way i.e. column 1/120, 2/119 to 60/61. This

allows single layer PCB or glass layout.

Table 9 Blink effect for icons and cursor character blink

PARAMETER EVEN PHASE ODD PHASE

Cursor character blink block (all on) normal (display character)

Icons state 1; CGRAM character 0 to 2 state 2; CGRAM character 4 to 6

2001 Dec 19 30

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

9.8 Display configuration

Bit P

P = 0: default.

P = 1: mirrors the column data.

Bit Q

Q = 0: default.

Q = 1: mirrors the row data.

9.9 Temperature control

Default is TC1 = 0 and TC2 = 0. Selects the default

temperature coefficient for the internally generated V

(see Table 10).

The ranges for TC are given in Chapter 13.

Table 10 TC1 and TC2 selection of V

temperature

LCD

coefficient

TC1 TC2 DESCRIPTION

00V

10V

01V

11V

9.10 Set V

TheV

LCD

valueisprogrammed by instruction. Two on-chip

LCD

registers, VAand VBhold V

temperature coefficient 0

LCD

temperature coefficient 1

LCD

temperature coefficient 2

LCD

temperature coefficient 3

LCD

values for the character

LCD

mode and the icon mode respectively. The generated

V

value is independent of VDD, allowing battery

LCD

operation of the chip.

LCD

V

programming:

LCD

1. Send ‘function set’ instruction with H = 1

2. Send ‘set V

a) DB7, DB6 = 10: DB5 to DB0 are V

’ instruction to write to voltage register:

LCD

of character

LCD

mode (VA)

b) DB7, DB6 = 11: DB5 to DB0 are V

LCD

of icon

mode (VB)

c) DB5 to DB0 = 000000 switches V

generator off

LCD

(when selected)

d) During ‘display off’ and power-down the V

LCD

generator is also disabled.

3. Send ‘function set’ instruction with H = 0 to resume

normal programming.

9.11 Reducing current consumption

Reducing current consumption can be achieved by one of

the options given in Table 11.

When V

lies outside the VDD range and must be

LCD

generated, it is usually more efficient to use the on-chip

generator than an external regulator.

Table 11 Reducing current consumption

ORIGINAL MODE ALTERNATIVE MODE

Character mode Icon mode (control bit IM)

Display on Display off (control bit D)

V

generator operating Direct mode

LCD

Any mode power-down (PD pin)

2001 Dec 19 31

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

10 INTERFACES TO MICROCONTROLLER

10.1 Parallel interface

ThePCF2113xcansenddataineithertwo 4-bit operations

or one 8-bit operation and can thus interface to 4-bit or

8-bit microcontrollers.

In 8-bit mode data is transferred as 8-bit bytes using the

8 data lines DB7 to DB0. Three further control lines E,

RS and R/W are required (see Chapter 6).

In 4-bit mode data is transferred in two cycles of 4 bits

each using pins DB7 to DB4 for the transaction.

The higher order bits (corresponding to DB7 to DB4 in

8-bit mode) are sent in the first cycle and the lower order

bits (DB3 to DB0 in 8-bit mode) in the second cycle. Data

transfer is completeafter two 4-bit data transfers.It should

be noted thattwo cycles are also requiredfor the busy flag

check. 4-bit operation is selected by instruction, see

Figs 17 to 19 for examples of bus protocol.

In 4-bit mode, pins DB3 to DB0 must be left open-circuit.

They are pulled up to VDD internally.

2

10.2 I

C-bus interface

The I2C-bus is for bidirectional, two-line communication

between different ICs or modules. The two lines are the

Serial Data line (SDA) and the Serial Clock Line (SCL).

Both lines must be connected to a positive supply via

pull-up resistors. Data transfer may be initiated only when

the bus is not busy.

Each byte of eight bits is followed by an acknowledge bit.

The acknowledge bit is a HIGH level signal put on the bus

by the transmitter during which time the master generates

anextraacknowledge related clock pulse. Aslavereceiver

which is addressed must generate an acknowledge after

the reception of each byte.

Also a master receiver must generate an acknowledge

after the reception of each byte that has been clocked out

of the slave transmitter.

The device that acknowledges must pull-down the SDA

line during the acknowledge clock pulse, so that the SDA

line is stable LOW during the HIGH period of the

acknowledge related clock pulse (set-up and hold times

must be taken into consideration).

RS

R/W

E

DB7

DB6

DB5

DB4

IR7 IR3 BF AC3 DR7 DR3

IR6 IR2 AC6 AC2 DR6 DR2

IR5 IR1 AC5 AC1 DR5 DR1

IR4 IR0 AC4 AC0 DR4 DR0

instruction

write

busy flag and

address counter read

data register

read

Fig.17 4-bit transfer example.

MGA804

2001 Dec 19 32

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

RS

R/W

E

internal

DB7

IR7, IR3: instruction 7th, 3rd bit.

AC3: address counter 3rd bit.

D7, D3: data 7th, 3rd bit.

RS

R/W

internal operation

IR7 IR3 AC3 D7 D3

instruction

write

busy

busy flag

AC3

check

not

busy

busy flag

check

instruction

Fig.18 An example of 4-bit data transfer timing sequence.

write

MGA805

E

internal

DB7

data busy busy

instruction

write

internal operation

busy flag

check

Fig.19 Example of busy flag checking timing sequence.

2001 Dec 19 33

busy flag

check

not

busy

busy flag

check

data

instruction

write

MGA806

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

A master receiver must signal an end of data to the

transmitter by not generating an acknowledge bit on the

last byte that has been clocked out of the slave. In this

event the transmitter must leave the data line HIGH to

enable the master to generate a STOP condition.

2

10.2.1 I

C-BUS PROTOCOL

Before any data is transmitted on the I2C-bus, the device

whichshouldrespond is addressed first. Theaddressingis

always carried out with the first byte transmitted after the

START procedure. The I2C-bus configuration for the

different PCF2113x read and write cycles is shown in

Figs 24 to 26. The slow down feature of the I2C-bus

protocol (receiver holds SCL LOW during internal

operations) is not used in the PCF2113x.

SDA

SCL

MASTER

TRANSMITTER/

RECEIVER

SLAVE

RECEIVER

TRANSMITTER/

10.2.2 D

EFINITIONS

• Transmitter: the device which sends the data to the bus

• Receiver: the device which receives the data from the

bus

• Master: the device which initiates a transfer generates

clock signals and terminates a transfer

• Slave: the device addressed by a master

• Multi-master: more than one master can attempt to

control the bus at the same time without corrupting the

message

• Arbitration: procedure to ensure that if more than one

master simultaneously tries to control the bus, only one

is allowed to do so and the message is not corrupted

• Synchronization: procedure to synchronize the clock

signals of two or more devices.

SLAVE

RECEIVER

MASTER

TRANSMITTER

MASTER

TRANSMITTER/

RECEIVER

MGA807

Fig.20 System configuration.

handbook, full pagewidth

SDA

SCL

data line

stable;

data valid

Fig.21 Bit transfer.

2001 Dec 19 34

change

of data

allowed

MBC621

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

SDA

SDA

handbook, full pagewidth

SCL

START condition

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

SCL FROM

MASTER

S

STOP condition

Fig.22 Definition of START and STOP conditions.

not acknowledge

S

START

condition

P

acknowledge

acknowledgement

SCL

MBC622

9821

clock pulse for

MBC602

Fig.23 Acknowledgement on the I2C-bus.

2001 Dec 19 35

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

MGG002

A

DATA BYTE

A

update

data pointer

handbook, full pagewidth

from PCF2113x

acknowledgement

S

1 byte n ≥ 0 bytes2n ≥ 0 bytes

CONTROL BYTE

0

A

DATA BYTE

A

CONTROL BYTE

RS RS

1

0A

0

A

Co

Co

R/W

Fig.24 Master transmits to slave receiver; write mode.

0

0

S

A

R/W

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2001 Dec 19 36

011101

slave address

S P

PCF2113x

011101

slave address

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

A

handbook, full pagewidth

(1)

DATA BYTE

A

1 byte n ≥ 0 bytes

CONTROL BYTE

0

A

DATA BYTE

A

Co

2n 0 bytes

P

DATA BYTE

1A DATA BYTE A 1

0

S

acknowledgement acknowledgement no acknowledgement

A

MGG003

update

data pointer

data pointer

n bytes last byte

Co update

R/W

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2001 Dec 19 37

CONTROL BYTE

RS RS

1

A

0

S

acknowledgement

A

011101

S

0

Co

R/W

slave address

SLAVE

ADDRESS

S

Fig.25 Master reads after setting word address; writes word address, set RS; ‘read data’.

Last data byte is a dummy byte (may be omitted).

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

handbook, full pagewidth

S

SLAVE

ADDRESS

acknowledgement

from PCF2113x

S

A

1A DATA BYTE A 1

0

R/W

Co update

acknowledgement

from master

DATA BYTE

n bytes last byte

data pointer

no acknowledgement

from master

P

update

data pointer

MGG004

Fig.26 Master reads slave immediately after first byte; read mode (RS previously defined).

11 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DD1

V

, V

DD2

V

LCD

V

i/o(n)

I

I

I

O

I

, ISSand I

DD

P

tot

P

O

V

es

DD3

logic supply voltage −0.5 +5.5 V

V

generator supply voltages −0.5 +4 V

LCD

LCD supply voltage −0.5 +6.5 V

voltage on

any V

any V

related input or output −0.5 VDD+ 0.5 V

DD

related input or output −0.5 V

LCD

LCD

DC input current −10 +10 mA

DC output current −10 +10 mA

LCDVDD

, VSS or V

supply current −50 +50 mA

LCD

total power dissipation − 400 mW

power dissipation per output − 100 mW

electrostatic handling voltage human body model;

− 2000 V

+ 0.5 V

C = 100 pF; R = 1.5 kΩ

electrostatic handling voltage machine model;

− 150 V

C = 200 pF; L = 0.75 µH

T

stg

storage temperature −65 +150 °C

12 HANDLING INSTRUCTIONS

Inputs and outputs are protected against electrostatic discharge in normal handling. However, to be totally safe, it is

desirable to take normal precautions appropriate to handling MOS devices (see

“Handling MOS Devices”

).

2001 Dec 19 38

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

13 DC CHARACTERISTICS

V

= 1.8 to 5.5 V; V

DD1

DD2=VDD3

specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

DD1

V

DD2,VDD3VLCD

logic supply voltage note 1 1.8 − 5.5 V

generator supply

voltages

V

V

LCD

POR

LCD supply voltage 2.2 − 6.5 V

Power-on reset voltage note 1 and 2 0.9 − 1.6 V

GROUND SUPPLY CURRENT; EXTERNAL V

I

SS1

I

SS3

I

SS4

I

SS5

ground supply current 1 − 70 120 µA

ground supply current 3 VDD=3V; V

ground supply current 4 icon mode; VDD=3V;

ground supply current 5 Power-down mode;

GROUND SUPPLY CURRENT; INTERNAL V

I

SS6

I

SS8

I

SS9

ground supply current 6 − 190 400 µA

ground supply current 8 VDD=3V; V

ground supply current 9 icon mode; VDD= 2.5 V;

Logic

V

IL

V

IH

V

IL(OSC)

LOW-level input voltage V

HIGH-level input voltage 0.7V

LOW-level input voltage on

pin OSC

V

IH(OSC)

I

OL(DB)

HIGH-level voltage pin OSC V

LOW-level output current on

pins DB7 to DB0

I

OH(DB)

HIGH-level output current on

pins DB7 to DB0

I

pu

pull-up current at

pins DB7 to DB0

I

L

leakage current VI=V

= 2.2 to 4.0 V; VSS=0V;V

LCD

; note 3

internal V

(V

DD2

V

LCD

VDD=3V; V

LCD

and V

DD3<VLCD

LCD

= 2.5 V; note 4

LCD

DB7 to DB0,RS and R/W=1;

OSC = 0; PD = 1

; notes 3 and 5

LCD

LCD

V

= 2.5 V; note 4

LCD

VOL= 0.4 V; V

VOH=4V; V

VI=V

SS1

DD1

DD1

or V

= 2.2 to 6.5 V; T

LCD

generation

= −40 to +85 °C; unless otherwise

amb

2.2 − 4.0 V

)

= 5 V; note 4 − 45 80 µA

− 25 45 µA

− 25 µA

= 2.5 V;

= 5 V; note 4 − 160 400 µA

− 120 −µA

SS1

DD1

V

SS1

− 0.1 − V

DD1

= 5 V 1.6 4 − mA

DD1

− 0.3V

− V

− V

DD1

DD1

DD1

DD1

− 1.2 V

=5V −1 −8 − mA

0.04 0.15 1 µA

SS1

−1 − +1 µA

V

V

V

2001 Dec 19 39

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I2C-bus; pins SDA and SCL

V

IL

V

IH

I

LI

C

i

I

OL (SDA)

LOW-level input voltage 0 − 0.3V

HIGH-level input voltage 0.7V

input leakage current VI=V

DD1

or V

SS1

−1 − +1 µA

DD1

− 5.5 V

DD1

input capacitance note 6 − 5 − pF

LOW-level output current on

pin SDA

VOL= 0.4 V; V

V

= 0.2 V

OL

DD1

>2V 3 −− mA

DD1

; V

<2V 2 −− mA

DD1

LCD outputs

R

O(ROW)

row output resistance of

note 7 − 10 30 kΩ

pins R1 to R18

R

O(COL)

column output resistance of

note 7 − 15 40 kΩ

pins C1 to C60

V

bias(tol)

bias voltage tolerance on

note 8 − 20 130 mV

pins R1 to R18 and C1 to C60

V

LCD2(tol)

TC0 V

TC1 V

TC2 V

TC3 V

voltage tolerance T

LCD

temperature coefficient 0 −−0.16 − %/K

LCD

temperature coefficient 1 −−0.18 − %/K

LCD

temperature coefficient 2 −−0.21 − %/K

LCD

temperature coefficient 3 −−0.24 − %/K

LCD

=25°C; note 5

amb

V

<3V −−160 mV

LCD

V

<4V −−200 mV

LCD

V

<5V −−260 mV

LCD

V

<6V −−340 mV

LCD

V

Notes

1. Spikes on V

2. Resets all logic when V

3. LCD outputs are open-circuit; inputs at V

4. T

amb

=25°C; f

5. LCD outputs are open-circuit; V

DD1

or V

= 200 kHz.

OSC

which cause V

SS1

DD1<VPOR

DD1

− V

≤ 1.6 V can cause a Power-on reset.

SS1

; 3 OSC cycles required.

or V

DD1

generator is on; load current I

LCD

; bus inactive.

SS1

VLCD

=5µA (at V

LCD

).

6. Tested on sample basis.

7. Resistance of output pins (R1 to R18 and C1 to C60) with a load current of 10 µA; outputs measured one at a time;

external V

8. LCD outputs open-circuit; external V

LCD

= 3 V, V

DD1, 2, 3

=3V.

LCD

.

V

2001 Dec 19 40

Philips Semiconductors Product specification

LCD controllers/drivers PCF2113x

14 AC CHARACTERISTICS

V

= 1.8 to 5.5 V; V

DD1

DD2=VDD3

specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

f

FR

f

osc

f

OSC(ext)

t

osc(st)

t

W(PD)

t

SW(PD)

LCD frame frequency (internal clock) VDD= 5.0 V 45 95 147 Hz