Page 1

查询P83C180供应商

INTEGRATED CIRCUITS

DATA SH EET

P83Cx80; P87C380

Microcontrollers for monitors

with DDC interface, auto-sync

detection and sync proc.

Product specification

File under Integrated Circuits, IC20

1997 Dec 12

Page 2

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

CONTENTS

1 FEATURES

1.1 Differences from the 80C51 core

1.2 Memory

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 BLOCK DIAGRAM

5 PINNING INFORMATION

5.1 Pinning

5.2 Pin description

6 FUNCTIONAL DESCRIPTION

6.1 General

7 MEMORY ORGANIZATION

7.1 Program memory

7.2 Internal data memory

7.3 Additional Special Function Registers

8 INTERRUPTS

8.1 Priority level structure

8.2 How interrupts are handled

8.3 Interrupt Enable Register (IE)

8.4 Interrupt Priority Register (IP)

9 WATCHDOG TIMER

10 INPUT/OUTPUT (I/O)

10.1 The alternative functions for Port 0, Port 1,

Port 2 and Port 3

10.2 EMI (Electromagnetic Interference) reduction

11 REDUCED POWER MODES

11.1 Power Control Register

11.2 Idle mode

11.3 Power-down mode

11.4 Status of external pins

12 OSCILLATOR

13 RESET

13.1 External reset

13.2 Power-on-reset

13.3 T2 (Watchdog Timer) overflow

14 ANALOG CONTROL (DC)

14.1 8-bit PWM outputs (PWM0 to PWM9)

14.2 14-bit PWM output (PWM10)

14.3 A typical PWM output application

15 ANALOG-TO-DIGITAL CONVERTER (ADC)

15.1 Conversion algorithm

16 DIGITAL-TO-ANALOG CONVERTER (DAC)

16.1 8-bit Data Registers for the DAC outputs

17 DISPLAY DATA CHANNEL (DDC)

17.1 Special Function Registers related to the DDC

17.2 Host type detection

17.3 DDC1 protocol

17.4 DDC2B protocol

17.5 DDC2AB/DDC2B+ protocol

17.6 RAM buffer for the system and DDC application

18 I2C-BUS INTERFACE

19 HARDWARE MODE DETECTION

19.1 Special Function Register for mode detection

19.2 System description

19.3 System operation

20 POWER MANAGEMENT

21 CONTROL MODES

22 ONE TIME PROGRAMMABLE (OTP)

23 LIMITING VALUES

24 HANDLING

25 DC CHARACTERISTICS

26 DIGITAL-TO-ANALOG CONVERTER

27 AC CHARACTERISTICS

28 PACKAGE OUTLINE

29 SOLDERING

29.1 Introduction

29.2 Soldering by dipping or by wave

29.3 Repairing soldered joints

30 DEFINITIONS

31 LIFE SUPPORT APPLICATIONS

32 PURCHASE OF PHILIPS I2C COMPONENTS

P83Cx80; P87C380

(DACn; n = 0 to 3)

INTERFACE

interface

and sync separation

VERSION

CHARACTERISTICS

1997 Dec 12 2

Page 3

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

1 FEATURES

• 80C51 type core

• On-chip oscillator with a maximum frequency of 16 MHz

(maximum 0.75 µs instruction cycle)

• A DDC interface:

– That fully supports DDC1 with specific hardware

– That is DDC2B, DDC2B+, DDC2AB (ACCESS.bus)

compliant, based on a dedicated hardware I2C-bus

interface.

– Contains a specific AUX-RAM buffer with

programmable size (128 or 256 bytes) that can be

used for DDC operation and shared as system RAM

• Automatic mode detection by hardware to capture the

following information:

– HSYNC frequency with 12-bit resolution

– VSYNC frequency with 12-bit resolution

– HSYNC and VSYNC polarity

– HSYNC and VSYNC presence; needed for the VESA

Device Power Management Signalling (DPMS)

standard

• On-chip sync processor comprising:

– Composite sync separation

– Free running mode

– Clamping

– Pattern generation

2

• Two specific ports for the software I

• 4 analog voltage outputs derived from an 8-bit

Digital-to-Analog Converter (DAC)

• Ten 8-bit Pulse Width Modulation (PWM) outputs for

digital control application

• One 14-bit PWM output for digital control application

• One 4-bit Analog-to-Digital Converter (ADC) with 2 input

channels (for keyboard interface)

• LED driver port (Port 0); eight port lines with 10 mA drive

capability

C-bus interface

• One 8-bit port only for I/O function

• 20 derivative I/O ports with the specific port type

• Watchdog Timer with a programmable interval

• On-chip Power-on-reset for low power detection

• Special Idle and Power-down modes for reduced power

• Optimized for Electromagnetic Compatibility (EMC)

• Operating temperature: −25 to +85 °C

• Single power supply: 4.4 to 5.5 V.

1.1 Differences from the 80C51 core

• No external memory connection; signals EA, ALE and

• Port 1, Port 2 and Port 3 (P3.0 to P3.3 only) mixed with

• Timer 0/Counter 0 and Timer 1/Counter 1: external

• External interrupt 0/INT0 replaced by Mode detection

• Standard serial interface (UART) and its control register

• Wake-up from Power-down mode is also possible by

1.2 Memory

Table 1 ROM/RAM sizes

P83C880 8 kbytes 512 bytes

P83C180 16 kbytes 512 bytes

P83C280 24 kbytes 512 bytes

P83C380 32 kbytes 512 bytes

P87C380 (OTP) 16 kbytes 512 bytes

P83Cx80; P87C380

configuration in each alternative function

operation

PSEN are not present.

other derivative functions.

input is removed.

function.

are removed.

means of an interrupt.

MEMORY

DEVICE

ROM RAM

1997 Dec 12 3

Page 4

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

2 GENERAL DESCRIPTION

The P83Cx80; P87C380 denotes the following types:

P83C880, P83C180, P83C280, P83C380 and P87C380,

hereafter referred to as the P83C880, are monitor

microcontrollers of the 80C51 family, with DDC (DDC1,

DDC2B, DDC2B+ and DDC2AB) interface to the PC host.

The internal hardware can separate composite sync

signals and detect the various display modes. The

digital/analog voltage outputs can be used to control the

video and deflection functions the monitor.

3 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

P83C880 SDIP42 plastic shrink dual in-line package; 42 leads (600 mil) SOT270-1 −25 to +85

P83C180

P83C280

P83C380

P87C380 (OTP)

This data sheet details the specific properties of the

P83C880, P83C180, P83C280, P83C380 and P87C380.

The shared characteristics of the 80C51 family of

microcontrollers are described in

which should be read in conjunction with this data sheet.

(1)

“Data Handbook IC20”

TEMPERATURE

RANGE (°C)

,

Note

1. For emulation the package CLCC84 is used.

1997 Dec 12 4

Page 5

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

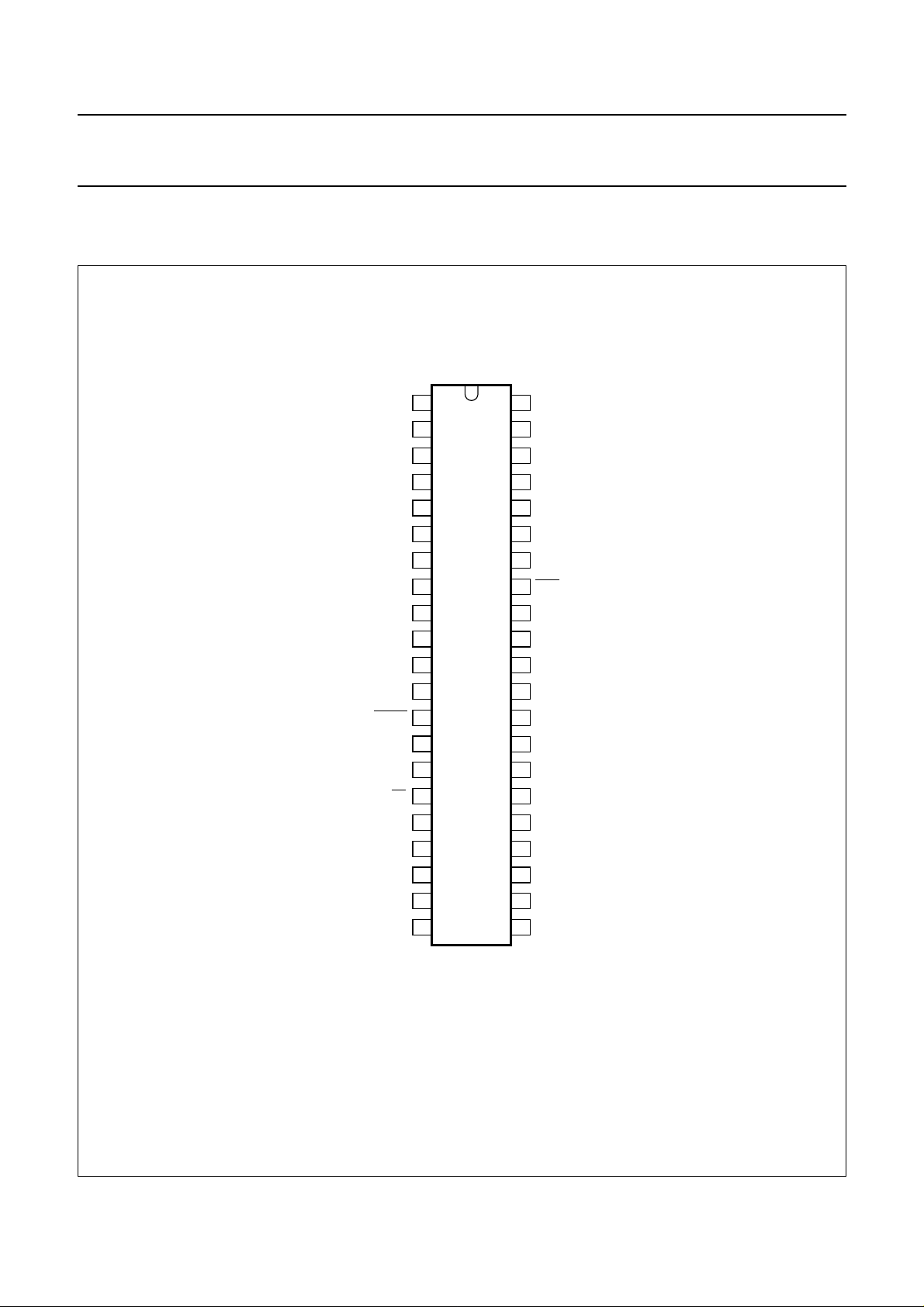

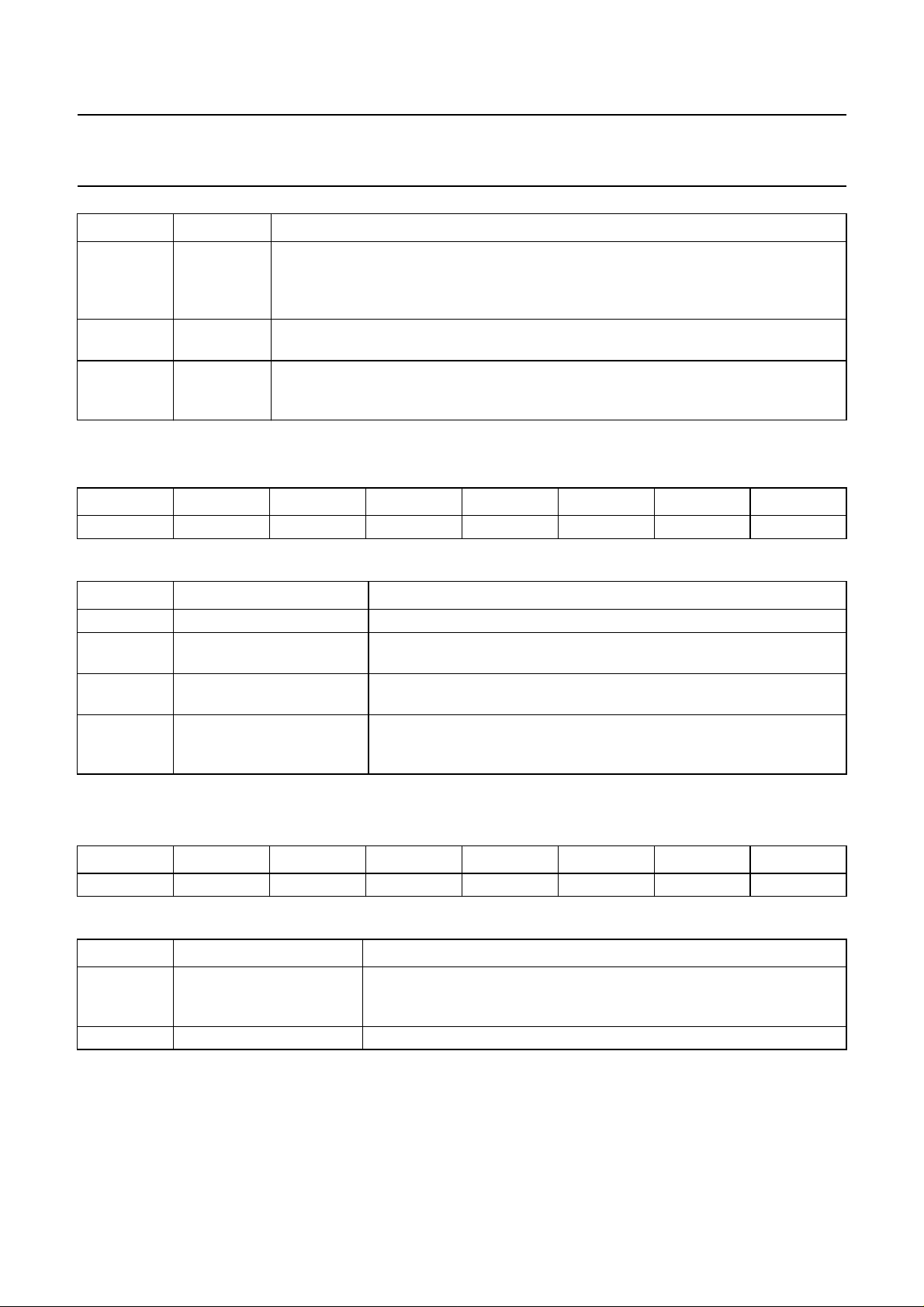

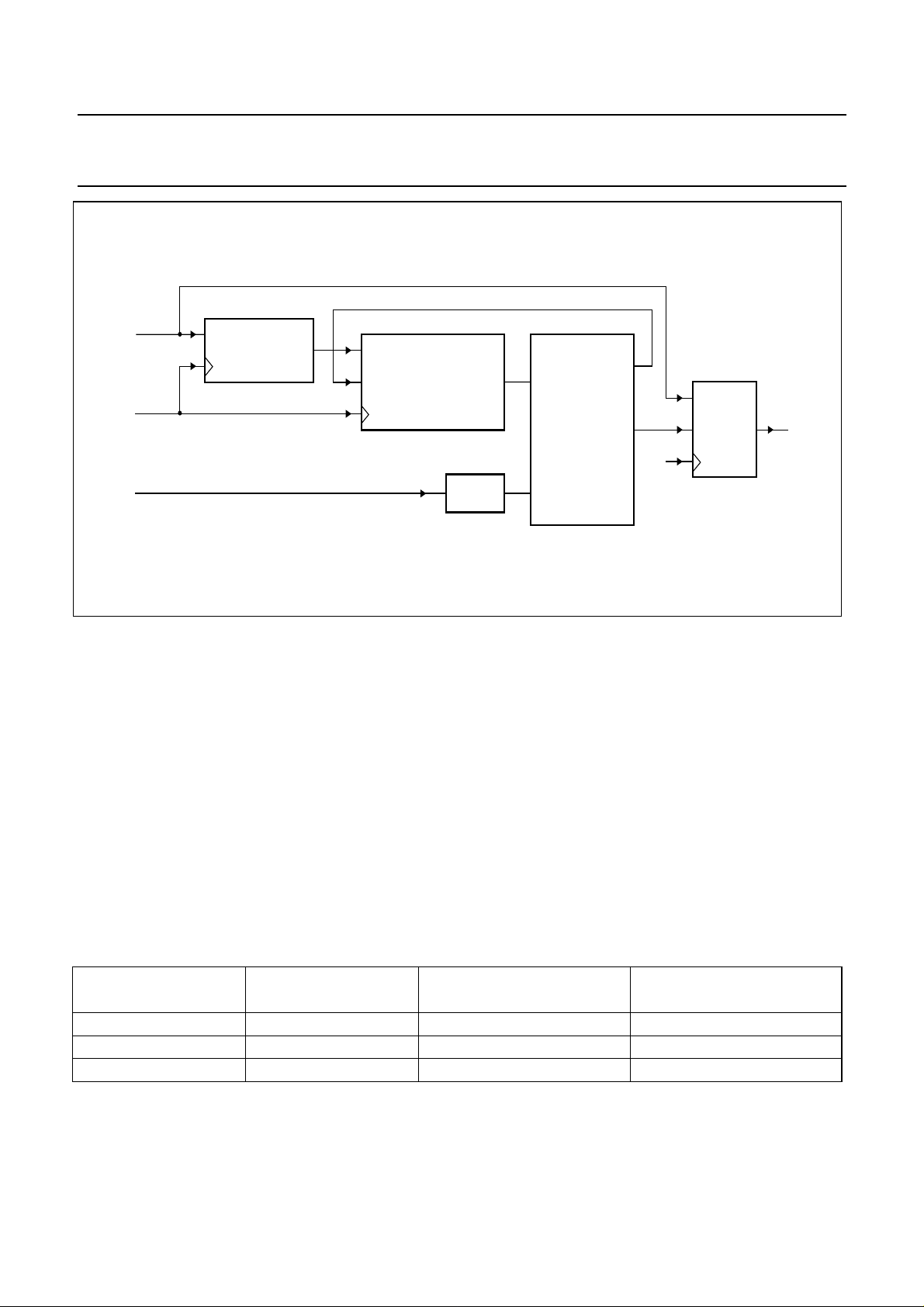

4 BLOCK DIAGRAM

8-bit

internal bus

P83C280

P83C380

P87C380

DDA

V

SSA

V

full pagewidth

(1)

SCL

(1)

SDA

(3)

ADC1

(3)

4

DAC0 to DAC3

SS

V

DD

V

C-BUS

2

SERIAL

I

SOFTWARE

ADC

4-BIT

DAC

4 × 8-BIT

DATA

MEMORY

512 BYTES

(4)

MEMORY

PROGRAM

I/O

RAM

P83C880

P83C180

(T2)

TIMER

WATCHDOG

PWM

14-BIT

PWM

10 × 8-BIT

DDC

INTERFACE

MODE

DETECTION

P83Cx80; P87C380

MGG021

RESET

internal reset

10

(1)

PWM10

;

(3)

(2)

PWM8 to PWM9

PWM0 to PWM7

(1)

SCL1

(1)

SDA1

in

in

(1)

VSYNC

in

HSYNC

CSYNC

(1)

out

(3)

(3)

HSYNC

PATOUT

CLAMP

(1)

out

VSYNC

Fig.1 Block diagram.

INT1INT1 ADC0

XTAL1

CPU

(T0, T1)

TIMERS

TWO 16-BIT

XTAL2

core

80C51

excluding

ROM/RAM

1997 Dec 12 5

INT0

&

PARALLEL

I/O PORTS

EXTERNAL BUS

4

P3P2P1P0

(1) Alternative function of Port 1.

(2) Alternative function of Port 2.

(3) Alternative function of Port 3.

(4) ROM: 8 kbytes (P83C880); 16 kbytes (P83C180); 24 kbytes (P83C280); 32 kbytes (P83C380). EPROM: 16 kbytes only in the P87C180A.

Page 6

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

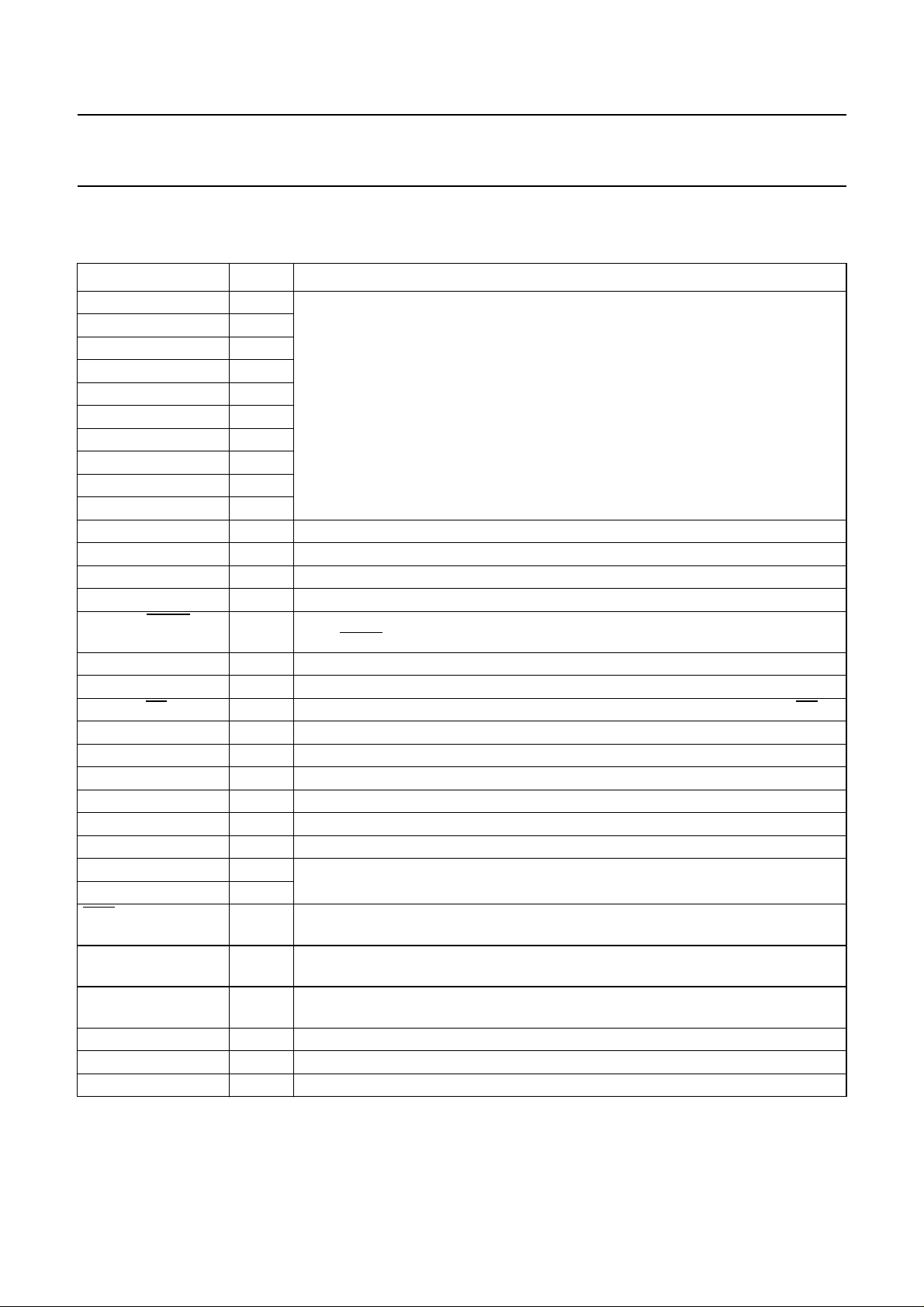

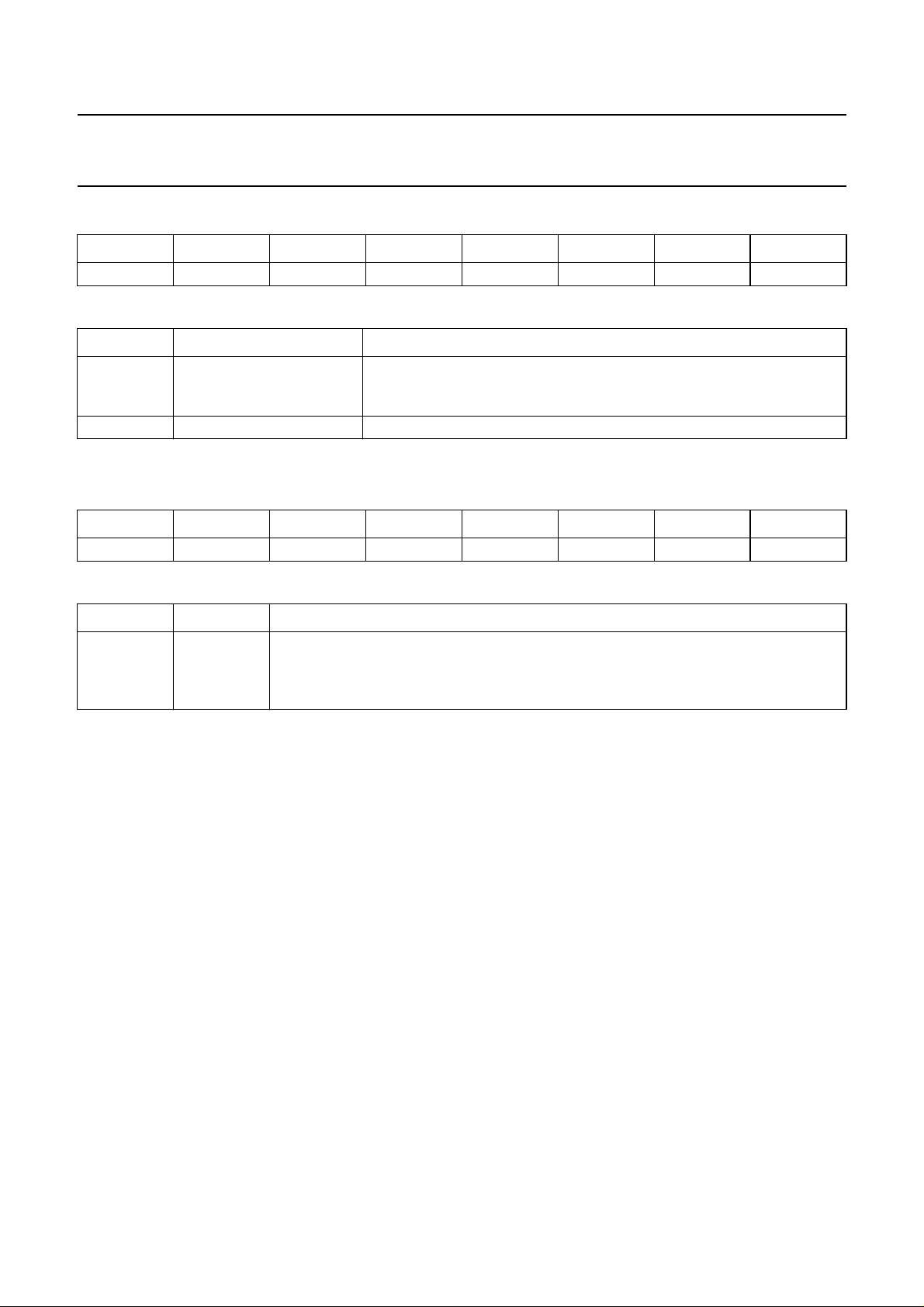

5 PINNING INFORMATION

5.1 Pinning

handbook, halfpage

PWM7/P2.7

PWM6/P2.6

PWM5/P2.5

PWM4/P2.4

PWM3/P2.3

PWM2/P2.2

PWM1/P2.1

PWM0/P2.0

HSYNCin/PROG

HSYNC

CSYNCin/P1.6

VSYNCin/OE

VSYNC

XTAL1

XTAL2

out

out

V

DD

V

SS

/P1.5

/P1.4

P0.7

P0.6

P0.5

P0.4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

P83C880

P83C180

P83C280

P83C380

P87C380

MGG020

42

PWM8/CLAMP/P3.0

41

PWM9/PATOUT/P3.1

40

PWM10/P1.7

39

SCL/P1.0

38

SDA/P1.1

37

SCL1/P1.2

36

SDA1/P1.3

35

INT1/V

PP

34

ADC1/P3.3

33

ADC0/P3.2

V

32

DDA

V

31

SSA

30

DAC3

29

DAC2

28

DAC1

27

DAC0

26

RESET

25

P0.0

24

P0.1

23

P0.2

2221

P0.3

P83Cx80; P87C380

Fig.2 Pinning configuration for SDIP42.

1997 Dec 12 6

Page 7

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

5.2 Pin description

Table 2 Pin description for SDIP42 (SOT270-1)

SYMBOL PIN DESCRIPTION

PWM9/PATOUT/P3.1 41 PWM9 to PWM0: 8-bit Pulse Width Modulation outputs 9 to 0. Pin 41 and 42 can

PWM8/CLAMP/P3.0 42

PWM7/P2.7 1

PWM6/P2.6 2

PWM5/P2.5 3

PWM4/P2.4 4

PWM3/P2.3 5

PWM2/P2.2 6

PWM1/P2.1 7

PWM0/P2.0 8

XTAL1 9 Oscillator input pin for system clock.

XTAL2 10 Oscillator output pin for system clock.

V

DD

V

SS

HSYNC

HSYNC

CSYNC

VSYNC

VSYNC

/PROG 13 Horizontal sync input pin. During OTP programming it is used as the program pulse

in

/P1.5 14 Horizontal sync output pin; alternative function: general I/O port P1.5.

out

/P1.6 15 Composite sync input pin; alternative function: general I/O port P1.6.

in

/OE 16 Vertical sync input pin. During OTP programming it is used as output strobe (OE).

in

/P1.4 17 Vertical sync output pin; alternative function: general I/O port P1.4.

out

P0.7 to P0.0 18 to 25 Port 0: general I/O ports; capability to drive LED.

RESET 26 Reset input; active HIGH initializes the device.

DAC0 to DAC3 27 to 30 8-bit DAC analog voltage output pins; output range: 0 to 5 V.

V

SSA

V

DDA

ADC0/P3.2 33 ADC analog input pins; alternative function: general I/O ports P3.2 and P3.3.

ADC1/P3.3 34

INT1/V

PP

SDA1/P1.3 36 I

SCL1/P1.2 37 I

SDA/P1.1 38 I

SCL/P1.0 39 I

PWM10/P1.7 40 14-bit Pulse Width Modulation output 10; alternative function: general I/O port P1.7.

also be used as the output pin of the test pattern display PATOUT and clamping out

signal CLAMP respectively; PATOUT and CLAMP always have the higher priority.

Alternative function general I/O ports; Port 3: P3.1 to P3.0 and

Port 2: P2.7 to P2.0.

11 Digital power supply (+5 V).

12 Digital ground.

input (PROG).

31 Analog ground for DAC and ADC.

32 Analog power supply (+5 V) for DAC and ADC.

35 External interrupt input pin. During OTP programming it is used as programming

supply voltage pin; VPP= 12.75 V.

2

C-bus serial data I/O port for the DDC2 interface; alternative function: general I/O

port P1.3.

2

C-bus serial clock I/O port for the DDC2 interface; alternative function: general I/O

port P1.2.

2

C-bus serial data I/O port; alternative function: general I/O port P1.1.

2

C-bus serial clock I/O port; alternative function: general I/O port P1.0.

1997 Dec 12 7

Page 8

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

6 FUNCTIONAL DESCRIPTION

This chapter gives a brief overview of the device.

Detailed functional descriptions are given in the following

chapters:

Chapter 7 “Memory organization”

Chapter 8 “Interrupts”

Chapter 9 “Watchdog Timer”

Chapter 10 “Input/Output (I/O)”

Chapter 11 “Reduced power modes”

Chapter 12 “Oscillator”

Chapter 13 “Reset”

Chapter 14 “Analog control (DC)”

Chapter 15 “Analog-to-digital converter (ADC)”

Chapter 16 “Digital-to-analog converter (DAC)”

Chapter 17 “Display Data Channel (DDC) interface”

Chapter 18 “I2C-bus Interface”

Chapter 19 “Hardware mode detection”

Chapter 20 “Power management”

Chapter 21 “Control modes”.

6.1 General

The P83C880, P83C180, P83C280, P83C380 and

P87C380 8-bit microcontrollers are manufactured in an

advanced CMOS process and are derivatives of the

80C51 microcontroller family. They have the same

instruction set as the 80C51.

They contain 512 bytes of data memory (RAM). ROM:

8 kbytes (P83C880); 16 kbytes (P83C180); 24 kbytes

(P83C280); 32 kbytes (P83C380) and 16 kbytes of

EPROM for the P87C180. The microcontrollers are

intended for use in monitors ranging from 14" to 21" that

can be controlled from the outside (e.g. by a PC) via the

external DDC interface.

In addition to the 80C51 standard functions, they provide a

number of dedicated hardware functions for monitor

application. Eight general I/O ports plus 20 functions

combined I/O ports cater for application requirements

adequately.

Ten sets of 8-bit PWM deliver the digital waveform for

analog control purposes. One 14-bit PWM can support

F to V application. The keyboard interface is achieved via

a 4-bit ADC. A Watchdog Timer with a maximum count

period of 5 s prevents the processor running out of control

due to malfunction. Four channels of linear DAC with 8-bit

resolution support more accurate analog controls.

One software I

connection. A DDC interface will cover all DDC protocols,

including DDC1, DDC2B, DDC2AB and DDC2B+.

A hardware mode detector will facilitate mode detection

even in power reduced modes, e.g. Idle mode.

The versatile HSYNC and VSYNC outputs can be

generated to serve the desired application. In the free

running mode, two display patterns can highlight the status

of the monitor. Accordingly, the following items will be

supported by these microcontrollers:

• Mode detection for:

• ACCESS.bus interfacing with external devices, e.g. PCs

• DDC1, DDC2B, DDC2AB and DDC2B+ protocols as

• Device Power Management Signalling (DPMS) as

Figure 1 shows the block diagram functions.

P83Cx80; P87C380

2

C-bus interface is dedicated for the internal

– Horizontal sync (HSYNC) frequencies from below

15 kHz up to 150 kHz

– Vertical sync (VSYNC) frequencies from below 40 Hz

up to 200 Hz

defined in the VESA DDC standard

described in VESA DPMS proposal.

1997 Dec 12 8

Page 9

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

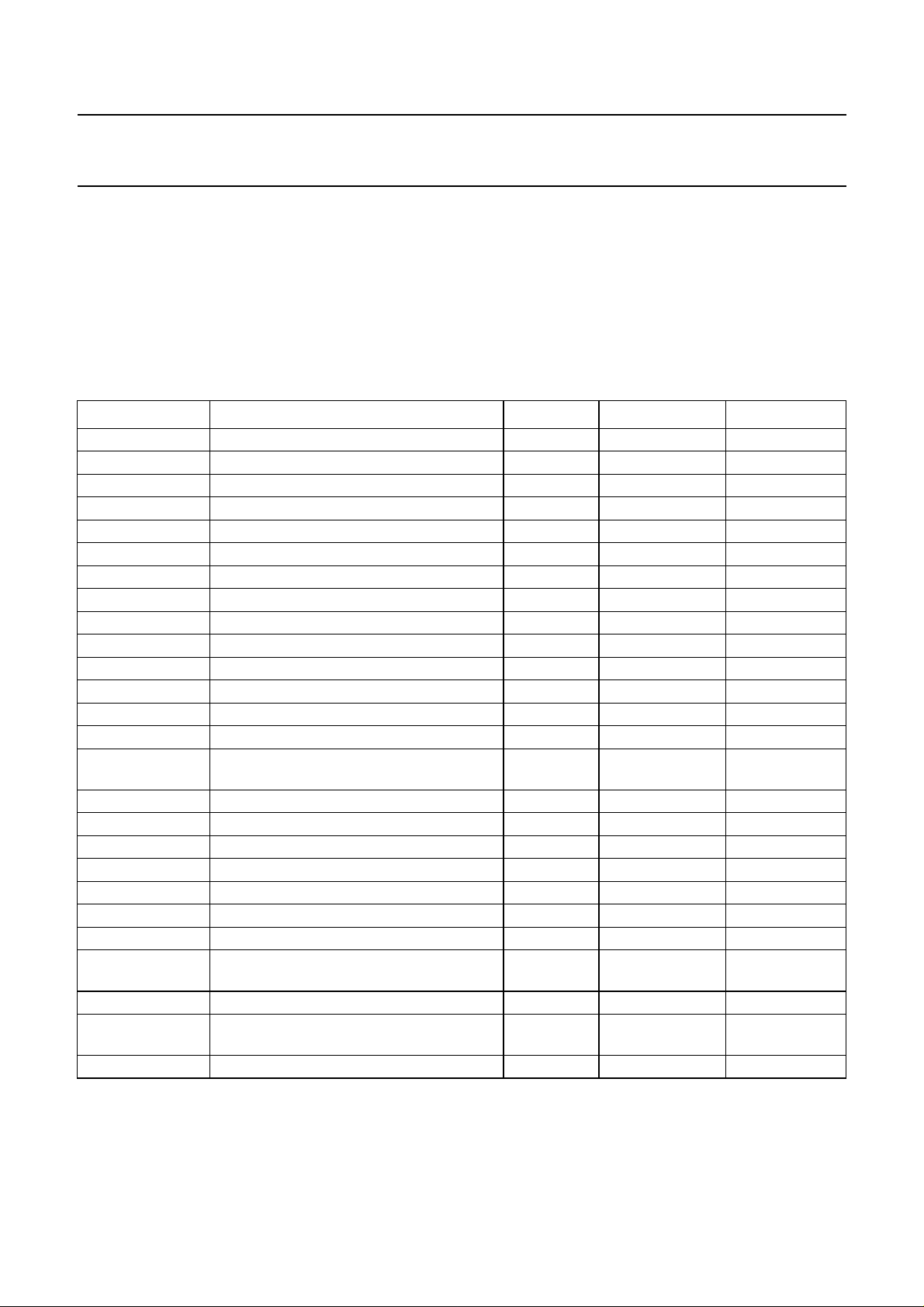

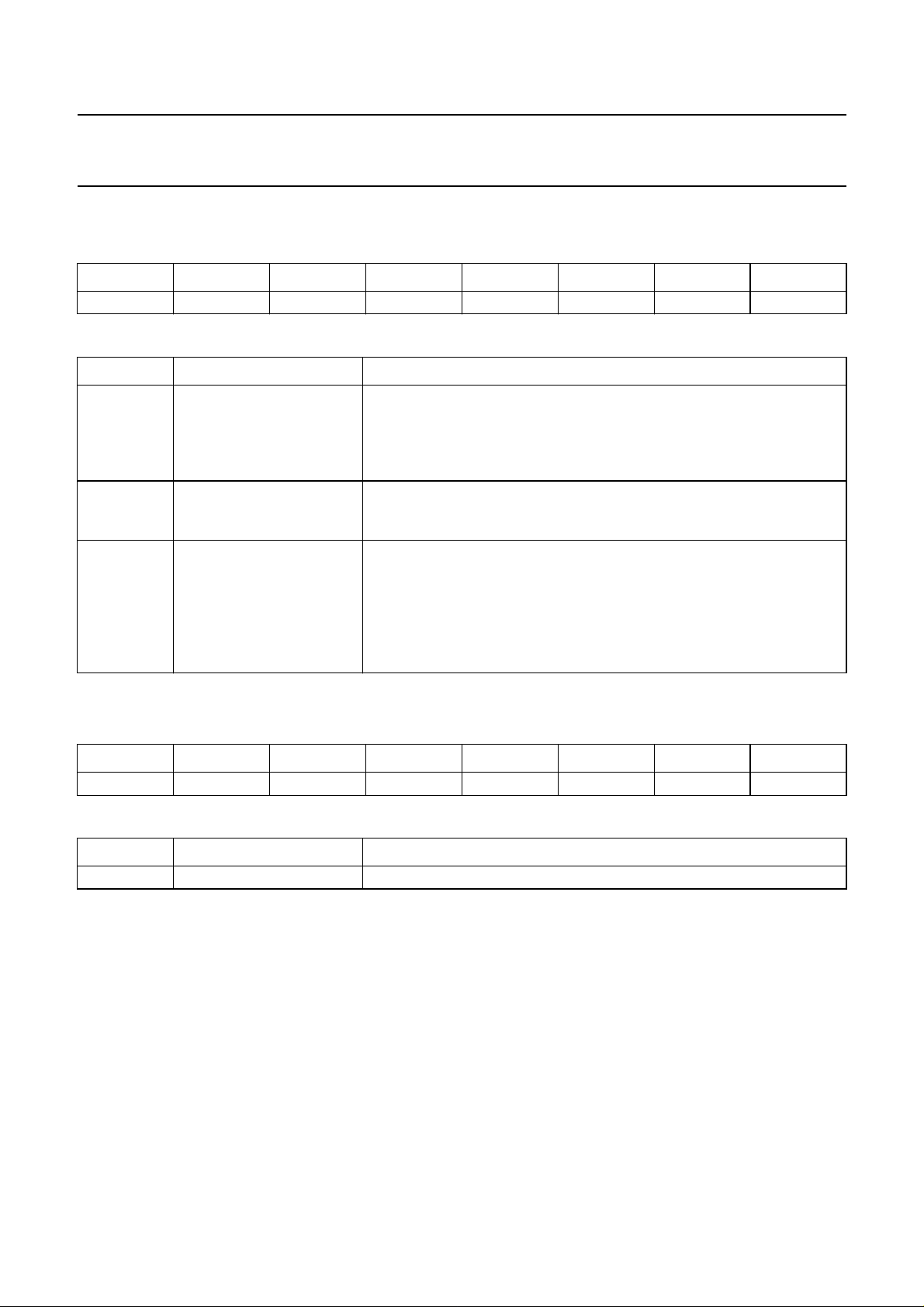

7 MEMORY ORGANIZATION

The Central Processing Unit (CPU) manipulates operands in two memory spaces. There are 512 bytes of internal data

memory, consisting of 256 bytes standard RAM and 256 bytes RAM buffer which is accessible as the Auxiliary RAM

(AUX-RAM) or addressed through DDCADR and RAMBUF. The memory map and address spaces are shown in Fig.3.

INDIRECT

ONLY

INDIRECT

overlapped space

SPECIAL

FUNCTION

REGISTERS

internal data memory area

255

AUX-RAM

BUFFER

INDIRECT

ONLY

0

MGG028

ndbook, full pagewidth

32767

24575

16383

8191

(1) P83C380 and P87C380.

(2) P83C280.

(3) P380C180.

(4) P83C880.

(1)

(2)

(3)

(4)

INTERNAL

0

program memory area

255

127

DIRECT AND

0

Fig.3 Memory map and address spaces.

7.1 Program memory

The program memory consists of ROM: 8 kbytes (P83C880), 16 kbytes (P83C180), 24 kbytes (P83C280) and 32 kbytes

(P83C380). The program memory implemented in the P87C380 is a 16 kbytes EPROM (OTP).

7.2 Internal data memory

The internal data memory is divided into three physically separated parts: 256 bytes of RAM, 256 bytes of AUX-RAM,

and a 128 bytes Special Function Registers (SFRs) area. These can be addressed each in a different way as described

in Sections 7.2.1 to 7.2.3 and Table 3.

Table 3 Internal data memory map

ADDRESS MODE

MEMORY LOCATION

POINTERS

DIRECT INDIRECT

RAM 0 to 127

128 to 255

AUX-RAM 0 to 255 − X

(1)

(2)

X X address pointers are R0 and R1 of the selected register bank

− X

(3)

address pointer DDCADR and RAMBUF

SFRs 128 to 255 X −−

Notes

1. RAM locations 0 to 127 can be addressed directly and indirectly as in the 80C51.

2. RAM locations 128 to 255 can only be addressed indirectly.

1997 Dec 12 9

Page 10

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

3. Indirect-addressable via MOVX-Datapointer or

MOVX-Ri instructions.

7.2.1 RAM

Four register banks, each 8 registers wide, occupy

locations 0 through 31 in the lower RAM area. Only one of

these banks may be enabled at a time. The next 16 bytes,

locations 32 through 47, contain 128 directly addressable

bit locations. The stack can be located anywhere in the

internal 256 bytes RAM. The stack depth is only limited by

the available internal RAM space of 256 bytes (see Fig.4).

7.2.2 S

The SFRs can only be addressed directly in the address

range from 128 to 255 (see Fig.3). Figure 5 gives an

overview of the Special Function Registers space. Sixteen

address in the SFRs space are both byte and

bit-addressable. The bit-addressable SFRs are those

whose address ends in 0H and FH. The bit addresses in

this area are 80H to FFH

7.2.3 AUX-RAM

AUX-RAM buffer 0 to 255 is indirectly addressable as

external data memory locations 0 to 255 via

MOVX-Datapointer instruction or via MOVX-Ri instruction.

Since the external access function is not available, any

access to AUX-RAM 0 to 255 will not affect the ports.

The 256 bytes of AUX-RAM buffer used to support DDC

interface is also available for system usage by indirect

addressing through the address pointer DDCADR and

data I/O buffer RAMBUF. The address pointer (DDCADR)

is equipped with the post increment capability to facilitate

the transfer of data in bulk (for details refer to Chapter 17).

However, it is also possible to address the AUX-RAM

buffer through MOVX command as usually used in the

internal RAM extension of 80C51 derivatives.

PECIAL FUNCTION REGISTERS (SFRS)

BYTE

ADDRESS

(HEX)

FFH

2FH

2EH

2DH

2CH

2BH

2AH

29H

28H

27H

26H

25H

24H

23H

22H

21H

20H

1FH

18H

17H

10H

0FH

08H

07H

00H

P83Cx80; P87C380

BIT ADDRESS

(HEX)

(MSB) (LSB)

7F 7E 7D 7C 7B 7A 79 78

77 76 75 74 73 72 71 70

6F 6E 6D 6C 6B 6A 69 68

67 66 65 64 63 62 61 60

5F 5E 5D 5C 5B 5A 59 58

57 56 55 54 53 52 51 50

4F 4E 4D 4C 4B 4A 49 48

47 46 45 44 43 42 41 40

3F 3E 3D 3C 3B 3A 39 38

37 36 35 34 33 32 31 30

2F 2E 2D 2C 2B 2A 29 28

27 26 25 24 23 22 21 20

1F 1E 1D 1C 1B 1A 19 18

17 16 15 14 13 12 11 10

0F 0E 0D 0C 0B 0A 09 08

07 06 05 04 03 02 01 00

BANK 3

BANK 2

BANK 1

BANK 0

MBH079

BYTE

ADDRESS

(DECIMAL)

255

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

24

23

16

15

8

7

0

1997 Dec 12 10

Fig.4 RAM bit addresses.

Page 11

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

handbook, full pagewidth

BYTE ADDRESS

(HEX)

FFH

F8H

F0H F6 F5 F4 F3 F2 F1 F0

E8H EE ED EC EB EA E9 E8

E0H E6 E5 E4 E3 E2 E1 E0

D8H

(MSB) (LSB)

FF

FE FD FC FB FA F9 F8

F7

EF

E7

DF

DE DD DC DB DA D9 D8

BIT ADDRESS

(HEX)

P83Cx80; P87C380

BYTE ADDRESS

(DECIMAL)

255

MDCST

B

PWME2

ACC

S1CON

D0H

C8H

C0H C6 C5 C4 C3 C2 C1 C0

B8H BE BD BC BB BA B9 B8

B0H B6 B5 B4 B3 B2 B1 B0

A8H AE AD AC AB AA A9 A8

A0H A6 A5 A4 A3 A2 A1 A0

98H 9E 9D 9C 9B 9A 99 98

90H 96 95 94 93 92 91 90

88H 8E 8D 8C 8B 8A 89 88

80H 86 85 84 83 82 81 80

D7 D6 D5 D4 D3 D2 D1 D0

CF CE CD CC CB CA C9 C8

C7

BF

B7

AF

A7

9F

97

8F

87

MGG029

PSW

PWME1

DFCON

IP0

P3

IEN0

P2

not used

P1

TCON

P0

Fig.5 Special Function Registers bit addresses.

1997 Dec 12 11

Page 12

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

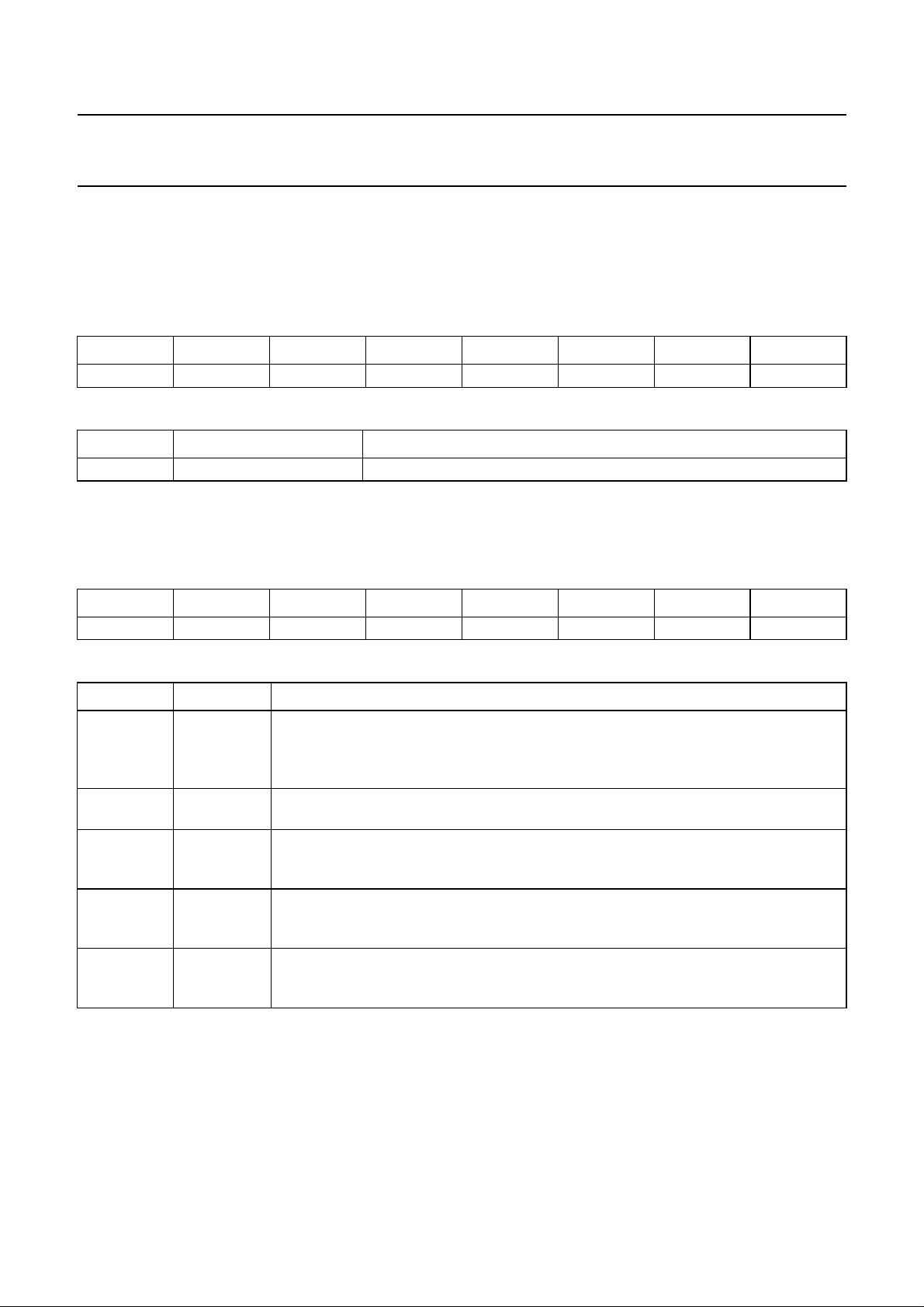

7.3 Additional Special Function Registers

The standard SFRs as used in 80C51 and the SFRs for some typical derivative functions like I2C-bus interface, Timer,

etc. are described in the

chapters. Some SFRs which are not mentioned or not dedicated to a certain function will be described in the following

sections.

All new additional SFRs used in the P83C880 are listed in Table 4. However, only some of them will be explained in detail

in Sections 7.3.1 to 7.3.7.

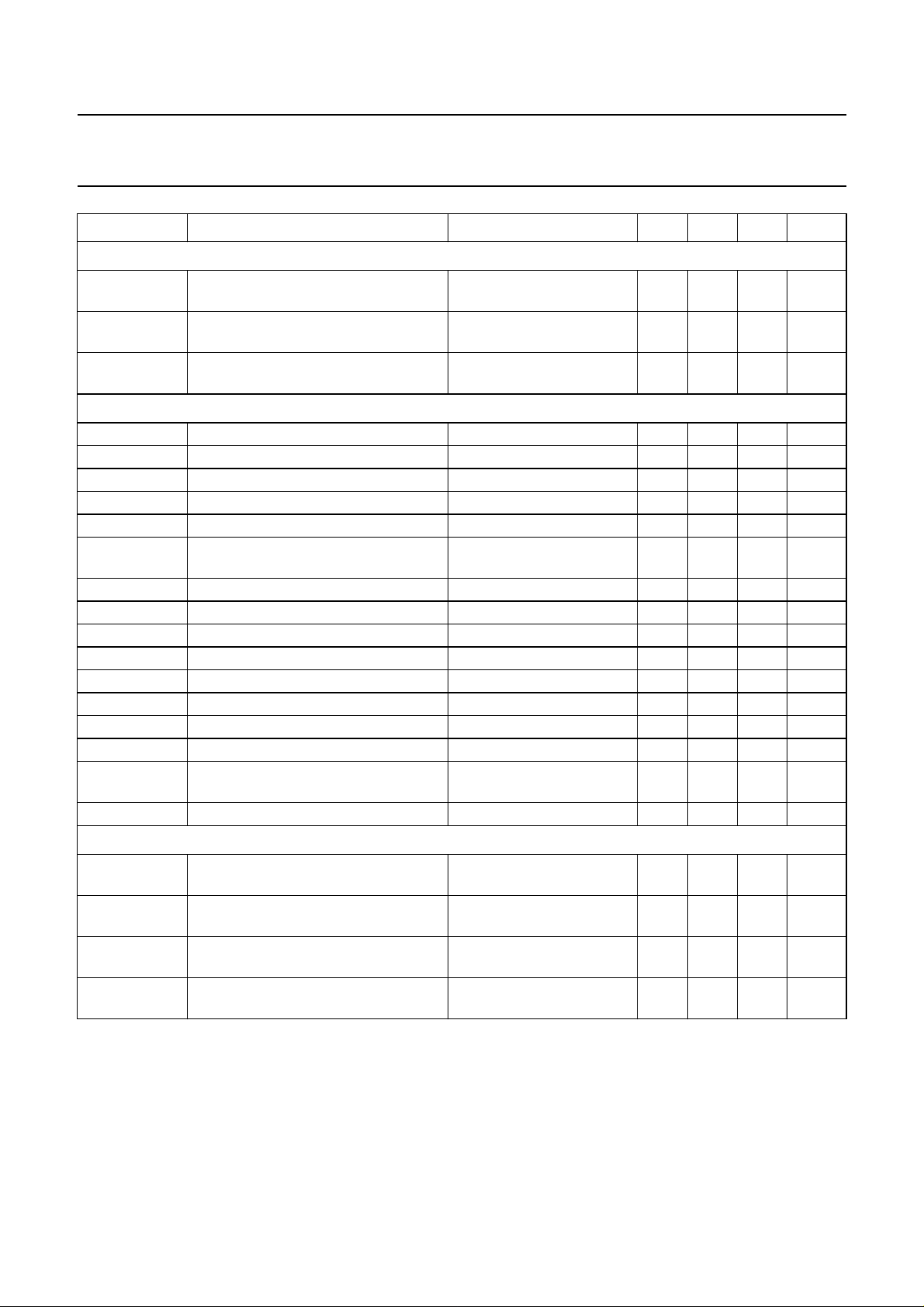

Table 4 Overview of additional SFRs

REGISTER DESCRIPTION ADDRESS RESET VALUE

RAMBUF RAM Buffer I/O Interface Register 9CH XXXXXXXX B

DDCCON DDC Control Register 9DH X00X0000 UBBUBBBB

DDCADR DDC Address Pointer 9EH 00000000 B

DDCDAT Data Shift Register for DDC1 9FH 00000000 B

DFCON Miscellaneous Control Register C0H 10000000 B

ADCDAT ADC Control Register C1H XX000000 UUBBBBBR

PWM10H PWM High-byte Data Latch C6H 00000000 B

PWM10L PWM Low-byte Data Latch C7H 10000000 B

S1CON Control Register for DDC2 D8H 00000000 B

S1STA Status Register for DDC2 D9H 11111000 R

S1DAT Data Shift Register for DDC2 DAH 00000000 B

S1ADR Address Register for DDC2 DBH 00000000 B

PWME1 PWM Output Control Register 1 C8H 00000000 B

PWME2 PWM Output Control Register 2 E8H 00000000 B

PWM0 to PWM9 Data Latches for 8-bit PWMs C9H to CFH,

DAC0 to DAC3 8-bit Data Latches for 8-bit DACs E9H to ECH 00000000 B

HFP Free run Control Register for HSYNC

HFPOPW Free run and Pulse width for HSYNC

MDCST Mode Detect Control and Status Register F8H 1X000000 BUBBRRRR

VFP Free run Control Register for VSYNC

VFPOPW Free run and Pulse width for VSYNC

PULCNT Pulse Generation Control Register FBH 00000000 B

HFHIGH Horizontal Period Counting High-byte

VFHIGH Vertical Period Counting High-byte Register FDH 00000000 R

VFLHFL Vertical and Horizontal Period Counting

T2 Watchdog Timer Data Register FFH 00000000 B

“Data Handbook IC20”

Register

Low-nibbles Register

. The specific SFRs for the P83C880 are introduced in the relevant

(1)

READ/WRITE

o

00000000 B

EDH to EFH

out

out

out

out

F6H 01100000 B

F7H 00011111 B

F9H 01000000 B

FAH XX000101 B

FCH 00000000 R

FEH 00000000 R

o

o

o

(2)

O

Notes

1. X = don’t care; even if it’s implemented.

2. B = both read/write and R

= read only; accessible for the entire byte or an individual bit. U = not implemented.

o

1997 Dec 12 12

Page 13

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

7.3.1 RAM BUFFER I/O INTERFACE REGISTER (RAMBUF)

RAMBUF is used as an I/O interface to the RAM buffer. If it is associated with the address pointer DDCADR which is

equipped with the capability of post increment, then it will be convenient to transfer the consecutive data stream. This

feature is useful to support the DDC/EDID data transfer.

Table 5 RAM Buffer I/O Interface Register (SFR address 9CH)

76543210

RAMBUF.7 RAMBUF.6 RAMBUF.5 RAMBUF.4 RAMBUF.3 RAMBUF.2 RAMBUF.1 RAMBUF.0

Table 6 Description of RAMBUF bits

BIT SYMBOL DESCRIPTION

7 to 0 RAMBUF.7 to RAMBUF.0 8-bit data which is read from or to be written into RAM buffer

7.3.2 M

This register is bit-addressable.

Table 7 Miscellaneous Control Register (SFR address C0H)

ISCELLANEOUS CONTROL REGISTER (DFCON)

76543210

EW2 SOGE SYNCE DDCE S1E ADCE P14LVL P8LVL

Table 8 Description of DFCON bits

BIT SYMBOL DESCRIPTION

7 EW2 Watchdog Timer enable flag. This flag is associated with the flags, EW1 (SFR

PWM10H) and EW0 in (SFR PWM10L) to form the enable/disable control key for the

Watchdog Timer (see Chapter 9). The Watchdog Timer is only disabled by

EW2 to EW0 = 101, else it is kept enabled for the rest of the combinations.

6 SOGE CSYNC

enable for pin CSYNCin/P1.6. If SOGE = 1, the pin function is CSYNCin. If

in

SOGE = 0, the pin function is I/O port P1.6.

5 SYNCE Sync separated signals output enable for pins VSYNC

If SYNCE = 1, the pins function as VSYNC

and HSYNC

out

/P1.4 and HSYNC

out

respectively.

out

out

If SYNCE = 0, the pins function as I/O ports P1.4 and P1.5 respectively.

4 DDCE Enable for DDC interface pins SCL1/P1.2 and SDA1/P1.3. If DDCE = 1, the pins

function as SCL1 and SDA1 respectively for the DDC interface. If DDCE = 0, the pins

function as I/O ports P1.2 and P1.3 respectively.

3 S1E Enable for I

2

C-bus interface pins SCL/P1.0 and SDA/P1.1. If S1E = 1, the pins

function as SCL and SDA respectively for the I2C-bus interface. If S1E = 0, the pins

function as I/O ports P1.0 and P1.1 respectively.

/P1.5.

1997 Dec 12 13

Page 14

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

BIT SYMBOL DESCRIPTION

2 ADCE ADC channel enable. This flag enables the ADC function and also switches the pins

ADC0/P3.2 and ADC1/P3.3 to the ADC inputs function. If ADCE = 1, the ADC function

is enabled and the pin functions are ADC0 and ADC1 respectively. If ADCE = 0, the

ADC function is disabled and the pin functions are I/O ports P3.2 and P3.3 respectively.

1 P14LVL Polarity selection bit for the PWM10 output (14-bit PWM). If P14LVL = 1, PWM10

output is inverted. If P14LVL = 0, PWM10 output is not inverted.

0 P8LVL Polarity selection bit for the PWM0 to PMM9 outputs (8-bit PWM). If P8LVL = 1,

PWM0 to PWM9 outputs are inverted. If P8LVL= 0, PWM0 to PWM9 outputs are not

inverted.

7.3.3 ADC CONTROL REGISTER (ADCDAT)

Table 9 ADC Control Register (SFR address C1H)

76543210

−−DACHL DAC3 DAC2 DAC1 DAC0 COMP

Table 10 Description of ADCDAT bits

BIT SYMBOL DESCRIPTION

7 to 6 − Reserved.

5 DACHL ADC input channels selection. If DACHL = 1, then input channel

ADC1 is selected. If DACHL = 0, then input channel ADC0 is selected.

4 to 1 DAC3 to DAC0 Reference voltage level selection. The 4 bits select the analog output

voltage (V

0 COMP Comparison result; read only. If COMP = 1, then the ADC input

voltage is higher than the reference voltage. If COMP = 0, then the ADC

input voltage is lower than the reference voltage.

7.3.4 14-

Table 11 PWM High-byte Data Latch (PWM10H; SFR address C6H)

EW1 PWM10H.6 PWM10H.5 PWM10H.4 PWM10H.3 PWM10H.2 PWM10H.1 PWM10H.0

Table 12 Description of PWM10H bits

6 to 0 PWM10H.6 to PWM10H.0 7 upper data bits for the 14-bit PWM.

BIT PWM DATA LATCHES (PWM10H AND PWM10L)

76543210

BIT SYMBOL DESCRIPTION

7 EW1 Watchdog Timer enable flag. This flag is associated with the flag EW2

(SFR DFCON) and EW0 (SFR PWM10L) to form the enable/disable

control key for the Watchdog Timer; see Tables 8 and 14.

) of the 8-bit DAC. For V

ref

values see Table 31.

ref

1997 Dec 12 14

Page 15

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

Table 13 PWM Low-byte Data Latch (PWM10L; SFR address C7H)

76543210

EW0 PWM10L.6 PWM10L.5 PWM10L.4 PWM10L.3 PWM10L.2 PWM10L.1 PWM10L.0

Table 14 Description of PWM10L bits

BIT SYMBOL DESCRIPTION

7 EW0 Watchdog Timer enable flag. This flag is associated with the flag EW2

(SFR DFCON) and EW1 (SFR PWM10H) to form the enable/disable

control key for the Watchdog Timer; see Table 8 and 12.

6 to 0 PWM10L.6to PWM10L.0 7 lower data bits for the 14-bit PWM.

7.3.5 PWM O

Table 15 PWM Output Control Register 1 (SFR address C8H)

76543210

PWME1.7 PWME1.6 PWME1.5 PWME1.4 PWME1.3 PWME1.2 PWME1.1 PWME1.0

Table 16 Description of PWME1 bits

UTPUT CONTROL REGISTER 1 (PWME1)

BIT SYMBOL DESCRIPTION

7 to 0 PWME1.7

to

PWME1.0

PWM outputs enable; n=7to0. If PWME1.n = 1, the corresponding PWM is enabled

and pins PWMn/P2.n are switched to PWMn outputs. If PWME1.n = 0, the

corresponding PWM is disabled and pins PWMn/P2.n are switched to I/O ports P2.n

function.

1997 Dec 12 15

Page 16

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

7.3.6 PWM OUTPUT CONTROL REGISTER 2 (PWME2)

Table 17 PWM Output Control Register 2 (SFR address E8H)

76543210

PATENA DACE3 DACE2 DACE1 DACE0 PWME2.2 PWME2.1 PWME2.0

Table 18 Description of PWME2 bits

BIT SYMBOL DESCRIPTION

7 PATENA PATOUT (pattern output) enable. If PATENA = 1, the pin

PWM9/PATOUT/P3.1 is switched to the PATOUT (display test pattern)

output. If PATENA = 0, the PATOUT function is disabled. The PATOUT

function always overrides other alternative functions such as PWM9 and

P3.1.

6 to 3 DACE3 to DACE0 DAC outputs enable (n=3to0). If DACEn = 1, the corresponding

DACs: DAC3 to DAC0 are enabled. If DACEn = 0, the corresponding

DACs: DAC3 to DAC0 are disabled.

2 to 0 PWME2.2 to PWME2.0 PWM outputs enable; n = 2 to 0. If PWME2.n = 1, the corresponding

PWMs: PWM8, PWM9 and PWM10, are enabled by PWME2.2,

PWME2.1 and PWME2.0 respectively and pins PWM8/CLAMP/P3.0,

PWM9/PATOUT/P3.1 and PWM10/P1.7 are switched to PWM output. If

PWME2.n = 0, the corresponding PWM is disabled. Pins

PWM8/CLAMP/P3.0, PWM9/PATOUT/P3.1 and PWM10/P1.7 are

switched to I/O port functions P3.0, P3.1 and P1.7 respectively.

7.3.7 D

Table 19 Data Latches for 8-bit PWMs (n = 0 to 9; SFR address C9H to CFH and EDH to EFH)

PWMn.7 PWMn.6 PWMn.5 PWMn.4 PWMn.3 PWMn.2 PWMn.1 PWMn.0

Table 20 Description of PWM0 to PWM9 bits

ATA LATCHES FOR 8-BIT PWMS (PWM0 TO PWM9)

76543210

BIT SYMBOL DESCRIPTION

7 to 0 PWMn.7 to PWMn.0 8-bit data for PWM channel n (n = 0 to 9)

1997 Dec 12 16

Page 17

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

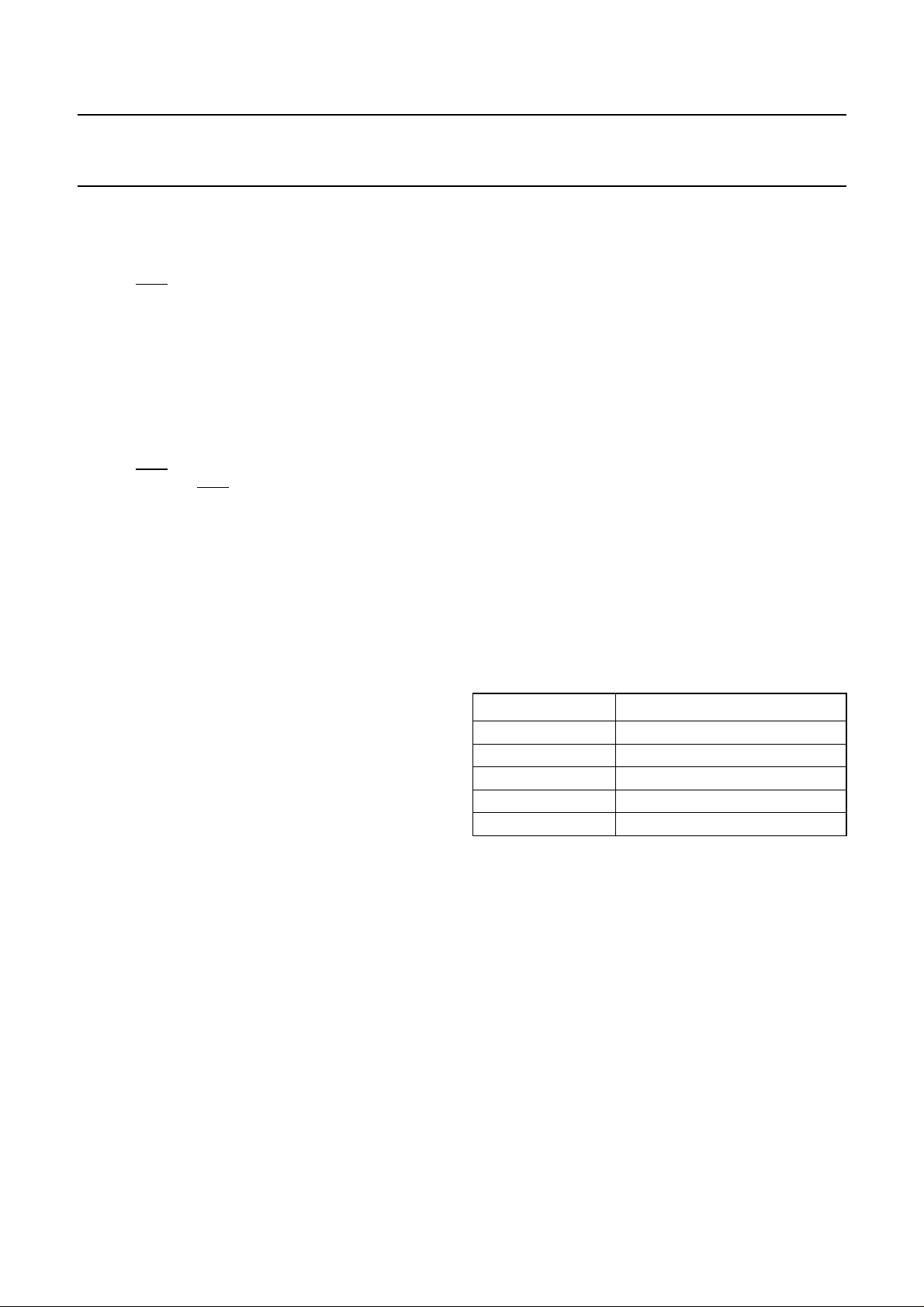

8 INTERRUPTS

The P83C880 has 5 interrupt sources; these are shown in

Fig.6.

Interrupt INT1 is generated as in a normal 80C51 device.

By means of IT1 in SFR TCON this interrupt can be

selected to be:

• Level sensitive, when IT1 = LOW; INT1 must be inactive

before a return from interrupt instruction (RETI) is given,

otherwise the same interrupt will occur again.

• Edge sensitive, when IT1 = HIGH; the internal hardware

will reset the latch when the LCALL instruction is

executed for the vector address (see Table 21).

Interrupt

detector. Interrupt INT0 is selected as edge or level

sensitive by the state of the IT0 bit in the SFR TCON.

However, it is recommended to always set IT0 to HIGH

(edge sensitive) so that IE0 will be reset by the internal

hardware when the LCALL instruction is executed for the

vector address.

Timer 0 and Timer 1 interrupts are generated by TF0 and

TF1 which are set by an overflow of their respective

Timer/Counter registers (except for Timer 0 in Mode 3;

see

Timer/Counters”

interrupt flag is cleared by the internal hardware when the

LCALL instruction is executed for the vector address.

The DDC interrupt is generated either by bit SI (SFR

S1CON) for DDC2B/DDC2AB/DDC2B+ protocols or by bit

DDC_int (SFR DDCCON) or by bit SWHINT (SFR

DDCCON). These flags must be cleared by software.

All bits that generate interrupts can be set or cleared by

software, with the same result as though it had been set or

cleared by hardware. That is, interrupts can be generated

or pending interrupts can be cancelled in software.

INT0 is generated by the mode change of mode

“Data Handbook IC20; 80C51 Family; Chapter

). When a timer interrupt is generated, the

Each of these interrupts sources can be individually

enabled or disabled by setting or clearing the bit in Special

Function Register IE (see Table 23). IE also contains a

global disable bit EA, which disables all interrupts at once.

8.1 Priority level structure

The priority level of each interrupt source can be

individually programmed by setting or clearing a bit in

Special Function Register IP (see Table 25). A low priority

interrupt can itself be interrupted by a high priority

interrupt, but not by another low priority interrupt. A high

priority interrupt can not be interrupted by another interrupt

source.

If two requests of different priority levels are received

simultaneously, the request of higher priority level is

serviced. If request of the same priority level is received

simultaneously, an internal polling sequence determines

which request is serviced. Thus within each priority level

there is a second priority structure determined as shown in

Table 21. The IP register contains a number of reserved

(in 80C51) bits: IP.7, IP.6 and IP.4. User software should

not write logic 1s to these positions, since they may be

used in other 80C51 family products.

Table 21 Priority within levels

Note

1. The ‘Priority within level’ structure is only used to

P83Cx80; P87C380

SOURCE PRIORITY WITHIN LEVEL

IE0′ 1 (highest)

SI 2

TF0 3

IE1′ 4

TF1 5 (lowest)

resolve simultaneous requests of the same priority

level.

(1)

1997 Dec 12 17

Page 18

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

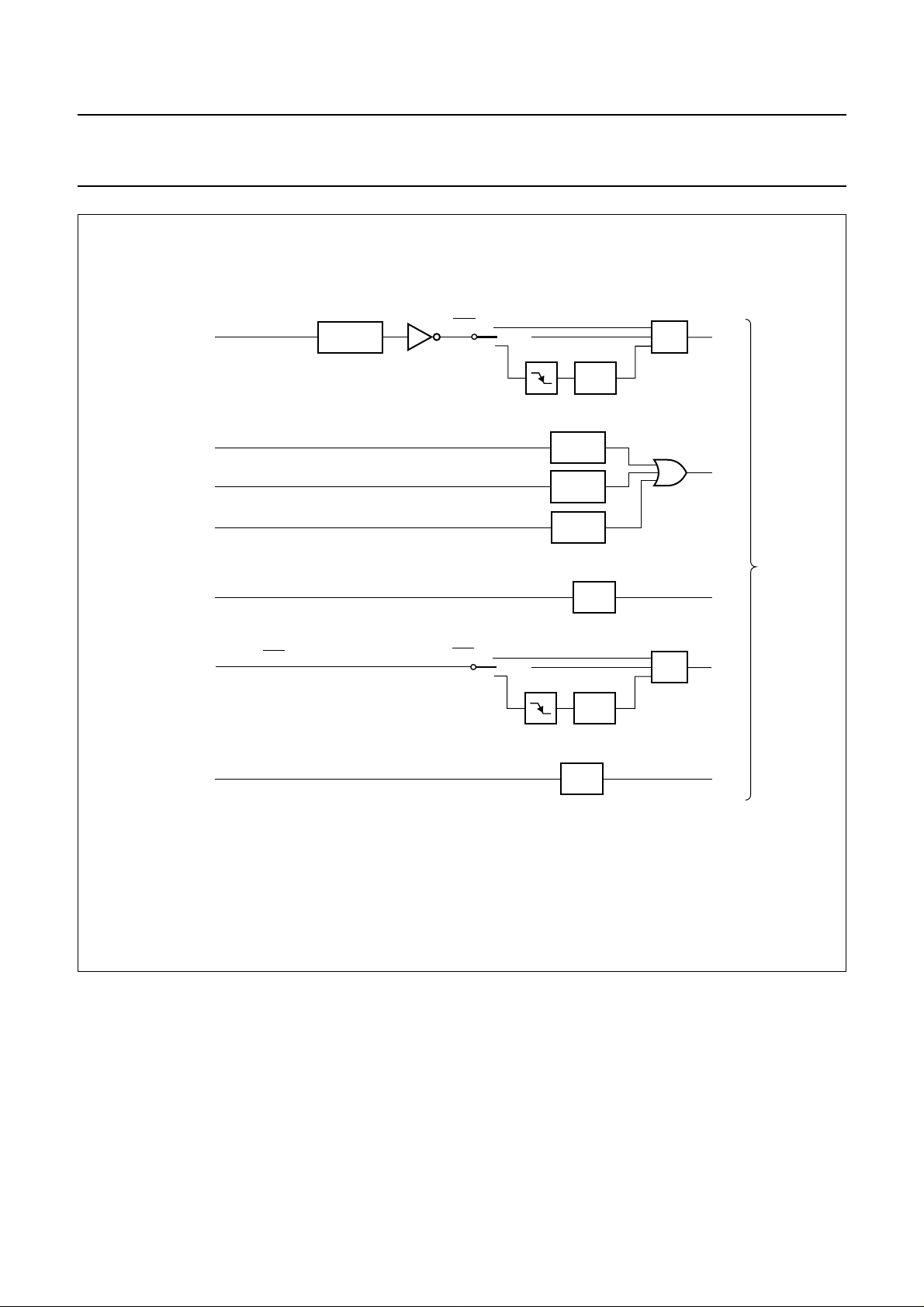

handbook, full pagewidth

mode change interrupt

SWITCH interrupt

DDC1 interrupt

DDC2 (DDC2B/DDC2AB/DDC2B+) interrupt

Timer 0 overflow

CHREQ

INT0

'0'

IT0

'1'

IE0

SWH INT

DDC INT

S12

TF0

P83Cx80; P87C380

MUX

IE0´

SI

interrupt

sources

TF0

external interrupt INT1

Timer 1 overflow

'0'

INT1

IT1

'1'

Fig.6 Interrupt sources.

TF1

IE1

MUX

IE1´

TF1

MGG024

1997 Dec 12 18

Page 19

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

8.2 How interrupts are handled

The interrupt flags are sampled at the S5P2 state of every

machine cycle. The samples are polled during the

following machine cycle. If one of the flags was in a set

condition at S5P2 of the preceding cycle, the polling cycle

will find it and the interrupt system will generate an LCALL

to the appropriate service routine, provided this hardware

generated LCALL is not blocked by any of the following

conditions:

1. An interrupt of equal priority or higher priority level is

already in progress.

2. The current (polling) cycle is not the final cycle in the

execution of the instruction in progress.

3. The instruction in progress is RETI or any write to the

IE or IP registers.

Any of these conditions will block the generation of the

LCALL to the interrupt service routine. Condition 2

ensures that the instruction in progress will be completed

before vectoring to any service routine.

Condition 3 ensures that if the instruction in progress is

RETI or any access to IE or IP, then at least one more

instruction will be executed before the interrupt is vectored

to.The polling cycle is repeated with each machine cycle,

and the values polled are the values that were present at

S5P2 of the previous machine cycle. Note that if an

interrupt flag is active but not being responded to for one

of the above mentioned conditions, and if the flag is still

inactive when the blocking condition is removed, then the

denied interrupt will not be serviced. In other words, the

fact that the interrupt flag was once active but not serviced

is not remembered. Every polling cycle is new.

The polling cycle/LCALL sequence is illustrated in

“Data

Handbook IC20; 80C51 family hardware description;

Figure: Interrupt Response Timing Diagram”

.

Note that if an interrupt of higher priority level becomes

active prior to S5P2 of the machine cycle labelled C3 (see

“Data Handbook IC20; 80C51 family hardware description;

Figure: Interrupt Response Timing Diagram”

accordance with the above rules it will be vectored to

during C5 and C6, without any instruction of the lower

priority routine having been executed. Thus the processor

acknowledges an interrupt request by executing a

hardware generated LCALL to the appropriate servicing

routine. The hardware generated LCALL pushes the

contents of the Program Counter on to the stack (but it

does not save the PSW) and reloads the PC with an

address that depends on the source of the interrupt being

vectored to as shown in Table 22.

Execution proceeds from that location until the RETI

instruction is encountered. The RETI instruction informs

the processor that the interrupt routine is no longer in

progress, then pops the top two bytes from the stack and

reloads the Program Counter. Execution of the interrupted

program continues from where it left off.

Note that a simple RET instruction would also return

execution to the interrupted program, but it would have left

the interrupt control system thinking an interrupt was still in

progress, making future interrupts impossible.

Table 22 Vector addresses

P83Cx80; P87C380

), then in

SOURCE VECTOR ADDRESS

IE0′ 0003H

SI 002BH

TF0 000BH

IE1′ 0013H

TF1 001BH

1997 Dec 12 19

Page 20

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

8.3 Interrupt Enable Register (IE)

Table 23 Interrupt Enable Register (SFR address A8H)

76543210

EA − ES1 − ET1 EX1 ET0 EX0

Table 24 Description of IE bits

BIT SYMBOL FUNCTION

7EADisable all interrupts. If EA = 0, then no interrupt will be acknowledged. If EA = 1, then

each interrupt source is individually enabled or disabled by setting or clearing its enable

bit.

6 − Reserved.

5 ES1 Enable DDC interface interrupt. If ES1 = 1, then DDC interface interrupt is enabled.

If ES1 = 0, then DDC interface interrupt is disabled.

4 − Reserved.

3 ET1 Enable Timer 1 overflow interrupt. If ET1 = 1, then the Timer 1 interrupt is enabled.

If ET1 = 0, then the Timer 1 interrupt is disabled.

2 EX1 Enable external interrupt 1. If EX1 = 1 then the External 1 interrupt is enabled.

If EX1 = 0 then the External 1 interrupt is disabled.

1 ET0 Enable Timer 0 overflow interrupt. If ET0 = 1 then the Timer 0 interrupt is enabled.

If ET0 = 0 then the Timer 0 interrupt is disabled.

0 EX0 Enable mode change. If EX0 = 1 then the mode change interrupt is enabled.

If EX0 = 0 then the mode change interrupt is disabled.

8.4 Interrupt Priority Register (IP)

Table 25 Interrupt Priority Register (address B8H)

76543210

−−PS1 − PT1 PX1 PT0 PX0

Table 26 Description of IP bits

BIT SYMBOL DESCRIPTION

7to6 − Reserved.

5 PS1 DDC interface Interrupt priority level. When PS1 = 1, DDC interface Interrupt is

assigned a high priority level.

4 − Reserved.

3 PT1 Timer 1 overflow interrupt priority level. When PT1 = 1, Timer 1 Overflow Interrupt is

assigned a high priority level.

2 PX1 External interrupt 1 priority level. When PX1 = 1, External Interrupt 1 priority is

assigned a high priority level.

1 PT0 Timer 0 overflow interrupt priority level. When PT0 = 1, Timer 0 Overflow Interrupt is

assigned a high priority level.

0 PX0 Mode change interrupt priority level. When PX0 = 1, Mode change Interrupt is

assigned a high priority level.

1997 Dec 12 20

Page 21

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

9 WATCHDOG TIMER

In addition to the standard timers, a Watchdog Timer

consisting of an 10-bit prescaler and an 8-bit timer is also

incorporated. The timer is increased every 19.5 ms for an

oscillator frequency of 16 MHz; this is derived from the

oscillator frequency (f

f

f

timer

=

clk

----------------------------304 1024×

) by the formula:

clk

When a timer overflow occurs, the microcontroller is reset.

To prevent a system reset, the timer must be reloaded

before an overflows occurs, by the application software.

If the processor suffers a hardware/software malfunction,

the software will fail to reload the timer. This failure will

produce a reset upon overflow thus preventing the

processor running out of control.

The Watchdog Timer can only be reloaded if the condition

flag WLE (PCON.4) has been previously set by software.

At the moment the counter is loaded the condition flag is

automatically cleared.

In the Idle mode the Watchdog Timer and reset circuitry

remain active.

The time interval between timer reloading and the

occurrence of a reset, depends on the reloaded value.

The Watchdog Timer’s time interval is:

tt

Where T2 = decimal value of the T2 register contents and

t

1

and t1=19µs (f

For example, this may range from 19.5 ms to 5.0 s when

using an oscillator frequency of 16 MHz.

Table 27 lists the resolution and the maximum time interval

of the Watchdog Timer using different system clocks.

The Watchdog Timer is controlled by the Watchdog control

bits:

• EW2; DFCON.7 (SFR address C0H)

• EW1; PWM10H.7 (SFR address C6H)

• EW0; PWM10L.7 (SFR address C6H).

Only when EW2 to EW0 = 101 the Watchdog Timer is

disabled and allows the Power-down mode to be enabled.

The rest of pattern combinations will keep the Watchdog

Timer enabled and disable the Power-down mode.

This security key with multiple flags split in two SFRs will

prevent the Watchdog Timer from being terminated

abnormally when the function of the Watchdog Timer is

needed.

1024

×=

-----------------------------

1

256 T2–()

= 15.2 µs (f

P83Cx80; P87C380

= 10 MHz); t1= 12.7 µs (f

clk

= 16 MHz).

clk

= 12 MHz)

clk

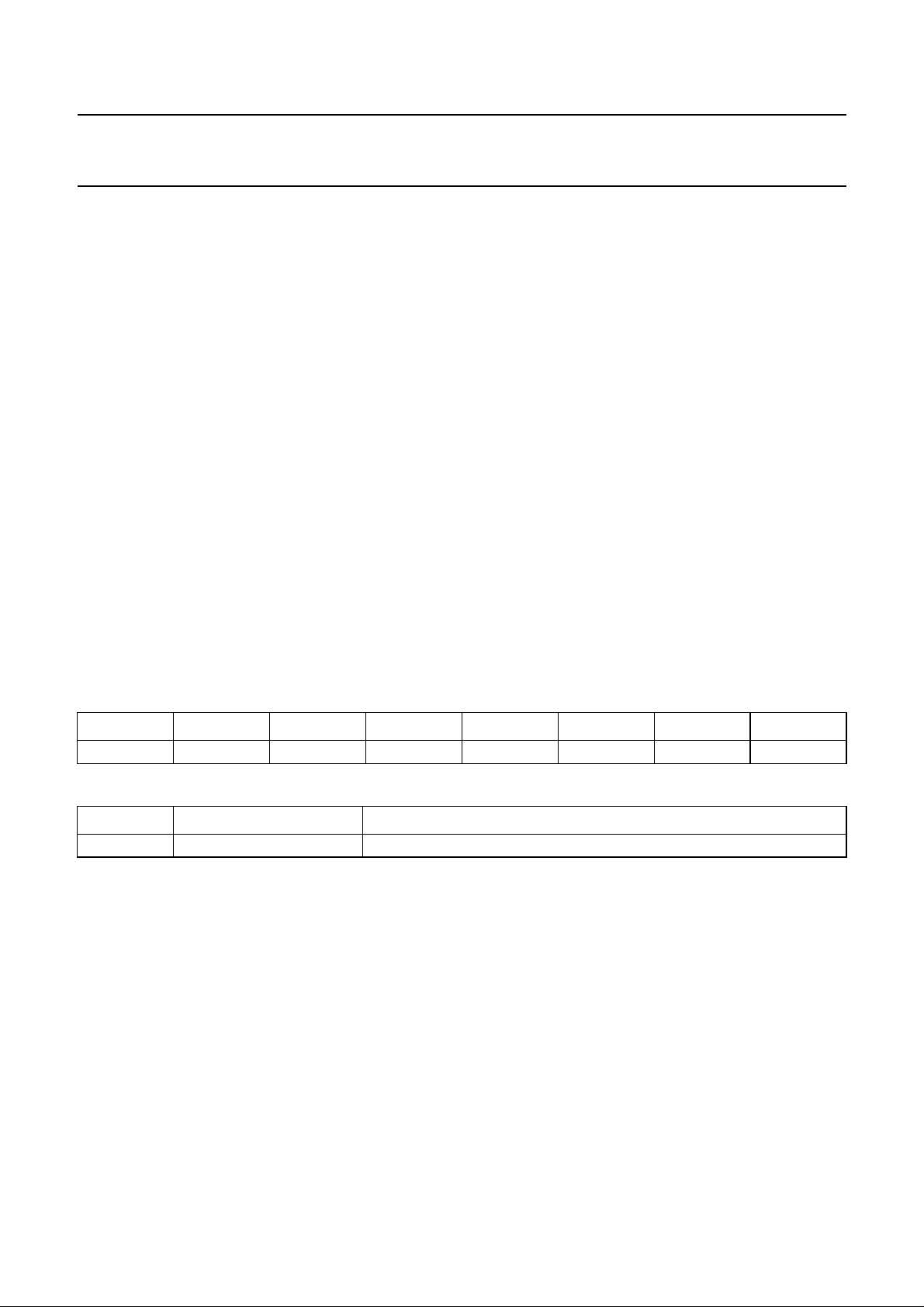

Table 27 Resolution and the maximum time interval of the WDT

f

clk

(MHz)

PRESCALER FACTOR

RESOLUTION

10 152 15.56 4.0

12 12.97 3.3

16 304 19.46 5.0

(ms)

MAXIMUM TIME INTERVAL

(s)

1997 Dec 12 21

Page 22

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

10 INPUT/OUTPUT (I/O)

The P83C880 has three 8-bit ports. Ports 0 to 2 are the

same as in the 80C51, with the exception of the additional

functions of Port 1 and Port 2. Port 3 only contains 4 bits.

Port 3 also has alternative functions.

All ports are bidirectional. Pins of which the alternative

function is not used may be used as normal bidirectional

I/Os.

The use of Port 1, Port 2 and Port 3 pins as an alternative

function is carried out automatically by the P83C880

provided the associated Special Function Register bit is

set HIGH.

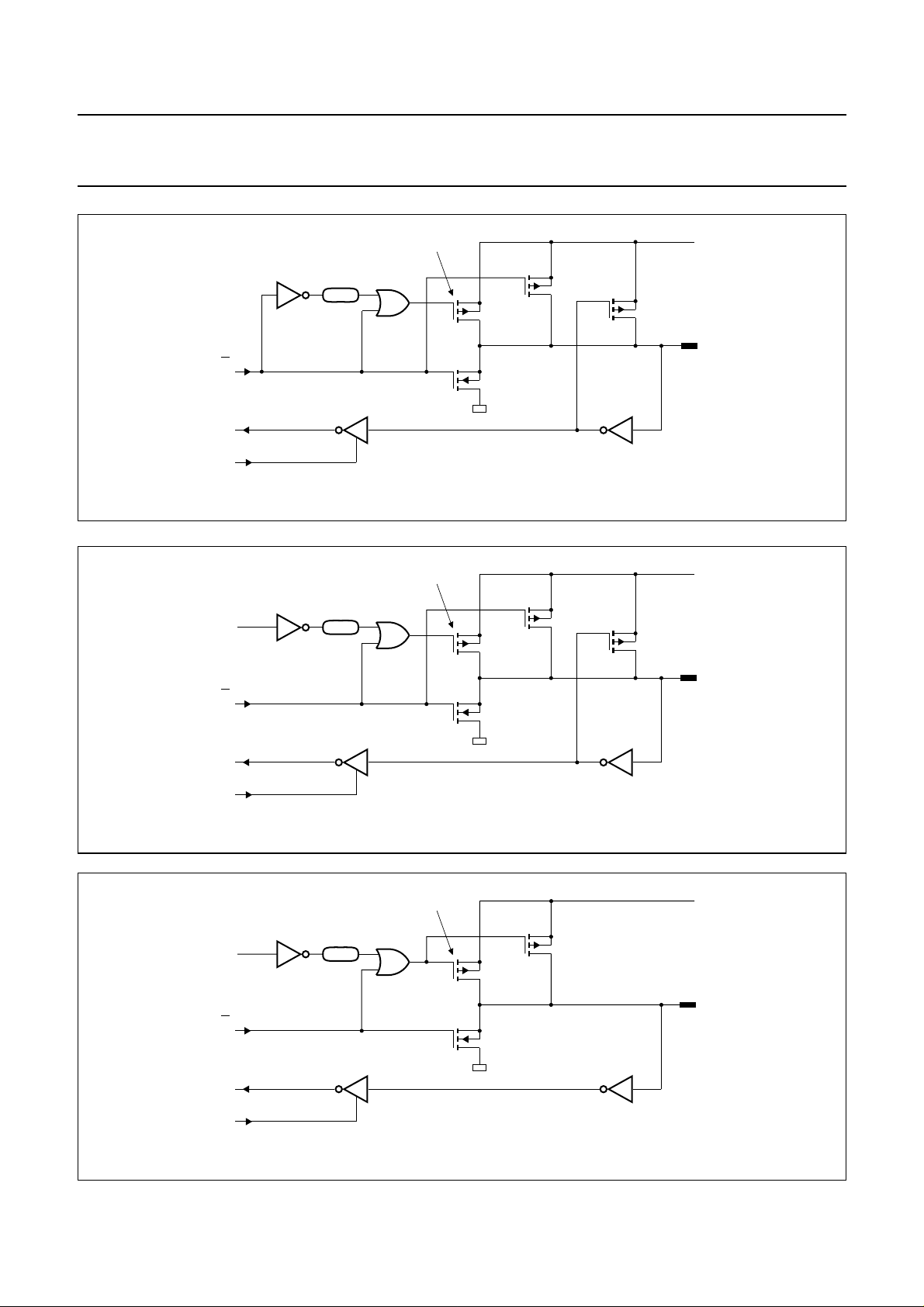

The quasi-bidirectional type of port is applied for Port 1,

Port 2 and Port 3. Port 0 is an open-drain I/O port with the

capability to drive LED. However, for any port with an

alternative function, while the alternative function is

performed, the port type will be switched to the appropriate

type against a specific function. The port types:

quasi-bidirectional, pull-up and open-drain are shown in

Figs 7, 8 and 9 respectively.

10.1 The alternative functions for Port 0, Port 1,

Port 2 and Port 3

Port 0 Provides the low-order address in

programming/verify mode for the P87C380.

Port 1 Used for a number of special functions:

• 2 I/O pins for I

2

C-bus interface: SCL/P1.0 and

SDA/P1.1. The port type in this situation is set as

open-drain.

• 2 I/O pins for DDC interface: SCL1/P1.2 and

SDA1/P1.3. The port type in this situation is set

as open-drain.

• 2 I/O pins for the outputs of sync separation:

VSYNC

/P1.4 and HSYNC

out

/P1.5. The port

out

type in this situation is set as push-pull.

• One pin for the composite sync input of sync on

green mode: CSYNCin/P1.6. There is no pull-up

protection diode for this input pin.

• One pin for the 14-bit PWM output:

PWM10/P1.7. As PWM function, the port type is

open-drain.

Port 2 Two alternative functions are provided:

Port 3 Two alternative functions are provided:

10.2 EMI (Electromagnetic Interference) reduction

In order to reduce EMI (Electromagnetic Interference) the

following design measures have been taken:

• Slope control is implemented on all the I/O lines with

• Placing the VDD and VSS pins next to each other

• Double bonding of the VDD and VSS pins,

• Limiting the drive capability of clock drivers and

• Applying slew rate controlled output drivers

• Internal decoupling of the supply of the CPU core.

P83Cx80; P87C380

• High-order address in Programming/Verify mode

for P87C380.

• 8 channels of PWM outputs:

PWM0/P2.0 to P2.7/PWM7. The port type in this

situation is set as open-drain.

• Two channels of PWM output:

PWM8/CLAMP/P3.0 and PWM9/PATOUT/P3.1.

The port type in this situation is set as

open-drain. PATOUT and CLAMP functions

always override PWM or port function even if

they are enabled. For the PATOUT (pattern

output) and CLAMP (clamping output)

application, the port type is defined as push-pull.

• Two pins for the software ADC input: ADC0/P3.2

and ADC1/P3.3. They are analog inputs.

alternative functions of the PWM, I2C-bus and DDC

interface. For port pins P1.4 and P1.5, since the

alternative functions VSYNC

incorporated, the driving capability is made as small as

possible to reduce radiation and the slope control

function is disabled to have a sharp output. Rise and fall

time (10% to 90%) for slope control are:

t

< rise/fall time < t

rf(min)

rf(max)

Refer to Chapter 27 for the detailed figures.

i.e. 2 bondpads for each pin

prechargers

and HSYNC

out

.

out

are

1997 Dec 12 22

Page 23

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

handbook, full pagewidth

from port latch

read port pin

handbook, full pagewidth

input data

2 oscillator

periods

Q

Fig.7 Standard output with quasi-bidirectional port.

2 oscillator

'1'

periods

strong pull-up

INPUT

BUFFER

strong pull-up

p1

n

p1

P83Cx80; P87C380

V

DD

p2

p3

I/O PIN

I1

MGG025

V

DD

p2

p3

from port latch

read port pin

handbook, full pagewidth

from port latch

read port pin

input data

input data

I/O PIN

Q

INPUT

BUFFER

n

I1

MGG026

Fig.8 Standard output with the pull-up current source.

strong pull-up

2 oscillator

'0'

Q

periods

INPUT

BUFFER

p1

n

p2

I1

V

DD

I/O PIN

MGG027

Fig.9 Standard output with the open-drain port.

1997 Dec 12 23

Page 24

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

11 REDUCED POWER MODES

Two software selectable modes of reduced power

consumption are implemented. These are the Idle mode

and the Power-down mode.

11.1 Power Control Register (PCON)

The Idle mode and Power-down mode are activated by

software via the Power Control Register (SFR PCON).

Its hardware address is 87H. PCON is not bit addressable.

The reset value of PCON is 00H.

11.2 Idle mode

Idle mode operation permits the interrupts, I

interface, DDC interface, mode detection and timer blocks

T0, T1 and T2 (Watchdog Timer) to function while the CPU

is halted. The following functions are switched off when the

microcontroller enters the Idle mode:

• CPU (halted)

• PWM0 to PWM10 (reset, output = HIGH)

• 4-bit ADC (aborted if conversion is in progress)

• DAC0 to DAC3 (output = indeterminate or frozen at the

final value prior to the Idle instruction; decided by

software).

The following functions remain active during Idle mode;

these functions may generate an interrupt or reset and

thus terminate the Idle mode:

• Timer 0, Timer 1 and Timer 2 (Watchdog Timer)

• The DDC interface

• External interrupt

• Mode detection.

The instruction that sets PCON.0 is the last instruction

executed in the normal operating mode before Idle mode

is activated. Once in the Idle mode, the CPU status is

preserved in its entirety: the Stack Pointer, Program

Counter, Program Status Word, Accumulator, RAM and all

other registers maintain their data during Idle mode.

The status of external pins during Idle mode is shown in

Table 28.

There are three ways to terminate the Idle mode:

• Activation of any enabled interrupt X0, T0, X1, T1 or S1

will cause PCON.0 to be cleared by hardware

terminating Idle mode. The interrupt is serviced, and

following return from interrupt instruction RETI, the next

instruction to be executed will be the one which follows

the instruction that wrote a logic 1 to PCON.0.

2

C-bus

• The second way of terminating the idle mode is with an

• The third way of terminating the Idle mode is by an

In all cases the microcontroller restarts after 3 machine

cycles.

11.3 Power-down mode

In Power-down mode the system clock is halted. The

oscillator is frozen after setting the bit PD in the PCON

register.

The instruction that sets PCON.1 is the last executed prior

to going into the Power-down mode. Once in Power-down

mode, the oscillator is stopped.The content of the on-chip

RAM and the Special Function Registers are preserved.

Note that Power-down mode can not be entered when the

Watchdog Timer has been enabled.

The Power-down mode can be terminated by an external

reset in the same way as in the 80C51 (but the SFRs are

cleared due to RESET) or in addition by the external

interrupt, INT1.

A termination with INT1 does not affect the internal data

memory and the Special Function Registers. This gives

the possibility to exit from Power-down without changing

the port output levels. To terminate the Power-down mode

with an external interrupt, INT1 must be switched to be

level-sensitive and must be enabled. The external interrupt

input signal INT1 must be kept LOW till the oscillator has

restarted and stabilized. The instruction following the one

that put the device into the Power-down mode will be the

first one which will be executed after the wake-up.

P83Cx80; P87C380

The flag bits GF0 and GF1 may be used to determine

whether the interrupt was received during normal

execution or during Idle mode. For example, the

instruction that writes to PCON.0 can also set or clear

both flag bits. When Idle mode is terminated by an

interrupt, the service routine can examine the status of

the flag bits.

external hardware reset. Since the oscillator is still

running, the hardware reset is required to be active for

two machine cycles (24 oscillator periods) to complete

the reset operation.

internal watchdog reset.

1997 Dec 12 24

Page 25

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

P83Cx80; P87C380

interface, auto-sync detection and sync proc.

11.4 Status of external pins

• If the HSYNC

, VSYNC

out

, PATOUT or CLAMP output

out

is selected (for selection see description in Tables 8

and 18) in Idle or Power-down mode, since sync

separation is still alive in Idle mode, HSYNC

VSYNC

, PATOUT or CLAMP output will be operating

out

as normal. In Power-down mode: HSYNC

out

, VSYNC

out

,

out

PATOUT or CLAMP output are pulled HIGH.

• In Idle or Power-down mode, if bit DDCE (SFR DFCON)

is set, the function of P1.2 and P1.3 will be switched to

Table 28 Status of external pins during Idle and Power-down modes

HSYNC;

VSYNC;

CLAMP;

PATOUT

MODE MEMORY

PORT0

TO

PORT 3

Idle internal data operative High-Z operative HIGH unknown

Power-down internal data HIGH High-Z High-Z HIGH unknown

the DDC interface pins SCL1 and SDA1 respectively. In

Idle mode SCL1 and SDA1 can be active only if DDC1

or DDC2 is enabled; otherwise these pins are in the

high-impedance (High-Z) state.

• If bit PWME.n (SFR PWME1/PWME2) is set, the

function of P1.7, P2.n, P3.0 and P3.1 will be switched to

the PWM output function. However, in both Idle and

,

Power-down modes, the output of those PWM pins are

pulled HIGH.

SCL

AND

SDA

SCL1

AND

SDA1

PWM0

TO

PWM10

DAC0

TO

DAC3

1997 Dec 12 25

Page 26

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

12 OSCILLATOR

The oscillator circuit of the P83C880 is a single-stage

inverting amplifier in a Pierce oscillator configuration. The

circuitry between XTAL1 and XTAL2 is basically an

inverter biased to the transfer point. Either a crystal or

ceramic resonator can be used as the feedback element to

complete the oscillator circuit. Both are operated in parallel

resonance.

handbook, halfpage

XTAL1 XTAL2

MBE311

a. Crystal oscillator; C = 20 pF.

XTAL1 is the high gain amplifier input, and XTAL2 is the

output (see Fig.10a). To drive the P83C880 externally,

XTAL1 is driven from an external source and XTAL2 left

open-circuit (see Fig.10b).

handbook, halfpage

P83Cx80; P87C380

XTAL1 XTAL2

n.c.

external clock

(not TTL compatible)

b. External clock drive.

MBE312

handbook, halfpage

XTAL1 XTAL2

external clock

(not TTL compatible)

MLC930 - 1

c. External clock drive for P87C380.

Fig.10 Oscillator configurations.

1997 Dec 12 26

Page 27

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

13 RESET

There are three ways to invoke a reset and initialize the

P83C880:

• Via the external RESET pin

• Via the built-in Power-on-reset circuitry

• Via the Watchdog Timer overflow.

Table 29 Reset values of the Special Function Registers

X = Undefined. The internal RAM is not affected by reset.

ADDRESS REGISTER CONTENT

80H P0 1111 1111

81H SP 0000 0111

82H DPL 0000 0000

83H DPH 0000 0000

87H PCON 00000000

88H TCON 0000 0000

89H TMOD 0000 0000

8AH TL0 0000 0000

8BH TL1 0000 0000

8CH TH0 0000 0000

8DH TH1 0000 0000

90H P1 1111 1111

9CH RAMBUF 0000 0000

9DH DDCCON X00X 0000

9EH DDCADR 0000 0000

9FH DDCDAT 0000 0000

A0H P2 1111 1111

A8H IEN0 0X0X 0000

B0H P3 XXXX 1111

B8H IP0 XX0X 0000

C0H DFCON 1000 0000

C1H ADCDAT XX00 0000

C6H PWM10H 0000 0000

C7H PWM10L 1000 0000

C8H PWME1 0000 0000

C9H PWM0 0000 0000

CAH PWM1 0000 0000

CBH PWM2 0000 0000

CCH PWM3 0000 0000

Figure 11 illustrates the reset mechanism. Each reset

source will activate an internal reset signal RSTOUT. The

CPU responds by executing an internal reset and puts the

internal registers in a defined state as shown in Table 29.

P83Cx80; P87C380

ADDRESS REGISTER CONTENT

CDH PWM4 0000 0000

CEH PWM5 0000 0000

CFH PWM6 0000 0000

D0H PSW 00000000

D8H S1CON 0000 0000

D9H S1STA 1111 000

DAH S1DAT 0000 0000

DBH S1ADR 0000 0000

E0H ACC 0000 0000

E8H PWME2 0000 0000

E9H DAC0 0000 0000

EAH DAC1 0000 0000

EBH DAC2 0000 0000

ECH DAC3 0000 0000

EDH PWM7 0000 0000

EEH PWM8 0000 0000

EFH PWM9 0000 0000

F0H B 0000 0000

F6H HFP 0110 0000

F7H HFPOPW 0000 0101

F8H MDCST 1X00 0000

F9H VFP 0100 0000

FAH VFPOPW XX00 0101

FBH PULCNT 0000 0000

FCH HFHIGH 0000 0000

FDH VFHIGH 0000 0000

FEH VFLHFL 0000 0000

FFH T2 0000 0000

1997 Dec 12 27

Page 28

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

handbook, full pagewidth

8 kΩ

V

10 µF

R

RESET

DD

SCHMITT

TRIGGER

RESET

on-chip circuit

Power-on-reset

Fig.11 On-chip reset configuration.

RSTOUT

overflow timer T2

P83Cx80; P87C380

RESET

CIRCUITRY

POC

MGG022

13.1 External reset

Pin RESET is connected to a Schmitt trigger for noise

reduction (see Fig.11). A reset is accomplished by holding

the RESET pin HIGH for at least 16 machine cycles (192

system clocks) while the oscillator is running.

An automatic reset can be obtained by switching on VDD,

if the RESET pin is connected to VDD via a capacitor and

a resistor as illustrated in Fig.11. The VDD rise time must

not exceed 10 ms and the capacitor should be at least

10 µF. The decrease of the RESET pin voltage depends

on the capacitor and the external resistor R

RESET

. The

voltage must remain above the lower threshold for at least

the oscillator start-up time plus 2 machine cycles.

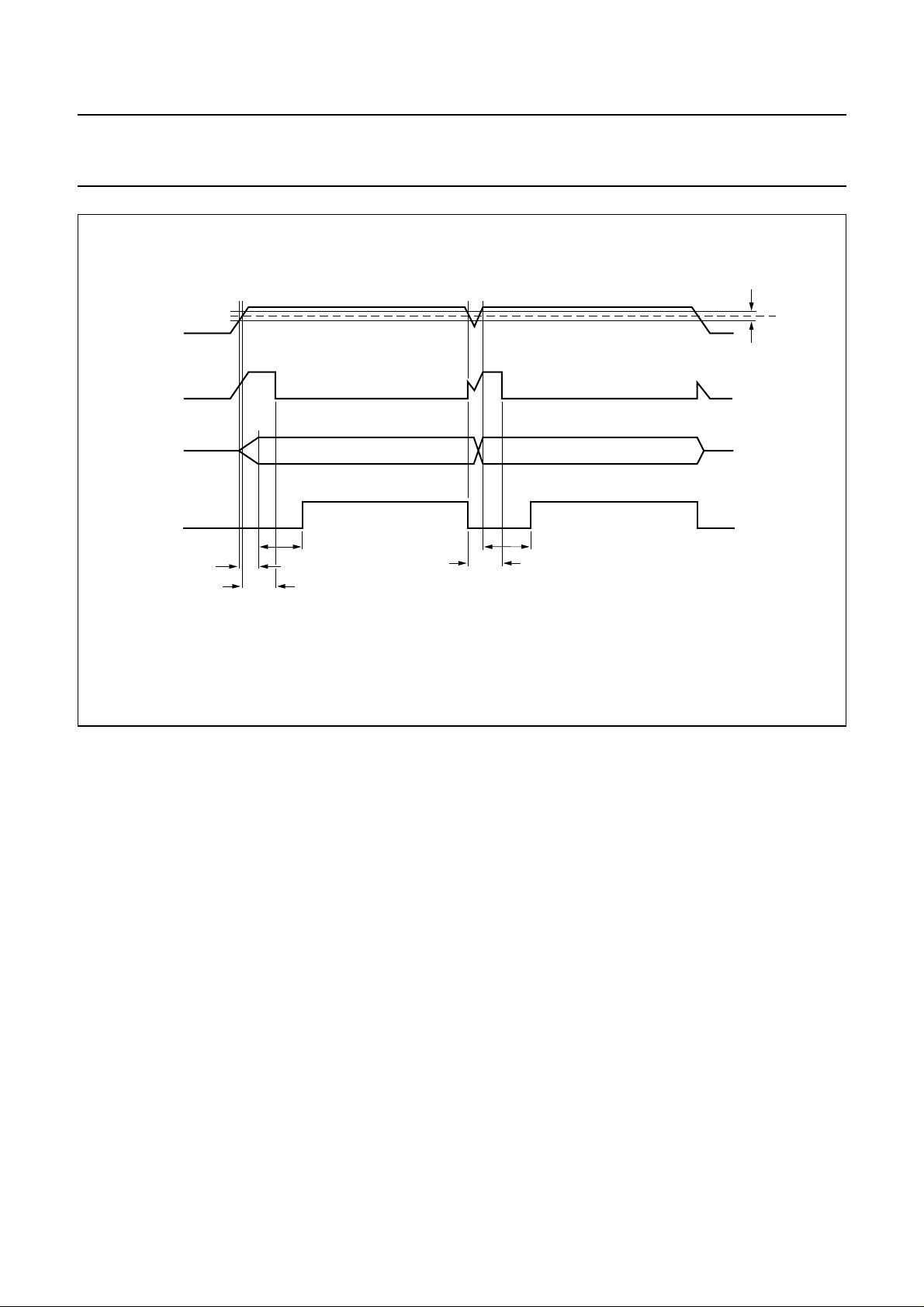

13.2 Power-on-reset

An on-chip Power-on-reset circuit that detects the supply

voltage rise or fall and accordingly generates a power-on

reset pulse (see Fig.12).

In the case of supply voltage rise, the power-on reset

signal will follow the supply voltage rise; after reaching the

trip level V

the power-on reset signal will maintain the

t

same behaviour, and returns to a LOW state after a time

interval Tp.

In the case of supply voltage fall, after the trip level V

is

t

reached, the power-on reset signal will follow the

waveform of the supply voltage for time interval Tp.

The time interval Tp guarantees that a complete power-on

reset pulse can trigger the internal reset signal. However,

to ensure that the oscillator is stable before the controller

starts, the clock signals are gated away from the CPU for

a further 2048 oscillator cycles.

The values of Vt, Tp and a process tolerance of ±∆Vt can

be found in Chapter 25; currently Vt= 3.9 V, Tp=10µs

and ∆Vt= 0.3 V.

13.3 T2 (Watchdog Timer Data Register) overflow

The length of the output pulse from T2 is 3 machine cycles.

A pulse of such short duration is necessary in order to

recover from a processor or system fault as fast as

possible.

1997 Dec 12 28

Page 29

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

handbook, full pagewidth

supply

voltage

Power-on-reset

oscillator

CPU

running

start-up

2048 clocks 2048 clocks

T

p

T

p

P83Cx80; P87C380

∆V

t

V

t

MGG023

Fig.12 Power-on reset switching level.

1997 Dec 12 29

Page 30

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

14 ANALOG CONTROL (DC)

The P83C880 has eleven Pulse Width Modulated (PWM)

outputs for analog control purposes e.g. brightness,

contrast, E-W, R (or G or B) gain control etc. Each PWM

output generates a pulse pattern with a programmable

duty cycle.

The eleven PWM outputs comprise:

• 10 PWM outputs with 8-bit resolution (PWM0 to PWM9);

described in Section 14.1.

• 1 PWM output with 14-bit resolution (PWM10);

described in Section 14.2.

A typical PWM output application is described in

Section 14.3.

14.1 8-bit PWM outputs (PWM0 to PWM9)

PWM outputs PWM0 to PWM9 share the same pins as

port lines P2.0 to P2.7, P3.0 and P3.1 respectively.

Selection of the pin function as either a PWM output or a

port line is achieved using the appropriate PWMnE bit in

SFRs, PWME1 (address C8H) and PWME2 (address

E8H); see Table 4.

The polarity of the PWM outputs is programmable and is

selected by the P8LVL bit in SFR DFCON (address C0H);

see Table 4.

The duty cycle of outputs PWM0 to PWM9 is dependent

on the programmable contents of the data latches: SFRs

PWM0 to PWM9. As the clock frequency of each PWM

circuit is

be calculated as:

Where (PWMn) is the decimal value held in the relevant

data latch.

The maximum repetition frequency of the 8-bit PWM

outputs is:

The block diagram for the 8-bit PWM outputs is shown in

Fig.13.

P83Cx80; P87C380

1

⁄4f

, the pulse width of the pulse generated can

clk

4 PWMn()×

=

---------------------------------f

clk

f

PWM

Pulse width

f

clk

=

------------ 1024

handbook, full pagewidth

internal data bus

f

clk

4

8-BIT PWM DATA LATCH

8-BIT DAC PWM

CONTROLLER

Q

Q

P8LVL

P2.x/P3.x data I/O

PWMnE

P2.x/P3.x/PWMn

MGG042

Fig.13 Block diagram for 8-bit PWMs.

1997 Dec 12 30

Page 31

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

f

handbook, full pagewidth

clk

4

256 1 2 3 m m + 1m + 2

00

01

m

255

decimal value PWM data latch

Fig.14 PWM0 to PWM9 output patterns.

P83Cx80; P87C380

256 1

MGG043

14.2 14-bit PWM output (PWM10)

PWM10 shares the same pin as port line P1.7. Selection

of the pin function as either a PWM output or as a port line

is achieved using the PWME2.0 bit in SFR PWME2

(address E8H); see Table 4.

The block diagram for the 14-bit PWM output is shown in

Fig.15 and comprises:

• Two 7-bit latches; SFRs PWM10H and PWM10L

• 14-bit data latch (PWMREG)

• 14-bit counter

• Coarse pulse controller

• Fine pulse controller

• Mixer.

Data is loaded into the 14-bit data latch (PWMREG) from

the two 7-bit data latches (PWM10H and PWM10L) when

PWM10H is written to. The upper seven bits of PWMREG

are used by the coarse pulse controller and determine the

coarse pulse width; the lower seven bits are used by the

fine pulse controller and determine in which subperiods

fine pulses will be added.

The outputs OUT1 and OUT2 of the coarse and fine pulse

controllers are then ‘ORed’ in the mixer to give the PWM10

output. The polarity of the PWM10 output is programmable

and is selected by the P14LVL bit in SFR DFCON (address

C0H); see Section 7.3.2.

1

⁄4f

As the 14-bit counter is clocked by

, the repetition

clk

times of the coarse and fine pulse controllers may be

calculated as shown below.

Coarse controller repetition time:

Fine controller repetition time:

t

t

r

sub

128 128

128

4

×=

------ f

clk

4

××=

------ f

clk

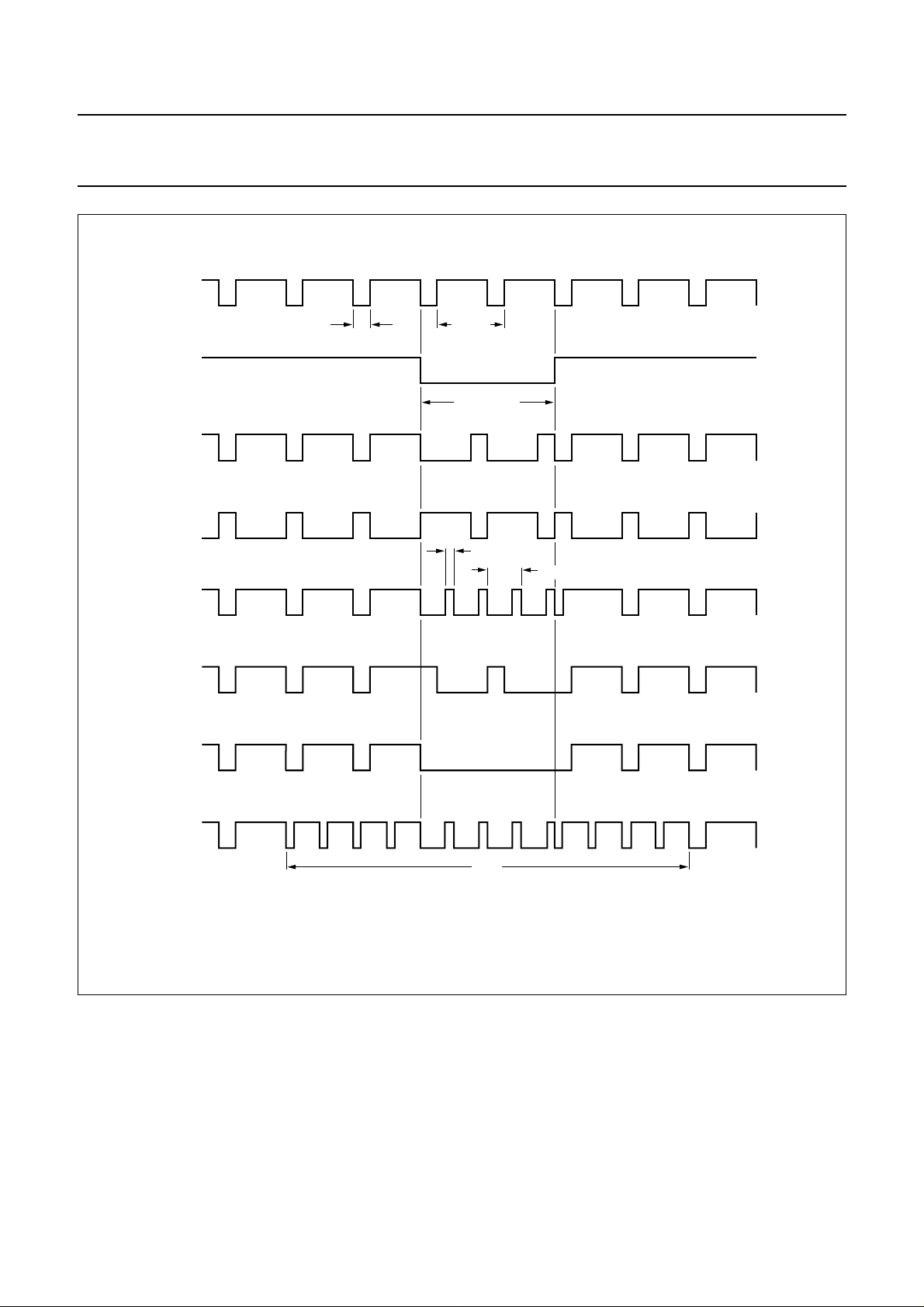

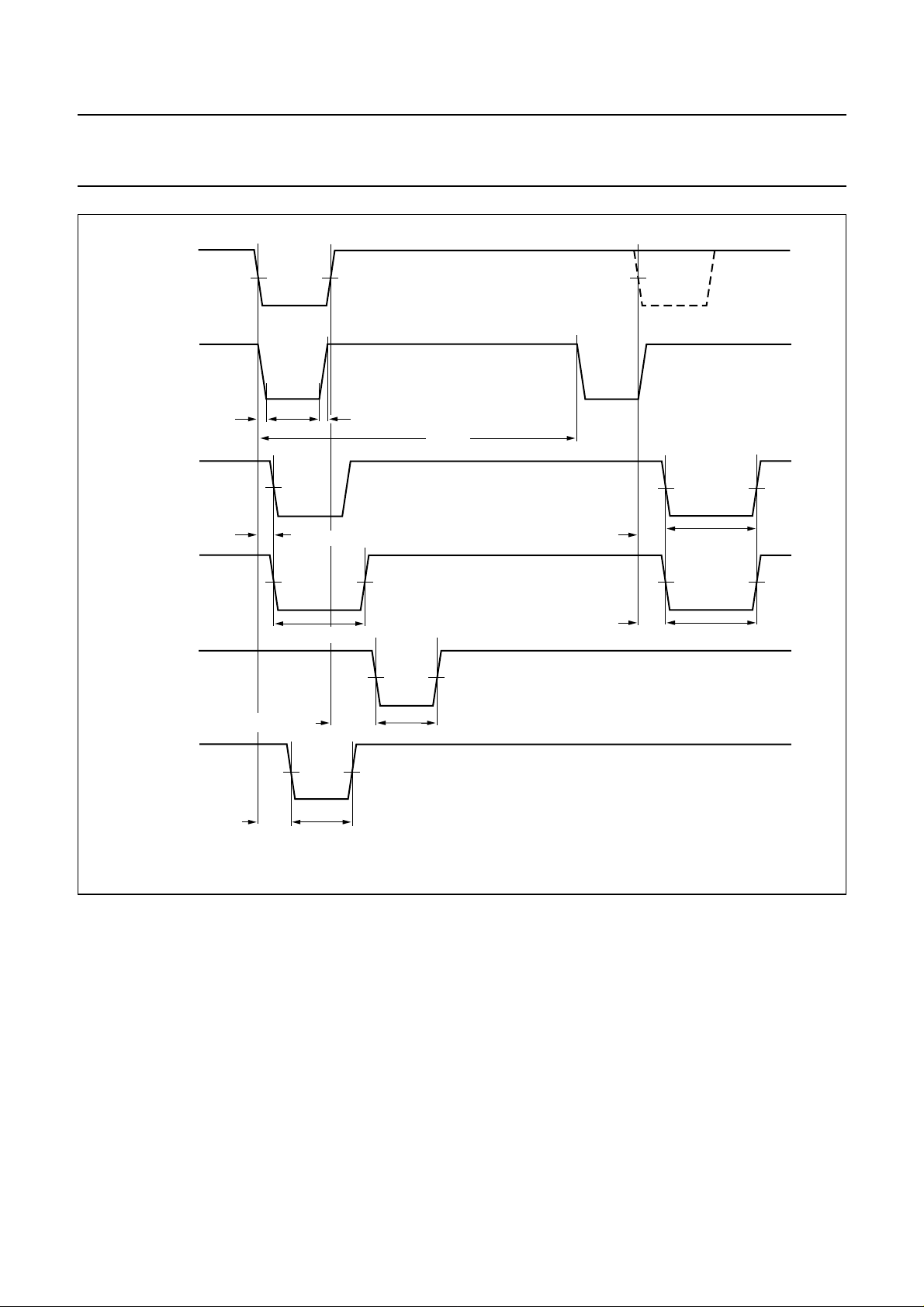

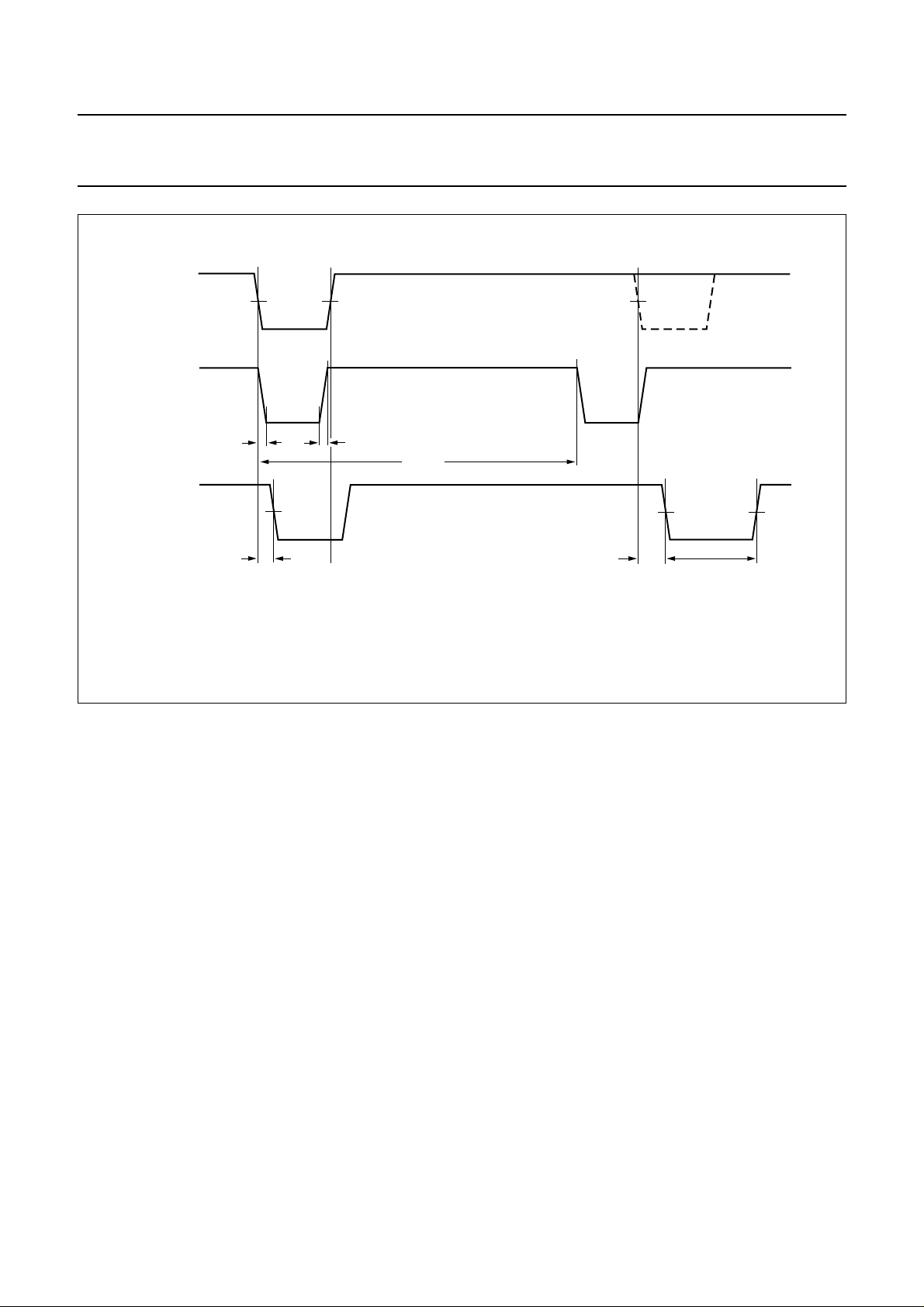

Figure 16 shows typical PWM10 outputs, with coarse

adjustment only, for different values held in PWM10H,

when P14LVL = 1. Figure 17 shows typical PWM10

outputs when P14LVL = 1, with coarse and fine

adjustment, after the coarse and fine pulse controller

outputs have been ‘ORed’ by the mixer.

When P14LVL = 1, the PWM10 output is inverted.

1997 Dec 12 31

Page 32

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

handbook, full pagewidth

‘MOVE instruction’

DATA LOAD

TIMING PULSE

PWM10H

LOAD

internal data bus

7 7

PWMREG

PWM10L

P83Cx80; P87C380

‘MOV instruction’

polarity

control bit

P14LVL

7 7

COARSE 7-BIT

PWM

MIXER

Q

Q14 to 8 Q7 to 1

14-BIT COUNTER

FINE PULSE

GENERATOR

OUT2OUT1

Q

PWM10 output

f

clk

4

MGG044

Fig.15 14-bit PWM block diagram.

1997 Dec 12 32

Page 33

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

14.2.1 COARSE ADJUSTMENT

An active HIGH pulse is generated in every subperiod; the

pulse width being determined by the contents of PWM10H.

The coarse output (OUT1) is HIGH at the start of each

subperiod and will remain HIGH until the time

[4/f

× (128 − PWM10H)] has elapsed. The output will

clk

then go LOW and remain LOW until the start of the next

subperiod. The coarse pulse width may be calculated as:

4

Pulse duration PWM10H()

14.2.2 F

INE ADJUSTMENT

×=

------ f

clk

Fine adjustment is achieved by generating an additional

pulse in specific subperiods. The pulse is added at the

start of the selected subperiod and has a pulse width of

4/f

. The contents of PWM10L determine in which

clk

subperiods a fine pulse will be added. It is the logic 0 state

of the value held in PWM10L that actually selects the

subperiods. When more than one bit is a logic 1 then the

subperiods selected will be a combination of those

subperiods specified in Table 30.

For example, if PWM10L = 000 0101 then this is a

combination of:

• PWM10L = 000 0001: subperiod 64

• PWM10L = 000 0100: subperiods 16, 48, 80 and 112.

Pulses will be added in subperiods 16, 48, 64, 80 and 112.

This example is illustrated in Fig.18.

When PWM10L holds 000 0000 fine adjustment is

inhibited and the PWM10 output is determined only by the

contents of PWM10H.

Table 30 Additional pulse distribution

P83Cx80; P87C380

PWM10L ADDITIONAL PULSE IN SUBPERIOD

000 0001 64

000 0010 32 and 96

000 0100 16, 48, 80 and 112

000 1000 8, 24, 40, 56, 72, 88, 104 and 120

001 0000 4, 12, 20, 28, 36, 44, 52...116 and 124

010 0000 2, 6, 10, 14, 18, 22, 26, 30...122 and 126

100 0000 1, 3, 5, 7, 9, 11, 13, 15, 17...125 and 127

f

handbook, full pagewidth

clk

4

127 0 1 2

00

01

m

127

decimal value PWM7H data latch

Fig.16 PWM10 output patterns: Coarse adjustment only.

128 − (m + 1) 128 − (m − 1)

128 − m

127 0 1

MGG045

1997 Dec 12 33

Page 34

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync

f

handbook, full pagewidth

clk

4

127 0 1 2

00

01

m

128 − (m + 1) 128 − (m − 1)

128 − m

P83Cx80; P87C380

127 0 1

127

handbook, full pagewidth

000 0001

000 0100

decimal value PWM10H data latch

Fig.17 PWM10 output patterns: Coarse and fine adjustment (PWM10L = 000 0000B).

t

r

t

sub0

t

sub16

t

sub32

t

sub48

t

sub64

t

sub80

t

sub96

t

sub112

MGG046

t

sub127

000 0101

PWM10L

Fig.18 Fine adjustment output (OUT2).

1997 Dec 12 34

MGG047

Page 35

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

14.3 A typical PWM output application

A typical PWM application is shown in Fig.19. The buffer is

optionally used to reduce the influence from supply/ground

bouncing to another circuit. R1 and C1 form the integration

network, the time constant of which should be equal to or

greater than 5 times the repetition period of the PWM

output pattern. In order to smooth a changing PWM output

a high value of C1 should be chosen. The value of C1 will

normally be in the range 1 to 10 µF. The potential divider

chain formed by R2 and R3 is used only when the output

voltage is to be offset. The output voltages for this

application are calculated using Equations (1) and (2).

V

max

V

min

R3 VDD×

=

------------------------------------R1 R2×

R3

+

---------------------R1 R2+

R1 R3×

--------------------- R1 R3+

=

--------------------------------------R1 R3×

R2

+

---------------------R1 R3+

V

×

DD

ndbook, halfpage

(1)

(2)

DEVICE

TYPE NR.

PWMn

(1)

V

SS

P83Cx80; P87C380

supply

voltage

R2

R1

C1 R3

analog

output

MGG048

The loop from the PWM pin through R1 and C1 to V

SS

will

radiate high frequency energy pulses. In order to limit the

effect of this unwanted radiation source, the loop should

be kept short and a high value of R1 selected. The value

of R1 will normally be in the range 3.3 to 100 kΩ. It is good

practice to avoid sharing V

(pin 12) with the return leads

SS

of other sensitive signals.

(1) P83Cx80; P87C380

Fig.19 Typical PWM output circuit.

1997 Dec 12 35

Page 36

Philips Semiconductors Product specification

Microcontrollers for monitors with DDC

interface, auto-sync detection and sync proc.

15 ANALOG-TO-DIGITAL CONVERTER (ADC)

The ADC inputs ADC0 and ADC1 share the same pins as

port lines P3.2 and P3.3 respectively. Selection of the pin

function as either an ADC input or as a port line is achieved

using bit ADCE in SFR DFCON (address C0H). When

ADCE = 1, the ADC function is enabled; see Section 7.3.2,

Table 8.

The two channel ADC comprises a 4-bit Digital-to-Analog

Converter (DAC); a comparator; an analog channel

selector and control circuitry. As the digital input to the 4-bit

DAC is loaded by software (a subroutine in the program),

it is known as a software ADC. The block diagram is shown

in Fig.20.

The 4-bit DAC analog output voltage (V

) is determined

ref

by the decimal value of the data held in bits DAC0 to DAC3

(DAC value) of SFR ADCDAT (address C1H). V

V

DD

calculated as:

V

Table 31 lists the V

----------

ref

valuesas function of DAC3 to DAC0.

ref

16

DAC value 1+()×=

When the analog input voltage is higher than V

ref

is

ref

, the

COMP bit in SFR ADCDAT (address C1H) will be HIGH.

The channel selector, consisting of two analog switches, is

controlled by bit DACHL in SFR ADCDAT; see Table 32.

Table 31 Selection of V

DAC3 DAC2 DAC1 DAC0 V

0000

0001

0010

0011

0100

0101

0110

0111

1000

100110⁄16× V

101011⁄16× V

101112⁄16× V

110013⁄16× V

110114⁄16× V

111015⁄16× V

1111 V

ref

(V)

ref

1

⁄

× V

16

2

⁄

× V

16

3

⁄

× V

16

4

⁄

× V

16

5

⁄

× V

16

6

⁄