Page 1

X--RAY GENERATION

LIST OF DOCUMENTATION IN THIS BINDER:

SUBSYSTEM MANUAL OPTIMUS R/F

UNIT MANUAL Converter R/F

○ UNIT MANUAL Extension set for an additional tube assembly WG/GWB

○ UNIT MANUAL 26 V DC / 230 V AC Adapter

○ UNIT MANUAL Handswitch for OPTIMUS

○ UNIT MANUAL Extension Photomultiplier (SEV)

○ UNIT MANUAL Mains group EWD

○ UNIT MANUAL Power Distribution Unit (PDU)

Note: indicated document present

LIST OF ALL BINDERS FOR X--RAY GENERA

-- SUBSYSTEM MANUAL OPTIMUS R/F (this binder)

TION:

4512 984 25672 REV AA

OPTIMUS_RF_01_25672_AA

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

0.1

Page 2

EW

Philips Medical Syst ems DMC GmbH

OPTIMUS R/F

SERVICE MANUAL

742

SUBSYSTEM

INTRODUCTION AND TECHNICAL DATA

INSTALLATION

1

2

9890 000 02182

FAULT FINDING

REPLACEMENT

PROGRAMMINGS

ADJUSTMENTS

3

4

5

6

358J92

CAN-controlled X-ray generator of the converter type

DMC Hamburg

Printed in Hamburg, Germany

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

ACCEPTANCE

SERVICE INFORMATION

PARTS LIST

SCHEMATIC DRAWINGS

7

8

P

Z1-

4512 984 25672 REV AA 1

OPTIMUS_RF_reg_25672_AA

WIRING DIAGRAMS

Z2-

Page 3

OPTIMUS R/F

SERVICE MANUAL -- SUBSYSTEM

OPTIMUS R/F

Author: U. Wente

Type No: 9890 000 02182

Techn. No: Basis 4512 104 70625

Release: 3.5

In case there are any questions concerning this manual,

please send this LOPAD via fax to 49/(0)40/5078 2481

File: OPTIMUS_RF_25672_AA

List of pages and drawings (LOPAD) Manual Order No: 4512 984 25672

released: 09/2002

0.1

1

3.1

3.2

_________________________________________

1--0.1 ... 0.2 (d/02.1)

1--1 ... 16 (d/02.1)

Z--1.1 (01.0) A4 4512 982 0092.

Z--1.2 (01.0) A4 4512 982 0092.

Z--1.3 (01.0) A4 4512 982 0099.

Z--1.4 (01.0) A4 4512 982 0099.

Z--6.1 (01.0) A4 4512 982 0099.

Z--6.2 (01.0) A4 4512 982 0099.

Z--7.1 (01.0) A3 4512 982 0088.

Z--7.2 (01.0) A3 4512 982 0088.

Z--7.3 (01.0) A3 4512 982 0088.

Z--7.4 (01.1) A3 4512 982 0088.

Z--7.5 (01.0) A3 4512 982 0088.

Z--7.10 (01.0) A3 4512 982 0010.

_________________________________________

2--0.1 ... 0.3 (c/02.1)

2--1 ... 86 (c/02.1)

2Z--2.0 3x (01.0) A4 4512 983 05591

2Z--2.1 (a/01.0) A4 4512 983 05601

2Z--2.2 (a/01.0) A4 4512 983 0561 1

2Z--2.3 (a/01.0) A4 4512 983 05621

2Z--2.4 (a/01.0) A4 4512 983 05631

2Z--2.5 (a/01.0) A4 4512 983 05641

_________________________________________

3--0.1 (b/02.0)

3--1 ... 93 (b/02.0)

3Z--1 (a/01.0) A4

3Z--21 (97.1) A4

_________________________________________

4--0.1 (a/02.1)

4--1 ... 25 (a/02.1)

_________________________________________

5Z--1 (a/01.0) A3

5Z--2 (a/01.0) A3

_________________________________________

6--0.1 (b/02.0)

6--1 ... 24 (b/02.0)

_________________________________________

7--0.1 (a/01.0)

7--1 ... 4 (a/01.0)

_________________________________________

8--1 (00.0) FCO--Checklist

8--2 (00.0) FCO--Checklist

_________________________________________

P--List OPTIMUS R/F (840061)

_________________________________________

2Z--2.6 (01.0) A4 4512 983 05651

2Z--2.7 (01.0) A4 4512 983 05661

2Z--2.8 (01.0) A4 4512 983 05671

2Z--2.9 (01.0) A4 4512 983 05681

2Z--2.10 (01.0) A4 4512 983 05691

2Z--3 (97.0) A3 4512 983 05721

2Z--4 (97.0) A4 4512 983 05771

2Z--5 (97.0) A4 4512 983 05731

2Z--10 (02.0) A3 4512 983 05701

_________________________________________

4512 984 25672 REV AA

OPTIMUS_RF_lopad_25672_AA

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

3.1

Page 4

Z0--1 (02.0)

Z1--1.1 (98.0) A3

Z1--1.2 (97.0) A3 4512 983 05561

Z1--2.1 (b/97.0) A3 4512 983 05581

Z1--2.2 (c/97.0) A3 4512 983 05931

Z1--2.3 (99.0) A3

Z1--3.3 (a/01.0) A3

Z1--4.1 (a/01.0) A3

Z1--4.2 (a/99.0) A3

Z1--5.1 (97.1) A3 4512 983 06551

Z1--6 (02.0) A3 4512 983 05531

Z1--11.1 (02.0) A3 4512 983 05521

Z1--11.2 (96.0) A4

Z1--13.2 (c/00.0) A3

Z1--14.1 (b/98.0) A3 4512 983 05541

Z1--14.2 (c/97.1) A3 4512 983 05551

Z1--15.1 (97.0) A3 4512 983 05571

Z1--15.2 (97.1) A3 4512 983 05711

_________________________________________

Z0--2 (02.0)

Z2--1.0 (96.0) A4

Z2--1.1 (d/99.0) A3 4512 983 06461

Z2--1.2 (e/99.0) A3 4512 983 06471

Z2--1.3 (c/98.0) A3 4512 983 06481

Z2--2.1.1 (97.0) A3 4512 983 06491

Z2--2.1.2 (97.0) A3 4512 983 06501

Z2--2.2.1 (96.0) A3 4512 983 06511

Z2--2.2.2 (a/97.0) A3 4512 983 06521

Z2--5.1 (a/02.0) A3

Z2--5.2 (b/02.0) A3 4512 983 0551 1

Z2--5.3 (a/02.0) A3

Z2--5.4 (02.0) A3

Z2--13 (d/00.0) A3

Z2--14.1 (b/99.0) A3

Z2--14.2 (a/96.0) A3

Z2--14.3 (a/96.0) A3

Z2--14.4 (97.0) A3

Z2--15.1 (97.0) A3 4512 983 05741

Z2--16 (97.0) A3

Z2--17 (97.0) A3

_________________________________________

(nur für Fabrik-- Auslieferung)

Service software No:

-- OMA : 4512 116 0220x

-- OMB : 4512 116 0230x

_________________________________________

OPTIMUS R/F

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

4512 984 25672 REV AA3.2

OPTIMUS_RF_lopad_25672_AA

Page 5

OPTIMUS R/F

1. Product information 1--1..................................................

1.1. Applications 1--1..........................................................

1.2. Options 1--1..............................................................

1.2.1. Hardware options 1--1......................................................

1.2.2. Software options 1--2......................................................

2. Compatibility 1--3........................................................

2.1. Generator components 1--3.................................................

2.2. Tubes 1--3................................................................

3. Mechanical data 1--4......................................................

4. Environmental data 1--5...................................................

4.1. Electrical environment 1--5..................................................

4.2. Climatic conditions 1--5.....................................................

4.3. Emission 1--5.............................................................

INTRODUCTION AND TECHNICAL DATA

INTRODUCTION AND TECHNICAL DATA

TEXT

Contents 1--0.1............................................................

5. Electrical data 1--6........................................................

5.1. Power data and mains conditions 1--6........................................

5.2. Power supply for applications 1--8...........................................

5.3. Operating data 1--8........................................................

5.4. Power supply 1--9.........................................................

5.4.1. Type of power supply 1--9..................................................

5.4.2. Calculating the mains resistances 1--10........................................

5.4.3. Earth-leakage circuit breaker 1--11............................................

5.4.4. Emergency--OFF device 1--11................................................

6. Tools 1--12................................................................

7. Traceable items 1--13......................................................

8. Preparation 1--14..........................................................

8.1. Installation material 1--14....................................................

8.2. Cables 1--14...............................................................

8.3. Manpower 1--15............................................................

9. Planned maintenance 1--16.................................................

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021_inh

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--0.1

Page 6

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

DRAWINGS

Generator cabinet Z--1.1......................................................

Room layout Z--1.2...........................................................

Operating panel Z--1.3........................................................

Power Distribution Unit (PDU) Z--1.4............................................

Connection of generator Z--6.1................................................

Connection of generator with PDU Z--6.2.......................................

Connection diagram Z--7.1....................................................

Connection diagram Z--7.2...................................................

Connection diagram Z--7.3....................................................

Connection diagram Z--7.4....................................................

Earthing diagram Z--7.5.......................................................

Legend for earthing and cabling diagram Z--20.1..................................

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--0.2

OPTIMUS_RF_1_d021_inh

Page 7

OPTIMUS R/F

INTRODUCTION AND TECHNICAL DATA

1. Product information

The Optimus family of generators for radiography is based on computer-controlled converter technology.

The converter operates in the non-audible frequency range.

Applicable options are essentially achieved by releasing software modules using customized PAL ICs.

Control between the internal Function Units (FUs) and the external online equipment takes place by a CAN bus.

Safety-relevant signals are transferred directly on the so-called “Signal bus”.

Units without any CAN interface are operated by the ”Adapter for 4 auxiliary units WA” option.

1.1. Applications

-- Radiography

-- Tomography

-- Fluoroscopy

1.2. Options

Component overview according to the commercial catalogue.

Only the versions in the current commercial catalogue can be ordered.

If an existing generator is to be upgraded the commercial department must order:

MGR0011 (upgrade of an existing configuration)

+ MGRxxxx

+S/N

1.2.1. Hardware options + MGR0011 + S/N

-- Dual-speed rotor control 9890 000 0268x MGR2082.............................. ............

-- Mains transformer PDU: 400 -- 480V; 50 / 60Hz,

also for 400V mains supply without neutral lead N

with taps for 400 / 440 / 460 / 480V 9890 000 0260x.....................

-- Mains transformer: 190--390V; 50 / 60Hz

with taps for 190 / 200 / 207 / 220 / 230 / 240 / 250 /

343 / 380 / 390V max. 50kW! 9803 720 8100x.......................

-- Adapter for 4 aux. units WA 9890 000 0231x MGR2131........................... ............

-- Adapter decade cable for 4 aux. units R/F WB 9890 000 0261x...........

-- Option rack 9890 000 0232x..........................................

-- Extension set for one additional tube 9890 000 0234x....................

-- Tube extension WG 9890 000 0238x..................................

-- Operating panel 9890 000 0240x......................................

-- Operating module Optimus 9890 000 0278x............................

-- Operating desk data cable 10m, 20m, 30m 9890 000 0241x / 2x / 3x..............

-- Stand for operating panel 9890 000 0244x MGR1482............................. ............

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--1

Page 8

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

-- Wall mounting of operating panel 9890 000 0245x.......................

-- 26VDC / 230VAC adapter 9890 000 0246x MGR2281............................. ............

-- Handswitch for Optimus 9890 000 0249x...............................

-- Patient Data Organizer (PDO) 9890 000 0255x MGR2091......................... ............

-- Decade cable set 14 x 4m top decade → AMP decade 9803 704 2010x....

-- Extension photo pick-up Optimus 9890 000 0258x.......................

1.2.2. Software options + MGR0011 + S/N

Software options are provided by the function key (see also 5Z--1, EZ 139 Central Unit D38).

Additional hardware components are not required.

-- Automatic Exposure Control (AEC) 9890 000 0281x

-- Anatomic Programmed Radiography / Fluorography (APR/F) 9890 000 0282x

1)

1)

-- Automatic Tomo Time Input (TTI) 9890 000 0222x MGR2121............................. .......

-- Tomo Density Control (TDC) 9890 000 0223x MGR2122................................. .......

-- VARIOFOCUS 9890 000 0227x MGR2101............................................. .......

-- Area dose calculator 9890 000 0256x MGR2141........................................ .......

1) = Options only for base 9890 000 0218x

Options are always included in base 9890 000 0216x

MGR2171........................... .....

MGR2181.... .....

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--2

OPTIMUS_RF_1_d021

Page 9

OPTIMUS R/F

INTRODUCTION AND TECHNICAL DATA

2. Compatibility

2.1. Generator components

-- Base OPTIMUS 9890 000 0218x..............................

-- H.V. transformer R/F 1 tube, 50kW 9890 000 0270x.. .........

-- H.V. transformer R/F 2 tubes, 50kW 9890 000 0271x MGR2061 (Upgrade 1 ----> 2) tubes.. ........ ....

-- H.V. transformer R/F 1 tube, 65 / 80kW 9890 000 0272x.. ......

-- H.V. transformer R/F 2 tubes, 65 / 80kW 9890 000 0273x MGR2062 (Upgrade 1 -- --> 2) tubes.. ..... ....

-- 50kW extension -- R/F 9890 000 0274x........................

-- 65kW extension -- R/F 9890 000 0275x........................

-- 80kW extension -- R/F 9890 000 0276x........................

-- Firmware Rel. 3.5 9890 000 0251x............................

2.2. Tubes

Recommended standard tubes:

-- RO 17 50

-- SRO 25 50

-- SRO 33 100

Further compatible tubes:

-- RO 30 -- SRO 09 51 -- SRO 20 55

-- RO 12 30 -- SRO 13 30 -- SRO 22 50

-- RO 16 48 -- SRO 20 50 -- SRO 32 100

-- RO 30 50

Compatible tube housings:

-- ROT 350

-- ROT 351

The latest information on further tubes which are connectable is available at the service center Hamburg.

Note

When the generator is retrofitted it is important to use the screened cable 3 x 1.31mm

2

(0722 215 02054) as the

stator cable.

If necessary exchange the old stator cable.

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--3

Page 10

3. Mechanical data

C

For installation dimensions and weights see drawings Z--1.1.

Transport data:

Weights [kg] Dimensions [cm]

aseNo.Contents

-- Generator cabinet

1

-- Operating panel

-- Cables

net gross length width height

178 226 210 82 84

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

1--tube version:

73

100

77 67 80

2

2--tube version:

88

115

Contents: H.V. generator

OPTIMUS R/F(d/02.1)1--4

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_RF_1_d021

Page 11

OPTIMUS R/F

INTRODUCTION AND TECHNICAL DATA

4. Environmental data

The environmental data comply with to PMS standard UXW 13600.

4.1. Electrical environment

Class S0 -- Dedicated mains supply, 3 phases and neutral. Thus single phase voltage is also available.

A low impedance, permanently installed connection, fed in by the step down transformer of the hospital to supply

large systems like in MR, CT and X--ray departments is required.

Note

Use always a mains cable with 4 wires and concentric PE--shield, type NYCY.

4.2. Climatic conditions

Ambient temperature 10_C--40_C...................

Relative humidity 15% -- 90%; no condensation.......................

Relative atmospheric pressure 70kPa -- 110kPa...........

4.3. Emission

Heat dissipation max. 1200W; average per hour........................

Noise level, normal operation ≈ 46dBA............

Noise level, maximum power operation ≈ 55dBA....

EMC IEC 950..................................

To avoid any possible annoying noise of the implemented fans it is advisable to install the generator cabinet

outside the examination room.

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--5

Page 12

5. Electrical data

withexternaltransformerPDU(option

)

I

3+1x1

0

2

(L1,L

2,L

3,PE)

5.1. Power data and mains conditions

Voltage

50kW 65kW 80kW

Mains voltage 3 x 400V ±10% (≅ 415V

3 x 400 / 440 / 460V ±10% *

6%

+

3 x 480V

=*=

The following connection cables are recommended:

|

--10%

+6%

/ 380V

*

-- 5 %

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

)

nput:

Output: 4 x 4mm

4+1x4mm

3 x 1,5mm

mm

2

Generator supply 3 x 400V

2

Device supply 3 x 220V (option)

2

Switch control and temperature supervision

3 x 190 ... 343V ±10% **

** = with external transformer; max. 50kW (option)

Frequency

50kW 65kW 80kW

Mains frequency 49 ... 61Hz

OPTIMUS R/F(d/02.1)1--6

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_RF_1_d021

Page 13

OPTIMUS R/F

(

)

INTRODUCTION AND TECHNICAL DATA

Max. mains current

Voltage

50kW 65kW 80kW

Exposure: 400V 145A 190A 230A

440V 135A 180A 215A

460V 125A 170A 210A

480V 120A 160A 205A

190V 300A -- --

Short--time power

consumption

100kVA 132kVA 160kVA

[I x U x √3]

Fluoro: 400V -- 8A

480V -- 7A

Fuse protection

slow blow

Connected load

[I

xUx√3]

Fuse

35A 50A

100A at ≤ 240V --

25kVA 35kVA

Emergency

power supply:

static

(Inverter)

Short--time power consumption

[I x U x √3]

dynamic

(Diesel generator

with flywheel mass)

Connected load

[I

xUx√3]

Fuse

Mains resistance

Voltage

50kW 65kW 80kW

400V ≤ 300mΩ ≤ 200mΩ

440V ≤ 350mΩ ≤ 240mΩ

460V ≤ 350mΩ ≤ 240mΩ

480V ≤ 400mΩ ≤ 300mΩ

480V valid for DOD only ≤ 300mΩ ≤ 240mΩ ≤ 180mΩ

Note

500m

Ω

is the absolute max. mains resistance.

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--7

Page 14

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

5.2. Power supply for applications

Generator power

Supply 50kW 65kW 80kW

Output 1 230V / 400V; generator switched and protected ----> I

Output 2 230V / 400V; generator switched and protected ----> I

Output 3 230V / 400V; generator not switched and protected ----> I

Sum value I

max(1+2+3)

≤ 10A

Only with external

transformer PDU

Output 4 127V / 220V generator switched and protected ----> I

Output 5 double socket 127V / 15A to phase L1;

generator not switched and protected ----> I

Sum value I

max (4 +5)

≤ 16A

5.3. Operating data

Generator power

1

2

3

4

5

Data

50kW 65kW 80kW

Exposure: Tube current 1 ... 650mA 1 ... 900mA 1 ... 1100mA

Tube voltage 40 ... 150kV in kV-- or %--steps

mAs product 0,5 ... 850mAs

Exposure time 1ms ... 6s / 16s

Exposure frequency ≤ 12exp./s

Interfacing option for door contact, external radiation warning indicator

Fluoro: Tube current 0,25 ... 6mA

Tube voltage 40 ... 110kV

kV/mA curves 3

Setting time ≤ 1s

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--8

OPTIMUS_RF_1_d021

Page 15

OPTIMUS R/F

5.4. Power supply

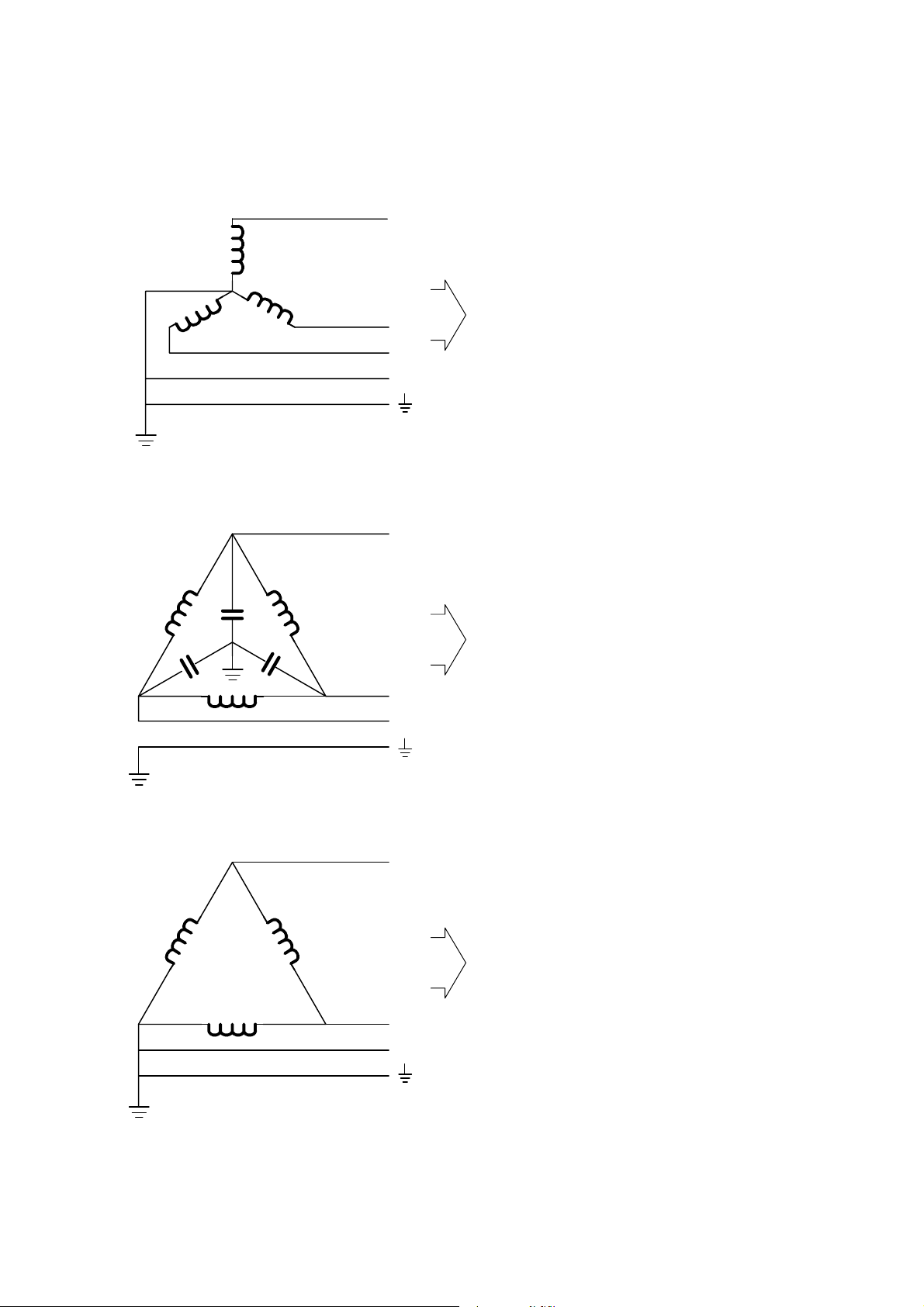

5.4.1. Type of power supply

3 phase WYE

INTRODUCTION AND TECHNICAL DATA

L1

L2

L3

(N)

3 phase DELTA,

balanced earth or floating

L1

L2

L3

X-ray

installation

X-ray

installation

-- 400V

-- 440V / 460V / 480V with

external mains transformer PDU

9890 000 0260x.

-- Neutral not required if the external

mains transformer PDU

9890 000 0260x is ordered.

-- 190V ... 343V with

external mains transformer

9803 720 8100x (max. 50kW).

-- External mains transformer PDU

9890 000 0260x is required.

-- 400V / 440V / 460V / 480V

-- 190V ... 343V with

external mains transformer

9803 720 8100x (max. 50kW).

3 phase DELTA,

grounded

L1

-- External mains transformer PDU

9890 000 0260x is required

(requires modification at the

EMC-- filter of the kV power unit).

X-ray

installation

L2

L3

Caution!

Ensure the sequence of phases in the wall junction box corresponds to designations L1, L2, L3.

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

-- 400V / 440V / 460V / 480V

1--9

Page 16

5.4.2. Calculating the mains resistances

Note

The cross section of lead l

must not exceed 25mm2. (See figure below).

3

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

If possible the sum of R

smaller than the R

requires.

XG

0,R1,R2

and R3should be

R

+R1+R2+R3<R

0

With higher internal mains resistances the generator

output is reduced correspondingly.

R

designates the mains resistance of the distributor transformer

0

R

depends on the length of lead l1between distributor transformer and mains distributor

1

L1

L2

L3

l

1

and on the selected cross section as well:

==> R

R

consists of upstream elements such as:

2

1=l1

× R

Cu

RCufrom table below

-- Emergency-OFF switch 4.0mΩ.................

-- Earth-leakage circuit breaker 5.5mΩ............

l

3

XG

MEX 100

L1

L2

L3

357J94

-- Fuse 5.5mΩ.................................

-- Surge arrester WN 23.0mΩ...................

R

depends on the length of lead l3between mains distributor and wall junction box

3

and on the selected cross section as well:

==> R

3=l3

× R

Cu

RCufrom table below

The resistances consider the go and return lines so that the calculation can be based on simple cable lengths.

Copper cross section

[mm

2

]

Resistance R

[mΩ/m]

Cu

16 2.19

25 1.4

35 1.0

50 0.7

70 0.5

95 0.38

120 0.30

150 0.24

Note

500m

Ω

is the absolute max. mains resistance.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--10

OPTIMUS_RF_1_d021

Page 17

OPTIMUS R/F

INTRODUCTION AND TECHNICAL DATA

5.4.3. Earth-leakage circuit breaker

To be provided between mains fuse and X-ray installation depending on local regulations.

Siemens earth-leakage circuit breaker:

-- Order No.: 5SZ3 466 OKG00

-- Rated fault current 30mA

-- Rated current 63A

-- Connection terminals for wire cross sections of up to 25mm

2

5.4.4. Emergency--OFF device

To be provided depending on local regulations.

There are 2 possibilities:

1. All the Emergency--OFF buttons are connected in series and looped into the switch--ON circuit (12VDC) of

the generator.

2. The Emergency--OFF circuit acts on an external mains contactor which switches OFF the power before it is

fed into the generator.

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--11

Page 18

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

6. Tools

-- Service engineer standard tool kit

-- Service-PC:

IBM-compatible, 640kB RAM, 3.5” floppy disk drive, ≥ 1 serial port

-- Installation and service software OMA: 4512 116 022xx / OMB: 4512 1 16 023xx.

Supplied on two floppy disks within this generator service manual.

-- PC-hardkey (DIAGGEN):

Necessary to carry out the installation and to run the service software (special programmings, fault finding).

-- 0-modem cable:

Minimum length is distance between generator cabinet and operating desk.

Male 25-pole D-Sub connector at the generator side.

A 5m data cable of bucky controller can be used: 4512 130 5693x

-- Mains resistance measuring instrument

-- Dose measuring instrument

-- mAs--meter

-- Multimeter

-- Digital oscilloscope with 2-beam memory

-- Recommended PLCC extraction tool (AMP 822154--1): 2422 487 89772

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--12

OPTIMUS_RF_1_d021

Page 19

OPTIMUS R/F

INTRODUCTION AND TECHNICAL DATA

7. Traceable items

The following items have serial numbers of the following format when delivered ex factory:

1. Generator cabinet 6 digit serial number........

2. H.V. tank 7 digit serial number................

3. Operating desk 8 digit serial number...........

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--13

Page 20

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

8. Preparation

Connection of the generator: see drawing Z--6.1................

Connection of the generator with PDU: see drawing Z--6.2.......

Operating panel: see drawing Z--1.3..........................

Connection diagram: see drawing Z--7.1/.2/.3/.4.......................

Earthing diagram: see drawing Z--7.5.........................

Legend for earthing and cabeling: see drawing Z--7.10...........

8.1. Installation material

To be ordered from the service department of PMS Hamburg:

-- Wall junction box 4512 103 7538x.............................

2

inclusive connection block (25mm

-- Relay for radiation warning indicator 4512 100 4523x............

1 interface relay with a floating contact (230V/1A) is included in the scope of delivery of the generator.

) for mains supply and connection block (10mm2) for unit supply.

8.2. Cables

H.V . cables

with O3 / O3 plugs: 9806 402 6xx02................................

length: 6m -- 30m in steps of 2m...........................................

capacity: 155pF/m.........................................

diameter: 16.5mm........................................

The cable length is indicated by the 9th and 10th digit of the numeric code.

Thermal contact cable

-- 2-wire screened for 1 excess temperature switch 4512 100 66151.............

-- 10-wire screened for additional supervision like

temperature alarm switch, buzzer, selection indicator 0722 215 19005.........

Stator cable

3×1.31mm

Note

The above described cables are part of the pre--installed systems.

2

, screened 0722 215 02054.....................................

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--14

OPTIMUS_RF_1_d021

Page 21

OPTIMUS R/F

INTRODUCTION AND TECHNICAL DATA

AMPLIMAT cable

with D-Sub and 3--Plus plug:

12m 9890 000 01721......................

16m 9890 000 01731......................

20m 9890 000 01741......................

24m 9890 000 01751......................

Caution!

AMPLIMAT cables 9803 507 0xx02 (for hybrid measuring chambers 9803 509 xxxxx) with 3--Plus plugs at

both ends must be connected in the generator by the following adapter for each cable:

Adapter for AMPLIMAT cable: 4512 108 09042. The generator includes 1 adapter.

The hybrid measuring chambers 9803 509 xxxxx require connection (chassis) between contacts:

D--Sub end GND (13) <---- --> RF 0V (8) (generator input)

or

3--Plus end GND (N) <------> RF 0V (J) (generator input)

This connection is established by the adapter for the AMPLIMAT cable.

See drawing Z1--6 ”Basic interface”.

In case a hybrid measuring chamber 9803 509 xxxxx is not operated with the required

AMPLIMAT cable 3--Plus / 3--Plus 9803 507 0xx02... ....

but with

AMPLIMAT cable D--Sub / 3--Plus 9890 000 017xx... ....

make sure to establish this connection (13 <-- -- --> 8) in the D--Sub connector!

For ALC measuring chambers 9890 000 016xx connection GND <------> RF 0V is not permitted.

Therefore, ALC measuring chambers AMPLIMAT cables 9890 000 017xx should always be used.

Operating desk

Note

Use the shortest cables. Noise immunity increases.

cable set 10m 9890 000 02411.......................

20m 9890 000 02421.......................

30m 9890 000 02431.......................

8.3. Manpower

At least two persons are necessary to insert the H.V. tank in the generator cabinet.

The weight of the 2--tube version is about 88kg.

OPTIMUS R/F (d/02.1)

OPTIMUS_RF_1_d021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

1--15

Page 22

OPTIMUS R/FINTRODUCTION AND TECHNICAL DATA

9. Planned maintenance

The technical documentation for carrying out maintenance work in compliance with the applicable regulations are

available at the responsible authority of Philips Medical Systems.

The importance of having maintenance implemented is pointed out to the operator in the operating instructions.

It must be guaranteed that the person carrying out maintenance work knows about the respective national

regulations and that this person observes these regulations throughout all steps of maintenance work.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(d/02.1)1--16

OPTIMUS_RF_1_d021

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

OPTIMUS R/F

1. Installing the wall junction box 2--1........................................

2. Preparatory work 2--2.....................................................

2.1. Mounting of the H.V. generator in the cabinet 2--2..............................

2.2. Electrical connection of the H.V. generator 2--3................................

3. Installing the operating panel 2--5.........................................

3.1. Desk version 2--5..........................................................

3.2. Stand version 2--7.........................................................

3.3. Wall mounted version 2--8..................................................

3.4. Supporting angle version 2--9...............................................

3.5. Additional release switch 2--10...............................................

4. Electrical connection 2--11.................................................

4.1. Earthing 2--11..............................................................

4.2. Mains connection 2--1 1......................................................

4.2.1. Mains connection of the generator 2--11.......................................

4.2.2. Mains connection of the PDU 2--12...........................................

4.3. Stator connection 2--13......................................................

4.3.1. Shielding 2--13.............................................................

4.3.2. Connection 2--14...........................................................

4.4. Signal cables 2--17.........................................................

4.4.1. Room decade cable 2--17....................................................

4.4.2. Tube supervision 2--19......................................................

4.4.3. CAN interface 2--19.........................................................

4.4.4. Adapter for 4 auxiliary units 2--20.............................................

4.4.5. Dose inputs 2--23...........................................................

4.4.6. Patient Data Organizer PDO (option) 2--23.....................................

4.5. H.V . cables generator side 2--24..............................................

4.6. Emergency--OFF circuit 2--24................................................

INSTALLATION

INSTALLATION

TEXT

Contents 2--0.1............................................................

5. Hardware programming 2--25...............................................

6. Switching--ON of the generator 2--26........................................

7. Installation software XRGSCOPE 2--27......................................

7.1. PC and generator settings to avoid problems during up/downloading of

CU complete files 2--27......................................................

7.1.1. Preparation of the service PC to guarantee a safe loading process 2--27...........

7.1.2. Preparation of the generator 2--27............................................

7.2. Installation procedure 2--29..................................................

8. Setting-to-work overview 2--32.............................................

8.1. Configuration 2--33.........................................................

8.1.1. Date and time 2--33.........................................................

8.1.2. Mains data 2--33...........................................................

8.1.3. Tubes 2--34................................................................

8.1.3.1. Tube data set 2--34.........................................................

8.1.3.2. Tube speed selection 2--35..................................................

8.1.3.3. Tube limits 2--35............................................................

8.1.3.4. Capacitance of tube connection 2--36.........................................

8.1.3.5. Tube operating modes 2--37.................................................

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021_i nh

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--0.1

Page 36

OPTIMUS R/FINSTALLATION

8.1.3.6. Disable tube 2--37..........................................................

8.2. Registration devices 2--38...................................................

8.2.1. Data set A ... B 2--38........................................................

8.2.2. Interface assignment 2--42...................................................

8.2.3. Examples for RGDV programming 2--43.......................................

8.3. Tube adjustment 2--44......................................................

8.3.1. Tube conditioning 2--44......................................................

8.3.1.1. Preconditions / Programmings 2--44...........................................

8.3.1.2. Procedure 2--45............................................................

8.3.2. Tube adaptation 2--49.......................................................

8.3.2.1. General information 2--49....................................................

8.3.2.2. Preconditions / Programmings 2--50...........................................

8.3.2.3. Procedure 2--52............................................................

8.3.3. Final tube adjustment work 2--53.............................................

8.3.4. Problems during adaptation -- Symptoms and solutions 2--54.....................

8.4. Dose rate control 2--55......................................................

8.4.1. AMPLIMAT sensitivity 2--55..................................................

8.4.2. Screen/film combinations 2--55...............................................

8.4.2.1. Automatic DRC processing 2--56.............................................

8.4.2.2. Manual DRC processing 2--57................................................

8.4.2.3. Density correction for AEC technique (option) 2--58.............................

8.4.3. Image intensifier(II) 2--59....................................................

8.4.4. Fault exposure detection 2--61...............................................

8.4.5. Continuous fluoroscopy 2--61................................................

8.5. Application limits 2--62......................................................

8.5.1. X--mode limits 2--62.........................................................

8.5.2. Thoravison limits 2--63......................................................

8.5.3. Overload-dependent limits 2--63..............................................

8.6. Human interface 2--64.......................................................

8.6.1. Additional program settings for generators without option APR 2--65...............

8.6.2. Language 2--66............................................................

8.6.3. Automatic programming of APRs (option) 2--66.................................

8.6.4. Manual programming of APRs (option) 2--69...................................

8.6.4.1. Creating menus 2--70.......................................................

8.6.4.2. Creating sub menus 2--70...................................................

8.6.4.3. Assigning APRs 2--71.......................................................

8.6.5. Changing of APR radiation parameters 2--72...................................

8.6.5.1. Density correction for non--AEC techniques 2--76...............................

8.6.5.2. AEC fixed current (kV--mA) 2--76.............................................

8.6.6. Moving / copying of an APR data set 2--77.....................................

8.6.7. Deleting of APRs 2--78......................................................

8.6.8. Manipulating menus 2--79...................................................

8.6.9. External APR assignment 2--80..............................................

8.7. Option: Tomo Density Control TDC 2--82......................................

8.8. Option: VARIOFOCUS 2--83.................................................

8.9. Option: Area Dose Calculator 2--83...........................................

8.10. Acceptance test 2--83.......................................................

8.11. Interlock facility for APR modification 2--84.....................................

8.12. Backup of all configuration data 2--84.........................................

9. Labels 2--85...............................................................

10. Final installation work 2--86................................................

OPTIMUS R/F(c/02.1)2--0.2

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_RF_2_c021_i nh

Page 37

OPTIMUS R/F

RGDV programming (3x) 2Z--2.0......................................................

RGDV programming example: 1 2Z--2.1................................................

RGDV programming example: 2 2Z--2.2................................................

RGDV programming example: 3 2Z--2.3................................................

RGDV programming example: 4 2Z--2.4................................................

RGDV programming example: 5 2Z--2.5................................................

RGDV programming example: 6 2Z--2.6................................................

RGDV programming example: 7 2Z--2.7................................................

RGDV programming example: 8 2Z--2.8................................................

RGDV programming example: 9 2Z--2.9................................................

RGDV programming example: 10 2Z--2.10..............................................

List of characters 2Z--3..............................................................

Data sets of chambers 2Z--4.........................................................

Programming of device interfaces 2Z--5................................................

Labelling 2Z--10.....................................................................

INSTALLATION

DRAWINGS

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021_i nh

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--0.3

Page 38

OPTIMUS R/F

INSTALLATION

1. Installing the wall junction box

S Mount the wall junction box at the place where the generator is intended to be installed.

(See drawing “Connection of generator” in section 1 and manual UNIT 4512 103 75380 for wall junction boxes).

S If necessary, install the optional surge arrester WN inside the wall junction box.

(See surge arrester documentation.)

S If applicable, mount the filler panels of the generator to the wall junction box.

S Have the mains cable present at the clinic connected to mains terminal MEX by a person who is authorized for

this job.

S Check the phase sequence of L1, L2 and L3.

Warning!

Switch OFF the mains supply present at the clinic and make sure that it cannot be switched

ON again accidentally

.

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--1

Page 39

OPTIMUS R/FINSTALLATION

2. Preparatory work

2.1. Mounting of the H.V. generator in the cabinet

Caution!

Do not tilt the H.V. generator while transporting it.

In case of a tilting angle larger than 45_, the setting-to-work of the generator can be started not before a

waiting time of about 8 hours has p assed. Otherwise the H.V. generator may be destroyed by electrical

sparkover.

S Unpack generator cabinet E.

S In case the packing material is strongly soiled with

oil check the oil level. Repair it if necessary.

Tolerance: 2mm

Oil: Shell Diala G in 2.5l container

4512 148 43172

deaerating hole

24mm at 20 - 30_C

22mm at 30 - 36_C

329H97

S Remove the deaerating screw completely from the cover of the H.V. generator. Only this way the precision of

the high voltage measuring divider corresponds to the specification.

In case of return shipment of the H.V. generator this screw must be fixed again. Therefore, keep the screw laying

on top of the cover.

Caution!

Make sure that no foreign matter falls into the oil. Otherwise the transformer must be exchanged.

S Take the two transport bars from the rear side of the cabinet.

S Lift the H.V. generator into the generator cabinet with the transport bars.

The 4 connecting bolts GX1001 to 1004 must point at the front of the generator cabinet.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--2

OPTIMUS_RF_2_c021

Page 40

OPTIMUS R/F

Generator

R

k

Routethecablesalongthefrontandlef

t

Seedrawingp

age2--4

thereasonofkVsymmetry

Not

e

k

W

Seedrawingp

age2--4

2.2. Electrical connection of the H.V. generator

S Connect the H.V. generator electrically:

INSTALLATION

Generator

version

50/65/80kW

50kW

Connection

emar

from <------> to

E1 (GND) <------> GX1100 (GND) Ground

ZX12 <------> G100X15

ZX35 <------> G100X14

Route the cables alongthe front and left-hand edge of the H.V. generator. Fix them.

Twist the cables!

QC13:1 <------> GX1003

Note

The sequence of the connecting bolts is not

in numerical order.

Push the screening cap forward over the

QC03:1 <------> GX1002

connecting bolts and tighten it. Attach the

converter cables including the screening to

the screening cap with cable ties.

The 50kW version might have direct links

GX1001 <------> GX1003

on each side or a link on one side and a

choke of 1 ... 6 loops on the other side for

.

.

GX1004 <------> GX1002

QC13:1 <------> GX1001

QC03:1 <------> GX1002

65/80

2QC13:1 <------> GX1003

2QC03:1 <------> GX1004

WGX61 <------> GK1:1

50/65/80kW WGX67 <------> GK1:2

2ndtube

WGX62 <------> GK2:1

WGX68 <------> GK2:2

Note

Do not change these links or chokes.

Twist the cables!

The sequence of the connecting bolts is not

in numerical order.

.

Push the screening cap forward over the

connecting bolts and tighten it.Attach the

converter cables including the screening to

the screening cap with cable ties.

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--3

Page 41

OPTIMUS R/FINSTALLATION

S Turn the two earthing angles of the H.V. generator outward and screw them on to the members of the cabinet.

converter cables (twisted)

fixed at the screening cap

earthing angles

Connection of

50kW version

screening cap

terminal for the screen

of the filament cable

fixing signal cable

199H96

Connection of

65/80kW version

Twist the cable

Link or choke

X1001

QC13:1

QC 03:1

X1002X1003 X1004

Link or choke

Twist the cables

QC13:1

QC03:1

X1001 X1003

X1002

2QC13:1

2QC03:1

X1004

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--4

OPTIMUS_RF_2_c021

Page 42

OPTIMUS R/F

3. Installing the operating panel

3.1. Desk version

See ”Operating panel” in section 1.

Accessories:

-- 2 feet for the unit

-- 2 elastic buffers, black

-- 5 insert strips for the RGDV buttons

-- sheet with RGDV symbols

-- release switch

S Unpack the desk carefully.

S Mount the release switch on the left-hand or

right-hand side of the desk:

Mount the holding bracket to the edge of the

desk (1) with the two M4x10 countersunk screws.

INSTALLATION

C300 X3

1

2

3

For visual reasons the release button should be in

line with the +/-- buttons on the control desk. Use

the appropriate holes in the bracket.

Slide the release switch onto the bracket.

Fasten it parallel to the desk edge with the two

M4x10 cheese-head screws, securing rings and

washers (2).

S Screw in the 2 feet for the unit at the bottom of the

desk.

S Glue the 2 black elastic buffers to the front edges

of the bottom of the desk such that they are acting

as the front feet.

184H95

2x

150H94

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--5

Page 43

S Define the assignment of the RGDV buttons 1 ...

8. Glue the respective symbols to the insert strips

which are provided with subsidiary lines (1).

OPTIMUS R/FINSTALLATION

S Raise the keyboard about 3mm above the desk.

Useanallenkey(2).

S Push the insert strips under the keyboard foil.

Press the angulated, protruding end of each insert

strip into the housing of the desk (3).

S Lower the keyboard to its initial position (4).

S Remove the cable cover at the rear side of the

desk.

S Connect the cables:

Supply cable EZX20 <-- ----> C200X1

EZX6 <------> earth

Data cable EZX46 <------> C300X1

Release switch <-- ----> C300X3

Patient Data Organizer <---- --> C300X2 (option)

(1)

(3)

(4)

3mm

(2)

151H96

S Check the function programming plug for X44 as shown in Z2--5.2 and put it into socket EZX44.

S Provide drag relief for the supply and data cables with the clamp present on the desk.

S Screw on the cable cover.

Make sure that the cable drag relief device of the release switch (1 cable tie) remains under the cover.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--6

OPTIMUS_RF_2_c021

Page 44

OPTIMUS R/F

3.2. Stand version

See ”Operating panel” in section 1.

Additional accessories:

-- 4 dowels S10

-- 4 hexagon cap screws 8 x 60mm

-- 4 washers

S Position the desk stand according to the respective room layout.

S Mark the fixing holes on the floor.

S Set the 4 dowels supplied into the floor (drill bit: 10mm).

S Screw on the desk stand with 4 screws and washers.

S Route the supply and data cables from the bottom to the top within the desk stand.

Provide the cables with drag relief.

Cable ends including plugs should protrude beyond the edge of the desk by about 500mm.

INSTALLATION

S Mount the release switch as described in chapter 3.1.

S Assign the RGDV buttons 1 ... 8 to the desired symbols as described in chapter 3.1.

S Connect the cables to the desk as described in previous chapter 3.1.

S Screw on the cable cover.

Ensure the cable drag relief device of the release switch (1 cable tie) remains under the cover.

S Mount the operating panel on the stand.

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--7

Page 45

3.3. Wall mounted version

See ”Operating panel” in section 1.

Additional accessories:

-- 4 ball-head bolts

-- 4 dowels S8

-- 4 hexagon cap screws 5 x 30mm

-- 4 washers

-- 2 screws 4 x 10mm

-- 2 angle plates

-- 4 nuts

OPTIMUS R/FINSTALLATION

S Screw on the angle plates into the wall frame.

The short ends of the angles must be pointing

upwards.

S Screw the 4 ball-head bolts into the wall support.

S Mark the 4 fixing holes of the wall frame at the

respective place on the wall.

S Set the dowels supplied into the wall

(drill bit: 8mm).

S Screw on the wall frame with the 4 hexagon cap

screws and washers.

S Provide drag relief for the supply and data cables

in the wall frame.

Cable ends including plugs should protrude

beyond the edge of the desk by about 500mm.

S Mount the release switch as described in chapter

3.1.

S Assign the symbols to the desired RGDV

buttons 1 ... 8 as described in chapter 3.1.

Desk fastening (2x)

Wall fastening (4x) Ball--head bolt (4x)

Cable passage

189H96

S Connect the cables to the desk as described in

previous chapter 3.1.

S Mount the operating panel on the wall frame and

fix it with the left two screws.

S Screw on the cable cover.

Ensure the cable drag relief device of the release

switch (1 cable tie) remains under the cover.

The wall frame is designed symmetrically.

In case connection cables come from above the

frame can be mounted upside down.

Only the ball-head bolts and the angle plates still

keep their position.

E 1998 Philips Medical Systems

OPTIMUS R/F(c/02.1)2--8

OPTIMUS_RF_2_c021

ALL RIGHTS RESERVED

Page 46

OPTIMUS R/F

3.4. Supporting angle version

INSTALLATION

S Screw the ball-head bolts (2) into the

supporting angles (1):

Left angle -- ----> on the left at the bottom

Right angle ------> on the right at the bottom

S Press the ball-head bolts (2) into the respective

snap bushing of the desk (4).

S Fix the supporting angles (2) to the desk (4) with

the2screwsM4(3).

3

2

1

4

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--9

Page 47

3.5. Additional release switch

An optional second release switch is supplied with a

longer spiral cable: 9890 000 0249x

The scope of delivery includes various wall hooks

and an adapter cable. Electrical connection is made

in parallel with the existing release switch which is

mounted on the desk itself.

S To do this, plug the pins of the adapter cable into

the D-Sub connector of the existing release

switch.

Sequence:

OPTIMUS R/FINSTALLATION

Adapter:

connector pin

<------>

D-Sub:

connector pin

1 <------> 6

2 <------> 9

3 <------> 7

Reference: Figure below and drawing Z1--11.1 “Operating panel C” in section Z1 “Schematic drawings”.

Hand switch with adapter (9890 000 0249x)

Hand switch 4512 103 7200x

(9803 700 3000x)

30-- / UI-- / --24V HS

S1

89

15

S2

11 1 2

36

32-- /HSPRRQ

31-- /HSEXRQ

br

1

bl

blk

2

3

1

2

3

Cable adapter

4512 104 3823x

br

bl

6

7

9

blk

Operating panel C

1

6

2

7

3

8

4

9

5

C300 X3

EXP PREP

096L99

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--10

OPTIMUS_RF_2_c021

Page 48

OPTIMUS R/F

Mai

INSTALLATION

4. Electrical connection

4.1. Earthing

See ”Earthing diagram” in section 1.

4.2. Mains conn ectio n

4.2.1. Mains connection of the generator

Warning!

Switch OFF the mains supply present at the clinic and make sure that it cannot be switched

ON again accidentally

See ”Connection diagram” in section 1.

S Measure the internal mains resistance at the terminal MEX with a suitable measuring instrument.

.

L1 - L2: R

L1 - L3: R

L2 - L3: R

= ............... mΩ

i

= ............... mΩ

i

= ............... mΩ

i

Required max. mains resistance at generator input:

ns voltage

190V * -- 40mΩ --

220V * 130mΩ 60mΩ --

240V * 160mΩ 80mΩ --

380V 500mΩ 300mΩ 200mΩ

400V 500mΩ 300mΩ 200mΩ

440V 500mΩ 350mΩ 240mΩ

460V 500mΩ 350mΩ 240mΩ

480V 500mΩ 400mΩ 300mΩ

Mains resistance

30kW 50kW 65/80kW

* with external mains transformer (max 50kW)

Maximum permissible internal mains resistance: 500mΩ

Internal resistance of Power Distribution Unit PDU: 20mΩ at 50Hz

23mΩ at 60Hz

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--11

Page 49

OPTIMUS R/FINSTALLATION

Caution!

Connect phase wires in correct phase sequence.

S Connect the mains cable of the generator to terminal MEX: L1 / L2 / L3 within the wall connection box.

If the optional Power Distribution Unit PDU WT is fitted, connect the cables at that point to terminal WTX2.

S Connect the examination unit supply (max. 10A) to (230V / 400V):

Output 1 Geometry power ENX2101/...5

Output 2 I.I. / TV; GECO; UI; SYSCO ENX2201/...9

Output 3 Imaging ENX2301/...9

Output 3 not switched by generator

4.2.2. Mains connection of the PDU

See delivered Unit Manual “Power Distribution Unit”.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--12

OPTIMUS_RF_2_c021

Page 50

OPTIMUS R/F

4.3. Stator connection

4.3.1. Shielding

Caution!

To suppress interferences of the high -speed

rotor control, the stator connections must be

provided with a 360_ screen at the tube and

generator end.

General remarks:

S Always use screened cables: 0722 215 02054.

S Shorten the stator cable to the required length.

Do not accommodate excess lengths at the

generator.

S Keep stator cable separate from all the other

signal cables to avoid interference.

S Earth the screen at both cable ends.

INSTALLATION

Screening procedure:

S Remove any enamel or dirt from the clamp

providing drag relief in the tube housing to make

sure the clamp is conductive.

S Remove the plastic covering around the clamp,

about 1cm (0.5”).

S Wrap copper foil around the visible screen of the

cable until the original diameter of the cable is

obtained.

S Remove the present red wire going from the

screen end to the earthing point of the tube

housing.

S Fix the screen of the stator cable with the clamp.

Ensure that the clamp is secured and the ground

contact works!

Wire must be discarded

Copper foil layers up to

the insulation diameter

ROT 350 fixing clamp

Screening of the stator cable.

327H97

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--13

Page 51

4.3.2. Connection

Caution!

Do not mix up the phases, otherwise components

of the rotor control may be destroyed.

OPTIMUS R/FINSTALLATION

At the tube

end

S Place the jumpers across terminals 100 and 200

according to the figure.

S Connect the stator cable:

wire 1 ------> phase U

wire 2 ------> phase V

wire 3 ------> phase W

U

SRO/RO

V

W

101 202

109 210

148H94

S Earth the screening of the stator cable at the tube

housing with the metallic clamp.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--14

OPTIMUS_RF_2_c021

Page 52

OPTIMUS R/F

INSTALLATION

At the generator end: One--tube

version

See ”Connection diagram” in section 1.

S Connect the stator cable to the terminal EX1100

(U-V-W).

S Check the stator connection by measuring the

resistances:

U -- V = wire 1 -- 2 ≈ 11Ω

U -- W = wire 1 -- 3 ≈ 20Ω

V -- W = wire 2 -- 3 ≈ 9Ω

S If an inductance meter is available, measure the

following inductance values:

U -- V = wire 1 -- 2 = 57mH ±10%

V -- W = wire 2 -- 3 = 34mH ±10%

S Fix the screen below the screening clamp.

S Relieve the tension of the stator cable by a cable

tie.

E

rotor control

U

1

X1100

VW

2

3

cable tie

screening

clamp

tube

191H96

At the generator end: Two--tube

version

See ”Connection diagram” in section 1.

S Connect the stator cables to the terminals

EWG:K11/K12.

S Check the stator connections of both tubes by

measuring the resistances:

U -- V = wire 1 -- 2 ≈ 11Ω

U -- W = wire 1 -- 3 ≈ 20Ω

V -- W = wire 2 -- 3 ≈ 9Ω

S If an inductance meter is available, measure the

following inductance values:

U -- V = wire 1 -- 2 = 57mH ±10%

V -- W = wire 2 -- 3 = 34mH ±10%

S Fix the screen below the screening clamp.

S Relieve the tension of the stator cables by cable

ties.

E

screening clamps

WG

K11

642

2

1

3

1

2

tube 1 tube 2

K12

64

3

2

cable ties

198H98

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--15

Page 53

At the generator end: Three--tube version

See ”Connection diagram” in section 1.

S Connect the stator cables to the terminals

E1WG:K12 and E2WG:K11/K12.

S Check the stator connections of all 3 tubes by

measuring the resistances:

U -- V = wire 1 -- 2 ≈ 11Ω

U -- W = wire 1 -- 3 ≈ 20Ω

V -- W = wire 2 -- 3 ≈ 9Ω

E

1WG

K11

OPTIMUS R/FINSTALLATION

2WG

K12

64

2

3

1

2

K11 K12

64

2

3

1

2

64

2

3

1

2

S If an inductance meter is available, measure the

following inductance values:

U -- V = wire 1 -- 2 = 57mH ±10%

V -- W = wire 2 -- 3 = 34mH ±10%

S Fix the screens below the screening clamps.

S Relieve the tension of the stator cables by cable

ties.

tube 2

screening clamps

cable ties

tube 1 tube 3

348H98

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--16

OPTIMUS_RF_2_c021

Page 54

OPTIMUS R/F

4.4. Signal cables

See: -- ”Connection diagram” in section 1.

-- Z1--6 ”Basic interface” in section “Schematic drawings”

4.4.1. Room decade cable

S Connect the door switches at the generator:

EZX1: 8 <------> switch <------> 10

or

EZX1

EWGX2

or

EWGX3

room 1

room 2

INSTALLATION

1WGX3room 2

or

2WGX2room 1

2WGX3room 3

E W B X 2 2 : 8 < -- -- -- > s w i t c h < -- -- -- > 1 0

In case no switch is present

l i n k : p i n 8 < -- -- -- > p i n 1 0

EZ150 K1:

max. switching and loading current = 1A

max. Load = 60VA AC

= 30W DC

Caution!

Make sure the polarity of the relay is correct.

SW UN EX

PO26V

CMSW

RM DR CT

RM DR 0V

4

5

6

8

9

10

Door switch connection.

Wall junction box

ME

--

+

screen

Umax.=230V

Imax.=1A

radiation

indication

door switches

143H94

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--17

Page 55

OPTIMUS R/FINSTALLATION

S In case of tube 2 or 3 is located in room 2 or 3 or

while room decades

-- W G X 3 o r

-- 1 W G X 3 o r

-- 2 W G X 3

are intended to be used for room supervision the

soldering link WG W1 must be placed.

Only when this link is placed it is guaranteed that

relay WG K3 pulls up and room decade WG X3 is

activated when switch-over of the tube takes

place.

See Z1--14.xx ”Tube extension”.

S If needed connect an external relay for each

examination room to control external radiation

warning devices.

One relay inclusive cable is part of delivery,

Additional ones can be ordered: 4512 100 4523.

X11

1

4

2

5

3

6

soldering link

X13

1

2

EWG

W1

door s witches

room 1

X1 X2

1

2

3

4

5

6

7

8

9

10

door s witches

room 2

1

2

3

4

5

6

7

8

9

10

X3

10

1

2

3

4

5

6

7

8

9

A mounting place is reserved on the mains

connection terminal MEX of the wall junction box.

Caution!

Make sure the polarity of the relay is correct.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--18

OPTIMUS_RF_2_c021

Page 56

OPTIMUS R/F

4.4.2. Tube supervision

S Connect the thermal switch or the thermal sensor

of the tube housing assembly.

S Check polarity of contacts 9 and 10 to CAN

adapter to remote systems like D96.

EZX3

EWGX8

or

EWGX9

tube 1

tube 2

INSTALLATION

E1 WG X9 tube 2

or

E2 WG X8 tube 1

E2 WG X9 tube 3

For U.S.A. and U.K. only:

S Connect the HHS-lamp to indicate the selected

3

4

tube housing assembly.

6

PO 26V

7

9

10

CM TH SW

screen

Tube supervision connection.

4.4.3. CAN interface

Only for examination units which are provided with a CAN syst em interface.

S Connect the following plugs:

TH OL

CM TH

TH OL SW

HHS lamp

24V / max. 5W

D76

D76plus

R/F controller

9

10

System Connector

EZX23

signal bus

EZX42 or

EZX42--1

system CAN

EZX43 or

EZX43--1

system CAN

BukyDiagnost TH / TH2 X X

DigitalDiagnost X X X

Thoravision X X X

EasyDiagnost with Bucky unit X X X

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--19

Page 57

4.4.4. Adapter for 4 auxiliary units

OPTIMUS R/FINSTALLATION

Adapter for 4 auxiliary units RAD (Bucky, Tomo) WA / 1WA / 2W

A

Used for Bucky examination units which provide their control signals individually via decade cables.

Each of the release circuits and the Bucky decades can be assigned to one or several of the RGDV buttons 1...8

via software programming.

Survey: ”Connection diagram” in section 1

Z1--1.2 ”Block diagram Expansions” in “Schematic drawings” section

Detail: Z1--15.1 ”Adapter 4 aux. units WA / 1WA / 2WA” in “Schematic drawings” section

It provides:

1. 4 release decades to be used for

-- grid / syncmaster auxiliaries

-- HHS cassette present interlock

2. 2 Bucky decades to be used for

-- format size contacts (collimator, side fields ON/OFF)

-- Bucky--tomo remote switch--over

-- tomo ready condition

-- Bucky ready condition

-- HHS cassette present interlock

to be activated by SW programming (see chapter 8.2)

After activation via SW: Signals not provided by the system must be simulated by jumpers.

3. 1 decade EXON signal for the system via opto coupler

4. 1 decade (output) for 8 tomo trajectories

5. 1 decade for 8 tomo time inputs

6. 1 decade for 8 external APRT

-- WA backpanel programmed as 1WA = 2 AUX + 6 APRT

-- WA backpanel programmed as 2WA = 8 APRT

7. 1 decade for PSC (Patient Size Correction)

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--20

OPTIMUS_RF_2_c021

Page 58

OPTIMUS R/F

INSTALLATION

Adapter for 4 auxiliary units R/F (Fluoro, Bucky)

WB

Used for fluoroscopy and Bucky examination units which provide their control signals individually via decade

cables.

Each of the release circuits and the Bucky decades can be assigned to one or several of the RGDV buttons 1...8

via software programming.

Survey: ”Connection diagram” in section 1

Z1--1.2 ”Block diagram Expansions” in “Schematic drawings” section

Detail: Z1--15.2 ”Adapter 4 aux. units WB” in “Schematic drawings” section

It provides:

1. 4 release decades to be used for

-- grid / syncmaster auxiliaries

-- HSS cassette present interlock

2. 1 Bucky decade to be used for

-- format size contacts (collimator, side fields ON/OFF)

-- Bucky system ready condition

3. 1 fluoroscopy decade supporting

-- dose rate limiter (short SID)

-- l o c k -- i n

4. 1 decade EXON signal for the system via opto coupler

5. 1 decade cassette / camera remote switch--over

6. 1 decade for image intensifier and Scopomat measuring chamber formats

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--21

Page 59

7. 1 system decade providing external signals

-- generator ready display

-- prep or fluoro display

-- 5 minute fluoro warning display / buzzer

-- under exposure display

-- system reset for under--exposure / 5min buzzer

-- EXON signal for the system (potential free relay contact)

-- door contact

8. 1 decade for 8 external APRT

9. 1 decade for PSC (Patient Size Correction)

OPTIMUS R/FINSTALLATION

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--22

OPTIMUS_RF_2_c021

Page 60

OPTIMUS R/F

INSTALLATION

4.4.5. Dose inputs

S Connect the measuring chambers to the D-Sub connectors EZX21 / 22 / 31 / 32 / 41.

There are no assignement restrictions because the measuring chambers are allocated to the auxiliaries in SW

programming.

S Withdraw pins 101--102--103 or A--D--H for measuring field selection at the junior / extremity measuring chamber.

These measuring chambers have only one measuring field. The terminal for the left-hand field is used in other

configurations for switching over intensification and must not be connected here.

S Connect the photosensor dose output of DSI from Central Part E (BHX 12) to EZX41.

Only EZX41 sends the necessary signal REL (or REL_CH = RELease CHamber) for automatic and

non-automatic techniques.

Note

AMPLIMAT cables 9803 507 0xx02 (for hybrid measuring chambers 9803 509 xxxxx) with 3--Plus plugs at both

ends must be connected in the generator by the following adapter for each cable:

Adapter for AMPLIMAT cable: 4512 108 09042. The generator includes 1 adapter.

The hybrid measuring chambers 9803 509 xxxxx require connection (chassis) between contacts

D--Sub end GND (13) <---- --> RF 0V (8) (generator input)

or

3--Plus end GND (N) <------> RF 0V (J) (generator input)

This connection is established by the adapter for the AMPLIMAT cable.

See Z1--6 ”Basic interface” in section “Schematic drawings” of the generator manual.

In case of a hybrid measuring chamber 9803 509 xxxxx is not operated with the required

AMPLIMAT cables 3--Plus / 3--Plus 9803 507 0xx02..... .....

but with

AMPLIMAT cables D--Sub / 3--Plus 9890 000 017xx..... .....

make sure to establish this connection (13 <-- -- --> 8) in the D--Sub connector!

For ALC measuring chambers 9890 000 016xx connection GND <------> RF 0V is not permitted.

Therefore, ALC measuring chambers AMPLIMAT cables 9890 000 017xx should always be used.

4.4.6. Patient Data Organizer PDO (option)

See operator’s manual Patient Data Organizer.

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--23

Page 61

OPTIMUS R/FINSTALLATION

4.5. H.V. cables generator side

See ”Connection diagram” in section 1.

S Mark the H.V. cables at the generator and the tube end with the correct polarity.

S Fix the H.V. cables on the left-hand side of the wall junction box on the middle rail to provide drag relief for the

cables. The short ends of the H.V . cables which are going to the H.V. generator must be routed in downward

direction in this area.

The free cable lengths including plugs should be about 1.5m.

S Twist the H.V. cables counter-clockwise by one turn and connect them to the H.V . generator.

The twisting of the cables allows that the H.V . cables can be put into a loop when the cabinet is placed against

the wall.

The H.V. sockets should always be filled with some oil. At least the lower half of the plugs must be wet with oil.

Caution!

Do not use a silicone washer.

Do not grease the plugs with silicone.

The union nuts of the high-voltageconnectors must be tightened up to ensure good electrical contact for

screening.

Only high-voltage connectors which have threaded flange halves may be used.

Older high-voltage cables still have connectors where the flange halves are kept together with a spring

washer.

In such cases the modification kit 4512 103 8085x is required.

4.6. Emergency--OFF circuit

S Connect the emergency--OFF buttons to EZX4:1/2.

If not necessary, link pins 1 -- 2.

See Z1--2.1 ”Power supply” in “Schematic drawings” section and Z2--5.2 “Backpanel Basic rack--2Z” in the

“Wiring diagrams” section.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--24

OPTIMUS_RF_2_c021

Page 62

OPTIMUS R/F

5. Hardware programming

Programmings on PCB EZ150 basic interface:

Note

Never change jumper W1.

S Voltage supply for the amplifiers of connected

measuring chambers:

Voltage\Soldering link EZ 150 W2 EZ 150 W3

INSTALLATION

EZ 150

Basic interface

15V default OFF ON

40V ON OFF

Working voltage range for ALC measuring

chambers: 15

... 45V

Working voltage range for hybrid measuring

chambers: 40

... 45V

ALC measuring chambers can be recognized by the

code No. 4512 104 xxxxx.

Hybrid measuring chambers are based on code No.

4512 102/103 xxxxx.

S Set the gain factor for AEC techniques with jumper

EZ150:W4:

-- Factor 1 ==> W4 in position 3 = default

For screen/film combination with at least one

system speed ≤ 200.

W1 do not change!

PCB layout print different from figure.

195H96

-- Factor 4 ==> W4 in position 1

For screen/film combinations with all system

speeds > 200.

S The software programming has to be set

accordingly.

The rest of the generator hardware has been

properly programmed at the factory.

If required, refer to section 5: PROGRAMMINGS.

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--25

Page 63

6. Switch--ON of the generator

S Switch ON the fuses present at the clinic.

S Switch ON automatic circuit-breakers ENF1, ENF2 and ENF3.

The yellow LED on EN100 power ON circuit must be illuminated.

OPTIMUS R/FINSTALLATION

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--26

OPTIMUS_RF_2_c021

Page 64

OPTIMUS R/F

INSTALLATION

7. Installation software XRGSCOPE

7.1. PC and generator settings to avoid problems during up/downloading of CU complete files

Optimus R/F release 2.x and 3.x CMOS data are up/downloaded in one string without handshake.

Any kind of interruption can cause the loading process to fail.

Problems occur mainly during the download to the PC.

A download file which is not complete cannot be used as a safety backup file.

7.1.1. Preparation of the service PC to guarantee a safe loading process

Start XRGSCOPE always from DOS if possible.

When using any WINDOWS version:

S Switch OFF all screensavers.

S Do not run other programs.

S Do not insert any CD in the drive.

Any kind of power management of the PC hardware (BIOS) as well as the windows power management should

be switched OFF.

If connected to mains power some of these might be automatically OFF.

7.1.2. Preparation of the generator

Preparation of generators without a CAN

interface:

S Switch ON the generator.

The loading process can be started once relay ENK1 has been energized.

OPTIMUS R/F (c/02.1)

OPTIMUS_RF_2_c021

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

2--27

Page 65

Preparation of generators which are connected via a CAN interface:

-- BuckyDiagnost TH and TH2

-- DigitalDiagnost

-- Thoravision

-- EasyDiagnost with Bucky unit

S Switch OFF the generator.

S Disconnect the following plugs:

System Connector

OPTIMUS R/FINSTALLATION

EZX23

signal bus

EZX42 or

EZX42--1

system CAN

EZX43 or

EZX43--1

system CAN

BukyDiagnost TH / TH2 X X

DigitalDiagnost X X X

Thoravision X X X

EasyDiagnost with Bucky unit X X X

S Switch ON the generator.

Note

The download procedure must not be started before relay ENK1 has been energized at least 2 minutes after

the generator has been switched ON.

Note

In case of mailing CU complete download files or any other xxx.TDL files use a zipped file format.

These files are ASCII files which might be destroyed while being mailed.

E 1998 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS R/F(c/02.1)2--28

OPTIMUS_RF_2_c021

Page 66

OPTIMUS R/F

7.2. Installation procedure

S Provide the service PC with the hardware key and switch it ON.