Philips NUDOS, HQ 4885-B, HQ 4865-B, HQ 4845-B, HQ 3865-B Service Manual

NUDOS NiCd Shavers

HQ 3865/B

Service

HQ 4845/B

HQ 4865/B

Service

HQ 4885/B

Service

Domestic Appliances and Personal Care

Circuit Description

INTRODUCTION

The Nudos shavers with NiCd cells can be recharged

in 30 minutes by means of a Fly Back Self Oscillating

Power Supply (SOPS).

This electronic circuit enables cells to be recharged at

100-240 V .

It is possible to shave directly from the mains,

provided the voltage exceeds 100V .

The on/off slide has a locking device, which prevents

the shaver from being switched on accidentally.

Leaving it connected to the mains after it is fully

charged will not damage the shaver.

However, the life of the cells may be shortened if the

shaver is kept permanently connected.

If the shaver is kept in the case when charging, make

sure that the lid is open to prevent overheating.

HINTS FOR REPAIRS

a. Disassembly

- Remove the shaving unit, to prevent damages

during repairs.

- Remove screws A1 (4X, of which 2 are under

trimmer slide).

- Put the shaver on the table and remove the cover

(item 26) from the shaver.

- The trimmer can be removed by pushing the hinge

points (‘Y’ in exploded view, near item 11) slightly

inwards.

- Detach the motor clamping springs (item 18) on the

bearing block with a small screwdriver.

- The PC-boards with motor can now be removed

from the housing.

- Remove screws A2 (2X).

- Unlock the snap connection (3X) between frame

(item 14) and hair chamber (item 11).

- If the Power Module (item 23) and Time Control

Module (item 7) have to be separated, read the

instructions under IMPORTANT.

b. Assembly

- The assembly must be carried out in reverse order

of what is described under a. Disassembly.

- The trimmer slide can be snapped into the cover

last.

Published by Philips Domestic Appliances and Personal Care Printed in The Netherlands Copyright reserved Subject to modification

4822 729 22107

97/04 - 99/01

PCS 99 106

©

NUDOS NiCd shavers

2

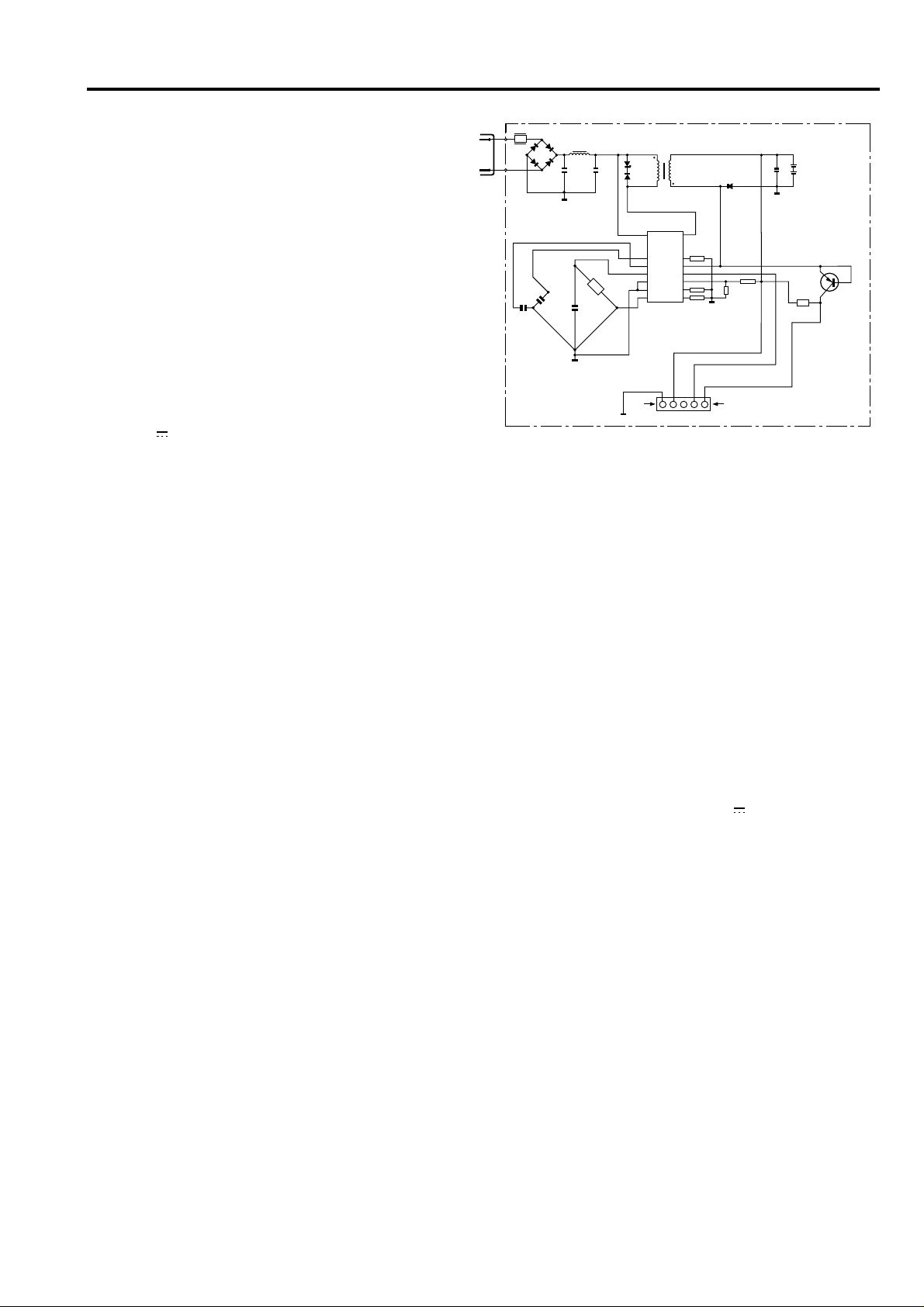

TECHNICAL DESCRIPTION

The electronics for the Nudos shavers with NiCd

cells consist of 2 modules:

a Power Module (PM) and a Time Control Module

(TCM), connected via a 5-pin connector.

POWER MODULE

The PM consists of a High Voltage Integrated Circuit

(HVIC) and some external components, regulating the

following functions:

a. a current controller to adjust the charge current at

1200 mA or at 100 mA.

b. a 2.5 V dynamic supply controller for shaving

from the mains.

c. a primary current limiter (max 400 mA) to protect

the transformer from saturation.

d. a frequency limiter (max 60 kHz).

e. an open cell protection (Vbat>5V).

f. a temperature protection (Tchip>140˚C).

R1

100-240 V

50/60Hz

L1

D4

C1

C2

C4

C6

R7

C5

D1

D2

T1

18

1

17

2

16

3

15

4

14

5

6

13

12

7

11

8

IC1

10

9

TEA 1402

12345

C3

D3

R5

R8

R9

R10

R12

MPMP

The TCM has 3 variants:

HQ3865 with 4 green LEDs and 1 red/green duoLED.

HQ4845 with 1 red LED and 1 green LED.

HQ4865 with 4 green LEDs and 1 red/green duoLED.

HQ4885 with LCD, 1 red LED and 1 green LED.

2 x AA

NiCd

A

TS1

R14

The mains voltage is full-wave rectified by D4 and

smoothed by π-filter C1-L1-C2.

This filter also serves as a radio interference filter

(RIF) for the SOPS and motor and as a suppressor of

voltage transients from the mains.

Resistor R1, which functions as a fuse, limits the

switch-on (inrush) current and the transient (surge)

current.

The resistor interrupts in case of a too large mains

current due to improper use or internal short circuit.

The primary-current circuit consists of the primary

winding of T1 and the high-voltage switch inside the

HVIC (IC1).

Snubber circuit D1-D2 limits the voltage across the

primary winding during commutation.

During the flyback of the converter (when the switch

is open) the secondary winding of T1 will deliver the

primary energy across D3 and R2 to the cells or to

the R26 sensed motor.

TIME CONTROL MODULE

The primary function of the TCM is:

Monitoring the capacity of the cells during charging

and discharging.

- controlling the 3 charging modes:

1. 1200 mA during max. 30 minutes.

2. 100 mA if the voltage across the 2 cells

exceeds 2.5.V and charging exceeds 30 minutes.

3. 200-1800 mA at 2.5 V when the motor is

switched on at the same time.

When the PM is connected to the mains, a signal will

be generated by the SOPS, which is recognised by

the TCM as ‘mains on’.

Depending on the frequency of this signal, the TCM

forces the PM into the quick charge mode as long as

the capacity counter has not reached the ‘full’ state.

After max. 30 minutes the PM is set to the slow

charge mode.

If during charging the shaver is switched on, the PM

is set to the dynamic 2.5 V mode, in which the control

switches from TCM to PM.

With empty cells this means that no charging takes

place till the cells reach the 2.5 V level,

consequently the capacity counter is not activated.

If the cell voltage is higher than 2.5 V, the motor

current will come from the cells.

The capacity counter will now count down, as

signalled via R26.

If the voltage drops below 2.5 V again, the PM takes

over the supply of the motor current.

During charging and discharging the IC calculates the

capacity available in the cells and subsequently

generates signals to activate the LEDs and/or LCD,

the sequence being:

Loading...

Loading...