Page 1

1PHILIPS MD 1.2E/AA

Recommended Safety Parts

Item Part No. Description

4822 265 30389 2P conn. L01,L02

4822 256 92053 Fuse holder

4822 492 62076 Spring transistor

1463 4822 252 11194 19398E1 (0,800A)

1501 4822 070 33152 2183.15 (3.15A)

1566 4822 252 51175 19398E1 (2,500)

1572 4822 071 52502 19372 (2.5A)

1580 4822 252 51186 19398E1 (2,0A)

2425 4822 121 70434 11nF 5% 1.6KV

2425 5322 121 44345 15nF 5% 1.6KV

2426 4822 121 42934 27nF 10% 400V

2427 4822 121 10563 0.82uF 5% 250V

2433 4822 126 12274 1500pF 10% 2KV

2450 4822 121 40518 100nF 10% 250V

2487 4822 124 40433 47uF 20% 25V

2500 4822 121 70285 470nF 10% 250V

2505 4822 124 11772 150uF 20% 385V

2505 4822 124 23492 220uF 50% 385V

2506 4822 121 40487 100nF 10% 400V

2511 4822 126 11141 2.2nF 10% 1KV

2512 4822 126 11141 2.2nF 10% 1KV

2540 4822 126 12426 330pF 10% 1KV

2543 4822 126 13451 2.2nF 10% 2KV

2544 4822 126 13451 2.2nF 10% 2KV

2550 4822 126 10727 3.3nF 20% 400V

2559 4822 124 40433 47uF 20% 25V

2568 4822 126 12426 330pF 10% 1KV

2609 4822 124 40433 47uF 20% 25V

2751 4822 124 41579 10uF 20% 50V

2752 4822 124 41579 10uF 20% 50V

2763 4822 124 41579 10uF 20% 50V

3401 4822 052 11229 22 ohm 5% 0.5W

3402 4822 052 11229 22 ohm 5% 0.5W

3430 4822 052 11471 470 ohm 5% 0.5W

3443 4822 052 10688 6 ohm8 5% 0.33W

3461 4822 052 10228 2 ohm2 5% 0.33W

3461 4822 052 11158 1 ohm5 5% 0.5W

3462 4822 052 10228 2 ohm2 5% 0.33W

3464 4822 052 11568 5 ohm6 5% 0.5W

3472 4822 052 10228 2 ohm2 5% 0.33W

3483 4822 050 24708 4 ohm7 1% 0.6W

3484 4822 050 24708 4 ohm7 1% 0.6W

3500 4822 116 21224 1MA/387V VDR

3502 4822 052 10338 3ohm3 5% 0.33W

3506 4822 117 12027 18ohm-3k ohm 25% PTC

3524 4822 052 10109 10ohm 5% 0.33W

3540 4822 116 83027 0.22 ohm 5% 3W

3541 4822 052 10102 1K 5% 0.33W

3545 4822 052 10159 15 ohm 5%m 0.33W

3588 4822 052 11338 3 ohm 3 5% 0.5W

3752 4822 052 10828 8 ohm 2 5% 0.33W

3753 4822 052 10828 8 ohm 2 5% 0.33W

5410 4822 142 40351 Line drive transf.

5421 4822 157 63079 LC coil (21”)

5421 4822 157 10992 LC coil (other)

5424 4822 157 53069 Balance coil

5430 4822 140 10595 LOT ELDOR (21”)

5430 4822 140 10584 LOT CML16P

5480 4822 158 10728 Bridge coil. 11uH

5503 4822 142 40315 Mains filter

5550 4822 146 10366 Transf. CE425V

5550 4822 146 31469 transf. 10290250

6423 4822 130 41275 BY228/20

6424 4822 130 41602 BYW95C/20

6457 4822 130 30621 1N4148

6480 4822 130 30621 1N4148

6481 4822 130 30621 1N4148

6510 4822 130 31933 1N5061

6511 4822 130 31933 1N5061

6512 4822 130 31933 1N5061

6513 4822 130 31933 1N5061

6524 4822 130 31631 BYV10-20

6530 4822 130 30621 1N4148

6571 4822 130 31982 BYV27-100

6591 4822 130 30621 1N4148

6600 4822 130 30621 1N4148

6601 4822 130 30621 1N4148

6763 4822 130 30621 1N4148

7420 4822 130 63271 BU2508AF

7421 4822 130 10779 BU1506DX

7450 4822 130 44197 BC558B

7520 4822 209 90025 MC44603P

7556 4822 130 10025 CNX82A

7561 4822 130 44197 BC558B

7580 4822 209 80817 MC7800

7591 4822 130 44197 BC558B

7602 4822 130 41344 BC337-40

7605 4822 130 44197 BC558B

1100 4822 071 51001 Fuse 19372(100mA)

2008 4822 124 40196 220uF 20% 16V (BG LI)

2009 4822 124 41579 10uF 20% 50V

2033 5322 126 10223 4.7nF 10% 63V

2034 5322 126 10223 4.7nF 10% 63V

2036 5322 126 10223 4.7nF 10% 63V

2037 4822 124 41579 10uF 20% 50V

2101 5322 126 10223 4.7nF 10% 63V

2104 5322 126 10223 4.7nF 10% 63V

Recommended Safety Parts

Item Part No. Description

2105 5322 126 10223 4.7nF 10% 63V

2108 5322 126 10223 4.7nF 10% 63V

2125 4822 122 33177 10nF 20% 50V

2127 4822 124 41579 10uF 20% 50V

2136 5322 122 34123 1nF 10% 50V

2137 4822 126 10002 100nF 20% 25V

2138 4822 122 33177 10nF 20% 50V

2139 4822 122 33177 10nF 20% 50V

2140 5322 122 34123 1nF 10% 50V

2144 5322 122 34123 1nF 10% 50V

2145 5322 122 34123 1nF 10% 50V

2158 4822 124 40433 47uF 20% 25V

2162 5322 126 10223 4.7nF 10% 63V (P/Sec.)

2169 4822 122 33177 10nF 20% 50V

2170 5322 126 10223 4.7nF 10% 63V

2171 4822 122 33177 10nF 20% 50V

2175 5322 122 34123 1nF 10% 50V

2176 5322 122 34123 1nF 10% 50V

2179 4822 124 40433 47uF 20% 25V

2600 4822 124 41579 10uF 20% 50V

2606 4822 122 33177 10nF 20% 50V

2607 4822 122 33177 10nF 20% 50V

2655 5322 122 34123 1nF 10% 50V

2665 4822 126 10002 100nF 20% 25V

2685 4822 122 33177 10nF 20% 50V

2700 4822 122 33177 10nF 20% 50V

2703 5322 122 32654 22nF 10% 63V

2708 4822 126 10002 100nF 20% 25V

2709 4822 122 33177 10nF 20% 50V

2711 4822 126 10002 100nF 20% 25V

2712 5322 122 32654 22nF 10% 63V

2715 4822 124 41579 10uF 20% 50V

2716 4822 124 41579 10uF 20% 50V

2830 4822 124 41579 10uF 20% 50V

2837 4822 126 10002 1nF 20% 25V

3031 4822 051 20472 4k7 5% 0.1W

3032 4822 051 20472 4k7 S% 0.1W

3033 4822 051 20472 4k7 5% 0.1W

3040 4822 052 10479 47ohm 5% 0.33W

3126 4822 051 20153 15k 5% 0.1W

3156 4822 051 20109 10ohm 5% 0.1W

3162 4822 052 10478 4ohm7 5% 0.33W

3169 4822 052 10478 4ohm7 5% 0.33W

3186 4822 052 10478 4ohm7 5% 0.33W

3190 4822 051 20332 3k3 5% 0.1W

3193 4822 051 20008 0 ohm (jumper)

3613 4822 051 20472 4k7 5% 0.1W

3614 4822 051 20472 4k7 5% 0.1W

3616 4822 051 20472 4k7 5% 0.1W

3617 4822 051 20472 4k7 5% 0.1W

3623 4822 051 20472 4k7 5% 0.1W

3624 4822 051 20472 4k7 5% 0.1W

3670 4822 051 20472 4k7 5% 0.1W

3680 4822 051 20472 4k7 5% 0.1W

3691 4822 051 20472 4k7 5% 0.1W

3692 4822 051 20472 4k7 5% 0.1W

3704 4822 051 20008 0 ohm (jumper)

3805 4822 052 10109 10 ohm 5% 0.33W

3817 4822 051 20472 4k7 5% 0.1W

3826 4822 051 20121 120 ohm 5% 0.1W

3847 4822 052 10109 10 ohm 5% 0.33W

3860 4822 051 20472 4k7 5% 0.1W

5106 4822 157 51462 10uH

6030 4822 130 30621 1N4148

6031 4822 130 30621 1N4148

6032 4822 130 30621 1N4148

6105 4822 130 30621 1N4148

6106 4822 130 30621 1N4148

6107 4822 130 30621 1N4148

6108 4822 130 30621 1N4148

6109 4822 130 30621 1N4148

6660 4822 130 30621 1N4148

6661 4822 130 30621 1N4148

6700 4822 130 30621 1N4148

6830 4822 130 31983 BAT85

7009 5322 130 41982 BC848B

7010 5322 130 41982 BC848B

7030 5322 130 41982 BC848B

7031 5322 130 41982 BC848B

7032 5322 130 41982 BC848B

7100 5322 130 41982 BC848B

7102 5322 130 41982 BC848B

7120 5322 130 41982 BC848B

7150 5322 130 41982 BC848B

7601 5322 130 41982 BC848B

7604 5322 130 41982 BC848B

7605 5322 130 41982 BC848B

7608 5322 130 41982 BC848B

7700 5322 130 41982 BC848B

7826 5322 130 41982 BC848B

7850 5322 130 41982 BC848B

7867 5322 130 41982 BC848B

4822 255 70261 Socket Pict. tube

2320 4822 122 33172 390pF 5% 50V

2383 4822 124 40433 47uF 20% 25V

3309 4822 052 10102 1K 5% 0.33W

3329 4822 052 10102 1K 5% 0.33W

Recommended Safety Parts

Item Part No. Description

3349 4822 052 10102 1K 5% 0.33W

3355 4822 051 20109 10 ohm 5% 0.1W

3356 4822 051 20008 0 ohm (jumper)

3386 4822 052 10128 1 ohm2 5% 0.33W

3387 4822 052 10109 10 ohm 5% 0.33W

3388 4822 052 10689 68 ohm 5% 0.33W

3391 4822 051 20008 0 ohm (jumper)

6344 4822 130 30621 1N4148

7301 5322 130 41982 BC848B

7321 5322 130 41982 BC848B

7340 5322 130 41982 BC848B

7365 5322 130 41982 BC848B

2352 4822 124 41579 10uF 20% 50V

2353 4822 124 41579 10uF 20% 50V

2354 4822 124 41579 10uF 20% 50V

2355 4822 124 41579 10uF 20% 50V

2356 4822 124 41579 10uF 20% 50V

2357 4822 124 41579 10uF 20% 50V

2358 4822 124 41579 10uF 20% 50V

2359 4822 124 41579 10uF 20% 50V

2360 4822 124 41579 10uF 20% 50V

2361 4822 124 41579 10uF 20% 50V

2362 4822 124 41579 10uF 20% 50V

2363 4822 124 41579 10uF 20% 50V

2365 4822 124 41579 10uF 20% 50V

2367 4822 124 41579 10uF 20% 50V

2368 4822 124 41579 10uF 20% 50V

2373 5322 126 10223 4.7nF 10% 63V

2378 5322 126 10223 4.7nF 10% 63V

2382 5322 122 34123 1nF 10% 50V

2383 5322 122 34123 1nF 10% 50V

2386 5322 122 34123 1nF 10% 50V

2387 5322 122 34123 1nF 10% 50V

2388 5322 122 34123 1nF 10% 50V

2389 5322 122 34123 1nF 10% 50V

2390 5322 122 34123 1nF 10% 50V

2394 4822 126 10002 100nF 20% 25V

2395 5322 122 34123 1nF 10% 50V

2396 4822 122 33172 390pF 5% 50V

2397 4822 122 33172 390pF 5% 50V

2398 4822 126 10002 100nF 20% 25V

2401 4822 126 10002 100nF 20% 25V

2408 4822 126 10002 100nF 20% 25V

2452 5322 126 10223 4.7nF 10% 63V

2453 5322 126 10223 4.7nF 10% 63V

2454 5322 126 10223 4.7nF 10% 63V

2455 5322 126 10223 4.7nF 10% 63V

3364 4822 051 20472 4k7 5% 0.1W

3376 4822 051 20472 4k7 5% 0.1W

3382 4822 051 20332 3k3 5% 0.1W

3383 4822 051 20332 3k3 5% 0.1W

3387 4822 051 20332 3k3 5% 0.1W

3389 4822 051 20332 3k3 5% 0.1W

3395 4822 051 20008 0 ohm (jumper)

5351 4822 157 51462 10uH

6384 4822 130 30621 1N4148

7350 4822 209 83163 LM833N

7351 4822 209 83163 LM833N

7382 5322 130 41982 BC848B

7383 5322 130 41982 BC848B

7387 5322 130 41982 BC848B

7389 5322 130 41982 BC848B

7415 5322 130 41982 BC848B

7420 5322 130 41982 BC848B

7427 5322 130 41982 BC848B

7430 5322 130 41982 BC848B

7432 5322 130 41982 BC848B

2000 5322 126 10223 4.7nF 5% 63V

7002 5322 130 41982 BC848B

2279 4822 124 40433 47uE 20% 25V

2285 5322 122 32654 22nF 10% 63V

3278 4822 051 20332 3k3 5% 0.1W

3288 4822 052 10399 39ohm 5% 0.33W

3292 4822 052 10689 68ohm 5% 0.33W

7276 5322 130 41982 BC848B

7282 5322 130 41982 BC848B

5013 4822 142 40344 Driver transformer

6011 4822 130 31631 BYV10-20

0022 4822 276 13592 Mains switch

4822 265 30389 2P conn. vert. K12

4822 267 51348 2P conn. K09

3520 4822 053 21475 4M7 5% 0.5W

3521 4822 053 21475 4M7 5% 0.5W

2810 4822 122 33342 33nF 10% 63V

2832 4822 122 33177 10nF 20% 50V

2834 4822 122 33177 10nF 20% 50V

3813 4822 051 20008 0 ohm (jumper)

3814 4822 051 20472 4k7 5% 0.1W

7840 5322 130 41982 BC848B

4822 276 13603 Mains switch

4822 265 30389 2P conn. vert. K101

4822 267 51348 2P conn. K104

4822 256 91766 LED holder

3520 4822 053 21475 4M7 5% 0.5W

3521 4822 053 21475 4M7 5% 0.5W

7811 4822 130 44197 BC558B

7812 4822 130 40937 BC548B

Recommended Safety Parts

Item Part No. Description

(For 16;9 & Surround Sound)

4822 265 30389 Con. 2P (L01, I02)

4822 256 92053 Fuse holder

4822 492 62076 Spring fix. transistor

1463 4822 252 11194 Prot dev 65V 800mA

1566 4822 252 51175 Prot dev 65V 2.5A

1572 4822 071 52502 Fuse T2.5A lEC 250V

1580 4822 252 51175 Prof dev 65V 2.5A

2420 4822 126 13435 1.2nF 10% 2KV

2425 4822 121 70434 11nF 5% 1.6KV

2425 5322 121 44345 15nF 5% 1.6KV

2426 4822 121 10653 22nF 5% 630V

2427 4822 121 10563 820nF 5% 250V

2433 4822 126 12274 1.5nF 10% 2KV

2433 4822 126 13449 1nF 10% 2KV

2450 4822 121 10619 220nF 10% 250V

2450 4822 121 40518 100nF 10% 250V

2487 4822 124 40433 47uF 20% 25V

2500 4822 126 13589 470nF 275V

2505 4822 124 11772 150uF 20% 385V

2505 4822 124 23492 220uF 50% 385V

2506 4822 121 40487 100nF 10% 400V

2511 4822 126 11141 2.2nF 10% 1KV

2512 4822 126 11141 2.2nF 10% 1KV

2540 4822 126 12426 330pF 10% 1KV

2543 4822 126 13451 2.2nF 10% 1KV

2544 4822 126 13451 2.2nF 10% 1KV

2550 4822 126 14105 3.3nF 20% 250V

2559 4822 124 40433 47uF 20% 25V

2568 4822 126 12426 330pF 10% 1KV

2609 4822 124 40433 47uF 20% 25V

2751 4822 124 41579 10uF 20% 10U

2752 4822 124 41579 10uF 20% 50V

2763 4822 124 41579 10uF 20% 10U

3401 4822 052 11229 22 ohm 5% 0.5W

3402 4822 052 11229 22 ohm 5% 0.5W

3430 4822 052 11471 470 ohm 5% 0.5W

3443 4822 052 10688 6 ohm 8 5% 0.33W

3461 4822 052 10228 2 ohm 2 5% 0.33W

3461 4822 052 11158 1 ohm 5 5% 0.33W

3462 4822 052 10228 2 ohm 2 5% 0.33W

3464 4822 052 11568 5 ohm 6 5% 0.33W

3472 4822 052 10228 2 ohm 2 5% 0.33W

3483 4822 050 24708 4 ohm 7 1% 0.6W

3484 4822 050 24708 4 ohm 7 1% 0.6W

3502 4822 052 10338 3 ohm 3 5% 0.33W

3506 4822 117 12027 PTC/PTC 18 ohm 276V

3507 4822 117 12027 PTC/PTC 18 ohm 276V

3524 4822 052 10109 10 ohm 5% 0.33W

3545 4822 052 10159 15 ohm 5% 0.33W

3588 4822 052 11338 3 ohm 3 5% 0.5W

3601 4822 050 24708 4 ohm 7 1% 0.6W

3602 4822 050 24708 4 ohm 15 0.6W

3603 4822 050 24708 4 ohm 7 1% 0.6W

3752 4822 052 10828 8 ohm 2 5% 0.33W

3753 4822 052 10828 8 ohm 2 5% 0.33W

5410 4822 142 40351 Line drive trafo

5421 4822 157 10992 Linearity coil LC90

5421 4822 157 63079 Linearity cor. AT4042/97

5424 4822 157 53069 Balance coil

5430 4822 140 10584 Line output trafo CML16P

5430 4822 140 10595 Line output trafo ELDOR

5480 4822 158 10728 Bridge coil

5503 4822 157 11236 Line filter 40mH

5550 4822 146 10366 Power trafo CE42SV

5550 4822 146 31469 Power trafo 10290250

6423 4822 130 41275 BY228/20

6424 4822 130 41602 BYW95C/20

6457 4822 130 30621 1N4148

6480 4822 130 30621 1N4148

6481 4822 130 30621 1N4148

6510 4822 130 31933 1N5061

6511 4822 130 31933 1N5061

6512 4822 130 31933 1N5061

6513 4822 130 31933 1N5061

6524 4822 130 31631 BYV10

6530 4822 130 30621 1N4148

6571 4822 130 31982 8YV27-100

6591 4822 130 30621 1N4148

6600 4822 130 30621 1N4148

6601 4822 130 30621 1N4148

6610 4822 130 30621 1N4148

6763 4822 130 30621 1N4148

7420 4822 130 63271 BU2508AF

7421 4822 130 10779 BU1506DX

7450 4822 130 44197 BC558B

7520 4822 209 90025 MC44603P

7556 4822 130 10025 CNX82A

7561 4822 130 44197 BC558B

7580 4822 209 80817 MC7805CT

7591 4822 130 44197 BC558B

7602 4822 130 41344 BC337-40

7605 4822 130 44197 BC558B

1100 4822 071 51001 Fuse T100mA

2008 4822 124 40196 220uF 20% 16V

2009 4822 124 41579 10uF 20% 50V

21" 90NN

Recommended Safety Parts

Item Part No. Description

2033 5322 126 10223 4.7nF 10% 63V

2034 5322 126 10223 4.7nF 10% 63V

2036 5322 126 10223 4.7nF 10% 63V

2037 4822 124 41579 10uF 20% 50V

2101 5322 126 10223 4.7nF 10% 63V

2104 5322 126 10223 4.7nF 10% 63V

2105 5322 126 10223 4.7nF 10% 63V

2108 5322 126 10223 4.7nF 10% 63V

2125 4822 122 33177 10nF 20% 50V

2127 4822 124 41579 10uF 20% 50V

2136 5322 122 34123 1nF 10% 50V

2137 4822 126 10002 100nF 20% 50V

2138 4822 122 33177 10nF 20% 50V

2139 4822 122 33177 10nF 20% 50V

2140 4822 122 33177 10nF 20% 50V

2144 5322 122 34123 1nF 10% 50V

2145 5322 122 34123 1nF 10% 50V

2158 4822 124 40433 47uF 20% 25V

2162 5322 126 10223 4.7nF 10% 63V

2169 4822 122 33177 10nF 20% 50V

2170 5322 126 10223 4.7nF 10% 63

2171 4822 122 33177 10nF 20% 50V

2175 4822 122 33177 10nF 20% 50V

2176 4822 122 33177 10nF 20% 50V

2179 4822 124 40433 47uF 20% 25V

2600 4822 124 41579 10uF 20% 50V

2606 4822 122 33177 10nF 20% 50V

2607 4822 122 33177 10nF 20% 50V

2655 5322 122 34123 1nF 10% 50V

2665 4822 126 10002 100nF 20% 50V

2685 4822 122 33177 10nF 20% 50V

2700 4822 122 33177 10nF 20% 50V

2703 5322 122 32654 22nF 10% 63V

2708 4822 126 10002 100nF 20% 50V

2709 4822 122 33177 10nF 20% 50V

2711 4822 126 10002 100nF 20% 50V

2712 5322 122 32654 22nF 10% 63V

2715 4822 124 41579 10uF 20% 50V

2716 4822 124 41579 10uF 20% 50V

2830 4822 124 41579 10uF 20% 50V

2837 4822 126 10002 100nF 20% 50V

3031 4822 051 20472 4k7 5% 0.1W

3032 4822 051 20472 4k7 5% 0.1W

3033 4822 051 20472 4k7 5% 0.1W

3040 4822 052 10479 47 ohm 5% 0.33W

3126 4822 051 20153 15k 5% 0.1W

3156 4822 051 20109 10 ohm 5% 0.1W

3162 4822 052 10478 4 ohm 7 5% 0.33W

3169 4822 052 10478 4 ohm 7 5% 0.33W

3186 4822 052 10478 4 ohm 7 5% 0.33W

3190 4822 051 20332 3k3 5% 0.1W

3193 4822 051 20008 0 ohm Jumper

3613 4822 051 20472 4k7 5% 0.1W

3614 4822 051 20472 4k7 5% 0.1W

3616 4822 051 20472 4k7 5% 0.1W

3617 4822 051 20472 4k7 5% 0.1W

3623 4822 051 20472 4k7 5% 0.1W

3624 4822 051 20472 4k7 5% 0.1W

3670 4822 051 20472 4k7 5% 0.1W

3680 4822 051 20472 4k7 5% 0.1W

3691 4822 051 20472 4k7 5% 0.1W

3692 4822 051 20472 4k7 5% 0.1W

3704 4822 051 20008 0 ohm Jumper

3720 4822 051 20472 4k7 5% 0.1W

3805 4822 052 10109 10 ohm 5% 0.33W

3817 4822 051 20472 4k7 5% 0.1W

3826 4822 051 20121 120 ohm 5% 0.1W

3847 4822 052 10109 10 ohm 5% 0.33W

3860 4822 051 20472 4k7 5% 0.1W

5106 4822 157 51462 10uH

6030 4822 130 30621 1N4148

6031 4822 130 30621 1N4148

6032 4822 130 30621 1N4148

6105 4822 130 30621 1N4148

6106 4822 130 30621 1N4148

6107 4822 130 30621 1N4148

6108 4822 130 30621 1N4148

6109 4822 130 30621 1N4148

6660 4822 130 30621 1N4148

6661 4822 130 30621 1N4148

6700 4822 130 30621 1N4148

6830 4822 130 31983 BAT8S

7009 5322 130 41982 BC848B

7010 5322 130 41982 BC848B

7030 5322 130 41982 BC848B

7031 5322 130 41982 BC848B

7032 5322 130 41982 BC848B

7100 5322 130 41982 BC848B

7102 5322 130 41982 BC848B

7120 5322 130 41982 BC848B

7150 5322 130 41982 BC848B

7601 5322 130 41982 BC848B

7604 5322 130 41982 BC848B

7605 5322 130 41982 BC848B

7608 5322 130 41982 BC848B

7700 5322 130 41982 BC848B

7720 5322 130 41982 BC848B

Recommended Safety Parts

Item Part No. Description

7826 5322 130 41982 BC848B

7850 5322 130 41982 BC848B

7867 5322 130 41982 BC848B

4822 255 70261 CRT socket

4822 267 51249 CRT socket DAF

4822 26731858 Con. 1P

2320 4822 122 33172 390pF 5% 50V

2383 4822 124 40433 47uF 25V

2508 4822 122 33893 18nF 10% 63V

2510 4822 122 33893 18nF 10% 63V

3306 4822 051 20153 15K 5% 0.1W

3308 4822 051 20008 0 ohm jumper

3309 4822 052 10102 1K 5% 0,33W

3329 4822 052 10102 1K 5% 0,33W

3349 4822 052 10102 1K 5% 0,33W

3354 4822 051 20109 10 ohm 2 5% 0,5W

3355 4822 051 20109 10 ohm 2 5% 0.1W

3356 4822 051 20008 0 ohm Jumper

3386 4822 052 10108 1 ohm 5% 0,33W

3386 4822 052 10128 1 ohm 5% 0.33W

3387 4822 052 10109 10 ohm 5% 0,33W

3388 4822 052 10689 68 ohm 5% 0,33W

3391 4822 051 20008 0 ohm jumper

3500 4822 052 10279 27ohm 5% 0,33W

3512 4822 051 20008 0 ohm Jumper

6344 4822 130 30621 1N4148

6501 4822 130 30621 1N4148

6504 4822 130 30621 1N4148

6505 4822 130 30621 1N4148

6506 4822 130 30621 1N4148

7301 5322 130 41982 BC848B

7321 5322 130 41982 BC848B

7340 5322 130 41982 BC848B

7365 5322 130 41982 BC848B

7366 5322 130 41982 BC848B

7503 4882 130 44196 BC548C

7504 5322 130 60068 BC558C

4882 265 31251 Con. 5P (I27)

1600 4882 071 51001 Fuse T100mA

2350 4822 126 10002 100nF 20% 50V

2352 4822 124 41579 10uF 20% 50V

2353 4822 124 41579 10uF 20% 50V

2354 4822 124 41579 10uF 20% 50V

2355 4822 124 41579 10uF 20% 50V

2356 4822 124 41579 10uF 20% 50V

2357 4822 124 41579 10uF 20% 50V

2358 4822 124 41579 10uF 20% 50V

2359 4822 124 41579 10uF 20% 50V

2360 4822 124 41579 10uF 20% 50V

2361 4822 124 41579 10uF 20% 50V

2362 4822 124 41579 10uF 20% 50V

2363 4822 124 41579 10uF 20% 50V

2365 4822 124 41579 10uF 20% 50V

2367 4822 124 41579 10uF 20% 50V

2368 4822 124 41579 10uF 20% 50V

2373 5322 126 10223 4.7nF 10% 63V

2378 5322 126 10223 4.7nF 10% 63V

2382 5322 122 34123 1nF 10% 50V

2383 5322 122 34123 1nF 10% 50V

2386 5322 122 34123 1nF 10% 50V

2387 5322 122 34123 1nF 10% 50V

2388 5322 122 34123 1nF 10% 50V

2389 5322 122 34123 1nF 10% 50V

2390 5322 122 34123 1nF 10% 50V

2391 4822 126 10002 100nF 20% 50V

2394 4822 126 10002 100nF 20% 50V

2395 5322 122 34123 1nF 10% 50V

2396 4822 122 33172 390pF 5% 50V

2397 4822 122 33172 390pF 5% 50V

2398 4822 126 10002 100nF 20% 50V

2401 4822 126 10002 100nF 20% 50V

2408 4822 126 10002 100nF 20% 50V

2436 5322 122 34123 1nF 10% 50V

2437 5322 122 34123 1nF 10% 50V

2438 5322 122 34123 1nF 10% 50V

2448 5322 122 34123 1nF 10% 50V

2449 5322 122 34123 1nF 10% 50V

2452 5322 126 10223 4.7nF 10% 50V

2453 5322 126 10223 4.7nF 10% 50V

2454 5322 126 10223 4.7nF 10% 50V

2455 5322 126 10223 4.7nF 10% 50V

2602 4822 122 33177 10nF 20% 50V

2604 4822 126 10002 100nF 20% 50V

2607 4822 124 41579 10uF 20% 50V

2619 4822 126 10002 100nF 20% 50

2620 4822 126 10002 100nF 20% 50V

2624 4822 126 10002 100nF 20% 50V

2625 4822 122 33893 18nF 10% 50V

2627 4822 124 41579 10uF 20% 50V

2628 4822 124 41579 10uF 20% 50V

3364 4822 051 20472 4k7 5% 0.1W

3376 4822 051 20472 4k7 5% 0.1W

3382 4822 051 20332 3k3 5% 0.1W

3383 4822 051 20332 3k3 5% 0.1W

3387 4822 051 20332 3k3 5% 0.1W

3389 4822 051 20332 3k3 5% 0.1W

3391 4822 051 20332 3k3 5% 0.1W

Page 2

2PHILIPS MD 1.2E/AA

Recommended Safety Parts

Item Part No. Description

3395 4822 051 20008 0 ohm jumper

3443 4822 051 20332 3k3 55 0.1W

3444 4822 051 20332 3k3 5% 0.1w

3613 4822 051 20008 0 ohm jumper

3614 4822 051 20008 0 ohm jumper

3615 4822 051 20008 0 ohm jumper

3616 4822 051 20008 0 ohm jumper

3626 4822 051 20153 15k 5% 0.1W

5351 4822 157 51462 10uH

6384 4822 130 30621 1N4148

7350 4822 209 83163 LM833N

7351 4822 209 83163 LM833N

7382 5322 130 41982 BC848B

7383 5322 130 41982 BC848B

7387 5322 130 41982 BC848B

7389 5322 130 41982 BC848B

7415 5322 130 41982 BC848B

7420 5322 130 41982 BC848B

7427 5322 130 41982 BC848B

7430 5322 130 41982 BC848B

7432 5322 130 41982 BC848B

7433 5322 130 41982 BC848B

4822 492 62076 Spring fix. transistors

4822 265 31251 Con. 5P eco-duo 1,25

2757 4822 124 41579 10uF 20% 50V

2758 4822 124 41579 10uF 20% 50V

2787 4822 122 30103 22nF 80% 63V

2788 4822 122 30103 22nF 80% 63V

3752 4822 052 10828 8 ohm 2 5% 0.33W

3753 4822 052 10828 8 ohm 2 5% 0.33W

6770 4822 130 30621 1N4148

2759 4822 124 41579 10nF 20% 50V

2760 4822 124 41579 10uF 20% 50V

2761 4822 124 41579 10uF 20% 50V

2762 4822 126 10002 100nF 20% 25V

2763 4822 124 41579 10uF 20% 50V

2776 4822 122 33893 18nF 10% 63V

2779 4822 126 10002 100nF 20% 25V

2786 4822 124 41579 10uF 20% 50V

2787 4822 124 41579 10uF 20% 50V

2788 4822 122 33893 18nF 10% 63V

2789 4822 126 10002 100nF 20% 25V

3761 4822 051 20332 3k3 5% 0.1W

3762 4822 051 20332 3k3 5% 0.1W

3779 4822 051 20332 3k3 5% 0.1W

3794 4822 051 20332 3k3 5% 0.1W

3798 4822 051 20332 3k3 5% 0.1W

3799 4822 051 20332 3k3 5% 0.1W

6775 4822 130 30621 1N4148

6790 4822 130 30621 1N4148

7770 5322 130 41982 BC848B

7771 5322 130 41982 BC848B

7773 5322 130 41982 BC848B

7780 5322 130 41982 BC848B

4822 276 13603 Mains switch

4822 265 30389 Con. 2P (Fixed pin)

4822 256 91766 Led holder

3520 4822 053 21475 4M7 5% 0.5W

3521 4822 053 21475 4M7 5% 0.5W

7811 4822 130 44197 BC558B

7812 4822 130 44197 BC558B

4822 265 10429 Pin strip (F92)

2406 4822 124 41579 10uF 20% 50V

2409 4822 124 40196 220uF 20% 16V

2410 5322 126 10223 4.7nf 10% 63V

2420 4822 122 33177 10nF 20% 50V

2424 4822 126 12944 47nF 10% 50V

2425 4822 126 12944 47nF 10% 50V

3420 4822 051 20472 4k7 5% 0.1W

3427 4822 052 10479 47 ohm 5% 0.33W

3429 4822 051 20332 3k3 5% 0.1W

3432 4822 051 20472 4k7 5% 0.1W

3448 4822 051 20472 4k7 5% 0.1W

6401 4822 130 30621 1N4148

6402 4822 130 30621 1N4148

6403 4822 130 30621 1N4148

6404 4822 130 30621 1N4148

6405 4822 130 30621 1N4148

6410 4822 130 42489 BYD33G

7402 5322 130 41982 BC848B

7403 5322 130 41982 BC848B

7404 5322 130 41982 BC848B

7405 5322 130 41982 BC848B

7406 5322 130 41982 BC848B

7411 5322 130 41982 BC848B

7420 5322 130 41982 BC848B

4822 276 13592 Mains switch

4822 265 30389 Con. 2P

4822 256 91766 LED holder

2604 4822 124 40196 220uF 20% 16V

3520 4822 053 21475 4M7 5% 0.5W

3521 4822 053 21475 4M7 5% 0.5W

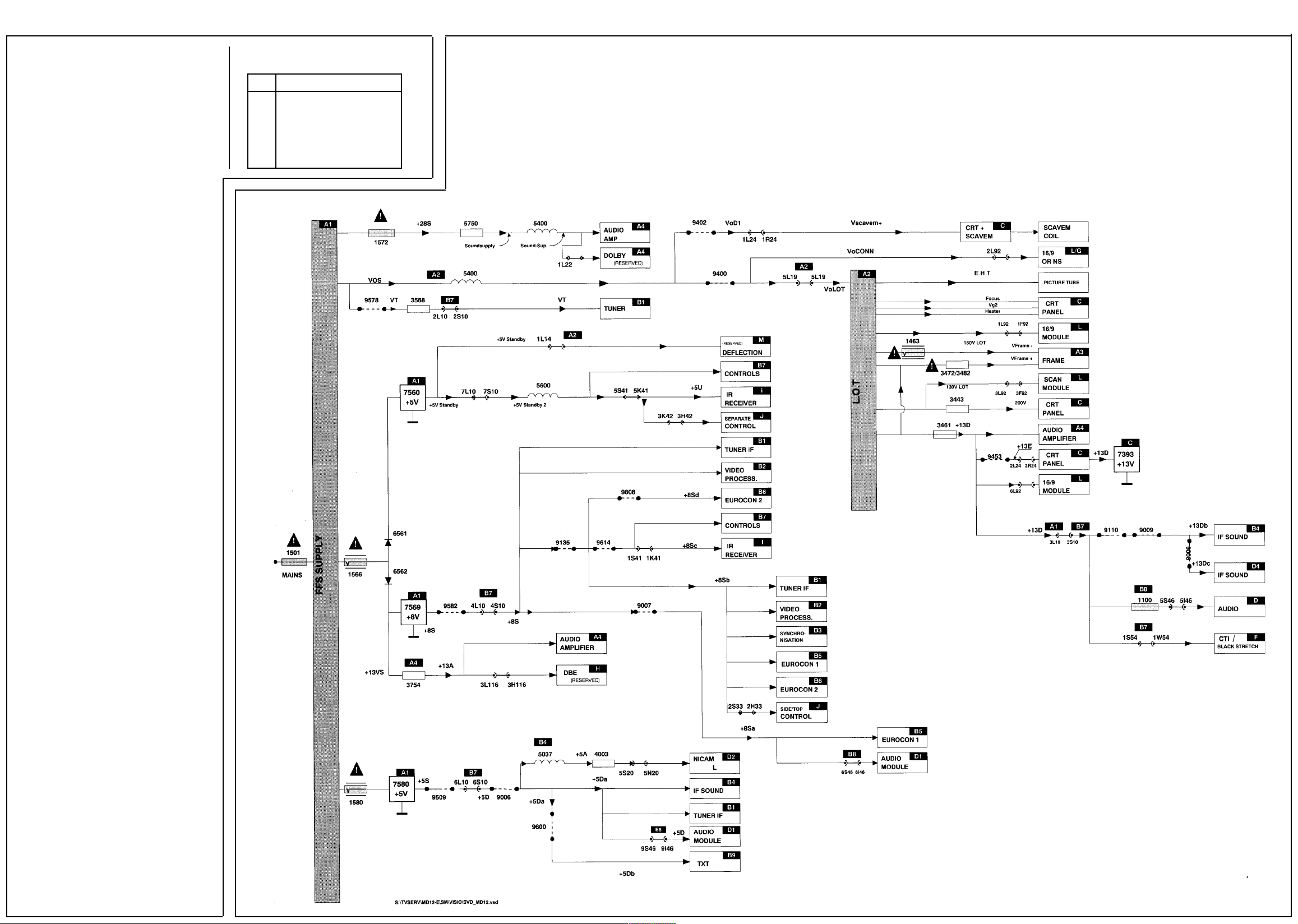

Text

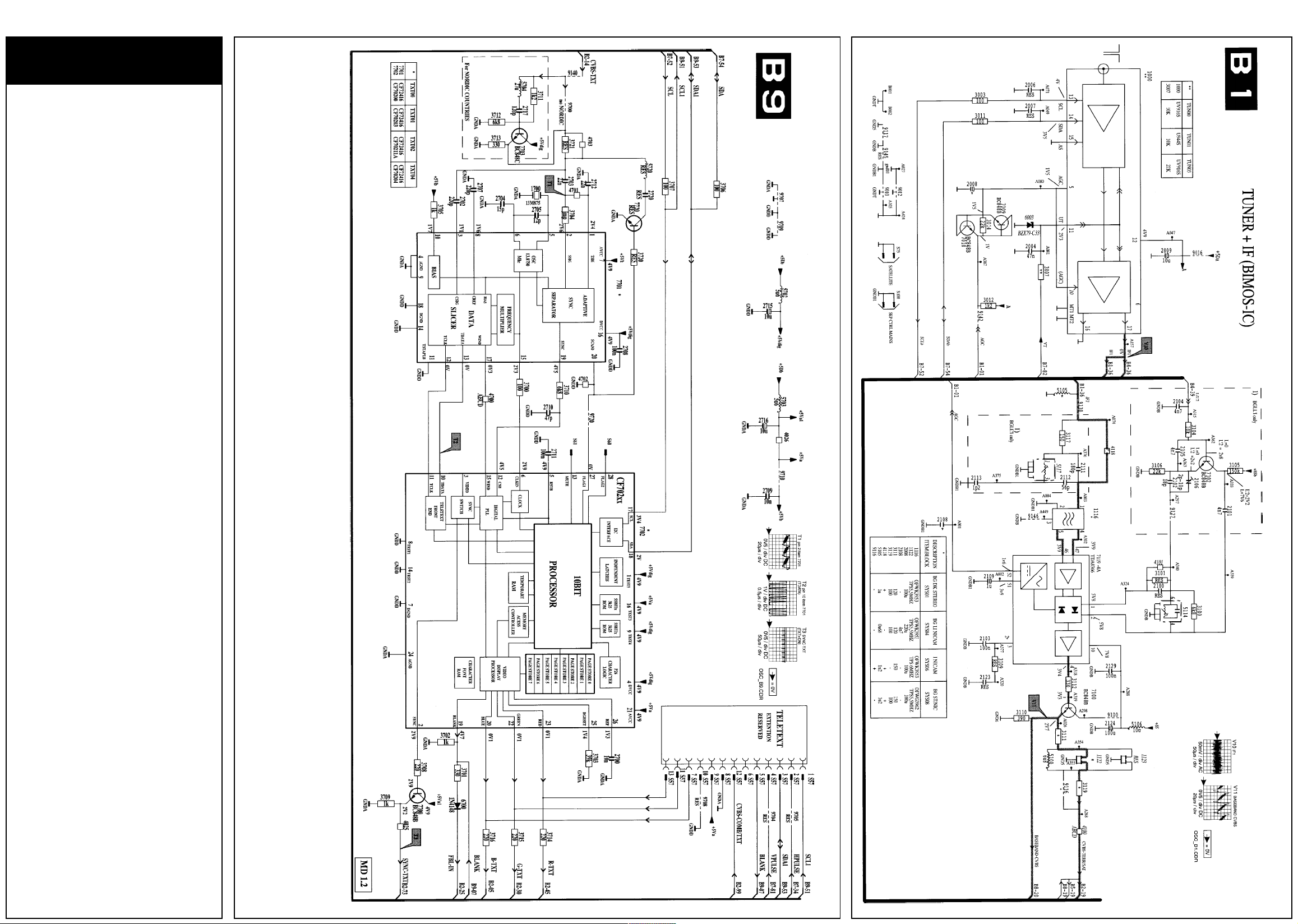

Diagram

Tuner & IF Diagram

Page 3

3PHILIPS MD 1.2E/AA

PCB Identification

Safety instructions for repairs,

Maintenance instructions,

Warnings and Notes

Safety instructions for repairs

1. Safety regulations require that during a repair

the set should be connected to the mains via

an isolating transformer;

safety components, indicated by the symbol

▲ should be replaced by components

identical to the original ones;

when replacing the CRT, safety goggles must

be worn.

2. Safety regulations require that after a repair

the set must be returned in its original

condition. In particular attention should be

paid to the following points:

As a strict precaution, we advise you to

resolder the solder joints through which the

horizontal deflection current is flowing, in

particular:

• all pins of the line output transformer (LOT);

• fly-back capacitor(s);

• S-correction capacitor(s);

• line output transistor;

• pins of the connector with wires to the

deflection coil;

• other components through which the deflection current flows.

- The cabinet should be checked for defects to

avoid touching of any inner parts by the

customer.

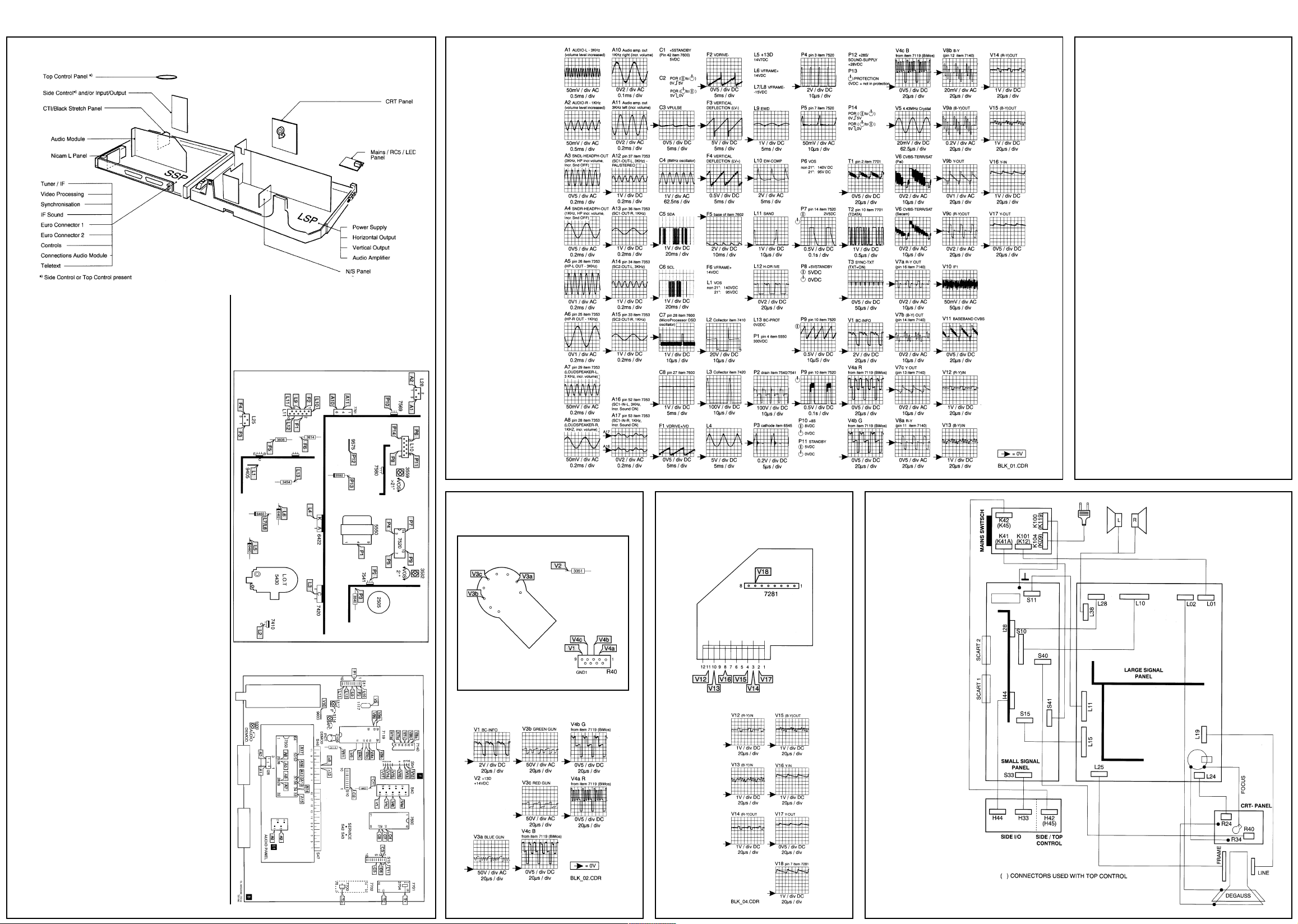

Test Point

Large signal panel

Waveforms

Test Point - CRT Panel

Test Point -

CTI/Black Stretch Panel

Service Modes

DST, Error messages, Protections,

Faultfinding and repair tips

In this chapter the following paragraphs are

included:

6.1 Test points

6.2 Service Modes and Dealer Service Tool

(DST)

6.3 Error codes and “blinking LED” procedure

6.4 Protections

6.5 Fault finding and repair tips

6.1 Test points

The MD1 chassis is equipped with test points in

the service printing. These test points are

referring to the functional blocks:

* A1-A2-A3, etc.:Test points for the audio

processing circuitry

* C1-C2-C3, etc.: Test points for the control

circuitry

* F1-F2-F3, etc.: Test points for the frame drive

and frame output circuitry

* L1-L2-L3, etc.: Test points for the line drive

and line output circuitry

* P1 -P2-P3, etc.: Test points for the power

supply

* T1-T2-T3, etc.: Test point for the teletext

circuitry

* V1-V2-V3, etc.: Test points for the video

processing circuitry

6.2 Service modes and Dealer Service

Tool(DST)

For easy installation and diagnosis the dealer

remote control RC7150 is introduced. The

RC7150 can be used for all new TV sets,

including all set of the MD1 chassis. The

Wiring

Diagram

Note:

This resoldering is advised to prevent bad

connections due to metal fatigue in solder

joints and is therefore only necessary for

television sets older than 2 years.

- The wire trees and EHT cable should be

routed correctly and fixed with the mounted

cable clamps.

- The insulation of the mains lead should be

checked for external damage.

- The mains lead strain relief should be checked

for its function in order to avoid touching the

CRT, hot components or heat sinks.

- The electrical DC resistance between the

mains plug and the secondary side should be

checked (only for sets which have a mains

isolated power supply).

This check can be done as follows:

• unplug the mains cord and connect a wire

between the two pins of the mains plug;

• set the mains switch to the on position (keep

the mains cord unplugged !);

• measure the resistance value between the

pins of the mains plug and the metal shielding

of the tuner or the aerial connection on the

set. The reading should be between 4.5 MO

and 12 MO;

• switch off the TV and remove the wire

between the two pins of the mains plug.

Small signal panel

Page 4

4PHILIPS MD 1.2E/AA

Service Modes Cont’d

RC7150 is also called Dealer Service Tool or

DST. The ordering number of the DST (RC7150)

is 4822 218 21232.

6.2.1Installation features for the dealer

The dealer can use the RC7150 for programming the TV-set with presets, TV-settings, Dish

settings.

10 Different program tables can be programmed

into the DST via a GFL or MD2 TV-set

(downloading from the GFL or MD2 to the DST;

see GFL or MD2 service manuals) or by the

DST-l (DST/PC interface; ordering code 4822

218 21277). For explanation of the installation

features of the DST, the directions for use of the

DST are recommended (For the MD1 chassis,

download code 4 should be used).

6.2.2 Diagnose features for the service

The MD1.2 sets can be put in the two service

modes via the DST RC7150. These are the

Service Alignment Mode (SAM) and the Service

Default Mode (SDM). SDM can also be entered

by short circuiting the “service” pins on the SSP.

6.2.2.1 Service Default Mode (SDM)

Entering the SDM:

- By transmitting the “DEFAULT’ command with

the RC7150 Dealer Service Tool.

- By temporarily shorting pins S42 and S43 on

the Small Signal Panel.

Exiting the SDM:

- Switch the set to stand-by (the error buffer is

also cleared).

Note:

When the mains power is switched off while the

set is in SDM, the set will enter to SDM immediately when the mains is switched on again.

The SDM has the following pre-defined conditions for all microprocessor controlled tuning

and linear functions:

- For recognition of the SDM “SER” is displayed

at the top of the screen.

- Tuning at 475.25 MHz (Secam on Multi

France sets (with Nicam L), PAL on other

sets).

- Volume level is set to 25% (of the maximum

volume level). Other picture and sound

settings are set to 50%.

- Auto switch off disabled (normally the set is

automatically switched off when no video

signal (IDENT) was received for iS minutes).

- Sleep timer is disabled.

- All other controls operate normally.

- When the microprocessor supports the

blinking LED” procedure (See 6.3) and an

error code is present in the error buffer, the

LED will blink the number of times, equal to

the value of the last error code.

This function will also work when there is

no sound or picture.

6.2.2.2 Service Alignment Mode (SAM)

Entering SAM:

- By transmitting the “ALIGN” command with the

RC7150 Dealer Service Tool (this works both

while the set is in normal operation mode or in

the SDM).

- By pressing the “MENU” and “-“ key on the

local keyboard simultaneously when the set is

in SDM.

Exiting SAM:

Switch the set to stand-by.

Note:

When the mains power is switched off while the

set is in SAM, the set will enter SDM immediately when the mains is switched on again.

In the SAM the following information is displayed on the screen:

- Software version (the software version of the

microprocessor in the set is displayed. This

software version identification corresponds

with the software versions in the Software

Survey as published in the Product Survey.

- Error code buffer (see paragraph 6.3).

- Options (see paragraph 8.4).

- Alignment and geometry information (see

paragraph 8.2.1, 8.3.1 and 8.3.2).

Service Modes, DST, Error messages,

(1)Software version

(2)Error buffer

(3)Options

(4)Alignments and geometry

M12XXx-x.x ①

ER0000000≠

③ E2 N AX xx RD xx

UO N VP xx GD xx

LL N 16 N VA xx BD xx

NI N SS xx VL xx HD xx

TT N D1 xx VS xx HW xx

ET N D2 xx VG xx HP xx

HI N D3 xx VA xx HC xx

14 N D4 xx NL xx HT xx

④

Figure 6.1

Screen of the Service Alignment Mode (SAM)

6.3 Error codes and “blinking LED” proce-

dure

The error code buffer contains all errors

detected since the last time the buffer was

erased. The buffer is written from left to right.

- The last error detected (actual) is the error at

the left side

- The error buffer will be reset in the following

cases:

1. exiting the SAM with the “standby” command

on the remote control

2. transmitting the commands “DIAGNOSE 9 9

OK” with the DST

- By leaving the SAM with the mains switch, the

error buffer is not reset.

Examples:

ERROR: 0 0 0 0 0 0: No error code detected

ERROR: 3 0 0 0 0 0: Error code 3 is the last and

ERROR: 5 3 0 0 0 0: Error code 3 first and error

only detected error

code 5 last detected

The contents of the error buffer can also be

made visible through the “blinking LED”

procedure. This is especially useful when there

is no picture. There are two methods:

1. When the SDM is entered, the LED will blink

the number of times, equal to the value of the

last

error code. The LED will stay off briefly

and blink again the number of times, equal to

the value to the

2. With the DST

last

error code

all

error codes in the error

buffer can be made visible. While in SDM,

transmit the command:

“DIAGNOSE x OK”

where x is the position in the error buffer to be

made visible x ranges from 1, (the last

(actual) error) to 7 (the first error)

The LED will operate in the same way as in

point 1, but now for the error code on position x.

Example:

Error code position

12345 67

Error buffer 2410 0 00

• after entering SDM blink (2x) -

pause

- blink

(2x)

• after transmitting

DST

blink (4x)

• after transmitting

OST

blink -

• after transmitting

DST

nothing happens

“DIAGNOSE 2 OK”

-pause

- blink (4x)

“DIAGNOSE 3 OK”

pause

- blink

“DIAGNOSE 4 OK”

with the

with the

with the

Note!

Note that it may take up to 7 seconds before the

set response to a DIAGNOSE command.

Interruption of the blinking sequence may lead

to incorrect results.

Important!

Not all software versions of the MD1.2E chassis

support the blinking LED procedure and the

DIAGNOSE 99 command. Software versions

NOT supporting the blinking LED procedure are

M12BAx-x.x

Error Error Description Blinking Possible

code LED deflective

0 No error detected — —

1 BIMOS 1x IC7119

2 M5P3400/341 0 2x IC7353

3I2C bus error 3x All 12C-related

4 Wrong EEPROM 4x IC7685 (SSP)

5 EEPROM 5x IC7685

6 Tuner error 6x U1000 (SSP)

7 TXT error 7x IC7702 (SSP)

8 Histogram Proc. 8x IC7210

9 16:9 processor 9x IC7440

10 WSSB module 10x IC7540

11 Dolby processor lix IC7600

and

M12COx-3.x.

components

(TDA8366) error (SSP)

error (SSP)

components

defective (SSP)

error (reserved)

error (16x9 module)

error (WSSB module)

error (Audio module)

Table 6.1 Error code list

Protections, Faultfinding and Repair tips

6.4 Protections

6.4.1 In the MD 1 .2E the following protections

are possible:

Protections generated by the power supply:

• Overload protection ➝ Hick up mode

• Underload ➝ Hick up mode

• Over voltage ➝ Hick up mode

• Under voltage ➝ Hick up mode

Deflection:

• Horizontal Protection ➝ Supply to standby

• EW-Protection ➝ Supply to standby

• Vertical Protection ➝ BIMOS standby

mode

Software protection

• BIMOS 1C71 19 defective ➝ (Error code 1)

Set can be switched between standby and

ON, but there is no picture, no OSD, sound is

only noise.

• SDA or SCL shorted ➝ (Error code 3) Set is

switched to standby via standby line, set tries

to restart.

• No +5Db or +85c at pC ➝ Set is switched to

standby via standby line, set tries to restart.

6.4.2 Power supply protections

The power supply will go to a very good audible

hick-up mode in the following situations:

• Overload protection

• Under load

• Over voltage

• Under voltage

In hick-up mode

Pin 1 of IC7520 starts up from the start circuit for

approximately 2 seconds, immediately after that

the protection is activated. This cycle is constantly repeated in hick-up mode. When the set

is in hick-up mode a short squeak is audible

every 2 seconds.

6.4.3 Horizontal-protection

When the beam current becomes too high for a

long period the voltage across C2450 will drop.

D6450 will start conducting and as soon as the

voltage drop across R3456 is 0V7, TS7450 will

conduct, making PROT high. Via the hold

circuitry of the power supply, the set will stay in

the protection mode (standby) and can only be

reset by switching the set off and on via the

mains switch. If the fault is still present, the set

will switch to standby (protection mode) again.

6.4.4 EW-protection (not for 21” sets)

The East/West protection switches the power

supply to standby via the signal line STANDBYSUPPLY PROTECTION. Via the hold-circuitry of

the power supply, the set will stay in the

protection mode (standby) and can only be reset

by switching the set off and on via the mains

switch. If the fault is still present, the set will

switch to standby (protection mode) again.

The East/West protection detects when the

current through the East/West power output

stage with T57480 is too high.

Note:

A current through the East/West stage that is too

high can be caused by a defective part in the

line-deflection circuitry!

The current through the East/West stage is

measured on the LSP via 2 precision resistors

(R3483 and R3484). In case of a line problem,

the east/west-current becomes too high and the

voltage across resistors R3483 and R3484 rises.

When the voltage level exceeds 0.6V, D6480

starts to conduct and STANDBY-SUPPLY

PROTECTION becomes HIGH. When the

voltage across C2480 is very high

(e.g. when a line problem is already present

when the set is switched on with the mains

switch), D6481 and D6482 conduct and EWPROTECTION is activated very fast.

The East/West protection becomes active in the

following cases:

1. Bad contacts of horizontal deflection circuit:

• bad contacts of horizontal deflection coil

• bad contacts of linearity corrector coil L5421

• bad contacts of S-correction capacitor C2427

2. Bad contacts of flyback capacitor C2425.

3. Shorted flyback diode D6421 or D6423.

4. Shorted S-correction capacitor C2427.

5. Bad solder contacts in the line output stage.

When EW-protection has been active, the line

output transistor 7420 may also be defective.

6.4.5 Vertical-protection

The vertical output stage creates VERTICALPROTECTION pulses at every flyback pulse

when it is functioning correctly. These pulses are

sensed by the BIMOS IC7119-4D on pin 37.

When the pulse train is interrupted, the BIMOS

will switch to BIMOS STANDBY mode. In the

BIMOS STANDBY mode, the BIMOS switches

off the VDRIVE+ and VDRIVE- while the RGB

outputs are blanked. Circuit breaker 1463 may

be open. Probably, the line output stage will not

work and the power supply will switch to hick-up

mode (under voltage protection).

6.4.6 Software protection

The software protection is managed by the

microprocessor. It continuously verifies the

presence of the +5 and +8 supply voltages on

pin 34 and the activity of the PC bus. When the

protection becomes active, the software will

switch the power supply on and off continuously

via the STANDBY line. In this situation the

power supply produces a squeaking sound.

Service Modes, DST, Error messages,

- I2C protection

The I2C bus is controlled at each I2C command. Therefore every I2C command has a

defined start/stop condition. When the defined

start/stop condition is repeatedly incorrect,

error 3 is placed in the error buffer and the set

switches to software protection.

I2C protection is generated in the following

situations:

• SDA shorted to earth

• SCL shorted to earth

• SDA and SCL shorted

When SCL or SDA is shorted, the set tries to

restart and the LED lights in a clearly recognisable pattern.

• SDA/SCL shorted when the set is switched

ON with the mains switch:

LED is 8 seconds RED, 8 seconds GREEN,

flashes RED, 8 seconds GREEN, flashes

RED, 8 seconds GREEN, flashes RED,

etcetera.

• SDA/SCL shorted during operation LED is 8

seconds GREEN, flashes RED, 8 seconds

GREEN, flashes RED, et cetera.

- +5Db and +8Sc protection of the microprocessor +5Db and +8Sc are the main supply

voltages of the entire small signal processing

of the set. At pin 34 the microprocessor

senses whether the supply voltages +5SDb or

+8Sc coming from the power supply are

present. When one or both the supply

voltages are missing, the set switches to

software protection.

6.5 Fault finding and repair tips

Note that for 21” sets, voltages and waveforms

may differ.

6.5.1 General

LED indication after start-up procedure is

completed

- No LED

Set is switched OFF, supply problem or

microprocessor problem.

- LED continuously

Set is in standby, control part defective,

standby mode defective.

- LED blinking

Set in SDM, transmitting error buffer.

Audible checks

- Demagnetisation audible: mains voltage is

present at LSP.

- EHT audible: supply is operational (line output

stage only works in case VOS (+140V for 25

& 29”; +95V for 21”) is present.

- Hick-up sound power supply audible: power

supply is shorted. Check the LOT (item 5430)

and the line output transistor T57420.

6.5.2 Fault finding in the power supply

In case of a power supply problem, the power

supply can be simplified to a stand alone power

supply at low voltages (low risk) as follows:

Control part of the power supply

1. Disconnect the SSP (as a result the line will

not function any more and therefore will no

longer be a load of the power supply) or

disconnect the line by removing jumper 9400

and R3400 (if present) on the LSP.

2. Connect an external DC power supply

between supply pin 1 IC7520 (via a diode e.g. BYD33D - with cathode to supply pin 1

IC7520) and hot earth (e.g. earth of the big

smoothing capacitor C2505).

3. Connect a oscilloscope to test point P4 at pin

3 IC7520.

4. Turn up the external DC supply voltage slowly

to 17V DC.

Remark:

The IC starts at a supply voltage of 14V DC,

after that the supply voltage can drop to approx.

9V DC. At approximately 18V DC, over voltage

protection becomes active, resulting in a supply

voltage drop below 7V DC before a new start-up

is performed by turning up the supply voltage

above 14V DC.

5. The correct (measured) situation is displayed

in . Other results indicate a defect in the

power supply control part (IC7520 or peripheral components at pins 10 or 11).

Figure 6.2

5V/div; 5u5/div

➝ 40KHz pulse

Energy transfer of the power supply (only if

control part is OK)

6. Apply action 1, 2 and 4 as described earlier..

7. Connect a lamp of 230V/100W across the

VOS output capacitor C2569.

8. Connect a 1kΩ resistor between the +5

STANDBY (connector 7L10) and the

STANDBY line (connector 8L10) to switch the

power supply to normal operation.

9. Connect the mains connector to a VARIAC

but leave it at 0.

10.Connect a voltmeter across C2569 and an

oscilloscope between the drain of T57541 (25

& 29”) or T57540 (21”) and hot earth.

11.Slowly increase the mains input voltage by

the VARIAC (in this way further damage to the

power supply can be avoided).

Protections, Faultfinding and Repair tips,

The waveforms for the following mains voltage

are given:

Mains in voltage

10V AC: 20kHz and VOS 7V5

20V AC: 40kHz and VOS 30V

40V AC: 40kHz and VOS 80V

65V AC: 40kHz and VOS 140V

> 65V AC: Stable situation, so 40kHz

and 140V

In case of a feedback problem, the situation will

not stabilise or the voltage will exceed 140V

(95V with 21”)

Page 5

5PHILIPS MD 1.2E/AA

Service Mode Cont’d

1. Figure 6.3:

Mains in 10VAC

10V/div; bus/div

2. Figure 6.4:

Mains in 20V AC

20V/div; 5uS/div

➝ 40kHz pulse

➝ VOS 30V

3. Figure 6.5:

Mains in 40V AC

50V/div; 5uS/div

➝ 40kHz pulse

➝ VOS 80V

4. Figure 6.6:

Mains in 65V AC

50V/div; 5uS/div

➝ 40kHz pulse

➝ VOS 140V

6.5.3 Fault finding of the horizontal circuitry

When the horizontal circuitry itself is defective, it

can be simplified to a stand alone “switched

mode supply” at low voltages (low risk) as

follows:

1. Disconnect the set from mains.

2. Disconnect the SSP by removing all cables to

the SSP.

3. Connect an external 50V DC (or 40V DC)

supply with current measurement possibility

across C2400.

4. Replace the HDRIVE by an external LF

generator (1TL level (between 0 and 5V); duty

cycle 50%) with a 16 kHz pulse at the base of

TS741 0 (near LOT at the side of the PCB).

5. Connect a oscilloscope to test point L1

(collector of line output transistor 7420).

Possibilities:

1. Figure 6.7:

L3; test point at collector line output transistor

(7420)

50V/div; 10pS/div

Current from external DC supply approx. 100mA

Observation: normal 16kHz pulses and 100mA

supply current

Correct horizontal circuitry

Note that the amplitude of the signal strongly

depends on the frequency of the generator.

2. Figure 6.8:

L3; test point at collector line output transistor

(7420)

50V/dlv; 10µS/div

Line deflection open:

Current from external DC supply is

approximately 100mA.

Observation: small pulse followed by wide

pulse and 100mA supply current

Causes: horizontal deflection coil open linearity

coil L5421 open S-correction C2427 open

3. Figure 6.9:

L3; test point at collector line output transistor

(7420)

50V/dlv; 10µS/div Current from external DC

supply approx 500mA!!

Observation: fast oscillations and 500mA

supply current

Cause:horizontal deflection shorted (e.g. line

deflection coil shorted)

When the line deflection is not completely

shorted but only a number of windings are

shorted, the waveform does not show the

oscillation and the current of the external DC

supply is approximately 200mA.

4. Figure 6.10:

L3; test point at collector line output transistor

(7420)

100V/div; 10µS/div

Current from external DC supply is

approxImately 150mA

Observation: flyback time is shorter, one extra

pulse in between, 150mA supply current

Cause: flyback capacitor C2425 open

5. Figure 6.11:

L3; test point at collector line output transistor

(7420)

100V/div; 10µS/div

Current from external DC supply > 1A

Observation: 2 pulses per cycle extra and

supply current from more than 1A

Cause: short-circuit in picture tube (e.g. EHT to

Aquadag)

Service Modes, DST, Error messages,

6.5.4 Fault finding “no picture, no protection” (problem in the video controller IC part

TDA8366-4C)

When there is no picture and no protection, it is

most likely that there is a problem with the

BC_INFO caused by the TDA8366, the RGB

amplifiers or the picture tube.

For measuring, connect a video generator (e.g.

PM5518) at the aerial input with a white pattern

to the tuner. Trigger the oscilloscope field

frequent. A stable picture is obtained if triggered

with VDRIVE+ at pin 4 S11.

Normal start up procedure

1.First phase of start up; 4 white measuring

lines (lines 15,16, 17, 18) and the main

picture is muted (wave forms are better visible

if the picture tube is cold);

Figure 6.12:

Red (pin 8 of connector R43 on the CRT panel)

and green gun (pin 6) 100V/div DC;

100 µs/div

The total beam current is measured and fed

back to pin 16 TDA8366 (IC7119)

The TDA8366 checks the voltage at pin 16 of

the TDA8366 during these lines

<4.5V: set remains in this phase

<4.5V: set continues with start up phase 2

2. Second phase of start up; each beam is

separately measured and the main picture is

still muted. Line 15 is Red, line 16 is Green

and line 17 is Blue. BC_INFO is measured.

- differences between the lines (guns) are

compensated

- when the differences are minimal the set

continues with phase 3, otherwise it remains

in phase 2

Figure 6.13:

Red (lower line) (pin 8 of connector R43 on the

CRT panel) and green (upper line) gun (pin 6)

50V/div AC; 100µs/div

3. After start up the picture is present and

differences in cut-off points of the R, the G

and the B gun are compensated continuously.

Repair procedure

Typical situation: no picture and no error

codes

- Switch the set on.

- In a 4:3 set, press “picture size” to switch the

set to “16:9 compressed” mode.

- In a 16:9 set, shift down the picture with the

cursor keys.

The start up phase of the set can be identified:

1. A bright white horizontal line at the top; the

rest of the picture is dark (set hangs in first

phase of start up procedure) Oscilloscope

picture of the voltage over the guns looks like

figure 6.12.

TDA8366 (IC7119), picture tube and RGB

amplifiers are OK

There should be 4.5V at pin 16 TDA8366.

Possible problem: if there is no 4.5V present at

pin 16 of TDA8366, there is a defect (in one or

more of the components) in the BC_INFO

feedback loop.

2. Small horizontal red, green and blue lines at

the top; the rest of the picture is dark (set

hangs in second phase of start up procedure)

TDA8366 is OK

Possible problem: one or more of the guns of

the picture tube are bad.

Measure at pin 16 TDA8366 which feedback

line(s) (the R or G or B line) is/are smaller; the

corresponding amplifier(s) or gun(s) is/are faulty.

3. No lines visible (picture dark)

Measure pin 16 TDA8366; possible measurements:

- 0V: Check TDA8366

(sandcastle and the

supply voltage)

-5V: Check RGB amplifiers

Short pin 16 TDA8366 to

ground, now there will be

measuring lines (at continuously

5V, phase 1 and 2 is bypassed)

- Pulses: there is a measuring line, so the

TDA8366 is OK

Measure on cathode on the CRT

panel if the measuring lines are

present:

Yes ➝ BC_INFO circuit is open

or no HEATER voltage

No ➝ RGB amplifier problem

8. Electrical alignments

General: the Service Default Mode (SDM) and

Service Alignment Mode (SAM) are

described in chapter 6.

Alignment conditions:

All electrical adjustments should be performed

under the following conditions:

• Power supply voltage: 240V±10%, 50Hz ±5%.

• Warm-up time: ≈ 10 minutes

• The voltages and oscillograms are measured

in relation to the tuner earth.

• Test probe: Ri > 10MΩ; Ci < 2,5 pF.

8.1 Adjustments on the large signal panel

8.1.1 95V/140V supply voltage

For 21” TV-sets

Connect a voltmeter to the cathode of D6567.

With the aid of R3532 adjust the power supply

voltage to 95V + 0,5V

For sets 21”

Connect a voltmeter to the cathode of D6567.

With the aid of R3559 adjust the power supply

voltage to 140V± lV.

8.1.2 VG2 adjustment

Connect a pattern generator displaying a full

black picture. Switch the TV-set to the service

default mode (see chapter 6). Connect an

oscilloscope to the picture tube cathodes for

red, green and blue (pins 6, 8 en 11 of the

picture tube socket). Set the oscilloscope to DC,

50 V/div and 2 ms/div. Measure the DC level of

the measuring pulses at the end of the

frameblanking (see fig. 8.1). Using the Vg2

potentiometer on the linetransformer (bottom

potentiometer) the measuringpulse with the

highest level must be set to +160V ± 2V.

8.1.3 Focusing

Is aligned using the focuspotentiometer on the

linetransformer (top potentiometer).

8.2 Alignments on the small signal panel

8.2.140.4 MHz IF filter (only for sets with

SECAM LL’ reception)

Using a signal generator (e.g. PM5326) and a

capacitor of 5,6 pF supply a 40,4 MHz signal to

pin 17 of the tuner. Connect an oscilloscope to

pin 1 of filter 1016. Switch on the set and select

in the installation menu MANUAL; SYSTEM

EUR.W. Align coil L5117 for maximum DC

output voltage.

8.2.2 AFC

Switch the set to service default mode (see

chapter 8).

Using a pattern generator (e.g. PM5518) supply

a signal on a frequency of 475,25 MHz

Align coil L5114 for optimal picture quality.

8.2.3 Picture demodulator (only for sets with

SECAM LL’ reception)

Using a signal generator (e.g. PM5326) supply a

32.95MHz signal via a 5,6 pF capacitor to pin 17

of the tuner. Align the signal level of the

generator so that the DC-voltage on pin 5 of the

tuner is 5V.

Switch on the set and select in the installation

menu MANUAL; SYSTEM FRANCE. Align

capacitor C2106 for minimal voltage on pin 5 of

the tuner.

8.2.4 RF-AGC

If the signal of a strong local transmitter is

distorted, align the value for AX (AGC crossover) in the service menu (see chapter 8) until the

picture is no longer distorted.

8.2.5 Audio demodulator (Not for sets with

LL’ and NICAM reception possibility)

Using a signal generator (e.g. PM5326) supply a

38.9MHz signal via a 5,6 pF capacitor to pin 17

of the tuner.

Connect an oscilloscope (2ms/div) to pin 12 of

IC7033 (TDA3845). Align coil L5030 for minimal

amplitude.

8.3 Picture tube alignments

8.3.1 White balance

Connect a pattern generator and select a white

picture. Set contrast to maximum (63) for 21” or

to 40 for 21” tv-sets. Use the / keys to

select an alignment and the / keys to

change the value. Set GD to 50, RD to 57 and

BD to 45.

If necessary change the settings for RD and BD

for a correct white balance.

8.3.2 Geometry adjustments (for software

versions M12COx-3.x and M12BAx-x.x)

Connect a pattern generator and select a

geometry pattern (signal at 475.25 MHz)

• Switch to the Service Default Mode, then to

the Service Alignment Mode.

• Select the desired alignment with the /

keys.

• Change the selected alignment with the /

keys.

• A value between 0 and 63 can be selected.

• Changed values are stored immediately.

Vertical

VP: Vertical Shift

Set this for the correct vertical position.

VA: Picture height

Set this for the correct picture height.

VL: Vertical linearity

Set this so that the vertical centre of the

➝

➝

➝

➝

➝

➝

➝

picture is at the centre of the tube.

VS: Vertical S-correction

Set this so that the height of the squares in the

top of the picture equal the height in the bottom

of the picture.

Horizontal

HD: Horizontal shift.

Set this so that the horizontal centre of

the picture is on the centre of the tube.

For sets with a screen size larger than 21”, the

following alignments can be done as well. For

21” sets these alignments have no function.

HW: East-west width

Align the picture width with this.

HP: East-west parabola correction

Set this so that the vertical lines at the

sides of the screen are straight.

HC: East-west corner-correction.

Set this so that the vertical lines are

straight in the corners.

HT: Trapezium correction

Set this so that the vertical lines are as

vertical as possible.

Adjustments for 16:9 sets (reserved)

16 = N 4:3 tube (options SS, D1, D2, D3 and

D4 not available (blue))

16 = Y 16:9 tube (options SS, D1, D2, D3 and

D4 available)

8.4 Options

E2: Number of Euro/Scart connectors

(options N or Y)

N 1 Euro/Scart connector present

Y 2 Euro/Scart connectors present

UO: Tuner type

N UHFNHF tuner (item 1000 is UV9165)

Y UHF tuner (item 1000 is UV9445).

Used in the United Kingdom (/05 sets)

LL:Nicam L (options N or Y)

N Nicam L not present

Y Nicam L present (Nicam L panel

required and item 7353 is M5P3410)

NI:Nicam (stereo) sound (options N or Y)

N Only 2C5 stereo, no Nicam (item 7353 is

M5P3400)

Y 2C5 and Nicam stereo (item 7353 is

M5P3410)

U: Teletext (options N or Y)

N No Teletext present

Y Teletext present

ET: (Eastern Europe) teletext type

(options N or Y)

N No Eastern Europe teletext

Y Eastern Europe teletext (/58 sets)

14: 14:9 Picture format supported by 4:3

tube (options N or Y)

N Not supported

Y Supported

HI: Histogram (not with software version M1

2BAx-x.x)

N No Histogram present (options VG, VA

➝

and NL not available (blue))

Y Histogram present (options VG, VA and

NL available)

M2: MD1 .1 E or MD1 .2E chassis

(only with software version M12BAx-x.x)

N MD1.1E chassis

Y MD1.2E chassis

Page 6

6PHILIPS MD 1.2E/AA

Alignments

(16;9 & Surround Sound)

8. See MD1.2E AA for a description of the basic

alignments for the MD1 .2E AA software.

Software version:

M12BAx-4.x

M1200x-3.2

4:3 sets (NO flashing LED procedure, replaced

by M12COx-4.0)

M12COx-4.0

4:3 sets (WITH flashing LED procedure,

replaces M1200x-3.2)

In the Service Default and Service Alignment

Mode widescreen sets switch to Wide Screen

format. All the geometry alignments also have to

made in the WideScreen mode.

In this supplement the additional options for

16:9 and Dolby Pro Logic sets with the following

software are described:

M12COx-5.1

(or later) 16:9 sets

(also suitable for 4:3 sets)

Ml 2DOx-1.0

(or later) Dolby Pro Logic sets

(4:3 and 16:9)

SS Picture dimension and rotation coil

dependent setting.

SS Picture tube / rotation coil

1 32” with rotation coil

2 28’ with rotation coil

3 24” with rotation coil

4 32” without rotation coil

5 28” without rotation coil

6 24” without rotation coil

Supply Voltage Diagram

8.1 Options and alignments

HI Histogram option. This option is not

used and is not selectable.

WB Format detection for 4:3,14:9 or 16:9

picture (16:9 sets only) and Dolby Pro

Logic sound (Dolby Pro Logic sets

only) by the teletext IC.

Y Automatic detection on

N Automatic detection off

Automatic 16:9 detection via the Scart

cable also functions if ‘WB N’ is set.

16 Picture tube aspect ratio

Y 16:9 picture tube

N 4:3 picture tube

If ‘16 N’ is set, parameters WB*, RT,

SS, Dl, D2, D3 and D4 automatically

become blue and are made

non-selectable.

* In Dolby Pro Logic sets the WB option can be

selected independently of the 16 option, as

the automatic sound detection can also be

switched on and off in this manner.

RT Rotation coil (picture tilt)

Y Rotation coil present; An option to tilt the

picture appears under the YELLOW key in

the operating menu.

N No rotation coil present.

D1 HD-value deviation in 4:3, Zoom 14:9

and Zoom 16:9 in relation to

WideScreen mode.

D2 HD-value deviation in SuperWide

(panorama) format in relation to

WideScreen mode.

D3 HP-value deviation in 4:3, Zoom 14:9

and Zoom 16:9 in relation to

WideScreen mode.

D4 HP-value deviation in SuperWide

(panorama) format in relation to

WideScreen mode.

The alignment settings are dependent on picture

tube format:

Picture tube format 20” 24” 28” 32”

D1 12 9 9 8

D2 2 3 3 5

D3 10 9 9 8

D4 7 9 9 8

Page 7

7PHILIPS MD 1.2E/AA

Controls Diagram

Page 8

8PHILIPS MD 1.2E/AA

Audio Module Diagram

Page 9

Audio Output Diagram

9PHILIPS MD 1.2E/AA

Audio Module Connections Diagram

Page 10

10PHILIPS MD 1.2E/AA

16:9 PCB Diagram

Page 11

11PHILIPS MD 1.2E/AA

Click Fit Diagram

DBE PCB Diagram

CTI/Black Stretch Diagram

Page 12

12PHILIPS MD 1.2E/AA

CRT Base PCB Diagram

(16:9 & Surround Sound)

Page 13

13PHILIPS MD 1.2E/AA

CRT PCB Diagram

Page 14

Control & Input/Output Diagram

14PHILIPS MD 1.2E/AA

Horizontal Output Diagram

N/S Panel Diagram

Page 15

15PHILIPS MD 1.2E/AA

Dolby Module Diagram

Page 16

16PHILIPS MD 1.2E/AA

Mains/RC5/LED PCB Diagram

Mains /RC5/LED PCB Diagram

(Classic Line)

Mains & Front Control PCB Diagram

Nicam L Module

Diagram

Sync Diagram

Page 17

17PHILIPS MD 1.2E/AA

Power Supply Diagram (21” only)

Page 18

18PHILIPS MD 1.2E/AA

Power Supply Diagram (Over 21”)

Page 19

19PHILIPS MD 1.2E/AA

Scart

Diagram 1

Sound IF Diagram

Scart Diagram 2

Surround Sound PCB Diagram

Page 20

20PHILIPS MD 1.2E/AA

Wiring Diagram

(16:9 & Surround Sound)

Vertical

Output

Diagram

Video

Processing

Diagram

Loading...

Loading...