Page 1

MCM279

Service AIDS & CD playability ...........................1-1...1-4

Specifications ................................................................2

Connection & Controls ...................................................3

Disassembly Instructions ...............................................4

Block & Wiring diagrams ................................................5

MAIN BOARD ................................................................6

KEY & USB JACK BOARD ............................................7

POWER & AMP BOARD ................................................8

EXPLODE DIAGRAM .....................................................9

SERVICE PARTLIST ....................................................10

FACTORY PARTLIST ...................................................11

3141 785 32151

Page 2

SERVICE AIDS

1-1

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

WARNING

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

Safety components are marked by the symbol

!

.

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

ESD

CLASS 1

LASER PRODUCT

Lead free

Page 3

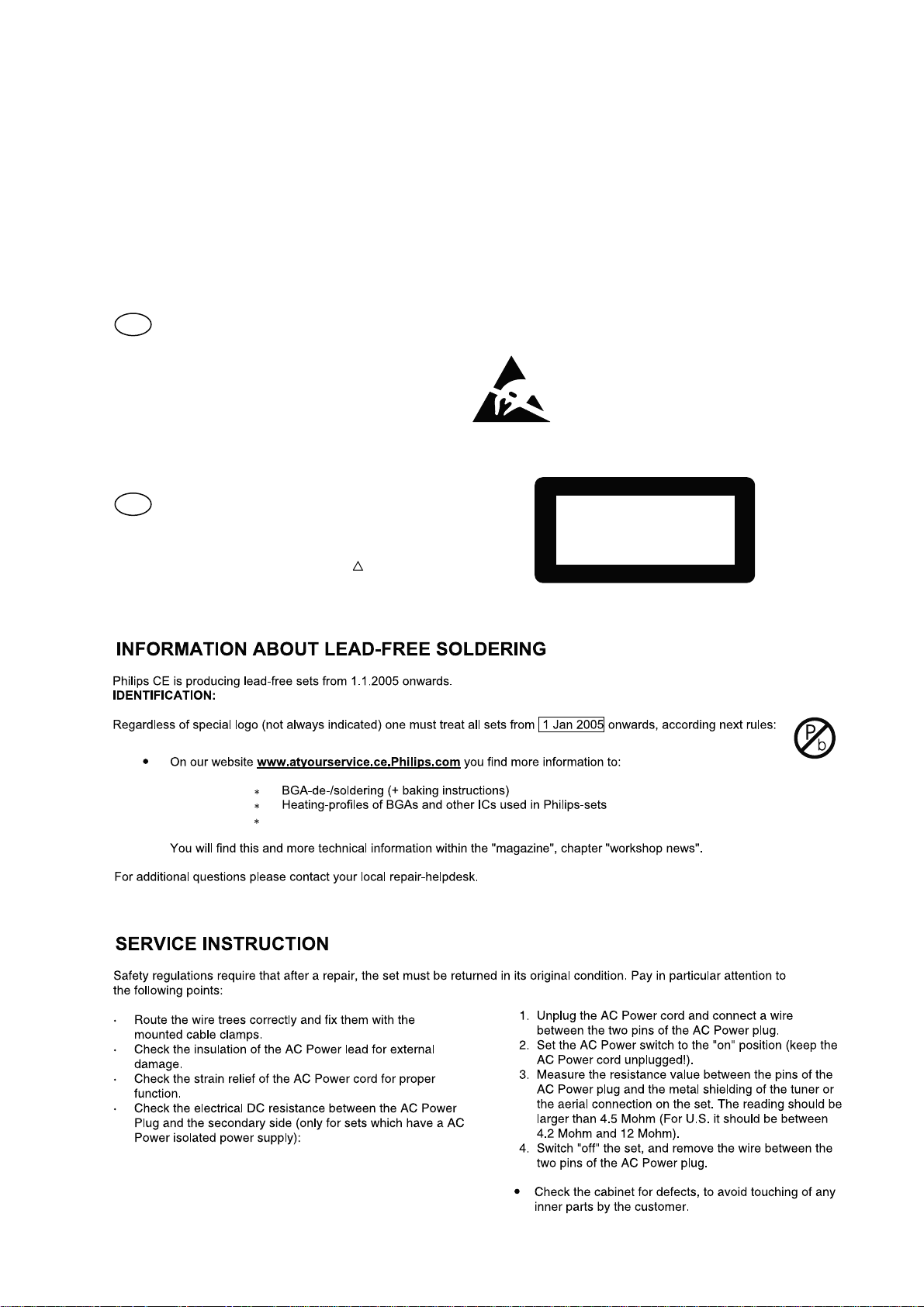

1-2

CD PLAYABILITY

Customer complaint

"CD related problem"

check playability

for at least 10 minutes

CHECK

playability

ok ?

Y

Play a CD

Set remains closed!

1

N

"fast" lens cleaning

check playability

playability

ok ?

Y

3

For flap loaders (= access to CD drive possible)

cleaning method

is recommended

4

Standard repair procedure

N

clean the lens

check playability

4

check playability

playability

ok ?

Y

add Info for customer

"SET OK"

return set

1

- 7

For description - see following pages

2

5

6

7

Y

return set

N

replace CD Drive

return set

N

replace CD Drive

return set

playability

ok ?

N

N

check "EYE-Pattern"

EYE-Pattern

ok ?

Y

check Laser current

Laser current

ok ?

Y

check CD Drive offsets

replace Signal Processor

return set

Y

CD Drive offsets

N

ok ?

replace CD Drive

return set

Page 4

1-3

CD PLAYABILITY

CHECK

1

PLAYABILITY CHECK

For sets which are compatible with

use CD-RW Printed Audio Disc....................7104 099 96611

TR 3 (Fingerprint)

TR 8 (600µ Black dot) maximum at 01:00

• playback of these two tracks without audible disturbance

playing time for: Fingerprint ≥

Black dot from 00:50 to 01:10

• jump forward/backward (search) within a reasonable time

For all other sets

use CD-DA SBC 444A..................................4822 397 30245

TR 14 (600µ Black dot) maximum at 01:15

TR 19 (Fingerprint)

TR 10 (1000µ wedge)

• playback of all these tracks without audible disturbance

playing time for: 1000µ wedge ≥10seconds

Fingerprint ≥10seconds

Black dot from 01:05 to 01:25

• jump forward/backward (search) within a reasonable time

CD-RW discs

10seconds

4

LIQUID LENS CLEANING

Before touching the lens it is advised to clean the

surface of the lens by blowing clean air over it.

This to avoid that little particles make scratches on

the lens.

Because the material of the lens is synthetic and coated

with a special anti-reflectivity layer, cleaning must be done

with a non-aggressive cleaning fluid. It is advised to use

“Cleaning Solvent B4-No2”, available with codenumber

4822 389 10026.

The actuator is a very precise mechanical component and

may not be damaged in order to guarantee its full function.

Clean the lens gently (don’t press too hard) with a soft and

clean cotton bud moistened with the special lens cleaner.

The direction of cleaning must be in the way as indicated in

the picture below.

2

CUSTOMER INFORMATION

It is proposed to add an addendum sheet to the set which

informs the customer that the set has been checked

carefully - but no fault was found.

The problem was obviously caused by a scratched, dirty or

copy-protected CD. In case problems remain, the customer

is requested to contact the workshop directly.

The lens cleaning (method 3) should be mentioned in the

addendum sheet.

The final wording in national language as well as the printing

is under responsibility of the Regional Service Organizations.

3

FAST LENS CLEANING (dry brush)

Use lens cleaning CD

SBC AC300...........................................9082 100 00043

Insert the lens cleaning CD, press PLAY and follow the

voice guide´s instructions on the CD.

Page 5

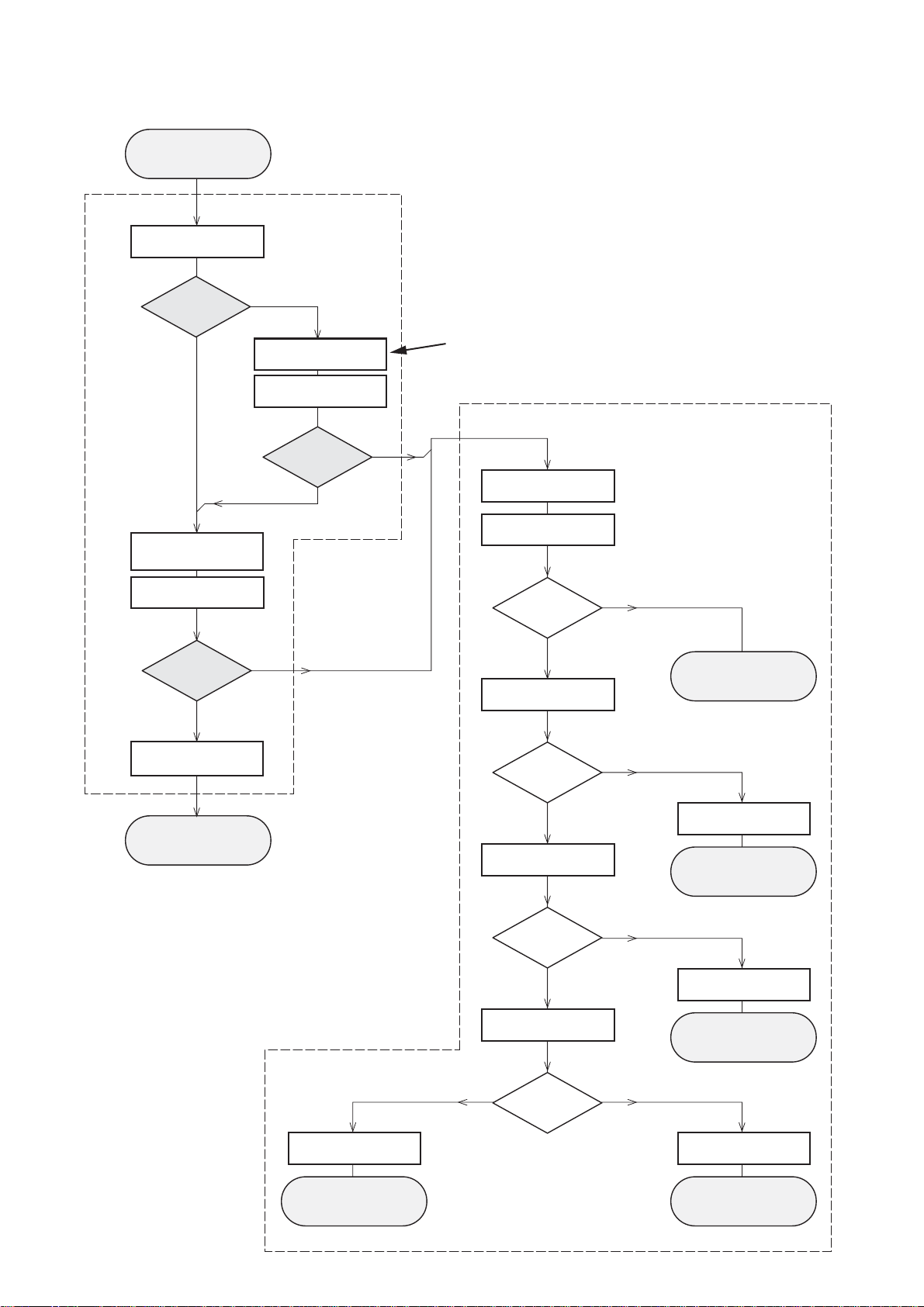

Sanyo DA12T3

CD Drive

A

A

F

C

B

E

C

D

E

VCC

B

VREF

F

D

9

10

11

12

13

14

15

16

1800

+5V_HF

VrefCD10

A

D

E

B

C

F

GND

8

E

D

A

B

C

F

Laser power control

100n

2878

470n

2876

3821

1R

1K

3823

2880

33p

+5V

BC807-40

7879

3817

47R

3820

4R7

47R

3819

1n

2879

2877

47u

1

8

4

7811-A

LM358D

3

2

10K

3822

47R

3818

2841

100n

47n

2869

+5V_HF

LASER DIODE

U >250mV

->Laser damaged !

4,6V

3V

3,3V

3,9V

2V

0,17V

0,17V

Sanyo

DA12T3

HF-Amplifier

D3

D2

D1

680R

3905

3903

3K3

BC847B

7877

47n

2818

1K5

3902

5

7

4

2

1

6

3

64

8

9

10

11

470R

3893

+3.3V

2K2

3908

10K

3923

BC847B

7878

BC847B

7876

4n7

2813

3896

100R

220u

2885

2881

560p

47n

2887

560R

3901

2883

470n

2817

4u7

3n3

2814

3898

220R

3895

27K

470n

2884

+3.3V

3909

820R

3907

100R

3920

33K

3897

2882

82p

3K3

3904

2K7

3899

3906

470R

+5V_HF

HFIN

VrefCD10

100p

28152816

22n

LDON

to 3826,3827

VREF GE

VDDA1

VRIN

VSSA1

ISLICE

LD

ON

D1

D2

D3

D4

HFIN

HFREF

IREF

CD_DA: 0V / CD_RW: 3V

Σ

(A-D)

800mVpp

TB = 0.5µs/div

EYE-PATTERN

1,8V

1,2V

2,4V

2,6V

0,65V

CD PLAYABILITY CHECK

1-4

5

EYE-PATTERN SIGNAL – JITTER MEASUREMENT

Measure the signal on the input of the Signal processor

using an analog oscilloscope. Please find the exact

measuring point in your Service Manual.

See below examples of the signal. Amplitude should read at

least 700mVpp using SBC444A.

6

CD DRIVE – LASER CURRENT MEASUREMENT

The laser current can be measured as a voltage drop on a

resistor. The resistor is marked in every Service Manual.

The value depends on the type of CD drive.

typical value most probably defect

VAMxxxx : 150-230mV

MCDxx : 170-230mV

DA1x : 210-250mV ≥350mV

DA2x : 175-200mV

Use SBC444A (CD-DA) for measurement.

≥

350mV

≥

300mV

250mV

≥

If the oscilloscope shows a signal like the ‘bad’ one, and/or

the amplitude decreases within 1 minute - the CD drive has

to be replaced.

good

bad

7

CD DRIVE – OFFSET MEASUREMENT

The photodiodes of the CD-drive may have an offset. These

offsets have to be compensated by the signal processor.

High offsets can lead to poor playability of some CDs

(skipping tracks).

To measure the offset values, start the

Program - section “Focus Test” without a CD.

The offsets can be measured with a DC Millivoltmeter

directly on the connector (see drawing below). Pin

numbering varies from drive to drive.

The values from diode A-D should read 0±10mV.

Diodes E and F are less critical.

If one of the offsets is higher than ±10mV the CD drive has

to be replaced. Otherwise replace the Signal Processor.

Service Test

Page 6

2 - 1

AMPLIFIER

Output power ................................................30 W RMS

Signal-to-noise ratio ....................................... ≥ 65 dBA

Frequency response ............. 100 – 18kHz, ± 3 dB

Input sensitivity AUX ....................... 0.5 V (max. 1 V)

Impedance loudspeakers .....................................≥ 6 Ω

Impedance headphones .................... 32

Ω

-1000

..................................................................................... <15mW

CD PLAYER

Frequency range ....................................... 100 – 18kHz

Signal-to-noise ratio ............................................ 65 dBA

TUNER

FM wave range ...................................87.5 – 108 MHz

MW wave range ................................ 531 – 1602 kHz

Number of presets ........................................................ 40

Antenna

FM .................................................................... 75 Ω wire

MW ......................................................... Loop antenna

USB PLAYER

USB ......................................................................... V2.0/ V1.1

......................................... support MP3 and WMA files

Number of albums/ folders ................ maximum 99

Number of tracks/titles ...................... maximum 999

Ω

SPEAKERS

Bass reflex system

Dimensions (w x h x d) .. 158 x 250x 185 (mm)

GENERAL INFORMATION

AC Power .......................... 110 – 240 V, 50 Hz/60Hz

Dimensions (w x h x d, with/without the stand)

............... 211 x 250 x 160/211 x 250 x 126 (mm)

Weight(with/without speakers) ......... 3.7 / 1.33 kg

Standby power consumption ............................ <2 W

Eco power standby ............................................... <1 W

Specifications and external appearance are

subject to change without notice.

Page 7

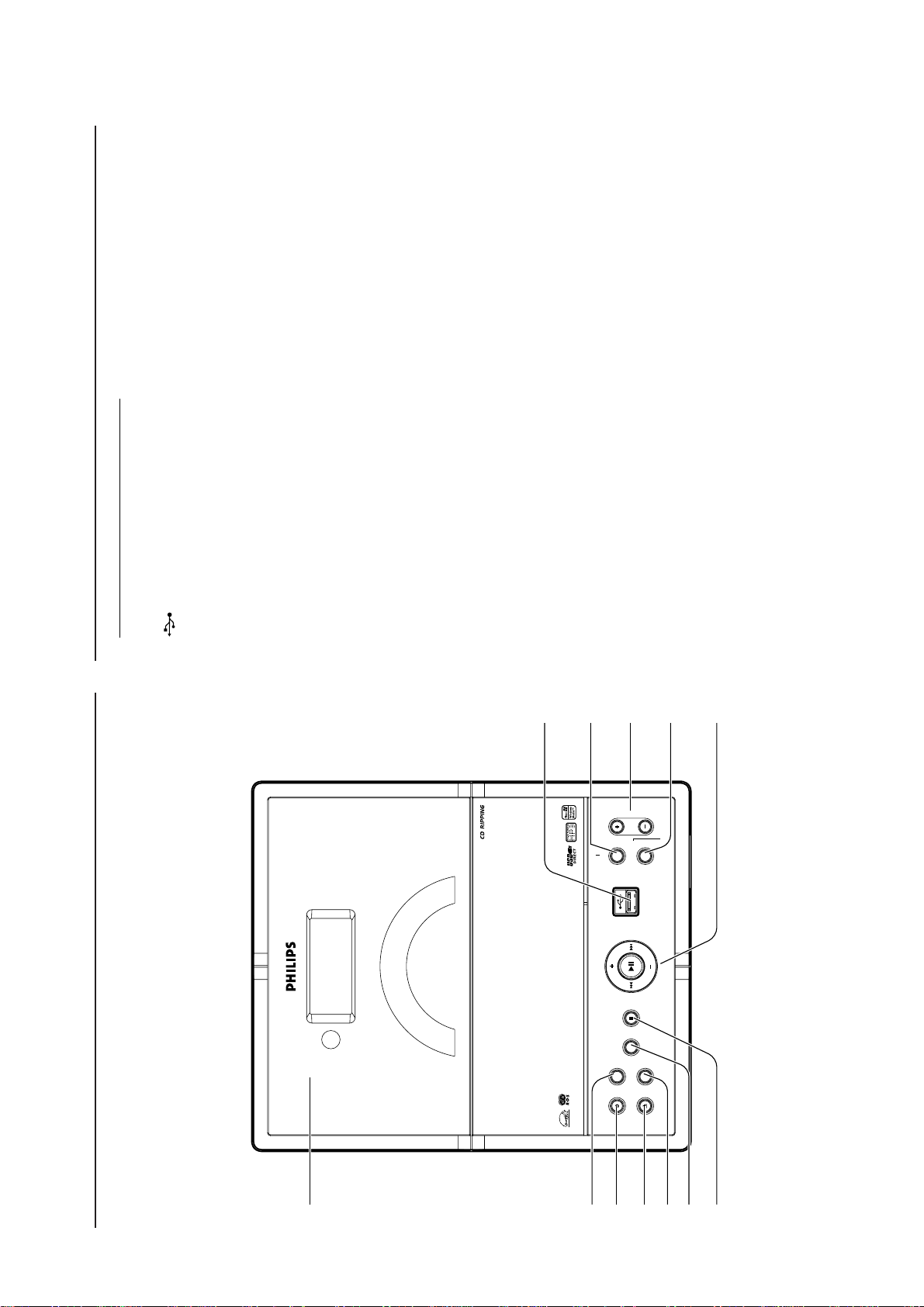

Connection

CONNECTION AND CONTROLS

3 - 1

Connection

Connecting a USB device or memory

Connecting an additional

appliance

FM antenna

VCR or other radiation source.

● Position the antenna as far as possible from a TV,

on the front

on the front panel of the main set.

card

By connecting a USB mass storage device

(including USB flash memory, USB flash players

or memory cards) to the Hi-Fi system, you can

enjoy the music stored on the external device

through the powerful speakers of Hi-Fi system.

Or,

panel of the main set.

for the devices with USB cable:

a. Insert one plug of the USB cable (not

supplied) to the socket

1 Insert the USB device’s USB plug into the socket

The wire antenna supplied can only be used to

receive nearby stations. For better reception we

recommend using a cable antenna system or an

outdoor antenna.

Extend the wire antenna and fit it to FM

ANTENNA as shown below

1

Insert the other plug of the USB cable to the

b.

USB output terminal of the USB device.

on the front panel of the main set.

the card reader to the socket .

optimal reception (as far away as possible from

the TV, VCR or other radiation sources)

Fix the antenna’s end to the wall.

3

Connecting a non-USB device

It is possible to use an additional appliance, e.g.

TV, VCR or CD recorder with the set. On

Helpful hints:

Or,

for the memory card:

a. Insert the memory card into a card reader

(not supplied).

b. Use a USB cable (not supplied) to connect

Note: If you are using a cable antenna system or

an outdoor antenna, fit the antenna plug, instead of

the wire antenna, to FM ANTENNA .

Move the antenna in different positions for

2

MCM279, you can playback music from an

external source.1Insert one plug of the audio cable (not supplied)

to the socket AUX IN at the rear panel of the

–To receive optimal radio reception, put the main

unit and the antennas as far away as possible from

the power adaptor.

main set.

Connect the other end of the audio cable to the

AUDIO OUT terminal of the additional

appliance.

2

Always refer to the owner’s manual of other

equipment for complete connection.

Helpful hints:

–

3 Select AUX mode on the set.

Antenna connections

MW antenna

Connect the supplied MW loop antenna to the

“AM aerial” terminal. Adjust the position of the

antenna for optimal reception.

6

9

Warning:

– Never make or change connections with

Rear connections

B

the mains supply switched on.

– Install your set near the AC outlet and

where the AC power plug can be reached

easily.

Use the supplied speakers only. Using other

speakers can damage the set or the sound

quality will be negatively affected.

A Speaker connections

(red and black) and the cable of the right

● Connect the cable of the left speaker to LEFT

(red and black) as follows:

RIGHT

speaker to

a. Press the clip of the red terminal and fully

insert the stripped portion of the colored (or

marked) speaker cable into the socket, then

release the clip

Press the clip of the black terminal and fully

b.

insert the stripped portion of the black (or

unmarked) speaker cable into the socket, then

release the clip

Page 8

CONNECTION AND CONTROLS

set on and selects sound source CD, USB,

SOURCE

9 OPEN/CLOSE 0

0 DBB (Dynamic Bass Boost)

!

– turns the bass enhancement on/off

– opens/closes the CD door.

AUX

– selects sound source CD, USB, TUNER, or

TUNER or AUX

– In standby or Eco Power mode: switches the

STOP

@

– CD/USB: stops playback; erase a program

3 - 2

switches between

Controls on the set (illustrations

Controls

on page 3)

1

– jack for the external USB mass storage device

2 PROGRAM

programs tracks

programs preset radio stations

– CD/USB:

– Tuner:

VOLUME

– adjusts the volume level

– Clock/Timer: adjusts the hours and minutes

3

DISPLAY/CLOCK

- displays the set time

– Clock:

4

enters the clock setting mode

(press and hold for more than 2 seconds)

clock

display and playback display

during playback

- In standby mode:

– TUNER/Audio CD/AUX:

– MP3/WMA files: displays disc information

MICRO SYSTEM MCM279

ALBUM/ PRESET + /-

5

4 / ¢

backwards/forwards

– CD/USB: selects albums (for MP3/WMA only)

– TUNER: selects a preset radio station

– CD/USB: skips or searches CD tracks/titles

1

4mm

– Tuner: tunes to radio stationsÉÅ– CD/USB: starts or pauses playback

2

VOLUMEPROGRAM

ALBUM/PRESET

Always point the remote control

towards this sensor.

6 IR

– sensor for the infrared remote control

Helpful hints:

7 DSC (Digital Sound Control)

4

3

DISPLAY/CLOCK

JAZZ, POP, CLASSIC, OFF

– selects predefined sound settings: ROCK,

5

– press briefly to switch the set on or off (standby/

8 STANDBY-ON/ ECO POWER

ECO POWER);

– In standby or Eco Power mode: press and

lights up red when the set is

hold to toggle between Standby and ECO

POWER mode (power-saving mode)

Red indicator:

switched to ECO POWER mode

–

Controls

6

IR

MPATIBLE

RW CO

-

R/CD

-

CD/CD

-

MP3

-

WMA

ECO POWER

7

SOURCE STOP

DSC

DBB

ON

-

ANDBY

OPEN/CLOSE

ST

@

!

0

9

8

Page 9

CONNECTION AND CONTROLS

Mounting the stand onto the set

MCM279 is supplied with a stand, you may

attach or detach the stand to/from the main set.

Placing MCM279

Locate the bottom of the main unit and find the

slot, then slide the stand in the slot until it stops,

as indicated in the figure below.

1

3 - 3

Controls

Controls

copies one file or all files of a disc to an

USB:

external portable USB storage device/MP3

–

– set the sleep timer

3 SLEEP

4 MUTE

5

4$

player.

& 0

– switches the sound off temporarily

during playback

switches the timer on/off

USB REC

– MP3/WMA files: displays disc information

$ DISPLAY

AUX

– selects the audio input from an additional

–

% TIMER ON/OFF

^

switches the set

connected appliance

on and selects the audio input from an

additional connected appliance

– In standby/Eco-power mode:

123

@

#

Remote control

– opens/closes the CD door.

à / á

– CD/USB: skips or searches CD tracks

5

6

7890!

^

*

&

ë

í/

– CD/USB: selects previous/next track

*

backwards/forwards

– Tuner: tunes to radio stations

(

Numeric keypad (0-9)

– CD/USB: stops playback; erase a program

( 9

)

selects the next/previous album (for

3 / 4

CD/USB:

MP3/WMA only)

–

– Tuner: selects a preset station

)

¡%™

– selects track or station number

ÉÅ

DSC (Digital Sound Control)

JAZZ, POP, CLASSIC, OFF™DBB (Dynamic Bass Boost)

– selects predefined sound settings: ROCK,

¡

– CD/USB: star ts or pauses playback.

– turns the bass enhancement on/off

USB DEL

USB device.

adjusts the volume level

– deletes one file or all files stored on the external

6

Notes for remote control:

– First select the source you wish to

–

7 VOL +/-

CD, TUNER).

control by pressing one of the source select

keys on the remote control (for example

System)

Data

adjusts the hours and minutes

REPEAT–selects continuous playback9SHUFFLE

– Clock/Timer:

8

).

ë

,

í

,

selects random playback0PROG–CD/USB: programs tracks

–

press and

RDS/NEWS

!

– Tuner: programs preset radio stations

– Tuner: selects RDS (Radio

ÉÅ

USB source

BBBB

ECO POWER);

In standby or Eco Power mode:

hold to toggle between Standby and ECO

POWER mode (power-saving mode)

– Then select the desired function (for

example

B

press briefly to switch the set on or off (standby/

Source buttons

USB

selects

TIMER

for more than 2 seconds)

information

– CD/USB/AUX: activates/deactivates news

In standby/Eco-power mode: switches the set

on and selects USB source.

CD

CLOCK–Clock:

– enters the timer setting mode (press and hold

@

#

switches the set

source

selects CD

on and selects CD source.

In standby/Eco-power mode:

enters the clock

In standby mode:

- displays the set time

-

setting mode (press and hold for more

than 2 seconds)

switches the set

TUNER source and toggles between the

TUNER

selects

wavebands: FM and MW

In standby/Eco-power mode:

TUNER/Audio CD/AUX: switches between

clock display and playback display

–

source

TUNER

on and selects

Page 10

DISASSEMBLY DIADRAMS

4 - 1

4 - 1

A. Remove stand

Rlease click and pull it out.

B. Remove Top Cabinet

Remove screws MP 3x10 - 6 pcs.

C. Remove Amplif ier board

C1: Remove screws 2 pcs.

C2: Remove screws 2 pcs.

C1

C1

C2

C2

D. Remove Main board

D1:Remove screws MP 3x10 - 3 pcs.

D1

D2:Remove screws MP 3x10 - 3 pcs.

Then remove lens frame cosmetic top_right&left

D2

E. Remove Key board

E1:Remove screws MP 2x8 - 8 pcs.

Then remove lens frame cosmetic botom_right&left

E1

E1

Page 11

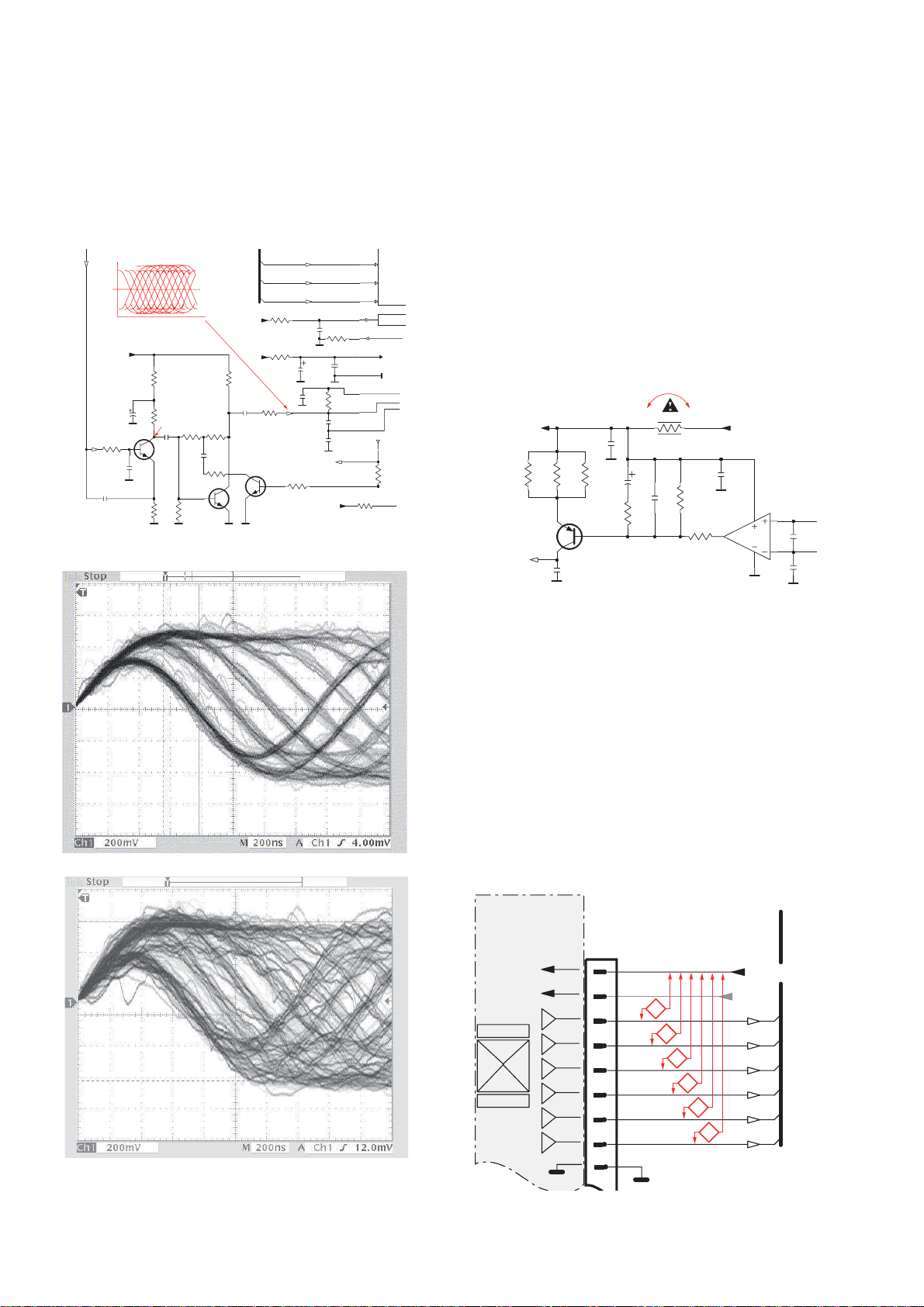

SET BLOCK DIAGRAM

5 - 1

5 - 1

Page 12

SET WIRING DIAGRAM

5 - 2

5 - 2

Page 13

CIRCUIT DIAGRAM - MAIN BOARD - PART1

6-1

6-1

Page 14

CIRCUIT DIAGRAM - MAIN BOARD - PART2

6 - 2

6 - 2

Page 15

6 - 3

6 - 3

LAYOUT DIAGRAM -

MAIN BOARD

Page 16

KEY & USB JACK BOARD

7 - 1

7 - 1

Page 17

8 - 1

8 - 1

CIRCUIT DIAGRAM

POWER & AMP BOARD

-

Page 18

8 - 2

LAYOUT DIAGRAM - POWER & AMP BOARD

8 - 2

Page 19

EXPLODE DIAGRAM

9-1

9-1

Page 20

ACCESSORY PARTS

T

2

S

R

A

B

K

R

)

R

A

C

R

10-1

! 9940 000 02082 A

9965 100 00308 FM ANT WIRE 75R L1.0M

! 9965 100 07794 SWITCHING POWER ADAPTOR 19V/4A

9965 100 00131

9965 100 07795 SPEAKER BOX FOR MCM279//00(for /55)

9965 100 10123 SPEAKER BOX FOR MCM279(for /12)

9965 100 07796 RC "PHILIPS" FOR MCM279

9965 100 07001 STAND PORTION OF MCM238/1

99651 000 0132 CONVERSION MAINS PLUG ADAPTOR (for /55)

C CORD VDE 2C L=1.5M

A

M LOOP ANT 18.1uH 8

MECHNICAL&MISCELLANEOUS PART

12 99651 000 9789 CABINET FRONT V1

2 9965 100 07777 LENS-SLIDE DOOR

71 9965 100 07778 CABINET REA

5 9965 100 07798 CARRIER - SLIDE DOOR -R

7 9965 100 07779 CARRIER - SLIDE DOOR -L

32 9965 100 07780 RACK BAR

13 9965 100 07781 LENS-CD AMBI LIGHT GUIDE

16 9965 100 06985 BUTTON POWER

47 9965 100 06982 BUTTON SET FUNCTION51 9965 100 06983 BUTTON SET FUNCTION-

52 9965 100 06980 BRACKET PLAY BUTTON

50 99651 001 0192 BUTTON SET-NAVIGATION V1

14 9965 100 06981 COVER POWER BUTTON

6 99651 000 9788 DOOR CD - SLIDE V1

44 99651 000 9790 DOOR CD - ROTATED V1

17 9965 100 07784 GEAR-ROTATED DOOR RAC

19 9965 100 07785 GEAR-SLIDE DOO

46 9965 100 07786 CONTROL PANEL (for /12)

46 9965 100 07950 CONTROL PANEL (for /55)

1 9965 100 07787 COVER- ROTATED CD DOOR(for /12)

1 9965 100 07951 COVER- ROTATED CD DOOR (for /55)

4 9965 100 07788 FRAME-LCD CHROME

48 9965 100 06991 COVER PLAY BUTTON(for /12)

48 9940 000 04315 COVER PLAY BUTTON(for /55)

49 9965 100 06992 COVER NAVIGATION BUTTON(for /12

49 9940 000 04309 BUTTON FW/FF (for /55)

23 9940 000 04317 GEAR WHEEL A

22 9940 000 04318 GEAR WHEEL B

28 9940 000 04316 PULLEY SERVO MOTO

15 9965 100 07789 CUSHION CD MECHANISM

64 9940 000 04323 CD DAMPER (BLACK) 20DEG

65 9965 100 07790 CD DAMPER (BLACK) 30DEGREE

74 9965 100 07791 RUBBER FOOT FOR FRAME-COSMETI

18 9965 100 07792 SHAFT FOR MCM279

24 9940 000 04325 BELT MOTO

CDMECH 9965 100 10437 CD MECHANISM M93BGP-BF

FFC1 9965 100 10376 FFC CBL 20PIN P=1.25MM L=120MM

FFC2 9965 100 07773 FFC CABLE10PIN P=1.25MML=130MM

FFC3 9965 100 10375 FFC CABLE 12PIN P=1.0MM L=70MM

Page 21

10-2

D

)

R

ELECTRICAL PARTS - MAIN BOAR

70 9965 100 00946 TUNER MODULE AM/FM ENG07821QF(for /12

70 9965 100 01360 TUNER MODULE ENG06835QF.(for /55)

IC19 9965 100 07759 IC PCF8563T CLOCK SOP8

X4 9965 100 07758 CRYSTAL 32.768KH Z/3*8 12.5pF

IC7 9965 100 07760 IC AM7072A L/FMOTORDRIVER DIP8

MOTO

Q28 9940 000 05691 TRANSISTOR PNP BC869SOT-89

Q29 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

R1 9940 000 04221 FUSE RES 2.2R 1/4W +/-5%

D3 9965 100 07742 CH-DIODE, HIGHBAS316SOT323

IC10 9940 000 05687 IC 16M SDRAM K4S161622H-UC60

IC15 9965 100 07747 IC, HEF4094BT PHILIPS SO16

IC16 9965 100 01347 IC ET2314 SOUND SO28

IC2 9965 100 07747 IC, HEF4094BT PHILIPS SO16

IC6 9965 100 07745 IC, OPT30 RESET OPTEK SOP-8

IC8 9965 100 07744 IC, SCF5250

IC9 9965 100 07746 IC, 8M FLASH KH29LV800CTTC-70G

Q17 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q5 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

X1 9965 100 06950 CRYSTAL 8.4672MHZ+/-20PPM 30PF

IC12 9965 100 07750 IC, SAA7824HL LQFP80

IC4 9965 100 06955 IC, D9258 MOTOR DRIVERCD

IC5 9965 100 07749 IC, YD4558 SOP8

L1 9965 100 07751 INDUCTOR RTB6046-101K-1A 100UH

Q10 9965 100 07748 CH-TRANSISTOR,BC807-40SOT-23

9940 000 04253 DC MOTOR JQ32-55K415 DC3V

Q3 9965 100 07748 CH-TRANSISTOR,BC807-40SOT-23

Q4 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q8 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q9 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

D2 9965 100 07752 CH-ZENER DIODE, UDZS 5.1B

IC17 9965 000 41703 IC, BH4453F

JK101 9940 000 03318 HP JACK D3.6MM

Q15 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q24 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q34 9965 100 07748 CH-TRANSISTOR,BC807-40SOT-23

Q6 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q7 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

IC1 9940 000 05675 IC AZ1117H-5.0 TRE1 REGULATOR

IC3 9965 000 41892 IC AZ1117H-3.3 REGULATOR

Q1 9965 100 07753 CH-PWR TRANSISTOR PNP 2SB1182

Q2 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q30 9940 000 05691 TRANSISTOR PNP BC869SOT-89

Q31 9940 000 05691 TRANSISTOR PNP BC869SOT-89

Q33 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

D5 9965 100 07092 ZENER DIODE 5.6V 1/2W

IC14 9940 000 04239 IC SAA6588T RADIO RECEIVERS

Q16 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

X3 9940 000 04238 CRYSTAL 4.332MHZ +/-20PPM

IC11 9940 000 05692 IC ISP1160BD/01 USB CONTROLLER

Q11 9940 000 05691 TRANSISTOR PNP BC869SOT-89

Q12 9965 100 06966 MOSFET P-CH APM2301 SOT-23

Q13 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Page 22

10-3

D

Y

D

D

ELECTRICAL PARTS - MAIN BOAR

X2 9965 100 07754 CRYSTAL 6MHZ/3*8 20PF +/-20ppm

IC13 9965 100 07755 IC ET8862Q PQFP64 LCD DRIVER

IR101 9965 000 41893 IR RECEIVER BRM-4050-8-FB2.2

LCD101 9965 100 07756 LCD FSTN TRANS 60X31.5X2.8mm

LED2 9940 000 05678 LED 3MM SUPER BLUE

LED3 9940 000 05678 LED 3MM SUPER BLUE

LED4 9965 100 07006 LED 4.8X4.4MM ROUND BLUE X

Q18 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

Q19 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

ELECTRICAL PARTS - DOOR BOAR

S1 9965 100 07757 DOOR SWITCH MST-002

S2 9965 100 07757 DOOR SWITCH MST-002

ELECTRICAL PARTS - KEY BOAR

JK1 9940 000 04263 USB JACK USB-1400A 4P

LED1 9965 100 00292 LED 3MM 3R4HD-7(RED) TAPING

Q14 9965 100 07743 CH-TRANSISTOR,BC817-40 SOT-23

T 9940 000 04259 SWITCH TACT TSA-06430-150

Page 23

10-4

D

A

A

A

T

T

ELECTRICAL PARTS - POWER& BOAR

D604 9965 100 06964 DIODE 1N5819 DO-41

JK601 9965 100 06969 DC JACK 3PIN DC-005 DIA6.3MM

JK602 9940 000 03318 HP JACK D3.6MM

L601 9965 100 07769 INDUCTOR15UH+/-20%DCR=0.045ohm

L602 9965 100 07769 INDUCTOR15UH+/-20%DCR=0.045ohm

L603 9965 100 07769 INDUCTOR15UH+/-20%DCR=0.045ohm

L604 9965 100 07769 INDUCTOR15UH+/-20%DCR=0.045ohm

L605 9965 100 07771 TOROID INDUCTOR 8UH 3.2

L606 9965 100 07771 TOROID INDUCTOR 8UH 3.2

L607 9965 100 07770 INDUCTOR47UH 7E05NBSMDIm=960m

L608 9965 100 07768 INDUCTOR220UH+/-20%DCR=0.45ohm

L609 9965 100 06959 28UH CORE:T9X5X3 6TURNS 715OHM

Q601 9965 100 06953 CH-TRANSISTOR, BC847C SOT-23

Q602 9965 100 06953 CH-TRANSISTOR, BC847C SOT-23

Q603 9965 100 06953 CH-TRANSISTOR, BC847C SOT-23

Q605 9940 000 05691 TRANSISTOR PNP BC869SOT-89

Q606 9965 100 06953 CH-TRANSISTOR, BC847C SOT-23

Q607 9965 000 41725 TRANS. 2SB1370PNP TO-220FP

Q608 9965 000 41726 TRANS. 2SC5343 NPN TO-92

Q609 9940 000 05649 TRANSISTOR DTA114YSAPNP SP

Q610 9965 000 41700 CH-TRANS. DTC114YKA NPN

Q611 9965 100 06953 CH-TRANSISTOR, BC847C SOT-23

Q613 9965 100 06953 CH-TRANSISTOR, BC847C SOT-23

Q614 9965 100 07765 CH-TRANSISTOR BC857C INFINEON

SP601 9940 000 01619 SP TERMINAL MSP-134V-05

U601 9965 100 07766 IC TDA8932BT/N2C CLASS D POWER

U602 9965 100 07766 IC TDA8932BT/N2C CLASS D POWER

U604 9965 100 07767 IC AZ34063AM-E1 DC-TO-DC CONV

ZD601 9965 100 07761 ZENER DIODE 5V1 1/2W TAPING.

ZD602 9965 100 07762 ZENER DIODE 9V1 1/2W TAPING.

ZD603 9965 100 07764 ZENER DIODE 22V 1/2W TAPING.

Note: Only these parts mentioned in the list are normal

service parts.

Page 24

,

,

,

,

,

11-1

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

0 0010 9008-027900012 PHILIPS MCM279//12 SET 1.000

.1 0010 8900-070400100 ELECTRICAL SECTION OF MCM279//12(W/RDS) SET 1.000

..2 0010 8901-070400100 MAIN PWB ASSEMBLY OF MCM279//12 SET 1.000

...3 0010 3702-027900130 MAIN PWB:DOUBLE 175x204x1.6MM FR4 MCM279-

...3 0020 8903-070400100 MCU SECTION ASSEMBLY OF MCM279/12 SET 1.000

....4 0010 1123-106033050 TANT. CH-CAP 10UF 6.3V +/-20% 3216-A TYP

....4 0020 1132-225083020 CAP ELECT, 2.2UF 50V +/-20% 4X5 TAPING PC

....4 0030 1132-226053020 CAP ELECT 22UF 16V +/-20% 4X5MM(TAPING PH=2.5MM) PC 1.000 C139

....4 0040 1132-476083100 CAP ELECT, 47UF 50V +/-20% 6.3X11 TAPING PC 3.000 C56,C66,C171

....4 0050 1132-107043060 CAP ELECT, 100UF 10V +/-20% 5X11 TAPING PC 2.000 C57,C112

....4 0070 1132-227053060 CAP ELECT, 220UF 16V +/-20% 5X11 TAPING PC 1.000 C143

....4 0080 1121-102082020 CH-CAP, CER1000PF50V+/-10%0603 PC 3.000 C60,C79,C173

....4 0090 1121-103052020 CH-CAP, CER 0.01UF16V+/-10%0603 PC 1.000 C77

....4 0100 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 26.000

....4 0110 1121-105044020 CH-CAP, CER1UF10V +80%/-20%0603 PC 1.000 C82

....4 0120 1121-220051020 CH-CAP, CER 22PF16V+/-5%0603 PC 2.000 C58,C59

....4 0150 1121-222052020 CH-CAP, CER 2200PF 16V+/-10%0603 PC 2.000 C

....4 0160 1121-224084030 CH-CAP, CER0.22UF50V+80%-20%0805 PC 2.000 C

....4 0170 1121-225032020 CH-CAP, CER2.2UF6.3V+/-10%0603 PC 1.000 C54

....4 0190 1121-475044020 CH-CAP, CER4.7UF 10V+80%-20%0603 PC 1.000 C

....4 0200 1121-681051020 CH-CAP, CER 680PF16V+/-5%0603 PC 3.000 C61,

....4 0210 1221-000052020 CH-RES, 0R1/10W+/-5%0603 PC 4.000 R28,R243,

....4 0220 1221-100052020 CH-RES,10R1/10W+/-5%0603 PC 2.000 R78,R80

....4 0230 1221-470052020 CH-RES,47R1/10W+/-5%0603 PC 5.000 R92,R93,R94,R207,R272

....4 0240 1221-101052020 CH-RES,100R1/10W+/-5%0603 PC 22.000

....4 0250 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 11.000

....4 0256 1221-272052020 CH-RES,2.7K0.1W+/-5%0603 PC 2.000 R238,R239

....4 0257 1221-332052020 CH-RES, 3.3K1/10W+/-5%0603 PC 2.000 R81,R10

....4 0260 1221-472052020 CH-RES, 4.7K1/10W+/-5%0603 PC 10.000

....4 0270 1221-103052020 CH-RES,10K1/10W+/-5% 0603 PC 14.000

....4 0280 1221-123052020 CH-RES, 12K1/10W+/-5%0603 PC 4.000 R209,R21

....4 0290 1221-153052020 CH-RES,15K1/10W+/- 5% 0603 PC 3.000 R142,R1

....4 0300 1221-223052020 CH-RES, 22K1/10W+/-5%0603 PC 7.000

....4 0310 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 1.000 R76

....4 0320 1221-104052020 CH-RES, 100K1/10W+/-5%0603 PC 4.000 R87,R11

....4 0330 1221-154052020 CH-RES, 150K1/10W+/-5%0603 PC 1.000 R77

....4 0340 1221-105052020 CH-RES, 1M1/10W+/-5%0603 PC 1.000 R129

....4 0350 1001-084672220 CRYSTAL, 8.4672MHZ +/-20PPM 30PF 3x8 PC 1.

....4 0360 1311-141480010 DIODE 1N4148. PC 1.000 D4

....4 0370 1321-003160010 CH-DIODE, HIGHBAS316SOT323 PC 1.000 D3 FA030154

....4 0380 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 2.000 Q5,Q17 FA030192

....4 0390 1502-002314010 IC ET2314 SOUND SO28 PC 1.000 IC16 FAP070031

....4 0400 1506-005250000 IC, SCF5250 PC 1.000 IC8 FA050919

....4 0410 1508-000030000 IC, OPT30 RESET OPTEK SOP-8 PC 1.000 IC6 FA050727

....4 0420 1511-829800160 IC, 8M FLASH KH29LV800CTTC-70G (OPT48) TSOP48 PC 1.000 IC9

....4 0430 1511-164161020 IC, 16M SDRAM TSOP(II)50 K4S161622H-UC60 PC 1.000 IC10 FAP060871

....4 0450 1513-004094000 IC, HEF4094BT PHILIPS SO16 PC 2.000 IC2,IC

....4 0460 2721-102020020 FERRITE BEAD SMD 1K+/-25%/100MHZ GZ1608U

....4 0470 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF)

....4 0475 2721-601020020 FERRITE BEAD 100MHz/600 OHM 0603. PC 1.000

....4 0480 3106-101221000 FFC CONNECTOR 12PIN PH=1.0MM STRAIGHT WHITE PC 1.000 CN10 FAP071095

...3 0030 8903-070400200 CD SECTION ASSEMBLY OF MCM279/12. SET 1.000

....4 0010 1123-107033060 TANT. CH-CAP 100UF 6.3V +/-20% 3528-BTYPE PC 1.000 C20

....4 0015 1123-227013060 TANT. CH-CAP 220UF 4V +/-20% 3528-BTYPE PC 1.000 C53

01(for dummy) PC 1.000

E PC 1.000 C114

C31,C128,C136,C140,C146,C148,C14

10.000

9

C151,C187,C188

C55,C62,C63,C64,C65,C67,C68,C69,

C70,C71,C72,C74,C75,C80,C83,C84,

C97,C113,C134,C142,C147,C150,C17

0

C172,C190,C192

144,C145

189,C191

81

C76,C167

R247,FB7

R88,R89,R121,R176,R180,R181,R182

,R183,R184,R185,R186,R193,R194,R

195,R196,R197,R198,R199,R200,R20

R202,R225

1

R13,R90,R102,R104,R108,R109,R134

R135,R268,R287,R288

7

R103,R105,R106,R110,R111,R141,R2

41

R245,R248,R249

R74,R75,R79,R86,R96,R97,R98,R100

,R101,R175,R192,R269,R282,R283

0,R226,R229

43,R144

R191,R227,R228,R240,R242,R244,R2

46

2,R113,R190

000 X1 FAP070981

15 FA050381

102 PC 2.000 FB11,FB12 FA060072

. PC 4.000 FB2,FB3,FB4,FB8 FA040575

FB9

FA040624,

FA051180

CA040218,

FA050621

FAP060920

FAP070117

FA040624,

FA051180

FA040624,

FA051180

Page 25

,

11-2

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

....4 0020 1132-107044040 CAP ELECT 100UF10V+80%-20% 5X5(TAPING PH

....4 0025 1132-476033030 CAP ELECT,47UF 6.3V +/-20% 4x7 TAPING PC 2

....4 0030 1132-476034020 CAP ELECT,47UF6.3V+80%-20% 4x5(TAPING PH

....4 0035 1132-107043060 CAP ELECT, 100UF 10V +/-20% 5X11 TAPING P

....4 0040 1132-107044040 CAP ELECT 100UF10V+80%-20% 5X5(TAPING PH

....4 0060 1132-227053060 CAP ELECT, 220UF 16V +/-20% 5X11 TAPING P

....4 0065 1132-477043100 CAP ELECT, 470UF 10V +/-20%6.3X11 TAPING

....4 0070 1121-101051020 CH-CAP, CER 100P16V+/-5%0603 PC 5.000 C21,C

....4 0080 1121-152052020 CH-CAP, CER 0.0015uF16V +/-10%0603 PC 2.00

....4 0090 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 15.000

....4 0100 1121-221051020 CH-CAP, CER 220PF16V+/-5%0603 PC 4.000 C47,

....4 0105 1121-102052020 CH-CAP, CER 1000PF16V+/-10%0603 PC 4.000 C3

....4 0110 1121-222052020 CH-CAP, CER 2200PF 16V+/-10%0603 PC 2.000 C

....4 0120 1121-223052020 CH-CAP, CER 0.022UF16V+/-10%0603 PC 1.000 C

....4 0130 1121-473052020 CH-CAP, CER 0.047UF16V+/-10%0603 PC 2.000 C

....4 0140 1221-000052020 CH-RES, 0R1/10W+/-5%0603 PC 3.000 R10,R11,R

....4 0150 1221-010052020 CH-RES,1R1/10W+/-5%0603 PC 10.000

....4 0160 1221-022052020 CH-RES,2.2R1/10W+/-5%0603 PC 1.000 R22

....4 0170 1221-100052020 CH-RES,10R1/10W+/-5%0603 PC 1.000 R60

....4 0180 1221-101052020 CH-RES,100R1/10W+/-5%0603 PC 6.000 R24,R54,R55,R56,R68,R72

....4 0185 1221-471052020 CH-RES, 470R1/10W+/-5%0603 PC 1.000 R32

....4 0190 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 6.000 R43,R44,R6

....4 0195 1221-222052020 CH-RES, 2.2K1/10W+/-5%0603 PC 2.000 R91,R95

....4 0196 1221-332052020 CH-RES, 3.3K1/10W+/-5%0603 PC 1.000 R57

....4 0200 1221-272052020 CH-RES,2.7K0.1W+/-5%0603 PC 1.000 R39

....4 0220 1221-392052020 CH-RES,3.9K1/10W+/-5%0603 PC 3.000 R31,R33,

....4 0230 1221-472052020 CH-RES, 4.7K1/10W+/-5%0603 PC 5.000 R23,R45

....4 0240 1221-512052020 CH-RES,5.1K 1/10W +/-5% 0603 PC 1.000 R35

....4 0260 1221-682052020 CH-RES, 6.8K1/10W+/-5%0603 PC 1.000 R30

....4 0270 1221-822052020 CH-RES,8.2K1/10W+/-5%0603 PC 1.000 R40

....4 0275 1221-912052020 CH-RES,9.1K1/10W+/-5%0603 PC 1.000 R36

....4 0280 1221-103052020 CH-RES,10K1/10W+/-5% 0603 PC 4.000 R38,R58,R59,R71

....4 0290 1221-123052020 CH-RES, 12K1/10W+/-5%0603 PC 1.000 R34

....4 0300 1221-183052020 CH-RES, 18K1/10W+/-5%0603 PC 4.000 R63,R64,R65,R66

....4 0310 1221-223052020 CH-RES, 22K1/10W+/-5%0603 PC 6.000 R49,R50,R51,R52,R67,R73

....4 0320 1221-243052020 CH-RES, 24K1/10W+/-5%0603 PC 1.000 R21

....4 0330 1221-104052020 CH-RES, 100K1/10W+/-5%0603 PC 2.000 R25,R53

....4 0340 1421-807400010 CH-TRANSISTOR,BC807-40SOT-23 PC 2.000 Q3,Q10 FA030193

....4 0350 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 3.000 Q4,Q8,Q9 FA030192

....4 0360 1502-004558010 IC, YD4558 SOP8 PC 1.000 IC5 FA050479

....4 0370 1503-009258000 IC, D9258 MOTOR DRIVERCD PC 1.000 IC4 FA0301

....4 0380 1509-007824000 IC, SAA7824HL LQFP80 PC 1.000 IC12 FA030165

....4 0390 1614-101110000

....4 0400 3101-150621010 HEADER 6PIN 1.5MM STRAIGHT PC 1.000 CN4 FAP0

....4 0410 3106-101621060 FFC CONNECTOR PH=1.0MM 16P 1.0S-10S-16PWB SMT PC 1.000 CN3 FAP071216

...3 0040 8918-070400100 EARPHONE SECTION ASSEMBLY OF MCM279/12 SET

....4 0010 1132-225083020 CAP ELECT, 2.2UF 50V +/-20% 4X5 TAPING PC

....4 0020 1132-476034020 CAP ELECT,47UF6.3V+80%-20% 4x5(TAPING PH=2.5MM) PC 1.000 C132

....4 0030 1132-227034080 CAP ELECT 220UF6.3V+80%-20%6.3X5MM(TAPIN

....4 0040 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 1.000 C15

....4 0050 1121-105044020 CH-CAP, CER1UF10V +80%/-20%0603 PC 1.000 C1

....4 0055 1221-680052020 CH-RES, 68R1/10W+/-5%0603 PC 2.000 R84,R85

....4 0060 1221-101052020 CH-RES,100R1/10W+/-5%0603 PC 1.000 R262

....4 0070 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 3.000 R82,R83,R2

....4 0080 1221-472052020 CH-RES, 4.7K1/10W+/-5%0603 PC 2.000 R17,R25

....4 0110 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 3.000 R232,R236,R261

....4 0120 1221-104052020 CH-RES, 100K1/10W+/-5%0603 PC 3.000 R230,R2

....4 0125 1323-000510030 CH-ZENER DIODE, UDZS 5.1B SOD-323 PC 1.000 D2 FAP061066

....4 0130 1421-807400010 CH-TRANSISTOR,BC807-40SOT-23 PC 1.000 Q34 FA030193

....4 0140 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 4.000 Q6,Q7,Q15,Q24 FA030192

....4 0150 1502-004453000 IC, BH4453F PC 1.000 IC17 FA040704

....4 0160 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF). PC 3.000 L2,L3,L4 FA040575

....4 0170 3202-070236000 HP JACK MSJ2000 (ST) 7P DIA.3.6MM 1800 PC 1.000 JK101 FA030079

POWER INDUCTOR RTB6046-101K-1A 100UH+/-10% 1.1 OHM

TAPING

=2.5MM) PC 1.000 C43

.000 C9,C29

=2.5MM) PC 1.000 C8

C 1.000 C15

=2.5MM) PC 2.000 C32,C33

C 2.000 C42,C45

PC 1.000 C22

48,C51,C157,C158

0 C35,C36

C7,C10,C13,C17,C19,C23,C26,C28,C

30,C34,C41,C44,C46,C182,C183

C49,C50,C52

7,C38,C39,C40

24,C27

14

18,C25

12

R9,R18,R19,R20,R41,R42,R237,R271

R273,R274

1,R62,R69,R70

R37

,R46,R47,R48

66

PC 1.000 L1 FA050703

60670

1.000

2.000 C135,C137

G PH=2.5MM) PC 3.000 C130,C131,C133

9

29

70

9

31,R234

Page 26

11-3

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

...3 0050 8905-070400300 CD POWER SUPPLY SECTION ASSEMBLY OF MCM27

....4 0010 1132-227053060 CAP ELECT, 220UF 16V +/-20% 5X11 TAPING P

....4 0015 1132-477043100 CAP ELECT, 470UF 10V +/-20%6.3X11 TAPING

....4 0030 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 3.000 C2,

....4 0040 1221-010052020 CH-RES,1R1/10W+/-5%0603 PC 3.000 R278,R279,

....4 0050 1221-221052020 CH-RES,220R1/10W+/-5%0603 PC 2.000 R3,R221

....4 0060 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 1.000 R281

....4 0070 1221-222052020 CH-RES, 2.2K1/10W+/-5%0603 PC 1.000 R284

....4 0080 1221-103052020 CH-RES,10K1/10W+/-5% 0603 PC 2.000 R5,R285

....4 0090 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 3.000 R2,R4,R2

....4 0100 1321-041480020 CH-DIODE RLS4148 LL-34 PC 1.000 D1

....4 0110 1421-211820000 CH-POWER TRANSISTOR PNP 2SB1182 CPT3 PC 1.

....4 0120 1421-008690000 CH-TRANSISTOR PNP BC869 SOT-89 PC 2.000 Q30

....4 0130 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 2.000 Q2,Q

....4 0140 1512-001117070 IC AZ1117H-5.0 TRE1 REGULATOR SOT-223 PC 1

....4 0150 1512-001117130 IC, AZ1117H-3.3TRE1 REGULATOR SOT-223 PC 1

....4 0160 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF)

....4 0170 3106-122021000 FFC CONNECTOR 20P P=1.25MM 180DEGREE PC 1.000 CN1

...3 0060 8915-070400100 RDS ASSEMBLY OF MCM279/12 SET 1.000

....4 0010 1122-225083130 ALUM. EL- CAP 2.2UF 50V +/-20% SMT 5x5.4MM PC 1.000 C100

....4 0015 1122-476033130 ALUM. EL- CAP 47UF 6.3V +/-20% SMT5x5.4MM PC 1.000 C180 FA040659

....4 0020 1122-107033110 ALUM.EL-CAP 100UF 6.3V +/-20% SMT6.3X5.4MM PC 1.000 C102 FA040659

....4 0030 1121-470081020 CH-CAP, CER47PF50V+/-5%0603 PC 1.000 C96

....4 0040 1121-471081020 CH-CAP, CER470PF50V+/-5%0603 PC 3.000 C120,

....4 0050 1121-561081020 CH-CAP, CER560PF50V+/-5%0603 PC 1.000 C99

....4 0055 1221-681052020 CH-RES,680R1/10W+/-5%0603 PC 1.000 R264

....4 0060 1121-820081020 CH-CAP, CER82PF50V+/-5%0603 NPO PC 1.000 C95

....4 0070 1121-102082020 CH-CAP, CER1000PF50V+/-10%0603 PC 1.000 C98

....4 0080 1121-222082020 CH-CAP, CER 2200PF50V+/-10%0603 PC 1.000 C1

....4 0090 1121-104084020 CH-CAP, CER0.1UF50V+80%-20%0603 PC 3.000 C9

....4 0100 1221-100052020 CH-RES,10R1/10W+/-5%0603 PC 1.000 R267

....4 0110 1221-101052020 CH-RES,100R1/10W+/-5%0603 PC 1.000 R169

....4 0120 1221-471052020 CH-RES, 470R1/10W+/-5%0603 PC 2.000 R189,R2

....4 0130 1221-102062020 CH-RES,1K1/16W+/-5%0603 PC 4.000 R162,R166,R167,R250

....4 0140 1221-152062020 CH-RES,1.5K1/16W+/-5%0603 PC 1.000 R164

....4 0150 1221-103062020 CH-RES,10K1/16W+/-5%0603 PC 3.000 R165,R187

....4 0160 1221-224062020 CH-RES, 220K1/16W+/-5%0603 PC 1.000 R163

....4 0165 1313-000560000 ZENER DIODE 5.6V 1/2W PC 1.000 D5 FAP060929

....4 0170 1001-043320200 CRYSTAL, HC-49/U 4.332MHZ +/-20PPM PC 1.00

....4 0175 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 1.000 Q16 F

....4 0180 1501-006588000 IC ,SAA6588TRADIO RECEIVERS PC 1.000 IC14 FA

....4 0190 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF)

...3 0070 8931-070400100 USB SECTION ASSEMBLY OF MCM279/12 SET 1.00

....4 0010 1121-180051020 CH-CAP, CER18PF16V+/-5%0603 PC 2.000 C89,C90

....4 0020 1121-101051020 CH-CAP, CER 100P16V+/-5%0603 PC 1.000 C87

....4 0030 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 3.000 C85

....4 0035 1121-106044030 CH-CAP, CER 10UF 10V +80%/-20% 0805 PC 1.000 C154

....4 0040 1132-107043060 CAP ELECT, 100UF 10V +/-20% 5X11 TAPING PC 2.000 C73,C179

....4 0050 1221-220052020 CH-RES, 22R1/10W+/-5%0603 PC 2.000 R256,R25

....4 0060 1221-101052020 CH-RES,100R1/10W+/-5%0603 PC 5.000 R122,R123,R124,R126,R132

....4 0065 1221-221052020 CH-RES,220R1/10W+/-5%0603 PC 1.000 R115

....4 0066 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 1.000 R131

....4 0067 1221-332052020 CH-RES, 3.3K1/10W+/-5%0603 PC 2.000 R125,R2

....4 0070 1221-472052020 CH-RES, 4.7K1/10W+/-5%0603 PC 1.000 R117

....4 0080 1221-103052020 CH-RES,10K1/10W+/-5% 0603 PC 5.000 R119,R127,R128,R130,R258

....4 0090 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 2.000 R114,R118

....4 0110 1221-104052020 CH-RES, 100K1/10W+/-5%0603 PC 2.000 R116,R133

....4 0120 1001-600000200 CRYSTAL 6MHZ/3*8 20PF +/-20ppm TEMPERATURE: 260C +/-5C PC 1.000 X2 FAP071219

....4 0130 1421-008690000 CH-TRANSISTOR PNP BC869 SOT-89 PC 1.000 Q11 FAP060729

....4 0140 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 1.000 Q13 FA030192

....4 0150 1424-023010010 MOSFET P-CHANNEL APM2301 SOT-23 PC 1.000 Q12 FAP071073

....4 0160 1509-001160000 IC, ISP1160BD/01 LQFP64 USB HOST CONTROLLER PC 1.000 IC11 FA060235

....4 0170 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF). PC 1.000 FB16 FA040575

9/12 SET 1.000

C 2.000 C4,C160

PC 1.000 C1

C3,C161

R280

22

FA060300,

FAP060547

000 Q1 FAP071213

,Q31 FAP060729

33 FA030192

.000 IC1 FA060249

.000 IC3 FAP061574

. PC 1.000 FB1 FA040575

FA060288,

FAP070895

C122,C163

64

4,C101,C165

51

,R188

0 X3 FA030238

A030192

030235

. PC 1.000 FB10 FA040575

0

,C86,C91

7

65

Page 27

,

11-4

GREY

.000

C 2.000 C103,C117

4,C115,C116,C118,C119

,R260

R161

11,R212

6,R157,R158,R204,R214

5

0 LED2,LED3 FA060293

000 LED4 FAP071069

Q19 FA030192

AP071093

FAP061109

PC 1.000 LCD101

FAP071094

FAP071240

OR BRACKET-LCD/IR FAP061778

PC 1.000 CN9 TO CN8 FAP071292

9/12 SET 1.000

1

PC 1.000 X4 FAP071220

F MCM279/12 SET 1.000

FA051333

FAP060729

FA030083,

FAP061602

PC 1.000 CN2 TO MOTOR CN5 FAP071293

,R170

,R171

2,R172

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

...3 0080 8907-070400100 DISPLAY SECTION ASSEMBLY OF MCM279/12 SET 1

....4 0010 1132-107043060 CAP ELECT, 100UF 10V +/-20% 5X11 TAPING P

....4 0020 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 5.000 C10

....4 0050 1221-100062020 CH-RES,10R1/16W+/-5%0603 PC 3.000 R203,R213

....4 0060 1221-101052020 CH-RES,100R1/10W+/-5%0603 PC 1.000 R206

....4 0070 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 3.000 R159,R160,

....4 0080 1221-472052020 CH-RES, 4.7K1/10W+/-5%0603 PC 3.000 R208,R2

....4 0090 1221-103052020 CH-RES,10K1/10W+/-5% 0603 PC 6.000 R155,R15

....4 0095 1221-000052020 CH-RES, 0R1/10W+/-5%0603 PC 1.000 R168

....4 0100 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 2.000 R205,R21

....4 0110 1316-030410000 LED 3MM SUPER BLUE LA304B1CT-2A/01 PC 2.00

....4 0120 1316-048300000 LED 4.8X4.4MM ROUND BLUE XY-048BLL30 PC 1.

....4 0130 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 2.000 Q18,

....4 0140 1513-008862000 IC ET8862Q PQFP64 LCD DRIVER PC 1.000 IC13 F

....4 0150 1801-000000150 IR RECEIVER BRM-4050-8-FB2.2 PC 1.000 IR101

....4 0160 2403-000000680

....4 0170 3106-121011010 FFC CONNECTOR 10PIN P=1.25MM 90DEGREE WHITE PC 1.000 CN11

....4 0180 5603-070400100 BRACKET - LCD /IR PC 1.000

....4 0190 5502-061100100 LENS - DISPLAY LIGHT GUIDE PC 1.000 FAP071139

....4 0200 6214-061100100 LCD DIFFUSION SHEET PC 1.000 FAP071123

....4 0210 6214-061100200 LCD REFLECT SHEET PC 1.000 FAP071125

....4 0220 6011-220080300 SCREW, ST P B 2X8 S A222008003 PC 2.000 2-F

...3 0090 8914-070400100 DOOR BORAD ASSEMBLY OF MCM279/12 SET 1.000

....4 0010 3309-010134010 DOOR SWITCH MST-002 PC 2.000 S1,S2 FAP071218

....4 0020 3101-200311010 HEADER 3PIN P=2.0MM 90DEGREE WHITE PC 1.000 CN9 FA051712

....4 0030 3501-030072020

...3 0100 8960-070400100 REAL TIME CLOCK SECTION ASSEMBLY OF MCM27

....4 0010 1121-120057020 CH-CAP, CER 12PF 16V +/-1% 0603 PC 1.000 C1

....4 0020 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 1.000 C12

....4 0030 1221-104052020 CH-RES, 100K1/10W+/-5%0603 PC 1.000 R26

....4 0040 1001-032768210

....4 0050 1508-008563000 IC PCF8563T CLOCK SOP8 PC 1.000 IC19 FA040303

...3 0110 8925-070400100 OPEN/CLOSE MOTOR DRIVER SECTION ASSEMBLYO

....4 0010 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 3.000 C6,C176,C186

....4 0020 1132-107053060 CAP ELECT, 100UF 16V +/-20% 5X11 TAPING PC 1.000 C5

....4 0030 1221-221052020 CH-RES,220R1/10W+/-5%0603 PC 1.000 R275

....4 0040 1221-472052020 CH-RES, 4.7K1/10W+/-5%0603 PC 1.000 R286

....4 0050 1221-103052020 CH-RES,10K1/10W+/-5% 0603 PC 2.000 R6,R277

....4 0060 1221-223052020 CH-RES, 22K1/10W+/-5%0603 PC 1.000 R8

....4 0070 1221-333052020 CH-RES, 33K1/10W+/-5%0603 PC 1.000 R7

....4 0080 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 1.000 R276

....4 0090 1233-022022000 FUSE RES, 2.2 1/4W +/-5% TAPING PC 1.000 R1

....4 0100 1421-008690000 CH-TRANSISTOR PNP BC869 SOT-89 PC 1.000 Q28

....4 0110 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 1.000 Q29 FA030192

....4 0120 1513-007072000 IC AM7072A L/F MOTOR DRIVER DIP8 (AMTEK)(932219636682) PC 1.000 IC7 FA050352

....4 0130 2201-000030000 DC MOTOR JQ32-55K415 DC3V. PC 1.000 FA051640

....4 0140 3101-200221010 HEADER 2PIN 2.0MM STRAIGHT PC 1.000 CN2

....4 0150 3501-020102010

..2 0020 8910-070400100 KEY PWB ASSEMBLY OF MCM279//12 SET 1.000

...3 0010 3701-062800310 KEY PWB 260x177x1.6MM/7 94V0 BTM628-03 REV1.0 PC 1.000

...3 0020 1221-000052020 CH-RES, 0R1/10W+/-5%0603 PC 2.000 FB13,FB14

...3 0030 1221-102052020 CH-RES,1K1/10W+/-5%0603 PC 1.000 R177

...3 0040 1221-681052020 CH-RES,680R1/10W+/-5%0603 PC 3.000 R145,R150

...3 0050 1221-122052020 CH-RES,1.2K1/10W+/-5%0603 PC 3.000 R146,R151

...3 0060 1221-222052020 CH-RES, 2.2K1/10W+/-5%0603 PC 3.000 R147,R15

...3 0070 1221-362052020 CH-RES,3.6K1/10W+/-5%0603 PC 3.000 R148,R153,R173

...3 0080 1221-512052020 CH-RES,5.1K 1/10W +/-5% 0603 PC 3.000 R149,R154,R174

...3 0090 1221-103062020 CH-RES,10K1/16W+/-5%0603 PC 1.000 R178

...3 0100 1221-473052020 CH-RES, 47K1/10W+/-5%0603 PC 1.000 R179

...3 0110 1121-101051020 CH-CAP, CER 100P16V+/-5%0603 PC 3.000 C105,C106,C107

...3 0120 1121-104052020 CH-CAP, CER 0.1UF16V+/-10%0603 PC 2.000 C108,C111

LCD FSTN TRANSMISIVE 60X31.5X2.8mm FC1005/ Heat

seal=42x51.5mm CT0802(Yeebo)

HOUSING 3P DISCRETE WIRE P=2.0 L=75MM UL1007 AWG#28

SINGLE HEADER GREY/GREY/BLCK

CRYSTAL 32.768KH Z/3*8 12.5pF +/-20ppmTEMPERATURE: 260C

+/-5C

HOUSING 2P DISCRETE WIRE P=2.0 L=100MM UL1007 AWG#26

SINGLE HEADER BLACK

Page 28

,

,

11-5

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

...3 0130 1316-033470000 LED 3MM 3R4HD-7(RED) TAPING PC 1.000 LED1 FA0

...3 0140 1422-817400010 CH-TRANSISTOR,BC817-40 SOT-23 PC 1.000 Q14 FA

...3 0160 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF).

...3 0170 3106-101211000 FFC CONNECTOR 12PIN PH=1.0MM 90DEGREE WHI

...3 0180 3209-040200000 USB JACK USB-1400A 4P PC 1.000 JK1 FA051716

...3 0190 3302-010143020 SWITCH TACT TSA-06430-150 LUP FUNG PC 15.00

...3 0200 3005-000000000 JUMPER WIRE PC 4.000 JW1,JW2,JW3,JW4

..2 0030 8905-070400100 POWER AMP PWB ASSEMBLY OF MCM279//12 SET 1.0

...3 0005 1112-108043160 CAP,ELECT, 1000UF10V+/-20%10X20 PC 1.000 C67

...3 0007 1112-228063180 CAP, ELECT, 2200UF25V+/-20%12X25 PC 1.000 C6

...3 0010 3702-027900430 POWER PWB:DOUBLE 141x145x1.6MM/2 FR4 MCM279-04 PC 1.000

...3 0020 1121-103082020 CH-CAP, CER0.01UF50V+/-10%0603 PC 8.000

...3 0040 1121-101081020 CH-CAP, CER100PF50V+/-5%0603 PC 3.000 C663,C

...3 0060 1121-331081020 CH-CAP, CER330PF50V+/-5%0603 PC 4.000 C605,C

...3 0070 1121-471081020 CH-CAP, CER470PF50V+/-5%0603 PC 7.000

...3 0100 1121-153082020 CH-CAP, CER15NF50V+/-10%0603 PC 4.000 C637,C

...3 0110 1121-104082020 CH-CAP, CER0.1UF50V+/-10%0603 PC 33.000

...3 0115 1121-225082030 CH-CAP, CER2.2UF50V+/-10%0805 PC 4.000 C629,

...3 0120 1121-474084030 CH-CAP, CER0.47UF50V+80%-20%0805 PC 6.000 C6

...3 0130 1121-105082030 CH-CAP, CER 1UF50V+/-10%0805 PC 1.000 C668

...3 0140 1132-476053040 CAP ELECT, 47UF 16V +/-20% 5x5 TAPING PC 3.

...3 0160 1132-227063220 CAP ELECT, 220UF 25V +/-20% 8X12 TAPING PC 3.000 C661,C662,C679

...3 0170 1132-477053060 CAP ELECT, 470UF 16V +/-20% 5X11 TAPING PC

...3 0190 1138-105082490 CAP MMF HMFS 5 1UF 50V +/-10% 11x6.5 TAPI

...3 0210 1221-022062020 CH-RES,2.2R1/16W+/-5%0603 PC 3.000 R647,R648

...3 0220 1221-100052030 CH-RES,10R1/10W+/-5%0805 PC 6.000 R615,R616,R625,R626,R629,R630

...3 0240 1221-471062020 CH-RES,470R1/16W+/-5%0603 PC 6.000 R623,R624,R631,R632,R643,R644

...3 0250 1221-102062020 CH-RES,1K1/16W+/-5%0603 PC 10.000

...3 0260 1221-122062020 CH-RES,1.2K1/16W+/-5%0603 PC 1.000 R659

...3 0280 1221-472062020 CH-RES,4.7K1/16W+/-5%0603 PC 6.000 R601,R602,R609,R610,R654,R655

...3 0290 1221-562062020 CH-RES,5.6K1/16W+/-5%0603 PC 5.000 R603,R604,R607,R608,R658

...3 0310 1221-103062020 CH-RES,10K1/16W+/-5%0603 PC 3.000 R613,R614,R656

...3 0320 1221-223062020 CH-RES,22K1/16W+/-5%0603 PC 2.000 R633,R634

...3 0330 1221-393062020 CH-RES,39K1/16W+/-5%0603 PC 3.000 R605,R606,

...3 0335 1221-224062020 CH-RES, 220K1/16W+/-5%0603 PC 1.000 R612

...3 0340 1211-022002201 RES,0.22R 1/4W +/-5% PC 1.000 R660

...3 0350 1211-100082000 RES 10R 2W +/-5% PC 1.000 R653

...3 0360 1211-220082000 RES, 22R 2W +/-5% PC 1.000 R652

...3 0370 1231-220062000 RES, 22R 1/16W +/-5% TAPING PC 4.000 R621,R622,R627,R628

...3 0375 1311-141480020 DIODE IN4148 TAPING. PC 1.000 D603 FAP061872

...3 0380 1312-158190000 DIODE 1N5819 DO-41 PC 1.000 D604 FA051721

...3 0390 1313-000510000 ZENER DIODE 5V1 1/2W TAPING. PC 1.000 ZD601

...3 0400 1313-000910010 ZENER DIODE 9V1 1/2W TAPING. PC 1.000 ZD602 FAP071212

...3 0410 1313-055150000 ZENER DIODE BZX55C15V TAPING. PC 1.000 ZD604 FA051709

...3 0420 1313-002200010 ZENER DIODE 22V 1/2W TAPING. PC 1.000 ZD603 FAP071211

...3 0440 1321-041480000 CH-DIODE, 1N4148 FDLL4148SILICON DIODE DO-35 PC 3.000 D602,D605,D606

...3 0450 1411-001140000 TRANSISTOR,DTA114YSAPNP SPT PC 1.000 Q609 FA040354

...3 0460 1411-213700000 TRANSISTOR,2SB1370PNP TO-220FP PC 1.000 Q607 FA040357

...3 0470 1412-253430000 TRANSISTOR, 2SC5343 NPN TO-92 PC 1.000 Q608 F

...3 0480 1421-008570040 CH-TRANSISTOR BC857C INFINEON PC 2.000 Q612

...3 0490 1421-008690000 CH-TRANSISTOR PNP BC869 SOT-89 PC 1.000 Q605

...3 0500 1422-008470010 CH-TRANSISTOR, BC847C SOT-23. PC 6.000 Q601,Q602,Q603,Q606,Q611,Q613 FA030190

...3 0510 1422-001140000 CH-TRANSISTOR, DTC114YKA NPN SMT3 PC 1.000 Q

...3 0520 1502-008932000 IC TDA8932BT/N2C CLASS D POWER AMPLIFIER. PC 2.000 U601,U602 FAP071209

...3 0530 1505-034063020 IC AZ34063AM-E1 DC-TO-DC CONVERTER SO8. PC 1.000 U604 FAP061651

...3 0550 1614-221045000

...3 0560 1614-150004000

...3 0570 1606-470012000 POWER INDUCTOR 47UH 7E05NB SMD DCR=0.26OHM Im=960mA PC 1.000 L607 FAP061733

POWER INDUCTOR 220UH +/-20% DCR=0.45ohm1.2A RT1014-221M

DIP

POWER INDUCTOR 15UH +/-20% DCR=0.045ohm 3.65A RTB1014150M DIP

50484

030192

PC 3.000 FB4,FB5,FB6 FA040575

TE PC 1.000 CN7 FA050574

SW1,SW2,SW3,SW4,SW5,SW6,SW7,SW8,

0

SW9,SW10,SW11,SW12,SW13,SW14,SW1

5

00

4

81

C613,C614,C635,C636,C655,C656,C6

65

C666

664,C667

606,C623,C624

C601,C602,C639,C640,C649,C650,C6

77

638,C651,C652

C611,C612,C615,C616,C617,C618,C6

21,C622,C625,C626,C631,C632,C633

,C634,C645,C646,C647,C648,C653,C

654,C657,C658,C659,C660,C671,C67

2,C673,C675,C678,C680,C682,C683,

C684

C630,C641,C642

03,C604,C607,C608,C609,C610

000 C619,C620,C669

2.000 C670,C676

NG PC 4.000 C627,C628,C643,C644

,R649

R617,R618,R619,R635,R642,R645,R6

46

R650,R651,R657

R611

,Q614 FAP061734

610 FAP061391

PC 1.000 L608 FAP071210

PC 4.000 L601,L602,L603,L604 CAP070100

FA051538

FAP061320

FAP070562

A040359

FAP060729

Page 29

11-6

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

...3 0580 1608-080001000 TOROID INDUCTOR 8UH CORE:T9*5*3 4.5T DCR:

...3 0590 1703-000000090 28UH CORE:T9X5X3 6TURNS 715OHM 1.2A (TX24

...3 0610 2105-000000010 FILTER BEAD RH3.5X6X0.8 PC 5.000 FB601,FB602

...3 0620 2721-272030010 CH-FB,2700OHM+/-25% 0805 SZ2012K272T(LF).

...3 0630 3106-122011000 FFC CONNECTOR 20P P=1.25MM 90DEGREE PC 1.00

...3 0640 3401-000000010 SP TERMINAL MSP-134V-05 LF PC 1.000 SP601 FA0

...3 0650 3201-030163000 DC JACK 3PIN DC-005 DIA6.3MM 90DEGREE. PC 1

...3 0660 3202-070236000 HP JACK MSJ2000 (ST) 7P DIA.3.6MM 1800 PC 1

...3 0670 8016-000000100 FM ANT CONTACT PIN PC 1.000 P7 FA030149

...3 0680 8031-000001000 OIL CLOTH TUBE DIA:1.5MM L=5MM PC 2.000

.1 0020 8900-070400300 ELECTRICAL ENCASING ASSEMBLY OF MCM279/12. S

..2 0010 3002-200090900 FFC CABLE 20PIN P=1.25MM L=90MM WHITE SAME

..2 0020 3002-100130910 FFC CABLE 10PIN P=1.25MM L=130MM WHITE OTH

..2 0030 3002-120050910 FFC CABLE 12PIN P=1.0MM L=50MM WHITE SAME

..2 0040 3801-000000090 TUNER MODULE AM/FM ENG07821QF (EUROPE). PC 1

..2 0050 3801-000000220 TUNER MODULE KST-MT004MS1-6 AM/FM CE VERSION PC 1.000

..2 0060 4401-120009320 CD MECHANISM CMS-M93BGPJ (SAMSUNG, FORROHM SOLUTION) PC 1.000 FAP070555

..2 0070 3001-000100160 WIRE 1P UL1007 AWG#24 L=100MM BLACK PC 1.000 FAP071140

..2 0080 2712-081140000 FERRITE CORE: RP26X9.5X5G 100MHz>/=80OHM. PC 1.000 FAP071249

.1 0030 8940-070400100 MECHANICAL SECTION OF MCM279//12 SET 1.000

..2 0010 8941-070400100 PLASTIC PART OF MCM279//12 SET 1.000

...3 0010 5001-070400100 CABINET FRONT PC 1.000

...3 0020 5506-061100100 LENS FRAME COSMETIC TOP_LEFT PC 1.000 FAP071

...3 0030 5506-061100200 LENS FRAME COSMETIC TOP_RIGHT PC 1.000 FAP07

...3 0040 5506-061100300 LENS FRAME COSMETIC BOTTOM_LEFT PC 1.000 FAP

...3 0050 5506-061100400 LENS FRAME COSMETIC BOTTOM_RIGHT PC 1.000 FA

...3 0060 5503-070400100 LENS-SLIDE DOOR PC 1.000

...3 0070 5002-070400100 CABINET REAR PC 1.000

...3 0080 5903-070400100 CARRIER - SLIDE DOOR -R PC 1.000

...3 0090 5903-070400200 CARRIER - SLIDE DOOR -L PC 1.000

...3 0100 5705-070400100 RACK BAR PC 1.000

...3 0110 5502-070400100 LENS-CD AMBI LIGHT GUIDE PC 2.000

...3 0120 5408-061100200 BUTTON POWER PC 1.000 FAP071130

...3 0130 5403-061100200 BUTTON SET FUNCTION-A PC 1.000 FAP071077

...3 0140 5404-061100200 BUTTON SET FUNCTION-B PC 1.000 FAP071081

...3 0150 5618-061100300 BRACKET PLAY BUTTON PC 1.000 FAP071083

...3 0160 5417-061100100 BUTTON SET NAVIGATION PC 1.000 FAP071087

...3 0170 5902-061100400 COVER POWER BUTTON PC 1.000 FAP071080

...3 0180 5608-061100100 BRACKET CDM PC 3.000 FAP071124

...3 0190 5629-061100100 BRACKET-FM TUNER MODULE PC 1.000

...3 0220 5201-070400100 DOOR CD - SLIDE PC 1.000

...3 0230 5201-070400200 DOOR CD - ROTATED PC 1.000

...3 0240 5705-070400200 GEAR-ROTATED DOOR RACK PC 1.000

...3 0250 5705-070400300 GEAR-SLIDE DOOR PC 1.000

...3 0260 5101-070400100 CONTROL PANEL PC 1.000

...3 0270 5904-070400100 COVER- ROTATED CD DOOR PC 1.000

...3 0280 6307-070400100 BRACKET - GEAR HOLDER A PC 1.000

...3 0290 6307-070400200 BRACKET - GEAR HOLDER B PC 1.000

...3 0300 5618-070400100 BRACKET-RACK HOLDER A PC 1.000

...3 0310 5618-070400200 BRACKET-RACK HOLDER B PC 1.000

...3 0320 5913-070400100 FRAME-LCD CHROME PC 1.000

...3 0340 5902-050700200 COVER PLAY BUTTON PC 1.000 FA060025

...3 0350 5403-050700100 BUTTON FW/FF PC 1.000 FA060015

...3 0360 5703-050700100 GEAR WHEEL A PC 1.000 FA060011

...3 0370 5703-050700200 GEAR WHEEL B PC 1.000 FA060007

...3 0380 5704-050700100 PULLEY SERVO MOTOR PC 1.000 FA060012

..2 0020 8942-070400100 METAL PART OF MCM279//12 SET 1.000

...3 0010 6802-061100100 STEEL FOR CABINET REAR. PC 1.000

...3 0020 6600-070400100 HEATSINK PC 1.000

...3 0030 6406-050700101 CUSHION CD MECHANISM A PC 2.000 FA060144

...3 0040 6405-050700100 CD DAMPER (BLACK) 20DEGREE PC 2.000 FA060277

...3 0045 6405-071100100 CD DAMPER (BLACK) 30DEGREE PC 1.000

...3 0050 6404-061100100 RUBBER FOOT FOR FRAME-COSMETIC PC 2.000 FAR071063

...3 0080 6818-070400100 SHAFT FOR MCM279 PC 1.000 FAP071253

0.015 OHM 3.2A PC 2.000 L605,L606 FAP071208

09033628LF) PC 1.000 L609 FA060002

,FB605,FB606,FB607 FA040323

PC 2.000 FB603,FB604 FA040575

0 CON601

.000 JK601 FAP071107

.000 JK602 FA030079

ET 1.000

SIDE PC 1.000 CN1 TO CN601 FAP071215

ER SIDE PC 1.000 CN1 TO TUNER FAP071221

SIDE PC 1.000 CN7 TO CN10 FAP071214

.000 CAP070087

FA060289,

FAP070896

30245

121

1122

071120

P071118

Page 30

11-7

FACTORY PARTLIST

Level Item Component Desc Unit Qty Location AppForm

...3 0090 6816-070400100 MAIN PCB SHIELDING FOR MCM-79 PC 1.000

...3 0100 6402-050700100 BELT MOTOR PC 1.000 FA051544

...3 0110 6210-070400300 PC SHEET_IR PC 1.000

..2 0030 8946-070400100 SCREW PART OF MCM279//12 SET 1.000

...3 0010 6011-230100100 SCREW, ST 3.0X10 PB PC 11.000

...3 0020 6023-230100100 SCREW, M B B3X10B (TOYO:A023010002) PC 3.000 HEATSINK FIXING FA051216

...3 0030 6011-226060100 SCREW , ST 2.6X6 PB (BLACK) PC 9.000

...3 0040 6011-220080300 SCREW, ST P B 2X8 S A222008003 PC 20.000

...3 0050 6012-226100110 SCREW, PTTN M 2.6X10 PB(DIA.:12.0) PC 4.000

...3 0060 6021-226060100 SCREW, M2.6X6 PB PC 2.000 FOR MOTO FIX FAP060

...3 0070 6023-230060100 SCREW, M B B3X6B PC 1.000 FOR RADIO MODULE F

...3 0080 6011-217040100 SCREW ST P B1.7X4 B PC 9.000

...3 0090 6011-220120200 SCREW ST P B2.0X12 N PC 1.000 FOR BRACKET-RA

..2 0040 8945-070400100 MINISTRANT PART OF MCM279//12 SET 1.000

...3 0010 7902-070400100 NITTO 500 DOUBLE SIDE TAPE 184x55MM PC 1.000 FAP071252

...3 0020 8036-000000200 CABLE TIE PC 4.000

..2 0050 8943-070400100 PACKING PART OF MCM279/12 SET 1.000

...3 0010 7103-030300100 LABEL DON'T TOUCH THE LENS PC 1.000

...3 0020 7107-030600100 LABEL (QC) PC 1.000 FA040038

...3 0030 7111-070400100 LABEL TYPE PLATE 37X60MM (MCM279/12). PC 1.000

...3 0040 7111-070400200 LABEL CARTON BOX 83x103MM (MCM279/12). PC 1.000

...3 0050 7112-050700100 LABEL "UWAGA! ......" PC 1.000 FA060197

...3 0060 7112-050700200 LABEL "VIGYAZAT! ......" PC 1.000 FA060195

...3 0070 7112-050700300 LABEL "CHRANTE SE ......" PC 1.000 FA060193

...3 0080 7202-070400100 INSTRUCTION BOOK-11 LANGUAGE (MCM279/12). PC 1.000

...3 0090 7202-070400200 INSTRUCTION BOOK-5 LANGUAGE (MCM279/12). PC 1.000

...3 0100 7203-070400100 QUICK START GUIDE ENG+FRE LANGUAGE. PC 1.00

...3 0110 7203-070400200 QUICK START GUIDE SPA+GER LANGUAGES. PC 1.0

...3 0120 7203-070400300 QUICK START GUIDE DUT+ITA LANGUAGES. PC 1.0

...3 0130 7201-041900200 GUARANTEE LEAFLET 10/07/2006 (9965 000 38

...3 0140 7603-070400100 DISPLAY BOX W=A. PC 1.000

...3 0150 7401-070400200 POLYFOAM TOP (MCM279). PC 1.000

...3 0160 7402-070400100 POLYFOAM BOTTOM (MCM279) PC 1.000

...3 0190 7903-061100100 EPE BAG L370xW330MM W/PE-LD04 MARK PC 1.000

...3 0200 7502-050700100 POLYBAG FOR I/B 203x305x0.04MM W/PE-LD04. PC 3.000 1-IFU,1-ACCESSORIES FA051563

...3 0210 7502-042200100 POLYBAG 9 x 14" W/WARNING & RECYCLE MARK PC 1.000 1-QSG FA050411

...3 0220 7905-030600200 POLYBAG FOR AM RING 155X203MM PC 2.000 1-AM AND FM ANTENNA,1-STAND FA030070

...3 0230 7905-061100100 POLYBAG 110x130x0.04MM W/PE-LD04 PC 1.000 1-

...3 0240 7907-042500100 ACETATE CLOTH ADHESIVE TAPE L95xW9MM PC 1.0

...3 0250 7206-030800100 SLIP SHEET 1400X1250MM PC 0.044 FA051273

...3 0260 7206-042500100 FITTING PALLET 46.125"X38.75" (3140 10638732) PC 0.044 FA050791

...3 0270 7206-030500200 WRAP FILM M 0.420

.1 0040 8944-070400200 ACCESSORIES OF MCM279//12 SET 1.000

..2 0005 2902-125007040

..2 0010 3009-001000100 FM ANT WIRE 75OHM L=1.0M BLACK W/STV8-1H PC

..2 0020 4011-080700000 SWITCHING POWER ADAPTOR 19V/4A PC 1.000

..2 0030 5926-060300100 AM LOOP ANT 18.1uH 8T PC 1.000 FAP061474

..2 0040 8919-070400100 SPEAKER BOX FOR MCM279//00 PAA 1.000

..2 0050 1901-000004000 REMOTE CONTROL "PHILIPS" FOR MCM279 PC 1.000

..2 0060 8951-061100100 STAND PORTION OF MCM238/12 SET 1.000

...3 0010 5912-061100100 AND BASE PC 1.000 FAP071088

...3 0030 6404-061100200 RUBBER FOOT FOR STAND BASE PC 2.000 FAR071066

AC CORD VDE H03VVH2-F 0.75MM2 2C L=1.5MLP-21/LS-7(2.5A

250V)

6-CABINET REAR,2-SPEAKER JACK,3FOR BRACKET CDM

3-BRACKET-RACK HOLDER A&CABINET

FRONT,3-BRACKET-GEAR HOLDER

A&CABINET FRONT,3-BRACKET-GEAR

HOLDER A&BRACKET-GEAR HOLDER B

13-FOR FRAME COSMETIC FIX,5- FOR

KEY-PCB FIX,2-FOR CARRIER- SLIDE

DOOR-L/R FIX

2-REAR CABINET STEEL,2-POWER

PCB&REAR CABINET

4-FOR FRONT CABINET&CONTROL

PANEL,5-FOR DOOR-CD-ROTATED

&COVER-ROTATED-CD DOOR

0

00

00

986) PC 1.000 FAP061187

STAND

00 STICK ON CD DOOR

PC 1.000 CA050094

1.000 FAP061702

IX FA051219

CK-HOLDER-BFIX FA060181

FAP061541

FA040269F

AP071085

FAP061778

FA050971

818

FAP060819

FAP061877

FA040034,

FAP070872

FAP071163

Loading...

Loading...