Philips MCM-159 Service Manual

Micro System

MCM159/61/98

TABLE OF CONTENTS

Page

Location of PCBs & Version Variations................................1-2

Specifi cations .......................................................................1-3

Measurement Setup .............................................................1-4

Service Aids, Safety Instruction, etc .....................................1-5

CD Playability Check ..................................................1-6 to 1-7

Software Version Checking ..................................................... 2

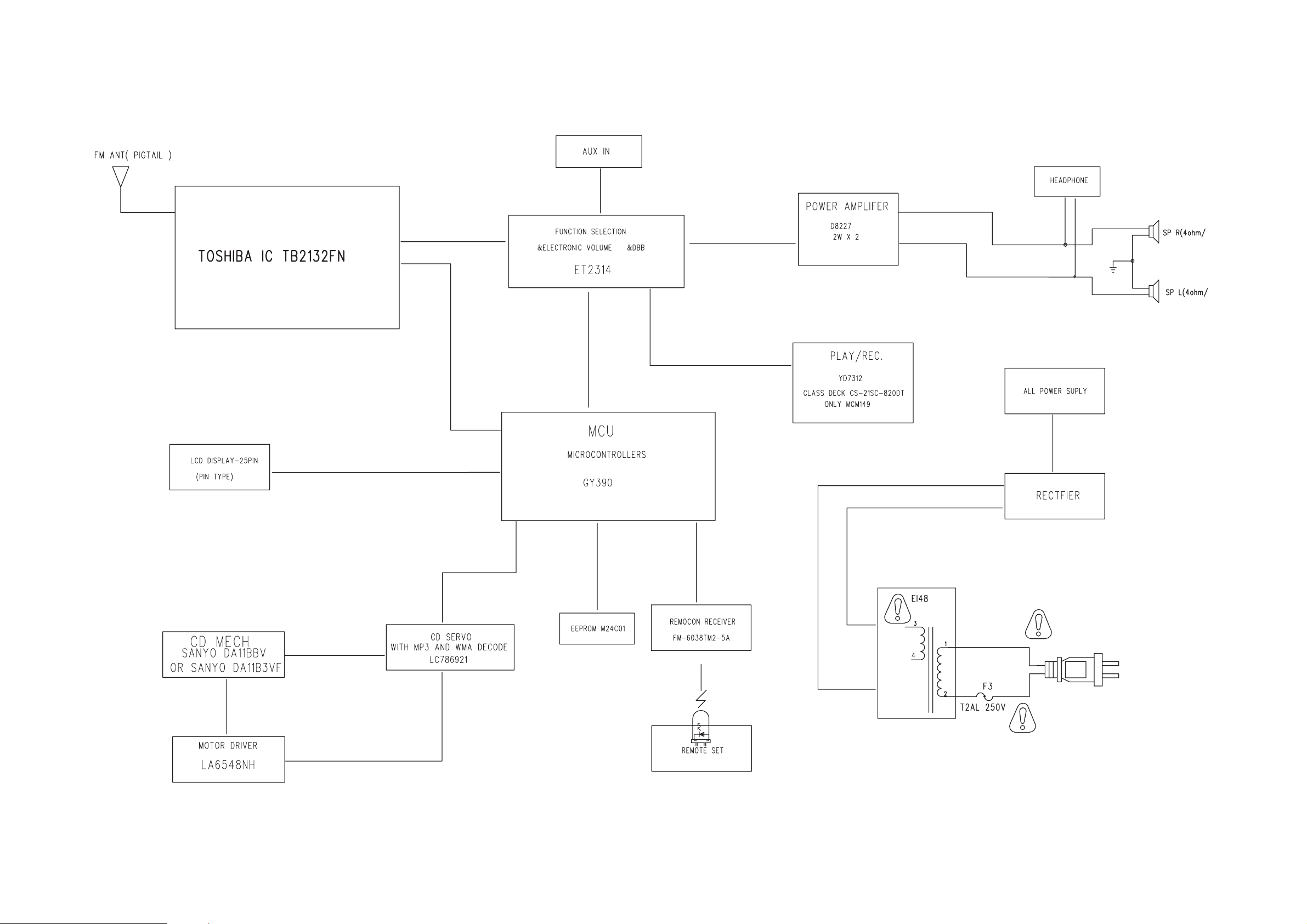

Set Block Diagram ...................................................................3

Set Wiring Diagram .................................................................4

Main Board .............................................................................. 5

Front Board..............................................................................6

Cass Board ..............................................................................7

Set Mechanical Exploded View & Parts List ............................8

Electrical Parts List ..................................................................9

Revision List ..........................................................................10

©

Copyright 2008 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise without

the prior permission of Philips.

Published by SL 0830 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

CLASS 1

LASER PRODUCT

© 3141 785 32951

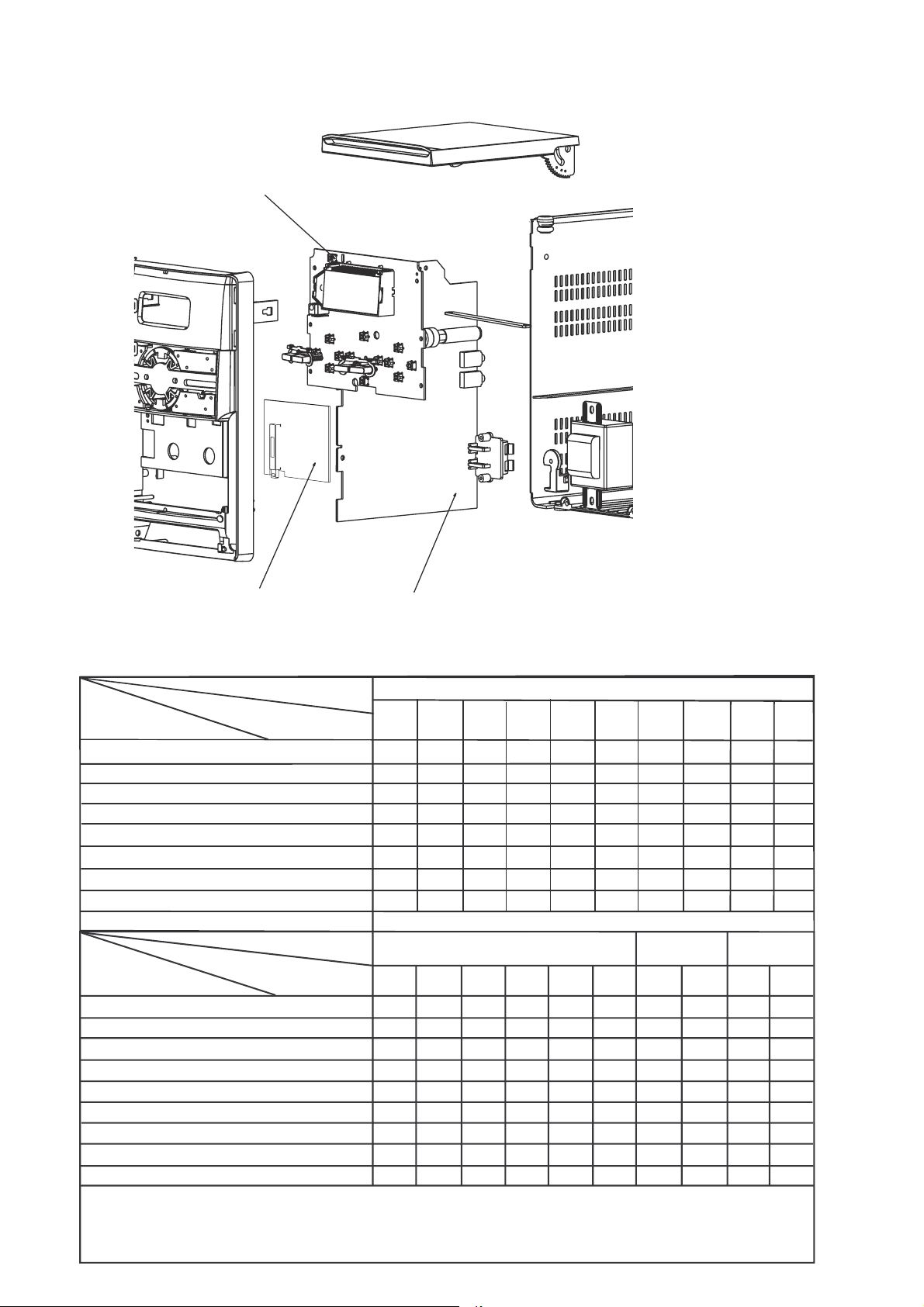

PCBS LOCATION

FRONT BOARD

1-2

CASS BOARD

VERSION VARIATIONS

Type /Versions:

Board in used:

MAIN BOARD

CASS BOARD

FRONT BOARD

Features

in used:

niRDC/nixuA

Line Out

Video Out

Headphone Out

Digital Out

Karaoke Features

Voltage Selector

ECO Power Standby (LCD Display Off)

USB Direct

Feature diffrence

MAIN BOARD

Service policy

Type /Versions:

/12 /05

/05

/12 /61

MCM159

8595//16/85/

C

C

C

MCM159

x

x

* TIPS : C -- Component Lever Repair.

M -- Module Lever Repair

-- Used

x

SPECIFICATIONS

1-3

AMPLIFIER

Output power ........................................... 2 x 2W RMS

Signal-to-noise ratio .......................... t 60 dBA (IEC)

Frequency response ....................... 125 – 16000 Hz

Impedance loudspeakers ........................................... 8:

CD PLAYER

Frequency range ............................... 125 – 16000 Hz

Signal-to-noise ratio ............................................ 65 dBA

TUNER

FM wave range ................................... 87.5 – 108 MHz

MW wave range ................................ 531 – 1602 kHz

Sensitivity

– FM 26 dB sensitivity .......................................... 20 µV

– MW 26 dB sensitivity ................................... 5 mV/m

Total harmonic distortion..................................... d 5%

TAPE DECK

Frequency response

Normal tape (type I) ...... 125 – 8000 Hz (8 dB)

Signal-to-noise ratio

Normal tape (type I) .................................... 40 dBA

Wow and flutter .............................................. d 0.4% JIS

SPEAKERS

Bass reflex system

Dimensions (w x h x d) . 134 x 230 x 152 (mm)

GENERAL INFORMATION

AC Power ............................ 110 – 127 / 220 – 240 V

....................................................... 50/60 Hz, switchable

Dimensions (w x h x d) .. 148 x 233 x 216 (mm)

Weight (with/without speakers) ..................................

......................................................... approx. 3.65 / 1.53 kg

Power consumption

Active .......................................................................... 15 W

Standby .................................................................... < 4 W

Specifications and external appearance are

subject to change without notice.

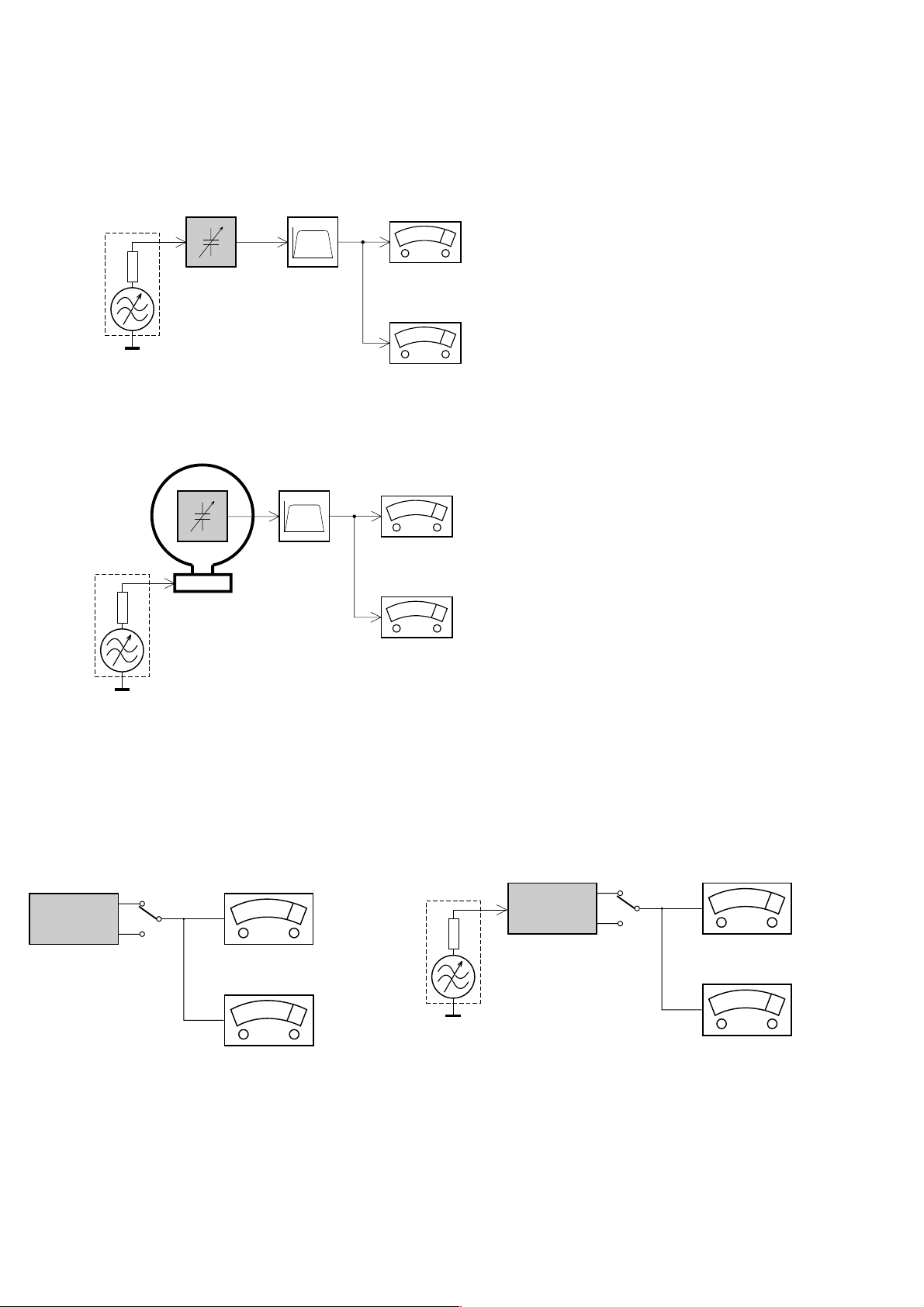

MEASUREMENT SETUP

Tuner FM

1-4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50Ω

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50Ω

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

L

R

SBC429 4822 397 30184

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette Fe SBC420 4822 397 30071

LF Generator

e.g. PM5110

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

SERVICE AIDS

1-5

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

WARNING

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

Safety components are marked by the symbol

!

.

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

ESD

CLASS 1

LASER PRODUCT

Lead free

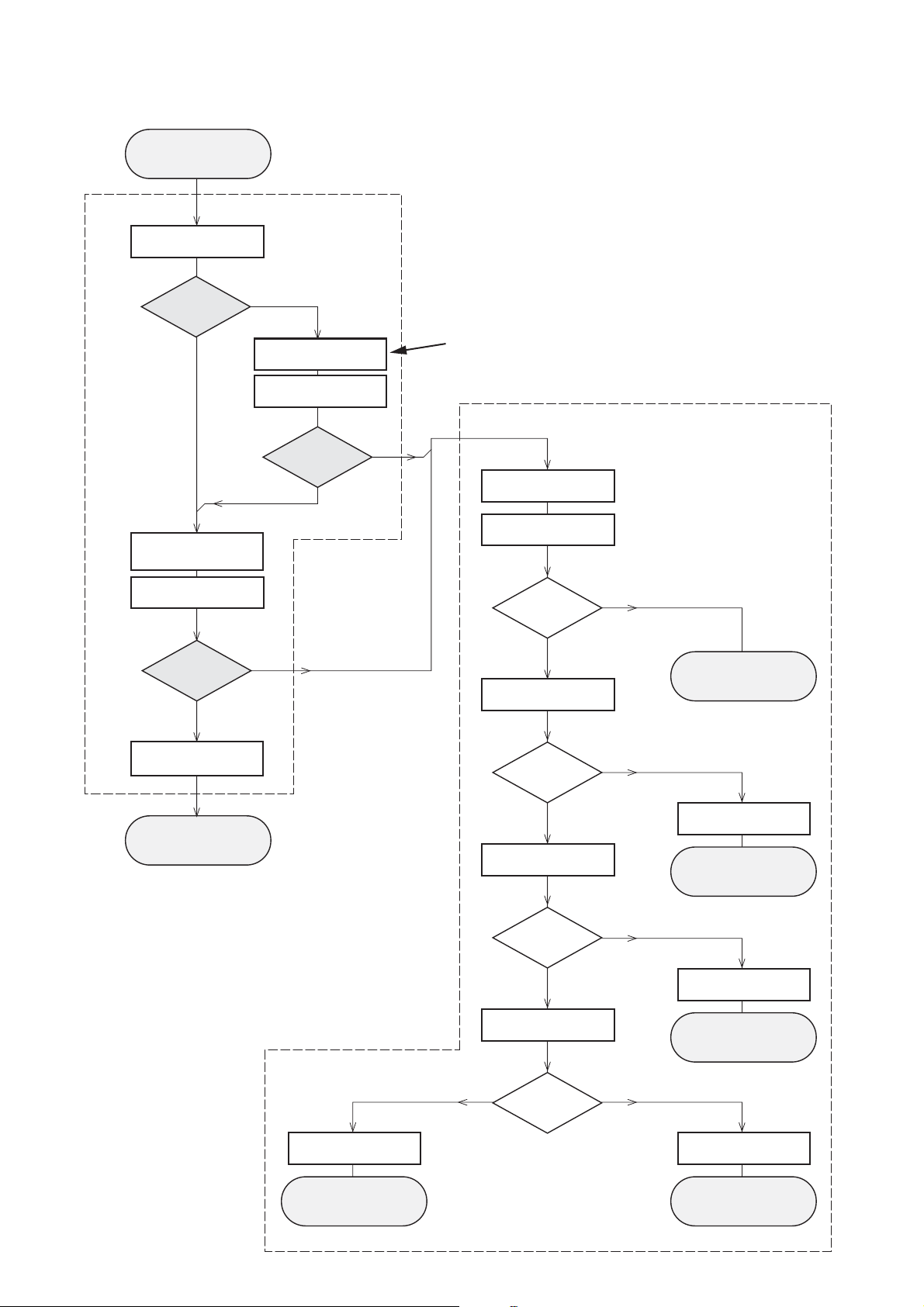

INSTRUCTIONS ON CD PLAYABILITY

Customer complaint

"CD related problem"

Set remains closed!

check playability

1

1-6

playability

ok ?

Y

Play a CD

for at least 10 minutes

check playability

playability

ok ?

Y

N

"fast" lens cleaning

check playability

playability

ok ?

N

3

For flap loaders (= access to CD drive possible)

cleaning method

4 is recommended

Standard repair procedure

N

Y

clean the lens

check playability

playability

ok ?

check "EYE-Pattern"

4

Y

N

5

return set

add Info for customer

"SET OK"

return set

1 - 7

For description - see following pages

2

replace Signal Processor

return set

EYE-Pattern

ok ?

Y

check Laser current

Laser current

ok ?

Y

check CD Drive offsets

Y

CD Drive offsets

ok ?

N

replace CD Drive

6

return set

N

replace CD Drive

7

return set

N

replace CD Drive

return set

INSTRUCTIONS ON CD PLAYABILITY

1-7

1

PLAYABILITY CHECK

For sets which are compatible with CD-RW discs

use CD-RW Printed Audio Disc....................7104 099 96611

TR 3 (Fingerprint)

TR 8 (600µ Black dot) maximum at 01:00

• playback of these two tracks without audible disturbance

playing time for: Fingerprint ≥10seconds

Black dot from 00:50 to 01:10

• jump forward/backward (search) within a reasonable time

For all other sets

use CD-DA SBC 444A..................................4822 397 30245

TR 14 (600µ Black dot) maximum at 01:15

TR 19 (Fingerprint)

TR 10 (1000µ wedge)

• playback of all these tracks without audible disturbance

playing time for: 1000µ wedge ≥10seconds

Fingerprint ≥10seconds

Black dot from 01:05 to 01:25

• jump forward/backward (search) within a reasonable time

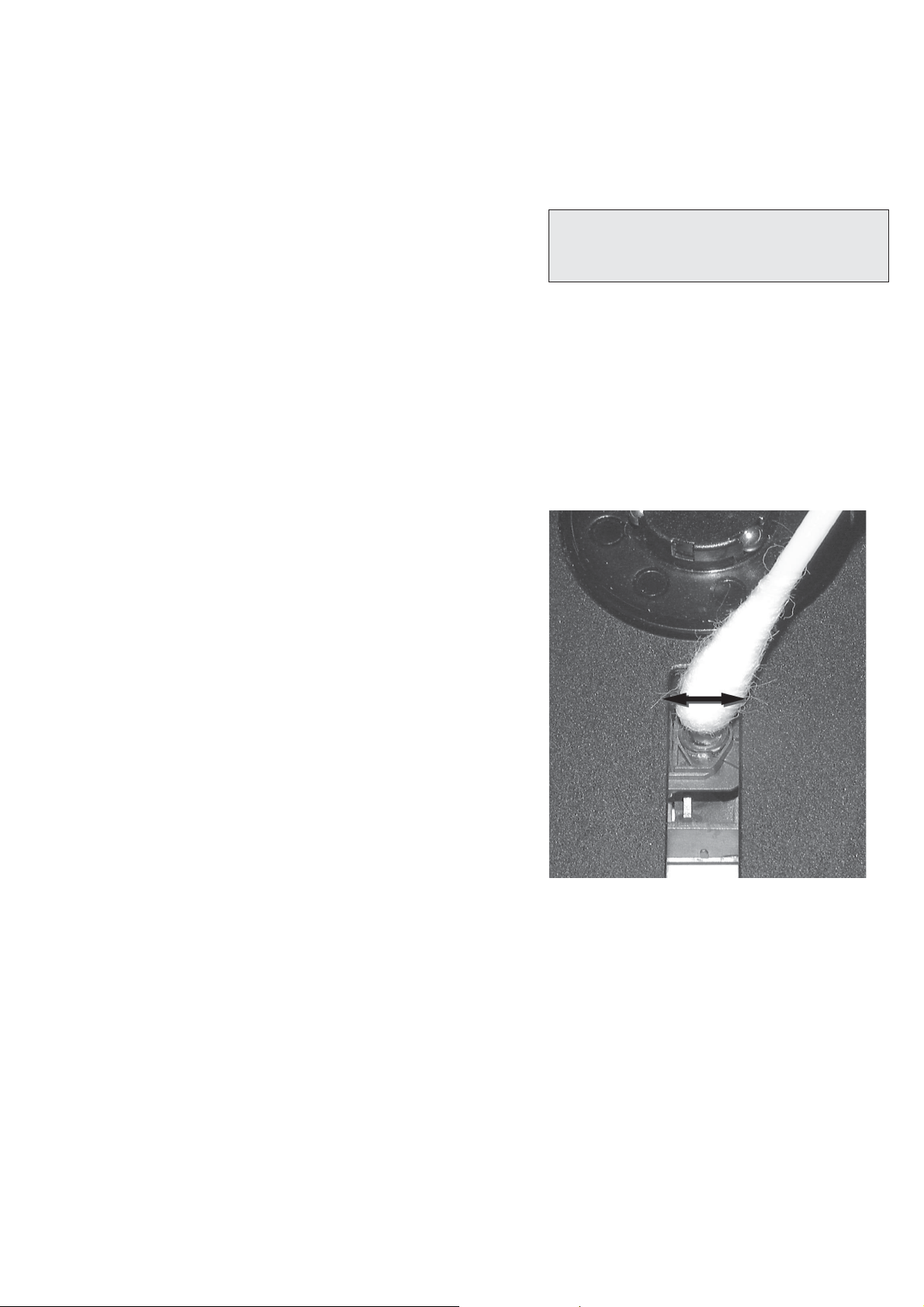

4

LIQUID LENS CLEANING

Before touching the lens it is advised to clean the

surface of the lens by blowing clean air over it.

This to avoid that little particles make scratches on

the lens.

Because the material of the lens is synthetic and coated

with a special anti-reflectivity layer, cleaning must be done

with a non-aggressive cleaning fluid. It is advised to use

“Cleaning Solvent B4-No2”, available with codenumber

4822 389 10026.

The actuator is a very precise mechanical component and

may not be damaged in order to guarantee its full function.

Clean the lens gently (don’t press too hard) with a soft and

clean cotton bud moistened with the special lens cleaner.

The direction of cleaning must be in the way as indicated in

the picture below.

2

CUSTOMER INFORMATION

It is proposed to add an addendum sheet to the set which

informs the customer that the set has been checked

carefully - but no fault was found.

The problem was obviously caused by a scratched, dirty or

copy-protected CD. In case problems remain, the customer

is requested to contact the workshop directly.

The lens cleaning (method 3) should be mentioned in the

addendum sheet.

The final wording in national language as well as the printing

is under responsibility of the Regional Service Organizations.

3

FAST LENS CLEANING (dry brush)

Use lens cleaning CD

SBC AC300...........................................9082 100 00043

Insert the lens cleaning CD, press PLAY and follow the

voice guide´s instructions on the CD.

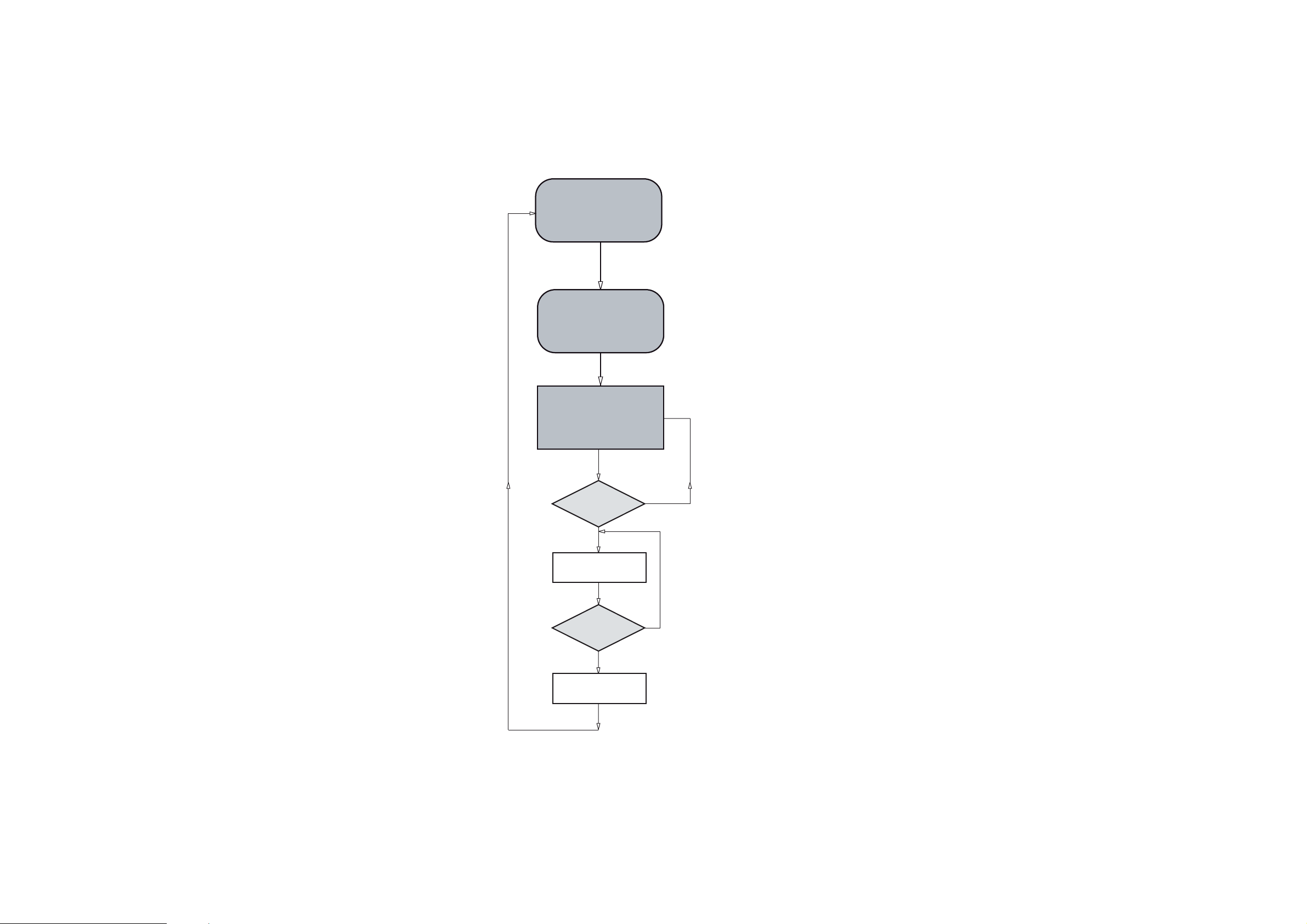

SOFTWARE VERSION CHECKING

2-1

2-1

Set on Standby.

T o hold DBB & SKIP

NEXT depressed

Display shows the

MCU software version

"VER y.yy MTP xx-xx-2007"

DISPLAY

TEST

SKIP NEXT

Button pressed?

Y

Display shows all patterns

SOFTWARE

RESET

9

Button pressed?

Y

Display shows "NEW"

VER refers to Version

y.yy refers to Software version number of the uProcessor

(counting up from 01 to 99)

xx refers to date number of the production.

N

N

SET BLOCK DIAGRAM

3-1

3-1

Loading...

Loading...