Philips M2720 Service Manual

Avalon CTS

Cordless Fetal Transducer System

M2720A

SERVICE GUIDE

M2720-9000A

12 NC Number: 453563474131

Printed in Germany

January 2003

Edition 1

ii

Contents

1 General Information 1

Who Should Read This Guide 1

What to Do Next 1

Repair Strategy 2

Pre-Installation Considerations 2

Warnings, Cautions and Important Information 2

Symbols on the System 3

Patient Safety 4

Protective Earth 4

Environment 5

General Description 5

Mounting Solutions 5

Applying the Velcro Fixing Tape 6

Antenna Extension Mounting Kit 7

Mounting on Philips Carts 7

Mounting on Wooden Carts and Other Flat Surfaces 7

Considerations for Choice of Configuration 8

Frequency Bands 8

Normal Delivery Configuration 8

When is a Different Configuration Needed? 8

When the Area of Reach is Not Sufficient 9

When the Normal Delivery Configuration is Unsuitable 9

Frequency Planning 9

Setting Expectations 9

Antenna System Guidelines 10

2 Theory of Operation 11

Receiver Board 12

Human Interface Board 12

Power Supply 12

Slot Control and Monitor Interface Board Hardware 12

Transducer Hardware Overview 13

Functional Description of the RF/CPU Hardware 13

Base Station Communication 13

Power Supply and Battery Charger 14

Modulator 14

RF Transmitter 14

Toco Frontend Hardware 14

iii

Ultrasound Frontend Hardware 14

ECG Frontend Hardware 14

3 System Interfaces 15

Fetal Monitor Interface 15

Service Interface 16

Compatible Fetal Monitors 17

4 Disassembly/Reassembly 19

Introduction 19

Removing the Top Cover Assembly 20

Replacing the Top Cover Assembly 21

Changing Fuses 22

Changing the Power Supply/Metal Chassis Assembly 25

5 Spare Parts 31

Exchange Parts 31

Non-Exchange Parts 32

Supplies and Accessories 32

Antenna and Base Station Part Numbers By Country 33

6 Preventive Maintenance and Safety 35

Care and Cleaning 35

Recommended Frequency of Testing 35

Performance Assurance Tests 36

Self Test 36

Parameter Test 36

Safety Tests 37

Safety Test Procedures 38

When to Perform Safety Tests 38

How to Carry Out the Test Blocks 38

Description of Applicable Safety Tests 40

S(1): Protective Earth Test 40

S(2): Enclosure Leakage Current Test

- Normal Condition (NC)

S(3): Enclosure Leakage Current Test

- Single Fault Condition (SFC) Open Supply

S(4): Enclosure Leakage Current

- SFC Open Earth (Ground)

Instrument Safety Test 41

System Test 42

Regular Preventive Maintenance 42

Mechanical Inspection 42

Visual Check 42

Toco Ventilation/Belt Button 42

40

41

41

iv

Testing the Ventilation Membrane 42

Battery Check 43

Starting the Battery Check 44

Stopping the Battery Test 44

Stages of the Battery Check 44

Reading Battery Check Data Using the Service Support Tool 45

Battery Exchange 45

7 Troubleshooting 47

System is Completely Inoperative 47

Common Problems 47

Troubleshooting a Cordless System: an Overview 49

System Reset 49

Checking Contacts 49

Checking the Fetal Monitor 50

RF Problems 50

Carrier to Noise Ratio 50

Gathering Data 50

Observe System Performance 51

Question the User 51

Area of Reach 51

Range Definition 52

Using the Base Station 52

Using the Service Support Tool 52

RF Interference 53

One-Channel or Narrowband Interference 53

Broadband Interference 53

Guidelines for Channel/Frequency Configuration 54

Scanning the Available Frequency Range 54

Excluding Frequencies 54

Base Station with Fixed Frequency 54

Transducers with Fixed Frequency 55

Transducers for Japan 55

Testing Transducers 56

Ultrasound Transducer Electrical Check 56

TOCO Transducer Electrical Check 57

ECG Transducer Electrical Check 58

In DECG Mode 58

In MECG Mode 59

Troubleshooting the Top Cover 60

Function Buttons 60

Display/Window 60

LEDs 60

Magnets 61

v

Factory Information Code Log 61

8 Changing Settings 63

Configuration Settings 63

Key Click, Transducer Insertion/Take Out Confirmation Volume 63

Acoustical Alarm Default 64

Function Settings 65

Bed Label Appearance 65

Enabling/Disabling Fixed Frequency 65

Selecting the Channel Frequency Spacing 66

Action Settings 67

Displaying the Software Revision 67

Clearing the Factory Information Code (FIC) Log 67

9 Upgrades 69

10 Specifications 71

General 71

Base Station 71

Tr a n s d u c e r s 72

Frequency Bands 73

Frontends 73

Cables 74

A Removing and Replacing the Transducer Battery 75

B Removing and Replacing the Transducer Belt Button 77

C Avalon CTS Frequency Table 79

vi

1

1General Information

This guide tells you how to service and repair the base station (M2720A) and transducers (M2725A,

M2726A, and M2727A) of the Avalon CTS Cordless Fetal Transducer System. It describes the system

hardware and software, tells you how to diagnose operating and servicing problems, and how to test the

system.

As this system is intended to be installed by the customer, refer to the Instructions for Use for details of how to

install the system.

The Avalon CTS Cordless Fetal Monitoring System Service Guide supplements the maintenance and

troubleshooting procedures, carried out by the operator, that are described in the Instructions for Use. Refer to

the Instructions for Use for maintenance and troubleshooting procedures that may be performed during

normal operation.

Only qualified service personnel should attempt to disassemble the base station, remove or replace any

internal assemblies, or replace the transducer batteries or belt buttons.

Who Should Read This Guide

This guide is for any qualified technical personnel servicing and repairing the Avalon CTS Cordless Fetal

Transducer System.

You must:

•understand English

• be familiar with standard medical equipment installation procedures

• be familiar with current conventional technical terms as used throughout this guide

What to Do Next

Familiarize yourself with the contents of this guide before attempting to service or repair the system.

1

1 General Information Repair Strategy

Repair Strategy

The Service Support Tool software helps you to determine whether a fault is a hardware, software or RFrelated problem. Any maintenance and repair procedures beyond the level covered in the Instructions for

Use are limited to:

• unit exchange for

–the base station

–the transducers

•replacement of

– the top cover assembly, including human interface board

– the power supply, including metal chassis

– two fuses in the power supply

– the transducer battery

– the transducer ventilation knob

Repair or replacement of individual components on the boards is not supported, and should never be

attempted.

For any problem related to connecting the base station to an antenna system, refer to the M2600A

Telemetry System’s Service Training and Reference Guide.

For tests that you are required to perform after repairs, refer to “When to Perform Safety Tests” on

page 38.

Pre-Installation Considerations

The Avalon CTS is intended to be customer installable under the following conditions:

• The system is an “out-of-the-box” stand-alone system.

• There are less than ten stand-alone systems in the institution.

• Connection to an antenna system is not planned.

• No other telemetry devices are used in the institution that can influence, or be influenced by, the

Avalon CTS.

• There are no other known or unknown sources of RF interference that influence the operation of the

Avalon CTS.

• There are no local regulations requiring special configuration.

If one or more of these conditions are not met, a special configuration of the Avalon CTS is needed. Refer

to “Considerations for Choice of Configuration” on page 8, and/or contact Philips Support to order the

appropriate services.

Warnings, Cautions and Important Information

WARNING A warning alerts you to a potential serious outcome, adverse event or safety hazard. Failure to observe a

warning may result in death or serious injury to the user or patient.

2

Symbols on the System 1 General Information

CAUTION

A caution alerts you to circumstances where special care is necessary for the safe and effective use of the

product. Failure to observe a caution may result in minor or moderate personal injury, damage to the

product or other property, and possibly in a remote risk of more serious injury.

In this book, graphical symbols (indicators or elements of the base station or transducer

displays) depicted in this way indicate that they are blinking.

Philips makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Philips shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance or use of this material.

© Copyright 2003 Philips Medizin Systeme Boeblingen GmbH.

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of

the copyright holder.

Symbols on the System

This attention symbol indicates that you should consult this book and the Instructions for Use, and

particularly any warning messages.

Power-On/Stand-by Switch.

Power-On/Stand-by Indicator.

Equipotential Terminal.

This symbol identifies terminals that are connected together, bringing various equipment or parts

of a system to the same potential. This is not necessarily earth potential. The value of potentials of

earth may be indicated adjacent to the symbol.

Protective Earth Terminal.

This symbol identifies the terminal for connection to an external protective earth system.

Antenna input symbol.

Service socket symbol.

This symbol appears on the device adjacent to the CE mark and defines Class 2 radio equipment

per Radio and telecommunications Terminal Equipment Directive 1995/5/EC.

3

1 General Information Patient Safety

IPX1

IP68

Ingress Protection code according to IEC 60529. Base station is rated IP X1 (protection against

vertical water drops only).

Ingress Protection code according to IEC 60529. All transducers are rated IP 68 (protection

against dust, access to hazardous parts, and the effects of continuous immersion in water to a

depth of 0.5 meter for five hours).

Type CF equipment.

Patient Safety

The Telemetry System should only be used by, or under the direct supervision of, a licensed physician or

other health care practitioner who is trained in the use of fetal heart rate monitors and in the

interpretation of fetal heart rate traces. US federal law restricts this device to sale by, or on the order of, a

physician.

The Telemetry Receiver is a Protection Class 1 instrument.

The device complies with the following safety standards:

• EN 60601-1:1990+A1:1993+A2:1995

(IEC 60601-1:1988+ A1:1991+A2:1995)

• EN 60601-1-1:2001 (IEC 60601-1-1:2000)

• UL2601-1 2nd Ed.

• CAN/CSA C22.2 No. 601.1-M90 and No. 601.1-S1-94

• JIS T 1001-1992

• JIS T 1002-1992

• AS 3200.1.0-1998

The cordless transducers are battery operated devices, applied parts (patient connectors) are Type CF

.

Protective Earth

WARNING Check each time before use that the system is in perfect working order and the base station is properly

grounded.

To protect hospital personnel and the patient, the cabinet must be grounded. Accordingly, the base

station is equipped with a 3-wire power cable which grounds it to the power line ground when plugged

into an appropriate 3-wire receptacle. Do not use a 3-wire to 2-wire adapter with the base station. Any

interruption of the protective earth grounding will cause a potential shock hazard that could result in

serious personal injury.

Whenever it is likely that the protection has been impaired, the base station must be made inoperative and

be secured against any unintended operation.

The patient cable must be positioned so that it does not come into contact with any other electrical

equipment.

Before operation, make sure that the base station is free from condensation. This can form when

equipment is moved from one building to another, and is exposed to moisture and differences in

temperature.

4

Environment 1 General Information

Environment

Before operation, make sure that the base station is free from condensation. This can form when

equipment is moved from one building to another, and is exposed to moisture and differences in

temperature.

Use the system in an environment which is reasonably free from vibration, dust, corrosive or explosive

gases, extremes of temperature, humidity, and so forth. It operates within specifications at ambient

temperatures between 0 and +45°C. Ambient temperatures that exceed these limits can affect the accuracy

of the system, the transmitter radio frequency transmission, and can damage the components and circuits.

The system can be stored at ambient temperatures between -20°C and +60°C.

The transducers are watertight to a depth of 1.0 meter, and comply with IEC 60529 (IP 68). The base

station is rated IP X1 according to IEC 60529.

General Description

Refer to the Instructions for Use for operating information of the base station and the transducers. It

includes descriptions of the installation and setup of the system and modes of operation.

Mounting Solutions

You can mount the Avalon CTS:

• In a standard cart drawer. The base station with docked transducers fits into Philips Carts CL, CX and

CM. Use the lower drawer, and secure the base station using the Velcro fixing tape supplied.

• On a cart shelf (for example that of the Philips Cart CP, M1326A), using either the Velcro fixing tape or

the mounting brackets supplied.

• On top of carts, desks or other flat surfaces using the mounting brackets supplied.

• In a wide variety of situations using the GCX mounting adapter for mounting the base station (order

directly from GCX, part number PH-0042-80).

• On top of Series 50 IX/XM/XMO fetal monitors using the mounting brackets supplied.

Mounting Brackets

Refer also to the fitting instructions that come with the relevant solution.

5

1 General Information Applying the Velcro Fixing Tape

Applying the Velcro Fixing Tape

Two self-adhesive Velcro fixing tape sets are supplied, each set consisting of two halves.

1 Strip off the paper backing on one half of the Velcro set and attach to one side of the underneath of the

base station. Repeat for the other side.

2 Strip off the paper backing on the other half of the Velcro set and attach to the fixing surface so that the

two halves of the Velcro set mate up when the base station is correctly positioned.

Apply one

half of

Velcro

tape in

position

shown

Apply other half of

Velcro tape to appropriate

place on fixing surface

6

Antenna Extension Mounting Kit 1 General Information

Antenna Extension Mounting Kit

If the base station is installed in a cart or other mounting solution where the standard antenna cannot be

attached directly to the base station, or does not provide sufficient transmission range, use the antenna

extension mounting kit (M1361A Option 1AA).

The kit contains:

• Antenna extension cable with BNC connectors (1.0m approx.)

• Mounting bracket, including fixings, for mounting onto Philips Carts.

The mounting bracket can also be fitted on walls, wooden carts, or other flat surfaces using fixings (not

supplied) appropriate for the surface material.

Mounting on Philips Carts

A

C

B

1 Remove the plastic cover (A).

2 Slide the fixings for the mounting bracket (C) into the groove (B) in the cart.

3 Replace the plastic cover (A) before sliding the mounting bracket fully down.

4 Slide the mounting bracket downwards in the groove (B) in the cart until the antenna holder part of the

bracket rests on the plastic cover.

5 Tighten the fixing screws to secure the mounting bracket.

Mounting on Wooden Carts and Other Flat Surfaces

7

1 General Information Considerations for Choice of Configuration

Considerations for Choice of Configuration

There are a number of factors that can influence how you finally configure the Avalon CTS.

Frequency Bands

Depending on the country of use, the system uses radio frequencies within one of two bands, the Wireless

Medical Telemetry Systems (WMTS) band, or the Industrial, Scientific and Medical (ISM) band. The

actual approved frequencies used depend on country-specific regulations. The following diagram gives an

example overview of the system’s frequency band configuration.

5

4

3

2

1

1 = The full (hardware) frequency range (10 MHz wide).

2 = The country-specific frequency range governed and approved by local regulatory bodies.

3 = The available frequency range: shows the real, current frequency range available within the country

range. This will differ from the country range due to:

– excluded frequency ranges

– frequency ranges already allocated to other Avalon CTS systems in the same establishment.

4 = Excluded frequency ranges (ranges occupied by other telemetry systems, or other RF interferers).

5 = Fixed frequency ranges.

Normal Delivery Configuration

The Avalon CTS is normally delivered with:

• Automatic channel search.

• A standard antenna.

Using the standard antenna, the potential operating range is up to 100 meters. The actual effective area of

reach will vary according to the geographical and physical characteristics of the building where the system

is installed, and is also influenced by the presence of other radio frequency (RF) devices or interference.

We recommend that you define effective operating range prior to putting the system into operation.

If the area of reach is adequate for the intended monitoring area, and the system’s operation is not

influenced by other RF sources, then the normal delivery configuration is sufficient.

When is a Different Configuration Needed?

This section deals with possible reasons why the normal delivery configuration may not be adequate.

8

Setting Expectations 1 General Information

When the Area of Reach is Not Sufficient

If the area of reach is not sufficient using the standard antenna supplied with the system, there are a few

things to consider:

– The placement of the antenna has an effect on the operating range. If it is located inside a metal cart

or other RF-absorbing material, then place the antenna externally by using the Antenna Extension

Mounting Kit (M1361A Option 1AA) to increase the range.

– Check the orientation of the antenna. In general, the antenna provides the greatest range when it is

positioned vertically.

– If the area of reach is still insufficient, consider installing an antenna system.

When the Normal Delivery Configuration is Unsuitable

The normal delivery configuration, with free base station channel search, may be unsuitable if:

• There are other telemetry systems installed in the hospital.

• There are multiple (more than ten) stand-alone Avalon CTS systems.

• There are other sources of RF interference.

• The Avalon CTS system causes interference on other telemetry or RF systems.

• If you connect the Avalon CTS to an antenna system.

Frequency Planning

For multiple cordless/telemetry installations in the same hospital, an RF frequency plan should be

implemented. Document all frequencies or frequency ranges occupied by:

• Other telemetry systems (adult and fetal).

• Multiple Avalon CTS systems (operating on fixed frequencies). Remember that the Avalon CTS is also a

potential interference source for other RF systems.

• Other sources of RF interference (other electrical equipment, broadcasting stations, or paging systems,

for instance).

Once you have identified all the occupied frequencies or frequency ranges (for example, by using the

Service Support Tool software) you can change the system’s configuration by following the guidelines for

RF channel/frequency configuration.

• Exclude frequency ranges already occupied by other telemetry systems or that are subject to interference

from other RF sources (see page 54).

• Use fixed frequencies for the base station, possibly in conjunction with altering the channel spacing (see

page 66).

• Use fixed frequencies for the transducers (see page 55).

Setting Expectations

No matter how good a telemetry system design is, it will always experience occasional loss of radio

communications, resulting in US/Toco/ECG dropouts. A telemetry system will never be as reliable as a

hard-wired monitor that transmits its signal through a wire. If occasional loss of US/Toco/ECG

monitoring is not acceptable for certain patients, they should be connected to a hard-wired bedside

monitor.

9

1 General Information Antenna System Guidelines

WARNING Telemetry should not be used for primary monitoring in applications where the momentary loss of the

US/Toco/ECG signal is unacceptable.

Following are guidelines to set proper expectations of hospital staff and to improve system performance:

• Clinicians will tend to see more motion related artifact on the US/Toco/ECG measurements of

ambulatory patients than on patients that are restricted to a bed.

• Patients should be restricted to the designated coverage area. Monitoring performance will degrade if

patients go outside the radius of coverage of the receiving antenna.

• Keep the size of the antenna system as small as possible. Telemetry system performance will degrade as

the system size increases. The larger a system is, the greater the potential for receiving interfering

signals. In addition, as more devices are added to the antenna system, the noise generated by the

antenna system itself increases.

• A patient location protocol is critical to a telemetry system. If a life-threatening event occurs, the

clinician must be able to locate the patient quickly. The importance of this increases as the antenna

system size increases.

• Philips Medical Systems has no control over the RF environment in the hospital. If interference exists at

the operating frequencies, telemetry system performance will be affected. Careful selection of

frequencies for all wireless devices used within a facility (telemetry transmitters, walkie-talkies,

ambulance radios, other wireless medical devices, etc.) is important to prevent interference between

them. Frequency management is the responsibility of the hospital.

Antenna System Guidelines

The Avalon CTS (M2720A) is compatible with the dual band antenna system components as used with

the M2600A adult telemetry system. Antenna systems must be designed according to adult telemetry

system rules, and presales activities and site preparation must be done according to the existing M2600A

series antenna systems rules. These activities are not bundled into the product price and have to be

ordered separately at the PSS or HPS organization.

Additional to the M2600A antenna system design rules, the following antenna specifications apply to the

Avalon CTS:

• Only original M2600A antenna system components will be supported.

• The antenna spacing must not exceed a radius of 10m (32ft).

• Any mixture of Avalon CTS and other telemetry devices (for example, M1310A or M2600A Adult

Telemetry Transmitter/Receiver) on the same antenna system is not supported.

• Contact Philips Support regarding antenna system design.

10

2

2Theory of Operation

This chapter describes the functional operation of the system, including the base station and transducers. It

incorporates features of the mechanical design, indicating the physical relationship of the assemblies and

components.

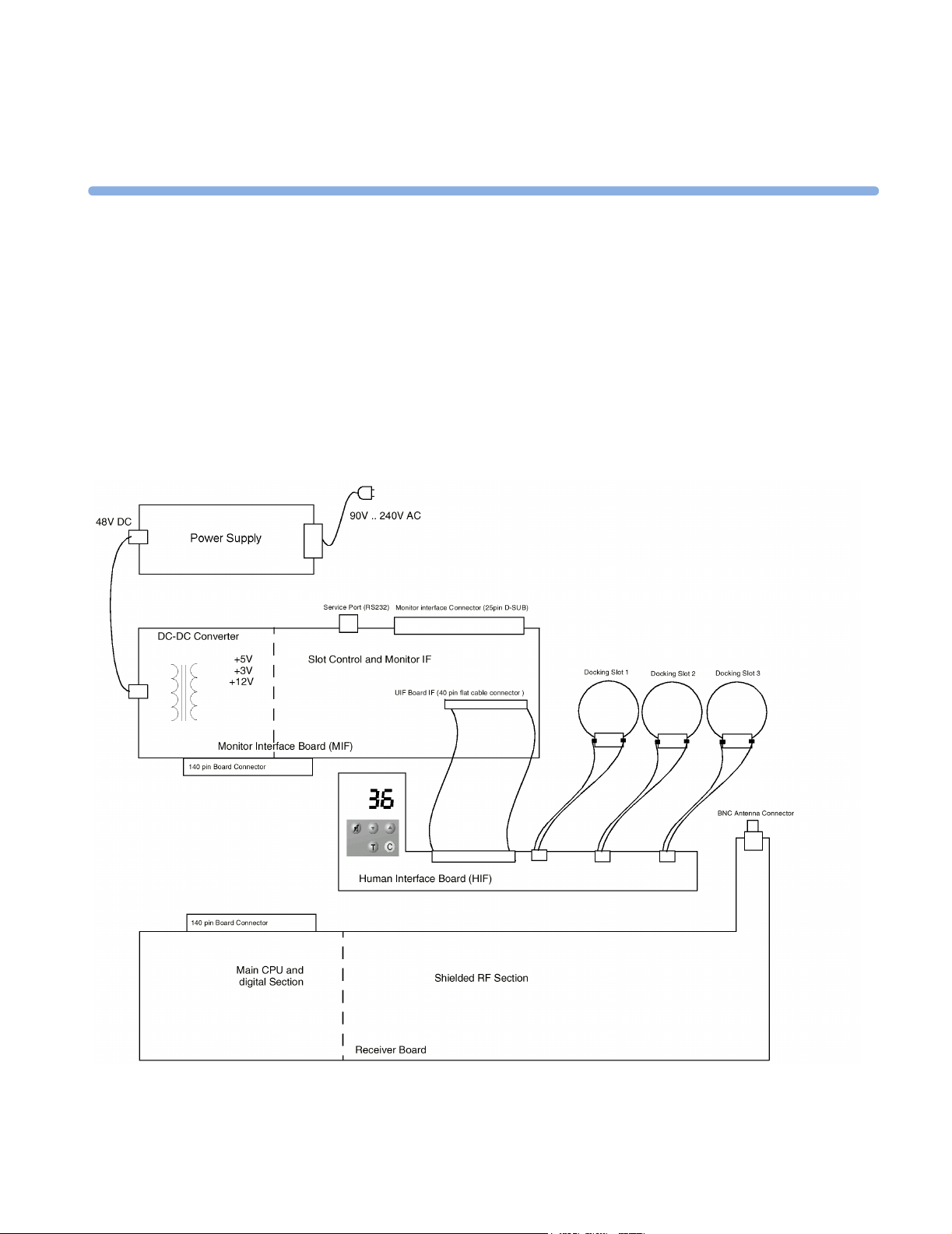

Base Station Hardware Overview

Figure 1 Base Station Boards

The Base Station consists of four functional components:

11

2 Theory of Operation

Receiver Board

The receiver is a double superheterodyne narrowband frequency modulation (FM) receiver, with two

mixers and two intermediate frequencies (IFs). Three radio frequency (RF) signals can be received

independently with three identical receiver channels.

for frequency shift key (FSK) detection, analog-to-digital conversion of the low frequency (LF signal),

signal filtering, and radio frequency (RF) channel management.

transducers.

and each docking slot.

While charge power is on, a serial communication link is established between the base station

The digital section of the main CPU is responsible

The main CPU communicates with the

Human Interface Board

The Human Interface (HIF) board provides the user interface, and the display, indicators, keys and the

slot charging contacts are all located on this board.

Power Supply

The power supply is a wide-range input swtching unit, with an output of +48V. It is located on the chassis

assembly.

Slot Control and Monitor Interface Board Hardware

The Monitor Interface (MIF) board provides the interface to the fetal monitor as well as the

communication interface to the transducer slots. Power conversion is performed by a DC-DC converter.

The digital (active) parts of the human interface also reside on this board.

The MIF board consists of the following functional blocks:

• DC-DC Converter - the 48V DC input for the DC-DC converter comes from the primary AC-DC

converter. Since the 48V DC voltage is sufficiently stabilized, two fixed pulse width step down

transformers are used to transform the high voltage down to the required 3V, 5V and 12V (postregulated for accuracy).

The +12V supply is mainly used for battery charging and you can access this voltage at the charge

contacts. The fuse on the MIF board are not replaceable, and if it blows, the board must be replaced. If

there is a short to ground, unlimited current will blow the fuse. To avoid this, a current limiter is used

to limit the output current.

• Monitor interface - three major blocks make up the monitor interface:

– PWM Toco digital-to-analog (D/A) converter

– Two PWM wave D/A converters for FHR low frequency (LF) 1, and FHR LF 2.

– Digital status ports

• Transducer slot interface - this block is responsible for transducer detection, safety features of the

charge power switch, serial communication between base station and transducers and synchronization

clock generation for the power supply.

contacts when there is no transducer docked in a slot, charge power in each slot is only applied after a

transducer has been detected.

To ensure that there is no charge power applied to the charge

12

• Drivers for the HIF board interface - this block contains the multiplexing and driving components for

the function buttons, the display backlight and the seven-segment LEDs.

Transducer Hardware Overview 2 Theory of Operation

Transducer Hardware Overview

The system has three transducer types:

•Toco

•US

•ECG

They all share the same modulation and digital processor circuitry, power supply, liquid crystal display, and

RF transmitter. The processor software is also the same for all transducers. The frontends, however, are

specific to each transducer type.

Functional Description of the RF/CPU Hardware

The RF/CPU section of the transducers is made up of the following functional blocks:

• CPU (micro controller)

•LCD

• Base Station communication

• EEPROM

•FLASH download port

• Clock generator

• Power supply and battery charger

• Modulator

• RF transmitter

Boards: M2725-66501,

M2726-66501,

M2727-66501

parameter

frontends

(see separate description)

power supply

and battery

charger

wave

frontend control

power management

base station communication

Figure 2 Transducer Block Diagram

Base Station Communication

An active base station communicates with docked transducers to check the correct transducer type, serial

number, to program the RF frequency, to initiate test cycles, and to check the current battery status.

gain control

Modulator

CPU

(micro

controller)

FSK signal

modulation signal

(wave +FSK)

frequency control

Clock

generator

RF

transmitter

FLASH

download

port

LCD

EEPROM

13

2 Theory of Operation Toco Frontend Hardware

Power Supply and Battery Charger

A Lithium-Ion (Li-Ion) battery powers the transducer. Batteries are charged whenever a transducer is

docked in an base station connected to AC power. Charge power is transferred by the spring-loaded, twopin charge contacts. Communication between the base station and the transducer processors is also done

using these contacts.

An intelligent Li-Ion charging circuit in the transducer controls the battery management. See page 72 for

battery charging times.

Modulator

The analog heart rate signals (ultrasound Doppler or fetal ECG) are pre-processed and band-limited by

filters. The signals are then fed into a programmable gain amplifier controlled by an automatic gain

control circuit and a digital FSK modulated subcarrier (1.6 kHz or 2.4 kHz) is added to the RF carrier

signal. The subcarrier is responsible for the digital transmission of the Toco data, along with safety and

status information, such as serial number, bed label, fetal movement data, battery information.

RF Transmitter

The RF transmitter block contains:

• a PLL synthesizer that divides the reference frequency down to 12.5 kHz, and can be tuned in steps of

12.5 kHz.

• a voltage controlled ocillator (VCO).

• a power amplifier (antenna driver).

Toco Frontend Hardware

Uterine activity is measured by evaluating the hardness of the mother’s abdomen with a pressure sensitive

resistor bridge (DMS element). The DMS element requires an excitation voltage and its differential

output signal is proportional to the pressure applied to the DMS element. An AC excitation voltage is

used, and the resulting AC output signal is amplified and converted to a pressure proportional DC voltage

by a synchronous rectifier followed by a low pass filter.

Ultrasound Frontend Hardware

The ultrasound frontend is a pulsed Doppler system with a 1.0 MHz ultrasound frequency, and a pulse

repetition rate of 3.2 kHz. Seven ultrasound crystals are used as transmitter and receiver.

ECG Frontend Hardware

Several parameter frontends are combined on the ECG frontend board. Currently supported parameters

are DECG and MECG.

A seven-pin ‘D-type’ socket carries all parameter related inputs and outputs. An external mode resistor,

connected to one of the pins, detects which ECG mode to set when an adapter cable is plugged in. The

M1362B ECG adapter cable, used with the M1364A patient module, is also used for the fetal scalp or

adult electrodes.

14

The Avalon CTS has two system interfaces:

• Fetal monitor interface

• Service Interface

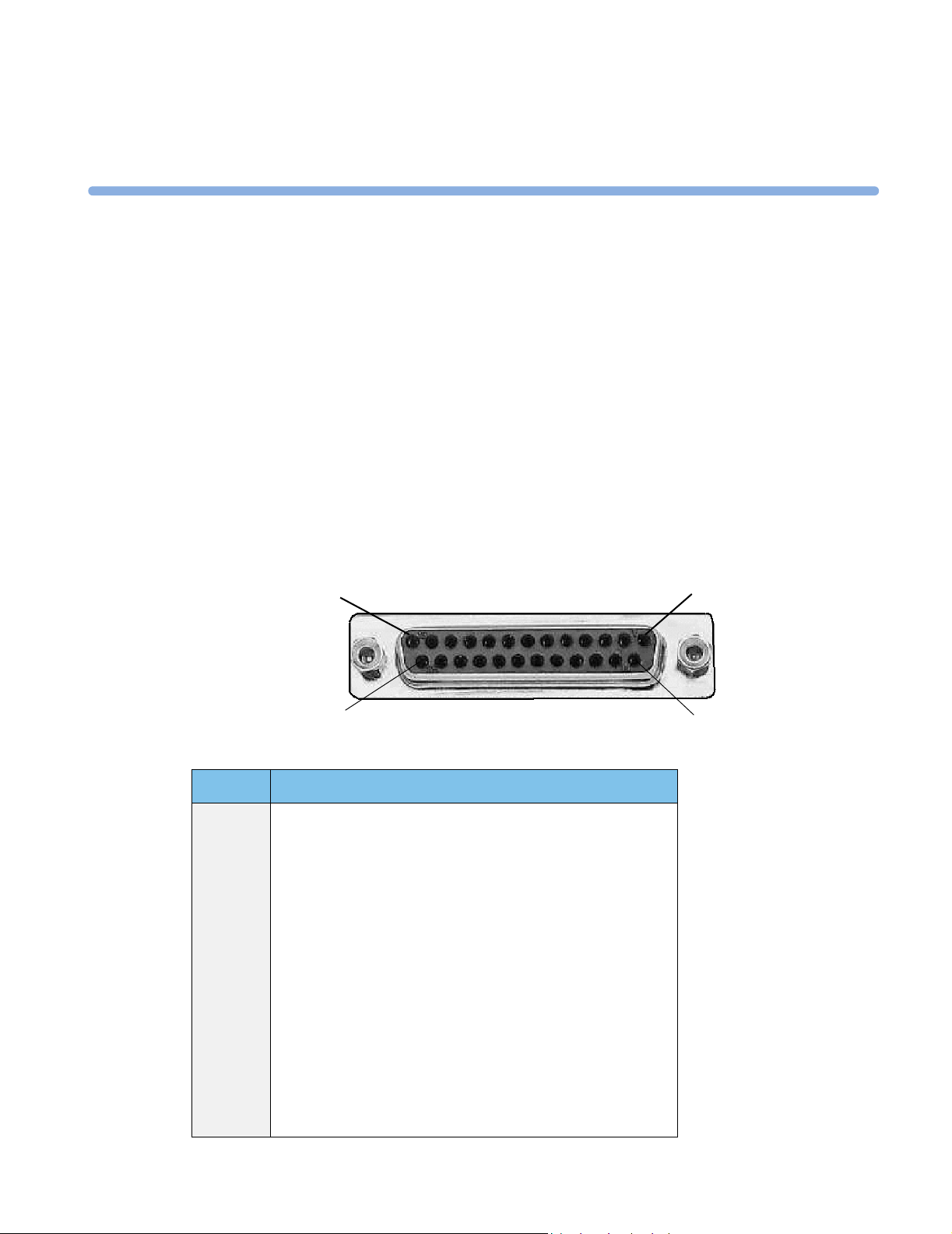

Fetal Monitor Interface

The Fetal Monitor Interface on the base station allows digital and analog outputs to the Series 50 fetal

monitors. The interface is enhanced to support additional transducer combinations for future fetal monitors.

The following table lists the signals at each pin.

3

3System Interfaces

PIN 13

PIN 25

Pin

1 MECG supported (Series 50 B/C fetal monitors only).

2 +3V RF (10 kΩ internal resistance)

3+12V RF (10 kΩ internal resistance)

4 +48V RF (100 kΩ internal resistance)

5 Base station on (L).

6 Reserved.

7DECG inop (L).

8 DECG Mode (L).

9 Reserved for future functionality.

10 US Mode (L).

11 Reserved.

12 IUP Mode (L).

13 TOCO External Mode (L).

Signal Details

PIN 1

PIN 14

15

3 System Interfaces Service Interface

Pin

14 US LF or ECG Signal.

15 TOCO/IUP signal.

16 Not connected.

17 Ground.

18 Ground.

19 Reserved. (Tele-Marker on the fetal monitor side.)

20 Tele-FMP on (L) if FMP available.

21 Tele-Fetal movement on (L).

22 MECG Inop.

23 Not connected.

24 Ground.

25 MECG Mode.

Service Interface

The service socket on the rear of the base station takes a stereo phone jack for RS232 connection to an

industry standard compatible PC installed with the Service Support Tool software. Use the interface cable

M1350-61675. The transducers must be docked in the base station for communication with the Service

Support Tool.

Signal Details

16

Figure 3 Interface cable for connecting an industry standard compatible PC to the Avalon

base station.

Compatible Fetal Monitors 3 System Interfaces

Compatible Fetal Monitors

A list of compatible fetal monitors (including interfaces) is given in the following table.

Parameter

Monitor / Interface (IF)

M1350x

with M1350-66531 IF

M1350x

with M1350-66536 IF

M1351A

with M1353-66531 IF

M1351A

with M1353-66531 E IF

M1353A

with M1353-66531 IF

M1353A

with M1353-66531 E IF

Key: ! = supported; - = not supported

HR 1 - HR 1 !!Only one FHR is transmitted.

HR 1

HR 1 --- ! No ECG processing. DECG mode generates

HR 1 ! - - ! Software revision A.02.00 or greater.

HR 1 - HR 1 - ! Only one HR transmitted.

HR 1 ! HR 1 - ! Software revision A.02.00 or greater.

!

CommentsUS FMP DECG MECG Toco

HR 1 !!Software revision A.04.01 or greater.

“Err 9”.

17

3 System Interfaces Compatible Fetal Monitors

18

4Disassembly/Reassembly

WARNING • Performance verification: do not place the system into operation after repair or maintenance has been

performed, until all performance tests and safety tests listed in Chapter 6 of this service manual have been

performed. Failure to perform all tests could result in erroneous parameter readings, or patient/operator

injury.

• Energized circuits are accessible with the covers open. Do not work on the base station with the covers open

and AC power connected. Only qualified service personnel should open or disassemble the base station.

• Before attempting to open or disassemble the base station, disconnect it from the AC mains supply.

CAUTION Observe ESD (electrostatic discharge) precautions when working within the unit.

4

Introduction

Remember to store all screws and parts in a safe place for later refitting.

How to Use this Chapter

The disassembly sections detail the step-by-step procedures you use to access replaceable parts of the base

station.

All the transducers are sealed at the factory and are not repairable. Replacement transducers are supplied

complete with both battery and belt button fitted.

The Avalon base station consists of two major assemblies:

• The top cover assembly

• The chassis assembly

The top cover assembly contains the human interface (HIF) board, the keypad inlay, and the battery charge

contacts and wiring. The top cover assembly is only available as a complete assembly, and a repair to any part

of the top cover assembly is effected by replacement of the whole assembly.

The chassis assembly contains the metal chassis and power supply, the receiver board and the monitor

interface (MIF) board. The power supply always comes complete with the chassis (without boards), and a

repair to either the power supply or the chassis is effected by replacement of this chassis/power supply

assembly.

There are no boards available individually as replacement parts. In the case of a defective receiver board or

MIF board, a repair is effected by exchanging the whole base station assembly (unit exchange).

19

4 Disassembly/Reassembly Removing the Top Cover Assembly

All part numbers of spare parts are listed in Chapter 5.

Tools Required

CAUTION When replacing the front cover, do not over-torque the screws. Excessive torque may damage the plastic

screw mountings.

You need the following tools:

•Torx-head screwdriver, size T-10

or

•Torx bit, for suitable driver, size T-10

Removing the Top Cover Assembly

6 Carefully place the base station upside down. To avoid scratches, place the unit on some cloth or other

soft surface.

Screw locations

7 Remove the six screws securing the top cover assembly to the chassis, using a T-10 Torx driver.

8 Holding both top cover and chassis assemblies together, place the base station upright again.

9 Lift the front edge of the top cover and disconnect the spade connector for the ESD ground wire from

the terminal on the metal chassis.

20

ESD ground

spade connector

Replacing the Top Cover Assembly 4 Disassembly/Reassembly

Now raise the cover a little more, and disconnect the multipin connector of the ribbon cable from the

10

MIF board. Pull straight up to avoid bending the pins. The top cover assembly is now free of the chassis

assembly.

Top

cover

assembly

Chassis

assembly

Ribbon cable

connector

Replacing the Top Cover Assembly

The serial number appears initially in two places on the base station - on the rear of the top cover

assembly, and on the bottom of the metal chassis. A replacement top cover does not carry a serial

number.

1 Ensure all items are replaced in the top cover assembly.

2 Reconnect the multipin ribbon cable connector to the socket on the MIF board.

Reconnect ribbon cable connector

3 Important! Reconnect the ESD ground wire spade connector to the terminal on the chassis.

4 Place the front cover back to its normal position.

ESD ground

spade connector

21

Loading...

Loading...