Page 1

PHILIPS

21XLP -2 Light Probe

for Brilliance 201CS monitor with Cyberscreen ® technology

Page 2

21XLP -2

Light Probe for Brilliance 201CS monitor with

Cyberscreen ® technology

User‘s Guide

First edition - November 1996

This guide has been made of recycled paper, to help protect the environment.

Page 3

IMPORTANT NOTICE

Because of a continuous product improvement poiicy, information in this guide and the

software furnished with it are subject to change without notice.

PHiLiPS Eiectronics N.V. shail not be iiable for any technicai or editoriai error contained

herein, nor for direct, indirect or consequentiai damages resulting from any defect in the

software or in its documentation.

This guide contains information protected by copyright.

No part of this document may be reproduced or copied, in whole or in part, or transiated into

other languages without prior written consent of PHILIPS Electronics N.V.

PHILIPS Electronics N.V. grants the license to install and use the software furnished with this

manuai on any computer owned by you. You are allowed to make up to two (2) copies of the

magnetic media for archiving purposes but you may not dupiicate the written documenta

tion.

You may not decompiie, disassembie, modify, adapt or create derivative works based on this

software for distribution on third parties.

TRADEMARKS ACKNOWLEDGMENT

Cyberscreen ® monitor is a Philips technology.

Brilliance is a registered trademark of PHILIPS Electronics N.V.

IBM PC is a registered trademark of International Business Machines Corp..

Microsoft is a trademark and Windows is a registered trademark of Microsoft Corporation.

Apple and Macintosh are trademark of Apple Computer Inc.

Other brands or product names used herein are for identification purposes only and may be

trademarks and/or registered trademarks of their respective holders.

RADIO INTERFERENCE WARNING

The 21XLP -2 Light Probe has been tested and found to comply with the limits for a class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses and may radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user is required to correct the interference at his own expense.

Page 4

Printing History

The firmware release printed after the date indicates the version level of the Light

Probe software at the time the manual was issued.

Edition 1, November 1996 Light Probe software release 3.0

Since many software updates do not require manual changes and viceversa, do

not expect a one-to-one correspondence between software releases and manual

editions.

Conventions

The following international conventions may appear in this manual:

NOTE: Calls attention to a procedure, condition or practice that requires special

attention by the reader.__________________________________________________

CAllTiON: calls attention to a procedure, condition or practice that could possibly

cause damage to equipment or permanent loss of data.

___________________________

WArnINC: calls attention to a procedure, condition or practice that could

possibly cause body injury or death.

______________________________________

Typographical Conventions

This font type indicates a menu command name, a file or directory name or

text that system or software displays on the screen.

Ill

Page 5

Preface

Thank you for purchasing the 21XLP -2 Light Probe for Briliance 201CS monitor with

Cyberscreen ® technology. We hope you will enjoy using it and we are confident that

this quality product will meet your highest expectations.

This user guide tells you how to install and operate the 21XLP -2 Light Probe packa

ge. Here is how the manual is organized:

Chapter 1 gives an overview of the Brilliance 201 CS technology and a brief intro

duction of the 21XLP -2 Light Probe.

Chapter 2 lists all the components of the 21 XLP -2 package, the system require

ments for its correct operation and how to install both hardware and software parts.

In Chapters 3, 4 & 5 you can find, respectively, a detailed description on how your

Brilliance 201 CS can be calibrated in terms of white balance, white uniformity and

convergence.

Chapter 6 gives you direction for cleaning and maintenance of the product.

Appendix A, What’s behind, introduces you to the theory of color perception and

describes how your monitor can display color images.

It briefly explains also the limitations of the traditional CRT technology and the inno

vations of the Brilliance 201 CS technology.

Appendix B, Warnings and error messages, lists all the error messages that can be

displayed by the application software and suggests the appropriate corrective

actions.

IV

Page 6

CONTENTS

Chapter 1 - Before you begin

A few words about the Cyberscreen ® technology

The 21XLP -2 Light Probe enhancement

Chapter 2 - Getting started

Package contents

System requirements

Installing the hardware

Installing the software

Display ID and preset values saving

How to start

Chapter 3 - White balance calibration

About color temperature selection

Calibrating the white point

Chapter 4 - Brightness and color uniformity calibration

About brightness and color uniformity

Calibrating the brightness and color uniformity

Loading factory presets and user correction tables

1

2

3

3

4

6

7

8

8

9

11

12

14

Chapter 5 - Convergence adjustment

About convergence

Adjusting the convergence

Loading factory presets and user correction tables

15

16

18

Page 7

Chapter 6 - Cleaning and maintenance

Cleaning and maintenance 19

Appendix A - What’s behind

Color basics

How displays create colors

About color uniformity

The Cyberscreen ® state of the art technology

Expressing colors: CIE system

Color temperature

The convergence problem

The Cyberscreen ® solution

Appendix B - Warnings and error messages

Warnings and error messages 25

20

21

21

22

22

23

24

24

VI

Page 8

1 Before you begin

A few words about the Cyberscreen ® technology

Your Brilliance 201CS has put a milestone in CRT color display technology.

Thanks to its unique DDA (Digital Dynamic Adjustment) system, color, brightness

and convergence are digitally optimized over the entire screen, providing an out

standing sharp, precise and uniform image.

The built in correction system divides the whole screen into a 16x16 virtual matrix

(@ 1024*768 resolution) and for each of the resulting 256 areas the image can be

refined for both brightness and color uniformity, as well as for convergence.

In other words, the monitor electronics is able to compensate for the lack of perfor

mances of the current Cathode Ray Tube technology.

In addition, the Brilliance 201 CS features a patented ‘magnetometer’ system that

automatically detects and compensates for any variation in the Earth Magnetic field

conditions, so that the superior performance of your display wilt be maintained under

any installation environment.

With its uncompromised image quality, the Brilliance 201 CS has been designed to

fully satisfy the increasing demands for ‘state of the art’ display performances,

coming from todays most powerful professional applications, like CAD/CAM/CAE,

Desktop Publishing, Color Prepress, Advanced Imaging and graphics intensive busi

ness applications.

Before you begin

Page 9

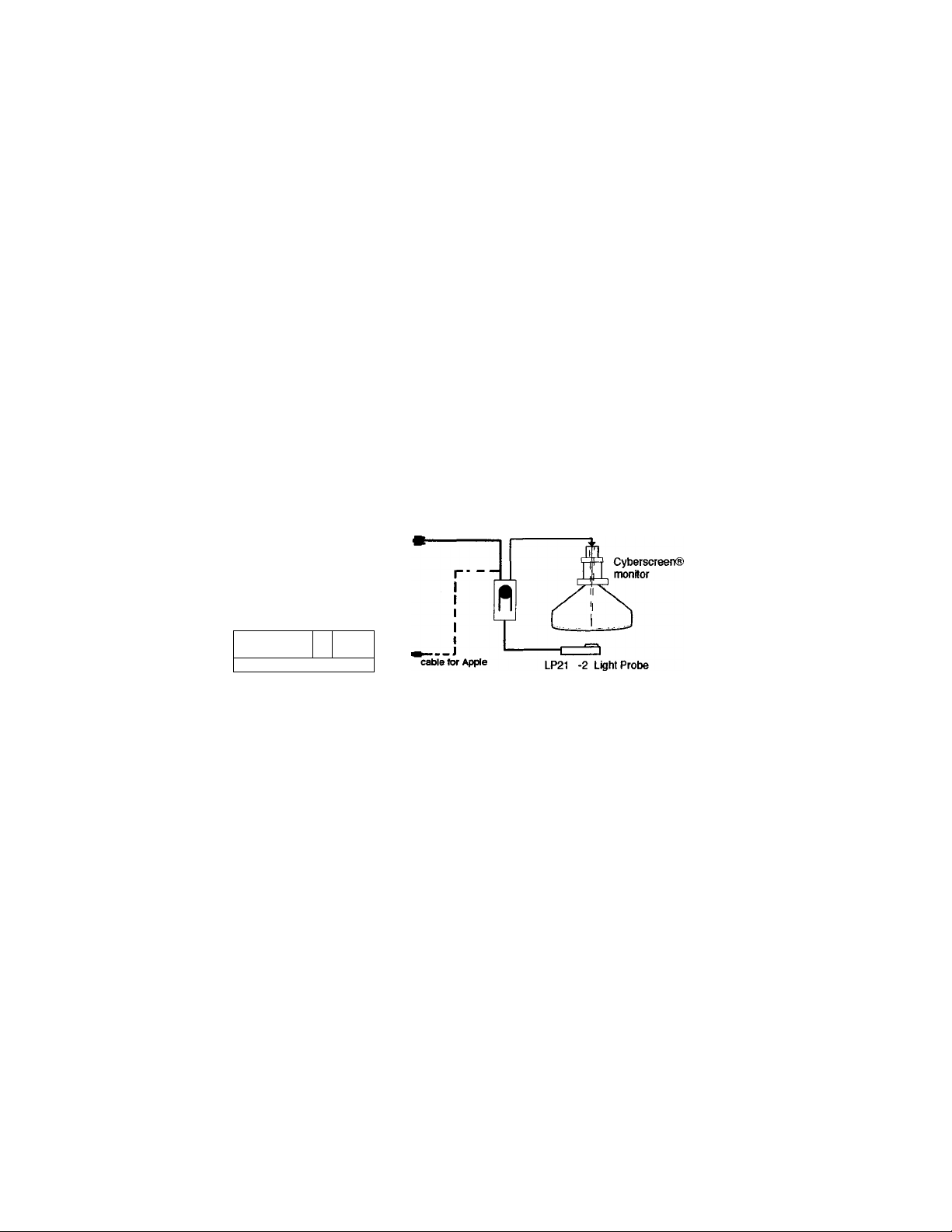

The LP21 -2 Light Probe enhancement

Specifically designed for the operation with the 21” Cyberscreen ® display, theLP21

-2 calibration package offers a precise, PC based adjustment of color/ brightness

uniformity as well as for convergence, for fast on-site recalibration and maintenan

ce of your display.

In other words, this product enables you to compensate any drift that may occur due

to the aging of the picture tube, maintaining the superior performances of your

display over the product lifetime.

mmi

cable tor PC

iM H i

□ |0O©e®—1

The calibrator system is based on a precision, high sensitivity light probe that com

municates with both the monitor and your computer thanks to a built in RS 232 inter

face provided to offer the maximum connection flexibility.

The Windows based software package provides an intuitive GUI (Graphic User

Interface) operation, so that you can start right now working with your new LP21 -2

Light Probe.

I

-J hI

Before you begin

Page 10

2 Getting started

Package Contents

Besides the 21XLP -2 Light Probe, the package also includes everything needed for

hardware installation and software configuration.

After unpacking, check that the shipment contains the following items:

- The 21XLP -2 Light Probe light probe unit

- The 21 XLP-2 Light Probe base unit

- Three (3) cables for interconnection

- This user guide

- The 21 XLP -2 Light Probe software disks (for Windows and Apple), enclosed in

the plastic envelope at the end of this guide

If any components are damaged or missing, contact your authorized dealer.

If you do not encounter problems at this stage, you can proceed with the installation.

IBM PC system requirements

The software requires an IBM PC compatible system (80386 or better) with:

- 4 Mb of extended memory

- Hard disk and a 3,5” high density FDD

- A free RS 232 port

- Miaosoft Windows 3.1 or greater

- Microsoft compatible mouse (recommended)

Appie PC system requirements

The software requires an Apple Personal Computer with:

- 4 Mb of extended memory

- Hard disk and a 3,5" high density FDD

- A freeModem port to connect the Mac RS232 adaptor

- System 7.0 or later

- mouse (recommended)

Your computer and monitor manuals would also be useful.

Getting started

Page 11

Installing the hardware

STEP 1

Choose a comfortable and secure location for the Light Probe unit, making sure that

the interconnection cables can reach both the monitor and the computer. Check that

either the device or the cables will not interfere when you tilt and swivel your moni

tor.

CauYioN: do not place the Light Probe unit on top of your monitor.

If you obstruct the air flow coming from the cabinet ventilation slots both the moni-

tor and the Light Probe unit can be damaged by excessive overheating.________________

CAuTloN: To prevent possible damage to equipment, both the computer and moni-

tor must be turned off before connecting or disconnecting any cable.

When connecting a cable, perform the operation carefully making sure that con-

nectors are well aligned during insertion.

STEP 2

Connect the cable having the 9 pin D - subminiature plug in type connector (male)

to the connector labeled SERIAL INTERFACE located on the back of your monitor.

STEP3

Connect the other end of the cable to the output port of the Light Probe unit, which

is marked as follows on the bottom of the unit:

_____________________________________

Gettin started

9

Page 12

STEP 4 (for Windows)

Connect the cable having the 9 pin D- sub miniature receptacle type connector

(female) to a free RS 232 port of your computer.

STEP 4 (for Apple)

Insert the RS232 Mac adaptor into the Modem port of your Apple PC and then con

nect on it the cable having the 9 pin D- sub miniature receptacle type connector

(female).

NOtE: In case all your serial ports are used, you will be required to temporarily

disconnect a peripheral device to allow the connection of the Light Probe unit.

If this is the case, choose any peripheral other than the mouse since its use will

greatly simplify the use of the Calibration software.

Use the adapter provided with the monitor accessories in case the Light Probe

should be connected to the 25 pole serial port of your PC..

STEP 5

Connect the other end of the cable to the input port of the Light Probe unit, which is

marked as follows on the bottom of the unit;

_________________________

9

STEP 6

Connect the cable of the 21XLP -2 Light Probe unit to the 8 pole Mini Din recepta

cle type connector located on the base unit. Keep the 21XLP -2 Light Probe in its

base housing.

Now that you have installed all the hardware parts of the 21XLP -2 Light Probe

package, you can proceed with the installation of the software.

Getting started

Page 13

Installing the software

Install software for Windows

STEP 1: Turn your system on and start the Windows session.

STEP 2: Insert the floppy disk with the 21XLP-2 Light Probe software.

STEP 3: From the Program manager File menu, select Run.

STEP 4: When the Windows dialog box appears, type the letter of the drive the

disk is in, followed by a colon and the word ‘setup’.

example : a ; setup

After a while , a ‘welcome’ box will appear on the screen. Just dick

‘Continue' to proceed with the installation.

Next, another box will be displayed, in which you need to select a dire

ctory where the installation program wiii install the files.

Default directory is C:\21XLP -2 ; you may change the target directory

by

typing a different one or just dick ‘Continue’.

In the next dialog box you will be requested to tell the program which

serial port of your computer the Light Probe is connected to.

Please check your computer documentation for identification of COM

ports. After this operation, the program will install the Light Probe softwa

re and, at the end of the installation, a new program group named

Cyberscreen II will be Created in the Program manager window.

This program group contains the calibration program icon labeled 21XLP

_2; just double dick on this icon to run the Light Probe application.

Install software for Apple

STEP 1 : Insert the floppy disk and double click on the floppy icon

STEP 2: Double click on the Installer Icon and select your language.

STEP 3: The set-up program will create a default folder named “Cyberscreen 11”

and will install all the files on the HD.

STEP 4: Now dick on the 21 XLP _2 icon from the “Cyberscreen II” folder to run

the software

Getting started

Page 14

Display identification and preset values saving

NOTE: every time the monitor is powered on, the first time you run the calibration

program a ‘zero calibration’ of the Light Probe is performed. During this operation,

identified by the program as

Dark measxire, place the probe in its base housing.

The first time you run the Light Probe appiication after the installation on your PC,

the program will perform the following steps:

STEP 1 - Display Identification

Since all the calibration and preset correction data are unique to the CRT of the

monitor you are now using, the program will prompt you to insert the serial ID num

ber of the display, which is printed on the back label of the monitor. For example , if

your monitor is labeled ‘prod.number: AN XXXXXX NNNNNN’, the useful ID number

consists of the last six NNNNNN digits.

Then, the number will be stored into the monitor memory and ail the correction data

saved on hard disk will be associated to it.

Every time you start the Light Probe software, the program will check if the monitor

in use is the one of which data are saved on hard disk.

STEP 2 - Data saving of preset corrections

After inserting the monitor serial number, the program will automatically create a

copy of all the preset correction values on your hard disk and will give you also the

option to create an additional back up copy on floppy disk.

During the copy, a window on the screen will indicate ‘Transmitting Data’.

CAUTION: in case you calibrate a different Brilliance 201CS on your PC, the program will notice the difference in the serial number (or absence, if the monitor is

brand new) and will prompt you the permission to ovenivrite the correction data on

hard disk. If you accept, you will permanently loose the data related to the previous

monitor unless you have previously made a back up copy on floppy disk.

_______________

Getting started

Page 15

How to start

From the Program manager window, open the cyberscreen ii program group

and double click on the 21xlp _2 icon to start the application.

You will be prompted to tell the program to which serial port the Light Probe is con

nected to and then, if necessary, a zero calibration of the Light Probe will be perfor

med.

Now the ‘Adjustment geometry’ pop up window will appears on the screen. By fol

lowing the instructions in the dialog box, adjust the black horizontal-verical borders.

3 White color calibration

About color temperature selection

If you are working with color images provided by different input sources (scanners,

laser discs, VCRs), calibration of the white coior temperature of your Brilliance

201CS according to the standard of the input source will enable the monitor to

display colors exactly as they were originally created.

On the other hand, if the work you create with your computer wiii be output on a TV

broadcast or reproduction system, or compared with an image created according to

a standard color proofing, white point calibration of the dispiay will ensure that what

you see on the screen will closely match what will be reproduced or printed out.

When you choose White color calibration from the White Temperature pop up

menu of the 21XLP -2 application window the following oalor reference models are

available;

-T1

-T2

■T3

Custom White settings

You can even select one of the above temperatures and then create Custom White

settings by typing the color temperature you wish to calibrate the display to, in case

you need to match a special Input or output device.

Steps of 100 Kelvin degrees are available inside the 5000 -10000 °K range.

9300 “K + 8 mpcd

6500 “K + 8 mpcd

5500<K

White color calibration

Page 16

Information on tvolcallv used color temperature:

D SO: this setting corresponds to the North American industry standard color temperature for

proofing coior photographs.

SSOO’K <T3 preseti : this settings is provided as an alternative to the D 50 standard, more

towards the blue end of the Black Body curve.

D 6S (T2 preset) : this setting reflects the NTSC color standard used for broadcast video.

Calibrate to this setting if the work you create wiil be output to a VRC or a TV unit.

9300°K + 8 mocd (T1 preset) : this is the brightest white point seiection, wideiy used in

CAD/CAM/CAE design environments.

Aithough used by most computer displays, this setting does not reflect any industry standard.

7500K ; this setting corresponds to the European industry standard coior temperature for

proofing color photographs.

In addition, with the white balance calibration option of the 21XLP -2 software you

can calibrate different Brilliance 201CS exactly to the same color reference model.

This wiil allow exchange of color image files with color consistency among all the

graphic workstations equipped with the Cyberscreen ® technology.

As a result, you can split works on a large color layout at several locations.

Calibrating the white color

NOTE: before you attempt to calibrate the white point, your system needs to be

‘warmed up’. Do not calibrate the display unless it has been operating for at least 30

min.

STEP 1

From the application window, select White color calibration from the white

tenperature pop up menu.

A dialog window will appear where you can select the white point you wish to adju

st. In the White preview box you will have an immediate preview of your selection

while the cie diagram will show you at which point of the black body curve is fal

ling the selected color temperature.

When you have done your selection, just click OK to continue.

White color calibration

Page 17

STEP3

After confirming the white seiection, the screen will turn into a full white page pat

tern. Put the Light Probe at the center of the screen and click OK.

NOYE: in case the purpose of the calibration is to match two 21” Cyberscreen ®

displays at different locations, make sure that ambient lighting conditions are simi

lar. Due to the fact that the calibration probe is slightly sensitive to ambient illumi

nation, if a monitor is calibrated in a very dark environment while another is cali

brated when the sun is shining on the screen from the office window you may have

different results.

NOTE: in case the purpose of the calibration is to match two 21” Cyberscreen ®

displays, make sure that settings of both Brightness and Contrast are the same.To

assure that, please take note of the reading of the luminance meter displayed on

the dialog box, below the level bar indicator.___________________________________

STEP3

At this point, the screen will turn into full red page pattern. Put the Light Probe at

the center of the screen and click OK to perform the calibration. The program will

automatically measure and adjust to the proper value the three RGB primary colors

and then the data will be saved into the monitor memory.

10

White color calibration

Page 18

4 Brightness and color uniformity calibration

About brightness and color uniformity

Your 21 ” Cyberscreen ® monitor has been precisely aligned at the factory to get the

best performances out of the picture tube/electronic drive system combination by

using the most advanced automatic alignment techniques.

However, like all the CRT based display systems, the color reproduction is sensiti

ve to drift during the product lifetime and this can create problems if you are invol

ved in creating color artworks with your computer.

With the LP21 -2 software you can keep your display performances under control

and, when necessary, perform by yourself an uniformity re-calibration which has the

same precision of the alignment we perform at factory.

Use the following procedure to easily determine if your display needs calibration:

NQI E: I he following procedure must be performed only after 30 min. monitor ‘warm

HEL

__________________________________________________________________________

STEP 1

From the Measure menu of the LP21 -2 application window, select Brightness

option. A full white page pattern divided into 25 areas will appear, together with a

dialog box displaying the current Light Probe reading (value is given in both Foot-

Lambert, Fl,.and Candela per Square meter. Nit).

NOTE: before proceeding with SIhP 2, select the color temperaure you want to

calibrate, from the dialog box that appears on the screen.

__________________________

STEP 2

Put the Light Probe to the screen center (area 13) and measure its brightness value

(Nit or FI).

At this point, just put the Light Probe on any area you think to be criticai

and, by comparing the current reading to the reference one taken at the screen cen

ter, you can check the overall brightness uniformity.

As option, you can also check the screen uniformity for each of the Red, Green and

Blue colors.

White uniformity calibration 11

Page 19

If the difference between readings at any point of the screen and the reference cen

ter is found to be greater than 10%, then the display needs to be re-calibrated.

In that case, two different calibration options are avaiiabie:

Local uniformity: this is a quick calibration process; use this option if just one area

of the screen needs to be calibrated.

Global uniformity: this is the complete calibration procedure; use this option if seve

ral areas on the screen need calibration.

Calibrating the screen uniformity

NOTE: before you attempt to calibrate the screen uniformity, your system needs to

be ‘warmed up’. Do not caiibrate the display unless it has been operating for at least

30 min.

Local uniformity

STEP 1

From the uniformity menu of the 21XLP -2 appiication window select Execute

Local Uniformity.

The screen will turn into a white pattern divided into 25 areas, a dialog box will

appear on the screen and you will be prompted to insert the area number you wish

to calibrate. When done, click OK to continue.

STEP 2

The screen will turn into a full white page; put the Light Probe at the center of the

screen and click OK.

Now the screen will turn into full red, full green and full blue.

Next, you will be prompted to lean the Light Probe on the area to be calibrated.

When done, just click OK and the program will adjust that point to the same value

as measured at the screen center, designated as reference point. This procedure

will be executed for the three RGB primary colors;

NOTE: During calibration you may see that the screen is ‘flashing’. This is simply

due to the high updating speed of the correction system.

The program will then repeat the above described operation for the green and blue

colors.

_________________________

12 White uniformity calibration

Page 20

When calibration has been completed, you will be asked to save the calibration

results: if you choose Cancel, the calibration will be discarded; if you want to save

just click OK and then assign a name to the new correction file (default extension is

.BRG).

Global uniformity

STEP 1

From the uniformity menu of the 21XLP -2 application window select Execute

Global Uniformity.

The screen will turn into a full red page pattern. Put the Light Probe at the center of

the screen and click OK.

At this point, the program will start increasing/decreasing step by step the correc

tion value for the red gun and for each value it will measure the light output respon

se. The purpose of this operation is to obtain a correlation between light output and

correction increment.

ImOtE: During measurements you may notice ‘flashing’ on the screen. This is sim

ply due to the high updating speed of the correction system._________________________

The program will then repeat the above described operation for the green and blue

guns.

STEP 2

After verifying the light output response for each of the RGB guns, the screen will

turn into a full white page again. Put the Light Probe at the screen center and click

OK; the program will measure the absolute value at this point and will keep it as a

target value for the calibration.

STEPS

Next, awhite page pattern divided into 25 areas will appear and you will be promp

ted step by step to put the Light Probe on the whole screen area, starting from Area

1 to Area 25.

STEP 5

When calibration has been completed, you will be asked to save the calibration

results: if you choose cancel, the calibration will be discarded; if you want to save

just click OK and then assign a name to the new correction file (default extension is

.BRS) .

White uniformity calibration 13

Page 21

Loading factory presets and user’s correction tables

The factory data of your monitor have been saved on hard disk during the 21XLP 2 software installation; to recall the original monitor uniformity correction table, just

select Restore factory data from the Uolformity menu of the 21XLP-2 appli

cation.

With the Get user data selection of the uniformity menu, you can down load

to the monitor any of the calibration tables you have previously saved on the disk.

14

White uniformity calibration

Page 22

5 Convergence adjustment

About convergence

Even though the purpose of the 21XLP -2 Light Probe is to measure and calibrate

colors, the software furnished with it allows you to get full control of the DDA cx3r-

rection system of your Brilliance 201CS display, including the digital convergence

correction section.

As already discussed in Chapter 1, the DDA correction system works by dividing the

screen into a 16x16 matrix and with the ability of controlling the beam position for

each of the resulting 256 areas. By using the Convergence option of the 21XLP 2 application software, you can refine by yourself the convergence virtually at any

point of the screen and then save your adjustment in the monitor memory.

As a matter of fact, convergence of your monitor has been already set for the best

performances in our factory and should not require any further adjustment, being a

parameter that normally does not show drifts due to picture tube aging.

However, you can check the performances of your monitor by activating the Test

pattern option, available from the Convergence pop up menu of the 21XLP -2

application.

NÖTE: Convergence check should be performed only after 30 min. monitor ‘warm

_______________________________________________________________

First, a Red-Green-Blue crosshatch pattern will be displayed; if you click the OK but

ton in the small dialog box then a White crosshatch will be displayed. Click OK again

and the last pattern, a Magenta (red + blue) crosshatch, will appear.

All of them are suitable for evaluating the convergence of your display; if you notice

some areas where performance could be improved, then proceed with the conver

gence adjustment.

Convergence adjustment 15

Page 23

Adjusting the convergence

NOTE: before you attempt to adjust the convergence, your system needs to be ‘war

med up’. Do not calibrate the display unless it has been operating for at least 30 min.

NOTE: every time you run the 21XLP -2 application, the program will be searching

for the Light Probe unit. For this reason, even if the Light Probe will not be used

during convergence adjustment it must remain connected to the system.

____________

__

STEP 1

From the 21XLP -2 application window, select Execute calibration from the

Convergence pop up menu. A dialog box will appear indicating saving present

values, while the program is saving the current monitor configuration.

STEP 2

Global convergence adjustment.

NOTE: Global convergence is provided tor screen center adjustment. It you do not

notice convergence errors in this area, just click OK to proceed with next step.

A Red-Blue crosshatch pattern will be displayed at the center of the screen, together

with a dialog box where all the adjustment options for this step are listed.

Two options are available, for both the horizontal and vertical lines of the crosshat

ch:

(Hor/Ver) R,B

This option adjusts the relative position of the Red and Blue beams so that they can

converge each other. In most cases, once you have assured the convergence of

Red and Blue beams, the convergence with the Green beam is automatically achie

ved since, due to the gun design, this beam is the central one.

However, due to small gun imperfections, in some cases even if the RB convergen

ce is adjusted, the Green beam can still be resolved as a single color. If that is the

case, you may use the next adjustment option.

(Hor/Ver) G,M

This option adjusts the position of the Green beam with respect to the position of

the Red and Blue beams together (the combination of which generates the Magenta

16

Convergence adjustment

Page 24

color).

Use this adjustment if, after performing the R,B adjustment, the Green beam can

still be perceived as a single color.

NÖTE: the Global convergence adjustment behavior reflects the so called ‘static

convergence’ adjustment as available on some computer displays. Although this

option is provided to adjust convergence errors at the screen center, remember that

any change in beam positions made with this option will change the beam positions

for the whole screen area.________________________________________________

When your adjustment is complete, click OK to continue.

STEP3

Local Convergence adjustment

A Green-Magenta crosshatch pattern will be displayed, together with a dialog box

where all the adjustment options for this step are listed.

This adjustment step, by using the same options as described in the step 2

(Red to Blue and Green to Magenta adjustments), allows you to correct the misconvergence individually at any point of the screen.

The green box identifies the area where the correction will take place; use the

tJt)/Down and Left/Right buttons to move the adjustment area to the point you

wish to correct, then act on ’+’ and buttons to adjust the convergence.

In addition to the single point adjustment (default), if you select the Row adjust

ment option the correction will apply horizontally for the whole area prior to and fol

lowing the green adjustment box.

If you select the column adjustment option, the correction will take place vertically

for the whole area prior to and following the green box.

When done, click OK to terminate the convergence adjustment.

STEP 4

When calibration has been completed, you will be asked to save the results of your

adjustment: if you choose Cancel, the calibration will be discarded; if you want to

save just click OK and then assign a name to the new correction file (default exten

sion is .CNV).

Convergence adjustment

17

Page 25

Loading factory presets and user’s correction tabies

The factory data of your monitor have been saved on hard disk during the 21XLP 2 software instaliation; to recaii the original monitor uniformity correction table, just

select

Restore factory data from the Convergence menu of the 21XLP -2

application.

With the Get user data selection of the Convergence menu, yOU can down load

to the monitor any of the adjustment tables you have previously saved on the disk.

18

Convergence adjustment

Page 26

6 Cleaning and maintenance

After a calibration process, the rubber cup of the Light Probe may leave circular

prints on the monitor screen.

To clean these rings, first shut down your computer and turn off the power to the

monitor.

Moisten a lint-free cloth with a diluted household glass cleaner and then use the

cloth to wipe the monitor screen.

The same cieaning can be used also for the rubber cup of the Light Probe.

fcALlTiONl: do not spray glass cleaner directly onto the screen. It may drip down

below the plastic case and damage circuitry within the monitor._______________________

Due to the very small power usage of the LP21 -2 Light Probe circuitry, you do not

need to disconnect it from the system after the calibration of your display.

However, if you plan not to use the device for a long period of time we suggest to

have it removed from the system and safely stored in its original packing.

Remember that the LP21 -2 Light Probe contains highiy sophisticated and delicate

circuits: use common sense when handiing it.

Cleaning and maintenance 19

Page 27

What’s behind

This last section of the User’s guide introduces you to the theory of color perception

and describes how your monitor can display color images.

It briefly explains also the limitations of a traditional CRT display system and the

innovations of the Cyberscreen ® technology.

Color basics

Surprisingly, color as such does not exist in nature.

What happens is that human eye is sensitive to different frequencies of the

Electromagnetic Radiation which we call light.

The fact that light is the source of color was demonstrated by Isaac Newton in 1666

with the so called ‘prism experiment’: he experienced that a beam of sunlight pas

sing through a glass prism was broken up into a rainbow made of all the visible

colors. Further to that, he passed the resulting rainbow of light through a second

prism and found that the array of colors was reassembled into the original white light

beam.

As a conclusion of the experiment, it was demonstrated that white light is made up

of and can be reproduced by a mix of colored lights.

According to the color theory fundamentals concerning transmitted light, just the

Red, Green and Blue colors are required to create white light, and it is demonstra

ted that by varying the intensity of these colors the whole color spectrum can be

reproduced.

For this reason, Red, Green and Blue color are defined as Additive Primary Colors.

20

Appendix A

Page 28

How displays create colors

A color display, being a CRT based device, acts itself as a light source and the way

how it creates colors is based on the aforesaid Additive principle.

The inside surface of the CRT screen is coated with three special type of phosphors

that, when struck by high energy electrons, glow with particular frequencies of light

perceived respectively as the Red, Green and Blue primary colors.

The phosphors are arranged in groups of 3, called triads, with each phosphor being

driven by one of the three RGB guns. A perforate metal shield known as shadow

mask acts as a filter to separate the three electron beams so that they can strike the

designated phosphors only.

As the three electron beams scan each video line, they pass in turn through each

slot in the shadow mask and impinge on their respective phosphor in the associa

ted triad.

The perceived color is thus a combination of the three primary colors depending on

the relative magnitude of the three RGB beam currents; if all the guns fire at full

intensity then white light is perceived; if just one gun hits its corresponding phosphor

then a single color is perceived; if none of the dots are hit the triad remains biack.

The combination of these glowing phosphors, addressed by the video input signal

coming from your computer, creates the color images you see on the screen.

About color uniformity

Because of traditional limitations in CRT technology, most large screen color moni

tors show uneven brightness over the total screen area.

For example, the fact itself that CRT glass thickness is increased at the screen cor

ners to improve mechanical resistance or a non uniformity in shadow mask hole

sizes will cause a lack of brightness in these areas, while a non uniformity in pho

sphors displacement or sensitivity will show some areas where color characteristics

are different from others.

When some areas of the screen are brighter or show different colors than others,

then image quality decreases and ‘real life’ images reproduction cannot be granted

anymore, especially when the monitor is used for creating color artworks electroni

cally.

Appendix A 21

Page 29

The 21” Cyberscreen ® monitor state of the art technology

Your Cyberscreen ® monitor has put a milestone in CRT color display technology.

Thanks to its unique DDA system (Digital Dynamic Adjustment), the drives of the

RGB guns are digitally controlled over the entire screen so that the monitor electro

nics can compensate for the lack of color and brightness uniformity of the picture

tube.

This system divides the screen into a 16x16 matrix (@ 1024*768) and for each of

the resulting 256 areas the RGB drive circuits of the electron guns can be indivi

dually tuned, resulting in an outstanding uniform and precise image.

With the Brilliance 201CS, the whole screen area can be really used as a ‘work

space’for creating professional color works, with an unconditional uniformity in color

and brightness from the center to the boundaries of the screen.

Expressing colors: CIE system

As previously described, by blending the three frequencies of light the eye is sensi

tive to, it is possible to represent any of the rainbow colors.

What happens is that these three signals are sent undecoded to the brain, where

they are mixed and interpreted. In other words. Humans perceive color rather than

‘see’ it.

For that reason, color expressions often means different colors to different people,

and so it is very hard to relate a color to another person and having the other per

son interpret it in the same way we perceive it.

The problem of expressing colors more precisely than with words was first faced in

1931 by the ‘Commission Internationale de L’Eclarage’, that designed the so called

Tristimulus Chart, more simply known as the CIE 1931 Chart.

By means of this chart, the Chromaticity of a color can be broken down in two coor

dinates called X and y, while the Luminance of the color is represented by Y.

In other words, x and y coordinates tell us ‘what color it is’, while the figure Y gives

us the ‘brightness’ of that color.

22

Appendix A

Page 30

The numbers x and y do not have units of measurements; while there are two main

units of measurement of factor Y in use today: ‘Candela per square meter” (Nit) and

‘Foot Lamberts’(FI).

If we consider your Brilliance 201CS monitor, it has three preset RGB white balan

ce adjustments that, according to the CIE xyY system, can be defined as follows:

Preset 1 X = 0,283 y -= 0,298 Y > 28 Foot Lamberts

Preset 2 x - 0,313 y = 0,329 Y > 23 Foot Lamberts

Preset 3 X = 0,332 y = 0,347 Y > 23 Foot Lamberts

Color temperature

According to the Black body radiation theory in physics, an ideal object will glow with

a characteristic color when heated. The color can be calculated mathematically and

it can be shown that as the temperature increases this glow moves from infra red

through dull red, orange, yellow, yellow white and eventually to bluish white.

As the color produced at a given temperature can be precisely predicted, then it is

possible to define white light in terms of color temperature.

The white point color temperature is therefore a measure in Kelvin degrees of ‘how

white’ a white is.

Back to your Brilliance 201 CS, the Preset 1 adjustment corresponds to a color tem

perature of 9300 Kelvin degrees and shows a bluish tint; Preset 2 is set to 6500

Kelvin degrees and has a reddish tint. Preset 3 is set to 5500 Kelvin degrees.

As an additional example, the color temperature of sunlight at noon, when the sun

is shining directly overhead, is approximately 5000 Kelvin degrees.

Appendix A

23

Page 31

The convergence problem

The electron guns in a color CRT are mounted alongside each other and in most

cases they are placed in line.

This is necessary for the shadow mask in fiitering out the eiectron beams on their

way to the front of the screen, so that they can reach the designated phosphor oniy.

The problem with this system is that the offset beams travei along different paths

and may fail to hit the same phosphor triad, as instructed by the computer. This is

caiied convergence error and it is usualiy perceived as a fringing around the dots

on the screen.

in severe cases, a dot or a iine designated to be as ‘white’, may be completely resol

ved into its red, green and blue components.

The problem of convergence is usually more noticeable when the beam approaches

the screen corners, where the beams path lengths offset reach its maximum.

The Cyberscreen ® solution

The convergence problem has been solved in your Brilliance 201CS by using the

same approach as previously described about the screen uniformity.

The built in DDA system divides the screen in a 16x16 matrix and, for each of the

resulting areas, the beams position and so the convergence can be precisely opti

mized.

As a result, all the conventional CRT errors can be cximpensated so that the

displayed image can only be as sharp and precise as you have never seen before.

24 Appendix A

Page 32

B Error messages

If system displays;

2lXliP not connected

It means that the application program is unable to locate the Light Probe unit at the

selected serial port. Check if aii the cabies are properiy connected and if the serial

port you specified is the right one.

Once you have fixed the problem, you need to switch the monitor off and then on

again to recover the error condition.

If system displays:

21XLP not connected

it means that the appiication program has detected a missing connection between

the base unit an the Light Probe unit of the 21XLP -2 Light Probe. Please check the

proper connection of the Light Probe cabie to the base unit.

Once you have fixed the probiem, you need to switch the monitor off and then on

again to recover the error condition.

if system displays:

Monitor not connected

it means that your dispiay does not respond to the caiibration program.

Please check if the sériai port of the monitor and the output port of the 21XLP -2

base unit are properiy connected.

if system displays:

2IXI1P setup error

means that during the Light Probe zero calibration (dark measure) an overfiow con

dition occurred. Please assure that the Light Probe is properiy placed in its base

housing and restart calibration.

Appendix B

25

Page 33

If system displays:

Fatal error - please restart the program

it means that an unrecoverable communication error has occurred during the cali

bration process(e.g. the monitor has been turned off).

Piease restart both the monitor and the calibration program.

If system displays:

Harnlog: the syst^ has detected a configuration error,

sor box does not match

.........

The sen-

it means that the you have mismatched either the Light Probe unit or the base unit

of your caiibration system with a device belonging to a different 21XLP Light Probe

package.

The Light Probe and base unit combination within each calibration package are pre

cisely matched and tuned, for the maximum measurement accuracy.

Please check if both components of your calibration system are belonging to the

same 21XLP -2 Light Probe shipment.

If system displays:

Measure of light not correct

it means that 21XLP Light Probe zerois not properly placed on the screen.

26 Appendix B

Page 34

СлЭ

CD

K>

О

<У)

tV)

00

03

03

*

Printed in itaiy - RevOI/9648

Loading...

Loading...