Page 1

Color Television Chassis

ME7

LC7.2HU

LB

ME7

G_16860_000.eps

200207

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 12

6. Block Diagrams, Test Point Overviews, and

Waveforms

Wiring Diagram 26” & 32” 23

Wiring Diagram 42” 24

Block Diagram Video 25

Block Diagram Audio 26

Block Diagram Control & Clock Signals 27

Test Point Overview SSB (Bottom Side) 28

I2C IC’s Overview 29

Supply Lines Overview 30

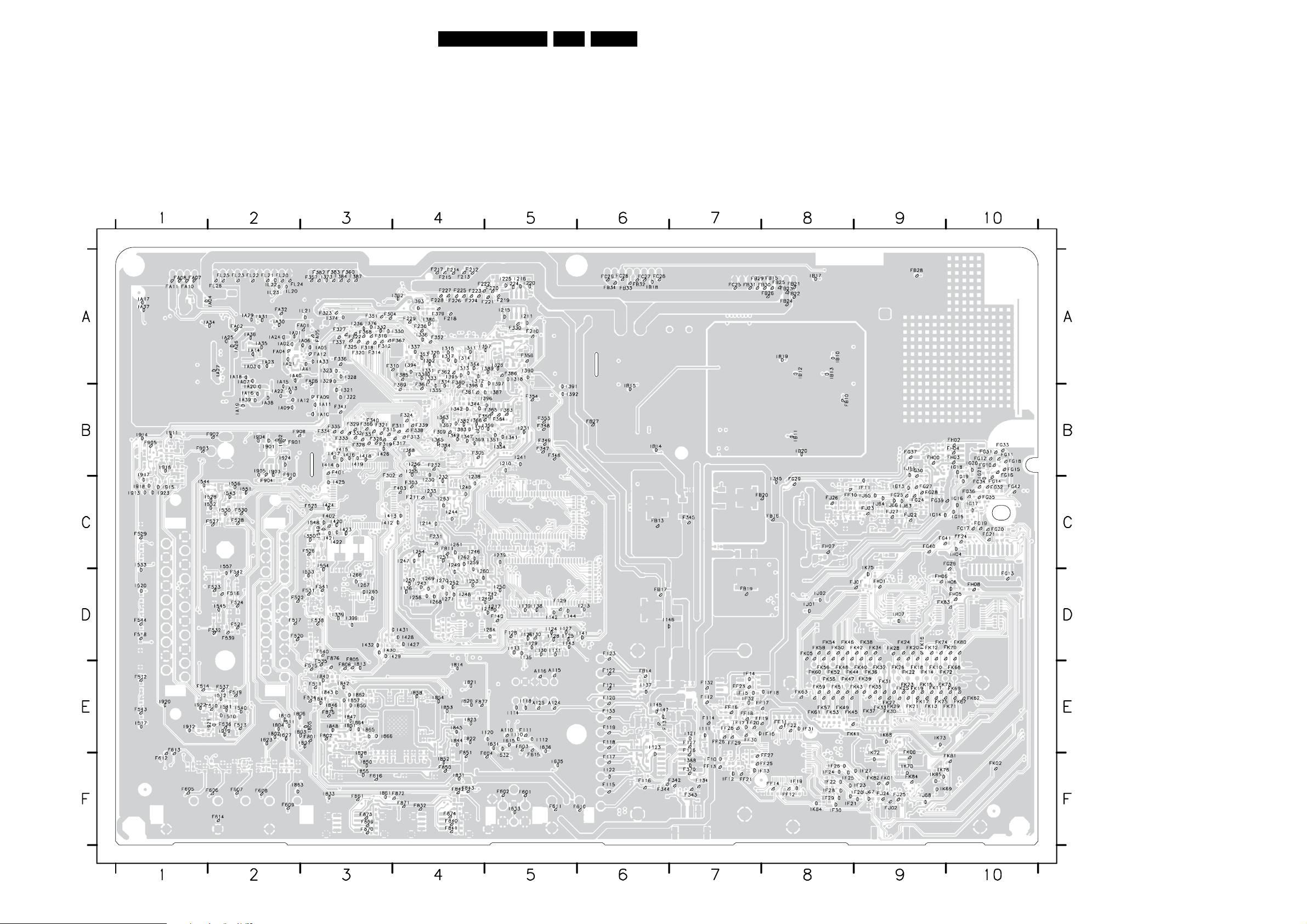

7. Circuit Diagrams and PWB Layouts Diagram PWB

SSB: DC/DC (B02) 31 47-56

SSB: Tuner & Demodulator (B03A) 32 47-56

SSB: DVB - Demodulator (B03B) 33 47-56

SSB: DVB - Common Interface (B03C) 34 47-56

SSB: DVB - Mojo (B03D) 35 47-56

SSB: DVB - Mojo Memory (B03E) 36 47-56

SSB: DVB - Mojo Analog Back End (B03F) 37 47-56

SSB: Micro Processor (B04A) 38 47-56

SSB: Video Processor (B04B) 39 47-56

SSB: PNX2015: Audio Processor (B04C) 40 47-56

SSB: YPBPR & Rear IO (B06A) 41 47-56

SSB: I/O Scart 1 & 2 (B06B) 42 47-56

SSB: HDMI (B06C) 43 47-56

SSB: Headphone Amp & Muting (B06D) 44 47-56

SSB: Audio (B07) 45 47-56

SSB: SRP List 46 47-56

Keyboard Control Panel (E) 57 58

©

Copyright 2008 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Front IR / LED Panel (J) 59 60

i-Board (HC1) 61 63-64

i-Board (HC2) 62 63-64

System Interface Panel (SI) 65 66

8. Alignments 67

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 74

Abbreviation List 78

IC Data Sheets 81

10. Spare Parts List 86

11. Revision List 91

Published by JH 0861 BU CD Customer Care Printed in the Netherlands Subject to modification EN 3122 785 17700

Page 2

EN 2 LC7.2HU LB1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 32” (82 cm), 16:9

Resolution (H × V pixels) : 1366 × 768

Dyn. contrast ratio : 7500:1

Min. light output (cd/m

Typ. response time (ms) : 8

Viewing angle (H × V degrees) : 178 × 178

Tuning system : PLL

Presets/channels : 125 presets

Tuner bands : VHF, UHF, S, H

TV Color systems : ATSC

Video playback : NTSC

Supported computer formats

(60, 70, 75, 85 Hz) : 640 × 480

Supported video formats (60 Hz) : 640 × 480i - 1fH

2

) : 500

:NTSC

: PAL

: 800 × 600

: 1024 × 768

: 640 × 480p - 2fH

: 1920 × 1080i - 2fH

: 1280 × 720p - 3fH

(terr.: 8VSB)

(cble: unscram. QAM)

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50 / 60

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 90% R.H.

Power consumption (values are indicative)

- Normal operation (W) : ≈ 150

- Stand-by (W) : < 1

Dimensions (W × H × D inch) : 31.7 × 21.5 × 4.4

Weight (lb.) : 32.1

) : 110 - 240

AC

1.1.2 Sound

Sound systems : Stereo

Maximum power (W

):2 × 10

RMS

: Dolby Digital (AC-3)

Page 3

Technical Specifications, Connections, and Chassis Overview

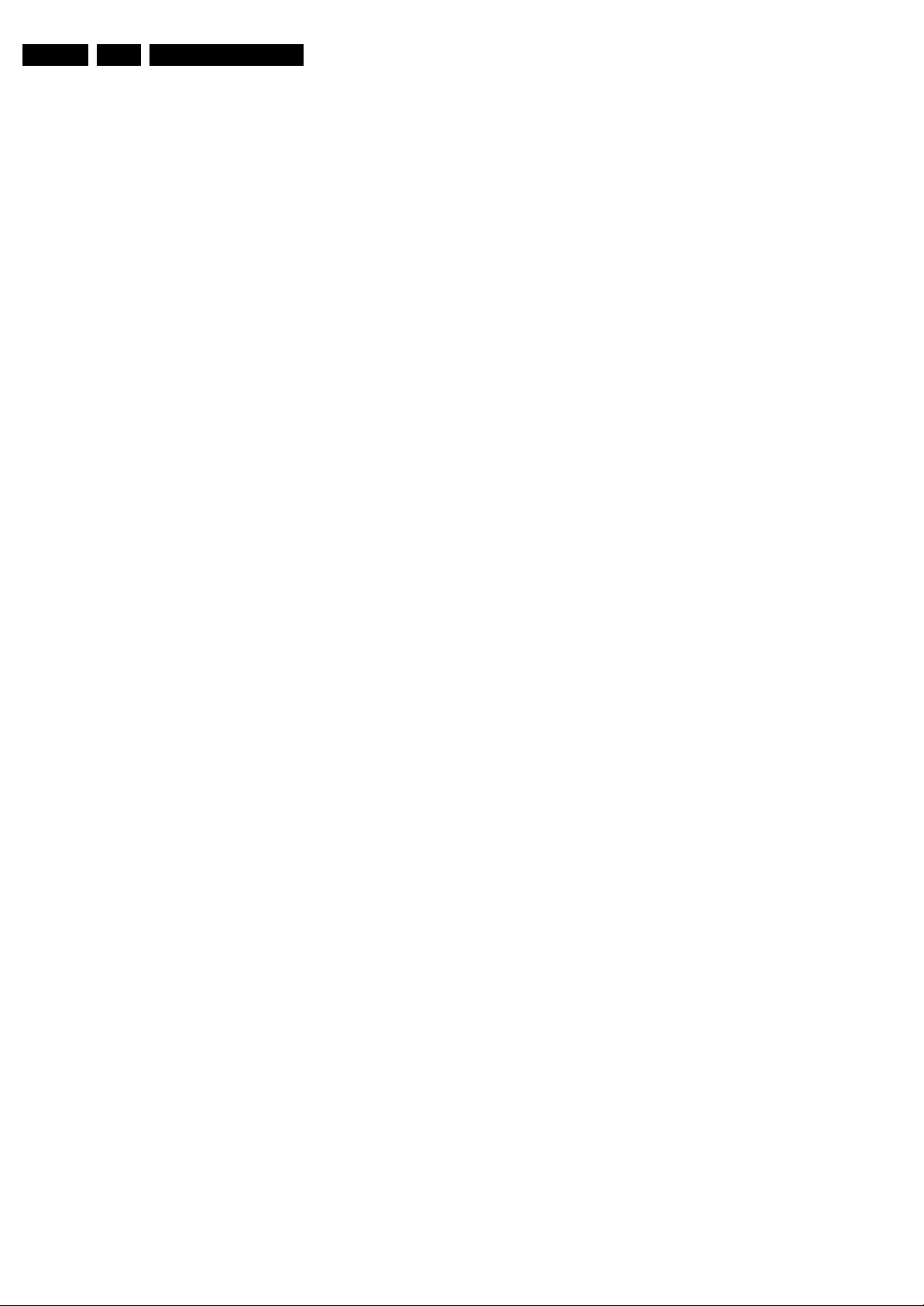

1.2 Connection Overview

EN 3LC7.2HU LB 1.

DATA 1

RJ12

JTAG

Special tool needed

(order via BDS)

VGA IN (D-SUB)

AUDIO OUT

(DIGITAL)

A

AV

DATA 2

RJ45

CVI

8 Ohm

H_16990_027.eps

270707

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Rear Connections (top)

RJ12 DATA1 (HM-Link - In/Out)

1 -LED_in < 0.3 V, active low j

2 -IR_in < 0.3 V, active low j

3 - MODE Vcc j

4 - TV Power Status 4.5 to 5 V: TV “On”

< 0.3 V: TV “Stdby”

High impedance: TV “Off” k

5 - Gnd Gnd H

6 - IR_out Signal k

RJ45 DATA2 (xpress Box - In/Out)

1 - +12V +12V/1W k

2 - Gnd Gnd H

3 - H-sync Signal k

4 - V-sync Signal k

5 - TXD232 Signal

6 - RXD232 Signal

7 - SDA3_IR-OUT Signal k

8 - DCM-POR Signal k

9 - CVBSterr Signal k

10 - Gnd CVBSterr Gnd H

Mini Jack: Speaker - Out

- Loudspeaker 8 ohm ok

Figure 1-1 Side and rear I/O connections

JTAG: Data In - Out

1 - +5 V +5 V power supply k

2 - POR Power On Reset input j

3 - NVM_LOAD NVM load input j

4 - Gnd Gnd H

5 - TDO Data Out Signal k

6 - TDI Test Data In Signal j

7 - TCK Test Clock Signal j

8 - TMS Test Mode Select Signal j

VGA: Video RGB - In

1 - Video Red 0.7 V

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

4-n.c.

5 - Ground Gnd H

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

9-+5V

10 - Ground Sync Gnd H

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

1

5

6

11

10

15

E_06532_002.eps

050404

Figure 1-2 VGA Connector

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

+5 V j

DC

Page 4

EN 4 LC7.2HU LB1.

Technical Specifications, Connections, and Chassis Overview

1.2.2 Rear Connections (bottom)

Aerial - In

- - F-type (US) Coax, 75 ohm D

Service Connector “A” (UART)

1 - UART_TX Transmit k

2 - Ground Gnd H

3 - UART_RX Receive j

Service Connector “C” (ComPair)

1 - SDA-S I

2-SCL-S I

2

C Data (0 - 5 V) jk

2

C Clock (0 - 5 V) j

3 - Ground Gnd H

Cinch: S/PDIF - In

Bk - Coaxial 0.2 - 0.6V

/ 75 ohm jq

PP

AV: Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

AV: S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

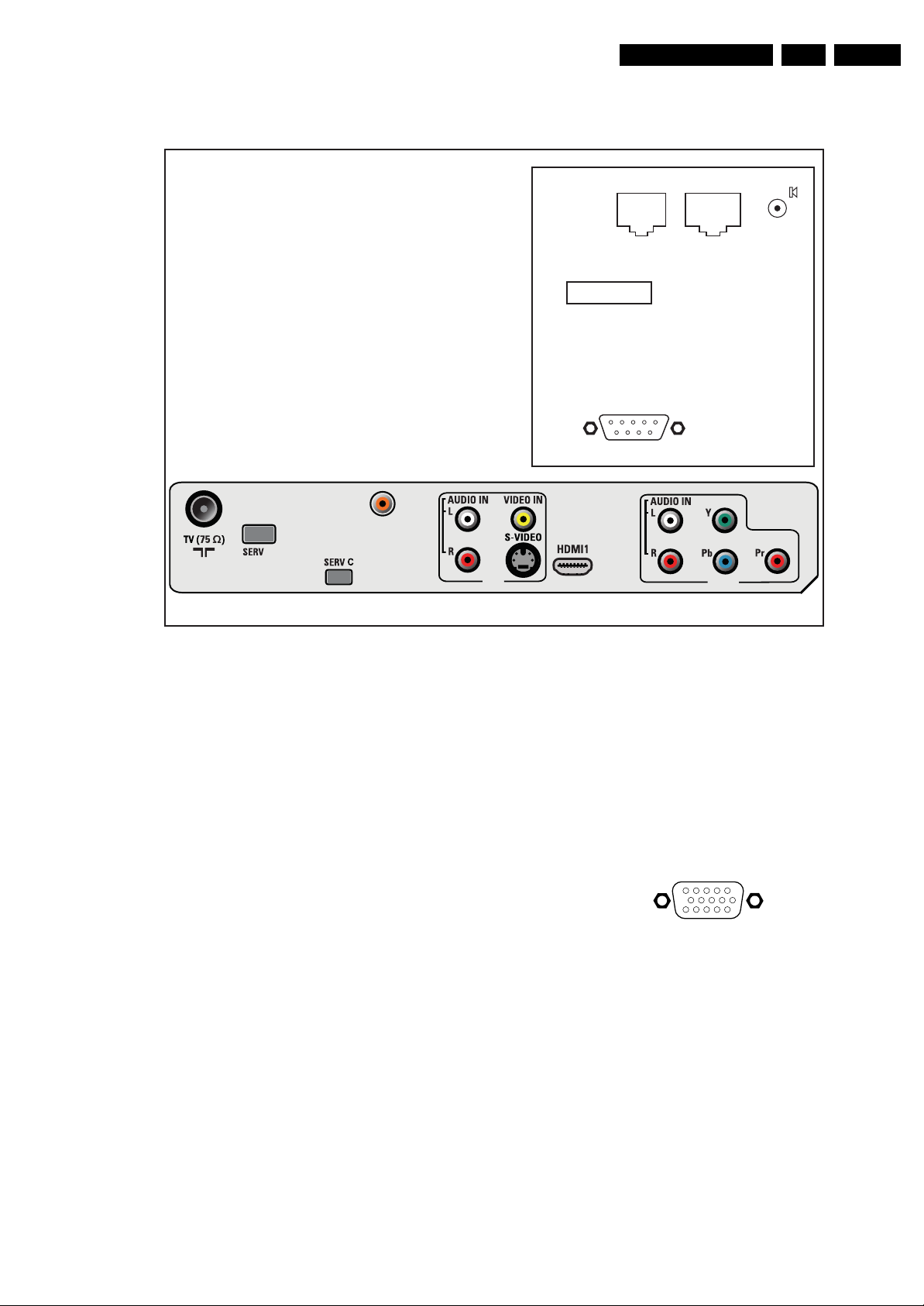

HDMI: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

CVI: Cinch: Audio - In, Video YPbPr - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

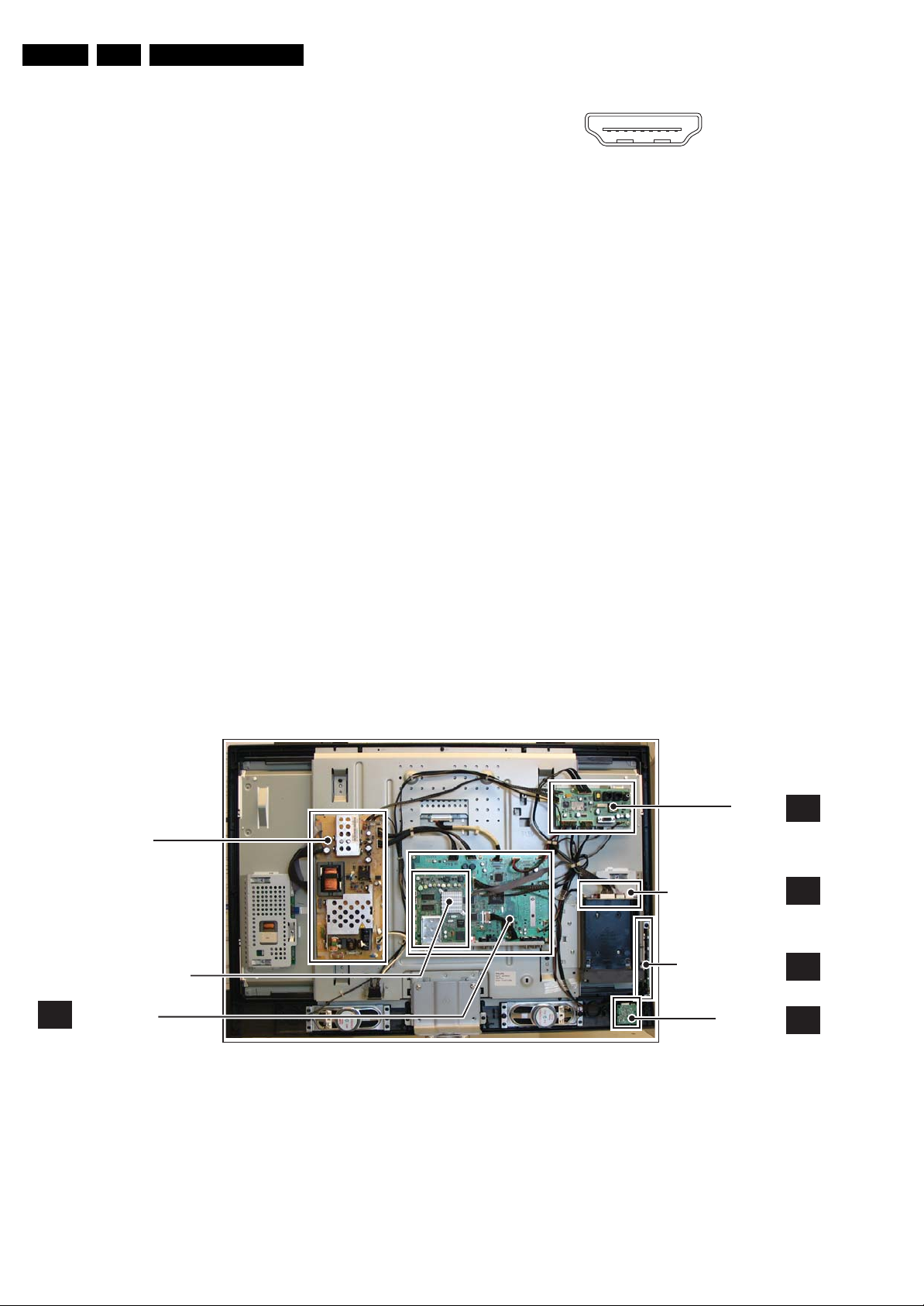

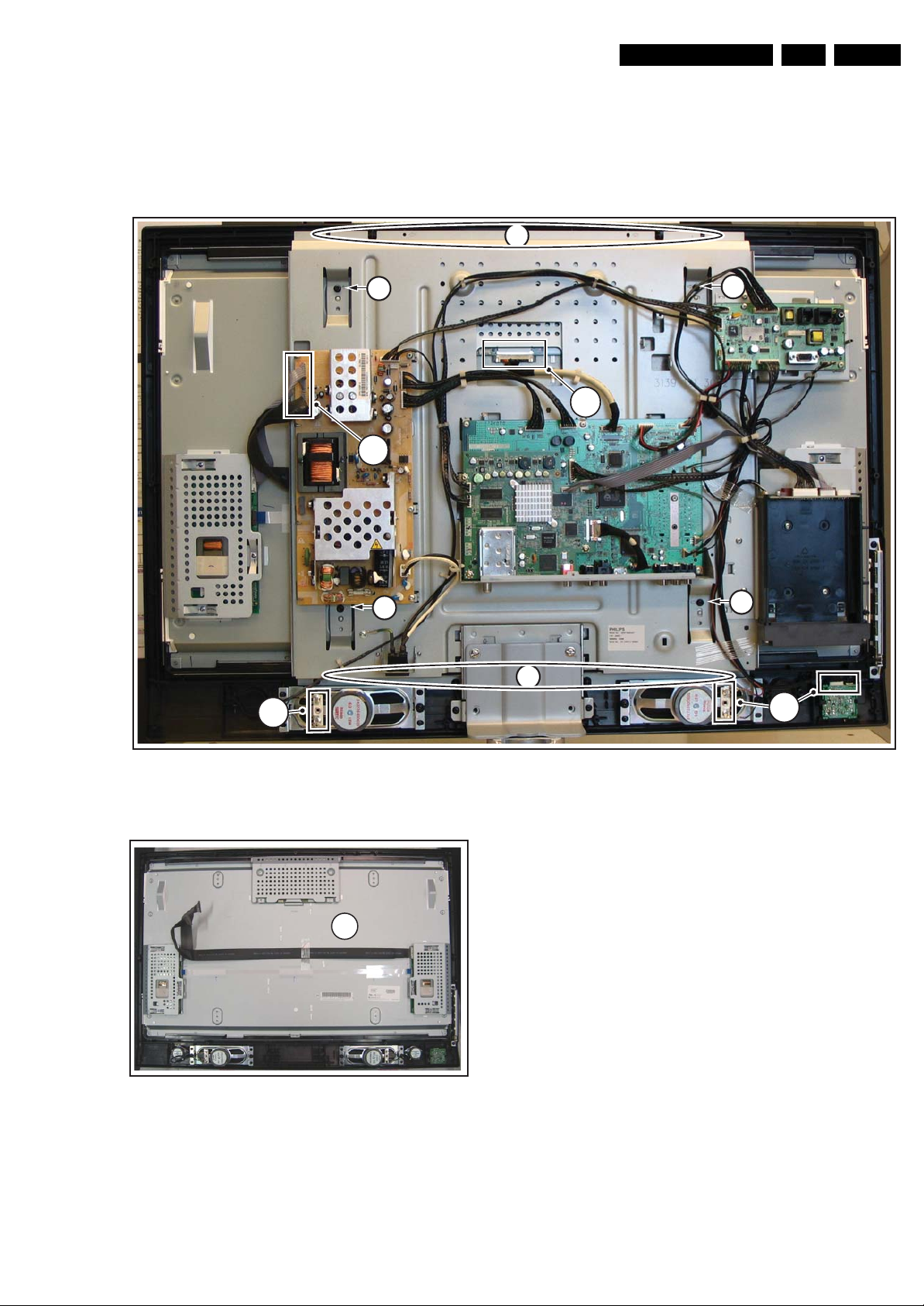

1.3 Chassis Overview

MAIN SUPPLY

AT SC/MPEG-4 PANEL

SMALL SIGNAL

B

BOARD

Figure 1-4 PWB/CBA locations

i-BOARD

SYSTEM INTERFACE

PA NE L

CONTROL PANEL

LED PANEL

H_17700_050.eps

HC

SI

E

J

211207

Page 5

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5LC7.2HU LB 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= × 10

nano-farads (n= × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

-9

), or pico-farads (p= × 10

-12

-6

),

).

Page 6

EN 6 LC7.2HU LB3.

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Directions for Use

MODEL :

PROD.NO:

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

• Always respect voltages. While some may not be

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number (example)

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

BJ3.0E LA

S

E_06532_024.eps

128W

130606

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 7

4. Mechanical Instructions

Mechanical Instructions

EN 7LC7.2HU LB 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging (see figure “Rear cover”).

• Foam bars (created for Service).

• Aluminium service stands (created for Service).

H_16990_026eps

260707

Figure 4-1 Cable dressing

Page 8

EN 8 LC7.2HU LB4.

Mechanical Instructions

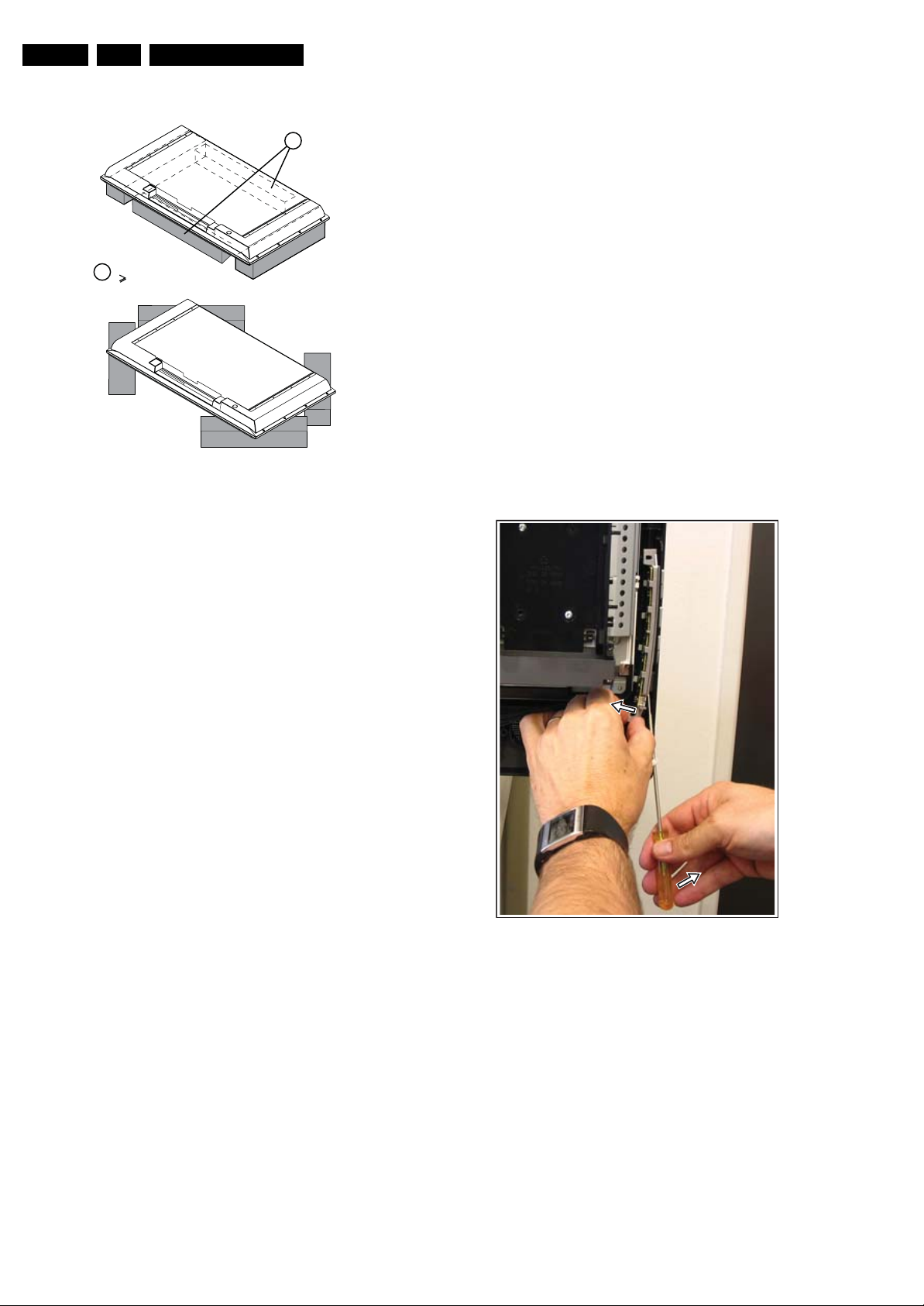

4.2.1 Foam Bars

1

Required for sets

1

42"

E_06532_018.eps

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42” and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

171106

4.3 Assy/Panel Removal

4.3.1 Rear Cover

Warning: Disconnect the AC/mains power cord before you

remove the rear cover.

1. Place the TV set upside down on a table top, using the

foam bars (see part “Service Position”).

2. Remove rear cover screws and the stand (if mounted).

3. Remove rear cover.

4.3.2 Keyboard Control Panel

1. Refer to next figure.

2. Remove the T10 parker screws.

3. Unplug connector.

4. Remove the unit. Note: as the unit is “secured” by bosses

located on the front cabinet, it can be difficult to remove the

unit. Therefore, it is advised to use a long thin screwdriver,

insert it vertically between the control knobs and the front

cabinet, and use it as a lever (see arrows) while pulling the

unit from the cabinet. You will here some “clicks” during

removal.

5. Release clips and remove the board.

When defective, replace the whole unit.

H_16990_051.eps

Figure 4-3 Keyboard control panel

270707

Page 9

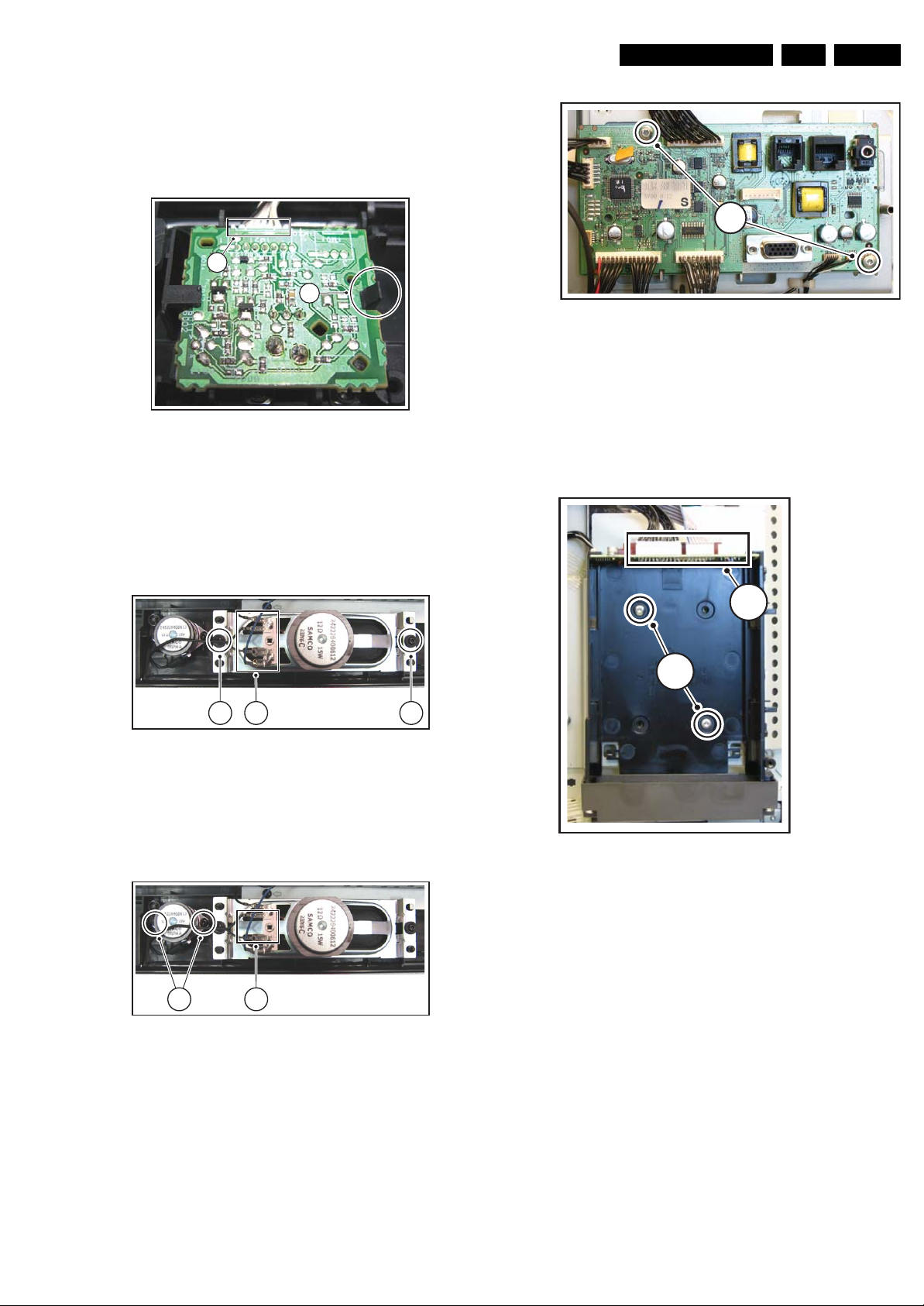

4.3.3 IR/LED Panel

1. Refer to next figure.

2. Unplug connector(s) [1].

3. Release clip [2] and remove the board.

When defective, replace the whole unit.

1

Mechanical Instructions

EN 9LC7.2HU LB 4.

21

4.3.4 Speakers

Mid-range Speakers

1. Refer to next figure.

2. Unplug connectors [1].

3. Remove screws [2].

2

G_16850_009.eps

110107

Figure 4-4 IR/LED panel

2 1 2

G_16850_010.eps

H_16990_031.eps

270707

Figure 4-7 i-Board

4.3.6 Integrated Card Slot (if present)

1. Refer to next figure.

2. Disconnect all cables [1] from the board.

3. Remove the fixation screws [2].

4. Take out the module.

1

2

110107

Figure 4-5 Mid-range speakers

Tweeters

1. Refer to next figure.

2. Unplug connectors [1].

3. Remove screws [2].

2 1

Figure 4-6 Tweeters

4.3.5 i-Board

1. Refer to next figure.

2. Disconnect all cables from the i-Board.

3. Remove the fixation screws [1].

4. Take out the i-Board.

G_16850_011.eps

110107

H_16990_032.eps

270707

Figure 4-8 Integrated Card Slot

Page 10

EN 10 LC7.2HU LB4.

s

7

s

7

Mechanical Instructions

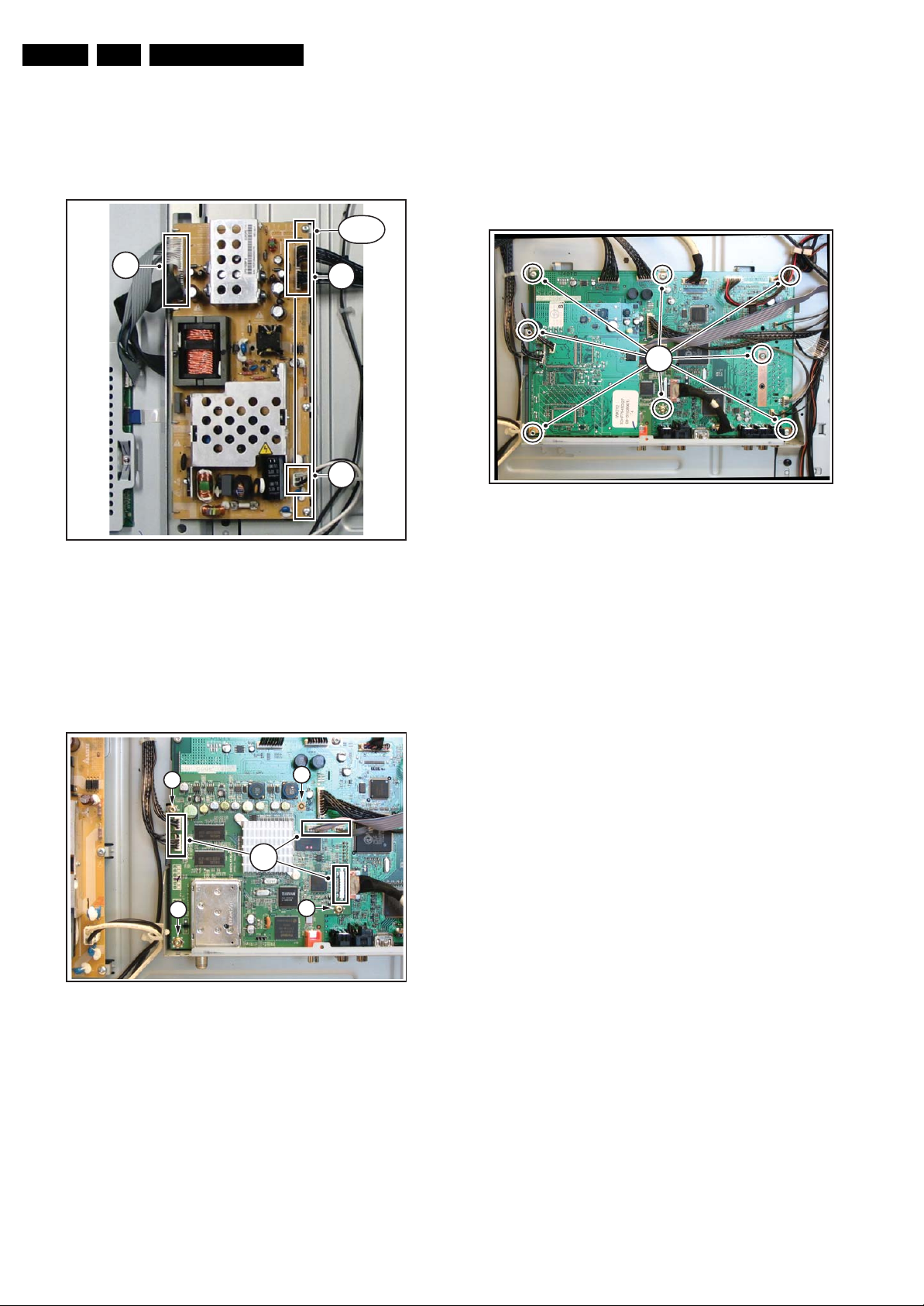

4.3.7 Main Supply Panel

1. Refer to next figure.

2. Unplug cables [a].

3. Remove the fixation screws [b].

4. Take the board out (it hinges at the left side).

a

b (3×)

a

a

G_16860_065.ep

01020

4.3.9 Small Signal Board (SSB)

1. Refer to next figure.

2. Disconnect all cables from the SSB.

3. Remove the screws [1] that hold the SSB.

4. Remove the screws that hold the CINCH and HDMI

connectors at the connector panel.

5. Lift the SSB from the set.

21

Figure 4-11 SSB removal

H_16990_030.eps

270707

Figure 4-9 Main supply panel

4.3.8 ATSC-MPEG-4 panel

1. Refer to next figure.

2. Disconnect all cables [1] on the SSB.

3. Remove the screws [2] that hold the ATSC-MPEG4 panel.

4. Lift the panel from the set.

2

2

1

2

2

Figure 4-10 ATSC-MPEG-4 panel removal

H_16990_033.ep

27070

Page 11

Mechanical Instructions

EN 11LC7.2HU LB 4.

4.3.10 LCD Panel

1. Refer to next figure(s).

2. Unplug the connectors on the Main Supply Panel, the LED

& IR board and the connectors from the loudspeakers [1].

3. Do NOT forget to unplug the LVDS connector [2] from the

SSB. Important: Be careful, as this is a fragile connector!

4. Remove the screw that holds the Side I/O module bracket.

1

5. Remove screws[3] of the central sub-frame.

6. Remove LCD panel fixation screws [4] and lift the complete

central sub-frame from the set (incl. the PSU, SSB, and

Side I/O boards and wiring).

7. Lift the LCD panel [7] from the front cabinet.

3

4

4

2

4

4

3

1

Figure 4-12 LCD panel [1/2]

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

7

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure “Cable

dressing”.

• Pay special attention not to damage the EMC foams.

Ensure that EMC foams are mounted correctly (one is

located above the LVDS connector on the display, between

the LCD display and the metal sub-frame).

1

H_16990_029.eps

270707

Figure 4-13 LCD panel 32” [2/2]

G_16850_015.eps

110107

Page 12

EN 12 LC7.2HU LB5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Hotel Mode

5.3 Service Modes

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Software Upgrading

5.8 Fault Finding and Repair Tips

5.1 Test Points

In the chassis schematics and layout overviews, the test points

(Fxxx) are mentioned. In the schematics, test points are

indicated with a rectangular box around “Fxxx” or “Ixxx”, in the

layout overviews with a “half-moon” sign.

As most signals are digital, it will be difficult to measure

waveforms with a standard oscilloscope. Several key ICs are

capable of generating test patterns, which can be controlled via

ComPair. In this way it is possible to determine which part is

defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Color bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Hotel Mode

Before the service modes can be activated, the set needs to be

switched into normal consumer mode (MTV-Mode) first. Use

an iTV setup remote control (type: RC2753/01, 12nc: 3139 228

88782) to key in the code ‘024995’ directly followed by the

MENU button. The text messages “TV Is Now In MTV Mode”

and “Please Do A Cold Start!” appears on the screen.

Disconnect the set for a few seconds from the mains supply,

reconnect the set to the mains supply again. The set is now in

the normal consumer mode (MTV-Mode).

After repair, place the set into hotel mode (iTV-Mode) again.

Key-in the same code on the remote control as described

above. The text message “TV Is Now In ITV Mode” appears.

A cold start must be performed as described above. The set is

now in the hotel mode (iTV-Mode) again.

5.3 Service Modes

Important: Only when the set is in normal consumer mode

(MTV Mode), all service modes can be accessed.

The Service Mode feature is split into four parts:

• Service Default Mode (SDM).

• Service Alignment Mode (SAM).

• Customer Service Mode (CSM).

• Computer Aided Repair Mode (ComPair).

SDM and SAM offer features, which can be used by the Service

engineer to repair/align a TV set. Some features are:

• A pre-defined situation to ensure measurements can be

made under uniform conditions (SDM).

• Activates the blinking LED procedure for error identification

when no picture is available (SDM).

• The possibility to overrule software protections when SDM

was entered via the Service pins.

• Make alignments (e.g. white tone), (de)select options,

enter options codes, reset the error buffer (SAM).

• Display information (“SDM” or “SAM” indication in upper

right corner of screen, error buffer, software version,

operating hours, options and option codes, sub menus).

• Fixed audio and video settings.

The CSM is a Service Mode that can be enabled by the

consumer. The CSM displays diagnosis information, which the

customer can forward to the dealer or call centre. In CSM

mode, “CSM”, is displayed in the top right corner of the screen.

The information provided and the purpose of CSM is to:

• Increase the home repair hit rate.

• Decrease the number of nuisance calls.

• Solved customers' problem without home visit.

ComPair Mode is used for communication between a computer

and a TV on I2C /UART level and can be used by a Service

engineer to quickly diagnose the TV set by reading out error

codes, read and write in NVMs, communicate with ICs and the

uP (PWM, registers, etc.), and by making use of a fault finding

database. It will also be possible to up and download the

software of the TV set via I2C with help of ComPair. To do this,

ComPair has to be connected to the TV set via the ComPair

connector, which will be accessible through the rear of the set

(without removing the rear cover).

5.3.1 General

Some items are applicable to all Service Modes or are general.

These are listed below.

Life Timer

During the life time cycle of the TV set, a timer is kept. It counts

the normal operation hours (not the Stand-by hours). The

actual value of the timer is displayed in SDM and CSM in a

decimal value. Every two soft-resets increase the hour by +1.

Software Identification, Version, and Cluster

The software ID, version, and cluster will be shown in the main

menu display of SDM, SAM, and CSM.

The screen will show: “AAAABCD X.YY”, where:

• AAAA is the chassis name: LC71 for analogue range (nonDVB/ATSC), LC72 for digital range (DVB/ATSC).

• B is the region indication: E= Europe, A= AP/China, U=

NAFTA, L= LATAM.

• C is the display indication: L= LCD, P= Plasma.

• D is the language/feature indication: 1= standard, H=

1080p full HD.

• X is the main version number: this is updated with a major

change of specification (incompatible with the previous

software version). Numbering will go from 1 - 9 and A - Z.

– If the main version number changes, the new version

number is written in the NVM.

– If the main version number changes, the default

settings are loaded.

• YY is the sub version number: this is updated with a minor

change (backwards compatible with the previous versions)

Numbering will go from 00 - 99.

– If the sub version number changes, the new version

number is written in the NVM.

– If the NVM is fresh, the software identification, version,

and cluster will be written to NVM.

Display Option Code Selection

When, after an SSB or display exchange, the display option

code is not set properly, it will result in a TV with “no display”.

Therefore, it is required to set this display option code after

such a repair.

To do so, press the following key sequence on a standard RC

transmitter: “062598” directly

“xxx”, where “xxx” is a 3 digit decimal value of the panel type:

see column “Panel Code” in table “Option and display code

overview” (chapter 8), or see sticker on the side/bottom of the

cabinet. When the value is accepted and stored in NVM, the set

followed by MENU and

Page 13

Service Modes, Error Codes, and Fault Finding

s

7

EN 13LC7.2HU LB 5.

will switch to Stand-by, to indicate that the process has been

completed.

Display Option

Code

39mm

040

PHILIPS

MODEL:

32PF9968/10

27mm

PROD.SERIAL NO:

AG 1A0620 000001

(CTN Sticker)

E_06532_038.eps

Figure 5-1 Location of Display Option Code sticker

During this algorithm, the NVM-content must be filtered,

because several items in the NVM are TV-related and not SSBrelated (e.g. Model and Prod. S/N). Therefore, “Model” and

“Prod. S/N” data is changed into “See Type Plate”.

In case a call centre or consumer reads “See Type Plate” in

CSM mode, he needs to look to the side/bottom sticker to

identify the set, for further actions.

5.3.2 Service Default Mode (SDM)

Purpose

Set the TV in SDM mode in order to be able to:

• Create a pre-defined setting for measurements to be

made.

• Override software protections.

• Start the blinking LED procedure.

• Read the error buffer.

• Check the life timer.

Specifications

290107

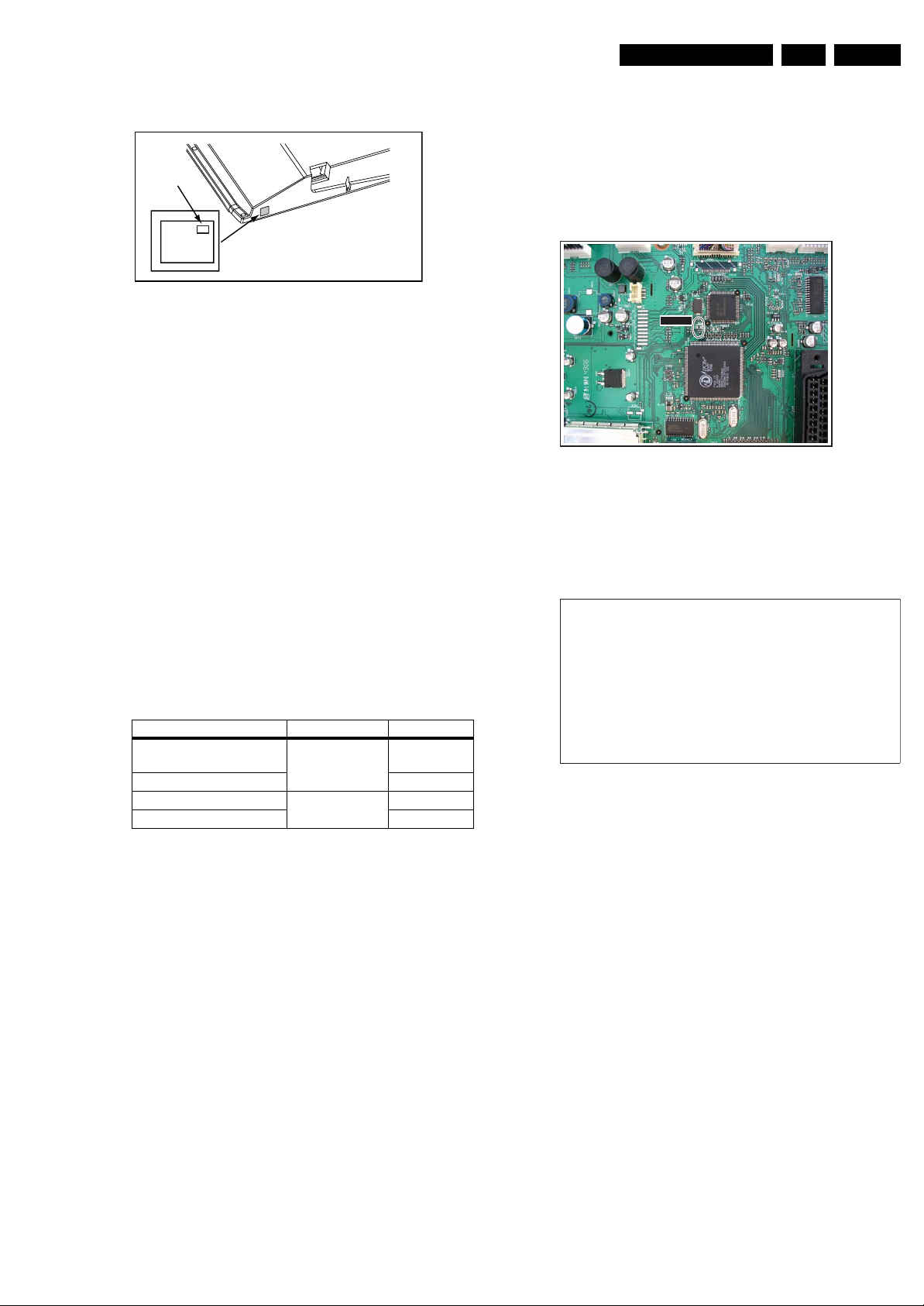

• Short one of the “Service” jumpers on the TV board during

cold start (see Figures “Service jumper”). Then press the

mains button (remove the short after start-up).

Caution: Activating SDM by shorting “Service” jumpers will

override the DC speaker protection (error 1), the General

I2C error (error 4), and the Trident video processor error

(error 5). When doing this, the service-technician must

know exactly what he is doing, as it could damage the

television set.

SDMSDM

G_16860_027.eps

260107

Figure 5-2 Service jumper (SSB component side)

On Screen Menu

After activating SDM, the following screen is visible, with SDM

in the upper right corner of the screen to indicate that the

television is in Service Default Mode.

HHHHH A A A A B C D- X . Y Y

ERR XX XX XX XX XX

O P X X X X X X X X X X X X X X X X X X

SDM

Table 5-1 SDM default settings

Region Freq. (MHz) Default syst.

Europe (except France),

475.25 PAL B/G

AP-PAL/-Multi

France SECAM L

NAFTA, AP-NTSC 61.25 (channel 3) NTSC M

LATAM PAL M

• Set linear video and audio settings to 50%, but volume to

25%. Stored user settings are not affected.

• All service-unfriendly modes (if present) are disabled, since

they interfere with diagnosing/repairing a set. These

service unfriendly modes are:

– (Sleep) timer.

– Blue mute/Wall paper.

– Auto switch “off” (when there is no “ident” signal).

– Hotel or hospital mode.

– Child lock or parental lock (manual or via V-chip).

– Skipping, blanking of “Not favorite”, “Skipped” or

“Locked” presets/channels.

– Automatic storing of Personal Preset or Last Status

settings.

– Automatic user menu time-out (menu switches back/

OFF automatically.

– Auto Volume levelling (AVL).

How to Activate

To activate SDM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU button

(do not allow the display to time out between entries while

keying the sequence).

G_16860_030.ep

26010

Figure 5-3 SDM menu

Menu explanation:

• HHHHH: Are the operating hours (in decimal).

• AAAABCD-X.YY: See paragraph “Service Modes” ->

“General” -> “Software Identification, Version, and Cluster”

for the SW name definition.

• SDM: The character “SDM” to indicate that the TV set is in

Service mode.

• ERR: Shows all errors detected since the last time the

buffer was erased. Five errors possible.

• OP: Used to read-out the option bytes. See “Options” in the

Alignments section for a detailed description. Seven codes

are possible.

How to Navigate

As this mode is read only, there is not much to navigate. To

switch to other modes, use one of the following methods:

• Command MENU from the user remote will enter the

normal user menu (brightness, contrast, color, etc...) with

“SDM” OSD remaining, and pressing MENU key again will

return to the last status of SDM again.

• To prevent the OSD from interfering with measurements in

SDM, command “OSD” or “i+” (“STATUS” or “INFO” for

NAFTA and LATAM) from the user remote will toggle the

OSD “on/off” with “SDM” OSD remaining always “on”.

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the OSD/

STATUS/INFO/i+ button to switch to SAM (do not allow the

Page 14

EN 14 LC7.2HU LB5.

Service Modes, Error Codes, and Fault Finding

display to time out between entries while keying the

sequence).

How to Exit

Switch the set to STANDBY by pressing the mains button on

the remote control transmitter or on the television set.

If you switch the television set “off” by removing the mains (i.e.,

unplugging the television), the television set will remain in SDM

when mains is re-applied, and the error buffer is not cleared.

The error buffer will only be cleared when the “clear” command

is used in the SAM menu.

Note:

• If the TV is switched “off” by a power interrupt while in SDM,

the TV will show up in the last status of SDM menu as soon

as the power is supplied again. The error buffer will not be

cleared.

• In case the set is in Factory mode by accident (with “F”

displayed on screen), by pressing and hold “VOL-” and

“CH-” together should leave Factory mode.

5.3.3 Service Alignment Mode (SAM)

Purpose

• To change option settings.

• To display / clear the error code buffer.

• To perform alignments.

Specifications

• Operation hours counter (maximum five digits displayed).

• Software version, error codes, and option settings display.

• Error buffer clearing.

• Option settings.

• Software alignments (Tuner, White Tone, and Audio).

• NVM Editor.

• ComPair Mode switching.

• Set the screen mode to full screen (all contents on screen

are viewable).

How to Activate

To activate SAM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the OSD/

STATUS/INFO/i+ button (it depends on region which

button is present on the RC). Do not allow the display to

time out between entries while keying the sequence.

• Or via ComPair.

After entering SAM, the following screen is visible, with SAM in

the upper right corner of the screen to indicate that the

television is in Service Alignment Mode.

LLLL L A AAABCD- X. YY

ERR XX XX XX XX XX

O P X X X X X X X X X X X X X X X X X X

C l e a r > Y e s

O p t i o n s >

T u n e r >

R G B A l i g n >

N V M E d i t o r >

C o m p a i r >

S W E V E N T S >

Figure 5-4 SAM menu

Menu explanation:

1. LLLLL. This represents the run timer. The run timer counts

normal operation hours, but does not count Stand-by

hours.

2. AAAABCD-X.YY. See paragraph “Service Modes” ->

“General” -> “Software Identification, Version, and Cluster”

for the SW name definition.

SAM

G_16860_031.eps

260107

3. SAM. Indication of the Service Alignment Mode.

4. ERR (ERRor buffer). Shows all errors detected since the

last time the buffer was erased. Five errors possible.

5. OP (Option Bytes). Used to read-out the option bytes. See

“Options” in the Alignments section for a detailed

description. Seven codes are possible.

6. Clear. Erases the contents of the error buffer. Select the

CLEAR menu item and press the MENU RIGHT key. The

content of the error buffer is cleared.

7. Options. Used to set the option bits. See “Options” in the

“Alignments” chapter for a detailed description.

8. Tuner. Used to align the tuner. See “Tuner” in the

“Alignments” chapter for a detailed description.

9. RGB Align. Used to align the White Tone. See “White

Tone” in the “Alignments” chapter for a detailed

description.

10. NVM Editor. Can be used to change the NVM data in the

television set. See also paragraph “Fault Finding and

Repair Tips” further on.

11. ComPaIr.

Can be used to switch the television to “In

Application Programming” mode (IAP), for software

uploading via ComPair. Read paragraph “Service Tools” > “ComPair”. Caution: When this mode is selected without

ComPair connected, the TV will be blocked. Remove the

AC power to reset the TV.

12. SW Events. Only to be used by development to monitor

SW behavior during stress test.

How to Navigate

• In the SAM menu, select menu items with the MENU UP/

DOWN keys on the remote control transmitter. The

selected item will be indicated. When not all menu items fit

on the screen, use the MENU UP/DOWN keys to display

the next / previous menu items.

• With the MENU LEFT/RIGHT keys, it is possible to:

– Activate the selected menu item.

– Change the value of the selected menu item.

– Activate the selected sub menu.

• When you press the MENU button twice while in top level

SAM, the set will switch to the normal user menu (with the

SAM mode still active in the background). To return to the

SAM menu press the MENU button.

• Command “OSD/i+” key from the user remote will toggle

the OSD “on/off” with “SAM” OSD remaining always “on”.

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU button

to switch to SDM (do not allow the display to time out

between entries while keying the sequence).

How to Store SAM Settings

To store the settings changed in SAM mode (except the

OPTIONS settings), leave the top level SAM menu by using the

POWER button on the remote control transmitter or the

television set.

How to Exit

Switch the set to STANDBY by pressing the mains button on

the remote control transmitter or the television set.

Note:

• When the TV is switched “off” by a power interrupt while in

SAM, the TV will show up in “normal operation mode” as

soon as the power is supplied again. The error buffer will

not be cleared.

• In case the set is in Factory mode by accident (with “F”

displayed on screen), by pressing and hold “VOL-” and

“CH-” together should leave Factory mode.

5.3.4 Customer Service Mode (CSM)

Purpose

The Customer Service Mode shows error codes and

information on the TV’s operation settings. A call centre can

instruct the customer (by telephone) to enter CSM in order to

Page 15

Service Modes, Error Codes, and Fault Finding

s

7

EN 15LC7.2HU LB 5.

identify the status of the set. This helps them to diagnose

problems and failures in the TV before making a service call.

The CSM is a read-only mode; therefore, modifications are not

possible in this mode.

Specifications

• Ignore “Service unfriendly modes”.

• Line number for every line (to make CSM language

independent).

• Set the screen mode to full screen (all contents on screen

are viewable).

• After leaving the Customer Service Mode, the original

settings are restored.

• Possibility to use “CH+” or “CH-” for channel surfing, or

enter the specific channel number on the RC.

How to Activate

To activate CSM, press the following key sequence on the

remote control transmitter: “123654” (do not allow the display

to time out between entries while keying the sequence).

Upon entering the Customer Service Mode, the following

screen will appear:

1 M O D E L : 3 2 P F L 5 5 2 2 D / 1

2 P R O D S / N : AG1A0712123456

3 S W I D : L C 7 1 E L 1 - 1 . x x

4 O P : X X X X X X X X X X X X X X X X X X X X X

5 C O D E S : X X X X X X X X X X

6 S S B : 3 1 39 1 27 12341

7 N V M : X X X X X X X X

8 F l a s h D a t a : X X . X X . X X . X X

9 L I F E T I M E R : L L L L L

1 0 T U N E R : W E A K / G O O D / S T R O N G

1 1 S Y S T E M : P A L / N T S C / S E C A M

1 2 S O U N D : M O N O / S T E R E O / N I C A M

1 3 H D A U : Y E S / N O

1 4 F O R M A T : X X X X X X X X

0

CS M

G_16860_032.ep

21020

Figure 5-5 CSM menu (example)

How to Exit

To exit CSM, use one of the following methods:

• Press the MENU button twice, or POWER button on the

remote control transmitter.

• Press the POWER button on the television set.

5.4 Service Tools

5.4.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. and offers the following:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. You do not

have to know anything about I

yourself, because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software upgrade possibilities.

Specifications

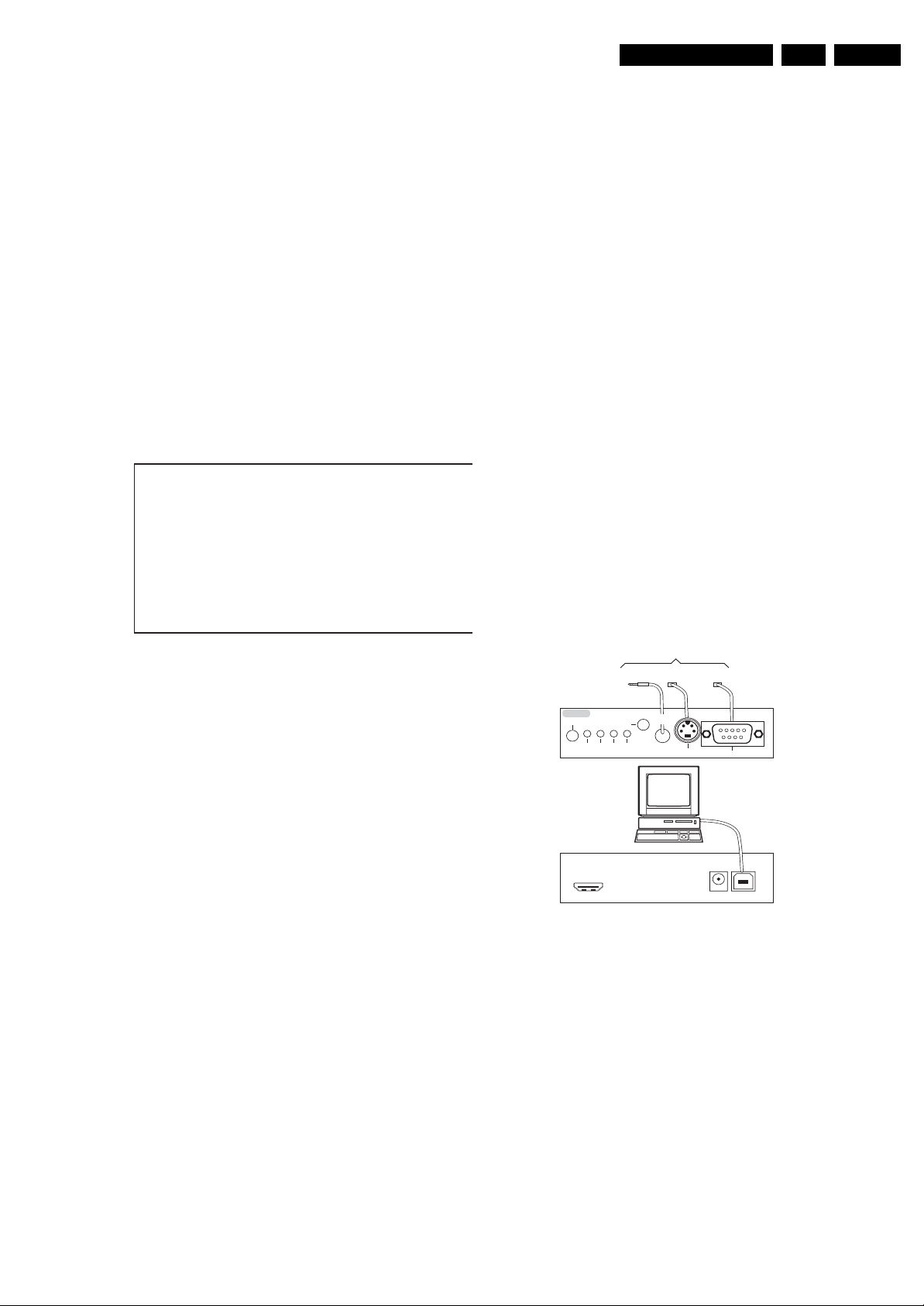

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The (new) ComPair II interface box is connected to the PC via

an USB cable. For the TV chassis, the ComPair interface box

and the TV communicate via a bi-directional cable via the

service connector(s).

How to Connect

This is described in the ComPair chassis fault finding database.

TO TV

TO

TO

I2C SERVICE

CONNECTOR

UART SERVICE

CONNECTOR

UART SERVICE

CONNECTOR

2

C or UART commands

TO

Menu Explanation

1. MODEL. Type number, e.g. 32HF7965D/27. (*)

2. PROD S/N. Product serial no., e.g. SV1A0701000008. (*)

3. SW ID. Software cluster and version is displayed.

4. OP. Option code information.

5. CODES. Error buffer contents.

6. SSB. Indication of the SSB factory ID (= 12nc). (*)

7. NVM. The NVM software version no.

8. Flash Data. PQ (picture quality) and AQ (audio quality)

data version. This is a sub set of the main SW.

9. LIFE TIMER. Operating hours indication.

10. TUNER. Indicates the tuner signal condition: “Weak” when

signal falls below threshold value, “Medium” when signal is

at mid-range, and “Strong” when signal falls above

threshold value.

11. SYSTEM. Gives information about the video system of the

selected transmitter (PAL/SECAM/NTSC).

12. SOUND. Gives information about the audio system of the

selected transmitter (MONO/STEREO/NICAM).

13. HDAU. HDMI audio stream detection. “YES” means audio

stream detected. “NO” means no audio stream present.

Only displayed when HDMI source is selected.

14. FORMAT. Gives information about the video format of the

selected transmitter (480i/480p/720p/1080i).

15. FPGA FW ID. Software version of the 1080p full HD

module (when present).

16. Reserved.

17. Reserved.

18. Reserved.

(*) If an NVM IC is replaced or initialized, the Model Number,

Serial Number, and SSB Code Number must be re-written to

the NVM. ComPair will foresee in a possibility to do this.

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

HDMI

I

2

C only

RC out

Multi

function

2

C

I

PC

ComPair II Developed by Philips Brugge

Optional power

5V DC

RS232 /UART

G_06532_036.eps

240807

Figure 5-6 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• ComPair32 CD (update): 3122 785 60160.

•ComPair I

with chassis L01, A02, A10, EMx, TPM1.xA, etc...).

•ComPair I

2

C interface cable: 3122 785 90004 (to be used

2

C interface extension cable: 3139 131 03791 (to

be used with chassis L01, A02, A10, L04, LC4, LC7.1,

LC7.2).

• ComPair UART interface cable: 3122 785 90630 (to be

used with chassis LC4, EJ3, BJ2, BL2, BP2, ...).

Page 16

EN 16 LC7.2HU LB5.

Service Modes, Error Codes, and Fault Finding

• ComPair RS232 cable: 3104 311 12742 (to be used with

chassis Q52x).

•ComPair I

9965 100 07325 (to be used with chassis LC7.5).

Note: For I

2

C interface cable (3.5 mm Jack-to-SVHS plug):

2

C it is compulsory to use this particular cable.

• ComPair UART interface cable (3.5 mm Jack-to-Jack):

3138 188 75051 (to be used with chassis LC7.5).

Note: For UART it is also allowed to use a standard “Jackto-Jack” cable.

Note: If you encounter any problems, contact your local

support desk.

5.4.2 LVDS Tool

Support of the LVDS Tool has been discontinued.

5.5 Error Codes

5.5.1 Introduction

Error codes are required to indicate failures in the TV set. In

principle a unique error code is available for every:

• Activated protection.

• Failing I2C device.

• General I2C error.

• SDRAM failure.

The last five errors, stored in the NVM, are shown in the

Service menu’s. This is called the error buffer.

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is displayed at the left side and all other errors shift one

position to the right.

An error will be added to the buffer if this error differs from any

error in the buffer. The last found error is displayed on the left.

An error with a designated error code may never lead to a

deadlock situation. This means that it must always be

diagnosable (e.g. error buffer via OSD or blinking LED

procedure, ComPair to read from the NVM).

In case a failure identified by an error code automatically

results in other error codes (cause and effect), only the error

code of the MAIN failure is displayed.

Example: In case of a failure of the I2C bus (CAUSE), the error

code for a “General I2C failure” and “Protection errors” is

displayed. The error codes for the single devices (EFFECT) is

not displayed. All error codes are stored in the same error

buffer (TV’s NVM) except when the NVM itself is defective.

5.5.2 How to Read the Error Buffer

You can read the error buffer in 3 ways:

• On screen via the SAM/SDM/CSM (if you have a picture).

Example:

– ERROR: 0 0 0 0 0: No errors detected

– ERROR: 6 0 0 0 0: Error code 6 is the last and only

detected error

– ERROR: 9 6 0 0 0: Error code 6 was detected first and

error code 9 is the last detected (newest) error

• Via the blinking LED procedure (when you have no

picture). See “The Blinking LED Procedure”.

•Via ComPair.

5.5.3 Error Codes

In case of non-intermittent faults, write down the errors present

in the error buffer and clear the error buffer before you begin

the repair. This ensures that old error codes are no longer

present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

and not the actual cause of the problem (for example, a fault in

the protection detection circuitry can also lead to a protection).

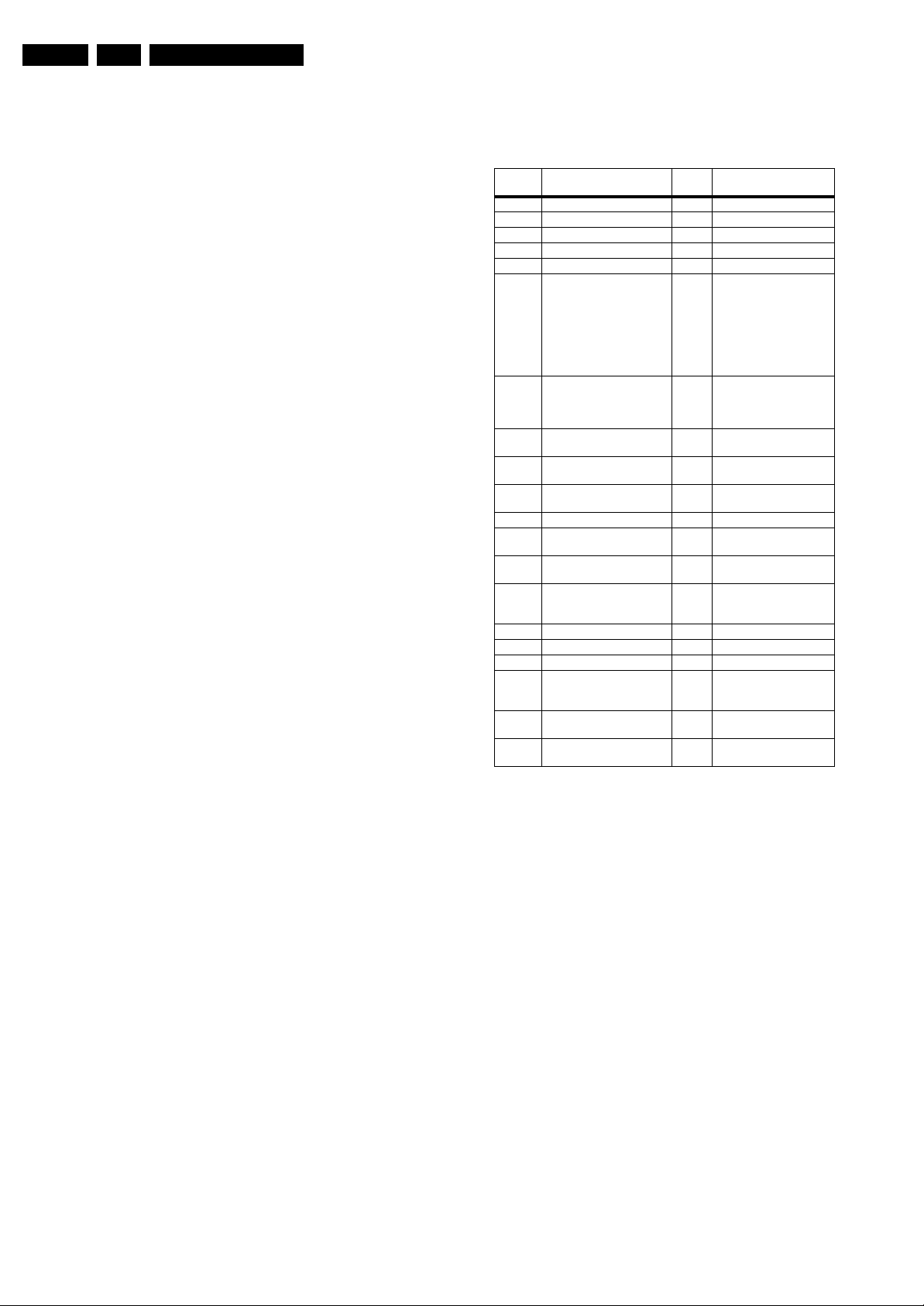

Table 5-2 Error code overview

Error

1)

code

0No error.

1 DC Protection of speakers.

2 +12V protection error. 12V missing or “low”.

3 Reserved.

4 General I2C error. Note 2

5 Trident Video Processor

6 I2C error while communicat ing

7 I2C error while communicat ing

8 I2C error while communicat ing

9 I2C error communicating with

10 SDRAM defective. 7204

11 I2 C error while communicating

12 I2 C error while communicating

13 DVB HW communication

14 SDRAM defective. 7205

15 Reserved.

16 Reserved.

17 I2 C error while communicating

18 I2 C error while communicating

19 I2 C error while communication

Description Item nr. Remarks

communication error.

with the NVM.

with the Tuner.

with the IF Demodulator.

the Sound Processor.

with the HDMI IC.

with the MOJO PNX8314.

error.

with the FPGA (AmbiLight

bolt-on).

with the i-Board processor.

with 1080p bolt-on module.

7202 When Trident IC is

defective, error 10 and 14

might also be reported.

Trident communicates via

parallel bus, not via the I2C

bus. The I2C bus of Trident

is only used in ComPair

mode.

7315 The TV will not start-up due

to critical data not available

from the NVM, but the LED

will blink the error code.

1101

7113

7411

7817

7G00 If applicable

7F01,

If applicable

7K00,

7G00

If applicable

If applicable

If applicable

Notes

1. Some of the error codes reported are depending on the

option code configurations.

2. This error means: no I2C device is responding to the

particular I2C bus. Possible causes: SCL/SDA shorted to

GND, SCL shorted to SDA, or SCL/SDA open (at uP pin).

The internal bus of the Trident platform should not cause

the entire system to halt as such an error can be reported.

3. The following error codes which must be trigger the

blinking LED automatically once detected, due to the fact

these error may cause no display on the screen: Errors 1,

2, 3, 4, 5, 6 and 10.

5.5.4 How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

• By using the CLEAR command in the SAM menu:

– To enter SAM, press the following key sequence on the

remote control transmitter: “062596” directly followed

by the OSD/i+ button (do not allow the display to time

out between entries while keying the sequence).

– Make sure the menu item CLEAR is selected. Use the

MENU UP/DOWN buttons, if necessary.

– Press the MENU RIGHT button to clear the error

buffer. The text on the right side of the “CLEAR” line will

change from “CLEAR?” to “CLEARED”

• If the contents of the error buffer have not changed for 50

hours, the error buffer resets automatically.

Page 17

Service Modes, Error Codes, and Fault Finding

EN 17LC7.2HU LB 5.

Note: If you exit SAM by disconnecting the mains from the

television set, the error buffer is not reset.

5.6 The Blinking LED Procedure

5.6.1 Introduction

The software is capable of identifying different kinds of errors.

Because it is possible that more than one error can occur over

time, an error buffer is available, which is capable of storing the

last five errors that occurred. This is useful if the OSD is not

working properly.

Errors can also be displayed by the blinking LED procedure.

The method is to repeatedly let the front LED pulse with as

many pulses as the error code number, followed by a period of

1.5 seconds in which the LED is “off”. Then this sequence is

repeated.

Example (1): error code 4 will result in four times the sequence

LED “on” for 0.25 seconds / LED “off” for 0.25 seconds. After

this sequence, the LED will be “off” for 1.5 seconds. Any RC5

command terminates the sequence. Error code LED blinking is

in red color.

Example (2): the content of the error buffer is “129600”

After entering SDM, the following occurs:

• 1 long blink of 5 seconds to start the sequence,

• 12 short blinks followed by a pause of 1.5 seconds,

• 9 short blinks followed by a pause of 1.5 seconds,

• 6 short blinks followed by a pause of 1.5 seconds,

• 1 long blink of 1.5 seconds to finish the sequence,

• The sequence starts again with 12 short blinks.

5.6.2 Displaying the Entire Error Buffer

Additionally, the entire error buffer is displayed when Service

Mode “SDM” is entered. In case the TV set is in protection or

Stand-by: The blinking LED procedure sequence (as in SDMmode in normal operation) must be triggered by the following

RC sequence: “MUTE” “062500” “OK”.

In order to avoid confusion with RC5 signal reception blinking,

this blinking procedure is terminated when a RC5 command is

received.

To erase the error buffer, the RC command “MUTE” “062599

“OK” can be used.

5.7 Software Upgrading

In this chassis, two SW “stacks” are used:

• TV main SW (processor and processor NVM).

•Digital TV SW.

5.7.1 TV Main SW Upgrade

For instructions on how to upgrade the TV Main software, refer

to ComPair.

5.7.2 “Digital TV” Software Upgrade

5.8.1 NVM Editor

In some cases, it can be convenient if one directly can change

the NVM contents. This can be done with the “NVM Editor” in

SAM mode. With this option, single bytes can be changed.

Caution:

• Do not change the NVM settings without

understanding the function of each setting, because

incorrect NVM settings may seriously hamper the

correct functioning of the TV set!

• Always write down the existing NVM settings, before

changing the settings. This will enable you to return to the

original settings, if the new settings turn out to be incorrect.

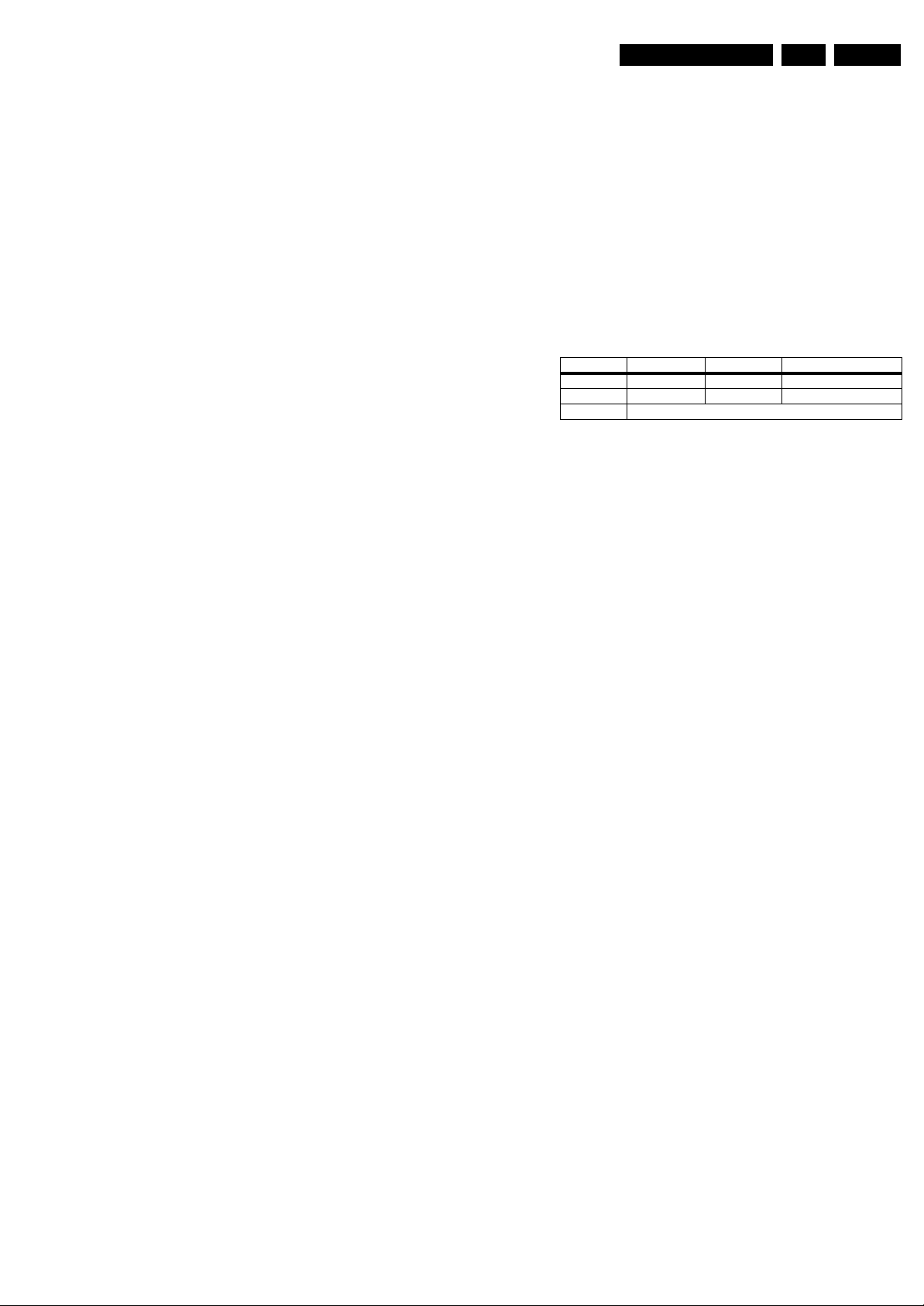

Table 5-3 NVM editor overview

Hex Dec Description

.ADR 0x000A 10 Existing value

.VAL 0x0000 0 New value

.Store Store?

5.8.2 Load Default NVM Values

It is possible to download default values automatically into the

NVM in case a blank NVM is placed or when the NVM first 20

address contents are “FF”. After the default values are

downloaded, it is possible to start-up and to start aligning the

TV set. To initiate a forced default download the following

action has to be performed:

1. Switch “off” the TV set with the mains cord disconnected

from the wall outlet (it does not matter if this is from “Standby” or “Off” situation).

2. Short-circuit the SDM jumpers on the SSB (keep short

circuited).

3. Press “P+” or “CH+” on the local keyboard (and keep it

pressed).

4. Reconnect the mains supply to the wall outlet.

5. Release the “P+” or “CH+” when the set is “on” or blue LED

is blinking.

When the downloading has completed successfully, the set

should be into Stand-by, i.e. red LED on.

Alternative method (1):

1. Go to SAM.

2. Select NVM Editor.

3. Select ADR (address) to 1 (dec).

4. Change the VAL (value) to 170 (dec).

5. Store the value.

6. Do a hard reset to make sure new default values took

place.

Alternative method (2):

It is also possible to upload the default values to the NVM with

ComPair in case the SW is changed, the NVM is replaced with

a new (empty) one, or when the NVM content is corrupted.

After replacing an EEPROM (or with a defective/no EEPROM),

default settings should be used to enable the set to start-up and

allow the Service Default Mode and Service Alignment Mode to

be accessed.

This is done automatically via OAD (Over the Air Download).

5.8 Fault Finding and Repair Tips

Notes:

• It is assumed that the components are mounted correctly

with correct values and no bad solder joints.

• Before any fault finding actions, check if the correct options

are set.

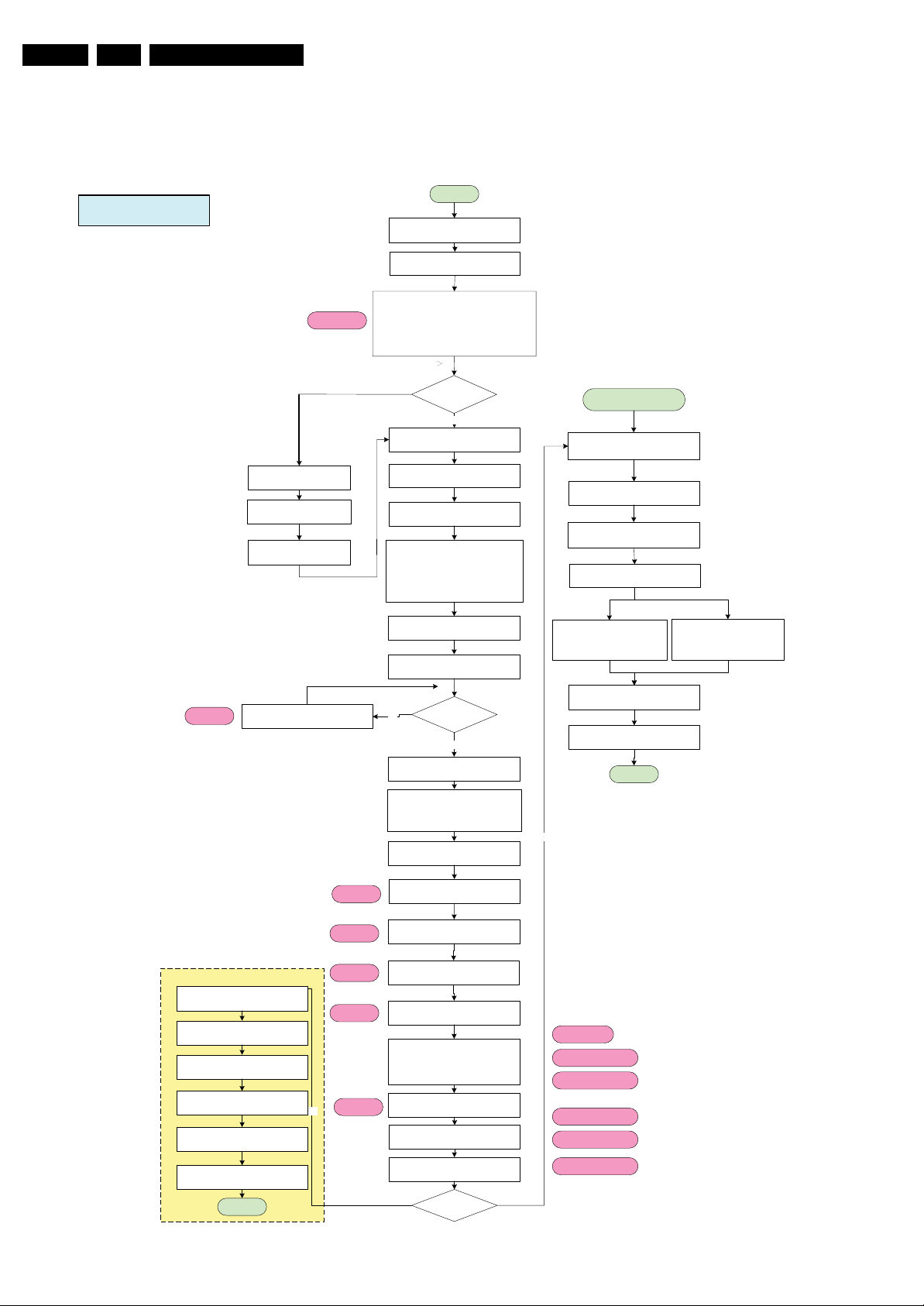

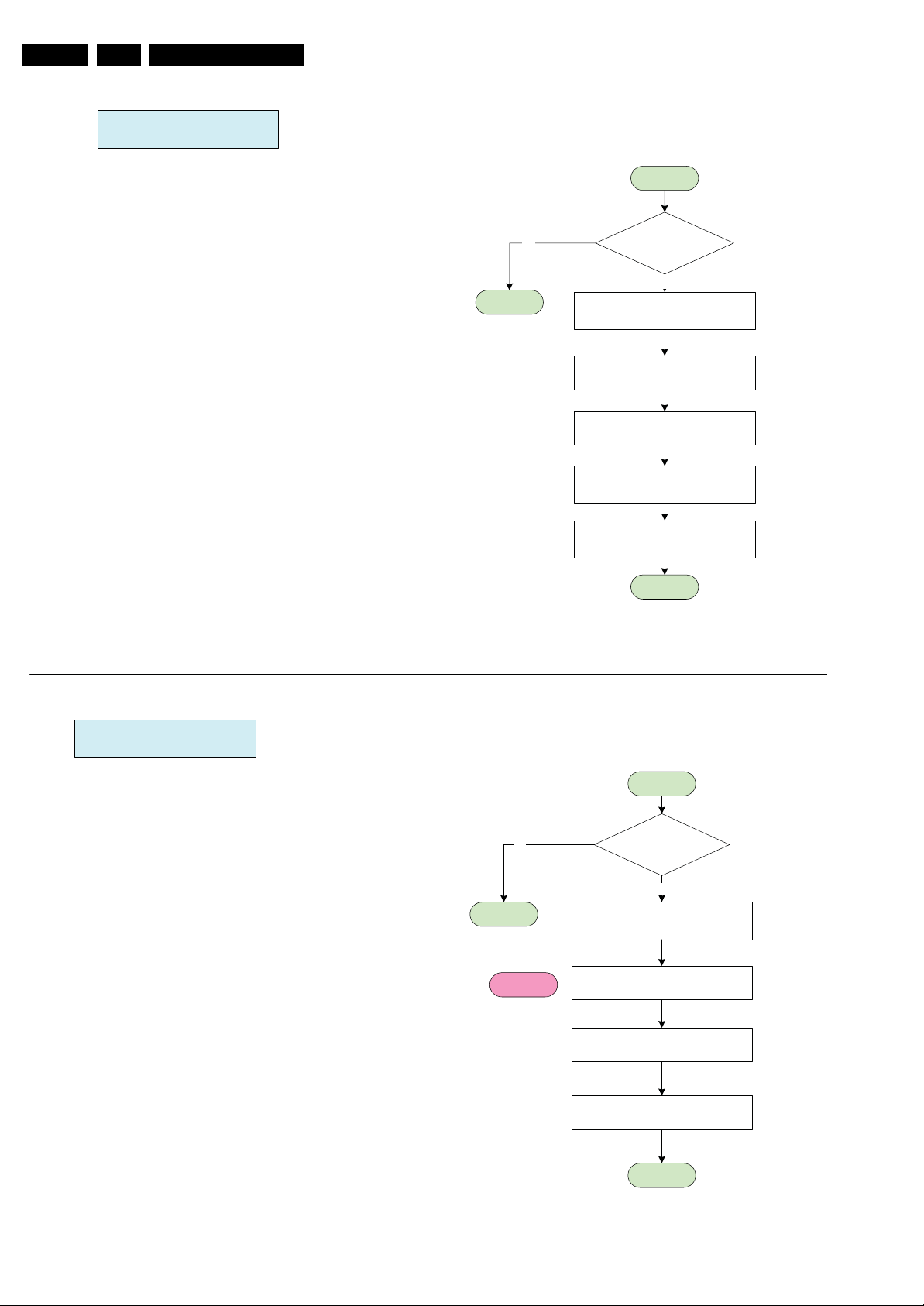

5.8.3 Start-up/Shut-down Flowcharts

Important note for DVB/ATSC sets:

• When you put a DVB/ATSC set into Stand-by mode with

an RC, the set will go to “Semi Stand-by” mode for 5

minutes. This, to facilitate “Over the Air download” (OAD).

If there is no activity within these 5 minutes, the set will

switch to Stand-by mode. In “Semi Stand-by” mode, the

LCD backlight and Audio Amplifier are turned “off” but other

circuits still work as normal. The customer might think the

set is in Stand-by. However, in real Stand-by mode, only

Page 18

EN 18 LC7.2HU LB5.

Service Modes, Error Codes, and Fault Finding

the uP and the NVM are alive and all other circuits are

switched “off”.

• If you press the mains switch at the local key board in a

DVB/ATSC set, the set will switch to Stand-by mode.

Start Up

160ms

InitCold Component:

1. Check SDM port.

Error 6 - NVM

[Protection]

Standby Normal Mode

(RED LED)

Port Assignment in STANDBY

Wait for RC key or

Wake up event

- If SDM pin = LOW and NVM first 20Byte =

0xFF, reload Software default NVM value.

2. Check Panel port.

- If Panel Pin = LOW and check slave address

0x65 = 0xA5, Enter Panel Mode.

On the next pages you will find start-up and shut-down

flowcharts, which might be helpful during fault finding.

Please note that some events are only related to PDP sets,

and therefore not applicable to this LCD chassis.

AC ON

+5VSTBY & +3V3STBY Available (1)

RENEAS POR by +3VSTBY (2)

STANDBYn = LOW

No

Last status is ON?

Yes

Read NVM completed.

STOP I²C activities.

LED = BLUE for Normal mode

LED = RED for Recording mode

BLOCK RC Key

M16C RST_H = HIGH

RST_HDMI = LOW

RST_AUD = LOW

RESET_n = LOW

LCD_PWR_ON = LOW

SDI PDP => CTRL_DISP1 = LOW

(1) +5VSTBY to be measured

at PDTC114ET (item 7322)

(2) to be measured at pin 4

of BD45275G (item 7312)

User wake up the sets

in DVB recording mode

LCD_PWR_ON = HIGH

(Same function as CTRL-DISP2)

SDI PDP => CTRL_DISP1 = LOW

20ms

1000ms to

1500ms

Wait for 20 ms

Switch ON LVDS Signal

Init. Warm Component

(For software)

Error 2

[Protection]

Notes:

---------

1. LC07 TV software only start communication with IBOZ once

receive the INT message from IBOZ.

For DVB Sets only (Semistandby)

Recording mode

SDI PDP => CTRL_DISP1 = HIGH

Recording Mode finished

Software Shutdown:

WP for NVM

Port Assignment in STANDBY

STANDBYn = LOW

Standby

Normal Mode

Wait for 100ms

Time out = 2000ms

Yes

500ms

100ms

Error 7

Error 8

Error 9

Error 11

1700ms

Error 3

[Protection]

STANDBYn = HIGH

(Same function as CTRL-DISP3)

Wait for 500ms

Is Power Down =

No

BL_ADJ = HIGH (100% Duty Cycle)

HIGH?

Yes

Wait for 100ms

M16C RST_H to LOW

RST_HDMI = HIGH

RST_AUD = HIGH

RESET_n = HIGH

Enable Power Down INT

Enable DC_PROT INT

Initialise Tuner

Initialise IF Demodulator, Afric

TDA9886T

Initialise Micronas

Mute Audio

Initialise HDMI, Sil9023

Initialise Trident CX

DPTVInit( )

Initialise FHP Panel

* For FHP PDP Sets only

Initialise Bolt-ON

* For iTV, 1080P, Ambi Light

Enable RC Key

DVB recording mode

For LCD:

BL_ON_OFF = HIGH

* BL_ADJ keep 100% for 3000ms

before dimming.

Blank Picture

Picture Mode Setup & Detection

unBlank Picture &

UnMute Audio

No

Error 5 - Trident

[Protection]

Error 10 – SDRAM 7204

[Protection]

Error 14 – SDRAM 7205

[Protection]

Error 17 – AmbiLight

Error 18 – iTV iFace

Error 19 – 1080P

End

For PDP:

3000ms delay

G_16860_070.eps

220207

Figure 5-7 Start-up flowchart

Page 19

Service Modes, Error Codes, and Fault Finding

EN 19LC7.2HU LB 5.

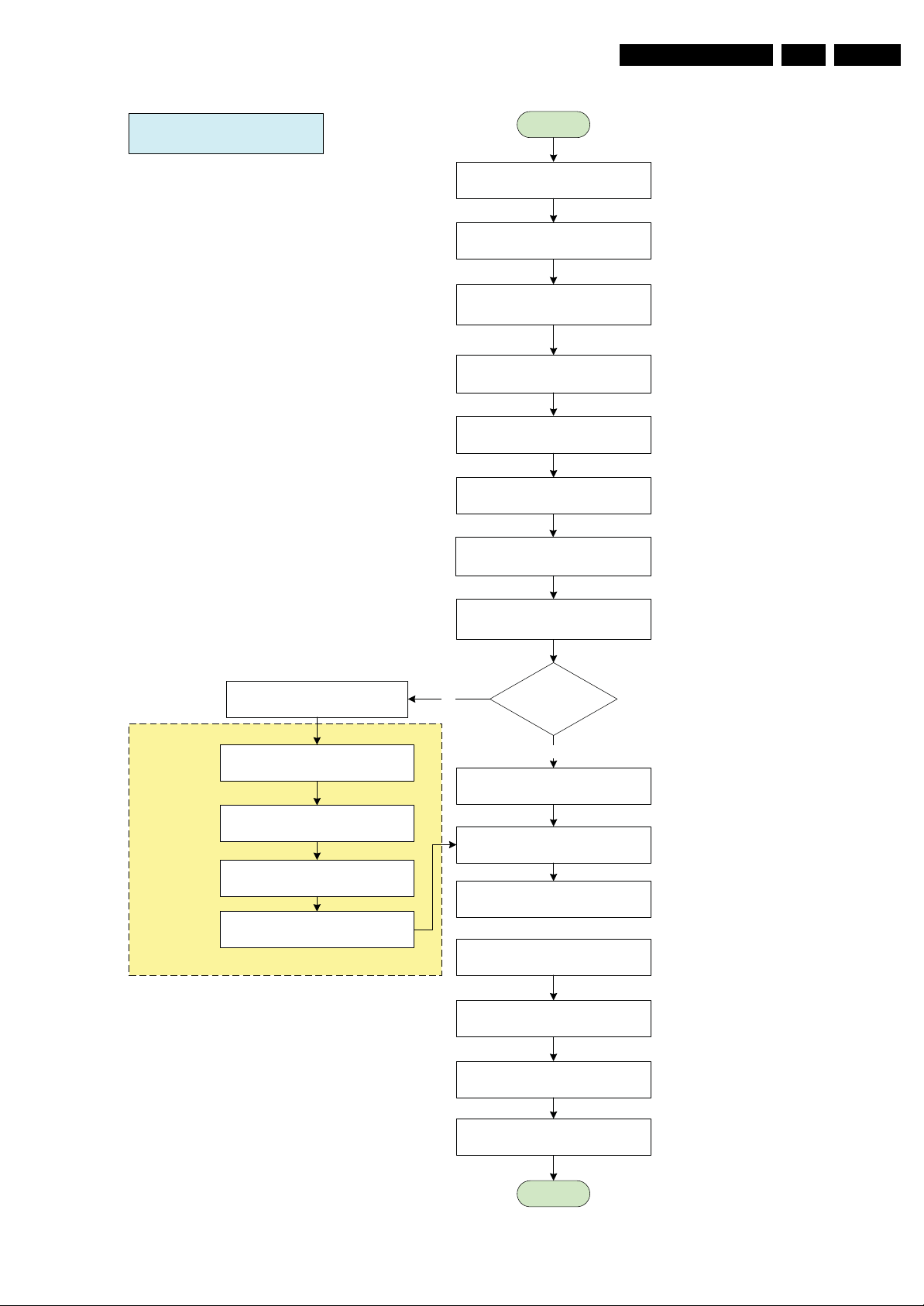

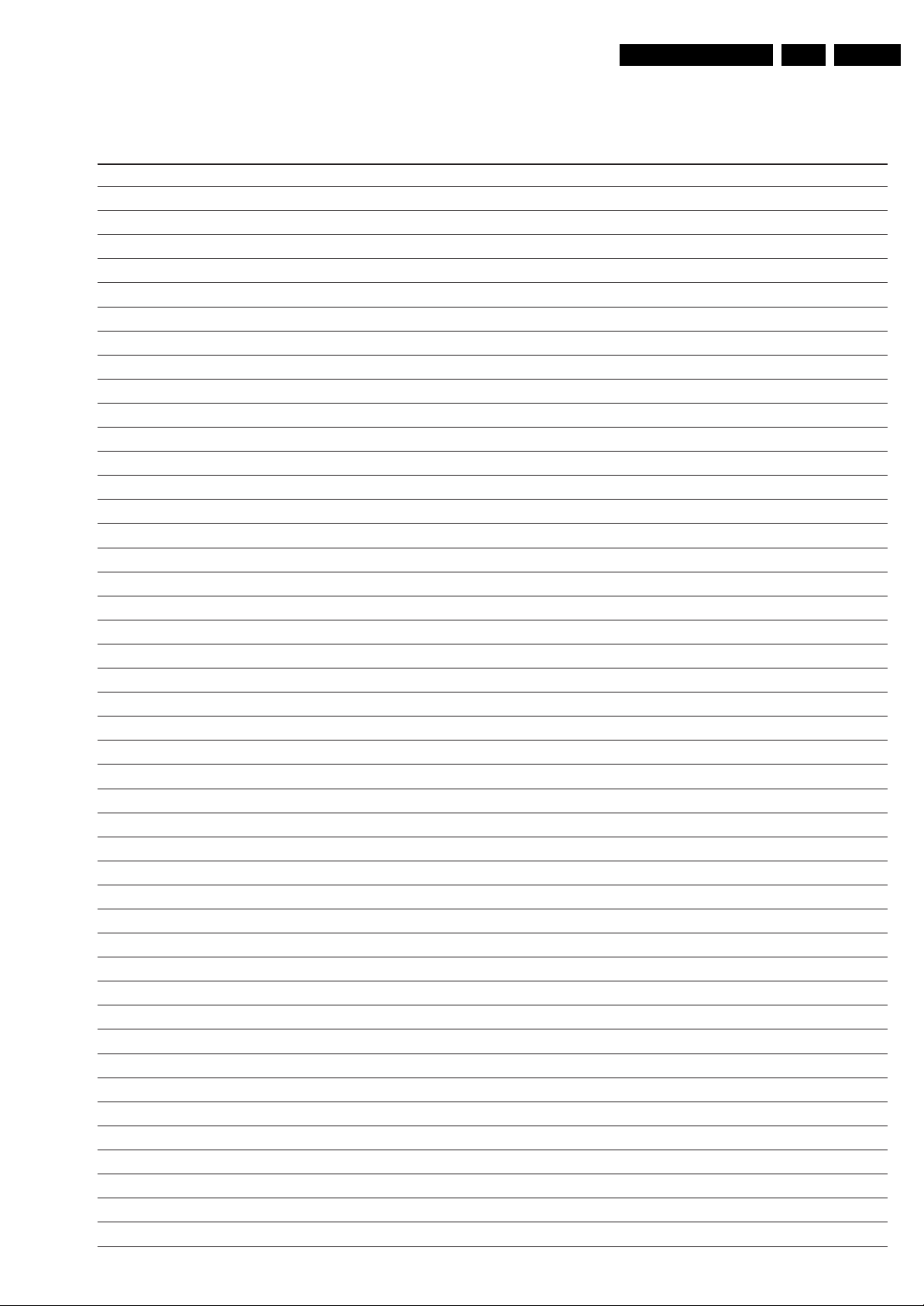

SEMISTANDBY/ STANDBY

300ms

20ms

Start

Mute Audio

BL_ADJ stop dimming

(PWM duty cycle 100%)

BL_ON_OFF = LOW

Wait 300ms

Switch OFF LVDS

Wait 20ms

LCD_PWR_ON = LOW

LED = RED No

For DVB Sets only (Semistandby)

Wait for 3000ms

Except power tact switch

SDI PDP => CTRL_DISP1 = HIGH

Off Air Downloading/ Recording Mode

IBOZ send shut down command

Software Shutdown:

Standby using

“power key”

Yes

LED = NO LED

for Standby soft mode

Disable Power Down INT &

DC_PROT_INT

BL_ADJ = LOW

(PWM duty cycle 0%)

WriteProtect for NVM

Port Assignment in STANDBY

Sets go to standby here

40ms

Total = 360ms

STANDBYn = LOW

Wait for 3000ms

End

Figure 5-8 Semi Stand-by/Stand-by flowchart

Blocking for the next start up to ensure

power supply discard properly.

G_16860_071.eps

220207

Page 20

EN 20 LC7.2HU LB5.

Service Modes, Error Codes, and Fault Finding

Power Down INT:

AC OFF or Transient INT

Start

Notes:

1. Power Down INT will be based on fall edge triggering

2. +3V3STBY will stay for 15ms, software must perform

WriteProtect for NVM within 15ms.

Avoid false trigger

No

End

Poll the Power Down

INT for 5 times

Yes

Mute Audio & VIdeo

WriteProtect for NVM

STANDBYn = LOW

Wait 5000 ms

Re-start: Start up

End

DC_PROT INT

Avoid false trigger

No

End

Error 1

[Protection]

Start

is DC_PROT = LOW

for 3 sec?

Yes

Mute Audio & VIdeo

Log Error Code

WriteProtect for NVM

STANDBYn = LOW

End

G_16860_072.eps

220207

Figure 5-9 Power Down & DC_PROT flowchart

Page 21

Personal Notes:

Service Modes, Error Codes, and Fault Finding

EN 21LC7.2HU LB 5.

E_06532_012.eps

131004

Page 22

EN 22 LC7.2HU LB5.

Service Modes, Error Codes, and Fault Finding

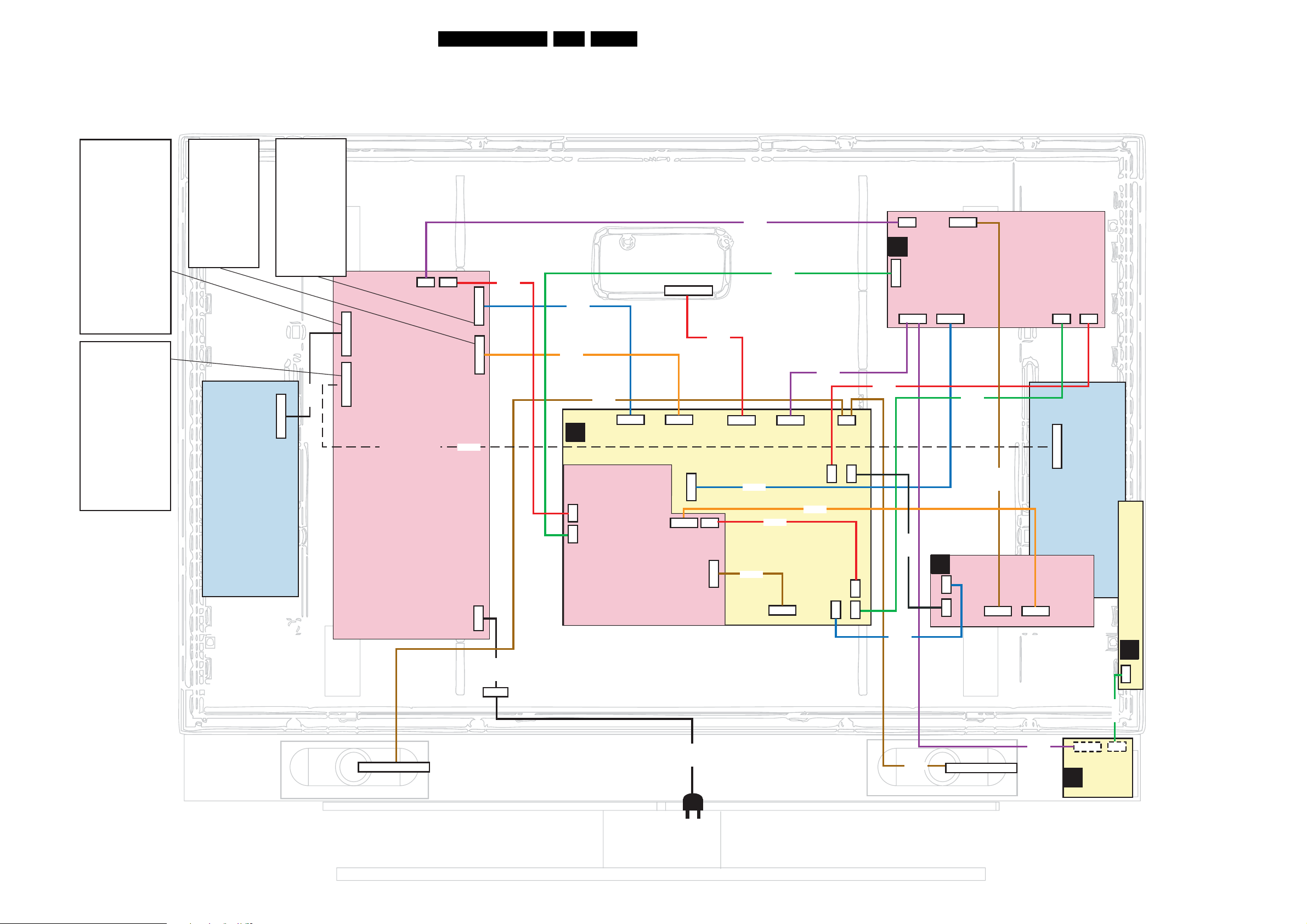

Page 23

Block Diagrams, Test Point Overviews, and Waveforms

6. Block Diagrams, Test Point Overviews, and Waveforms

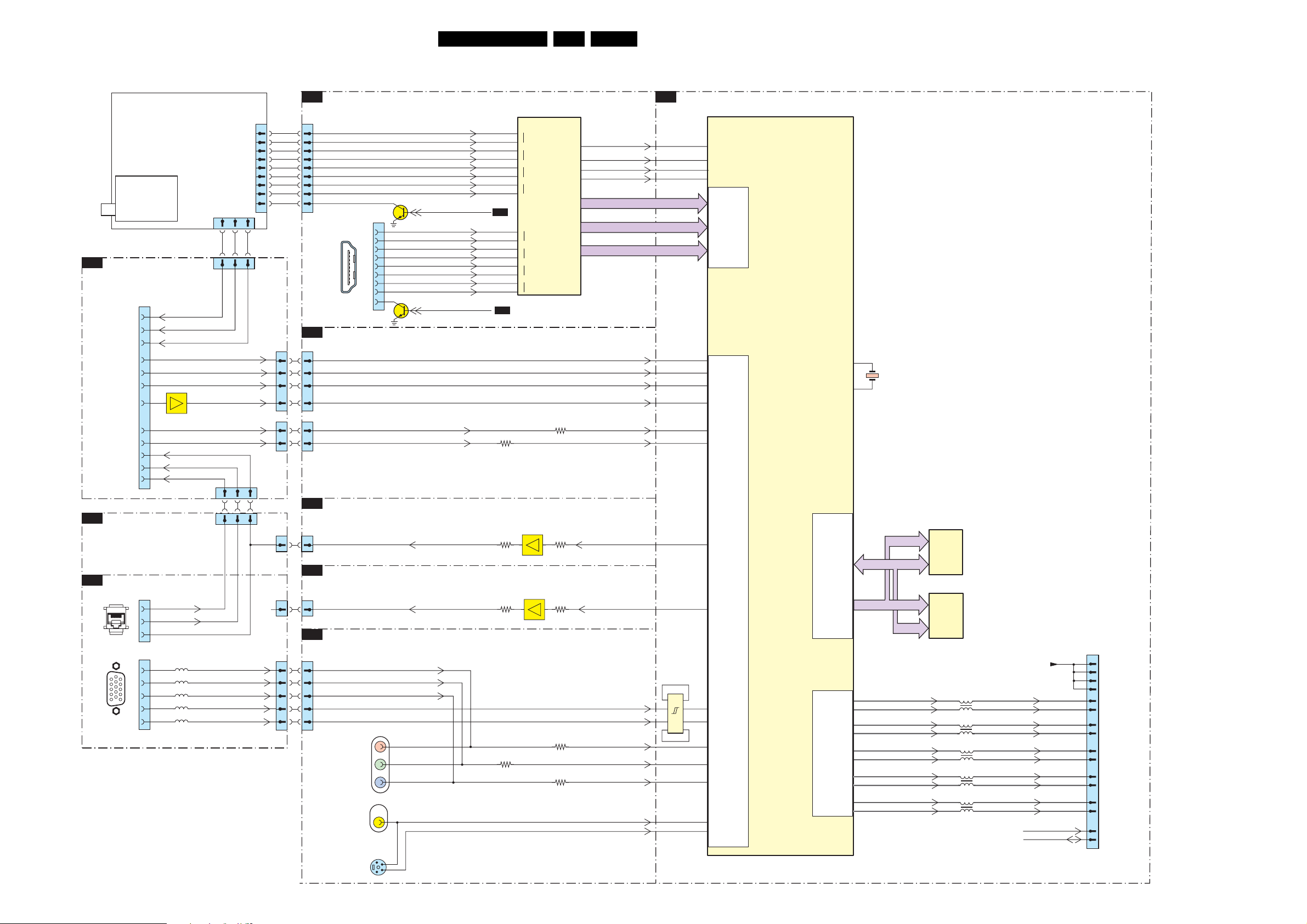

Wiring Diagram 26” & 32”

WIRING 26”- 32” LCD (STYLING ME7)

23LC7.2HU LB 6.

CN2

DISPLAY SUPPLY

1. +24V

2. +24V

3. +2 4V

4. +24V

5. +24V

6. GND

7. GND

8. GN D

9. GND

10. GND

11. DIM

12. BL-ON

13. PWM

14. N.C.

CN3

DISPLAY SUPPLY

1. +24V

2. +24V

3. +2 4V

4. +24V

5. +24V

6. GND

7. GND

8. GN D

9. GND

10. GND

11. N.C.

12. N.C.

CN7

CONTROL:

1. BL-DIM

2. PG

3. BL-ON

4. GND

5. N.C.

6. PSON

7. N.C.

8. 12 V

INVERTER

CN6

CONTROL:

1. -12VA

2. +12VA

3. GN D

4. 5.2VS

5. 5.2VS

6. 5.2VS

7. GND

8. GN D.

9. GND

14P

CN2

LCD DISPLAY

(1004)

1205

10P

SI

1301

12P

1207

8P02

SYSTEM

INTERFACE

(1184)

8P

5P

1302

12P

1300

8H05

1108

1102

4P

6P

12P

CN3

INVERTER

7P

1306

KEYBOARD CONTROL

E

(1114)

8H03

HC

5P

8H08

4P

1209

(1182)

1204

1103

14P

iBOARD

8H07

8H04

8H01

8H09

8H10

8H13

1812

21P

7P

1M20

8H11

8M20

1901

1526

4P

4P

1735

1525

8P

5P

1619

3P

6P

1527

4P

4P

CN5

CN4

14P

CN2

12P

CN3

8316

MAIN SUPPLY

(1005)

ONLY USED

FOR LPL PANEL

8317

CN6

CN7

CN1

8H12

9P

8P

2P3

8C01

8P11

8735

9P

1C01

SSB

B

4P

CN5

5P

P1204

ATSC

MPEG4* PANEL

(1128)

LV DS

30P

8P

1P11

10P

1312

P5017PP201

8G51

3P

P600

30P

1G51

21P

RIGHT SPEAKER

(5200)

*MPEG4 ONLY FOR CHASSIS LC7.2HU_LB

INLET

8308

8191

8192(UK)

8735

8M20

LEFT SPEAKER

(5200)

7P

1M20

IR/LED/LIGHT

J

SENSOR

(1112)

H_16990_039.eps

3P

1M01

8M01

3P

1M01

211207

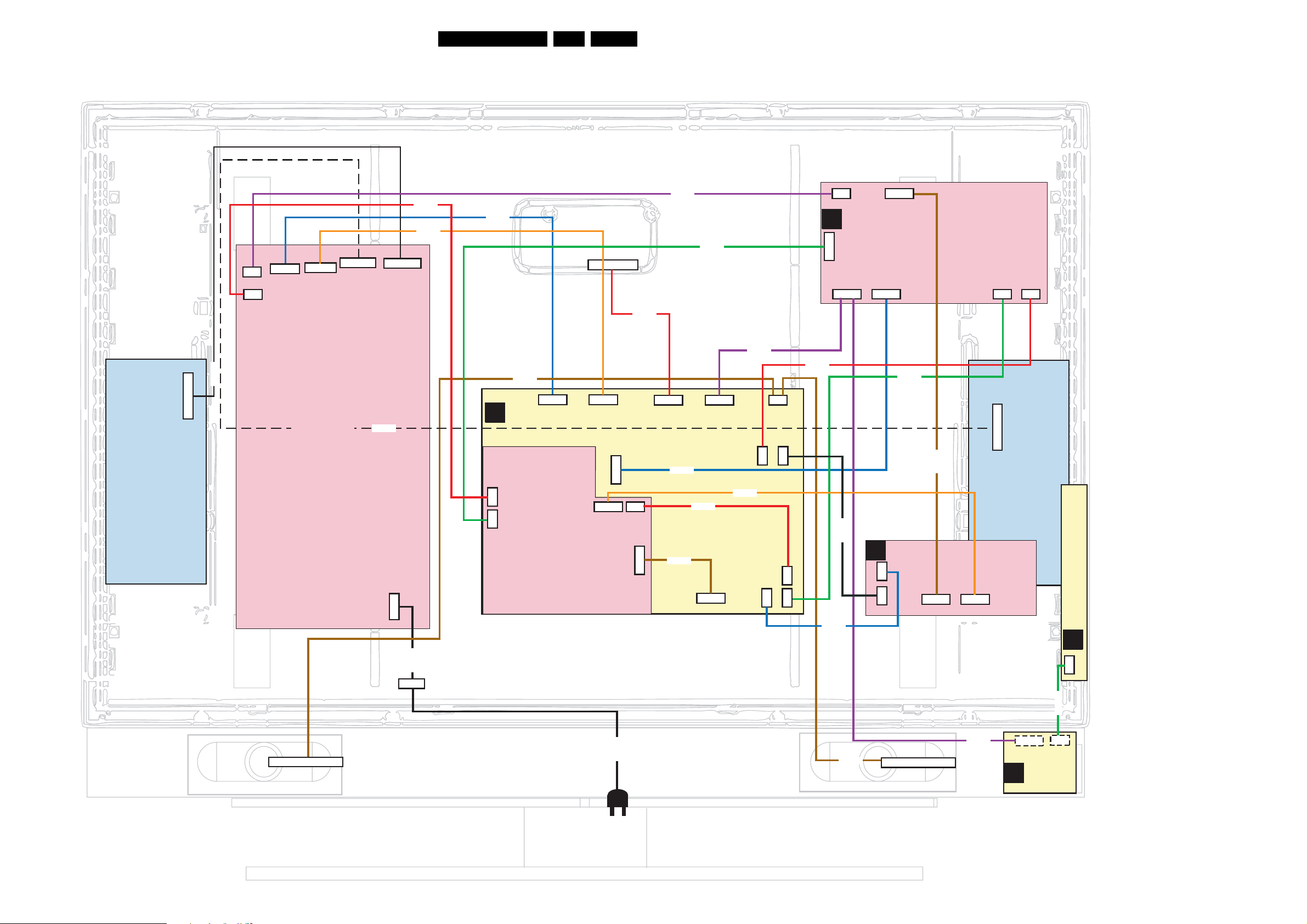

Page 24

Block Diagrams, Test Point Overviews, and Waveforms

Wiring Diagram 42”

24LC7.2HU LB 6.

WIRING 42” LCD

14P

CN2

(STYLING ME7)

4P

X405

4P

X411

8316

MAIN SUPPLY

(1005)

9P

X412

ONLY USED

FOR LPL PANEL

8P

X406

12P

X404

8317

14P

X403

8H12

8P11

8C01

B

LCD DISPLAY

(1004)

8735

9P

SSB

1C01

8P

1P11

LV DS

30P

8G51

30P

1G51

8H04

8H10

1M20

7P

8M20

4P

1735

8H03

HC

5P

4P

1209

(1182)

1204

1103

14P

iBOARD

1205

10P

12P

1207

8H02

1102

6P

12P

1108

4P

CN3

INVERTER

RIGHT SPEAKER

(5200)

CN1

2P3

INLET

5P

4P

1525

4P

CN5

5P

ATSC

P1204

MPEG4* PANEL

(1128)

10P

1312

3P

P5017PP201

P600

21P

8H01

8H09

8H13

1812

21P

8H11

1901

1526

8H05

8H07

3P

1527

6P

8P

1619

8H08

SI

1301

SYSTEM

INTERFACE

(1184)

8P

5P

1302

12P

1300

INVERTER

7P

1306

(1114)

KEYBOARD CONTROL

E

8308

8191

8192(UK)

8735

8M20

LEFT SPEAKER

(5200)

7P

1M20

IR/LED/LIGHT

J

SENSOR

(1112)

3P

1M01

8M01

3P

1M01

*MPEG4 ONLY FOR CHASSIS LC7.2HU_LB

H_16990_041.eps

211207

Page 25

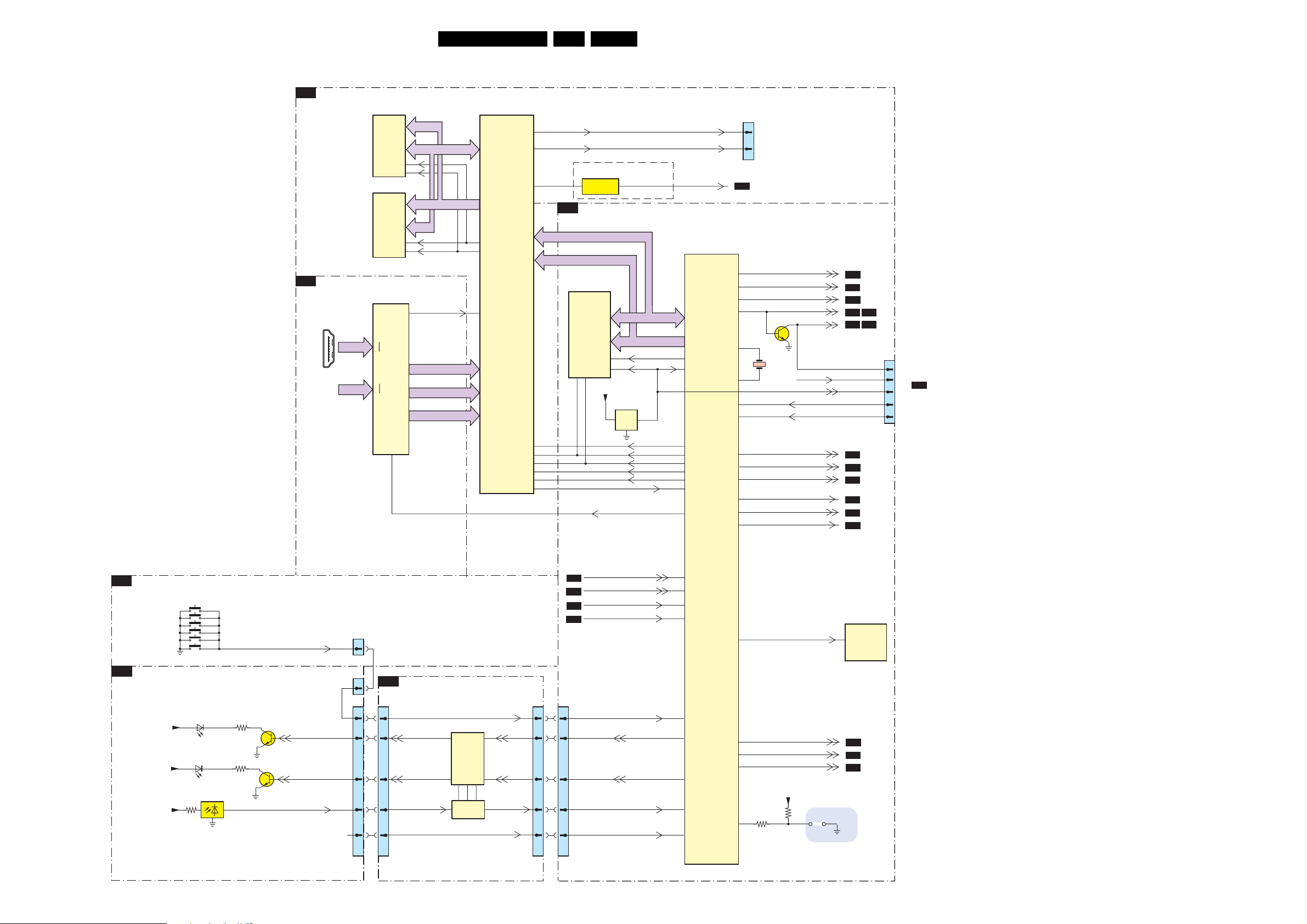

Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram Video

VIDEO

ATSC/MPEG4 PANEL

MPEG4 ONLY FOR CHASSIS LC7.2HU_LB

TUNER

SI

SYSTEM INTERFACE

1305

25

Y_OUT

24

Pb_OUT

23

Pr_OUT

17

18

INTEGRATED

CARD SLOT

19

7300

20

31

32

22

11

13

EF

SC2_Y_CVBS_IN

CVBSterr

HSYNC_OUT

HSYNC_OUT

1

1

1306 P501

SC1_B_IN

SC1_G_IN

SC1_R_IN

SC1_FBL_IN

SC2_C_IN

P600 1812

1

3

4

6

7

9

10

12

19

2

332

B06C

1

3

4

6

7

9

10

12

19

B06B

1301 1526

1

1

2

2

3

3

4

4

1302 1525

1

1

2

2

HDMI

1

HDMI 1

18 2

19

IO - SCART 1 & 2

1810

1

3

4

6

7

9

10

12

19

7860

HDMI_HOTPLUG_RESET

7814

HDMI_HOTPLUG_RESET

SC2_Y_CVBS_IN_ITV

SC2_C_IN_ITV

RX2+B

RX2-B

RX1+B

RX1-B

RX0+B

RX0-B

RXC+B

RXC-B

RX2+A

RX2-A

RX1+A

RX1-A

RX0+A

RX0-A

RXC+A

RXC-A

B04A

B04A

3552

7817

SII9025CTU

71

+

70

-

67

+

66

-

63

+

62

-

59

+

58

-

52

+

51

-

48

+

47

-

44

+

43

-

40

+

39

-

R1X2

R1X1

R1X0

R1XC

R0X2

R0X1

R0X0

R0XC

ADC

HDMI

(MAIN)

3529

ODCK

DE

HSYNC

VSYNC

25LC7.2HU LB 6.

HDMI_VCLK

121

HDMI_DE

1

2

3

SC1_B_IN

SC1_G_IN

SC1_R_IN

SC1_FBL_IN

SC2_Y_CVBS_IN

SC2_C_IN

HDMI_H

HDMI_V

HDMI_Cb(0-7)

HDMI_Y(0-7)

HDMI_Cr(0-7)

B04B

VIDEO PROCESSOR

197

181

189

173

190

23

DP-CLK

6

DP_DE_FLD

4

DP_HS

5

DP_VS

DIN_PORTD

7202

SVP CX32-LF

PB_B2

Y_G2

PR_R2

FB1

PR_R3

70

FS2

ANALOG

(24BIT)

MUX

VIDEO

PROCESSOR

XTALI

XTALO

205

204

1201

14M31

HC02

HC01

IBOARD

IBOARD

RJ45

CONNECTOR

10

15

5

1

6

11

VGA

CONNECTOR

1107

1101

11

8

7

8

7

1207 1300

3

VSYNC

4

HSYNC

8

CVBSterr

5102

1

5103

9

5104

2

5105

13

5106

14

HD_PR_IN_ITV

11

HD_Y_IN_ITV

HD_PB_IN_ITV

VGA_H

VGA_V

B04A

1205 1312

10

10

B06D

1108 1901

1

1

B06A

1102 1619

1

1

2

2

3

3

5

5

6

6

MICROPROCESSOR

SC1_CVBS_RF_OUT

HEADPHONE AMP & MUTING

SC2_CVBS_MON_OUT_ITV

YPBPR & REAR IO

HD_PR_IN_ITV

HD_Y_IN_ITV

HD_PB_IN_ITV

1615

Pr

Y

Pb

1601-2

VIDEO

1601-1

1

3

5

S VIDEO

4

2

3554

3555

3618

7503

EF

7500

7204

IS42S16400D-6TL

3537

3521

EF

3617

3619

SC1_RF_OUT_CVBS

SC2_CVBS_MON_OUT

VGA_H

VGA_V

HD_Pr_IN

HD_Y_IN

HD_Pb_IN

FRONT_Y_CVBS

FRONT_C

163

CVBS_OUT1

DQ(0-31)

MEMORY

162

CVBS_OUT2

7211

2

3

1

4

158

AIN_HS

AIN_VS

159

5

8

9

6

188

180

196

182

192

PR_R1

Y_G1

PB_B3

Y_G3

C

8-BIT

SINGLE

LVD S TX

TA1

TB1

TC1

TCLK1

TD1

CX_MA

51

50

49

48

45

44

43

42

41

40

(0-11)

(0-15)

(0-11)

(16-31)

TXCLKn

TXCLKp

TXAn

TXAp

TXBn

TXBp

TXCn

TXCp

TXDn

TXDp

DRAM

1Mx16x4

7205

IS42S16400D-6TL

DRAM

1Mx16x4

1210

1211

1212

1213

1214

TXAn1

TXAp1

TXBn1

TXBp1

TXCn1

TXCp1

TXCLKn1

TXCLKp1

TXDn1

TXDp1

VDISP

BOLT_ON_SCL

BOLT_ON_SDA

1G51

1

3

5

7

2

4

6

8

12

14

18

20

24

26

27

29

LVD S

CONNECTOR

TO DISPLAY

H_16990_042.eps

211207

Page 26

Block Diagrams, Test Point Overviews, and Waveforms

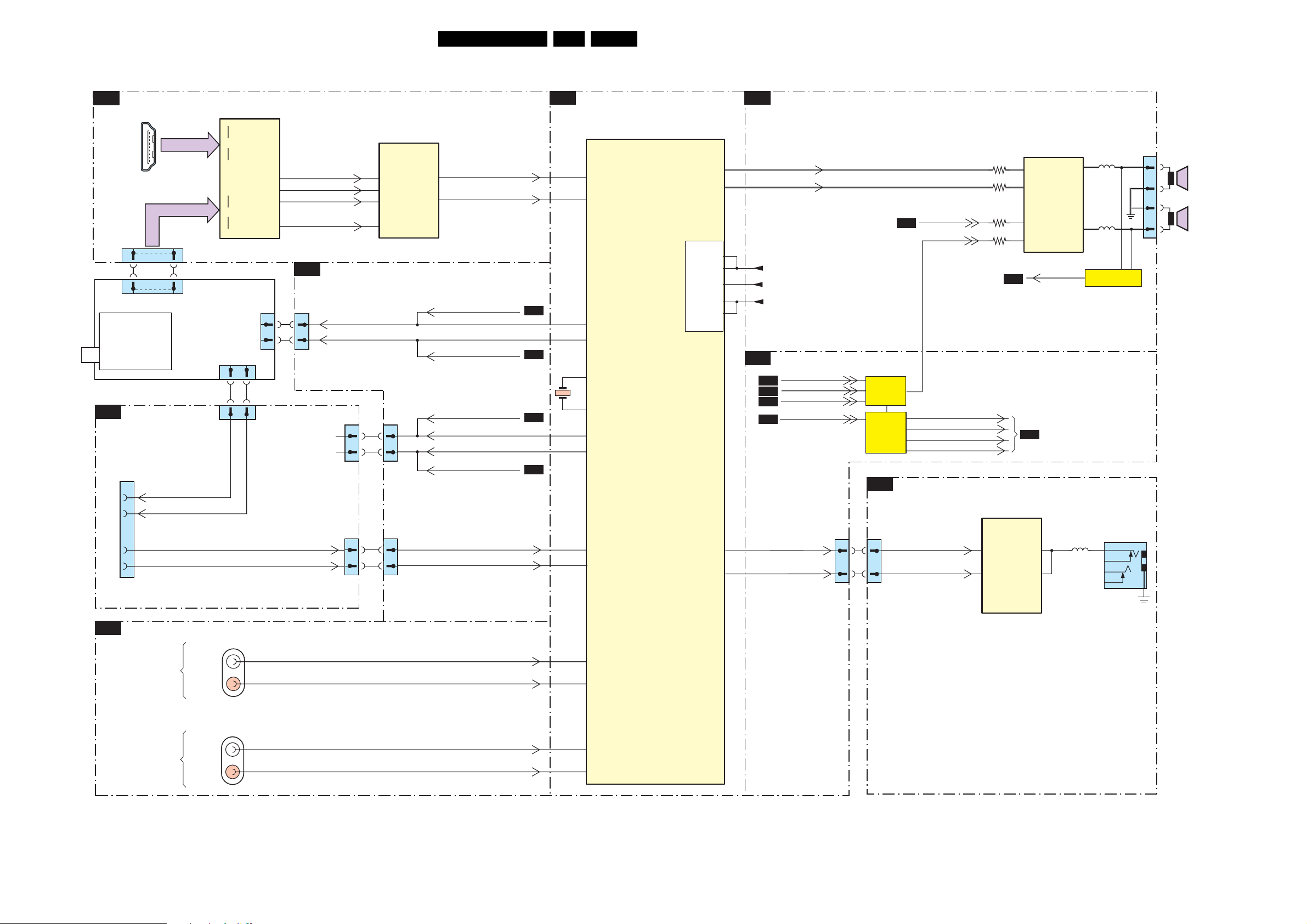

Block Diagram Audio

AUDIO

B06C

HDMI

1

HDMI 1

1

1

P600 1812

TUNER

SI

SYSTEM

INTERFACE

1305

27

28

29

30

INTEGRATED

CARD SLOT

B06A

YPBPR & REAR IO

RXxxA

18 2

19

RXxxB

21

21

MPEG4 PANEL

MPEG4 ONLY FOR

CHASSIS LC7.2HU_LB

SC1_AUDIO _OUT_R

SC1_AUDIO _OUT_L

AUDIO

EXT3

L/R IN

7817

SII9025CTU

+

-

+

-

+

-

+

-

ATSC

1306 P501

RX2

RX1

RX0

RXC

576

1603

HDMI

SCK

WS

SD0

MUTE

P201 1527

1

2

6

SC2_AUDIO_IN_R

SC2_AUDIO_IN_L

86

HDMI_I2S_SCK

85

HDNI_I2S_WS

84

HDMI_I2S_SD

77

B06B

1

2

7810

UDA1334ATS/N2

1

BCK

2

WS

3

DATAI

8

MUTE

I0 - SCART 1 & 2

SC2_AUDIO _OUT_R

SC1_AUDIO _OUT_L

1301 1526

7

N.C.

6

N.C.

1302 1525

7

6

AUDIO

7

6

7

6

DAC

14

VOUTL

16

VOUTR

SC2_AUDIO _MUTE_R

SC2_AUDIO _MUTE_L

SC1_AUDIO _MUTE_R

SC1_AUDIO _OUT_R