Page 1

1-1 LC5131/5141

1. Safety guidelines

Portable LCD projector

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all Philips Consumer Electronics Company** Equipment.

The service procedures recommended by Philips and described in this service manual are effective methods of performing

service operations. Some of these service operations require the use of tools specially designed for the purpose. The special

tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in order to

minimize the risk of personal injury to service personnel. The possibility exists that improper service methods may damage the

equipment. It also is important to understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Philips could not

possibly know, evaluate and advise the service trade of all conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not recommended by Philips must first satisfy himself thoroughly that

neither his safety nor the safe operation of the equipment will be jeopardized by the service method selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company will be referred to as Philips.

WARNING

Critical components having special safety characteristics are identified with an by the Ref. No. in the parts list

and enclosed within a broken line* (where several critical components are grouped in one area) along with the

safety symbol on the schematics or exploded views.

Use of substitute replacement parts which do not have the same specified safety characteristics may create shock,

fire, or other hazards.

Standby

/O

n

In

p

u

S

t

ta

tus

Au

to im

age

LC5131/00

LC5141/00

UGO S-light/X-light

Under no circumstances should the original design be modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of any unauthorized modification of design. Servicer

assumes all liability.

* Broken Line

Contents Page

1. Safety guidelines 1-1

2. Specifications 2-1

3. Warnings & Notes 3-1

4. Mechanical instructions 4-1

5. Block diagrams, Wiring diagram & Oscillograms 5-1

6. Directions for use 7-1

7. Alignments & Protections 8-1

8. Parts lists 9-1

PCS 106 634

Published by Consumer Electronics Printed in The Netherlands©Copyright reserved Subject to modification

PCS 106 633

3122 435 40280

Page 2

2. Specifications

54

3

21

11 121314

15

10

98

7

6

1

234

5

12

3

4

17.3

Height to

screen (H)

Screen

Width

Screen size

(inches in diagonal dimension)

Height

Main unit

Projection distance (L)

o

0

0

1

2

34

56

1

2

3

4

5

(m)

1.2m

2.7m

3.4m

5.1m

6.8m

Projection distance

Center lens

Projection height

36

80

100

150

200

Screen size

(m)

17.3

o

LC5131/5141 2-1 2-2 LC5131/5141

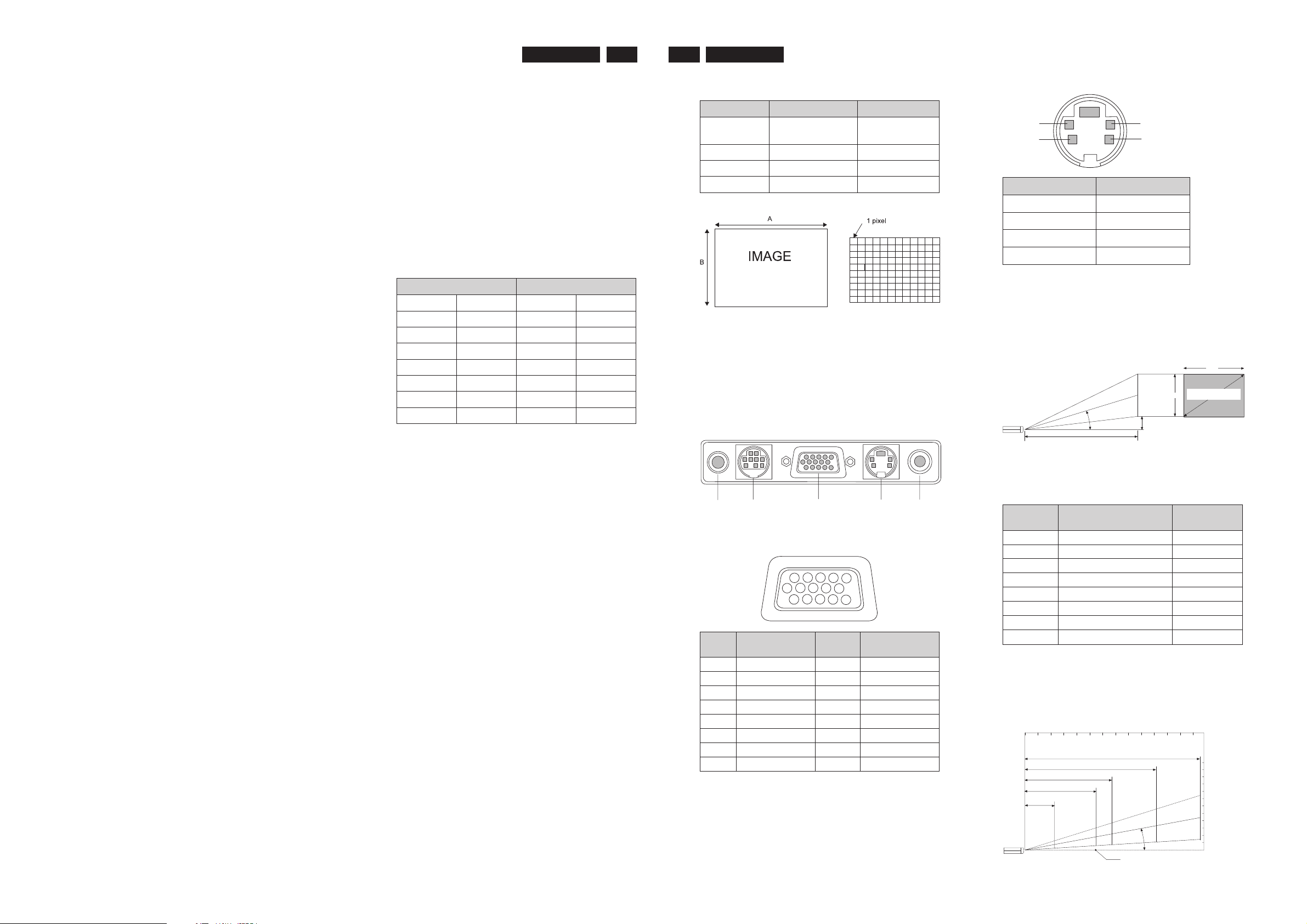

2.1 Product specifications

Package

UGO LC5141/LC5131

:

2.2 DMD Chip

Relationship between S-video terminal and signal.

Remote Control + 2x AAA batteries

UGO UGO

X-lite S-lite

800 ANSI lumens 800 ANSI lumens

XGA resolution SVGA resolution

Compact design - < 2 dm

Ultra lightweight just 1.3 kg

Easy plug&play

Digital picture enhancement

Dimensions; 227 x 48 x 177 mm (WxHxD) < 2 dm

•

Net weight 1.3 kg; ca 2.86 lbs

•

Advanced compatibility for both data and video input;

•

compatible with main notebook computers

High contrast ratio; 800:1 (Full on/off)

•

Digital picture enhance technologies;

•

Digital Zoom (x10), Digital Freeze, Digital

•

Keystone correction

•

Intuitive Graphic User Interface (GUI) for ease of use

•

Auto voltage for safe usage around the world

•

Robust, reliable technical design

•

Suitable for meeting rooms for 2 to 20 people

•

Kensington lock

•

Technical specifications

DMD™

3

1x 0.67" DMD™

:

LC5141 786,432 pixels,Time sequential

(1024x768)

LC5131 480,000 pixels,Time sequential

(800x600)

3

Executions

Optional acc.:New 130 W UHP lamp

Image diagonal size Projection distance

[inch] [meters] [inch] [meters]

37 0,94 47 1,2

60 1,52 79 2,0

80 2,03 106 2,7

100 2,54 134 3,4

120 3,05 161 4,1

150 3,81 201 5,1

200 5,08 268 6,8

Power cord (1,8m) (2 cords,

Continental Europe and USA)

VGA Cable (1m)

PC Audio cable

Mouse cable set; 1m, PS/2 ; 1m, USB

Audio/Video RCA Cable

(1m,Video/Audio stereo)

S-Video cable (1m)

Soft carrying bag

User Guide (8 languages - CD-Rom,

plus Quick Reference Guide)

LC 5141/00 Global product in native XGA

:

LC5131/00 Global product in native SVGA

:

Product type LC5141 LC5131

Number of

pixels

1024 (horizontal) x

768 (Vertical) x 1

Size 0.67 inches 0.67 inches

A 1024 pixels 800 pixels

B 768 pixels 600 pixels

2.3 Input termina

1. AUDIO IN (stereo mini-jack)

2. Mouse output terminal (mini-DIN9pin)

3. RGB/Y CbCr IN (miniD-SUB15pin)

4. S-VIDEO IN (S-video terminal)

5. VIDEO IN (video RCA x 1)

Relationship between RGB input terminal and signal

800 (horizontal) x

600(Vertical) x 1

Pin No. Single

1 GND

2 GND

3 Luminance signal

4 Chrominance signal

2.4 Projection size and projection distance

The projection size ranges from a minimum of 36 inches to a

maximum of 300 inches. The focusing projection distance is

between 1.2 and 6.8 meters from the lens surface. Install

within this range.

Brightness : 800 ANSI lumens

Contrast : 800:1 (Full on/off )

Lamp : 130 W UHP lamp

End user replaceable1000 hours

Lens : F3.0 ;f=23mm

Fixed Focal length; Manual Focus

• Horizontal projection position: Left-right symmetry with

lens in center.

• Vertical projection position (for XGA)

Proj. Dist. 1,2 - 5,8m; Diagonal

(42 - 200)"

Digital features:Digital Zoom (x10), Digital Freeze,

Input signals

Video

:

NTSC 3.85, 4.43 /PAL BG, N, M /Secam

in 4:3 and 16:9 formats

Data

:

PC and Mac compatible, Multi scan

VGA, SVGA, XGA, SXGA via high

advanced scaling technology.

Auto image control Hor. scan rate:

15-91 kHz; Vert. Refresh rate 50-85 Hz.

Power in

Input connections

Video

Data

Mains

Specialities

Dimensions

Net weight

:

:

:

:

:

:

:

110-120 V / 220-240 V; 50/60 Hz; 180 W

S-Video (Y/C DIN)/Video (RCA)/ Stereo

Audio (2x RCA)/ YCbCr

Mini sub-D data (15 pin)/PC Stereo

Audio (M3.5 stereo jack) / Serial mouse

(9pin Mini DIN); USB port / PS/2

Mains input socket (3 pin)

48 mm Ultra Thin Profile

800 : 1 Contrast Ratio

Advanced compression technology for

full automatic adjust multi scan

data input handling, VGA up to SXGA

resolutions to full screen

Intuitive Graphic User Interface (GUI)

for ease of use

Full plug&play compatible (DCC 1 / 2b)

Full Mirror function

Acoustical Noise <39 dBA

227x 48 x 177 mm (WxHxD); <2 dm3

1,3 kg; ca 2,86 lbs

Pin

No.

PCS 106 635 PCS 106 636

Single Pin No. Single

1 Red 9 No Connection

2 Green 10 Digital GND

3 Blue 11 GND

4 GND 12 SDA

5 GND 13 Horizontal Sync

6 Red GND 14 Vertical Sync

7 Green GND 15 SCL

8 Blue GND

Screen

size

Projection distance L m

Dimension

H cm

Inches Meters Millimeters

36 1.2 99

60 2.0 169

80 2.7 225

100 3.4 281

120 4.1 337

150 5.1 422

200 6.8 562

•

These values are based on design values, and their error

is within +/-5%.

Projection distance and projection size

Page 3

3. Warnings & Notes

LC5131/5141 3-1 4-1 LC5131/5141

4. Mechanical Instructions

Warnings

1.

Safety regulations require that the unit should be returned in

its original condition and that components identical to the

original components are used. The safety components are

indicated by the symbol .

2. ESD

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten the life. Make sure that during

repair you are connected by a pulse band with resistance to

the same potential as the earth of the unit. Keep components

and tools also at this same potential.

3. When repairing a unit, always connect it to the mains voltage

via an isolating transformer.

The lamp supply and the lamp housing are not mains

isolated.

4. Be careful when taking measurements in the high-voltage

section.

5. Never replace modules or other components while the unit is

switched on.

6. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a circuit

becoming unstable.

7. After repair the wiring should be fastened once more in the

cable clamps for this purpose.

8. In order to prevent measuring errors, the heat sinks should

not be used as reference points for measurements.

9. The Lamp house and the lamp get hot during operation.

Please ensure that they are cooled down before servicing.

Notes

1.

The direct voltages and oscillograms should be measured

with regard to earth (4), or hot earth (5) as this is called.

2. The semiconductors indicated in the circuit diagram and in the

parts lists are completely interchangeable per position with

the semiconductors in the unit, irrespective of the type

indication on these semiconductors.

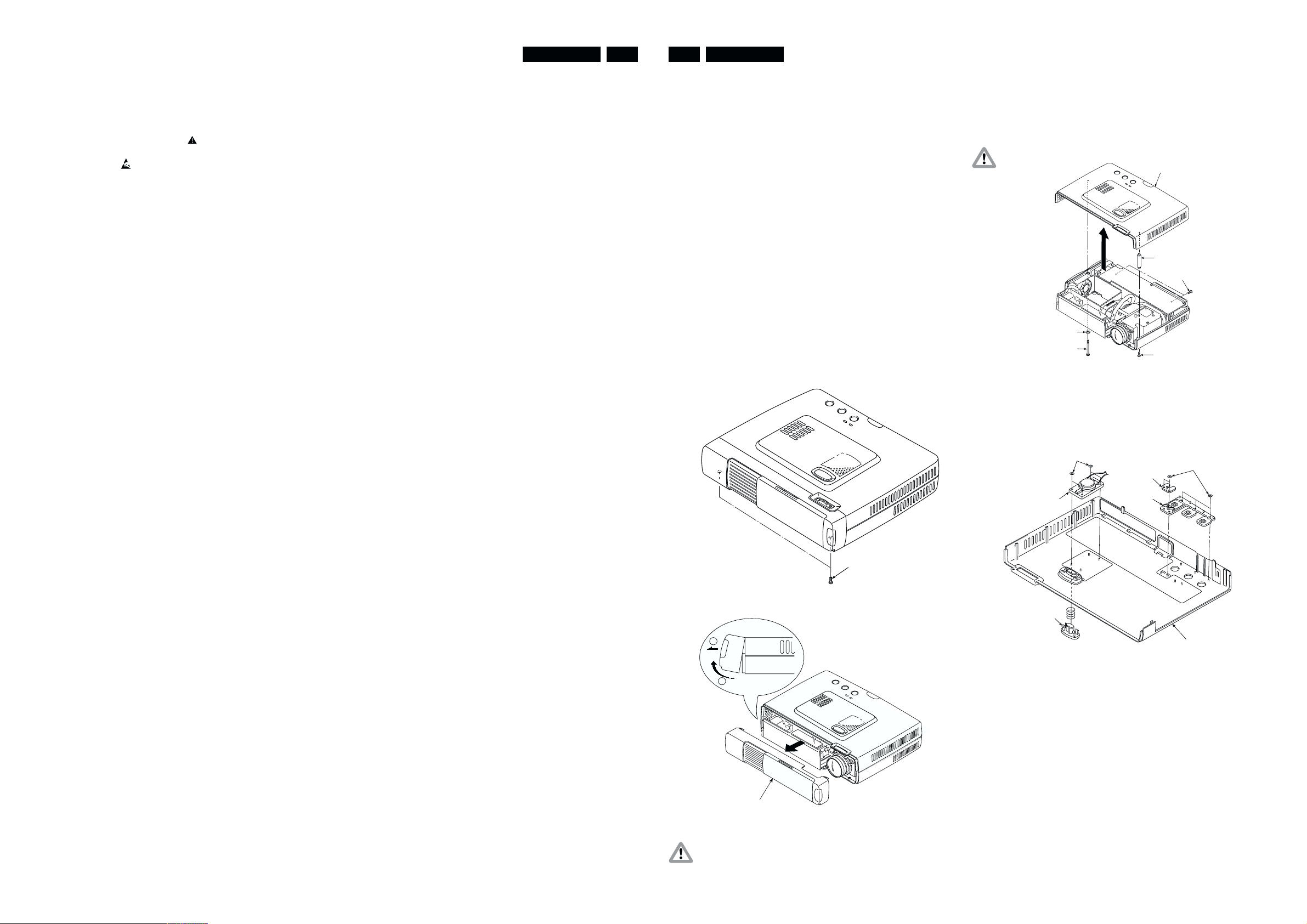

4.1 Preparations and Cautions

Items to have on hand:

1. Number 1 and 2 Philip’s head screwdrivers.

2. Precision screwdrivers (Philip’s head and flat head)

3. Wristband to remove static electricity.

Cautions during disassembly and assembly.

1. When carrying out operations remove the power lamp

beforehand.

2. Some parts may still be hot immediately after use. Be

sure all parts have cooled sufficiently before starting

operations.

3. Make sure all parts, screw tightenings and wirings are in

the original position.

4. Cautions have been included concerning areas which

require particular care when handling parts and carrying

out operations. Be sure to observe all cautions.

5. Special parts which are specified for the LC5131/LC5141

models should not be attached to other models.

6. Do not attempt to remodel the equipment.

4.2 Disassembly, Assembly

1. Front Panel Section (See Fig 1 and Fig 1-A).

Remove the screws (S-8: 2 screws) as shown in Fig 1.

2. Upper cover Section (See Fig 2)

Remove the screws (S-8, 3 screws, louver screw) as

shown in Fig 2.

Remove the upper cover as shown in Fig 2.

Caution: Be careful not to disconnect or break the speaker

Upper cover

Spacer D/M

S-8

S-1

Louver

screw

Cable

3. Speakers, Buttons, etc. (See Fig 3)

Remove the S-20 as shown in Fig 3 and then remove

the speaker button OP and LED lens.

Also push the catches on the front button to remove.

S-20

Speaker Assy

LED

lens

Button

OP

S-8

Fig 2

S-20

10. The lighthouse (optical part) is extremely sensitive to dust.

This part should only be opened in a dust-free environment

(class 100 according to the US federal standard 209).

S-8

Remove the front panel as shown in Fig 1-A.

2

1

Front panel

Caution: Be careful to disconnect the IR cable.

Fig 1

Front foot

Upper cover

Fig 3

Fig 1-A

PCS 106 637 PCS 106 638

Page 4

LC5131/5141 4-2 4-3 LC5131/5141

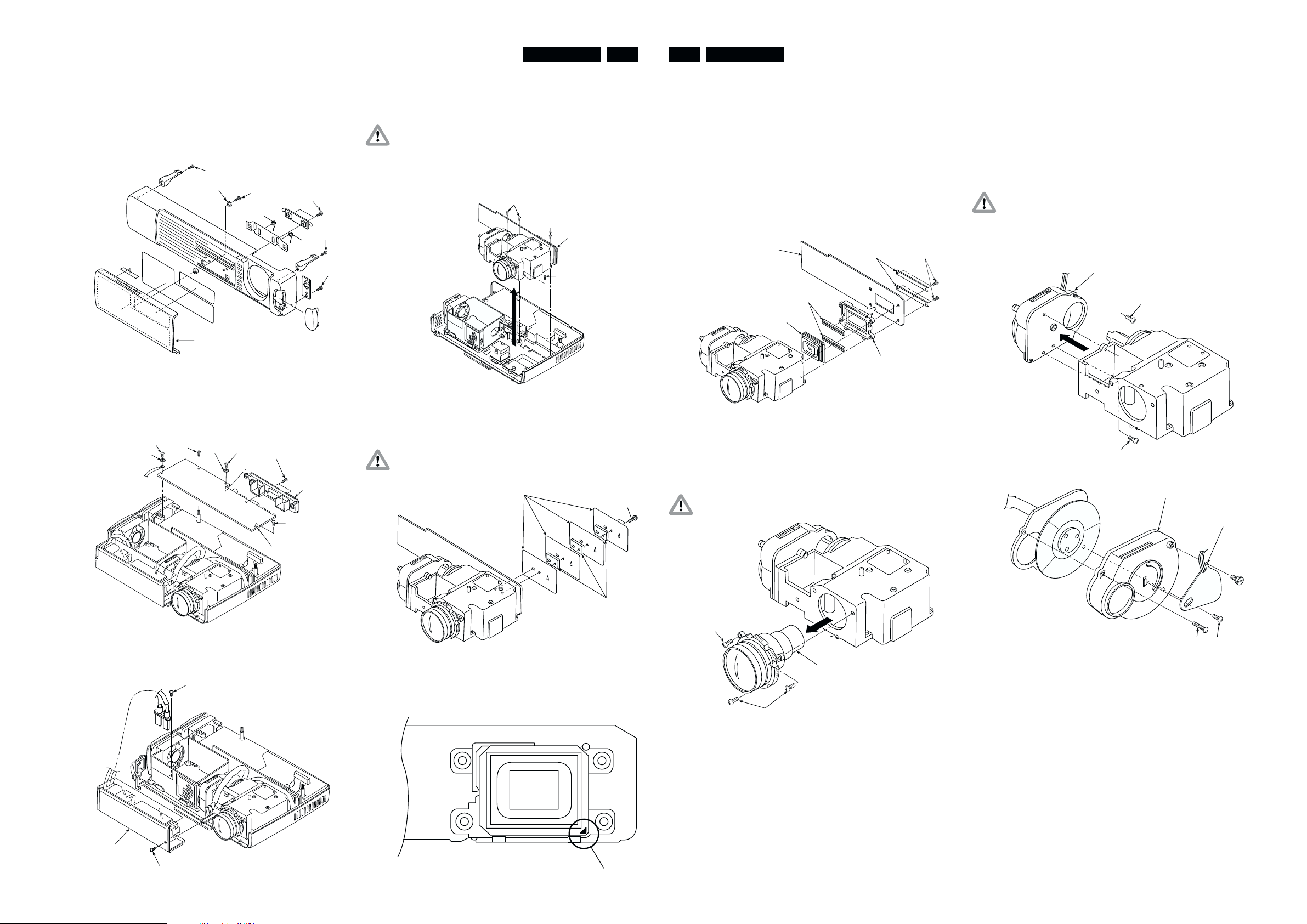

4. Disassembly of the front panel section (See Fig 4)

Remove the screw (S-12: 1 screw) as shown in Fig 4

and then remove the front door.

Remove the IR board. (S-4: 1 screw)

Remove the plates. (S-2: 2 screws)

Remove the front hooks on the left and right.

(S-7: 1 screw)

S-7

S-22

S-12

Front door

Fig 4

5. F/E board (See Fig 5)

Remove the screws (S-13:1screws, S-5:2screws) shown

in Fig 5 and then remove the connectors.

Remove the connector panel.

(S-13: 1 screw, RGB spacer: 2 spacers)

S-13

S-18

S-5

S-18

S-13

RGB spacers

S-5

Connector

panel

S-2

S-7

S-4

7. Lens Base Section (See Fig 7)

Remove the screws (S-7: 4 screws) as shown in Fig 7

and then remove the lens base.

Caution: Be careful when disassembling and assembling

equipment that there is no catching of wires, etc.

Do not remove the spherical mirror on the inside

of the lens base or the cylinder mirror from the

lens base as this could cause maladjustments and

shadows in the corners of the screen.

S-7

S-7

Lens

Base Section

S-7

Fig 7

8. Heat sink (See Fig 8)

Remove the screws (S-11: 2 screws) as shown in Fig 8

and then remove the heat sink.

Caution: Be careful of the attachment direction of the heat

sink

Heat sink A

S-11

10. DMD, F/M board (See Fig 10)

Remove the screws (S-9: 4 screws) shown in Fig 10

and remove these items from the lens base.

Caution: Be careful not to avoid direct finger contact with

the elastomer, the DMD surfaces and terminals or

the F/M board terminals.

Also be careful of dust or dirt adhering during

attachment.

The DMD, elastomer and F/M board have a direct

influence on the image and require special care

when handling.

F/M PWB

Elastomer

DMD

F/M Hold

Holder

Elastomer

S-9

Fig 10

11. Projection Lens (See Fig 11)

Remove the screws (S7: 3 screws) shown in Fig 11

and remove the projection lens.

Caution: When assembling be careful to avoid breaking the

spherical mirror on the inside of the lens base.

12. Color Wheel Section (See Figs 12 and 13)

Remove the screws (S-9: 3 screws) shown in Fig 12

and then remove the color wheel from the lens base.

This is a sticky connection, so pull carefully.

Remove the screws (S-4: 2 and S-14:1 screws) shown

in Fig 13 and then remove the wheel cover from the

color wheel.

Remove the wheel screw shown in Fig 13 and then

remove the wheel sensor.

Caution: Excessive tightening of screws during assembly

could cause the color wheel to contact other parts

so that it does not rotate properly. Assemble the

parts to be parrallel. When replacing the color

wheel and wheel sensor, readjustments are

required. (See page 6).

Color wheel section

S-9

S-9

Wheel cover

Fig 12

Wheel sensor

F/E board

6. Lamp Driver (See Fig 6)

Remove the screws (S-3, 17: 1 screw each) as shown in

Fig 6 and then remove the lamp driver.

S-3

Lamp

driver

S-17

Fig 5

Fig 6

9. DMD chip (See Fig 9)

Install the DMD chip so that the A portion is at the

lower right as shown in Fig 9.

Fig 9

Heat sink B

Fig 8

A

S-7

S-7

Projection Lens

Fig 11

S-14

S-4

Fig 13

PCS 106 639

PCS 106 640

Page 5

LC5131/5141 4-4 5-1 LC5131/5141

5. Block diagrams, Wiring diagram & Oscillograms

13. Light Tunnel, Aperture (See Fig 14)

Remove the screws (S-7: 3 screws) shown in Fig 14

and then remove the light tunnel from the lens base.

Remove the screws (S- : 2 screws) shown in Fig 14

and then remove the aperture from the lens base.

Caution: Do not disassemble the light tunnel.

Do not touch the glass.

S-7

Light tunnel

Aperture

S-4

S-7

Fig 14

14. Lamp House Section (See Fig 15)

Remove the screws (S-7: 3 screws) shown in Fig 15

and then remove the lamp house from the lower cover.

Remove the screw (S-15: 1 screw) shown in Fig 15

and then remove the thermistor and thermistor plate.

Remove the screw (S-7: 1 screw) shown in Fig 15 and

then remove the ballast lock base.

Removing the lamp house causes the 40 square fan

assembly to come out.

Caution: Be careful of the wiring method for the 40 square

fan. The fan passes under the lamp house from

below.

S-7

Lamp hous

S-15

40FAN(L)

S-7

Thermistor Assy

Thermistor plate

S-15

Fig 15

15. Power source section (See Fig 16)

Remove the screws (S-7: 2 screws) shown in Fig 16

and then remove the fan base from the cover.

Remove the screws (S-5, 10: 1 screw each, Spacer

D/M: 2 spacers) and then remove the power source.

Note: The power supply fan must be mounted with the wires

up. The lamp fan must be mounted with the wires

down.

S-7

S-5

Spacers D/M

Power source

40FAN DC

S-7

Fan base

Fan

gard

S-10

S-21

Fig 16

16. Front and Rear Foot, etc. (See Fig 17)

As shown in Fig 17 remove the front foot in the

following order: (1) Press the catch. (2) Push out.

S-7

Rear foot

Front foot

Lamp limit switch

2

1

Fig 17

Rotate the rear foot and remove.

Remove the screw (S-7: 1 screw) shown in Fig 17 and

remove the lamp limit switch.

5.1 Optical system principle block diagram

Description of function

1. Lamp

Light source: Flashes 300 times per second as AC

lamp.

2. RGBW color wheel

Divides light into the RGBW components using color

filters.

The W component allows a bright white to be

reproduced.

A rotation detecting sensor is used to time the lamp

which is turned OFF at the color filter seam.

The maximum speed is 7,200 rpm.

3. Condenser lens and light tunnel

Collects light divided into RGBW components by the

color filter and projects them on the effective surface of

reflection mirror 1.

Use of the light tunnel lens increases the peripheral

intensity of illumination. It reduces the difference of

brightness between the screen center and periphery,

reproduces a clear view of even the corners of the

screen.

4. Reflection mirror 1 and 2

Reflects light beamed on the mirror effective surface, to

the DMD effective surface.

5. DMD chip

Reflects the light by switching on and OFF according to

the input source at the ratio of color components for

each dot.

6. Projection lens

Enlarges and projects light from the DMD.

7. Screen

The projected light (RGBW components) forms a picture

with colors synthesized through afterglow.

PCS 106 641 PCS 106 642

Page 6

5.2 Wiring diagram

SPEAKER

PORM

POSP

PODC

PODB

POLB

POLA

POFA POFB

CN20

CN2

LAMP

DRIVER

LAMP

F/M PWB

F/E PWB

J2

CN1

WHEEL-SENSOR

DC

POWER

SUPPLY

UNIT

LAMP-SW

LAMP-FAN

DC-PSU-FAN

TEMPERATURE-SENSOR

POPA

IR-SENSOR

LC5131/5141 5-2 6-1 LC5131/5141

6. Directions for use

PCS 106 643 PCS 106 644

Page 7

LC5131/5141 6-2 6-3 LC5131/5141

PCS 106 645 PCS 106 646

Page 8

LC5131/5141 6-4 6-5 LC5131/5141

PCS 106 647 PCS 106 648

Page 9

LC5131/5141 6-6 6-7 LC5131/5141

PCS 106 649 PCS 106 650

Page 10

LC5131/5141 6-8 6-9 LC5131/5141

PCS 106 651 PCS 106 652

Page 11

LC5131/5141 6-10 6-11 LC5131/5141

PCS 106 653 PCS 106 654

Page 12

LC5131/5141 6-12 7-1 LC5131/5141

7. Alignments & Protections

8-1. Color wheel sensor adjustment

Adjustment is required in the following cases:

1. After color wheel unit replacement

2. After color wheel sensor replacement

3. After optical engine unit replacement (to be adjusted if

failure is found by inspection)

4. After F/E board replacement (to be adjusted if failure is

found by inspection)

Preparation

1. PC (Windows95/98-based computer)

2. RGB cable

3. Special-purpose software (white.exe)

4. Wrench (5 mm)

Caution: When adjusting be careful not to touch hot areas

such as the lamp. Also be careful not to short the

substrates or other parts.

8-2. Lamp replacement

Preparation

1. A cushion to prevent the main unit fro being damaged

when it is placed in a reverse position

2. A Phillips screwdriver No.1

Cautions for lamp replacement and handling

1. Before starting lamp replacement, be sure to unplug the

power supply. (Otherwise, electric shock may occur.)

2. Start lamp replacement after making sure that the lamp

is cooled.(Otherwise, fire may occur.)

3. Do not allow the lamp to be exposed to strong shock or

vibration.(Otherwise, damage or injury may occur.)

4. Do not disassemble the lamp.

Lamp replacement

1) Remove the lamp cover fastening screw.

Fig 1

Procedure

1. Make adjust when the upper and front cover has been

removed.

2. Connect between the projector and PC. (mode RGB)

3. Start the special-purpose software with the PC.

4. Press the “6" key on the keyboard. After the Figure on

the right (Fig. 1) is displayed, press the ”R" key to display

the red picture. Then check the image. Check other

than red, too (*1).

5. If there is any portion on the screen that does not turn

red, loosen the wheel screw and adjust the wheel sensor

in Fig. 2 in the vertical direction and fasten it at a position

where there is no color misalignment.

6. After adjustment, press the “Q” key on the keyboard to

terminate the software.

2) Remove the lamp cover.

3) Remove three lamp cartridge fastening screws

Note: *1. The basic black-and-white pattern s are registered

PCS 106 655 PCS 106 656

Fig 2

on the number keys (0-9), and colors can be

changed with the following letter keys:

W (white), K (black), R (red), G (green), B (blue),

M (magenta) and C (cyan)

Page 13

LC5131/5141 7-2 7-3 LC5131/5141

4) Hold the handle and take out the lamp housing.

5) Install a new lamp housing.

8) Reset the lamp time.

After the Information Menu appears, select “Reset Lamp

Time” and press the ENTER button.

To reset, press the ENTER button. To quit, press the

CANCEL button

9) When power cuts off after lamp was used over 1100 hours

After replacing the lamp housing, connect the power cord

and set in standby. Hold down the unit SOURCE and

AUTO buttons simultaneously for at least 5 seconds.

8.3. Protections

8.3-1. Internal Temperature Detection

There is a thermostat in the lamp housing, which switches off

the lamp when thermostat temperature has reached 90°C or

more.

The power supply, like the lamp driver, has a thermostat.

These two thermostats switch the power off at respective

temperatures of 120 and 115 degrees Centigrade or higher.

Status Meaning Solution

OFF (lamp off) Normal

ON (lamp on)

Flashing at intervals of one second

(ON for 0.5 sec./OFF for 0.5 sec.)

Flashing at intervals of 4 seconds

(ON for 2 sec./OFF for 2 sec.)

The lamp has been used in excess of 1,000

hours

The lamp is not installed correctly. Install the lamp correctly

The temperature protector has been triggered

Power may not be turned on if you switch ON

the main power switch immediately after the

temperature protector has been triggered and

the main power switch has been

turned OFF.

The lamp lighting voltage failure detection

protector has been triggered.

Replace with a new lamp and reset the lamp

usage time

If the room temperature is high, move the

projector to a cooler location.

If the temperature inside the projector is high,

check the cooling fan vents and bottom vents,

and clean and remove any substance with which

these vents are clogged.

Wait for one minute; then turn ON the switch.

Wait for one minute; then turn ON power.

6) Fasten three lamp housing fastening screws.

7) Install the lamp cover and fasten it with fastening screws

8.3-2. Lamp Unit and Interlock Switch

If the lamp cover is not mounted, the lamp does not turn on

even if it is provided.

8.3-3. Status LED Specifications

The Status LED lamp flashes if the lamp is not turned on.

The flashing cycle allows you to trace the cause of the

trouble. (See the drawing on the right and Table below.)

Flashing at intervals of 8 seconds

(ON for 4 sec./OFF for 4 sec.)

Flashing at intervals of 12 seconds

(ON for 6 sec./OFF for 6 sec.)

The fan is stopped Inspect the exhaust fan

Wait for one minute; then turn it ON. If this does

The lamp fails to light up

not solve the problem, check

the inside.

PCS 106 657 PCS 106 658

Page 14

8. Parts list

LC5131/5141 8-1 8-2 LC5131/5141

Upper Cover Section

1 Upper cover assy 9965 000 07243

2 Upper cover no spare part

3 Button op no spare part

4 Led lens no spare part

5 Foot button no spare part

6 Foot button spring no spare part

7 Sensor cover r no spare part

8 Upper plate no spare part

9 Upper tape s no spare part

10 Upper tape b no spare part

11 Insulate tape no spare part

12 Plate spacer no spare part

13 Urethane form l no spare part

14 Upper cover mesh no spare part

15 Insulate sheet f/e no spare part

16 U3 gasket no spare part

17 Speaker assy 9965 000 07137

18 Front panel 9965 000 07138

19 Slider plate 9965 000 07296

20 Slider spring 1 9965 000 07297

21 Slider spring 2 9965 000 07298

22 Slider roller 9965 000 07299

23 Push slider 9965 000 07300

24 IR pwb 9965 000 07170

25 IR cable assy 9965 000 07301

26 Front hook 1 9965 000 07171

27 Front hook 2 9965 000 07172

28 Front door assy (no 29-32) 9965 000 07244

29 Front door no spare part

30 Front door sheet 1 no spare part

31 Front door sheet 2 no spare part

32 Front door sheet 3 no spare part

33 Louver screw 9965 000 07302

34 Spacer d/m 9965 000 07305

PCS 106 659

pwb section

35 F/E PWB LC5131 9965 000 07139

35 F/E PWB LC5141 9965 000 07186

36 Connector panel 9965 000 07140

37 Connector sheet 9965 000 07141

38 Spacer rgb 9965 000 07306

39 Lens base urethane form 9965 000 07307

40 Lamp driver stud 9965 000 07173

41 Limit sw board 9965 000 07142

42 Lamp driver 9965 000 07143

43 Insulate sheet l/d 9965 000 07308

44 Radiation sheet l/d 9965 000 07309

45 Lamp driver lock base 9965 000 07174

46 Louver panel 9965 000 07144

47 Lamp house assy (no 48-52) 9965 000 07145

48 Lamp house no spare part

49 Lamp house mesh no spare part

PCS 106 660

50 Lamp house guard no spare part

51 Lamp house sheet no spare part

52 Lamp house mesh tape no spare part

53 Thermister plate 9965 000 07310

54 Thermister assy 9965 000 07146

55 40fan assy T-20H 9965 000 07147

56 40fan assy DC 9965 000 07148

57 Fan cushion 9965 000 07311

58 Fan vibration proof rubber 9965 000 07312

59 Fan guard 9965 000 07313

60 Fan base 9965 000 07175

61 Core 9965 000 07314

62 Fan fence 9965 000 07315

63 Gnd cable 9965 000 07316

134 Lamp sync cable assy 9965 000 07433

Page 15

LC5131/5141 8-3 8-4 LC5131/5141

Lower Cover Section

64 Lower cover 9965 000 07149

65 Inlet spacer 9965 000 07317

66 Spacer D/M 9965 000 07305

67 DC psu 9965 000 07150

68 Insulate sheet DC-1 9965 000 07318

69 Insulate sheet DC-2 9965 000 07319

70 Rear foot 9965 000 07151

71 Rear foot rubber 9965 000 07152

72 front foot 9965 000 07153

73 Lamp cover assy (no 74-77) 9965 000 07278

74 Lamp cover no spare part

75 Lamp cover screw no spare part

76 Lamp cover screw sp no spare part

77 Lamp cover guard no spare part

78 lamp 8670 931 13009

PCS 106 661 PCS 106 662

Optical Section

79 Lens base assy 9965 000 07154

80 Lens base no spare part

81 Spherical mirror assy no spare part

82 Cylinder mirror asy no spare part

83 Aparture no spare part

84 Lens base cover no spare part

85 Lens base sheet no spare part

86 Insulate sheet l/b 9965 000 07320

87 Lens unit 9965 000 07155

88 Condenser lens assy 9965 000 07156

89 Color wheel 9965 000 07154

90 Wheel cover 9965 000 07176

91 Rubber sheet 9965 000 07177

92 Wheel sensor board assy 9965 000 07157

93 Wheel screw 9965 000 07321

94 Sticker sd-10 9965 000 07322

95 Dmd set LC5131 9965 000 07158

95 Dmd set LC5141 9965 000 07187

96 push F/M PWB 9965 000 07323

97 Heat sink A 9965 000 07324

98 Heat sink B 9965 000 07325

Page 16

LC5131/5141 8-5 8-6 LC5131/5141

Label Section

99 Rating Label LC5131 9965 000 07326

99 Rating Label LC5141 9965 000 07332

100 Caution seal a(hot) 9965 000 07327

101 Caution seal c(lens) 9965 000 07328

102 Lamp caution seal a no spare part

103 FCC label 9965 000 07329

104 Logo mark 9965 000 07185

105 Pop label LC5131 no spare part

105 Pop label LC5141 no spare part

Accessories Section

106 Out carton no spare part

107 Carton box 9965 000 07178

108 Packing 9965 000 07179

109 Bag(machine) 9965 000 07180

110 Accessory box 9965 000 07181

111 Bag(manual,accessory) 9965 000 07182

112 Operation manual 9965 000 07160

113 Quick start guide no spare part

114 Inlay sheet no spare part

115 Warranty card no spare part

116 Warranty card envelope USA no spare part

117 Warranty card envelope EU no spare part

118 Carrying case 9965 000 07183

119 Accessory pad 9965 000 07330

PCS 106 663 PCS 106 664

120 Cable case 9965 000 07184

121 Remote controller 9965 000 07159

122 Remote controller label 9965 000 07331

123 AAA battery no spare part

124 Power cable (1.8m) ul 9965 000 07161

125 Power cable (1.8m) cee 9965 000 07162

126 Video cable(1p 1m) 9965 000 07163

127 Audio adapter 9965 000 07164

128 s-video cable(1m) 9965 000 07165

129 RGB cable (1m) 9965 000 07166

130 Mini jack cable(1m) 9965 000 07167

131 ps/2 mouse cable 9965 000 07168

132 USB mouse cable 9965 000 07169

133 Desiccant(30g) no spare part

Loading...

Loading...