Page 1

Colour Television Chassis

LC1.15E

AA

Contents Page

Safety Precautions 2

Servicing Precautions 3

Description of Controls 5

Troubleshooting 8

Wiring Diagram 9

Block Diagram 10

Main Board for LC151x01-A3 LCD Panel 11

Main Board PWB for LC151x01-A3 LCD Panel 12-13

Control and Tuner Panel PWB 14

Main Board for LC151x01-C3P1 LCD Panel 15

Main Board PWB for LC151x01-C3P1 LCD P. 16-17

Control and Tuner Panel PWB 18

Adjustment Instruction 19

Exploded View 21

Spare Parts List 22

Revision List 24

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by LM 0367 Printed in the Netherlands Subject to modification EN 3122 785 12511

Page 2

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5

!1.5KV: 14-19 inch, 26!1.5KV: 19-21 inch,

29.0

!1.5KV: 25-29 inch, 30.0 ! 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

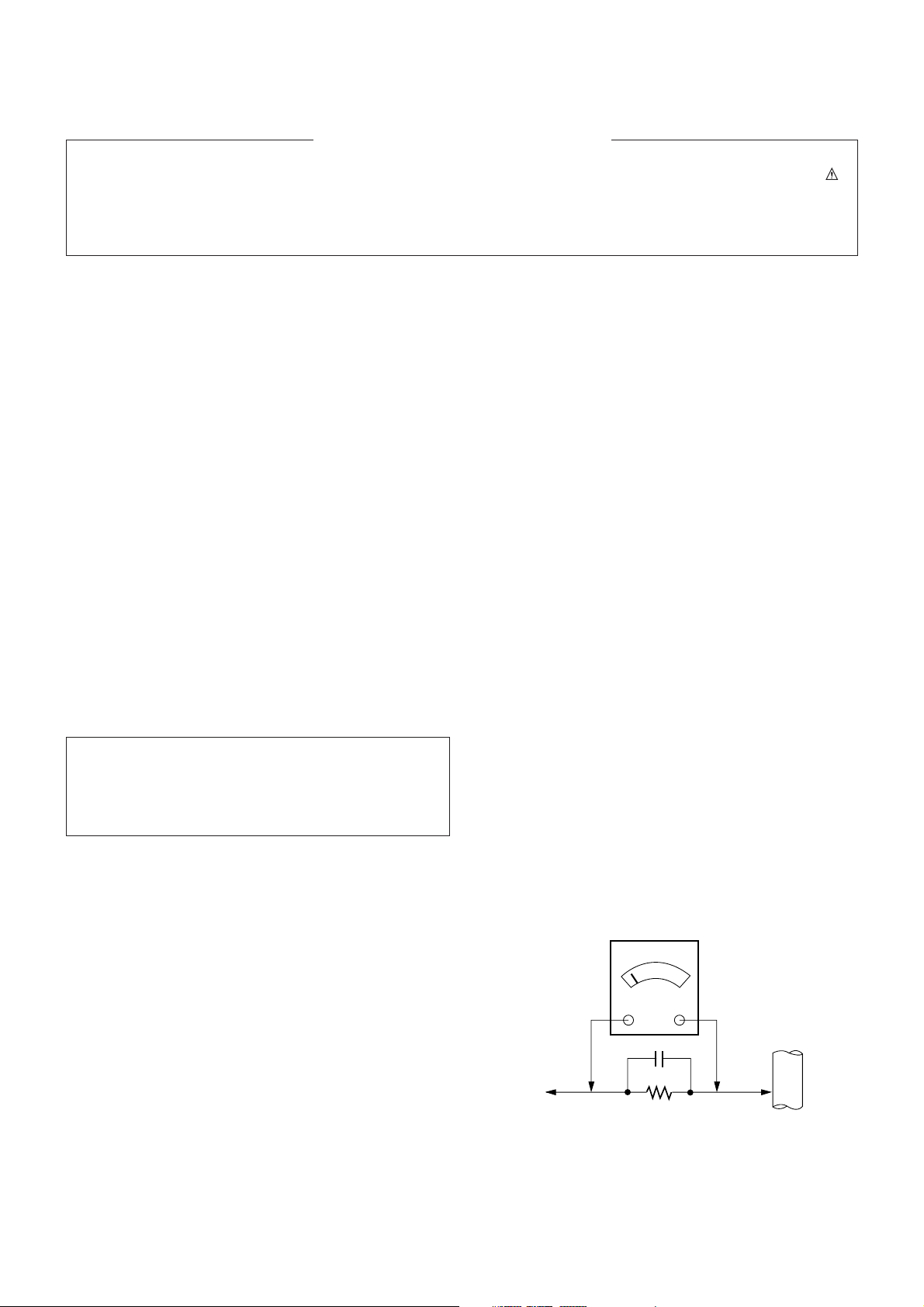

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

replacement tube must be the same type tube as specified in

the Replacement Parts List.

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS

on page 3 of this publication.

NOTE:

If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug

or other electrical connection.

c.

Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first connecting

one end of an insulated clip lead to the degaussing or kine

aquadag grounding system shield at the point where the

picture tube socket ground lead is connected, and then (b)

touch the other end of the insulated clip lead to the picture

tube anode button, using an insulating handle to avoid

personal contact with high voltage.

4. Do not spray chemicals on or near this receiver or any of its

assemblies.

5. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator; 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%-99%

strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication

of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which receivers covered by this service manual might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test receiver

positive lead.

Always remove the test receiver ground lead last.

9.

Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to

any heatsink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called

Electrostatically Sensitive (ES) Devices.

Examples of

typical ES devices are integrated circuits and some fieldeffect

transistors and semicounductor "chip" components. The

following techniques should be used to help reduce the

incidence of component damage caused by static by static

electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed to prevent potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as "anti-static" can

generate electrical charges sufficent to demage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a repalcement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the ieads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

CAUTION:Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such

as the bruching together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintan tip

temperature within the range or 500

cF to 600cF.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thorohly clean the surfaces to be soldered. Use a mall

wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500cF to 600cF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuiboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500cF to 600cF)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

SERVICING PRECAUTIONS

Page 4

c. Qulckly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it

there only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess

or splashed solder with a small wire-bristle brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following

technique should be used to remove and replace the IC. When

working with boards using the familiar round hole, use the

standard technique as outlined in parapraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit boare.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the "U" with long nose pliers to insure metal to metal

contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicula y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them

and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board

to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board.

The following guidelines and procedures should be followed

whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely

necessary).

2. carefully scratch away the solder resist and acrylic coating

(if used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped end

of the good copper pattern. Solder the overlapped area and

clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involoves the installation of a jumper wire on the component

side of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of

the nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so

the it does not touch components or sharp edges.

Page 5

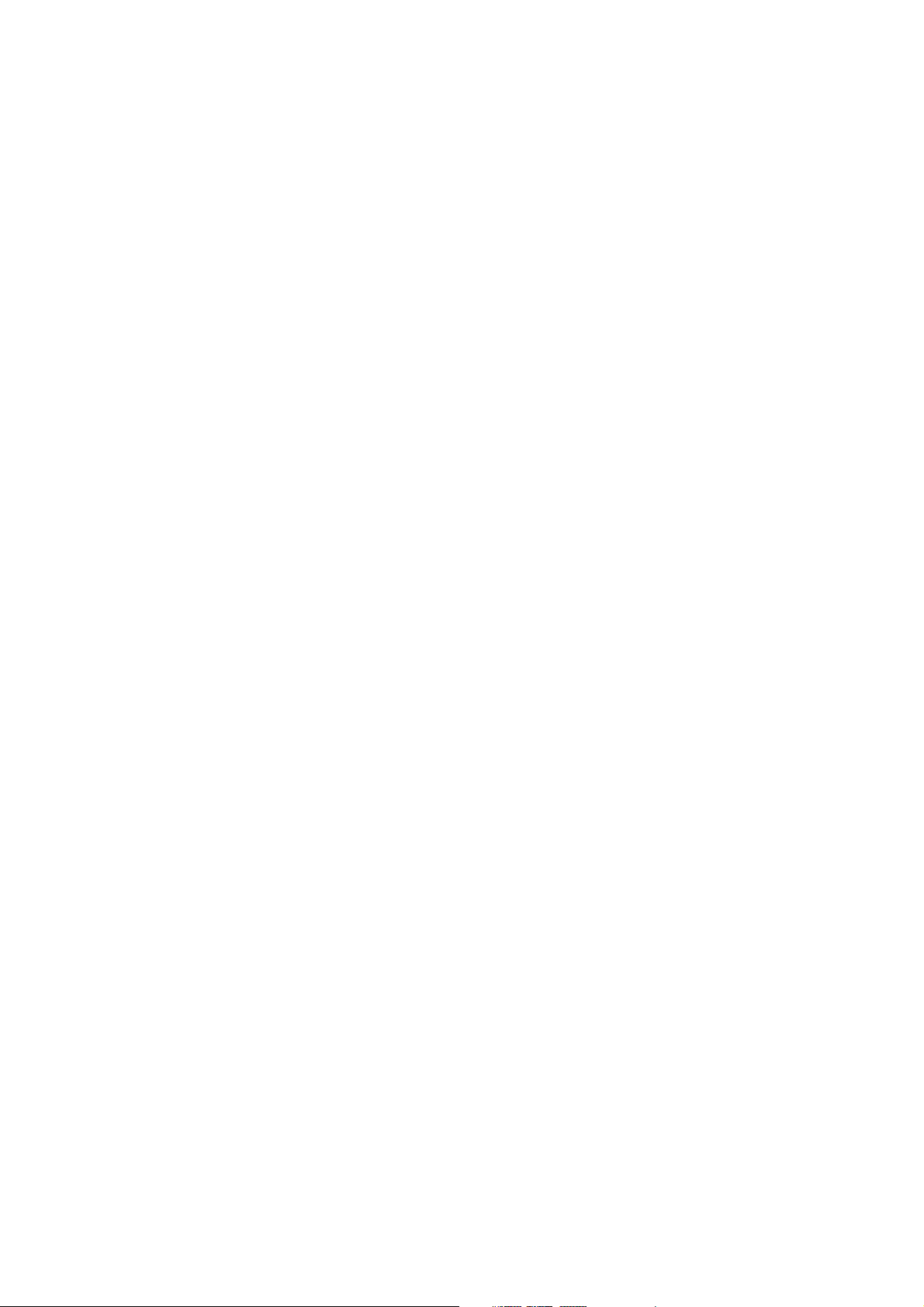

DESCRIPTION OF CONTROLS

MENU

OK

PV

¬

5

1

3

2

4

6

7

9

8

0

0

LIST

h

f g

Ò

‡

π

c

b

®

†

U

e

k

C

a

D

B

M

AUTO

AUTO

w

Y-Z

w Source

Select your computer or other

peripherals:press repeatedly to

select

TV, AV1, AV2,S-VIDEO

or PC monitor mode.

X Bilingual choice and

sound mode selection

Press this key

• to switch from

Stereo to

Mono sound in case of

stereo transmission,or from

Nicam Stereo to Nicam

Mono

,in case of digital

transmission

• to switch from

Nicam Dual

Y to Nicam Dual Z or

Nicam Dual X in case of

Nicam Dual transmission

• to choose between

Dual Y,

Dual Z or Dual X in case

of bilingual transmission:

Dual Y sends the primary

broadcast language to the

loudspeakers;

Dual Z sends the secondary

broadcast language to the

loudspeakers;

Dual X sends a separate

language to each loudspeaker.

Note: in case of weak stereo

sound signals, with stereo or

Nicam stereo transmission,select

mono reception.

Sound output selection in AV mode

In AV mode, you can select the output sound for the left and right loudspeakers.

Press the X key repeatedly to select:

• L+R:the audio signal from the audio L input is sent to the left loudspeaker, the audio signal

from the audio R input to the right loudspeaker

• L+L:the audio signal from the audio L input is sent to the left and right loudspeakers

• R+R:the audio signal from the audio R input is sent to the left and right loudspeakers.

B Standby

Switches the TV on from

standby or off to standby.

AUTO keys

To select predefined picture

and sound settings.

a

AUTO picture

Each time it is pressed,a

different picture setting is

selected,corresponding with

specific factory settings of

Contrast,Brightness, Colour

and Sharpness.

M

AUTO sound

Each time it is pressed,a

different sound setting is

selected,corresponding with

specific factory settings of

treble and bass.

Personal refers to the personal

preference settings of picture

and sound selected and stored

in the picture and sound menu.

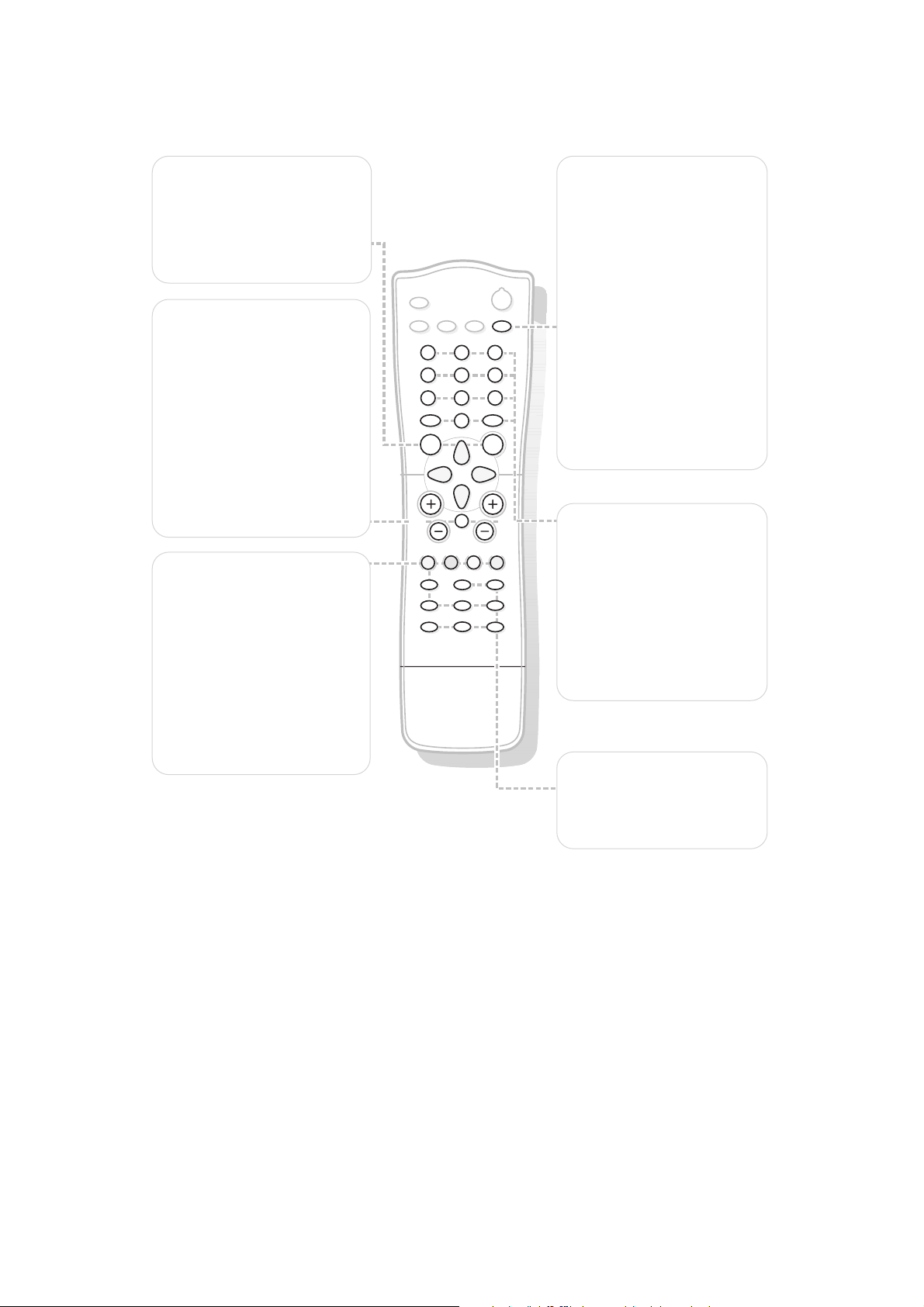

Page 6

B

M

a

AUTO

AUTO

w

Y-Z

C

h

f g

c

b

e

k

Ò

‡

π

®

†

U

D

1

2

9

3

6

5

7

4

8

0

0

LIST

MENU

OK

P

¬

V

V Volume

Press + or - to adjust the

volume.

¬ Mute

Temporarily interrupt the

sound or restore it.

P Programme selection

• to browse through the TV

channels which are not

skipped

• to switch the TV on from

standby.

®Ò‡π† Video

recorder keys

U Time display

The time, downloaded from the

TV channel (with teletext

broadcast) stored on

programme number 1 or the

lowest not skipped programme

number, is displayed on the

screen.

0/9 Digit keys

To select a TV channel.

0 Previous programme

To display the previously

selected TV channel.

LIST Programme list

To display the programme list.

b Teletext on/off

Teletext functions

hUfgcek

D Sleeptimer

With this key you can set a

time period after which the

TV should switch itself to

standby.

Press the key repeatedly to

select the number of minutes.

The counter runs from B 0,

10,20, 30... to 240 minutes.

The timer begins to count

down from the number of

minutes selected.

Note:To view the remaining time,

press the

D key once.To cancel

the sleep time, repeatedly press

the

D key until B 0 appears.

MENU Press repeatedly to

display each menu.

OK Press this key to activate

your choice,when in the menus.

Page 7

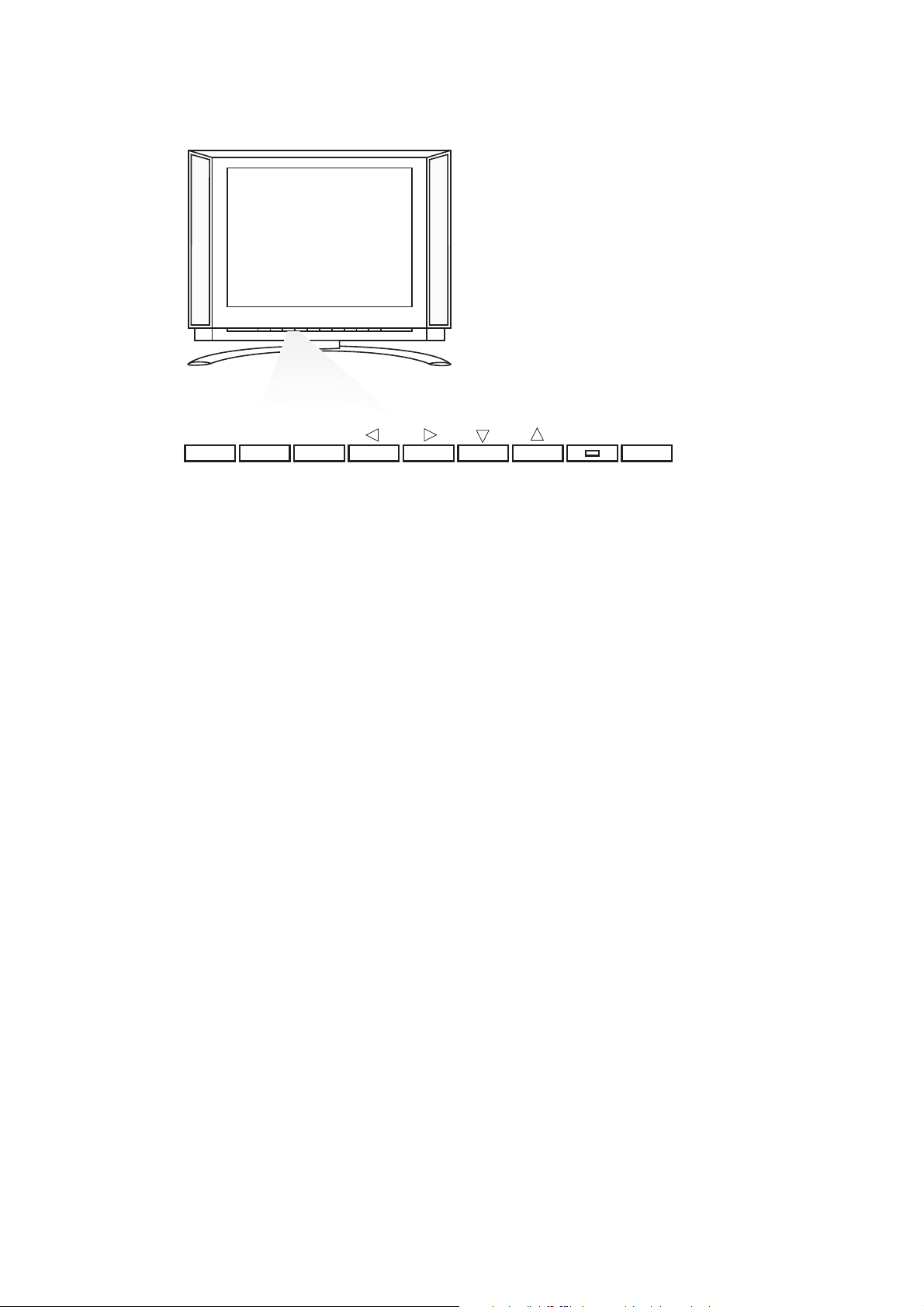

Should your remote control be lost or broken you can still operate your TV with the keys

in front of the TV.

ON/OFF:Press the power ON/OFF key to switch the TV on or off

TV/VIDEO:Press repeatedly to select TV,AV or PC monitor mode

MENU:Press repeatedly to display each menu

OK: - Press this key to activate your choice when in the menu

-

Auto demonstration:Keep the OK key pressed for about 10 seconds.

All the menus are being displayed automatically one after the other.

To stop Auto demonstration, press any key on the front panel.

- VOL + : - Press - or + to select a menu item;

- Press - or + to adjust the volume;

- Press - or + to adjust the menu settings.

- CH/PR +:- Press - or + to browse through the TV channels which are not skipped;

- Press - or + to select a menu item;

- To switch the TV on from standby.

B: Switches the TV on from standby or off to standby.

The B indicator lights up brightly when the TV is in standby,dims when the TV is

switched on.

TV / VIDEO MENU

OK

_

VOL

+

_

CH / PR

+

B

ON / OFF

Page 8

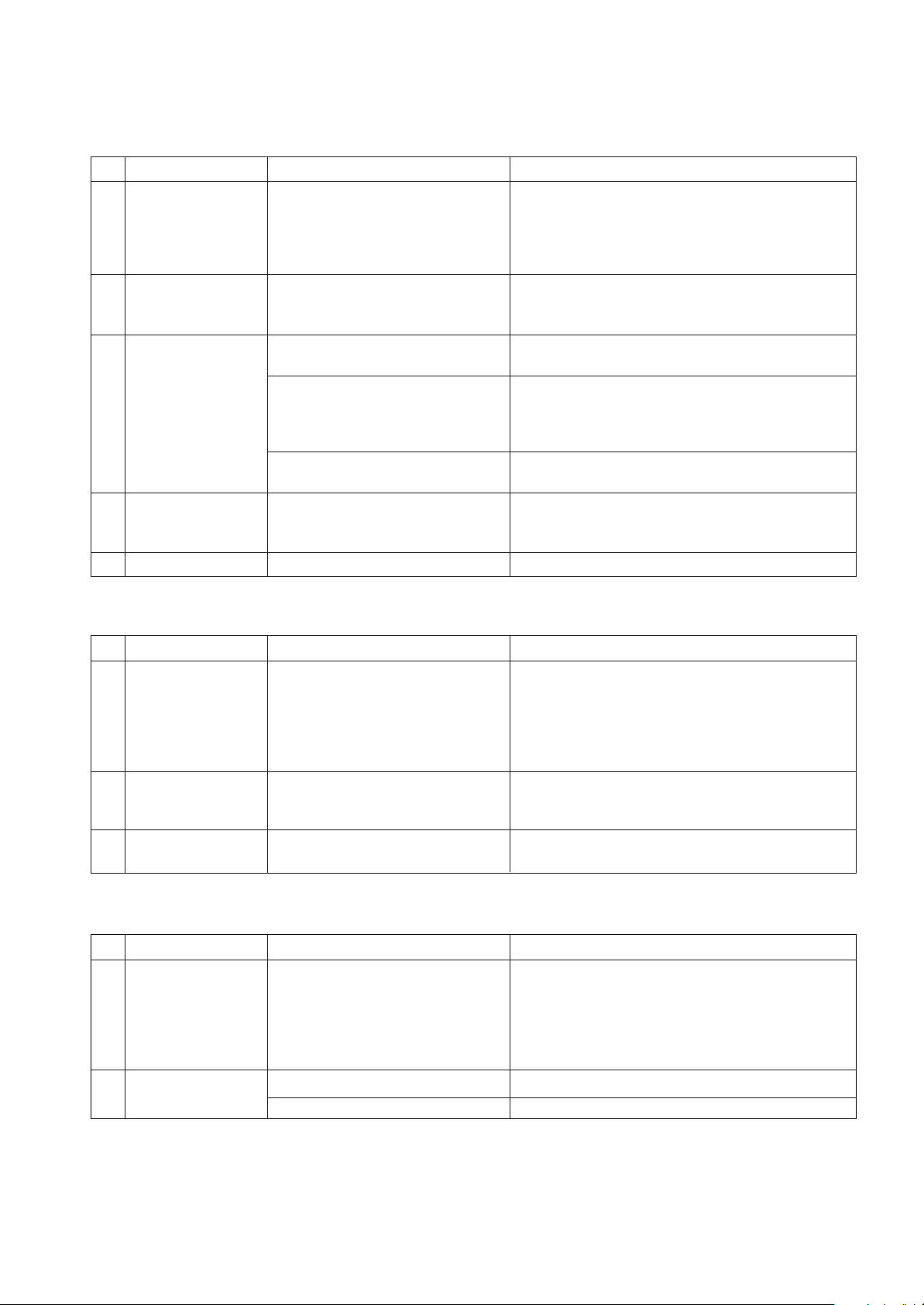

9 No sound Defective Reset IC of IC603 1) Check volume and speaker

- Speaker Defective MSP3400D of IC601 - Sound comes out only when being inputted into Audio

- Earphone Defective B+(8V,5V) of IC604,605. L/R

2) Check after replacing IC603

3) Replace IC601

4) Check and replace B+ of IC604,605.

10 Video color beat noise Earphone shield case being touched

Check the mould of shield and JA401, Replace shield case

Soldering IC301 and IC507 Re-soldering

1 Soft touch doesn’t Defective speaker wire 1) Make some space between the speaker wire and

function properly and inverter wire the Soft touch Board by sticking the speaker wire

to the guide hole of the cabinet.

2) Arrange working state of A1. Tape in the inverter wire

and correct working state of the Shield case.

2 Soft touch doesn’t 1) Broken components and 1) Check Soft touch with eyes

function soldering of them Check and repair soldering

2) P101 connector error 2) Check and repair the P101 connector

3 No screen Input error of inverter connector 1) Bend the pin legs of P801 connector -> recheck them

2) Check and repair the IC801,802 SI4925

P502 and Pin 21 connector 1) Check and fix P502 connector

being slipped out 2) Check and fix the components at P502 LCD module

and at main board.

3) Check Pin21.

Cracked components and 1) Check and repair tuner board and main board

soldering at tuner board 2) Solder Q403, Q402 and C153

4 Dark screen 1) Defective LCD lamp 1) Replace the inverter

2) Defective inverter 2) Replace the LCD lamp

3) Input error of inverter connector 2) Check the connector input.

5 Broken OSD display Defective the font rom of IC501 Check and replace the font rom of IC501

TROUBLESHOOTING

1. General Features

2. PC Mode

No. Symptom Cause Check Point

No. Symptom Cause Check Point

Check Point

6 Screen noise Clock or phase being 1) Resettig is needed according to the video card of each

not able to be adjusted PC

2) Horizontal noise : adjust phase until no horizontal

noise occurres

3) Vertical noise : adjust clock in menu until no vertical

noise occurres

7 Screen position error Screen position error 1) Play the Auto Configure in Menu.

horizontally or vertically 2) Adjust horizontal and vertical position until the screen

displayes normally

8 Color beat noise Soldering AD converter Recheck adn repair AD9884

or making it short

3. TV and external input

No. Symptom Cause

Page 9

To Lamp

9965 000 20401 (A3 Panel)

9965 000 20402 (C3 Panel)

To Control PWB

P401

To Lamp

RE/RL-15LA40 Wiring Diagram (15.1”)

P801

Tuner

P601

P602

6631V25016G (3P)

6631V25016P (4P)

To Speaker

P502

9965 000 20403 (A3 Panel)

9965 000 20404 (C3 Panel)

To Panel

Page 10

Tuner & IF

- TAUC-S120D

- TAFC-M130D

- TAFC-Z140D

Audio

Processor

- MSP3410D

Ext- L

Micro-Controller

- INFINEON ( SDA55XX )

L

LCD

< LCD TV System Block Diagram >

Video

Decorder

- VPC3230D

Video Scaler

- MX88L284

Computer

Signal

- D-Sub

R/G/B

H/V

D-R/G/B,

H / V -Sync,

Den, Clock

From

Computer

OSD -IC

MC141585

CVBS

Audio-Amp

LA4282

R

Ext- R

SIF

For MNT Application

LM151X3 - 8-bits

1H/1V

A to D Converter

- AD9884

For PC Input

- Contrast

- Brightness

- Color

Ext_Video

Ext_Y/C

OSD B/R/G/B

Scart RGB

For TV

. Contrast

. Brightness

. Color

. Tint

CVBS For TXT

AM

Interface

- TMDS (8bits)21 pin

RGB Switching

TDA8601

Y / Cb / Cr

RGB in

Back Light

Inverter Assy

CVBS OUT

Page 11

Service Sheet of MF-004A

P/N : 3854VA0077A-S

DATE : 2000.10.02

Main Board for LC151X01-A3 LCD Panel

Page 12

Main Board for LC151X01-A3 LCD Panel (Top Side)

Page 13

Main Board for LC151X01-A3 LCD Panel (Bottom Side)

Page 14

CONTROL

TUNER(TOP)

TUNER(BOTTOM)

Page 15

Main Board for LC151X01-C3P1 LCD Panel

Page 16

Main Board for LC151X01-C3P1 LCD Panel (Top Side)

Page 17

Main Board for LC151X01-C3P1 LCD Panel (Bottom Side)

Page 18

CONTROL

TUNER(TOP)

TUNER(BOTTOM)

Page 19

- 9 -

1. Application Object

This instruction is for the application to the LCD TV.

2. Notes

(1) This set uses an adapter, so connect the adapter and the

set correctly before adjustment.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25

! 5cC of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220V, 60Hz in

adjusting.

(5) The set must be operated for 30 minutes preliminarily

before adjustment if there is no specific designation.

[ Ô Heat RunÕ must be performed with the full white signal or TV

noise signal in the internal part of the set.

[ The time for Ô Heat RunÕ can be changed owing to production

plan.

3. PC Input Mode Adjustment

3-1. Required Test Equipment

(1) A pattern generator being in proportion to VG819 ; Pattern

of 64 tones

(2) A remote control

3-2. Preparation for Adjustment

(1) Perform Ô Heat RunÕ for more than 30 minutes in white

pattern.

(2) Connect the signal of pattern generator with LCD TV.

(3) Lean the set 45¡ backward. (Adjustment is easy.)

(4) Set the PC mode menu as below.

3-3. White Adjustment

(1) Approve the signal of 64 tones of XGA(1024 * 768).

(2) Select all the gain of R, B and G with using ADJ of remote

control.

(3) After making 62 tones, 63 tones and 64 tones not

distinguished with using each signal of R, G and B, finish

adjusting at the moment when the signal 62, 63 and 64 is

distinguished.

ADJUSTMENT INSTRUCTION

45¡

Initial Value

Contrast

70

Brightness

100

R

0.63 0.34

0x02

G

0.30 0.60

0x03

B

0.14 0.10

0x04

Error

! 0.03

Register

Color Coordinates(x,y)

AD9884

45¡

Initial Value

Contrast

70

Brightness

100

R

0.63 0.34

0x02

G

0.30 0.60

0x03

B

0.14 0.10

0x04

Error

! 0.03

Register

Color Coordinates(x,y)

AD9884

45¡

Initial Value

Contrast

70

Brightness

100

R

0.63 0.34

0x02

G

0.30 0.60

0x03

B

0.14 0.10

0x04

Error

! 0.03

Register

Color Coordinates(x,y)

AD9884

45¡

Initial Value

Contrast

70

Brightness

100

R

0.63 0.34

0x02

G

0.30 0.60

0x03

B

0.14 0.10

0x04

Error

! 0.03

Register

Color Coordinates(x,y)

AD9884

Default option settings

Option Default value

S-B 23

FP 21

NP 89

S1VOL 105

S2VOL 105

200PR 0

TEXT 1

I II SA 0

TOP 1

SCART 1

A2 ST 1

SYS 0 (Eu), 1 (Fr)

ACMS 1

VOL 0

BBACK 0

LANG 6

TSS 0

PANEL 0

IICT 0

INVT 0

MD SA 0

MONO 0

CH+AL 0

T-LANG 0

Page 20

3-4. Position of Mode Adjustment

Timing of Mode Table * H[dot]/V[line]

Mode

H_Total

H_Display

H_Blanking

H_Sync

H Polarity

H_Bp

H_Fp

H-Freq[KHz]

/Clk[MHz]

V_Total

V_Display

V_Blanking

V_Sync

V Polarity

V_Bp

V_Fp

VGA-60

800

640

160

96

NEG.

48

16

31.469

25.175

525

480

45

2

NEG

33

10

VGA-67

864

640

224

64

NEG.

96

64

35.0

30.24

525

480

45

3

NEG

39

3

VGA-72

832

656

176

40

NEG.

120

16

37.861

31.5

520

496

24

3

NEG

20

1

VGA-75

840

640

200

64

NEG.

120

16

37.5

31.5

500

480

20

3

NEG

16

1

VGA-85

832

640

192

56

NEG.

80

56

43.269

36.0

509

480

29

3

NEG

25

1

TEXT-70

900

720

180

108

NEG.

54

18

31.469

28.324

449

400

49

2

POS

34

13

SVGA-56

1024

800

224

72

POS

128

24

35.156

36.0

625

600

25

2

POS

22

1

SVGA-60

1056

800

256

128

POS

88

40

37.879

40.0

628

600

28

4

POS

23

1

SVGA-72

1040

800

240

120

POS

64

56

48.077

50.0

666

600

66

6

POS

23

37

Mode

H_Total

H_Display

H_Blanking

H_Sync

H Polarity

H_Bp

H_Fp

H-Freq[KHz]

/Clk[MHz]

V_Total

V_Display

V_Blanking

V_Sync

V Polarity

V_Bp

V_Fp

SVGA-75

1056

800

256

80

POS

160

16

46.875

49.5

625

600

25

3

POS

21

1

SVGA-85

1048

800

248

64

POS

152

32

53.674

56.25

631

600

31

3

POS

27

1

XGA-60

1344

1024

320

136

NEG

136

160

48.363

65.0

806

768

38

6

NEG

29

3

XGA-70

1328

1024

304

136

NEG

144

24

56.476

75.0

806

768

38

6

NEG

29

3

XGA-75

1312

1024

288

96

POS

176

16

60.23

78.75

800

768

32

3

POS

28

1

MAC-75

1152

832

320

64

NEG

224

32

49.725

57.283

667

624

43

3

NWG

39

1

Page 21

EXPLODED VIEW

112

540

500

550

521

541

120

530

310

400

401

410

Page 22

Spare Parts List

LC1.15E

Various

9965 000 20401 Cable assy P801 A3 PANEL

9965 000 20402 Cable assy P801 C3 PANEL

9965 000 20403 Cable assy P502 A3 PANEL

00A1 9965 000 16515 Directions for Use

00A1 9965 000 16519 DFU MF004A

00A2 9965 000 14330 RC25109/01

00A3 9965 000 16428 Adapter SAD3612E

0112 9965 000 16410 LC151X01-A3

0112 9965 000 16743 LC151X01-C3P1

0120 9965 000 16411 Loud speaker C073A01-126K14

0174 9965 000 14327 Mains cord for M2511A-001 EUR

0174 9965 000 16412 Mains cord MP5004

0300 9965 000 16416 Cabinet

0300A 3139 120 01511 W/MARK 8.5X35(P/SILVER 11007)

0310 9965 000 16417 Push buttons (7x)

0320 9965 000 16418 Coil

0330 9965 000 16419 Mains knob

0400 9965 000 16420 Back cover

0401 9965 000 16421 Cover plate A/V

0410 9965 000 16516 Stand

0420 9965 000 14326 Hinge for stand

0500 9965 000 16422 Main board MF-004A

0500 9965 000 16517 Main board MF-004A -/19

0500 9965 000 19696 Main board for c# panel -/12

0500 9965 000 19697 Main board for C3 panel -/19

0521 9965 000 16423 Metal frame for main board

0530 9965 000 16424 Control panel MF-004A

0540 9965 000 16425 Inverter 12V

0540 9965 000 17796 Inverter 12V for C3 panel

0541 9965 000 16426 Case for inverter

0550 9965 000 16427 Tuner LE-15A10

0550 9965 000 16518 Tuner LL-15A10

F501 9965 000 16454 Filter HH-1M3216-501 1206

P1001 9965 000 16491 12P 300MM H-B UL 100

P1002 9965 000 16492 4P 200MM H-B UL1007

PA1001 9965 000 16493 TSOP2238MQ1

S001 9965 000 14752 15" VESA PLATE (15PF9925)

S002 9965 000 14332 VGA cable 7M

S030 9965 000 20079 Service RC

SW1001 9965 000 16502 SDKLA11100

SW1002 9965 000 16503 Tact switch SKHV17910B

SW1003 9965 000 16503 Tact switch SKHV17910B

SW1004 9965 000 16503 Tact switch SKHV17910B

SW1005 9965 000 16503 Tact switch SKHV17910B

SW1006 9965 000 16503 Tact switch SKHV17910B

SW1007 9965 000 16503 Tact switch SKHV17910B

SW1008 9965 000 16503 Tact switch SKHV17910B

TU301 9965 000 16507 Tuner TAFC-M130D

TU301 9965 000 16521 Tuner TAFC-S120D

X101 9965 000 16508 Crystal 6 MHz HC49U

X301 9965 000 16509 Crystal 20.250 MHz HC49U

X501 9965 000 16510 Crystal 14.318MHz

X502 9965 000 16511 Crystal 500kHz CSB500F9

X601 9965 000 16512 Crystal 18.432 MHz HC49U

ZD101 9965 000 16513 MTZJ33B

ZD410 9965 000 16514 UDZS TE-17

ZD411 9965 000 16514 UDZS TE-17

ZD412 9965 000 16514 UDZS TE-17

ZD413 9965 000 16514 UDZS TE-17

ZD414 9965 000 16514 UDZS TE-17

ZD415 9965 000 16514 UDZS TE-17

ZD416 9965 000 16514 UDZS TE-17

ZD417 9965 000 16514 UDZS TE-17

ZD418 9965 000 16514 UDZS TE-17

ZD419 9965 000 16514 UDZS TE-17

ZD420 9965 000 16514 UDZS TE-17

ZD421 9965 000 16514 UDZS TE-17

ZD423 9965 000 16514 UDZS TE-17

ZD430 9965 000 16514 UDZS TE-17

ZD431 9965 000 16514 UDZS TE-17

ZD432 9965 000 16514 UDZS TE-17

g

C1001 9965 000 16429 100µF 10V

C1002 9965 000 16430 0.01µF 80% 50V

C101 9965 000 16431 10µF 16V

C115 9965 000 16432 100µF 16V

C117 9965 000 16432 100µF 16V

C120 9965 000 16431 10µF 16V

C121 9965 000 16433 47µF 16V

C125 9965 000 16434 10µF 50V

C127 9965 000 16432 100µF 16V

9965 000 20404 Cable assy P502 C3 PANEL

C131 9965 000 16432 100µF 16V

C133 9965 000 16435 4.7µF 50V

C133 9965 000 16441 22µF 16V

C134 9965 000 16433 47µF 16V

C137 9965 000 16436 1µF 50V

C140 9965 000 16437 0.056µF 5% 100V

C141 9965 000 16431 10µF 16V

C146 9965 000 16433 47µF 16V

C153 9965 000 16438 220µF 16V

C156 9965 000 16438 220µF 16V

C211 9965 000 16432 100µF 16V

C307 9965 000 16439 220000pF 16V 0805

C311 9965 000 16439 220000pF 16V 0805

C317 9965 000 16440 1µF 50V

C318 9965 000 16440 1µF 50V

C319 9965 000 16440 1µF 50V

C320 9965 000 16440 1µF 50V

C327 9965 000 16439 220000pF 16V 0805

C328 9965 000 16439 220000pF 16V 0805

C329 9965 000 16439 220000pF 16V 0805

C342 9965 000 16439 220000pF 16V 0805

C404 9965 000 16438 220µF 16V

C404 9965 000 16441 22µF 16V

C409 9965 000 16441 22µF 16V

C410 9965 000 16441 22µF 16V

C418 9965 000 16442 2.2µF 50V

C544 9965 000 16443 680µF 10V

C586 9965 000 16444 470µF 16V

C587 9965 000 16443 680µF 10V

C595 9965 000 16429 100µF 10V

C595 9965 000 16443 680µF 10V

C597 9965 000 16443 680µF 10V

C598 9965 000 16443 680µF 10V

C601 9965 000 16432 100µF 16V

C602 9965 000 16432 100µF 16V

C613 9965 000 16433 47µF 16V

C619 9965 000 16432 100µF 16V

C621 9965 000 16431 10µF 16V

C622 9965 000 16431 10µF 16V

C623 9965 000 16432 100µF 16V

C625 9965 000 16445 3.3µF 50V

C628 9965 000 16439 220000pF 16V 0805

C629 9965 000 16439 220000pF 16V 0805

C630 9965 000 16439 220000pF 16V 0805

C631 9965 000 16439 220000pF 16V 0805

C635 9965 000 16431 10µF 16V

C637 9965 000 16446 0.01µF 100V

C638 9965 000 16442 2.2µF 50V

C639 9965 000 16432 100µF 16V

C640 9965 000 16432 100µF 16V

C642 9965 000 16432 100µF 16V

C643 9965 000 16444 470µF 16V

C644 9965 000 16444 470µF 16V

C648 9965 000 16444 470µF 16V

C649 9965 000 16442 2.2µF 50V

C650 9965 000 16438 220µF 16V

C652 9965 000 16446 0.01µF 100V

C801 9965 000 16447 330µF 16V

C804 9965 000 16433 47µF 16V

C805 9965 000 16438 220µF 16V

C811 9965 000 16432 100µF 16V

C812 9965 000 16448 100µF 25V

C813 9965 000 16432 100µF 16V

C816 9965 000 16435 4.7µF 50V

C819 9965 000 16435 4.7µF 50V

C821 9965 000 16438 220µF 16V

C821 9965 000 16443 680µF 10V

C822 9965 000 16438 220µF 16V

C822 9965 000 16444 470µF 16V

C823 9965 000 16438 220µF 16V

C823 9965 000 16444 470µF 16V

C823 9965 000 16449 470µF 10V

C824 9965 000 16432 100µF 16V

C824 9965 000 16444 470µF 16V

C824 9965 000 16449 470µF 10V

C825 9965 000 16450 47µF 50V

C826 9965 000 16438 220µF 16V

C826 9965 000 16449 470µF 10V

C827 9965 000 16451 EU1ZV(1)

C958 9965 000 16443 680µF 10V

C959 9965 000 16443 680µF 10V

f

R1001 9965 000 16498 4.7k 5% 1/6W

R1003 9965 000 16499 1.2k 5% 1/6W

R1004 9965 000 16500 330Ω 5% 1/6W

R1006 9965 000 16498 4.7k 5% 1/6W

R1007 9965 000 16498 4.7k 5% 1/6W

Page 23

R1008 9965 000 16498 4.7k 5% 1/6W

R1009 9965 000 16498 4.7k 5% 1/6W

R1010 9965 000 16498 4.7k 5% 1/6W

R1011 9965 000 16498 4.7k 5% 1/6W

R443 9965 000 16501 120Ω 5% 1/2W

R444 9965 000 16501 120Ω 5% 1/2W

R540 9965 000 16483 Filter HB-1M2012-800JT 0805

RA507 9965 000 16489 Filter 3216 4S600

b

L1001 9965 000 16482 22µH 2.3 X 3.4

L101 9965 000 16483 Filter HB-1M2012-800JT 0805

L102 9965 000 16483 Filter HB-1M2012-800JT 0805

L103 9965 000 16454 Filter HH-1M3216-501 1206

L104 9965 000 16454 Filter HH-1M3216-501 1206

L105 9965 000 16454 Filter HH-1M3216-501 1206

L202 9965 000 16484 Filter HB-1S2012-080JT 0805

L401 9965 000 16483 Filter HB-1M2012-800JT 0805

L402 9965 000 16454 Filter HH-1M3216-501 1206

L403 9965 000 16454 Filter HH-1M3216-501 1206

L405 9965 000 16483 Filter HB-1M2012-800JT 0805

L406 9965 000 16483 Filter HB-1M2012-800JT 0805

L407 9965 000 16483 Filter HB-1M2012-800JT 0805

L408 9965 000 16483 Filter HB-1M2012-800JT 0805

L410 9965 000 16483 Filter HB-1M2012-800JT 0805

L411 9965 000 16483 Filter HB-1M2012-800JT 0805

L412 9965 000 16483 Filter HB-1M2012-800JT 0805

L413 9965 000 16483 Filter HB-1M2012-800JT 0805

L414 9965 000 16485 12µH 2.3 X 3.4

L415 9965 000 16486 27µH 2.3 X 3.4

L416 9965 000 16485 12µH 2.3 X 3.4

L502 9965 000 16484 Filter HB-1S2012-080JT 0805

L503 9965 000 16484 Filter HB-1S2012-080JT 0805

L504 9965 000 16454 Filter HH-1M3216-501 1206

L505 9965 000 16454 Filter HH-1M3216-501 1206

L506 9965 000 16454 Filter HH-1M3216-501 1206

L519 9965 000 16483 Filter HB-1M2012-800JT 0805

L601 9965 000 16454 Filter HH-1M3216-501 1206

L602 9965 000 16454 Filter HH-1M3216-501 1206

L603 9965 000 16454 Filter HH-1M3216-501 1206

L604 9965 000 16454 Filter HH-1M3216-501 1206

L801 9965 000 16454 Filter HH-1M3216-501 1206

L802 9965 000 16454 Filter HH-1M3216-501 1206

L803 9965 000 16454 Filter HH-1M3216-501 1206

L804 9965 000 16454 Filter HH-1M3216-501 1206

L805 9965 000 16487 9.5µH

L806 9965 000 16488 26µH

L807 9965 000 16488 26µH

L809 9965 000 16454 Filter HH-1M3216-501 1206

L810 9965 000 16454 Filter HH-1M3216-501 1206

LA501 9965 000 16489 Filter 3216 4S600

LA502 9965 000 16489 Filter 3216 4S600

LA503 9965 000 16489 Filter 3216 4S600

LA504 9965 000 16489 Filter 3216 4S600

LA505 9965 000 16489 Filter 3216 4S600

LA506 9965 000 16489 Filter 3216 4S600

LA507 9965 000 16489 Filter 3216 4S600

LA508 9965 000 16489 Filter 3216 4S600

LA509 9965 000 16489 Filter 3216 4S600

LA510 9965 000 16489 Filter 3216 4S600

LA511 9965 000 16489 Filter 3216 4S600

LA512 9965 000 16489 Filter 3216 4S600

LA513 9965 000 16489 Filter 3216 4S600

LA514 9965 000 16489 Filter 3216 4S600

LA515 9965 000 16489 Filter 3216 4S600

LA516 9965 000 16489 Filter 3216 4S600

LA517 9965 000 16489 Filter 3216 4S600

LA518 9965 000 16489 Filter 3216 4S600

LA519 9965 000 16489 Filter 3216 4S600

LA520 9965 000 16489 Filter 3216 4S600

LA521 9965 000 16489 Filter 3216 4S600

LA522 9965 000 16489 Filter 3216 4S600

LA523 9965 000 16489 Filter 3216 4S600

LA524 9965 000 16489 Filter 3216 4S600

LA525 9965 000 16489 Filter 3216 4S600

LD1001 9965 000 16490 LED assy

T101 9965 000 16504 MKT40.4MA110P-TF0

T101 9965 000 16520 Filter MKT41.4MA110P-TF01

T102 9965 000 16505 MKT40.9MA110P-TF01

T801 9965 000 16506 Transformer 13-Z320UH DC-DC

ce

IC101 9965 000 16455 SDA555X

IC102 9965 000 16456 AT24C16-10PC-2.7

IC103 9965 000 16457 PQ3RF23

IC104 9965 000 16458 KA75270Z

IC105 4822 209 16128 KIA7805PI

IC106 9965 000 16459 LA7217M

IC107 9965 000 16460 TDA8601T

IC108 9965 000 16461 KIA7808API

IC109 9965 000 16462 KIA7809AP

IC201 9965 000 16463 AD9884

IC202 9965 000 16457 PQ3RF23

IC301 9965 000 16464 VPC3230D-QA-B3

IC401 9965 000 16465 74F08D

IC402 9965 000 16466 AT24C2-10SI-2.5

IC501 9965 000 16467 MX88L284AEC

IC502 9965 000 16468 K4S161622D-TC80

IC503 9965 000 16468 K4S161622D-TC80

IC505 9965 000 16469 SC786107DWR2

IC506 9965 000 16470 SI4963DY

IC507 9965 000 16471 SIL100

IC601 9965 000 16472 MSP3410D-QA-C5

IC601 9965 000 20400 MSP3410G-QA-B8 V3

IC602 4822 209 16128 KIA7805PI

IC603 9965 000 16473 KIA7042AF

IC604 9965 000 16461 KIA7808API

IC605 4822 209 31855 LA4282

IC801 9965 000 16474 SI4925DY

IC802 9965 000 16474 SI4925DY

IC803 4822 209 16128 KIA7805PI

IC804 9965 000 16475 SI786

IC805 9965 000 16476 SI9936DY

IC805 9965 000 16573 SI4808DY

IC806 9965 000 16477 SI9410DY

IC807 9965 000 16476 SI9936DY

IC807 9965 000 16573 SI4808DY

IC808 9965 000 16477 SI9410DY

IC809 9965 000 16462 KIA7809AP

Q1001 9965 000 16494 KTA-1266

Q103 9965 000 16495 2SC3875S

Q105 9965 000 16495 2SC3875S

Q106 9965 000 16495 2SC3875S

Q107 9965 000 16495 2SC3875S

Q108 9965 000 16496 2SA1504S

Q109 9965 000 16497 2N7000TA

Q110 9965 000 16497 2N7000TA

Q111 9965 000 16495 2SC3875S

Q112 9965 000 16495 2SC3875S

Q113 9965 000 16495 2SC3875S

Q114 9965 000 16495 2SC3875S

Q115 9965 000 16495 2SC3875S

Q301 9965 000 16495 2SC3875S

Q302 9965 000 16495 2SC3875S

Q402 9965 000 16496 2SA1504S

Q403 9965 000 16496 2SA1504S

Q501 9965 000 16495 2SC3875S

Q502 9965 000 16495 2SC3875S

Q503 9965 000 16496 2SA1504S

Q601 9965 000 16496 2SA1504S

Q602 9965 000 16496 2SA1504S

Q604 9965 000 16496 2SA1504S

Q801 9965 000 16495 2SC3875S

J401 9965 000 16478 Connector 15P

J402 9965 000 16479 Socket scart

J403 9965 000 16480 Socket SHVS

J801 9965 000 16481 Socket headphone

d

D101 9965 000 16452 KDS181

D102 9965 000 16452 KDS181

D603 9965 000 16452 KDS181

D604 9965 000 16452 KDS181

D801 9965 000 16452 KDS181

D802 9965 000 16453 MBRS190T3

D803 9965 000 16453 MBRS190T3

D805 9965 000 16451 EU1ZV(1)

Page 24

Revision list

Manual 3122 785 12511

1. In the version with the A3 LCD panel IC601 has been

changed from MSP3410D-QA-C5 (9965 000 16472) into

MSP3410G-QA-B8 V3 (9965 000 20400) to improve the

sound quality. This is change is introduced in June 2002.

2. In the version with the A3 LCD panel IC507 has been

changed from SIL100 (9965 000 16471) into the SIL140.

Both IC’s are interchangeable.

3. In the version with the A3 LCD panel IC805 and IC807 are

changed from SI9936DY (9965 000 16476) into SI4808DY

(9965 000 16573) to improve the function.

4. The LCD panel LC151X01-A3 has been changed into the

LC151X01-C3P1. This change is introduced in sets with

serial number AG990230 and higher. At the same time also

the following parts are changed:

• LCD panel LC151X01-A3 (9965 000 16410) into

LC151X01-C3P1 (9965 000 16743).

• Main board from 9965 000 16422 into 9965 000 19696.

• Inverter panel from 9965 000 16425 into 9965 000

17796.

• Cable to LCD panel (P502) from 9965 000 20403 into

9965 000 20404.

• Cable to Inverter (P801) from 9965 20401 into 9965

000 20402.

Loading...

Loading...