SM 40

Surv eillance Centre

Philips

Communication &

Security Systems

LBB 1360 & LBB1370

Instructions for use

Eng

TABLE OF CONTENTS

1

1

2

3

4

5

6

1. GENERAL INTRODUCTION AND OPERATING PRINCIPLES

1.1 Introduction

2. SYSTEM UNPACKING AND INSTALL ATION

2.1 Introduction

3. SM 40 BASIC SURVEILL ANCE CENTRE

3.1 Basic System - BS LBB 1370

3.2 Extension Frame - EF LBB 1360

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

4.1 Central Processor Card - CPC

4.2 Display and Keyboard - DK

4.2.1 Display readout

4.3 SM40 Programmng

4.3.1 User Programming Menu

4.3.2 Installer Programming Menu

5. SM40 MODULES

5.1 Interconnection Board - IB

5.2 Termination Board

5.3 Pilot-tone Generator Card (PGC) LBB 1369

5.4 Surveillance Switch Card (SSC) LBB 1374

5.5 Loudpeaker Surveillance Board (LSB) LBB 1367

5.6 Amplifier Surveillance Board (ASB) LBB 1368

5.7 Control Relay Card (CRC) LBB 1356

5.8 Termination Board (TB) LBB 1377

6. TECHNICAL DATA

1. GENERAL INTRODUCTION

2

1

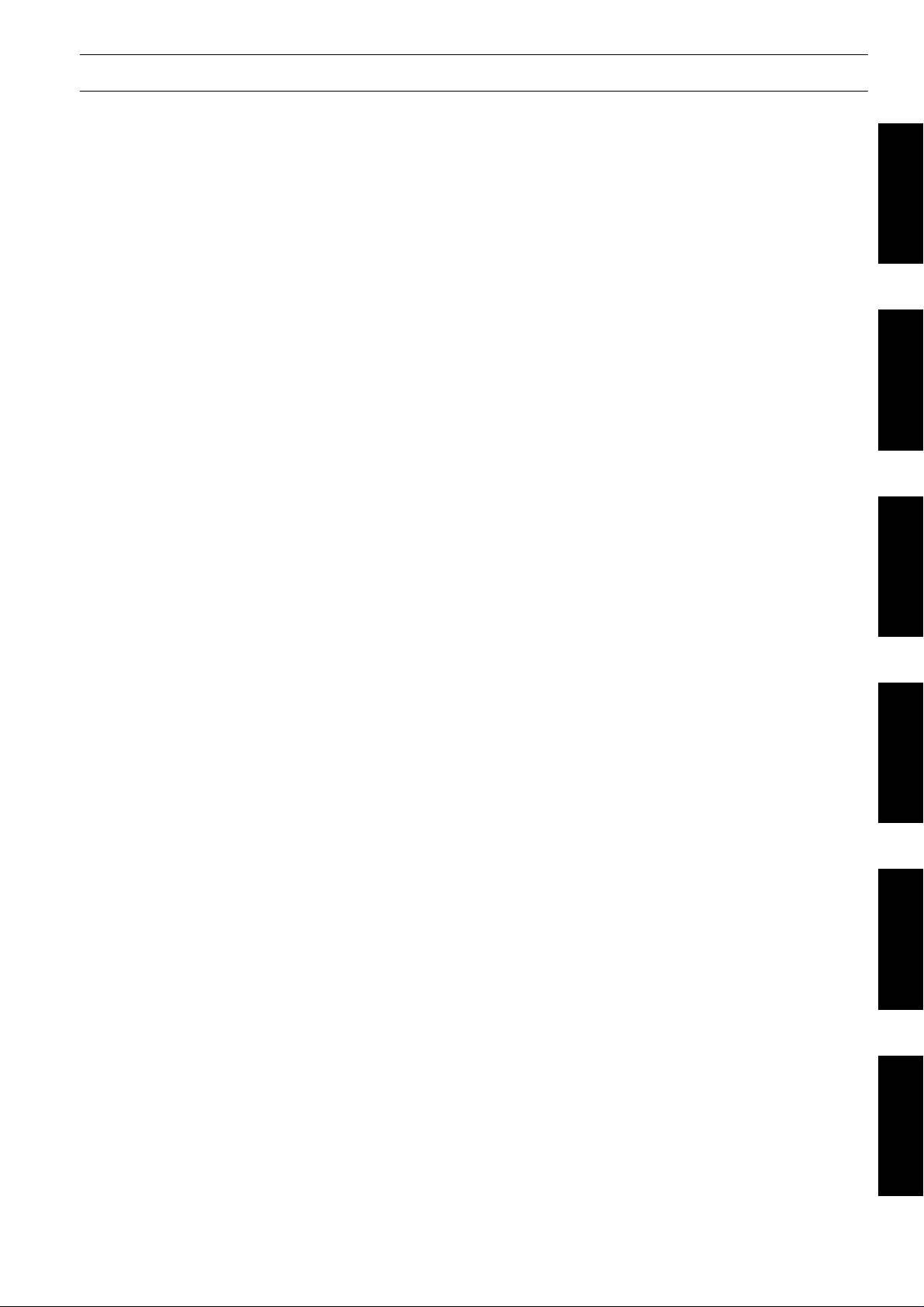

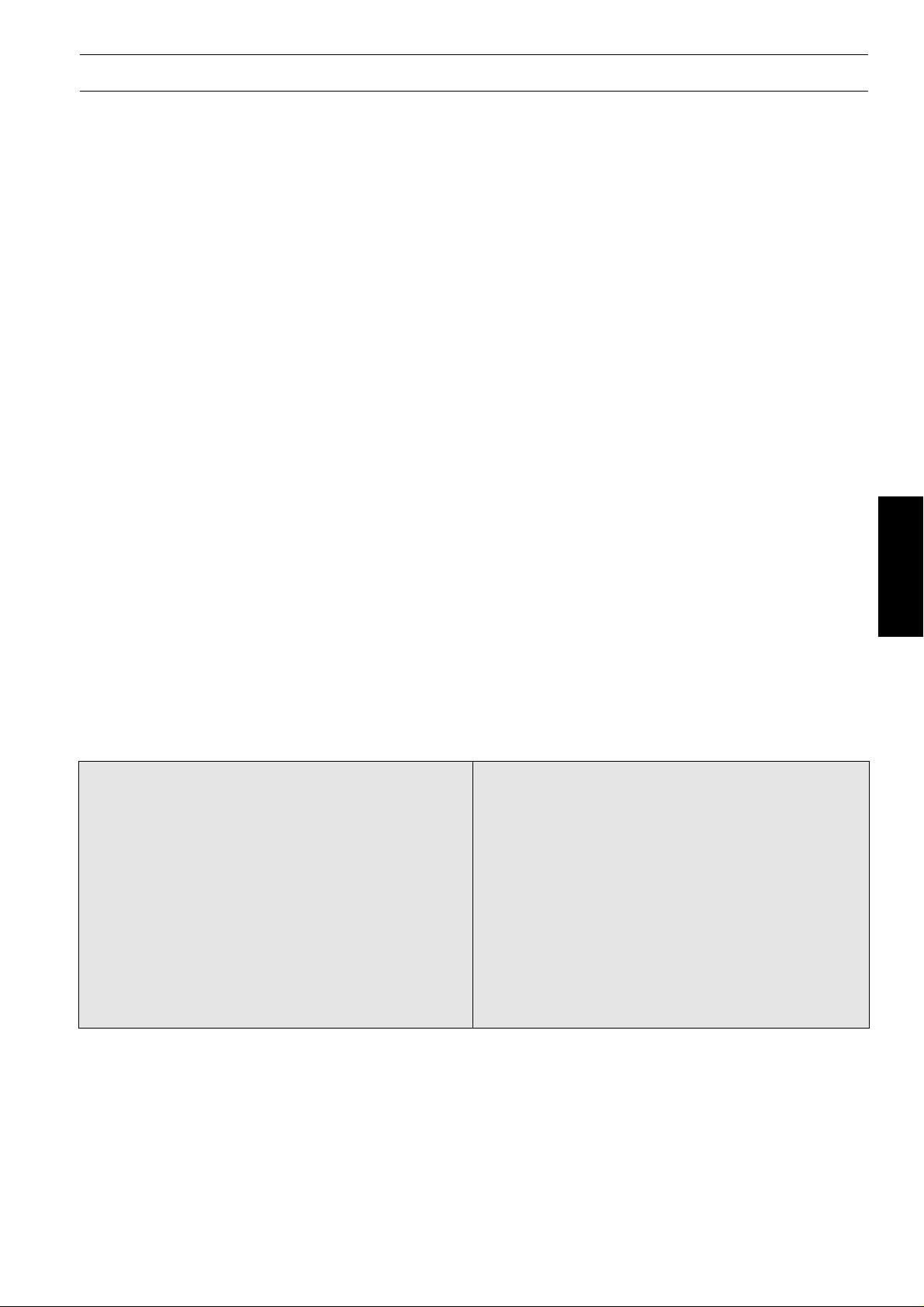

SM40 SURVEILLANCE CENTRE

(maximum system layout)

1. GENERAL INTRODUCTION

3

1

1.1 Introduction to the SM40 Surveillance Centre

In large public address distribution systems, which often play a key role in alarm and evacuation

installations, it is vital that the correct functioning of the large number of amplifiers and loudspeakers used

can be verified.

The SM40 Surveillance Centre is designed to monitor the status of amplifiers, loudspeakers, and cabling in

large PA systems. Because it pinpoints any failures in the system, it saves a great deal of time, minimising

repair costs as well as ensuring that the system is fully functional at the earliest possible moment.

On detection of a malfunction, error messages are generated automatically, giving the precise time and

location of the fault. These messages can either be relayed to the system’s LCD display, or sent to an external

printer for a permanent hard-copy record of the malfunctions. The messages can also be linked to warning

lamps, buzzers, or personal paging units, alerting security and maintenance personnel.

The possibility also exists to automatically switch in a spare amplifier in place of an amplifier which becomes

faulty.

A pilot tone signal is generated which is inserted into the Test inputs of Philips SQ45 power amplifier range.

The Surveillance Centre is able to scan for the presence of this signal in up to 4096 monitoring devices,

located in strategic places (at amplifier outputs, loudspeaker cabling junction boxes, inside loudspeaker

enclosures) throughout a PA distribution system. It can also receive ‘internal error’ information from an

SM40 Routing System itself, as well as responding to external sensing devices such as smoke detectors and

micro switches.

Being controlled by a microprocessor, the system is particularly flexible, specific functions being easily

programmed and changed to allow for alterations in the PA system configuration and surveillance

requirements.

Because the system is built around 19-inch rack mounted Euro Card circuit boards, expansion or alterations

to the system are quickly and easily carried out.

A total Surveillance Centre would comprise:

- 19-inch rack unit, containing a microprocessor controlled SM40 Surveillance Centre

- 100V loudspeaker line, and low voltage loudspeaker, monitoring devices; external warning devices

(lamps, buzzers, etc.)

- printer, or computer/printer combination.

All SM40 Surveillance Centre internal wiring is particularly installer friendly due to the ‘Quick Fit’

connectors used.

Standard twisted two core screened microphone cable is used to carry data and 15V power between the

system and the interlinked Amplifier/Loudspeaker Surveillance Boards.

All SM40 Surveillance Centres are built around the LBB 1370 Basic (starter) System, which is able to

sequentially scan 8 Test Lines, each containing up to 128 monitoring devices; receive error input from

2 external sources, activates several relay error sets and synchronises the real-time clock.

The single 19-inch rack frame, capable of holding 9 circuit cards, has enough room to accomodate the Basic

System plus 5 extra cards. Adding these cards expands the system, enabling it to feed more amplifiers with

the Pilot Test Tone; scan a greater quantity of Test Lines and/or receives a larger amount of error inputs

from external devices. However the system is limited by the number of Termination Boards installed.

When a system’s requirements exceed the space offered in a single rack frame, or extra termination boards

are required the SM40 Extension Frame LBB 1360 is available. These frames can be linked together to

expand the system.

2. UNPACKING AND INSTALLATION

4

2

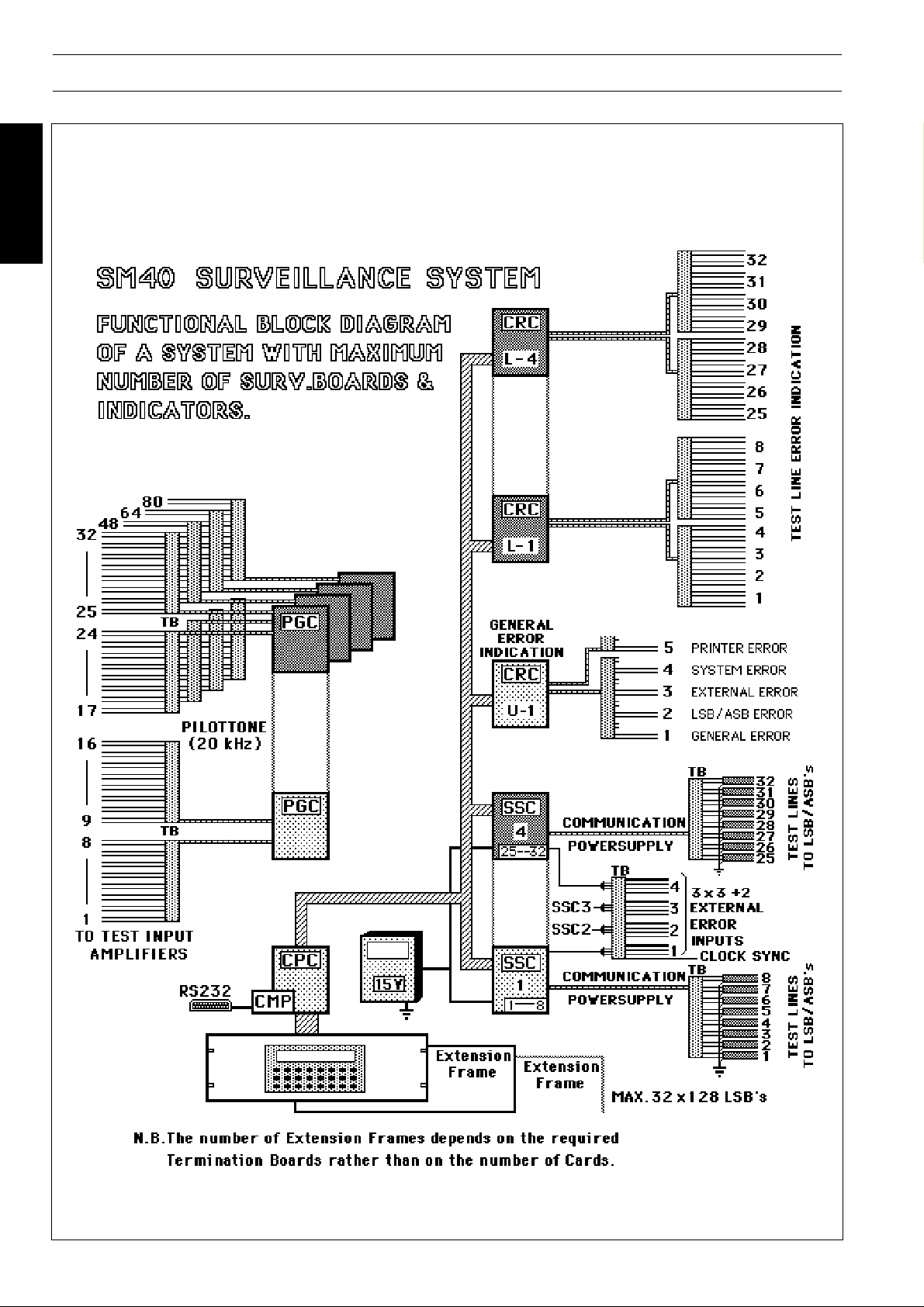

SURVEILLANCE BASIC SYSTEM

LBB 1370

PE 1141

TB3 TB4 TB5TB1

RS 232

connection

PE 1268

Processor card

Control Relay Card

Surveillance Switch Card

FRONT TOP VIEW

INTERCONNECTION BOARDS

PGC CPC CRC SSC

1

8

10

17

21

25

30

ba

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

U-1

I/O Board

Pilot-tone Generator Card

1268/10 1141/52

1

8

10

17

21

25

30

TEST SIGNALS TEST LINES

42

ERROR

OUTPUT

ERROR

INPUT

TERMINATION BOARDS

(REAR VIEW)

2. UNPACKING AND INSTALLATION

5

2

2.1 SM40 Surveillance Centre - Unpacking and installation

In order to ensure that your SM40 Surveillance Centre functions properly, please follow these few simple

instructions after unpacking your unit.

1 Carefully check the enclosed system components for physical damage caused during shipping. Any

complaints should be made immediately to the shipping company.

2 Mount the Basic System frame in the appropriate position in the 19-inch rack unit (not higher

than shoulder height, so that the display and keyboard can be clearly seen).

3 Extension Frames are available to expand the Basic System into a larger system. These should now

be mounted, and wired according to the appropriate wiring diagrams.

4 Mount the amplifiers and auxiliary equipment in the rack(s).

If power amplifiers are mounted beneath SM40 frames, a heat shield should be installed above

them to deflect hot air currents.

5 Taking care to avoid earth (ground) loops, wire the mains power to the units. The SM40

Surveillance Centre will operate successfully on mains voltages from 175 V to 264 V when tapped

for 220 V, and from 90 V to 140 V when tapped for 110 V. Be sure to check that your system is

wired for the correct mains voltage.

Caution: When tapping the system for the correct mains voltage, refer to the documentation

supplied with the SM40 system.

NOTE: Because it is possible to touch the mains voltage terminals when the frame back panels are

opened, it is advisable not to turn the power on at this stage.

6 Open the back panel of the Basic system, and check that all of the connectors on the

Interconnection Board and Termination boards are firmly in place. If, in the unlikely event that one

of the connectors has become disconnected, refer to the enclosed basic system wiring diagram.

7 Refering to Termination Board illustrations in chapter 10, wire the Test Lines, Amplifier Test

Inputs, and Error Inputs/Outputs, to the screwblock connectors. If a printer or computer is to be

used with the system, it should be wired to the RS232 serial interface socket at this time

8 Plug the screwblock connectors into the termination boards, ensuring that they are in the correct

locations.

9 Open the front panel of the rack frame and gently push each of the circuit cards to make sure that

they are all firmly connected to the Interconnection Board.

10 If, after double checking that all of the mains power and signal wiring is correct, and that the

system is adequately earthed, switch on the mains power to the rack.

3. SM 40 BASIC SYSTEM AND EXTENSION FRAME

6

3

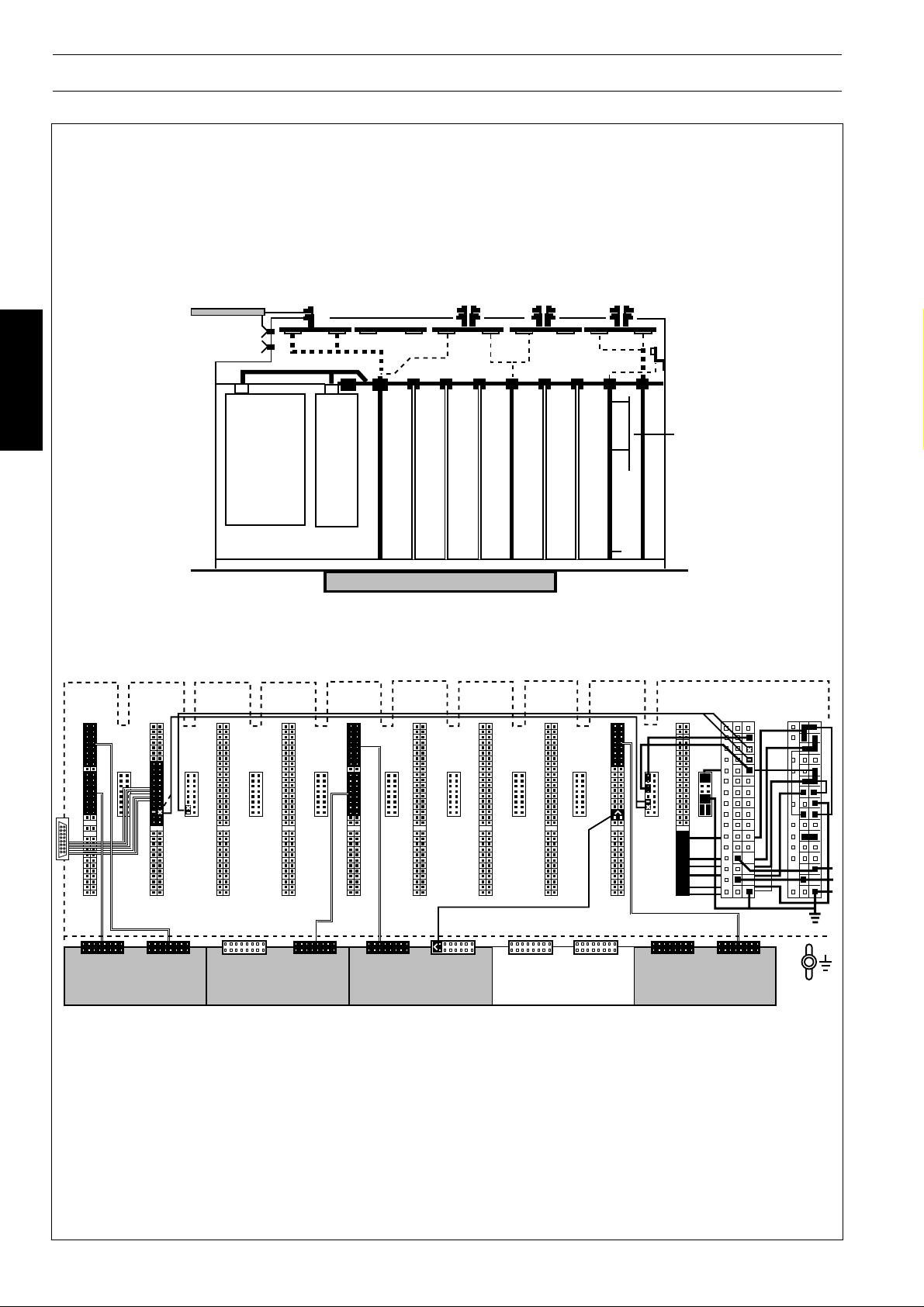

SURVEILLANCE BASIC SYSTEM

LBB 1370

Error

indication

CRC

16

9

TB

PGC

8

CPC

PE

15V

U-1

SSC

1

RS232

1

1-8

PGC CPC CRC SSC

RS232

1

8

10

17

21

25

30

ba

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

U-1

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

L-2 L-1

5

4

3

2

1

Communication &

Power supply

1

8

10

17

21

25

30

1

8

10

17

21

25

30

Printer error

System error

External error

LSB/ASB error

General error

To

8x128

LSBs

1268/10 1141/52

TEST SIGNALS TEST LINES

ERROR

OUTPUT

ERROR

OUTPUT

ERROR

INPUT

INTERCONNECTION BOARD WIRING AS VIEWED FROM REAR OF RACK UNIT

ERROR

TEST SIGNALS

91

10

11

12

13

14

15

16

2

3

4

5

6

7

8

TERMINATION BOARD WIRING AS VIEWED FROM REAR OF RACK UNIT

ERROR OUTPUT

General

Printer

ASB/LSB

External

System

INPUT

Clock sync.

1

2

3

TEST LINES

1

2

3

4

5

6

7

8

3. SM 40 SURVEILLANCE BASIC SYSTEM

7

3

3.1 SM40 Surveillance Basic System LBB 1370

Self contained, fully operational system, around which all SM40 Surveillance Centres are built.

Comprises 4 circuit cards, mounted in a single 19-inch rack frame.

The Surveillance Basic (starter) System is the heart of the SM40 Surveillance Centre. When supplemented

with a variety of Euro-cards and PCB’s, a wide range of system configurations are possible, and many

different application needs are succesfully met.

Containing, in its single rack frame, the Display and Keyboard, and the Central Processor Card (CPC);

(along with its other circuit cards) the Basic System is a self contained, fully working unit in its own right.

Being supplied with one Surveillance Switch Card (SSC) the system is able to sequentially scan 8 seperate

test lines, each having upto 128 Amplifier Surveillance Boards (ASB’s) and/or Loudspeaker Surveillance

Boards (LSB’s) connected.

The +15V required to power each test line in turn is provided by the in-built PE 1268/10 power

supply.unit.

The Basic System is also able to display error information generated by 2 external sources and clock

synchronisation using a single contact.

The communication PCB can send information generated by the CPC, via its RS232 port, to a printer or a

computer for the production of detailed hard copy of all monitored errors. The control relay card may be

used to activate external warning devices (lamps, buzzers, etc.) when an error occurs.

When a centre’s requirement exceed the facilities available in the Surveillance Basic System, further circuit

cards (plus the extension frames LBB 1360 necessary to accomodate them) are ordered, expanding the

system to meet specific application needs.

Because the Surveillance Basic system is supplied fully wired, adjusted, tested, and mounted in its own

19-inch rack unit, ready for use, it is an ideal model from which to build a larger system.

Units included with Basic System LBB 1370:

1x Single 19-inch Rack Frame

1x Power Supply +15V/-15V/+5V PE 1141/52

1x Power Supply +15V PE 1268/10

1x IB Interconnection Board

4x TB Termination Boards LBB 1377/00

1x CPC Central Processor Card + I/0 +

Surveillance System Software

1x CRC Control Relay Card LBB 1356/00

1x SSC Sur veillance Switch Card LBB 1374/00

1x PGC Pilot Tone Generator Card LBB 1369/00

Optional Euro-Cards:

CRC Control Relay Card LBB 1356

SSC Surveillance Switch Card LBB 1374

PGC Pilot Tone Generator Card LBB 1369

TB Termination Board LBB 1377

Optional PCB’s:

Loudspeaker Surveillance Board LBB 1367

Amplifier Surveillance Board LBB 1368

3. SM 40 BASIC SYSTEM AND EXTENSION FRAME

8

3

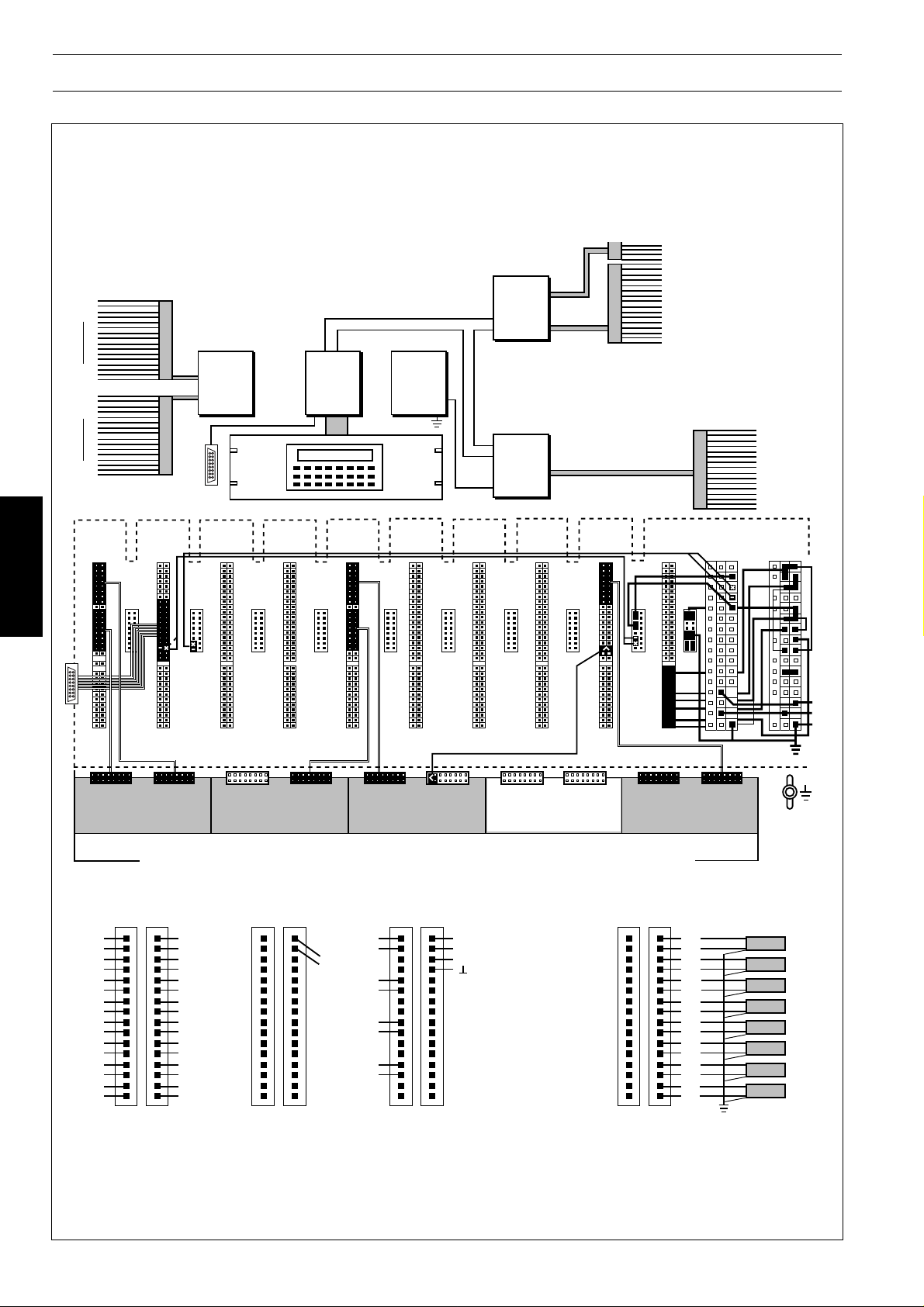

SURVEILLANCE BASIC SYSTEM LBB 1370

Plus 1 EXTENSION FRAME LBB 1360

INTERCONNECTION BOARD WIRING AS VIEWED FROM REAR OF RACK UNIT

PGC PGCCPC CRC SSCSSC SSC SSC

1

8

10

17

21

25

30

1

8

10

17

21

25

30

ba

TEST SIGNALS

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

1

8

10

17

21

25

30

U-1

TEST SIGNALS TEST LINES TEST LINES

ERROR

OUTPUT

ERROR

INPUT

25 - 32 17 - 2425 - 32 17 - 24

PGC PGC PGC CRCCRC CRCCRC

1

8

10

1

8

10

1

8

10

1

8

10

1

8

10

1

8

10

1

8

10

1

8

10

1

8

10

PE 1268/10 PE 1141/52

1

8

10

17

21

25

30

9 - 16 1 - 89 - 16 1 - 8

LBB 1360

1

8

10

17

20

24

30

ba

17

20

25

30

17

21

25

30

17

21

25

30

17

21

25

30

17

21

25

30

17

21

25

30

17

21

25

30

17

21

25

30

L-2L-3L-4

17

21

25

30

L-1

TEST SIGNALS TEST SIGNALS TEST SIGNALS ERROR OUTPUT ERROR OUTPUT

73 - 80 65 - 72 41 - 48 33 - 40 25 - 32 17 - 24 9 - 16 1 - 8

57 - 64 49 - 56

SIDE VIEW FRAMES

Basic frame

Front Rear

Extension frame

+

3. SM 40 BASIC SYSTEM AND EXTENSION FRAME

9

3

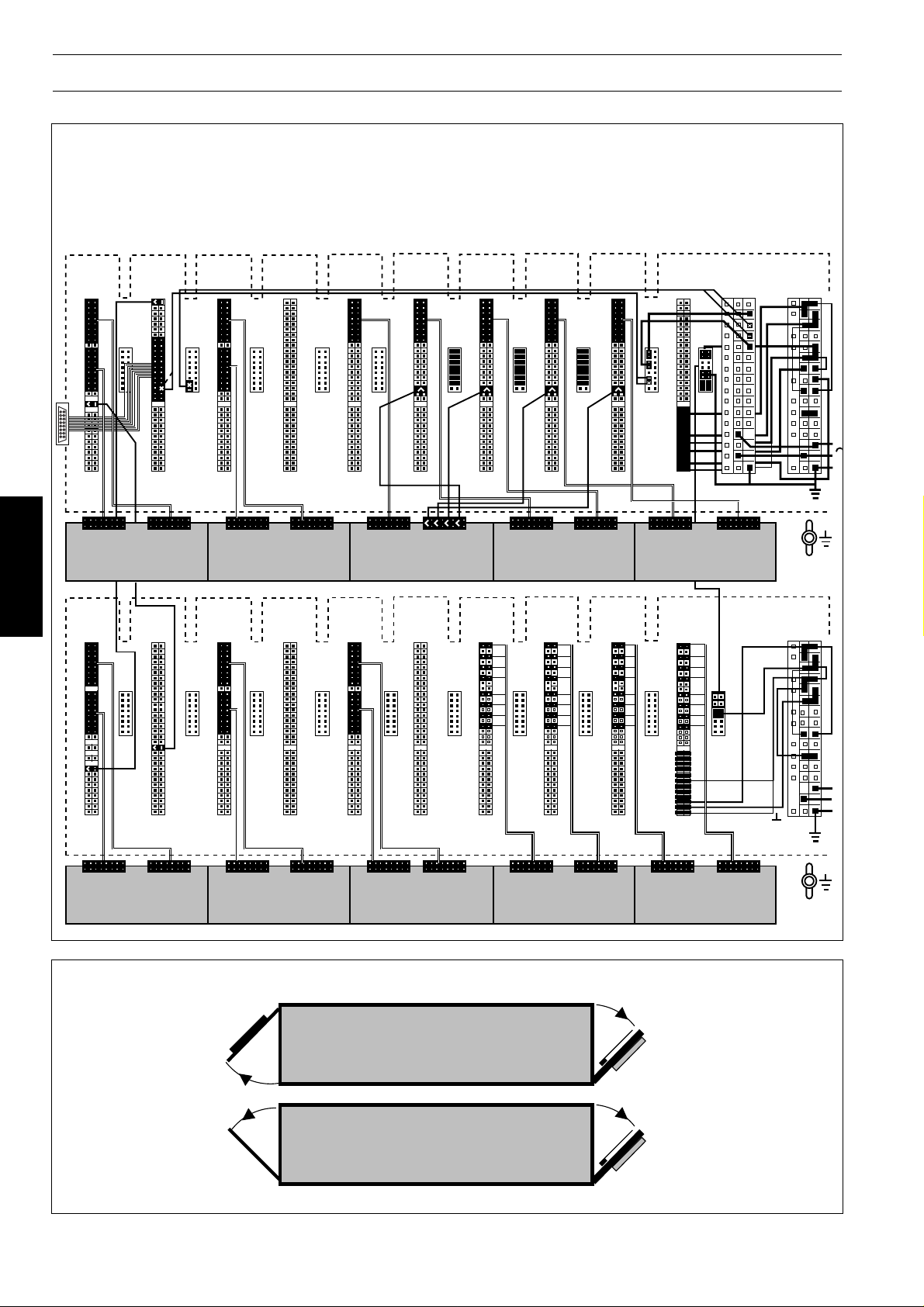

3.2 Extension Frame LBB 1360

Single 19-inch rack frame, capable of holding 10 SM40 circuit cards. Complete with power supply, and

one Interconnection and Termination Board.

A single rack frame, capable of holding, and interconnecting 10 SM40 circuit cards, has enough room to

accomodate the Basic (starter) System, described elsewhere, plus additional Pilot-tone generator cards,

Control Relay Cards and Surveillance Switch Cards.

When the number of terminations boards required in an SM40 system exceeds the amount of space offered

in this single rack frame, Extension Frame LBB 1360, is available.

These components, mounted in the 19-inch rack frame, are supplied tested, and wired to accept and power

up to 10 SM40 circuit cards.

Units included with Extension Frame LBB 1360:

1x Single 19-inch rack frame

1x Power Supply Unit +15V/ -15V PE1113/50

1x IB Interconnection Boards

1x TB Termination Boards LBB 1377/00

TB1

PE 1113

FRONT TOP VIEW

SM40 EXTENSION FRAME

LBB 1360

3. SM 40 BASIC SYSTEM AND EXTENSION FRAME

10

3

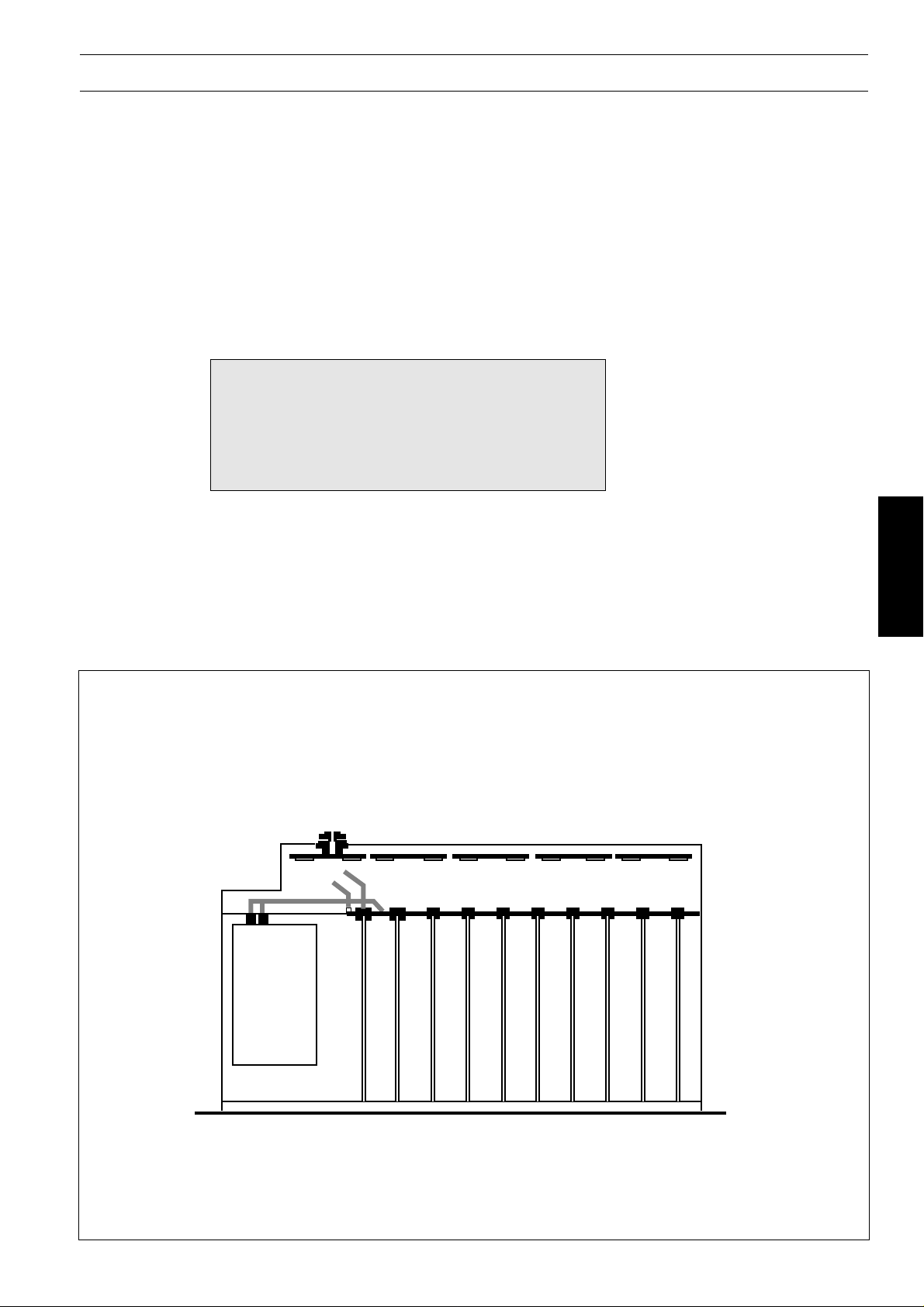

SURVEILLANCE

BASIC FRAME

+15V supply & comm

1811612345

Pilot-tone Error

SSC PGC CRC CPC

RS232

I/O

2

IC

supply

PE1141/50

Supply for

eurocards

DISPLAY

BUFFER

X-tal.

5.068 MHz

220 V

MICRO-

PROCESSOR

Z80 B

PE1268/10

Supply for

surveillance boards

32K

EPROM

REAL-TIME

CLOCK

32K

RAM

X-tal.

32.768 KHz

2

INTERFACE

DATA

CLOCK

serial/buffers

DATA BUS

ADDRESS BUS

CONTROL BUS

I/O BOARDIC

Clock data 2

Clock data 3

Clock data 4

Clock data 5

RS232

CENTRAL PROCESSOR CARD

Clock data 1

2

I C Comm.

Clock data 6

Communication

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

11

4

4.1 Central Processor Card - CPC

Eurocard 10 x 22 cm with an ‘a b’ connector (2 x 32). A microprocessor which can scan over 4000

monitoring devices, and activate more than 100 relays, via the communication line.

At the heart of the SM40 Surveillance Centre is the Central Processor Card (CPC). Capable of sequentially

scanning 4096 monitoring devices; activating 64 SSC solid state relays, and 40 CRC relay sets; and sending

error information to a display, external computer, or printer; this is a powerful piece of equipment. It

provides a system of this type with a great amount of possibilities.

A Display & Keyboard mounted in the rack unit’s front panel, is used to display the scanning status and any

detected errors, and also to carry out the user programming.

When programming is complete the CPC returns to its normal scanning mode and, until a secret password

is entered, the keyboard has no influence on the processor.

The basic functions of the Central Processor Card are as follows:

SCANNING of Amplifier Surveillance Boards (ASB’s) and/or Loudspeaker Surveillance Boards (LSB’s).

This is done by sequentially sending 15V power to each of the 8 Test Lines of the Surveillance Switch Cards

(SSC’s) in turn, then sending communications data to each board in each line sequentially.

Translating the error data received from the ASB’s and LSB’s, along with external sensing devices, and

relaying this information to the display, or via the RS232 port, to a printer or external computer.

ACTIVATING of relays, to switch on external warning devices (lamps, buzzers, paging units, etc.) via

Control Relay Cards (CRC’s).

CHECKING of system hardware. The processor acts as a “watchdog”, continuously patrolling the SM40

Surveillance Centre hardware to check for errors, malfunctions or disconnections. If a problem exists,

information, stating which card is faulty, is relayed to the display or printer.

An automatic restore function is also incorporated, so that when an internal error occurs, the system will not

hang-up, and when an error is rectified no manual system reset is required.

REAL TIME CLOCK is built into the unit, and (in the program’s ‘Enable Print’ mode) is displayed on the

LCD, giving date, hours and minutes. When an error occurs, the current time and date are transmitted to

the printer. Synchronisation is via A17 on Surveillance Switch Cards No.1.

SERIAL INTERFACE. The standard RS232 serial interface connector mounted on a bracket on the frame,

and wired to the CPC, allows the system to communicate with a wide variety of personal, mini, and mainframe computers as well as direct to serial printers.

The communication has 8 data bits, and the baud-rate is selectable between 300, 1200, 2400, 4800 and

9600 baud.

This, and the other I/O port parameters, such as number of Stop Bits, and Parity can be set in the installer

programming menu.

SM40’s standard default parameters are:

2400 baud, 8 data bits, 1 stop bit, even parity.

A yellow LED, mounted on the front edge of the card indicates that the CPC is in communication with the

rest of the SM40 Surveillance Centre, and 1 green LED indicates that adequate supply voltage is present.

The CPC has additional driver stages for the communication lines of 5 of the Extension Frames used to

expand the Surveillance Basic System.

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

12

4

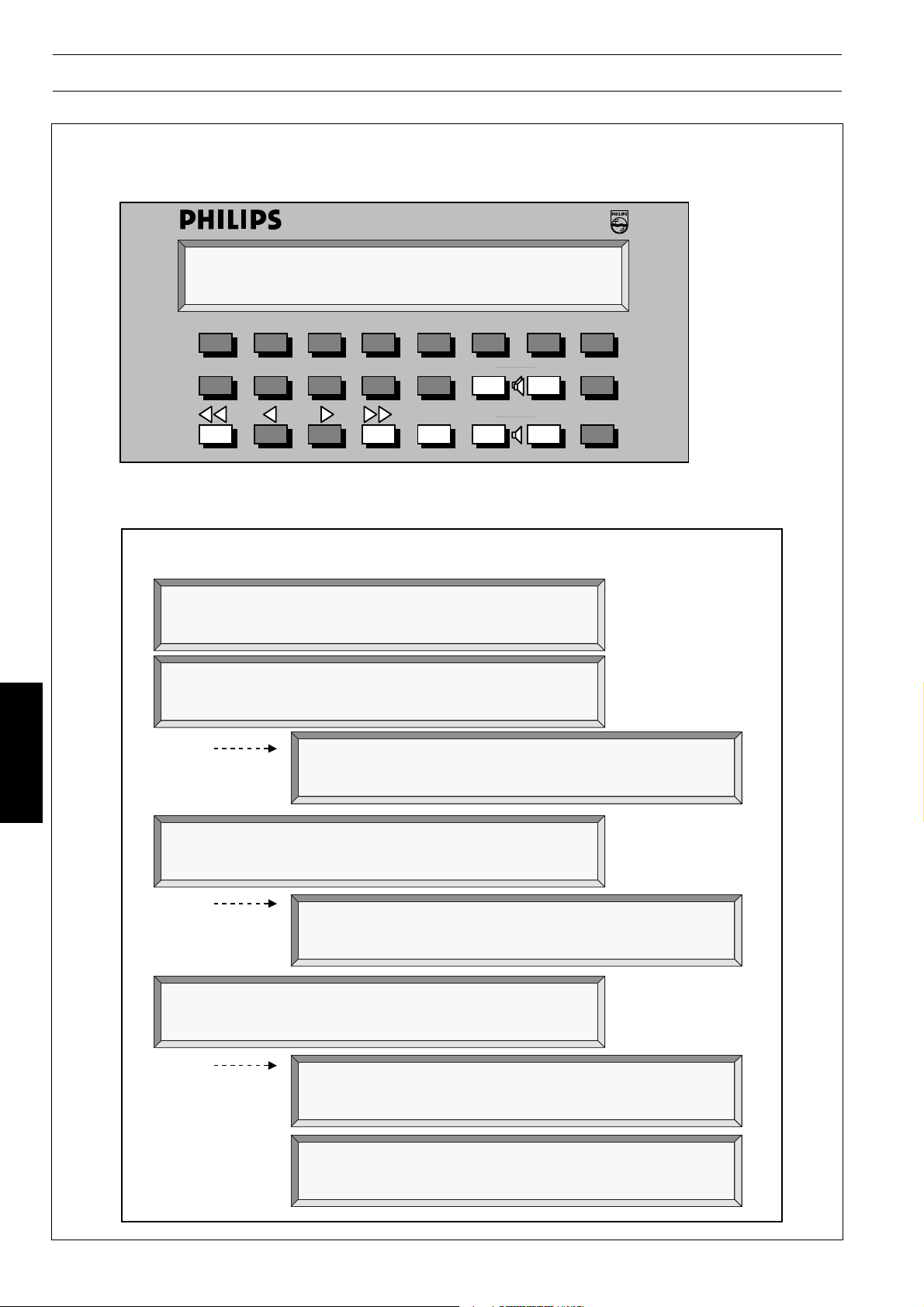

DISPLAY & KEYBOARD

* * * SM40 SURVEILLANCE SYSTEM * * *

DAY:XX-XX TIME:XX:XX

CBA21430

7691085

Mute Enter

Grey shaded keys are functional in the programming mode. i.e

USER MENU, INSTALLER MENU & SERVICE MENU

DISPLAY READOUTS AFTER ENTERING 'USER-MENU' PASSWORD (9, 6, ENTER)

>WELCOME TO SURVEILLANCE PROGRAMMING<

>> VERSION 1.21 DATE: XX-XX-XX <<

*USER MENU* Scroll with 'ENTER'

PRESS '1' TO SELECT ERROR PRINTING

1

DIPSLAY OF ERRORS ON PRINTER

PRESS '0' TO DISABLE; '1' TO ENABLE: _

10

Break

*USER MENU* Scroll with 'ENTER'

PRESS '2' TO PRINT CURRENT ERRORS

2

*USER MENU* Scroll with 'ENTER'

PRINTER NOT READY; PLEASE CHECK

*USER MENU* Scroll with 'ENTER'

PRESS '3' TO SET REAL-TIME CLOCK

3

ENTER DD-MM-HH:MM

XX-XX XX:XX

ENTER LAST 2 DIGITS OF CURRENT YEAR: XX

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

13

4

4.2 Display and Keyboard

A programming tool, containing a keyboard for user key assignment and a display which shows the

sequence of programming. Mounted in the front panel of the rack unit.

Users of the SM40 Surveillance Centre are able to program and make changes to the functions of their

system, quickly and easily, with the aid of the Display And Keyboard. This is a simple programming tool

comprising a 24 key keyboard and a 2x40 character lcd display which shows the sequence of programming.

SM40 KEY FUNCTIONS

0-9 Numeric keys to type-in password; select

programs and functions; and to insert the

time and date in the User Programming

menu.

Moves the cursor 1 position to the right

when setting the real-time clock in the User

Programming menu.

Moves the cursor 1 position to the left when

setting the real-time clock in the User

Programming menu.

Non-functional

Non-functional

Non-functional

Non-functional

Non-functional

Non-functional

Mute Non-functional

A Non-functional

B Non-functional

C Non-functional

Break In most cases this key will abort a command

and return the user to the main menu for the

next programming sequence without any new

information being stored. When in the main

menu, pressing will return the system to the

normal scan mode.

Enter Enters numerical inputs into the memor y and

moves to the next program stage, or at the

end of a program sequence; to the main

menu ready for the next program.

When programming is completed, the system returns to its

normal scanning mode and, until the correct password is

entered, the keyboard has no influence on the processor,

thus guarding the system from unauthorized tampering.

The unit is mounted in the rack units’ front panel, which

may be flipped up, locking automatically in a horizontal

position. This is an ideal angle from which to view and

operate the unit.

0

1

0

1

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

14

4

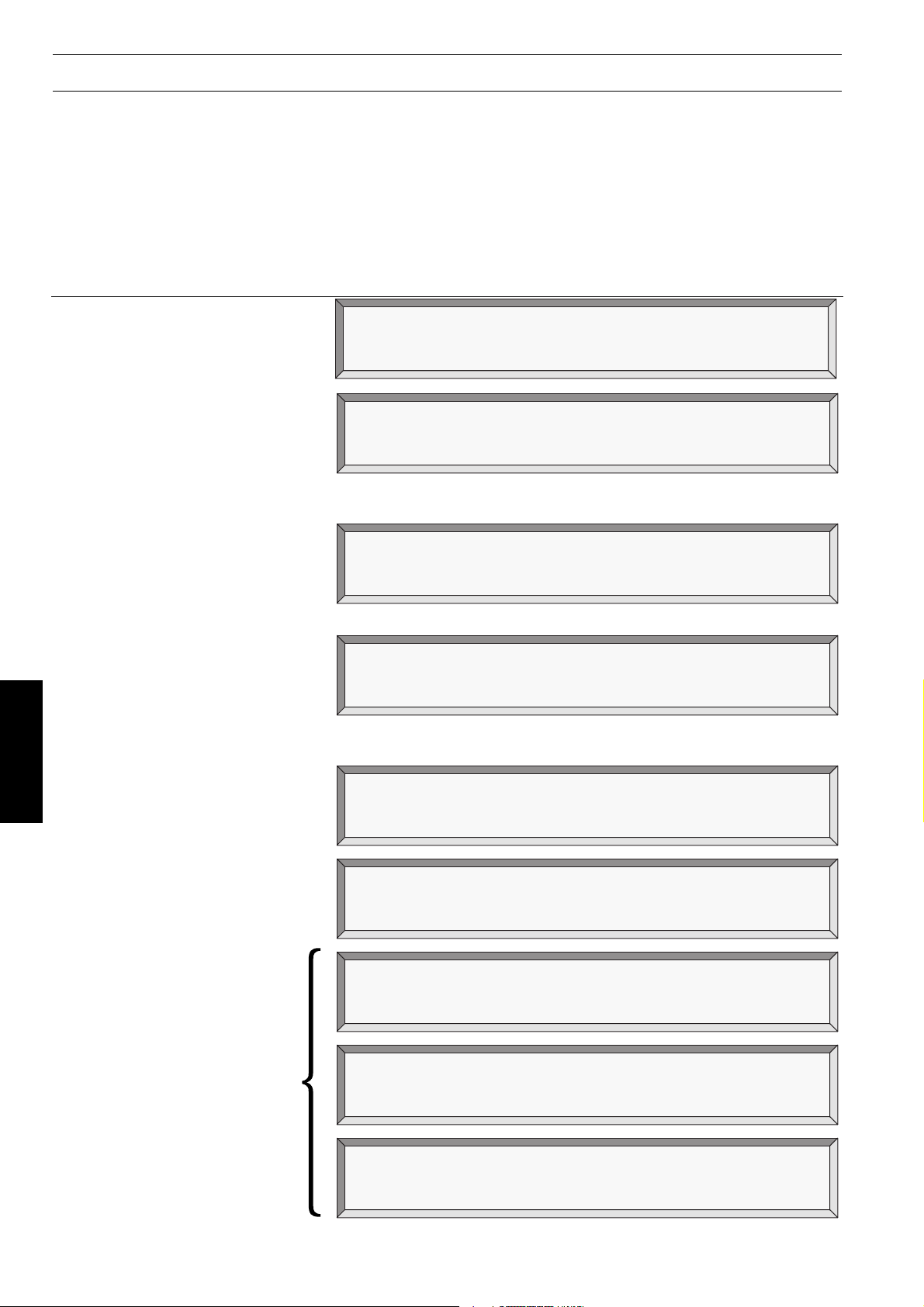

4.2.1 Display readout

During the remainder of this chapter, specific contexts (status) and user actions are shown in the left

column, and possible display results are shown in the right column. Characters between quotes (e.g. ‘Key’)

denote keyboard inputs, and occurrances of XX and YY in any displays shown in the right column denote

information which is dependant on the system configuration, or entered by the user.

When the SM40 system is powered up, either one of the following two displays is shown:

Status / Action

When memory was cleared the display shows:

When the system was installed previously,

the display shows:

This message will disappear after 2-seconds,

and the system will start scanning.

When scanning and error printing are enabled

(refer to User Programming Menu) the

display shows:

The second display line is used to display the

current date and time.

When scanning and error printing are

disabled (refer to User Programming Menu)

the display shows:

The second display line is used to display

errors. Errors are indicated one by one in a

continuous cycle.

Loudspeaker/amplifier errors are displayed as

follows:

External errors are displayed as follows:

System errors are displayed as follows:

Result / Remarks

SCANNING ZONE: XX UNIT: XXX

<ERROR> RELAY CARD: II-XX

SCANNING ZONE: XX UNIT: XXX

<ERROR> RELAY CARD: I-XX

SCANNING ZONE: XX UNIT: XXX

<ERROR> SWITCH CARD: XX

SCANNING ZONE: XX UNIT: XXX

<ERROR> EXTERNAL INPUT: XX

SCANNING ZONE: XX UNIT: XXX

ERROR IN ZONE: XX UNIT: XXX

SCANNING ZONE: XX UNIT: XXX

SCANNING ZONE: XX UNIT XX

DATE: XX-XX TIME: XX:XX

* * * SM40 SURVEILLANCE SYSTEM * * *

DATE:XX-XX TIME:XX:XX

* * * SYSTEM MUST BE PROGRAMMED * * *

* * * GO TO INSTALLER MENU * * *

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

15

4

The printer produces a listing of errors as follows:

<ERROR> DATE:XX-XX TIME:XX:XX ZONE:XX UNIT:XXX

<ERROR> DATE:XX-XX TIME:XX:XX ZONE:XX UNIT:XXX

<ERROR> DATE:XX-XX TIME:XX:XX ZONE:XX UNIT:XXX

<ERROR> DATE:XX-XX TIME:XX:XX ZONE:XX UNIT:XXX

<ERROR> DATE:XX-XX TIME:XX:XX ZONE:XX UNIT:XXX

If the <ERROR> is rectified the same message is sent to the printer followed by: ‘RECOVERED’.

ERROR INDICATION

Errors are communicated to external indication devices (i.e warning lamps, alarm buzzers, etc..) via

relay cards.

Relay cards I, 1,2,3 and 4 indicate errors in zones 1 to 32

Relay cards II, 1, indicates general error indication with the following indications:

Relay 1 is activated when any error occurs.

Relay 2 is activated when a loudspeaker/amplifier error occurs.

Relay 3 is activated when an external error occurs.

Relay 4 is activated when a system error occurs.

Relay 5 is activated when a printer error occurs.

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

16

4

4.3 SM40 USER PROGRAMMING

Specific contexts (status) and user actions are shown in the left column, and possible display results are

shown in the right column. Characters between quotes (e.g. ‘Key’) denote keyboard inputs, and occurrances

of XX and YY in any displays shown in the right column denote information which is dependant on the

system configuration, or entered by the user.

Unless stated otherwise, ‘Enter’ stores typed information in the memory. ‘Break’ aborts a command without

storing new information.

4.3.1 SM40 SURVEILLANCE USER PROGRAMMING

Status / Action

When the system is ‘powered up’, one of the

next two displays is shown:

The first display shows when the memory has

been cleared. The system is inoperative until

installed (via the Installer menu).

The second display shows when the system is

installed.

To enter the user programming mode, press

keys ‘9’, ‘6’, followed by the ‘Enter’ key. The

display shows:

Display after pressing ‘1’.

Display after selection:

Result / Remarks

The ‘welcome’ display shows the current software version and its release date. After

three seconds this message is cleared and the first programming mode is displayed.

The first programming mode is displayed as follows:

The current selection will be displayed. Selecting ‘0’ will show all errors displayed

on the lower line. Selecting ‘1’ will send all errors to the printer, with the lower line

showing the current date and time

Pressing ‘2’ will produce a printout of loudspeaker, external, and system errors

(regardless of the settings in user menu ‘1’ shown above). The header will show the

date and time.

This function is useful for incidental printing, when no permanent printer is

connected. If the printer is not powered, off-line, or the serial board parameters are

not correctly programmed (via the installer program), the display will show (see

next page):

*USER MENU* Scroll with 'ENTER'

PRESS '2' TO PRINT CURRENT ERRORS

DISPLAY OF ERRORS ON PRINTER

PRESS '0' TO DISABLE; '1' TO ENABLE

*USER MENU* Scroll with 'ENTER'

PRESS '1' TO SELECT ERROR PRINTING

> WELCOME TO SURVEILLANCE PROGRAMMING <

>> VERSION X.X DATE XX-XX-XX <<

* * * SM40 SURVEILLANCE SYSTEM * * *

DATE:XX-XX TIME:XX:XX

* * * SYSTEM MUST BE PROGRAMMED * * *

* * * GO TO INSTALLER MENU * * *

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

17

4

Status / Action

(Continued from previous page...)

Pressing ‘Break’ will return the system back to

display the Main Menu. The display will

show:

Display after pressing ‘3’.

After pressing ‘Enter’ the display shows:

Result / Remarks

Printing will begin when the printer problem has been solved.

The clock can be set by either entering the complete time or by shifting the cursor

to the digit that must be altered using the single arrow keys and .

After entering the 2 digits and after pressing ‘Enter’ the display shows:

After pressing ‘Break’ the system will return to its normal scanning mode.

USER PROGRAMMING IS NOW COMPLETE.

*USER MENU* Scroll with 'ENTER'

PRESS 'BREAK' TO EXIT PROGRAMMING

ENTER LAST 2 DIGITS OF CURRENT YEAR: XX

PRINTER NOT READY; PLEASE CHECK

*USER MENU* Scroll with 'ENTER'

PRESS '3' TO SET REAL TIME CLOCK

ENTER DD-MM HH:MM

XX-XX XX:XX

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

18

4

4.3.2 SM40 SURVEILLANCE INSTALLER PROGRAMMING MENU

Status / Action

To enter the INSTALLER programming

mode, press keys ‘8’, ‘1’, followed by the

‘Enter’ key. Ther display shows:

Display if system is installed:

Display after pressing ‘4’.

After pressing ‘5’ the display shows:

Display after pressing ‘Enter’.

Display after pressing ‘Enter’.

Display after pressing ‘Enter’.

Result / Remarks

The ‘welcome’ display shows the current software version and its release date. After

three seconds this message is cleared and the first programming mode is displayed.

Programs 1, 2 and 3 are identical to that of the User Programming. In the ‘installer

mode’ the first display is as follows:

To enable the system to operate correctly, the current hardware configuration must

be stored. This is done by pressing key ‘4’.

The display is only shown during storing, then continues as follows:

This program stores all the loudspeaker/amplifier surveillance boards which are

present in the system’s memor y. However a zone will only be scanned if:

- The corresponding surveillance switch card is present.

- The unit with adddress ‘1’ is connected to that zone and recognised.

*INSTALL MENU* Scroll with 'ENTER'

PRESS '6' FOR AUTO-STORE OF ALL UNITS

I/O BOARD MOUNTED: YES

RELAY CARDS I: XX XX XX XX

II: XX XX XX XX

SWITCH CARDS: XX XX XX XX

*INSTALL MENU* Scroll with 'ENTER'

PRESS '5' TO DISPLAY SYSTEM SETUP

*INSTALL MENU* Scroll with 'ENTER'

STORING HARDWARE CONFIGURATION

*INSTALL MENU* Scroll with 'ENTER'

PRESS '4' TO STORE SYSTEM HARDWARE

> WELCOME TO SURVEILLANCE PROGRAMMING <

>> VERSION X:XX DATE DD-MM-YY <<

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

19

4

SM40 SURVEILLANCE INSTALLER PROGRAMMING MENU

Status / Action

After pressing ‘6’ the display shows:

When ready the display will show:

Display after pressing ‘Enter’:

Display after pressing ‘7’:

Display after input of zone number (1-32)

and after pressing ‘Enter’.

Display after input of zone number (1-128)

and after pressing ‘Enter’.

Display after pressing ‘0’, if the selected unit

was present.

Display after pressing ‘1’, if the selected unit

was present.

Display if the selected unit was NOT present.

Result / Remarks

All the relevant zones will be scanned and the units present will be stored in

memory.

This is the time interval between two scans of the same unit. This information is

relevant for ‘priority scanning’’ programming.

This program is used to manually add or delete surveillance units.

At this stage in the programming a new unit number may be entered, and the

proces repeated.

Pressing ‘Break’ will return to ‘ENTER ZONE NUMBER’.

Pressing ‘Break’ again will return to the main menu.

ZONE: XX UNIT: XXX NOT FOUND

ENTER UNIT NUMBER

ZONE: XX UNIT: XXX ADDED

PRESS '7' TO ADD/DELETE UNITS

ZONE: XX UNIT: XXX DELETED

PRESS '7' TO ADD/DELETE UNITS

ZONE: XX UNIT: XXX

PRESS '0' TO DELETE; '1' TO ADD

ZONE: XX

ENTER UNIT NUMBER

ENTER ZONE NUMBER:

*INSTALL MENU* Scroll with 'ENTER'

PRESS '7' TO ADD/DELETE UNITS

TOTAL SYSTEM SCAN TIME: XX MIN XX SEC

Press 'ENTER' to continue . . . .

SCANNING ZONE:XX UNIT:XXX

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

20

4

SM40 SURVEILLANCE INSTALLER PROGRAMMING MENU

Status / Action

The display shows the following:

Display after pressing ‘8’.

Display after pressing ‘2’.

Display after input of zone number (1-32)

and after pressing ‘Enter’.

Display after pressing ‘9’.

Display after pressing ‘1’.

Display after input of zone ‘1’ or ‘2’ and

‘Enter’.

Result / Remarks

Pressing ‘1’ will send a list of stored units (zone-by-zone) to the printer.

The header will show date and time.

Pressing ‘Enter’ will show the next 10 units. Pressing ‘Break’ will repeat zone input

request, pressing ‘Break’ again will return to main menu. The display will show:

This program cause the scanning sequence to be interrupted, while zone 1 or 2

(or both) are scanned at a programmed time interval

Pressing ‘0’ will disable priority scanning and return to main menu.

Input of ‘0’ minutes will disable priority scanning for that zone. Input of any other

time (1-9 minutes) will cause an extra scan of that zone to occur at the

programmed time interval. The current zone scan however will finish first.

PRIORITY SCAN OF ZONE (1 OR 2):X

ENTER INTERVAL TIME (O-9 MIN.):

PRIORITY SCAN OF ZONE (1 OR 2):

PRIORITY SCANNING

PRESS '0' TO DISABLE; '1' TO ENABLE

*INSTALL MENU* Scroll with 'ENTER'

PRESS '9' TO SET PRIORITY SCANNING

ZONE: XX UNITS CONNECTED

XXX XXX XXX XXX XXX XXX XXX XXX XXX XXX

ENTER ZONE NUMBER: XX

DISPLAY OF ALL UNITS FOUND

PRESS '1' FOR PRINTER; '2' FOR DISPLAY

*INSTALL MENU* Scroll with 'ENTER'

PRESS '8' TO SHOW ALL UNITS

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

21

4

SM40 SURVEILLANCE INSTALLER PROGRAMMING MENU

Status / Action

The display shows the following:

Display after pressing ‘A’.

Display after pressing ‘1’.

Display after pressing ‘B’.

Display after entering ‘1’, ‘2’, ‘3’, ‘4’, or ‘5’

and after pressing ‘Enter’.

Display after entering ‘1’ or ‘2’.

Result / Remarks

The scanning of a priority zone will be indicated by an ‘asterix’ in the upper right

corner of the display.

After entering the ‘interval time’ and after pressing ‘Enter’ the display will repeat

the zone number request. Pressing ‘Break’ will return to the main menu.

During installer programming scanning is halted. The program ‘Shut-off Timer’

causes the system to automatically exit programming, and to start scanning at the

preprogrammed time after the last key stroke.

Pressing ‘0’ will disable the timer and return to main menu.

After input of the desired time, and after pressing ‘Enter’, the display will return to

the main menu. The display will show.

This program will set the serial (printer or P.C.) parameters. If the memory was

previously cleared, the serial port will be set by default at 2400 baud, 8 databits,

1 stop bit and even parity.

After entering ‘1’, ‘2’, or ‘3’ and ‘Enter’, the display returns to the main menu.

PARITY SELECTION (1-3): 1

1 = EVEN 2 = ODD 3 = NO PARITY

SELECT NUMBER OF STOPBITS (1-2): 1

SELECT BAUD RATE (1-5): 3

1=300 2=1200 3=2400 4=4800 5=9600

*INSTALL MENU* Scroll with 'ENTER'

PRESS 'B' TO SET I/O PARAMETERS

ENTER TIME (1-9) MINUTES BETWEEN

LAST KEYSTROKE AND SHUT-OFF: 3

PROGRAMMING MODE SHUT-OFF TIMER

PRESS '0' TO DISABLE; '1' TO ENABLE

*INSTALL MENU* Scroll with 'ENTER'

PRESS 'A' TO SET PROGRAM SHUT-OFF TIMER

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

22

4

SM40 SURVEILLANCE INSTALLER PROGRAMMING MENU

Status / Action

The display shows the following:

Pressing ‘0’ will display:

The display if the memory was not cleared.

Result / Remarks

Because this program clears the complete memory, caution must be taken. The

display after pressing ‘C’ is as follows:

Pressing any key except ‘0’ will return to the main menu

After 3 seconds the following message is displayed

The system is now no longer in the programming mode.

Pressing ‘Break’ now will return to the normal scan mode.

*INSTALL MENU* Scroll with 'ENTER'

PRESS 'BREAK' TO EXIT PROGRAMMING MODE

* * * SYSTEM MUST BE PROGRAMMED * * *

* * * GO TO INSTALLER MENU * * *

* * * WARNING * * * MEMORY CLEARED

CLEAR ALL MEMORY: ARE YOU SURE ?

'0' CLEARS; ANY OTHER KEY ABORTS

*INSTALL MENU* Scroll with 'ENTER'

PRESS 'C' TO CLEAR ALL MEMORY

4. OPERATING AND PROGRAMMING THE SM40 SURVEILLANCE CENTRE

23

4

This page has been left blank intentionally

5. SM40 SURVEILLANCE CENTRE MODULES

24

5

BOARD MOUNTED IN

SURVEILLANCE BASIC FRAME

5. SM40 SURVEILLANCE CENTRE MODULES

25

5

5.1 Interconnection board (IB)

Interconnection board for 10 SM40 Eurocards. Eurocard pressfit a + b (2 x 32) connectors.

Mounted at the rear of the 19-inch rack frame.

In any sophisticated communications system, convenient and dependable interconnection of the various

component units is vital.

The use of the Interconnection Board (IB) gives the SM40 Surveillance Centre both reliability and a great

deal of flexibility.

One IB is mounted at the rear of each 19-inch frame unit, and contains 10 Eurocard ‘Pressfit’ connectors of

the ‘a+b’ (2x32) format, into which 9, SM40 Surveillance Centre circuit cards can be plugged into the Basic

System Frame, and 10 in the Extension Frames (see frame layout drawings in Chapters 1 & 3.2).

The SM40 circuit card slides along rails within the frame unit and, with a light extra push, is mated securely

with the IB.

Removal of a card is done in the same way; a gentle tug with the special tool supplied, and the card then

slides out of the frame unit for service.

Each connector on the IB is universal, so that the cards may be located in the any position within the frame,

making alteration or expansion of the system both easy and economical. Even so, a logical positioning of the

circuit cards should be observed.

The system configuration should determine the position of the cards in the rack frames.

Some examples of typical systems, and the position of the cards in the frames are shown at the end of this

manual.

The power supply and reference signals, common to all of the circuit cards, are carried on rails printed on

the IB, but because the SM40 system has such a wide range of configuration possibilities, a certain amount

of cross-wiring between circuit cards is necessary.

This is easily accomplished by terminating the individual connector wires or flat cables with female Pressfit

connectors. These are then pushed onto the pins of the Eurocard connectors which are exposed on the rear

side of the IB.

Interconnection between the IB and the Termination Boards (TB’s) is also accomplished using flat cables

fitted with female ‘Pressfit’ connectors.

Located between the 10 connectors, on the rear of the IB, are Pressfit (2x8) connector blocks, whose

function is to join certain contacts of adjacent cards together.

Small Pressfit jumper plugs are used for this purpose (making the time consuming use of a soldering iron

unnecessary).

This ‘through connection’ of boards is necessary when using more than one Surveillance Switch Card (SSC)

in a frame (see System examples in Chapter 16).

5. SM40 SURVEILLANCE CENTRE MODULES

26

5

PRINTED CIRCUIT BOARDS CONNECTOR PIN CONFIGURATION

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

1

2

3

4

5

6

7

8

9

1011121314151617181920212223242526272829303132

CARD

ba

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

CONTROL RELAY

BREAK

MAKE

BREAK

MAKE

BREAK

MAKE

BREAK

MAKE

BREAK

MAKE

BREAK

MAKE

BREAK

MAKE

BREAK

+5V

+5V

+5V+5V +5V

SDA SCL

C 1

2

+15V

+15V

+15V

+15V

-15V -15V

-15V

-15V

DATATOTEST

1

2

3

1

2

3

ba

1

2

1

2

3

+15VtoTEST

3

SURVEILLANCE

SWITCH CARD

PILOT TONE

GENERATOR CARD

LINES

1

2

EXT.

3

ERROR

INPUT

+5V

+5V +5V

PSU. PSU.

SCL

SDA

C 1 I

2

I

+15V

+15V

+15V

+15V

- 15V - 15V

- 15V - 15V

4

5

6

7

8

+15V

4

5

6

7

8

9

1011121314151617181920212223242526272829303132

4

5

6

7

8

+15V

LINES

4

5

6

7

8

IN for

9

1011121314151617181920212223242526272829303132

TEST

LINE

DATA

FEED

ZONE 1 MAKE

ZONE 2

ZONE 3

ZONE 4

ZONE 5

ZONE 6

ZONE 7

IIC

IIC

IIC

SCL

1

2

3

4

5

6

7

ba ba

SDAI

SDA SCL

SDA SCL

SDA SCL

CENTRAL PROCESSOR CARD

C 2

C 3

C 4

2

2

2

I

C 5

2

I

I

ZONE 8

ZONE 9

ZONE 10

ZONE 11

ZONE 12

ZONE 13

ZONE 14

ZONE 15

ZONE 16

TXD

GND

8

9

1011121314151617181920212223242526272829303132

SDA SCL

RXD

2

C 6

I

CTS RTS

I/O

+15V

COMM

R/T

+5V

+5V

REF

+5V

+5V

+5V

+5V

PSU

SDA SCL

C 1

2

I

DIG

+15V

+15V

PSU PSU PSU

+15V

+15V

5. SM40 SURVEILLANCE CENTRE MODULES

27

5

DETAILED VIEW OF INTERCONNECTIONS

+15V

1234567

1234567

9

8

101112131415161718

RIBBON CABLE

8

101112131415161718

Mains

PSU 2

TO EXTERNSION FRAME

TO PSU No.1

19

TO EXTERNSION FRAME

19

1234567

SSC SSC PE 1268/10

1

2

456

2

456

1

1

1234567

PGC CPC

RIBBON CABLE

= Jumper

8

101112131415161718

9

7

8

101112131415161718

7

1

1

TO EXTENSION FRAME

RIBBON CABLE

999

8

101112131415161718

19

212121

19

TO EXTERNSION FRAME

RS232

5. SM40 SURVEILLANCE CENTRE MODULES

28

5

TERMINATION BOARDS

(wiring configur ations as viewed from rear of unit)

Amp.9

Amp.10

Amp.11

Amp.12

Amp.13

Amp.14

Amp.15

Amp.1

Amp.2

Amp.3

Amp.4

Amp.5

Amp.6

Amp.7

Amp.8Amp.16

To test inputs of amplifiersTo test inputs of amplifiers

116116

To PGC To PGC

Shielded cablesShielded cables

Test lines with power supply

& communication to the LSB's

To error indicators:

make = red LED

Break = green LED

1

2

3

4

Make

Break

Make

Break

Make

Break

Make

Break

116116

To SSC To SSC

1

2

3

4

5

6

7

8

9

10

11

12

116116

shield grounding to screwed

solder tag

Clock

synchronisation

Error inputs from

external detectors

To CRC To SSC

5. SM40 SURVEILLANCE CENTRE MODULES

29

5

5.2 Termination board (TB) (max. 5 per 19-inch rack frame)

Connector board mounted on the 19-inch frame back panel, connecting:

a) 16 Pilot Tone Generator Card outputs to the ‘Test’ inputs of Philips power amplifiers.

b) The outputs of 2 Surveillance Switch Cards to 16 individual ‘Test Lines’.

c) 8 Control Relay Card relay sets to remote warning devices.

d) 11 Error inputs to 4 Sur veillance Switch Cards.

e) 1 clock synchronisation contact.

The task of the termination boards described here is to connect the circuit cards, located in the central rack

unit, to the amplifier inputs, monitoring boards and external warning devices which make up the external

part of the SM40 Surveillance Centre.

Five boards are mounted on the back panel of each rack frame, which hinges down to expose the boards for

service.

The use of ‘push-fit-support-studs’ to mount the boards onto the back panel makes fitting or removal a fast

and simple matter.

Each Termination Board can be connected to the Interconnection Board (IB) by flat cable and/or individual

wires fitted with female ‘Pressfit’ connectors.

External devices are wired as shown, to screw connector blocks which are plugged into sockets mounted on

the termination boards.

This has the advantage that if, for some reason, an SM40 rack frame, or a Termination Board, has to be

removed, the screw connector block is simply unplugged, leaving the periferal equipment wiring intact.

This avoids the tedious and risky business of rewiring the blocks in their original configurations.

Two of these connector blocks, each containing 16 screw connectors, are mounted on each Termination

Board.

A Termination Board is capable of carrying out one of (or a mixture of) the following functions:

1 Connecting the 16 outputs of a Pilot Tone Generator Card to the ‘Test’ inputs of Philips power

amplifiers (SQ45).

2 Connecting the data communications and +15V power outputs of a Surveillance Switch Card to 8

individual ‘Test Lines’.

3 Connecting 8 Control Relay Card (CRC) relay sets to remote warning devices. The ‘make’ contacts to red

(‘ERROR’) warning lamps, buzzers, or paging units; and the ‘break’ contacts to green

(‘FUNCTIONING’) lamps.

4 Connecting 11 Error inputs from external closed contact switches (dedicated error relay in an SM40

Routing System, smoke alarm, micro-switch, etc.) to 4 Surveillance Switch Cards, plus 1 clock

synchronisation contact.

Position of termination boards on back panel

TB5 TB4 TB3

TB2 TB1

For testing

line screens

5. SM40 SURVEILLANCE CENTRE MODULES

30

5

PILOT TONE GENERATOR CARD LBB 1369

Level adjust

20 kHz

OSCILLATOR

+15V

0 V

-15V

Burst

DC SUPPLY

Continuous

STABILIZER

+

-

LEDs

1

2

3

4

5

6

7

8

Balanced

outputs

1

1 - 8

8

-15V

+15V

Level

adjust

R207

MP

10

11

12

13

14

15

16

9

9

Balanced

outputs

9 - 16

16

X2

Burst

123

Continuous

5. SM40 SURVEILLANCE CENTRE MODULES

31

5

5.3 Pilot tone generator card (PGC) LBB 1369

Eurocard 10 x 22 cm with an ‘ab’ connector (2 x 32) containing a 20 kHz

tone oscillator and 16 independent electronically balanced outputs. These

are connected to amplifier test inputs.

The SM40 Surveillance Centre uses an ultrasonic (20kHz) pilot tone, inserted at the specially developed test

input of the Philips SQ45 amplifier. This tone is then relayed to all the loudspeakers throughout the

corresponding zone. The Surveillance Centre checks for the presence of this tone at various strategic points

in the zone. If the tone is not present at a particular point, it is obvious that the normal audio signal is not

going to be broadcast at that point either.

In each card a single oscillator is used to drive 16 electronically balanced outputs, which are floating free of

earth (ground). One PGC therefore can feed 16 amplifiers/loudspeaker zones with pilot tone signals.

The Central Processor Card (CPC) does not control, and has no infuence upon, the Pilot Tone Generator

Card (PGC). Neither is the PGC connected to any other card in the system.

The only dependence that the card has on the system is the fact that it requires +/- 15 Volt powering, which

is normally supplied from either the Basic System or an Extension Frame. Because of this, the amount of

PGC’s used in a system is unlimited.

Two green leds, mounted on the front edge of the card, advise that adequate supply voltages are present.

In order for the system to operate correctly, it is essential that the Volume Adjust control (see board layout

illustration) is set so that 10V is measured at the 100V output tap of the SQ45 amplifiers. All SQ45

amplifier Input Sensitivity Switches should be in the 1000 mV position. One master switch on the Pilot

tone generator card then sets the sensitivity level for all SQ45 amplifiers.

5.3.1 Reduction of power dissipation in amplifiers

To reduce the power dissipation in amplifiers when surveillance is used, the Amplifier Surveillance Board

(LBB 1368/00), the Loudspeaker Surveillance Board (LBB 1367/00) and the Pilot Generator Card (LBB

1369/00) have been modified. The modification enables a 20kHz ‘burst-pilot-tone’ to be used instead of a

continuous 20 kHz ‘pilot-tone’. This feature can be selected by a jumper located on the Pilot Generator

Card. The modified type number versions are compatible with previous versions and can be used all together

in a single system.

Selecting ‘continuous mode’ or ‘burst-mode’

Using jumper X2 the following mode can be selected:

Continiuous mode: X2 in position 2-3 (output frequency 20kHz ±1kHz).

Burst-mode: X2 in position 1-2 (output frequency 20kHz ±1kHz).

- 20kHz present: 35 ±5msecs.

- 20kHz absent: 260 ±30msecs.

Note: When the modified PGC is used in a system where LSBs and/or ASBs are NOT CAPABLE of

working with the 20kHz ‘burst-tone’, jumper X2 must ALWAYS be placed in the continuous mode to

prevent malfunction of the Surveillance Centre. Where possible, it is advisable to set X2 in the 20kHz

‘burst-tone’ position in systems where only NEW (modified) LSBs and/or ASBs are installed. This will

greatly reduce the dissipation of the SQ45 amplifier. The modification to the PGC is implemented from

serial number 431 onwards. The modified PGC (LBB 1369/00) has been installed as standard in the LBB

1370/30 surveillance basic frame from serial number 734 onwards.

For modification details to the ASB and LSB refer to the relevant sections.

5. SM40 SURVEILLANCE CENTRE MODULES

32

5

SURVEILLANCE SWITCH CARD LBB 1374

COMMUNICATION

From

CPC

Comm.

1

2

DECODER

ADDRESS

SELECT

1

2

3

External contacts

(contact '1'is dedicated for clock synchronisation)

3

4

5

6

7

8

CONTROL

CONTROL

Power supply

CIRCUIT

CIRCUIT

1

8

1

2

SWITCHES

1 - 8

15

16

+5V

Comm

TS

R

b

b

a

c

c

1

aa

8

Address

selection

5. SM40 SURVEILLANCE CENTRE MODULES

33

5

5.4 Surveillance Switch Card - SSC LBB 1374

Eurocard 10 x 22 cm with an ‘a b’ connector (2 x 32) containing 8 individual ‘Test Line’ outputs, and

three ‘Error’ inputs. Each Test Line supplies up to 128 monitoring devices with power and individual

data communications.

Because the SM40 Surveillance Centre is incapable of reading information from all of the monitoring

devices at the same time, it must do this sequentially. It does this by sending and receiving data from each

ASB or LSB in turn.

Up to 128 of these monitoring devices can be linked together in individual ‘Test Lines’, with the

Surveillance Switch Card (SSC) sending +15V power and data to each of the 8 lines in sequence.

A maximum of 4 SSC’s may be used in an SM40 Surveillance Centre, giving it the capability of individually

scanning up to 4096 units.

The sequence in which each board in a Test Line communicates with the Central Processor Card is

dependent on the address that the board has been given (refer to the address setting list at the end of

this chapter).

The SSC receives its data input from the Central Processor Card and its +15V power from a separate power

supply.

The common earth (ground) connection to the ASB’s and LSB’s are provided by wiring the cable screen to

the rack frame (see the Termination Board layout illustration in chapter 5.2).

As well as supplying the monitoring devices with data and power, the SSC has 3 External Error Inputs

which are activated by a closed contact. This could be supplied from the dedicated error relay (CRC U-1) in

an SM40 Routing System; a smoke detector; micro switch; etc.*

An SSC’s position in the Surveillance Centre is defined by the “address” it is given. This address setting is

accomplished by repositioning a jumper on the Switch Card itself (see circuit board layout).

All connections to and from the SSC are made via the Interconnection Board and Termination Boards (see

chapter 5.2 for correct wiring, plus the System examples at the end of this chapter).

A yellow led on the front edge of the card indicates that the SSC is in communication with the Central

Processor Card (CPC) and a green led indicates that adequate supply voltage is present. If extra SSC’s are to

be installed, the basic frame includes 4 reserved slots at the extreme left of the basic frame.

Note : These 4-slots can also be used for other purposes, but only if an SSC is not installed.

* With the exception of SSC nr. 1, contact ‘1’ which is reserved for clock synchronisation. If the contact is

closed at time x plus less than 30 seconds, the time is set to x minutes and zero seconds. If the contact is

closed at time x plus closed for more than 30 seconds, the time will be set to x plus one minute and zero

seconds.

5. SM40 SURVEILLANCE CENTRE MODULES

34

5

LOUDSPEAKER SURVEILLANCE BOARD LBB 1367

Mounting LSBs inside loudspeaker cabinets

5

4

data

power

ON

LSB

SW-1

18

MSB

LED

IC2

Data Trafo +15V

3

Current

sensing

detector

3

Microprocessor

13

111122

SW-2

5

1412 2 1113

Test

Address

ON

LSB

18

DATA

Set at 1/2 power

SW-1

MSB

LED

IC2

TRAFO

SW-2

ON

TEST

0

LBB 1367

Adjust

+15V

P24PP

+15V GND

ON

LSB

18

DATA

SW-1

MSB

LED

IC2

TRAFO

Set at full power

SW-2

ON

TEST

LBB 1367

Adjust

+15V

0P24PP

LSB cabling 0722 215 01003 (2 x 0.75 screened 23 Ohm/km)

LSB cabling 0722 571 00111 (2 x 0.75 twisted 23 Ohm/km)

5. SM40 SURVEILLANCE CENTRE MODULES

35

5

5.5 Loudspeaker Surveillance Board - LSB LBB 1367

PCB of 8.0 x 6.0 cm with solder-pin connection points. Used to monitor the secondary side of

the loudspeaker transformer and voicecoil, and for sensing the presence of the 20kHz pilot tone

signal and inside loudspeaker cabinets.

The Loudspeaker Surveillance Board is mounted inside a loudspeaker cabinet in order to monitor the

continuity of the loudspeaker’s transformer (secondary ) the loudspeakers voice coil, and the wiring to the

amplifier by checking the presence of the 20kHz pilot tone signal. A quantity of LSB’s are placed at strategic

points throughout the distribution system, monitoring the loudspeakers, and sending error information back

to the Central Processor.

The unit, a small circuit board, can easily be mounted inside a loudspeaker cabinet using standard wood

screws and spacing bushes (insulating posts). The LSB is wired in series with the secondary side of the 100V

transformer and the loudspeaker voice coil (see Fig.7). In this position it is able to sense any dramatic

changes in the current drawn by the loudspeaker, at 20kHz.

If the unit senses that no pilot tone signal is present, or that the loudspeaker voice coil is open circuited, a

message is sent (via the system’s communication line) to the CPC, which would give visual, or printed,

information about the error. This unit is designed to monitor low voltage applications and is therefore not

suitable for use with amplifier outputs or 100V loudspeaker lines.

In total more than 4000 Loudspeaker Surveillance Boards (LBS’s) (and/or Amplifier Surveillace Boards

(ASB’s)) can be connected, via 4 Surveillance Switch Cards (SSC’s)) (see chapter 12), to the Central

Processor Card CPC. The amount of LSB’s used in a system is dependent on the amount of surveillance

coverage required. In principle an LSB may be used to monitor each loudspeaker in every column in the

system, but one LSB per column should be adequate. Because of the wide range of variations possible using

the 100V line principle, both at the amplifier output and the loudspeaker transformer, a sensitivity adjuster

is provided on each LSB. When the LSB has been installed it may be adjusted for loudspeaker optimum

sensitivity. Adjustment may be carried out, either in its installed position, or in a much more convenient

place such as a workplace. All that is required is a 10V dc source and a pilot tone generator (20 Khz).

To adjust the LSB for the optimum sensitivity, in its installed position, place the DIL switch on the LSB

(SW2) to its TEST position, and turn the ADJUST potentiometer (R8) until the LED just begins to

illuminate. On the threshold of the LED illuminating carefully turn the adjust till the LED switches off.

Adjustment is now complete. Place the switch back to its ON position again (see Fig.7).

To adjust the LSB in a more convenient position such as a workplace for instance, connect a +15V dc power

supply between pins 1 (+15V) and pin 2 (Gnd). Now connect a 20 kHz pilot tone signal between pins 4

and 5. Adjust the LSB as described above.

Information can be communicated to the SM40 Surveillance Centre via the DATA contacts on the LSB (see

Fig.5). A single, standard 2 core, 0.75mm screened microphone cable may be used for connection of all the

LSB’s (and ASB’s), which are linked via the same SSC line, to the CPC. In order for the Central Processor to

“recognise” which LSB is giving the error indication, and in which sequence it receives its communications

data, each unit is given an “address”. This address setting is accomplished by setting the DIP switches on the

board (see address settings list in chapter 17).

The 15V power required to drive the LSB (distributed via an SSC), connected to the +15V and contacts, is

provided by the Basic System. All In and Out connections are simply made using ‘faston’ push connector

tags. The DATA, and +15V tags are duplicated in order to simplify connection of the communications line

and the power supply to the following LSB (or ASB).

5. SM40 SURVEILLANCE CENTRE MODULES

36

5

AMPLIFIER SURVEILLANCE BOARD LBB 1368

FIG.1

AMPLIFIER SURVEILLANCE BOARD

100 V/20 kHz

Ext. IN

data

power

1

11

2

12

3

13

5

4

13

S1

+

ON

LSB MSB

28

1

DATA

100 V

4

Pilot tone

detection

5

8

9

3

Microprocessor

S3

IC2

Power

+5V

14

S4

S2

111 2

12

BC

S4

1

Relay

Address

S1

BC

S2

14

1

RE1

BC

6

6

7

15

+5V

8

9

S3

15

7

+15V GND

5. SM40 SURVEILLANCE CENTRE MODULES

37

5

5.6 Amplifier Surveillance Board - ASB LBB 1368/00

P.C.B. of 6.5 x 7.2 cm with solder-pin connection points. Used for sensing the presence of the 20kHz

pilot tone signal at amplifier outputs and in loudspeaker lines (100V system). Can be mounted using

Phoenix interconnection modules or normal set-screws.

The Amplifier Surveillance Board is the device which constantly checks the 100V loudspeaker lines for the

presence of the 20kHz pilot tone signal. It is possible to adapt the ASB for 70V and 50V loudspeaker lines

by changing a resistor (see fig.4).

The unit, a small circuit board, can easily be mounted in the back of a 19-inch rack unit, near to the

amplifiers, to monitor the amplifier output.

It may also be mounted in a small enclosure on a loudspeaker cabinet, or in a junction box, to monitor the

100V loudspeaker lines.

The signal is tapped off the loudspeaker line or amplifier output (in parallel with the loudspeaker line), and

enters the ASB via the LINE IN contacts.

It is possible to add amplifier monitoring and spare amplifier switching to a public address system, because

the ASB is fitted with a relay with one make/break contact,which can be used to activate warning devices or

switch in spare amplifiers (see Figs. 2 & 4). A jumper (S2) is provided to allow this relay to be active or nonactive (see Fig.4). If no errors are detected, this relay is activated and provides a contact closure between

points 6 and 7 (see relay output fig.1).

In spare amplifier switching, external relays are used for switching the audio input and output signals of the

defective amplifier to the spare amplifier. These external relays must be wired to the OUT contacts on the

ASB (see Fig.4). The corresponding Pilot Tone Generator Card (PGC) should be mounted in the SM40

Routing and Switching frame, a separate 15V power supply must be used to power both the ASB’s and the

spare amplifier signal switching relays (see Fig. 2).

As well as switching in the spare amplifier, error information can be communicated to an SM40 Surveillance

Centre via the DATA contacts on the ASB (see Fig.3)

If the unit senses that no pilot tone signal is present, the built in relay is de-activated and a message is sent

(via the system’s communication line) to the CPC, which would give visual, or printed, information about

the error.

This communication function may also be used alone, where a quantity of ASB’s are placed at strategic

points throughout the distribution system, monitoring the loudspeaker lines, and sending error information

back to the Central Processor.

The unit is also provided with an external contact input, marked EXT IN. Any external device (smoke

detector, micro switch, etc,.) which provides a ‘break’ contact, for use as an alarm/error may be used to

activate the ASB, giving the system an error warning. A jumper (S3) is provided to allow either the 20kHz

LINE IN or external (EXT IN) contacts to be used (see Fig.1).

In order for the Central Processor to “recognise” which ASB is giving the error indication, and in which

sequence the ASB is to receive its data communications, each unit is given an “address”. This address setting

is accomplished by setting the DIP switches on the board itself (see settings list at the end of this chapter).

Up to 128 ASB’s, and/or Loudspeaker Surveillance Boards (LSB’s), may be linked to the same

communications bus.

A single, standard 2 core, 0.75mm

2

screened microphone cable may be used for connection of all the ASB’s

(and LSB’s), linked via the same communications bus, to the Central Surveillance Centre.

The DATA, and + solder pins are duplicated in order to simplify wiring of the communications line and the

power supply to the following ASB, or LSB (see Fig.4).

5. SM40 SURVEILLANCE CENTRE MODULES

38

5

FIG.2

FIG.3

SM40 PUBLIC ADDRESS DISTRIBUTION SYSTEM

ROUTING AND SWITCHING

Pilot-tone

Constant powering 15V

SQ40 AMPLIFIER LOUDSPEAKER

Audio

Test

For spare amplifier switching

100

70

50

ASB

SM40 PUBLIC ADDRESS DISTRIBUTION SYSTEM

ROUTING AND SWITCHING

SQ40 AMPLIFIER LOUDSPEAKER

Audio

Test

100

70

50

ASB

ASB

failure indication

as make-contact

available for endof line monitoring

LSB

SURVEILLANCE

PRINTER

Error

PERSONAL

COMPUTER

Pilot-tone

Test-line 'x'

Remote error

indication contacts

Switched power

+data comm.

To max.128

LSBs/ASBs

P

1/4 P

LSB

P

1/4 P

LSB

ASB

etc.

5. SM40 SURVEILLANCE CENTRE MODULES

39

5

FIG.4

Amplifier Surveillance Board (ASB) LBB 1368

100V/20kHz

LINE

100V

70V

50V

+15V

Data

R(Ohms)

1K8

820

560

+

ON

1

11

LSB MSB

2

28

12

3

5

Line

4

1

100 V

13

S1

IC2

BC

S4

1

BC

S2

14

1

RE1

BC

S3

Loudspeaker Surveillance Board (LSB) LBB 1367

ON

LSB

SW-1

MSB

SW-2

18

LED

10K

6

7

15

+5V

8

9

IC2

DATA TRAFO +15V

3

SM40 SURVEILLANCE BASIC SYSTEM (LBB 1370)

TB

16

9

8

1

TB

PGC

SM40 SURVEILLANCE

CENTRE (LBB 1370)

RS232

CPC PSU

15V

5

1412 21113

5. Printer error

4. System error

3. External error

TB

2. LSB/ASB error

1. General error

TO

8 x 128

LSBs/ASBs

CRC

U-1

SSC

1

1- 8

External error

IN

Communication

Power supply

5. SM40 SURVEILLANCE CENTRE MODULES

40

5

SM40 I/O WIRING FOR EXTERNAL PC

(XT/AT or Compatible)

11421531641751861972082192210231124122513

11421531641751861972082192210231124122513

Cable

11421531641751861972082192210231124122513

162738495

EXTERNAL COMPUTER

(XT or compatible)

1627384

Cable

11421531641751861972082192210231124122513

EXTERNAL COMPUTER

(AT or compatible)

5

9

11421531641751861972082192210231124122513

TXD

RXD

RTS

CTS

GND

a12

b12

a13

b13

a14

SM40 CPC

INTERCONNECTION

BOARD

SM40 SIDE

11421531641751861972082192210231124122513

TXD

RXD

RTS

CTS

GND

a12

b12

a13

b13

a14

SM40 CPC

INTERCONNECTION

BOARD

SM40 SIDE

5. SM40 SURVEILLANCE CENTRE MODULES

41

5

5.6.1 Reduction of power dissipation in amplifiers.

To reduce the power dissipation in amplifiers when surveillance is used, the Amplifier Surveillance Board

(LBB 1368/00), the Loudspeaker Surveillance Board (LBB 1367/00) and the Pilot Generator Card (LBB

1369/00) have been modified. The modification enables a 20kHz ‘burst-pilot-tone’ to be used instead of a

continuous 20 kHz ‘pilot-tone’. This feature can be selected by a jumper located on the Pilot-tone

Generator Card. The modified type number versions are compatible with previous versions and can be used

all together in a single system.

Modification to Amplifier Surveillance Board LBB 1368/00

The 20 kHz detection circuit, built around TS32 is additional for the burst-mode. The relay K1 has been

changed into a ‘make-and-break’ contact relay. The modifications are implemented in the factory from serial

number 7238 onwards.

Modification to Loudspeaker Surveillance Board LBB 1367/00

The 20 kHz detection circuit, built around IC1 has been modified for the ‘burst-mode’. The modification

has been implemented in the factory from serial number 19366 onwards.

5. SM40 SURVEILLANCE CENTRE MODULES

42

5

CONTROL RELAY CARD LBB 1356

YELLOW

FROM

CPC

LED

DECODER

ADDRESS

SELECT

1

2

3

4

5

6

7

8

CONTROL

CIRCUIT

CONTROL

CIRCUIT

1

RELAY-SETS

1-8

8

FROM

+5V

CPC

+15V-15V

Comm

SSC

1

CRC

L - 1

SSC

2

CRC

L - 2

SSC

3

CRC

L - 3

SSC

4

CRC

L - 4

Relation of the Error indication

on the 'Locked' CRC's to the test

lines of the Surveillance Switch cards

b

Address

selection

1

a

c

8

AB = 'Unlocked'

AC = 'Locked'

5. SM40 SURVEILLANCE CENTRE MODULES

43

5

5.7 Control Relay Card - CRC LBB 1356

Eurocard 10 x 22 cm with an ‘a b’ connector (2 x 32) containing 8 make and 8 break contacts to

activate external warning devices. The contacts are activated by the CPC via the internal

communication bus.

A Control Relay Card (CRC) has 8 ‘make’ and 8 ‘break’ contacts which give the system the facility to switch

on remote warning lamps and buzzers, or in a more sophisticated system, to activate a personal pager, etc..

This feature is of great importance in situations where system faults must be clearly indicated and

speedily investigated.

A CRC’s position in the system, and the functions it carries out are defined by the “address” it is given. This

address setting is accomplished by repositioning jumpers on the Control Relay Card itself (see circuit

board layout).

A CRC with its function switch in the ‘unlocked’ (U) state (position a-b), and address 1 ( this is standard

upon delivery in the Basic System) provides a number of useful functions:

Relay set 1 activated when any error occurs.

Relay set 2 activated when an ASB or LSB error occurs.

Relay set 3 activated when an external error occurs.

Relay set 4 activated when an internal system error occurs.

Relay set 5 activated when a printing I/O error occurs.

Relay set 6, 7, and 8 not used

The CRC’s which have their function switches in the ‘Locked’ (L) state (position a-c) are dedicated to

indicating errors on the corresponding Surveillance Switch Card (SSC) Test Lines.

The CRC with address L1 therefore indicates faults on the SSC with the corresponding address L1. Every

relay of the CRC indicates errors on the corresponding Test Line. E.g. relay 6 of CRC with address L1

indicates errors on Test Line 6 of SSC with address L1, etc.

Up to four ‘Locked’ CRC’s may be used in an SM40 Surveillance System (see the System examples at the

end of this chapter for typical applications).

Because the CRC is unique in having two relays for each circuit, the possibility exists to connect both a red

‘Error’ lamp, and a green ‘Functioning’ lamp as an external display.

The red lamp should be connected to the make relay contact which is open when the CRC is not activated,

and the green lamp should be connected to the break relay contact which is closed.

All connections to and from the CRC are made via the Interconnection Board and Termination Boards (see

chapters 5.1 and 5.2 and the System examples at the end of this chapter).

A yellow led on the front edge of the card indicates that the CRC is in communication with the Central

Processor Card (CPC) and the 3 green leds indicate that adequate supply voltages are present.

5. SM40 SURVEILLANCE CENTRE MODULES

44

5

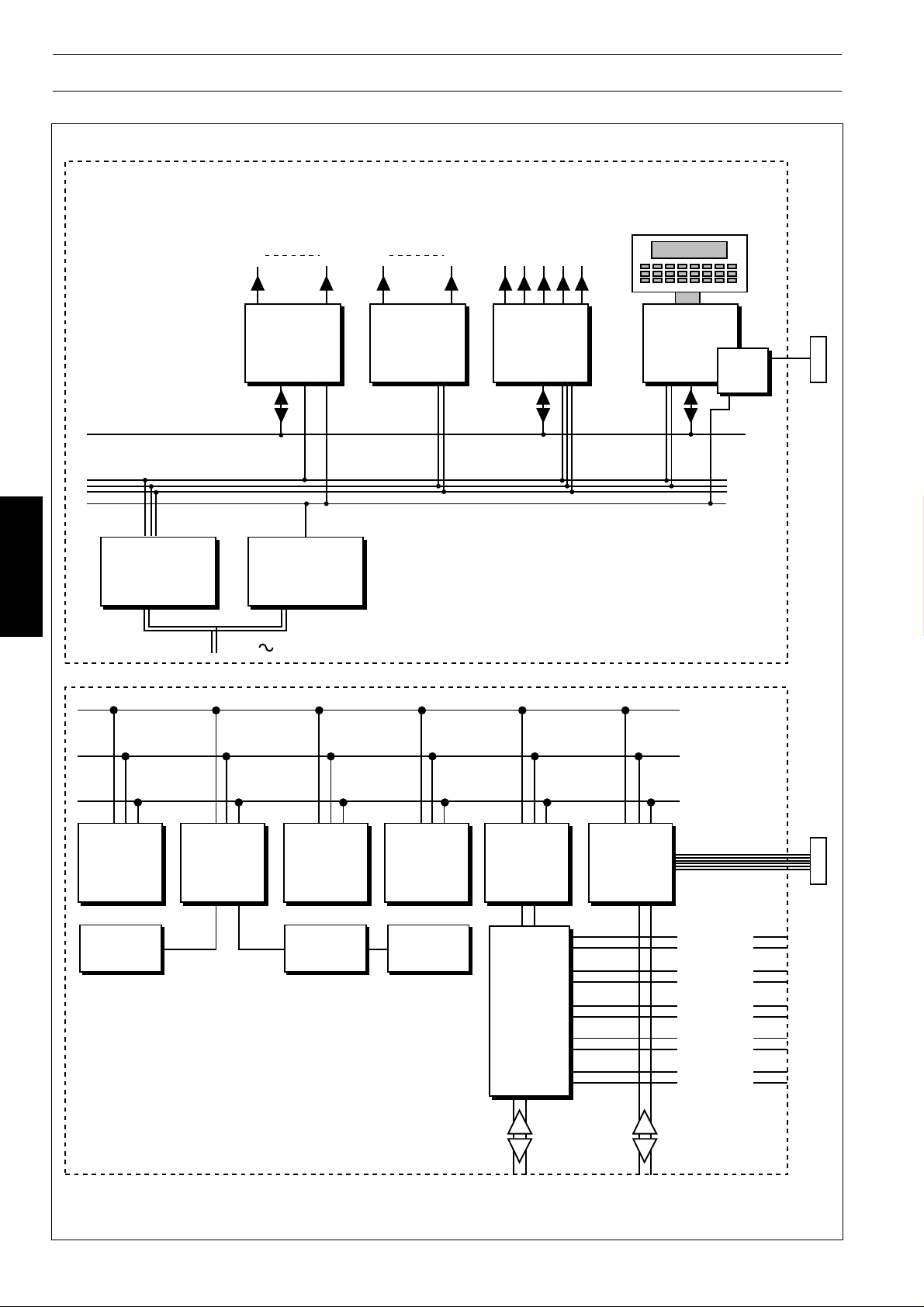

SM40 SURVEILLANCE SYSTEM

A

Error

indication

16

9

TB

PGC

8

CPC

PSU

15V

1

RS232

PGC CPC CRC SSC SSC

1

1

1

1

1

1

CRC

U-1

SSC

2

9-16

SSC

1

1-8

1

1

Communication

Power supply

Ext. errors

Communication

Power supply

Ext. errors

Clock sync.

1

Printer error

5

4

System error

3

External error

2

LSB/ASB error

1

General error

TB

1268/10 1141/52

1

To

8x128

LSBs

To

8x128

LSBs

8

10

17

21

25

30

ba

TEST SIGNALS TEST LINES

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

8

10

17

21

25

30

U-1

ERROR

OUTPUT

ERROR

OUTPUT

ERROR

INPUT

916 -18 -

INTERCONNECTION BOARD WIRING AS VIEWED FROM REAR OF RACK UNIT

ERROR

TEST SIGNALS

91

10

11

12

13

14

15

16

2

3

4

5

6

7

8

ERROR OUTPUT

General

Printer

ASB/LSB

External

System

INPUT

Clock

sync.

1

2

3

4

5

6

TEST LINES

1

2

91

10

11

12

13

14

15

16

2

3

4

5

6

7

8

TERMINATION BOARD WIRING AS VIEWED FROM REAR OF RACK UNIT

5. SM40 SURVEILLANCE CENTRE MODULES

45

5

SM40 SURVEILLANCE SYSTEM

B

Printer error

System error

External error