Philips L7.2E Service Manual

1

Colour Television Chassis

L7.2E

AA

CL 86532008_004.ai

160298

ServiceManual

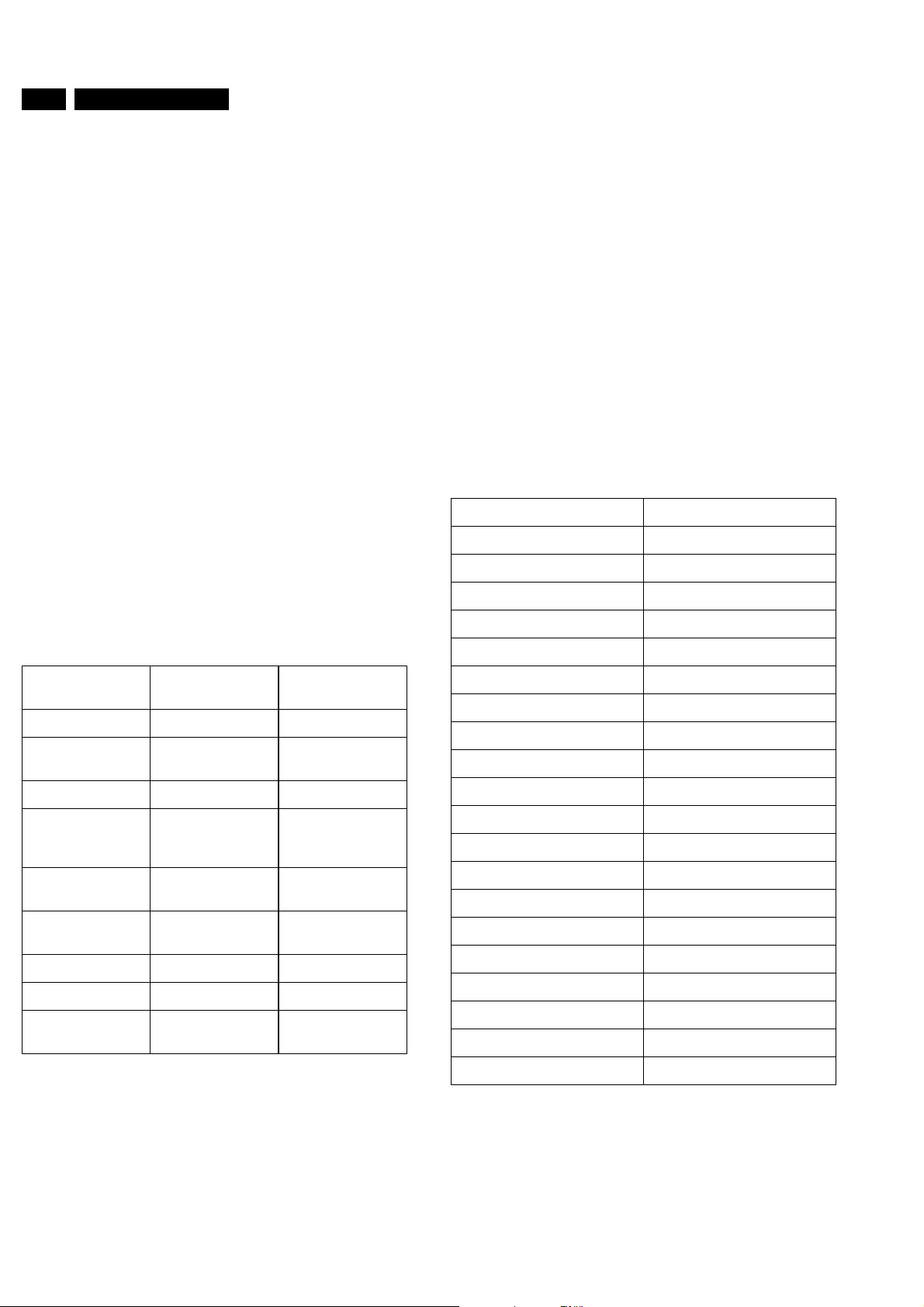

Table of contents Page

1 Technical specifications 2

Location of panels

2 Connection facilities 3

3 Safety instructions, Warnings 4

and Notes

4 Mechanical instructions 6

5 Repair facilities 7

Software adjustments

and Hotel mode

6 Fault finding tree 13

Block diagram, 14

Survey of testpoints 15

Diagram supply voltages survey 15

7 Electrical Diagrams and print lay-outs

Diagram PWB

Power supply diagram A1 16 17,19

Sync, Horizontal + Vertical output diagram A2 18 17,19

Tuner, IF,Video,Chroma diagram A3 20 17,19

Control diagram A4 21 17,19

Sound processing, Sound interfacediagram A5 22 17,19

CRT panel diagram B 23 23

Sound Multi-mono panel diagram C 24 25

Sound Nicam-2CS panel diagram D 26 25

8 Electrical adjustments 27

9 Circuit diagram description (new circuits) 29

10 Directions for use 32

11 List of abbreviations 36

Published by FM 9863 TV Service DepartmentPrinted in The NetherlandsCopyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The Netherlands. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwisewithout the prior permision of Philips.Subject to modification5 4822 727 21567

12 Spareparts list 37

©

Copyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored ina retrievalsystem ortransmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise without the prior permision of Philips.

Published by FM 9863 TV Service Department Printed in The Netherlands Subject to modification 5 4822 727 21567

2 L7.2E

1 Technical specifications

Mains Voltage: : 220 - 240 V AC

1 Technical specifications

: (+/- 10%)

Power consumption : 17” 50 W

: (stand by < 7 W)

: 21” 57 W

: (stand by < 7 W)

Pull in range colour sync : +/- 300 Hz

Pull in range horizontal sync : +/- 600 Hz

Pull in range vertical sync : 45 - 64.5 Hz

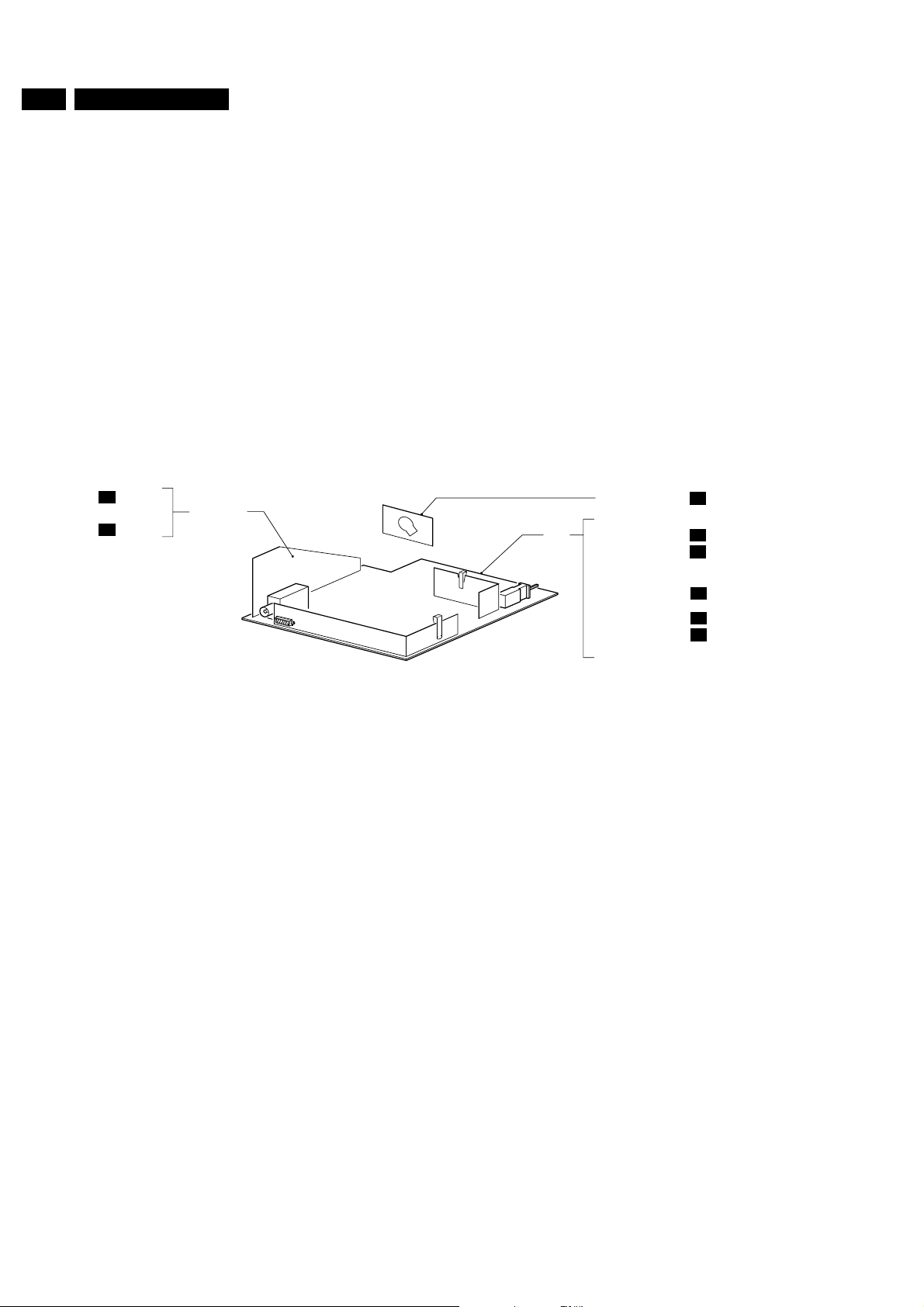

Location of panels

C

OR

D

MULTIMONO

NICAM,

AUDIO PANEL

MAIN

CRT

POWER SUPPLY

SYNCHRONISATION

HOR.DEFLECTION

VERT. DEFLECTION

TUNER IF

VIDEO PROCESSING

CONTROL

AUDIO SOURCE INPUT

AUDIO PROCESSING

B

A1

A2

A3

A4

A5

CL 86532008_005.ai

260398

2 Connection facilities

2 Connection facilities

3L7.2E

2.1 Cinch

IR Video

Red

EXT1

(Ext2)

L R

Audio

CL86532008_008.ai

++--

ChannelVolume

170298

4.5-7V:EXT 16:9

- Video 1Vpp/75Ω q

- Audio L(0.5Vrms ≥10kΩ) q

- Audio R(0.5Vrms ≥10kΩ) q

2.2 Head phone

- (32-600Ω≥10mW) ot

2.3 Euroconnector

1- Audio R (0.5Vrms ≤1kΩ) k

2- Audio R (0.5Vrms ≥10kΩ) j

3- Audio L (0.5Vrms ≤1kΩ) k

4- Audio v

5- Blue v

6- Audio L (0.5Vrms ≥10kΩ) j

7- Blue (0.7Vpp/75Ω)

8- CVBS-

status 0-1.3V:INT

9.5-12V:EXT 4:3 j

9- Green v

1011- Green (0.7Vpp/75Ω)

1213- Red v

14- RGB-

status v

15- Red (0.7Vpp/75Ω)

16- RGB-

status (0-0.4V:INT

1-3V:EXT/75Ω)

17- CVBS v

18- CVBS v

19- CVBS (1Vpp/75Ω) k

20- CVBS (1Vpp/75Ω) j

21- Earth

socket

4 L7.2E

3 Safety instructions, Maintenance instruction,

3 Safety instructions, Maintenance instruction, Warnings and Notes

3.1 Safety instructions for repairs

Figure 3-1

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer;

– safety components, indicated by the symbol (see fig.

3.1), should be replaced by components identical to

the original ones;

– when replacing the CRT, safety goggles must be worn.

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– As a strict precaution, we advise you to resolder the

solder joints through which the horizontal deflection

current is flowing, in particular:

• all pins of the line output transformer (LOT);

• fly-back capacitor(s);

• S-correction capacitor(s);

• line output transistor;

• pins of the connector with wires to the deflection

coil;

• other components through which the deflection

current flows.

Note: This resoldering is advised to prevent bad

connections due to metal fatigue in solder joints and is

therefore only necessary for television sets older than

2 years. The wire trees and EHT cable should be

routed correctly and fixed with the mounted cable

clamps.

– The insulation of the mains lead should be checked for

external damage.

– The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets which have a mains isolated power supply). This

check can be done as follows:

• unplugthe mains cordand connecta wirebetween

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MW and 12 MW;

• switchoff the TV andremove the wire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

– When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

– The maintenance inspection contains thefollowing actions:

• Execute the above mentioned 'general repair

instruction'.

• Clean the power supply and deflection circuitry on the

chassis.

• Cleanthe picture tube panel and the neck of thepicture

tube.

3.3 Warnings

1. ESD

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically. When repairing, make

sure that you are connected with the same potential as the

mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

– Available ESD protection equipment:

– anti-static table mat (large 1200x650x1.25mm) 4822

466 10953

– anti-static table mat (small 600x650x1.25mm) 4822

466 10958

– anti-static wristband 4822 395 10223

– connection box (3 press stud connections, 1 M ohm)

4822 320 11307

– extension cable (2 m, 2 M ohm; to connect wristband

to connection box) 4822 320 11305

– connecting cable (3 m, 2 M ohm; to connect table mat

to connection box) 4822 320 11306

– earth cable (1 Mohm; to connect any product to mat or

connection box) 4822 320 11308

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

2. In order to prevent damage to ICs and transistors, all highvoltage flashovers must be avoided. In order to prevent

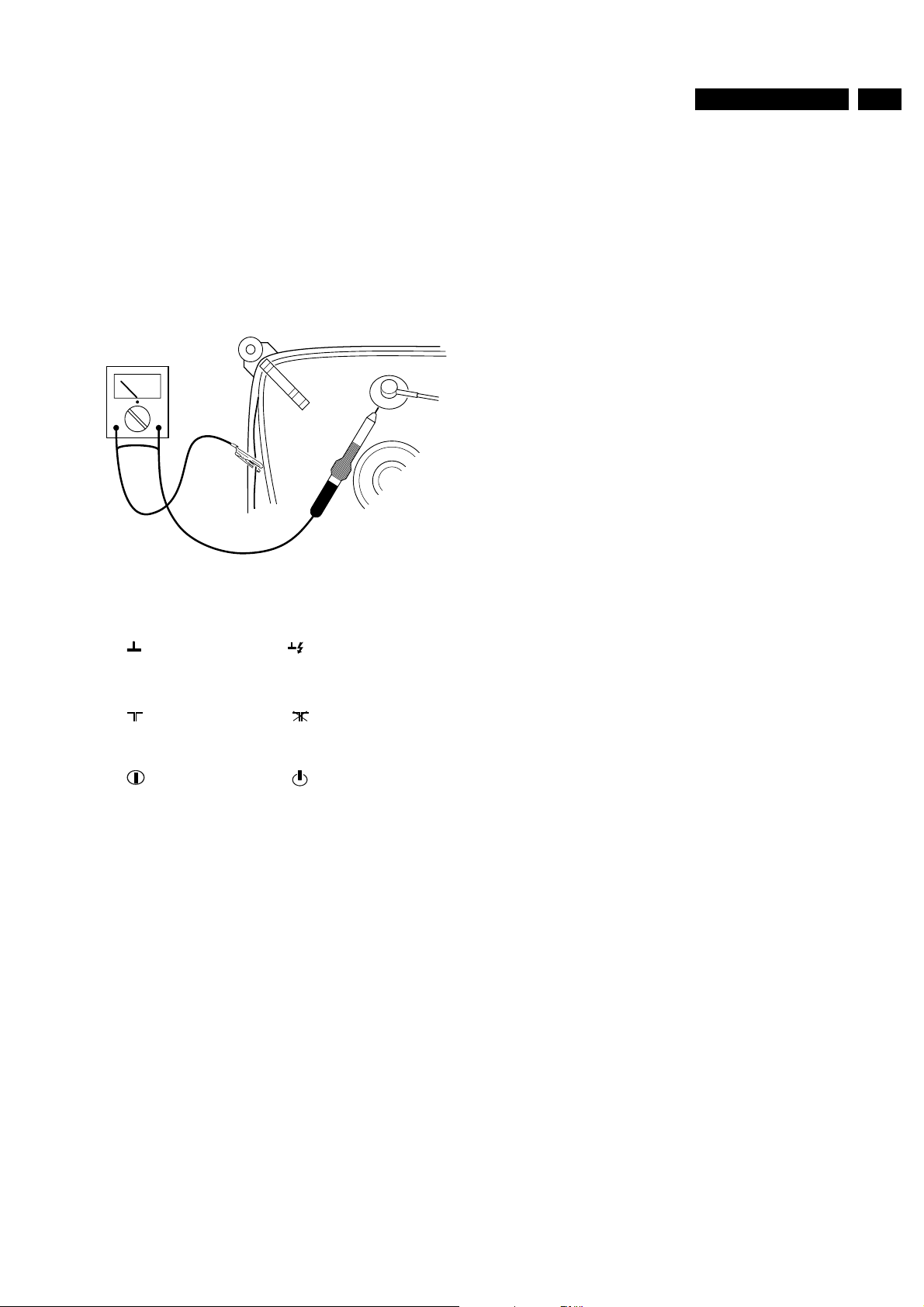

damage to the picture tube, the method shown in Fig. 3.2

should be used to discharge the picture tube. Use a highvoltageprobe and a multimeter (positionDC-V). Discharge

until the meter reading is 0V (after approx. 30s).

3. Togetherwith the deflection unit and anymultipole unit, the

flat square picture tubes used from an integrated unit. The

deflection and the multipole units are set optimally at the

factory.Adjustmentofthisunit during repair is therefore not

recommended.

4. Be careful during measurements in the high-voltage

section and on the picture tube.

5. Never replace modules or other components while the unit

is switched on.

6. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

7. Wearsafety goggles during replacement ofthe picture tube

3.2 Maintenance instruction

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

– When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3 to

5 years.

3.4 Notes

1. The direct voltages and oscillograms should be measured

with regard to the tuner earth , or hot earth as this is called

(see fig. 3.3)

2. The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 8) with a colour bar

signal and stereo sound (L:3 kHz, R:1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

3 Safety instructions, Maintenance instruction,

3. Wherenecessary, the oscillograms and directvoltages are

measured with and without aerial signal. Voltages in the

power supply section are measured both for normal

operation and in standby . These values are indicated by

means of the appropriate symbols (see fig. 3.3).

4. The picture tube PWB has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

5. The semiconductors indicated in the circuit diagram and in

the parts lists are completely interchangeable per position

with the semiconductors in the unit, irrespective of the type

indication on these semiconductors.

V

CL 26532098/042

140792

Figure 3-2

5L7.2E

tuner earth

tuner aarde

la masse du tuner

Tuner-Erde

massa del tuner

tierra del sintonizador

with aerial signal

met antenne signaal

avec signal d'antenne

mit Antennensignal

con segnale d'antenna

con la señal de antena

normal condition

normaal bedrijf

fonctionnement normal

normaler Betrieb

funzionamento normale

funcionamiento normal

massa calda

zonder antenne signaal

Figure 3-3

hot earth

hete aarde

la terre directe

heißen Erde

tierra caliente

without aerial signal

sans signal d'antenne

.ohne Antennensignal

senza segnale d'antenna

sin la señal de antena

stand by

stand by

position de veille

in Bereitschaft

modo di attesa

posición de espera

6 L7.2E

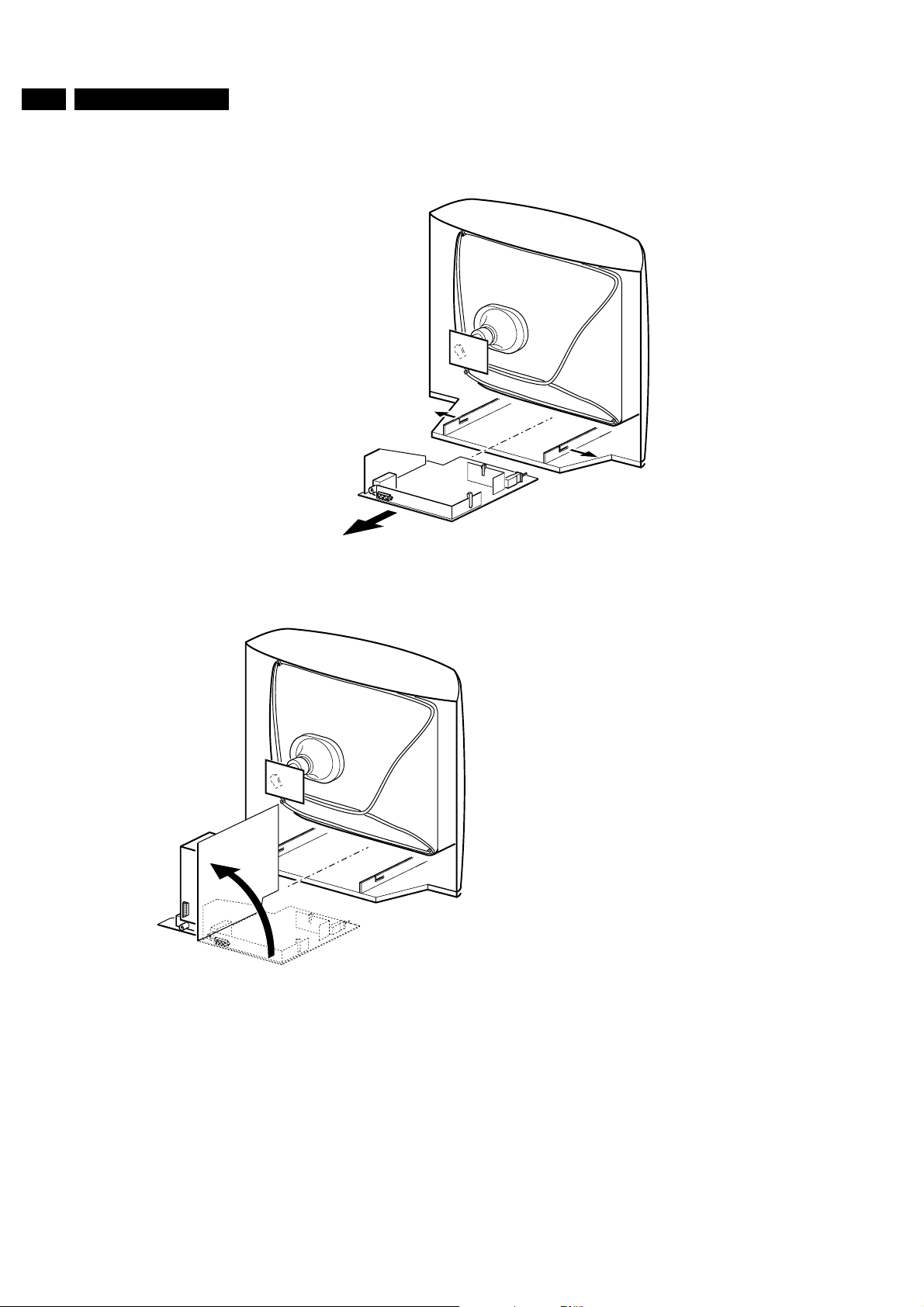

4 Mechanical instructions

For the service position of the main carrier see Fig. 4.1.

The main carrier can be removed by releasing the 2 carrier

blocking lips (1) and pulling the carrier panel backwards.

4 Mechanical instructions

1

11

B

A

CL 86532008_007.ai

160299

Figure 4-1

5 Repair facilities

7L7.2E

5 Repair facilities

5.1 Test points

The PWB boards have service printing on both sides. In the

service printing test points are included. These test points are

referring to the electrical function as mentioned below:

Test pointElectrical function

• A1,A2, etc.: Audio

• C1,C2, etc.: Control

• F1,F2, etc.: Frame drive and frame output

• L1,L2, etc.: Line drive and line output

• P1, P2,etc.: Power supply

• S1,S2- etc.: Synchronisation

• V1,V2, etc.: Video

The numbering is done in a for diagnostics logical sequence.

Example: Checking the power supply, start with test point P1,

P2 etc.).

5.2 Service mode

The service mode is split into two parts:

– Service Default Mode (SDM).

– Service Alignment Mode (SAM).

– For Multi-Europe setsPAL-BG

– For Multi-France setsSECAM-L

Tuning:

– For sets with VST tuner: Programme number 1is selected .

Further settings:

– The automatic switch off (no IDENT) timer and the sleep

timer will be ignored.

– The child lock will be disabled.

– If the TV set was in hotel mode, this mode is disabled as

long as the TV is in SDM or SAM mode.

– Brightness, saturation, sharpness, contrast and balance

are initialised on 50% level.

– The volume is set to 25% level.

– The TV set is normally controllable.

– All displayed text in SDM and SAM menu are in English.

5.4 SDM (Service Default Mode)

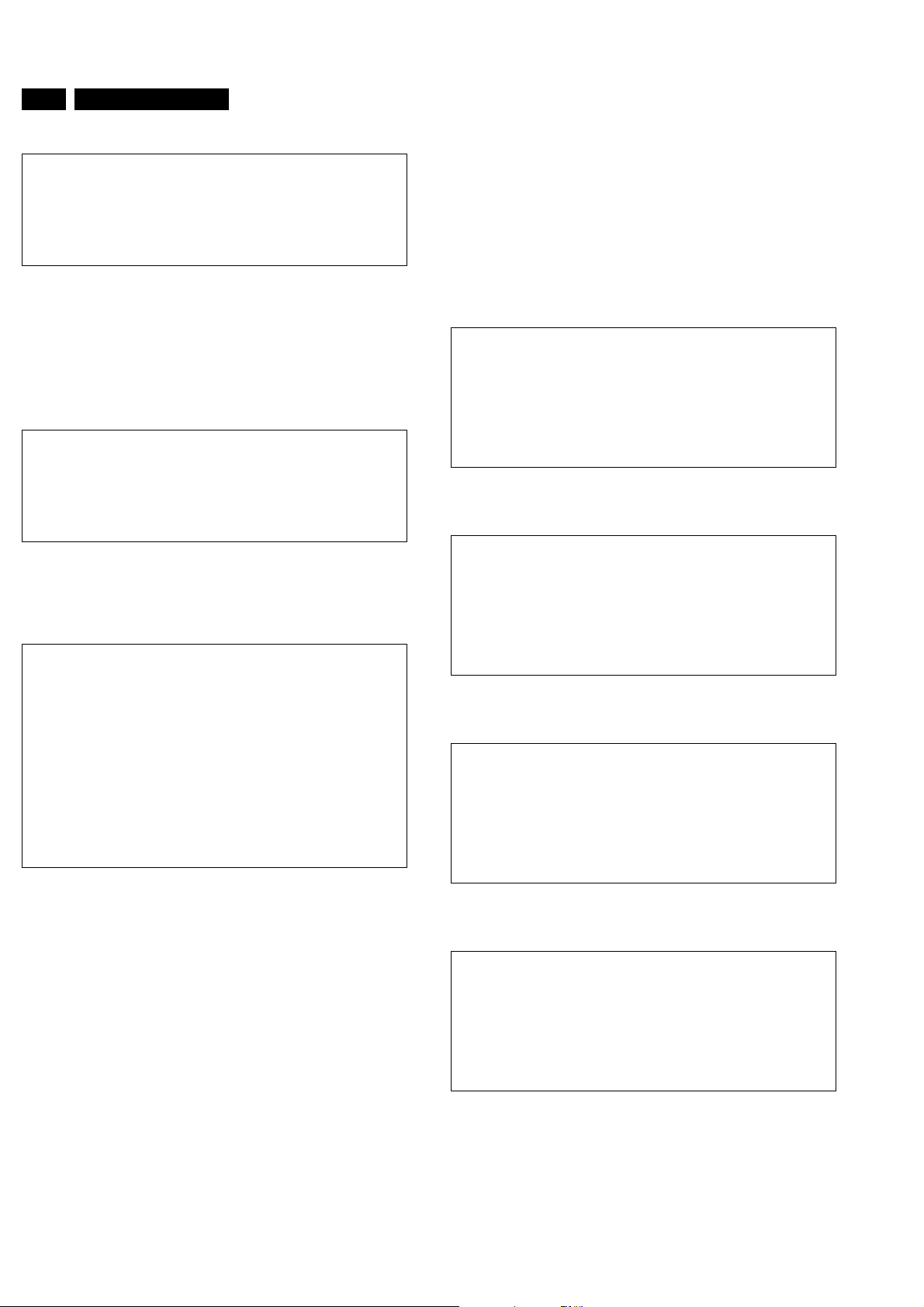

5.4.1 SDM menu

Below in Fig.6.1 an example of the SDM menu is shown.

Between clamps a short explanation of each item is added.

5.2.1 Entering and leaving SDM and SAM

1. Entering SDM

• To entry the SDM , there are two possibilities:

– Via the "DEFAULT" button on the DST (Dealer

Service Tool)

– Via short circuiting the service pins 0025 and 0024

(mass), while switching on the set via the mains

switch. For 0025 and 0024 see Diagram A4 and

the PWB drawing of the main panel.

• Inthe SDM mode aS (in green) and the SDM menu(in

red) is displayed.(see Fig.6.1).

2. Entering SAM

• To entry the SAM , there are two possibilities.

– Viathe "ALIGN" button on the DST (Dealer Service

Tool)

– Via short circuiting the Service pins M28 and M29

(mass), while switching on the set via the mains

switch. For M28 and M29 see Diagram A4 and the

PWB drawing of the main panel.

• In the SAM mode a S (in green) and the SAM main

menu (in red) is displayed.(see Fig.6.2).

Remark: After the set is in the SDM or SAM mode the short

circuit can be removed.

001E 2.17.6 S

(life timer) (software

indication)

AS ON

(option abbreviation) (option status)

ERR 0 0 0 0 0

(error) (error buffer)

OPT 36C8 B805 2401

(option) (12 digit option

code)

Fig.6.1

(service mode

indication)

5.2.2 Leaving SDM or SAM

To leave the SDM or SAM mode , push the stand-by button on

the remote control

Remark:After switching off and on bythemains switch , the set

remains in the SDM or SAM mode.

5.3 Initial states

The initial state after switching on in the SDM or SAM mode is:

System:

Below a more detailed information of each item is given

5.4.2 Life timer

The indication is in hexadecimal notation. Each hour the set is

switched on (not standby) the number is incremented by 1.

Also each time the set is switched on the number is

incremented by 1.

8 L7.2E

5 Repair facilities

5.4.3 Software indication number.

For each software change this number will be changed.

5.4.4 Service mode indication.

The S indicates that the set is in SDM or SAM mode.

5.4.5 ERROR and ERROR buffer

(ERR refers to the "ERROR BUFFER")

00000 represent the contents of the so called "ERROR

BUFFER". This buffer consist of 5 digits. In each digit an

ERROR code can be displayed. Thelast five errors, are stored

in the EEPROM, and are shown in this buffer. An error will be

added to the buffer if this error differs from the last error in the

buffer. The last detected error is displayed on the most left

digit.

Example: Suppose the display shows: 3 4 1 3 1. This means

the last found error is error code 3; the last found error but one

is error code 4, etc.

Remark: The ERROR BUFFER is erased when the set is

switched from SDM or SAM in stand by , or via code 99 via

DST.(Dealer service Tool).

5.4.7 Option abbreviation and Option status.

To select another option abbreviation use the MENU UP/

DOWN buttons and to change the status use the MENU LEFT/

RIGHT buttons.

Elucidation:

With above items the option statuses stored in the EEPROM

can be changed.

This is necessary if the EEPROM is replaced by a fresh

EEPROM, because a fresh EEPROM is initial loaded with

default options and statuses by the microcomputer. The

options stored in the factory can differ per type and stroke

number. Therefore it is necessary to load the EEPROM with

the correct statuses These options with statuses are indicated

on a sticker glued on the CRT. For an example of the sticker

see table 6.1 (this table is valid for 21PT1663/00).

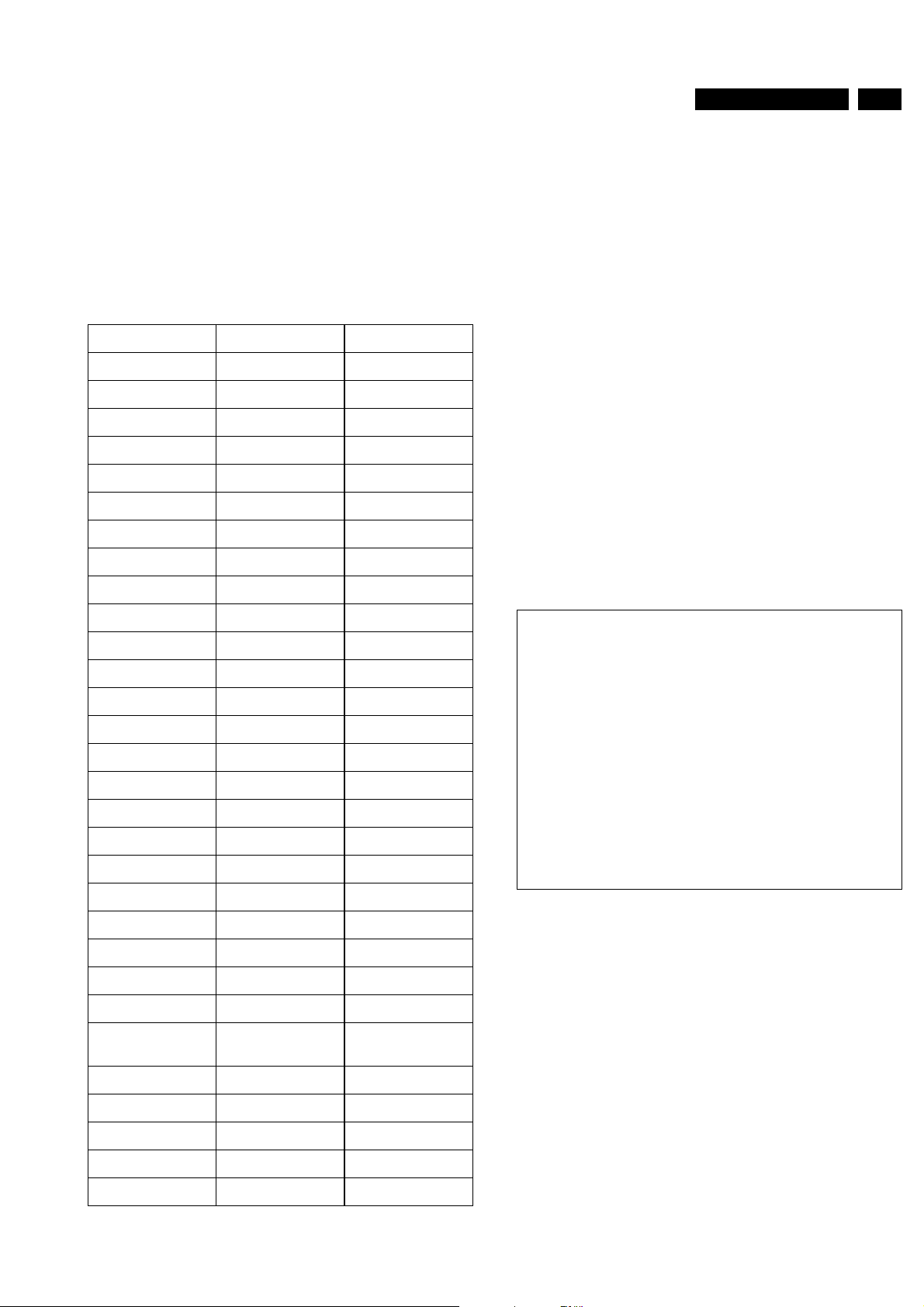

Table 6.1

Option abbreviation Status

AT ON

AV ON

The following error codes have been defined:

Error code Error description Possible defective

omponent

0 No error

1 Internal RAM error

of æC

2 General I2C error

3 EEPROM

Configuration error

(Checksum error)

4 I2C error audio

processor

5 I2C error TV

processor

6 EEPROM error ST24C04

7 I2C error PLL tuner PLL tuner

8 POR bit high (43-

IC7600)

IC7600

Set not correct

configured

MSP3410 on

NICAM panel

TDA8373/74

BA ON

BL ON

CO OFF

GM ON

HO ON

MT PH

PG ON

PR 99

SA ON

SB IN

SP ON

SS ON

SU ON

SY EW

TR ON

UH OFF

VI OFF

5.4.6 ERROR code indication via blinking stand by LED

The ERROR codes 2, 5 and 8 are also indicated via blinking of

the stand by LED. This is important if no OSD function or

picture is available.

The method is to show LED blinks as many as the error code.

Example: Error code 5 will result in five blinks ( 0.25 seconds

ON and 0.25 seconds OFF).

After this sequence the LED will be OFF for 3 seconds.

XT ON

(Table only valid for 21PT1663/00)

Loading a fresh EEPROM

– Switch on the TV via the power switch.

– Audio mute the TV (to get no big noise).

– Change the option statuses as indicated on the sticker on

theCRT.

– Put TV in stand by via the remote control.

– Switch on the TV again via the remote control.

5 Repair facilities

9L7.2E

– Switch OFF the TV via the power switch

– Switch on the TV again via the power switch.

In table 2 all the possible option abbreviation with full option

name and possible statuses for "Europe" sets are listed. The

status can be "ON", "OFF" or can have another indication.

Table 2 : Options

Option abbr Option full name Status possibilities

AT Auto tuning system ON/OFF

AV AVL ON/OFF

BA Bass ON/OFF

BL Balance ON/OFF

CO Clock In Menu ON/OFF

GM Game mode ON/OFF

HO Hotel mode ON/OFF

MT Menu type PH = Philips

5.4.8 OPTION code

OPT is the abbreviation of OPTION, this abbreviation refers to

the following 12 digit hexadecimal option codes (36C8 B805

2401)

The option code can not be selected. It only give a quick

indication in hexadecimal form of the options settings of the

relevant set.

5.5 SAM (Service Alignment Mode)

Via the SAM, service software alignments can be executed.

When entering SAM a main menu is displayed Via the main

menu sub menus can be selected.

5.5.1 SAM main menu (see Fig. 6.2)

In the main menu the items of the basic software alignments

are indicated.

Theitems can be selected withthe UP(+)/DOWN(-) arrow keys

on the remote control. Entry into the sub menus is executed

with the VOL.(+)/VOL.(-) arrow keys.

SAM MAIN MENU

NB = National brand

MV = Magnavox

PG Program guide ON/OFF

PR Presets 99

59

79

SA Spatial ON/OFF

SB Sound Board IN = ITT NICAM

IT = ITT 2CS

MA = MONO ALL

MM = Multi Mono

SP Smart picture ON/OFF

SS Smart Sound Full ON/OFF

SU Surf ON/OFF

SY System Cluster EW = Europe West

EE = Europe East

EM = Europe

Manual

SS = Single System

TR Treble ON/OFF

UH UHF only ON/OFF

VI Virgin Mode ON/OFF

XT EXT 2 Available ON/OFF

S

AKB ON

TUN.FOA ON

TUN.FOB ON

EXT.FOA ON

EXT.FOB OFF

TUNER >

WHITE TONE >

GEOMETRY >

Fig.6.2

Below each item is explained.

5.5.2 AKB (Auto Kine Biasing)

With the option AKB the "black current loop" can be enabled

or disabled

ON =enabled, OFF = disabled.

5.5.3 TUNER Speed setting.

With the items TUN.FAO and TUN.FOB the speed ( time

constant) for internal signals is set. The speed can be set to

normal, slow or fast.

Table 3: Options for Tuner Speed settings

10 L7.2E

5 Repair facilities

5.5.6 White tone

TUN.FOA TUN.FOB Speed

OFF OFF Normal

OFF ON Slow

ON X Fast

5.5.4 EXTERNAL A/V Speed setting

With the items EXT.FAO and EXT.FOB the speed ( time

constant) for external signals is set. The speed can be set

normal, slow and fast.

Table 4: Options for External AV Speed settings

EXT.FOA EXT.FOB Speed

OFF OFF Normal

OFF ON Slow

ON X Fast

5.5.5 Tuner

Below an example of the sub menu Tuner is shown.

Below an example of the white tone sub menu and the derived

"WARM", "COOL" and "NORMAL" sub menus are given. With

these menus the WARM, COOL and NORMAL colour

temperatures can be changed.

MAIN WHITE TONE MENU

S

WARM <

COOL <

NORMAL <

WARM TEMPERATURE SUB MENU

WARM S

RED 39

Tuner S

AGC 23

F-PLL 3

IF PLL L' 0

AFW 240 KHz

AFA 0

AFB 1

Item AGC:

For the setting of the item AGC see RF AGC adjustment

paragraph 8.1.4 of chapter 8.

Item IF-PLL, IF-PLL L ACCENT, AFW, AFA and AFB,

When the main signal processor IC TDA8373/74 is changed,

the IF-PLL and IF-PLL L ACCENT need to be realigned

GREEN 39

BLUE 25

COOL TEMPERATURE SUB MENU

COOL S

RED 39

GREEN 39

BLUE 25

NORMAL TEMPERATURE SUB MENU

NORMAL S

RED 39

GREEN 39

BLUE 25

Forthe settings of IF-PLL, IF-PLL L ACCENTandAFW see the

picture demodulator adjustments paragraph 8.1.5 of chapter 8.

Remark: AFA and AFB are adjusting indicators and therefore

not selectable.

Remark:

Only one of the 3 items (RED, GREEN or BLUE) will be

displayedonthescreen.Via"scrollingwiththeUP/DOWN keys

the items can be changed.

The item's red, green or blue can be changed by first pressing

the control left/right keys to highlight the desired setting. With

the desired setting high lighted, the user can increment or

decrement the setting by using the control up/down key. All

5 Repair facilities

11L7.2E

changed data are stored into the EEPROM after returning to

the SAM main menu via the OK key.

The initial default value for all setting is 37.

The factory settings of the colour temperatures are:

WARM; R = 45, G = 32, B = 26

NORMAL; R = 37, G = X, B = Y

COOL; R = 37, G = 32, B = 31

Remark: In NORMAL position the values X (G) and Y (B) are

adjusted for 8500K colour temperature.

5.5.7 GEOMETRY

The geometry menu contains the following information:

S

HSH 25

VSL 32

VAM 23

– All software is suspended till the DST mode is left.

– The dealer mode status is left if the stand-by command is

received

5.7 Hotel-mode

Entering the hotel-mode :

– Select channel 38

– Push the menu button on the local keyboard (vol. + & vol.

- ) and the OSD-button of the RC simultaneously for 3

seconds.

– The screen shows the "HOTEL MODE SUB MENU "ON".

Via this menu the wanted blanked channels can be

selected.

Leaving the hotel mode :

– Same as entering the hotel mode.

– The screen shows the "HOTEL MODE SUB MENU "OFF".

Remarks:

– In the HOTEL mode the Installation menu cannot be

entered.

– When entering the hotel mode the maximum volume will

be the current value.

– The set will always switch to a selectable channel when

set is switched on.

SC 13

VSH 27

Uponenter into the picture geometry menu, thefirstitem will be

highlighted.

The value can be incremented or decremented by pressing the

control right or left key.

Therestof the parameters can be scrolled through by usingthe

control up/down keys.

All changed data will be stored into the EEPROM after

returning to the service main menu via the OK key.

Abbreviation explanation

– HSH - Horizontal shift

– VSL - Vertical linearity

– VAM - Vertical amplitude

– SC - S-correction

– VSH - Vertical shift

5.6 Use of Dealer Service Tool (DST)

With the SDM, under mentioned extra service features can be

executed

HOTEL MODE SUB MENU "ON"

38 HOTEL ON

EXIT >

HOTEL CHANNEL 38

HOTEL MODE SUB MENU " OFF "

38 HOTEL OFF

– Direct entering SDM via the "DEFAULT" button on the

DST.

– Direct entering SAM via the "ALIGN" button on the DST.

– Incase of no (OSD)picture theerror buffercan be readout

using the "BLINKING LED"procedure (see also paragraph

6.7) by pressing the "DIAGNOSE" button on the DST.

Remark:

– Entry of the SDM and SAM via the DST is possible in all

states, except from stand-by.

Remark: The Hotel mode can only be activated if the Hotel

mode option status (HO=ON), see table 2.

12 L7.2E

5 Repair facilities

Loading...

Loading...