Page 1

Industrial Vision

Intelligent Camera

12NC: 8122 410 5680.0

-

Inca 311

Hardware

Philips Applied Technologies

Manual

Page 2

Inca 311 Hardware Manual

Version 1.3

A publication of:

Philips Applied Technologies

www.apptech.philips.com/industrialvision

© 2005 Philips Electronics N.V.

Eindhoven, The Netherlands

All rights are reserved.

Reproduction in whole or in part is prohibited without the written consent of the copyright owner.

The information in this publication is furnished for guidance, and with no guarantee as to its accuracy or

Philips Applied Technologies does not assume liability for any consequences to its use;

specifications and availability of goods mentioned in it are subject to change without notice

Printed in the Netherlands, 2005-12-12

Industrial Vision

completeness.

8122 410 5688.4

Page 3

CONTENTS

Inca 311 Hardware Manual...............................................................................................................................2

1 INTRODUCTION ........................................................................................................................................2

1.1 ABOUT THIS MANUAL...............................................................................................................2

1.2 SUPPLIED PARTS......................................................................................................................2

1.3 ABOUT THE INSTALLATION .....................................................................................................2

2 HARDWARE ..............................................................................................................................................3

2.1 TRIMEDIA PROCESSOR ........................................................................................................... 3

2.2 CMOS SENSOR .........................................................................................................................4

2.3 CAMERA CONNECTIONS ......................................................................................................... 4

2.4 POWERING UP ........................................................................................................................11

3 SOFTWARE INSTALLATION.................................................................................................................. 12

4 MECHANICAL INTERFACE....................................................................................................................13

5 TROUBLE SHOOTING............................................................................................................................ 14

5.1 KNOWN PROBLEMS USING THE INCA.................................................................................. 14

5.2 SERVICE AND SUPPORT........................................................................................................ 15

6 TECHNICAL SPECIFICATION................................................................................................................16

Page 4

1 INTRODUCTION

Congratulations on buying the Inca vision system!

An Inca is a high quality intelligent camera for image

acquisition and processing. Inca offers a complete vision

system that is ACCURATE, FAST, COMPACT and COSTEFFECTIVE. The high-resolution, high dynamic range

sensor provides the best basis for the development of a

very accurate vision system. Having all the processing

power close to the sensor and the capability of region of

interest processing reduces processing time and th us

faster systems can be realised. Because of this integrated

processor, display capabilities and industrial I/O, the Inca

offers a very compact total vision solution, without any

need for additional hardware like e.g. a PC. This makes an

Inca solution besides very cost-effective also transparent

and easy to work with. Finally the industrial housing

provides optimal possibilities for incorporating the Inca in

almost every (industrial) environment.

1.2 SUPPLIED PARTS

The supplied equipment comprises the following:

• One Inca 311 camera.

• One hardware manual (this document).

If any of these items is not included notify your supplier

immediately.

1.3 ABOUT THE INSTALLATION

The installation consists only of making the right

connections to the Inca. Start-up and running an

application is completely done under software control.

Software is not provided with the Inca, but is a separate

product that can be purchased from Industrial Vision. Refer

to chapter 3 for available software.

1.1 ABOUT THIS MANUAL

This manual explains how to install your Inca camera and

how to check that it is working correctly.

Page 2 2005-12-12

Page 5

2 HARDWARE

The Inca hardware consists of the following modules:

• TriMedia processor

• CMOS sensor

• IEEE 1394 (FireWire™) interface

• RS232 serial interface

• Video outputs VGA and CVBS

• Digital inputs and outputs

• Trigger input and flashlight output

• Reset input and watchdog output

• Four general purpose LED’s

• One system LED

• 8 MByte on-board flash memory

• 32 MByte SDRAM

2.1 TRIMEDIA PROCESSOR

The core of the Inca is the TriMedia 1300 processor. This

Very Long Instruction Word CPU (max. 5 parallel

instructions) with image co-process or run s on 143 MHz or

even 180 MHz. Among others, this processor handles:

Image and control data flows

Storage of acquired images. The images are stored in the

32 MByte on-board SDRAM.

Processing of the image stored in on-board SDRAM

Interaction with its environment for product information and

measurement results

Programming this TriMedia processor can be done using

the Rhapsody C/C++ software package or a graphic al

development environment called Clicks. The TriMedia part

of this software is based on the real time operating system

pSos™. Especially for high-end vision applications this is

very important, because in this way the timing of the

application is deterministic, this in contrast to programs

running in Windows™.

Clicks allow application engineers to graphically compose

the tasks to perform. Without the need of programming

expertise this tool is easily accessible for most engineers

and offers a very natural and interactive way to realize your

application.

2005-12-12 Page 3

Page 6

2.2 CMOS SENSOR

2.2.1 Inca 311

In the Inca 311 a monochrome sensor PCS2112-LM from

Zoran is implemented. This high performance CMOS

imaging sensor has an extreme ‘uniform pixel array’ and

an extremely low ‘fixed-pattern noise’ because of its

‘Distributed Pixel Amplifier’ architecture. The following

main features, supported by the Inca 311, are available:

• 1280 x 1024 Pixels

• 10 bit ADC resolution

• 2/3” sens or housing

• One region of interest

• Programmable exposure time

• Mirror an d flipped scan modes

• 16 MHz or 24 MHz pixelclock

• Full frame rate 9.3 or 14 frames per second

• Programmable gain 0..14 dB

• Dynamic range 66dB

• Synthetic test image

• Decimation factor 2 and 4 for higher frame rates of

sub- sampled images

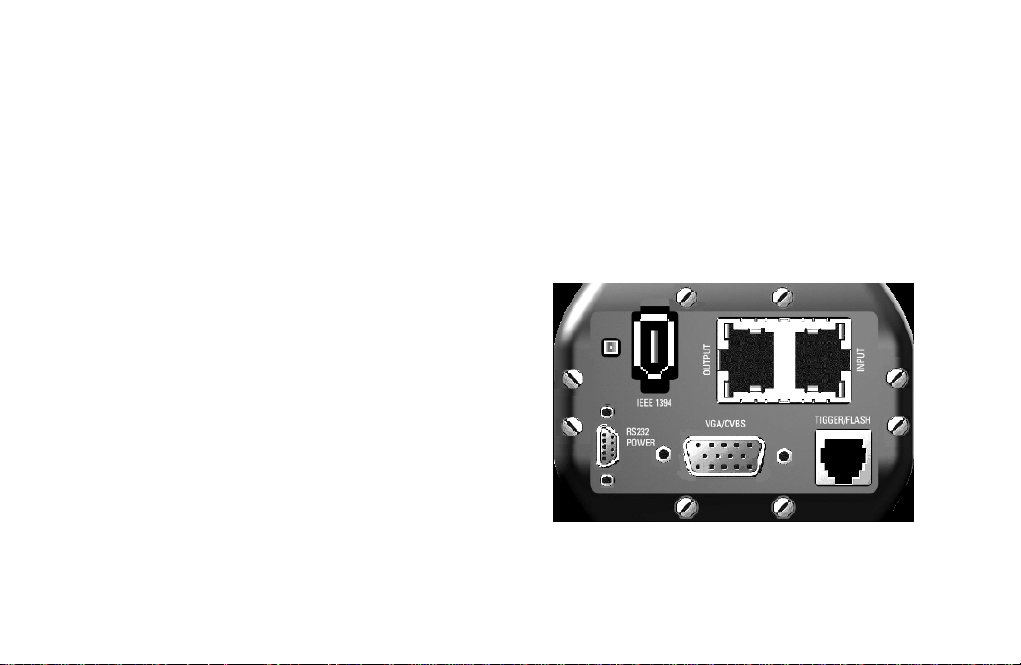

2.3 CAMERA CONNECTIONS

The rear side of the camera gives the user a great number

of possibilities for interfacing the camera.

• IEEE 1394 ( also known as Firewire™)

• One trigger input and one output for flash control

• Digital input 6 bits optically isolated

• Digital output 6 bits optically isolated

• RS232

• Camera reset

• Watchdog

• VGA and CVBS for display purposes

Figure 2-1 Inca 311 back side connectors

Page 4 2005-12-12

Page 7

2.3.1 IEEE 1394 (FireWire™)

TRIGGER / FLASH

For the interconnection of the Inca camera to the host PC

a so-called IEEE 1394 inter face, also known as

FireWire™, is used. For this link the PC must be equipped

with an IEEE 1394 interface. This IEEE 1394 can be an

1 234

onboard OHCI version, a PCILynx- or OHCI- IEEE 1394

PCI expansion board in case of a desktop PC or a

PCMCIA expansion card in case of a notebook. The

number of Inca’s that can be connected to a single IEE E

1394 interface depends on the number of ports available

on the interface. The number of ports can be in the range

one to six but is typically three. The integration of the

physically IEEE 1394 interface into your Windows™

operating system is achieved via a so called device driver.

A device driver for the OHCI and the PCILynx version of

the IEEE 1394 interface will be available for;

Windows NT4, Windows 2000 and Windows XP.

2.3.2 Trigger and Flash

TRIGGER/FLASH

PIN FUNCTION

Flash 1(p)

1

Flash 1(n)

2

Trigger 1(p)

3

Trigger 1(n)

4

The Inca has an optically isolated trigger input and flash

output.

The trigger input enables the feature to prepare the

capture of an image. If programmed so the capture

process will start immediate when the trigger input is

signaled. A rising or a falling edge on the input can indicate

the trigger.

The flash output can control the external flash unit if

required. The active sta te (high or low) can be

programmed, see the note for side effect.

Figure 2-2 Trigger/Flash connector

Note: The start-up sequence for the Inca has

consequences for the flash output. In case the flash ou tput

is configured as a non-inverting output the output is zero

and stays zero and awaits control by the software.

If the output is configured as an inverting output tha n

during the start-up sequence the output equals the value of

the power supply. This situation stays that way until the

software has taken over the control. In case a flash unit is

2005-12-12 Page 5

Page 8

switched to the on position with a positive input, the flash

unit will flash or lit continuously.

2.3.2.1 Using the Trigger Input

Inca

2K7

p

24V

The trigger input is optically isolated.

The following diagram shows and example of how to use

the optical Isolated input.

Inca

p

2K7

24V

Figure 2-4: Optical isolated flash and watchdog

outputs

n

When the flash output is defined as active high and the

n

Figure 2-3 Optical isolated trigger input

When the diode is conducting and thus emitting light, the

software will interpret this as a binary ‘1’.

The input is TTL level compatible.

• input current 6.3 mA < Ion < 10 mA

• Pmax 20 mW

software sets the flash as active, then the state of the

output is Ioff, and the transistor will not be conducting.

When the flash output is defined as active low, and the

software sets the flash as active, then the state of the

output is Ion, and the transistor will be conducting.

The watchdog will behave the same as the flash output in

the active high definition.

The inputs and outputs are not protected in any way, so

care must be taken when connecting anything to these

inputs and/or outputs.

2.3.2.2 Using the Flash and Watchdog Outputs

The flash and watchdog outputs are optically isolated .

The following diagram shows an example of how to use

the optical output.

All inputs and outputs are TTL level compatible.

• output current 0.9 mA < Ion < 18 mA, Vce max 40 volt

• Pmax 20 mW

Page 6 2005-12-12

Page 9

2.3.3 Digital I/O

p

The Digital Input and Output connectors give the user

the possibility to connect and control a number of devices.

For that purpose 6 output and 6 input lines are available.

These output and input lines are optically isolated from the

Inca (see explanation: 2.3.4 How to use the isolated

input/output).

Input 6 differs from the other inputs in a way that it has a

special purpose. Input 6 can be used as an interrup t input

either level or edge sensitive.

All inputs and outputs are TTL level compatible.

• input current 6.3 mA < Ion < 10 mA

• Pmax 20 mW

• output current 0.9 mA < Ion < 18 mA, Vce max 40 volt

DIGITAL I/O

PIN INPU T

1

2

3

4

5

6

7

8

(p/n see: 2.3.4 How to use the isolated input/output)

Input 1(p)

Input 2(p)

Input 3(p)

Input 4(p)

Input 5(p)

Return input 1..5( n)

Input 6(p)

Return input 6(n)

PIN OUTPUT

Return output 4..6(n)

1

Output 6(p)

2

Output 5(p)

3

Output 4(p)

4

5

Return output 1..3(n)

Output 3(p)

6

Output 2(p)

7

Output 1(p)

8

Note: The common grounds of the outputs are clustered in

two groups of three outputs. Five input common grounds

are clustered.

Output

In

ut

Figure 2-3: Digital input and output connections

Table 2-1: LED control by Rhapsody software

LED 1 green or yellow

LED 2 green or yellow

LED 3 green or yellow

LED 4 green (only!)

2005-12-12 Page 7

Page 10

(n)

2.3.4.2 OUTPUT

2.3.4 How to use the isolated input/output

In this part the user will find how the optical isolation is

implemented in the Inca. Not only the digital input and

output lines are optically isolated but also the flash and

watchdog output and the trigger input.

Return

Input(p)

1M

1M

Inverting

output(p)

Figure 2-4: Circuit for optical isolation

The above circuit is the one used in the camera. Hereafter

will be explained how these circuitry can be used by the

user of the Inca.

2.3.4.1 INPUT

As already mentioned in paragraph 2.3.3 Digital I/O the

input current for Ion is between 6.3 mA and 10 mA. Ion is

the current whereby the output transistor is conducting. In

order to prevent the input from left floating, the return (n) is

internally connected with a high impedance to ground. In

order to let the input functioning properly the user must

connect the common ground to the signal ground.

The optically isolated output is only a transistor. As can be

seen in figure: 2-6 the emitter is connected via a 1M

resistor to ground. It prevents the output transistor from left

floating. If the output is conducting the output current Ion

must be in the range 0.9 mA < Ion < 18 mA. The maximum

Vce is 40 volt.

2.3.4.3 Suggestion for Output and Input :

Figure 2-6: Opto-isolated output Figure 2-5: Opto-isolated input

Warning:

in an Ioff (out = high because of pull-up resistor), on the

contrary writing a False or Zero to the Digital output results

in a Ion (out = low because of transistor short circuit).

24V

2K7

24V input

Out signal

User

Writing a True or One to the digital output results

2K7

User side

1M

Page 8 2005-12-12

Page 11

2.3.5 Multi-purpose connector

Looking at the back of the Inca the connector in the left

bottom corner is a multi-purpose connector. The

connector, a 9 pole micro-D connector, contains

connections for an external power supply, 3-wire serial I/O,

the input for an external system reset and a watchdog

function.

Micro D; MULTI-PURPOSE I/O

PIN FUNCTION

1

2

9

8

3

7

6

4

5

6

7

8

9

Ext. Power

RS232 TxD

RS232 RxD

W-dog alarm-p

W-dog alarm-n

Ext. Power ground

Digital ground

Ext. Reset-n

Ext. Reset-r

5

4

3

2

1

9p-Male

2.3.5.2 RS232

Pin 2 is the RS232 transmit data line.

Pin 3 is the RS232 receive data line.

The RS232 digital ground is connected to pin 7.

Warning:

When using the Micro D to Sub D cable (8122

410 81530) which is also included in the starter kit please

notice that the point 7 and 5 are interchanged all other

points are interconnected one to one.

2.3.5.3 Watchdog

The watchdog connection is an opto-isol at ed ou tput. Pin 4

is the p connection and pin 5 is the n connection. This

output can be switched under software control and can be

made dependent of among others (software) timers. (p/n

see: 2.3.4 How to use the isol ated input/output)

2.3.5.1 Power supply

The Inca is powered by connecting the external power pin

1 to the + pole and pin 6 to the ground of a power supply.

The voltage must be in the range 8..40 volts, but is

typically 12..15 Volt. (The Inca starter kit; PCI 8122 410

56851 or PCMCIA 8122 410 5651 contains a 15 volt 2

Amp. power supply.)

2.3.5.4 Reset

A single pole pushbutton connected between the pins 8

and 9 can be used as an external system reset. (Available

in the starterkit). For an internal reset the watchdog output

can be connected directly to the reset input ( pin 4 - pin 8

and pin 5 - pin 9) for this reason the reset input is not Opto

isolated.

2005-12-12 Page 9

Page 12

2.3.6 The display connector

The display connector can be used for the connection of a

VGA or a CVBS monitor. Only one of these two

possibilities can be activated at a time. The VGA output

has a resolution of 680x480 pixels in a non-interlaced

mode. The CVBS mode is either CCIR or RS170

compatible depending on the mode set via software. Both

VGA and CVBS outputs support a non-destructive colour

overlay. For connecting a VGA monitor a standard cable

can be used. For the CVBS monitor connection no

standard cable is available. A user made cable must be

connected between the connector pins 9 and 10 where pin

9 is the CVBS connection and pin 10 the gr ound

connection. A 75 ohm coax cable is preferred.

VGA/CVBS connections

PIN FUNCTION

RED analog video

1

GREEN analog video

2

BLUE analog video

3

Monitor ID #2

4

Digital ground

5

RED ground

6

GREEN ground

7

BLUE ground

8

CVBS analog video

9

SYNC/CVBS ground

10

Monitor ID #0

11

Monitor ID #1

12

Horizontal sync

13

Vertical sync

14

Not connected

15

Figure 2-6: VGA connector pinning

Note 1: The RED, GREEN and BLUE signals are 0.7 Vpp

Figure 2-5: DB15 VGA female connector

signals terminated with 75 ohm load. All other signals are

TTL level.

Note 2: Some type of video cards use monitor ID #0..#2 to

determine the type of monitor used. The Inca does not

support automatic monitor detection

Page 10 2005-12-12

Page 13

2.4 POWERING UP

When the Inca is powered up, the Inca will boot. One of the

first things it will do is to start a self-test to make sure that it

is functional. After correct completion of the test a check is

added for the presence of a host that waits to download an

application. If a host is connected the camera waits for the

download of the application to be executed. The download

is done via the IEEE1394 interface connection. When a

download is in progress the Inca waits until the download

is completed. After completion it starts the execution of the

program.

If the test for the host is negative then the Inca will load the

program, if available, stored on the flash file system to the

SDRAM and starts the execution. If no application is

available the Inca starts capturing images and send the

images to the VGA output. The latter will be the case if an

Inca is powered-up for the very first time.

2.4.1 System LED

The system LED is situated next to the IEEE1394

connector. The system LED can illuminate in 3 colours

namely red, green and orange. By connecting the power to

the Inca the LED illuminates red. During start-up the LED

is illuminating orange.

Once start-up has finished the next step is the hardware

initialization. During the start of this initializin g ph as e the

LED will blink for a very short time green and stays

constant green when this phase is terminated successfu lly.

If during this phase something goes wrong the led will blink

in red constantly.

During the time that a host can download an application

the general purpose LEDs 1 and 2 blink orange alter nat ely.

After 3 seconds or a successful application download the

Inca will (try to) start the default or downloaded

application. If the system LED is blinking during this phase

probably the file ‘RapIB311Lcm.rbf’ or the appropriate

license file (Rhapsody.key or Clicks.key) don’t reside on

the flash file system.

For a more detailed meaning of the system led colors

during the boot sequence please refer to the software

manual.

2005-12-12 Page 11

Page 14

3 SOFTWARE INSTALLATION

There is no special software supplied with the Inca for

installation purposes, so no installation is necessary. The

start-up procedure and running an application is

completely done by software control.

A number of software products are available su pp orting the

Inca and can be purchased from Industrial Vision.

Available are:

• The ‘Rhapsody’ package, a powerful set of softw are

tools for writing industrial vision applications. Rhapsody

gives freedom of programming a specific user

application with maximum performance and the least

overhead.

• ‘Clicks’ a graphical Inca user interface easy to be used

by engineers.

• The Inca is also supported by ‘Promise’, a National

Instruments LabVIEW add-on library, for developing

industrial vision applications for measurement in subpixel accuracy. Using graphical representations for

functions, selected and connected together, the

application builder can create a program capable of

executing a complex vision function.

Page 12 2005-12-12

Page 15

4 MECHANICAL INTERFACE

For the purpose of installation and handling the camera in

an application two mechanical preparation s have been

made to the camera body:

• Three M4 screw holes in the bottom of the camera

The one in the camera front end is the most important

one because this comprises the sensor.

• The camera neck can be clipped onto a fixed ring

(50mm h7)

In both cases it is advisable to design a alignment pin into

your mechanical placeholder

Figure 4-2: Inca 3d view

Figure 4-3: Inca front view

Figure 4-1: Inca bottom view

2005-12-12 Page 13

Page 16

5 TROUBLE SHOOTING

This chapter describes the action to take if the Inca board

does not operate correctly. Moreover, the means of

support are described.

5.1 KNOWN PROBLEMS USING THE I NCA

When using the Micro D to Sub D cable (8122 410 81530)

that is also included into the starter kit please notice that

the point 5 and 7 are interchanged all other points are

interconnected one to one.

The Digital IO of the Inca does not have a defined reset

status. Only after a complete boot of the Inca including the

start of the user application the IO ports will have a defined

level.

The cleanness of the sensor is of major importan ce for the

image quality. During the production of the Inca special

account is taken with respect to the cleanness of the

sensor. However when you remove the sensor protection

cap from the Inca front end prior to the mounting of the

lens, the sensor can attract some dust or dirt. This pollution

can affect the image captured with the Inca. Remove the

sensor protection cap only in a clean environment by

holding the Inca with the sensor facing down. After

removing the sensor protection cap inspect the cleanness

of the sensor and immediate assemble the required lens to

the Inca.

In case of a red blinking system LED (see 2.4.1 Sy stem

LED) during the boot sequence but after the three seconds

of blinking the general purpose LEDs 1 and 2 one of the

following files are probably missing on the flash file system;

‘RapIB311Lcm.rbf’ or the appropriate license file

Rhapsody.key or Clicks.key. These files are required when

you like to use the Inca either under Rhapsody or Clicks

software control.

Page 14 2005-12-12

Page 17

5.2 SERVICE AND SUPPORT

5.2.1 Service

The Inca has built-in identification codes for hard and

software in order to fa cilitate service and support. These

codes are displayed during the boot time. If a problem

occurs these codes can hel p to determine quickly the level

of equipment being used. The programmable hardware

can be altered or updated by downloading a file. There is

no need for changing components.

5.2.3 Support Channels

Support can be received through the following chann els:

E-Mail:

Internet: www.apptech.philips.com/industrialvision/

apptech.industrial.vision.support@philips.com

5.2.2 Software Support Agreement

Although no software is delivered with the Inca, apart from

buying an Inca software can be purchased from Industrial

Vision. At the same time a Software Support Agreement

can be purchased. A Softwar e Support Agreement offers

several benefits, which are not available t o oth er user s.

The most important are:

• free telephone support

• free fax support

• free release updates

Although free telephone and fax support are also available

to other users, users with a Software Support Agreement

will be given a higher priority when support questions are

raised. Holders of the agreement will also automatically

receive new releases of the software.

2005-12-12 Page 15

Page 18

6 TECHNICAL SPECIFICATION

Power requirements +8..40V, 8 Watt (max)

Typically 12..15 Volt

Optics C-mount

Mechanical

Dimensions: 137 x 75 x 50 mm (l x w x h)

Sensor

Size 2/3”

Number of pixels 1280 x 1024

ADC resolution 10 bits

Regions of interest 1

Exposure time programmable

Inca 311

Frame rate 9.3 or 14 fields / second

Scan modes mirror and flip mode

Gain programmable 0..14 dB

Sub-sampling factor 2 and 4

FPN: < 1.2% pp

PRNU: < 2.5% pp

Inputs

Maximum Ion: 10 mA

Digital input: 6 bits isolated

TTL level compatible

Trigger input: 1 bit isolated

TTL level compatible

Outputs

Maximum Vce: 40 volt, maximum Ic: 10 mA

Digital output: 6 bits isolated

TTL level compatible

Flash output: 1 bit isolated

TTL level compatible

delay and duration

programmable

Watchdog output: 1 bit isolated

TTL level compatible

Reset not isolated

Page 16 2005-12-12

Page 19

Environmental

Inca complies to:

EFT immunity: IEC1000-4-4

ESD immunity: IEC1000-4-2

at 4 kV contact discharge

and 8 kV through the air

EN50082-2

Emission standard EN50082-1

EMC: EN55022 (not mandatory)

EN55011

EN61000-4-3

EN61000-4-6

EDT EN61000-4-2

CE: Certified

Operating

Temperature: 10

o

C to 50 oC

Relative humidity: 20% to 80%, non condensing

Vibration: 0.5 g

Non-operating

Temperature: -20

o

C to 70 oC

Relative humidity: 20% to 80%, non condensing

Vibration: 2 g

2005-12-12 Page 17

Loading...

Loading...